Peterbilt Conventional Service Manual

OPERATOR’S

MANUAL

Quick Table of Conte nts

•Introduction............................................1

•Cab And Frame Access............................5

•Getting To Your Engine .................................9

•Controls And Disp lays ...................................16

•Seat And Restraint Systems............................. 63

•Driver’s Checklists ................................................76

•Starting And Operating The Vehicle........................ 80

•Maintenance and Ser vice. ........................................ 112

•V ehi cle Identification.................................................... 184

•Consumer Inf o rma tion .................................................... 185

•Subject Index ............................................................ 187

California

Proposition 65 Warning

• Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

• Other chemicals in this vehicle are also known to the

State of California to cause cancer, birth defects or

other reproductive harm.

• Battery posts, termi nals, and related accessor ies con-

tain lead and lead compounds, chemicals known to the

State of California to cause cancer and reproductive

harm. Wash hands after handling.

PART 1: INTRODUCTION

This manual contains useful information for the safe and efficient

operation of your Peterbilt vehicle. It also provides information on

maintaining your vehicle in the best condition, with an outline for performing safety checks and basic preventive maintenance inspections.

We have tried to present the information you’ll need to learn about

your vehicle’s functions, controls, and operation - and to present it as

clearly as possible. We hope you’ll find this manual easy to use.

Please remember, though -- this manual is not a training manual. It

can’t tell you everything you need to know about driving your Peterbilt

vehicle. For that you need a good training program or truck driving

school. If you have not been trained, get the proper training before

you drive. Only qualified d rivers should drive this vehicle.

There will be times when you need to take this manual out of your

Peterbilt. When you do, please be sure to return it to the cab when

you are finished using it. That way it will be there when you need it

the next time or when you pass the vehicle on to the next user.

How to Find What You Want

There are several tools built into this manual to help you find what y ou

need quickly and easily.

First is the Quick Table of Contents. Located at the front of the

manual, this lists the main subject s c overed and gives pa ge num bers

where you can find these subjects. Use the Quick Table of Con tents

to find information on a large subject like “Maintenance.”

Cross-referenced citations also help you get the information you

need. If some other par t of the manual contains fur ther information

on the subject you are reading about, we’ll indicate that in a cross-reference like this: (See PART 6: DRIVER’S CHECKLIST

have to go searching for more information.

Finally you’ll find a helpful Subject Index. It’s in the back of the manual and alphabetically lists the subjects covered. So if you want information on brakes, for example, just look under Bra ke

Index. You’ll find all the pages listed where brakes or braking are discussed.

). You won’t

in the Subject

A Special Word about Repairs

Your Peterbilt dealer’s ser vice center is the best place to have your

vehicle repaired. You can find Peterbilt dealers all over the country

with the equipment and trained personnel to get you back on the road

quickly - and keep you there.

Your vehicle is a complex machine. Anyone attempting repairs on it

needs good mechanical training and the proper tools. If you are sure

you have these requirements, then you can probably perform some

repairs yourself. However, all warranty repairs must be performed by

an autho rized Peterbilt se rvice facility. If you aren ’t an experie nced

mechanic, or don’t have the r ight equipm ent, plea se leave all repairs

PB1317 (CAT. NO. 5229 ) —1— 22-01510 (R12/01)

PART 1: INTRODUCTION

to an aut horized ser vice facility. They are the one s equipped to d o

the job safely and correctly.

WARNI NG! Attempting repair work without sufficient

training, service manuals, and the proper tools can be

dangerous. You could be injured or you could make

your truck unsafe. Do only those tasks you are fully

qualifie d to do.

Maintenance Manuals. If you do decide to do any complex repair

work, you’ll need the Peterbilt Maintenance manuals. Order them

from your authorized dealer. Please provide your Chassis Serial

Number when you order, to be sure you get the correct manuals for

your vehicle. Allow about four weeks for delivery. There will be a

charge for these manuals.

Final Chassis Bill of Material. A complete, nonillustrated computer

printout listing of the parts used to cust om -build your Peterbilt vehicle

is available through the Peterbilt dealer from whom your p urchased

your vehicle.

WARNI NG! Modifying your vehicle can make it unsafe.

Some modifications can affect your truck’s electrical

system, stability, or other impor tan t functions. Before

modifying your vehicle, check with your dealer to make

sure it can be done safely.

Additional Sources of Information

Operator’s manuals are also s upplied by the manuf act urers of components such as the engine, seats, transmission, and radio in your

Peterbilt. If you are missing any of these manuals, ask your Peterbilt

dealer to supply them.

Your new Peterbilt’s glove box also contains a copy of the Tru ck

Driver’s Handbook, published by the American T rucking Association.

Refer to it for important information on driving your vehicle. Another

place to learn more about trucking is a local truck driving school.

Contact one near you to find out what kinds of instruction it offers.

Federal and state agencies also have information you can ask for.

The Interstate Commerce Commission can give you information

about regulations governing transportation across state lines. And

various agencies in state governments are sources for regulations

that differ from state to state.

Warnings

We’ve put a number of warning m essages in this manual. They are

there for your protection and information. Please read them and follow them. They can h elp you to avoid injury to yourself and your passengers as well as to p revent costly damage to your vehicle. We’ve

PB1317 (CAT. NO. 5229 ) —2— 22-01510 (R12/01)

PART 1: INTRODUCTION

used certain symbols and “signal words” to indicate what kind of message is going to follow. When you see these symbols & words, you

know that you need to p ay special attention. P lease don’t ignore any

of these signals.

WARNI NG!

When you see this symbol & word, the message that fo llows is especially vital. This signals something that c an cause serious injury or

death. This message will tell you what the hazard is, what can happen if you don’t heed the warning, and how to avoid it. For examp le:

WARNI NG! Attempting repair work without sufficient

training, service manuals, and the proper tools can be

dangerous. You could be injured or you could make

your vehicle unsafe. Do only those tasks you are fully

qualifie d to do.

CAUTION:

This symbol & word signals something that could damage your vehicle. And you might receive an injur y, too. For example:

CAUTION: Continuing to operate a vehicle with insufficient oil pressure will cause serious engine damag e .

NOTE:

Gives you information we feel you ’d like to have. It could have to do

with care of your vehicle or with driving more efficiently:

NOTE: A cold compressor can cause refrigerant to liquefy

and warp the valve plates or cause a hydraulic lock. Warm

the engine before starting the air conditioner.

Please take the time to read these messages when you see the m.

And remember:

WARNING! Something that could injure you seriously.

CAUTION: Something that could cause injury to you or your

vehicle.

NOTE: Useful information.

PB1317 (CAT. NO. 5229 ) —3— 22-01510 (R12/01)

PART 1: INTRODUCTION

Vehicle Safety

Make sure your Peterbilt is in top working condition before heading

out on the road—it is the

the vehicle according to PART 6: DRI VER ’ S C HE CKL IST

WARNING! Do not drink and drive. Your reflexes, perceptions, and judgment can be affected by even a small

amount of alcohol. Y ou could have a serious—or even fatal

accident—if you drive after drinking. Please do not drink

and drive or ride with a driver who has been drinking.

WARNING! The use of alcohol, drugs, and certain medications will seriously impair perception, reactions, and driving ability . These cir cumstances can substantiall y increase

the risk of an accident and personal injury.

Please remember, this manual is not a training manual. It cannot tell

you everything you need to know about driving your Peterbilt vehicle.

For that you need a good t raining program or truck d riving school. If

you have not been trained, get the proper training before you drive.

Only qualified drivers should drive this vehicle.

Every new Peterbilt vehicle is designed to conform to all Federal

Motor Vehicle Safety Standards applicable at the time of manufacture.

However, even with these safety featu res, continued safe and reliable

operation depends greatly upon regular vehicle maintenance. The

vehicle must be operated within the range of its mechanical capabilities and the limits of its load ratings. (See the Tire and Rim Weight

Ratings label on the driver's door edge.)

responsible

driver's duty to do so. Inspect

.

PB1317 (CAT. NO. 5229 ) —4— 22-01510 (R12/01)

