Mitsubishi WS-65313, WS-65413, WS-55313, WS-55413, WS-48413 Service Manual

...

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2003 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

MITSUBISHI ELECTRIC

Service

Manual

2003

Weight and dimensions shown are approximate.

Design specifications are subject to change without notice.

PROJECTION TELEVISION

V22 / V22+ CHASSIS

SPECIFICATIONS

Power : AC 120V, 60Hz

240W

Frequency : VHF 54 ~ 470MHz

Range UHF 470 ~ 806MHz

Antenna Input : VHF/UHF 75Ω unbalanced

CRT Size : 7 inches

High Voltage : 30.8KV

• Speakers : [WS-48313 / WS-48413]

Two 5" round, full range (8Ω 10W)

: [WS-55313 / WS-55413 / WS-65313/

WS-65413]

Two 6" round, full range (8Ω 10W)

Weight / Cabinet Demensions

• Input Level : VIDEO IN JACK (RCA Type)

1.0Vp-p 75Ω unbalanced

: AUDIO IN JACK (RCA T ype)

-4.7dBm 43kΩ unbalanced

: S-VIDEO IN JACK (Y/C separate)

Y=1.0 Vp-p C=0.286Vp-p(BURST)

75Ω unbalanced

: COMP / Y, Cr , Cb (RCA T ype)

Y=1.0 Vp-p. Cr , Cb=700mVp-p

: DTV / Y(G), Pr(R), Pb(B), H, V

Y 1.0Vp-p with sync 75Ω (RCA Type)

Pr, Pb: 700mV 75Ω

H, V: 3.0Vp-p 75Ω

• Digital Inputs

:MonitorLink

TM

/DVI

:MonitorLink

TM

Control/RS-232C

• Output Level : VIDEO OUT JACK (RCA T ype)

1.0Vp-p 75Ω unbalanced

: AUDIO OUT JACK (RCA

Type)

-4.7dBm 4.7kΩ unbalanced

V22 Chassis

MODELS

WS-48313

WS-55313

WS-65313

V22+ Chassis

MODELS

WS-48413

WS-55413

WS-65413

WS-48313

Model Weight Height Width Depth

WS-48313

172 lbs 49" 44.5" 24"

WS-48413 172lbs 49" 44.5" 24"

WS-55313 213 lbs 50.4" 50.5" 25.4"

WS-55413 221 lbs 50.4" 50.5" 27.8"

WS-65313

327 lbs 62" 59" 28"

WS-65413 327 lbs 62" 59" 28"

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 3

INTRODUCTION ............................................................................................................................... 5

PRODUCT SAFETY NOTICE ...........................................................................................................5

SAFETY PRECAUTIONS ................................................................................................................. 6

DISASSEMBLY PROCEDURES ......................................................................................................... 7

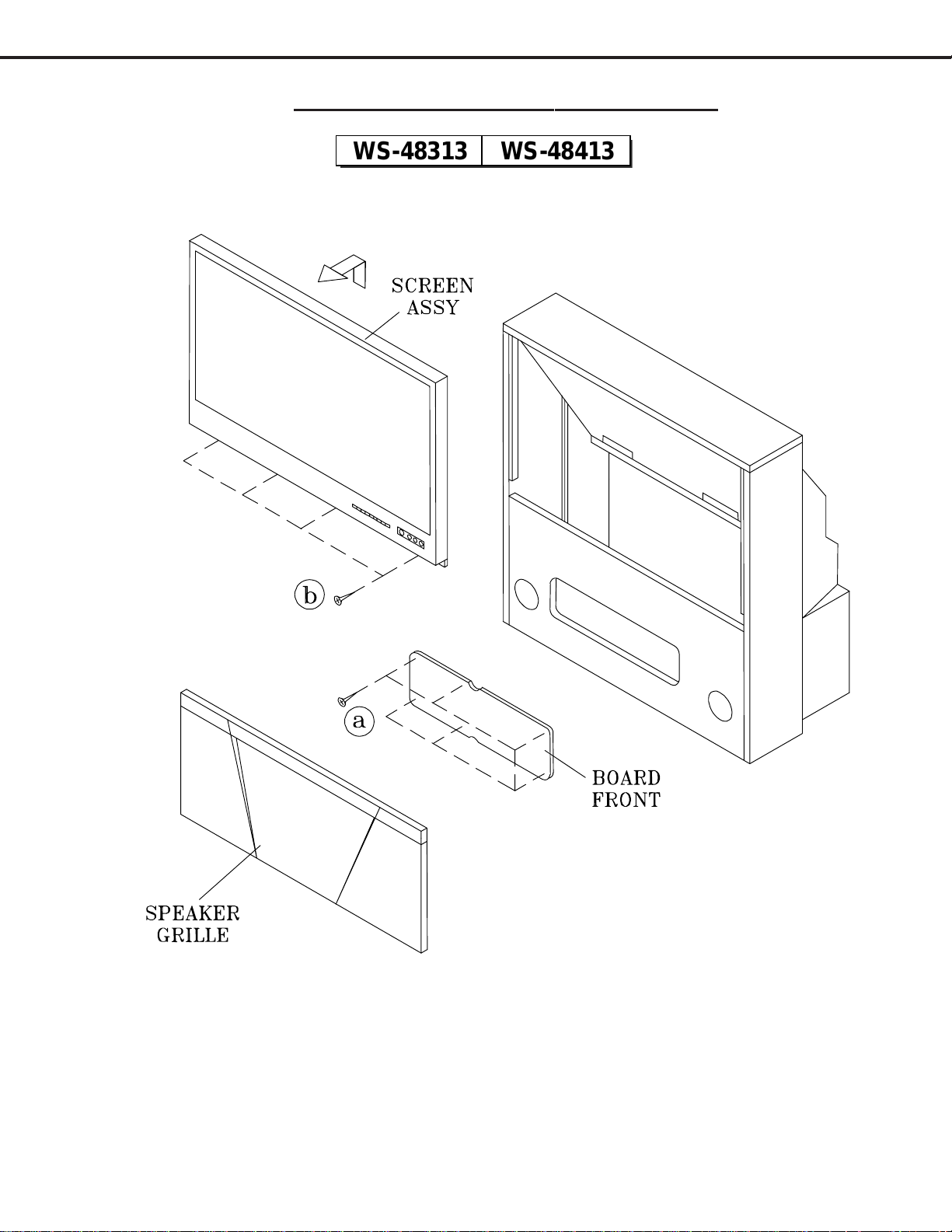

WS-48313 / WS-48413

Front Cabinet Components .................................................................................................... 7

Rear Cabinet Components ..................................................................................................... 8

WS-55313 / WS-55413 / WS-65313 / WS-65413

Front Cabinet Components .................................................................................................... 9

Rear Cabinet Components ................................................................................................... 10

SERVICING THE LENTICULAR LENS AND FRESNEL SCREEN ................................................ 11

WS-48313 / WS-48413

Removal of the Lenticular Screen and Fresnel Lens .......................................................... 11

WS-55313 / WS-55413 / WS-65313 / WS-65413

Removal of the Lenticular Screen and Fresnel Lens .......................................................... 12

All Models

Installation of the Lenticular Screen and Fresnel Lens ....................................................... 13

CABINET SEPARATION PROCEDURES .......................................................................................... 14

WS-65313 / WS-65413 ................................................................................................................. 14

SERVICING THE DIAMONDSHIELDS

TM

r ........................................................................................ 15

DiamondShields

TM

Removal ......................................................................................................... 15

