Nissan XTrail T30 2005 User Manual

ENGINE CONTROL SYSTEM

B ENGINE

A

EC

SECTION EC

ENGINE CONTROL SYSTEM

CONTENTS

INDEX FOR DTC ........................................................ 8

DTC No. Index ......................................................... 8

Alphabetical Index ...................................................11

PRECAUTIONS ........................................................ 14

Precautions for Supplemental Rest raint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 14

On Board Diagnostic (OBD) System of Engine and

A/T ............................ ............. ............. ............. ....... 14

Precaution ...................... ........................................ 14

Wiring Diagrams and Trouble Diagnosis ................ 17

PREPARATION ......................................................... 18

Special Service Tools ............................................. 18

Commercial Service Tools ...................................... 19

ENGINE CONTROL SYSTEM .................................. 21

System Diagram ..................................................... 21

Multiport Fuel Injection (MFI) System .................... 22

Electronic Ignition (EI) System ............................... 24

Fuel Cut Control (at No Load and High Engine

Speed) ...................... ............. ............. ............. ....... 25

AIR CONDITIONING CUT CONTROL ..................... 26

Input/Output Signal Chart ................................ ....... 26

AUTOMA TIC SPEED CONTROL DEVICE (ASCD) ... 27

System Description ................................................ 27

Component Description .......................................... 28

CAN COMMUNICATION .......................................... 29

System Description ................................................ 29

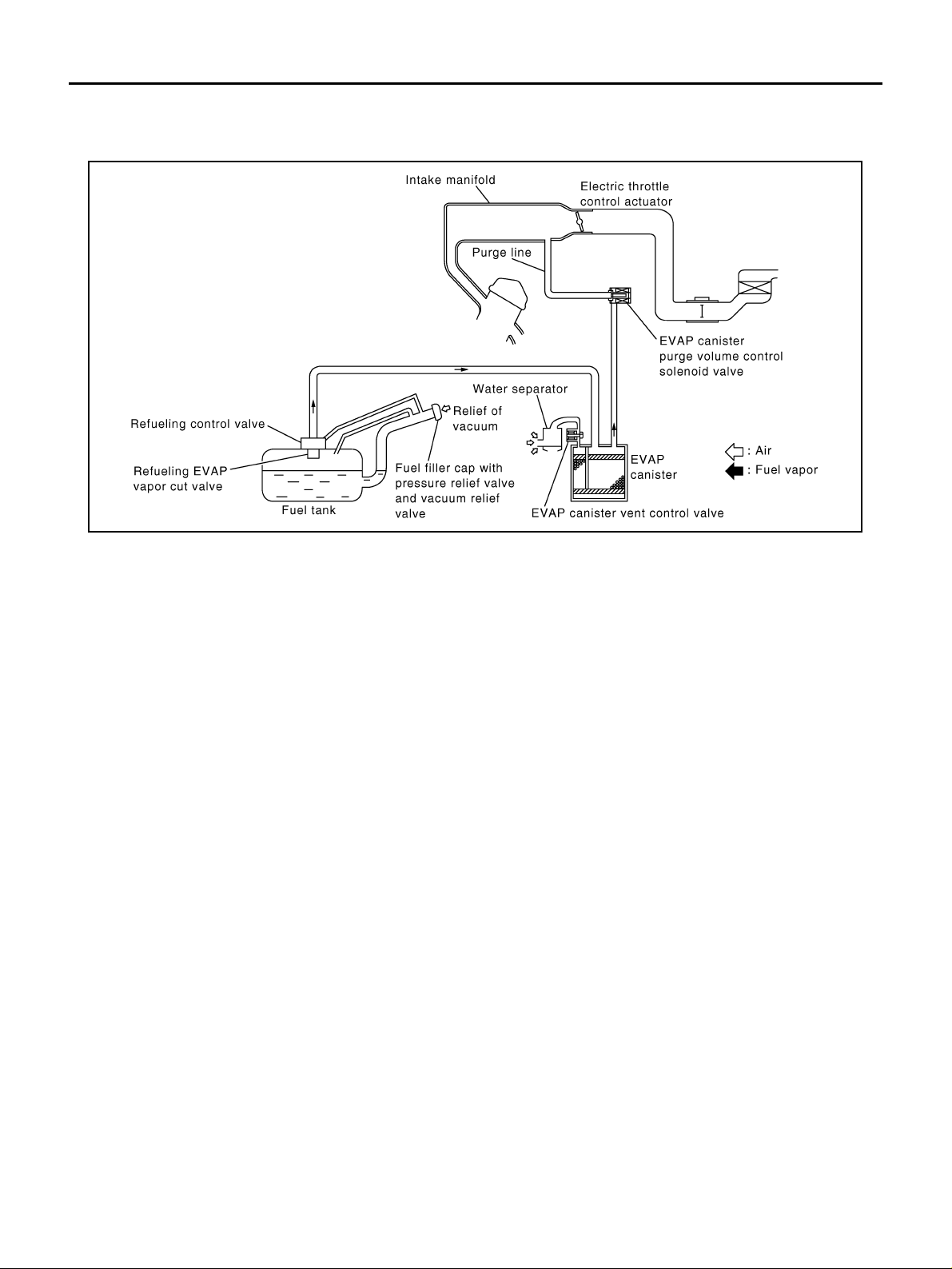

EV APORATIVE EMISSION SYSTEM ....................... 30

Description ............................................................. 30

Component Inspection ........................................... 33

Removal and Installation ........................................ 34

How to Detect Fuel Vapor Leakage ....................... 34

ON BOARD REFUELING VAPOR RECOVERY

(ORVR) ..................................... ...... ....... ...... ....... ....... 37

System Description ................................................ 37

Diagnostic Procedure ............................................. 38

Component Inspection ........................................... 41

POSITIVE CRANKCASE VENTILATION ................. 44

Description ............................................................. 44

Component Inspection ........................................... 44

NVIS (NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS) ............................. ........................................... 46

Description ................... ...... ....... ...... ........................46

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............47

Introduction .................. ....................................... ....47

Two Trip Detection Logic ....................... ...... ...........47

Emission-Related Diagnostic Information ...............48

Malfunction Indicator Lamp (MIL) ...........................61

OBD System Operation Chart ................................65

BASIC SERVICE PROCEDURE ........................... .... 70

Basic Inspection ..................................................... 70

Idle Speed and Ignition Timing Check ....................75

Idle Mixture Ratio Adjustment .................................77

VIN Registration ..................................................... 87

Accelerator Pedal Released Pos i tio n Lear nin g ......88

Throttle Valve Closed Position Learning .................88

Idle Air Volume Learning ........................................88

Fuel Pressure Check ..............................................90

TROUBLE DIAGNOSIS ............................................94

Trouble Diagnosis Introduction . ..............................94

DTC Inspection Priority Chart ...............................100

Fail-Safe Chart ............................... ....... ...... ....... ..102

Symptom Matrix Chart ..........................................103

Engine Control Component Parts Location ..........107

Vacuum Hose Drawing .......................... ...... ....... ..112

Circuit Diagram .....................................................113

ECM Harness Connector Terminal Layout ...........115

ECM Terminals and Reference Value ...................115

CONSULT- II Func tio n (ENGI NE) ..........................123

Generic Scan Tool (GST) Function .......................136

CONSULT-II Reference Value in Data Monitor .....138

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................142

TROUBLE DIAGNOSIS - SPECIFICA TION V ALUE .144

Description ................... ...... ....... ...... ......................144

Testing Condition ..................................................144

Inspection Procedure ............................................144

Diagnostic Procedure ...........................................145

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .............................. .........................................154

