Page 1

Page 2

Page 3

Page 4

Page 5

Contents

Safety

Emergency

Controls

Driving

Maintenance

Information

Index

1

2

3

4

5

6

7

Page 6

Contents

©2017PACCARInc-AllRightsReserved

Thismanualillustratesanddescribestheoperationoffeaturesorequipmentwhichmaybeeitherstandardoroptionalon

thisvehicle.Thismanualmayalsoincludeadescriptionoffeaturesandequipmentwhicharenolongeravailableorwere

notorderedonthisvehicle.Pleasedisregardanyillustrationsordescriptionsrelatingtofeaturesorequipmentwhichare

notonthisvehicle.

PACCARreservestherighttodiscontinue,changespecications,orchangethedesignofitsvehiclesatanytime,without

noticeandwithoutincurringanyobligation.

TheinformationcontainedinthismanualisproprietarytoPACCAR.Reproduction,inwholeorinpart,byanymeansisstrictly

prohibitedwithoutpriorwrittenauthorizationfromP ACCARInc.

Page 7

TruckModelExample

i

Page 8

Page 9

PREVENTIVEMAINTENANCESCHEDULE

Introduction..................5-9

MaintenanceSchedule............5-12

LUBRICANTSPECIFICATIONS

Introduction.................5-41

Engine...................5-41

MasterLubricationIndex............5-44

FullerTransmissionLubrication.........5-48

AllisonTransmissionLubrication........5-50

SpicerTransmissionLubrication........5-50

OilChanges.................5-51

MeritorAxleLubrication............5-52

Eaton/DanaAxleLubrication..........5-53

WheelBearingLubrication...........5-54

UniversalJointLubrication...........5-55

SteeringGearLubrication...........5-55

MAINTENANCE

5

(03/17)Y53-6077-1B15-1

Page 10

MAINTENANCE

AIRSYSTEM

Introduction.................5-57

AirDryer...................5-60

AirT anks..................5-62

AirGaugesandAirLeaks...........5-63

AirCompressor................5-64

BRAKESYSTEM

BrakeAdjustment...............5-66

CAB

ExteriorMaintenance.............5-71

Cleaning,ProtectingandWeatherStripping...5-72

5

COOLINGSYSTEM

SafetyRestraintSystem-Inspection......5-78

WindshieldWiper/Washer...........5-81

Coolingsystemmaintenance.........5-82

Engine(Block)Heater.............5-86

5-2Y53-6077-1B1(03/17)

Page 11

MAINTENANCE

ELECTRICAL

ElectricalSystem...............5-87

LightBulbs..................5-88

BulbSpecications..............5-89

Fuses,CircuitBreakersandRelays.......5-89

FuseInspectionandReplacement.......5-92

AddingElectricalOptions...........5-92

Batteries...................5-93

BatteryCare.................5-97

BatteryCharging...............5-97

ElectricalandAlternatorPrecautions......5-99

RemoteKeylessEntry.............5-100

ENGINE

EngineMaintenance.............5-101

EngineLubrication..............5-102

AccessoryDriveBelts.............5-105

EngineFan.................5-106

AirIntakeSystem...............5-107

5

(03/17)Y53-6077-1B15-3

Page 12

MAINTENANCE

Turbocharger.................5-107

AirCleaners.................5-108

ServiSignal™MiniIndicator..........5-109

ExhaustSystem...............5-110

EngineMounting...............5-110

FUELSYSTEM

LocationofFuelShut-offValves.........5-111

Specication.................5-111

FuelFilters..................5-11 1

FRAME

Introduction.................5-112

5

5-4Y53-6077-1B1(03/17)

FRONTAXLEANDSUSPENSION

AxleLubrication...............5-116

Inspection..................5-1 17

WheelAlignment...............5-117

U-BoltT orque................5-1 18

Page 13

HEATERANDAIRCONDITIONER

NOISEEMISSIONCONTROL

REARAXLEANDSUSPENSION

STEERINGSYSTEM

Introduction.................5-120

Heater....................5-121

AirConditioner................5-121

NoiseEmissionWarranty...........5-123

InspectionandMaintenanceInstructions.....5-124

NoiseControlSystem-MaintenanceLog....5-128

GeneralMaintenance.............5-131

VisualInspection...............5-132

RearSuspensionFasteners..........5-132

RearAxleLubrication.............5-134

RearAxleAlignment.............5-135

PowerSteering................5-136

FluidLevelandRell.............5-137

MAINTENANCE

5

(03/17)Y53-6077-1B15-5

Page 14

MAINTENANCE

SteeringShaft................5-138

DRIVELINE

DriveshaftMaintenance............5-139

U-Joints...................5-139

TIRESANDWHEEL

Tires....................5-140

WheelMountingandFastening.........5-146

WheelReplacementwithDiscBrakeOption...5-148

DiscWheels.................5-150

WHEELBEARING

WheelBearingAdjustment...........5-151

5

TRANSMISSIONMAINTENANCE

Introduction.................5-152

TransmissionLubricants............5-153

AutomaticTransmissions...........5-154

5-6Y53-6077-1B1(03/17)

Page 15

MAINTENANCE

CLUTCH

Introduction.................5-155

ClutchAdjustment-NormalWear........5-155

5

(03/17)Y53-6077-1B15-7

Page 16

Page 17

PREVENTIVE MAINTENANCE SCHEDULE

Introduction

Preventivemaintenanceprogram

beginswiththedailychecks.See

Driver’sCheckListfortheseroutine

checks.Routinevehiclecheckscan

helpavoidmanylarge,expensive,

andtimeconsumingrepairs.The

vehiclewilloperatebetter,be

safer,andlastlonger.Neglectof

recommendedmaintenancecan

voidyourvehicle’swarranty.Some

maintenanceoperationsdemand

skillsandequipmentyoumaynot

have.Forsuchsituations,pleasetake

yourvehicletoanauthorizedService

Center.

PREVENTIVEMAINTENANCESCHEDULE

WARNING!

Beforeattemptinganyproceduresin

theenginecompartment,stopthe

engineandletitcooldown.Hot

componentscanburnskinoncontact.Failuretocomplymayresultin

death,personalinjury,equipmentor

propertydamage.

WARNING!

Iftheenginemustbeoperatingtoinspect,bealertandcautiousaround

theengineatalltimes.Failureto

complymayresultindeath,personal

injury,equipmentorpropertydamage.

WARNING!

Ifworkhastobedonewiththe

enginerunning,always(1)setthe

parkingbrake,(2)blockthewheels,

and(3)ensurethattheshiftlever

orselectorisinNeutral.Failureto

complymayresultindeath,personalinjury ,equipmentorproperty

damage.

WARNING!

Exerciseextremecautiontoprevent

neckties,jewelry ,longhair,orloose

clothingfromgettingcaughtinthe

fanbladesoranyothermovingengineparts.Failuretocomplymayresultindeath,personalinjury,equipmentorpropertydamage.

5

(03/17)Y53-6077-1B15-9

Page 18

PREVENTIVEMAINTENANCESCHEDULE

WARNING!

Disconnectthebatterygroundstrap

wheneveryouworkonthefuelsystemortheelectricalsystem.When

youworkaroundfuel,donotsmoke

orworknearheatersorotherre

hazards.Keepanapprovedreextinguisherhandy.Failuretocomply

mayresultindeath,personalinjury ,

equipmentorpropertydamage.

WARNING!

Alwayssupportthevehiclewithappropriatesafetystandsifitisnecessarytoworkunderneaththevehicle.

5

Ajackisnotadequateforthispurpose.Failuretocomplymayresult

indeath,personalinjury ,equipment

orpropertydamage.

WARNING!

Whenworkingunderneaththevehiclewithoutappropriatesafetystands

butwiththewheelsontheground

(notsupported),makesurethat(1)

thevehicleisonhardlevelground,

(2)theparkingbrakeisapplied,(3)

allwheelsareblocked(frontand

rear)and(4)removetheignition

keysothattheenginecannotbe

started.Failuretocomplymayresult

indeath,personalinjury ,equipment

orpropertydamage.

WARNING!

Neverstartorlettheenginerunin

anenclosed,unventilatedarea.Exhaustfumesfromtheenginecontain

carbonmonoxide,acolorlessand

odorlessgas.Carbonmonoxidecan

befatalifinhaled.Failuretocomply

mayresultindeath,personalinjury ,

equipmentorpropertydamage.

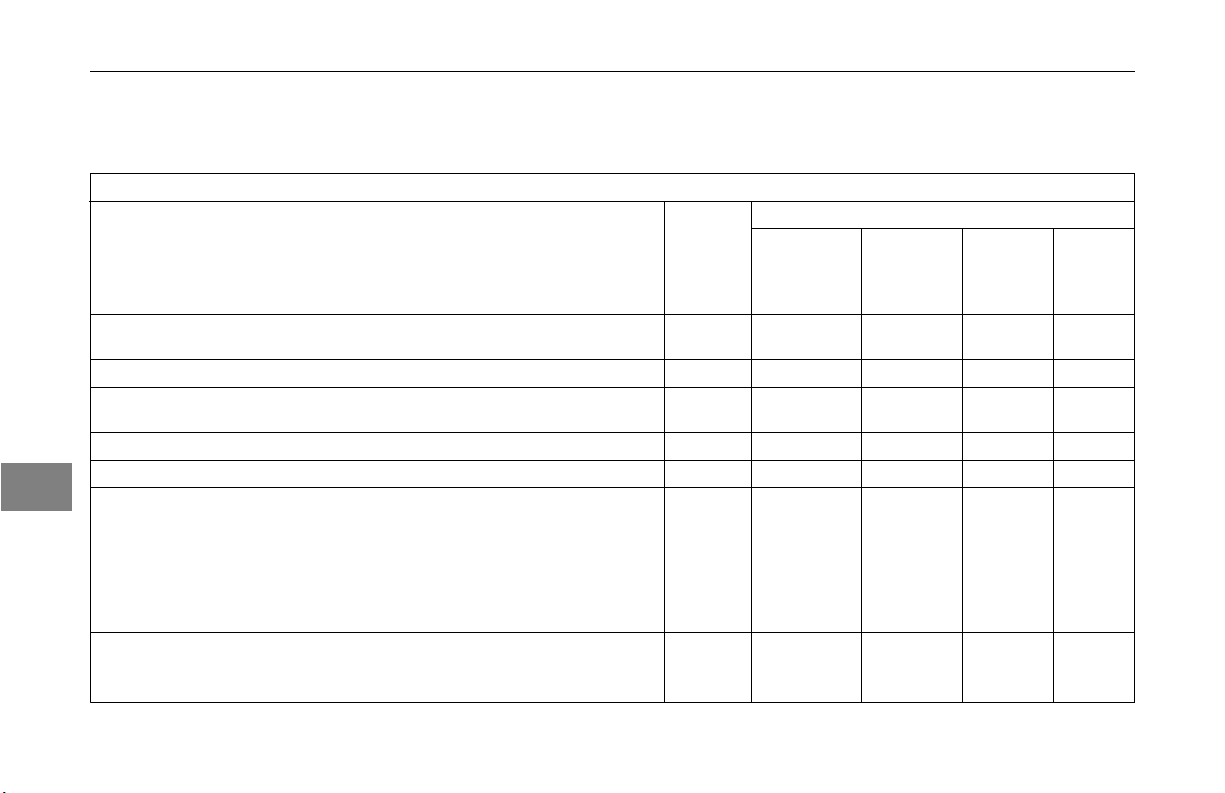

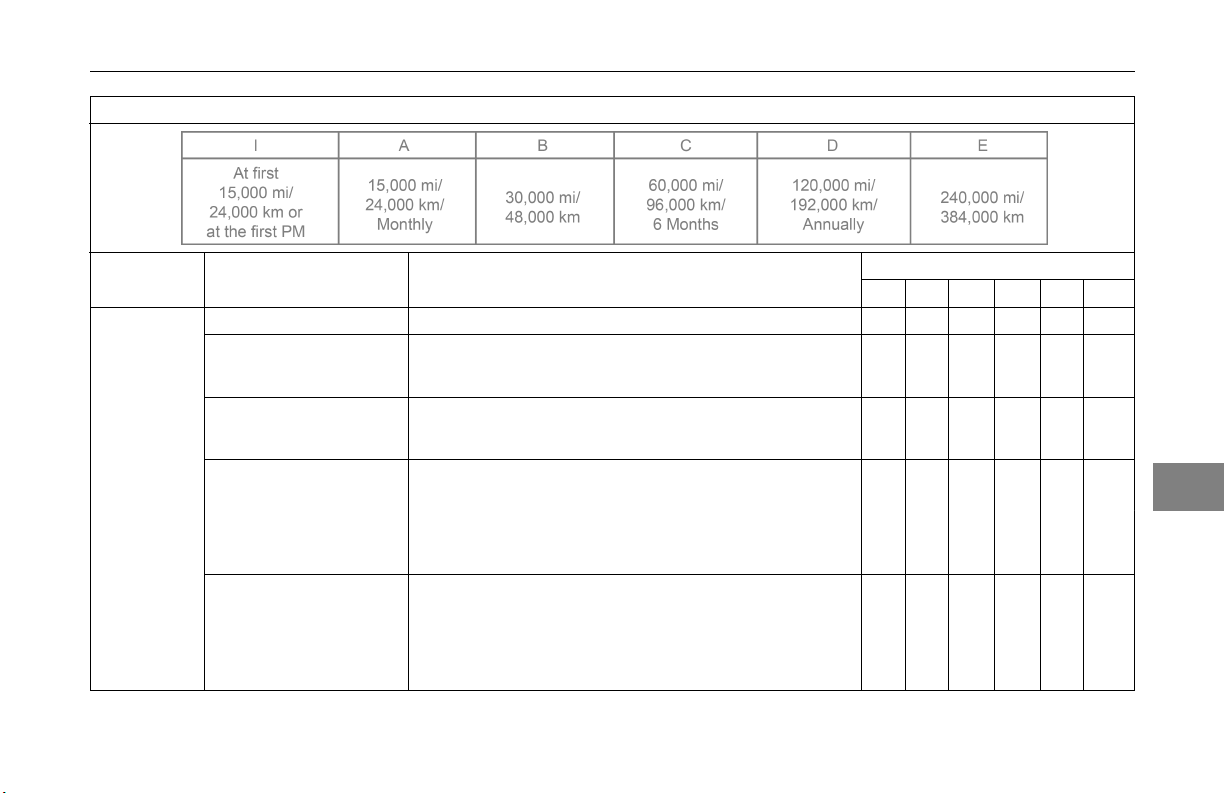

Thefollowingpagescontainatable

ofmaintenancetaskswiththerelated

intervalsforeachtaskontheright

sideofthetable.Thetopofthetable

displaysaguidetoamaintenance

intervalanditsschedule.Some

tasksaredependentonthevehicle

application.Thesetaskswillbe

shownasseparatetasksandwillhave

thewords“ONHIGHWAY”,“CITY

DELIVERY”or“OFF-HIGHWA Y”

afterthedescription.Thesetasks

aredifferentiatedbecausetheyare

dependentonthevehicle’soperating

environment.