DiamondShields

TM

Installation ...................................................................................................... 15

SERVICING PCBs ............................................................................................................................ 16

Chassis Removal .......................................................................................................................... 16

PCB Locations .............................................................................................................................. 16

Major Parts Locations ................................................................................................................... 16

ANODE LEAD REMOVAL ................................................................................................................. 17

CRT REPLACEMENT ....................................................................................................................... 17

CRT Removal ................................................................................................................................17

CRT Installation ............................................................................................................................ 18

ELECTRICAL ADJUSTMENTS ...................................................................................................... 20

Equipment .................................................................................................................................... 20

Initial Setup ................................................................................................................................... 21

LED Indicator Diagnostics ............................................................................................................. 22

Circuit Adjustment Mode ............................................................................................................... 23

Convergence Adjustment Mode ..................................................................................................... 24

Adjustment Items List ................................................................................................................... 26

Adjustment Procedures ................................................................................................................ 29

Test Point Locations ............................................................................................................29

HV Regulation ...................................................................................................................... 30

Main / Sub Y Level ............................................................................................................... 30

Main / Sub Color Level ......................................................................................................... 31

CRT Cutoff ........................................................................................................................... 31

White Balance (NTSC) ......................................................................................................... 32

CONTENTS

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 4

White Balance (HD) ............................................................................................................. 32

Black Level .......................................................................................................................... 33

Sub Contrast ....................................................................................................................... 33

Dynamic Focus Presets ...................................................................................................... 34

Lens Focus.......................................................................................................................... 34

Alignment Magnet & Electrostatic Focus ............................................................................. 35

Charactrer Position .............................................................................................................. 35

Geometry Presets ............................................................................................................... 36

Deflection Geometry Adjustments ........................................................................................ 37

Convergence Geometry Adjustments ................................................................................... 38

Centering & Static Convergence ........................................................................................... 39

Coarse Convergence Adjustments ........................................................................................ 40

Fine Convergence Adjustments ............................................................................................ 41

CHIP PARTS REPLACEMENT ......................................................................................................... 42

REPLACEMENT PARTS .................................................................................................................. 43

Parts Ordering .............................................................................................................................. 43

Critical and Warranty Parts Designation........................................................................................ 43

Parts Tolerance Codes .................................................................................................................. 43

Quick Reference List .................................................................................................................... 44

SERVICE PARTS LIST .................................................................................................................... 45

SCREEN ASSEMBLY PARTS LIST.................................................................................................. 57

CIRCUITRY BLOCK DIAGRAMS ..................................................................................................... 60

Part 2

Schematic Diagrams

CONTENTS Page

SCHEMATIC DIAGRAMS

PCB Interconnect Diagram.............................................................................................................. 1

PCB-MAIN ...................................................................................................................................... 2

PCB-POWER ................................................................................................................................. 3

PCB-SIGNAL-1 (TUNER I/O) ........................................................................................................... 4

PCB-SIGNAL-2 (MICRO) ................................................................................................................. 5

PCB-SIGNAL-3 (VIDEO / CHROMA) ............................................................................................... 6

PCB-SIGNAL-4 (CONVERGENCE GENERATOR) .......................................................................... 7

PCB-DOUBLER-1 ........................................................................................................................... 8

PCB-DOUBLER-2 ........................................................................................................................... 9

PCB-DOUBLER-3 ......................................................................................................................... 10

PCB-TERMINAL-1 (A/V I/O) .......................................................................................................... 11

PCB-TERMINAL-2 (MonLink) ........................................................................................................ 12

PCBsCRT, CONTROL, FRONT and PREAMP .............................................................................. 13

PCB LAYOUT DIAGRAMS ............................................................................................................... 14

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 5

INTRODUCTION

This service manual provides service instructions for the PTV Models listed below. Service personnel should read this

manual thoroughly before servicing these chassis.

This service manual includes:

1. Assembly and disassembly instructions for the front and rear cabinet components.

2. Servicing of the Lenticular Screen and Fresnel Lens.

3. Servicing printed circuit boards (PCBs).

4. CRT replacement procedure.

5. Electrical adjustments.

6. Chip parts replacement procedures.

7. Circuit path diagrams.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Schematic and block diagrams of the above listed models are included in this service manual for better under-

standing of the circuitry. PCB drawings are also included for easy location of parts and test points.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be

obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagram and by bold

type in the parts list of this service manual. The replacement for any safety part should be identical in value

and characteristics.

V22 Chassis V22+ Chassis

WS-48313 WS-48413

WS-55313 WS-55413

WS-65313 WS-65413

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 6

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. Do not install, remove or handle the picture tubes in any manner unless shatterproof goggles are

worn. People not so equipped should be kept away while the picture tube is being handled. Keep

the picture tube away from the body while handling.

3. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

X-Radiation warning

The surface of the cathode ray tubes (CRTs) may generate X-Radiation, so take proper precautions when servic-

ing. It is recommended that a lead apron be used for shielding while handling the CRT. Use this method if

possible.

When replacing the CRTs, use only the designated replacement part since it is a critical component with regard to

X-Radiation. High voltage must be set as prescribed under the section titled Electrical Adjustments.

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to

the following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal

part (i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts, etc.), particu-

larly any exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts

having a return path to the chassis should be a minimum of 1Mega Ohm. Any resistance below this value

