Nespresso EF748, EF749 Schematic

en

Service Manual Coffee Machine

Service Manual Coffee Machine

1 |

EF 748 EF 749

01.2004 DOG

Contents

Main Components ........................................................ |

5 |

Overview ....................................................................................... |

5 |

Jaw ................................................................................................ |

6 |

Overview of rating plates .............................................................. |

7 |

Water circuit .................................................................................. |

8 |

Technical Data............................................................................... |

9 |

Operation .................................................................... |

10 |

Preparation.................................................................................. |

10 |

Making coffee ............................................................................... |

11 |

Preparing hot water ..................................................................... |

11 |

Frothing aids ............................................................................... |

12 |

Heating with steam ..................................................................... |

12 |

Frothing ....................................................................................... |

12 |

LED status diagram .................................................................... |

13 |

Troubleshooting ......................................................... |

14 |

Checking the machine - receipt (1) ............................................ |

14 |

Checking the machine - receipt (2) ............................................ |

15 |

Coffee temperature too low ........................................................ |

16 |

Coffee temperature too high ...................................................... |

16 |

No function.................................................................................. |

16 |

No outflow ................................................................................... |

17 |

No steam function or too little steam ......................................... |

18 |

No capsule ejection .................................................................... |

18 |

Jaw does not close ..................................................................... |

18 |

Water on the jaw ......................................................................... |

18 |

Water on side of machine or below machine............................. |

19 |

Pump noisy ................................................................................. |

19 |

Not enough froth when frothing milk ......................................... |

19 |

2

Contents

Repair .......................................................................... |

20 |

General disassembly (stage 1) ................................................... |

20 |

General disassembly (stage 2) ................................................... |

21 |

Replacing thermoblock .............................................................. |

22 |

Replacing NTC ............................................................................ |

22 |

Replacing pump .......................................................................... |

23 |

Replacing fine-wire fuse ............................................................. |

24 |

Replacing control board ............................................................. |

25 |

Replacing main switch or steam switch .................................... |

26 |

Replacing LED ............................................................................ |

26 |

Replacing steam pipe ................................................................. |

26 |

Replacing jaw .............................................................................. |

27 |

Complete jaw disassembly......................................................... |

28 |

Complete jaw disassembly......................................................... |

29 |

Replacing heating PTC ............................................................... |

30 |

Replacing pyramid plate ............................................................. |

31 |

Replacing capsule cage ............................................................. |

31 |

Electronic mainboard, wiring diagram ....................................... |

32 |

Maintenance................................................................ |

33 |

Descaling .................................................................................... |

33 |

Measuring rate of flow ................................................................ |

35 |

Checking for leaks and pump pressure (1) ................................ |

36 |

Checking for leaks and pump pressure (2) ................................ |

37 |

Checking extraction chamber for leaks ..................................... |

38 |

Measuring coffee temperature ................................................... |

39 |

Measuring closing force ............................................................. |

40 |

Checking reed contact................................................................ |

41 |

Daily maintenance and final cleaning ........................................ |

42 |

Spare parts ................................................................. |

43 |

3

Preface

The purpose of this Service Manual is to provide the service personnel with all necessary information with regards to correct handling, maintenance and repair of the coffee machine EF 748 and EF 749.

This manual should be used by the technicians as a valuable aid to guarantee the permanent readiness for use of the machine. In order to take full advantage of all the functions, it is absolutely necessary to follow the instructions in this manual.

Please keep this manual together with the corresponding service documentation. This way you are assured to have the necessary information.

For fast access to information directly from the PC or MAC monitor, this manual is also available on CD-ROM. The required utility (Adobe Acrobat), also on this CD-ROM, runs on PC and MAC computers. At the Internet address www.adobe.com you can obtain the utility Adobe Acrobat for additional platforms, free of charge.

