Peterbilt Rear Air Adjustment Service Manual

FIELD

SERVICE

BULLETIN

A DIVISION OF

ilqN

Date:

File

Group:

ATTENTION:

ServiceManager

Distribution

Copy:

/Dealer Principal

lWarranly Manager

/Parls Manager

/Sales Manager

Setting/Adiusting

RearAxle Angles:

Proprietary

RearAir

Susoensions Except FLEXA|TTM

This

bulletin is

applicable to vehicles

equipped with

proprietary

rear

air suspensions

exceot FLEX AirrM

suspensions;

i.e., Air Leaf,

Low Air Leaf, Low

Low Air Leaf, and Air

Trac

suspensions. lt

provides

a

procedure

to set ride height

and adjust rear

axle angles

on those vehicles.

.

This

bulletin

supersedes the information

on

"Measuring

Pinion Angle"

and

"Setting

Air

Spring Height

(Ride

Height)" in

Section 6,

"Rear

Suspension" of the master mainte-

nance manual

for vehicles

equipped

as described

above. The manual will

be

updated in

the near future

to reflect the

changes made

by this bulletin.

The

ride height

of

proprietary

rear

air suspensions

is set

at the

factory.

The specifications

used

are designed to

provide

the vehicle

with the best

possible

axle travel

and

ride

charac-

teristics.

There

are occasions when

a customer will

reset or

adjust the ride height

after a

vehicle has

been

put

in

service. Peterbilt recommends

against this for

the

following

reasons:

'

Changing the ride height results

in

a change in rear

axle driveline

angles.

This

situa-

tion can lead

to driveline vibration.

'

Changing

the

ride

height may

have

a detrimental effect

on axle travel, and may

also

result in

complaints

of

rough

ride.

Peterbilt

recommends

that

customers be

encouraged

to avoid these

potential problems

by maintaining

the ride height

at the factory

setting.

When necessary

the

rear

axle

angle(s)

should be returned

to the original factory

specification. A new

adjustment

pro-

cedure that removes

the

effect of

frame

rake variation

on

pinion

angles was implemented

on 6/26199

(Denton)

and 814199

(Madison).

Using this method

permits

setting

rear

driver

and interaxle

driveshaft angles

to

provide

the best

possible

axle travel

and U-joint can-

cellation as well

as keep torsional

acceleration

within

specifications. The

procedure

and

supporting information

is

contained in

this bulletin. The

special ride height

tool required

for

this

procedure

is available from

PACCAR Parts

(see

Parts

Notes below).

Parts

Notes

The

parts

referred

to in

this bulletin are listed

below

and available from PACCAR

Parts

using normal

ordering

procedure.

April7,2004

03 Section:

Rear

Suspension

Part Number

Description

+z-uuz]v-uu1

Kroe

nergnr roor (gauge)

J3-U6 /6U-0U1

,

-002,

-003, -004

Axle

shim

(for

Low Air

Leaf

suspensions on/after 415104)

Pro

3600 Anglemaster

Inclinometer (available

at

http://www.

penntoolco.

com/cataloq/products/697.

cfm)

PS803035

F.S.B.

# 3-00R

Page

1 of 42

Setting and Adjusting Ride

Height and Rear Axle Angles

WARNING!

This

procedure

requires

seruicing

the

vehicle with

the trans-

mission in neutral

and the

parking

brakes

released. The vehicle must

be

parked

on a completely

flaUlevel

surface with

both

front wheels

chocked

on both

sides.

Failure

to adequately

chock the

wheels may lead

to the

vehicle rolling into

someone/something,

causing an accident and

possi-

ble serious

personal

injury

and/or equipment

damage.

NOTE: Suitable wheel

chocks are at a minimum

an

18-inch

(46

cm)

long 4x4

Follow

this

procedure

to set ride height

and adjust

rear

axle angles

(pinion

angles).

1.

Ensure that

the

following

tools are available:

.

Ride height tool

(gauge)

.

Pro-3600

or

Pro-360 Anglemaster

(inclinometer)

.

Adapter for Anglemaster

2.

Drive the vehicle

onto a

flaUlevel

surface. Back

straight out for the

length

of the

vehi-

cle and slowly

drive back onto the flaUlevel

surface. Gently roll to a stop.

Place

the

transmission in neutral

and set the

parking

brakes.

3. Chock the front wheels

on both sides.

4. Release

the

parking

brakes.

5.

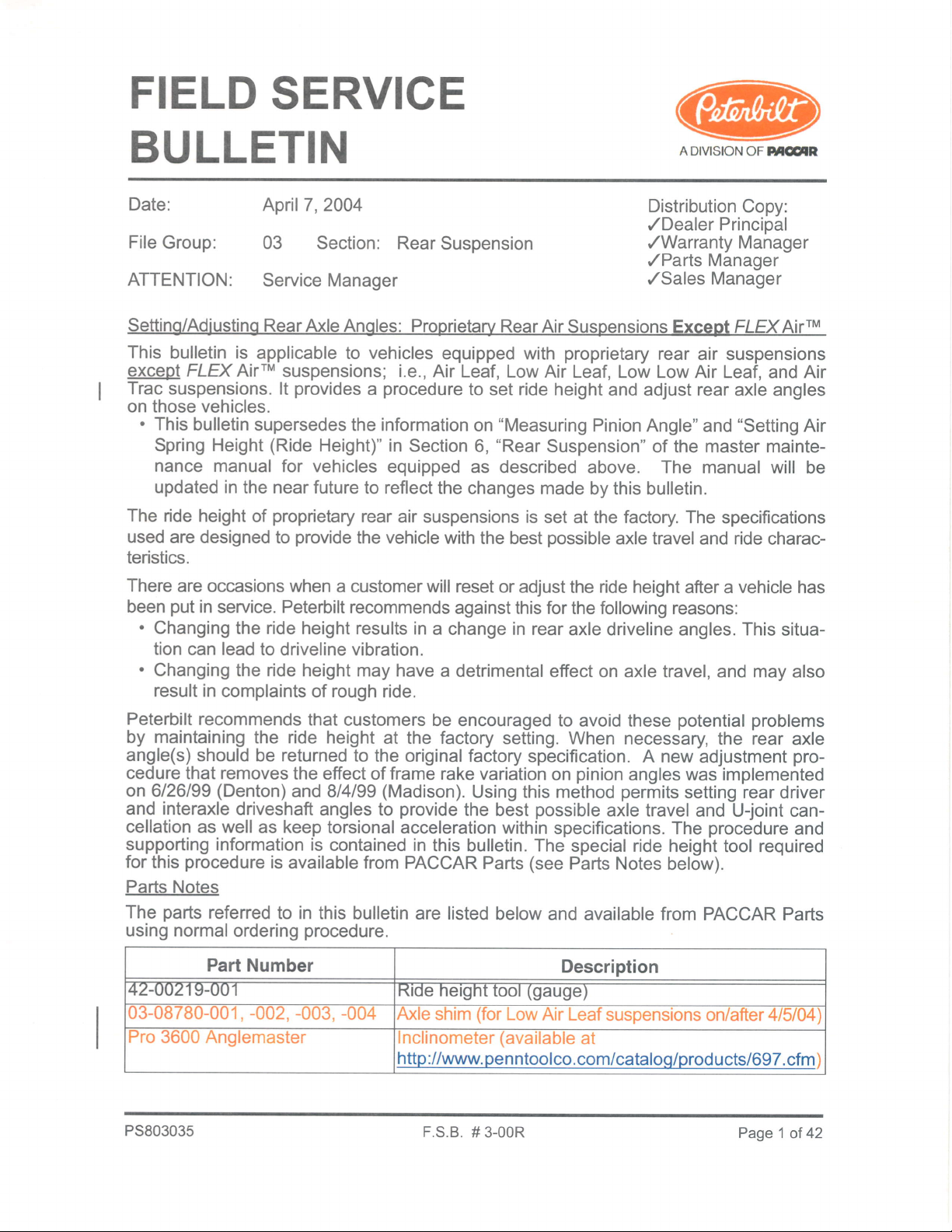

Ensure

that the ride height

gauge

has

the correct slide installed for

the suspension

on

the vehicle

(see

"NOTES"

in Figure

1).

