Page 1

Conventional

Models

2007 EPA Compliant Vehicles

Page 2

Q

uick Table of Contents

Introduction . . . . . . . . . . . . . . . . . . 1

Cab And Frame Access . . . . . . . . . . . .5

Getting To Your Engine. . . . . . . . . . . . . . . 11

Controls And Displays. . . . . . . . . . . . . . . . . . . 13

Seat And Restraint Systems . . . . . . . . . . . . . . . . . 73

Driver’s Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Starting And Operating The Vehicle. . . . . . . . . . . . . . . . . . 88

Consumer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Subject Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Vehicle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

California Proposition 65 Warning

• Diesel engine exhaust and some of its constituents are known to the State of

California to cause cancer, birth defects, and other reproductive harm.

• Other chemicals in this vehicle are also known to the State of California to

cause cancer, birth defects or other reproductive harm.

• Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of Calif ornia to cause cancer and reproductive harm. Wash hands after handling.

Page 3

PART 1: INTRODUCTION HOW TO FIND WHAT YOU WANT

PART 1: INTRODUCTION

This manual contains useful information for the safe and

efficient operation of your P eterbilt vehicle . It also provides

information on maintaining your vehicle in the best condition, with an outline for performing safety checks and

basic preventive maintenance inspections.

We have tried to present the information you’ll need to

learn about your vehicle’s functions, controls, and operation - and to present it as clearly as possible. We hope

you’ll find this manual easy to use.

Please remember -- this manual is not a training manual.

It can’t tell you everything you need to know about driving

your Peterbilt vehicle. For that you need a good training

program or truck driving school. If you have not been

trained, get the proper training before you drive. Only

qualified drivers should drive this vehicle.

There will be times when you need to take this manual out

of your Peterbilt. When you do, please be sure to return it

to the cab when you are finished using it. That way it will

be there when you need it th e next time or when you pass

the vehicle on to the next user.

How To Find What You Want

There are several tools built into this manual to help you

find what you need quickly and easily.

First is the Quick Table of Contents. Located at the front

of the manual, this lists the main subjects covered and

gives page numbers where you can find these subjects.

Use the Quick Table of Contents to find information on a

large subject like “Maintenance.”

Cross-referenced citations also help you get the information you need. If some other part of the manual contains

further information o n the subject you are reading about,

we’ll indicate that in a cross-reference like this: (See

“PART 6: DRIVER’S CHECKLIST”). You won’t have to go

searching for more information.

Finally you’ll find a helpful Subject Index. It’s in the back

of the manual and alphabetically lists the subjects covered. So if you want information on brakes, for example,

just look under Brake in the Subject Index. You’ll find all

the pages listed where brakes or braking are discussed.

(08/06) Y53-6004 – 1 –

Page 4

A SPECIAL WORD ABOUT REPAIRS PART 1: INTRODUCTION

A Special Word About Repairs

WARNING ! Attempting repair work without sufficient training, service manuals, and the proper

tools can be dangerous. You could be injured or

you could make your truck unsafe. Do only

those tasks you are fully qualified to do.

Your Peterbilt dealer’s service center is the best place to

have your vehicle repaired. You can find Peterbilt dealers all

over the country with the equipment and trained personnel

to get you back on the road quickly - and k eep you there.

Your vehicle is a complex machine. Anyone attempting

repairs on it needs good mechanical training and the

proper tools. If you are sure you have these requirements,

then you can probably perf orm some repairs yourself . However, all warranty repairs must be performed by an authorized Peterbilt service facility. If you aren’t an experienced

mechanic, or don’t have the right equipment, please leave

all repairs to an authorized service facility. They are the

ones equipped to do the job safely and correctly.

Maintenance Manuals. If you do decide to do any complex repair work, you’ll need the Peterbilt Maintenance

manuals. Order them from your authorized dealer. Please

provide your Chassis Serial Number when you order, to

be sure you get the correct manuals for your vehicle.

Allow about four weeks f or deliv ery. There will be a charge

for these manuals.

Final Chassis Bill of Material. A complete, nonillustrated

computer printout listing of the parts used to custom-build

your Peterbilt vehicle is available through the Peterbilt

dealer from whom your purchased your vehicle.

WARNING! Modifying y our ve hicle can make it

unsafe. Some modifications can affect your

truck’s electrical system, stability, or other

important functions. Before modifying your

vehicle, check with your dealer to make sure it

can be done safely.

Additional Sources of Information

Operator’s manuals are also supplied by the manufacturers of components such as the engine, seats, transmission, and radio in your Peterbilt. If you are missing any of

these manuals, ask your Peterbilt dealer to supply them.

Your new Peterbilt’s glove box also contains a copy of the

Truck Driver’s Handbook, published by the American

Trucking Association. Refer to it for important information

on driving your vehicle . Another pl ace to learn more about

– 2 – Y53-6004 (08/06)

Page 5

PART 1: INTRODUCTION WARNINGS

trucking is a local truck driving school. Contact one near

you to find out what kinds of instruction it offers.

Federal and state agencies also have inf ormation you can ask

for . The Interstate Commerce Commission can give you information about regulations governing transportation ac ross

state lines. And various agencies in state governments are

sources for regulations that differ from state to state.

Warnings

We’ve put a number of warning messages in this manual.

They are there f or y ou r prot ection and information. Please

read them and follow them. They can help you to avoid

injury to yourself and your passengers as well as to prevent costly damage to your vehicle. We’ve used cer tain

symbols and “signal words” to indicate what kind of message is going to follow. When you see these symbols &

words, you know that you need to pay special attention.

Please don’t ignore any of these signals.

WARNING!

When you see this symbol & word, the message that follows is especially vital. This signals something that can

cause serious injury or death. This message will tell you

what the hazard is, what can ha ppe n if you don’t heed the

warning, and how to avoid it. For example:

WARNING! Attempting repair work without

sufficient training, service ma nuals, and the

proper tools can be dangerous. You could be

injured or you could make your vehicle

unsafe. Do only those tasks you are fully qualified to do.

CAUTION:

This symbol & word signals something that could damage

your vehicle. You might receive an injury, too. For example:

CAUTION: Continuing to operate a vehicle

with insufficient oil pressure will cause serious engine damage.

NOTE:

Gives you infor mation we feel you’d like to have. It could

have to do with care of your vehicle or with driving more

efficiently:

(08/06) Y53-6004 – 3 –

Page 6

VEHICLE SAFETY PART 1: INTRODUCTION

NOTE: A cold compressor can cause refrigerant

to liquefy and warp the valve plates or cause a

hydraulic lock. Warm the en gine before starting

the air conditioner.

Please take the time to read these messages when you

see them. And remember:

WARNING! Something that could injure y ou seriousl y.

CAUTION: Something that could cause injury to you

or your vehicle.

NOTE: Useful information.

Vehicle Safety

Make sure your Peterbilt is in top working condition before

heading out on the road—it is the responsible driver's duty

to do so. Inspect the vehicle according to “

DRIVER’S CHECKLIST.”

WARNING!

reflexes, perceptions, and judgment can be

affected by even a small amount of alcohol. You

could have a serious—or even fatal accident—if

you drive after drinking. Please do not drink and

drive or ride with a driver who has been drinking.

Do not drink and drive. Your

PA R T 6:

WARNING! The use of alcohol, drugs, and certain medications will seriously impair perception, reactions, and driving ability. These

circumstances can substantially increase the

risk of an accident and personal injury.

Please remember, this manual is not a training manual. It

cannot tell you everything you need to know about driving

your Peterbilt vehicle. For that you need a good training

program or truck driving school. If you have not been

trained, get the proper training before you drive. Only

qualified drivers should drive this vehicle.

Every new Peterbilt vehicle is designed to conform to all

Federal Motor Vehicle Safety Standards applicable at the

time of manufacture. However, even with these safety features, continued safe and reliable operation depends

greatly upon regular vehicle maintenance. The vehicle

must be operated within the range of its mechanical capabilities and the limits of its load ratings. (See the Tire and

Rim Weight Ratings label on the driver's door edge.)

– 4 – Y53-6004 (08/06)

Page 7

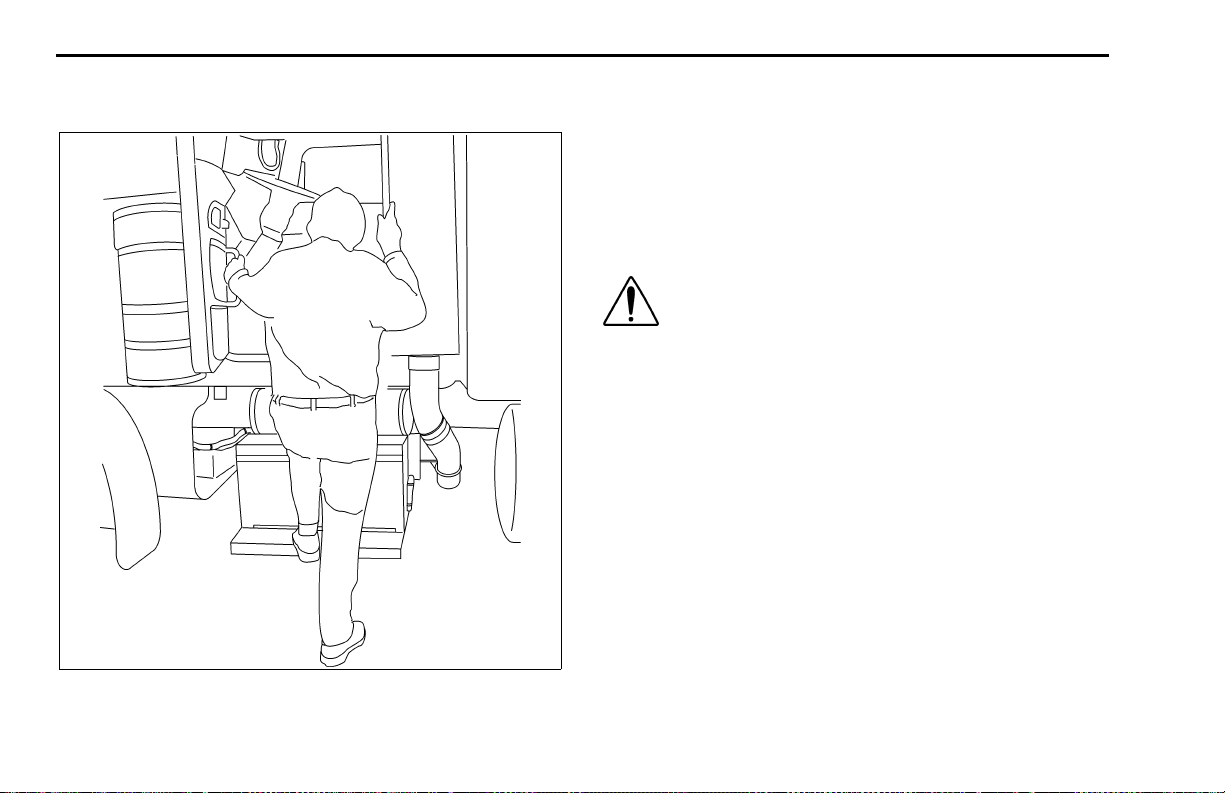

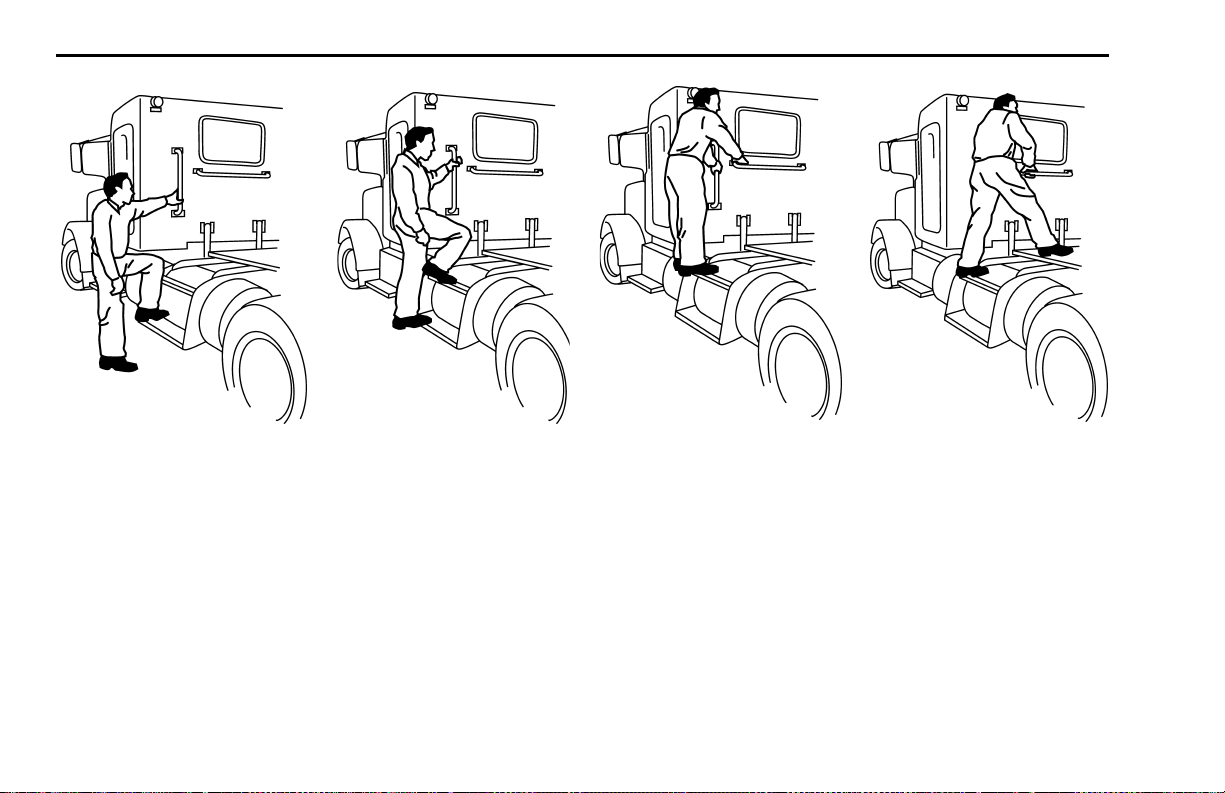

PART 2: CAB AND FRAME ACCESS

PART 2: CAB AND FRAME ACCESS

Be careful whenever you get into or out of your vehicle’s

cab. Always maintain at least three points of contact with

your hands on the grab handles and your feet on the

steps.

WARNING! Jumping out of the cab or getting

into the cab without proper caution is dangerous. You could slip and fall, possibly suffering

a serious injury. Keep steps clean. Clean any

fuel, oil, or grease off of the steps before

entering the cab. Use the steps and grab handles provided, and always keep at least three

points of contact between your hands and

feet and the truck. Look where you are go ing.

(08/06) Y53-6004 – 5 –

Page 8

DOOR LOCK AND KEYS PART 2: CAB AND FRAME ACCESS

The picture below shows the best way to enter and exit a

Conventional Cab.