C

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-1

Description ................ .......................... ..................154

Diagnostic Procedure ...........................................154

POWER SUPPLY AND GROUND CIRCUIT ...........155

Wiring Diagram .....................................................155

Diagnostic Procedure ...........................................156

Component Inspection ..........................................162

Ground Inspection ................................................162

DTC U1000, U1001 CAN COMMUNICATION LINE .163

Description ................ .......................... ..................163

On Board Diagnosis Logic ....................................163

DTC Confirmation Procedure ................... ....... .....163

Wiring Diagram .....................................................164

Diagnostic Procedure ...........................................165

DTC P0011 IVT CONTROL .....................................166

Description ................ .......................... ..................166

CONSULT-II Reference Value in Data Monitor Mode

.166

On Board Diagnosis Logic ....................................167

DTC Confirmation Procedure ................... ....... .....167

Diagnostic Procedure ...........................................168

Component Inspection ..........................................169

Removal and Installation ......................................169

DTC P0031, P0032 HO2S1 HEATER .....................170

Description ................ .......................... ..................170

CONSULT-II Reference Value in Data Monitor Mode

.170

On Board Diagnosis Logic ....................................170

DTC Confirmation Procedure ................... ....... .....171

Wiring Diagram .....................................................172

Diagnostic Procedure ...........................................173

Component Inspection ..........................................175

Removal and Installation ......................................175

DTC P0037, P0038 HO2S2 HEATER .....................176

Description ................ .......................... ..................176

CONSULT-II Reference Value in Data Monitor Mode

.176

On Board Diagnosis Logic ....................................176

DTC Confirmation Procedure ................... ....... .....177

Wiring Diagram .....................................................178

Diagnostic Procedure ...........................................179

Component Inspection ..........................................181

Removal and Installation ......................................181

DTC P0101 MAF SENSOR .....................................182

Component Description ........................................182

CONSULT-II Reference Value in Data Monitor Mode

.182

On Board Diagnosis Logic ....................................182

DTC Confirmation Procedure ................... ....... .....182

Overall Function Check ........................................184

Wiring Diagram .....................................................185

Diagnostic Procedure ...........................................186

Component Inspection ..........................................189

Removal and Installation ......................................190

DTC P0102, P0103 MAF SENSOR .........................191

Component Description ........................................191

CONSULT-II Reference Value in Data Monitor Mode

.191

On Board Diagnosis Logic ....................................191

DTC Confirmation Procedure ................... ....... .....191

Wiring Diagram ................................................... ..193

Diagnostic Procedure ............................................194

Component Inspection ..........................................197

Removal and Installation .......................................198

DTC P0112, P0113 IAT SENSOR ............................199

Component Description ........................................199

On Board Diagnosis Logic ....................................199

DTC Confirmation Procedure ................................199

Wiring Diagram ................................................... ..201

Diagnostic Procedure ............................................202

Component Inspection ..........................................204

Removal and Installation .......................................204

DTC P0117, P0118 ECT SENSOR ..........................205

Component Description ........................................205

On Board Diagnosis Logic ....................................205

DTC Confirmation Procedure ................................206

Wiring Diagram ................................................... ..207

Diagnostic Procedure ............................................208

Component Inspection ..........................................210

Removal and Installation .......................................210

DTC P0122, P0123 TP SENSOR ............................211

Component Description ........................................211

CONSULT-II Reference Value in Data Monitor Mode

.211

On Board Diagnosis Logic ....................................211

DTC Confirmation Procedure ................................212

Wiring Diagram ................................................... ..213

Diagnostic Procedure ............................................215

Component Inspection ..........................................218

Remove and Installation .......................................218

DTC P0125 ECT SENSOR ......................................219

Description ............................................................219

On Board Diagnosis Logic ....................................219

DTC Confirmation Procedure ................................219

Diagnostic Procedure ............................................220

Component Inspection ..........................................221

Removal and Installation .......................................221

DTC P0127 IAT SENSOR ........................................222

Component Description ........................................222

On Board Diagnosis Logic ....................................222

DTC Confirmation Procedure ................................222

Diagnostic Procedure ............................................223

Component Inspection ..........................................224

Removal and Installation .......................................224

DTC P0128 THERMOSTAT FUNCTION .................225

On Board Diagnosis Logic ....................................225

DTC Confirmation Procedure ................................225

Diagnostic Procedure ............................................225

Component Inspection ..........................................226

Removal and Installation .......................................226

DTC P0132 HO2S1 .................................................227

Component Description ........................................227

CONSULT-II Reference Value in Data Monitor Mode

.227

On Board Diagnosis Logic ....................................227

DTC Confirmation Procedure ................................228

Wiring Diagram ................................................... ..229

Diagnostic Procedure ............................................230

Revision: 2005 March 2005 X-Trail

EC-2

Component Inspection ......................................... 232

Removal and Installation ...................................... 233

DTC P0133 HO2S1 ................................................. 234

Component Description ........................................ 234

CONSULT-II Reference Value in Data Monitor Mode

. 234

On Board Diagnosis Logic ................................... 234

DTC Confirmation Procedure ............................... 235

Overall Function Check ........................................ 236

Wiring Diagram .................................................... 237

Diagnostic Procedure ........................................... 238

Component Inspection ......................................... 242

Removal and Installation ...................................... 243

DTC P0134 HO2S1 ................................................. 244

Component Description ........................................ 244

CONSULT-II Reference Value in Data Monitor Mode

. 244

On Board Diagnosis Logic ................................... 244

DTC Confirmation Procedure ............................... 245

Overall Function Check ........................................ 246

Wiring Diagram .................................................... 247

Diagnostic Procedure ........................................... 248

Component Inspection ......................................... 250

Removal and Installation ...................................... 251

DTC P0138 HO2S2 ................................................. 252

Component Description ........................................ 252

CONSULT-II Reference Value in Data Monitor Mode

. 252

On Board Diagnosis Logic ................................... 252

DTC Confirmation Procedure ............................... 252

Wiring Diagram .................................................... 254

Diagnostic Procedure ........................................... 255

Component Inspection ......................................... 257

Removal and Installation ...................................... 258

DTC P0139 HO2S2 ................................................. 259

Component Description ........................................ 259

CONSULT-II Reference Value in Data Monitor Mode

. 259

On Board Diagnosis Logic ................................... 259

DTC Confirmation Procedure ............................... 260

Overall Function Check ........................................ 260

Wiring Diagram .................................................... 262

Diagnostic Procedure ........................................... 263

Component Inspection ......................................... 265

Removal and Installation ...................................... 266

DTC P0171 FUEL INJECTION SYSTEM FUNCTION . 267

On Board Diagnosis Logic ................................... 267

DTC Confirmation Procedure ............................... 267

Wiring Diagram .................................................... 269

Diagnostic Procedure ........................................... 270

DTC P0172 FUEL INJECTION SYSTEM FUNCTION . 274

On Board Diagnosis Logic ................................... 274

DTC Confirmation Procedure ............................... 274

Wiring Diagram .................................................... 276

Diagnostic Procedure ........................................... 277

DTC P0181 FTT SENSOR ...................................... 280

Component Description ........................................ 280

On Board Diagnosis Logic ................................... 280

DTC Confirmation Procedure ............................... 280

Wiring Diagram .....................................................282

Diagnostic Procedure ...........................................283

Component Inspection ..........................................285

Removal and Installation ......................................285

DTC P0182, P0183 FTT SENSOR ........... ...... ....... ..286

Component Description ........................................286

On Board Diagnosis Logic ....................................286

DTC Confirmation Procedure ...............................286

Wiring Diagram .....................................................287

Diagnostic Procedure ...........................................288

Component Inspection ..........................................290

Removal and Installation ......................................290

DTC P0222, P0223 TP SENSOR ...... ....... ...... ....... ..291

Component Description ........................................291

CONSULT-II Reference Value in Data Monitor Mode

.291

On Board Diagnosis Logic ....................................291

DTC Confirmation Procedure ...............................292

Wiring Diagram .....................................................293

Diagnostic Procedure ...........................................295

Component Inspection ..........................................298

Remove and Installation .......................................298

DTC P0300 - P0304 MULTIPLE CYLINDER MIS-

FIRE, NO. 1 - 4 CYLINDER MISFIRE .....................299

On Board Diagnosis Logic ....................................299

DTC Confirmation Procedure ...............................299

Diagnostic Procedure ...........................................300

DTC P0327, P0328 KS ..................... ....... ...... ....... ..306

Component Description ........................................306

On Board Diagnosis Logic ....................................306

DTC Confirmation Procedure ...............................306

Wiring Diagram .....................................................307

Diagnostic Procedure ...........................................308

Component Inspection ..........................................310

Removal and Installation ......................................310

DTC P0335 CKP SENSOR (POS) ........................ ..311

Component Description ........................................311

CONSULT-II Reference Value in Data Monitor Mode

.311

On Board Diagnosis Logic ....................................311

DTC Confirmation Procedure ...............................312

Wiring Diagram .....................................................313

Diagnostic Procedure ...........................................315

Component Inspection ..........................................318

Removal and Installation ......................................318

DTC P0340 CMP SENSOR (PHASE) ............ ....... ..319

Component Description ........................................319

On Board Diagnosis Logic ....................................319

DTC Confirmation Procedure ...............................320

Wiring Diagram .....................................................321

Diagnostic Procedure ...........................................322

Component Inspection ..........................................325

Removal and Installation ......................................326

DTC P0420 THREE WAY CATALYST FUNCTION . 32 7

On Board Diagnosis Logic ....................................327

DTC Confirmation Procedure ...............................327

Overall Function Check ........................................328

Diagnostic Procedure ...........................................329

DTC P0441 EVAP CONTROL SYSTEM .. ...... ....... ..332

A

EC

C

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-3

System Description ...............................................332

On Board Diagnosis Logic ....................................332

DTC Confirmation Procedure ................... ....... .....333

Overall Function Check ........................................333

Diagnostic Procedure ...........................................334

DTC P0442 EVAP CONTROL SYSTEM .................338

On Board Diagnosis Logic ....................................338

DTC Confirmation Procedure ................... ....... .....339

Diagnostic Procedure ...........................................341

Component Inspection ..........................................347

DTC P0444, P0445 EVAP CANISTER PURGE VOL-

UME CONTROL SOLENOID VALVE ......................348

Description ................ .......................... ..................348

CONSULT-II Reference Value in Data Monitor Mode

.348

On Board Diagnosis Logic ....................................349

DTC Confirmation Procedure ................... ....... .....349

Wiring Diagram .....................................................350

Diagnostic Procedure ...........................................352

Component Inspection ..........................................353

Removal and Installation ......................................354

DTC P0447 EVAP CANISTER VENT CONTROL

VALVE .....................................................................355

Component Description ........................................355

CONSULT-II Reference Value in Data Monitor Mode

.355

On Board Diagnosis Logic ....................................355

DTC Confirmation Procedure ................... ....... .....356

Wiring Diagram .....................................................357

Diagnostic Procedure ...........................................358

Component Inspection ..........................................360

DTC P0451 EVAP CONTROL SYSTEM PRESSURE

SENSOR ............................ ....... ...............................362

Component Description ........................................362

CONSULT-II Reference Value in Data Monitor Mode

.362

On Board Diagnosis Logic ....................................362

DTC Confirmation Procedure ................... ....... .....363

Diagnostic Procedure ...........................................363

Component Inspection ..........................................364

DTC P0452 EVAP CONTROL SYSTEM PRESSURE

SENSOR ............................ ....... ...............................365

Component Description ........................................365

CONSULT-II Reference Value in Data Monitor Mode

.365

On Board Diagnosis Logic ....................................365

DTC Confirmation Procedure ................... ....... .....366

Wiring Diagram .....................................................367

Diagnostic Procedure ...........................................368

Component Inspection ..........................................371

DTC P0453 EVAP CONTROL SYSTEM PRESSURE

SENSOR ............................ ....... ...............................372

Component Description ........................................372

CONSULT-II Reference Value in Data Monitor Mode

.372

On Board Diagnosis Logic ....................................372

DTC Confirmation Procedure ................... ....... .....373

Wiring Diagram .....................................................374

Diagnostic Procedure ............................................375

Component Inspection ..........................................379

DTC P0455 EVAP CONTROL SYSTEM .................380

On Board Diagnosis Logic ....................................380

DTC Confirmation Procedure ................................381

Diagnostic Procedure ............................................382

DTC P0456 EVAP CONTROL SYSTEM .................388

On Board Diagnosis Logic ....................................388

DTC Confirmation Procedure ................................389

Overall Function Check .........................................390

Diagnostic Procedure ............................................391

Component Inspection ..........................................398

DTC P0460 FUEL LEVEL SENSOR .......................399

Component Description ........................................399

On Board Diagnostic Logic ...................................399

DTC Confirmation Procedure ................................399

Diagnostic Procedure ............................................400

Removal and Installation .......................................400

DTC P0461 FUEL LEVEL SENSOR .......................401

Component Description ........................................401

On Board Diagnostic Logic ...................................401

Overall Function Check .........................................401

Diagnostic Procedure ............................................402

Removal and Installation .......................................402

DTC P0462, P0463 FUEL LEVEL SENSOR ...........403

Component Description ........................................403

On Board Diagnostic Logic ...................................403

DTC Confirmation Procedure ................................403

Diagnostic Procedure ............................................404

Removal and Installation .......................................404

DTC P0500 VSS ......................................................405

Description ............................................................405

On Board Diagnosis Logic ....................................405

DTC Confirmation Procedure ................................405

Overall Function Check .........................................406

Diagnostic Procedure ............................................406

DTC P0506 ISC SYSTEM .......................................407

Description ............................................................407

On Board Diagnosis Logic ....................................407

DTC Confirmation Procedure ................................407

Diagnostic Procedure ............................................408

DTC P0507 ISC SYSTEM .......................................409

Description ............................................................409

On Board Diagnosis Logic ....................................409

DTC Confirmation Procedure ................................409

Diagnostic Procedure ............................................410

DTC P0550 PSP SENSOR ......................................411

Component Description ........................................411

CONSULT-II Reference Value in Data Monitor Mode

.411

On Board Diagnosis Logic ....................................411

DTC Confirmation Procedure ................................411

Wiring Diagram ................................................... ..412

Diagnostic Procedure ............................................413

Component Inspection ..........................................415

Removal and Installation .......................................415

DTC P0605 ECM .....................................................416

Component Description ........................................416

On Board Diagnosis Logic ....................................416

Revision: 2005 March 2005 X-Trail

EC-4

DTC Confirmation Procedure ............................... 416

Diagnostic Procedure ........................................... 417

DTC P1065 ECM POWER SUPPLY ....................... 419

Component Description ........................................ 419

On Board Diagnosis Logic ................................... 419

DTC Confirmation Procedure ............................... 419

Wiring Diagram .................................................... 420

Diagnostic Procedure ........................................... 421

DTC P1111 IVT CONTROL SOLENOID VALVE .... 423

Component Description ........................................ 423

CONSULT-II Reference Value in Data Monitor Mode

. 423

On Board Diagnosis Logic ................................... 423

DTC Confirmation Procedure ............................... 423

Wiring Diagram .................................................... 424

Diagnostic Procedure ........................................... 425

Component Inspection ......................................... 426

Removal and Installation ...................................... 426

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR ............................................................ 427

Component Description ........................................ 427

On Board Diagnosis Logic ................................... 427

DTC Confirmation Procedure ............................... 427

Diagnostic Procedure ........................................... 428

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION ........................ .......................... ............ 429

Description ........................................................... 429

On Board Diagnosis Logic ................................... 429

DTC Confirmation Procedure ............................... 429

Wiring Diagram .................................................... 430

Diagnostic Procedure ........................................... 432

Component Inspection ......................................... 436

Remove and Installation ....................................... 436

DTC P1124, P1126 THROTTLE CONTROL MOTOR

RELAY .................................................................... 437

Component Description ........................................ 437

CONSULT-II Reference Value in Data Monitor Mode

. 437

On Board Diagnosis Logic ................................... 437

DTC Confirmation Procedure ............................... 437

Wiring Diagram .................................................... 439

Diagnostic Procedure ........................................... 440

Component Inspection ......................................... 442

DTC P1128 THROTTLE CONTROL MOTOR ........ 443

Component Description ........................................ 443

On Board Diagnosis Logic ................................... 443

DTC Confirmation Procedure ............................... 443

Wiring Diagram .................................................... 444

Diagnostic Procedure ........................................... 446

Component Inspection ......................................... 447

Removal and Installation ...................................... 447

DTC P1143 HO2S1 ................................................. 448

Component Description ........................................ 448

CONSULT-II Reference Value in Data Monitor Mode

. 448

On Board Diagnosis Logic ................................... 448

DTC Confirmation Procedure ............................... 449

Overall Function Check ........................................ 449

Diagnostic Procedure ........................................... 450

Component Inspection ..........................................452

Removal and Installation ......................................453

DTC P1144 HO2S1 ........................... ....... ...... ....... ..454

Component Description ........................................454

CONSULT-II Reference Value in Data Monitor Mode

.454

On Board Diagnosis Logic ....................................454

DTC Confirmation Procedure ...............................455

Overall Function Check ........................................455

Diagnostic Procedure ...........................................456

Component Inspection ..........................................458

Removal and Installation ......................................459

DTC P1146 HO2S2 ........................... ....... ...... ....... ..460

Component Description ........................................460

CONSULT-II Reference Value in Data Monitor Mode

.460

On Board Diagnosis Logic ....................................460

DTC Confirmation Procedure ...............................461

Overall Function Check ........................................461

Wiring Diagram .....................................................463

Diagnostic Procedure ...........................................464

Component Inspection ..........................................466

Removal and Installation ......................................467

DTC P1147 HO2S2 ........................... ....... ...... ....... ..468

Component Description ........................................468

CONSULT-II Reference Value in Data Monitor Mode

.468

On Board Diagnosis Logic ....................................468

DTC Confirmation Procedure ...............................469

Overall Function Check ........................................469

Wiring Diagram .....................................................471

Diagnostic Procedure ...........................................472

Component Inspection ..........................................474

Removal and Installation ......................................475

DTC P1148 CLOSED LOOP CONTROL ................476

On Board Diagnosis Logic ....................................476

DTC Confirmation Procedure ...............................476

Overall Function Check ........................................476

Diagnostic Procedure ...........................................477

DTC P1211 TCS CONTROL UNIT ..........................478

Description ................... ...... ....... ...... ......................478

On Board Diagnosis Logic ....................................478

DTC Confirmation Procedure ...............................478

Diagnostic Procedure ...........................................478

DTC P1212 TCS COMMUNICATION LINE ............479

Description ................... ...... ....... ...... ......................479

On Board Diagnosis Logic ....................................479

DTC Confirmation Procedure ...............................479

Diagnostic Procedure ...........................................479

DTC P1217 ENGINE OVER TEMPERATURE ........480

Description ................... ...... ....... ...... ......................480

CONSULT-II Reference Value in Data Monitor Mode

.481

On Board Diagnosis Logic ....................................481

Overall Function Check ........................................481

Wiring Diagram .....................................................484

Diagnostic Procedure ...........................................485

Main 12 Causes of Overheating ...........................492

Component Inspection ..........................................493

A

EC

C

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-5

DTC P1225 TP SENSOR ........................................495

Component Description ........................................495

On Board Diagnosis Logic ....................................495

DTC Confirmation Procedure ................... ....... .....495

Diagnostic Procedure ...........................................496

Remove and Installation ........ ...............................496

DTC P1226 TP SENSOR ........................................497

Component Description ........................................497

On Board Diagnosis Logic ....................................497

DTC Confirmation Procedure ................... ....... .....497

Diagnostic Procedure ...........................................498

Remove and Installation ........ ...............................498

DTC P1229 SENSOR POWER SUPPLY ................499

On Board Diagnosis Logic ....................................499

DTC Confirmation Procedure ................... ....... .....499

Wiring Diagram .....................................................500

Diagnostic Procedure ...........................................501

DTC P1444 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE ...............................504