-3t MOVE GAGE UNDER RAIL BETWEEN TANDEMS

,/

ANO

RAISE SLIDE TO CONTACT BOTTOi' FI-ANGE

"tr-t@

LOW AIR LEAF

(Srngle

axle conirgurations burll

on & atter 4/904) and

SOUEEZ E TABS TO

SLIDE POINTER

LOWLOWAIR

----->

2) AL|GN POTNTER W|TH AXLE HUB HOLE

Lol^/ AIR LEAF

(includes

Srngle

conliguralons built

belore 4/5/04)

TIGHTEN WING NUT

TO HOLD POINTER

POSITION

l

DOES PROPER INDICATOR

GROOVE

APPEAR IN TOLEMNCE AOX?

YES.

G@D

NO

-

ADJUST BIDE HEIGHT

APPLY PN, REV LEVEL

AND

SUPPLIER CODE

LooK HERE TO

DETERMINE PROPER

INDICATOR GROOVE PER SI.JSPENSION

o

1) PLACE BASE ON LEVEL GROUNO

NEAR REAR REAR AXLE

Figure

1 lllustration

of

Ride Height

Gauge

MATERIAL LIST

1 ,42d218-001.

BASE

2 42{n'217

-0o1,SLIDE

(ALTERMTE

SLTDE 42-00220-001, SEE NOTES 1 AND 2)

3

142{0216{01,

POINTER

n

lseecen

lwr

.zso' ALuMTNUM TUBTNG, 4-1l,16'

LoNG)

NOTES:

1) WITH

AIR LEAF, AIR TRAC, LOW AIR LEAF

AND LOW LOW AIR LEAF USE STANDARD

sLIDE

42-0021

7-001

2) WITH

REYCO 1O2AR AND NEWAY AIR SUSPENSIONS

-USE

ALTERNATE SLIDE 42.OO22O.OO1

(NOT

INCLUDED

wrTH

ASSEMBLY

42-00219-001

)

3) SPACER

(ITEM

4)

SITS

LOOSE IN

BOTTOM OF

OUTER TUBE OF ITEM 1

4) DASH VARIATION

INDICATES TOOL NUMBER

U\

Page2

of

42

F.S.B. # 3-00R PS803035

6.

7.

Place

the

ride height

gauge

near

the

rearmost

axle such that

the base

is

on

level

ground

(see

Figure

1 and Figure 2

).

Align the

pointer

of the

gauge

with the axle hub hole

(see

Figure 2).

a. Squeeze the tabs to slide

the

pointer

into

proper position.

b. Tighten the wing nut

to

hold

the

pointer

in that

position.

ALIGN POINTER WITH AXLE HUB HOLE

,-

-->

Figure

2 lllustration

of

Aligning The

Pointer of a Ride Height

Gauge

PS803035

F.S.B.

# 3-00R Page

3 of

42

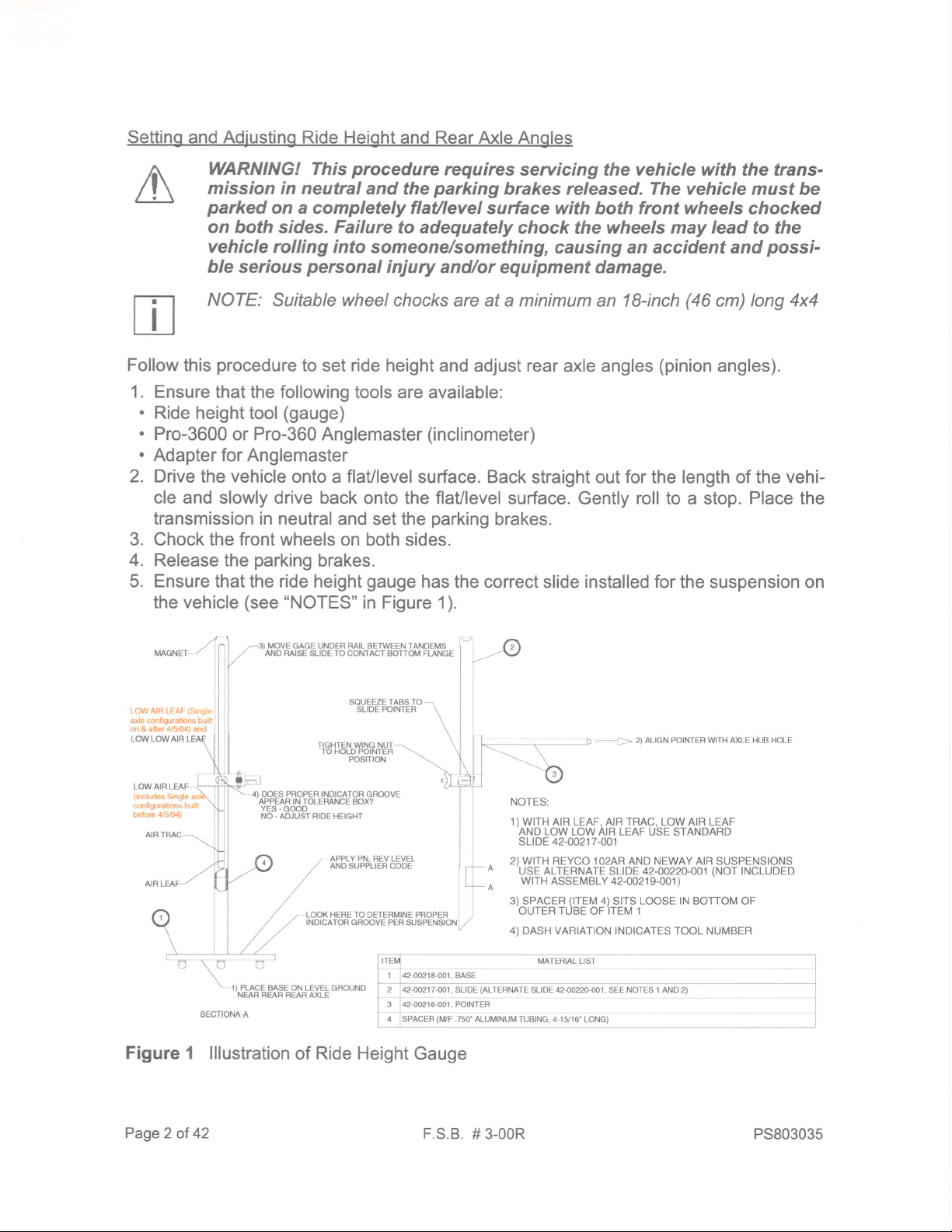

8. Move the ride height

gauge

under the frame rail,

either

forward

of a single axle

(but

not forward

of the suspension

bracket) or between

tandem axles

(see

Figure 3).

Figure

3

lllustration

of Measuring The

Ride Height

on a

Tandem

Suspension

9. Raise the slide

to bring the magnet

at

its

tip

into

contact with

the bottom

flange

of the

frame rail.

Page

4 ot 42

F.S.B.

# 3-00R

PS803035

,\

,/

.)