Onhighwayisdenedforapplications

wherethevehicleisNOTusedoffofa

pavedroadduringnormaloperation.

CityDeliveryisdenedforapplications

wherefrequentstartandstoppingis

requiredduringnormaloperationand

thehighwayisusedinfrequentlyand

forshortperiodsoftime.

5-10Y53-6077-1B1(03/17)

Page 19

PREVENTIVEMAINTENANCESCHEDULE

Offhighwayisdenedforapplications

wherethevehiclemaybedrivenoff

thepavementonaregularbasis,even

ifitisaninfrequentbasisand/orfora

brieftimeperiod.

Pleasecontactanauthorized

servicedealershipifthereare

questionsregardingwhichinterval

tofollow.Consultthesupplierfor

specicrecommendationswhere

discrepanciesdevelopbetweenthese

recommendationsinthistableand

componentsupplierrecommendations.

•Enginelubricatingoilchange

intervalsaren’tlistedhere.Refer

toyourengine’soperatingmanual

forrecommendations.Forspecic

informationonmaintenance

proceduresconsultyourvehicle

maintenancemanual.

•Theinitialllofdriveaxlelubricant

mustbechangedbeforetheend

oftherstscheduledmaintenance

interval.RefertoOilChangeson

page5-51beforeyouputanew

vehicleintoservice.

•Theinitiallloflubricantin

manualtransmissionsmustbe

changedbeforetheendoftherst

maintenanceinterval.SeeFuller

TransmissionLubricationonpage

5-48forspecicinformation.

•Ifyourvehicleisequippedwithan

automatictransmission,consult

theowner’smanualforitthatcame

withyourvehicletoobtainlubricant

checkandchangeintervals.

5

(03/17)Y53-6077-1B15-11

Page 20

PREVENTIVEMAINTENANCESCHEDULE

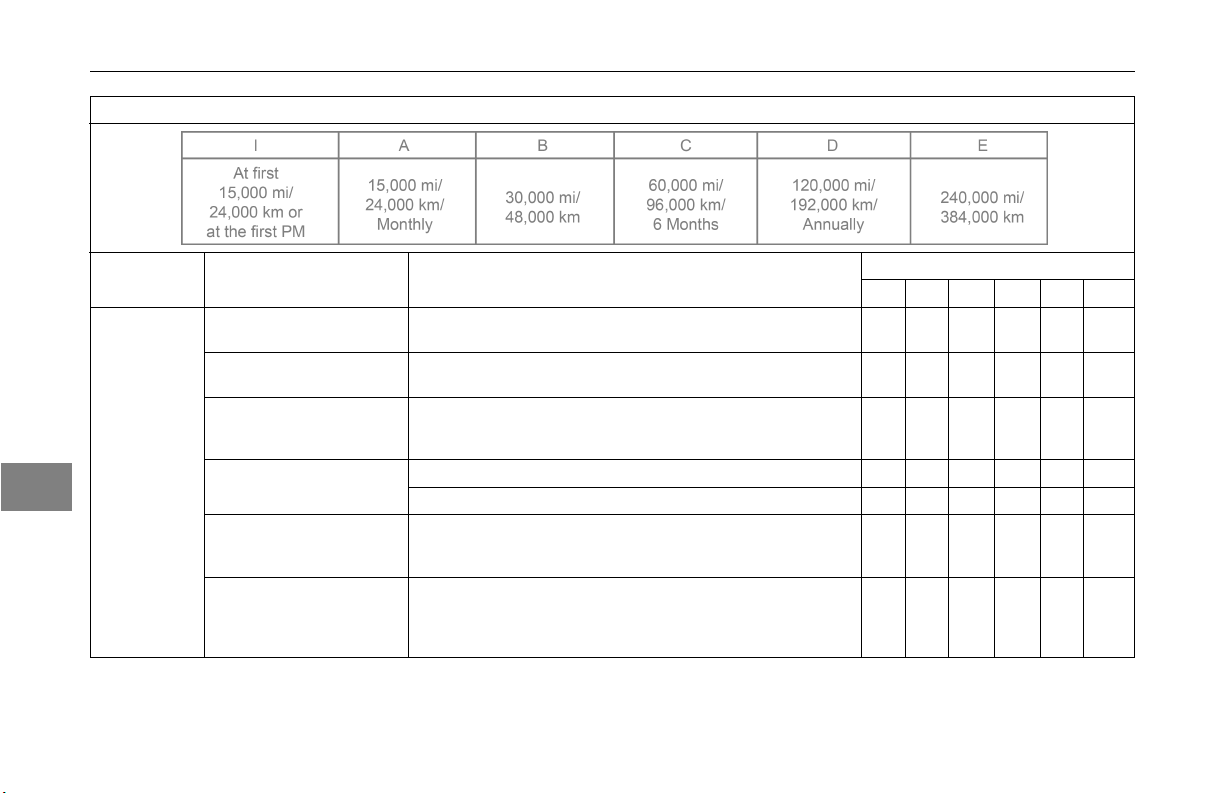

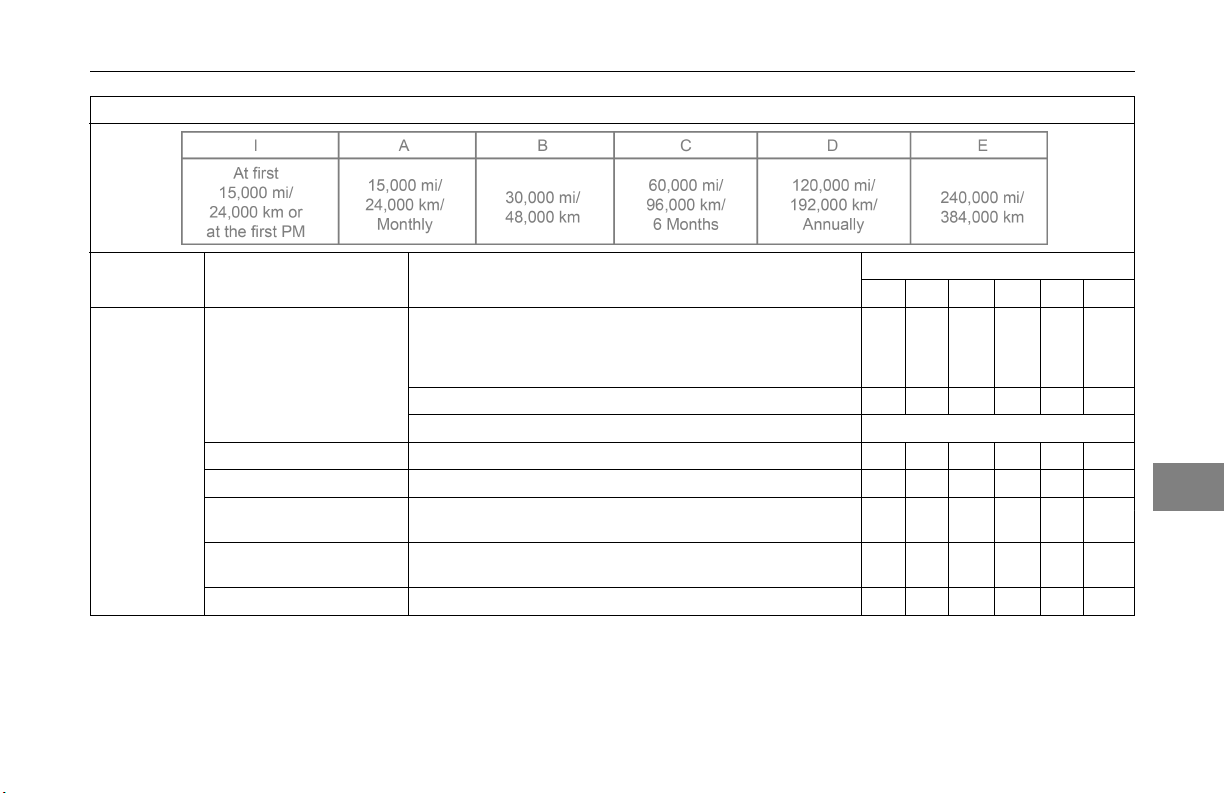

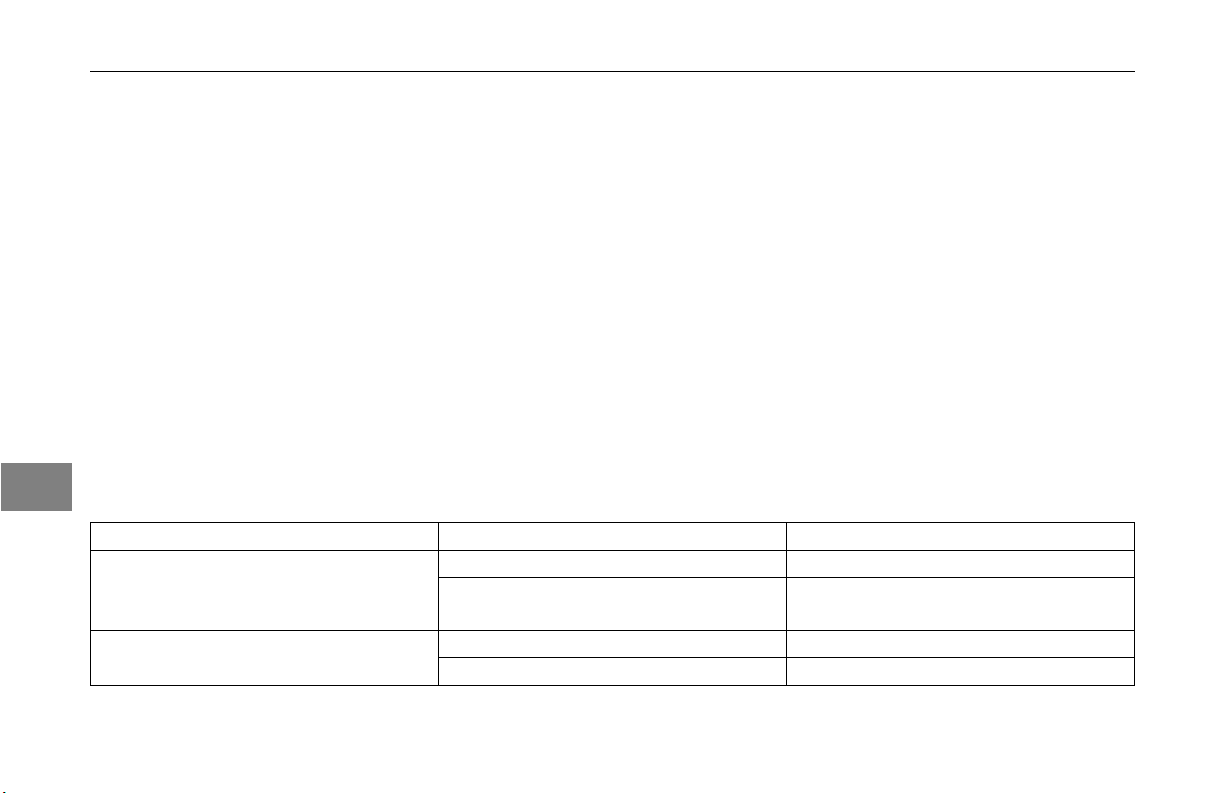

MaintenanceSchedule

NewVehicleMaintenanceSchedule

SteeringShaftU-Bolts.(OFF-HIGHWA Y)SeeSteeringSystemonpage

5-136.

WheelMounting.SeeWheelMountingandFasteningonpage5-146.

FrontAxleU-BoltT orque.SeeFrontSpringSuspensionU-Boltsonpage

5-118.

ChargeAirCoolerandAirIntakePipeClamps,re-torquefasteners.

5

RearSuspensionFasteners.SeeRearSuspensionFastenersonpage5-132.

TransmissionLubrication.

1.ForFullertransmission,seeFullerTransmissionLubricationonpage

5-48.

2.ForAllisontransmission,seeAllisonTransmissionLubricationonpage

5-50.

3.ForSpicertransmission,seeSpicerTransmissionLubricationonpage

5-50.

AxleLubrication.

1.ForMeritoraxle,seeMeritorAxleLubricationonpage5-52.

2.ForEaton/Danaaxle,seeEaton/DanaAxleLubricationonpage5-53.

NewVehicleMaintenanceSchedule

AfterFirstMiles(km)

Operation\Frequency

First

Day

X

50–100

(80–160)

X

500(800)

X

X

2,000

(3218)

X

3,000

–5,000

(4800

–8000)

X

X

5-12Y53-6077-1B1(03/17)