02958B

Door Lock and Keys

Doors can be locked from th e insid e b y usin g the lock button. Close the door then push the button down to lock.

Doors automatically unlock when you open them from

inside, and can be locked from the outside with the key

only.

WARNI NG! To lessen the chance and/or s everity of personal injury in case of an accident,

always lock the doors while driving. Along

with using the lap/shoulder belts properly,

locking the doors helps prevent occupants

from being thrown from the vehicle.

To lock or unlock the doors from outside the cab , insert the

key in the lock.Turn the key toward the rear to lock; forward to unlock.

Keys and Loc ks

The same key fits your ignition, doors, and sleeper luggage compartment.

Frame-mounted tool box locks and locking fuel tank caps

each have individual keys.

– 6 – (08/06) (08/06)

Page 9

PART 2: CAB AND FRAME ACCESS DOOR LOCK AND KEYS

Remote Keyless Entry (optional)

This vehicle may be equipped with a Remote Keyless

Entry (RKE) system that adds security and convenience

to your vehicle. The system will lock or unlock the driver’s

door and passenger’s door with the key fob and alert you

with parking lights when the selected door’s are locked or

unlocked. The system includes two key fobs that provide

secure rolling code technology that prevents someone

from recording the entry signal.

Operation

To Unlock The Driver’s Door

Press the UNLOCK button once. The driver's door will

unlock and the parking lights will come on for 40 seconds.

To Unlock The Passenger’s Door

Press the UNLOCK button once and press again

within 5 seconds. The passenger door will unlock.

To Lock Both Doors

Press the LOCK button. The doors will lock and the

parking lights will come on for 2 seconds. If the doors

are open they will not lock. The range of the RKE sys-

tem should be approximately 30 ft. This will be

reduced if it is operated close to other RF sources

such as TV/radio transmitters and cell tow ers.

Batteries

The key fob uses one CR2032, 3V battery. Batteries

should last approximately three years, depending on use.

Consistently reduced range is an indicator that the battery

needs replacement. Batteries are available at most discount, hardware and drug stores.

To Replace The Battery

1. Remove rear cover from key fob.

2. Remove the battery.

3. Install new battery.

4. Reinstall cover.

5. Synchronize the key fob.

Synchronization

The key fob may need to be synchronized to the tr uck

when the battery is replaced or when the key fob has not

been used for an extended period time.

(08/06) Y53-6004 – 7 –

Page 10

DOOR LOCK AND KEYS PART 2: CAB AND FRAME ACCESS

To Synchronize A Key Fob

1. Hold the key fob near the receiver.

NOTE: The receiver is located behind the Speedometer/

Tachometer cluster assembly.

2. Press and hold both the Lock and Unlock buttons at

the same time for approximately 7 seconds.

3. When the key fob is resynchronized, the doors will

lock then immediately unlock.

4. If the fob fails to synchronize, it could be programmed to a different truck or could have failed.

Contact your dealer to re-program your key fob.

– 8 – (08/06) (08/06)

Page 11

PART 2: CAB AND FRAME ACCESS CLIMBING ONTO THE DECK PLATE

Climbing Onto the Deck Plate

When you are climbing onto and off the deck plate, maintain at least three points of contact with your hands on the

grab handles and your feet on the steps.

WARNING!

• You can be hurt if you aren’t careful climbing onto and off the deck plate. You can slip

and fall, especially if the surfaces are wet or

icy, or if you step in oil, fuel, or grease. Keep

steps clean. Always maintain at least three

points of contact between your hands and

feet and the steps and deck plate.

• Do not climb onto and off the dec kplate–use

steps and grabhandle provided. If there is no

deck plate, or if proper steps and grab handles aren’t provided, don’t c limb onto the area

behind the cab. Peterbilt did not intend for the

area to be a step if handrails or proper steps

are not provided.

WARNING! Do not step on vehicle components without antiskid surfaces or use components not designed for entry-and-exit use.

You could fall and injure yourself if you step

on a slippery surface. For example:

• You could fall and injure yourself if you step

onto a fuel tank surface. A fuel tank is not a

step. The tank surface can get very slippery,

and you might not be able to prevent a fall.

Don’t step onto the surface of a fuel tank. Use

only the steps and handholds provided, not

chain hooks, quarter fenders, etc.

• Always reinstall steps before entering the

cab or accessing the deck plate. Without

steps, you could sli p and fall, resulting in possible injury to yourself.

NOTE: Any alteration (adding bulkheads, headache racks, tool boxes, etc.) behind the cab or

sleeper that affects the utilization of grab handles ,

deck plates, or frame access steps installed by

Peterbilt must comply with FMCSR 399.

The pictures on the next page show you the right way to

get on and off the area behind your cab.

(08/06) Y53-6004 – 9 –

Page 12

CLIMBING ONTO THE DECK PLATE PART 2: CAB AND FRAME ACCESS

Hold handles as you

step up.

– 10 – (08/06) (08/06)

Maintain three points

of contact.

Maintain three points of

contact as you reach the

deck area.

Maintain three points of

contact as you step to

deckplate.

Page 13

PART 3: GETTING TO YOUR ENGINE HOOD HOLD DOWNS

PART 3: GETTING TO YOUR ENGINE

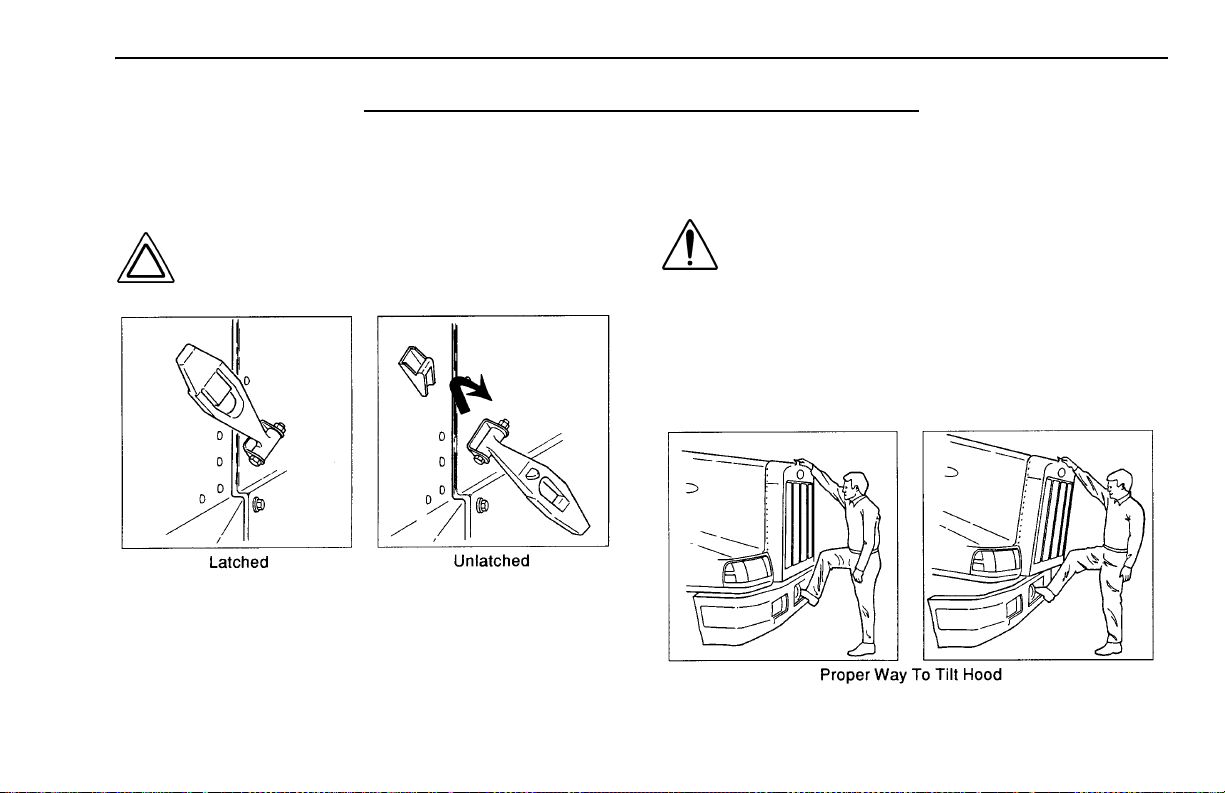

Hood Hold Downs

Hood hold downs keep a hood fr om opening une xpectedly

CAUTION: A hood not latched securely could

open during operation and cause vehicle

damage. Be sure to latch the hood securely.

02961

Hood Tilt

To open your hood, unlock the hood hold downs by

unlatching them. Put one hand on the top of the hood

front, one foot on the bumper, and one f oot o n the g round.

Tilt the hood forwar d

WARNING! Before opening or closing a hood,

ensure no people or objects are in the way. A

hood could hurt someone in the way of its

descent. If the hood falls, anyone under it

could be injured. Always ensure the hood

hold-open latch is engaged to keep the hood

open any time any one gets under the hood f or

.

any reason.

02962

(08/06) Y53-6004 – 11 –

Page 14

HOOD TILT PART 3: GETTING TO YOUR ENGINE

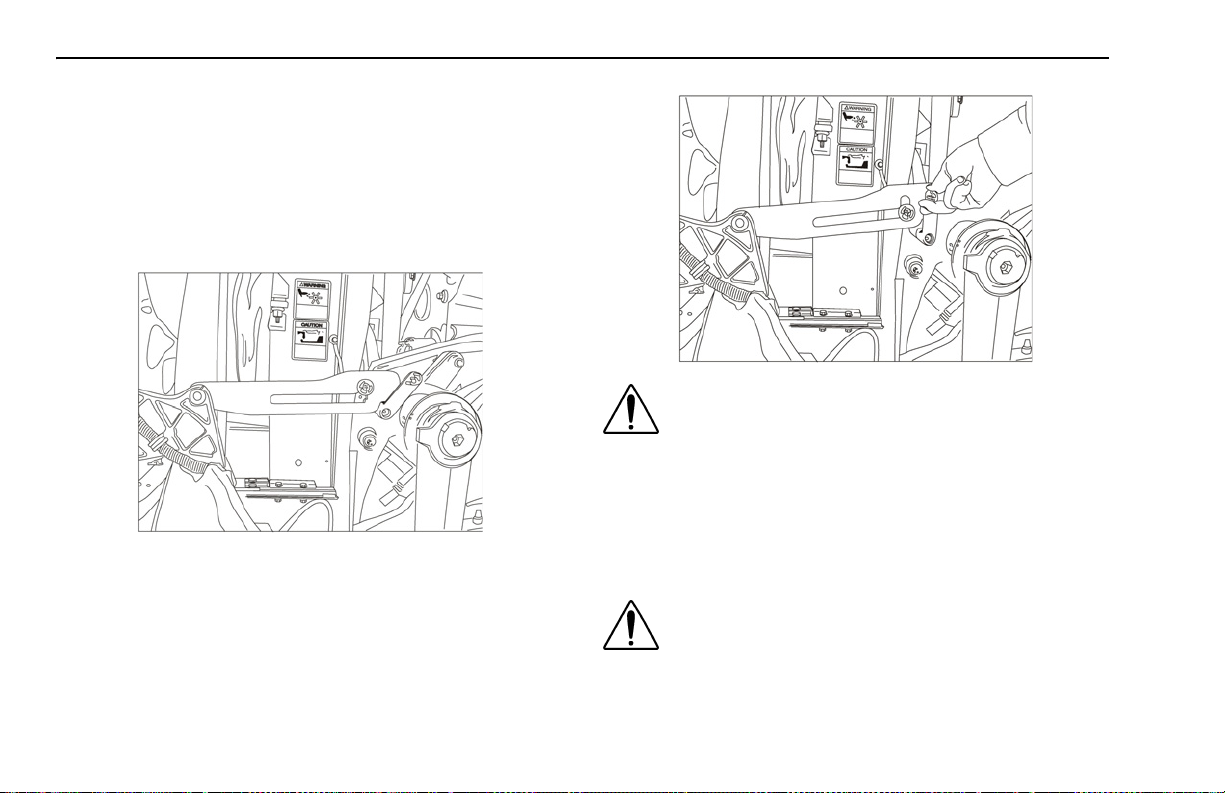

Hood Hold-Open Device

The hood is equipped with a hood hold-open device. In

order for the hood hold-open device to become engaged,

the vehicle hood must be fully open. Once the vehicle

hood is fully open, the hold-open latches will automatically

engage and will need to be disengaged by the operator.

WARNING!

• Ensure the hood is fully opened. Failure to

fully open the hood will prevent engagement

of the hold-open device causing possible serious bodily injury.

• Ensure the hold-open device is engaged

To disengage the latch f or hood closure, rotate the release

lever fully forward.

when underneath hood. A closing hood can

crush causing possible serious bodily injury.

WARNING! K eep people or objects clear when

opening or closing a hood. Failure to do so

can cause hood to strike or crush causing

possible serious bodily injury and/or property

damage.

– 12 – Y53-6004 (08/06)

Page 15

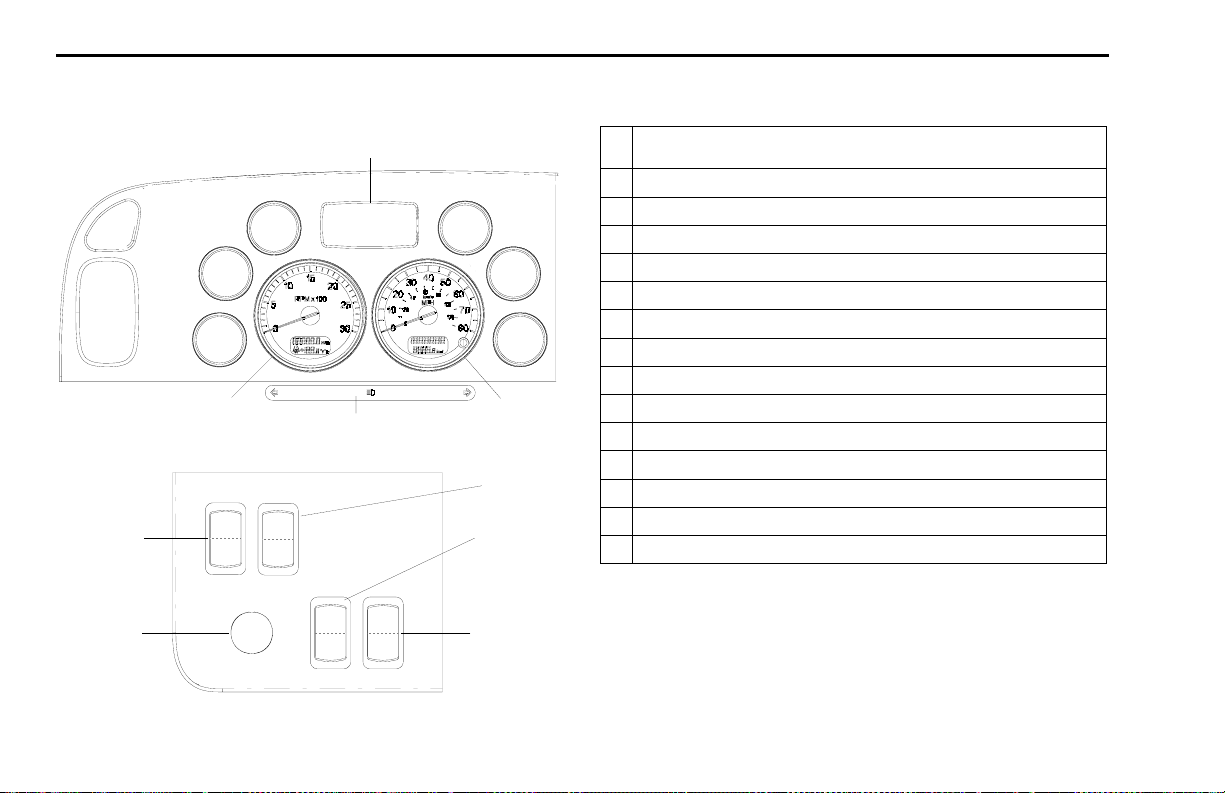

PART 4: CONTROLS AND DISPLAYS YOUR INSTRUMENT PANEL

PART 4: CONTROLS AND DISPLAYS

Your Instrument Panel

This part explains the location of the various features on

your vehicle and describes their function. For information

on using these features in driving, see the paragr aphs that

follow. Please remember that each Peterbilt is custommade. Your instrument panel may not look exactly like the

one in the pictures that follow. We have tried to describe

the most common features and controls a vailab le. You can

pick out the parts that apply to you and read them to be

fully informed on how your par ticular vehicle operates.