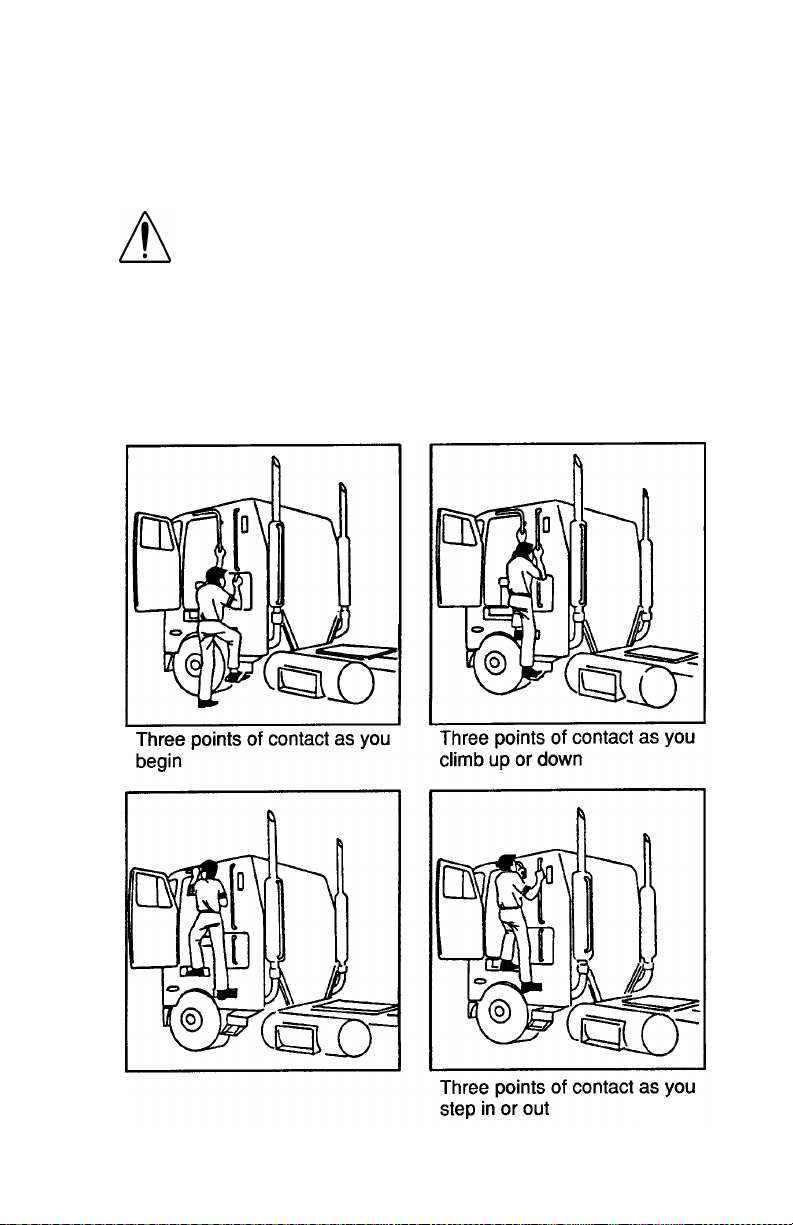

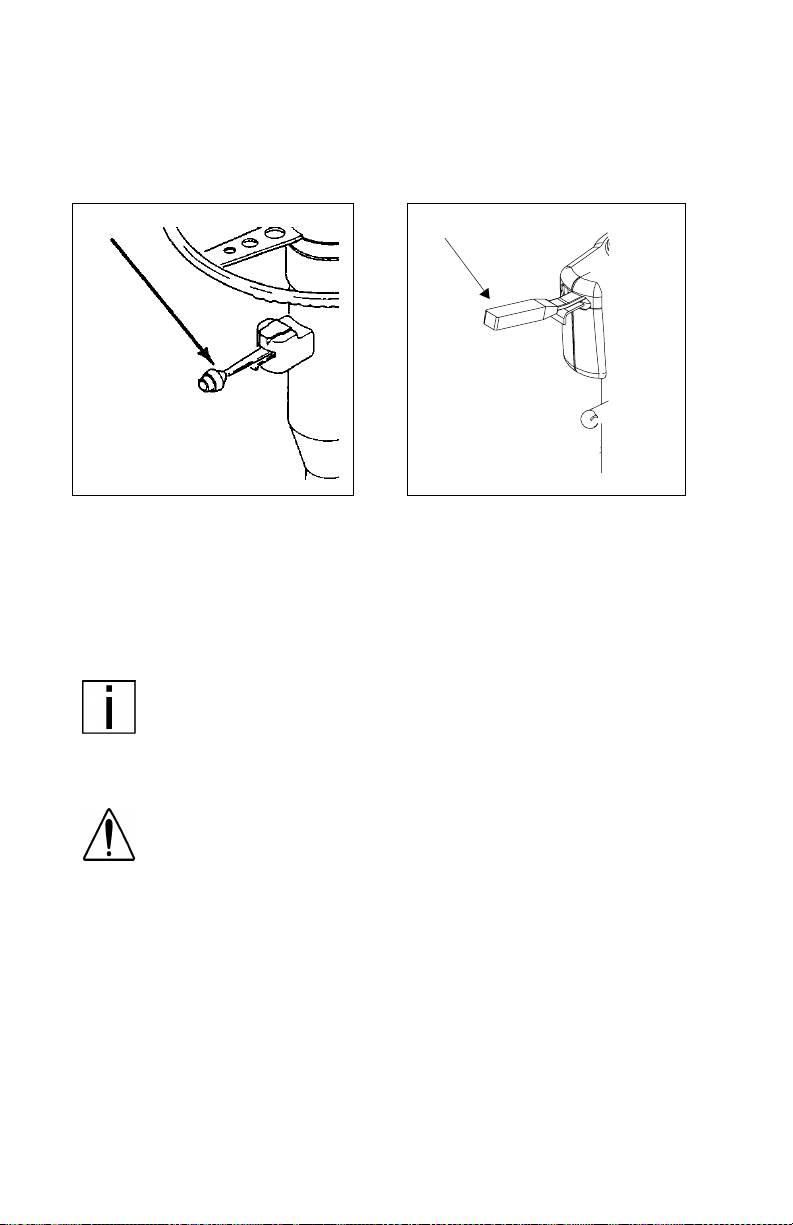

PART 2: GETTING INTO AND OUT OF THE

CAB AND FRAME ACCESS

Be careful whenever you get into or out of your vehicle’s cab.

Whether you have a COE or conventional cab, always maintain at

least three points of contact with your hands on the grab handles and

your feet on the steps.

WARNING! Jumping out of the cab or getting into the

cab without proper caution is dangerous. You could slip

and fall, possibly suffering a serious injury. Keep steps

clean. Clean any fuel, oil, or grease off of the steps

before entering the cab. Use the steps and grab handles provided, and always keep at least three points of

contact between your hands and feet and the truck.

Look where you are going.

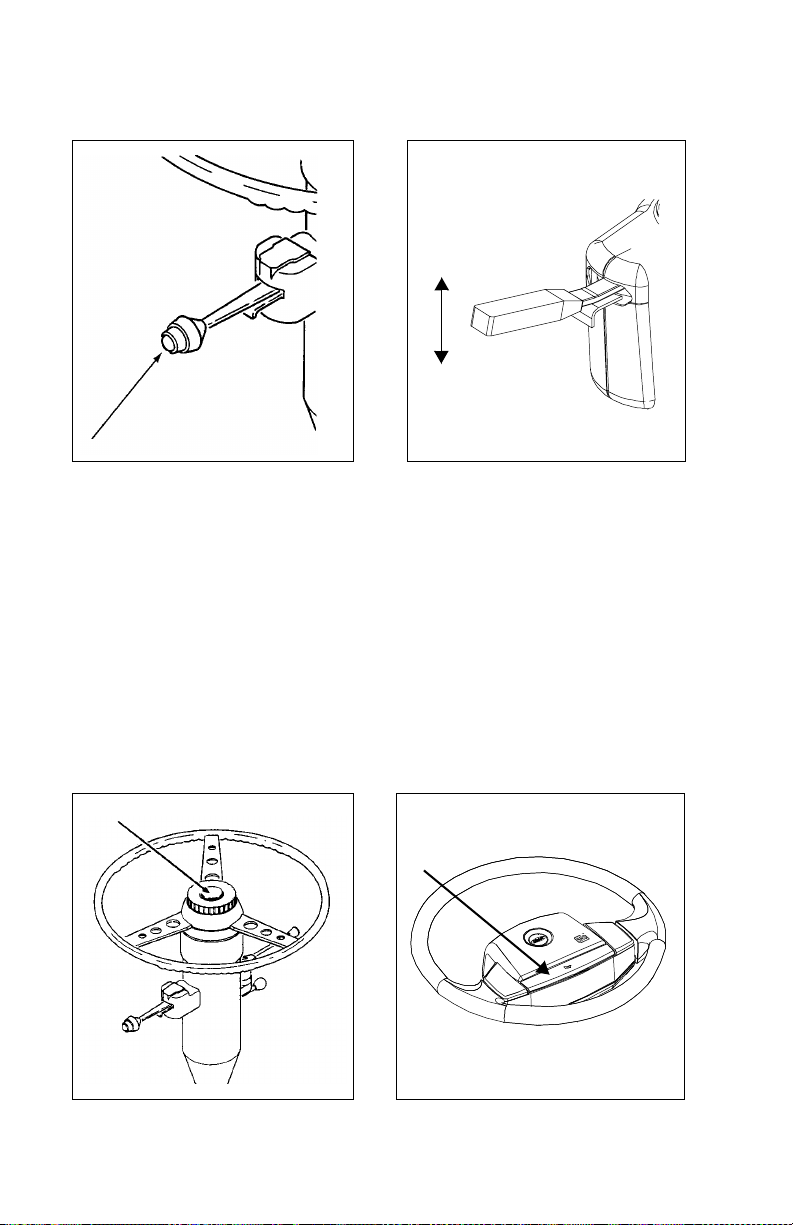

COE: The pictures below show the best way to enter and exit a COE

cab.

02957

PB1317 (CAT. NO. 5229 ) —5— 22-01510 (R12/01)

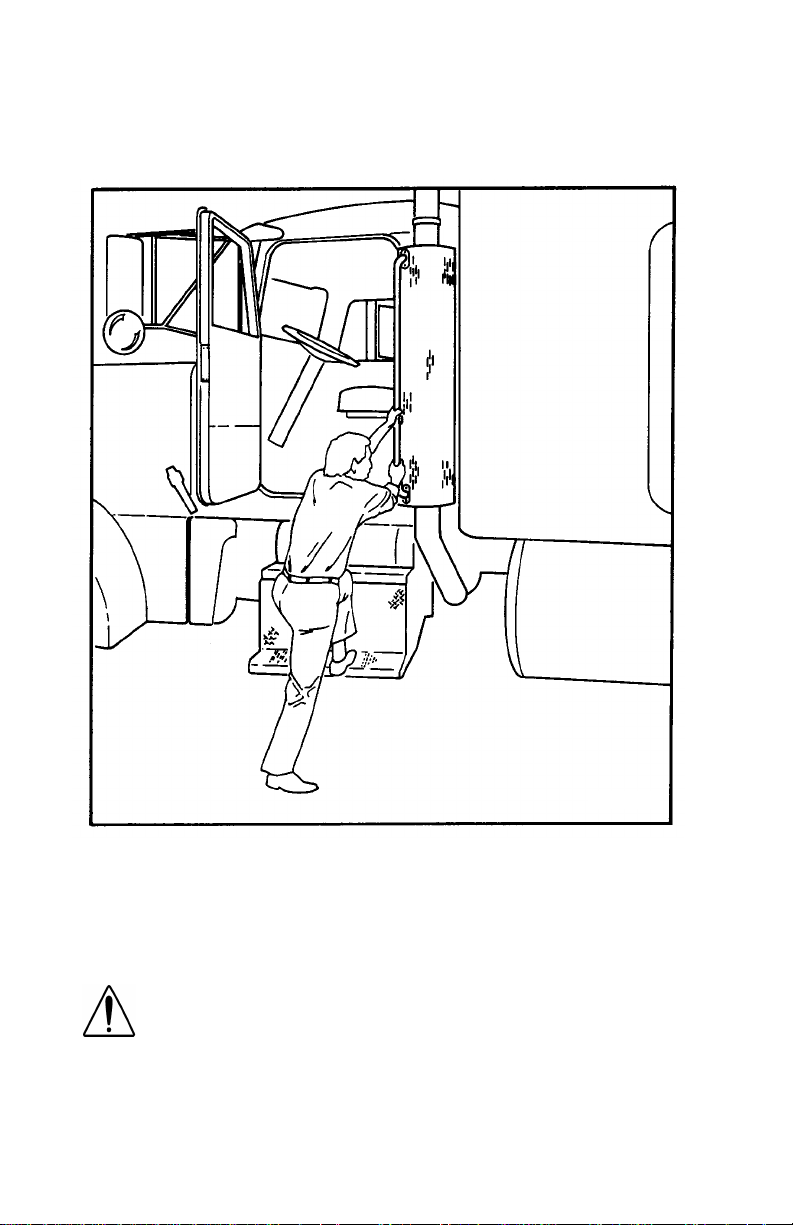

PART 2: GETTING INTO AND OUT OF THE

CAB AND FRAME ACCESS

CONVENTIONAL: The picture below shows the best way to enter

and exit a Conventional Cab.

02958

Door Lock and Keys

Doors can be l ocked from the inside by us i ng the lock b utton. Close the

door then push the button down to lock. Doors automatically unlock

when you open them from inside, and can be locked from the outside

with the k ey only.

WARNING! To lessen the chance and/or severity of p ersonal injury in case of an accident, always lock the

doors while driving. Along with using the lap/shoulder

belts proper ly, locking the doors helps prevent occu pants from being thrown from the vehicle.

To lock or unlock the doors from outside the cab, insert the key in the

lock.Turn the key toward the rear to lock; forward to unlock.

