Peterbilt 387 Service Manual

Model 387

Instrument System

Service Manual

Document Number 072-40245

Rev. D

Every effort has been made to keep the information in this document current and accurate as of the date of publication or revision. However, no guarantee is given or implied that the document is error-free or that it is accurate with regard to any specification. AMETEK Dixson reserves the right to modify product designs and specifications without notice.

|

|

Revision Table |

|

|

|

Revision |

Date |

Description |

|

|

|

|

01/27/99 |

Initial release. |

|

|

|

A |

05/14/99 |

Changed all occurrences of “2100” to “387”, and of “self test” to |

|

|

“initialization”; Fig. 5-22, corrected pin designations on J3 illus- |

|

|

tration. |

|

|

|

B |

09/28/99 |

Added Chapter 6, “Using the Handheld Diagnostic Tool"; re- |

|

|

moved all references to PTM/VTM replacement and to the ABS |

|

|

system; improved Pyrometer troubleshooting instructions; up- |

|

|

dated Warning Messages tables to reflect current configuration; |

|

|

various other updates and changes resulting from Engineering |

|

|

Dept. review. |

|

|

|

C |

03/01/04 |

Updated and renamed Figure 5-16. |

|

|

|

D |

01/01/07 |

Removed contact information. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ii |

072-40245 D |

Model 387 Instrument System Service Manual

Table of Contents

1 Introduction |

|

|

|

|

|

|

|

|

|

|

|

|

1-1 |

|

1.1 |

Purpose and Scope . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

1-1 |

1.2 |

How To Use This Manual . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

1-1 |

1.3 |

System Components . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

1-2 |

1.4 |

What Makes the Model 387 Instrument System Different . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

1-2 |

2 Operation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-1 |

|

2.1 |

Activating the Instrumentation . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

2-1 |

2.2 |

Select/Reset Switch . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

2-1 |

2.3 |

Speedometer with Integral Message Center . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

2-1 |

2.4 |

Using the Speedometer Message Center . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

2-2 |

2.4.1 Clock Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 2.4.2 Trip Odometer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 2.4.3 Clock Alarm Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5 Warning Alarms . . . . . . . . |

. . . . . . . . . . . . . . . . . . 2-3 |

|

2.5.1 Red Warning LEDs . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 |

|

2.5.2 |

Vehicle Safety Warning Messages . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 |

2.5.3 |

System Fault Messages . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 |

3 Functional Description |

|

|

|

|

|

|

|

|

3-1 |

||

3.1 |

The Interface Module . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . . |

3-2 |

||

|

3.1.1 |

Pressure and Vacuum Inputs . . . . . . . . . . . . . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. . . . |

. |

3-2 |

|

3.1.2 |

Transducer Modules . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. . . . |

. |

3-3 |

|

|

3.1.2.1 Pressure Transducer Module...................................................................................... |

|

|

|

|

|

|

|

|

3-3 |

|

|

3.1.2.2 Vacuum Transducer Module (VTM) ............................................................................ |

|

|

|

|

|

|

|

|

3-4 |

|

3.1.3 |

Vacuum/Pressure and Pressure/Vacuum Transducer Modules . . |

. |

. . |

. |

. . |

. . |

. |

. . . . |

. |

3-4 |

3.2 |

J1708 Data Bus . . . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . |

. |

3-4 |

|

3.3 |

Electronic Control Units . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . |

. |

3-5 |

|

3.4 |

Speedometer with Integrated Message Center . . . . . . . |

. |

. |

. |

. |

. |

. |

. . . |

3-5 |

||

|

3.4.1 |

Select and Reset Switches . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. |

. . |

. . |

. |

. . . . |

. |

3-6 |

|

3.4.2 |

Power Take-Off (PTO) Input . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

. . |

. . . |

. |

3-6 |

|

3.4.3 |

Two-Speed Axle Input . . . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

. . |

. . . |

. |

3-6 |

3.5 |

Diagnostic Capabilities. . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . . |

3-6 |

||

|

3.5.1 |

Power-On Initialization . . . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

. . |

. . . |

. |

3-6 |

|

3.5.2 |

Diagnostic Connector . . . . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

. . |

. . . |

. |

3-7 |

3.6 |

Private Data Bus . . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . . |

3-7 |

||

|

3.6.1 |

Five-Wire Cable Assemblies . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

. . |

. . . |

. |

3-7 |

|

3.6.2 |

Two-Inch Gauges . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

. . |

. . . |

. |

3-7 |

|

3.6.3 |

J1708 Data Bus and Private-Bus-Driven Gauges . . . . . . . . . |

. |

. . |

. . |

. |

. . |

. . |

. . . |

. |

3-8 |

072-40245 D |

iii |

3.6.4 Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-8 |

|

3.6.4.1 |

Ammeter........................................................................................................................ |

3-9 |

3.6.4.2 |

Voltmeter ..................................................................................................................... |

3-10 |

3.6.4.3 |

Pyrometer .................................................................................................................... |

3-11 |

3.6.4.4 |

Transmission and Axle Temperature Gauges................................................................ |

3-12 |

3.6.4.5 |

Fuel Level..................................................................................................................... |

3-13 |

3.7 Backlighting . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4 Service Procedures |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4-1 |

||

4.1 |

Some Important Dos and Don’ts . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

4-1 |

|

4.2 |

Replacing the Speedometer and Tachometer. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

4-1 |

|

4.3 |

Servicing the Two-Inch Gauges . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. . |

. |

4-2 |

||

|

4.3.1 |

Removal and Reinstallation . . . . . . . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

4-2 |

|

4.3.2 |

Disassembling a Two-Inch Gauge . . . . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

4-3 |

|

4.3.3 |

Reassembling a Two-Inch Gauge . . . . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

4-4 |

4.4 |

Reprogramming a Two-Inch Gauge. . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

4-6 |

|

4.5 |

Servicing the Interface Module . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. . |

