okuma OSP-U100M User Manual

CNC

OSP-U100M

OSP-U10M

SYSTEMS

SPECIAL

(2nd

Pub.

Edition)

4202-E-R1

No.

FUNCTION

(ME51-197-R2)

MANUAL

October

(No.

1999

1)

L

OKUMA

ME00-001-R1

SAFETY

P-(i)

PRECAUTIONS

SAFETY

The

machine

hazards

from

safety

devices:

accident-free

This

instruction

Okuma

1.

Precautions

(1)

Install

the

-

-

-

(2)

Prepare

-

PRECAUTIONS

equipped

is

arising

they

operation.

can

predict.

the

guaranteed

Ambient

Ambient

Site

not

corrosive

a

Voltage:

manual

Relating

machine

temperature:

humidity:

subject

gases,

primary

with

from

unforeseen

also

must

and

Be

aware

a

at

accuracy)

direct

to

and

power

safety

become

the

warning

that

to

site

apply.

salt

supply

devices

accidents.

fully

familiar

signs

do

they

Machine

where

the

C

25

to

7

1

40%to75%

as

that

V

or

possible.

complies

sunlight

spray

200

serve

which

However,

with

attachedtothe

all

cover

not

Installation

to

20*0

with

conditions

77

following

(62.6

at

excessive

to

operators

safety

the

possible

T)

(68°F)

vibration;

the

protect

guidelines

machine

hazards.

(the

(no

condensation)

environment

following

personnel

must

cover

conditions

and

not

rely

presented

only

for

requirements.

the

machine

exclusively

below

those

hazards

achievement

free

as

of

on

to

dust,

itself

these

ensure

which

of

acid,

(3)

Voltage

-

Power

-

Do

-

source

malfunction

If

-

but

(such

supply

draw

not

possible

useacommon

to

as

Installation

Observe

-

Make

-

Make

-

Make

or

-

The

-

The

-

The

the

sure

sure

sure

shock.

permissible

permissible

maximum

fluctuation:

frequency:

the

primary

(for

example

the

of

connect

an

electric

Environment

following

that

the

that

the

that

the

ambient

ambient

altitudeatwhich

10%

±

Hz

50/60

power

supply

electric

an

unit.

CNC

the

machine

ground,

welderorelectric

points

CNC

control

control

to

the

when

will

unit

enclosure

enclosure

temperature

humidity

the

max.

a

from

welderorelectric

a

ground

other

discharge

installing

be

not

will

and

range

range

control

distribution

used

not

equipment

control

the

subject

for

to

splashed

be

not

operation

for

the

the

control

enclosure

machine).

panel

discharge

any

by

must

not

enclosure.

sunlight.

direct

panel

are

control

enclosure

can

that

machine)

other

equipment.

generate

chips,

with

subject

not

enclosure

is

be

used

30

is

also

water,

is

to

1

000

supplies

since

large

a

or

excessive

to

40°C

to

0

95%

m

a

major

this

could

there

If

isnochoice

amount

oil.

(32

(no

condensation).

ft.).

(3281

noise

cause

of

noise

vibrations

104°F).

to

ME00-001-R1

SAFETY

P-(ii)

PRECAUTIONS

2.

3.

Points

Close

(1)

chips,

Make

(2)

are

(3)

When

ON

Check

to

all

the

and

absolutely

obstacles

no

turning

switchonthe

Precautions

(1)

(2)

(3)

(4)

turning

After

inspection

Use

tools

specifications.

not

for

could

that

Do

spindle

Check

doorsofthe

dust.

sure

around

the

on

Relating

the

on

procedure

whose

any

rotate:

the

dimensions

Do

reason

workpiece

before

control

that

the

power,

operation

power,

described

use

not

touch

this

is

Turning

enclosure

there

is

nobody

machine,

on

turn

panel.

Operation

to

carry

out

this

in

type

and

worn

badly

the

spindle

dangerous.

and

tool

before

the

main

inspection

instruction

are

tools

or

are

properly

on

the

and

operation

near

the

moving

starting

power

appropriate

since

tool

disconnect

adjustment

and

manual.

they

while

secured.

Power

panel

parts

machine

the

for

can

cause

spindle

to

prevent

of

operation.

switch

in

accordance

work

undertaken

accidents.

indexing

the

first,

is

the

entry

machine,

then

with

progress

in

and

the

and

the

the

of

water,

there

that

CONTROL

daily

machine

since

the

(5)

(6)

(7)

(8)

(9)

(10)

(11)

Never

Do

stop

Do

touch

not

the

not

machine

Always

Do

not

Do

not

Before

a

workpiece

remove

machine

operate

any

with

the

stop

approach

touch

any

any

using

or

tool

whileitis

by

chips

the

machine

or

switchorbuttononthe

hand

while

remove

then

first,

machine

the

of

with

covers

removed

before

any

touch

switchorbutton

moving

any

mountingorremoving

with

rotating:

machining

the

chips

safety

of

the

unless

of

part

hands.

wet

operation

this

in

progress

is

a

brushorbroom.

with

devices

necessary

is

it

the

machine

This

panel,

is

extremely

since

removed.

tool.

a

while

is

extremely

check

dangerous.

this

do

to

operating.

is

it

thatitis

dangerous.

is

Do

not

operate

so.

dangerous.

one

the

Always

the

intended.

ME00-001-R1

SAFETY

P-(iii)

PRECAUTIONS

4.

5.

Precautions

The

(1)

(2)

(3)

(4)

On

(1)

(2)

(3)

(4)

tool

clamps

tool

couldbereleased

a

the

not

do

inspect

chips

use

ATC

off,

danger:

Always

Remove

misoperation.

Do

If

power

Finishing

finishing

On

Return

Always

To

main

turn

the

turn

off

power

Relating

the

of

touch

not

change

and

adhering

compressed

during

stops

do

touch

not

Work

work,

clean

ATC,

APC

the

off

power

the

power,

disconnect

to

magazine,

and

approach

or

toolsinthe

the

to

air

to

operation

ATC

the

vicinity

the

and

other

the

to

off

turn

switch.

the

spindle,

in

the

fall

the

magazine

remove

for

since

equipment

machine

CONTROL

the

ATC

event

ATC

magazine

these

some

it

the

of

are

etc.,

designed

ofanunforeseen

mechanism

in

appropriate

at

chips

since

reason

may

andithastobe

start

moving

machine.

predetermined

the

to

before

leaving

switchonthe

ON

during

the

intervals

for

ATC

manual

it

will

only

suddenly.

it.

reliability,

accident,

operation.

magazine

since

push

inspected

retraction

operation

butitis

exposing

interrupt

they

can

chips

the

position.

panel

possible

you

cause

further

without

first,

to

mode.

turning

then

that

in.

the

the

ME00-001-R1

SAFETY

P-(iv)

PRECAUTIONS

6.