indicates an abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure

the leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 7

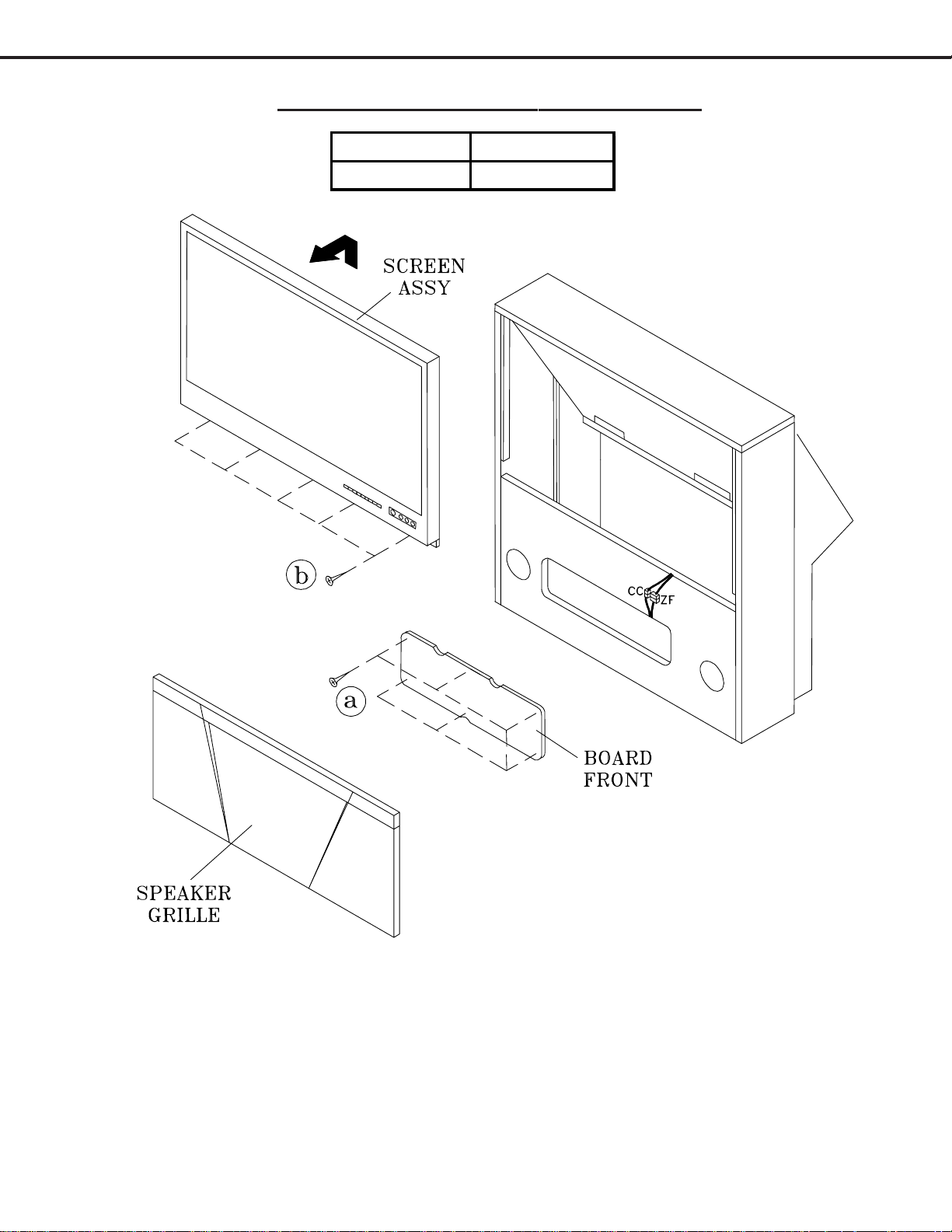

*Refer to PARTS LIST for Part Numbers

CABINET DISASSEMBLY (FRONT VIEW)

Front Cabinet Disassembly

1. Remove the Speaker Grille by pulling forward.

2. Remove the Board-Front by removing six screws "a".

3. Remove the Screen Assembly by removing four screws "b". Disconnect all cable harnesses between the

Screen Assembly and the PCB-Signal.