PB1317 (CAT. NO. 5229 ) —6— 22-01510 (R12/01)

PART 2: GETTING INTO AND OUT OF THE

CAB AND FRAME ACCESS

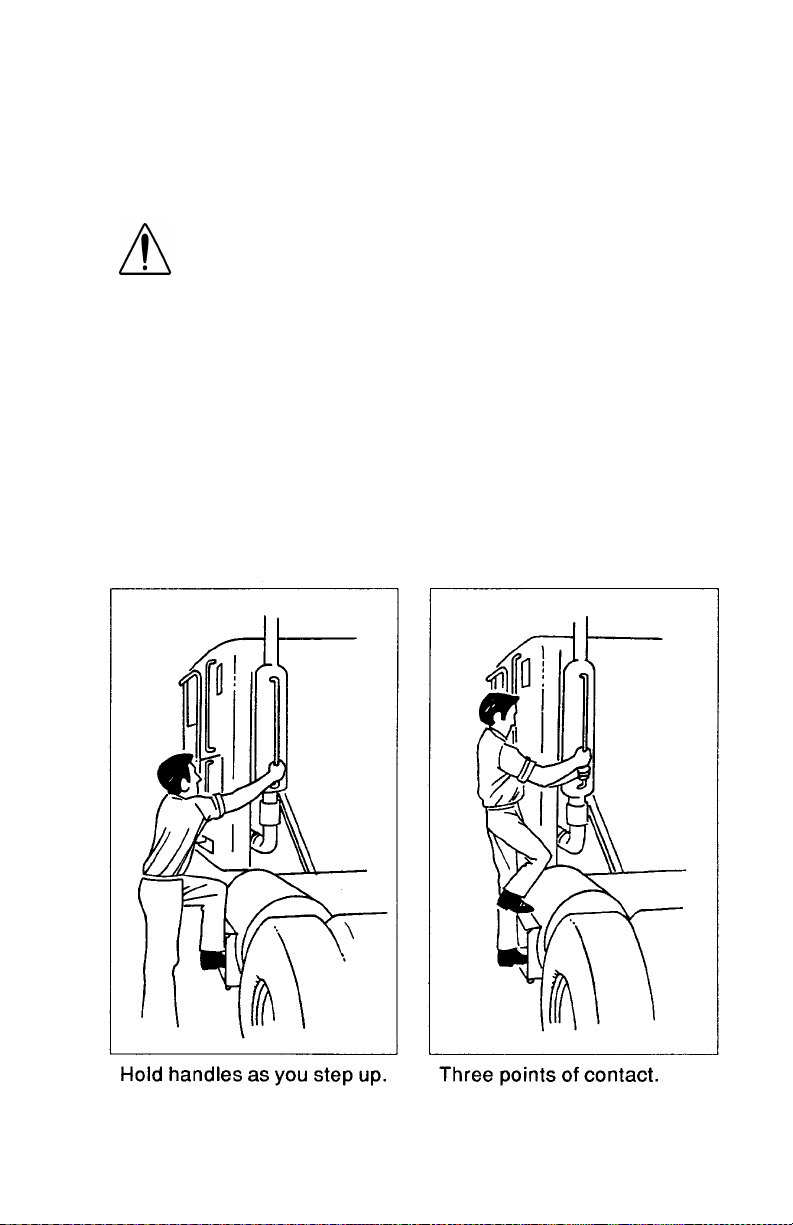

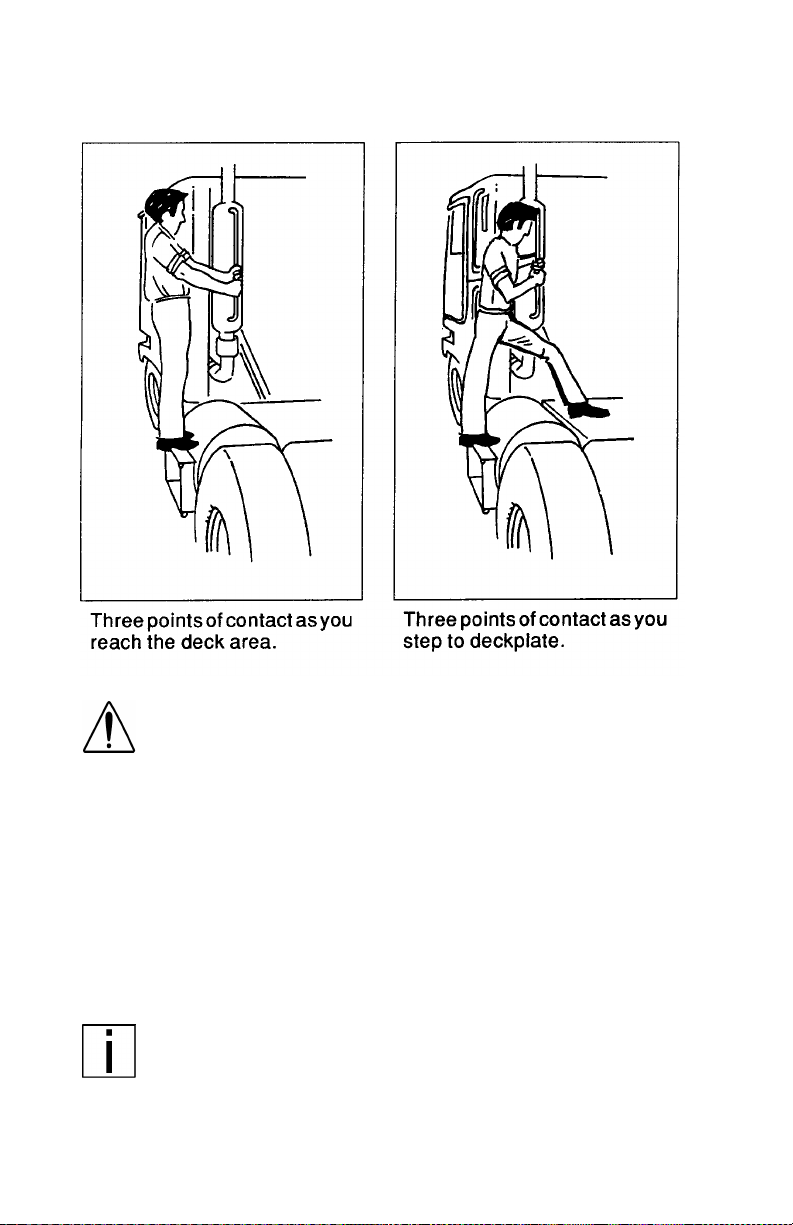

Climbing Onto the Deck Plate

When you are climbin g onto and of f the deck plate, maintain a t least

three points of contac t with your hands on the grab ha ndles and your

feet on the steps.

WARNI NG!

•

You can be hur t if you aren’t careful climbing onto

and off the deck plate. You can slip and fall, especially if the surfaces are wet or icy, or if you step in

oil, fuel, or grease. Keep steps clean. Always maintain at least three points of contact between your

hands and feet and the steps and deck plate.

•

Do not climb onto and off the deckplate–use steps

and grabhandle provided. If there is no de ck plate,

or if proper steps and grab handles aren’t provided,

don’t climb on t o t he ar ea behind the cab . Peter bi lt

did not intend for the area to be a step if handrails or

proper steps are not provided.

The pictures below show you the right way to get on and off the area

behind your cab.

02959

PB1317 (CAT. NO. 5229 ) —7— 22-01510 (R12/01)

PART 2: GETTING INTO AND OUT OF THE

CAB AND FRAME ACCESS

02960

WARNI NG! Do not step on vehicle components without

antiskid surfaces or use components not designed for

entry-and-exit use. You could fall and injure yourself if

you step on a slippery surface. For example:

•

You c o uld fa ll and in jure you rself if you step o nt o a

fuel tank surface. A fuel tank is not a step. The tank

surface can get very slippery, and you might not be

able to prevent a fall. Don’t step onto the surface of a

fuel tank. Use only the step s and handholds provided,

not chain hooks, quarter fenders, etc.

•

Always reinstall steps before entering the cab or

accessing the deck plate. Without steps, you could

slip and fall, resulting in possible injury to yourself.

NOTE: Any alteration (adding bulkheads, headache racks,

tool boxes, etc.) behind the cab or sleeper that affects the

utilizatio n o f grab ha nd les , de ck p lat e s, or fra m e acc es s

steps installed by Peterbilt must comply with FMCSR 399.

PB1317 (CAT. NO. 5229 ) —8— 22-01510 (R12/01)