(08/06) Y53-6004 – 13 –

Page 16

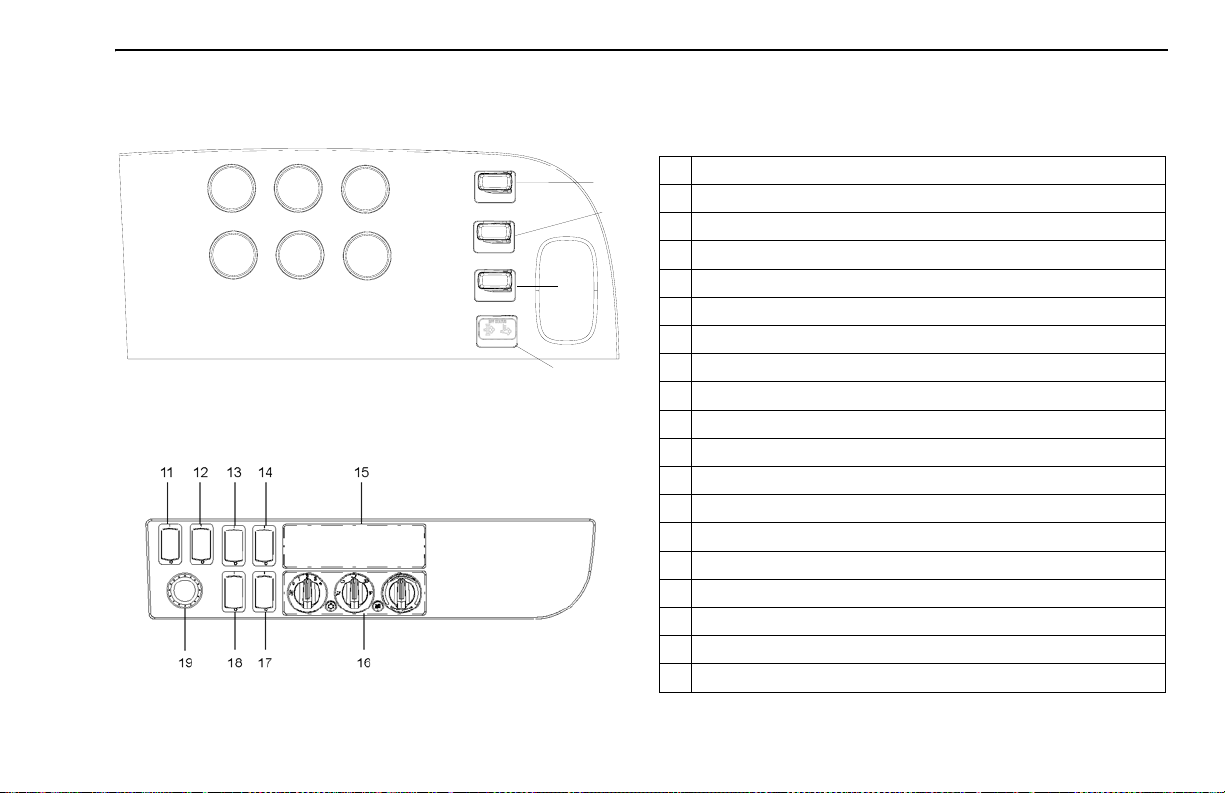

YOUR INSTRUMENT PANEL PART 4: CONTROLS AND DISPLAYS

Typical Conventional Cab Instruments and

Controls

6

5

4

3

2

1

I

I

12

O

O

I

I

11

O

O

7

8

9

10

Panel A

13

14

15

Panel C

LEFT SIDE

1 Directional Signal and High Beam Indicators (standard) (Note: Custom warning lights

are added in this area.)

2Tachometer

3 Oil Pressure

4 Coolant Temperature

5 Voltmeter

6 Driver Information Display

7Fuel Level

8Primary Air Pressure

9 Secondary Air Pressu re

10 Speedometer

11 Igni ti on Key Switch

12 Headlamps

13 Clearance Lamps

14 Panel Light Dimmer

15 Hazard Flasher

– 14 – Y53-6004 (08/06)

Page 17

PART 4: CONTROLS AND DISPLAYS YOUR INSTRUMENT PANEL

Conventional

RIGHT SIDE

1

4

2

5

3

6

7

8

9

10

Panel B

1 Oil Temperature

2 Transmission Oil Temperature

3 Front Driver Oil Temperature

4 Brake Application Pressure

5 Air Cleaner Restriction

6 Rear Driver Oil Temperature

7 Air Suspension Deflate

8 Fifth Wheel Lock

9 Interaxle Differential Lock

10 Exhaust Regeneration Display

11 Engine Fan

12 Fuel Tank Selector

13 Engine Brake On/Off

14 Engine Brake Selector

15 Radio

16 HVAC Control Panel

17 Cruise Control Select

18 Cruise Control On/Off

19 Menu Control Switch (MCS)

(08/06) Y53-6004 – 15 –

Page 18

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

Instruments And Controls

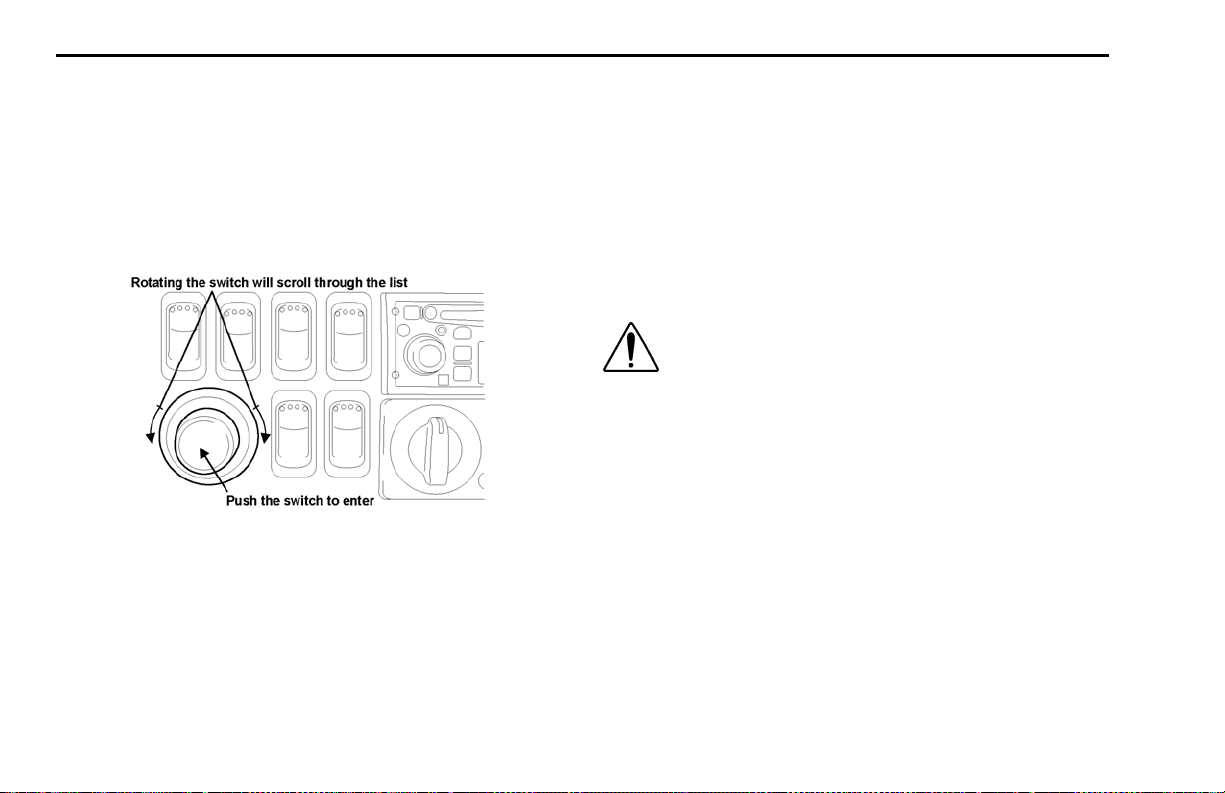

Menu Control Switch (MCS)

The MCS is used to navigate the Driver Information Display unit.

as shown in the illustration below.

The MCS has the following functions:

• Rotating the MSC

The Menu Control Switch is located on the D Panel

– Selecting display

• Pushing the MSC

– Confirming desired selection

Standard Warning Lights and Audible Alarm

The warning lights and audible alarm may indicate a system malfunction. Check the lights frequently, and respond

properly as soon as you see one go on. These lights could

save you from a serious accident.

WARNING! Do not ignore a warning light or

audbile alarm. These signals tell you something is wrong with your vehicle. It could be a

failure in an important system, such as the

brakes, which could lead to an accident. Have

the appropriate system checked immediately.

– Setting values

– 16 – Y53-6004 (08/06)

Page 19

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

active, the menu control switch (MCS) can be used to

scroll through the additional warnings.

2. Status Indicator:

Additional lights and indicator symbols are displayed in

the Status Indicator. They are limited to:

a. Park Brake

b. Transmission Gear (Automatic transmissions

only)

c. Warnings:

Number of active warnings.

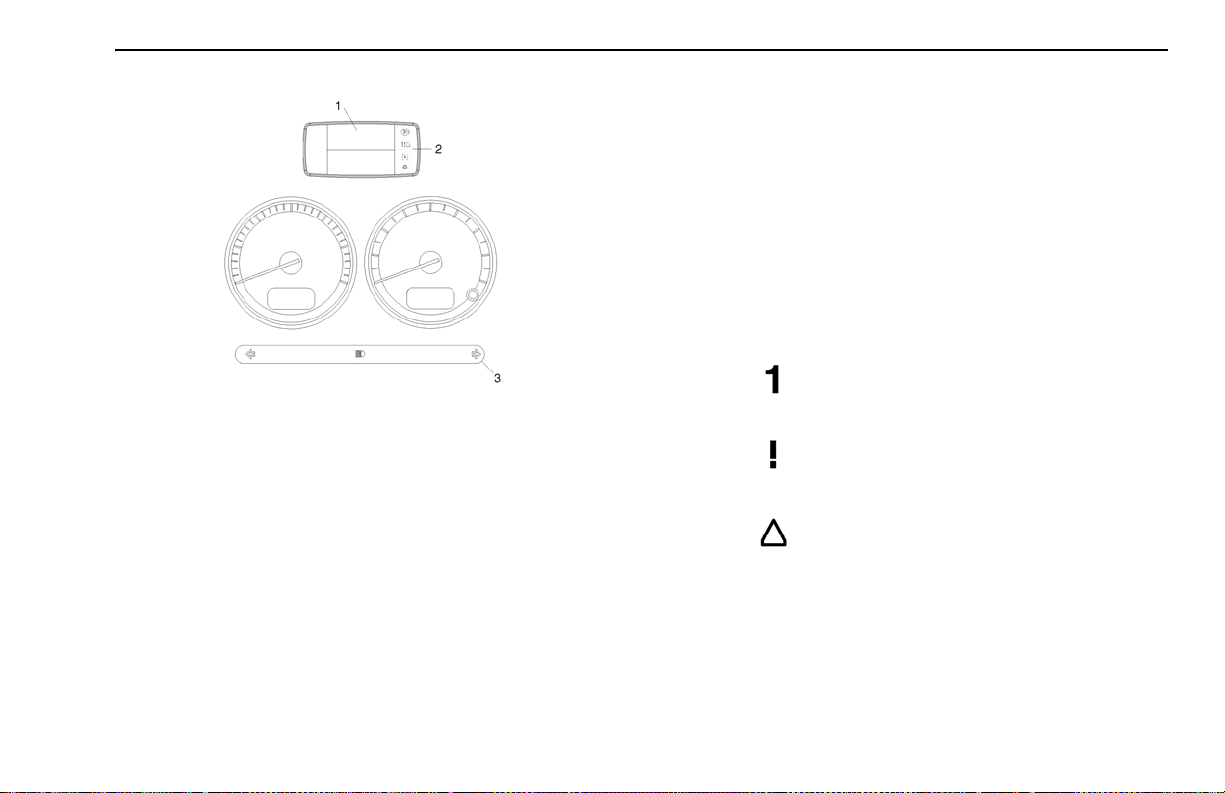

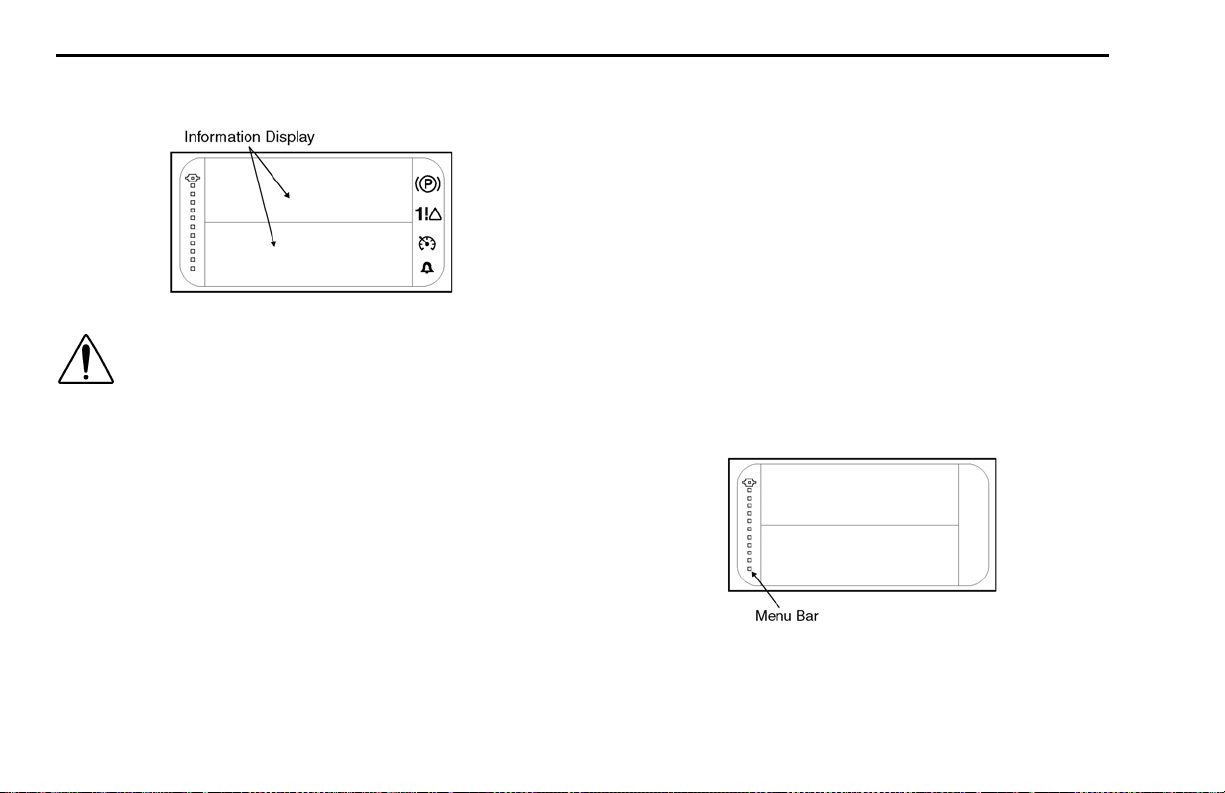

1. Driver Information Display 2. Status Indicator

3. Lower Light Bar

A red warning is active.