Page 21

PREVENTIVEMAINTENANCESCHEDULE

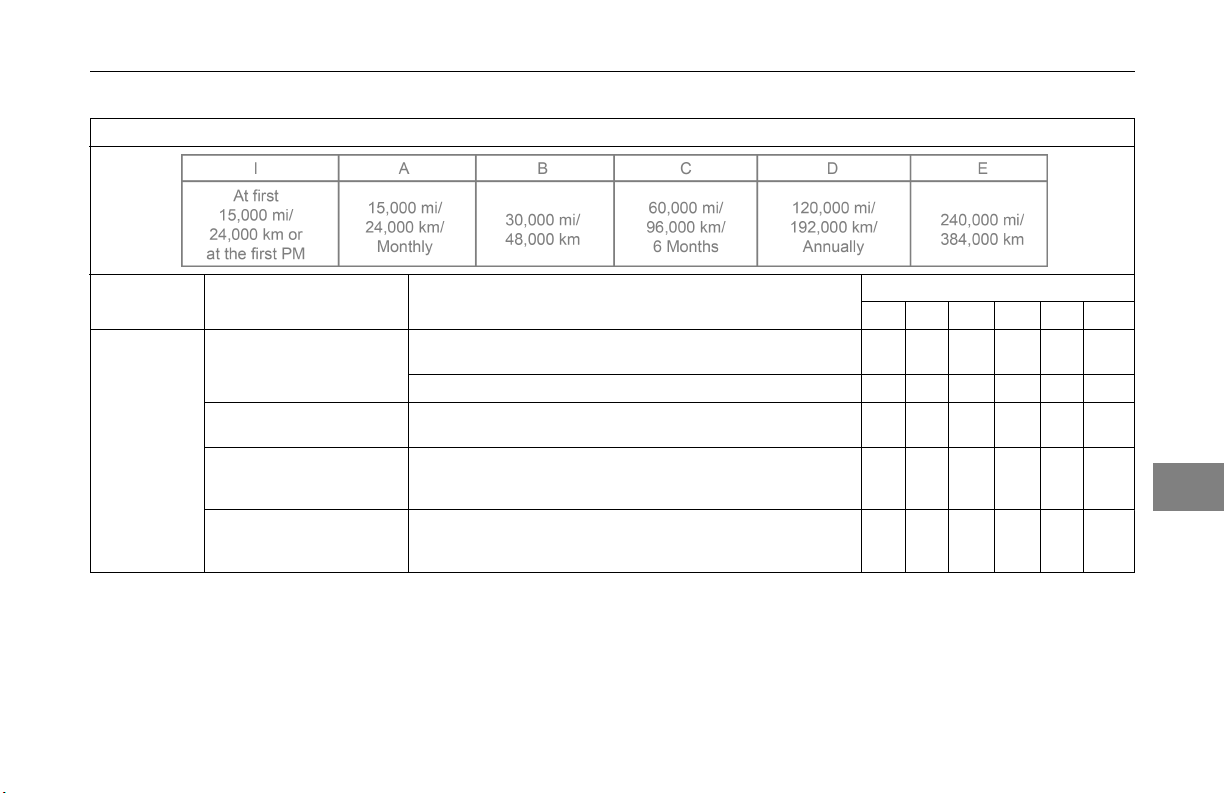

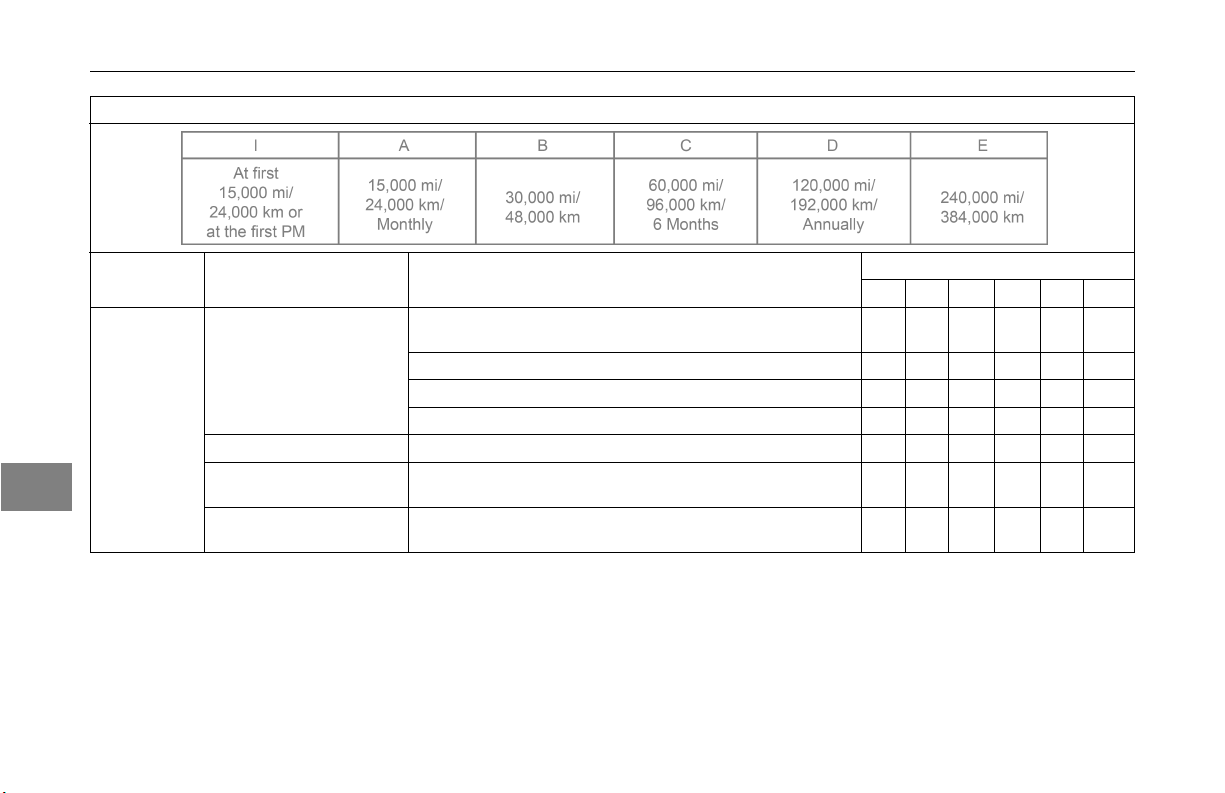

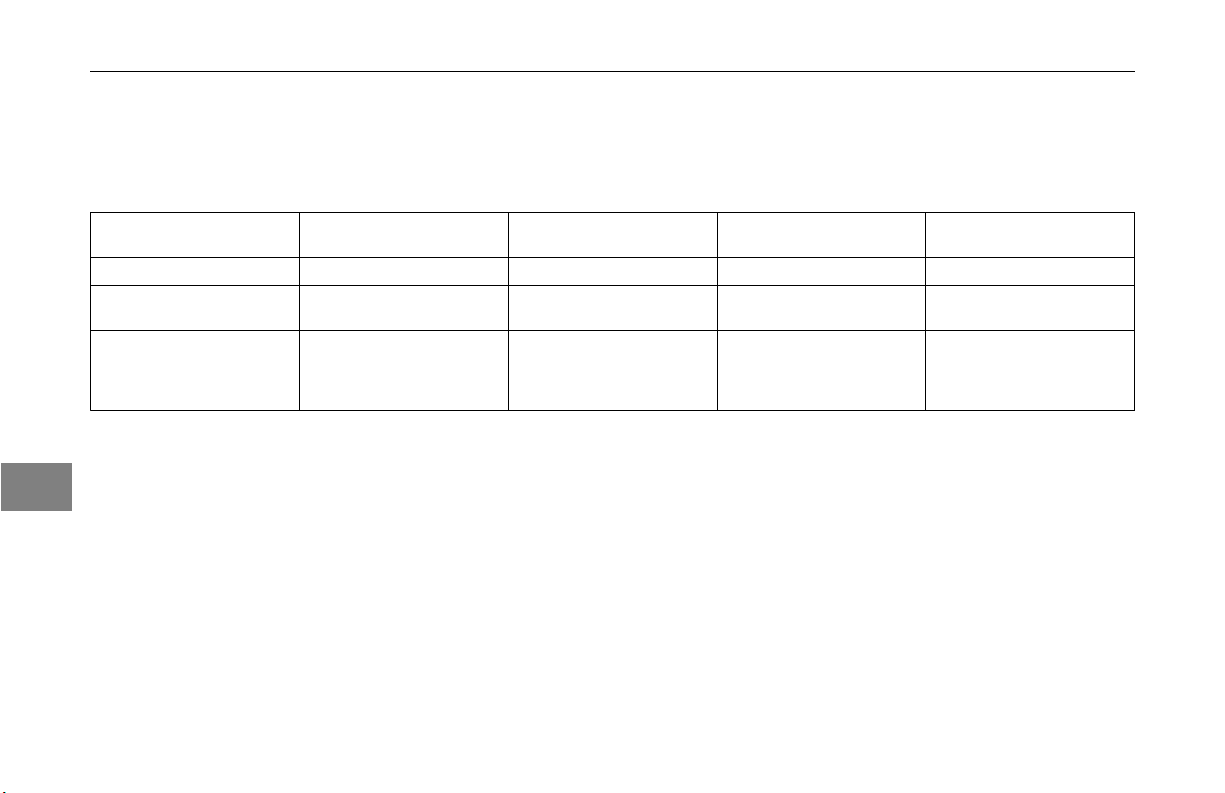

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Frame

(03/17)Y53-6077-1B15-13

FifthWheel

FrameFasteners

Crossmembersand

MountingBrackets

EngineMounting

Checkthekingpinlockandplateforwearandfunction;

lubricate(NLGI#2grease).

Inspectfthwheeloperation(shownonpage5-113)

Checkfortightness;tightentothespeciedtorquevalueas

required(shownonpage5-114).

Inspectforcracksandloosefasteners.Replaceortighten

tothespeciedtorquevalueasrequired(shownonpage

5-114).

Inspectenginemountsevery60,000miles(96,560km)

(shownonpage5-110).ContactanauthorizedvehicleOEM

dealershipifenginemountsneedservicing.

RecommendedPMInterval

IAB

X

C

X

X

DE

X

X

5

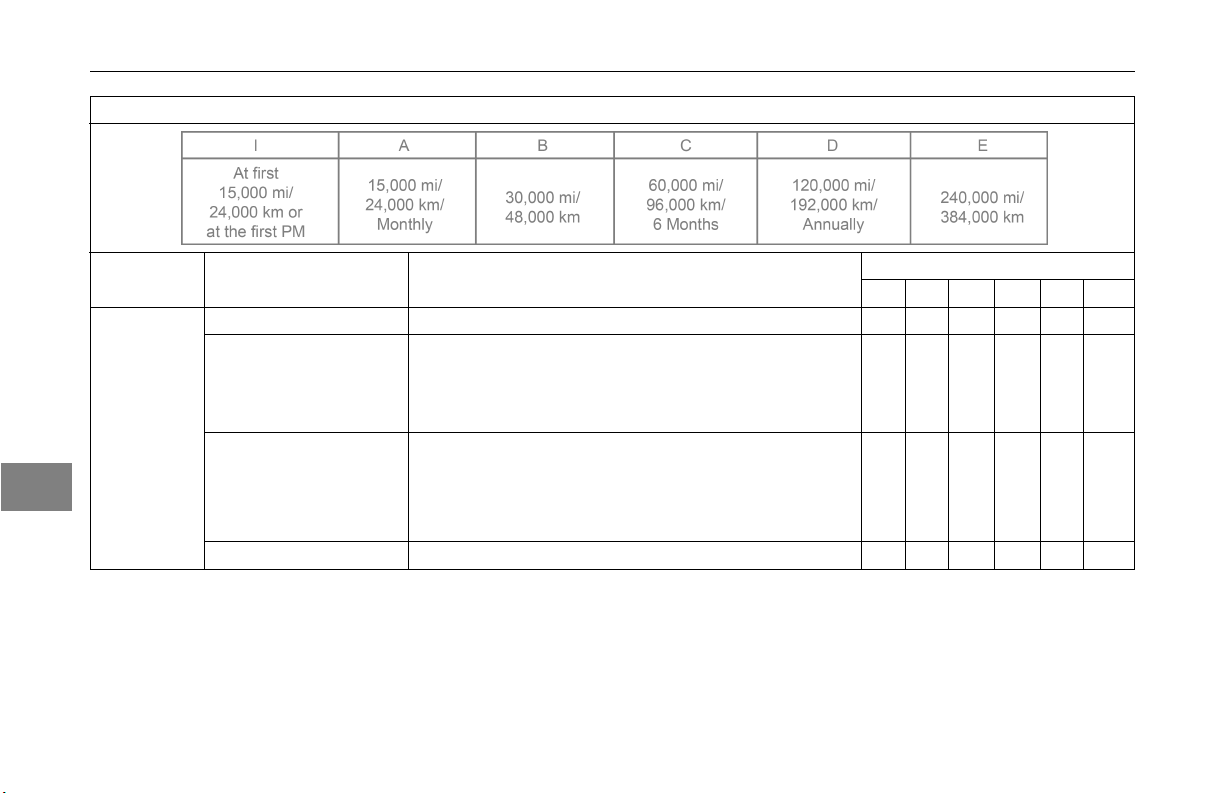

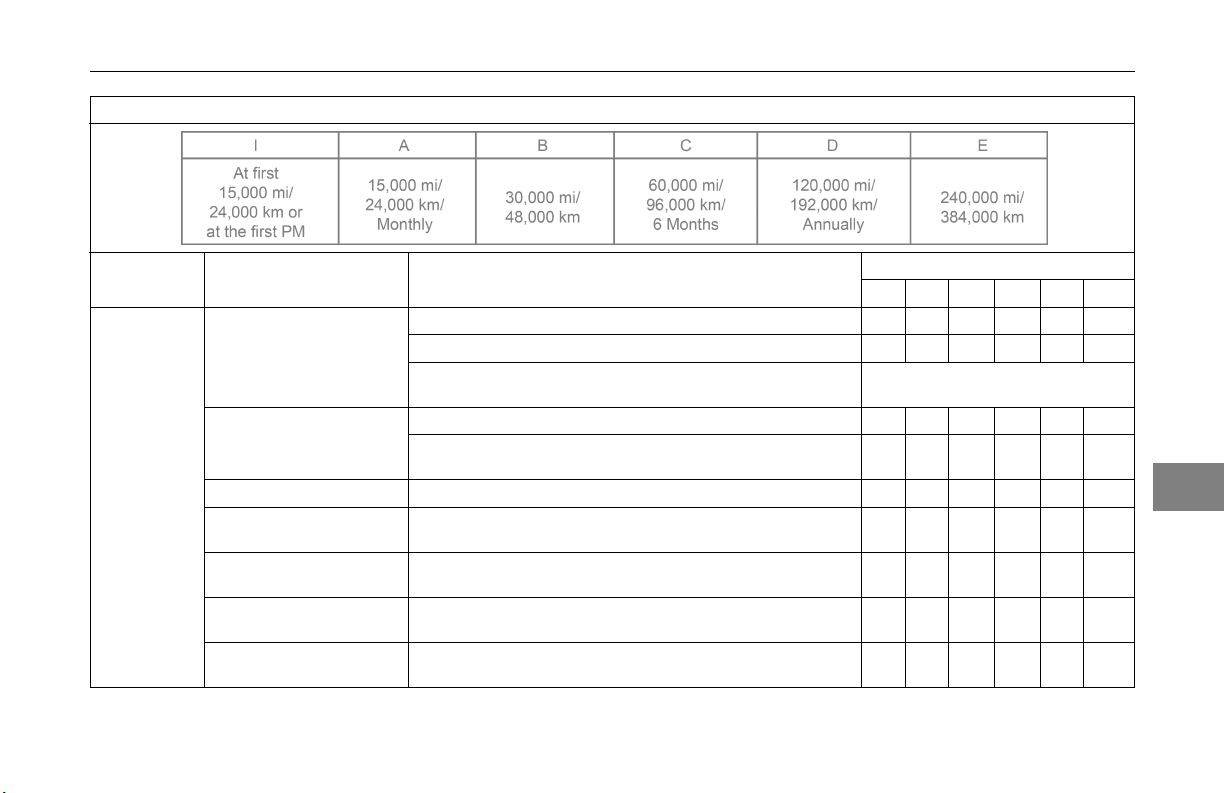

Page 22

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

FrontAxle

(Meritor)

5

TotalVehicleAlignment

Steeringknuckle

spindles,thrustbearings,

kingpins,drawkeys,tie

rodends,steeringstops,

andbushings

Kingpinbushings,thrust

bearings,andtierodball

ends

DrawkeysTightennutsXX

Checkandadjustasrequired.

Inspectforwearanddamageandendplay .Shimorreplace

asrequired(shownonpage5-136).

