Page 1

Installation Manual

Model 377, 379, 386, 388, 389

70 inch Sleeper

2390 Blackhawk Road ● P.O. Box 6007 ● Rockford, IL 61125 ● www.nitesystem.com ● 1-866-204-8570

Page 2

1-2

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

Table of Contents

Introduction

Before You Start

Parts List

Tools Required

Installation Procedures

Electrical Installation

Espar Heater Install

1-3

1-4

1-5

1-8

1-9

2-1

3-1

4-1

5-1

6-1

Wiring Diagrams

Operating Instructions

Battery Management

Webasto Heater Install

Page 3

1-3

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

Congratulations. You have chosen the

premier no-idle climate control system

on the market today—the NITE®

Phoenix from Bergstrom.

The NITE Phoenix is a powerful 12V

rechargeable DC system that keeps sleeper

compartments cool in hot weather and

warm in cold weather (with optional

heater) without having to idle the truck’s

engine—and without a genset. It not only

dramatically reduces fuel burned, it’s also

very environmentally friendly.

Your NITE Phoenix is a self-contained,

hermetically sealed, compact A/C system

that produces approximately 7,500

BTU/h and has been quality engineered

for years of reliable service. The system

operates independently from your truck’s

engine using its own deep cycle batteries

that are completely separated from the

truck’s starting batteries.

The deep cycle batteries used are the

most advanced ever—and will efficiently

power the system for 7 to 9 hours. The

batteries are then fully recharged after

just 4 to 6 hours of driving.

Add it all up, and you have a

revolutionary no-idle system that will

save you money and fuel year after

year—the NITE Phoenix from

Bergstrom.

Introduction

NOTE:

The NITE Phoenix A/C system is

designed to maintain a comfortable

temperature inside the sleeper without

running the engine.

For optimal comfort, the curtain between

the cab and the sleeper must be closed

when using the unit. To enhance cooling

efficiency during the day, solar reflectors

or curtains should be placed over

windshield and all windows to block

sunlight from entering the cab and

sleeper.

The NITE Phoenix A/C unit will not pull

down a hot sleeper that has been sitting

in the sun without the factory A/C

running. To assist the NITE Phoenix

unit in cooling down the sleeper, start the

engine and run the factory A/C until

desired temperature is reached. The

NITE Phoenix unit will then maintain a

comfortable temperature depending on

solar load & ambient temperature.

Page 4

1-4

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

Before You Start

A typical installation of the NITE Phoenix generally

takes between 8 to 10 hours, although your particular

situation may vary. This manual contains step-by- step

installation instructions. It is divided into three

categories:

● General installation

● Electrical installation

● Heater installation (optional)

There is also a section on how to check your NITE

Phoenix to make sure the installation was successful,

and a section on how to operate your NITE Phoenix.

If relocation or reinstallation of any pre-installed

equipment is necessary for installation of the NITE Phoenix

equipment - please refer to the components manufacturer's

instructions or safety guidelines for proper installation.

Before you start, we highly recommend doing the

following to help make your installation as easy as

possible.

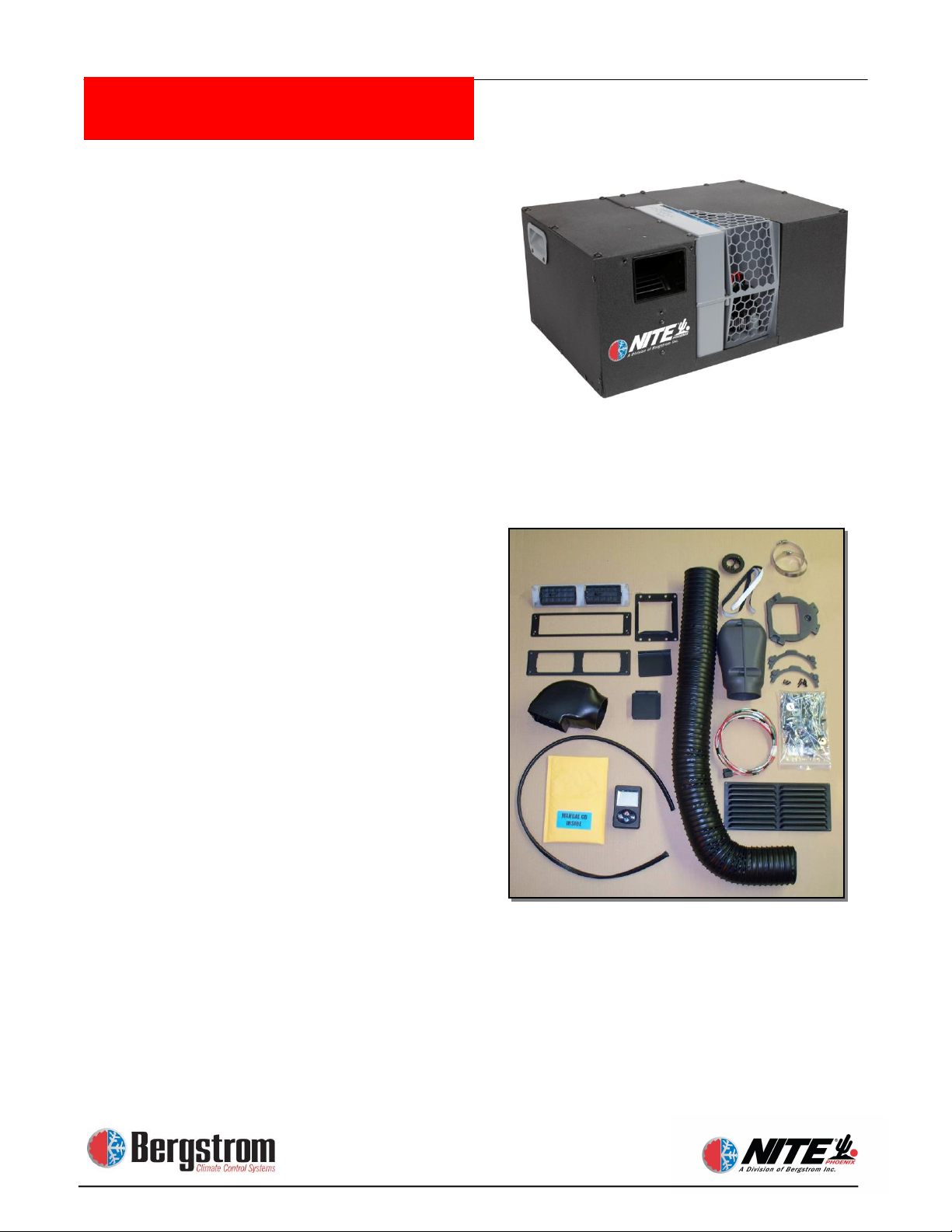

1. Lay out all parts and check to make sure you have

all parts listed on the parts list.

Depending on truck, some hardware may not

be used. If you are missing any parts, please call

1-866-204-8570.

2. To prevent damage to compressor, keep the NITE

Phoenix unit in an upright position at all times. If

unit is tipped, place back in upright position for a

minimum of 6 hours prior to running.

3. Check the list of tools needed for installation and

make sure you have all of them. Keep all tools

within easy reach.

4. Look through the whole installation manual to get

an understanding of the order in which

components are installed.

5. Make sure you have good lighting and enough

space to work in.

6. You may want to get an assistant to help you to

reduce the number of times you have to climb in

and out of the cab.

7. Make sure you wear all appropriate safety

equipment.

Photo above is representative of kit

1000236701 only.