4. Lift the Screen Assembly and pull up and away from the cabinet as shown.

WS-48313 WS-48413

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 8

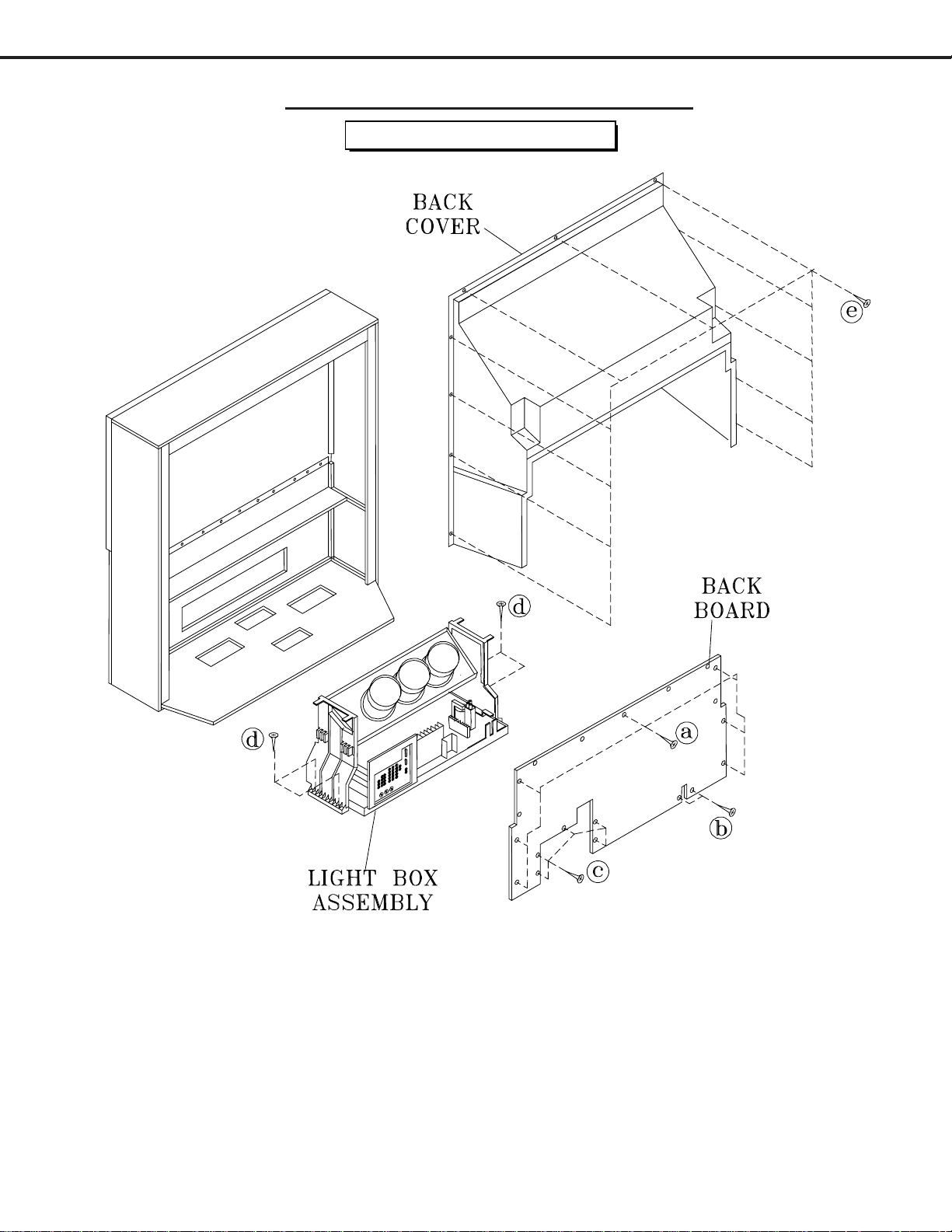

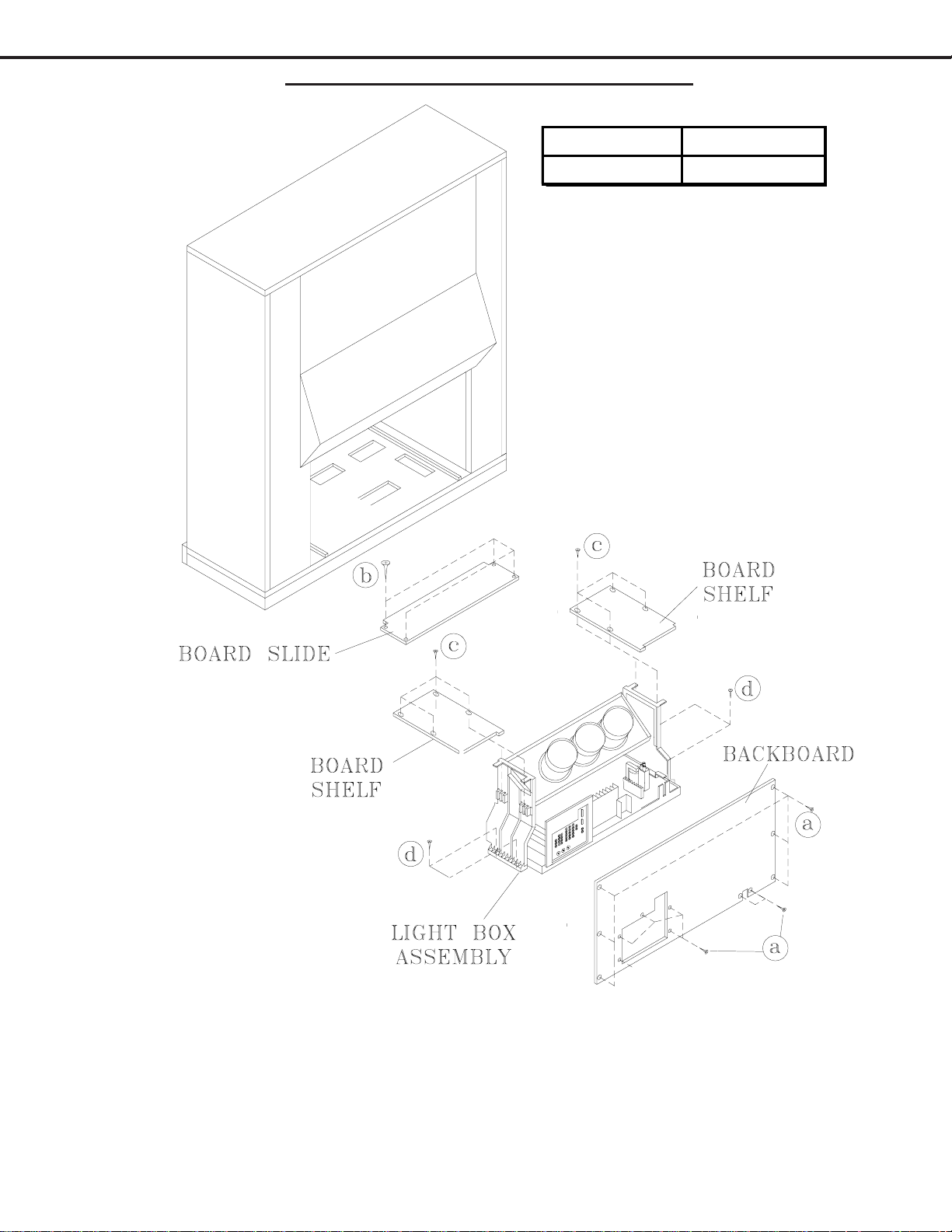

CABINET DISASSEMBLY (REAR VIEW)

Rear Cabinet Disassembly

1. Remove the Back Board by removing 14 screws "a", b and c.

2. Remove the Back Cover by removing screws "e".

3. Remove 4 screws "d" securing the Light Box Assembly.

4. Be certain that all cables and connectors between the Light Box Assembly and external items are discon-

nected (e.g. speaker plugs).

5. Slide the Light Box Assembly out of the cabinet.

WS-48313 / WS-48413

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 9

CABINET DISASSEMBLY (FRONT VIEW)

Front Cabinet Disassembly

1. Remove the Speaker Grille by pulling forward.

2. Remove the Front-Board by removing screws "a".

3. Remove the Screen Assembly by removing 5 screws "b". Disconnect connectors CC and ZF between the

Screen Assembly and the PCB-Signal.

4. Lift the Screen Assembly and pull up and away from the cabinet as shown.

WS-55313 WS-55413

WS-65313 WS-65413

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 10

CABINET DISASSEMBLY (REAR VIEW)

Rear Cabinet Disassembly

1. Remove the Back Board by removing 13 screws "a" (15 screws a in 65 inch models).

2. Remove the Board Slide by removing four screws b.

3. Remove the two Board Shelves by removing 8 screws c.

4. Remove 4 screws "d" securing the Light Box Assembly.

5. Be certain that all cables and connectors between the Light Box Assembly and external items are discon-

nected (connectors CC, ZF and EJ)).

6. Slide the Light Box Assembly out of the cabinet.

WS-55313 WS-55413

WS-65313 WS-65413

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 11

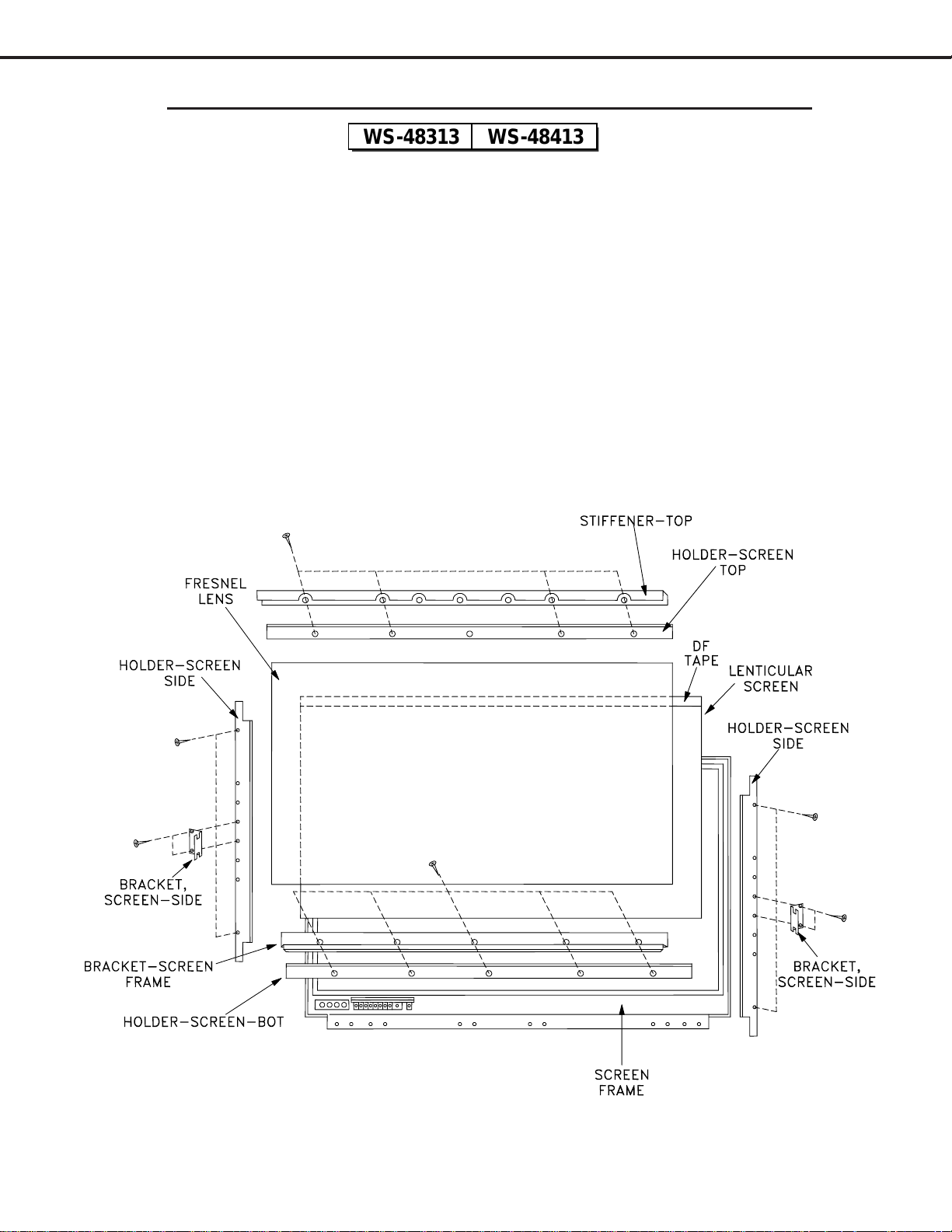

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

1a. Lenticular Screen and Fresnel Lens Removal

1. Remove the screen assembly as shown in the Cabinet Disassembly procedure.

2. Remove the Top, Bottom and Side Holder Screens..

3. Carefully lift the Lenticular Screen and Fresnel Lens combination from the Screen Frame Assembly.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