/

MOVEGAGEUNDERRAILBETWEENTANDEMS

MAGNET

,/

AND RAISE SLIDE TO

COMTACT BOTTOM FLANGE

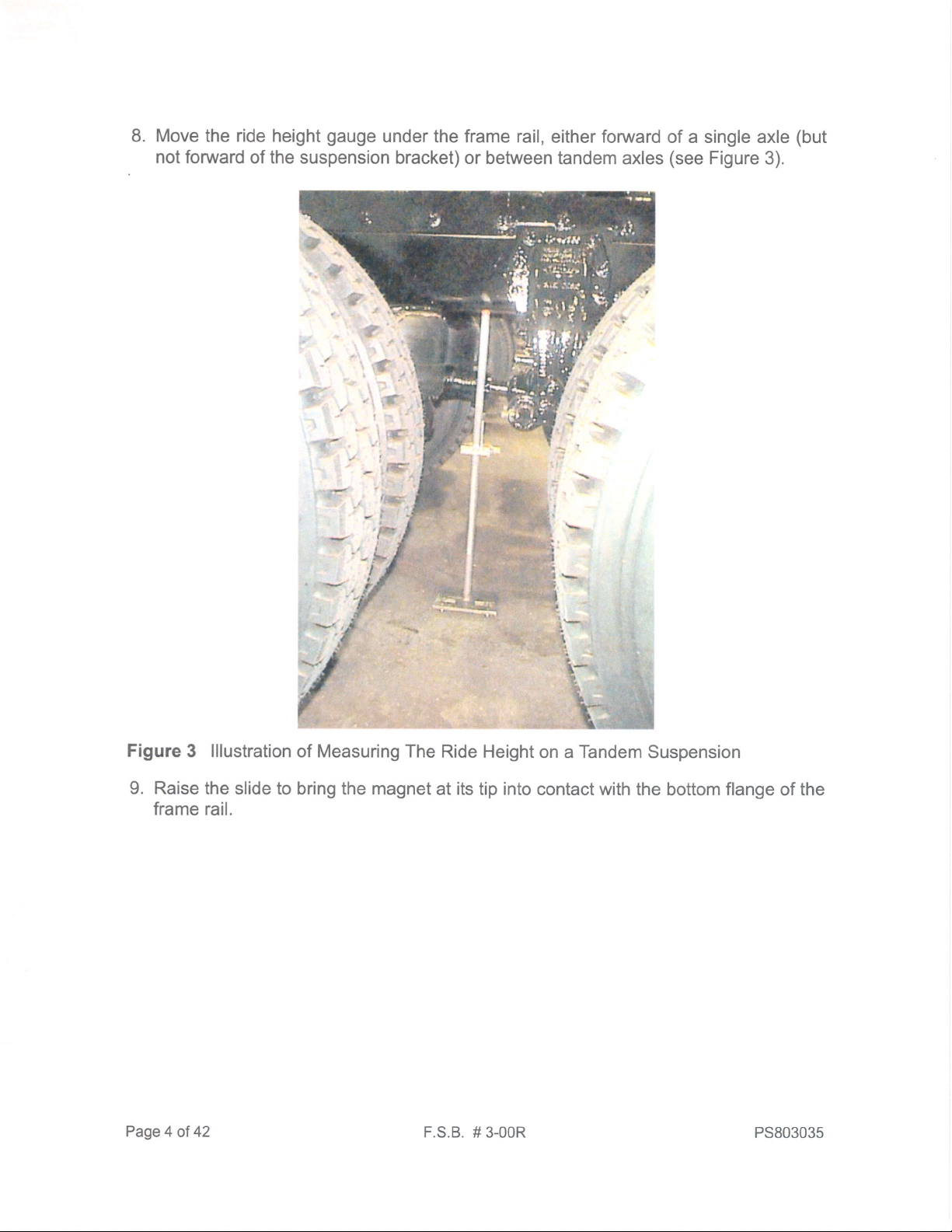

10. Look in

the tolerance box

and

note

what indicator

groove

appears

(see

Figure 4).

.

lf

the

proper

groove

appears, skip to

Step

16

in this

procedure.

.

lf

the

proper

groove

doesn't appear,

perform

all remaining

steps in this

procedure.

LOW AIF

LEAF

(Srngle

axle conliguraions buill

on & after 4/5/G) and

LOWLOWAIR

LOW AIR LEAF

(nrcludes

Single a)

configuralons burll

belore 4/Y04)

DOES PROPER INOICATOR

GROOVE

APPEAR IN TOLEMNCE BOX?

YES.

G@D

NO.

ADJUST RIDE HEIGHT

";1\

.|

f

orr/il

LOOK HERE TO OETERMINE PROPER

INOICATOR

GROOVE PER SUSPENSIoi']

Figure 4 lllustration

of

Checking Ride Height lndicator

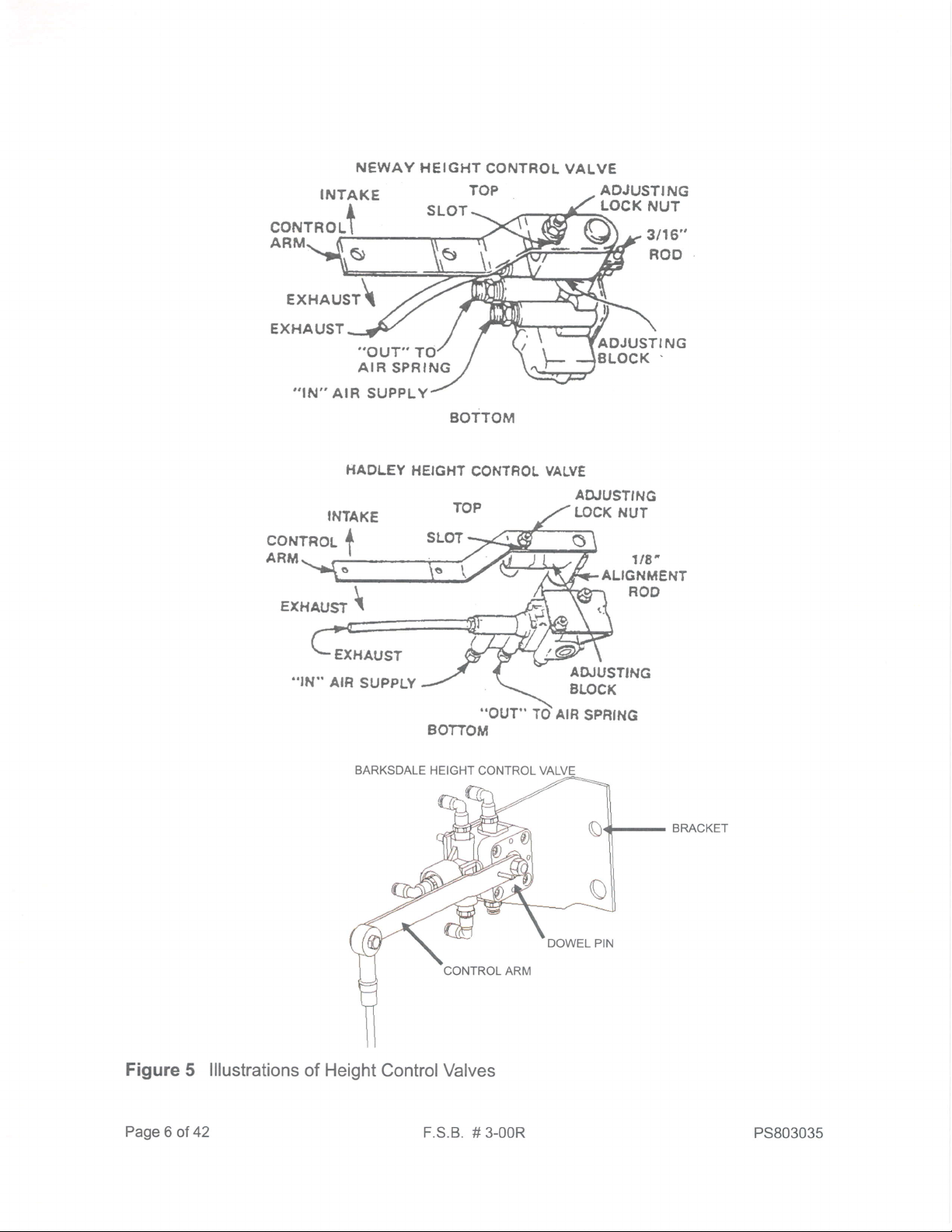

11.Loosen

the fasteners

mounting

the height control valve

to its bracket.