Page 5

1-5

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

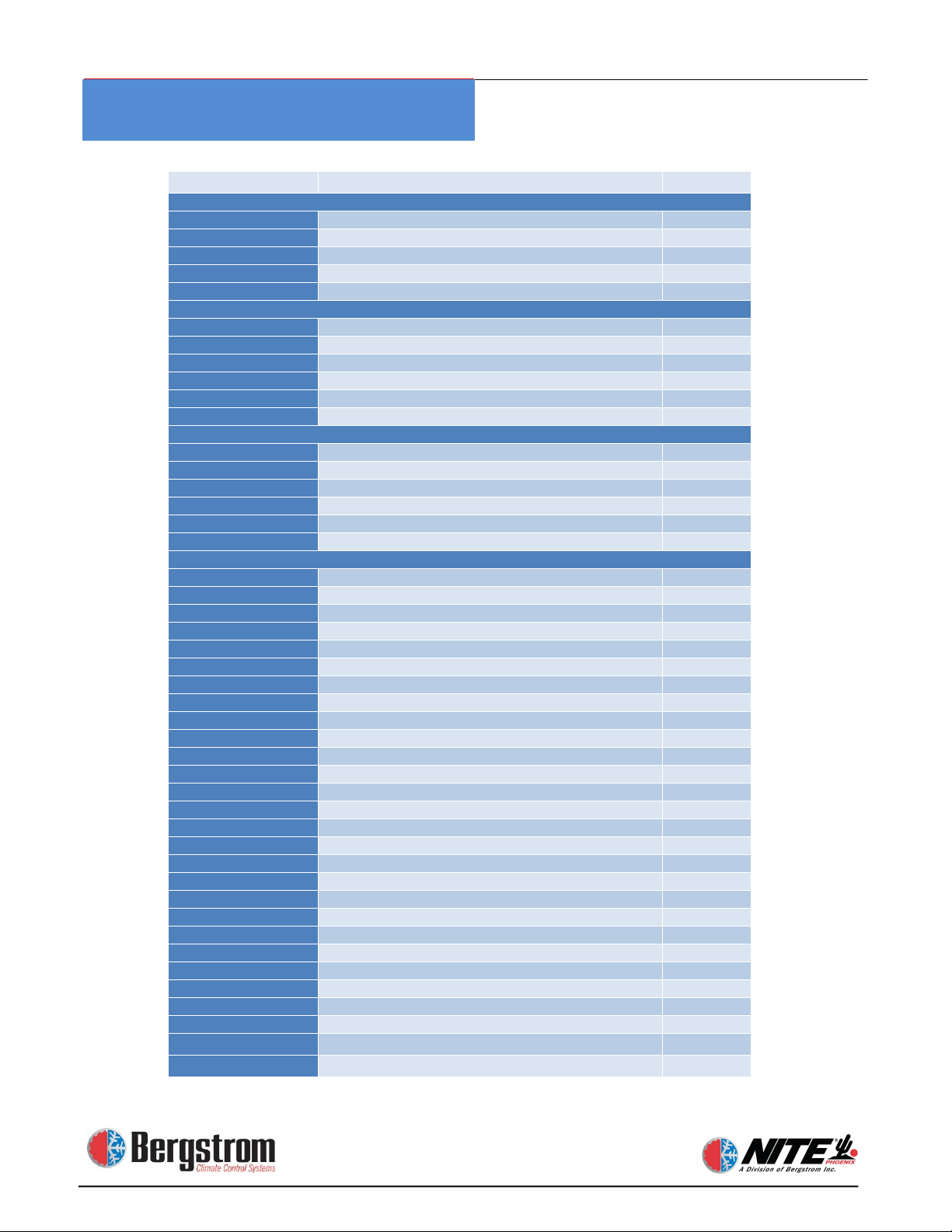

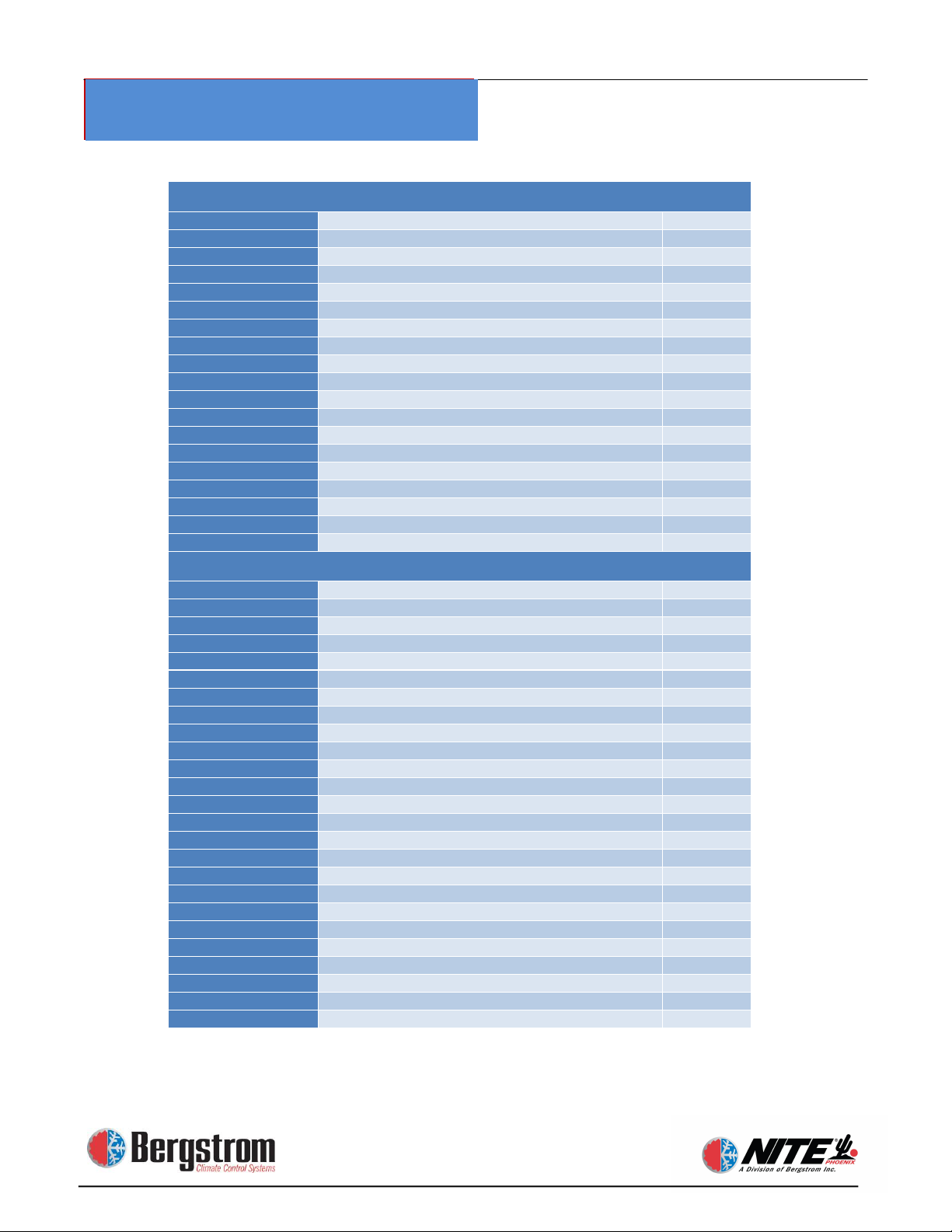

Bergstrom Part #

Part Description

Quantity

1000230789 NITE PHOENIX AC ONLY

1000386342

NITE UNIT

1

1000342516

PHOENIX POWER KIT*

1

1000007552

NITE WARRANTY POLICY

1

1000251583

OPERATION CARD

1

585511

NITE WARRANTY CARD/SURVEY

1

1000230787 NITE PHOENIX AC/HEAT - ESPAR

1000386342

NITE UNIT

1

1000038693

ESPAR HEATER KIT

1

1000342516

PHOENIX POWER KIT*

1

1000007552

NITE WARRANTY POLICY

1

1000251583

OPERATION CARD

1

585511

NITE WARRANTY CARD/SURVEY

1

1000342523 NITE PHOENIX AC/HEAT-WEBASTO

1000386342

NITE UNIT

1

Not sold separately

WEBASTO HEATER KIT

1

1000342516

PHOENIX POWER KIT*

1

1000007552

NITE WARRANTY POLICY

1

1000251583

OPERATION CARD

1

585511

NITE WARRANTY CARD/SURVEY

1

1000236701 INSTALLATION KIT

B290303

CLAMP, HOSE 4.12 I.D.

2

B360692

GROMET-NO6 AND NO10 HOSE ADPTR

1

454651

ANGLE – DUCT COLLAR

1

454691

PLATE, DUCT BLOCK P387

1

454799

PLATE TEMPLATE MOUNT P379

1

454802

ANGLE, LOUVER PANEL P379

1

455322

ANGLE BLOCKAGE PLATE

1

500198

GRILLE, AIR RETURN

1

560235

HOSE, DEFROST 4 X 45”