Warning lights and indicator symbols will be shown in both

areas 1 and 2. Area 3 is dedicated to the tur n and high

An amber warning is active.

beam indicator symbols.

1. Driver Information Display:

The display can show up to six warning lights. Warnings

do not have fixed positions and are displayed in order of

criticality. The most critical warning will be displayed on

d. Cruise Control - active

e. Clock alarm bell

Refer to “War ning Light / Indicator Symbols” on page 19

for inform ation on each symbol.

the top row and to the left. If more than six warnings are

(08/06) Y53-6004 – 17 –

Page 20

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

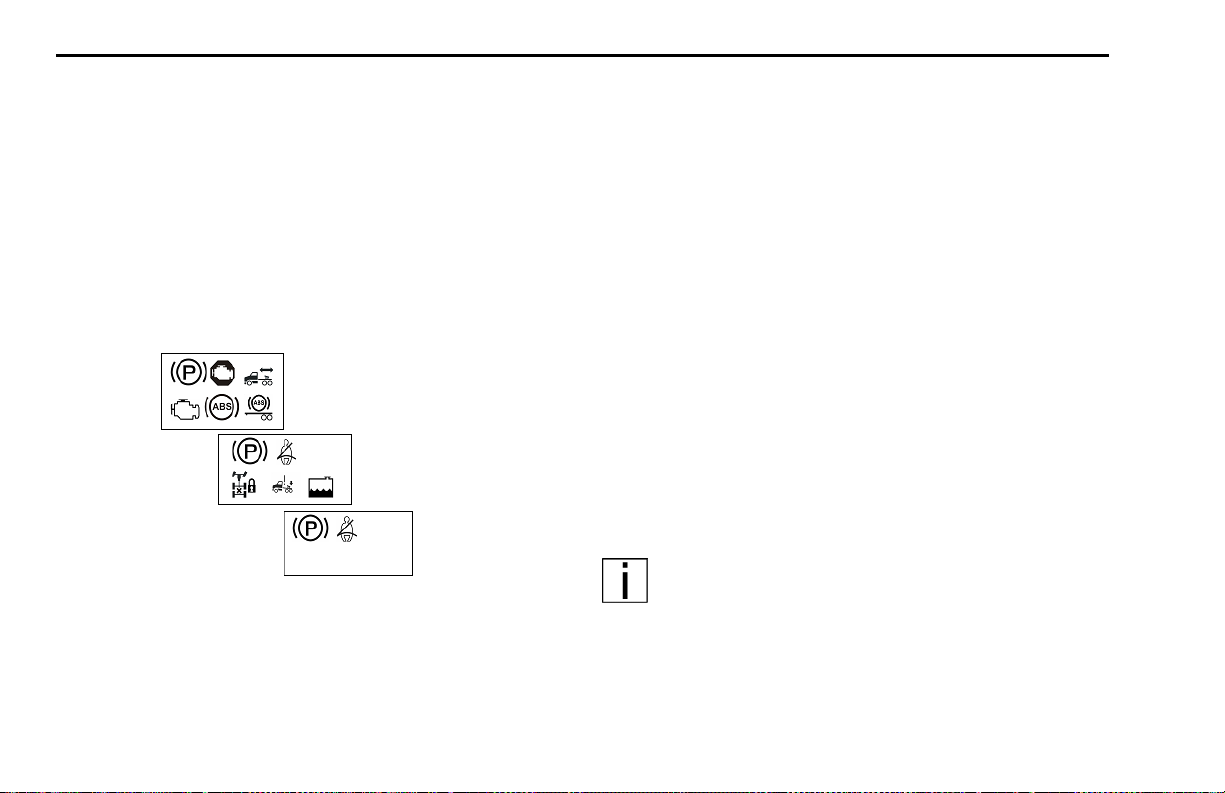

Instrument System Self Test:

When the ignition switch is turned on the instrumentation

system will undergo a Self Test. This test will verify the

operation of the gauges and warnings.

During the Instrumentation System Self Test, three

screens will sequentially display warning icons (approximately 3 seconds each screen) on the Information Display. These are:

First

Second

Third

Refer to “War ning Light / Indicator Symbols” on page 19

for information on each symbol.

Completing this sequence will indicate a successful Self

Test. Have your instrumentation system checked by a

qualitfied service technician if does not successfully complete.

Audible Alarm:

The audible alarm will sound during the In strumenta tion

System Self Test. The audible alarm will also sound in

conjunction with most warning lights. These events

include but are not limited to headlight on, fifth wheel, stop

engine, primary/secondar y air, and driver door open

warnings.

Optional Lights:

Additional lights may be operatio nal depend ing on individual vehicle specifications. These will be included in the

Instrument System Self Test.

NOTE: Some optional lights may illuminate even

though your vehicle is not equipped with that particular feature.

– 18 – Y53-6004 (08/06)

Page 21

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

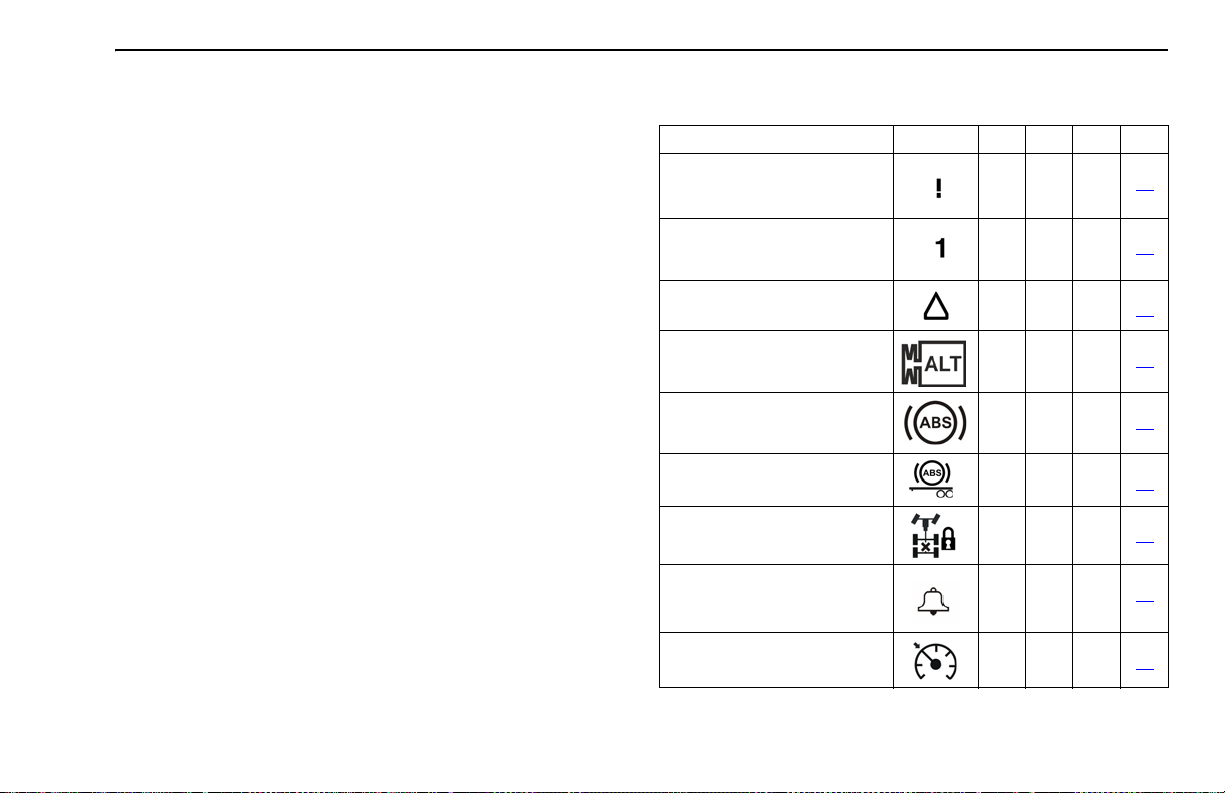

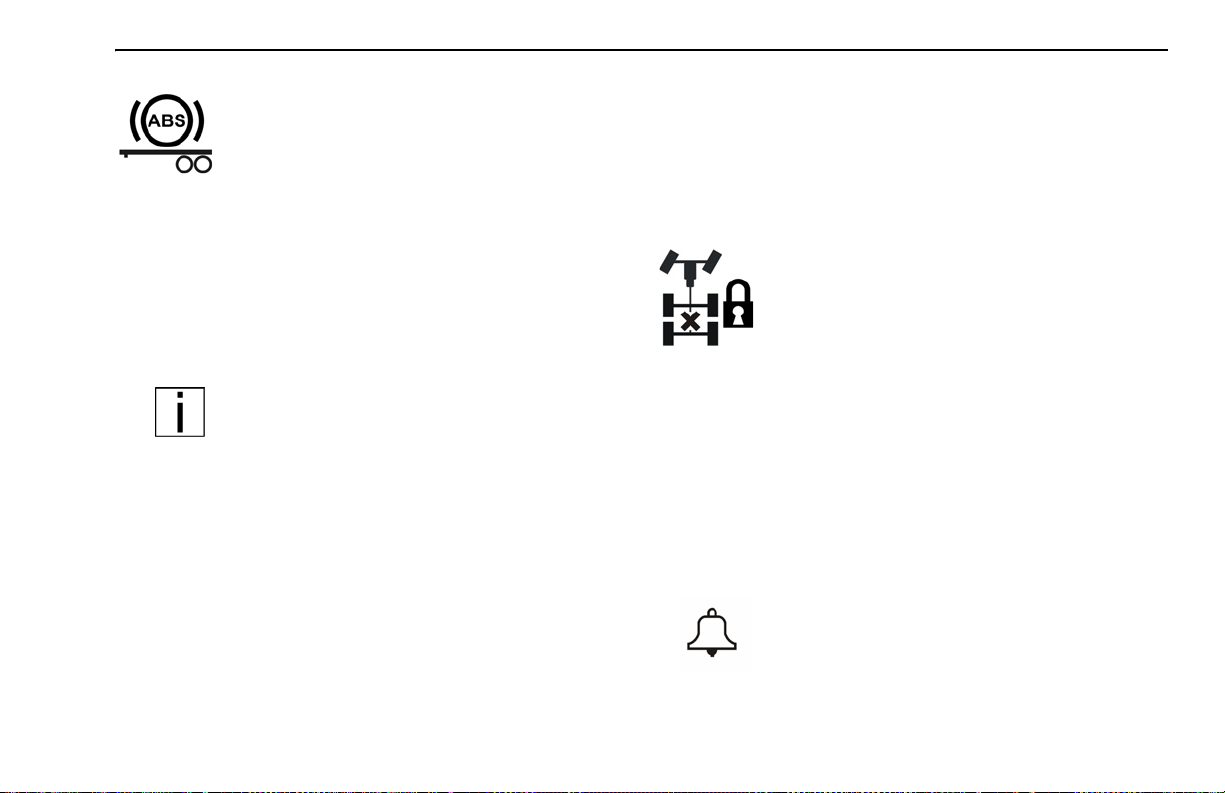

Warning Light / Indicator Symbols

The following is a list of W arning Light / Indicator Symbols.

Reading left to right, the table header identifies

• the Symbol Name

• the appearance of the Symbol

• the Symbol Color when it is illuminated

• whether the symbol is standard (Std) or op tional (Op t)

• the Page Number reference for additional information

Symbols are listed by major component sections.

Example: Engine, and then in alphabetical order.