Description ................ .......................... ..................504

CONSULT-II Reference Value in Data Monitor Mode

.504

On Board Diagnosis Logic ....................................505

DTC Confirmation Procedure ................... ....... .....505

Wiring Diagram .....................................................506

Diagnostic Procedure ...........................................508

Component Inspection ..........................................510

Removal and Installation ......................................511

DTC P1446 EVAP CANISTER VENT CONTROL

VALVE .....................................................................512

Component Description ........................................512

CONSULT-II Reference Value in Data Monitor Mode

.512

On Board Diagnosis Logic ....................................512

DTC Confirmation Procedure ................... ....... .....513

Wiring Diagram .....................................................514

Diagnostic Procedure ...........................................515

Component Inspection ..........................................517

DTC P1564 ASCD STEERING SWITCH ................519

Component Description ........................................519

CONSULT-II Reference Value in Data Monitor Mode

.519

On Board Diagnosis Logic ....................................519

DTC Confirmation Procedure ................... ....... .....520

Wiring Diagram .....................................................521

Diagnostic Procedure ...........................................523

Component Inspection ..........................................526

DTC P1572 ASCD BRAKE SWITCH ......................527

Component Description ........................................527

CONSULT-II Reference Value in Data Monitor Mode

.527

On Board Diagnosis Logic ....................................527

DTC Confirmation Procedure ................... ....... .....528

Wiring Diagram .....................................................529

Diagnostic Procedure ...........................................531

Component Inspection ..........................................536

DTC P1574 ASCD VEHICLE SPEED SENSOR .....538

Component Description ........................................538

On Board Diagnosis Logic ....................................538

DTC Confirmation Procedure ................................538

Diagnostic Procedure ............................................539

DTC P1706 PNP SWITCH .......................................540

Component Description ........................................540

CONSULT-II Reference Value in Data Monitor Mode

.540

On Board Diagnosis Logic ....................................540

DTC Confirmation Procedure ................................540

Overall Function Check .........................................541

Wiring Diagram ................................................... ..542

Diagnostic Procedure ............................................543

DTC P1800 VIAS CONTROL SOLENOID VALVE ..545

Component Description ........................................545

CONSULT-II Reference Value in Data Monitor Mode

.545

On Board Diagnosis Logic ....................................545

DTC Confirmation Procedure ................................545

Wiring Diagram ................................................... ..546

Diagnostic Procedure ............................................547

Component Inspection ..........................................548

Removal and Installation .......................................549

DTC P1805 BRAKE SWITCH .................................550

Description ............................................................550

CONSULT-II Reference Value in Data Monitor Mode

.550

On Board Diagnosis Logic ....................................550

DTC Confirmation Procedure ................................550

Wiring Diagram ................................................... ..551

Diagnostic Procedure ............................................552

Component Inspection ..........................................554

DTC P2122, P2123 APP SENSOR .........................555

Component Description ........................................555

CONSULT-II Reference Value in Data Monitor Mode

.555

On Board Diagnosis Logic ....................................555

DTC Confirmation Procedure ................................556

Wiring Diagram ................................................... ..557

Diagnostic Procedure ............................................559

Component Inspection ..........................................561

Removal and Installation .......................................561

DTC P2127, P2128 APP SENSOR .........................562

Component Description ........................................562

CONSULT-II Reference Value in Data Monitor Mode

.562

On Board Diagnosis Logic ....................................562

DTC Confirmation Procedure ................................563

Wiring Diagram ................................................... ..564

Diagnostic Procedure ............................................566

Component Inspection ..........................................569

Remove and Installation .......................................569

DTC P2135 TP SENSOR ........................................570

Component Description ........................................570

CONSULT-II Reference Value in Data Monitor Mode

.570

On Board Diagnosis Logic ....................................570

DTC Confirmation Procedure ................................570

Wiring Diagram ................................................... ..572

Diagnostic Procedure ............................................574

Revision: 2005 March 2005 X-Trail

EC-6

Component Inspection ......................................... 577

Remove and Installation ....................................... 577

DTC P2138 APP SENSOR ..................................... 578

Component Description ........................................ 578

CONSULT-II Reference Value in Data Monitor Mode

. 578

On Board Diagnosis Logic ................................... 578

DTC Confirmation Procedure ............................... 579

Wiring Diagram .................................................... 580

Diagnostic Procedure ........................................... 582

Component Inspection ......................................... 585

Remove and Installation ....................................... 585

IGNITION SIGNAL .................................................. 586

Component Description ........................................ 586

Wiring Diagram .................................................... 587

Diagnostic Procedure ........................................... 590

Component Inspection ......................................... 595

Removal and Installation ...................................... 596

VIAS ............................ ............................................ 597

Description ........................................................... 597

CONSULT-II Reference Value in Data Monitor Mode

. 598

Wiring Diagram .................................................... 599

Diagnostic Procedure ........................................... 601

Component Inspection ......................................... 605

Removal and Installation ...................................... 606

INJECTOR CIRCUIT ............................................... 607

Component Description ........................................ 607

CONSULT-II Reference Value in Data Monitor Mode

. 607

Wiring Diagram .................................................... 608

Diagnostic Procedure ........................................... 609

Component Inspection ......................................... 612

Removal and Installation ...................................... 612

FUEL PUMP CIRCUIT ............................................ 613

Description ........................................................... 613

CONSULT-II Reference Value in Data Monitor Mode

. 613

Wiring Diagram .................................................... 614

Diagnostic Procedure ........................................... 615

Component Inspection ......................................... 618

Removal and Installation ...................................... 618

REFRIGERANT PRESSURE SENSOR ................. 619

Component Description ........................................ 619

Wiring Diagram .................................................... 620

Diagnostic Procedure ........................................... 621

Removal and Installation ...................................... 624

ELECTRICAL LOAD SIGNAL ................................625

CONSULT-II Reference Value in Data Monitor Mode

.625

Wiring Diagram .....................................................626

Diagnostic Procedure ...........................................627

Wiring Diagram .....................................................632

Diagnostic Procedure ...........................................633

Wiring Diagram .....................................................635

Diagnostic Procedure ...........................................636

ASCD BRAKE SWITCH .........................................638

Component Description ........................................638

CONSULT-II Reference Value in Data Monitor Mode

.638

Wiring Diagram .....................................................639

Diagnostic Procedure ...........................................641

Component Inspection ..........................................646

ASCD INDICATOR ..................................................648

Component Description ........................................648

CONSULT-II Reference Value in Data Monitor Mode

.648

Wiring Diagram .....................................................649

Diagnostic Procedure ...........................................651

SNOW MODE SWITCH .............. ...... ....... ...... .........652

Description ................... ...... ....... ...... ......................652

CONSULT-II Reference Value in the Data Monitor

Mode .....................................................................652

Wiring Diagram .....................................................653

Diagnostic Procedure ...........................................655

Component Inspection ..........................................658

MIL AND DATA LINK CONNECTOR ......................659

Wiring Diagram .....................................................659

SERVICE DATA AND SPECIFICATIONS (SDS) ....663

Fuel Pressure .......................................................663

Idle Speed and Ignition Timing .............. ...... ....... ..663

Calculated Load Value ..........................................663

Mass Air Flow Sensor ...........................................663

Intake Air Temperature Sensor .............................663

Engine Coolant Temperature Sensor ...................663

Heated Oxygen Sensor 1 Heater .........................663

Heated Oxygen Sensor 2 Heater .........................663

Crankshaft Position Sensor (POS) .......................663

Camshaft Position Sensor (PHASE) ....................663

Throttle Control Motor ............... ...... ....... ...............664

Fuel Injector ..........................................................664

Fuel Pump ............................................................664

A

EC

C

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-7

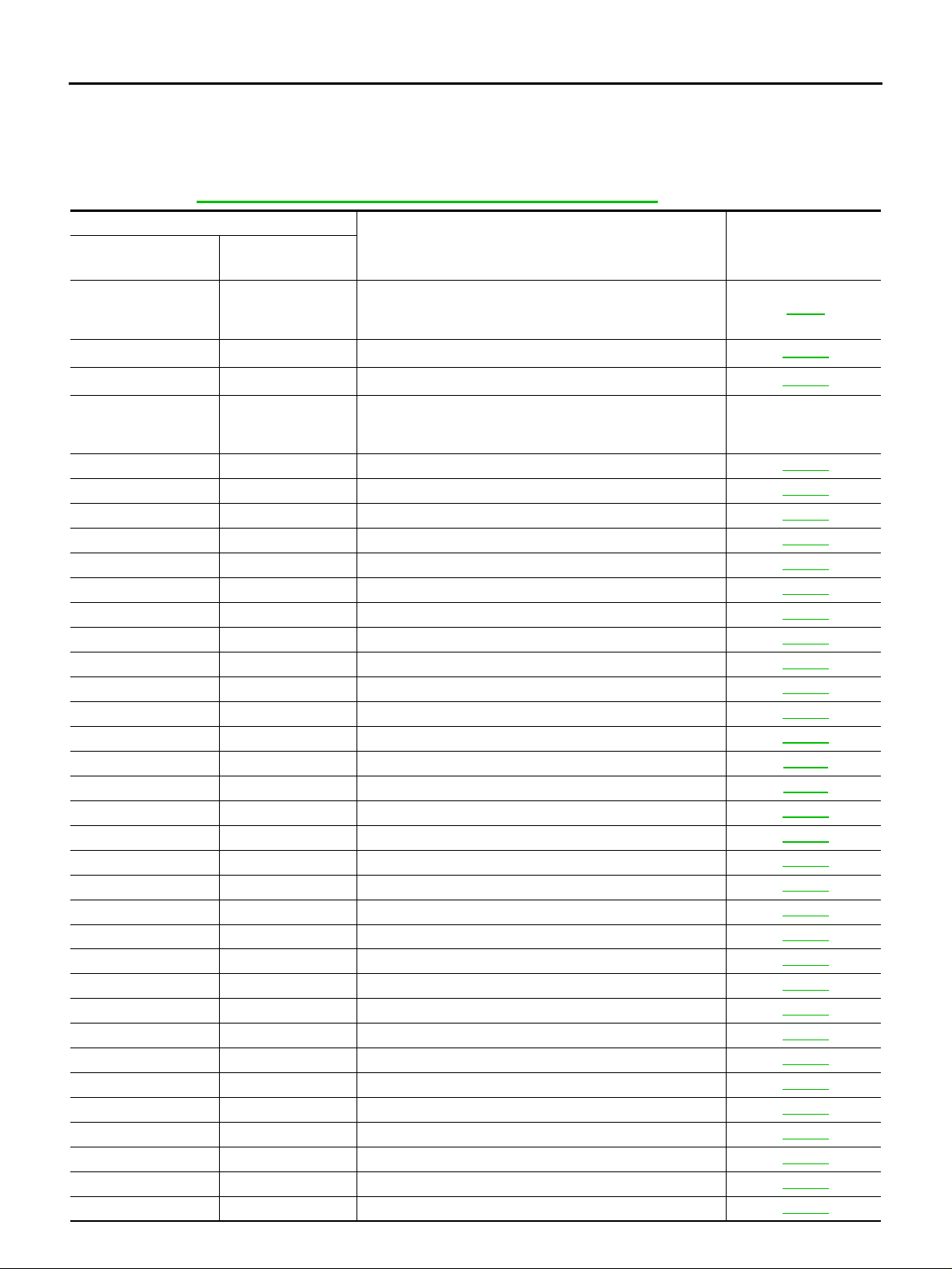

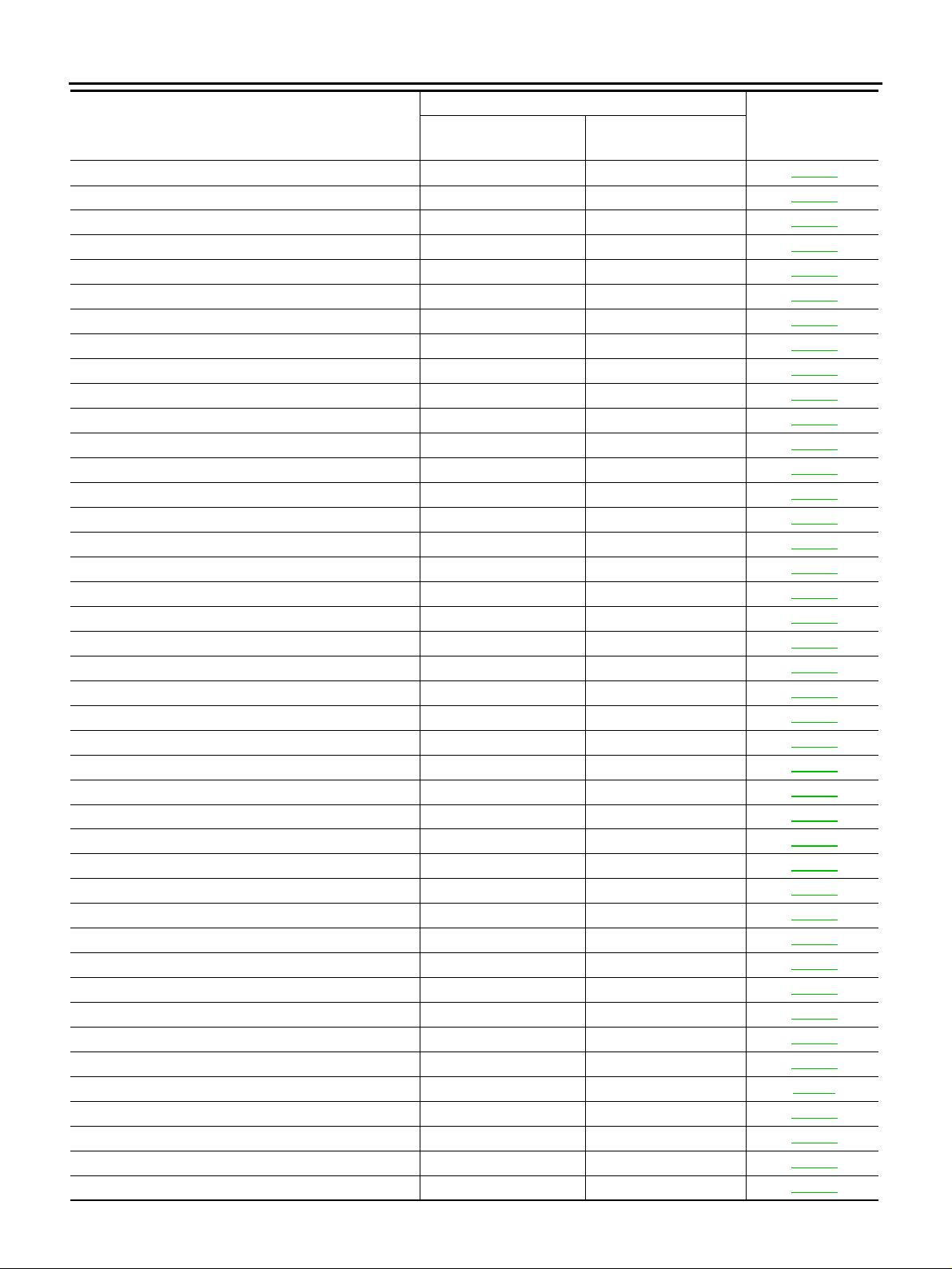

INDEX FOR DTC

INDEX FOR DTC PFP:00024 DTC No. Index ABS00D80

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-163, "

DTC*1

CONSULT-II

2

GST*

No DTC

U1000

U1001

P0000 0000

P0011 0011 INT/V TIM CONT-B1 EC-166

P0031 0031 HO2S1 HTR (B1) EC-170

P0032 0032 HO2S1 HTR (B1) EC-170

P0037 0037 HO2S2 HTR (B1) EC-176

P0038 0038 HO2S2 HTR (B1) EC-176

P0101 0101 MAF SEN/CIRCUIT EC-182

P0102 0102 MAF SEN/CIRCUIT EC-191

P0103 0103 MAF SEN/CIRCUIT EC-191

P0112 0112 IAT SEN/CIRCUIT EC-199

P0113 0113 IAT SEN/CIRCUIT EC-199

P011 7 0117 ECT SEN/CIRC EC-205

P011 8 0118 ECT SEN/CIRC EC-205

P0122 0122 TP SEN 2/CIRC EC-211

P0123 0123 TP SEN 2/CIRC EC-211

P0125 0125 ECT SENSOR EC-219

P0127 0127 IAT SENSOR EC-222

P0128 0128 THERMSTAT FNCTN EC-225

P0132 0132 HO2S1 (B1) EC-225

P0133 0133 HO2S1 (B1) EC-234

P0134 0134 HO2S1 (B1) EC-244

P0138 0138 HO2S2 (B1) EC-252

P0139 0139 HO2S2 (B1) EC-259

P0171 0171 FUEL SYS-LEAN-B1 EC-267

P0172 0172 FUEL SYS-RICH-B1 EC-274

P0181 0181 FTT SENSOR EC-280

P0182 0182 FTT SEN/CIRCUIT EC-286

P0183 0183 FTT SEN/CIRCUIT EC-286

P0222 0222 TP SEN 1/CIRC EC-291

P0223 0223 TP SEN 1/CIRC EC-291

P0300 0300 MULTI CYL MISFIRE EC-299

P0301 0301 CYL 1 MISFIRE EC-299

DTC U1000, U1001 CAN COMMUNICATION LINE" .

Items

ECM*

Flashing*

1000*

1001*

3

6

4

4

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.

CAN COMM CIRCUIT EC-163

CAN COMM CIRCUIT EC-163

NO DTC IS DETECTED.

FURTHER TESTING

MA Y BE REQUIRED .