Lubricatewithapprovedgrease.X

RecommendedPMInterval

IAB

XX

5-14Y53-6077-1B1(03/17)

DE

C

X

Page 23

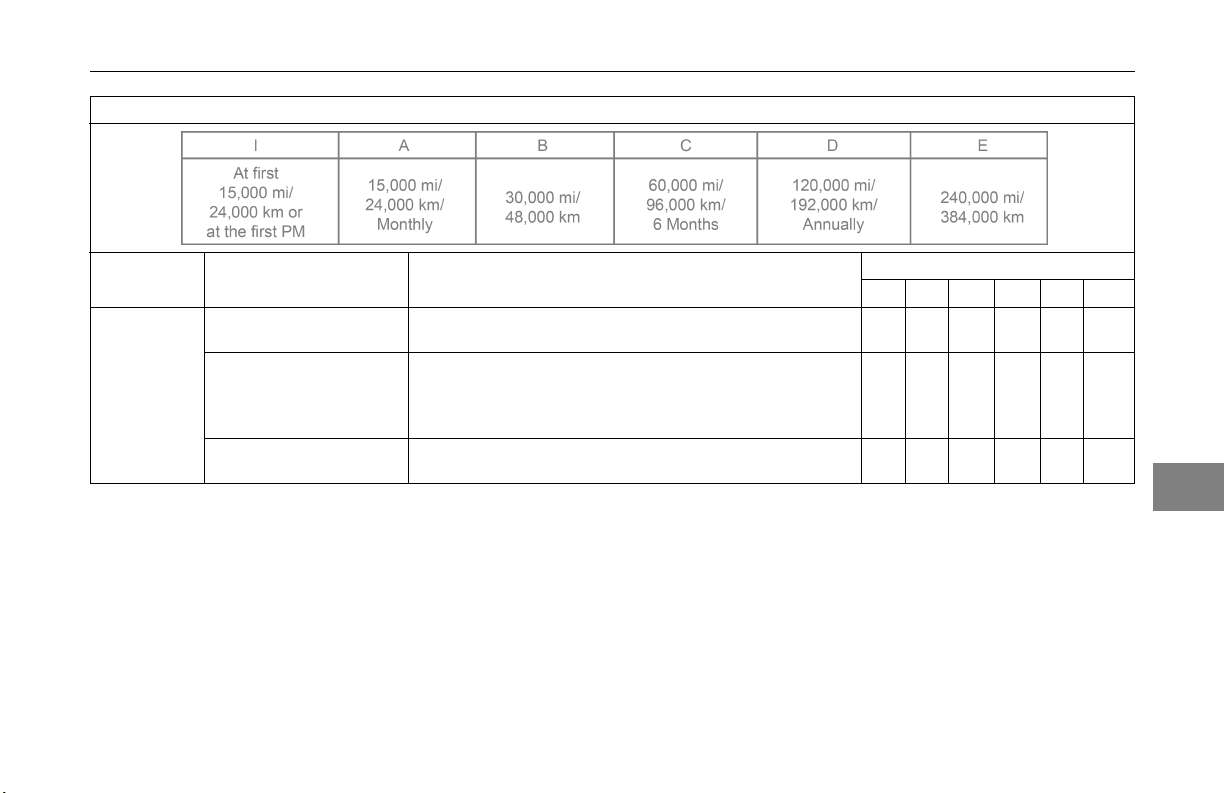

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

FrontAxle

(Dana)

(03/17)Y53-6077-1B15-15

TotalVehicleAlignment

Kingpinbushings,thrust

bearings,andtierodball

ends(ONHIGHWA Y)

Kingpinbushings,thrust

bearings,andtierodball

ends(OFF-HIGHWAY)

Steeringknuckle

spindles,thrustbearings,

kingpins,drawkeys,

tierodends,steering

stops,andbushings(ON

HIGHWAY)

Steeringknuckle

spindles,thrustbearings,

kingpins,drawkeys,

tierodends,steering

stops,andbushings

(OFF-HIGHWAY)

Checkandadjustasrequired.

Lubricatewithapprovedgrease.X

Lubricatewithapprovedgrease.X

Inspectforwearanddamageandforendplay.Shimor

replaceasrequired.

Inspectforwearanddamageandforendplay.Shimor

replaceasrequired.

RecommendedPMInterval

IAB

XX

C

X

DE

X

5

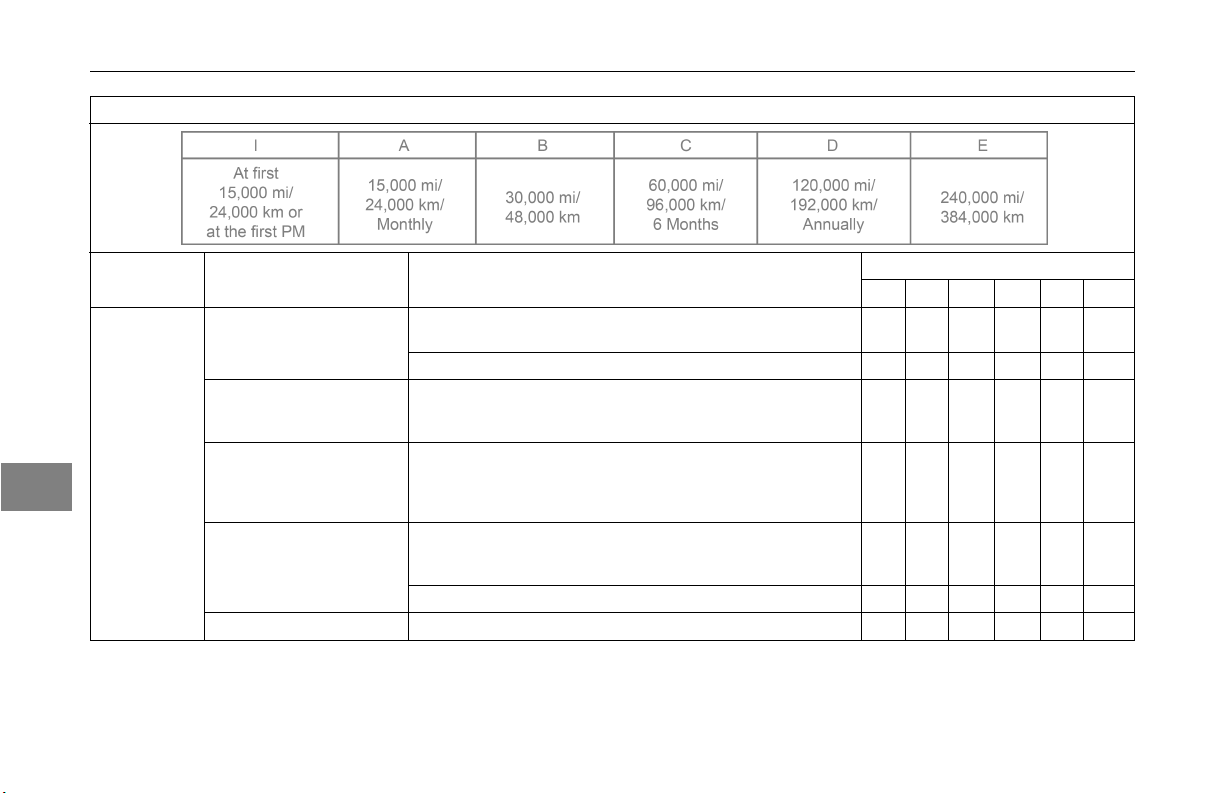

Page 24

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Front

Suspension

5

FrontSpringInspectforcrackedleaves,wornbushings,andexcessive

SpringPinsand

Shackles

ShockAbsorbersInspectforleaking,bodydamage,anddamagedorworn

SpringPins

U-bolts(ONHIGHWAY)Checkthegeneralconditionandthetightnessofthenuts.

U-bolts(OFFHIGHWAY)Checkthegeneralconditionandthetightnessofthenuts.

corrosion.

Inspectforwornpartsandexcessivejointclearance.Shim

orreplaceasrequired.

bushings.Replaceasrequired.Checktheshockmounting

studtorque.

Lubricatewithapprovedgrease.X

Checkforproperfunction.

Tightenthenutstothespeciedtorquevalueasrequired

(shownonpage5-118).

TightentheU-boltsaftertherstdayortwoofoperation.

Thentightenthenutstothespeciedtorquevalueas

required(shownonpage5-118).

RecommendedPMInterval

IAB

X

XX

X

5-16Y53-6077-1B1(03/17)

DE

C

X

X

X

Page 25

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

DriveAxle

(Dana)

(03/17)Y53-6077-1B15-17

AxleHousing

AirShiftUnit

Breather

LubePump(ON

HIGHWAY)

LubePump(OFF

HIGHWAY)

LubeFilter(ON

HIGHWAY)

LubeFilter(OFF

HIGHWAY)

Visuallyinspectfordamageorleaks.

Checkoillevel.Check“cold.”T orquethedrainplug.

Drainthelubricantwhilewarm.Flusheachunitwithclean

ushingoil.Changethelubricant.

Checkthelubricantlevel.

Removethehousingcoveranddrainthelubricant.Wash

thepartsthoroughlyanddryinair.

Cleanorreplace.

Removethemagneticstrainerandinspectforwearparticles.

Washinsolventanddryinair.

Removethemagneticstrainerandinspectforwearparticles.

Washinsolventanddryinair.

Change.

Change.

RecommendedPMInterval

IAB

Seeinformationonpage5-53

C

X

X

X

X

X

DE

X

X

X

X

5

Page 26

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Magneticdrainplugand

(Dana)

breather(ONHIGHWA Y)

Magneticdrainplug

andbreather(OFF

HIGHWAY)

Cleanorreplace.

Cleanorreplace.

RecommendedPMInterval

IAB

5

5-18Y53-6077-1B1(03/17)

DE

C

X DriveAxle

X

Page 27

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

DriveAxle

(Meritor)

(03/17)Y53-6077-1B15-19

AxleHousing

LubricantlterChangethelter.

Breather

Inputshaftandpinion

shaft

AxleshaftTightentherearaxleangenutstothespeciedtorque

InteraxledifferentialChecktheoperation.

Checkthe“cold”lllevelatthedifferentialcarrierplugfora

pinionangleoflessthan7degrees,orattheaxlebowlplug

forapinionangleofgreaterthan7degrees.Tightenthe

plugto35-50Lb.ft.(47-68N.m.)

Visuallyinspectfordamageorleaks.

Drainandreplacethelubricant.

Checktheoperation.Ifthecapdoesn’trotatefreely,replace.

Checkandadjusttheendplay .

value.

RecommendedPMInterval

IAB

Seeinformationonpage5-51

C

X

X

X

DE

X

5

X

X

X

Page 28

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

DriveAxle

(SISU)

5

AxleHousing

Breather

LubeFilter

S-cambrakesOverhaulthebrakes;degreaseallmovingparts;checkthe

Changetheoilinthedifferentialcarrierandthehubs,and

cleanthemagneticoildrainplugs.

Checkthewheelbearinghubsandadjustifnecessary.

Visuallyinspectfordamageorleaks.

Checktheoillevelinthedifferentialcarrierandhubs.

Checkthebreatherforproperoperation.

Cleanthesuctionlterfortheoptionalpressurelubrication

system.

bushingsandsealsforwear .

RecommendedPMInterval

IAB

XX

XX

XX

5-20Y53-6077-1B1(03/17)

DE

C

X

X

X

X

Page 29

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Rear

Suspension

(03/17)Y53-6077-1B15-21

U-bolts

Frameandcrossmember

bolts

Mountingbracketsand

fasteners

Checkthetorque.T ightentospeciedtorquevalueas

required(shownonpage5-133).

Checkthetorque.T ightentospeciedtorquevalueas

required(shownonpage5-114).

Checktheconditionandthefastenertorque.Tightentothe

speciedtorquevalueasrequired(shownonpage5-114).

RecommendedPMInterval

IAB

XX

XX

C

DE

X

5

Page 30

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Drum

Brakes(All)

Slackadjusters

BrakecamshaftbearingCheckforexcessivecamshaftpalyintheaxialandradial

Braketreadlevalve

5

BrakeliningInspect;replaceasrequired.X

Checkthepushrodtravelandcheckthecontrolarmfor

cracks.Adjustatreline(shownonpage5-69).

Lubricate(NLGI#2grease).

directions.Maxallowableplayis0.003in.Lubricate(NLGI

#2grease).

Cleantheareaaroundthetreadle,boot,andmountingplate.

Checkthepivotandmountingplateforintegrity .Checkthe

plungerbootforcracks.Lubricaterollerpin,pivotpin,and

plunger(NLGI#2grease).

Checkairlinesandttingsforleaks(shownonpage5-57).

Adjustroutingasrequiredtopreventchang.Checktank

mountingandcondition.

Cleanorreplacetheinlinelters.

RecommendedPMInterval

IAB

X

X

X Brakeairsystem

5-22Y53-6077-1B1(03/17)

DE

C

X

X

X

Page 31

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

DiscBrakes

(Bendix®)

(03/17)Y53-6077-1B15-23

BrakepadsInspect;replaceasrequired.X

Brakedisc/rotorInspectforvisiblecracks,heatchecking,galling,orscoring

ofsurface.Checkforrunout(maxallowableis0.002in.).

CaliperslidingfunctionEnsurecaliperslidesfreelywithnoobstructionsorexcessive

play.

CaliperslidepinsInspectprotectivecapsoftheguidepinsfordamageor

cracking.

SystemoperationCheckoperation;inspectaspermanufacturer’sservice

literature.

RecommendedPMInterval

IAB

C

X

X

X

X

DE

5

Page 32

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Hub,Drum,

andHubcap

5

Hubs(non-LMS)Checkthebearingendplayandadjustasrequired(shown

Hubs(non-LMS)with

outrunnerseals

Hubs(non-LMS)with

standardseals

Hubseals(all)Checkforleaks;replaceasrequired.

LMSHubs(Dana)Inspectforleaks.Checkthebearingendplayandadjustas

LMSHubs(Dana)with

SyntheticLubricant

LMSHubs(Dana)with

MineralLubricant

onpage5-54).

Cleanthecomponentsandcheckforexcessivewearor

damage.Changetheoilandseal(shownonpage5-54).

Cleanthecomponentsandcheckforexcessivewearor

damage.Changetheoilandseal(shownonpage5-54).

required(shownonpage5-54).

Servicethebearings,sealsandoil.Thisintervalmaybe

differentdependingontheresultsoftheregularinspection.

(shownonpage5-54).

Servicethebearings,sealsandoil.Thisintervalmaybe

differentdependingontheresultsoftheregularinspection.

(shownonpage5-54).

RecommendedPMInterval

IAB

500,000miles/800,000km

350,000miles/560,000km

5-24Y53-6077-1B1(03/17)

DE

C

X

X

X

X

X

Page 33

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

andHubcap

Brakedrums

Hubcaps

(03/17)Y53-6077-1B15-25

Inspectforvisiblecracks,heatchecking,gallingorscoringof

thebrakingsurface,andforseverecorrosionontheoutside

surface.Checkforout-of-roundoroversizecondition[0.080

in.(2mm)morethantheoriginaldiameter].Replaceas

required.

Cleanthesightwindow.Checkthecenterplug,mounting

ange,andllplugforleaksandforproperinstallation.