. |

4-6 |

||

|

4.5.1 |

Removing the Interface Module . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

4-6 |

|

4.5.2 |

Reinstalling the Interface Module . . . . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

4-6 |

|

4.5.3 |

Reprogramming the Interface Module. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

4-6 |

4.6 |

Spare Parts Listing. . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

4-7 |

|

5 Troubleshooting Procedures |

|

|

|

|

|

5-1 |

||

5.1 |

Required Test Equipment . . . . . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

5-1 |

|

5.2 |

Troubleshooting Procedure Start Point. . . . . . . . . . . . . . . |

. |

. |

. . |

. |

5-2 |

||

|

5.2.1 |

The Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

5-3 |

5.3 |

Troubleshooting Procedures for Two-Inch Gauges . . . . . . . . . . . |

. |

. |

. |

. |

. |

5-4 |

|

|

5.3.1 |

Two-Inch Gauge Fails Initialization, No Pointer Movement, LED Never Lights. |

. . . . . . . . . 5-5 |

|||||

|

5.3.2 |

Two-Inch Gauge Passes Initialization but LED Flashes. . . . . . . . . . . . . |

. . . |

. |

. . |

. . |

. |

5-6 |

5.3.2.1 |

Air and Fuel Pressure Gauges |

........................................................................................5-7 |

5.3.2.2 |

Temperature Gauges...................................................................................................... |

5-9 |

5.3.2.3 J1708 Data Bus Gauges .............................................................................................. |

5-11 |

|

5.3.2.4 Vacuum Gauges........................................................................................................... |

5-11 |

|

5.3.2.5 |

Voltmeter Gauge .......................................................................................................... |

5-13 |

5.3.2.6 Ammeter Gauge........................................................................................................... |

5-14 |

|

5.3.2.7 |

Fuel Level Gauge.......................................................................................................... |

5-16 |

5.3.2.8 |

Pyrometer .................................................................................................................... |

5-17 |

5.4 Troubleshooting Procedures for the SMC . |

. . . . . . . . . . . . . . . . . 5-19 |

|

5.4.1 SMC Pointer Never Moves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20 5.4.2 Speedometer and Odometers Inaccurate . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21 5.4.3 Speedometer Accurate, Odometer Inaccurate . . . . . . . . . . . . . . . . . . . . . . . . . 5-21 5.4.4 Odometer Advances When PTO Engaged . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22 5.4.5 Speedometer Does Not Change Speed When Two-Speed Axle Engaged . . . . . . . . . . . 5-23 5.4.6 Engine Hours Do Not Advance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

iv |

072-40245 D |

Model 387 Instrument System Service Manual

5.5 |

One or More Gauge Pointers Sweep . . . . . . . . . . . . |

. |

. |

. |

. |

. . |

. |

5-25 |

||

|

5.5.1 A J1708 Data Bus Gauge Pointer Sweeps . . . . . . . . . . . . . . |

. |

. . |

. . |

. |

. . |

. . |

. |

5-26 |

|

|

5.5.2 A Non-J1708 Data Bus Gauge Pointer Sweeps . . . . . . . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-26 |

|

|

5.5.3 |

Several (But Not All) Gauge Pointers Sweep . . . . . . . . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-27 |

|

5.5.4 SMC Pointer and All J1708 Data Bus Gauge Pointers Sweep . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-27 |

|

|

5.5.5 |

All J1708 Data Bus Gauge Pointers (Except the SMC Pointer) Sweep |

. . |

. |

. . |

. . |

. |

. . |

. |

5-29 |

|

5.5.6 |

All Gauge Pointers Except the SMC Pointer Sweep . . . . . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-30 |

|

5.5.7 Only the SMC Pointer Sweeps, and No Messages Appear . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-32 |

|

|

5.5.8 SMC Pointer Sweeps, and a NO DATA Message Appears. . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-32 |

|

5.6 |

Warning Messages . . . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. . 5-33 |

|||

5.7 |

Backlighting Problems . . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. . |

. |

5-34 |

||

|

5.7.1 |

Two-Inch Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-34 |

|

|

5.7.1.1 One Gauge Has No Backlighting .............................................................................. |

|

|

|

|

|

|

|

5-34 |

|

|

5.7.1.2 More Than One Gauge Has No Backlighting ............................................................ |

|

|

|

|

|

|

|

5-34 |

|

|

5.7.1.3 All Gauges Plus Tachometer Have No Backlighting.................................................. |

|

|

|

|

|

|

|

5-35 |

|

5.7.2 SMC Has No Backlighting . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

. . |

. . |

. |

. . |

. |

5-36 |

|

5.8 |

Select/Reset Switches not Working . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. . 5-36 |

|||

5.9 |

Wiring Diagrams . . . . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

5-38 |

|

6 Using the Handheld Diagnostic Tool |

|

|

|

|

|

|

|

|

|

|

6-1 |

||

6.1 |

Care and Cleaning . . . . . . . . . . . . . . |

. . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

6-1 |

|

6.2 |

Description . . . . . . . . . . . . . . . . |

. . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

6-2 |

|

6.3 |

Reading Engine ECU Gauge Data . . . . . . . . . |

. . |

. |

. |

. |

. |

. |

. |

. . |

. |

6-3 |

||

|

6.3.1 |

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

. |

. 6-3 |

6.4 |

Reading Private Bus Gauge Data. . . . . . . . . . |

. . |

. |

. |

. |

. |

. |

. |

. . |

. |

6-6 |

||

|

6.4.1 |

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

6-6 |

6.5 |

Viewing Configuration Data . . . . . . . . . . . |

. . |

. |

. |

. |

. |

. |

. |

. . |

. |

6-8 |

||

|

6.5.1 |

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. . |

6-8 |

6.6 |

Programming and Verifying Ports 5A and 5B . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. . |