(CONSULT-II screen terms)

Reference page

EC-62

—

Revision: 2005 March 2005 X-Trail

EC-8

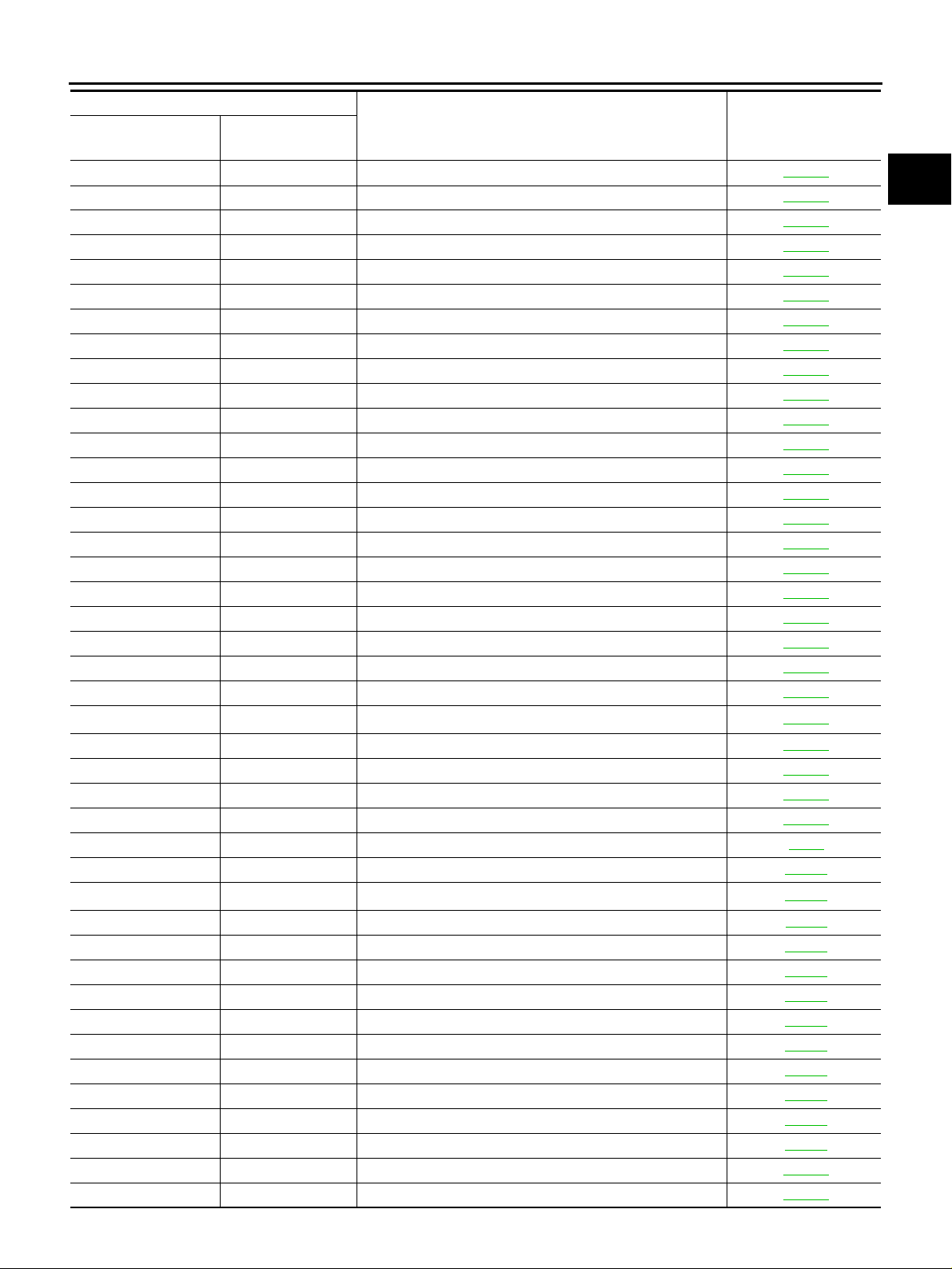

INDEX FOR DTC

DTC*1

CONSULT-II

2

GST*

P0302 0302 CYL 2 MISFIRE EC-299

P0303 0303 CYL 3 MISFIRE EC-299

P0304 0304 CYL 4 MISFIRE EC-299

P0327 0327 KNOCK SEN/CIRC-B1 EC-306

P0328 0328 KNOCK SEN/CIRC-B1 EC-306

P0335 0335 CKP SEN/CIRCUIT EC-311

P0340 0340 CMP SEN/CIRC-B1 EC-319

P0420 0420 TW CATALYST SYS-B1 EC-327

P0441 0441 EVAP PURG FLOW/MON EC-332

P0442 0442 EVAP SMALL LEAK EC-338

P0444 0444 PURG VOLUME CONT/V EC-348

P0445 0445 PURG VOLUME CONT/V EC-348

P0447 0447 VENT CONTROL VALVE EC-355

P0451 0451 EVAP SYS PRES SEN EC-362

P0452 0452 EVAP SYS PRES SEN EC-365

P0453 0453 EVAP SYS PRES SEN EC-372

P0455 0455 EVAP GROSS LEAK EC-380

P0456 0456 EVAP VERY SML LEAK EC-388

P0460 0460 FUEL LEV SEN SLOSH EC-399

P0461 0461 FUEL LEVEL SENSOR EC-401

P0462 0462 FUEL LEVL SEN/CIRC EC-403

P0463 0463 FUEL LEVL SEN/CIRC EC-403

P0500 0500

P0506 0506 ISC SYSTEM EC-407

P0507 0507 ISC SYSTEM EC-409

P0550 0550 PW ST P SEN/CIRC EC-411

P0605 0605 ECM EC-416

P0705 0705 PNP SW/CIRC AT-98

P0710 0710 ATF TEMP SEN/CIRC AT-104

P0720 0720

P0725 0725 ENGINE SPEED SIG AT-115

P0731 0731 A/T 1ST GR FNCTN AT-120

P0732 0732 A/T 2ND GR FNCTN AT-125

P0733 0733 A/T 3RD GR FNCTN AT-130

P0734 0734 A/T 4TH GR FNCTN AT-135

P0740 0740 TCC SOLENOID/CIRC AT-142

P0744 0744 A/T TCC S/V FNCTN AT-147

P0745 0745 L/PRESS SOL/CIRC AT-155

P0750 0750 SFT SOL A/CIRC AT-162

P0755 0755 SFT SOL B/CIRC AT-167

P1065 1065 ECM BACK UP/CIRC EC -419

P1111 1111 INT/V TIM V/CIR-B1 EC-423

ECM*

3

VEH SPEED SEN/CIRC*

VEH SPD SEN/CIR AT*

(CONSULT-II screen terms)

5

Items

5

Reference page

A

EC

C

D

E

F

G

H

I

J

EC-405

K

L

M

AT-109

Revision: 2005 March 2005 X-Trail

EC-9

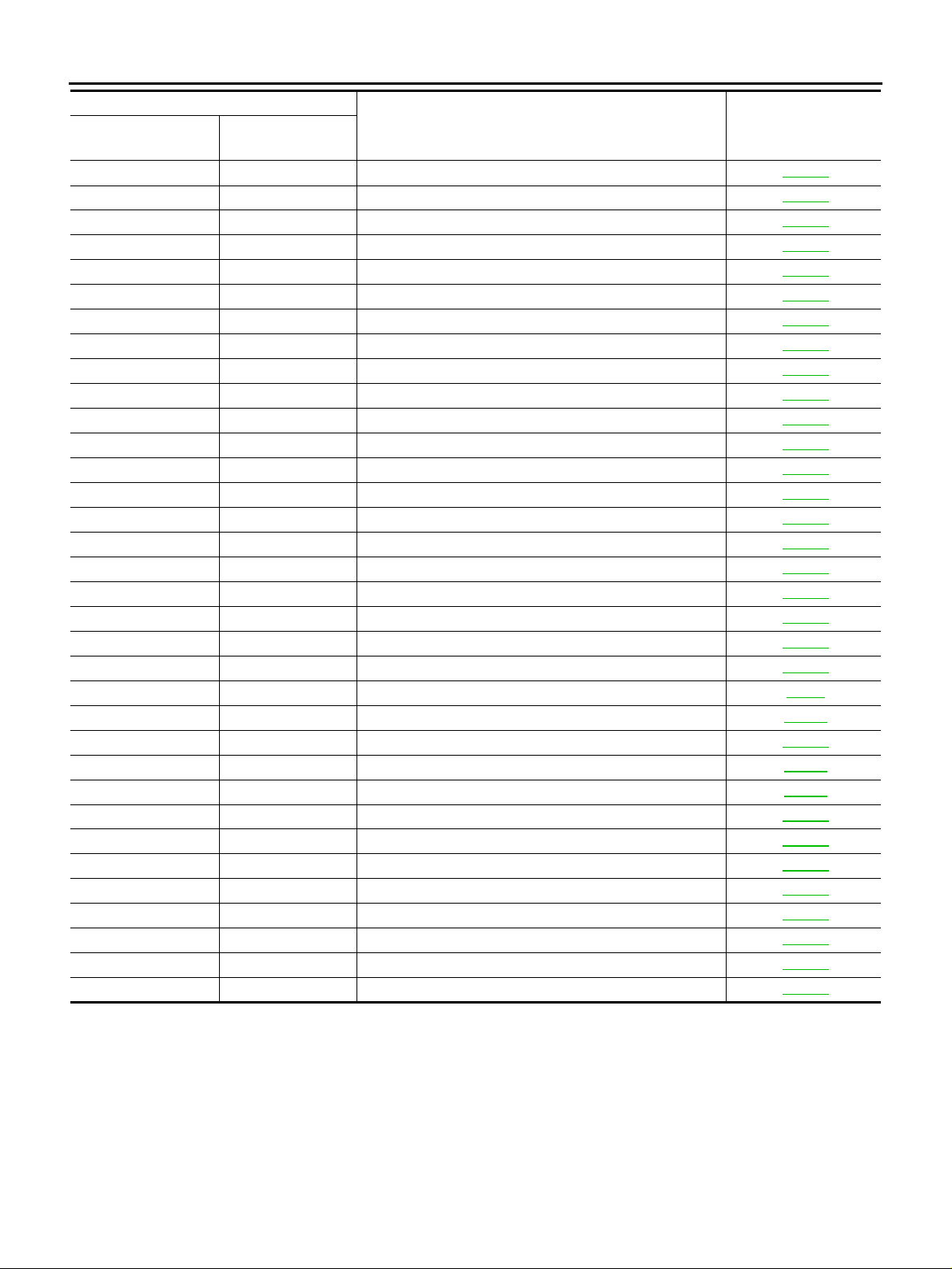

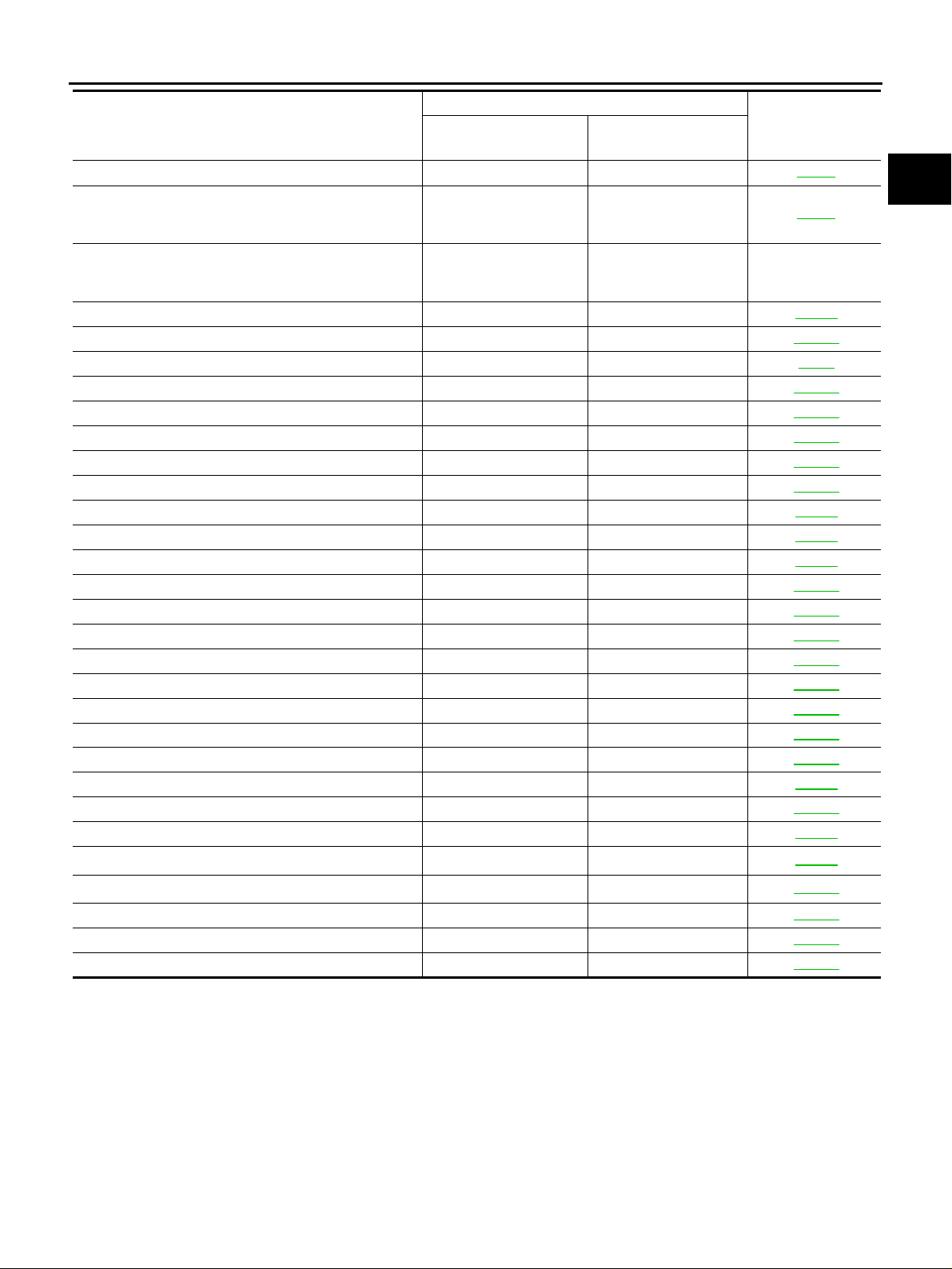

INDEX FOR DTC

DTC*1

CONSULT-II

P1610 - P1615 1610 - 1615 NATS MALFUNCTION EC-46

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Tes t Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*4: The troubleshooting for this DTC needs CONSULT-II.

*5: When the fail-safe operations for both self -diagnoses occur, the MIL illuminates.

*6: When engine is running.