Replacebrokenordamagedparts.Checkthelubricantlevel

andaddasrequired.

RecommendedPMInterval

IAB

X

C

X Hub,Drum,

DE

5

Page 34

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Mainand

auxiliary

transmission

5

Mainandauxiliary

transmissionandtransfer

case

MountingBracketsand

Fasteners

OilcoolerCleanthens(air-to-oiltype)andbody .Checkthehose

Mainandaux.

transmission

Mainandauxiliary

transmission(ON

HIGHWAY)

Mainandauxiliary

transmission(OFF

HIGHWAY)

Inspectforvisibledamage,signsofoverheating,andleaks.

Checkthedrainplugsfortightness.

Checktheconditionofthefastenersandtheirtorque.

Tightentothespeciedtorquevalueasrequired.

conditionandforleaks;replaceasrequired.

Checktheoillevel;rellasrequired.

Drainlubricantwhilewarm.Flusheachunitwithclean

ushingoil.

Drainlubricantwhilewarm.Flusheachunitwithclean

ushingoil.

RecommendedPMInterval

IAB

XX

500,000miles/800,000km

XX

5-26Y53-6077-1B1(03/17)

DE

C

X

X

X

X

Page 35

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Auxiliary

transmission

Clutch

(03/17)Y53-6077-1B15-27

CottaTransferCase

TR2205

FabcoTransferCase

TC142/TC143/TC170/

TC270

Marmon-Harrington

TransferCase

MVG2000/MVG2000SD

Airintakepiping,

mounting,andchargeair

cooler

Aircleaner

Clutchlinkage

Clutchreleasebearing

Inspect:Checkoillevel;inspectforleaksandanyvisible

damage.

Initialoilchange:Drainoilwhilewarm;ushcasewithgear

oil-compatibleuid;cleanmagneticdrainplug;rell.Donot

ushthecasewithanysolvent.

Changeoil.

Checkthesystemforbrokenpipes,leaks,jointintegrity,

cleanliness,andpropersupport(shownonpage5-109).

Replacetheengineintakeaircleanerelement(shownon

page5-108).

Lubricate.X

Lubricate.X

Inspectandadjustwhennecessary(noadjustmentrequired

forSOLOtypeclutches)

RecommendedPMInterval

IAB

X

XX

Whenrequiredbyairrestriction

indicatororrequiredbytheengine

manufacturer'soperatormanual.

X

C

X

X AirIntake

DE

5

Page 36

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Cooling

5

Hoses

ExtendedLifeCoolant

(ELC)

Fanclutch

SolenoidvalveCheckthefandriveforproperengagementand

Checktheradiatorandheaterhosesforleaks.

Checkthefreezepoint(shownonpage5-83).

Checkforcontaminationusingteststrips(shownonpage

5-82).

Replaceblankwaterlterifapplicable.

Performlabanalysis(shownonpage5-82).

Iflabanalysisshowscoolantisunsuitableforcontinueduse:

Flush,drain,andrell(shownonpage5-82).

AddELCExtender(shownonpage5-82).

Flush,drain,andrellwithnewcoolant(shownonpage

5-82).

Checkforairleaks.(shownonpage5-106).

Checkthefandrivebearings(turnthesheaveinboth

directionstocheckforwornhubbearings).

disengagement.

RecommendedPMInterval

IAB

XX

XX

XX

5-28Y53-6077-1B1(03/17)

DE

C

X

X

X

X

X

Page 37

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Tiresand

Wheels

(03/17)Y53-6077-1B15-29

Tires

Discwheels

DemountablerimsInspectthemountingring,rimgutter ,sidering,andlockring

Wheelnutsandstuds

Checkinationpressure(shownonpage5-140).Weekly“cold”usingcalibrated

Inspectforcuts,irregularwear,missinglugs,sidewall

damage,etc.

Inspectthewheeldiscforanycracksorsurfaceirregularities.

Inspecttherimedgeandbeadseatareafordamage.

Replaceanydamagedwheels-DONOTA TTEMPTTO

REPAIR.

fordamage;replaceasrequired.

Checkthetightnessofthefastenersandtightenthe

fastenerstothespeciedtorqueasrequired(shownon

page5-146).

Inspectfordamagedhexcorners,strippedordamaged

threads,andexcessivecorrosion;cleanorreplaceas

required.

RecommendedPMInterval

IAB

X

X

X

X

X

C

gauge

DE

5

Page 38

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Power

Steering

5

Reservoir

Reservoir(ON

HIGHWAY)

Reservoir(OFF

HIGHWAY)

Steeringgear

Powerassistcylinder

Hosesandtubes

SteeringlinkageCheckalljointsforexcessivelash;replaceasrequired

Checktheuidlevel(shownonpage5-55).

Drain,replacethelter,andrell(shownonpage5-55).

Drain,replacethelter,andrell(shownonpage5-55).

Checkthelashofthesectorshaft;adjustasrequired.

Greasethetrunnionbearing(EPNLGI#2lithium-based,

moly-lled,HDgrease).

Greasetheinputshaftseal(EPNLGI#2lithium-based,

moly-lled,HDgrease).

Lubricatetheballjoints.Inspectforleakingrodseals,

damagedballjointboots,anddamagetocylinderrodor

barrel.

Checkforleaksandchang.

(shownonpage5-136).

RecommendedPMInterval

IAB

X

XX

XX

X

5-30Y53-6077-1B1(03/17)

DE

C

X

X

X

X

X

Page 39

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Power

Steering

(03/17)Y53-6077-1B15-31

Draglinktubeclampand

ballsocket

Pitmanarmclampbolt

andnut

Steeringintermediate

shaft

Steeringintermediate

shaftU-joints(ON

HIGHWAY)

Steeringintermediate

shaftU-joints(OFF

HIGHWAYorCITY

DELIVERY)

Draglinkandtierod

armballsockets(ON

HIGHWAY)

Draglinkandtierod

armballsockets(OFF

HIGHWAYorCITY

DELIVERY)

Checkthetorque;tightentospeciedtorquevalueas

required.

Checkthetorque;tightentospeciedtorquevalueas

required.

Checkthetorqueonthepinchboltandnut.

Lubricate[EPNLGI#2HDgrease,+325°Fto-10°F(+163°

Cto-23°C)range].

Lubricate[EPNLGI#2HDgrease,+325°Fto-10°F(+163°

Cto-23°C)range].

Lubricate(EPNLGI#2lithium-based,moly-lled,HD

grease).

Lubricate(EPNLGI#2lithium-based,moly-lled,HD

grease).

RecommendedPMInterval

IAB

XX

XX

XX

XX

XX

XX

XX

C

DE

5

Page 40

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Fueland

Tanks

Fueltanks

Fueltankbreathers

Fueltankstraps

Inspecttanks,brackets,hoses,andttingsforcorrect

location,tightness,abrasiondamage,andleaks;repairor

replaceasrequired.

Checkforproperfunction;cleanthedrainhoses.

Checkthestraptightness;tightentopropertorquevalue

asrequired:

Aluminumtank:30Lb.ft.(41N.m.)

CylindricalSteeltank:8Lb.ft.(11N.m.)

RecommendedPMInterval

IAB

XX

5

5-32Y53-6077-1B1(03/17)

DE

C

X

X

Page 41

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Driveshafts

(03/17)Y53-6077-1B15-33

ModelsSPL-90,1710

and1810slipmember

andU-joints

ModelSPL-100slip

memberandU-joints

ModelsSPL140/140HD/170/

170HD/250/250HDslip

membersandU-joints

(ONHIGHWAYand

LINEHAUL)

Lubricate*.

Inspect.U-jointinspectionsshould

Lubricate*.

Inspect.U-jointinspectionsshould

Lubricate*.

Inspect.U-jointinspectionsshould

RecommendedPMInterval

IAB

XX

beperformedeverytimea

vehiclecomesinforscheduled

maintenance.**

X

beperformedeverytimea

vehiclecomesinforscheduled

maintenance.**

beperformedeverytimea

vehiclecomesinforscheduled

maintenance.**

C

X

DE

5

Page 42

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Driveshafts

5

ModelsSPL140/140HD/170/

170HD/250/250HDslip

membersandU-joints

(OFFHIGHWAY)

ModelsSPL-140XL/

170XL/250XLslip

membersandU-joints

(ONHIGHWA YandLINE

HAUL)

ModelsSPL-140XL/

170XL/250XLslip

membersandU-joints

(OFFHIGHWAYand

CITY)

*UseonlySpicerDriveshaftapprovedlubricantswhengreasingSpicerU-joints.

**RefertoSpicerDriveshaftservicemanualDSSM-0100(3264-SPL)fordetailedinstructions.

Lubricate*.

Inspect.U-jointinspectionsshould

Lubricate*.350,000mi(560,000km)1st

Inspect.U-jointinspectionsshould

Lubricate*.

Inspect.U-jointinspectionsshould

RecommendedPMInterval

IAB

X

beperformedeverytimea

vehiclecomesinforscheduled

intervalandthenevery100,000mi

(160,00km)afterthat.

beperformedeverytimea

vehiclecomesinforscheduled

beperformedeverytimea

vehiclecomesinforscheduled

5-34Y53-6077-1B1(03/17)

DE

C

maintenance.**

maintenance.**

X

maintenance.**

Page 43

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Battery

Boxes,T ool

Boxes,and

Steps

(03/17)Y53-6077-1B15-35

Batterycables

Batteries(ONHIGHWAY

andLINEHAUL)

Batteries(OFFHIGHWAY)

Batteryboxandtray(ON

HIGHWAYandLINE

HAUL)

Batteryboxandtray

(OFF-HIGHWAY)

BatteryCableFastenersCheckbatterycablefastenersandtightenasnecessaryto

Checktheconditionofthecables,cushionclamps,nylontie

straps,androuting.Replaceacushionclampiftherubber

hasdeteriorated.Repairortightenterminals,andsecure

cablestopreventchang.Replacedamagedcables(cuts,

cracks,orexcessivewear)(shownonpage5-87).

Checkforcracksanddamage,electrolytelevel,conditionof

terminals,andtightnessofholddowns(shownonpage5-87).

Checkforcracksanddamage,electrolytelevel,conditionof

terminals,andtightnessofholddowns(shownonpage5-87).

Checktheboxintegrity.Cleanthedraintubeandcheckfor

acidleaks.Checkconditionofallequipmentmountedunder

thebox.

Checktheboxintegrity.Cleanthedraintubeandcheckfor

acidleaks.Checkconditionofallequipmentmountedunder

thebox.

10-15Lb.ft.(13.6-20.3N.m.)asspeciedonthebattery

label.

RecommendedPMInterval

IAB

X

X

X

X

C

X

X

DE

5

Page 44

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Electrical

andlights

5

Headlamps

Warninglightsinlightbar

Turn,Stop,Reverse

lightsandsignals

Alternator

StarterChecktorqueonhexnuts.

ECMconnectorCheckthetightnessoftheECMconnector .

Wheelsensors

Fuelanddieselexhaust

uidtanksendingunit

Checktheaimandadjustasrequired.

Checkattheignitionstartpositiontoverifybulbsanddriver

informationdisplayfunction.

Visualcheck.X

Checkoperationandoutput.

Checktightnessofthepulleynut.

Checkthetensionofthedrivebelt(shownonpage5-105).

Checktightnessoftheterminalhexnuts.

Checkfordamagedsensorsandconnectors,andwornor

frayedwires.

Checkthemountingscrewsandelectricalconnectionsfor

wornordamagedwiresandconnectors.

RecommendedPMInterval

IAB

X

XX

5-36Y53-6077-1B1(03/17)

DE

C

X

X

X

X

X

X

X

X

Page 45

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Electrical

andlights

Cab

structure,

doorsand

hoods

Heatingand

AirConditioning

(03/17)Y53-6077-1B15-37

Powersupplyharnesses

(engine,transmission,

etc.)

Hood

HingesandlatchLubricatewithsiliconespray.X

Bodyandcabholddown

bolts

Airconditioner

conditioner

CondenserClearanydebrisfromthefrontofthecondenser.

Checkforwornordamagedinsulation,corrodedterminals,

frayedwires,andoiloruidleaksontheconnectorsor

wiring.

Washtoremoveexcessgrease.X

Lubricatethelowerhoodpivot(onlyiflubettingsare

present).

Checktheconditionandtightness.

Operatethesystem.

Performthecheckslistedshownonpage5-120.

Fulloperationalanddiagnosticcheck.X

RecommendedPMInterval

IAB

X

X

C

X

X Heaterandair

X

DE

X

5

Page 46

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

AftertreatmentSystem

SystemCheckforleaksandpropersupport(shownonpage5-123).

DieselparticulatelterCleanlter.RefertotheEngineMaintenance

DieselexhaustuidtankInspectthetank,straps,brackets,hosesandttingsfor

Dieselexhaustuid

supplymodule

abrasiondamage,leaks,tightnessandfullyengaged

connectors.

Replacelter.RefertotheEngineMaintenance

RecommendedPMInterval

IAB

X

5

5-38Y53-6077-1B1(03/17)

DE

C

Manual.

X

Manual.

Page 47

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

Air

(03/17)Y53-6077-1B15-39

AircompressorgovernorReplaceairstrainer.X

Airlines

SystemLubricate(shownonpage5-60).

Inlinelters

Airdryer

Airdryer(ONHIGHWAY)Overhaul.360,000miles/576,000km

Airdryer(OFF

HIGHWAY)

Checkconditionandroutingtopreventchang.

Replaceelementsorcleanwithsolvent.X

Performthecheckslisted(shownonpage5-57).

Overhaul.

RecommendedPMInterval

IAB

C

X

X

X

DE

X

5

Page 48

PREVENTIVEMAINTENANCESCHEDULE

PREVENTIVEMAINTENANCE(PM)INTERVALS

SYSTEMCOMPONENTMAINTENANCETASK

EngineBasicEngine

SafetyThree-pointSafetyBelt

System

Maintenanceandserviceintervalrecommendationsaredetailedintheenginemanufacturer’s

OperationsandMaintenanceManualincludedwiththevehicle.Theenginemanufacturer’s

recommendationsvarydependingenginemodel.Informationisalsoavailablefromauthorized

dealers,theenginemanufacturer’sauthorizedservicecenters,andtheenginemanufacturer’s

website.

Inspect.

5

RecommendedPMInterval

IAB

20,000miles/32,000km

Ifthevehicleisexposedto

severeenvironmentalorworking

conditions,morefrequent

inspectionsmaybenecessary.

5-40Y53-6077-1B1(03/17)

DE

C

Page 49

LUBRICANTSPECIFICATIONS

LUBRICANT

SPECIFICATIONS

Introduction

WARNING!

Handlelubricantscarefully.Vehiclelubricants(oilandgrease)can

bepoisonousandcausedeath,personalinjuryorsickness.Theycan

alsodamagethepaintonthevehicle.