4

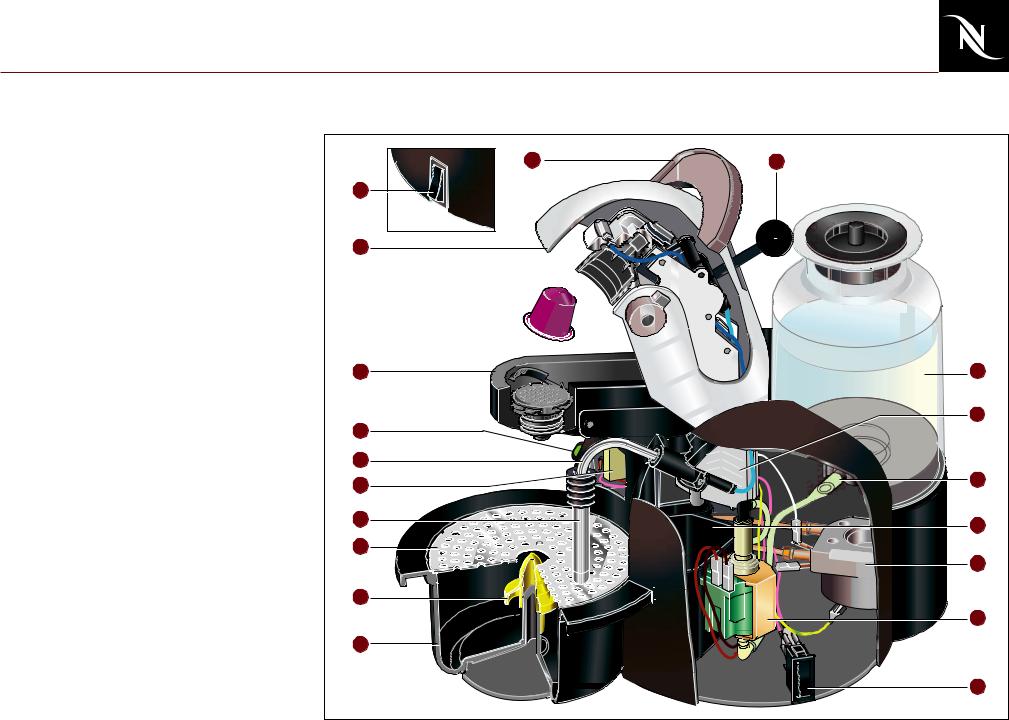

Main Components

Overview

1 Switch On/ Off

2 Switch steam

3 Upper part Jaw

4Lower part Jaw

5LED

6 Electronic mainboard

7 Steam pipe

8Frothing aid

9 Floater

10Drip tray

11Drip grid

12Closing handle

13Jaw stick coffee / hot water

14Water tank

15Water tank connector

16Condensation room

17Thermoblock

18Pump

19Container for used capsules

12 |

13 |

|

1 |

|

|

3 |

|

|

4 |

14 |

|

5 |

16 |

|

|

||

7 |

15 |

|

6 |

||

|

||

8 |

19 |

|

|

||

11 |

17 |

|

|

||

9 |

|

|

|

18 |

|

10 |

|

|

|

2 |

|

5 |

|

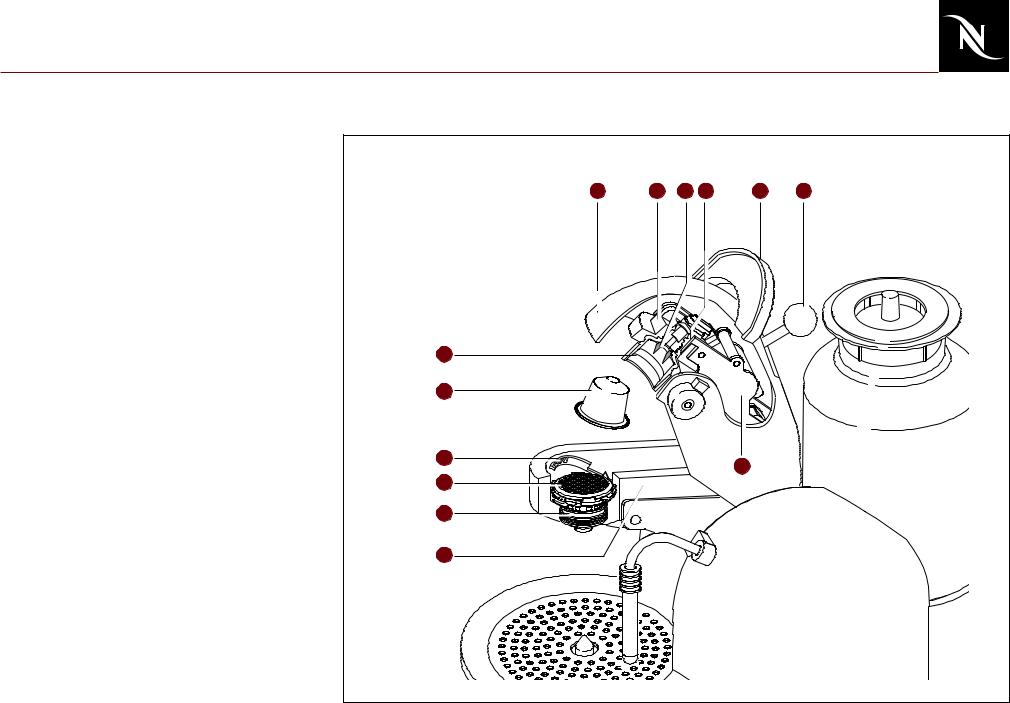

Main Components

Jaw

20Support for brewing unit

21Capsule cage