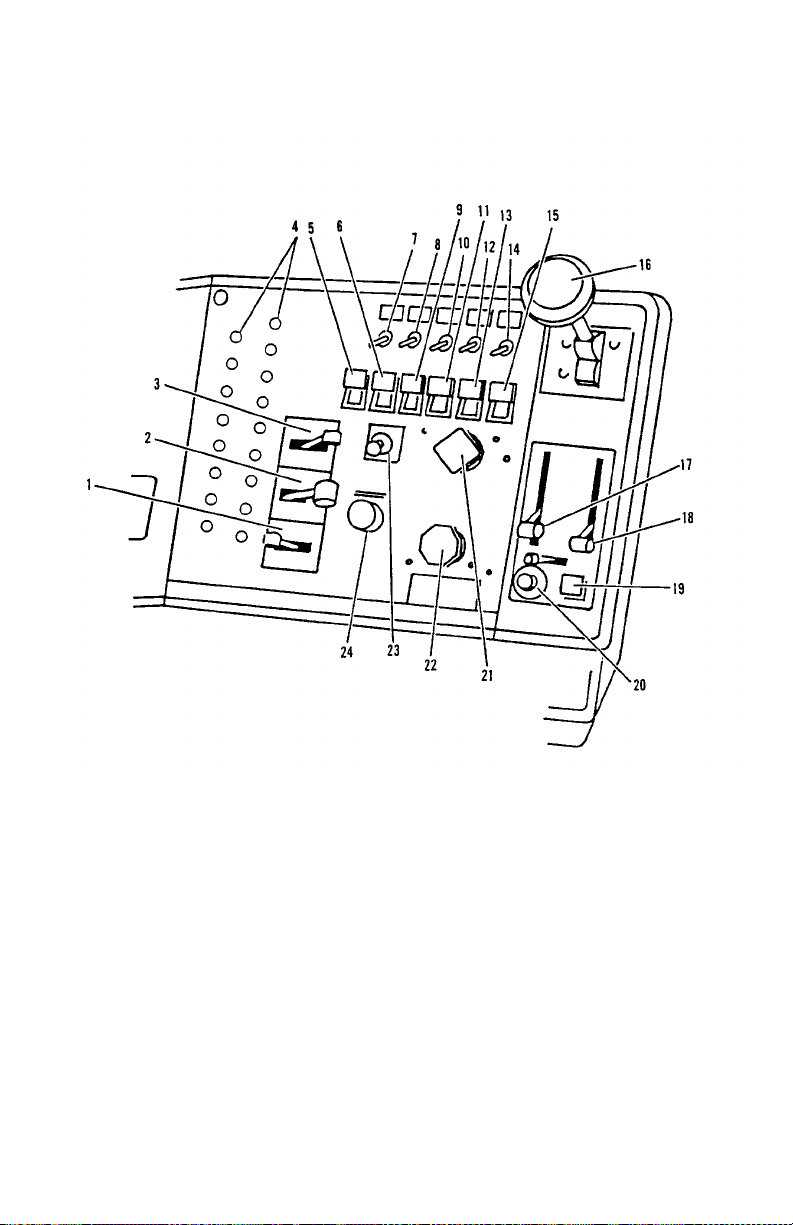

PART 3: GETTING TO YOUR ENGINE

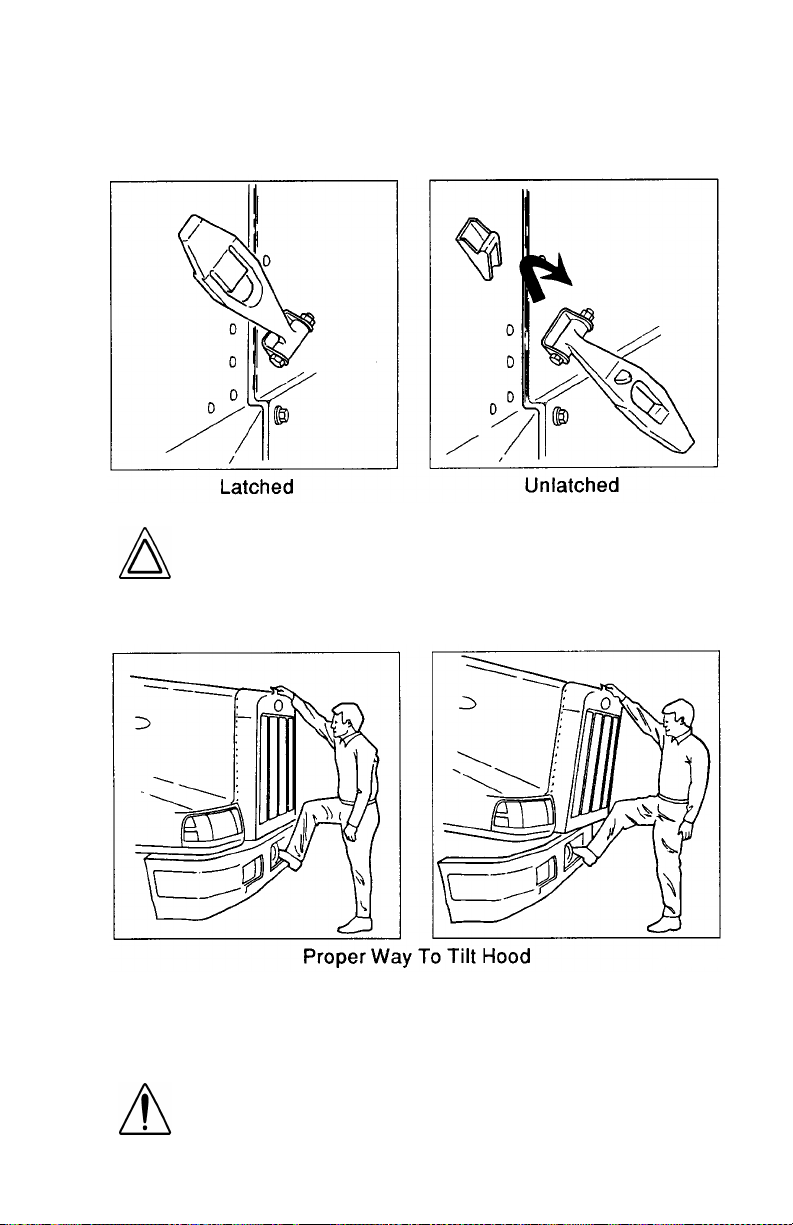

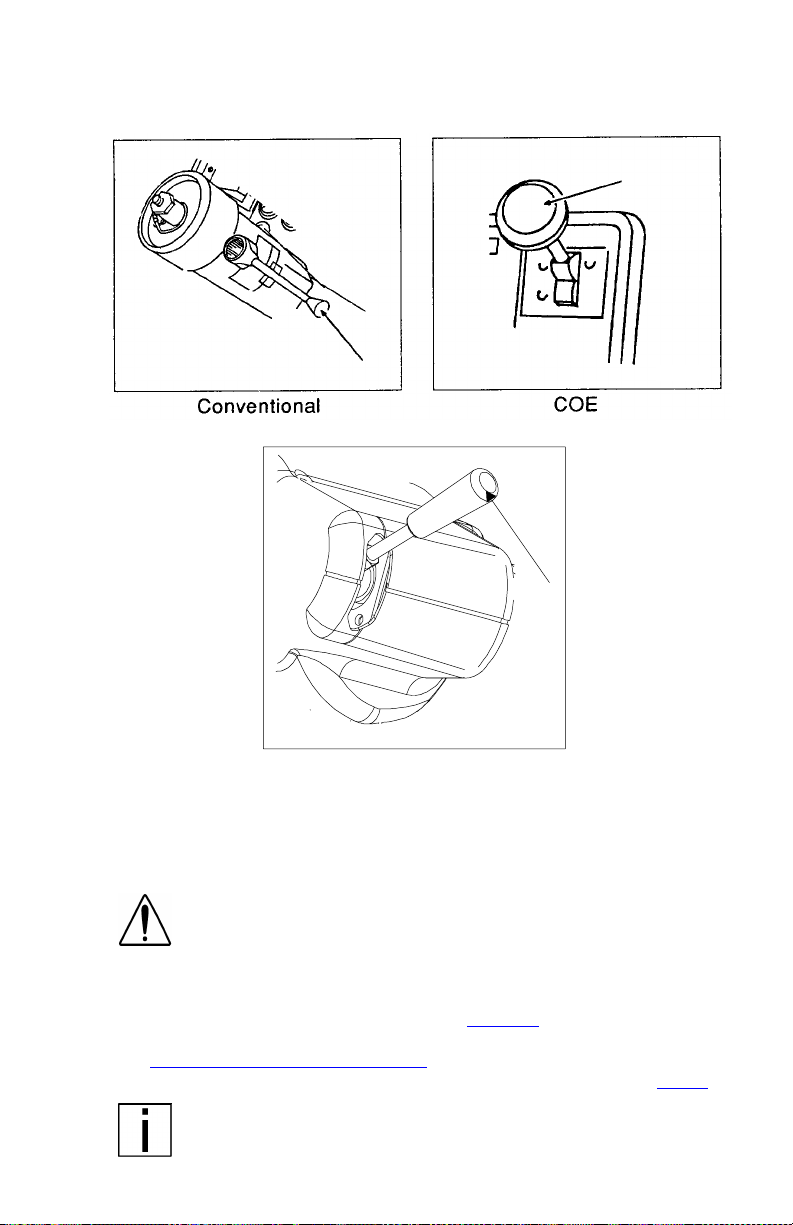

Hood Hold Downs (Conventional Cabs)

Your hood hold downs keep your hood from opening unexpectedly

02961

CAUTION: If you do not latch your hood securely, it

coul d open duri ng oper ation and caus e vehic le dama ge.

Be sure to latch the hood securely.

Hood Tilt (Conventional Cabs)

02962

To open your hood, unlock the hood hold downs by unlatching them.

Put one hand on the top of the hood front, one foot on the bumper,

and one foot on the ground. Tilt the hood forward.

WARNI NG! Before opening or cl osing the hood, be sure

there are no people or objects in the way. A hood could

hurt someone in the way of its descent.

PB1317 (CAT. NO. 5229 ) —9— 22-01510 (R12/01)

PART 3: GETTING TO Y O UR ENGINE

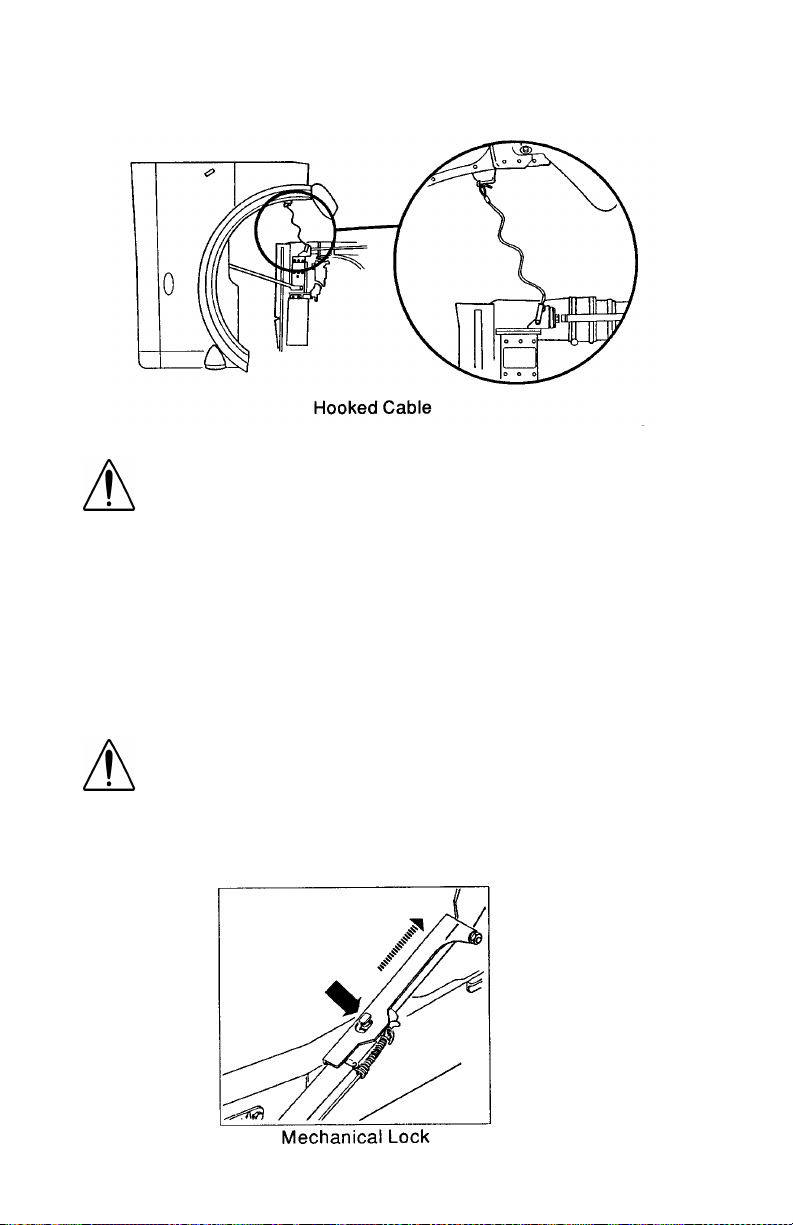

Safety Cable

02963

WARNING! If the hood falls, anyone under it could be

injured. Always attach the safety cable to keep a hood

open any time anyone gets under a hood for any reason.

To attach the safety cable: The cable is on the driver’s side of the

radiator. Attach it to the hook on the hood.