. |

6-10 |

||

|

6.6.1 |

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. |

6-10 |

6.7 |

Programming the Main Transmission Temperature Warning LED |

. |

. |

. |

. |

. |

. |

. |

. . |

. |

6-13 |

||

|

6.7.1 |

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

. . |

. . |

. |

. . |

. . |

. |

. . |

. |

6-13 |

6.8 |

HDT Spare Parts . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

6-16 |

|

072-40245 D |

v |

List of Illustrations

Figure 1-1 |

Panel and Interface Module . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

1-2 |

Figure 2-1 |

System Initialization . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

2-1 |

Figure 2-2 |

Speedometer Message Center Displays . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

2-2 |

Figure 3-1 |

Instrumentation Block Diagram . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

3-1 |

Figure 3-2 |

387 System Interface Module . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

3-2 |

Figure 3-3 |

Pressure Circuit . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

3-3 |

Figure 3-4 |

Pressure, Vacuum, and Pressure/Vacuum Transducer Modules |

. |

. |

. |

. |

. |

. |

. |

. |

3-4 |

Figure 3-5 |

387 Speedometer with Message Center . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

3-5 |

Figure 3-6 |

System Initialization . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

3-6 |

Figure 3-7 |

J1708 Data Bus Gauges . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

3-8 |

Figure 3-8 |

Ammeter Circuit . . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

3-9 |

Figure 3-9 |

Voltmeter Circuit . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 3-10 |

||

Figure 3-10 |

Pyrometer Circuit . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 3-11 |

||

Figure 3-11 |

Axle and Transmission Temperature Circuits. . . . . . |

. |

. |

. |

. |

. |

. |

. . 3-12 |

||

Figure 3-12 |

Fuel Level Circuit . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 3-13 |

||

Figure 4-1 |

Two-Inch Gauge Removal and Reinstallation . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

4-3 |

Figure 4-2 |

Scaleplate Alignment . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

4-5 |

Figure 4-3 |

Two-Inch Gauge Disassembly . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

4-5 |

Figure 4-4 |

Removing the Interface Module . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

4-6 |

Figure 5-1 |

Gauge Initialization . . . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

5-3 |

Figure 5-2 |

Checking 2-inch Gauge Power . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

5-5 |

Figure 5-3 |

Checking Pressure Gauges with Standard Test Gauge . . . |

. |

. |

. |

. |

. |

. |

. |

. |

5-7 |

Figure 5-4 |

Checking Temperature Sensor Wiring . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-10 |

||

Figure 5-5 |

Testing the Air and Fuel Restriction Gauges . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-12 |

||

Figure 5-6 |

Testing the Voltmeter Gauge . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-13 |

||

Figure 5-7 |

Testing the Ammeter Gauge. . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-15 |

||

Figure 5-8 |

Testing the Fuel Level Gauges . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-16 |

||

Figure 5-9 |

Testing the Pyrometer . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-17 |

||

Figure 5-10 |

Testing the Pyrometer (continued) . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-18 |

||

Figure 5-11 |

Troubleshooting SMC Power and Ground . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-20 |

||

Figure 5-12 |

Troubleshooting the PTO (Power Take-Off) Input . . . . |

. |

. |

. |

. |

. |

. |

. . 5-22 |

||

Figure 5-13 |

Troubleshooting the Two-Speed Axle Input . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-23 |

||

Figure 5-14 |

SMC Pointer and All J1708 Data Bus Gauge Pointers Sweep |

. |

. |

. |

. |

. |

. |

. . 5-28 |

||

Figure 5-15 |

All J1708 Data Bus Gauge Pointers (except SMC) Sweep . |

. |

. |

. |

. |

. |

. |

. . 5-29 |

||

Figure 5-16 |

Checking Power to the Interface Module . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-31 |

||

Figure 5-17 |

Checking Private Bus Wire Continuity. . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-31 |

||

Figure 5-18 |

Gauge Backlighting Problem (except SMC) . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-35 |

||

Figure 5-19 |

SMC Backlighting Problem . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-36 |

||

Figure 5-20 |

Troubleshooting the Select and Reset Switches. . . . . |

. |

. |

. |

. |

. |

. |

. . 5-37 |

||

Figure 5-21 |

Instrumentation Harness Layout . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. . 5-38 |

||

Figure 5-22 |

Gauge Connector Wiring . . . . . . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

5-39 |

vi |

072-40245 D |

Model 387 Instrument System Service Manual

Figure 5-23 |

Instrumentation Connector Pinout Diagram . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. . 5-40 |

||

Figure 6-1 |

Hand-Held Diagnostic Tool. . . . . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

6-2 |

Figure 6-2 |

Connecting the HDT to the Diagnostic Connector. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

6-3 |

Figure 6-3 |

Connecting the HDT to the Private Bus . . . . |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

. |

6-6 |

List of Tables

Table 2-1 |

Red Warning LEDs . . . . . . . . . . . . . . . . . . . . . |

. |

2-5 |

Table 2-2 |

Vehicle Safety Warning Messages . . . . . . . . . . . . . . . . |

. |

2-6 |

Table 4-1 |

387 System Spare Parts . . . . . . . . . . . . . . . . . . . |

. |

4-7 |

Table 5-1 |

Troubleshooting Starting Point . . . . . . . . . . . . . . . . . |

. |

5-2 |

Table 5-2 |

Two-Inch Gauge Problems. . . . . . . . . . . . . . . . . . . |

. |

5-4 |

Table 5-3 |

Problems Indicated by Flashing Gauge LEDs . . . . . . . . . . . . . |

. |

5-6 |

Table 5-4 |

SMC Problems . . . . . . . . . . . . . . . . . . . . . . |

. |

5-19 |

Table 5-5 |

Problems Indicated by Sweeping Pointer(s) . . . . . . . . . . . . . |

. |

5-25 |

Table 5-6 |

Warning Messages . . . . . . . . . . . . . . . . . . . . |

. |

5-33 |

Table 5-7 |

System Fault Messages . . . . . . . . . . . . . . . . . . . |

. |

5-33 |

Table 6-1 |

HDT Spare Parts . . . . . . . . . . . . . . . . . . . . . |

. |

6-16 |

072-40245 D |

vii |

Notes: |

|

viii |

072-40245 D |

Model 387 Instrument System Service Manual

1Introduction

1.1Purpose and Scope

The purpose of this manual is to provide Peterbilt with the knowledge required to produce their own repair procedures. This manual contains the technical repair information necessary to diagnose and repair the Model 387 Instrument System (also referred to as simply the “instrumentation”). The information in this manual is not proprietary and can be used as Peterbilt sees fit.