Inthissectionyouwillndthebasic

informationyouneedtodotheroutine

lubricationyourvehiclerequires.Of

courseyouwillwanttoschedule

servicemorefrequentlyifyouare

operatingundersevereconditions

suchasextremeheatorcold,with

veryheavyloads,off-road,etc.For

anyspecialservicerequirements,

consultyourservicemanualsandyour

lubricantsupplier .Pleaseremember:

onekeytokeepingyourtruckrunning

attopeconomyandinprolonging

itslifeisproperlubricationservicing.

Neglectingthisessentialaspectof

vehiclecarecancosttimeandmoney

inthelongrun.

CAUTION

Donotmixdifferenttypesoflubricants.Mixinglubricants(oiland

grease)ofdifferentbrandsortypes

coulddamagevehiclecomponents;

therefore,drain(orremove)oldlubricantsfromtheunitbeforerelling

it.

Engine

Properenginelubricationdepends

ontheoutsidetemperatureswhere

youwillbedriving.Usetheoil

recommendedfortheconditionsyou

aremostlikelytobeoperatingin.You

willndacompleteenginelubrication

serviceguideintheEngineOperation

Manualthatcamewithyourvehicle.

Theengineoperatormanualcontains

specicmaintenancetasksthatyouor

aqualiedservicetechnicianneedto

performtomaintaintheengine.

5

(03/17)Y53-6077-1B15-41

Page 50

LUBRICANTSPECIFICATIONS

WARNING!

Exhaustfumesfromtheengine

containcarbonmonoxide,acolorlessandodorlessgas.Apoorly

maintained,damaged,orcorroded

exhaustsystemcanallowcarbonmonoxidetoenterthecabor

sleeper.Failuretoproperlymaintainyourvehiclecouldcausecarbonmonoxidetoenterthecaband

causedeath,personalinjuryorseriousillness.

5

WARNING!

Neveridleyourvehicleforprolonged

periodsoftimeifyousensethatexhaustfumesareenteringthecab.

Investigatethecauseofthefumes

andcorrectitassoonaspossible.

Ifthevehiclemustbedrivenunder

theseconditions,driveonlywiththe

windowsslightlyopen.Failuretorepairthesourceoftheexhaustfumes

mayleadtodeath,personalinjuryor

seriousillness.

NOTE

Keeptheengineexhaustsystem

andthevehicle’scabventilation

systemproperlymaintained.Itis

recommendedthatthevehicle’sexhaustsystemandcabbeinspected:

•Byacompetenttechnicianevery

15,000miles/24,000km,

•Wheneverachangeisnoticedin

thesoundoftheexhaustsystem,

•Whenevertheexhaustsystem,

underbody,caborsleeperis

damaged.

NOTE

Useonlyanexactreplacementparts

inAftertreatmentexhaustsystem.

Usinganoncompliantreplacement

partcouldviolateemissionsrequirementsandalsovoidtheemission

system’swarranty.

5-42Y53-6077-1B1(03/17)

Page 51

LUBRICANTSPECIFICATIONS

PipeandHoseClamps

Usethefollowingtablefortorque

specicationstocheckpipeandhose

clamps.

PipeandHoseClampTorqueV alues

TORQUEAPPLICATIONAPPROVEDCLAMP

NmLb-In

RadiatorandHeatExchangerHoses

HeaterHoses

AirIntakePipesHi-TorqueHTM-L11.3-14.2100-125

PlasticAirIntakePipes

ChargeAirIntakeHoses

Fuel,Oil&WaterHeatExchangers

(forhoseslessthan9/16diameter)

Constant-TorqueCT-L

ConstantT ension

Constant-T orqueCT-L

FlexSeal667

B92966-750-60

Miniature3600L1.1-1.710-15

10.2-12.590-110

notrequirednotrequired

4.5

7.9-11.370-100

40(maximum)

5

(03/17)Y53-6077-1B15-43

Page 52

LUBRICANTSPECIFICATIONS

MasterLubricationIndex

ATF

BB

CBEngineoilformildtomoderaterequirements

CC/CDEngineoilforsevererequirements(MIL-L-2104B/MIL-L-45199Bw/1.85%max.sulfatedashcontent)

CDEngineoilmeetingAPI“Fiveenginetestsequence”

CD50SAE50Wsynthetictransmissionuid

CEEngineoilmeetingseveredutyservicerequirementsfordirect-injectionturbochargedengines

CJ-4EngineoilforPACCARMXandCumminsEGRengines

CL

EP

GLStraightmineralgearlubricant

5

HD

HT

MP

DOT3orDOT4

LubricantSymbolKey

MD3orMERCON®-approvedautomatictransmissionuid

Hightemperatureballbearinggrease.ChevronSRIMobileGreaseHP ,T exacoMultifax2orequivalent

Multipurposechassisgrease

ExtremePressureLubricant(Lithium12-hydroxystearatebaseNGLI2)

HypoidGearOil,A.P .I.-GL-5,SAE75W-90FEsyntheticgearlubricant

HighT emperaturegrease(T imkenSpec.0-616)

Multipurposegearlubricant(MIL-L-2105B)

BrakeFluid

5-44Y53-6077-1B1(03/17)

Page 53

NOTE

Theresponsibilityformeetingthese

specications,thequalityofthe

product,anditsperformanceinservicerestswiththelubricantsupplier.

Foroilreservoirwithsidellerplugs

(transmission,axles,steeringgear

boxes,transfercases,etc.)theoil

mustbelevelwiththelleropening.

LUBRICANTSPECIFICATIONS

1ImproperOilLevel

2ProperOilLevel

Usecarewhencheckingtheoillevel

withanger.Justbecauseyoucan

reachtheoillevelwithanger,does

notmeantheoilleveliscorrect.

(03/17)Y53-6077-1B15-45

5

Page 54

LUBRICANTSPECIFICATIONS

UniversalJoints

DriveShaftSplinesCL*

SteeringColumnCL

AlternatorBearing

FanHub

PowerSteeringReservoir

SteeringDragLinkCL

SteeringKnucklesCL

SpringPinsCL

ClutchReleaseBearings

BrakeShoeAnchorPins

BrakeCamBearings

5

SlackAdjustersCL

StarterBearingsCC

TurbochargerAneroid

WaterPump

SuspensionFittings(otherthanthreadedpinsandbushings)

SteeringAxle:GreaseFittingsonSteeringArm;TieRodEnds;Drag

Link;KingPins

SteeringShaftGreaseFittings

ComponentLubricationIndex

EP*

BB*

BB*

ATF

BB

HT

HT

CC

BB*

EP

EP

EP

5-46Y53-6077-1B1(03/17)

Page 55

ComponentLubricationIndex

BrakeTreadleHingeandRollerEngineoil

LockCylinders

DoorHinges

DoorLatchesandStrikerPlates

DoorWeatherstrip

Hub-pilotedAluminumWheels

ManualTransmissionHydraulicClutchDOT3orDOT4(BrakeFluid)

*Consultmanufacturerorlubricantsupplierforspecialdetails.

Locklubricant

Notrequired-T eonbushings

Polyethylenegreasestick

Siliconelubricant

CoatthewheelpilotorhubpadswithFreylube#3lubricant(light

colored)orChevronZinclube.Donotgetlubricantonthefaceof

thewheelorthehub.

LUBRICANTSPECIFICATIONS

5

(03/17)Y53-6077-1B15-47

Page 56

LUBRICANTSPECIFICATIONS

FullerTransmission Lubrication

Fullertransmissionsaredesignedso

thattheinternalpartsoperateina

bathofoilcirculatedbythemotionof

gearsandshafts.Greyironpartshave

built-inchannelswhereneededto

helplubricatebearingsandshafts.All

partswillbeamplylubricatedifthese

proceduresarecloselyfollowed:

1.Maintainoillevel;checkit

regularly.

2.Changeoilregularly.

3.Usethecorrectgradeandtypeof

5

oil.

4.Buyoilfromareputabledealer.

LubricationChangeandInspection

Off-HighwayUse

RefertotheEatonFullertransmission

manualforservicinginformation.

HighwayUse

•RefertotheEatonFuller

transmissionmanualforservicing

information.

•Refertotheoilchangevs.

temperaturechartthatfollowsfor

specialoilchangeinformation.The

“intermittentpeaktemperature”

isthemaximumtemperature

observedforashorttimeina

fullyloadedvehicleperforming

normally.

CAUTION

Exceedingtherecommendedoil

changeintervalsmaybeharmfulto

thelifeofthetransmissionandthe

transmissionoilcooler.

5-48Y53-6077-1B1(03/17)

Page 57

RecommendedLubricants

LUBRICANTSPECIFICATIONS

Type

HeavyDutyEngineOilMIL-L-2104B,C,orD;

API-SF ,orAPI-CD

Mineralgearoilwithrustandoxidation

inhibitorAPI-GL-1

SyntheticLubricant*

*Seeyourdealerforapprovedbrands.

Grade(SAE)

50

40

30

90

80W

50All

AmbientTemperature

Above10°F(-12°C)

Above10°F(-12°C)

Below10°F(-12°C)

Above10°F(-12°C)

Below10°F(-12°C)

5

(03/17)Y53-6077-1B15-49

Page 58

LUBRICANTSPECIFICATIONS

AllisonTransmission Lubrication

LubricationChangeandInspection

•Refertoyourtransmission

•RefertotheAllisonTransmission

5

manual(furnishedseparately)for

lubricationinformation.

manualforservicinginformation.

Type

orMIL-L-46152B,API-SForAPI-CD

(MIL-L-2104BorCorMIL-L-46152

designationsareacceptable)

Mineralgearoil(RandOtype)API-GL-1

SpicerTransmission Lubrication

Itisextremelyimportanttousethe

properlubricantsandmaintainthe

correctoillevelsinSpicerunits.This

willensureproperlubricationand

operatingtemperaturesintheseunits.

Grade(SAE)

30,40,or50

30

90

80

RecommendedLubricants

Thelubricantslistedbeloware

recommended,inorderofpreference,

foruseinallSpicermechanical

transmissions,auxiliaries,and

transfercases.Donotuseextreme

pressureadditivessuchasthose

foundinmultipurposeorrearaxle-type

lubricants.Theseadditivesarenot

requiredinSpicertransmissions,

andmayinsomecasescreate

transmissionproblems.Multipurpose

oils,asagroup,haverelativelypoor

oxidationstability,ahighrateofsludge

formation,andagreatertendencyto

reactwithorcorrodethesteeland

bronzeparts.

AmbientTemperature

Above0°F(-18°C) HeavyDutyEngineOilMIL-L-2104D

Below0°F(-18°C)

Above0°F(-18°C)

Below0°F(-18°C)

5-50Y53-6077-1B1(03/17)

Page 59

LUBRICANTSPECIFICATIONS

Type

SyntheticEngineOilmeetingMIL-L-2104Dor

MIL-L-46152B,API-SForAPI-CD

*SyntheticGearOilMeetingMIL-2105Cor

API-GL5

*EPGearOilsarenotrecommendedwhenlubricantoperatingtemperaturesareabove230°F(1 10°C).

OilChanges

CD50

CD30

EP75W90

EP75W140

24hoursbutbefore100hoursof

Grade(SAE)

servicehaveelapsed.

CAUTION

Whenaddingoil,typesandbrands

ofoilshouldnotbeintermixedbecauseofpossibleincompatibility,

whichcoulddecreasetheeffectivenessofthelubricationorcause

componentfailure.

Aninitialoilchangeandushshould

beperformedafterthetransmission

hasbeenplacedinactualservice.

Thischangeshouldbemadeanytime

after3000miles(4800km)butnever

longerthan5000miles(8000km)of

over-the-roadservice.Inoff-highway

use,thechangeshouldbemadeafter

AmbientTemperature

All

All

Relling

Removealldirtaroundllerplug.Rell

withnewoilofthegraderecommended

fortheexistingseasonandprevailing

service.Filltothebottomofthe

leveltestingplugpositionedonthe

sideofthetransmission.Donot

overllthetransmission.Overlling

usuallyresultsinoilbreakdowndue

toexcessiveheatandaerationfrom

thechurningactionofthegears.Early

breakdownoftheoilwillresultinheavy

varnishandsludgedepositsthatplug

upoilportsandbuilduponthesplines

andbearings.Overowofoilcanalso

escapeontoclutchorparkingbrakes.

Whenaddingoil,donotmixdifferent

typesofoil.

5

(03/17)Y53-6077-1B15-51

Page 60

LUBRICANTSPECIFICATIONS

MeritorAxleLubrication

Axlesutilizedin100%off-highway

usearenoteligibleforMeritor’sAdvancedLubeRearDriveAxleprogram.

RS-17-145RS-23-180

RS-19-145RS-26-180

RS-21-145RS-30-180SQ-100A

RS-23-160

RS-23-161

5

Meritorrearaxlesthatdonotappear

onthelistabovewillcontinueto

requireaninitialdrainat3000-5000

miles(4800-8000km).

•RefertotheMeritorField

MaintenanceManualfora

particularaxleforlubricant

specications.

UnderMeritor’sAdvancedLubeRear

NOTE

DriveAxleprogram,theaxleslisted

belowareexemptfromaninitial

lubricantchange:

AV AILABLEADVANCEDLUBEAXLES

RT-40-145RT-44-145P

RT-40-145PRT-46-160

RT-46-160P

RT-34-145

RT-34-145PRT-44-145RT-52-160P

SQ-100AP

RT-52-160

•Seeyourdealerfor

Meritor-approvedlubricant

brands.