1

870224

SUB ASSY LOUVER MOUNT

1

1000007618

DUCT, TRANSITION

1

1000081269

TIE, CHRISTMAS TREE WIRE

4

1000168631

COLLAR, DUCT

2

1000183274

BRACKET, UNIT MNT

4

1000185196

COLLAR, SIDE

1

1000186017

DUCT, ASSY

1

1000218364

DUCT, INTAKE

1

1000224619

GASKET, STRIP

2

1000230502

WIRE HARNESS, PHOENIX CONTROL

1

100230622

BRACKET, INTAKE SIDE

1

1000230630

BRACKET, INTAKE SIDE

1

1000230729

WIRE HARNESS, PHOENIX CONTROL XTN

1

1000251573

CD ROM, PHOENIX INSTALL MANUALS

1

1000256319

TEMPLATE, PHOENIX CONTROLS

1

1000415466

TEMPLATE, RECIRC GRILLE

1

1000439603

KIT, DOOR GRAVITY NGP

1

1000513102

TEMPLATE, PHOENIX FLOOR

1

1000564554

DUCT, 4 INCH ELBOW

1

Page 6

1-6

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

1000230794 KIT, NITE PHOENIX STD HARDWARE

B203305

NUT, 1/4-20 W/EXT. LOCK WASHER

14

509700

WASHER, .25IN FLAT FS 4B4276

18

600047

SCREW, M6 X 20 MM HEX HD 8T4138

20

600059

SCREW, M6X16MMTORXHD .9X2044

10

600129

SCREW, NO 10 TH 8-15 X .437

5

600159

SCREW, NO 12-16 X 1 INCH HI-LO

20

600187

PLASTITE NO8-16 C.75 IN TORX

10

600282

BOLTCARRIAGE .25-20 X 3 IN

10

600283

SCREW, SELF DRILL

52

605007

WASHER, .25 IN HARD FLAT 6V7646

20

620001

POP RIVET, .125 IN 0 9N1995

6

620002

POP RIVET, .812 IN DIA FS

2

620011

POP RIVET, .812 IN DIA FS

6

621820

SCREW, TRUSS HD NO 10 SLF TP FS

24

1000173097

SCREW, 1/4-20 X 1'' HX HS SS

4

1000214538

SCREW, #10 1/2 SELF TAPPING

12

911-C059

SCREW,10-32 X ¾ RND HD SLOT

8

912-C006

WASHER, FLAT #10 SS

4

912-C007

WASHER, LOCK #10 SS

8

*1000342516 NITE PHOENIX POWER KIT

B223109

FUSE HOLDER

1

B360113

TIE-PLASTIC

50

600283

SCREW, SELF DRILL

2

650119

TERM, INS MALE BLADE

3

651462

TUBING HEAT SHRINK

22

660706

ASSY,WIRE,BATT.CABLE 5300MMBL

2

660707

ASSY,WIRE,BATT.CABLE 5000MMRE

3

670136

TERMINAL RING 5/16 4 GA

2

670137

TERMINAL RING 3/8 4 GA

20

1000049325

ENCLOSURE, ELECTRICAL

1

1000173480

HARNESS, DAYCAB POWER 4 GA

1

1000174251

FUSE, MEGA 100A YELLOW

1

1000174286

FUSEHOLDER, MEGA BOLT-ON

1

1000230085

FUSE, 5A ATO

1

1000493450

WIRE HARNESS, PHOENIX CAN BUS

1

1000235371

WIRE LOOM .413 ID X 140 FT

1

1000247777

TERM, 3/8" RING 14-16GA SEALE

1

1000247778

TERM, 3/8" RING 18-22GA SEALE

1

1000247779

BUTT CONN, STEP 14-16 TO 18-2

1

1000282660

POWER RELAY, TERRA 300A

1

1000295771

WIRE HARNESS, NITE PHOENIX

1

1000299202

KIT, NITE PHOENIX CONTROLS

1

1000309203

KIT, CONN DEUTSCH DTM04-6P

1

1000309205

TERM, LUG 4AWG 90 DEG

2

1000376501

BATTERY MONITOR SYS, NITE

1

Page 7

1-7

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

Parts Breakdown

Cardboard Template Layout

Page 8

1-8

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

Tools Required

1) Drill Bit Set

2) Hole saws (1″, 1-5/8″, 2″, 2-1/2″ and 4-3/4″ )

3) Electric/Air Drill

4) Screwdrivers/Assorted Bits (Flat Head & Phillips Head)

5) Impact Gun

6) Air saw/Jigsaw (Cutting Sheet metal)

7) Torx Head (T20-T25) Bit Set

8) Metric Wrenches

9) SAE Wrenches

10) 1/4″, 3/8″ Drive Ratchets

11) SAE Socket Set

12) Metric Socket Set

13) Wire Cutters

14) Terminal Crimpers

15) Wire Strippers

16) Razor Knife

17) Electrical Tape

18) Cable Cutters

19) #4 Professional Grade Cable Crimpers

20) Cable Strippers

21) Work Light

22) Torque Wrench up to 50 in/lbs

23) U-barrel Crimper

24) Pop Rivet Gun

25) Deutsch Crimpers

Page 9

1-9

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

1 2 3

4

Remove 90° section of original OE

duct by removing 2 Philips head

screws.

Install duct elbow. Turn duct upside

down. Place elbow flanged bracket

against the flared end of the duct.

Fasten with 1″ X 5 /16 self-drilling

screws. Cut the section of duct out

following the inside of the flanged

bracket, now install the elbow so that

it will point towards the passenger’s

side of the truck. DO NOT INSTALL

BLOCK OFF PLATE.

Seal around elbow with silicone

sealant. NOTE: Silicone sealant is

not included in kit.

Reinstall the 90° section in the

truck.

Page 10

1-10

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

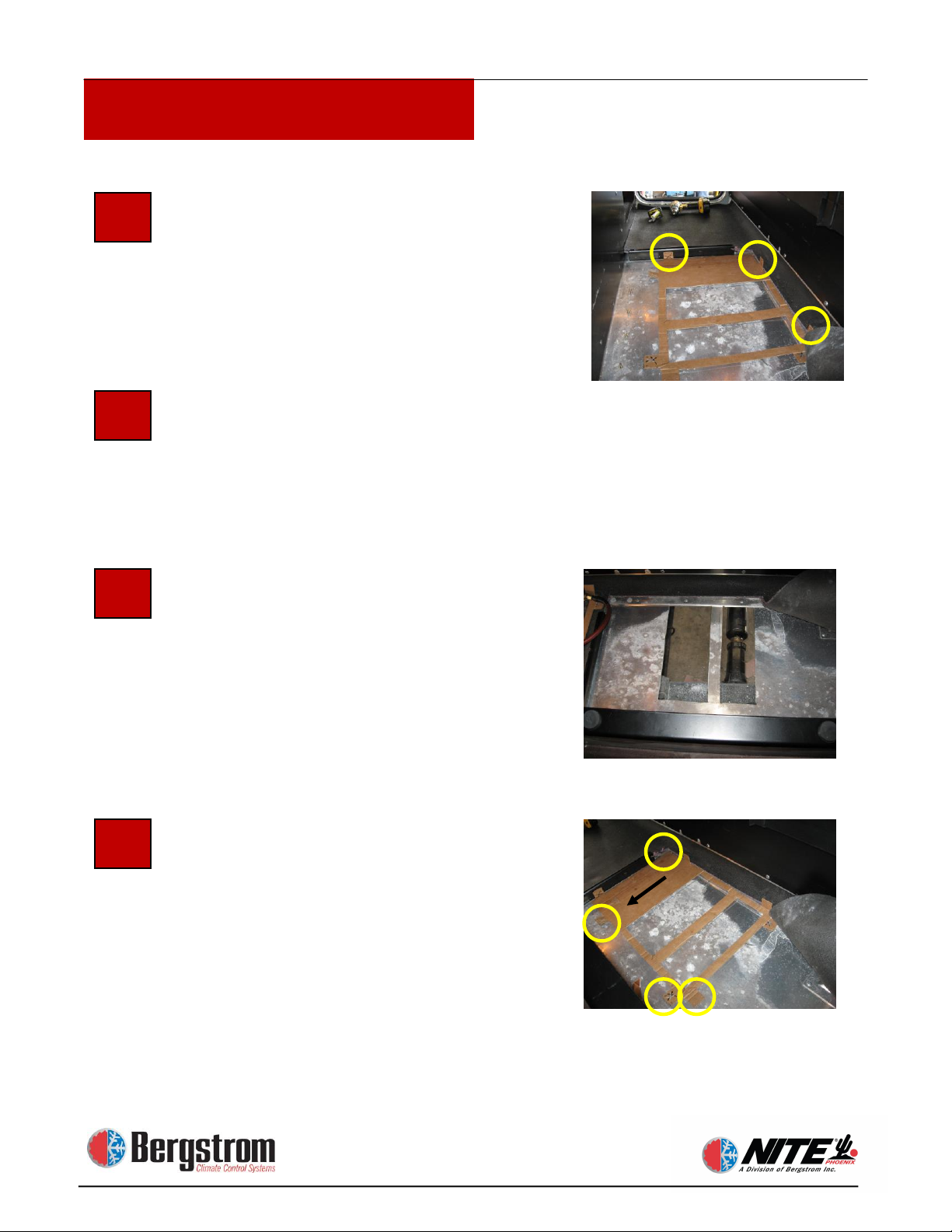

Position end of template against the

passenger side floor stiffener and

approximately 6″ from the front bunk

support wall. Cut and remove floor mat from

this area. With floor mat removed reposition

template against passenger side floor

stiffener

Bend the end tab on the end closest to the

flow arrow so the end of the unit is against

the stiffener. Leave the rear tab out. You

will use this one for mounting. Remember to

allow approximately 6″ in front of the

template for the elbow.

Mark and Cut Holes in Truck Floor

Mark the two rectangular openings in the

template. Drill starter holes in all four

corners of the two areas marked for cutting.

Note location of cross members prior to

drilling holes. Use air saw/jigsaw to cut

through truck floor.

Mark and drill pilot holes for 4 mounting

feet. The unit has 8 possible locations but

you will only use 4. Use locations as

indicated in the photo.