2

GST*

P1121 1121 ETC ACTR EC-427

P11 22 1122 ETC FUNCTION/CIRC EC-429

P1124 1124 ETC MOT PWR EC-437

P1126 1126 ETC MOT PWR EC-437

P1128 1128 ETC MOT EC-443

P1143 1 1 43 HO2S1 (B1) EC-448

P1144 1 1 44 HO2S1 (B1) EC-454

P1146 1 1 46 HO2S2 (B1) EC-460

P1147 1 1 47 HO2S2 (B1) EC-468

P1148 1148 CLOSED LOOP-B1 EC-476

P1211 1211 TCS C/U FUNCTION EC-478

P1212 1212 TCS/CIRC EC-479

P1217 1217 ENG OVER TEMP EC-480

P1225 1225 CTP LEARNING EC-495

P1226 1226 CTP LEARNING EC-497

P1229 1229 SENSOR POWER/CIRC EC-499

P1444 1444 PURG VOLUME CONT/V EC-504

P1446 1446 VENT CONTROL VAL VE EC-512

P1564 1564 ASCD SW EC-519

P1572 1572 ASCD BRAKE SW EC-527

P1574 1574 ASCD VHL SPD SEN EC-538

P1705 1705 TP SEN/CIRC A/T AT-172

P1706 1706 P-N POS SW/CIRCUIT EC-540

P1720 1720 V/SP SEN (A/T OUT) AT-109

P1760 1760 O/R CLTCH SOL/CIRC AT-177

P1800 1800 VIAS S/V CIRC EC-545

P1805 1805 BRAKE SW/CIRCUIT EC-550

P2122 2122 APP SEN 1/CIRC EC-555

P2123 2123 APP SEN 1/CIRC EC-555

P2127 2127 APP SEN 2/CIRC EC-562

P2128 2128 APP SEN 2/CIRC EC-562

P2135 2135 TP SENSOR EC-570

P2138 2138 APP SENSOR EC-578

ECM*

3

(CONSULT-II screen terms)

Items

Reference page

Revision: 2005 March 2005 X-Trail

EC-10

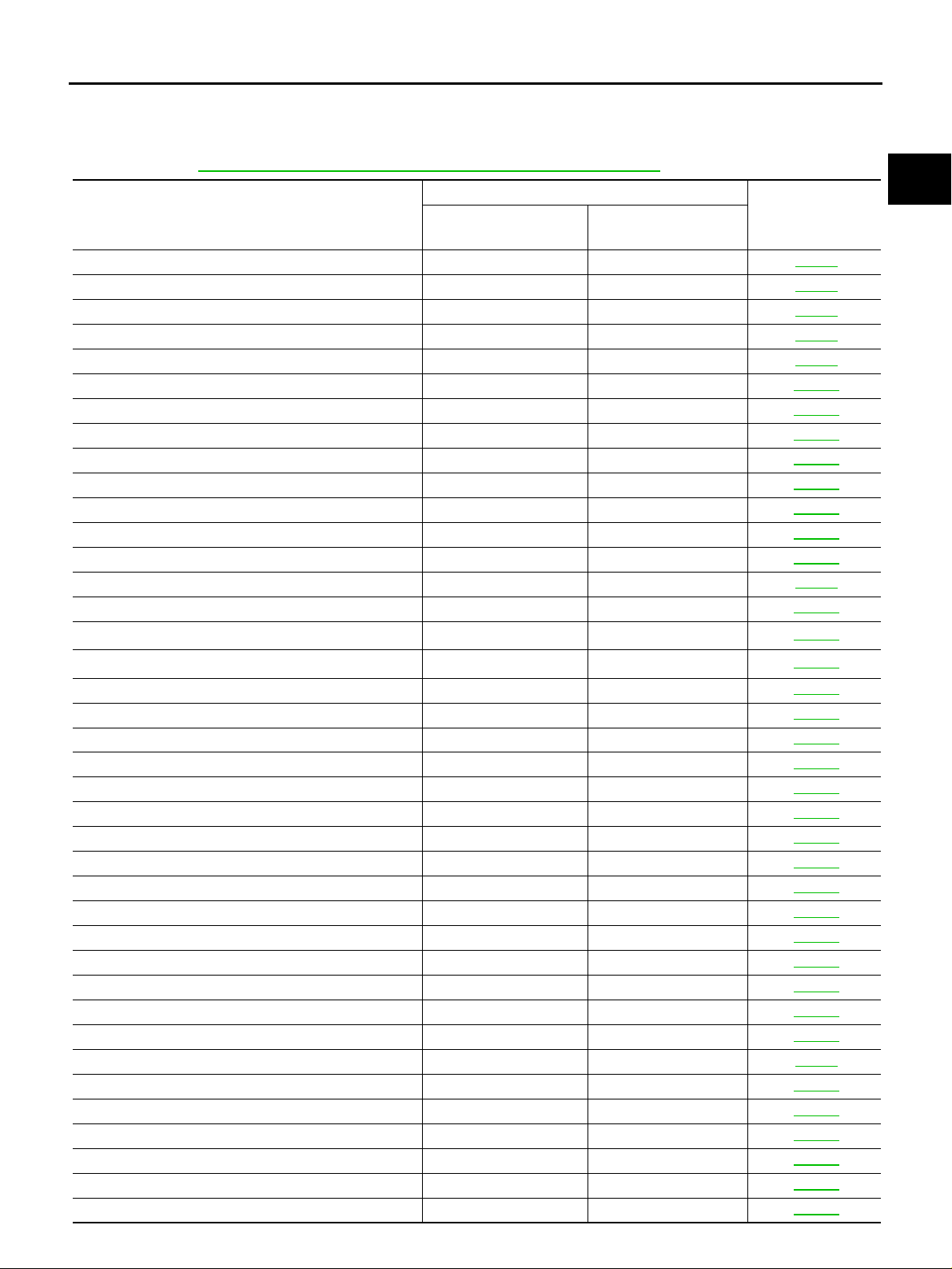

INDEX FOR DTC

Alphabetical Index ABS00D7Z

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-163, "

(CONSULT-II screen terms)

A/T 1ST GR FNCTN P0731 0731 AT-120

A/T 2ND GR FNCTN P0732 0732 AT-125

A/T 3RD GR FNCTN P0733 0733 AT-130

A/T 4TH GR FNCTN P0734 0734 AT-135

A/T TCC S/V FNCTN P0744 0744 AT-147

APP SEN 1/CIRC P2122 2122 EC-555

APP SEN 1/CIRC P2123 2123 EC-555

APP SEN 2/CIRC P2127 2127 EC-562

APP SEN 2/CIRC P2128 2128 EC-562

APP SENSOR P2138 2138 EC-578

ASCD BRAKE SW P1572 1572 EC-527

ASCD SW P1564 1564 EC-519

ASCD VHL SPD SEN P1574 1574 EC-538

ATF TEMP SEN/CIRC P0710 0710 AT-104

BRAKE SW/CIRCUIT P1805 1805 EC-550

CAN COMM CIRCUIT U1000

CAN COMM CIRCUIT U1001

CKP SEN/CIRCUIT P0335 0335 EC-311

CLOSED LOOP-B1 P1148 1148 EC-476

CMP SEN/CIRC-B1 P0340 0340 EC-319

CTP LEARNING P1225 1225 EC-495

CTP LEARNING P1226 1226 EC-497

CYL 1 MISFIRE P0301 0301 EC -299

CYL 2 MISFIRE P0302 0302 EC -299

CYL 3 MISFIRE P0303 0303 EC-299

CYL 4 MISFIRE P0304 0304 EC -299

ECM P0605 0605 EC-416

ECM BACK UP/CIRC P1065 1065 EC-419

ECT SEN/CIRC P0117 0117 EC-205

ECT SEN/CIRC P0118 0118 EC-205

ECT SENSOR P0125 0125 EC-219

ENG OVER TEMP P1217 1217 EC-480

ENGINE SPEED SIG P0725 0725 AT-115

ETC ACTR P1121 1121 EC-427

ETC FUNCTION/CIRC P1122 1122 EC-429

ETC MOT P1128 1128 EC-443

ETC MOT PWR P1124 1124 EC- 437

ETC MOT PWR P1126 1126 EC- 437

EVAP GROSS LEAK P0455 0455 EC-380

DTC U1000, U1001 CAN COMMUNICATION LINE" .

Items

CONSULT-II

GST*

DTC*1

2

ECM*

1000*

1001*

3

4

4

Reference page

EC-163

EC-163

A

EC

C

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-11

INDEX FOR DTC

Items

(CONSULT-II screen terms)

EVAP PURG FLOW/MON P0441 0441 EC-332

EVAP SMALL LEAK P0442 0442 EC-338

EVAP SYS PRES SEN P0451 0451 EC-362

EVAP SYS PRES SEN P0452 0452 EC-365

EVAP SYS PRES SEN P0453 0453 EC-372

EVAP VERY SML LEAK P0456 0456 EC-388

FTT SEN/CIRCUIT P0182 0 182 EC-286

FTT SEN/CIRCUIT P0183 0183 EC-286

FTT SENSOR P0181 0181 EC-280

FUEL LEV SEN SLOSH P0460 0460 EC-399

FUEL LEVEL SENSOR P0461 0461 EC-401

FUEL LEVL SEN/CIRC P0462 0462 EC-403

FUEL LEVL SEN/CIRC P0463 0463 EC-403

FUEL SYS-LEAN-B1 P0171 0171 EC-267

FUEL SYS-RICH-B1 P0172 0172 EC-274

HO2S1 (B1) P0132 0132 EC-227

HO2S1 (B1) P0133 0133 EC-234

HO2S1 (B1) P0134 0134 EC-244

HO2S1 (B1) P1143 1143 EC-448

HO2S1 (B1) P1144 1144 EC-454

HO2S1 HTR (B1) P0031 0031 EC-170

HO2S1 HTR (B1) P0032 0032 EC-170

HO2S2 (B1) P0138 0138 EC-252

HO2S2 (B1) P0139 0139 EC-259

HO2S2 (B1) P1146 1146 EC-460

HO2S2 (B1) P1147 1147 EC-468

HO2S2 HTR (B1) P0037 0037 EC-176

HO2S2 HTR (B1) P0038 0038 EC-176

IAT SEN/CIRCUIT P0112 0112 EC-199

IAT SEN/CIRCUIT P0113 0113 EC-199

IAT SENSOR P0127 0127 EC-222

INT/V TIM CONT-B1 P0011 0011 EC-166

INT/V TIM V/CIR-B1 P1111 1111 EC-423

ISC SYSTEM P0506 0506 EC-407

ISC SYSTEM P0507 0507 EC-409

KNOCK SEN/CIRC-B1 P0327 0327 EC-306

KNOCK SEN/CIRC-B1 P0328 0328 EC-306

L/PRESS SOL/CIRC P0745 0745 AT-155

MAF SEN/CIRCUIT P0101 0101 EC-182

MAF SEN/CIRCUIT P0102 0102 EC-191

MAF SEN/CIRCUIT P0103 0103 EC-191

MULTI CYL MISFIRE P0300 0300 EC-299

CONSULT-II

GST*

DTC*1

3

2

ECM*

Reference page

Revision: 2005 March 2005 X-Trail

EC-12

INDEX FOR DTC

Items

(CONSULT-II screen terms)

NATS MALFUNCTION P1610 - P1615 1610 - 1615 EC-46

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.

O/R CLTCH SOL/CIRC P1760 1760 AT-177

P-N POS SW/CIRCUIT P1706 1706 EC-540

PNP SW/CIRC P0705 0705 AT-98

PURG VOLUME CONT/V P0444 0444 EC-348

PURG VOLUME CONT/V P0445 0445 EC-348

PURG VOLUME CONT/V P1444 1444 EC-504

PW ST P SEN/CIRC P0550 0550 EC-411

SENSOR POWER/CIRC P1229 1229 EC-499

SFT SOL A/CIRC P0750 0750 AT-162

SFT SOL B/CIRC P0755 0755 AT-167

TCC SOLENOID/CIRC P0740 0740 AT-142

TCS C/U FUNCTIION P1211 1211 EC-478

TCS/CIRC P1212 1212 EC-479

THERMSTAT FNCTN P0128 0128 EC-225

TP SEN 1/CIRC P0222 0222 EC-291

TP SEN 1/CIRC P0223 0223 EC-291

TP SEN 2/CIRC P0122 0122 EC-211

TP SEN 2/CIRC P0123 0123 EC-211

TP SENSOR P2135 2135 EC-570

TP SEN/CIRC A/T P1705 1705 AT-172

TW CATALYST SYS-B1 P0420 0420 EC- 327

V/SP SEN (A/T OUT) P1720 1720 AT-109

VEH SPD SEN/CIR AT*

VEH SPEED SEN/CIRC*

VENT CONTROL VALVE P0447 0447 EC-355

VENT CONTROL VALVE P1446 1446 EC-460

VIAS S/V CIRC P1800 1800 EC-545

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*4: The troubleshooting for this DTC needs CONSULT-II.

*5: When the fail-safe operations for both self-di agno ses occur, the MIL illuminates.

*6: When engine is running.

5

5

CONSULT-II

GST*

No DTC

P0000 0000 —

P0720 0720 AT-109

P0500 0500 EC-405

DTC*1

3

2

ECM*

Flashing*

6

Reference page

EC-62

A

EC

C

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-13

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front sea t belt , helps t o redu ce th e r isk or s everi ty of injury to th e driv er an d front passenge r for c ertain

types of collision. Info rmation necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

● To avoid rendering the SRS inoperativ e, which cou ld increase the risk of persona l injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, in cluding incorrect removal a nd installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For rem ova l of Sp iral Ca ble an d Ai r

Bag Module, see the SRS section.

● Do not use electrical test equipme nt on any circuit related to the SRS unle ss instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnes ses or

harness connectors .

ABS00DCS

On Board Diagnostic (OBD) System of Engine and A/T ABS00CKO

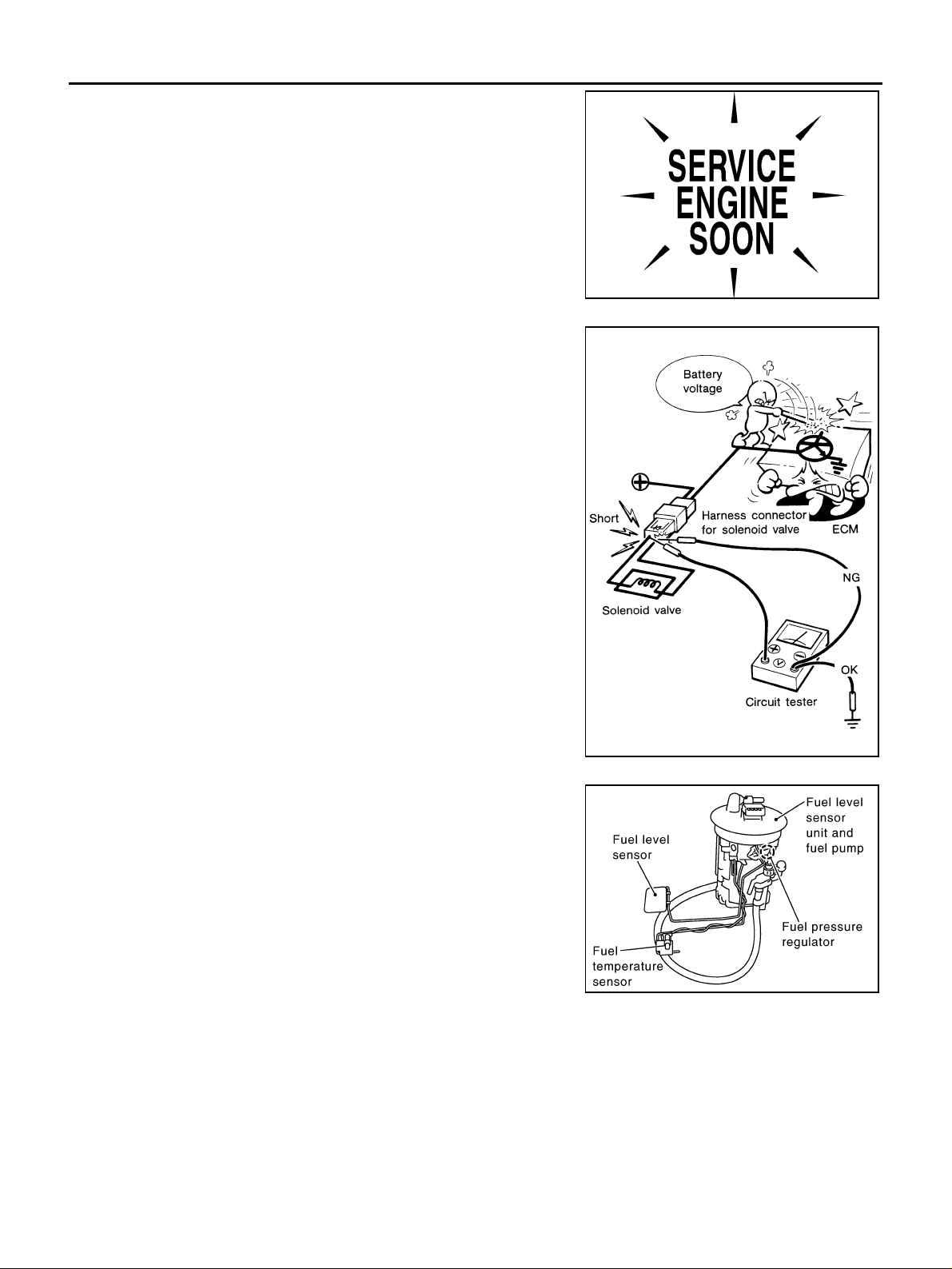

The ECM has an on bo ard d iagn ostic syste m. It w ill light up th e ma lfunct ion indicat or (MIL ) to w arn the drive r

of a malfunction causing emission deterioration.