The manual describes how to operate, service, and troubleshoot the instrumentation installed in vehicles that broadcast engineand speed-related information over a public data bus (the SAE J1708 data bus). For information about the vehicle’s Electronic Control Unit(s), wiring diagrams, the SAE J1708 data bus, external sensors and other components that are not part of the instrumentation, please refer to the appropriate vehicle service documentation.

1.2How To Use This Manual

The manual is divided into six chapters:

•Introduction - Contains a brief introduction to the product and to the manual itself.

•Operation - A complete operator’s manual. Written for the vehicle operator, this chapter describes how to use the instrumentation and how to interpret the information it presents. If you are going to operate the vehicle, you should read and understand the information in this chapter.

•Functional Description - Describes the components that make up the instrumentation and how they communicate with other systems in the vehicle. An understanding of the information in this chapter will help you diagnose and find problems in the instrumentation. If you are going to service the instrumentation, you should read and understand the information in this chapter.

•Service - Describes how to remove, disassemble, and reinstall the components of the instrumentation. It contains a spare parts list, and other important information. Do not service the instrumentation until you have read and understand the information in this chapter.

•Troubleshooting - Provides detailed troubleshooting information that will help you identify faulty components within the instrumentation.

•Using the Handheld Diagnostic Tool (HDT) - Describes the operation of the handheld diagnostic tool used to help diagnose problems with the instrumentation.

072-40245 D |

1-1 |

Introduction |

1.3System Components

The instrumentation consists of a 33 8-inch speedometer with an integrated message center, a 33 8-inch tachometer, several 2-inch gauges, a Select/Reset switch, and a remotely mounted Interface Module. Figure 1-1 shows how a typical system with four 2-inch gauges might look, along with an Interface Module.

Figure 1-1 Panel and Interface Module

1.4What Makes the Model 387 Instrument System Different

In conventional instrumentation, each electrical gauge is connected to a sensor by a signal wire and a return wire. Additional wires for illumination, power, ground and warning lights could total as many as six wires per gauge. Thus, a panel with 10 gauges plus a speedometer and a tachometer could require up to 60 separate wires. By comparison, the Model 387 Instrument System uses a single 5-wire cable to connect all the gauges. This significantly reduces the number of wires behind the instrument panel and makes the system much easier to troubleshoot and service.

The instrumentation is easy to repair. The 2-inch gauges can be disconnected, removed from the panel, disassembled, reassembled, and reinstalled without tools, and they are maintenance-free.

With the exception of the scaleplate, all 2-inch gauges are identical. Each scaleplate is coded and when installed in the gauge, configures the gauge to the function shown on the scaleplate. This reduces the spare parts inventory by requiring only a few blank gauges and a supply of inexpensive scaleplates rather than a complete spare gauge of each type.

The instrumentation can also display warning messages and audible alarms, and has built-in diagnostic capabilities to help diagnose problems.

Introduction |

1-2 |

072-40245 D |

Model 387 Instrument System Service Manual

2Operation

2.1Activating the Instrumentation

Turning on the ignition activates the instrumentation and starts the initialization described in Figure 2-1.

Figure 2-1 System Initialization

Service the vehicle if any of the following conditions occur after the initialization:

•The speedometer or tachometer pointer sweeps back and forth in a windshield wiper motion.

•A 2-inch gauge pointer sweeps back and forth in a windshield wiper motion and stops at a 10:00 position with its red LED on.

•A 2-inch gauge pointer stays at a 7:00 position and its red LED flashes.

•A 2-inch gauge pointer goes to and remains at a 12:00 position with its red LED on.

2.2Select/Reset Switch

A Select/Reset switch on the dash allows you to select, set, and reset message center displays. It also allows you to scroll through active system warning messages.

2.3Speedometer with Integral Message Center

The speedometer and its message center together are called the SMC. The SMC normally displays road speed and the odometer reading. The SMC can also display other functions as shown in Figure 2-2.

072-40245 D |

2-1 |

Operation |

To view a different function, press and release the Select switch until the desired function appears.

Figure 2-2 Speedometer Message Center Displays

The message center goes into a “sleep” mode (i.e. goes blank) when the ignition is turned off. Each time you press the Select switch, the message center is “awakened” for 10 seconds. This allows you to scroll through the different functions.

If a warning alarm is triggered, a warning message will override all other displays until the condition that caused the warning alarm is corrected. Some warning alarms include an audible warning. Warning alarms are described in detail in Section 2.5.

2.4Using the Speedometer Message Center

2.4.1Clock Operation

To display the clock time, press and release the Select switch until the clock is displayed.

To change the clock time -

1.Press and release the Reset switch. The Hours display will flash, indicating the value can be changed.

2.Press the Select switch to change the Hours value, or press the Reset switch to accept the displayed value and enable the Minutes value to be changed. To change from AM to PM, scroll through 12 hours.

3.When the Minutes value is flashing, press the Select switch to change the value, or press the Reset switch to accept the displayed value and exit the Change Time function. Scrolling the Minutes value past 59 will not change the Hours value.