5 6 7

8

Page 11

1-11

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

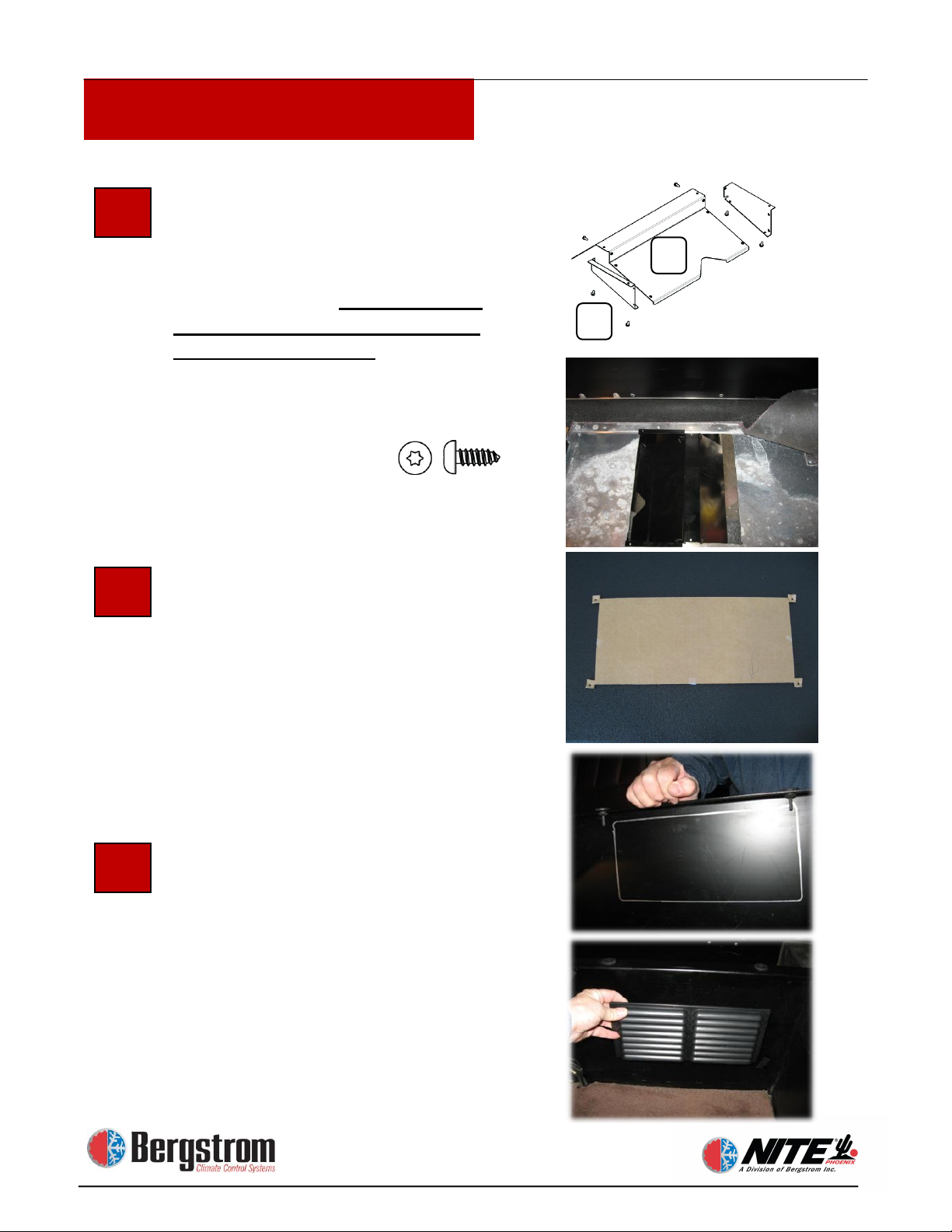

9

10

TEMPLATE

11

Pre-assemble the air intake using

#10 X 1/2″ T20 screws (see below).

Place assembled unit in the condenser

hole. Fasten with 1″ screw with 5/16

head self-drilling. Modification of

this assembly may be required to

allow proper air flow. In this

application piece (B) may need to be

trimmed to allow proper air flow.

Determine Location for

Recirculation Grill Install the grill in

the center support wall (see photo

showing outline for cutout marked on

center support wall)The opening

should be positioned in front of where

the NITE Phoenix unit will be

positioned. The size should be 11-1/2″

x 4-5/8″. Use provided template for

marking.

Cut Opening for

Recirculation Grill

Cut an opening (A) with a metalcutting air saw or jigsaw for the

recirculation grill in the support wall.

Attach grill (B) to the center wall

using black Phillips head screws.

NOTE: Take precautions not to damage carpet

or upholstery.

B

A

Page 12

1-12

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

13

12

14

Attach seal strip to duct bracket

and elbow.

Prepare to Install Unit

Install the duct elbow mounting bracket

to the Phoenix unit using #10 X 1/2″

T20 elbow bracket screws

Now install one half of the elbow

support ring using elbow flange screws

#8 X 3/4″ T20. Do not completely

tighten screws at this time.

Page 13

1-13

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

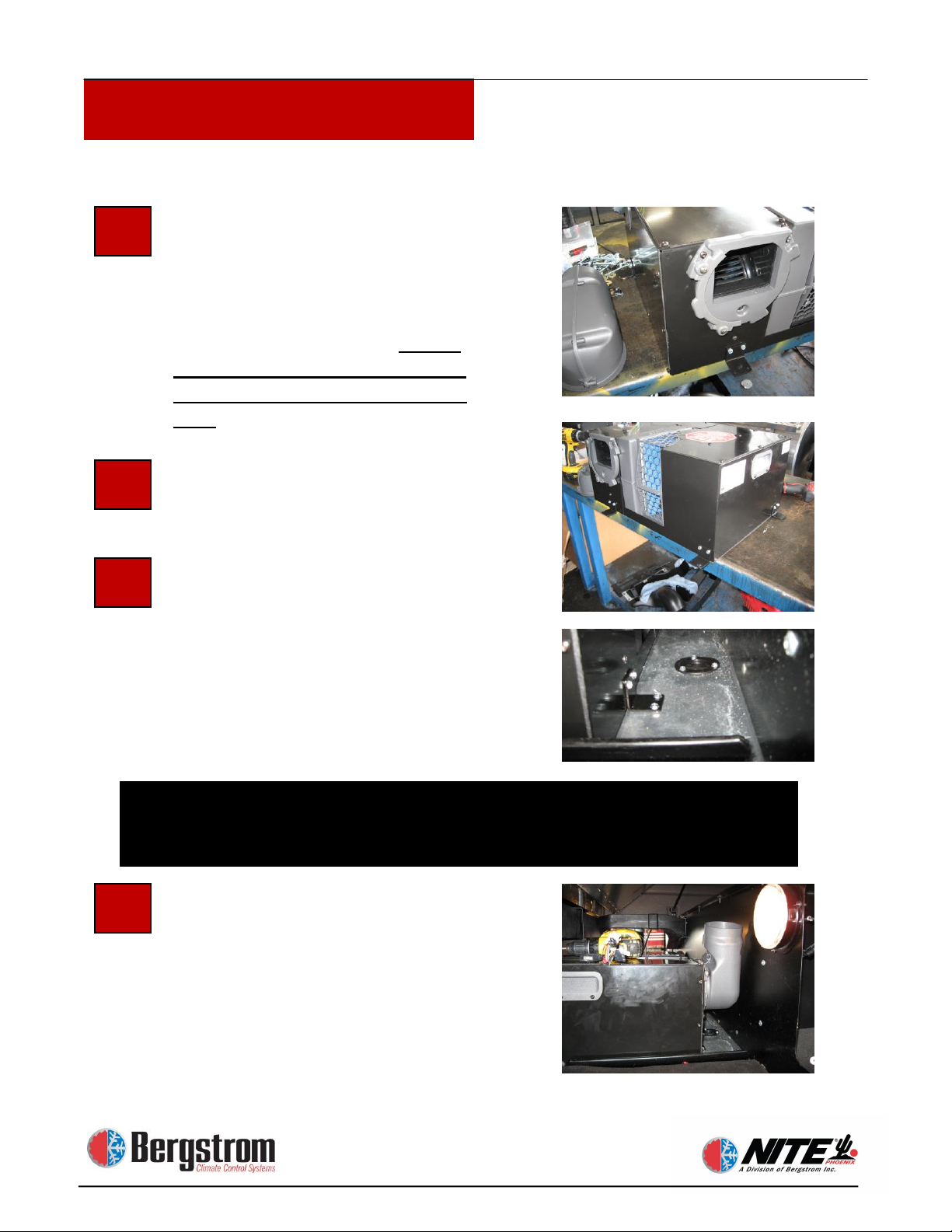

15

16

17

Install mounting feet

The Phoenix unit has 8 pre-dimpled

locations. Fasten feet in the 4 locations

matching the predrilled holes from

page 1-12 step 7. Use 1″ X 5/16 hex

head self-drilling screws. Do not

install feet where the case is not

dimpled or you will damage the

unit.

Attach Phoenix unit to floor of the

truck using 1″ X 5/16 hex head self-

drilling screws.

Install the NITE Phoenix Unit

Power Harness Grommet. Chose a

good location for the flanged grommet

provided. Drill a 2″ hole and install

provided grommet in the floor. Route

all Phoenix and heater cables through

this grommet.

Slide the elbow into the support ring

and install the second half. Once

it’s installed you can snug all screws.

Now connect flex hose from unit to

elbow.

18

Failure to use the proper cable loom and/or grommet will result in damage to cables,

unit and/or vehicle. Always seal all open areas in grommet with silicone when

installation is complete. Silicone is not provided in kit.