WS-48313 WS-48413

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 12

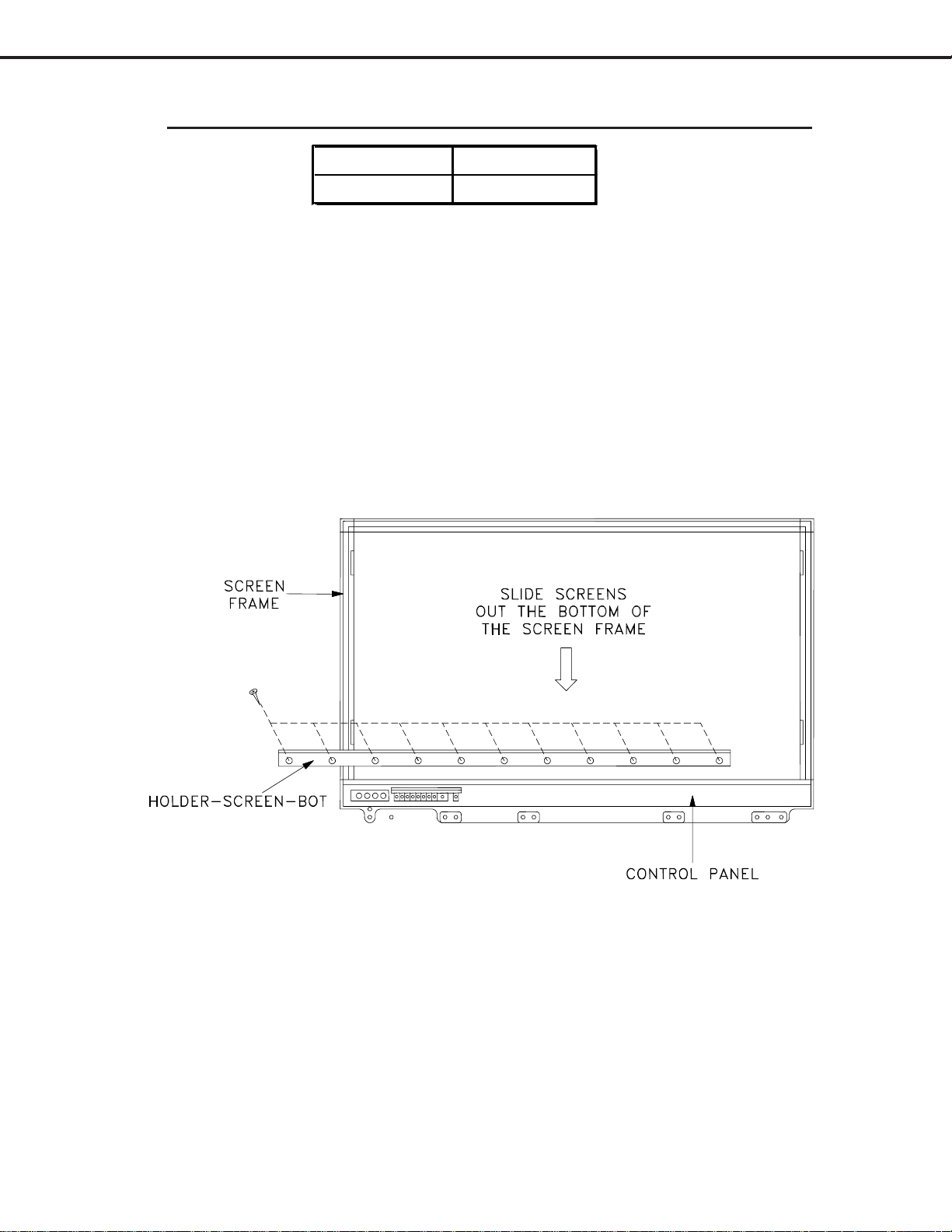

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

1b. Lenticular Screen and Fresnel Lens Removal

1. Remove the screen assembly as shown in the Cabinet Disassembly procedure.

2. Remove the HOLDER-SCREEN-BOTTOM.

3. Carefully slide the Lenticular Screen and Fresnel Lens combination from the upper Screen Frame Assembly.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

WS-55313 WS-55413

WS-65313 WS-65413

1b. Installing the Fresnel Lens and Lenticular Screen

1. Insert the Lenticular Screen and Fresnel Lens combination into the upper Screen Frame.

2. Install the HOLDER-SCREEN-BOTTOM, install the end screws first. .

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 13

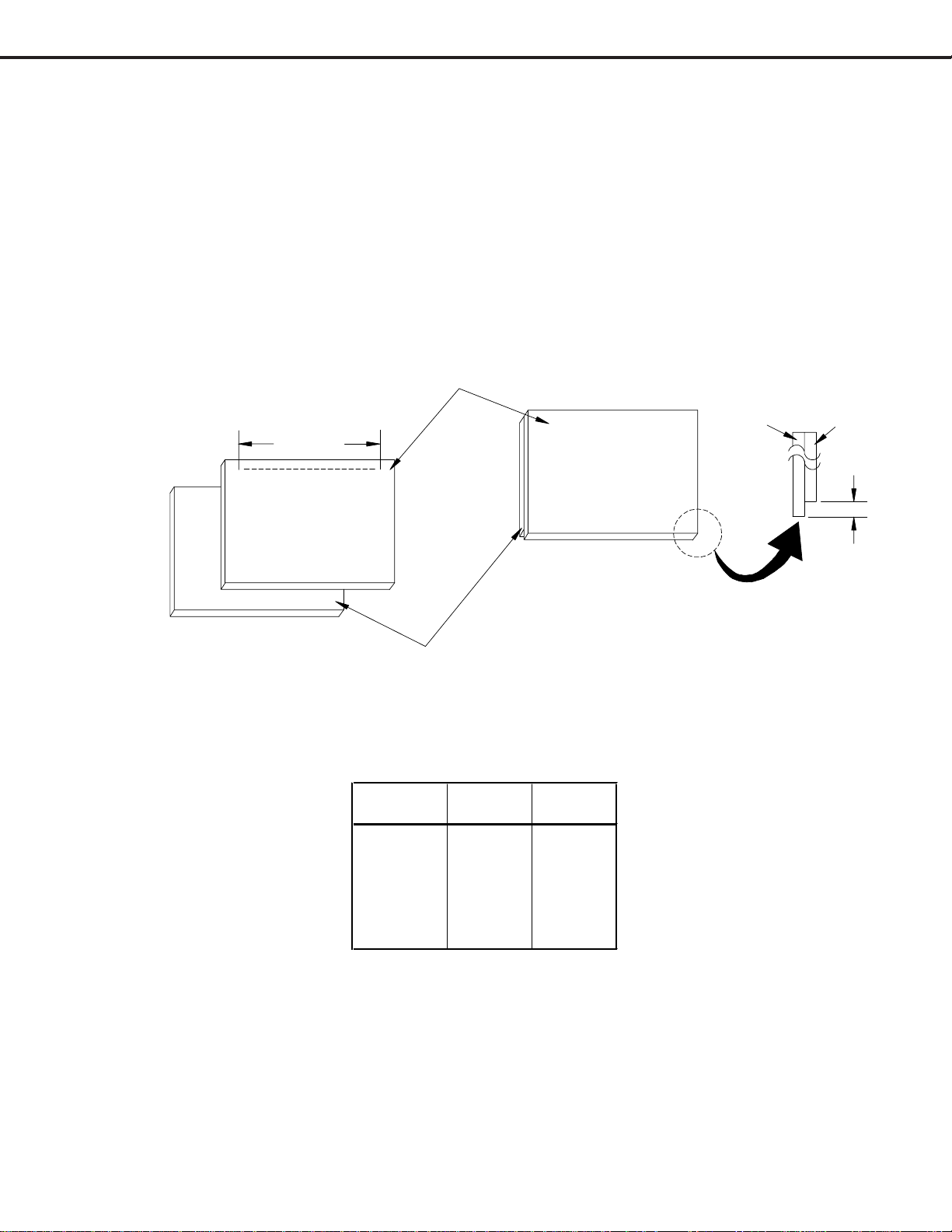

2. Installation of the Lenticular Screen and Fresnel Lens

Note: Store the Lenticular Screen and Fresnel Lens in a cool dry place. High humidity may

deform the Lenticular Screen and Fresnel Lens.