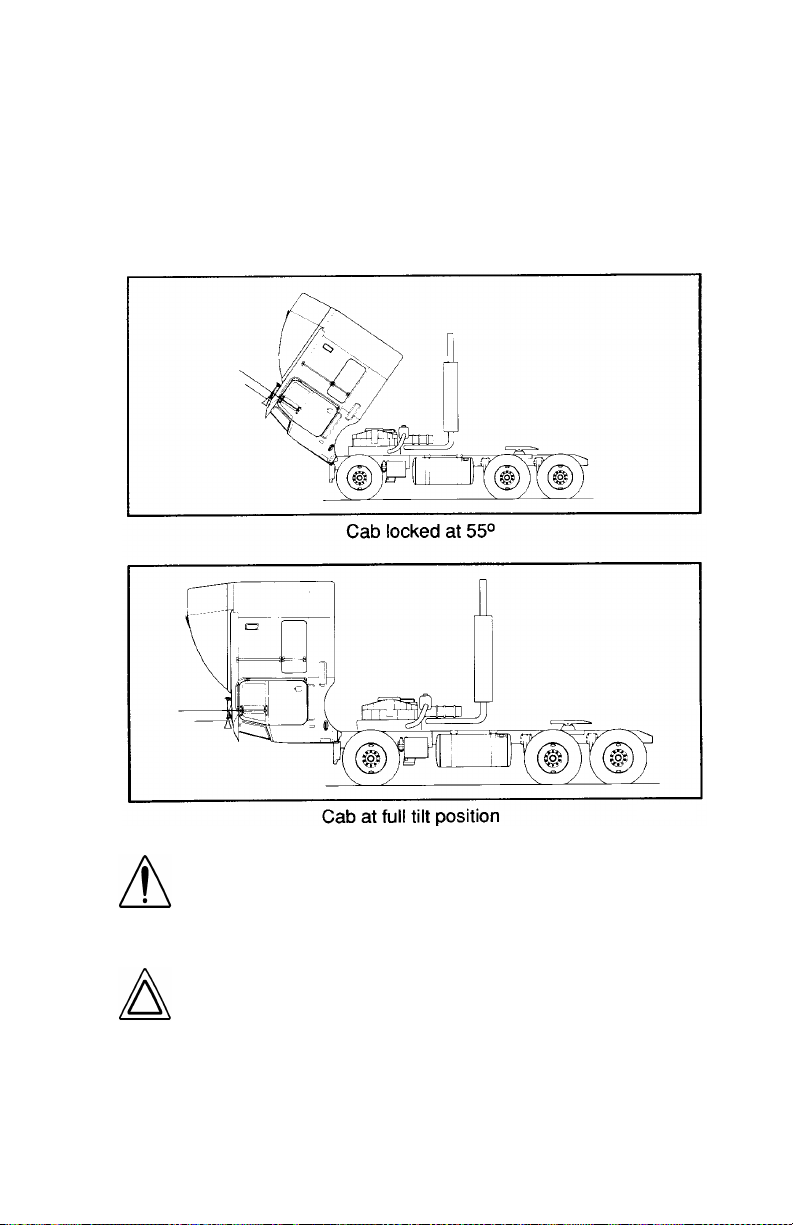

COE Cab Tilt System

If you have a COE type of vehicle, your cab tilts forward for maintenance on the engine and other components. An independent hydraulic system raises and lowers the cab. And a positive dual locking

device increases safety and reduces the danger of mishaps while you

are driving.

WARNING! Getting any part of your body under an

unsecured cab could cause a serious or fatal acciden t.

The cab could fall and crush you. Always make sure the

mechanical lock is fully engaged before getting under

the cab, or before letting anyone else get under it. See

below for instructions on using the mechanical lock.

02964

PB1317 (CAT. NO. 5229 ) —10— 22-01510 (R12/01)

PART 3: GETTING TO YOUR ENGINE

CAUTION: R aising the cab with heavy objects in the

cab, sleeper, or luggage compartment can cause serious damage to the cab tilting mechanism and cab.

Before tilting the cab, remove heavy items such as tire

chains and tools. Remove or stow securely any loose

items. And shut the doors tightly.

Cab tilting instructions are labeled and in stalled on t he base of the

passenger seat in your cab.

WARNI NG! You can be seriously injured by the cab if

you do not follow safety precautions. Whenever you

raise or lower the cab, or when you work under the cab,

please remember the following safety rules:

•

Be sure no one is under the front of the cab. Whether

you are raising or lowering the cab, KEEP CLEAR.

•

Never work under a raised cab unless it is properly

supported. This means use an overhead hoist of sufficient capacity to support the cab safely. Never prop

the cab up instead of using a hoist. The prop could fail

and let the cab fall on you or anyone else working

under the cab.

•

Always be sure the safety latch is engaged when you

or anyone else works under the cab.

•

Perform w ork only when the cab is in th e mechanically

locked position or in the full tilt position.

•

When your cab’s hydraulic system needs ser vi ce or

repair:

- Have maintenance and repair done only by someone

qualified in hydraulic systems.

- Be sure no one tries to bleed the system with the cab

raised. This will defeat the safety system. The cab

can fall and crus h a nyone under it.

- Do not tamper with any part of the cab tilt cylinders,

including removing the velocity fuses. To do so will

defeat their purpose. The cab could fall and crush

anyone under it. If you have any need for repair

involving the velocity fuses, have a qualified truck

mechanic do the work.

NOTE: In case of oil loss i n the syst em or a lo ck-up in the til t

cylinders, refer to the maintenance manual for repair instructions.

PB1317 (CAT. NO. 5229 ) —11— 22-01510 (R12/01)

PART 3: GETTING TO Y O UR ENGINE

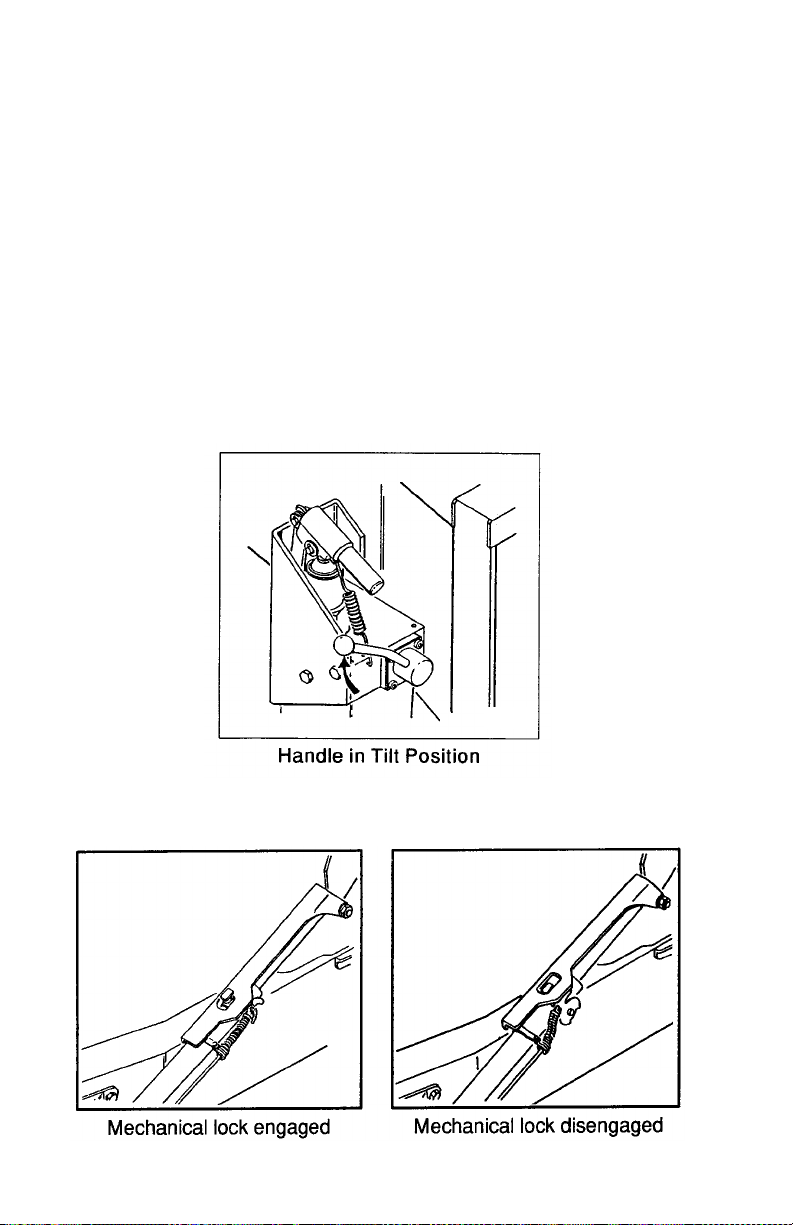

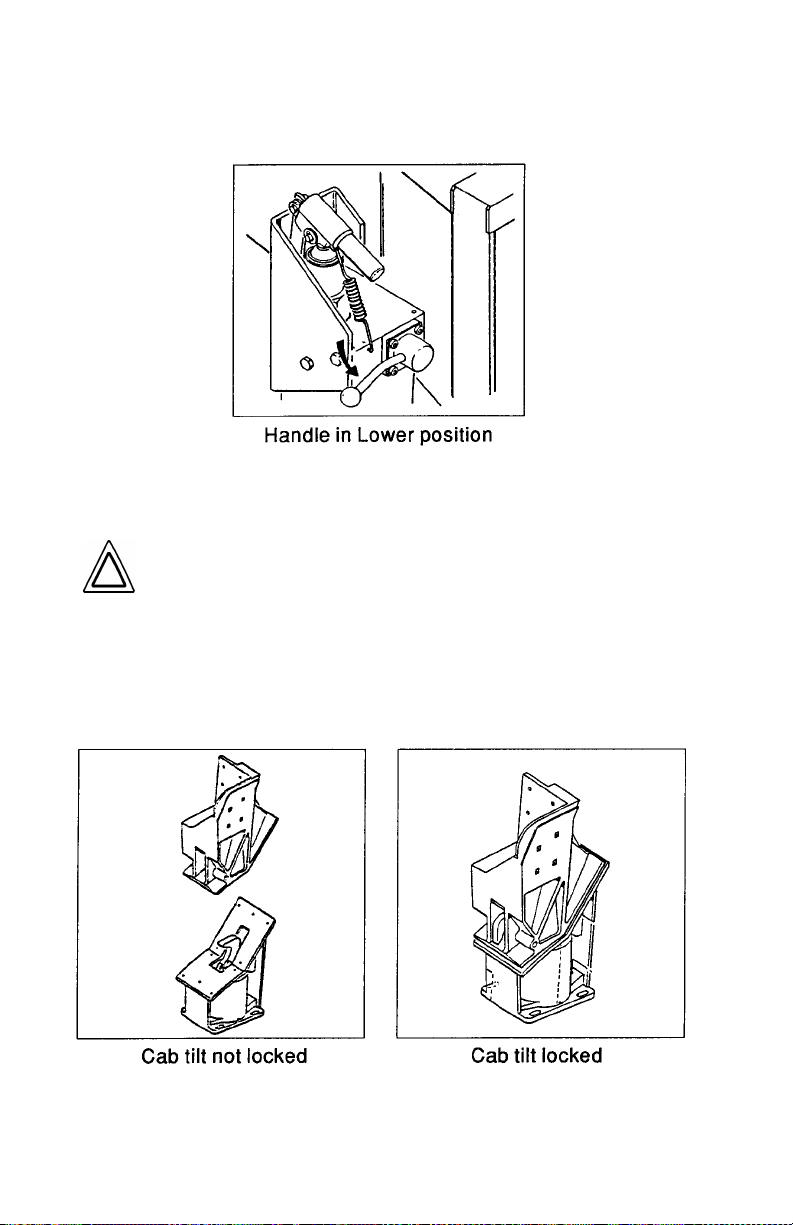

To Raise the Cab:

1. Park the vehicle on a lev el surf ace to ensure proper hook and latch

alignment.

2. Apply the parking brake.

3. Make sure the shift lever is in Neut ral. This will prevent the shift

lever from g etting caught on the cab duri ng tilt operation.

4. Secure or remove all loose items in the cab and luggage compartments. Close all doors.

5. Check the clearance above and ahead of the cab. Be sure there

will be enough room to clear roof antennae, roof fairings, and side

extenders when you tilt the cab. Chec k for obstructions overhead,

such as branches, power lines, lights, etc. Check also for obstructions in front, such as walls, work benches, other vehicles, etc.