Precautions

Occurs

order

In

following

occurred.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

to

prevent

points

When

trouble

machine.

Consult

be

taken.

or

two

If

confirm

Use

only

Always

parts

When

secure

and

carrying

When

checks

the

more

safety

the

turn

-

during

when

occurs,

person

specified

the

are

them

make

unforeseen

performing

press

responsible

persons

before

power

must

proceeding

replacement

off

removed

properly

out

inspections

the

sure

Maintenance

accidents,

the

work

before

during

with

instrument

damage

maintenance

emergency

for

maintenance

together,

to

each

parts

starting

inspectionorrepair

screws,

their

which

in

measuring

is

properly

Inspection

the

to

inspections

button

stop

to

establish

new

step.

fuses.

and

inspection

etc.

calibrated.

machine,

or

during

the

on

determine

signals

or

changing

work,

always

instruments

and

etc.,

operation

what

so

that

parts.

replace

are

When

is

it

checking

corrective

they

used

Trouble

essentialtoobserve

when

panel

to

measures

communicate

can

them

as

-

for

example

stop

they

trouble

the

need

were

voltage

the

has

to

to

(8)

Do

(9)

Check

leakage

(10)

Maintenance

a)

b)

c)

keep

not

that

cables

and

Switch

Even

the

permitted

precautions.

-

the

when

servo

Servo

Discharge

Spindle

-

Discharge

The

control

whose

the

memory

are

memory

contents

handled,

personnel

combustible

and

wires

electric

inside

amplifier

is

shocks.

the

power

main

the

main

amplifier

perform

to

the

residual

drive

unit

the

residual

enclosure

stores

this

of

supplied

the

should

contents

handle

materialsormetals

are

free

of

Control

Enclosure

disconnect

power

and

any

memory

with

disconnect

spindle

work

voltage

voltage

contains

the

machining

will

power

the

of

these

drive

these

on

one

one

the

be

byabattery.

memory

boards.

inside

damage:

switch

switch

unit,

units.

minute

minute

unit,

NC

programs,

retained

may

the

damaged

OFF

before

is

and

for

Even

after

after

and

even

Depending

be

control

enclosure

cables

opening

there

OFF,

this

reason

then,

they

NC

off

unit

the

off

the

turning

turning

the

parameters,

when

on

destroyed

and

the

may

only

must

the

main

has

etc.

power

how

and

or

wires

control

some

service

observe

breaker

power

printed

a

order

In

switched

is

printed

the

for

this

terminal

cause

will

enclosure

residual

personnel

the

inside

disconnect

circuit

ensure

to

circuit

reason

box.

charge

following

the

board

off,

the

boards

only

current

door.

in

are

unit.

switch.

that

service

ME00-001-R1

SAFETY

P-(v)

PRECAUTIONS

7.

(11)

Periodic

a)

General

(1)

Keep

(2)

Wear

training.

Make

(3)

operators

Inspection

cooling

inside

every

the

fan

motor

the

external

is

it

blocked,

the

the

Cleaning

The

rise

points

Is

-

The

Is

-

If

Precautions

the

vicinity

appropriate

that

sure

must

your

wear

of

cooling

unit

control

three

motor

is

normal

the

of

clothing

clothes

the

the

in

months.

inside

air

inlet

clean

machine

safety

Control

unit

doorofthe

enclosure

the

cooling

there

if

blocked?

it

with

clean

while

working,

and

hair

equipment

Enclosure

control

and

increase

unit

a

is

strong

compressed

tidy.

and

and

such

become

as

cannot

enclosure

the

working?

draft

from

air.

follow

the

safety

serves

reliability

the

unit.

instructions

entangled

shoes

to

prevent

theNCunit.

of

the

in

and

safety

of

someone

machine.

goggles.

excessive

Inspect

with

Machine

temperature

the

following

sufficient

Machine

(4)

procedure

Memorize

(5)

time

Do

(6)

high-voltage

If

(7)

confirm

not

two

and

access

or

safety

operators

before

the

position

from

any

the

terminals

more

persons

before

read

must

operating

the

of

position.

insideofthe

and

other

must

proceeding

the

instruction

the

machine.

emergency

control

components

work

together,

to

panel,

each

manual

button

stop

transformer,

which

establish

new

step.

carefully

that

so

extremely

are

signals

and

you

motor,

so

make

can

press

etc.,

since

dangerous.

that

they

sure

of

it

immediately

they

can

communicate

the

correct

contain

at

any

to

ME00-001-R1

SAFETY

P-(vi)

PRECAUTIONS

8.

ADANGER

|AMiG|

ACAUTION

-

'

Symbols

The

following

importance.

'

NOTICE

Read

Indicatesanimminent

:

:

Indicates

|

:

lnclicates

or

equipment.

:

Indicates

Used

warning

the

hazards

hazards

precautions

This

in

indications

instructions

which,

which,

Manual

are

usedinthis

marked

hazard

if

not

if

not

relating

with

which,

avoided,

avoided,

to

operation

manualtodraw

symbols

these

not

if

avoided,

could

result

could

result

or

use.

attention

carefully

resultindeathorserious

will

in

death

in

minor

to

and

follow

or

serious

injuries

information

or

them.

injury.

damage

of

particular

injury.

devices

to

INTRODUCTION

4202-E

INTRODUCTION

P-(i)

This

great

most

OSP”,

special

complete

function

assistance

as

the

manual

obtaining

in

understanding,

manuals

two

contains

the

this

are

very

full

manual

benefit

closely

instructions

of

all

should

related.

for

the

be

the

OSR

superior

read

A

careful

functions

in

conjunction

reading

the

machine

with

of

“Operation

the

the

has

manual

offer.

to

will

be

For

Manual

of

the

for

A.

ANIMATION

FUNCTION

B.

C.

D.

E.

F.

G.

H.

TOOL

NC

Hi2-NC

PATH

OPERATION

FUNCTION

DISPLAY

SYNCHRONIZED

TOOL

TOOL

PPC

FOR

MANAGEMENT

LIFE

(PALLETE

MANAGEMENT

POOL

HORIZONTAL

FUNCTION

MONITOR

(HIGH-SPEED

TAPPING

FUNCTION

LINE

MC

MULTI-PLANE

NC)

FUNCTION

FUNCTION

CONTROL)

APC

(FOR

MX

SERIES)

I

J.