CAUTION:

● Be sure to turn the ignition switch O FF a nd di sc onne ct the ba tte ry grou nd c abl e be fore any repair

or inspection work. The open/s hort circuit of related swi tches, sensors, s olenoid valves, etc . will

cause the MIL to light up.

● Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

● Certain systems and compon ents, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer to PG-44, "

NESS CONNECTOR" .

● Be sure to route and secu re the harnesses properly afte r work. The interference of the ha rness

with a bracket, etc. may cause the MIL to light up due to the short circu it.

● Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up du e to the ma lfunc tio n of the EVAP system or fuel injection syste m,

etc.

● Be sure to erase the unneces sary mal function in formation (repairs compl eted) from th e ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

HAR-

Precaution ABS00CKP

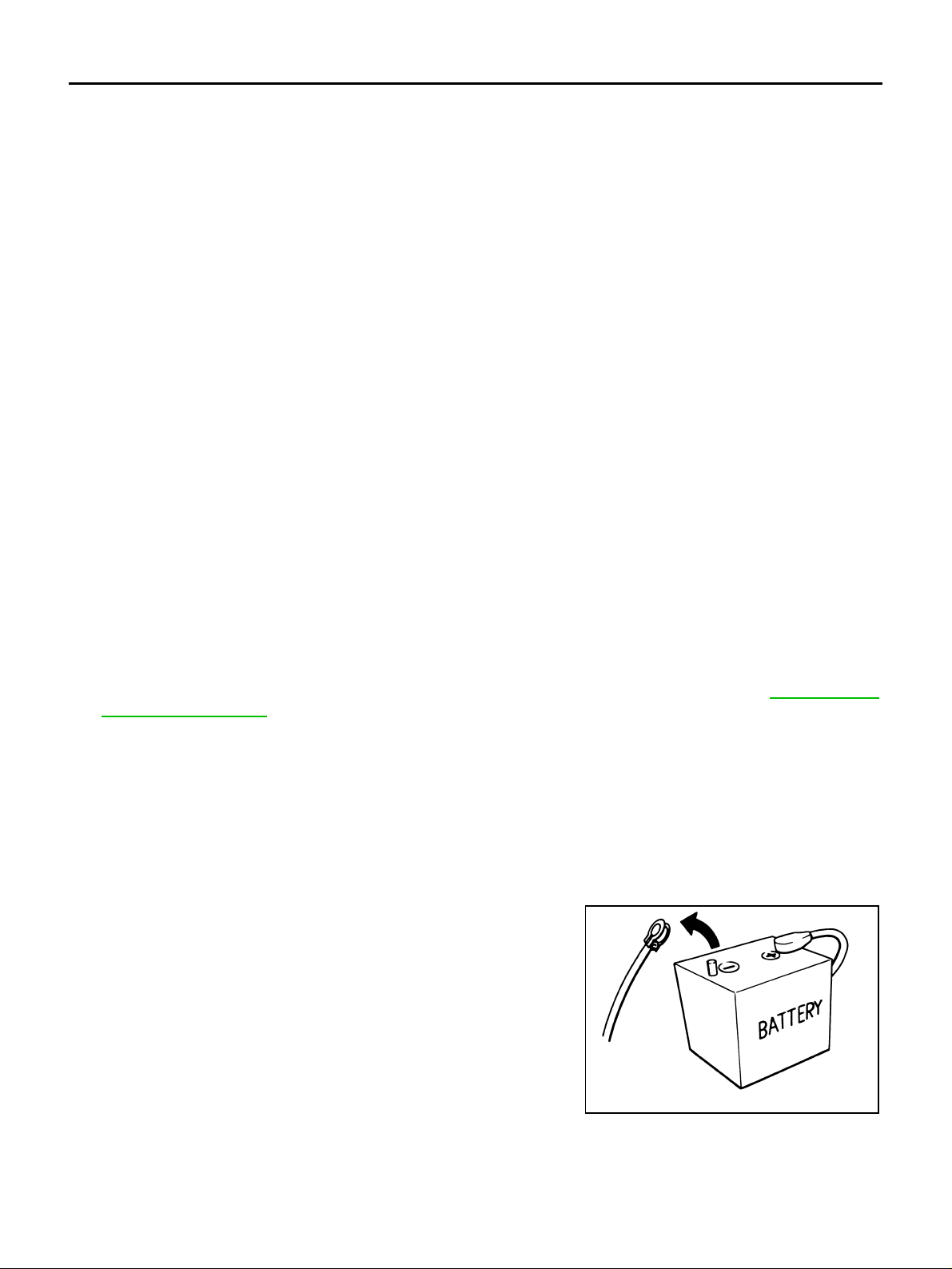

● Always use a 12 volt battery as power source.

● Do not attempt to disconnec t battery cables while engi ne i s

running.

● Before connecting or dis connecting the ECM harness con-

nector, turn ignition switch OFF and disconnect battery

ground cable. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned OFF.

● Before removing parts, turn ignition switch OFF and then

disconnect battery ground cable.

Revision: 2005 March 2005 X-Trail

EC-14

SEF289H

PRECAUTIONS

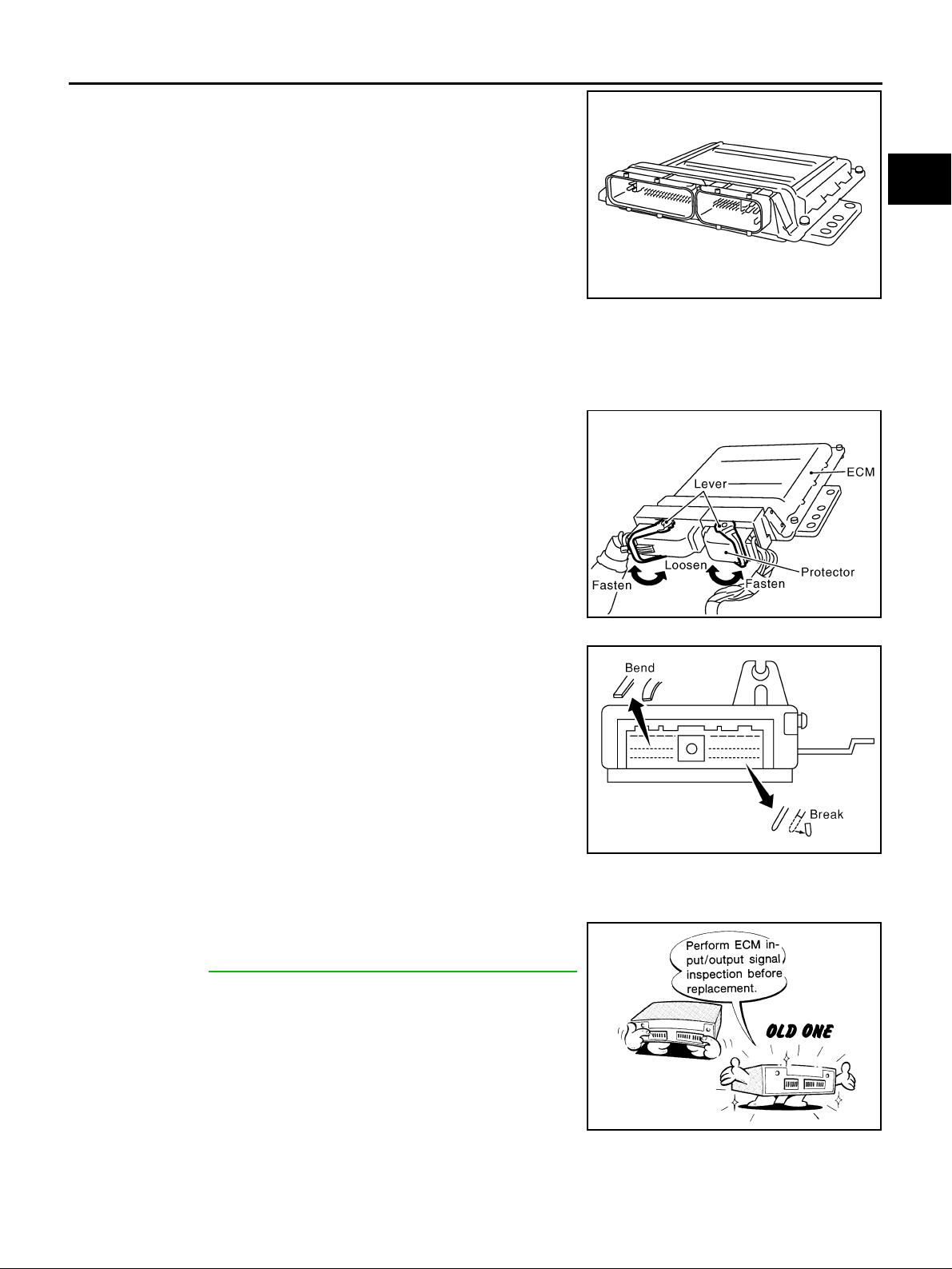

● Do not disassemble ECM.

● If battery cable is disconnected, the memory will return to

the initial ECM values.

The ECM will now start to self-contro l at its initial values.

Engine operation can vary slightly when the cable is disconnected. Howe ver, this is not an indication of a malfunc tion. Do not replace parts be cause of a sligh t variation.

● If the battery is disconnected, the following emission

related diagnostic information will be lost within 24 hours.

– Diagnostic trouble codes

– 1st trip diagnostic trouble codes

– Freeze frame data

– 1st freeze f rame data

– System readiness test (SRT) codes

– Test values

● When connecting ECM harness connector, fasten it

securely with a lever as far as i t will g o as shown in th e figure.

A

EC

C

PBIB1164E

D

E

F

G

PBIB1512E

● When connec ting or disconnecting pin connector s into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

● Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in co il and condenser, thus resulting in

damage to ICs.

● Keep engine control system harness at least 10 cm (4 in)

away from adjacent harness, to prevent engine control sys-

PBIB0090E

tem malfunctions due to receiving external noise, degraded

operation of ICs, etc.

● Keep engine control system parts and harness dry.

● Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspection and make sure ECM functions properly. Refer to EC-115, "

ECM Terminal s an d Ref er en c e Value"

.

● Handle mass air flow sensor carefully to avoid damage.

● Do not disassemble mass air flow sen sor.

● Do not clean mass air flow sensor with any type of deter-

gent.

● Do not disassemble electric throttle control actuator.

● Even a slight leak in the air intake system can cause seri-

MEF040D

ous incidents.

● Do not shock or jar the camshaft position sensor (PHASE), crankshaft position sensor (POS).

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-15

PRECAUTIONS

● After performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Overall Function Check.

The DTC should not be displa yed in the DTC Confirmation

Procedure if the repair is completed. The Overall Fun ction

Check should be a good result if the repair is completed.

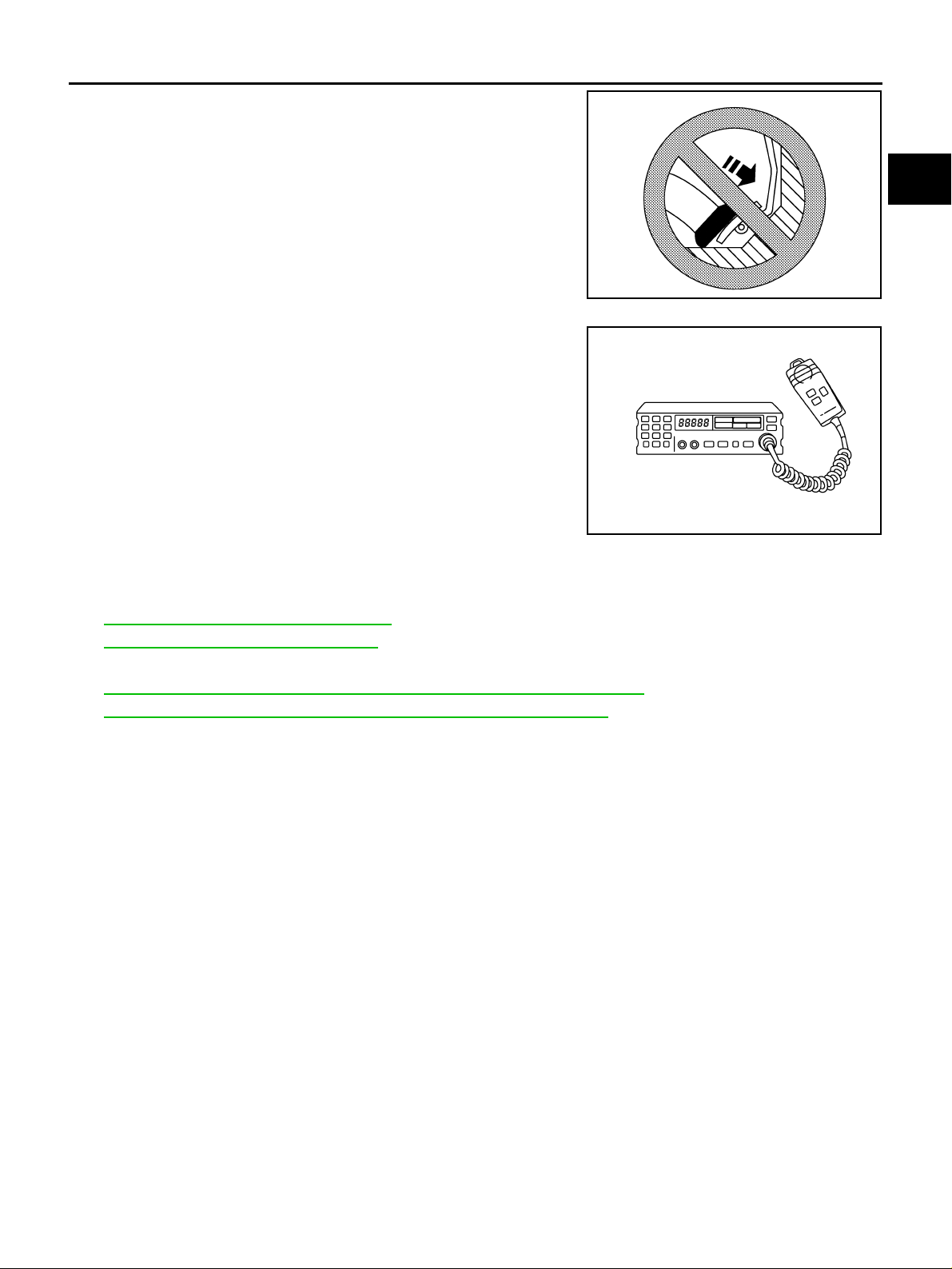

● When measuring ECM sig nals with a circui t tester, connect

a break-out box (SST) and Y-cable adapter (SST) between

the ECM and ECM harness connector.