6. Place the control valve handle in the Tilt (Raise) position.

02965

7. Pump the cab up until the mechanical lock engages. Now put the

control valve handle in the center position.

02966

PB1317 (CAT. NO. 5229 ) —12— 22-01510 (R12/01)

PART 3: GETTING TO YOUR ENGINE

When the cab is raised to the point where the weight of the cab is

greater in front of its hi nges than to the rear, gravity wi l l mak e i t fall forward. It will fall at a controlled rate.

8. If you want the cab in the full forward position, pull the cable to disengage the mechanical lock. You may have to free the lock by

raising or lowering the cab to relieve pressure on the locking

mechanism.

02967

WARNING! When the cab is tilted fully (90°), the roofmounted antenna mast could injure someone. Remove

or flag the mast before tilting the cab a ll the way forward.

CAUTION: When tilting the cab to the full tilt, or vice

versa, hold the safety lock bar up to prevent it from

engaging at the locked position. If it does lock, you r cab

could be severely damaged.

PB1317 (CAT. NO. 5229 ) —13— 22-01510 (R12/01)

PART 3: GETTING TO Y O UR ENGINE

To Lower the Cab

1. Place the control valve handle in the Return (Down) position.

02968

2. Release the mechanical lock. Hold the safety lock bar up.

3. Pump until the cab starts to descend. The valve system will co ntrol the speed in either direction automatically.

CAUTION: Do not try to pump the cab down or hold it

down with hydraul i c force. If you do, ca b damage will

occur.

4. Leave the handle in the down position for at least 20 seconds after

the cab touches down. This allows time for the full spring force to

develop in the cab latch. Inspect the hooks to be sure they are

closed. If they are not properly engaged, raise the cab slightly and

guide the latch, if necessary, w hile lowering the cab.

02969

PB1317 (CAT. NO. 5229 ) —14— 22-01510 (R12/01)

PART 3: GETTING TO YOUR ENGINE

WARNI NG! Placing any part of your body between the

cab and the frame could result in serious injury. Keep

hands and feet out from under the cab if it must be

raised to re-engage the cab latches. Guide the cab from

the outer surfaces only.

5. Return the control valve handle to the Lock (Ce nter) position for

normal operation.

CAUTION:

•

Do not continue to operate the pump after the cab is in

the full Down pos i tio n. Addit io nal pumping could

cause structural damage to the cab.

•

Driving with the cab tilt lock unsecured can damage

your vehicle. Check daily to be sure the lock is closed

securely .

NOTE: In case of oil loss i n the syst em or a lo ck-up in the til t

cylinders, refer to the maintenance manual for repair instructions.

PB1317 (CAT. NO. 5229 ) —15— 22-01510 (R12/01)

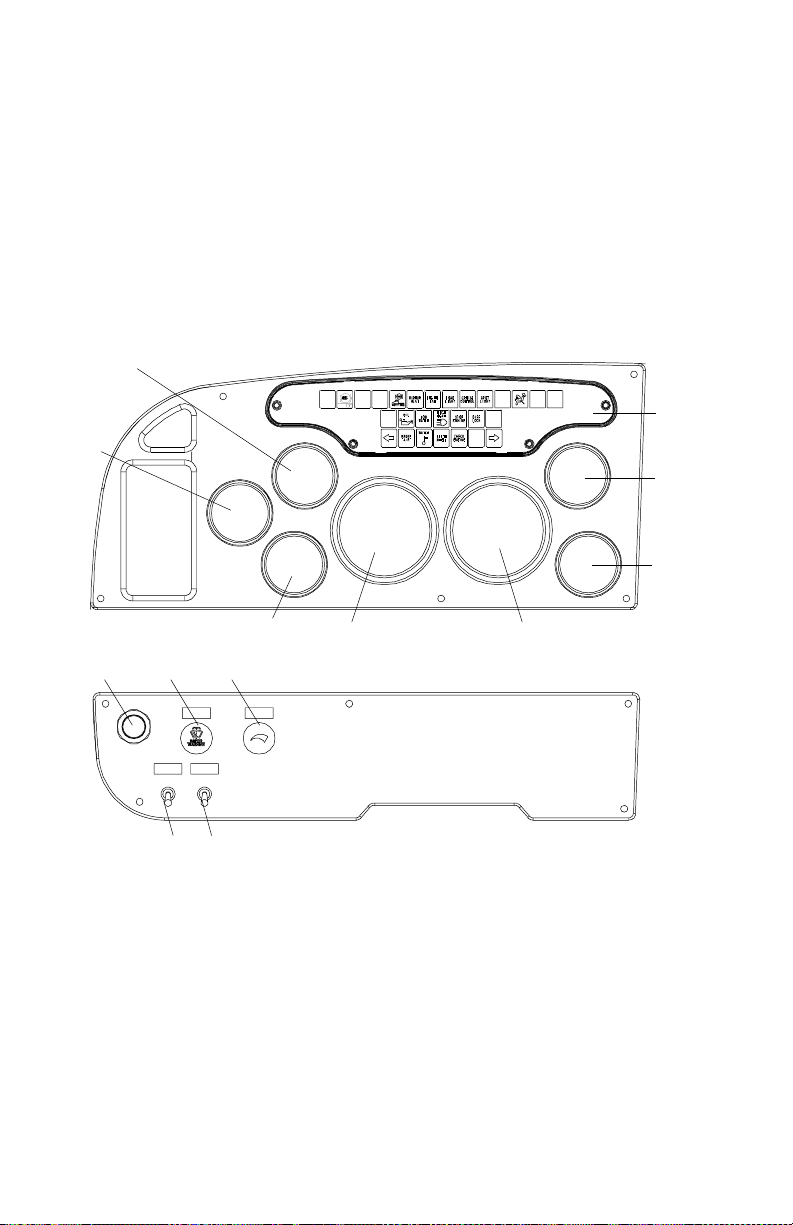

PART 4: CONTROLS AND DISPLAYS

Your Instrument Panel

This part explains the location of t he vari ous feat ures on your vehicle

and describes their function. Fo r informa tion on using these features

in driving, see the paragraphs below. Please remember that each

Peterbilt is custom-made. Your instrument panel may not look exactly

like the one in the pictures below. We have tried to describe all the

most common features and controls available. You can pick out the

parts that apply to you and read them to be fully informed on how your

particular vehicle operates.

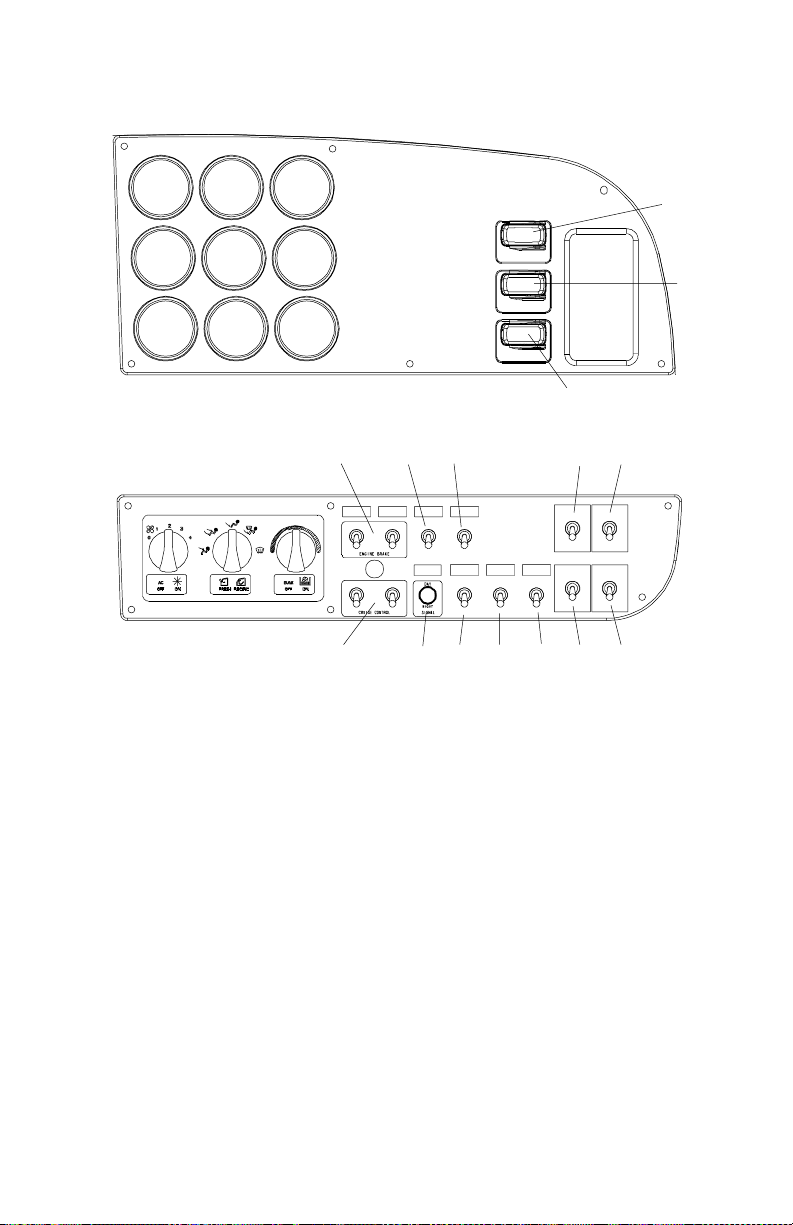

Typical Conventional Cab Instruments and Controls

4

5

3

6

7

Panel A

Panel C

11 12 13

910

1

82

LEFT SIDE

1. Tachometer 8. Speedometer

2. Oil Pressure 9. Clearance Lamps

3. Clock 10. Headlamps

4. Oil Temperature 11. Ignition Key Switch

5. Warning Lamp Clust er 12. Windshield Wiper/Washer

6. Water Temperature 13. Panel Light Dimmer

7. Dual Air Pressure

PB1317 (CAT. NO. 5229 ) —16— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

Conventional

12 3

45 6

7 8 9

13 14 15 16 17

RIGHT SIDE

1. Fuel 13. Engine Brake

2. Air Cleaner Restriction 14. Engine Fan

3. Transmission Oil T em perature 15. Fuel Tank Selector

4. Voltmeter 16. LH Air Window

5. Manifold Pressure 17. RH Air Window

6. Front Driver Oil Temperature 18. Sleeper Door Lock

7. Air Applica t ion 19. Ca b D oor Lock

8. Pyrometer 20. RH Mirror

9. Rear Driver Oil temperature 21. Mirror Heat

10. Air Suspension 22. LH Mirror

1 1. Fifth Wheel 23. Day/Night Signal

12. Interaxle Differential Lock 24. Cruise Control

12

10

11

Panel B

18192021222324

Panel D

PB1317 (CAT. NO. 5229 ) —17— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