K.

L.

PPC

FOR

(PALLETE

HORIZONTAL

SPINDLE

(FOR

STANDARD

READ/WRITE

(WITH

Hi-CUT

Since

this

operation

some

portions

Specifications

Final

may

THERMAL

FILE

INPUT/OUTPUT

manual

not

apply

check

to

POOL

AND

describes

to

your

the

LINE

MULTI-STATION

MC

DEVIATION

AND

ATTACHMENT

GET/PUT

the

special

machine.

specifications

CONTROL)

COMPENSATION

FUNCTIONS

FUNCTION)

specifications

Refer

before

to

reading

your

machine’s

this

APC

(FOR

MOUNTABLE

(optional

manual.

specifications)

SERIES)

MC

SYSTEM

SPINDLES)

of

OSP,

v2

A.

ANIMATION

FUNCTION

TABLE

OF

CONTENTS

TABLE

4202-E

CONTENTS

OF

P-(i)

PAGE

SECTION

1.

Special

Main

2.

Screen

3.

4.

Animation

SECTION

1

.

Graphic

2.

Explanation

2-1.

2-2.

2-3.

2-4.

2-5.

2-6.

1

GENERAL

Features

Functions

Layout

2

Screen,

TYPES

Display

OF

Coordinate

Animation

of

Explanation

Trace/Animation

Tool

Kind

Material

Graphic

Data

High

Erase

ON/OFF

Draw

Terminology

of

ANIMATION

System

Related

Functions

..

A-1

A-1

A-1

A-5

A-6

A-1

A-1

A-1

A-1

A-20

A-22

A-22

A-23

A-23

2

2

6

8

2-7.

2-8.

2-9.

2-10.

2-11.

2-12.

3.

Explanation

4.

Rotary

SECTION

Graphic

Auto

Scale

Area

Change

Change

Angle

Blank

Definition

Shape

Tool

of

Axis,

Parallel

3

ANIMATION

Data

Setting

Animation

Function

Related

Axis,

5-Face

DISPLAY

(Blank

NC

Cutting

Define)

Program

.

METHOD

A-23

A-40

A-41

A-44

A-46

A-78

A-82

A-91

A-94

TABLE

4202-E

CONTENTS

OF

P-(ii)

PAGE

TOOL

B.

SECTION

1

.

Features

2.

Major

SECTION

Data

.

1

2.

Graphic

3.

Data

PATH

1

2

DISPLAY

OVERVIEW

Functions

SETTING

Data

in

Setting

in

Setting

Setting

SECTION3TOOL

1.

Operations

the

Graphic

the

Plane

PATH

FUNCTION

DISPLAY

OF

Data

Parameters

Chance

DRAWING

Mode

Mode

DATA

B-1

B-1

B-1

B-3

B-3

B-4

B-1

B-1

B-1

2

4

4

Contents

2.

3.

Restart

SECTION

C.

OPERATION

NC

SECTION

SECTION

Contents

.

1

Count

2.

3.

Alarm

of

Display

Sequence

and

PARAMETERS

4

MONITOR

1

OVERVIEW

HOUR

NC

2

of

Display

and

Data

Set

Restart

METER

Data

Operations

B-1

B-1

B-1

C-1

C-2

C-2

C-3

C-3

4

5

7

TABLE

4202-E

CONTENTS

OF

P-(iii)

PAGE

SECTION

1

.

Content

Count

2.

3.

Alarm

Hi2-NC

D.

SECTION

SECTION

SECTION

.

1

Designating

3

NC

of

Data

WORK

Display

and

FUNCTION

1

OVERVIEW

2

HIGH-SPEED

3

TOLERANCE

Tolerance

COUNTER

Set

Data

(HIGH-SPEED

NC

CONTROL

Control

NC)

INTERPOLATION

FUNCTION

Mode

FUNCTION

C-4

C-4

C-4

C-5

D-1

D-2

D-3

D-3

Tolerance

2.

Tolerance

3.

Tolerance

4.

Alarm

5.

E.

SYNCHRONIZED

SECTION

SECTION

SECTION

1

2

3

Control

Control

Control

Parameters

Mode

Guide

TAPPING

OVERVIEW

COMMANDS

TAPPING

CYCLE

Designation

FUNCTION

OPERATIONS

D-4

D-7

D-1

D-1

E-1

E-2

E-5

3

5

SECTION4PRECAUTIONS

E-7

TABLE

4202-E

CONTENTS

OF

P-(iv)

PAGE

SECTION

SECTION

F.

TOOL

SECTION

Overview

.

1

SECTION

1

.

Tool

2.

Group

3.

Tool

TORQUE

5

DURING

PARAMETERS

6

MONITORING

SYNCHRONIZED

MANAGEMENT

OVERVIEW

1

DESCRIPTION

2

Number

Offset

Number

Management

(optional)

Mode

FUNCTION

OF

MANAGEMENT

(optional)

FUNCTION

TAPPING

FOR

EACH

TOOL

NUMBER

...

E-8

E-13

F-1

F-1

F-2

F-2

F-4

F-4

4.

5.

6.

OK/NG

Tool

Distinction

Evaluation

Life

Management

between

(optional)

Data

Commanded

SECTION3CHANGEOVER

Selection

1

.

2.

Changeover

SECTION

1.

Tool

ATC

2.

3.

Tool

4.

Tool

4

Length

Tool

Management

Group

Spare

of

Tool

of

ENTRY

Offset

Set

Tool

Offset

AND

DISPLAY

Cutter

and

Function

Number

(optional)

Tool

OF

SPARE

Radius

Spare

and

TOOL

OF

TOOL

Compensation

(optional)

Tool

(OPTIONAL)

MANAGEMENT

DATA

F-5

F-6

F-6

F-7

F-7

F-7

F-8

F-8

F-10

F-1

F-1

1

2

TABLE

4202-E

CONTENTS

OF

P-(v)

PAGE

SECTION

SECTION

Command

.

1

2.

Tool

Supplements

3.

SECTION

TOOL

G.

SECTION

RESETTING DEFECTIVE

5

MANAGEMENT

6

Format

Setting

Data

7

ALARM

LIFE

MANAGEMENT

OVERVIEW

1

LIST

OF

TOOL

TOOLS

FOR

FUNCTION

DATA

WHICH

ATC

IS

NOT

USED

F-13

F-14

F-14

F-15

F-15

F-16

G-1

SECTION

1

.

Setting

1

-1

.

2.

Setting

2-1.

2-2.

2-3.

SECTION

SECTION

For

.

1

Changing

2.