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

1. Active Warnings, Exclamation

Point

2. Active Warnings, Number

3. Active Warnings, Triangle

4. Alternator

5. Anti-Lock Brake System

(ABS)

6. Anti-Lock Brake System

(ABS), Trailer

7. Axle, Inter-Axle Differential

Locked (Tandem Axles)

8. Clock, Alarm Bell

9. Cruise Control, Active

Red

Yellow

Yellow

Red

Yellow

Yellow

Yellow

Yellow

Yellow

22

22

22

22

22

23

23

23

24

(08/06) Y53-6004 – 19 –

Page 22

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

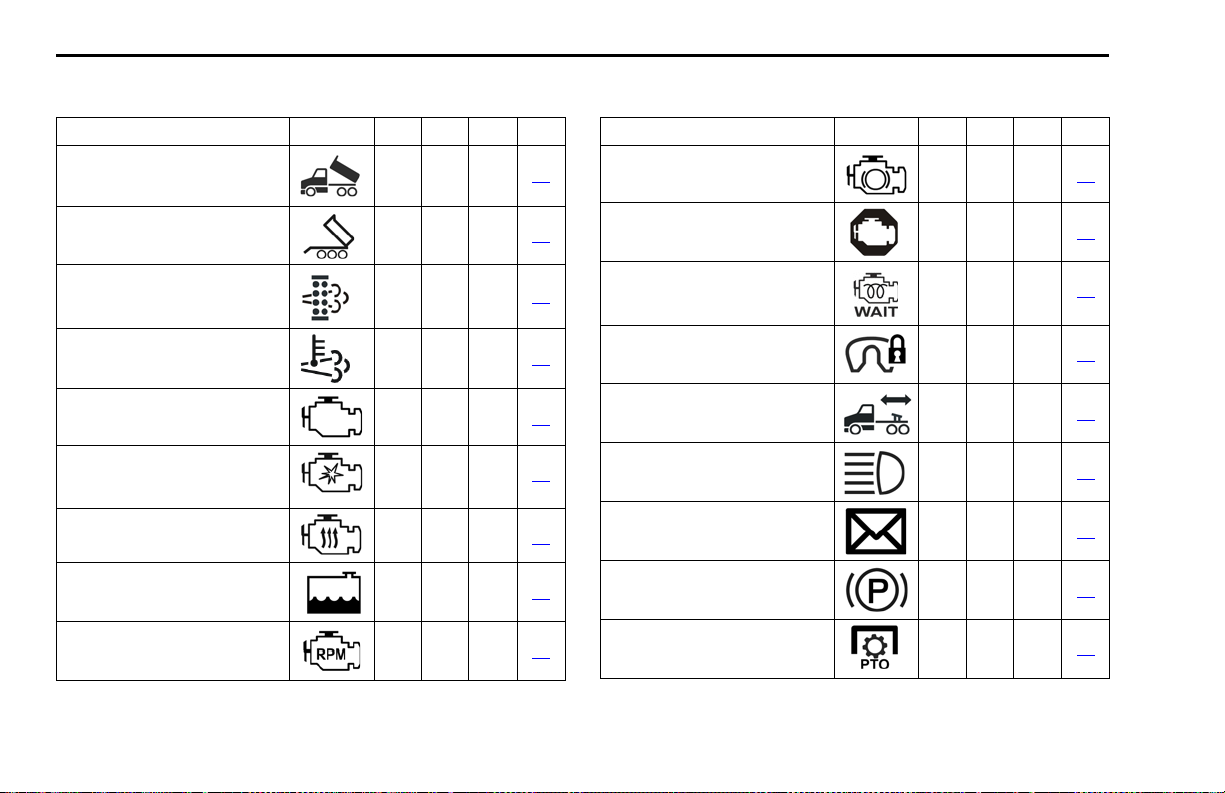

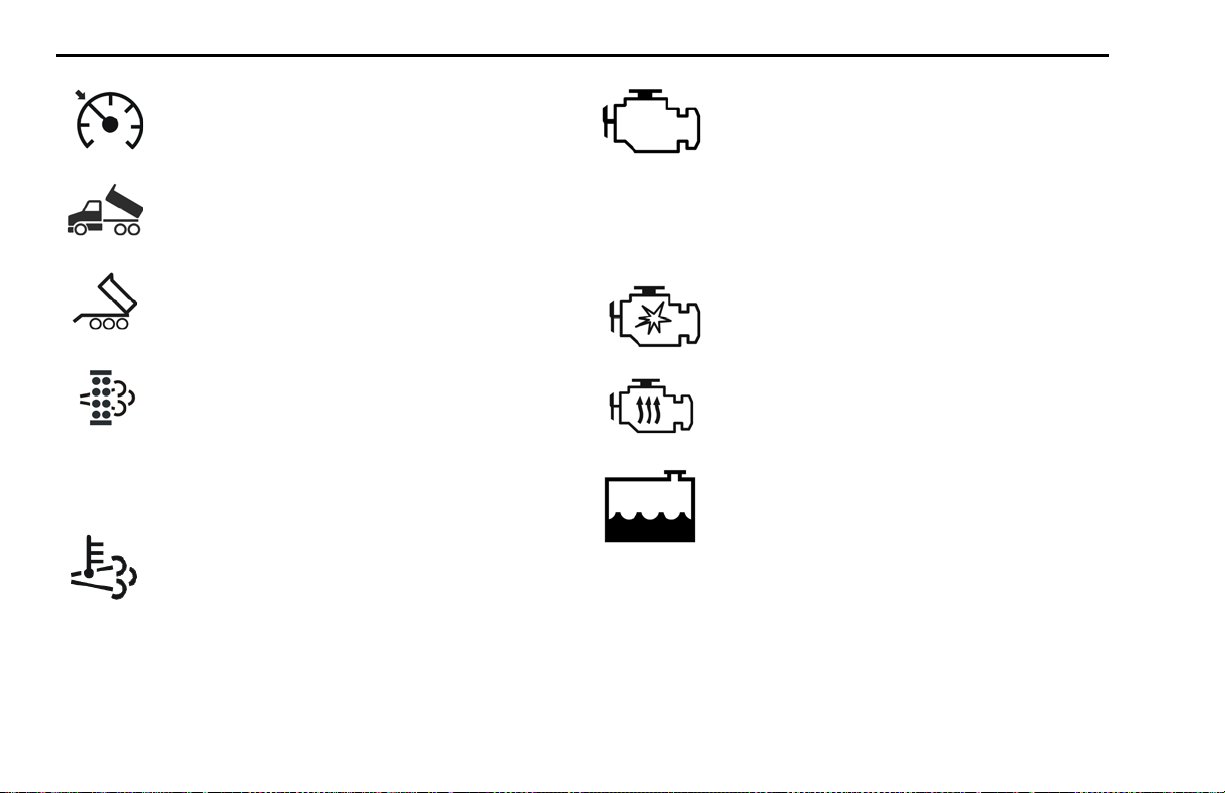

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

10. Dump Truck, Body Up

11. Dump Truck, Trailer Body Up

12. Emissions, Diesel Particulate Filter (DPF)

13. Emissions, High Exhaust

System Temperture (HEST)

14. Engine, Check Engine

15. Engine, Ether Start

16. Engine, Heater

17. Engine, Low Coolant Level

18. Engine, Overspeed

Yellow

Yellow

Yellow

Yellow

Yellow

Green

Yellow

Yellow

Red

24

24

24

24

24

24

24

24

25

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

19. Engine, Retarder (Brake)

20. Engine, Stop Engine

21. Engine, Wait To Start

22. Fifth Wheel, King Pin Lock

23. Fifth Wheel, Slide Unlocked

24. Lights, High Beam

25. Message Waiting

26. Park Brake

27. Power Take-off (PTO)

Green

Red

Yellow

Red

Red

Blue

Green

Red

Green

25

25

25

25

25

26

26

26

26

– 20 – Y53-6004 (08/06)