Page 14

1-14

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

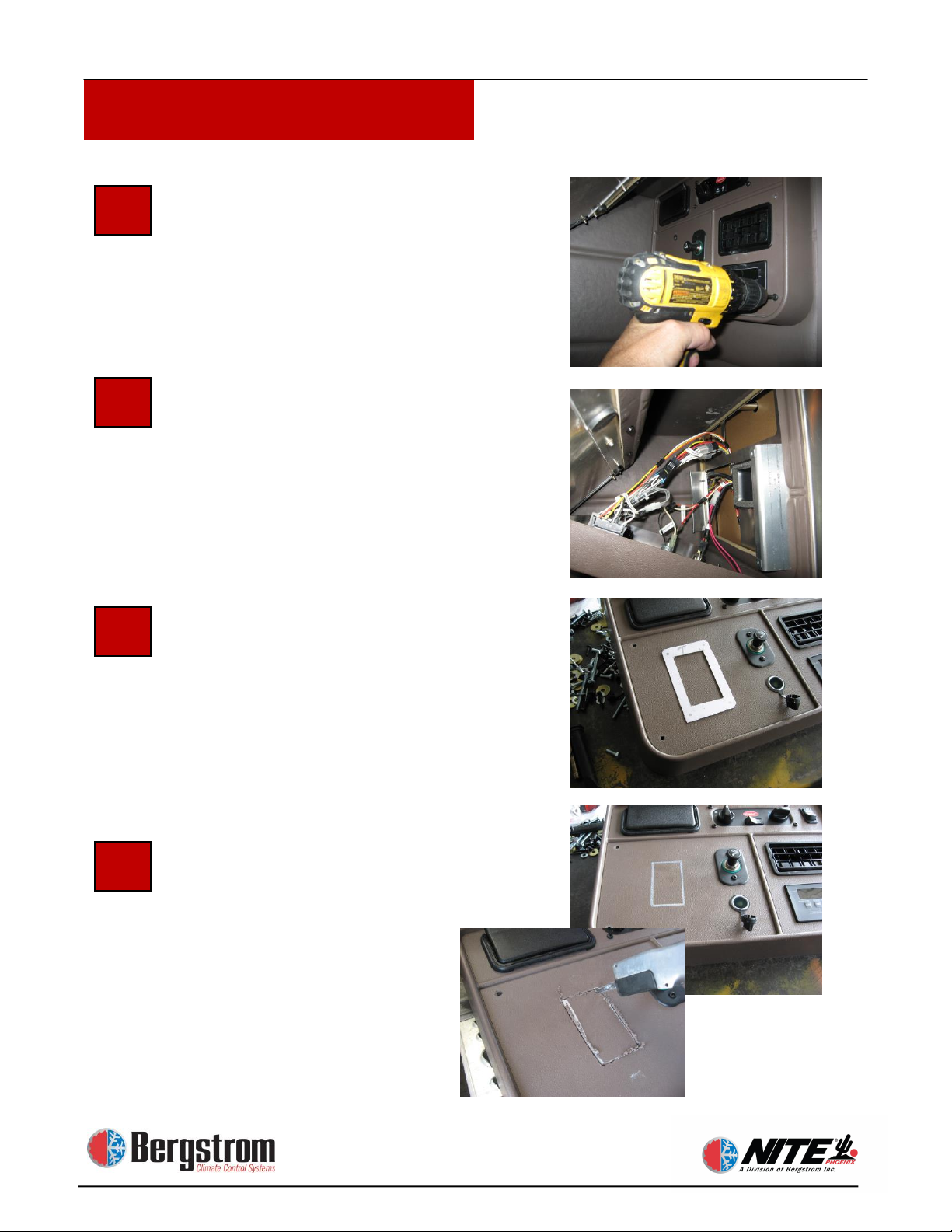

Remove OE bunk control center

Disconnect all OE wires and cables

Place template over area to be cut

for Phoenix controller. Mark and

remove.

Drill starter holes for airsaw. Cut

out marked section.

19

20

21

22

from the control panel and remove.

Page 15

1-15

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

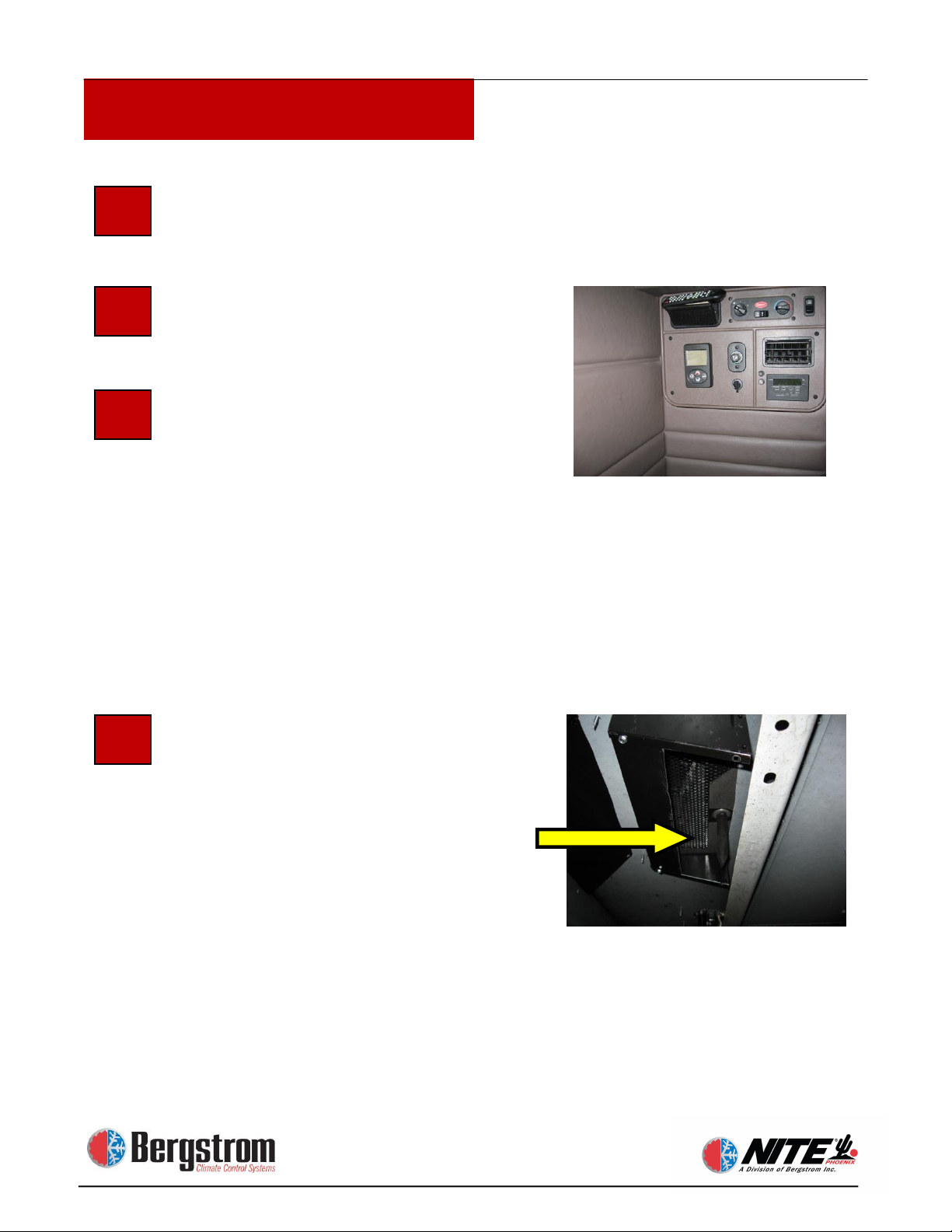

Attach Control Panel to the sleeper

control center. Carefully depress the

lock and remove the controller cover.

Install the controller to the control

center using #10 x ½” T 20 torque head

screw (PN 600129). Do not over

tighten. Replace cover.

Routing Phoenix Controller Harness.

Remove end cap from closet wall.

Open interior closet wall, exposing the

existing wire harnesses. Loom and

route Phoenix control harness across

OE bunk unit and through the square

hole indicated in photo and up the

inside of closet wall to the controller

location.

23

24

25

Page 16

1-16

Peterbilt 70 inch Sleeper rev 1-15-14

Installation Procedures

27

Connect the Phoenix control harness

to the controller.

Reconnect all OE wires and cables

and reinstall the OE panel.

Reassemble the closet wall and end

cap.

Install Drip Tube Under Truck

26

29

28

Page 17

Rev 9/25/2013

Section 2

Electrical Installation

Page 18

2-1

Electrical Installation

2

NOTE: Bergstrom does not condone putting batteries under the sleeper bunk. The floor is not

designed to carry that amount of weight and even deep cycle AGM batteries can emit gas under

certain circumstances. Bergstrom can only support batteries being placed in battery boxes or tool

Steel Battery Box Installation

Locate the battery box on the frame as close as possible to the sleeper NITE

Phoenix unit. When positioning the box, always keep the top of the box as

close to the top of the frame rail as possible – Some manufacturers recommend

no drilling within 2″ of top or bottom of frame rail. Check truck manufacturer

guidelines prior to drilling.

of 4 holes. Always use the holes in the rear outer corner area where you have

double walled steel. Of the 3 holes available on each side of the outer most

edge of box, choose the top and center holes on each side (see photo A). Drill

frame rail using ½″ HS bit. Install box with ½″ grade 8 bolts and hardware

provided. Tighten securely.