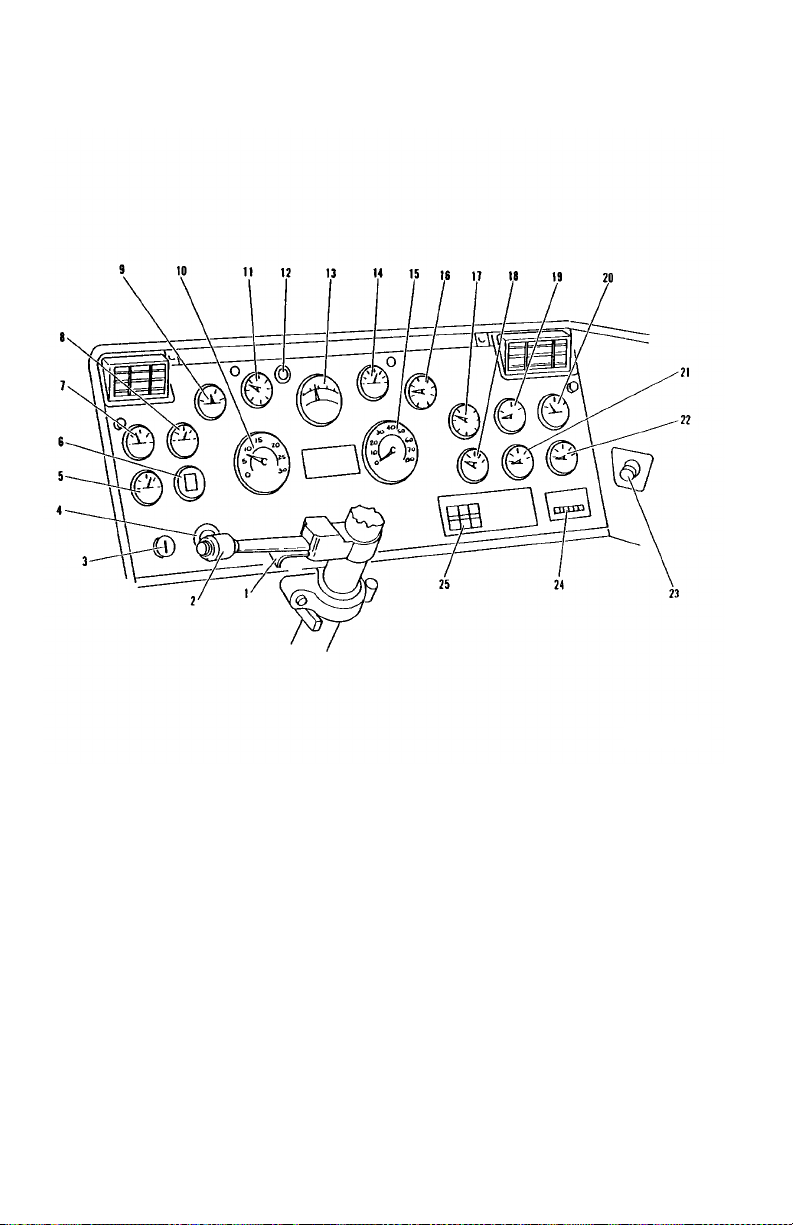

Typical COE Instruments and Controls

02973

LEFT SIDE

1. Hazard Flasher 14. Water Temperature

2. Turn Signal 15. Speedometer

3. Ignition Switch 16. Air Pressure

4. Start Button 17. Air Pressure

5. Manifold Pressure 18. Transmission Temperature

6. Air Cleaner Restriction G auge 19. Fuel Gauge

7. Ammeter 20. Clock

8. Voltmeter 21. Front Driver T em perature

9. Engine Oil Temperature 22. Rear Driver Temperature

10. Tachometer 23. Lighter

1 1. Oil Pressure 24. Trip Odometer

12. ABS Warning Lamp 25. Shift Pattern Decal (if used)

13. Pyrometer

PB1317 (CAT. NO. 5229 ) —18— 22-01510 (R12/01)

COE

PART 4: CONTROLS AND DISPLAYS

02974

RIGHT SIDE

1. Air Suspension Switch 13. Engine Fan

2. 5th Wheel Lock 14. Headlamps

3. Lockout Differential Switch 15. Ether Switch

4. Reset Circuit Breakers 16. Trail er Brake Hand Valve

5. Retarder Switch 17. Cab Air Selector

6. Loading Lamp 18. Cab Heat Control

7. Fuel Tank Selector L/R 19. Cab Ve nti lation

8. Light Toggle Switch 20. Cab A/C Control

9. Spot Light 21. Parking Brake Valve

10. Engine Brake 22. Trailer Air Supply

1 1. Mirror Heat 23. Right Hand Air Window

12. Clearance Lamps 24. Windshield Washer / Wiper

PB1317 (CAT. NO. 5229 ) —19— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

Steering Column-Mounted Controls

Turn Signal and Indicator Lights

02882

Model 379 vehicles built on

or after 5/1/98 with SRS

Your turn signal lever is mounted on the left side of the steering column below the steering wheel. Green directional indicator lights

appear on the instrument panel.

NOTE: The ignition key must be turned to ON for the signal/

switch to operate.

To operate the signal, move the lever in the direct i on of the turn.

02882A

W ARNI NG! Af t er yo u c ompl et e a tu rn , s hut the sy stem of f

by returning the lever to the “O FF” (center) positi on. The

switch's lever action is NOT self-canceling. Failure to shut

off a turn signal could confuse other drivers and res ul t in

an injury accident. An indicator light in the instrument

panel will flash until the turn signal is turned off.

PB1317 (CAT. NO. 5229 ) —20— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

Hazard Flasher

02883

or after 5/1/98 with SRS

The four-way Hazard Flasher switch is on the turn signal body, just

below the turn signal lever. It will operate with the key switch in the on

or off position. Use your hazard flasher whenever you are off the

road or on the side of the road, or in a potentially hazardous situation.

Pull it out to activate the system. All turn si gnals will flash at once. To

turn it off, move the turn signal lever up or down. Of course, in normal

stopping in traffic, such as at a stop light, you do not use your flashers.

WARNING!

time you have to stop off the road or on the side of the

road, day or night. A hard-to-see vehicle can result in an

injury accident. Another vehicle could run into you if you

do not set your flashers. Always move the vehicle a safe

distance off the road when stalled or stopped for repairs.

Use your Hazard Flasher Warning System any

02883A

Model 379 vehicles built on

A

disabled vehicle can be dangerous for you and others.

•

The hot exhaust system could ignite dry grass, spilled

fuel, or other substances. Do not park or operate your

vehicle where the exhaust system could contact dry

grass, brush, spilled fuel, or any other material that

coul d cause a fire.

Air Horn

Your Peterbilt has an air horn in ad dition to an e lectric horn. Control

the air horn by pulling on the lanyard extending from the overhead

header panel.

PB1317 (CAT. NO. 5229 ) —21— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

High Beam Headlights

02884

02884A

Model 379 vehicles built on

or after 5/1/98 with SRS

All Pe te rbilt vehicles c om e equipped with a combination t urn signal and

high beam/low beam s witch. To switch your headlights lower or higher

• For Model 379 vehicles built on or after 5/1/98 with SRS: Gently

pull the turn signal lever up, towards the steering wheel, until you

hear the switch “click” and the beam changes.

• For all other vehicles: Push and release the button on the end of

the turn signal lever

Electric Horn

Your Peterbilt has an ele ctric horn. To sound the horn, press on th e

button or bar in the center of the steering wheel.

02886

27884

Model 379 vehicles built on

or after 5/1/98 with SRS

PB1317 (CAT. NO. 5229 ) —22— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

Trailer Brake Hand Valve

02975

02975A

Model 379 vehicles built on or after 5/1/98 with SRS

This hand valve provides air pressure t o a pply t he tr ailer brak es only.

It operates independently of the foot treadle valve.

To operate the trailer brake hand valve: Pull down on the lever

under the ri ght sid e of the st eeri ng whee l or on th e dash (C OE model s).

W ARNING! Grabbing th e trailer hand brake lever instea d

of the BrakeSaver lever could lead to an accident. If you

have the se l evers, they may be clos e to gether on your

steering wheel column. Be sure you get the one you

want. T he BrakeSaver lev er is bent, while the trailer p arking brake le ver is straight (see

Brake Safety and Emergency” for more complete information on

See “

page 36

).

when and how to use your trailer brake. Or see the Index, under Brake

NOTE: The trailer brake is not to be used as the main

means of braking. T o use this brake frequently instead of

using the foot brake will wear out the trailer brake sooner.

PB1317 (CAT. NO. 5229 ) —23— 22-01510 (R12/01)

.”

PART 4: CONTROLS AND DISPLAYS

WARNING! It is dange rous to use air-a ppl ied trailer

brakes for parking or holding a vehicl e. Air system pressure can bleed d o wn an d release the brakes. You could

have a vehicl e roll-away result ing in an accident. You or

others could be badly injured. Always apply the parking

brakes for parking or holding your vehicl e on grade.

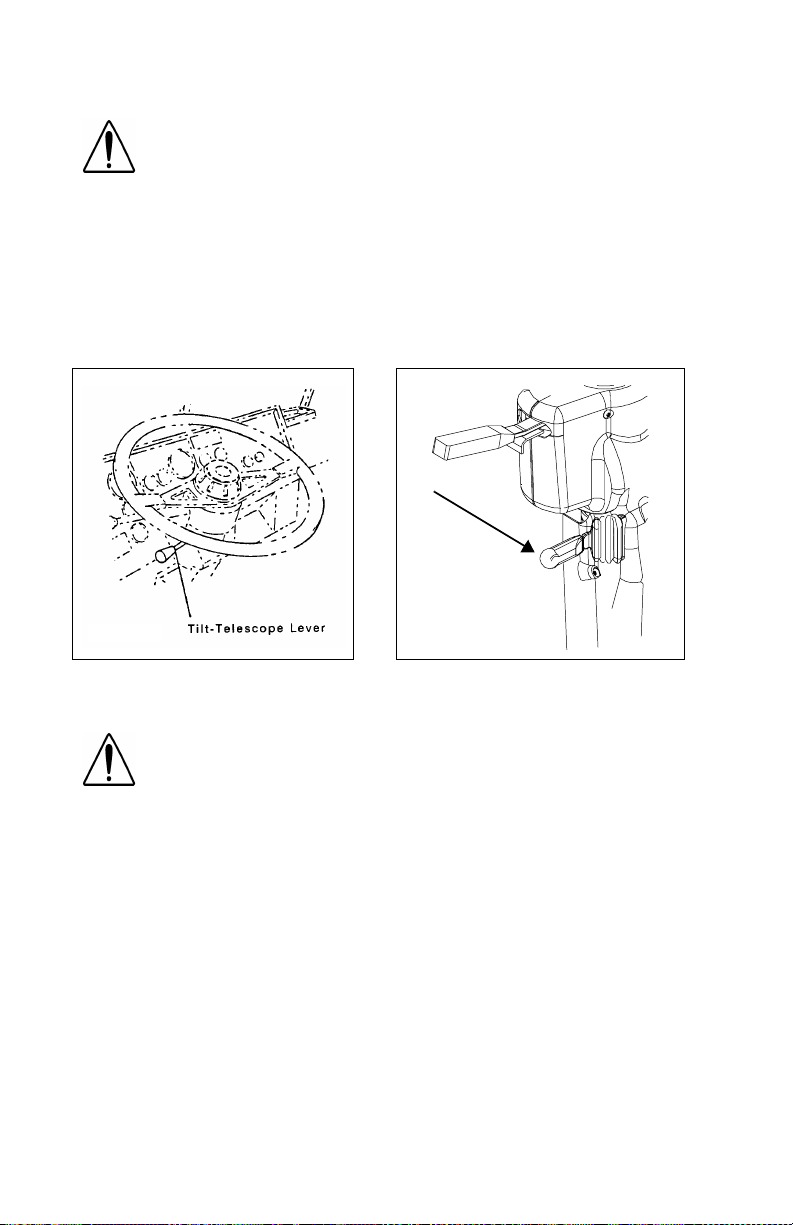

Tilt- Telescoping Steering Column

The tilting feature of the steering wheel allows forward and rearward

movement of the wheel . T he t elescopi ng f eature al lows y ou to m ove

the wheel up and down.