22Closing handle

23Jaw stick coffee, hot water/ steam

24Blades

25Cover

26Heating PTC (until Sept. 2003 only)

27Coffee capsule

28Ejector

29Pyramid plate (PPP, plastic)

30Pyramid plate support

31Brewing unit with ceramic valve and reed contact board

32Capsule cage connection

25 |

26 |

24 32 |

22 |

23 |

21 |

|

|

|

|

27 |

|

|

|

|

28 |

|

|

31 |

|

29 |

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

20 |

|

|

|

|

6 |

|

|

|

|

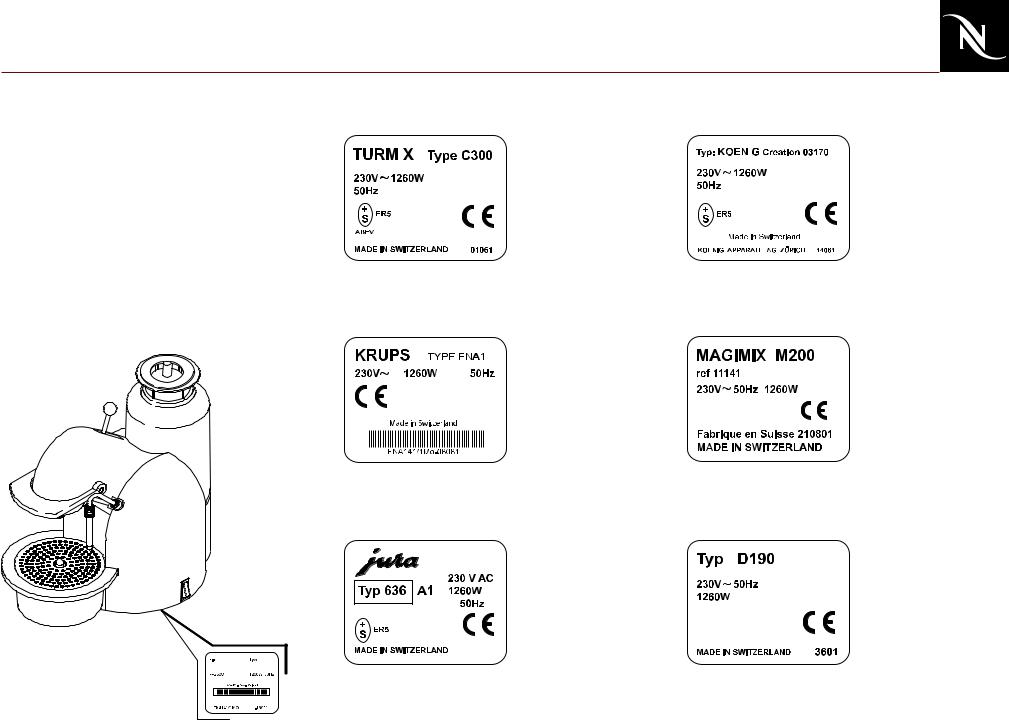

Main Components

Overview of rating plates

Depending on the brand, the rating plate may |

Turmix |

be of varying design. |

|

|

|

|

The rating plates carry the following

information:

Date code DDMMY

Krups

FNA141 = type

1M = factory

0 = internal number

08081 = Date code DDMMY

Jura

636 = type

A = colour code 1 = Appliance

modification status

7

König

03170 = Item number with colour code

Date code DDMMY

Magimix

M200 = type code

Item number with colour and country coding

Date code DDMMYY

Saeco

Date code WWYY

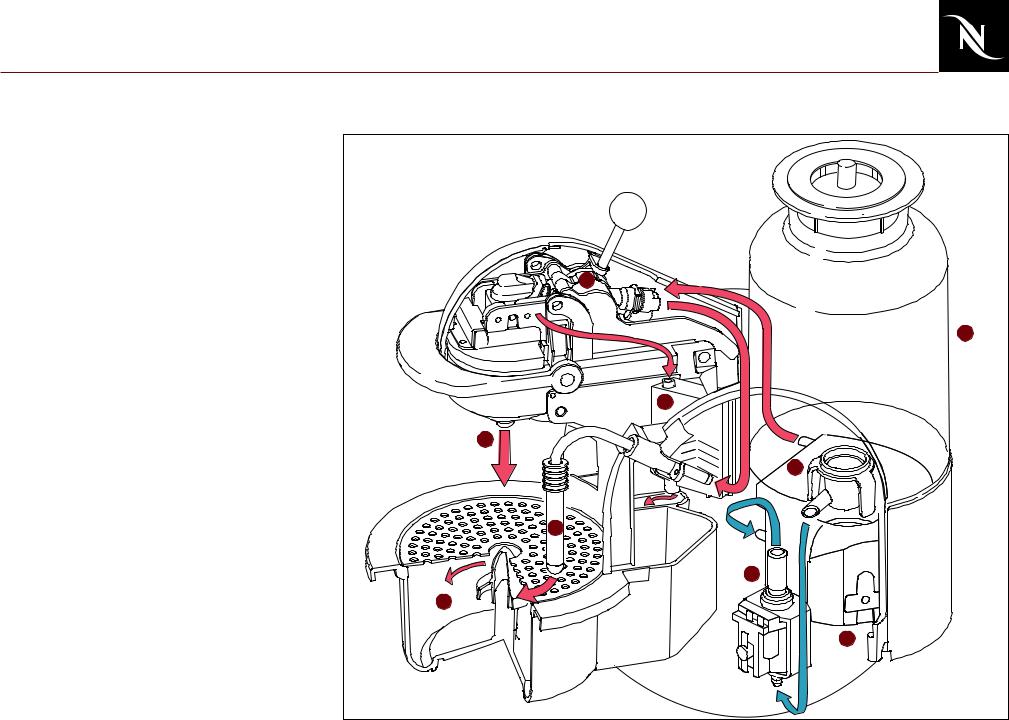

Main Components

Water circuit

1Water tank

2Water tank valve

3Pump

4 |

Thermoblock |

5 |

Ceramic valve |

6Coffee outlet

7 Steam pipe and frothing aid

8 Condensation room

9Drip tray

5 |

1 |

8 |

6 |

2 |

7 |

3 |

9 |

4 |

8 |

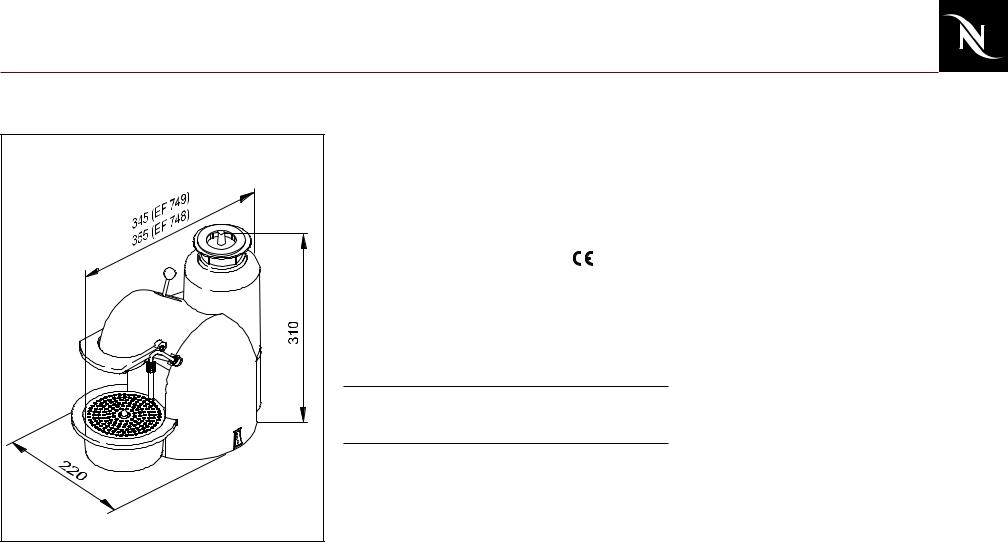

Main Components

Technical Data

Dimensions in mm

Mains |

EUR: 230V / 50 |

Hz |

|

Pre-heating time approx. |

ca. 45 s |

|

USA /CAN:120 V / 60 Hz |

|

|

|

|

|

JAP: 110 V / 50-60 |

Hz |

|

Safety temperature (thermal cut-off) |

184° C |

Cable length |

|

~1,5 m |

Approvals |

SEV, CENELEC, - conform |

|

|

|

UL, CUL, MITI |

Pump pressure: |

|

|

- max. permissible |

17,5 bar ±1,5 bar |

|

- during coffee preparation |

9 - 13 bar |

|

(depending on brand of coffee)

Power consumption

(at all voltages and frequencies):