1

A

Correct

Incorrect

Available Battery Boxes Options

Refer to

for styles and part numbers. Aluminum clamp-on

boxes include between rail and vertical box styles. Steel battery boxes require

frame drilling and must be attached to frame rail with bolts (see instructions in the

following steps 2 and 3).

Vertical

Between Rail

Steel Battery Box

boxes designed to support the weight of the batteries outside the cab of the truck.

www.nitesystem.com

(2 required)

Clamp-On Box

Clamp-On Box

Using box as template, mark and drill a minimum

Page 19

2-2

Electrical Installation

3

5

4

Attaching Hold-down Brackets

Set two batteries side-by-side in the

battery box and place a hold-down

bracket on top, with the u-channel

facing up. Take two 5/16″ bolts, place

a 5/16″ flat washer on each, and then

put the bolts through the outer holes.

Tighten each bolt securely from under-

neath using the supplied nuts and

washers. Repeat the procedure for the

other two batteries.

Preparing Cables

The batteries are wired series/parallel

for 6 volt or parallel only for 12 volt.

See diagrams on pages 2-3 and 2-4

Make and Install All Cables described

in steps 6a or 6b depending on which

batteries you are using.

NOTE: Before performing any wiring, Disconnect Truck Batteries.

Page 20

2-3

Electrical Installation

Step 1: Make and install the two short

battery cables. These cables connect

the positive (+) of one battery to the

negative (-) of the other to create a set

or bank. We refer to this as a series

connection. See drawing below.

NOT connect any other cables or

wires to these terminals.

Step2: For the positive to positive

parallel connections, measure and cut

a piece of red cable to the proper

length. Attach a ring terminal to each

end using a professional grade

crimper. Place heat shrink around each

6a

terminal and heat. Then loom it. Use

this cable to connect the positive (+) of

one bank of batteries to the positive

(+) of the other bank of batteries.

Step3: Repeat procedure for the

negative to negative connection using

a black cable. Then loom it. Use this

black cable to connect the

negative (-) of one bank of batteries to

the negative of the other bank of

batteries.

Do NOT use truck frame as a ground

Directions for Wiring A 6-Volt Series/Parallel,

4 Battery NITE Phoenix

Connect positives here: AC

=12V

Battery Set

Battery Set

BMS=Battery Management System

DO

Unit, Heater, and Separator

Connect negatives here:

AC Unit, Heater, and Truck

Battery negative

Page 21

2-4

Electrical Installation

Step 1: For the positive (+) to positive

(+) parallel connections measure and

cut pieces of red cable to length. Attach

a ring terminal to each end using a

professional grade crimper. Place heat

shrink around each terminal and heat.

Then loom it. Use these cables to

connect all positive (+) terminals on all

4 NITE Batteries.

Step2: For the negative to negative

connections repeat procedure using

black cables. Then loom it. Connect all

negative (-) terminals of the 4 NITE

Batteries together.

Do NOT use truck frame as a ground

6b

Directions for Wiring A 12-Volt Parallel, 4 Battery NITE Phoenix

Parallel is all positives connected together and all negatives connected

together.

Battery Set

Battery Set

Connect

positives here:

negatives here:

BMS=Battery Management System

AC Unit,

Heater, and

Separator

Connect

AC Unit,

Heater, and

Truck Battery

negative

Page 22

2-5

Electrical Installation

Install the NITE Phoenix Power

Harness.

place the protective split plastic loom

around each cable. Route the cables

from the NITE Phoenix unit, down

through the floor grommet and along

the frame rails to the NITE Batteries.

Secure harness at the unit to prevent

stress on harness connectors.

7

Take the power harness and

Page 23

2-6

Electrical Installation

8

DO NOT CONNECT POSITIVE TRUCK BATTERY CABLE YET. WE

WILL CONNECT THIS CABLE ONCE FINISHED.

9

Install Battery Management System

Lug with (open hole) mounts on the

battery negative post. Grounds for the

Phoenix and Aux heater will connect to

the threaded stud post (A-bottom photo)

along with the ground cable from the

truck starting batteries

monitoring amps drawn from the batteries

as well as the charging current to the

batteries. It also controls the separator

solenoid.

Connect Power Cables from Phoenix

Unit to the

positive cable from the NITE Phoenix unit

to the 100 amp mega fuse in the fuse

holder. Kit contains 2 lugs with 5/16

diameter holes. Make a short (jumper)

battery cable to go from the fuse to the

Aux battery positive terminal of the NITE

Batteries. Trim end of lug if necessary to

prevent damage to fuse.

Connect the negative cable from the

NITE Phoenix

threaded stud (A) (see photo at right)

on the BMS. Also see diagrams on

pages 2-3 and 2-4.

Battery Management System Installed

5/16 lugs

NITE Batteries. Connect

unit to the negative

. This device is

Page 24

2-7

Electrical Installation

STOP!

SEPARATOR

TERRA POWER

KISSLING

PROCEED TO PAGE 2-10, STEPS 20-41 FOR THE TERRA POWER

FOLLOW STEPS 10-19 FOR KISSLING SEPARATOR

Page 25

2-8

Electrical Installation

11

Mounting the Separator Enclosure

The battery separator can be located in a

battery box or in the supplied protected

enclosure. Mark and drill two ¼″ holes

through the back of the plastic box and

the support it will be mounted to. Before

permanently attaching the separator

enclosure, prepare and mount the

separator in the box. The separator will

mount to the side of the box with 2 ¼″

bolts and hardware. Drill large holes in

the bottom of the box and route the cables

through the holes to the separator.

Securely fasten the separator and box

using the provided ¼″ bolts, washers and

lock nuts.

Run Cables from Truck Batteries

Loom 2 full length battery cables, 1 red

and 1 black. The red (pos) cable will

connect the truck starting batteries

positive post to the (start) post #88 of the

battery separator. The black (neg) will

connect the truck (neg) to the threaded

stud (A) of the BMS(see photo).

Connect

Separator.

measure and cut to proper length. Crimp

ring terminals and heat shrink. Connect

one end to the appropriate positive (+)

terminal of the NITE Batteries. See

diagrams on pages 2-3 and 2-4. Connect

the other end to the AUX terminal # 88a

of the battery separator.

Threaded Stud

Disregard the enclosure

separator inside the battery box.

10

88A

88

12

Note: The separator ties to the truck’s

starting batteries and allows charging priority to the

starting batteries. The NITE Batteries begin

charging after the starting batteries reach 13.2 volts.

instructions if you mount the

NITE Batteries to Battery

Using red battery cable,

Page 26

2-9

Electrical Installation

Battery Management System Wiring

Harness.

BMS. Auxiliary battery power wire with

fuse connects to battery pos on the aux.

batteries. This harness splits three ways:

Red/black goes to truck starting batteries,

orange/tan/white go to separator,

green/yellow go to can bus on Phoenix

unit inside the truck. All three must be

loomed.

Install Y connector at BMS connection

(A) - wires green and yellow

Install resistor plug (B) into Y

connector

Connect Can Bus harness from the

Battery Management System wiring

harness.

(C). Route this harness inside the truck

through the floor grommet and connect at

the Phoenix unit.

13

C

15

C B A

16

14

Systems built after 9/1/2013 do not use a Y connector and resistor

8 pin connector plugs into the

This harness must be loomed

Page 27

2-10

Electrical Installation

Connect Battery Management System

to Start Batteries. 2 wire harness from 8

pin connector. This harness routes from

the BMS in the Aux battery box to the

truck starting battery box.

must be loomed.

through the supplied, field installed, 5

amp mini fuse and holder (A) to any 12

volt POS post in the truck starting battery

box. The black connects to any 12 volt

NEG post in the battery box. It is vital

that these wires connect in each box.

Attach Can Bus Cable to Unit.

Connect can bus harness, coming from

the BMS, into connector at the NITE

Phoenix unit – it only fits one way.

connect the digital controller harness

installed in an earlier step.

17

18

Red

Black

The red connects

This harness

Also

Page 28

2-11

Electrical Installation

88

88A

85

86A

86B

Connect Battery Management System

to Battery Separator Solenoid This 3

wire harness from the 8 pin connector

routes to the battery separator solenoid.

Cut wires to length, crimp snap fork

terminals on each wire and connect to

designated terminals. This switch

separates the Aux batteries from the

starting batteries. It closes when the truck

batteries are at or above 13.2 and opens at

12.5 volts. Location can be in the AUX

battery box, truck starting battery box or

the supplied plastic enclosure.

This harness must be loomed.

Notice: the terminal connecting points

are printed on each wire.

Terminals are marked as:

19

Orange

White

Tan

88 – Starting battery cable (POS)

88A – Aux battery cable (POS)

85 – Solenoid common (White wire)

86A – solenoid disengage (Tan wire)

86B – solenoid engage (Orange wire)

Page 29

2-12

Electrical Installation

Install Separator Enclosure

Remove the enclosure cover, Place the

separator mounting bracket, centered on

the inside of the cover. Mark and drill 4

holes to secure the bracket to the cover.

Before installing the bracket, secure the

separator to the bracket with four

10 x 32 x ¾″ screws and lock washers

provided.