1. Apply double coated tape (Part # LENS-TAPE) along the top front edge of the Fresnel Lens

as shown in Figure 2-2. Refer to Table B for proper tape length.

2. Place the Fresnel Lens on top of the Lenticular Screen and apply pressure at the top edge to

bond them together as shown in Figure 2-2.

3. Reverse the disassembly procedure for that model to install the screens in the screen frame.

Lenticular Screen

Fresnel Lens

0.16 inch

Figure 2-2

Lenticular

Screen

Fresnel

Lens

To p

Bottom

Double Sided Tape

(Part# LENS-TAPE)

( * X ) inch

To p

Bottom

Model

Screen

Size

Tape

Length

WS-48313 48" 41.76

WS-48413 48" 41.76

WS-55313 55" 47.85

WS-55413 55" 47.85

WS-65313 65" 56.55

WS-65413 65" 56.55

Table A

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 14

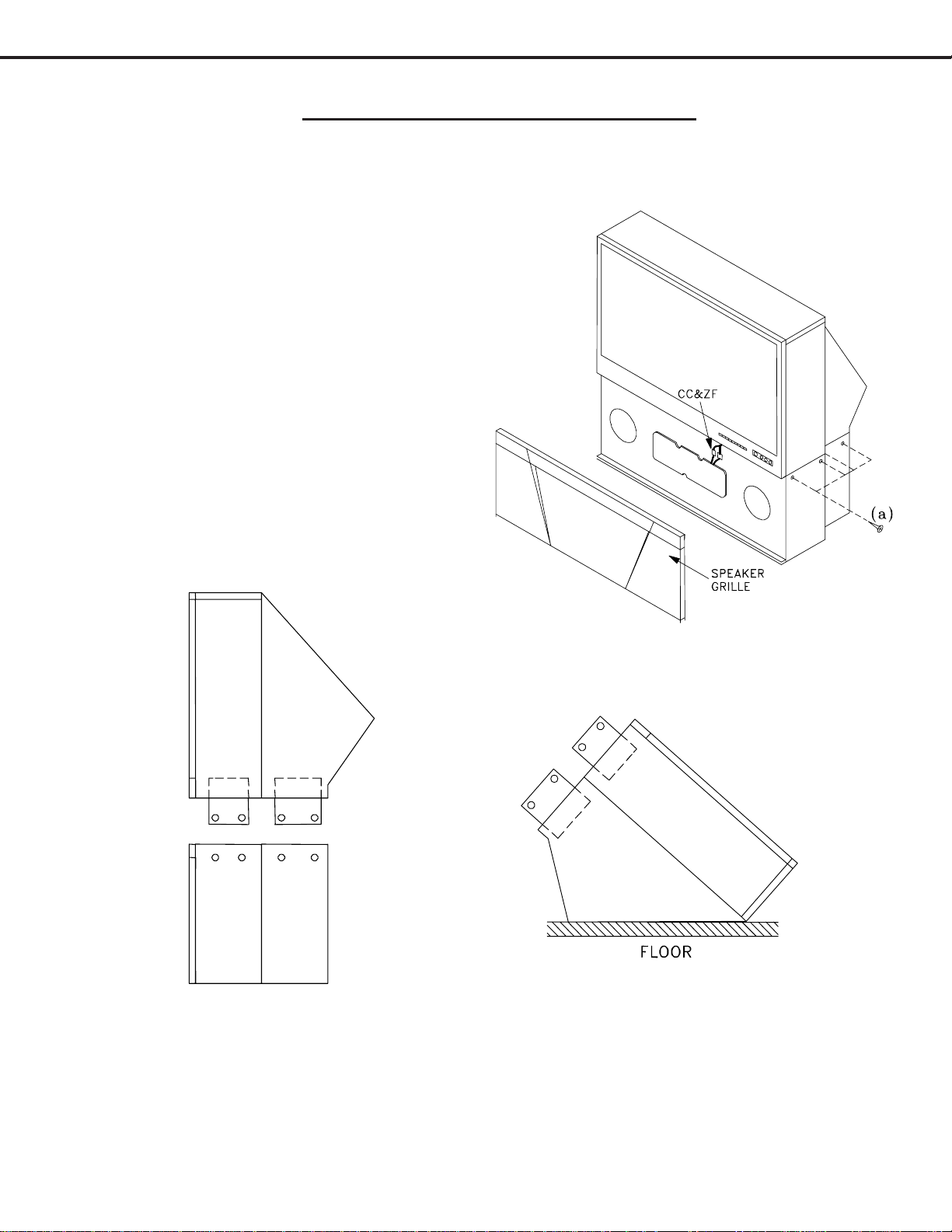

CABINET SEPARATION PROCEDURE

(WS-65313 / WS-65413)

Cabinet Separation Precedure

(Figure 1)

1. Pull the Speaker Grille off.

2. Unplug connectors CC and ZF.

3. Remove 4 screws a on both sides of the

cabinet.

(Figure 2)

4. Carefully lift the cabinet top until the support

tabs clear the bottom cabinet.

(Figure 3)

5. Carefully rotate the cabinet top and place it on

the floor.

6. Reverse the procedure and mount the cabinet

top on the cabinet bottom.

Models WS-65313, and WS-65413 cabinets are assembled in two pieces. These two pieces may be separated to

allow easier delivery and setup.