Setting

3.

2

ENTRY

Tool

No.

Setting

Setting

Setting

3

4

Usable

Tool

Tool

Life

Setting

Management

SET

COMMAND

RESETTING

Tools

Life-expired

a

LEFT

TIME

OF

TOOL

for

Pot

No

No.

Management

Tool

TIME

Pot

for

Group

and

Mode

FOR

TOOL

Tool

the

to

Data

MANAGEMENT

LIFE

No

Data

TIME

LEFT

Data

ACTIVATING

LIFE

DATA

One

New

with

Same

Value

TOOL

as

SET

LIFE

TIME

DATA

MANAGEMENT

Data

for

All

Tools

G-2

G-4

G-4

G-6

G-6

G-8

G-10

G-1

G-1

G-1

G-1

G-1

2

4

4

5

5

TABLE

4202-E

CONTENTS

OF

P-(vi)

PAGE

SECTION

1

.

Tool

Tool

2.

SECTION

PPC

H.

(PALLETE

SECTION

SECTION

SECTION

PROGRAM

5

Management

Life

Life

Management

ALARM

6

PREFACE

1

2

PPC

3

CREATING

FOR

LIST

POOL

CYCLE

PPC

CYCLE

EXAMPLES

by

Tool

Used

Count

by

LINE

Data

CONTROL)

OPERATION

MACHINING

THE

OPERATION

Time

Data

of

Machining

FOR

HORIZONTAL

PROCEDURES

PROGRAM

Cycles

MC

MULTI-PLANE

G-16

G-16

G-17

G-18

APC

H-1

H-3

H-4

1

.

Creating

2.

Creating

SECTION

Touch

.

1

1-1.

1-2.

1-3.

1-4.

1-5.

2.

PPC

Schedule

3.

3-1.

3-2.

3-3.

the

the

4

PPC

Panel

Status

Carry-in

Pallet

Carry-out

Pallet

Machining

Manual

Mode

Switch

Automatic

Waiting

Interrupt

Pallet

PPC

Cycle

PANEL

transition

Schedule

Operation

Switch

Schedule

Schedule

Schedule

Exchange

Operation

OPERATION

the

using

Screen

Screen

Display

Screen

Machining

Machining

MENU

Screen

Program

PAGE

and

Program

Keys

on

the

Touch

Panel

H-4

H-4

H-5

H-6

H-6

H-8

H-10

H-1

H-1

H-1

H-1

H-1

H-1

H-1

2

4

7

7

7

7

7

3-4.

WAITING

SCHEDULE

STOP

Switch

H-1

8

TABLE

4202-E

CONTENTS

OF

P-(vii)

PAGE

EMPTY

4.

IN

5.

OUT

6.

PPC

7.

.

7-1

7-2.

EMG.

8.

RESTART

9.

SECTION

1

.

Carry-in

2.

Carry-in

2-1

.

PALLET

Switch

Switch

CYCLE

PPC

CYCLE

on

the

PPC

CYCLE

the

on

STOP

CARRYINGINPALLETS

5

by

by

Machining

Carry-in

START

Machine

Machine

Switch

Switch

the

Automatic

the

Interrupt

Schedule

START

START

Switch

Switch/CYCLE

Switch

Operation

Switch

Operation

and

Schedule

in

on

Panel

on

Panelinthe

Waiting

the

Interrupt

START

PPC

the

the

in

the

PPC

Schedules

Schedule

Switch

Panel

PPC

Panel

PPC

and

ON

and

OFF

Mode

the

(CONT,

the

State

on

CYCLE

ONE

CYCLE

PPC

Panel

START

CYCLE

START

H-18

H-18

H-18

H-19

Switch

H-19

Switch

H-20

H-20

H-20

H-21

H-22

H-24

H-26

Carring

3.

Carry-in

4.

SECTION

Carry-out

1.

Automatic

2.

SECTION

1

.

Assigning

SECTION

SECTION

in

the

While

CARRYING

6

while

Carrying-out

7

ASSIGNING

PALLET

TO

Procedures

EDTING

8

MACHINING

9

Empty

the

the

Pallet

PPC

PPC

MACHINING

Off

is

PALLETS

OUT

OnorOff

is

Processed

of

PPC

CYCLE

NUMBERS

PROGRAM

Pallet

when

OPERATION

SCHEDULE

AND

SYSTEM

Only

Two

Pallets

Are

MACHINING

VARIABLES

Used

PROGRAMS

H-28

H-30

H-32

H-33

H-35

H-36

H-36

H-39

H-43

1

2.

.

VPLDT

VPLNO

[1]

to

VPLDT

[1

2J/VPPCP

H-43

H-46

TABLE

4202-E

CONTENTS

OF

P-(viii)

PAGE

SECTION

1

.

Setting

2.

Setting

3.

Communication

(RS232C

SECTION

SECTION

SECTION

Error

1

.

Errors

2.

10

SETTING

Dataonthe

Dataonthe

Communication

CHECKING

11

NP

12

ERRORS

13

at

Carry-in

at

Carry-out

SYSTEM

SETUP.WAITING

[Pallet

Interface

between

Parameters)

THE

COMMAND

DISPLAYED

Operation

Operation

MAINTENANCE

ST/MAC.CIR

Station

PPC

No.-Pallet

the

SYSTEM

ON

..

Touch

THE

PARAMETERS

PNO.

Table

and

Screen]

No.

Panel

CONDITION

PPC

PANEL

NC

SET

Screen

H-47

H-47

H-48

H-49

H-50

H-51

H-52

H-52

H-52

3.

Other

SECTION

I.

PPC

(PALLETE

SECTION

SECTION

SECTION

.

1

Creating

Creating

2.

Errors

14

GENERATED

POOL

1

PREFACE

PPC

2

3

CYCLE

CREATING

FOR

PPC

the

Pallet

PPC

the

LINE

OPERATION

THE

CYCLE

Exchange

Operation

Cycle

ALARMS

CONTROL)

MACHINING

OPERATION

Machining

Machining

FOR

HORIZONTAL

PROCEDURES

PROGRAM

Program

Program

MC

MULTI-STATION

APC

H-53

H-54

1-1

-3

I

I

-4

I

-4

-4

I

TABLE

4202-E

CONTENTS

OF

P-(ix)

PAGE

SECTION

1

.

Touch

1-1.

1-2.

1-3.

1-4.

1-5.

PPC

2.

3.

Schedule

3-1.

3-2.

3-3.

3-4.

4.

EMPTY

5.