See

Figure5

for

illustrations

of

height

control valves.

NOTE:

At least

one of the mounting holes

in the height

control

valve

bracket will

be slotted

to

permit

rotating

the valve.

12.Rotate

the valve

either clockwise

or counterclockwise

to obtain the appropriate ride

height

as measured

with the ride height

gauge.

13.When

at the

appropriate ride height,

ensure that

the height control valve lever is in

the neutral

position,

then install either

the built-in

alignment

pin

or a 1/8-inch

(3

mm)

dowel.

14.Torque

the mounting

fasteners to

55

-

75 Lb. in.

(6.2

-

8.5 N.m.).

15. Remove

the alignment

pin

or dowel.

PS803035

F.S.B.

# 3-00R

Page

5 of 42

NEWAY

HEIGHT

CONTROL

VALVE

INTAKE

CONTROLT

ADJUSTING

LOCK

NUT

3t16"

ROO

ADJUSTING

LOCK

.

ARM

EXHAUST\

EXHAUST

.,OUT"

T

AIR

SPRING

,,IN''

AIR SUPPLY

BOTTOM

HADLEY

HEIGXT

CONTROL

VALVE

AIUUSTING

LOCK NUT

INTAKE

EXHAUST

\

€XHAUST

..IN"

AIR

SUPPLY

Figure

5 lllustrations

of Height ControlValves

Page

6 of

42

F.S.B.

# 3-00R

7tE',

ALIGNMENT

ROD

80770M

PS803035

[Tl

NOTE:

Contact PACCAR

Pafts Research

(1-800-477-0251)

to obtain rear

LU

axle

angle

information

for newer

vehicles whose

records

are

not

yet

in

ECAT.

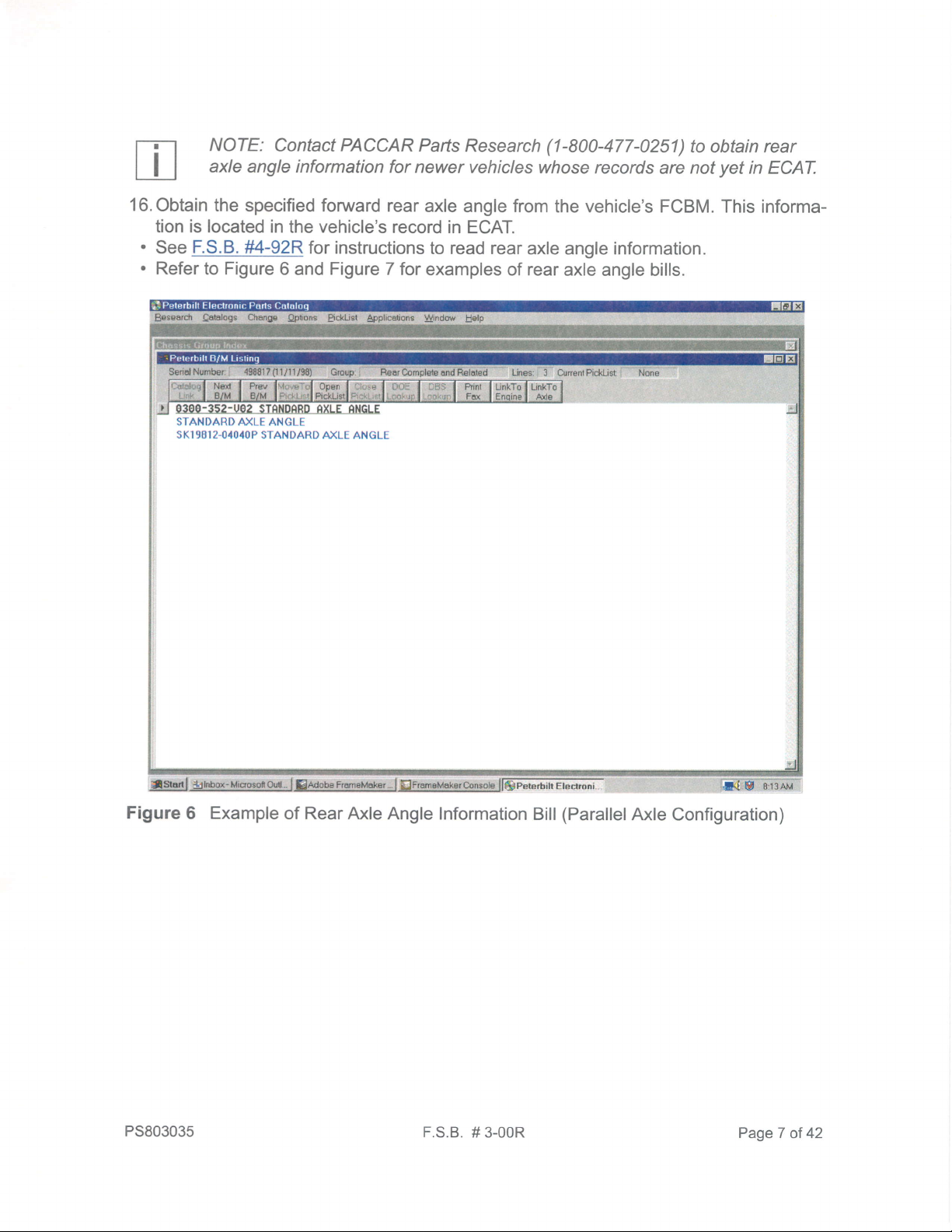

16.Obtain

the

specified forward rear

axle

angle

from

the vehicle's FCBM.

This informa-

tion is located in

the

vehicle's

record

in ECAT.

.

See

F.S.B.

#4-92R

for instructions

to read rear

axle angle information.

.