WIRING THE TERRA POWER SEPARATOR

the separator inside the battery box.

20

21

Disregard the enclosure instructions if you mount

Page 30

2-13

Electrical Installation

Install the assembly to the cover using 4

10 x 32 x ¾″ screws, lock and flat

washers provided.

Next, drill a 2″ hole in the center of the

bottom

Trim the hole on each side as shown,

creating a 2″ slot.

Install enclosure on truck

22

23

24

of the box as shown.

Page 31

2-14

Electrical Installation

Run Cables from Truck Batteries

Loom 2 full length battery cables, 1 red

and 1 black. The red (pos) cable will

connect the truck starting batteries

positive post to the (start) post (A) of the

battery separator.

provided 90 degree battery terminal

end at the Terra Power separator

rotated to the center of the switch.

Torque specs for separator terminals

88(recommended) to 132(maximum) inch

lbs.

The black (neg) will connect the truck

(neg) to the threaded stud (C) of the

BMS.

Connect

Separator.

measure and cut to proper length. Crimp

ring terminals and heat shrink. Connect

one end to the most appropriate positive

(+) terminal of the NITE Batteries.

Connect the other end to the AUX

terminal (B) of the battery separator. See

top photo.

90 degree battery terminal end at the

Terra Power separator rotated to the

center of the switch

Install the separator assembly

Once you have torque the battery cable

connections, install the cover assembly on

the enclosure.

25

26

27

28

29

A

B

C

You must use the

NITE Batteries to Battery

Using red battery cable,

You must use the provided

.

Page 32

2-15

Electrical Installation

Battery Management System Wiring

Harness.

BMS. Auxiliary battery power wire with

fuse connects to battery pos on the aux.

batteries. This harness splits three ways:

Red/black goes to truck starting batteries,

orange/white go to separator,

green/yellow go to can bus on Phoenix

unit inside the truck. All three must be

loomed.

Install Y connector at BMS connection

(A) - wires green and yellow

Install resistor plug (B) into Y

connector

Connect Can Bus harness from the

Battery Management System wiring

harness.

(C). Route this harness inside the truck

through the floor grommet and connect at

the Phoenix unit.

C

C A B

30

31

32

33

Systems built after 9/1/2013 do not use a Y connector and resistor

8 pin connector plugs into the

This harness must be loomed

Page 33

2-16

Electrical Installation

Attach Can Bus Cable to Unit.

Connect can bus harness, coming from

the BMS, into connector at the NITE

Phoenix unit – it only fits one way

Also connect the digital controller

harness installed in an earlier step.

34

.

Page 34

2-17

Electrical Installation

Connect Battery Management System

to Start Batteries. 2 wire harness from 8

pin connector. This harness routes from

the BMS in the Aux battery box to the

truck starting battery box.

must be loomed.

through the supplied, field installed, 5

amp mini fuse and holder (A) to any 12

volt POS post in the truck starting battery

box. The black connects to any 12 volt

NEG post in the battery box. It is vital that

these wires connect in each box.

Connect Battery Management System

to Battery Separator.

harness from the 6 pin connector routes to

the battery separator solenoid.

This harness must be loomed. Notice:

the terminal connecting points are

printed on each wire.

Deutsch connector kit.

This connector connects the orange and

white control wires to the Terra Power

switch. This requires the special Deutsch

crimping tool. See crimping tool

instructions on page

proceeding.

35

36

Red

Black

Orange

White

A

The red connects

This 2 wire

This harness

2-18 before

Page 35

2-18

Electrical Installation

Page 36

2-19

Electrical Installation

Cut wires to length, strip insulation as

instructed in the Deutsch tool section.

Crimp terminals on each wire.

Install 4 sealing plugs into the unused

terminal locations 3 through 6.

Install separator control wires into

Deutsch connector

Terminals are marked as:

After wires are installed, slide the

terminal lock into place, inside the

connector

37

38

39

40

1– Solenoid common (White wire)

2– Solenoid engage (Orange wire)

Page 37

2-20

Electrical Installation

Connect the assembled connector to the

existing connector on the Terra Power

switch

Complete Electrical Wiring

Recheck and tighten all battery and

separator connections. Zip tie cables

where necessary. Your wiring should look

like the diagram on page 5-1.

41

This completes the electrical section of the installation. If you are installing the

ESPAR heater proceed to section 3. If you are installing the WEBASTO heater

proceed to section 4. If you are not installing an aftermarket heater, your

installation is complete and you may reconnect the truck batteries.

WARNING: If you have a fuel operated heater that was installed at the

factory or prior to the Phoenix install, you can continue to operate the

heater with the existing controller.

IF you choose to wire the existing factory installed heater to the Phoenix

controller, YOU WILL VOID THE FACTORY WARRANTY OF THE

HEATER!

Page 38

Section 3

ESPAR Fuel Operated Heater

Installation

Page 39

3-1

Heater Installation

The heater instructions in this manual are generic. For the latest install information

please refer to the Espar D2 heater install manual

WARNING: If you have an Espar fuel operated heater that was installed at the

factory or prior to the Phoenix install, you can continue to operate the heater with

the existing controller. IF you choose to wire the existing factory installed Espar

heater to the Phoenix controller, YOU WILL VOID THE FACTORY WARRANTY

OF THE HEATER!

Unpack Heater Parts

Take out the parts to the heating

unit.

Prepare Heater Mounting Location.

Choose the most appropriate location to

install the heater—in this case we have

chosen a side box floor location. Check

underneath truck for any obstructions or

supports. Use the mounting plate as a

template to cut an opening in the rubber

mat. Cut around the mounting plate,

then remove the piece of rubber to

expose truck floor.

1

2

Page 40

3-2

Heater Installation

Drill Outlet Hole for Heat Unit. Mark

the floor of the truck using the 5 small

holes of the mounting plate. Remove

mounting plate, place a 4 ¼″ hole saw

over the middle of the floor marks, and

drill the outlet hole for the heater,

intake, exhaust and pickup tube. Also

drill a 1/2″ hole approximately 1 to 2″

from mounting plate corner.

NOTE: DO NOT USE PHOENIX

DUCT FOR HEATER VENT

Install Sleeper Heat Vent. Select

location for the vent in the lower left

side of the center support wall closest to

heater. Drill a 2 ½″ hole (A) to allow

distribution of heat into the sleeper.

After hole is drilled, use 5/16″ x 1″ selftapping screws to attach heat port then

snap louver into place (B).

3

4

Page 41

3-3

Heater Installation

Heater Unit Assembly –Attach

Mounting Plate. Snap end cap on

heater unit (A). Place mounting plate

over heater unit (B). Attach with flat

lock washers and 10mm lock nuts—

tighten down securely.

Heater Unit Assembly – Attach

Gasket and Fuel Line Connection

Peel off backing from gasket and place

gasket over mounting plate edges,

sticky-side down. Place small black

rubber fuel line connector over the fuel

intake tube and push down. Place a

small clamp over connector, push to

bottom and tighten.

Heater Unit Assembly – Attach Fuel

Line

Now take the clear pick up tube, place a

small clamp over it, and push the tube

all the way to the bottom of the fuel

intake tube. Place clamp flush with top

of black connector and tighten securely.

5 6 7

B

A

Page 42

3-4

Heater Installation

Heater Unit Assembly – Identify

Intake and Exhaust Ports. Look

closely at the two small metal tubes.

One has an arrow pointing out away

from the unit—this is the exhaust. One

has an arrow pointing in towards the

unit—this is the intake.

Heater Unit Assembly – Attach

Exhaust Hose. Take the heavy duty

silver metal hose and place a large,

heavy duty clamp over the end of it.

Place the hose and clamp over the

exhaust tube, push all the way down,

and tighten securely.

Heater Unit Assembly –Attach Intake

Hose. Take the black flex hose and

place a small clamp over the end of it.

Place the hose and clamp over the

intake tube, push all the way down, and

tighten securely.

Heater is now ready to install in the

truck.

8 9 10

Page 43

3-5

Heater Installation

PREPARE TO MOUNT UNIT

Check to make sure truck batteries are still

disconnected. Carry unit into truck. It will

be mounted over the 4 ¾″ hole that was

drilled earlier. Make sure hoses and tubes

don’t get tangled or caught on anything.

Run Lines Through Cab Floor

Feed exhaust hose, intake hose, and fuel

line through the 4 ¾″ hole, making sure

they are not bent, crimped or rubbing on

the side of the hole.

Mount Heater Unit to Cab Floor

Make sure that the heater unit is set with

the fan (intake) end opposite the 2 ½″ hole

for the vent/louver drilled earlier. Set unit

flush to floor and attach with a selftapping screw at each corner of the

mounting plate.

11

13

12

Page 44

3-6

Heater Installation

Attach Heat Line to Sleeper Vent.

Take the black metallic flex tube,

measure and cut length to run from

heater unit to louver/vent opening (A).

Place two clamps over ends of tube, and

clamp tube to heating unit and louver.

Tighten clamps securely but do not over

tighten. Snap Intake Grill onto intake

end of heater (B). Keep this area clear

of debris or install return air hose.

Attach Wiring Harness

Attach plug end of wiring harness into

wiring plug at bottom of heating unit.