IN

4

PPC

Panel

Status

Pallet

Pallet

Machining

Manual

Mode

Automatic

Waiting

Interrupt

WAITING

PALLET

Switch

PANEL

transition

Carry-in

Carry-out

Schedule

Operation

Switch

Switch

Schedule

Schedule

Schedule

SCHEDULE

using

Screen

Screen

Carry-in

OPERATION

MENU

the

Display

Screen

Switch

STOP

Screen

Switch

and

PAGE

Keys

on

the

Touch

Panel

1-5

I

-6

I

-6

I-7

-9

I

1-11

1-13

1-15

1-15

1-15

1-15

1-16

1-16

1-16

1-16

OUT

6.

7.

PPC

.

7-1

7-2.

EMG.

8.

RESTART

9.

SECTION

1

.

Carry-in

2.

Carry-in

2-1.

Carring

3.

4.

Carry-in

Switch

CYCLE

PPC

on

PPC

on

STOP

CYCLE

the

Machine

CYCLE

the

Machine

START

START

START

Switch

Switch/CYCLE

Switch

Operation

Switch

Operation

Switch

CARRYINGINPALLETS

5

the

by

the

by

Machining

in

the

While

Automatic

Interrupt

Schedule

Empty

the

PPC

Schedule

Pallet

is

and

in

Off

the

START

on

the

in

Panel

the

on

Panelinthe

Waiting

Schedules

Interrupt

Switch

Panel

PPC

the

PPC

Panel

PPC

PPC

Schedule

and

ON

and

OFF

Mode

the

(CONT,

the

State

on

CYCLE

ONE

CYCLE

PPC

Panel

START

CYCLE

START

1-16

1-16

Switch

1-17

Switch

1-18

1-18

1-18

1-19

I-20

I-22

I-24

I-26

I-28

TABLE

4202-E

CONTENTS

OF

P-(x)

PAGE

SECTION

Carry-out

5.

SECTION

6.

Assigning

SECTION

SECTION

1

.

VPLDT

VPLNO

2.

6

CARRYING

while

7

ASSIGNING

TO

PALLET

Procedures

EDTING

8

MACHINING

9

to

[1]

VPLDT

OUT

the

PPC

is

PPC

NUMBERS

MACHINING

PROGRAM

[1

2J/VPPCP

PALLETS

OnorOff

CYCLE

OPERATION

SCHEDULE

AND

SYSTEM

MACHINING

VARIABLES

1-30

1-31

PROGRAMS

I-33

I-33

I-36

I-39

I-39

I-42

SECTION

.

1

Setting

2.

Setting

Communication

3.

(RS232C

SECTION

SECTION

SECTION

Parameter

.

1

DNC-B

2.

SETTING

10

Dataonthe

Dataonthe

Interface

Communication

CHECKING

11

12

EXCHANGING

DNC-B

13

Setting

Operation

SYSTEM

SETUP,

PALLET

THE

DNC-DT

AND

Screen

the

from

MAINTENANCE

MAC-INT.

CARRIER

between

Parameters)

PPC

the

SYSTEM

PALLETS

OPERATION

PPC

.

SET

PNO.

NO.-PALLET

Touch

Panel

CONDITION

WITH

THE

PARAMETERS

Screen

NO.

TABLE

NC

and

FUNCTION

PPC

Screen

OFF

I-43

I-43

I-44

I-45

I-46

I-47

I-48

i-48

I-49

3.

DNC-DT

Operation

from

the

PPC

I-50

TABLE

4202-E

CONTENTS

OF

P-(xi)

PAGE

SECTION

1

.

Error

Errors

2.

3.

Other

APC

4.

SECTION

SPINDLE

J.

(FOR

SECTION

SECTION

14

ERRORS

Carry-in

at

at

Carry-out

Errors

Interlock

GENERATED

15

Operation

Error

THERMAL

STANDARD

OUTLINE

1

2

COMPENSATION

DISPLAYED

..

Operation

ALARMS

DEVIATION

AND

ATTACHMENT

THE

ON

COMPENSATION

MOUNTABLE

SYSTEM

CONFIGURATION

PPC

PANEL

SYSTEM

1-51

1-51

1-51

I-52

I-53

I-54

v2

SPINDLES)

J-1

J-2

SECTION

.

1

Screen

1-1.

1-2.

1-3.

1-4.

1-5.

1-6.

1-7.

1-8.

2.

Alarm

Precaution

3.

3-1.

4.

Thermal

4-1.

3

SYSTEM

Checking

for

SAMPLING

A/D

A/DAVE

TEMPERATURE

ESTIMATE

COMP.

OVERALL

AXIS

(Thermal

ROTARY

Message

Regarding

Screen

COMPENSATION

Transition

Deviation

I

TIMES

VALUE

DEV.

Comp.

Thermal

Deviation)

Thermal

Common

(No.

SW

Deviation

1/2/3

Deviation

Parameter

1)

Compensation

Compensation

Screen

Data

Parameters

1

(Page

1)

J-3

J-3

J-3

J-3

J-3

J-3

J-3

J-3

J-4

J-4

J-5

J-8

J-8

J-9

J-10

TABLE

4202-E

CONTENTS

OF

P-(xii)

PAGE

5.

6.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

6-1.

6-2.

6-3.

SENSOR

SCREEN

TEMP

AVERAGING

TRAVERSE

CODE

M

Thermal

Deviation

QUIT

ROTARY

PROCESS

COMPENSATE

JUDGING

SIDE

Thermal

Deviation

OVERALL

ROTARY

ROTARY

(CH1

SWITCH

SAMPLING

TIMES

(X),

COMP.

Comp.

VALUE

(No.1)

FACTOR

SWITCH

TIMING

STEPS

(X3)

Comp.

LIMIT

DEV.

DEV.

to

CH8)

(No.

(No.11)

(No.

(Y),

(Z)

(NO.

16)

Common

(No.2,

(No.4)

(No.5)

SEC

(No.6)

(Y3,

Common

(X),

(Y),

LIMIT

(NO.

FACTOR

(No.2

10)

12)

(No.

Z1

(Z)

1

3)

,

,

Z2,

15)

2,

to

13

(NO.

3,

9)

to

15)

Parameter

Z3)

(No.

Parameter

to14)

12

4

(NO.

Screen

7

to

Screen

1

6

to

J-10

J-10

J-10

J-11

J-11

J-11

1

(Page

2)

J-12

J-13

J-13

J-13

J-13

J-13

1

1

)

(Page

3)

1

J-13

J-14

J-14

J-14

1

9)

J-14

7.

8.

9.

6-4.

7-1.

7-2.

7-3.

7-4.

7-5.

7-6.