02976

02976A

Model 379 vehicles built on

or after 5/1/98 with SRS

WARNING! Adjustin g the Tilt-Telescoping Steering

Wheel while the vehicle is in motion could cause loss of

control. You wouldn’t be able to steer properly and

could have an accident. Make all adjustments to the

steering mechanism while the vehicle is stopped.

• Model 379 vehicles

To tilt the wheel: Push the lever away from yourself. Move the

steering wheel to the desired angle, then release the lever to lock.

To raise or lower the wheel: Pull the lever towards y ourself. Push

or pull the wh eel to the desi red he ight , th en rel ease t he lever to lo ck.

• All other models

To tilt the wheel : Pull the lever towards yourself. Move the steering wheel to the desired angle, then release the lever to lock.

To raise or lower the wheel: Push the lever away from yours el f .

Push or pul l the wheel to the des i red height, then re l ease the lever

to lock.

PB1317 (CAT. NO. 5229 ) —24— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

Dash-Mounted Features

Keys and Locks

Conventional Models: The same key fits your ignition, doors, and

sleeper luggage compartment.

COE Models: The same key operates the ignition and opens the

doors and the glove box.

Frame-mounted tool box locks and locking fue l tank caps each have

individual keys.

Ignition Switch

Your ignition switch has three (COE) or four (conventional) positions:

OFF

ACC ONLY

IGN & ACC

START

02977A

ACC (Accessory): With your key in this position you can play the

radio or use other accessories, but your engine

won’t start.

OFF: In this position all systems are off, and you can

remove yo ur key.

IGN & ACC: This position allows you to turn on the engine

and all accessory power.

START: Starter activation to start engine (conventional

models only).

PB1317 (CAT. NO. 5229 ) —25— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

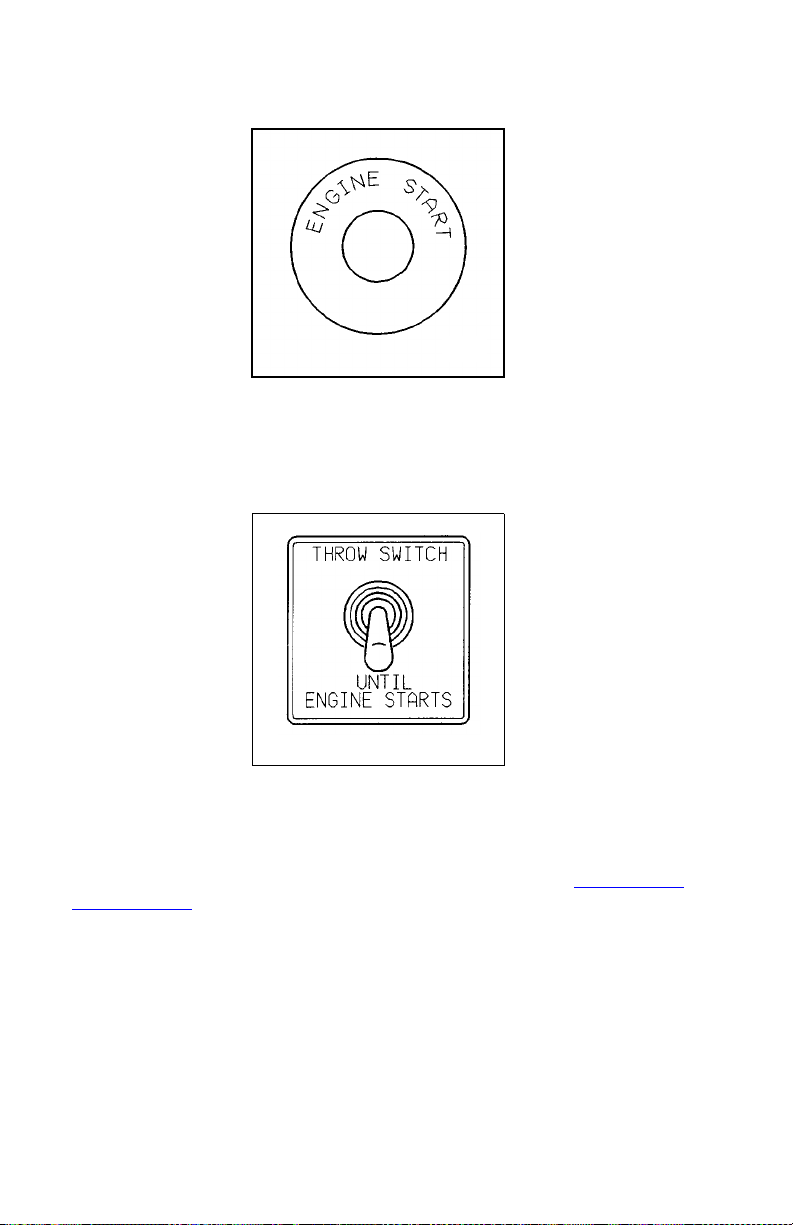

Starter Button

02887

On COE models: with the key switch in the IGN & ACC position, push

the starter button; this will engage the starter motor and crank the

engine.

Manual Override for Engine Shutdown

02889

On vehicles with an engine shutdown, you will have to hold the manual throw switch in the UP position until normal engine pressures are

reached. If you have one of t hese systems, a label on the control

panel will say so.

For detailed starting procedures, see the Index, under St arting and

Operating 80.

PB1317 (CAT. NO. 5229 ) —26— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

Hand Throttle Control

WARNING! Do not use the hand throttle control as a

cruise control. It could cause an accident and you

could be seriously injured. In an emergency you m ight

not be able to unset it in time to save yourself and your

vehicle from an accident. Never try to control road

speed with your hand throttle control. Always push in

the hand throttle before driving the vehicle.

If you have a hand throttle, in conventional cabs it is usually located to

the left of the driver’s seat, mounted on the floor. In COEs it is un der

the lefthand dash. It can be especially helpful in cold weather to keep

your engine running at above idle speed when you leave the vehicle

briefly.

For more information on idling your engine safely, see the Index,

under Engine

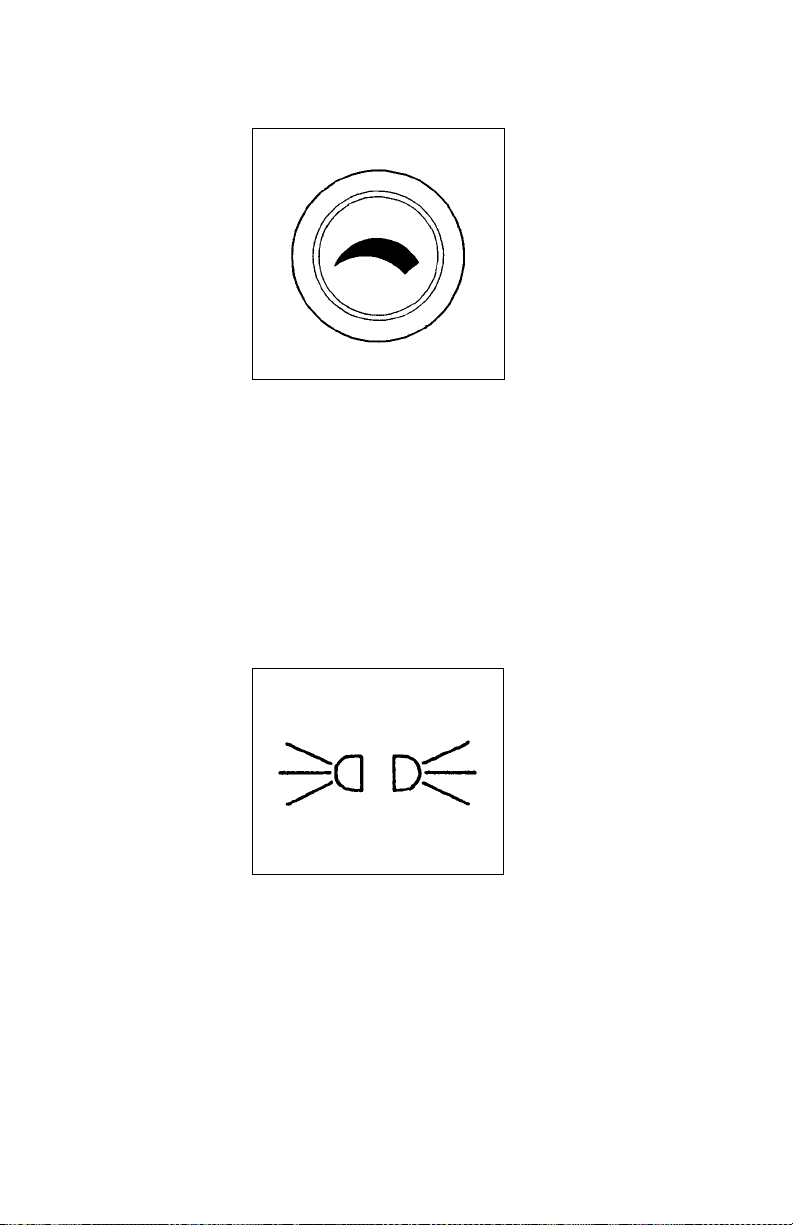

Headlights

.

02890

The headlights are controlled by the control panel switch showing this

symbol. When the headlights are ON, the dash lights, side, and tail

lamps are also on.

WARNING! Do not use daytime running lights (DRL)

during periods of darkness or reduced visibility. Do not

use DRL as a substitute for headlights or other lights

during ope rat i on s tha t re qu ire l ig ht i ng of your vehicle.

Doing so could lead to an injury accident

NOTE: On vehicles equipped with daytime running lights

(DRL), the high-beam headlamps go on automatically at

reduced brightness if the engine is running and the headlamp switch is turned off. The daytime running lights are

turned off automatically while the parking brake is engaged.

If the headlamp switch is turned on, the DRL system is overridden & headlamps operate normally.

PB1317 (CAT. NO. 5229 ) —27— 22-01510 (R12/01)

PART 4: CONTROLS AND DISPLAYS

Panel Light Knob

02891

The Panel Light Knob lets you vary the brightness of your instrument

panel lights.

To Operate Your Panel Light Knob:

1. Turn on either the headlights, clearance lights, or fog / driving

lights.

2. To brighten the instrument panel lights, turn the knob clockwise (to

the right).

3. To dim the instrument lights or to turn them off, turn the knob counterclockwise (to the left).

ID and Clearance Lights Switch

02892

These are the ambe r lights on top o f your cab, the lights on the front

and sides of the trailer, and the red lights on the rear of a truck or

trailer. They are controlled by the control panel switch labelled CL

LPS.

PB1317 (CAT. NO. 5229 ) —28— 22-01510 (R12/01)

Loading...

Loading...