•Refertothefollowingchartfor

lubricantchangeintervals:

5-52Y53-6077-1B1(03/17)

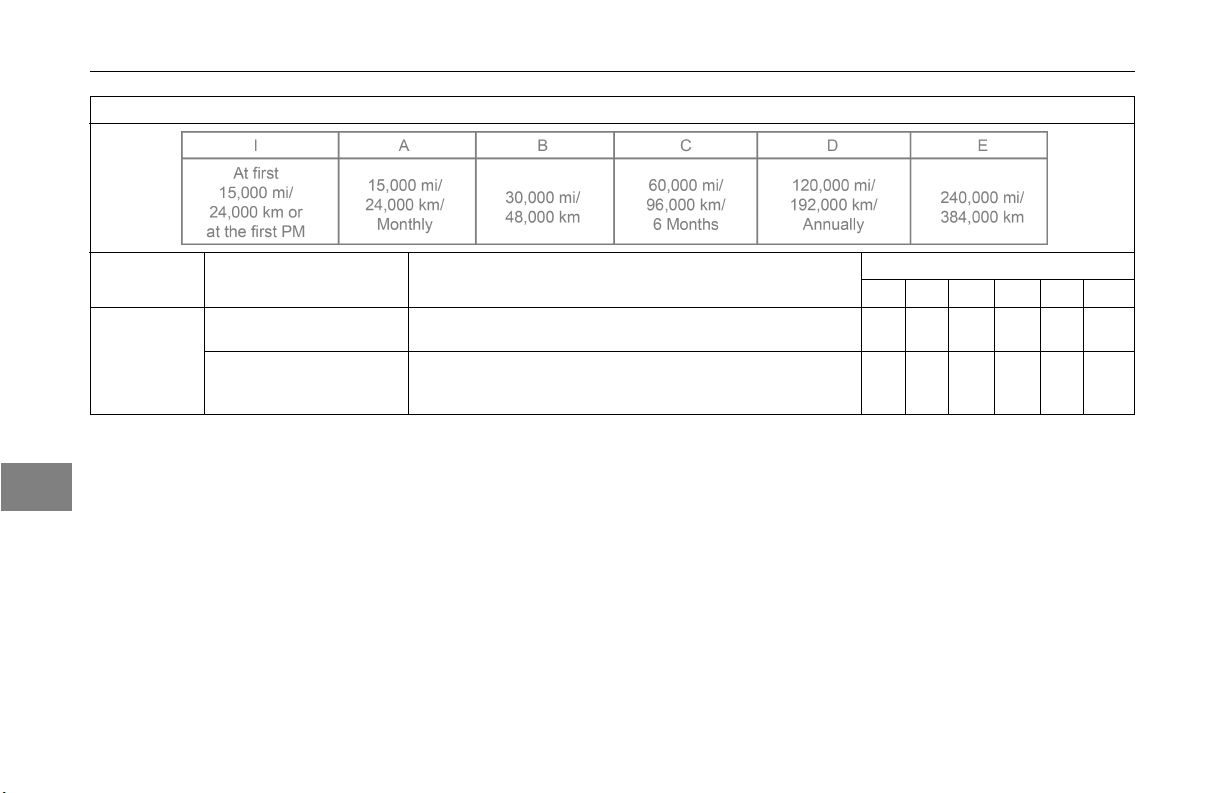

Page 61

LUBRICANTSPECIFICATIONS

Application

OnHighway

CityDelivery

OffHighway

•Changethelubricantlterevery

120,000miles(192,000km).T op

offthelubricantlevelwithasimilar

lubricant.

TypeOfLubricant

Synthetic240,000mi.(384,000km)

SyntheticwithPumpandFilter500,000mi.(800,000km)

MineralBase

Synthetic120,000mi.(192,000km)

SyntheticwithPumpandFilter240,000mi.(384,000km)

MineralBase

Synthetic120,000mi.(192,000km)

SyntheticwithPumpandFilter120,000mi.(192,000km)

MineralBase

120,000mi.(192,000km)

120,000mi.(192,000km)

120,000mi.(192,000km)

Eaton/DanaAxleLubrication

•Theoriginalmineral-based

lubricantmustbedrainedwithin

3000-5000miles(4800-8000

km)onallEatonaxles.This

initialchangeisveryimportant

becauseitushesoutbreak-in

contaminantsthatmightotherwise

causeprematurewear .

•Mineral-basedlubesmustbe

•Changethelubricantwithinthe

•Noinitialdrainisrequiredon

Eatonaxlesthatarefactorylled

MileageInterval

withanEaton-approvedsynthetic

lubricant.

drainedwithintherst5000miles

(8000km)ifconvertingtoan

Eaton-approvedsyntheticlube.

rst5000miles(8000km)of

operationafteracarrierhead

replacement,regardlessofthe

lubricanttype.

5

(03/17)Y53-6077-1B15-53

Page 62

LUBRICANTSPECIFICATIONS

•RefertotheEatonField

MaintenanceManualfora

particularaxleforlubricant

specications.

TypeofLubricantOn-HighwayMi.(km)MaximumChange

Mineral-Based

Eaton-Approved

Synthetic

Eaton-Approved

Syntheticinaxlewith

extendeddraininterval

option

WheelBearingLubrication

Oil-lubricatedDrivenHubs

5

Usehypoidoil,A.P .I.-GL-5SAE

75W-90FEsyntheticgearlubricant

orequivalent.Aminimumof1quart

(921ml)ofoilisrequiredforproper

lubricationofeachdrivehub.Addoil

throughthellerholeinthehub;if

none,addoilthroughthedifferential

llerhole.(Note:Remembertoreplace

ventplugorthreadedllerplugwhen

•Seeyourdealerfor

Eaton-approvedlubricantbrands.

Interval

120,000(192,000)

240,000(384,000)

350,000(560,000)

Yearly

2Years

done.)Allowtimefortheoiltoseep

On/OffHighwaySevere

60,000(96,000)

120,000(192,000)

•Refertothechartbelowfor

lubricantchangeinterval.

ServiceMi.(km)

Oil-lubricatedNondrivenHubs

MaximumChange

Interval

Yearly

Yearly

throughthebearingswheninitially

llingahub.Maintainthedifferential

oillevelbyaddingoiluntilitssurfaceis

evenwiththebottomofthellerhole

(seeillustrationonpage5-45).

UseCD50synthetictransmissionuid

SAE50Worequivalent.Aminimumof

9oz.(270ml)oflubricantisrequired

forproperlubricationofanLMS™hub;

10-13oz.(295-400ml)isrequiredfor

anon-LMShub,dependingonwheel

design.Allowtimefortheuidtoseep

throughthebearingswheninitially

llingahub.Whenproperlylled,the

5-54Y53-6077-1B1(03/17)

Page 63

LUBRICANTSPECIFICATIONS

uidlevelwillliebetweentheuidlevel

lineand1/4”abovetheline.

NOTE

Remembertoreplaceventplug

whendone.

UniversalJointLubrication

RefertotheSpicerUniversalJoints

andDriveshaftsservicemanualand

lubricationspecications.

SteeringGearLubrication

FluidRell

Thefollowingrecommendationsare

forgeneralpurposesteeringsystems

(bothTRWandSheppard).

•Fornormaltemperatures,use

AutomaticTransmissionFluid

(ATF)TypeEorForDexron®III.

•Forcoldtemperaturesof-22ºF

(-30ºC)andaboveuseATFT ype

A.

•Forextremelycoldtemperatures

between-22ºF(-30ºC)and-40º

F(-40ºC)useATFTypeB.

5

(03/17)Y53-6077-1B15-55

Page 64

LUBRICANTSPECIFICATIONS

Inspection

NOTE

Beforeremovingreservoircover ,

wipeoutsideofcoversothatnodirt

canfallintothereservoir.

1.Checktheuidlevel;adduidif

required.

2.Checkuidforcontamination,

discoloration,orburntsmell;

correctsourceofsuchproblems

beforereplacinguidandlter.

CAUTION

Whenaddinguid,besuretouse

5

uidofthesametype.Whilemany

uidshavethesamedescriptionand

intendedpurpose,theyshouldnot

bemixedduetoincompatibleadditives.Mixingincompatibleuids

mayleadtoequipmentdamage.

Ifincompatible(insoluble)uidsare

mixedinapowersteeringsystem,

airbubblescanbeproducedatthe

interfaceofthetwouids.Thiscan

causecavitation,whichreducesthe

lubricationbetweenmovingpartsin

thegear.Thiscouldresultinworn

components.

Themixtureoftwodifferentuids,

althoughharmlesstoindividual

internalcomponents,mayinitiatea

chemicalreactionthatproducesanew

compoundthatwillattacksealsand

otherinternalcomponents.

Donotmixdifferentuids.

5-56Y53-6077-1B1(03/17)

Page 65

AIRSYSTEM

AIRSYSTEM

Introduction

WARNING!

Donotattempttomodify ,alter,repair

ordisconnectanycomponentofthe

airsystem.Repairsormodications

totheairsystem,otherthanwhat

isdescribedinthissection,should

onlybeperformedbyanauthorized

dealer.Failuretocomplymayresult

indeathorpersonalinjury .

WARNING!

Priortotheremovalofanyairsystemcomponent,alwaysblockand

holdthevehiclebyasecuremeans

otherthanthevehicle'sownbrakes.

Depletingairsystempressuremay

causethevehicletorollunexpectedlyresultinginanaccidentcausing

deathorpersonalinjuries.Keep

handsawayfromchamberpush

rodsandslackadjusters,theymay

applyassystempressuredrops.

WARNING!

Aftercompletinganyrepairstothe

airsystem,alwaystestforairleaks,

andcheckthebrakesforsafeoperationbeforeputtingthevehicleinservice.Failuretocomplymayresultin

death,personalinjury,equipmentor

propertydamage.

WARNING!

Neverconnectordisconnectahose

orlinecontainingairpressure.It

maywhipasairescapes.Neverremoveacomponentorpipeplugunlessyouarecertainallsystempressurehasbeendepleted.Failureto

complymayresultindeath,personal

injury,equipmentorpropertydamage.

WARNING!

Neverexceedrecommendedair

pressureandalwayswearsafety

glasseswhenworkingwithairpressure.Neverlookintoairjetsordirect

thematanyone.Failuretocomply

mayresultindeath,personalinjury ,

equipmentorpropertydamage.

5

(03/17)Y53-6077-1B15-57

Page 66

AIRSYSTEM

WARNING!

Neverattempttodisassemblea

componentuntilyouhavereadand

understoodrecommendedprocedures.Somecomponentscontain

powerfulspringsandinjurycanresultifnotproperlydisassembled.

Useonlypropertoolsandobserve

allprecautionspertainingtouse

ofthosetools.Failuretocomply

mayresultindeath,personalinjury ,

equipmentorpropertydamage.

5

WARNING!

CompletelybypassingaBendix®

AD-ISairdryerwillbypassthesystem’spressureprotectionvalves.

Thiscouldleadtolossofairpressureordamagetothevehicle’s

airsystem,whichcouldcausean

accidentinvolvingdeathorpersonalinjury .Alwaysadheretothe

manufacturer’sprocedureifitis

necessaryinanemergencytotemporarilybypassanAD-IS-seriesair

dryer.Failuretocomplymayresult

indeath,personalinjury ,equipment

orpropertydamage.

Theoperationofthevehicle’sbraking

systemandmanyvehicleaccessories

dependsuponthestorageand

applicationofahigh-pressureair

supply.

Yourvehicle’scompressortakes

outsideairandcompressesit,usually

to100-120psi(689-827kPa).The

compressedairthengoestothe

reservoirstobestoreduntilneeded.

Whenyouoperateyourairbrakes,the

storedcompressedairowsintothe

chamberswhereitisusedtoapply

yourtruckandtrailerbrakes.Thatis

why,whenyoupushdownonyour

brakepedal,youdon’tfeelthesame

amountofpressureonthepedalthat

youdowhenyouapplythebrakeson

yourcar.Allyouaredoingonyour

truckisopeninganairvalvetoallow

airtoowintothebrakechambers.

Contaminationoftheairsupplysystem

isthemajorcauseofproblemsin

air-operatedcomponentssuchas

brakevalves,andsuspensionheight

controlvalves.T okeepcontaminants

tothelowestpossiblelevel,follow

thesemaintenanceprocedures.

5-58Y53-6077-1B1(03/17)

Page 67

AIRSYSTEM

WARNING!

Ifthesupplyandservicetanksare

notdrainedattherecommended

frequency,watercouldenterthe

airlinesandvalves.Thiscould

causecorrosionorblockage,which

couldcompromisethebrakesystem

safetyandpotentiallycauseanaccidentinvolvingdeathorpersonal

injury.

Daily

•Drainmoisturefromthesupply

andserviceairtanks.

•Operateairdevicestocirculate

lubricantswithintheunit.

Periodically

•Cleanlterscreensaheadofthe

valvesbyremovingthescreens

andsoakingtheminsolvent.Blow

themdrywithpressurizedair

beforereinstallingthem.

5

(03/17)Y53-6077-1B15-59

Page 68

AIRSYSTEM

TwiceaYear

•Maintaintheaircompressorto

preventexcessiveoilby-pass.

Seeyourmaintenancemanualfor

details.

•Replacewornsealsinvalvesand

airmotorsastheyareneeded.

5

AirDryer

Thefunctionoftheairdryeristocollect

andremoveairsystemcontaminantsin

solid,liquidandvaporformbeforethey

enterthebrakesystem.Itprovides

clean,dryairtothecomponentsof

thebrakesystem,whichincreases

thelifeofthesystemandreduces

maintenancecosts.

NOTE

Becausenotwovehiclesoperate

underidenticalconditions,maintenanceandmaintenanceintervals

willvary .Experienceisavaluable

guideindeterminingthebestmaintenanceintervalforanyoneparticularoperation.

Every900operatinghoursor25,000

miles(40,200km)oreverythree(3)

monthscheckformoistureintheair

brakesystembyopeningairtanks,

draincocks,orvalvesandcheckingfor

presenceofwater.

NOTE

Asmallamountofoilinthesystem

maybenormalandshouldnot,initself,beconsideredareasontoreplacethedesiccantcartridge.Oil

staineddesiccantcanfunctionadequately.

Atablespoonofwaterfoundinthe

airtankwouldpointtotheneedfora

desiccantcartridgechange.However,

thefollowingconditionscanalso

causewateraccumulationandshould

beconsideredbeforereplacingthe

desiccantcartridge.

•Airusageisexceptionallyhigh

andnotnormalforahighway

vehicle.Thismaybedueto

accessoryairdemandsorsome

unusualairrequirementthat

doesnotallowthecompressor

toloadandunload(compressing

5-60Y53-6077-1B1(03/17)

Page 69

AIRSYSTEM

andnon-compressingcycle)ina

normalfashionoritmaybedueto

excessiveleaksintheairsystem.

•Inareaswheremorethana30°

F(17°C)rangeoftemperature

occursinoneday,smallamounts

ofwatercanaccumulatein

theairbrakesystemdueto

condensation.Underthese

conditions,thepresenceofsmall

amountsofmoistureisnormal

andshouldnotbeconsideredas

anindicationthatthedryerisnot

performingproperly .

•Anoutsideairsourcehasbeen

usedtochargetheairsystem.

Thisairdidnotpassthroughthe

dryingbed.

Overhaul

Maintenanceintervalstypicalfor

on-highwayoperationwouldbe2-3

years,350,000milesor10,800hours.

Maintenanceintervalstypicalforhigh

dutycycleusagesuchastransitbus,

refusehauler,dumptruck,cement

mixersandoff-highwayoperation

wouldbe1year,100,000milesor

3,600hours.

NOTE

Reviewthewarrantypolicybefore

performinganymaintenanceprocedures.Anextendedwarrantymay

bevoidedifunauthorizedmaintenanceisperformedduringthisperiod.

Bendix®AD-ISSeriesAirDryer

Yourvehiclemaybeequippedwitha

Bendix®AD-ISseriesairdryer.Any

airdryerreplacementshouldbemade

withanidenticalcomponent.

WARNING!

Ifadifferentairdryerbrandormodel

isinstalledonthevehicleotherthan

whatwasoriginallyinstalled,itcould

causetheairsystemtonotperform

correctlyunlessthefullairsystem

designisreviewedandmodicationsmadetocomplywithFederal

MotorVehicleSafetyStandards

(FMVSS)121-AirBrakeSystems.

Failuretoabidebythiswarningand

maintaincompliancetoFMVSS121

couldcauselossofvehiclecontrol

andmayleadtodeathorserious

personalinjury .