7-7.

7-8.

8-1.

8-2.

8-3.

8-4.

ROTARY

Thermal

HOT

BASE

TMP

CONVERSION

CORRECT

TMP

FIXED

TEMP

Thermal

RISE

(No.

DROP

QUIT

STOP

Thermal

DEV.

Deviation

SENSOR

TEMP

ZERO

Compensation

SENSOR

ADJUST

FACTOR

TIME

CONST

CONST

TIME

RISE

LIMIT

Deviation

Compensation

PARAMETER

11)

to

9

PARAMETER

FACTOR

RATIO

Deviation

(NO.

Compensation

FACTOR

(No.1)

(No.3)

TABLE

(No.5)

(No.6)

(No.7)

(No.8)

RISE

1,

1,

1,

QUIT

17)

(NO.

5

Parameter

(No.2)

(No.4)

Parameter

PARAMETER

DROP

FACTOR

Parameter

20)

Screen

Screen

2,

PARAMETER

2

15,

(No.

Screen

RISE

2,

16)

2

(Page

2

(Page

BASE

DROP

3

(Page

1)

2)

MIN

BASE

)

1

MIN

(No.

12

to

14)

J-14

J-15

J-16

J-16

J-16

J-16

J-16

J-16

J-16

J-16

J-17

J-18

J-18

J-18

J-18

J-19

9-1.

Thermal

Deviation

Compensation

Amount

J-19

TABLE

4202-E

CONTENTS

OF

P-(xiii)

PAGE

SECTION

1

.

Screen

1-1.

1-2.

1-3.

1-4.

1-5.

1-6.

1-7.

1-8.

1-9.

2.

Alarm

3.

Precaution

3-1.

Thermal

4.

4-1.

4

SYSTEM

Checking

for

SAMPLING

A/D

A/DAVE

TEMPERATURE

TIMES

ESTIMATE

COMP.

OVERALL

AXIS

ROTARY

AT.

SPNDL

Message

Screen

Deviation

VALUE

(Thermal

DEV.

Regarding

Transition

Comp.

COMPENSATION

II

Thermal

Deviation)

Thermal

Common

SW

Deviation

1/2/3

Deviation

(No.

1)

Compensation

Compensation

Parameter

Screen

Data

Parameters

1

(Page

1)

J-20

J-20

J-20

J-20

J-20

J-20

J-20

J-21

J-21

J-21

J-21

J-22

J-25

J-26

J-27

J-28

5.

5-1.

5-3.

5-4.

6.

6-1.

7.

7-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

5-2.

5-5.

SENSOR

SCREEN

TEMP

AVERAGING

TRAVERSE

CODE

M

Thermal

QUIT

PROCESS

COMPENSATE

JUDGING

SIDE

Thermal

OVERALL

Thermal

HOT

(CH1toCH8)

SWITCH

SAMPLING

COMP.

Deviation

VALUE

SWITCH

TIMING

STEPS

Deviation

LIMIT

Deviation

SENSOR

(No.2to9)

(No.

10)

(No.11)

(Y),

(NO.

1)

SEC

(No.12)

(Z)

(No.

16)

Common

(No.2)

(No.3)

TIMES

(X),

Comp.

(No.

(No.4)

(Z1,Z2)

Comp.

Common

(X),

(Y),

(No.

Compensation

(No.1)

13

Parameter

6)

5

to

Parameter

(Z)

(NO.

Parameter

to

15)

7

to

Screen

Screen

9)

Screen

1

1

2

(Page

(Page

(Page

J-28

J-28

J-28

J-28

J-29

J-29

2)

J-30

J-31

J-31

J-31

J-31

J-31

3)

J-32

J-32

)

.

.

1

J-33

J-34

7-2.

7-3.

BASE

TMP

TEMP

ZERO

SENSOR

ADJUST

(No.2)

(No.3)