Heating |

1’200 W |

Pump |

60 W |

Heating |

PTC 15 W |

Flow performance

100 - 240 ml/min. at 12 bar

Weight of machine |

4,8 kg |

(without water) |

|

Capacities |

|

Water tank |

1.2 l |

Drip tray |

0.45 l |

Capsule container |

10-12 pcs. |

Ratings: |

|

|

Preheating |

15.5 |

Wh |

1 small cup |

(45ml) 5.5 |

Wh |

1 large cup |

(110ml) 9 |

Wh |

Stand-by mode |

(24 hours) 575 |

Wh |

9

Operation

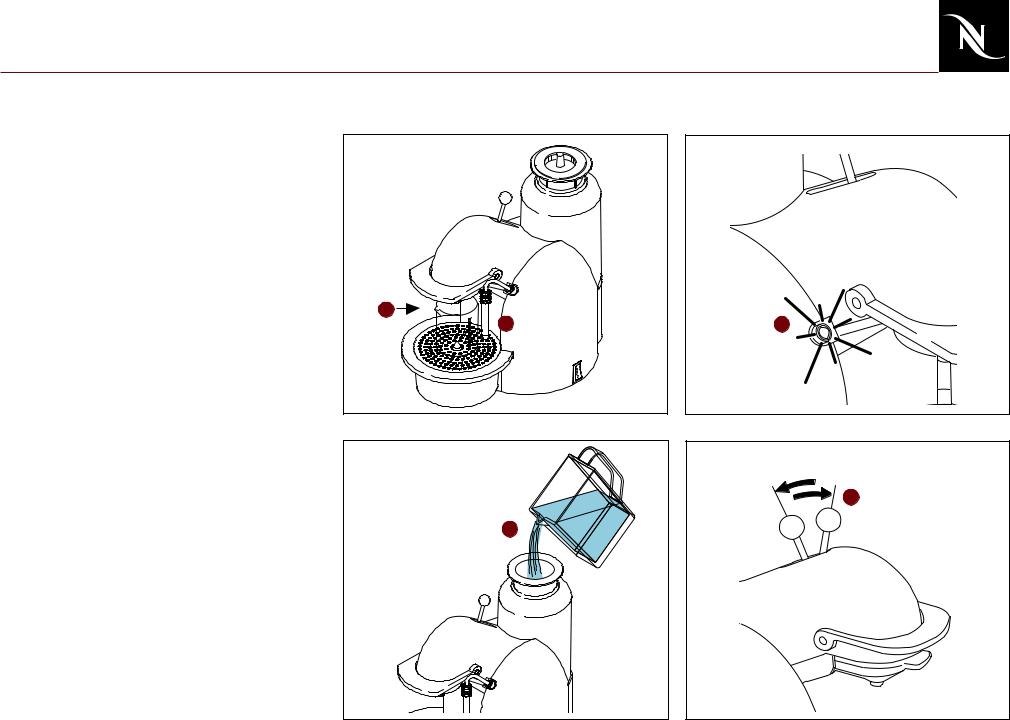

Preparation

1Switch on machine

2 Position pot underneath

3 LED flashes green

4Fill with water

5 Flush JAW

1 |

3 |

2 |

5

4

10

Operation

Making coffee

1Open jaw

2 Insert capsule

3 Close jaw

4Position cup

5LED must be green

6Place jaw stick in the front position, coffee flows into the cup

7Once the cup contains the required amount, return the jaw stick to the middle position