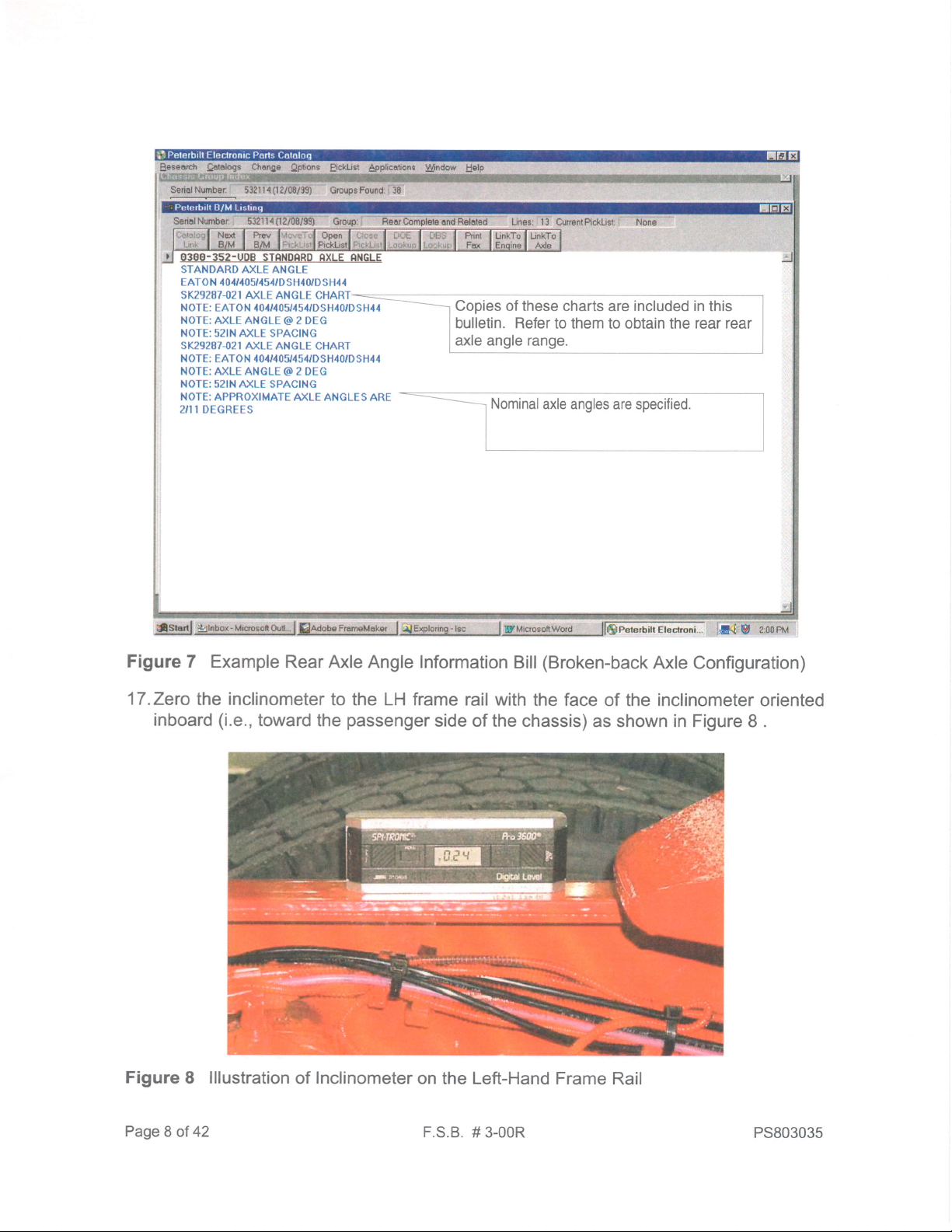

Refer to Figure

6 and Figure 7 for

examples

of

rear

axle angle bills.

Figure

6 Example

of

Rear

Axle Angle Information

Bill

(Parallel

Axle

Configuration)

PS803035

F.S.B.

# 3-00R

PageT

of 42

Figure

7 Example Rear

Axle Angle Information

Bill

(Broken-back

Axle Configuration)

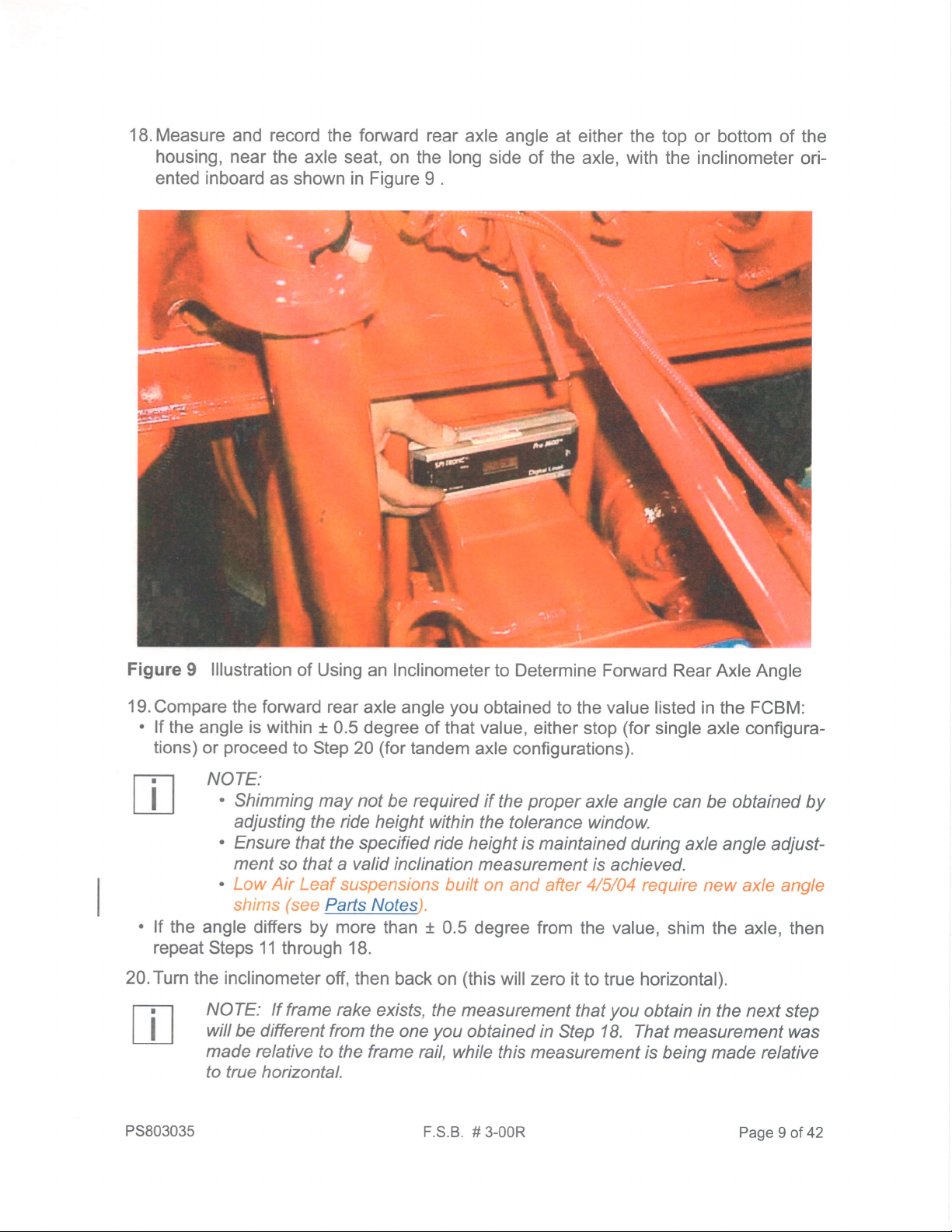

17.Zero

the inclinometer

to the LH frame rail with

the face

of the inclinometer oriented

inboard

(i.e.,

toward the

passenger

side of the chassis)

as shown in Figure 8 .

Figure

8 lllustration

of

Inclinometer

on the Left-Hand Frame

Rail

Page

8 of 42

F.S.B.

# 3-00R PS803035

iB.Measure

and record the forwarci

rear axle

angie

housrng, near

the

axle seat, on the long

side of

ented

inboard

as

shown

in Fioure

9 .

/

\

at either the

ihe axle, with

top

or bottom of the

the

inclinometer

ori-

.#

Figure

I lllustration

of Using an Inclinometer

to Determine Forward

Rear Axle Angle

l9.Compare

the forward rear

axle angle

you

obtained

to the

value

listed in the FCBM:

'

lf

the angle is within t

0.5 degree of

that value, either

stop

(for

single axle configura-

tions)

or

proceed

to Step 20

(for

tandem

axle configurations).

NOTE:

'

Shinirning may not

be requireci if

the

proper

axle angle can be obtained

by

adjusting the ride height

within the

tolerance window.

'

Ensure

that the specified ride

height is

maintained

during axle angle adjust-

.

ment so

that a

valid

inclination measurement

is

achieved.

|e4s_l'/qteo

"

lf the

angle difters by more

than t 0.5

degree from

the

value,

shim the axle, then

repeat

Steps 11 through 18.

20.Turn

the

inclinometer

off, then back

on

(this

wiil zero it

to true horizontal).

NOTE: lf

frame rake

exists, the measurement

that

you

obtain in the next step

will

be different from

the one

you

obtaineci in Step 18. That measurement

was

maoe relative

to the frame rail,

while this measurement

is

beinq

made relative

to lrue horizontal.