J-34

J-34

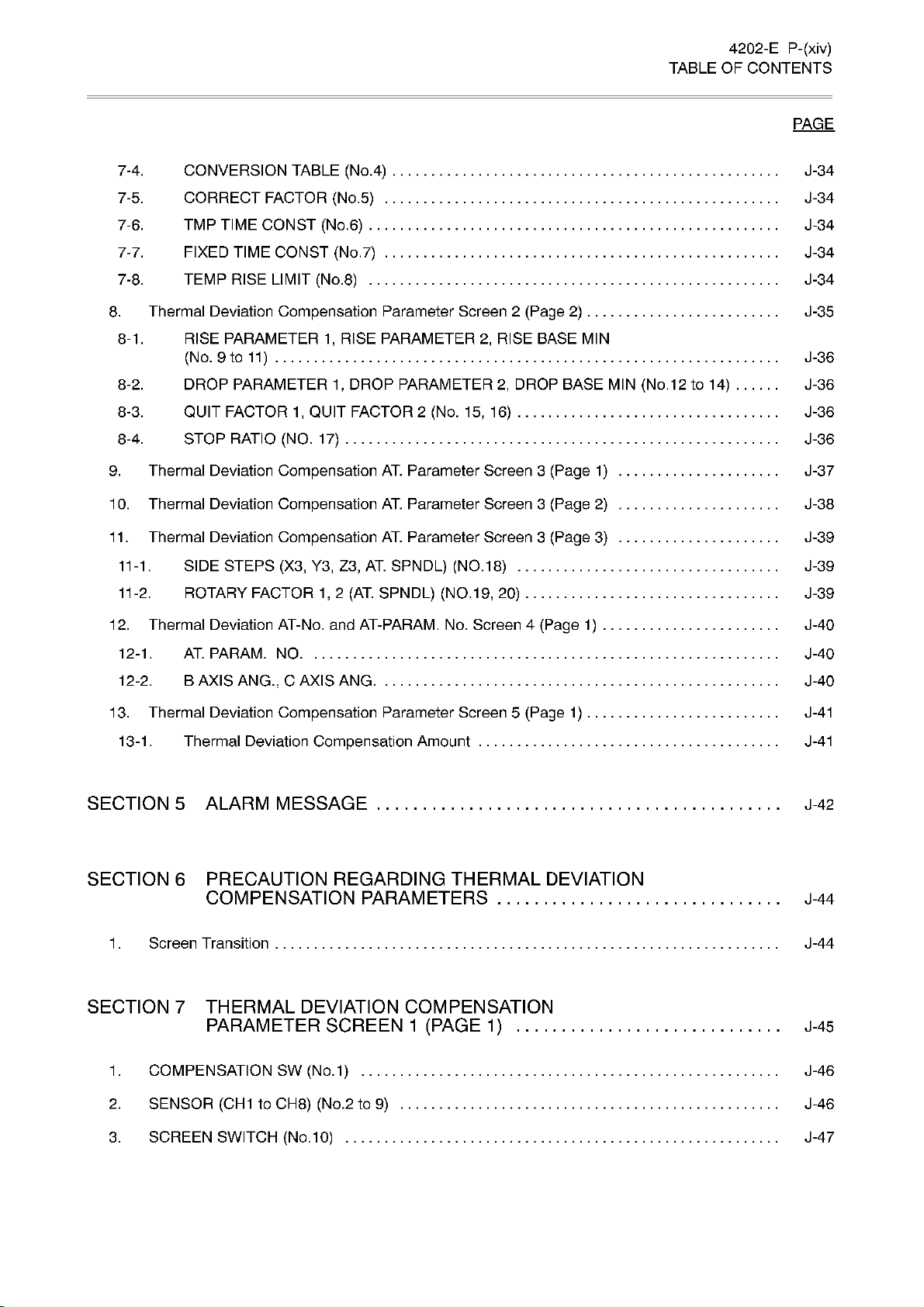

TABLE

4202-E

CONTENTS

OF

P-(xiv)

PAGE

7-4.

7-5.

7-6.

7-7.

7-8.

8.

8-1.

8-2.

8-3.

8-4.

9.

0.

1

11

11-1.

11-2.

.

CONVERSION

CORRECT

TMP

FIXED

TEMP

Thermal

RISE

(No.

DROP

QUIT

STOP

Thermal

Thermal

Thermal

SIDE

ROTARY

FACTOR

TIME

CONST

TIME

CONST

RISE

LIMIT

Deviation

PARAMETER

to

9

Compensation

11)

PARAMETER

FACTOR

RATIO

Deviation

Deviation

Deviation

STEPS

Compensation

Compensation

Compensation

(X3,

FACTOR

TABLE

,

QUIT

1

(NO.

(No.5)

(No.

(No.

(No.8)

1,

1,

17)

Y3,

2

1,

(No.4)

6)

7)

Parameter

RISE

PARAMETER

DROP

FACTOR

AT.

AT.

AT.

AT.

Z3,

(AT.

SPNDL)

Screen

PARAMETER

(No.

15,

2

Parameter

Parameter

Parameter

SPNDL)

(NO.18)

(NO.

RISE

2,

2,

16)

Screen

Screen

Screen

19,

20)

2

(Page

BASE

DROP

3

3

3

2)

BASE

(Page

(Page

(Page

MIN

1)

2)

3)

(No.12to14)

MIN

J-34

J-34

J-34

J-34

J-34

J-35

J-36

J-36

J-36

J-36

J-37

J-38

J-39

J-39

J-39

Thermal

12.

12-1.

12-2.

Thermal

1

3.

.

13-1

SECTION

SECTION

Screen

1.

SECTION

COMPENSATION

1.

Deviation

AT-No.

AT.PARAM.NO

B

Thermal

5

6

ANG.,

AXIS

Deviation

C

Compensation

Deviation

ALARM

MESSAGE

PRECAUTION

COMPENSATION

Transition

7

THERMAL

PARAMETER

SW

and

AT-PARAM.

AXIS

ANG

Parameter

Compensation

REGARDING

PARAMETERS

DEVIATION

SCREEN

1)

(No.

....

No.

Screen

Screen

Amount

THERMAL

4

(Page

(Page1)

5

DEVIATION

COMPENSATION

1

(PAGE

1)

1)

...

.

J-40

J-40

J-40

J-41

J-41

J-42

J-44

J-44

J-45

J-46

2.

3.

SENSOR

SCREEN

(CH1toCH8)

SWITCH

(No.

(No.2to9)

10)

J-46

J-47

TABLE

4202-E

CONTENTS

OF

P-(xv)

PAGE

TEMP

4.

AVERAGING

5.

TRAVERSE

6.

SECTION

QUIT

1.

2.

ROTARY

3.

PROCESS

4.

COMPENSATE

JUDGING

5.

SIDE

6.

SECTION

SAMPLING

TIMES

(X),

8

THERMAL

PARAMETER

VALUE

STEPS

9

(No.1)

FACTOR

SWITCH

TIMING

(X)

THERMAL

PARAMETER

(No.11)

(No.

(Y),

(Z)

DEVIATION

(No.2,

(No.

(No.

SEC

(No.

,

Z1

(Y,

DEVIATION

12)

13

(No.

SCREEN

3)

4)

5)

6)

Z2,

Z3)

SCREEN

15)

to

COMPENSATION

(PAGE

1

7

to

11

)

(No.

COMPENSATION

1

(PAGE

2)

2)

J-47

J-47

J-47

J-48

J-49

J-49

J-49

J-49

J-49

J-49

J-50

HOT

1.

BASE

2.

TMP

3.

CONVERSION

4.

CORRECT

5.

TMP

6.

7.

FIXED

TEMP

8.

SECTION

1.

RISE

(No.

2.

DROP

QUIT

3.

SENSOR

TEMP

ZERO

TIME

10

SENSOR

ADJUST

FACTOR

CONST

CONST

TIME

LIMIT

RISE

THERMAL

PARAMETER

PARAMETER

to

22)

20

PARAMETER

FACTOR

(No.1

2)

(No.

TABLE

(No.

(No.1

(No.

(No.1

DEVIATION

1,

1

QUIT

1,

(No.13)

..

1

4)

15)

(No.

..

16)

...

7)

18)

....

9)

SCREEN

PARAMETER

RISE

,

DROP

FACTOR

.

COMPENSATION

(PAGE

2

2,

PARAMETER

26,

27)

2

(No.

RISE

2,

DROP

2)

BASE

MIN

BASE

MIN

(No.23to25)

J-51

J-51

J-51

J-51

J-51

J-51

J-51

J-51

J-52

J-53

J-53

J-53

SECTION

THERMAL

11

PARAMETER

DEVIATION

SCREEN

COMPENSATION

(PAGE

3

1)

TABLE

4202-E

CONTENTS

OF

P-(xvi)

PAGE

J-54

1.

Thermal

K.

READ/WRITE

Deviation

Compensation

AND

GET/PUT

FUNCTION)

SECTION

SECTION

.

1

2.

1

GENERAL

2

CONFIGURATION

Configuration

Configuration

1

2

SECTION3FUNCTION

1

2.

.

READ

WRITE

Function

Function

Amount

FUNCTIONS

(WITH

FILE

INPUT/OUTPUT

I

J-54

K-1

K-2

K-2

K-2

K-3

K-3

K-3

3.