Operation |

2-2 |

072-40245 D |

Model 387 Instrument System Service Manual

2.4.2Trip Odometer Operation

To display the Trip 1 or 2 Odometer, press and release the Select switch until XXXXT1 or XXXXT2 is displayed (XXXX = the actual mileage reading).

To reset a trip odometer to zero -

1.Display the odometer to be reset (Trip 1 or Trip 2)

2.Press and hold the Reset switch for 3 seconds.

2.4.3Clock Alarm Operations

To display the alarm time, press and release the Select switch until an AL appears along with a time value.

To change the alarm time -

1.Press and release the Reset switch. The Hours digits will begin to flash, indicating the values can be changed.

2.Press the Select switch to change the Hours value, or press the Reset switch to accept the displayed value and enable the Minutes value to be changed. To change from AM to PM, scroll through 12 hours.

3.When the Minutes value is flashing, press the Select switch to change the value. Scrolling the Minutes value past 59 will not change the Hours value.

4.Press the Reset switch to accept the displayed value and exit the Change Alarm Time function. This also activates the alarm and an asterisk ( * ) will appear in the first digit of the Clock display to indicate the alarm is on.

To activate or deactivate the alarm tone, from any display, press and hold the Select switch longer than three seconds.

To silence the alarm tone while it is sounding, press and release the Select switch while the alarm is sounding.

2.5Warning Alarms

A warning alarm indicates that some condition in the vehicle requires attention. A warning alarm can be indicated in the following ways:

•Red warning LEDs in the 2-inch gauges

•Vehicle safety warning messages in the SMC

•System fault warning messages in the SMC

A warning alarm will continue until the condition that caused it is corrected. At that time, the SMC will display a Reset message for 10 seconds, and the warning indications will cease. Pressing the Reset switch clears the Reset message sooner.

2.5.1Red Warning LEDs

Table 2-1 on page 2-5 lists the conditions which light the red warning LEDs. Some of the LEDs light when the Interface Module receives the appropriate message

072-40245 D |

2-3 |

Operation |

over the J1708 data bus. Other LEDs light as determined by Interface Module programming, and some warning LEDs are not used. Column 3 lists the condition that causes the warning LED to light.

You cannot dismiss or override red warning LED indications. A red warning LED will remain on until the condition causing it is corrected.

Note - Not all gauges listed are currently available.

2.5.2Vehicle Safety Warning Messages

Messages advising of unsafe operating conditions can appear in the SMC. Examples are a major engine or transmission problem (low oil pressure, high temperature, low coolant level) and a problem with the brake safety (low air pressure). An audible alarm will accompany these warning messages.

Vehicle safety warning messages are listed in Table 2-2 on page 2-6. Column 1 shows the warning message as it appears in the SMC, and column 2 identifies its meaning. Column 3 identifies the gauge whose red warning LED lights. Column

4shows the associated Reset message.

You can temporarily override vehicle safety warning messages two ways:

1.Press the Reset switch for 3 seconds. This will dismiss the message and silence the buzzer. If an active alarm still exists, the message and buzzer will return.

2.Press the Reset switch for 1 second, then press the Select switch to display any other function. The warning message will disappear for 60 seconds. It will then reappear and remain until the condition causing it is corrected. The audible alarm will continue to sound.

2.5.3System Fault Messages

A system fault message indicates a problem exists with the Model 387 Instrument System that does not directly affect vehicle safety. These occur when the ignition is first switched on. The messages are:

IM CAL, IM CFG, IM DIAG, IM LIN, IM SLFT, ODO ERR, NO DATA, SMC MEM.

System fault messages are detected by the Interface Module or the SMC. No gauge LED is associated with them, no audible warning will sound, and no Reset message will appear.

The NO DATA message can occur any time, not just during System Initialization.