\

rb

PS803035

F.S

B. # 3-00R

Page

I of

42

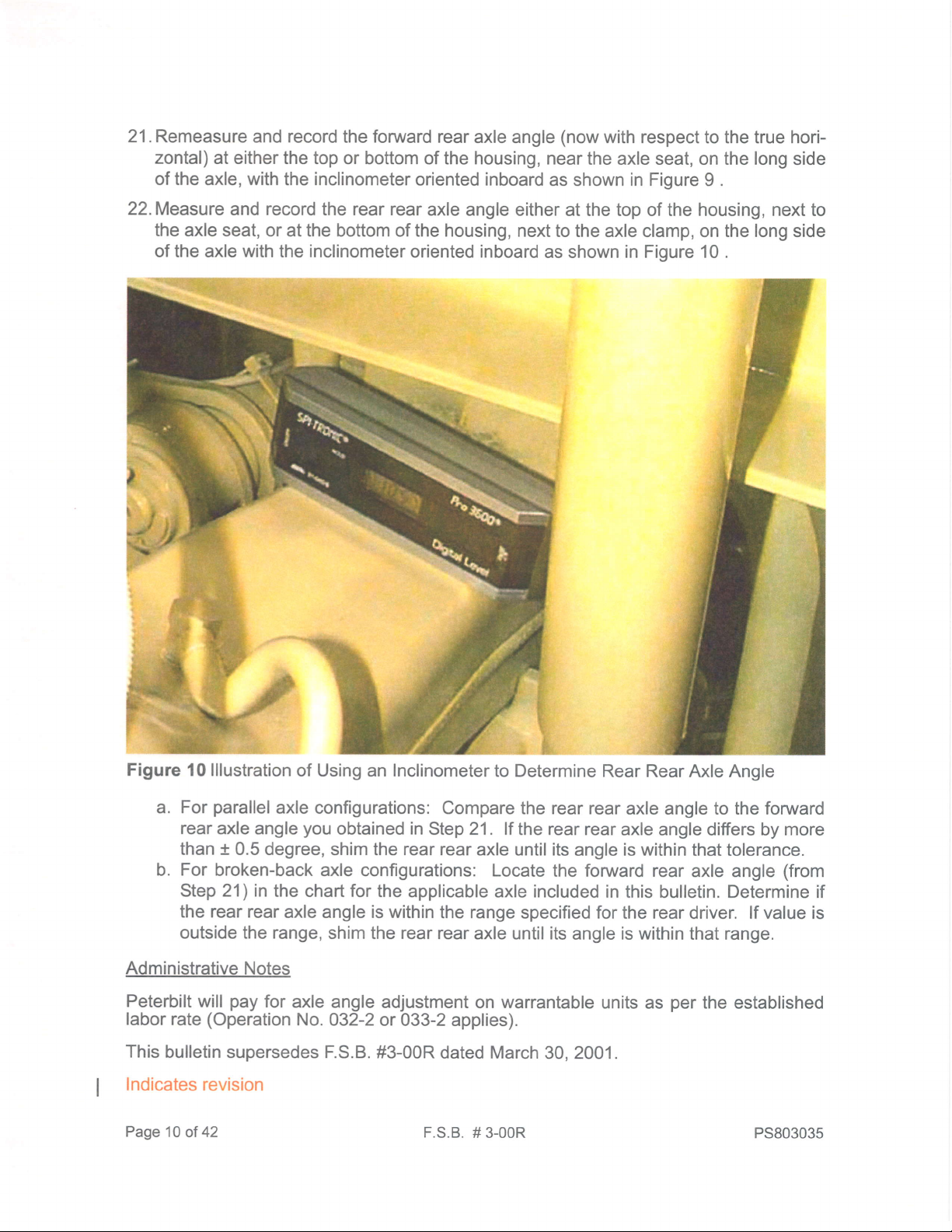

21. Remeasure

and record the forward rear

axle angle

(now

with respect

to the true hori-

zontal)

at either the top

or bottom of the housing, near

the axle seat, on the long side

of the axle, with

the

inclinometer

oriented inboard

as shown in Figure

9

.

22.Measure

and record the rear rear

axle angle either

at the top of the housing,

next

to

the axle seat, or

at the bottom of the housing, next

to the axle clamp, on the long side

of the axle with the inclinometer

oriented inboard

as shown

in Figure 10 .