4.

GET

PUT

Function

Function

SECTION4FUNCTION

FOPENA

.

1

2.

3.

4.

5.

6.

7.

8.

FWRITC

READ

WRITE

GET

PUT

CLOSE

Supplements

(FOPENB)

Function

Function

Function

Function

Function

Function

II(FILE

Function

INPUT/OUTPUT

FUNCTION)

K-4

K-5

K-7

K-7

K-7

K-8

K-8

K-9

K-9

K-9

K-9

TABLE

4202-E

CONTENTS

OF

P-(xvii)

PAGE

SECTION

1

.

Data

Data

2.

SECTION

Data

.

1

2.

Data

SECTION

1

.

NC

NC

2.

SECTION

EXAMPLE

5

Using

Input

Output

6

Input

Output

7

Optional

Optional

8

Using

EXAMPLE

FOPNEA(B),

by

by

FWRITC,

PARAMETERS

Parameter

Parameter

ALARM

PROGRAM

READ

PUT

and

and

PROGRAM

(Word)

(Bit)

GET

WRITE

READ,

PUT,

Commands

and

and

.

I

Commands

II

(FILE

GET

Commands

WRITE

Commands

.

.

INPUT/OUTPUT

FUNCTION)

.

K-10

K-10

K-11

K-12

K-12

K-13

K-14

K-14

K-15

K-17

SECTION

L.

Hi-CUT

SECTION

SECTION

Designating

1.

2.

Hi

3.

Hi-Cut

4.

Hi-Cut

APPENDIX

9

OVERVIEW

1

2

Hi-CUT

-Cut

Control

Control

Control

CONTROL

Hi-Cut

Control

Parameters

Mode

Guide

OF

Hi-CUT

Mode

Designation

FUNCTION

K-20

L-1

L-2

L-2

L-2

L-4

L-6

A.

ANIMATION

FUNCTION

ANIMATION

A.

4202-E

A-1

FUNCTION

SECTION

9.

10.

Special

The

animation

movement,

High-speed

and

VIEW

Main

(1)

Display

SPLIT

possible

1

GENERAL

Features

function

cutting

a

drawing

SOLID

depth

is

VIEW,

Functions

Mode

mode

VIEW

at

time.

any

HUTO

it

SPLIT

ACTUAL

z

F

1000

5

H=

SCALE

CUTTING

makes

by

etc.,

possible

with

(Fig.

OPERATION

VIEW*

P05I.

300.000

300.000

560.000

0.0

0

D=

0

91.152

TINE

0:

1:15

possible

it

simulation

to

(drawing).

whileinMachine

switching

1-1),

106

e

-100

0

and

possible

SOLID

monitor

VIEW

GR°1

Lock

between

.MIN

a-

blank

the

condition.

the

mode

(Fig.

0

97,'04,'0i

$

~T?

machining

Graphic

two

at

1-2),

N

I

2:

any

18:08

tilliH

time.

with

73

conditions

display

switching

consists

between

such

of

as

a

the

tool

SPLIT

two

PROGRAM!

SELECT

ACTUAL

POSIT.

I

BLOCK

DATA

PART

PROGRAM]

Fig.

-203

SEARCH

1-1

ATC/APC

SPLIT

&

VIEW

CHECK

DATA

[EXTENDI

AUTO

*SOLID

ACTUAL

X

V

2

F

S

1000

H=

0

SCALE

CUTTING

OPERATION

VIEW*

POSI.

3G0.000

300.000

560.000

0.0

0

D=

69.

120

TIME

0:

1:15

A-2

GRPi

.MIN

0

97/04/01

N

2

ESSs

18:34

r

_SQ3i9

V

A.

ANIMATION

73

4202-E

FUNCTION

JL

,

o

B

z

(2)

Projection

SOLI

the

In

be

viewed

PROGRAM

SELECT

F

I

Anglo

DVIEW

the

from

Al~0

WANGLE

PAN

TILT

CURSOR

CURSOR!

CURSOR*-:

CURSOR-*:

ACTUAL

POSIT,

1

IfTTK

Change

mode,

desired

OPERATION

CHANGE*

60

43

ECvJH

t

:

UP

:

RIGHT

LEFT

PART

PROGRAM

the

direction

BLOCK

DATA

3)rF7»4fF~5l(T~6lfF~7ÿrF~Bl

F

1-2

Fig.

angle

and

Tl

L

(Fig.

GRPI.

1

SEARCH

SOLID

PAN

1-3).

MEN

z

T

ATC/APC

angle

|

S'

VIEW

can

0

97/04/01

CHECK

E'ATA

be

N

[

EXTEND]

freely

1:29:41

changed

1

so

that

the

object

can

(3)

Display

The

display

Area

=

GS

>Q

GA

—

(

F

Change

area

)(7T1I

1

settings

F

13(ZZ3(Z!13(Z!13CEzI)CElD

1

can

Fig.

be

Projection

-3

changed

for

both

Angle

the

QUIT

Change

SPLIT

and

SOLID

VIEW

modes

(Fig.

1-4).

(4)

Painting

ANIMATION

A.

4202-E

A-3

FUNCTION

Display

of

the

pattern

cut

AUTO

OPERATION

CHANGE*

*AREA

CENTER

0.

0.000

20.

—

PAGEt:MAGNI

PAGEI

REDUCE

:

91.152

=EX

-GS

(

1

F

IfTTK

000

000

.

changes

100

e

-

-1-30

m"-

I

0

-103

p

3lf"F7l'

Fig.

the

according

to

GRFi.MIN

+

-200

MARKER

0

}rF~5~irÿ60rÿ70fF~Bl

Display

1

-4

Area

cutting

0

S7V04/Q1

Change

depth

QUIT

N

200

of

1:15:07

•

REDUCE!

the

machined

1

H

T*

—

area.

(5)

Blank

Settings

Definition

can

be

PROGRAM

.Am..

>EN

>-

CREATE

made

-4

1-

-4-

for

OPERATION

0

DELETE

the

blank

m

I

AMEND

T

pfgl

contour

S

il

BLANK

T

T

:

and

BEF

SYMBOL

SELECT

position

fFTirFÿrrT)rFTTirrTirETirrTirF~B~)

go

97/04/01.

i

:

(Fig.

No

ajDIREC-

IND=*

MESH

SELECT

’

b

x

1

2

"a

120

M

QUIT

No.=

1-5).

1:27:07

=01

Cz

V

=

10mrn

SYMBOL

0

=

0G

Fig.

1-5

Blank

Definition

Loading...

Loading...