Figure 1

Figure 2

Figure 3

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 15

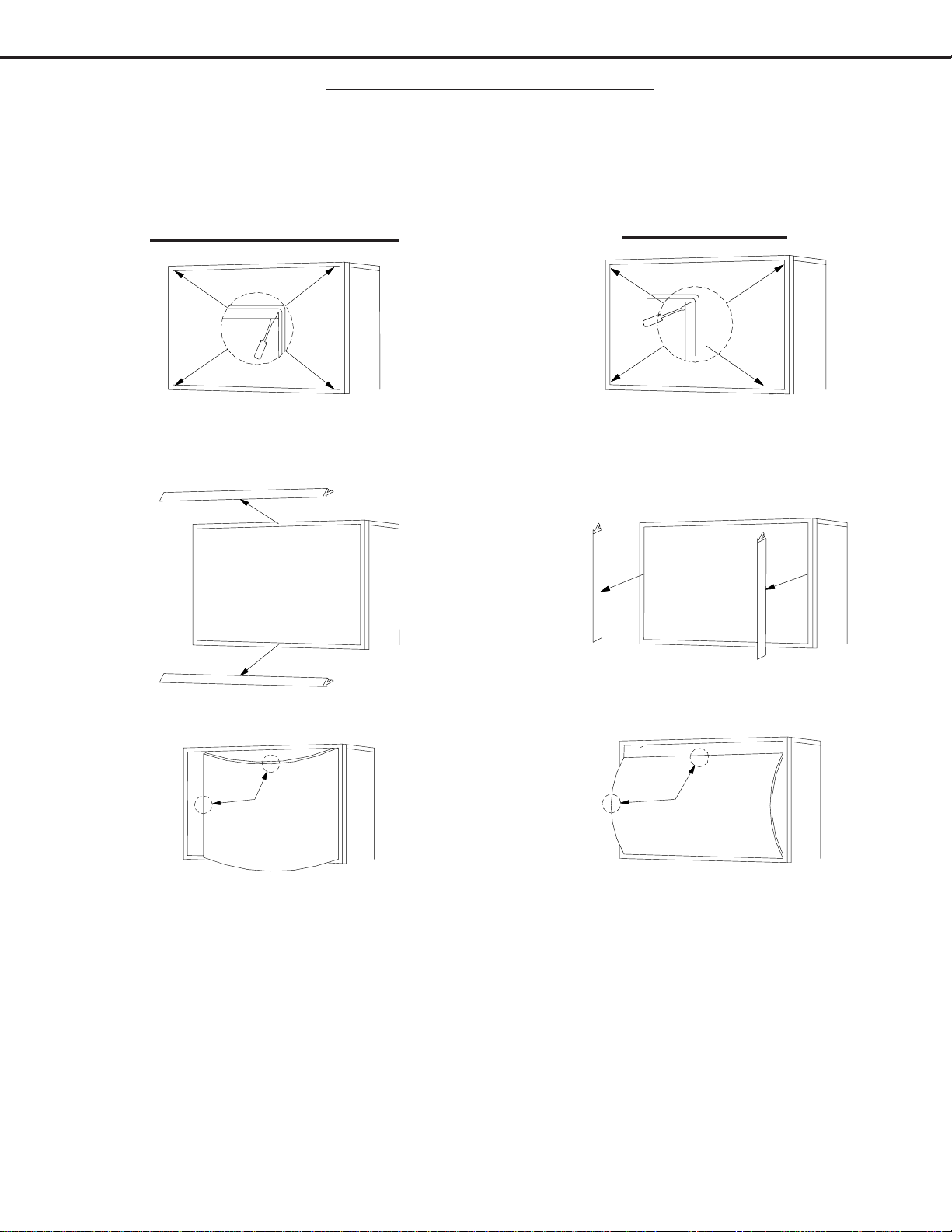

SERVICING THE DIAMONDSHIELD

1. DiamondShield Removal Procedure

The location of the DiamondShield

TM

molding clips may vary between models, top and bottom, or sides. Use

the appropriate disassembly procedure given below.

Note: Wear gloves when handling the DiamondShield to prevent finger prints.

1. Gently insert a small screwdriver between the

DiamondShield and one end of the clip to pry

the clip loose.

2. Remove both clips by pulling them toward you.

3. Carefully insert a small screwdriver into the gap

at the top/center point of the Shield and pull the

Shield slightly away from the unit. Place your

hands at the points shown and gently bow the

Shield toward you and remove from the unit.

Then re-install the two clips.

Top & Bottom Molding Clips

Side Molding Clips

1. Gently insert a small screwdriver between the

DiamondShield and one end of the clip to pry

the clip loose.

2. Remove both clips by pulling them toward you.

3. Carefully insert a small screwdriver into the gap

at the side/center point of the Shield and pull the

Shield slightly away from the unit. Place your

hands at the points shown and gently bow the

Shield toward you and remove from the unit.

Then re-install the two clips.

2. DiamondShield Installation Procedure

*(See the Parts List for DiamondShield part numbers)

To install the DiamondShieldTM, reverse the above Removal Procedure.

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 16

SERVICING PCBs

Chassis Removal and PCB Locations

Major Parts Locations

Chassis Removal

1) Remove screw a from the Main Chassis.

2) Raise the two chassis locks on the inner sides of the

Lightbox Assembly and slide the chassis towards the

rear.

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 17

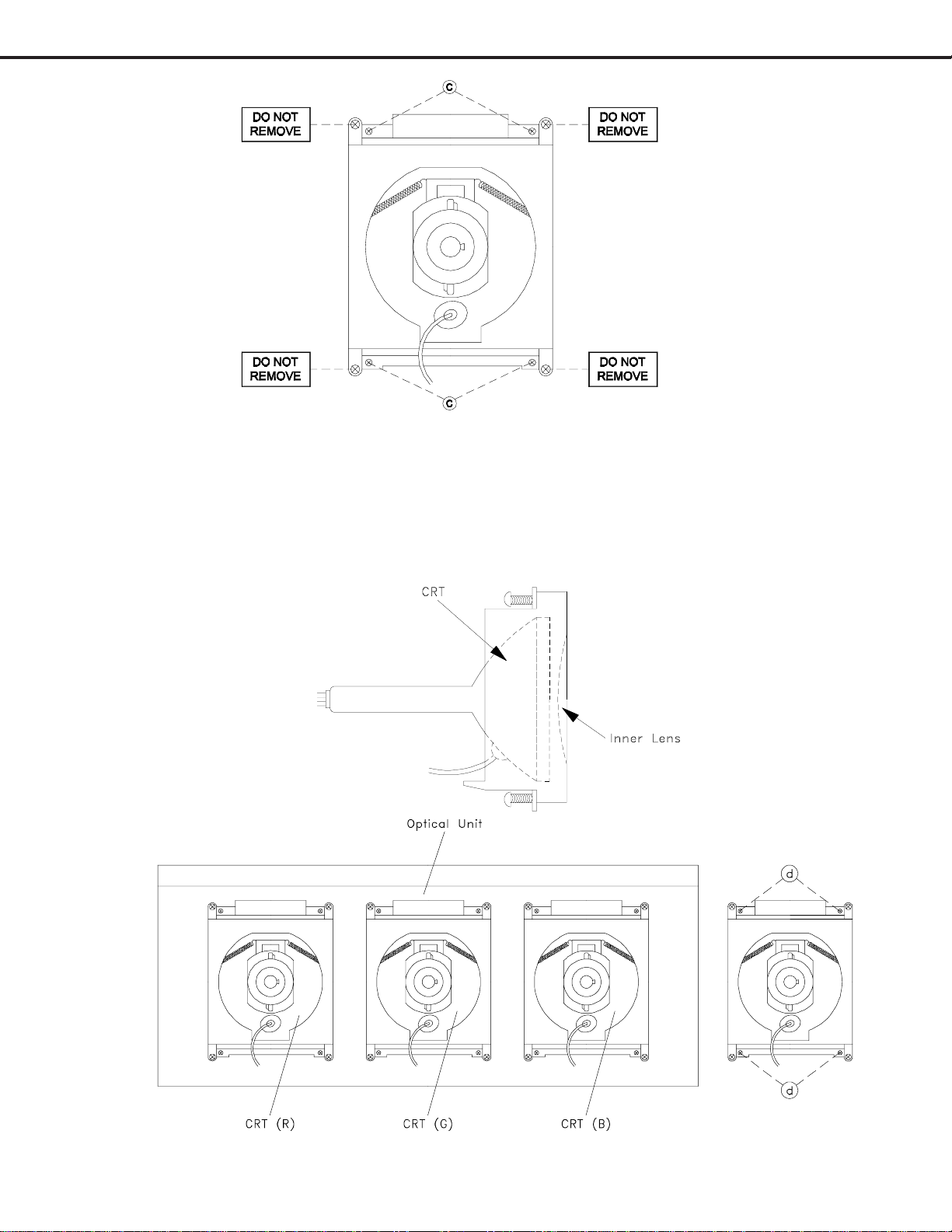

ANODE LEAD REMOVAL

CAUTION: To prevent damage, the following procedure must be used when removing an

Anode Lead from the Flyback Transformer.