8Briefly open jaw and eject capsule into the capsule container

Preparing hot water

1 Position cup underneath steam pipe

2LED illuminates green

3Place jaw stick in the rear position, hot water flows into the cup

4Once the cup contains the required amount, return the jaw stick to the middle position

3 |

1 |

7 |

6 |

|

|||

|

|

|

|

2 |

|

|

|

4 |

|

|

|

|

|

5 |

|

|

|

|

4 |

|

|

3 |

|

1 |

|

2 |

|

|

|

11 |

|

Operation

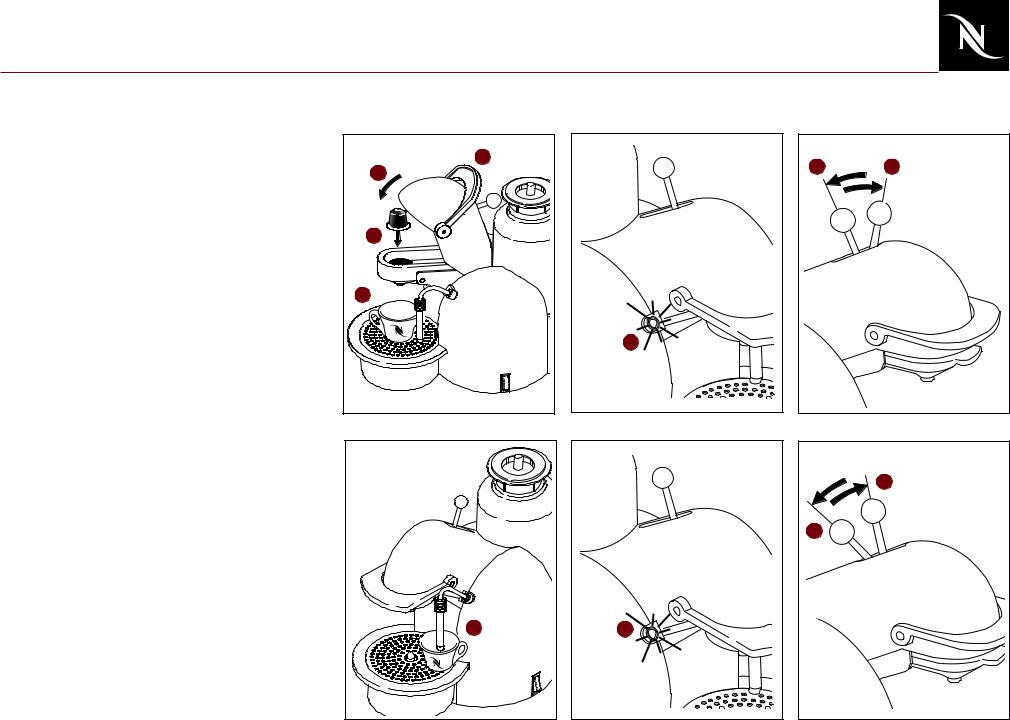

Heating with steam

1Slide down frothing pipe (only frothing aid A and B)

2Press steam switch

3LED flashes orange, wait until LED illuminates orange

4Immerse frothing pipe approx. 1cm deep in the liquid

5Place jaw stick in the rear position until

the required temperature is reached

6Return jaw stick to the middle position

Frothing

1Slide down frothing pipe (only frothing aid A and B)