Figure

10 lllustration

of Using an Inclinometer

to Determine Rear

Rear Axle Angle

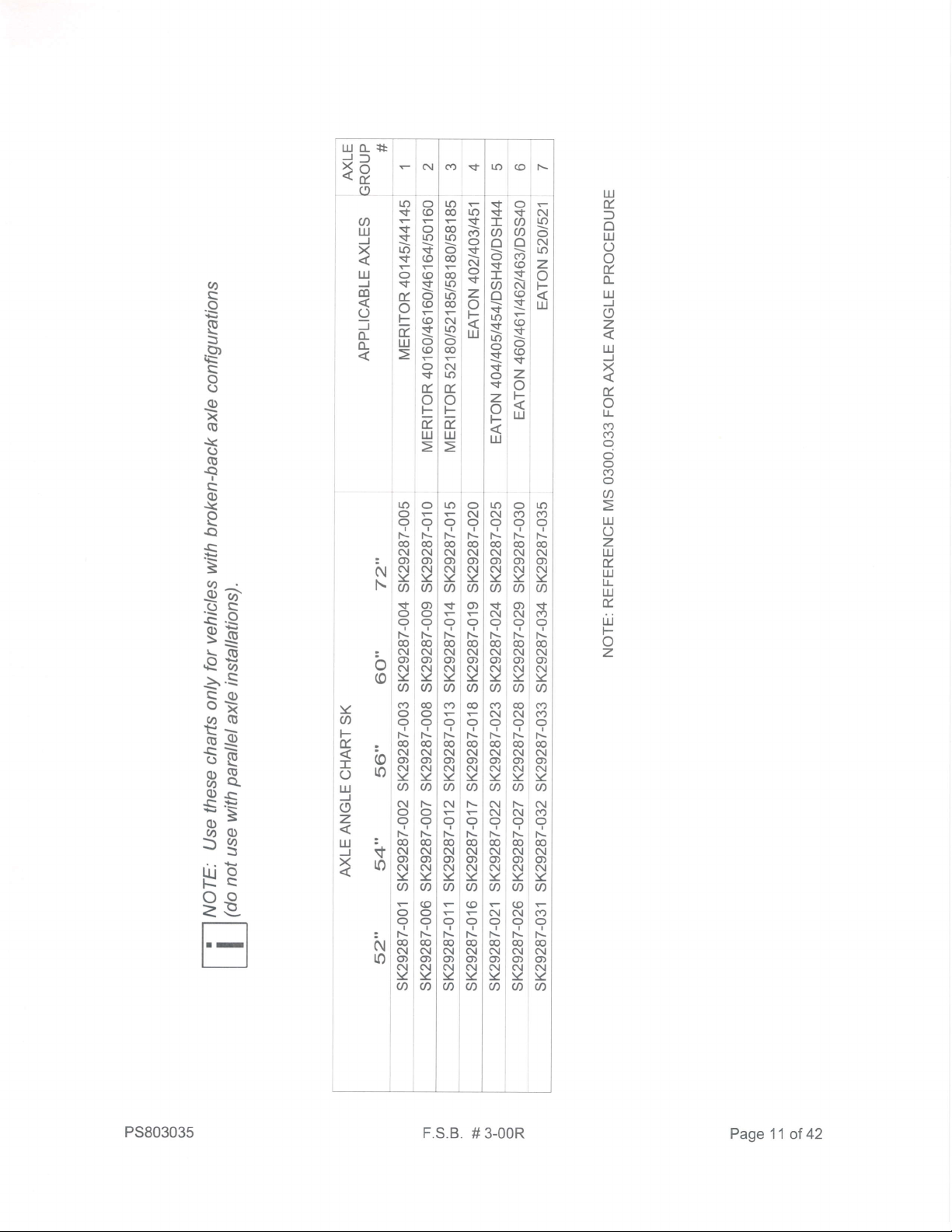

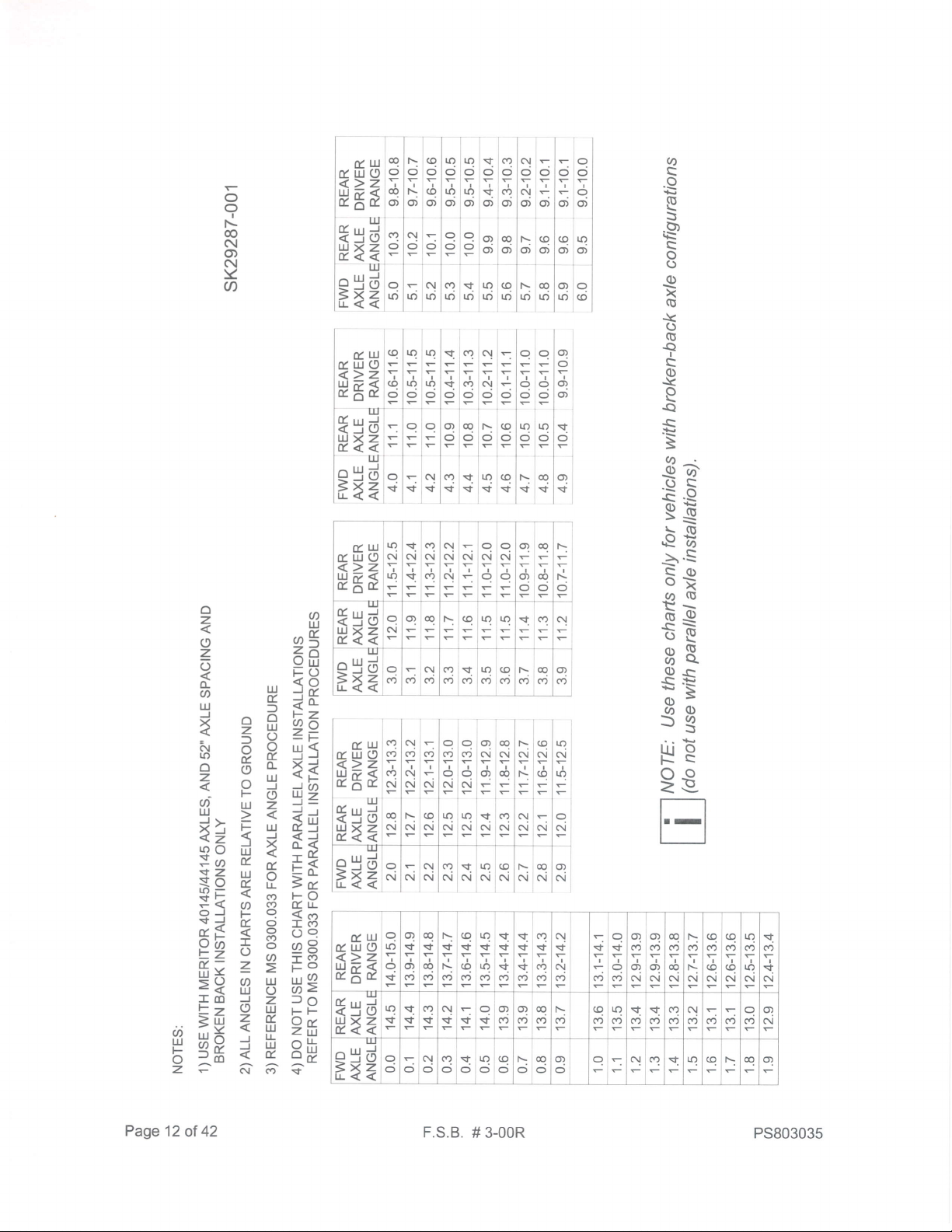

a.

For

parallel

axle configurations:

Compare the rear rear

axle angle to the forward

rear

axle angle

you

obtained in

Step 21 . lf

the

rear

rear axle angle

differs by

more

than

+

0.5 degree,

shim the rear rear

axle until its

angle

is within

that tolerance.

b. For

broken-back axle

configurations: Locate

the foruyard rear

axle angle

(from

Step 21) in

the chart for the

applicable axle included

in this bulletin. Determine if

the rear rear

axle angle is within

the range

specified for the rear driver. lf value is

outside the range,

shim the rear rear

axle until its

angle

is within

that range.

Administrative

Notes

Peterbilt

will

pay

for

axle angle

adjustment on warrantable

units as

per

the established

labor

rate

(Operation

No.

032-2 or

033-2 applies).

This

bulletin supersedes F.S.B.

#3-00R

dated March 30, 2001.

Indicates revision

Page

1O of 42

F.S.B.

# 3-00R

PS803035

ut

tr

f

o

uJ

o

o

tr

(L

lrJ

J

o

z

uJ

X

tr

o

lr

(Y)

(v)

q

o

o

(Y)

o

o

lrJ

o

z

lrJ

t

uJ

lr

uJ

t

ui

F

o

z

to

s

€

E

s

R

s

8

E

x

a

t

G

f

s

o

E

a

s

.E

sd

.gF

EE

e8

5.s

s*

OG

Fg

RQ

E8.

$E

sg

HR

9s

lu tL:+t

J]

.o

\E

F

N

(Y'

sf

ro

@

F-

a

IIJ

X

ut

@

o

=

I

(L

ro

sf

s

s

K'

$

o

t

tr

o

F

t

uJ

o

(o

o

u)

s

(o

@

s

o

@

@

\

c,

(o

o

$

tr

e.

IIJ

lo

@

@

ID

o

o

r

@

ro

r4t

@

ol

ro

o

@

F

(\

|o

t

F

e

ul

F

ro

{

(v)

o

{

N

o

$

z

o

F

t!

s

sf

-

a

o

b

sf

I

a

o

t

lo

{

r4t

o

s

t

o

s

z

o

F

Lrl

o

$

@

CN

o

(r)

(0

{

N

(o

{

(o

s

o

(o

s

z

o

F

ul

F

(\l

ro

o

(\l

ro

z

o

F

IrJ

3

N

N

b

o

Y

a

F

*b

oo

IJJ

J

o

z

IIJ

3.

JV

ao

N

o

lo

o

o

I

@

(\

o)

(\l

Y

a

I

o

t

@

(\l

ct)

ol

Y

a

c')

o

o

FI

@

(\

o)

6l

Y

U'

(\l

o

o

I

@

N

o

N

Y

o

o

o

I

o

(\l

CD

N

Y

a

o

o

*

@

ol

CD

ot

Y

@

o)

o

o

I

@

(\l

CD

ol

Y

a

@

o

o

I

@

C\

CD

6l

Y

a

o

o

t

@

N

CD

N

Y

a

(o

o

o

I

@

ol

CD

N

Y

o

t{)

o

t

@

(\

o)

6l

Y

U)

$

o

I

@

N

CD

(\

Y

o

(Y)

r

o

I

@

GI

CD

(\t

Y

a

(!

o

I

@

N

ct)

N

Y

a

F

o

I

@

ol

CD

(\l

!<

o

o

ol

o

I

@

ol

o)

6l

Y

o

CD

o

*

@

6l

CD

(\l

Y

U'

@

o

I

€

(\

qt

6l

Y

q,

o

I

@

(\l

CD

6l

Y

U'

@

o

I

@

ol

CD

6t

Y

a

to

(\l

o

I

@

C\I

o)

(\l

Y

o

N

o

I

@

N

o)

sl

Y

U'

(Y)

N

o

I

@

(\

g)

N

Y

o

(\l

N

o

I

@

(\

ct)

C\

Y

U'

N

?