Page 23

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

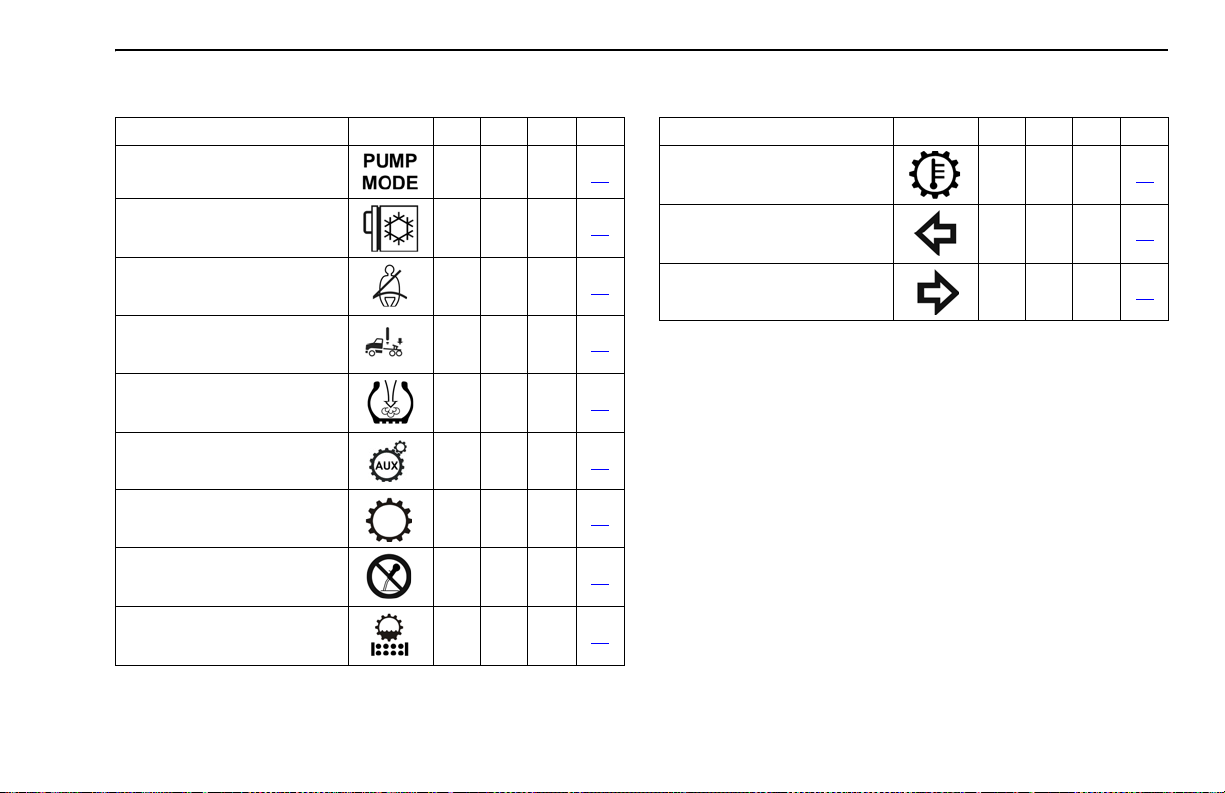

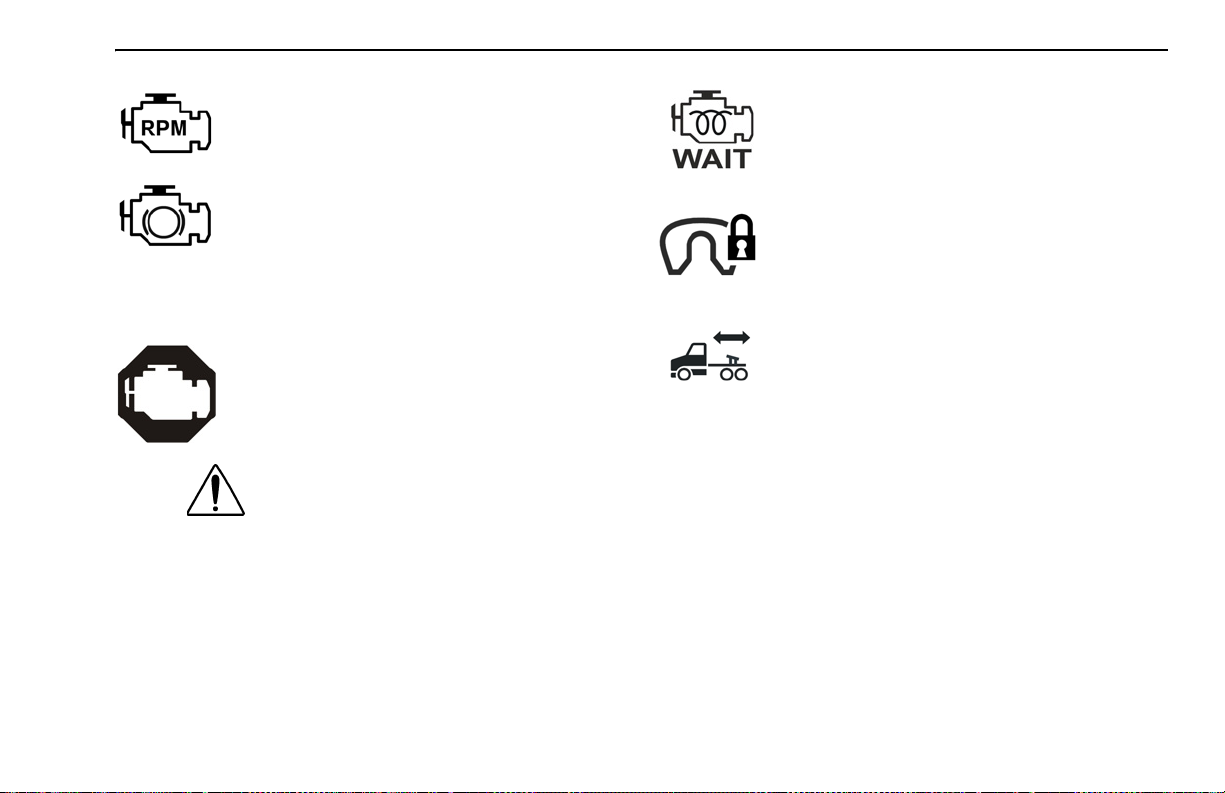

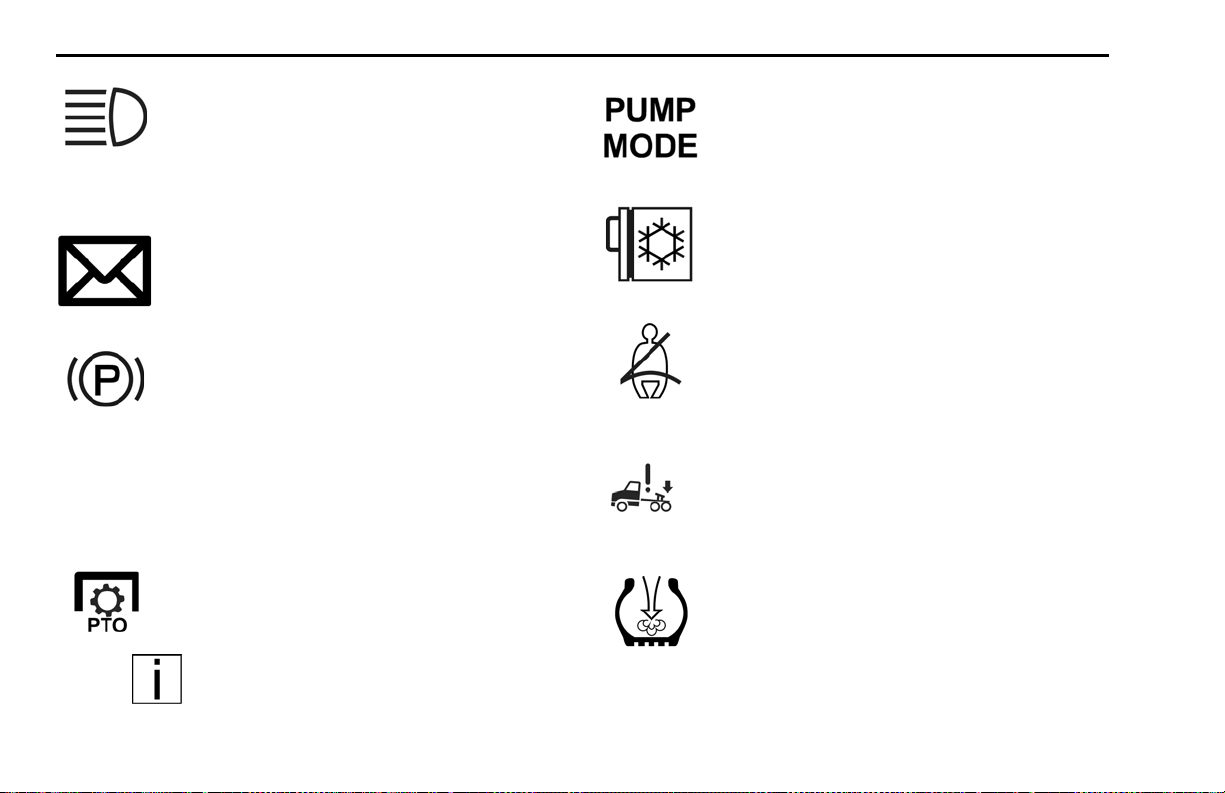

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

28. Power Take-off (PTO), Pump

Mode

29. Refrigerator

30. Seat Belt, Fasten

31. Suspension Dump

32. Tire Inflation

33. Transmission, Auxiliary

34. Transmission, Check

35. Transmission, Do Not Shift

36. Transmission, Oil Filter

Green

Green

Red

Yellow

Yellow

Yellow

Red

Red

Yellow

26

26

26

26

26

27

27

27

27

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

37. Transmission, Oil Temperature High

38. Turn Signal, Left

39. Turn Signal, Right

Yellow

Green

Green

27

27

27

(08/06) Y53-6004 – 21 –

Page 24

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

Warning Light/Indicator Symbol Descriptions

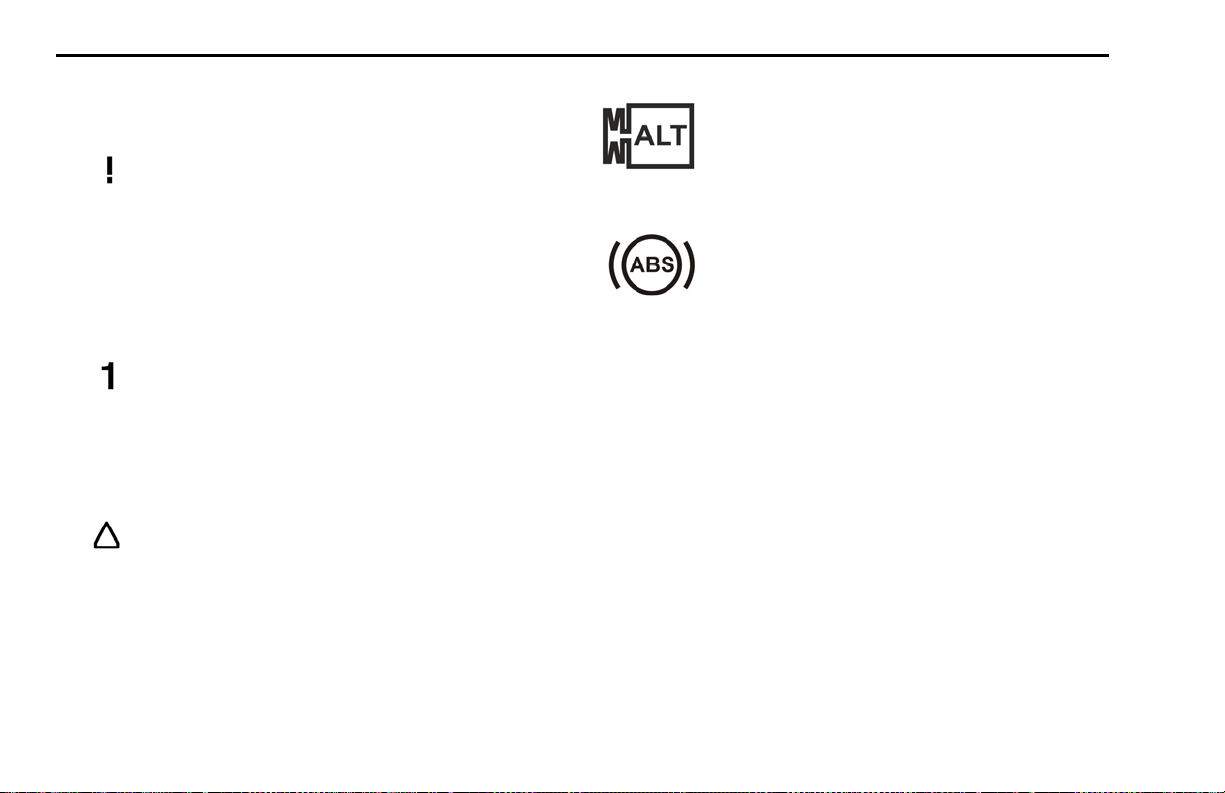

1. Active Warnings, Exclamation Point

Illuminates when a red warning is active. Use

the MCS knob to view the warnings that are

active. Refer to the preceedin g Figure ,

“Warning Light / Indicator Symbols,” on

page 19 for warning color classification.

2.Active Warnings, Number

Illuminates the total number of red and y ellow

active warnings.

active warnings if the display shows a > symbol.

Use the MCS to view the

3.Active Warnings, Triangle

Illuminates when an yellow warning is active.

Use the MCS knob to view the warnings that

are active. Refer to the preceeding Figure ,

“Warning Light / Indicator Symbols,” on

page 19 for warning color classification.

4.Alternator

Illuminates if the alternator is not charging.

(For alternators with warning lamp output

signal.)

5. Anti- L ock Brake System (A BS)

Illuminates during the Instrumentation System Self Test. Have the ABS system checked

by a Peterbilt dealer if the ABS War ning

Lamp stays on for more than 3 seconds.

Illuminates during normal operating conditions to indicate a problem with the ABS System. See “ABS Warning Lamps” on page 104

for more information.

Illuminates when a problem exists with the

optional Wheel Spin Control feature. See

“Advanced ABS with Stability Control” on

page 106 more infor mation.

– 22 – Y53-6004 (08/06)

Page 25

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

6. Anti-Lock Brake System (ABS), Trailer

Illuminates during the Instrumentation System Self Test and the tractor/truck is connected with a ABS equipped trailer.

Illuminates during normal operating conditions to indicate a problem with the Trailer

ABS System. This should be checked by a

Peterbilt dealer as soon as possible. See

“ABS Warning Lamps” on page 104 for more

information.

NOTE:

• Tractors/Trucks and trailers built after 3/1/01

must be able to turn on an In-Cab Trailer ABS

Warning Lamp (per U.S. FMVSS121). The

industry chose Power Line Communication

(PLC) as the standard method to turn it on.

See “Trailer ABS Warning Lamp” on page 104

for more information

• On trailers built prior to 3/1/01 verify trailer

ABS system status via the required external

warning lamp mounted on the trailer. The

indicator lamp on the trailer should be yellow

and identified with the letters "ABS".

7. Axle, Inter-Axle Differential Locked

(Tandem Axles)

Illuminates when the inter-axle differential

switch is ON thus locking the inter-axle differential. This powers the forward rear and the

rear rear differentials equally. When the

switch is turned off (inter-axle differential

unlocked) the en gine pow er is allow ed to flo w

to any of the 4 drive tires based on the diffe rential effect (mostly to the forward rear differential). (This feature is standard on all

tandem axles).

8. Clock, Alarm Bell

Illuminates when the alarm is set. It will flash

when the clock alarm is active.

(08/06) Y53-6004 – 23 –

Page 26

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

9. Cruise Control, Active

Illuminates when cruise control is active.

10. Dump Truck, Body Up

Illuminates when Truck Dump Body is up.

11. Dump Truck, Trailer Body Up

Illuminates when Trailer Dump Body is up.

12. Emissions, Diesel Particulate Filter

(DPF)

Illuminates when diesel par ticulate trap is

plugged. This warning will also illuminate

when regeneration operation is disabled.

13. Emissions, High Exhaust System

Temperture (HEST)

Illuminates when the exhaust gas temperature and exhaust components become

extremely hot.

14. Engine, Check Engine

Illuminates when a problem exists, but the

vehicle can still be safely driven. Vehicle

should be serviced to correct the problem

but the situation should not be considered

an emergency.

15. Engine, Ether Start

Illuminates when ether start switch is on.

16. Engine, Heater

Illuminates when Engine Heater switch is on.

17. Engine, Low Coolant Level

Illuminates with an audible alarm indicating

critically low coolant level. The vehicle must

be serviced to correct the problem but the situation should not be considered an emergency.

– 24 – Y53-6004 (08/06)

Page 27

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

18. Engine, Overspeed

Illuminates when engine RPM is exceeded.

19. Engine, Retarder (Brake)

Illuminates when the engine retarder (compression brake or exhaust brake) switch is

turned on. (Engine retarders are an option.)

20. Engine, Stop Engine

Illuminates and an audible alarm tone will

sound when a major engine system problem

exists.

WARNING! This should be considered

an emergency. You should stop the vehicle as safely as possible and turn OFF

the ignition. The vehicle must be serviced and the problem corrected before

driving again. Failure to do so may cause

severe engine damage or cause an accident.

21. Engine, Wait To Start

Illuminates when engine grid heater is on

(Cummins ISB and ISC engines).

22. Fifth Wheel, King Pin Lock

Illuminates when air actuated fifth wheel King

Pin is unlocked.

23. Fifth Wheel, Slide Unlocked

Illuminates and an audible warning tone will

sound when the air operated sliding fifth

wheel switch is on, thus unlocking the sliding

fifth wheel. The light and an audible warning

tone should NOT be considered an emergency but simply as a reminder to turn off the

switch to lock the sliding fifth wheel before

driving. This switch should not be operated

while driving. (Sliding fifth wheels are an

option).

(08/06) Y53-6004 – 25 –

Page 28

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

24. Lights, High Beam

Illuminates when the high beams are on.

This icon will flash with audible alarm if the

headlamps are left on when the door is open.

25. Message Waiting

Illuminates with telematic equipped messaging.

26. Park Brake

Illuminates in the status indicator when parking brakes are applied and the vehicle is stationary. This symbol will also illuminate in the

Driver Information Display if the parking

brakes are applied and the vehicle is in

motion.

27. Power Take-off (PTO)

Illuminates when the PT O is engaged.

NOTE: Do not drive vehicle with PTO

engaged.

28. Power Take-off (PTO), Pump Mode

Illuminates with remote throttle application.

Indicates pump mode is active.

29. Refrigerator

Illuminates to indicate that the refrigerator is

on and ignition is off.

30. Seat Belt, Fasten

Illuminates when the ignition key is turned on

as a reminder to fasten your seat belt.

31. Suspension Dump

Illuminates when suspension air bags are

deflated.

32. Tire Inflation

Illuminates when tire pressures need to be

checked. (Tire Pressure Monitoring System

is an option)

– 26 – Y53-6004 (08/06)

Page 29

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

33. Transmission, Auxiliary

Illuminates to indicate auxiliar y transmission

is in neutral.

34. Transmission, Check

Illuminates when transmission has recorded

a fault code. This icon ma y also a ppear in the

Transmission Display menu of the Driver

Information Display unit (see item G; page

31). If the user is in this display menu, the

icon does not indicate a fault code.

35. Transmission, Do Not Shift

Illuminates with automatic transmissions

equipped with “Don’t Shift” output.

36. Transmission, Oil Filter

Illuminates when service is required (Allison

transmissions only).

37. Transmission, Oil Temperature High

Illuminates when transmission lubricant temperature is too high.

CAUTION: This should be considered an

emergency. You should stop the vehicle as

safely as possible and turn OFF the ignition.

The vehicle must be serviced and the problem corrected before driving again. Failure to

do so may cause severe transmission damage.

38. Turn Signal, Left

Blinks when the left turn signal or the hazard

light function is operating.

39. Turn Signal, Right

Blinks when the right turn signal or the hazard light function is operating.

(08/06) Y53-6004 – 27 –

Page 30

DRIVER INFORMATION DISPLAY PART 4: CONTROLS AND DISPLAYS

Driver Information Display

WARNING! Do not look at the Driver Information Display for prolonged periods while the

vehicle is moving. Only glance at the monitor

briefly while driving. Failure to do so can

result in the driver not being attentive to the

vehicle’s road position, which could lead to an

accident and possible personal injury or

equipment damage.

The Driver Information Display, located at the top of the

instrument cluster, displays important vehicle information

through a constant monitoring of systems when any of the

following conditions are met:

• ignition key in ON or ACC positions

• MCS button is pushed (independent of ignition key

switch position)

• clock alarm sounds

• driver or passenger door is opened

• hazard warning lamp switch is on

The various functions may be accessed by navigating

through Menu Screens using the MCS. Refer to “Menu

Control Switch (MCS)” on page 16 for more detail for the

MCS.

The bullets in the Menu Bar allow access to each item by

pushing the MCS when the desired bullet is highlighted.

• ignition timer is active

– 28 – Y53-6004 (08/06)

Page 31

PART 4: CONTROLS AND DISPLAYS DRIVER INFORMATION DISPLAY

In addition to a blank screen, the f ollowing are men u items

and the information available within each menu selections.

NOTE: Some Driver Inf ormation Displa y functions are

only accessible when the vehicle is parked. Other

functions are accessible while the vehicle is moving

or when parked. Each function is identified in the following descriptions.

A. Fuel Economy (Accessible while parked or

driving)

1. Current fuel economy - Indicates instantaneous

fuel economy.

2. Trip fuel economy - Indicates trip fuel economy.

B. RPM Detail (Accessible while parked or driving)

RPM reading of actual engine RPM. Engine RPM

within the bar graph indicates the engine is operating in the most efficient RPM range. The display

color will change if you are operating outside of this

range.

C. Ignition Timer (Accessible while parked only)

Ignition timer is set from this menu. The ignition

timer may be set for up to 30 minutes.

(08/06) Y53-6004 – 29 –

Page 32

DRIVER INFORMATION DISPLAY PART 4: CONTROLS AND DISPLAYS

D. Trip Information

NOTE: When accessing the trip information

menu, push the MCS on this menu (bullet).

To exit, push the MCS again. To reset the trip

values, press the Tr ip Odometer Reset Button on the main gauge instrument cluster.

Certain Trip Information functions area accessible

when driving or when parked:

– Trip Economy

– Trip Average Speed

Other Trip Information functions are accessible only

when parked:

– Trip Distance

– Trip Engine Hours

– Trip Idle Hours

– Trip Idle Percentage (%)

– PTO Hours

– PTO Trip Hours

– PTO Trip Percentage (%)

To reset the Tr ip Values, press the Trip Odometer

Reset Button on the main gauge instrument cluster.

E. Truck Information (Accessible only while parked)

NOTE: When accessing the truck information menu, push the MCS on this menu (bullet). To exit, push the MCS again.

1. Chassis Number

2. Engine Make

3. Engine Model

4. Engine SW Version

5. Transmission Make

6. Transmission Model

– 30 – Y53-6004 (08/06)

Page 33

PART 4: CONTROLS AND DISPLAYS DRIVER INFORMATION DISPLAY

7. Transmission SW Version

8. ABS (Antilock Braking System) Make

9. ABS Model

10. ABS SW Version

11. CECU (Cab Electronic Control Unit) Software

Version

12. CECU Hardware Version

F. Diagnostic Display (Accessible only while parked)

NOTE: “Faults Found” will only be active if a

red or yellow warning lamp is illuminated.