● When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short c ircuit and

damage the ECM power transistor.

● Do not use ECM ground te rminals when measuring input/

output vol tage. Doi ng so m ay re su lt i n da ma g e to t he E CM's

transistor. Use a ground other than ECM terminals, su ch as

the ground.

SEF217U

● Do not operate fuel pump when there is no fuel in lines.

● Tighten fuel hose clamps to the specified torque.

SEF348N

PBIB2344E

Revision: 2005 March 2005 X-Trail

EC-16

PRECAUTIONS

● Do not depress accelerator pedal when starting.

● Immediately after starting, do not rev up engine unneces-

sarily.

● Do not rev up engine just prior to shutdown.

SEF709Y

● When installing C.B. ham radio or a m obile phone, b e sure

to observe the following as it may adversely affect electronic control systems depending on installation location.

– Keep the antenna as far as possible from the electronic

control units.

– Keep the antenna feed er line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

– Adjust the antenna and feeder line so that the standing-

wave radio can be kept smaller.

– Be sure to ground the radio to vehicle body.

SEF708Y

Wiring Diagrams and Trouble Diagnosis ABS00CKQ

A

EC

C

D

E

F

G

H

When you read wiring diagrams, refer to the following:

● GI-14, "How to Read Wiring Diagrams"

● PG-2, "POWER SUPPLY ROUTING" for power distribution circuit

When you perform trouble diagnosis, refer to the followi ng:

● GI-10, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"

● GI-26, "How to Perform Efficient Diagnosis for an Electrical Incident"

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-17

PREPARATION

PREPARATION PFP:00002 Special Service Tools ABS00CKR

The actual shapes of Kent-Moore tools may differ from those of spe ci al se rvice tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

EG17650301

(J-33984-A)

Radiator cap tester

adapter

KV10117100

(J-36471-A)

Heated oxygen

sensor wrench

KV10114400

(J-38365)

Heated oxygen

sensor wrench

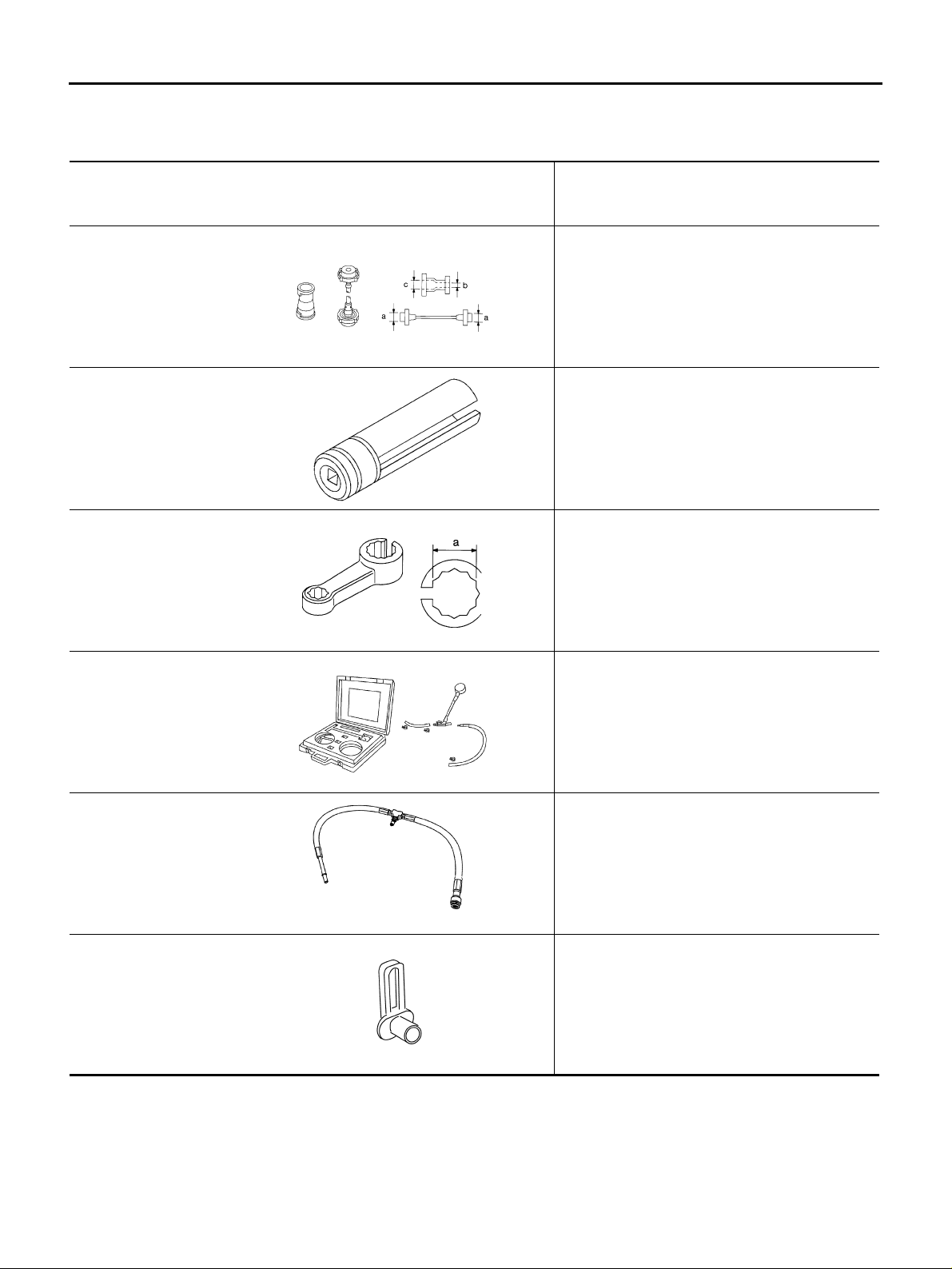

(J-44321)

Fuel pressure gauge

kit

Adapting radiator cap tester to radiator cap and

radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

S-NT564

Loosening or tightening heated oxygen sensors

with 22 mm (0.87 in) hexagon nut

S-NT379

Loosening or tightening heated oxygen sensors

a: 22 mm (0.87 in)

S-NT636

Checking fuel pressure

(J-44321-6)

Fuel pressure adapter

(J-45488)

Quick connector

release

LEC642

Connecting fuel pressure gauge to quick

connector type fuel lines.

LBIA0376E

Remove fuel tube quick connectors in engine

room.

PBIC0198E

Revision: 2005 March 2005 X-Trail

EC-18

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

KV109E0010

(J-46209)

Break-out box

S-NT825

KV109E0080

(J-45819)

Y-cable adapter

S-NT826

Description

Measuring ECM signals with a circuit tester

Measuring ECM signals with a circuit tester

Commercial Service Tools ABS00CKS

Tool name

(Kent-Moore No.)

Leak detector

i.e.:(J-41416)

Description

Locating the EVAP leak

A

EC

C

D

E

F

G

H

S-NT703

EVAP service port

adapter

i.e.:(J-41413-OBD)

S-NT704

Fuel filler cap adapter

i.e.: (J-41416)

S-NT815

Socket wrench Removing and installing engine coolant

S-NT705

Applying positive pressure through EVAP service

port

Checking fuel tank vacuum relief valve opening

pressure

temperature sensor

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

EC-19

PREPARATION

Tool name

(Kent-Moore No.)

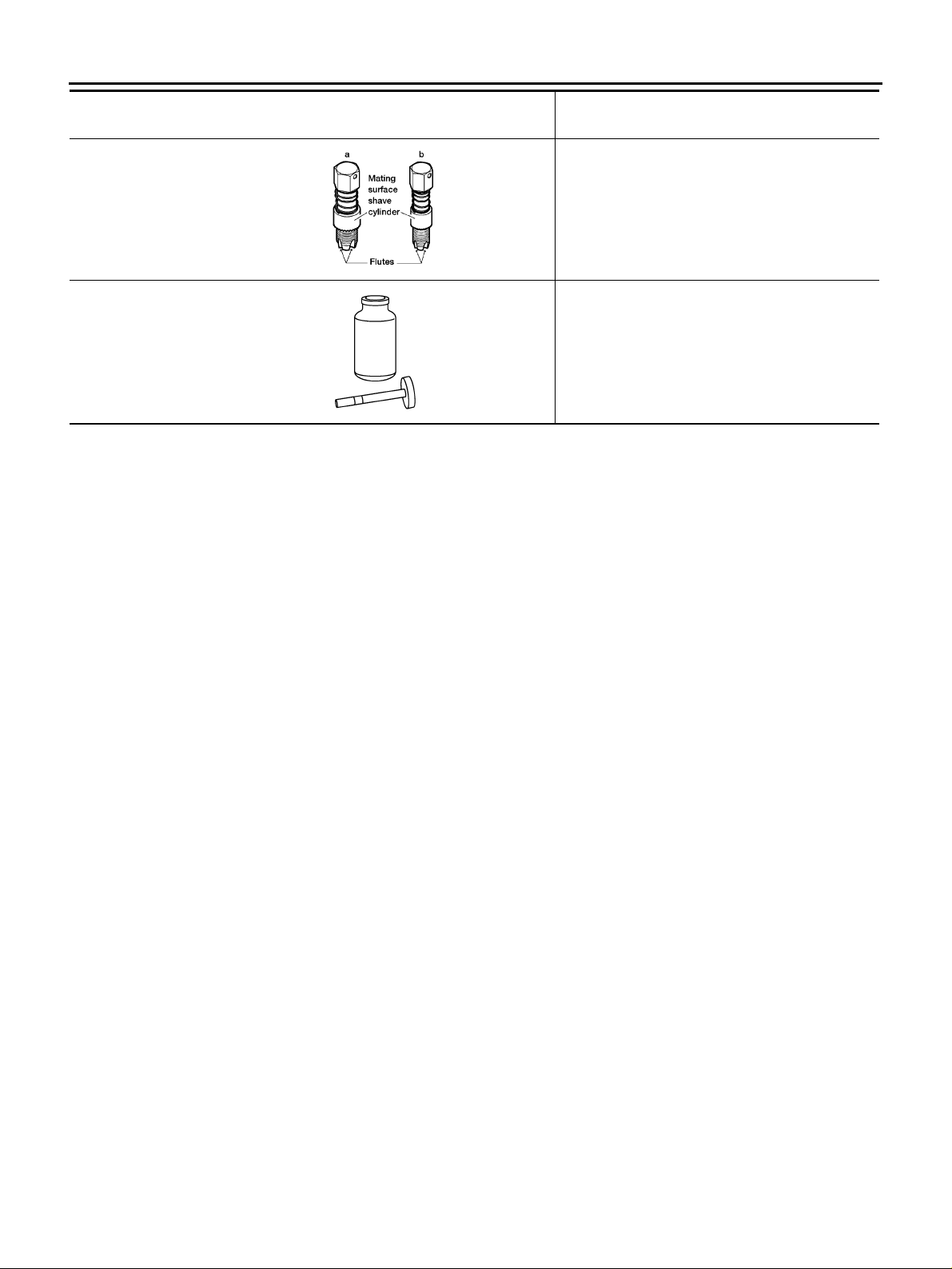

Oxygen sensor thread

cleaner

i.e.: (J-43897-18)

(J-43897-12)

Anti-seize lubricant

i.e.: (Permatex

133AR or equivalent

meeting MIL

specification MIL-A-

907)

TM

Description

Reconditioning the exhaust syst em threads

before installing a new oxygen sensor. Use with

anti-seize lubricant shown below.

a: 18 mm diameter with pitch 1.5 mm for

Zirconia Oxygen Sensor

b: 12 mm diameter with pitch 1.25 mm for

Titania Oxygen Sensor

AEM488

Lubricating oxygen sensor thread clea ni ng to ol

when reconditioning exhaust system threads.