€

ol

CD

N

Y

a

o

(l)

o

I

@

N

o)

ol

Y

U)

q)

N

o

I

o

6l

CD

ol

Y

U)

@

N

o

t

o

ol

CD

6l

Y

(t,

ol

o

I

@

(\l

o)

6t

Y

o

(o

(\

o

I

@

(\

o)

(\

Y

U'

K'

(v)

o

I

o

(\l

ct)

ol

Y

a

$

o

I

o

(\l

ct)

(\l

Y

a

c)

(Y)

o

I

o

(\t

o,

o,l

Y

U'

N

(v)

o

I

@

N

o)

ol

Y

a

(o

o

I

@

(\l

ct)

N

Y

a

Page 1'l

of

42

F.S.B.

# 3-00R

PS803035

q

c

s

e

5

P

c

o

o

e

x

G

A<

o

G

f

c

o

r<

Q

a

€

=

-Ea

or

G.9

sE

FS

5.S

qq)

oI

(aG

EE

EQ

E8.

.PS

:s

6c)

f,3

lrJ 9

c)o

=e.

Iq

oo

IE

'l'

qiq

o)

o)

.,I;

r]'

T

o

I

nl

o)l

i

o?

o)

I

u?l

to1

o

o?

o,

n

o

o?

{

qq

5rE

3ie

qu?

oo

-l-

\oq

$$

li

atc?iq:

;l;l;t;

a

a? ollr

ooo;o

FFFi-

tf t

o?oq\q

ololo

o

-1-1-l-

c?inlq q

ololo]=

I tl

aul

9lu?iQ

rulo

-lFlF

<>z TlTl.;

wp

<

(olrolto

t

^X.

ci

lci cj

Flr

-

trl] 1 I

tgdl-lc

q

uJxz

ir tF

F

t

<<

l-l-l-

lul

ll

e5d

ol-i*

t1<+l+l+

\jq

c\r

ic.,l

\le

==

I

ol

:

c!N

u?

N

I

u?

o

o.i

(t

d

d?

N

@

c.i

q

l'

n

llJ

F*

o

o

I

@

N

O)

c!

Y

@

"frU

<>z

lllt<

0lE,t

q

ll)

q

\f

o?

s

I

o,

c.j

oq

s

oq

(9

\

$

I

\

q

$

q

(f)

u?

v

q

(f)

n

$

n

CO

a

s

a

cf,

.f

I

c?

(9

ol

s

ol

cr)

s

q

s

o

o?

(9

o?

C\

o?

(r)

I

q

N

oq

(f)

oq

N

\

cf)

\

N

q

(o

I

q

N

q

I

q

N

;

I

u?

N

n

\

N

iri

UJXZ

t<<

lu?

ls

a

s

a?

s

c!

\f

s

q

s

o?

(v)

o?

oq

(o

\

(Y)

(o

ri

q

(9

a

(9

n

(o

a?

(o

q

(f)

<.i

(f)

c

(7)

N

f*?

o

d ci

N

o

c?

o

n

lu?

oo

q

o

\

oq

o

qr

c! cf)

Y

u? q

\

oq

I

"ffU

<>z

V_8fi

IU

tsa

|,J'jxz

tr

<<

?#

o9=

z

=o

fiqle

ilEHfri

;

H

9-22

$EEII#

$I

fi E =*

E3t

e EE

siglFaE

o

u.l

ex

q

I

q

o)

ci

\

o

I

1\

o;

q

o

oq

o

I

oq

o,

c?

o

tu

oauJ(9

<>z

rtJp<

E6t

TU

isu

uJxz

E<<

tu

(ur(,

<>z

VNfr

u?

N

q

n

N

I

a

c?

C!

I

a

c\l

N

I

c\l

c.i

I

q

N

q

c

N

q

-

o?

o

oq

I

@

c;

f-

N

isU

uJxz

t<<

q

(\

o?

oq

\

q q

rO .q

c?

c!

e5d

sxz

tL<<

o

c.j <'i

c!

(Y)

cin

(9

CO

l.()

c.j

(o

(f)

t\

c.j

@ o?

(o

q

N

@

ic.i

lF

l"c

l-

c?

N

u?q

NC!

o?

N

Y

ol

l=

I

in

lC\l

q

I

q

N

u?

(\I

a

N

c

(a

q

N

u?

N

a?

N

<'i

I

oi

q

ol

q

c!

c!

cf)

I

c!

N

\

N

c.i

PS803035

F.S.B.

#

3-00R

Page 12

of 42

q

q

o

e

R

o

o

e

x

G

f<

o

$

s

s

c)

.r<

e

a

=

P:.

te

E.e

ss

nff

5.S

qo

o>

(/)G

Eo

EQ

oF

(/J \<.

d)e

SE

:=

6a)

)3

Lll O

tl'

c

C)o

=e-

u?na?

ooo

:l:5

u?na?

or,o, o)

I

oQ

\;9

o olo

t5Y

oe\q

o)

o, o,

qo?

-O

TT

qo?

OO)

:

I

o

t:

I

o

tr*U

<>z

'"8fr

N

o

o

I

@

c!

o,

N

Y

a

tu

(r.uO

<>z

'"8fi

IIJ

*5d

wxz

t

<<

oq

N

oq

ni

\

N

I

\

(\l

N

@(o

c.i c.i

TT

(o(o

I

c.i

I

c.i

qna?

NN(\T

T-;:

q

nlc?

r r':-

q

Io?

oq

N--

c!

r.r

NNN

ITT

Nrr

---

IT

\qq

F*?

c

N c.j

qc?

NN

a

(\l

1rllq

*lN

\q

NN

o?

C\l

"ffU

S

<>z \

uJt<

ro

E^t

c.)

Y

s

n

(7'

c? e!

9S

TT

(tN

c.i c.j

:qo?

\t \t

(fJ

557

:qo?

(f)

,(f)

c!

o?oq\

(o

(f) (o

r:5

o?,0q

\

NNN

J

qu?

cD

l(f)

EE

NN

a

I

n

N

a

(f)

n

N

("?

I

N

c!

(f,

c.l

N

d

oi

c

q

N

o?

N

I

o?

o?

N

-

{sdl"

uJxz

s

E<<

-

o?

(f)

o

d

t\ q

(o

lr)

(?)

a n

(f)

N

<.i <"i

d c.j

O)

N

oq

N

\

C\I

q

N N

n

N

a

N

;t:ls

d

C\l

,a?

oio

.t |r?

o

q

o

\

i09

oo

o

Oir

--

o! c?

a

rn

\

oq

o?

?,s

rt

q5H

i

ee

fr5

;

r

9i2

$gEilgE

fg

ZE

fiE

p,ag3[iF

{99

?

uEfl 3

tsHl.

H{?r.

o{

o

ry

o,

\

o)

:

oi

q

o,

o

I

o

o;

u?

O)

o? oq

?9

o?

oq

@€o

o)

a

o,

oq

o)

oq

@

a?

o,

F-

(O

tO

++"

f\

(O

tO

ddd

c!rq

o) o) o)

R

O)

I

Y

@

o?

si9;

rJ-<<

d

q

r() 1r)

a

ro

u?q

lo tr)

\qo?

lrjtolr)

Y

gorco

3"tot

rq

io

o

z

$

l\

lco

9rt

au?q

s s]s

C.l c?

st

I

$

c

s

n

I

a

o

oq\

5t

oq\

oo

o?

I

o?

s

c

N

I

q

rrq

I

u?q

(f)(f)

Page

13

of

42

F.S.B.

# 3-00R

PS80303s

Loading...

Loading...