Operation |

2-4 |

072-40245 D |

Model 387 Instrument System Service Manual

Gauge |

Indication When Led Is On |

Activating Condition |

|

|

|

|

|

|

Air Cleaner Restriction |

Clogged |

More than 25“ of water (H2O) |

Air Tank 1 |

Too low |

Less than 66 psi |

Air Tank 2 |

Too low |

Less than 66 psi |

Air Starter Air Pressure |

No indication |

Not activated |

Ammeter |

Incorrect discharge rate |

>25 amps when RPM <1200, or |

|

|

>2 amps when RPM >1200 |

Auxiliary Transmission Oil Temp |

Too high |

Higher than 230° F |

Brake Saver Application Air Pressure |

No indication |

Not activated |

Brake Saver Oil Temp |

Too high |

Higher than 230° F |

Center Drive Axle Oil Temp |

Too high |

Higher than 230° F |

Engine Load |

No indication |

Not activated |

Engine Oil Pressure |

Too low |

Engine ECU |

Engine Oil Temperature |

Too high |

Engine ECU |

Front Drive Axle Oil Temp |

Too high |

Higher than 230° F |

Fuel Filter Restriction |

Clogged |

More than 7“ of mercury |

Fuel Level (left, right, or main tank) |

Low fuel |

18 tank or less |

Fuel Pressure |

No indication |

Not activated |

Load Gauge Air Pressure |

No indication |

Not activated |

Main Transmission Oil Temp |

Too high |

Programmable |

Manifold Boost |

No indication |

Not activated |

Pusher Suspension Air Pressure |

No indication |

Not activated |

Pyrometer |

Too high |

Higher than 1200° F |

Tractor Brake Applic. Air Pressure |

No indication |

Not activated |

Rear Drive Axle Oil Temp |

Too high |

Higher than 230° F |

Tag Suspension Air Pressure |

No indication |

Not activated |

Trailer Brake Applic. Air Pressure |

No indication |

Not activated |

Voltmeter |

Too low or too high |

>15 volts or <10 volts |

Engine Coolant Temp |

Too high |

Engine ECU |

6X6 Front Drive Axle Oil Temp |

Too high |

Higher than 230° F |

Air Deflector Position |

No indication |

Not activated |

Transfer Case Oil Temp |

Too high |

Higher than 230° F |

|

|

|

Table 2-1 Red Warning LEDs |

|

|

072-40245 D |

2-5 |

Operation |

Warning |

Condition |

Associated |

Reset |

Message |

|

Gauge LED |

Message |

|

|

|

|

H2O TMP |

Coolant temperature high |

Water Temperature |

H2OT OK |

LOW AIR1 |

Air tank #1 pressure low |

Primary Air Pressure |

AIR1 OK |

LOW AIR2 |

Air tank #2 pressure low |

Secondary Air Pressure |

AIR2 OK |

OILPRES |

Engine oil pressure low |

Engine Oil Pressure |

OIL OK |

OIL TEMP |

Engine oil temperature high |

Engine Oil Temperature |

OILT OK |

TRANTMP |

Main transmission oil |

Main Transmission Oil Tem- |

TRAN OK |

|

temperature high |

perature |

|

CAUTION! If a message that is not listed in this table appears, do not ignore it. The vehicle should be serviced regardless of the message that appears.

Table 2-2 Vehicle Safety Warning Messages

Operation |

2-6 |

072-40245 D |

Model 387 Instrument System Service Manual

3 Functional Description

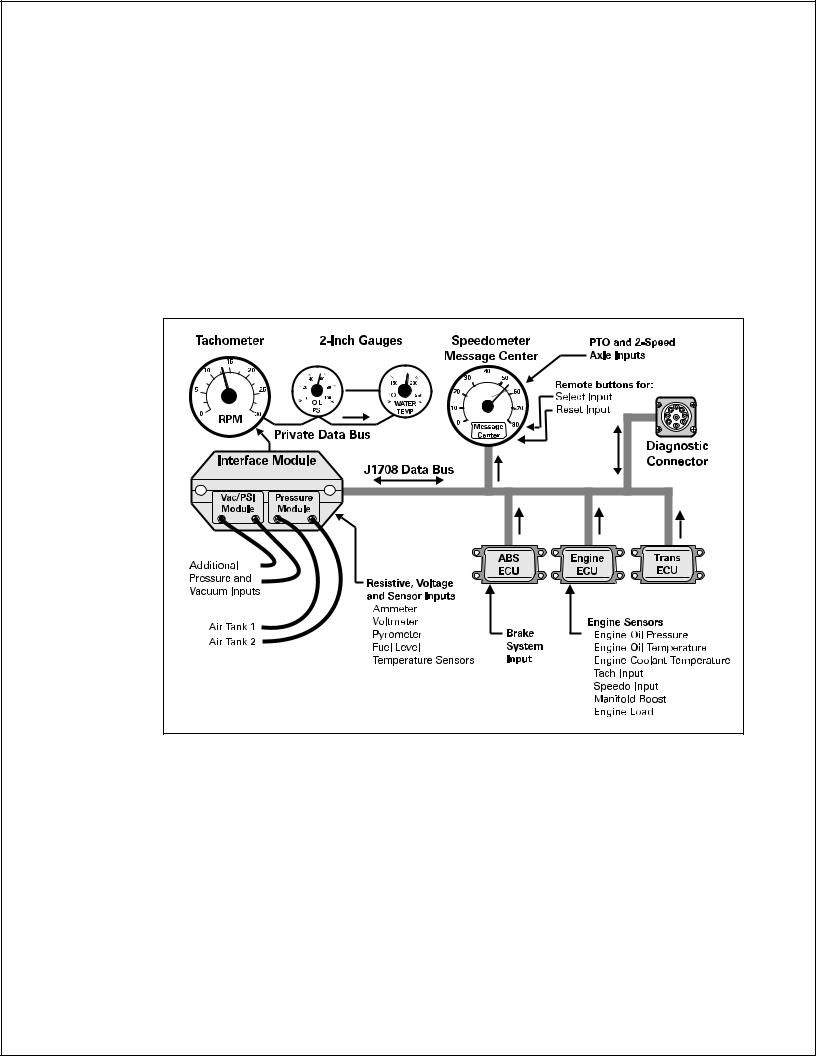

This section describes the instrumentation on a functional level. It is not necessary to read this section to troubleshoot and service the system. It is intended to provide a more detailed understanding of how the system works. Figure 3-1 illustrates the major components and signal flow.

Note - Throughout this manual, the terms “public data bus” or “public bus” refer specifically to the J1708 data bus.

Figure 3-1 Instrumentation Block Diagram

Caution! Never store gauges face down. The gauge meter movements use an oil damping suspension. If a gauge is left face-down longer than 15 minutes, the oil may begin to run out. This causes inaccurate gauge readings, premature gauge failure, and voids the warranty.

072-40245 D |

3-1 |

Functional Description |

3.1The Interface Module

The Interface Module controls the instrumentation by collecting information from various sources and converting that information into gauge pointer information which it then sends to the gauges. It is an environmentally sealed unit and it is usually mounted beneath the cab and against the frame rail. It is connected to the J1708 data bus, and to switches, sensors and pressure/vacuum hoses throughout the vehicle.

Figure 3-2 387 System Interface Module

All gauge and display information is gathered by the Interface Module except:

•Road Speed and Engine Hours - Road Speed and Engine Hours messages are sent directly to the SMC over the J1708 data bus. The SMC also uses road speed messages to compute mileage and display it on the odometers.

•Select and Reset Input - These switched inputs are applied directly to the SMC.

•Clocks - Clock and Alarm Clock information is generated within the SMC.

•Gauge Backlighting - Power for the gauge backlighting comes from an external dimming control and completely bypasses the Interface Module.

3.1.1Pressure and Vacuum Inputs

Hose connections to the transducer modules provide pressure or vacuum to the Interface Module. The Interface Module converts the pressure and vacuum signals to data and places that data on the private data bus to drive the pressure gauges. Connections are shown in Figure 3-3.