2Press steam switch

3LED flashes orange, wait until LED illuminates orange

4Immerse frothing pipe approx. 1cm

deep in the milk

5Place jaw stick in the rear position until

the required foam is produced

6Return jaw stick to the middle position

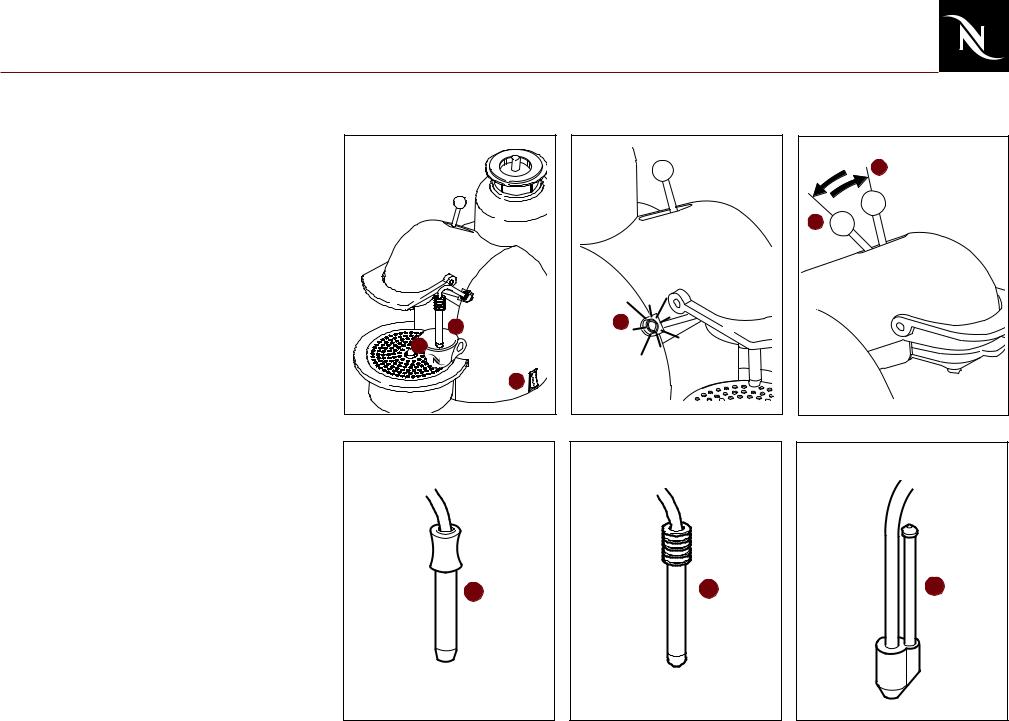

Frothing aids

There are three different types of frothing aid.