The diagnostic display menu (bullet) will indicate a

fault that is generated by the vehicle's Engine, ABS

and/or Transmission systems. While on this menu

item the display will either indicate "No Faults

Found" or "F aults Found". If "Faults Found" is active ,

pushing the MCS will display new menus for more

information.

G. Transmission Display (Automated Transmissions

only - Accessible while parked or driving)

NOTE: Refer to the Automated Transmission

Operator’s Manual for additional information.

This menu will show gear number that coincides with

the current transmission gear selected. The menu

also displays the transmission icon to let the user

know what screen they are in. (Does not indicate a

fault code.)

H. Settings Menu (Accessible only while parked)

The Settings menu screen allows the driver to view

and/or change the following menu items:

(08/06) Y53-6004 – 31 –

Page 34

DRIVER INFORMATION DISPLAY PART 4: CONTROLS AND DISPLAYS

• Display Format 12 Hour (AM/PM) or 24 Hour

(military)

• Home/Local Time

• Alarm ON/OFF

•Alarm Time

• Units of measure

• Language (English, Spanish or French)

To Set Home, Local or Alarm Time:

1. When in the Settings Menu, scroll through the

list of menu items. Press the MCS to select the

item to change.

2.

To Set Clock Display Format:

1. When in the Settings Menu, scroll through the

list of menu items to "Format".

3. Rotate the MCS knob to change the hour. Press

the MCS.

2. Press the MCS to display either 12 hour (AM/

PM) or 24 hour (military) time.

– 32 – Y53-6004 (08/06)

Page 35

PART 4: CONTROLS AND DISPLAYS DRIVER INFORMATION DISPLAY

1. When in the Settings Menu, scroll through the

list of menu items to "Units". Press the MCS.

2. Press the MCS to display either Standard or

Metric units. Refer to “Engine Hours / Outside

Air Temperature” on page 36 for another

method to change units.

4. Rotate the MCS knob to change the minutes.

Press the MCS.

5. Rotate the MCS to toggle AM/PM. Press the

MCS

6. Rotate the MCS to select Exit. Press the MCS to

exit the settings function.

To Turn Alarm ON/OFF:

To Set Language:

1. When in the Settings Menu, scroll through the

list of menu items to "Language". Press the

MCS.

2. Rotate the MCS to display either English, Spanish or French. Press the MCS knob to select the

desired language.

1. When in the Settings Menu, scroll through the

list of menu items to "Alarm". Press the MCS.

2. Press the MCS to turn the alarm ON or OFF.

To Set Units of Measure:

(08/06) Y53-6004 – 33 –

Page 36

STANDARD GAUGES PART 4: CONTROLS AND DISPLAYS

Standard Gauges

On the pages that follow you will find descriptions of some

of the gauges on your instrument panel. For more information about using them in driving, see “PART 7: STARTING & OPERATING THE VEHICLE.” Also check the Index

under the name of the gauge or function you w ant to know

more about.

WARNING! Do not ignore a warning light or

audbile alarm. These signals tell you something is wrong with your vehicle. It could be a

failure in an important system, such as the

brakes, which could lead to an accident. Have

the appropriate system checked immediately.

Odometer / Trip Meter

Odometer

Trip Reset

Button

Some gauges will display a red LED warning light, with

some accompanied by an audible alarm, whenever the

limits of the function being displayed are exceeded.

Speedometer

The speedometer indicates the ve hicle speed in miles pe r

hour (mph) and in kilometers per hour (km/h). The speedometer also includes an odometer, trip meter, and trip

reset button.

– 34 – Y53-6004 (08/06)

The LCD display in the lower par t of the speedometer

contains the odometer and trip meter.

The odometer displays the total distance your vehicle has

traveled. It will displa y in miles on an English speedometer

or in kilometers on a metric speedometer. The maximum

Trip

Meter

Page 37

PART 4: CONTROLS AND DISPLAYS STANDARD GAUGES

distance that can be shown on the odometer is

“1 999 999” before it rolls over to zero.

The trip odometer displays how far the vehicle has gone

on a particular trip. The trip odometer will display in miles

on an English speedometer or in kilometers on a metric

speedometer, in one tenth divisions. The maximum distance that can be shown on the trip odometer is “9999.9”

before it rolls over to zero.

To reset the trip odometer, press and hold the trip reset

button on the speedometer. The numbers will reset to 0

and begin to count new miles/km traveled. This also

resets the trip values in the Driver Information Display.

The trip reset button also toggles all displays between

English and Metric. (See page 36.)

NOTE: The Odometer/Trip Meter comes on when

the door is opened or the key is in the accessory

or ignition position. The Odometer/Tr ip Meter will

remain on for 3 seconds after the door is closed

or the ignition switch is turned off. This allows

driver and service personnel to read the odometer without ignition switch being turned on.

Tachometer

Your tachometer measures the engine speed in revolutions-per-minute (RPM). The tachometer also includes an

engine hour meter and outside air temperature display.

Watching your tachometer is important to dr iving efficiently. It will let you match driving speed and gear selection to the operating range of your engine. If your engine

speed gets too high, you can select a higher gear to lo w er

the RPM. If your engine speed drops too low, you can

select a lower gear to raise the RPM.

(08/06) Y53-6004 – 35 –

Page 38

STANDARD GAUGES PART 4: CONTROLS AND DISPLAYS

Engine Hours / Outside Air Temperature

Hour Meter

Snowflake

Symbol

The LCD display in the lower part of the tachometer contains the engine hour meter and the outside air temperature display.

The engine hour meter will display the total number of

hours the engine has been running. The maximum hours

that can be shown are “99999.9” before the meter rolls

over to zero.

The outside air temperature (OAT) will display the temperature outside the vehicle. The temperature can be displayed from -40° to 158° in Fahrenheit or -40° to 70°

Celsius.The display will also alert the driver when the outside temperate approaches freezing (32°F or 0°C) by displaying a snowflake symbol. The symbol will turn on when

the temperature drops below 34°F or 11°C and flash for

the first 3 seconds, then stay on until the temperature

goes above 37°F or 28°C.

Outside

Air

Temperature

The temperature can display using Standard or Metric

units. Press the trip reset button on the Speedometer 4

times within 4 seconds. This will also change the units

shown by the Driver Information Display.

Refer to “To Set Units of Measure:” on page 33 fo r another

method to change units.

NOTE: The OAT will come on when the door is

open and the key switch is in the accessor y or

ignition position. The OAT display will turn off

when the ignition switch is turned off.

NOTE: The OAT uses a sensor (loc ated at the

bottom of the driver’s side mirror assembly) to

measure outside air temperature only. It is not

capable of displaying the temperature of the road

surface on either the temperature display or the

snowflake icon.

NOTE: The effects of direct sunlight, or the use of

mirror heat, will increase the outside air temperature displayed while the vehicle is stationary.

– 36 – Y53-6004 (08/06)

Page 39

PART 4: CONTROLS AND DISPLAYS STANDARD GAUGES

Engine Oil Pressure Gauge

It is important to maintain oil pressure within acceptable

limits. Your engine manual will give normal operating pressures for your engine.

CAUTION: Continuing to operate your vehicle

with insufficient oil pressure will cause serious

engine damage.

• If your oil pressure fails to rise within 10 seconds after

your engine starts, stop the engine and determine the

cause.

• If your oil pressure suddenly drops while you are driving, bring the vehicle to a stop as soon as possible in

a safe location off the road and turn off the engine.

Wait a f ew min utes to allow oil to dr ain into the oil pan,

and then check the oil le v el. Add oil if necessary. If the

problem persists, contact an authorized service center.

Check the engine manufacturer’s manual for the correct

oil pressure ranges for your engine.

Water Temperature Gauge

The water temperature gauge shows the temperature of

the engine coolant. Under normal operating conditions the

(08/06) Y53-6004 – 37 –

Page 40

STANDARD GAUGES PART 4: CONTROLS AND DISPLAYS

water temperature gauge should register between 16 5°

and 205°F (74° and 90°C). Under cer tain conditions,

somewhat higher temperatures may be acceptable. But

the maximum allowable temperature is 210°F (99°C) with

the cooling system pressurized, except for cer tain special

engines. Check your engine manual to be sure.

Engine Overheating

WARNING! Do not remove the radiator fill cap

while the engine is hot. Scalding steam and

fluid under pressure may escape and cause

serious personal injuries. You could be badly

burned.

• Wait until the coolant temperature is below

122°F (50°C).

• Protect face, hands, and arms by covering

the cap with a large, thick rag to protect

against escaping fluid and steam.

• Carefully and slowly turn the cap one-quarter of a turn or until it reaches the first stop—

allowing excess pressure to escape—push

down and turn for final removal.

Wait until the coolant temperature is below 122° F (50°C).

Protect your face, hands, and arms by covering the cap

with a large, thick rag to protect y ou aga inst escaping fluid

and steam. Before you completely remove the cap, carefully and slowly turn the cap part way to allow excess

pressure to escape. Then push down and turn for final

removal.

The cooling system may overheat if the coolant level is

below normal or if there is a sudden lo ss of co olant (s uch

as a worn hose splitting). It may also temporarily overheat

during severe operating conditions such as climbing a

long hill on a hot day or stopping after high-speed driving.

If the “Engine Coolant Temperature” warning light comes

on, or you have any other reason to suspect the engine

may be overheating:

• Stop the vehicle, but DO NOT TURN OFF THE

ENGINE unless a low water warning device indicates

a loss of coolant.

• With the transmission in neutral, check to be cer tain

the oil pressure gauge reads nor mal. Increase the

engine speed to about 1100 - 1200 RPM, maximum.

Return the idle speed to normal after 2 or 3 minutes. If

– 38 – Y53-6004 (08/06)

Page 41

PART 4: CONTROLS AND DISPLAYS STANDARD GAUGES

the warning light does not go off or the temperature

gauge does not begin to drop, then turn the engine

off.

• If the overheating came from severe operating conditions, the temperature should have cooled by this

time. If it has not, stop the engine and let it cool bef or e

checking to see if the coolant is low.

Voltmeter

The voltmeter displays the voltage at which your batteries

are being charged while the engine is operating.

Fuel Gauge

WARNING! Do no t remove a fuel tank cap near

an open flame. Hot fuel vapors are combustible and can cause an explosion or fire resulting in injury or death.

CAUTION: Use Ultra Low Sulfer Diesel fuel only.

Failure to do so may damage components of the

Diesel Particulate Filter (DPF).

The fuel gauge shows the approximate amount of fuel in

the fuel tanks. Besides empty and full, the gauge also indicates 1/4, 1/2, and 3/4 of total capacity. You will want to

keep your fuel tanks at least half full to reduce condensa-

(08/06) Y53-6004 – 39 –

Page 42

STANDARD GAUGES PART 4: CONTROLS AND DISPLAYS

tion of moisture in the tanks. This moisture can damage

your engine.

Primary (Secondary) Air Pressure Gauge

(Air Reservoir)

The air pressure gauge indicates the amount of air pressure in the brake system in pounds per square inch (psi).

• The primary gauge shows front reservoir air pressure.

• The secondary gauge shows pressure in the rear reservoir.

Ensure the air pressure registers more than 100 psi in

both service systems before you move the vehicle. If the

pressure in either circuit is too low for normal brake operation, the warning light will glow and the audible alarm will

sound.

– 40 – Y53-6004 (08/06)

Page 43

PART 4: CONTROLS AND DISPLAYS OPTIONAL GAUGES

WARNING! The air pressure warning light and

the audible alarm indicate a dangerous situation. There is not enough air pressure in the

reservoirs for repeated braking and the brake

system has failed. If air pressure falls below

60 psi (414 kPa) the spring brakes could suddenly apply, causing a wheel lockup, loss of

control, or your vehicle to be overtaken by following vehicles. You could be in an accident

and severely injured. If these alarms come on

while you are driving, bring your vehicle to a

safe stop right away. If the light and alarm do

not turn off at start-up, do not try to drive the

vehicle until the problem is found and fixed.

Optional Gauges

Air Filter Restriction Indicator or Gauge

This gauge indicates the condition of the engine air

cleaner and is measured by inches of water (H

clean filter should register 7 in. H

O (may vary with sys-

2

tem design) and a filter whose life is over will register

approximately 25 in. H

O.

2

O). A

2

(08/06) Y53-6004 – 41 –

Page 44

OPTIONAL GAUGES PART 4: CONTROLS AND DISPLAYS

CAUTION: Continued operation with the Air Filter

Restriction Gauge reading 25 in. H

damage to the engine. Inspect the filter and

replace if necessary. Holes in the paper element

render an air cleaner useless and may cause the

Air Filter Restriction Gauge to give a false reading, even if the element is clogged. Replace the

element if it is damaged.

O may cause

2

Manifold Pressure Gauge

Your ma nifold pressure gauge indicates the power your

engine is putting out by showing the amount of turbo

boost. If the pressure indicated by your manifold pressure

gauge goes down, there may be something wrong with

your engine. Have it checked by a qualified service person.

Fuel Pressure Gauge

Your vehicle may also have a fuel pressure gauge.

WARNING! Carrying ad ditional fuel container s

in your vehicle is dangerous. Full or empty,

they may leak, explode, and cause or feed a

fire. Don’t carry extra fuel containers - even

empty ones.

– 42 – Y53-6004 (08/06)

Page 45

PART 4: CONTROLS AND DISPLAYS OPTIONAL GAUGES

Air Application Gauge

This gauge shows how m uch air pressure is being applie d

from your foot brake valve or trailer brake hand valve.

Transmission Temperature Gauge

Your Transmission Temperature Gauge indicates the temperature of the oil in your transmission. Watch this gauge

to know when your transmission is overheating. If it is,

have it chec ked by an authorized service representative.

Maximum transmission temperature may vary, depending

upon the transmission and type of lubricant. Check your

transmission’s owner’s manual.

(08/06) Y53-6004 – 43 –

Page 46

OPTIONAL GAUGES PART 4: CONTROLS AND DISPLAYS

Forward Drive Axle Temperature Gauge

Rear Drive Axle Temperature Gauge

These gauges indicate the temperature of the lubricant in

your vehicle’s axle(s). These temperatures will vary with

the kind of load you are carrying and the driving conditions you encounter. Maximum axle temperature may

vary, depending upon the axle and type of lubricant. Very

high temperatures signal a need to hav e y our axle(s) lubrication checked.

CAUTION: Driving with very hot temperatures in

your rear drive axles can cause serious damage

to axle bearings and seals. Have your axle lubrication checked if you notice a sign of overheating.

– 44 – Y53-6004 (08/06)

Page 47

PART 4: CONTROLS AND DISPLAYS STEERING COLUMN-MOUNTED CONTROLS

Steering Column-Mounted Controls

Turn Signal and Indicator Lights

NOTE: The ignition key must be turned to ON for

the signal/switch to operate.

Your turn signal lever is mounted on the left side of the steering column below the steering wheel. Green directional indicator lights appear on the instrument panel. To operate the

signal, move the lever in the direction of the turn. Each time

the turn indicator is activated the audbile alarm emits a short

beep.