S-NT779

Revision: 2005 March 2005 X-Trail

EC-20

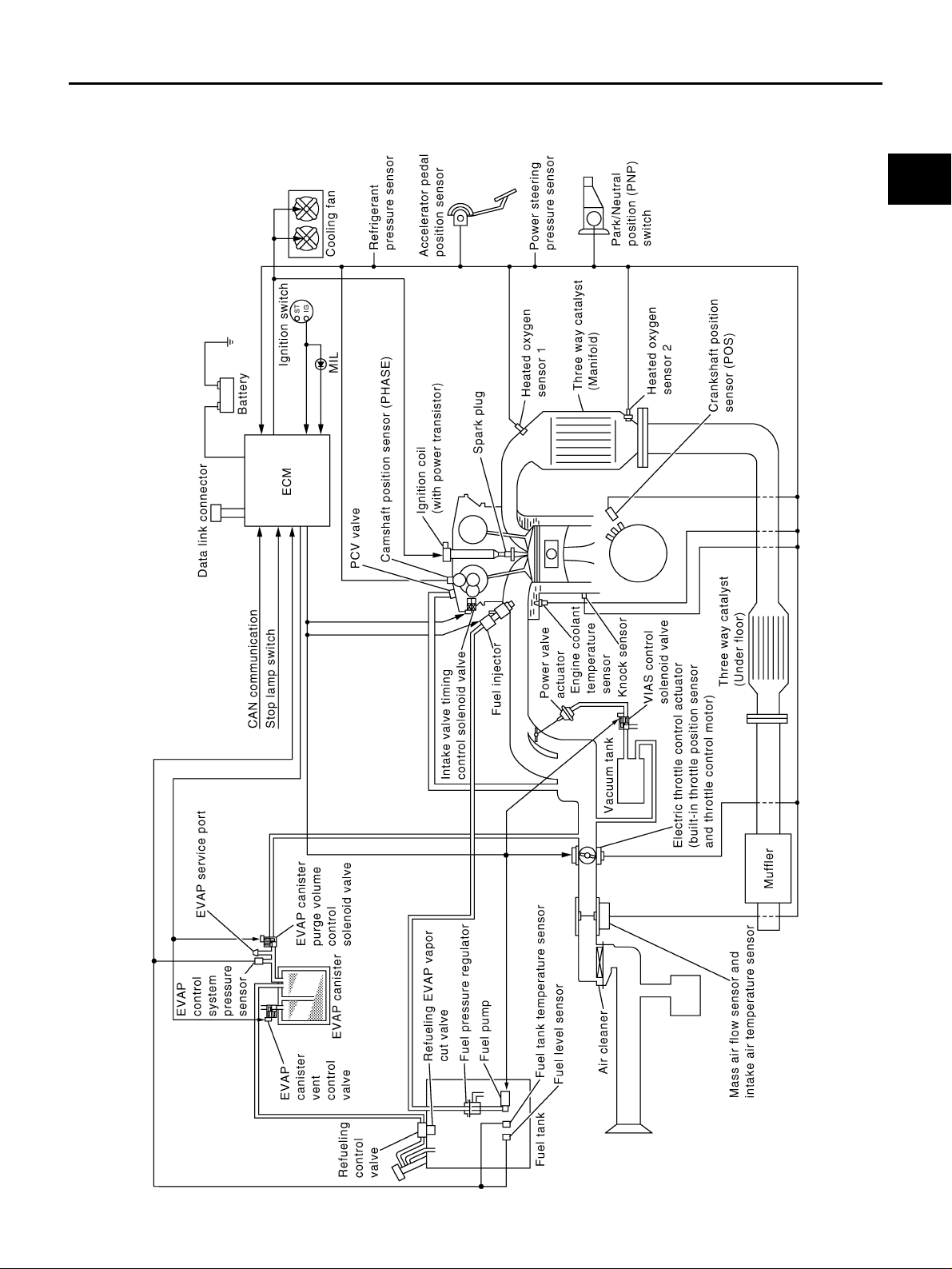

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM PFP:23710

System Diagram ABS00CKT

A

EC

C

D

E

F

G

H

K

M

I

J

L

PBIB2361E

Revision: 2005 March 2005 X-Trail

EC-21

ENGINE CONTROL SYSTEM

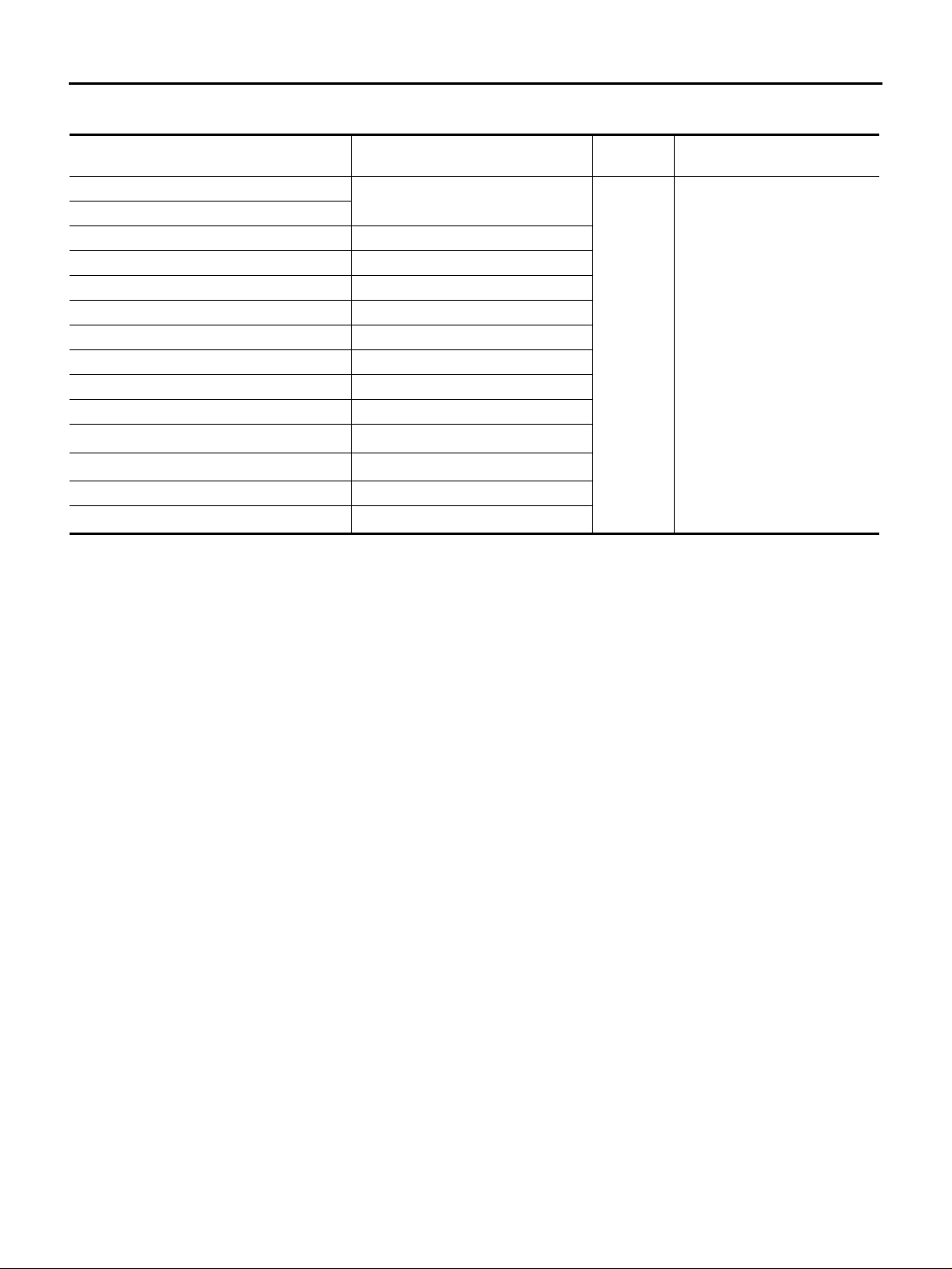

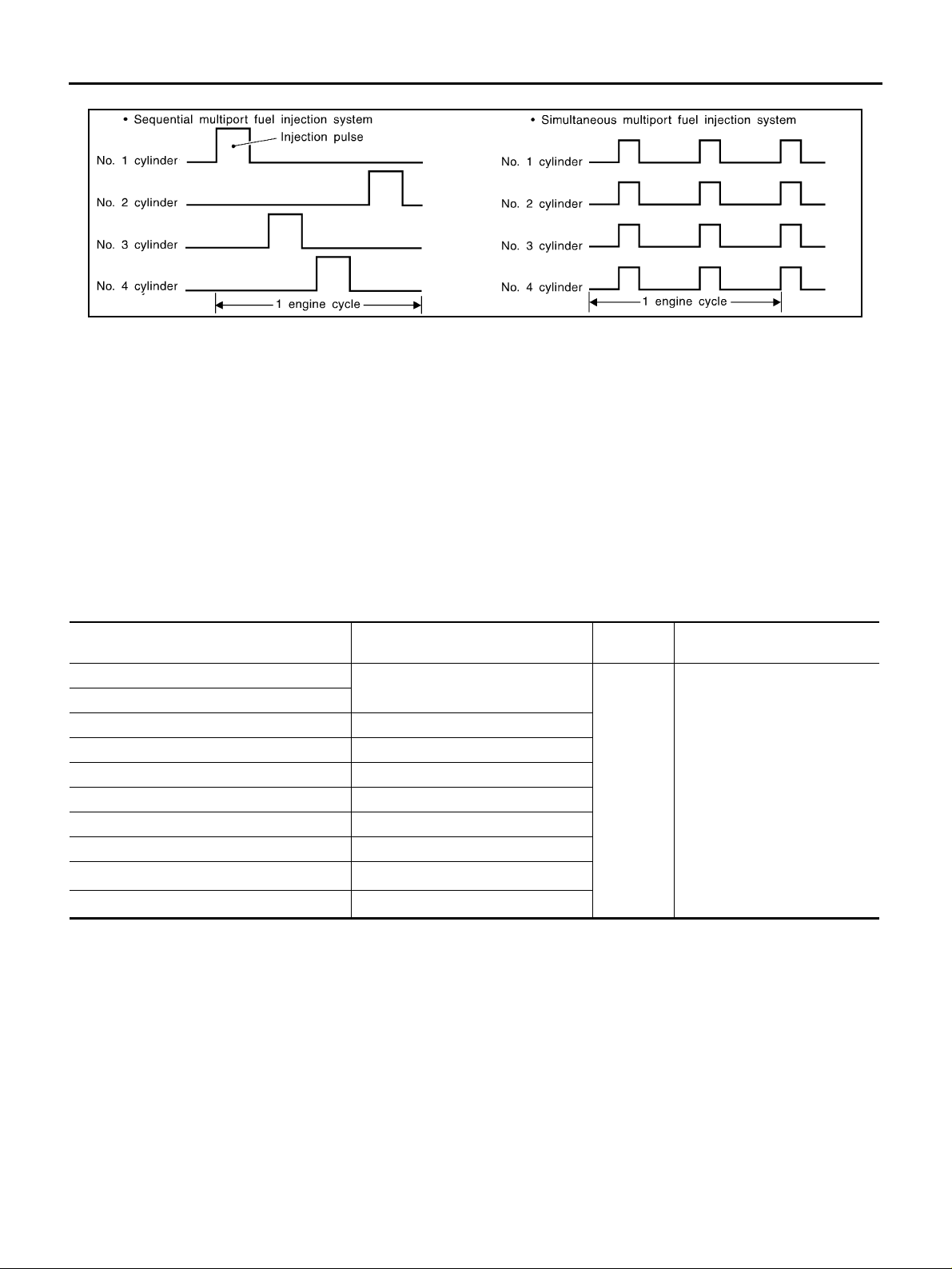

Multiport Fuel Injection (MFI) System ABS00CKW

INPUT/OUTPUT SIGNAL CHART

Sensor Input Signal to ECM

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Power steering pressure sensor Power steering operation

Heated oxygen sensor 1 Density of oxygen in exhaust gas

Heated oxygen sensor 2*

Wheel sensor*

Air conditioner switch Air conditioner operation

Battery

*1: This sensor is not used to control the engine sys tem under normal conditions.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signal of engine speed and battery voltage.

2

1

Engine speed*

Piston position

Density of oxygen in exhaust gas

Ve hicle speed

Battery voltage*

3

3

ECM

function

Fuel injection & mixture ratio

control

Actuator

Fuel injector

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (inj ection pu lse durati on). The a mount of fuel inject ed is a pr ogram val ue in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signal s (for engine speed an d intake air) from both the cra nkshaft positio n sensor and the mas s air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operating conditions as listed below.

<Fuel increase>

● During warm-up

● When starting the engine

● During acceleration

● Hot-engine opera tio n

● When selector lever is changed from N to D (A/T models)

● High-load, high-speed operation

<Fuel decrease>

● During deceleration

● During high engine speed operation

Revision: 2005 March 2005 X-Trail

EC-22

ENGINE CONTROL SYSTEM

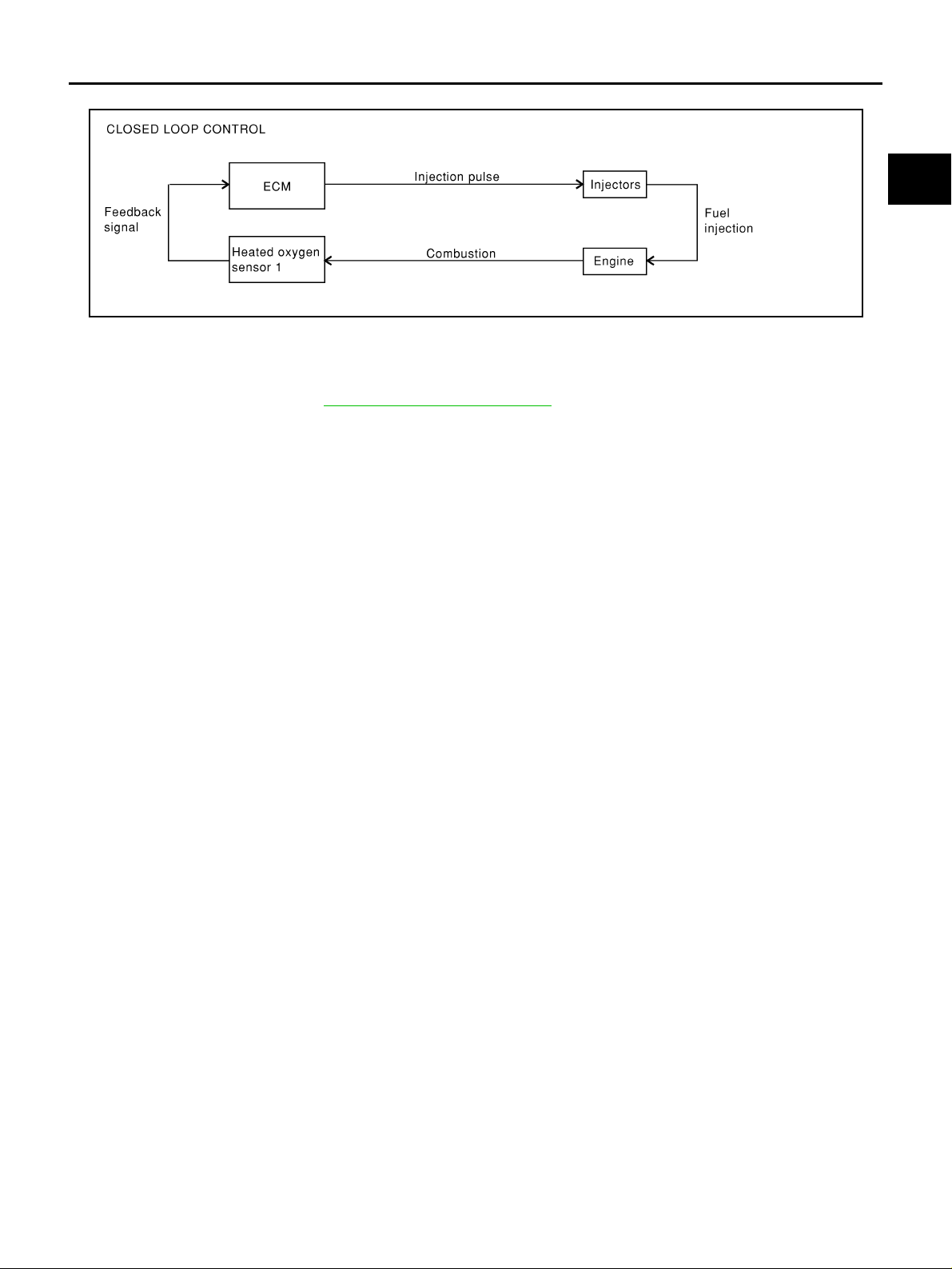

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

A

EC

C

PBIB0121E

The mixture r atio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses

heated oxygen sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to the sensor voltage signal. For more information about

heated oxygen sensor 1, refer to EC-227, "

DTC P0132 HO2S1" . This maintains the mixture ra tio within the

range of stoichiometric (ide al air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sens or 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of heated oxyge n sensor 1 shift , the air-fuel ratio is controlled to stoichiometric by the signal