A)EF 749

B)EF 748 Turmix and Nespresso

C)EF 748 Krups

|

6 |

|

5 |

1 |

3 |

4 |

|

|

2 |

A |

B |

C |

12

Operation

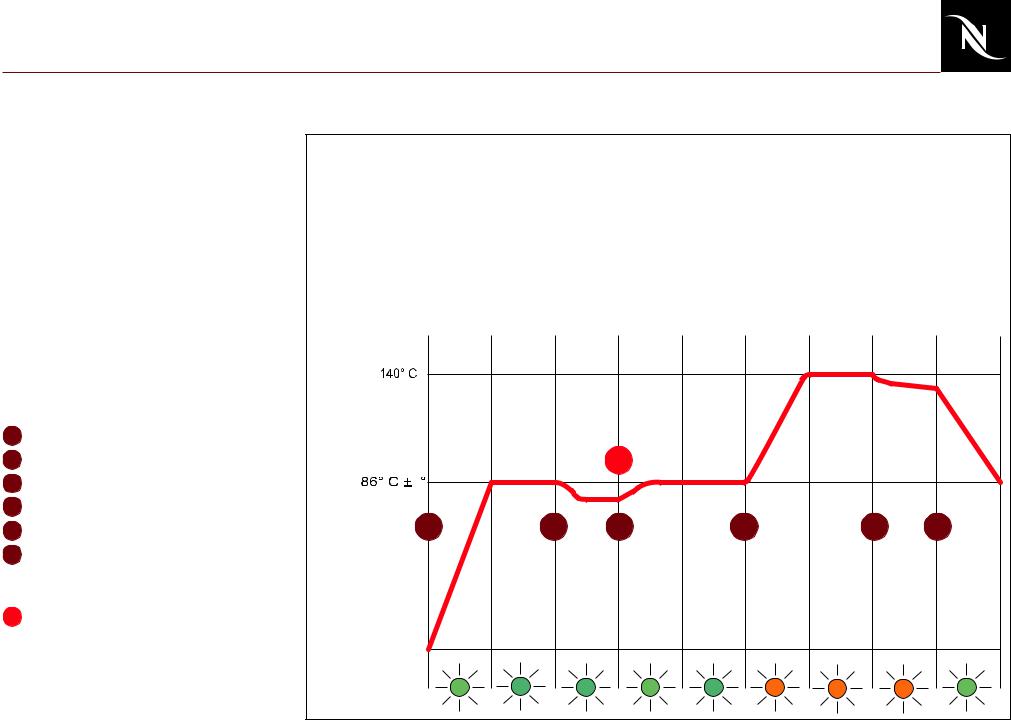

LED status diagram

The LED status diagram shows the behaviour of the LED depending on temperature and function.

LED-status

1 LED flashes green slowly

LED flashes green slowly

2 LED illuminates green

LED illuminates green

3 LED flashes orange slowly

LED flashes orange slowly

4 LED illuminates orange

LED illuminates orange

5 LED flashes green quickly

LED flashes green quickly

Operating sequence

A Switch on main switch

B Jaw stick forward or back

C Jaw stick in middle

D Operate steam switch

E Jaw stick back

F Jaw stick in middle

Note

!After the preparation of coffee or hot water, the green LED may flash rapidly for a short time due to overtemperature.

Steam |

Heatingup |

Ready |

waterCoffeehot/ |

preparation |

Heatingup |

Ready |

Heatingup |

readySteam |

preparationSteam |

Cooling |

|

preparation |

|||||||||||

|

|

|

|

|

|

|

|

|

|

||

Coffee and |

|

|

|

|

|

|

|

|

|

|

|

hot water |

|

|

|

|

! |

|

|

|

|

|

|

preparation |

3 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

A |

B |

|

|

C |

|

D |

|

E |

F |

|

|

1 |

2 |

|

2 |

1 |

2 |

3 |

4 |

4 |

5 |

|

|

|

13 |

|

|

|

|

|

|

|

|

Troubleshooting

Checking the machine - receipt (1)

The receipt check enables you to rapidly locate faults on the machine and to initiate appropriate repair action.

Keep to the order given in the table.

Repair any faults found and repeat the repair routine to the end.

• Check appliance for visible damage |

- Parts of housing broken or damaged? |

|

- Mains cable damaged? |

|

- Has the customer opened the machine? |

|

|

• Check mechanical elements |

- Does the jaw stick engage? |

|

- Does the closing handle work? |

|

- Is the ejector mechanism in working order? |

|

|

• Switch on |

- LED flashes during heating up |

|

- How long does the machine need for |

|

heating up (typical time approx. 45s)? |

|

|

• Fill water tank |

- Water tank leaks? |

|

|

• Coffee preparation without capsule |

- Does the reed contact work? |

|

- Does the pump work? |

|

- Does hot water escape? |

|

|

• Hot water preparation |

- Does the reed contact work? |

|

- Does hot water escape? |

14

Troubleshooting

Checking the machine - receipt (2)

• Steam preparation |

- Does the steam switch work correctly? |

|

LED must flash orange slowly during |

|

heating up and then illuminate continuously. |

|

- Does steam escape? |

|

|

• De-scale |

- See page 33 |

|

|

• Flow rate |

- See page 34 |

|

|

• Check for leaks |

- See page 35 to 37 |

|

|

• Temperature measurement |

- See page 38 |

|

|

• Clean |

- See page 41 |

|

|

• Measure closing force |

- See page 39 |

|

|

• Check reed contact |

- See page 40 |

|

|

15

Loading...

Loading...