Functional Description |

3-2 |

072-40245 D |

Model 387 Instrument System Service Manual

If an Air Filter Restriction gauge is present, its input must be connected to port 5A. If a Fuel Filter Restriction gauge is present, its input must be connected to port 5B. Other pressure inputs are connected to port 5A or 5B, whichever is available depending upon whether an Air Filter or a Fuel Filter Restriction gauge is present.

Whenever the Interface Module is replaced, you must reprogram it recognize the pressure gauges. You do not need to reprogram it when replacing defective gauges.

Figure 3-3 Pressure Circuit

3.1.2Transducer Modules

Four different transducer modules are available. All modules consist of pressure or vacuum transducers (or both) mounted in a common thermoplastic base inside a metal housing. Each transducer converts pressure (or vacuum) into a DC voltage that can be used by the Interface Module.

Transducer modules cannot be replaced in the field.

3.1.2.1Pressure Transducer Module

A pressure transducer module (PTM) contains two identical pressure transducers, each capable of handling up to 150 psi. It can be connected to air, fuel, or oil pressure inputs. It is mounted at port 1A/1B and connected to Air Tank 1 and Air Tank 2 air pressure. A second PTM may also be mounted at port 5A/5B and connect to additional pressure sources. See Figure 3-4 on page 3-4.

072-40245 D |

3-3 |

Functional Description |

Figure 3-4 Pressure, Vacuum, and Pressure/Vacuum Transducer Modules

3.1.2.2Vacuum Transducer Module (VTM)

A vacuum transducer module (VTM) contains two vacuum transducers. The VTM is used for the Air Filter Restriction and Fuel Filter Restriction gauges. The VTM must be mounted at port 5A/5B only.

The vacuum transducers are not identical. The Air Filter Restriction end must go to port 5A, and the Fuel Filter Restriction end must go to port 5B as shown in Figure 3-4.

3.1.3Vacuum/Pressure and Pressure/Vacuum Transducer Modules

Two types of combination modules are available. One type contains a pressure transducer and an Air Restriction transducer; the other type contains a pressure transducer and a Fuel Filter Restriction transducer. Combination modules are not interchangeable and are mounted at port 5A/5B. If used, the Air Filter Restriction end must go to port 5A, and the Fuel Filter Restriction end must go to port 5B as shown in Figure 3-4.

CAUTION - The sudden application of pressure to transducer modules can destroy them and void their warranties. Always apply pressure gradually and at a rate that does not exceed 150 PSI per second.

3.2J1708 Data Bus

The J1708 data bus is a public data bus consisting of a pair of twisted-wires. It allows electronic devices and other equipment in the vehicle to send and receive data. The two wires making up the J1708 data bus are part of the vehicle’s wiring harness. Because it connects to many different components in widely separated locations, a problem with the data bus or with one of the component’s connected to it can sometimes be hard to isolate. For a complete description of the J1708 data bus and data format, refer to SAE J1708 document Standard For Data Communications Interface and to SAE J1587 document, Standard For Data Interchange.

Functional Description |

3-4 |

072-40245 D |

Model 387 Instrument System Service Manual

3.3Electronic Control Units

Electronic Control Units (sometimes called ECUs) are computerized units that control a particular vehicle subsystem. For example, an Engine ECU helps maximize engine efficiency, a Transmission ECU helps control transmission operation, and an ABS (Anti-lock Brake System) ECU maximizes braking performance. An ECU designed for one system cannot be interchanged with an ECU designed for another.

ECUs are connected to the J1708 data bus. They send and receive data to each other and to other devices on the bus. Each ECU is programmed to respond to and to generate specific data.

3.4Speedometer with Integrated Message Center

The SMC is connected to the J1708 data bus and responds to data from the Engine ECU. It uses road speed data from the Engine ECU to calculate its own pointer information. It also responds to other data on the J1708 data bus and can display it on the Message Center. Examples are engine hours and diagnostic messages. The SMC has no calibration switches and requires no programming. See Figure 3-5.

Figure 3-5 387 Speedometer with Message Center

The SMC calculates and stores its own odometer, trip odometer, clock and alarm clock information independent of the Interface Module, and has a built-in audible alarm. The SMC automatically displays warning messages when an alarm condition is detected.

072-40245 D |

3-5 |

Functional Description |

3.4.1Select and Reset Switches

The Select and Reset switches select, set, and reset the clock, the alarm clock, and the trip odometers. Their inputs are connected to the SMC by a 4-pin connector on the rear of the speedometer housing.

If these inputs are not connected, the SMC will display odometer information and warning messages only.

3.4.2Power Take-Off (PTO) Input

This input provides a ground from a switch in the PTO system to the SMC. It prevents the SMC from accumulating miles when the PTO system is in use and the vehicle is not moving.

3.4.3Two-Speed Axle Input

This input to the back of the SMC is a positive voltage that comes from the 2-speed axle actuator on the gearshift lever. When the 2-speed axle is engaged, this input causes the SMC to reduce the road speed indication by a factor of 0.73 to 1.

3.5Diagnostic Capabilities

The instrumentation has a built-in initialization routine and several diagnostic capabilities that can indicate if the system is functioning properly or if a problem exists with it or with the system inputs.

3.5.1Power-On Initialization

When the ignition is first turned on the instrumentation performs an initialization to verify correct operation. The initialization is described in Figure 3-6.

Figure 3-6 System Initialization

Functional Description |

3-6 |

072-40245 D |

Model 387 Instrument System Service Manual

3.5.2Diagnostic Connector

The diagnostic connector allows test equipment such as the Handheld Diagnostic Tool described in Chapter 6 to be connected to the J1708 data bus. The diagnostic connector is usually located underneath the driver’s side of the dashboard.

Note - The diagnostic connector is not part of the instrumentation and is mentioned for reference only.