Be sure the lock-in pin seats securely.

Run Power and Fuel Pump Wires

Through Floor. Run the power wire

and fuel pump power wire through the

grommet (installed in section 1) to the

underside of the truck. If the fuel pump

wire will not reach using this grommet,

use the rubber grommet supplied with

the heater and drill a second hole.

14

15

16

A

B

Page 45

3-7

Heater Installation

Optional Heater controlled by the

Phoenix controller.

WARNING: If you have an Espar fuel

operated heater that was installed at the

factory or prior to the Phoenix install, you

can continue to operate the heater with the

existing controller. IF you choose to wire

the existing factory installed heater to the

Phoenix controller, YOU WILL VOID

THE FACTORY WARRANTY OF

THE HEATER!

Attach Espar Heater Control

Harness to Phoenix Unit

Espar control harness terminates the

same as when using the Espar mini

controller. Connector kit for the control

harness is included in the heater kit.

Route the control cable along the bed

towards the heater control panel. Use

zip ties as needed. Strip off 6″ of black

outer jacket from cable coming from

heater. Fold all wires back and cut off

the outer jacket, the blue, solid gray and

solid brown wires. Save the brown

wire and make a jumper wire. Strip

down ends of solid brown wire.

Connect one end of solid brown jumper

to brown/white wire. Add clips to ends

of wires and crimp on with crimper. On

connector, the numbers 1, 3, and 5 are

on one side, 2, 4, and 6 are on the other.

Insert wires into plug as follows: 1 = red,

2 = yellow, 3 = other end of jumper

including brown/white wire,

4 = gray with red stripe, 5 = brown jumper.

Now connect the heater control harness

to the Phoenix unit as shown in photo.

17

Page 46

3-8

Heater Installation

B

19

Finish Intake and Exhaust Hose

Installation. First, attach intake air

tube to truck structure with zip ties. Put

cap on bottom of intake tube. Next, run

exhaust hose to the back of cab, attach

with clamps to the structure of the

truck. Cut off excess

exhaust hose, and place End

Sleeve on the end of the hose.

NOTE: HOT – Keep exhaust

hose away from wiring or flammable

material. Make sure exhaust exits

behind the vehicle.

Assemble the Fuel Pump Mount and

Hoses. Take rubber mount bushing and

L bracket and put them together to

make mounting bracket for fuel pump.

Slide fuel pump into rubber bushing

(A). Take plastic caps off both ends of

fuel pump. Attach large fuel hose to

larger diameter end (B), figure out

length needed to connect to pick up tube

and cut off excess. Secure with clamp.

Attach small precut hose to smaller

diameter end of the fuel pump and

secure with clamp (C).

NOTE: Bracket show n in photo (B)

will always set the fuel pump at the

desired angle. Make sure the inlet of the

fuel pump is down.

18

A

C

Page 47

3-9

Heater Installation

Drill Hole in Fuel Tank, Insert

Pickup Tube and Mount Fuel

Assembly. Use a 1″ hole saw to scribe

initial location for two outer holes. Drill

the two outer 1/4″ holes centered on

scribe. Then complete drilling the 1″

hole. See diagram A. Option: When

possible drill holes in the fuel sender

block off plate. Slide pickup tube into

fuel tank through hole, install with

bottom washer then put on rubber seal

and place metal washer on top of pickup

tube followed by pump mounting

bracket and nut. Tighten slightly. Put

clamp over end of large fuel line from

fuel pump, attach to pickup tube and

clamp down. Finish snugging up large

nut, but do not over tighten. Cut off

excess from small feeder tube fuel line

and attach to fuel pump. Secure with

clamp.

Prepare and Attach Fuel Pump

Harness. Measure and cut fuel pump

harness wires to appropriate length.

Strip wires, put on rubber boots, then

attach ends and crimp (A). Attach wires

to plug: 1 = green, 2 = brown. Make

sure rubber boots are seated to keep out

moisture (B). Connect the harness

spring loaded plug to the fuel pump (C).

Secure all wires and hoses with zip ties.

A

B

20

21

C

1/4″

Diagram A

Hole drilled in blank

sending unit plate

Hole drilled in tank

1/4″

1″

Page 48

3-10

Heater Installation

Run Heater Unit Power Cable to

NITE Batteries. Take the heater unit

power cable, run it under the truck

(attach with zip ties where necessary)

over to the NITE Batteries. Strip back

outer cover to expose two inner wires.

Attach Connectors. Strip end off

brown wire. Before stripping red wire,

put the housing of the fuse holder on,

and pull the red wire through. Now strip

the end of the red wire, attach terminal

and crimp. Pull red wire back into fuse

holder. Push rubber seal into place.

Attach ring terminal to ground wire and

crimp.

Attach Wires to NITE Batteries.

Connect Aux heater ground wire to

ground terminal threaded stud of

Battery Management System. Connect

heater unit positive wire to positive

terminal of NITE Batteries. Insert 20

amp fuse into fuse holder. Tighten all

connections.

YOU CAN NOW RECONNECT

THE TRUCK’S BATTERIES TO

TEST THE SYSTEM.

22

23

24

Page 49

Section 4

WEBASTO Fuel Operated Heater

Installation

Page 50

4-1

Heater Installation

Optional Webasto Heater controlled

by the Phoenix controller.

WARNING: If you have a Webasto

fuel operated heater that was installed at

the factory or prior to the Phoenix

install, you can continue to operate the

heater with the existing controller. IF

you choose to wire the existing factory

installed Webasto heater to the Phoenix

controller, YOU COULD VOID THE

FACTORY WARRANTY OF THE

HEATER!

DO NOT USE PHOENIX DUCT FOR

HEAT VENT.

ATTN: Refer to Webasto manual for

all heater installation instructions

then proceed to steps below for

connecting Webasto heater to the

Phoenix unit.

Attach Webasto heater control harness

to Phoenix Unit. Route the control

cable along the bed towards the Phoenix

unit. Use zip ties as needed.

Now connect the heater control harness

to the Phoenix unit harness (as shown in

photo). The Webasto heater in the

Phoenix kit is prewired to connect

directly into the Phoenix unit harness.

For pin numbers and wire colors see

wiring diagram in section 5.

Page 51

Rev 7/10/14

Section 5

Wiring Diagrams

NOTE:

Pages 5-1 and 5-2 are for unit manufactured after 2/8/2012

Pages 5-3 and 5-4 are for units manufactured prior to 2/8/2012

Page 52

5-1

External Wiring Diagram

Use for units manufactured after 2/08/2012

Page 53

5-2

Internal Wiring Diagram

Use for units manufactured after 2/08/2012

Page 54

5-3

External Wiring Diagram

Use for units manufactured prior to 2/08/2012

Page 55

5-4

Internal Wiring Diagram

Use for units manufactured prior to 2/08/2012

Page 56

Operating Instructions

Section 6

Page 57

6-1

Operating Instructions

ON/OFF

ENTER

ENTER

To start the system push ON/OFF button. Display will

show current mode/ temperature setting / battery level.

Initial default setting is blower speed 1/ AUTO- MODE /60 °F

Changing MODE – press ENTER, while mode is flashing

use up or down arrows to select AUTO / COOL / HEAT.

After 5 seconds selection will be set.

Changing BLOWER SPEED – press ENTER until display

shows FAN and SPEED. Press up or down arrows to

select 1 – 2 – 3 speed. After 5 seconds selection will be

set.

Page 58

6-2

Operating Instructions

ENTER

ENTER

Changing TEMPERATURE set point. Anytime the

temperature set point is displayed on the screen, push

the up or down arrows to change. Temperature range

is from 60 °F (coolest) to 85 °F (warmest).

NOTE: Control will always default to the last setting

when the unit is turned on.

To view system runtime/hours – press ENTER until

“Hrs” show on display. When hours are displayed,

pressing ENTER for 7 seconds will reset the hours to

zero.

To change from °F to °C press ENTER until temperature

symbol only shows – push the up or down arrow to

change. After 5 seconds selection will be locked.

Anytime the control is idle for 5 seconds the screen will

return to the temperature set point screen.

Page 59

6-3

Operating Instructions

ENTER

ON/OFF

ENTER

ENTER

To enter SERVICE MODE: Push both the ON/OFF and

ENTER button simultaneously at any time.

Display will show service indicator and a code #1 to #3.

Use up and down arrows to scroll through the Fault

Codes.

1) Evap sensor open or shorted high

2) Evap sensor shorted low

3) High pressure switch open or shorted high

Press the ENTER button to proceed through the

available service screens.

1) SV = Starting batteries Voltage

2) AV = Auxiliary batteries Voltage

3) AA = Unit Amperage draw

4)

Pressing ENTER arrow after viewing service screen will

return you to the fault code screen.

Pressing the ON/OFF button will return you to the

Temperature Display screen.

When necessary, Check Filter light will notify you that

the Phoenix filter must be cleaned or changed. To reset

filter: at screen 1 press and hold enter button for 3

seconds.

Page 60

Section 7

Battery Management

System (BMS) Installation

Page 61

7-1

Battery Management

Bergstrom NITE System

BMS 100 Installation

Page 62

7-2

Battery Management

Page 63

7-3

Battery Management

Loading...

Loading...