WARNING! After you complete a turn, shut the

system off by returning the lever to the “OFF”

(center) position. The switch's lever action is

NOT self-canceling. Failure to shut off a turn

signal could confuse other drivers and result in

an injury accident. An indicator light in the

instrument panel will flash until the turn signal

is turned off.

High Beam Headlamps

NOTE: The headlamps must be “ON” for the high

beam switch to operate.

• To switch your headlamps to lower or higher beam,

gently pull the turn signal lever towards the steering

wheel, until you hear the switch click and the beam

changes. The blue indicator light in the instrument

panel will be ON when the high beam is being used.

• To return to previous beam: pull the lever towards the

steering wheel again.

(08/06) Y53-6004 – 45 –

Page 48

STEERING COLUMN-MOUNTED CONTROLS PART 4: CONTROLS AND DISPLAYS

Headlamp Flash

To activate headlamp flash, gently push the turn signal

lever away from the steering wheel until you hear and feel

the switch click. Release lever to deactivate.

• If your headlamps are off, low beams will flash on.

• If your headlamps are on, they will dim. Maximum

duration of dimming is 3 seconds. When the function

ends, your headlamps will return to low beams.

ID And Clearance Lights Flash

To flash, press the button on the end of the turn signal

lever and ho ld. To cancel the flash, release the button.

Press In For Washer Pump

Rotate To Change Wiper Mode

Press Button For ID and Clearance Lights Flash

Windshield Wipers/Washer

Your vehicle is equipped with a two-speed, intermitten t

windshield wiper system. A seven-position rotary wiper

switch (located on the turn signal lev er) oper ates the windshield wipers and washer (see next illustration). Rotate

the end of the turn signal lever to change the wipe r mode.

NOTE:

ACC for the wiper/washer switches to operate.

The first position after OFF is the intermittent #1 cycle.

The next positions are intermittent #2, #3, and #4. The last

two positions are wiper low speed and wiper high speed.

See the wiper switch settings table that follows for intermittent delay times.

The ignition key must be turned to ON or

If your ID and clearance lights are on, they will flash off.

– 46 – Y53-6004 (08/06)

Page 49

PART 4: CONTROLS AND DISPLAYS STEERING COLUMN-MOUNTED CONTROLS

Wiper Switch Settings

Wiper Switch Position Wiper Speed

Off Off

Intermittent #1 20 Second Delay

Intermittent #2 17 Second Delay

Intermittent #3 7 Second Delay

Intermittent #4 4 Second Delay

Low Low Speed

High High Speed

To Wash The Windshield

Push the rotary wash/wipe knob in (towards steering column), hold for more than 0.8 seconds and then releas e.

Hold the knob in to extend the washing cycle. After the

lever is released, the wipers will shut off automatically or

resume the wiper’s setting speed.

To activate the wipers for one swipe without activating the

washer (“mist” function), push the turn signal lever in

(towards the steering column) and release in less than 0.5

seconds. The wipers will perform a single swipe and then

resume the wiper’s setting speed.

WARNING! Do not drive with worn or dirty

wiper blades. They can reduce visibility, making driving hazardous. Clean blades regularly

to remove road film and wax build-up. Use an

alcohol-based cleaning solution and a lintfree cloth, and wipe along the blades.

CAUTION:

• Do not use antifreeze or engine coolant in

the windshield washer reservoir—damage to

seals and other components will result.

• If the electric pump is operated for a long

period (more than 15 seconds) with a dry reservoir, the pump motor may be damaged.

(08/06) Y53-6004 – 47 –

Page 50

STEERING COLUMN-MOUNTED CONTROLS PART 4: CONTROLS AND DISPLAYS

Check the windshield washing fluid level daily. If necessary, fill to top.

Clean all inside and outside windows regularly. Use an

alcohol-based cleaning solution and wipe dry with either a

lint-free or a chamois cloth. Avoid running the wiper

blades over a dry windshield to prevent scratching the

glass. Spray on washer fluid first. A scratched windshield

will reduce visibility.

Electric Horn

Your Peterbilt has an electric hor n. To operate, press on

the horn symbol near the center of the steering wheel.

Air Horn

Your Peterbilt has an air horn in addition to an electric

horn. Control the air horn by pulling on the lanyard e xte nding from the overhead header panel.

Trailer Brake Hand Valve

This hand valve provides air pressure to apply the trailer

brakes only. It operates independently of the foot treadle

valve.

To operate the tr ailer brake hand valve: Pull down on

the lever under the right side of the steering wheel.

– 48 – Y53-6004 (08/06)

Page 51

PART 4: CONTROLS AND DISPLAYS STEERING COLUMN-MOUNTED CONTROLS

WARNING!

lever instead of the BrakeSaver lever could lead

to an accident. If you have these levers, they

may be close together on your steering wheel

column. Exercise care to choose the appropriate

lever. The BrakeSaver lever is located lower and

closer to the driver on the steering column (see

page 59).

See “Brake Safety and Emergency” on page 112 for more

complete information on when and how to use your trailer

brake. Or see the Index, under Brake

NOTE: The trailer brake is not to be used as the

main means of braking. To use this brake frequently instead of using the foot brake will wear

out the trailer brake sooner.

WARNING! It is dangerous to use air-applied

trailer brakes for parking or holding a vehicle.

Air system pressure can bleed down and

release the brakes. You could have a vehicle

roll-away resulting in an accident. You or others could be badly injured. Always apply the

parking brakes for parking or holding your

vehicle on grade.

Activating the trailer hand brake

Tilt- Telescoping Steering Column

Depending on your vehicle’s configuration, you may have

either a Tilt/Telescoping or a fixed steering column.

• The tilt feature allows forward and rearward movement of the wheel.

• The telescoping feature allows you to move the wheel

up and down.

To activate these features, locate the Tilt/Telescoping

pedal.

(08/06) Y53-6004 – 49 –

Page 52

DASH- AND DOOR-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

WARNING! Adjusting the Tilt-Telescoping

Steering Wheel while the vehicle is in motion

could cause loss of control. You wouldn’t be

able to steer properly and could have an accident. Make all adjustments to the steering

mechanism while the vehicle is stopped.

To adjust the steering wheel, PUSH and HOLD the pedal

down fully. Push or pull the wheel to the desired height

and angle, then RELEASE the pedal to lock the wheel at

the correct position.

Dash- And Door-Mounted Features

Ignition Switch

Your ignition switch has four (unmarked) positions:

OFF

ACC ONLY

IGN & ACC

START

• ACC (Accessory): With your key in this position you

can play the radio or use other accessories, but your

engine won’t start.

• OFF:In this position all systems are off, and you can

remove your key.

• IGN & ACC:This position allows you to turn on the

engine and all accessory power.

• START:Starter activation to start engine.

Hazard Flasher

The four-way Emergency Flasher switch is located to the

right of the ignition key switch. With the switch in the ON

position, the emergency flasher makes a ll four turn signals

(front and rear) flash simultaneously. The flasher works

independently of the ignition switch. You should always

use the flasher if the vehicle is disabled or parked under

emergency conditions.

– 50 – Y53-6004 (08/06)

Page 53

PART 4: CONTROLS AND DISPLAYS DASH- AND DOOR-MOUNTED FEATURES

Headlamps

The headlamps are controlled by the control panel switch

showing the next symbol. When the headlights are ON,

the dash lights, side, and tail lamps are also on.

WARNING!

System any time you have to stop off the r oad or

on the side of the road, day or night. A hard-tosee vehicle can result in an injury accident.

Another vehicle could run into you if you do not

set your flashers and follow the placement of

emergency signals per FMCSR 392.22. Always

move the vehicle a safe distance off the road

when stalled or stopped for repairs.

vehicle can be dangerous for you and others.

The hot exhaust system could ignite dry

grass, spilled fuel, or other substances. Do

not park or operate your vehicle where the

Use your Hazard Flasher Warning

A disabled

WARNING! Do not use daytime running lights

(DRL) during periods of darkness or reduced

visibility. Do not use DRL as a s ubstitute for

headlamps or other lights during operations

that require lighting of your vehicle. Doing so

could lead to an injury accident.

exhaust system could contact dry grass,

brush, spilled fuel, or any other material that

could cause a fire.

(08/06) Y53-6004 – 51 –

Page 54

DASH- AND DOOR-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

CAUTION:

running lights (DRL), the high-beam h eadlamps

go on automatically at reduced brightness if the

engine is running and th e headlamp switch is

turned off. The daytime running lights are turned

off automatically while the parking brake is

engaged. If the headlamp switch is turned on, the

DRL system is overridden & headlamps operate

normally .

On vehicles equipped with daytime

Panel Light Dimmer

The Panel Light Dimmer lets you var y the brightness of

your instrument panel lights.

To Operate Your Panel Light Dimmer:

1. Turn on either the headlights or clearance lights.

2. To brighten the instrument lights, rotate the thumbwheel up.

3. To dim the instrument lights, rotate the thumbwheel

down.

ID and Clearance Lights Switch

These are the amber lights on top of your cab, the lights

on the front and sides of the trailer, and the red lights on

the rear of a truck or trailer. They are controlled by the

control panel switch labelled CL LPS or with the symbol

shown above.

– 52 – Y53-6004 (08/06)

Page 55

PART 4: CONTROLS AND DISPLAYS DASH- AND DOOR-MOUNTED FEATURES

Dome Light

The center-mounted dome light is operated by gently

pushing on the lens until a click is heard. The same action

turns the light on or off, depending on its previous state.

Fog Lights Switch

If your vehicle has fog lights, turn them ON or OFF with

the control panel switch with the symbol shown above.

NOTE: Across the U . S. A. and Canada, St ate/Provincial requirements vary as to when high beams

and fog lights can and cannot be used together.

Some states allow only four lights to be used

together, while some allow more. How your lights

are arranged will affect whether you can operate headlights and fog lights concurrently—always comply with the

state or provincial requirements where you are driving.

Air Suspension Deflate Switch (Dump Valve)

AIR SUSPENSION

Your Peterbilt vehicle may have an air suspension deflation switch which allows the air in the suspension to be

exhausted from a switch on the dash. The pur pose of this

feature is to allow you to lower your tractor to get under a

trailer. You may notice a guard over the switch. This prevents you from accidentally deflating the suspension.

WARNING! Operating the Air Suspension

Deflate Switch (Dump Valve) while driving can

lead to an accident. Sudden deflation while

(08/06) Y53-6004 – 53 –

Page 56

DASH- AND DOOR-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

your vehicle is moving can affect handling and control. Use this switch only when your vehicle is not

moving.

CAUTION: Operating a vehicle with air suspension bags either overinflated or underinflated

may cause damage to driveline components. If a

vehicle must be operated under such conditions, do not exceed 5 mph.

Engine Fan Switch

The engine fan s witch allo ws y o u to control the en gine fan

manually or automatically. With the ignition key switch ON

and the fan switch in the ON position, the engine fan will

be on regardless of engine temperature. With the engine

fan switch in the AUTOMATIC position, the engine fan will

automatically turn on when the engine coolan t reaches a

temperature of about 200

°F.

WARNING! Do not work on the fan with the

engine running. Anyone near the engine fan

when it turns on could be badly injured. If it is

set at ON, it will turn on any time the ignition

key switch is turned to the ON position. In

AUTOMATIC, it could engage suddenly without warning. Before turning on the ignition or

switching from AUTOMATIC to ON, be sure no

one is near the fan.

CAUTION: The fan or equipment near it could be

damaged if the fan turns on suddenly when you

don’t expect it. Keep all tools and equipment

such as rags away from the fan, and take care no

one turns on the ignition when someone is

working near the fan.

CAUTION: Do not operate the engine fan in the

manual (ON) position for extended periods of

time. The fan hub was designed for intermittent

operation. Sustained operation will shorten the

fan hub’s service life as well as reduce fuel

economy.

– 54 – Y53-6004 (08/06)

Page 57

PART 4: CONTROLS AND DISPLAYS DASH- AND DOOR-MOUNTED FEATURES

Cruise Control Switch

The master switch turns the cruise control ON or OFF.

The second switch allows you to SET the desired speed

or RESUME the desired speed after the cruise control

function has been interrupted.

WARNING! Do not operate the cruise control

when operating on road surfaces with poor

traction (wet, icy , or snow co vered roads) or in

heavy traffic. Accelerations caused by the

normal operation of the cruise control could

cause you to lose control of the vehicl e resulting in an injury accident.

NOTE: Cruise control functions and features may

vary depending upon which engine you have. For

specific explanation of your cruise control, see

the cruise control or engine manual included with

your vehicle.

In conventional models with Eaton transmissions, the

cruise control switches may be located on the shift control

knob (see illustration).

Power Mirror Switch

If your vehicle is equipped with power mirrors, the mirror

controls will be located on the driver side door pad. Aerody-

(08/06) Y53-6004 – 55 –

Page 58

DASH- AND DOOR-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

namic-style mirrors are controlled for 4-way adjustable

movement, while Moto mirrors are controlled for 2-way

adjustable movement.

Mirror Directional

Control Pad

WARNING! Convex mirrors can distort images

and make objects appear smaller and farther

away than they really are. You could have an

accident if you are too close to another vehic le

or other object. Keep plenty of space between

your vehicle and others when you turn or

change lanes. Remember that other objec ts

are closer than they ma y appear.

Mirror Selector

Switch

NOTE: The Power Mirror Switch does not control

the adjustment of the convex mirrors.

To Adjust Aerodynamic-Style Mirrors

1. Move the mirror selector switch to the right or left from

the neutral center position to select the desired mirror

for adjustment.

2. Depress the mirror directional control pad in one of its

four arrow directions to adjust the mirror in/out or up/

down.

NOTE: After mirror adjustments have been completed, return the mirror selector switch back to

the center (neutral) position, to prevent unintentional adjustments to the mirrors.

To Adjust Moto Mirrors

1. For in/out mirror adjustment: Move the mirror selector

switch to the right or left from the neutral center position to select the desired mirror for adjustment.

NOTE: If the mirror is fixed (non-motor ized) on

the left side, then the mirror selector switch will

ONLY allow selection of the neutral and right mirror switch positions.

– 56 – Y53-6004 (08/06)

Page 59

PART 4: CONTROLS AND DISPLAYS DASH- AND DOOR-MOUNTED FEATURES

2. Depress the mirror directional control pad towards the

arrows pointing left or right to adjust the mirror in/out.

NOTES:

• Because the Moto mirrors have only 2-way

adjustment, the mirror directional control pad is

also restricted in its movement to left or right ONLY .

• After mirror adjustments have been completed,

return the mirror selector switch back to the center (neutral) position, to prevent unintentional

adjustments to the mirrors.

Mirror Heat Switch

Mirror Heat

Mirror Heat

Switch Button

Your vehicle may be equipped with optional heated mirrors.

Mirror heat is controlled by the mirror heat switch button,

which is part of the mirror switch module located on the

driver side door pad. Motorized mirrors with mirror heat

Indicator Light

have an automatic 15-minute “time out” feature, where the

mirror heat-only module is automatically deactivated.