3.6Private Data Bus

The private data bus connects the Interface Module to the tachometer and the 2-inch gauges. It carries data from the Interface Module to the tachometer and 2-inch gauges. The private data bus consists of a pair of wires in the 5-wire cable assemblies. It is not connected to the J1708 data bus.

3.6.1Five-Wire Cable Assemblies

Identically wired 5-wire cable assemblies make up the private data bus that connects the tachometer and 2-inch gauges. These cable assemblies carry power, ground, backlight power and private data bus signals from one gauge to the next. Their 5-pin plugs are polarized and cannot be plugged in backwards. Identical pinouts allow either end to be plugged into either of two identical sockets on the back of the gauges. The plugs are held in place by a locking tab. Depressing the locking tab lets you remove the connector from the gauge.

3.6.2Two-Inch Gauges

Each 2-inch gauge consists of a printed circuit board and meter assembly, and a scaleplate with programming tab. These parts are mounted together with a glass faceplate and a sealing ring in a plastic, twist-apart housing. Figure 4-3 on page 4-5 shows how these parts are assembled.

The printed circuit board has a red warning LED, two LEDs for backlighting, a microprocessor that converts messages from the private data bus into LED and pointer information, a pair of private data bus connectors, and small 5-pin contact assembly that accepts the programming tab on the scaleplate.

The scaleplate’s programming tab automatically configures a gauge to the function shown on the scaleplate. Holes in the tab perform the actual programming by allowing certain contact pins to make contact with the circuit board. A microprocessor on each gauge circuit board converts the private data bus messages into meter drive signals. Figure 4-2 on page 4-5 shows the contact assembly and the placement of the tab.

072-40245 D |

3-7 |

Functional Description |

3.6.3J1708 Data Bus and Private-Bus-Driven Gauges

The sensors for the Tachometer, Engine Oil Pressure, Engine Coolant, Engine Oil Temperature, Engine Load %, and Manifold Boost gauges are connected to the Engine ECU. The Engine ECU converts these sensor inputs into data which it sends to the Interface Module over the J1708 data bus. For that reason, these gauges are called J1708 data bus gauges. J1708 data bus gauges and connections are shown in Figure 3-7.

Figure 3-7 J1708 Data Bus Gauges

The axle and transmission temperature sensors, the ammeter, fuel level and pyrometer sensors, and pressure/vacuum inputs are connected directly to the Interface Module and are referred to as private-bus-driven gauges.

3.6.4Tachometer

The tachometer is similar in construction to the 2-inch gauges except that it is larger and is not programmable.

Engine speed data originates at a sensor mounted on the engine. The Engine ECU receives the data, converts it into rpm data and sends it over the J1708 data bus. The Interface Module reads the rpm data on the J1708 data bus and converts it into tachometer data which it places on the private data bus. The tachometer receives the data and converts it into pointer drive signals. Connections are shown in Figure 3-7.

Functional Description |

3-8 |

072-40245 D |

Model 387 Instrument System Service Manual

3.6.4.1Ammeter

The signal for the ammeter begins at a sense wire coiled up in the battery box (between the battery’s positive terminal and the megafuse leading to the alternator). As current from the vehicle’s charging system flows through the sense wire, a voltage of a few millivolts is generated. This voltage is applied to the Interface Module which converts it into ammeter messages on the private data bus.

If the system is charging, the positive voltage at the sense wire causes the ammeter to read in the positive ( + ) area. If the system is discharging, the sense wire voltage goes negative and causes the ammeter to read in the negative ( – ) area. See Figure 3-8 for the actual wire connections.

Figure 3-8 Ammeter Circuit

072-40245 D |

3-9 |

Functional Description |

3.6.4.2Voltmeter

Battery voltage is fed to the Interface Module through the ignition switch. The Interface Module converts the voltage into data that it places on the private data bus. See Figure 3-9 for the actual wire connections.

Figure 3-9 Voltmeter Circuit

Functional Description |

3-10 |

072-40245 D |

Model 387 Instrument System Service Manual

3.6.4.3Pyrometer

The signal for the pyrometer begins at a Type K thermocouple that is mounted in the exhaust stream and connected to the Interface Module. A thermocouple creates a small voltage (less than 33 millivolts) that changes depending upon its temperature. As the exhaust temperature rises, the thermocouple output voltage increases. The Interface Module converts the voltage into data that it places on the private data bus. Connections are shown in Figure 3-10.

Figure 3-10 Pyrometer Circuit

072-40245 D |

3-11 |

Functional Description |

3.6.4.4Transmission and Axle Temperature Gauges

Temperature senders installed in the appropriate axle or transmission housing and connected to the Interface Module sense the temperature of the gear oil. Each sender contains a thermistor whose value decreases as the temperature increases. The Interface Module converts the thermistor resistance and into data that it places on the private data bus. Connections are shown in Figure 3-11.

Figure 3-11 Axle and Transmission Temperature Circuits

Functional Description |

3-12 |

072-40245 D |

Model 387 Instrument System Service Manual

3.6.4.5Fuel Level

The signal for the fuel level comes from a sender unit that is mounted inside the fuel tank and connected to the Interface Module. The sender unit contains a float device attached to a variable resistor. As the fuel level drops, the float drops and the resistance of the variable resistor increases. The Interface Module converts the resistance into data that it places on the private data bus. Connections are shown in Figure 3-12.

Figure 3-12 Fuel Level Circuit

3.7Backlighting

Light-emitting diodes (LEDs) permanently mounted inside the gauge provide backlighting. The LEDs are not replaceable. Theyreceive power from a dimming control located on the vehicle dash, and that power is passed from one gauge to the next through the 5-wire cable assemblies. If a gauge’s backlighting fails, the gauge must be replaced. More information is available in Chapter 5.

Backlight power for the SMC comes from the same source used for the gauge backlighting.

072-40245 D |

3-13 |

Functional Description |

Notes: |

|

|

Functional Description |

3-14 |

072-40245 D |

Loading...

Loading...