TheAD-ISSeriesairdryerhas

incorporatedintoitsdesignvarious

5

(03/17)Y53-6077-1B15-61

Page 70

AIRSYSTEM

componentsthathavetypicallybeen

installedseparatelyonthevehicle(see

belowforcomponents/areasaffected):

•Pressureprotectionvalves

•Safetyvalve

•Governorandplumbing

•Plumbingofthefrontandrear

serviceairtanks

•Plumbingtoaccessorysystems

Thesecomponentsarerequiredto

meettheFederalMotorVehicleSafety

Standards(FMVSS121-AirBrake

Systems).AstheWarningabove

5

states,anyothertypeofairdryer

installedintheplaceofanAD-ISSeries

willrequirechanges,modications

and/oradditionstoyourvehicle’sair

systemtomaintaincompliancewith

FMVSS121.

AirTanks

Toejectmoisturefromtheairsystem

tanks,pullthelinethatisconnectedto

themoistureejectionvalve.Continue

pullinguntiltheaircomesoutfreeof

water.

Daily:Thesupplyandserviceair

tanks,mustbedrainedonadaily

basis.Operateairdevicesdailyto

circulatelubricantswithintheunit.

Periodically:Cleanlterscreens

aheadofthevalvesbyremovingthe

screensandsoakingtheminsolvent.

Blowthemdrywithpressurizedair

beforereinstallingthem.

WARNING!

Ifthesupplyandserviceairtanks

arenotdrainedattherecommended

frequency,watercouldenterthe

airlinesandvalves.Thiscould

causecorrosionorblockage,which

couldcompromisethebrakesystem

safetyandpotentiallycauseanaccident.Failuretocomplymayresult

indeath,personalinjury ,equipment

orpropertydamage.

5-62Y53-6077-1B1(03/17)

Page 71

AIRSYSTEM

CAUTION

Donotusepenetratingoil,brake

uid,orwax-basedoilsintheairsystem.Theseuidsmaycausesevere

damagetoairsystemcomponents.

•Maintaintheaircompressorto

preventexcessiveoilbypass.

•Replacewornsealsinvalvesand

airmotorsastheyareneeded.

Yourauthorizeddealercarries

rebuildkitsformostunits.

AirGaugesandAirLeaks

Yourvehiclecomeswithairpressure

gaugesfortwoseparatesystems,

PrimaryandSecondary:thePrimary

gaugeindicatespressureintherear

brakingsystem;theSecondarygauge

indicatespressureinthefrontbraking

system.Eachgaugeindicatesthe

amountofairpressureinpoundsper

squareinch(psi).

WARNING!

Donotoperatethevehicleifleakageintheairsystemisdetected.

Conductthefollowingprocedure

andcontactanauthorizeddealer(or

anyotherproperlyequippedservice

center)ifaleakisdetected.Failure

tocheckthebrakesorfollowthese

procedurescouldcauseasystem

failure,increasingtheriskofan

accidentandmayresultindeath,

personalinjury,equipmentorpropertydamage.

Ifthelightandalarmdonotturnoffat

start-up,donottrytodrivethevehicle

untiltheproblemisfoundandxed.If

thepressureineitherorbothsystems

istoolowfornormalbrakeoperation,

i.e.,thepointerofonegaugefalls

below65psi(448kPa),awarninglight

onthegaugewillglowandtheaudible

alarmwillsound.

NOTE

Parkbrakeslockupat60psi(414

kPa),theaudiblealarmwillsoundat

65psi(448kPa).

5

PrimaryAirPressureGauge

(03/17)Y53-6077-1B15-63

Page 72

AIRSYSTEM

SecondaryAirPressureGauge

Followtheprocedurebelowto

checkthecompressedairsystem

forleaks:

1.Periodically,oraftermaintenance

orreplacementofairsystem

components:

2.Buildupairpressureinthesystem

tothegovernorcutoutpointoruntil

5

120psi(827kPa)isreached.

3.Stoptheengineandreleasethe

servicebrakes.

4.Withoutapplyingthebrakepedal,

observetherateofairpressure

drop.Thisrateshouldnotexceed

2.0psi(14kPa)perminute.

5.Starttheengineandbuildupthe

airpressureagain.

6.Stoptheengine,andapplythe

brakesfully.Applythebrakepedal

andholditdownforveminutes.

Thepressuredropshouldnot

exceed3.0psi(21kPa)per

minute.

7.Ifyoudetectexcessiveleakage

(airpressurelossgreaterthan3.0

psi(21kPa)afterveminutesof

brakeapplication),aleakagetest

shouldbemadeattheairline

connectionsandatallairbrake

controlunits.Thesetestsshould

determinewhereairisescaping.

AirCompressor

Operation

Allcompressors,regardlessofmake

ormodel,runcontinuouslywhilethe

engineisrunning.Systempressure

iscontrolledbythegovernor.The

governoractsinconjunctionwith

theunloadingmechanisminthe

compressorcylinderblocktostart

andstopcompressionofair.The

compressorisunloadedwhenthe

systempressurereaches120psi(827

kPa)andcompressionisreestablished

whensystempressurefallsto100psi

(690kPa).

5-64Y53-6077-1B1(03/17)

Page 73

AIRSYSTEM

PreventiveMaintenance

Thefollowingservicechecksare

providedforyourinformationonlyand

shouldbeperformedbyacertied

mechanic.Contactyourdealerorthe

enginemanufacturer'sMaintenance

Manualforfurtherinformationon

servicingaircompressors.

Aftercompletinganyrepairstotheair

system,alwaystestforairleaks,and

checkthebrakesforsafeoperation

beforeputtingthevehicleinservice.

Belowisalistofareastomaintainfor

theaircompressor:

•Inspectcompressorairlter

element,ifsoequipped,and

replaceelementifclogged.Check

compressormountinganddrive

foralignmentandbelttension.

Adjustifnecessary .

•Removecompressordischarge

valvecapnutsandcheckfor

presenceofexcessivecarbon.If

excessivecarbonisfound,clean

orreplacethecompressorcylinder

head.Also,checkcompressor

dischargelineforcarbon,and

cleanorreplacethedischargeline

ifnecessary .

•Disassemblecompressorand

thoroughlycleanandinspect

allparts.Repairorreplace

allwornordamagedparts,or

replacecompressorwithafactory

exchangeunit.

CAUTION

Whendrainingtheenginecooling

systemisrequired,topreventdamagefromfreezing,thecompressor

mustalsobedrainedatthecylinder

headandblock.Enginedamage

couldoccurifthecoolingsystemis

notperiodicallydrainedandmaintained.SeeCoolingSystemonpage

5-82forfurtherinformation.

5

(03/17)Y53-6077-1B15-65

Page 74

BRAKESYSTEM

BRAKESYSTEM

BrakeAdjustment

WARNING!

Donotworkonthebrakesystem

withouttheparkingbrakesetand

wheelschockedsecurely .Ifthe

vehicleisnotsecuredtoprevent

uncontrolledvehiclemovement,it

couldrollandcausedeath,serious

personalinjuryordamagetothe

vehicle.

Tooperateyourvehiclesafely

andprotably ,youneedsome

5

understandingofitsbrakesystems.

Formoreonbrakes,seetheIndex,

underBrakes.

Brakeadjustmentandbrakebalance

mustbesetcarefullyto(1)make

themostefcientuseoftheforces

availableforbrakingand(2)allow

equalstoppingforcesatallwheels.

CAUTION

Theairbrakesystemofthisvehicle

wasconguredforONEofthefollowingoperations:tractorortruck,

andcomplieswiththerespective

portionsofFMVSS121.Atractor

shallnotbeoperatedorcongured

asatruck,norshallatruckbeoperatedorconguredasatractor,

withoutsignicantmodicationsto

theairbrakesysteminordertoretaincompliancewithFMVSS121.

Contactyourdealerforinstructions.

Onceabrakesystemissetto

specications,changinganyoneof

itscomponentsoranycombinationof

componentsmaycausethesystem

tonotworkaswell.Allpartshave

toworktogethertoperformasthey

should.Anyreplacementcomponents

inyourbrakesystemshouldbeexactly

equaltotheoriginalcomponents.

Anychangesfromtheoriginal

specicationscanaffectthewhole

system.Allofthefollowingareas

areinterrelatedandmustconformto

originalspecications:

•TireSize

•Drumbrakes

a.CamRadius

b.WedgeAngle

c.DrumRadius

d.BrakeLinings

e.BrakeChambers

f.SlackAdjusters

•DiscBrakes

a.DiscRotors

5-66Y53-6077-1B1(03/17)

Page 75

BRAKESYSTEM

WARNING!

Donotuseanyreplacementpartin

thebrakesystemunlessitconforms

exactlytooriginalspecications.A

nonconformingpartinyourvehicle'sbrakesystemcouldcausea

malfunctionresultinginanaccident

causingdeathorpersonalinjury .

Sizesandtypesaresorelatedto

oneanotherthataseeminglyunimportantchangeinonemayresult

inachangeinhowwellthebrakes

workforyouontheroad.Ifparts

donotworktogetherproperly,you

couldlosecontrolofyourvehicle,

whichcouldcauseaseriousaccident.

Allvehicleoperatorsshouldcheck

theirbrakesregularly .

WARNING!

Donotusebrakeliningswithathicknessbelowthespeciedminimum.

Suchliningswillhaveliningrivets

exposedthatcandamagethebrake

drumandreducebrakeefciency,

whichcouldcausedeath,personal

injuryorsystemfailure.

AirDiscBrakes

Havebrakepadsinspectedbya

qualiedmechanicforwearatregular

intervalsaccordingtothePreventive

MaintenanceScheduleonpage5-12.

Insevereserviceoroff-highway

applicationsinspecttheliningsmore

frequently.

Regularlyinspectforpad/rotorwear:

•Parkonlevelgroundandchock

thewheels.

•T emporarilyreleasetheparking

brakes.

•Comparetherelativeposition

oftwonotches;onelocatedon

thecaliperandtheotheronthe

carrier.Seetheillustrationbelow

todetermineifthebrakesrequire

adetailedinspectionbyaqualied

mechanic.

5

(03/17)Y53-6077-1B15-67

Page 76

BRAKESYSTEM

5

•Haveaqualiedmechanic

performadetailedinspection

ifthenotchesarenotfound.

Thepadsandrotorsshould

bemeasuredandcompared

againstthemanufacturer's

specicationslocatedinthebrake

manufacturer’sservicemanual.

CaliperDetail

1.BrakeCaliperAssembly

2.LocationofInspection

Grooves

3.NotchesLine-Up(Timeto

scheduleinspectionofPads

andRotors)

4.BrakeRotor

5.BrakeCarrierAssembly

RegularlyinspectcaliperforRunning

Clearance:

•Stopthevehicleonlevelground

andletthebrakescooldown.Hot

brakecaliperscanburnskinon

contact.

•Chockthewheels.

•T emporarilyreleasetheparking

brakes.

•Grabthecaliperandmoveit.This

movementisRunningClearance.

•ProperRunningClearanceis

0.08inch(2mm)ofmovementof

thebrakecaliper(approximately

thethicknessofanickel)inthe

inboard/outboarddirection.

•Haveaqualiedmechanicprovide

furtherinspectionifthecaliper

doesnotmoveorappearstomove

morethanthespeciedclearance.

5-68Y53-6077-1B1(03/17)

Page 77

BRAKESYSTEM

DrumBrakes

Havebrakedrumliningsanddisc

brakepadsinspectedbyaqualied

mechanicforwearatregularintervals

accordingtothemaintenance

schedule.Insevereserviceor

off-highwayapplicationsinspectthe

liningsmorefrequently .

AutomaticSlackAdjusters

PeriodicallychecktheBrakeChamber

Stroke.Replacetheslackadjusterif

properstrokecannotbemaintained.

Operationalchecksofautomatic

slackadjusters

•Measurebrakechamberstroke

withthespringbrakereleasedand

theairpressurenolessthan100

psi(690kPa).

•BrakeChamberStrokeisthe

differencebetweentheapplied

andtheretractedpositionofthe

airchamberpushrod.

•Acorrectlyinstalledand

functioningautoslackadjusterwill

producethefollowingstrokes:

ChamberT ypeStroke

36(rearbrakes)1-1/2"-2-1/4"

30(rearbrakes)1-1/2"-2"

16,20and24(front

brakes)

(38-57mm)

(38-51mm)

1"-1-3/4"

(25.4-44.4mm)

BrakeChamberStroke

5

(03/17)Y53-6077-1B15-69

Page 78

BRAKESYSTEM

WARNING!

Manualadjustmentofautomatic

slackadjustersisadangerouspracticethatcouldhaveseriousconsequences.Itgivestheoperator

afalsesenseofsecurityaboutthe

effectivenessofthebrakes.ContacttheServiceDepartmentatyour

dealershipifthestrokeexceedsthe

abovespecications.Astrokeexceedingthesevaluesmayindicate

aproblemwiththeslackadjusteror

thebrakefoundation.

5

5-70Y53-6077-1B1(03/17)

Page 79

CAB

CAB

ExteriorMaintenance

PaintedSurfaces

Washpaintedsurfacesfrequentlyto

removegrimeandcausticdeposits

whichmaystainthenish.See

Cleaning,Protecting,andWeather

Strippingonpage5-72.

ChromeandAluminumSurfaces

Topreventrust,keepchromedparts

cleanandprotectedwithwaxatall

times,especiallyinwinterconditions

wheretheroadsaresalted.

•Ifnecessary,useacommercial

chromecleanertoremovelight

rust.

•Chromesurfacesarebest

cleanedwithfreshwater.Wipe

drytopreservetheirluster.A

commercialchromecleanerwill

removelightrust.Aftercleaning,

waxatsurfacesandapplyathin

coatofrustpreventivelubricant

aroundboltsorotherfasteners.

•Cleanaluminumwheelsand

bumperswithwarmwater.Tar

removerwillgetridofheavy

depositsofroadgrime.T oprevent

spotting,wipealuminumsurfaces

dryafterwashing.

•Undercorrosiveconditions,such

asdrivingonsaltedroads,clean

aluminumpartswithsteamorhigh

pressurewaterfromahose.A

mildsoapsolutionwillhelp.Rinse

thoroughly.

5

(03/17)Y53-6077-1B15-71

Page 80

CAB

TailPipeSurfaceCleaning

Alwaysallowhotsurfacestocool

downbeforeattemptingtoworknear

them.Failuretocomplymayresult

indeathorpersonalinjury .

Tomaintainyourqualitynish,wash

withasoftcloth,mildsoapandwater

orglasscleaner.Anon-abrasive

chromepolishcanbeusedsparingly

onhardtocleanareas.DoNotclean

yourhighheatchromeusingscouring

pads,abrasivechromepolish,highly

acidicchemicalcleanersoranyother

5

abrasivecleaners.

StainlessSteel

WARNING!

Evenhighqualitystainlesssteelparts