1) Push the Anode Lead down.

CRT REPLACEMENT

1. Removal of the CRT

Caution! High voltage should be completely discharged prior to CRT removal.

Since the CRTs receive high voltage from the Flyback transformer, discharge

by shorting the open end of the respective high voltage cable to chassis ground.

Note: Refer to Cabinet Disassembly when performing steps 1 through 2.

1. Remove the Speaker Grille, Front Board, and Screen Assy.

2. Remove the Back Board.

3. Remove the Anode Lead Wire from the Flyback transformer. (Use the above procedure)

4. Remove the PCB-CRT.

5. Remove 4 hex-screws "a" retaining the Optical Unit. [Figure 5-1]

6. Remove 4 screws "b" retaining the Lens.

Note: DO NOT loosen the RED screws. Doing so will break the seal between the

C-Element and the # 6 Lens, causing leakage of the CRT Coolant.

7. Remove 4 screws "c" retaining the CRT. [Figure 5-2]

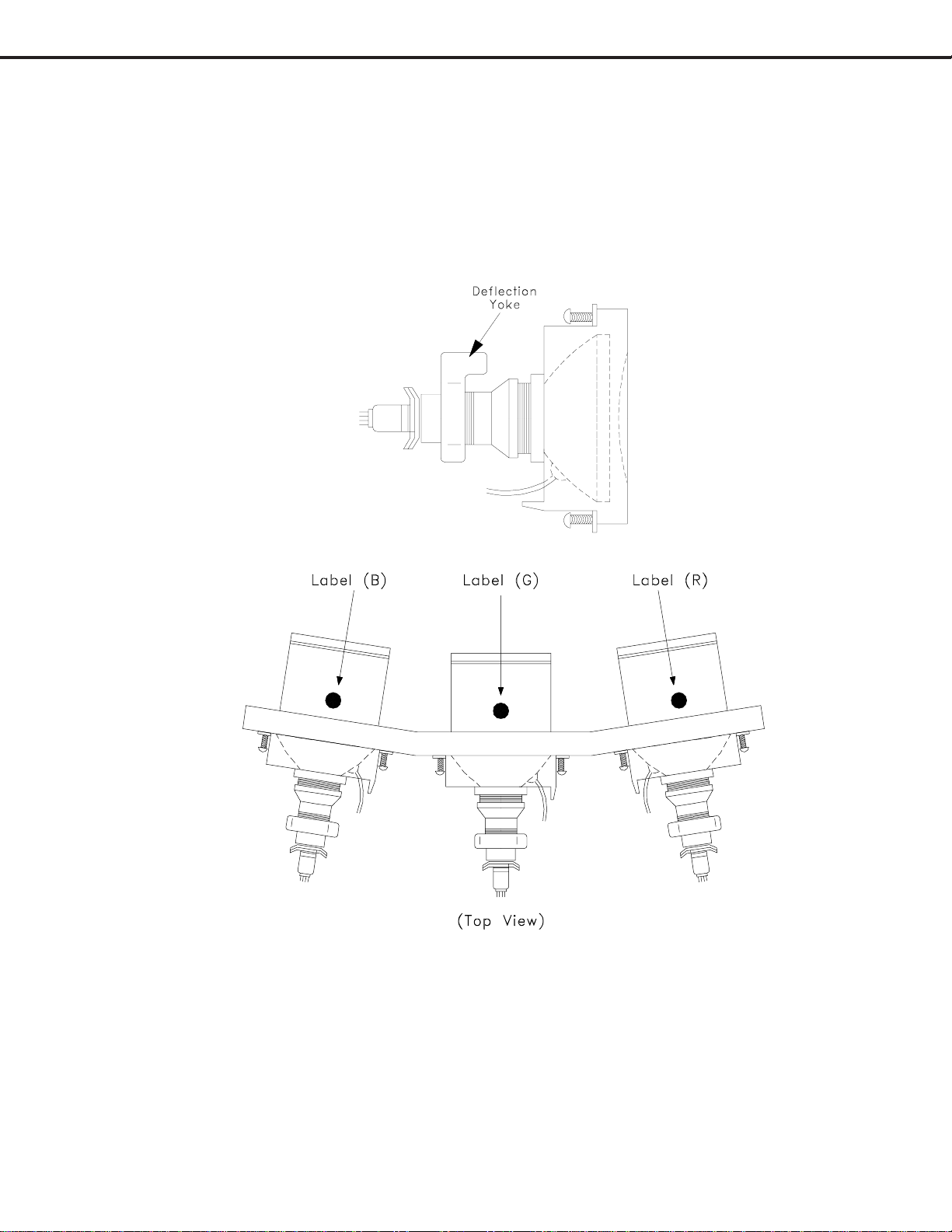

8. Remove the Deflection Yoke and other CRT components from the neck of the CRT. [Figure 5-6]

2) While holding the lead down rotate

the lead 90º counter clockwise.

3) Carefully remove the Anode Lead

from the Flyback Transformer.

Figure 5-1

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 18

Figure 5-2

Note: The 4 spring-loaded screws shown

in Fig 5-2 and labeled as "DO NOT

REMOVE", should not be loosened

under any circumstance. Doing so

will break the seal between the

CRT and the CRT-Spacer, causing

leakage of the CRT Coolant.

2. Installation of the CRT

Note: The replacement CRT is supplied as an assembly comprised of the CRT and the

Inner Lens with the space between them filled with ethylene glycol. Care should

be taken during handling and installation to prevent shock from disrupting the seal

or alignment between the CRT and Inner Lens. [Figure 5-3]

Figure 5-3

Figure 5-5

Figure 5-4

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 19

1. Carefully position the replacement CRT and fasten in place using 4 screws "d". [Figure 5-5]

2. Install the Deflection Yoke and other CRT components back in there original position on the CRT neck.

[Figure 5-6]

3. Install the Lens that was removed in step6 of Removal Of The CRT. [ Figures 5-1 and 5-2 ]

a) Position the Lens so that the Label faces the direction shown in Figure 5-7

b) Install the mounting screws b. [Figure 5-1]

4. Insert the Optical Unit into the Light Box Assembly.

5. Install the PCB-CRT.

6. Insert the Anode Lead Wire into the Flyback Transformer.

7. Re-clamp the Lead Wire in its original position.

Figure 5-6

Figure 5-7

Adjustment procedures after replacing the CRT(s)

CRT Cut Off / White Balance Adjustment

Static Convergence Adjustment

Dynamic Convergence Adjustment

Page 20

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

1H

40%

40%

100%

75%

Monoscope Signal

Split-Field Color Bars (100% window)

ELECTRICAL ADJUSTMENTS

Note: Perform only the adjustments required.

Do not attempt an alignment if proper equipment is not available.

1. Test Equipment

Oscilloscope (Unless otherwise specified, use 10:1 probes)

Signal Generator (both SD and HD capable)

Frequency Counter

Direct Current Voltmeter

Direct Current Power Supply

Multiplex Audio Signal Generator

Direct Current Ampere Meter

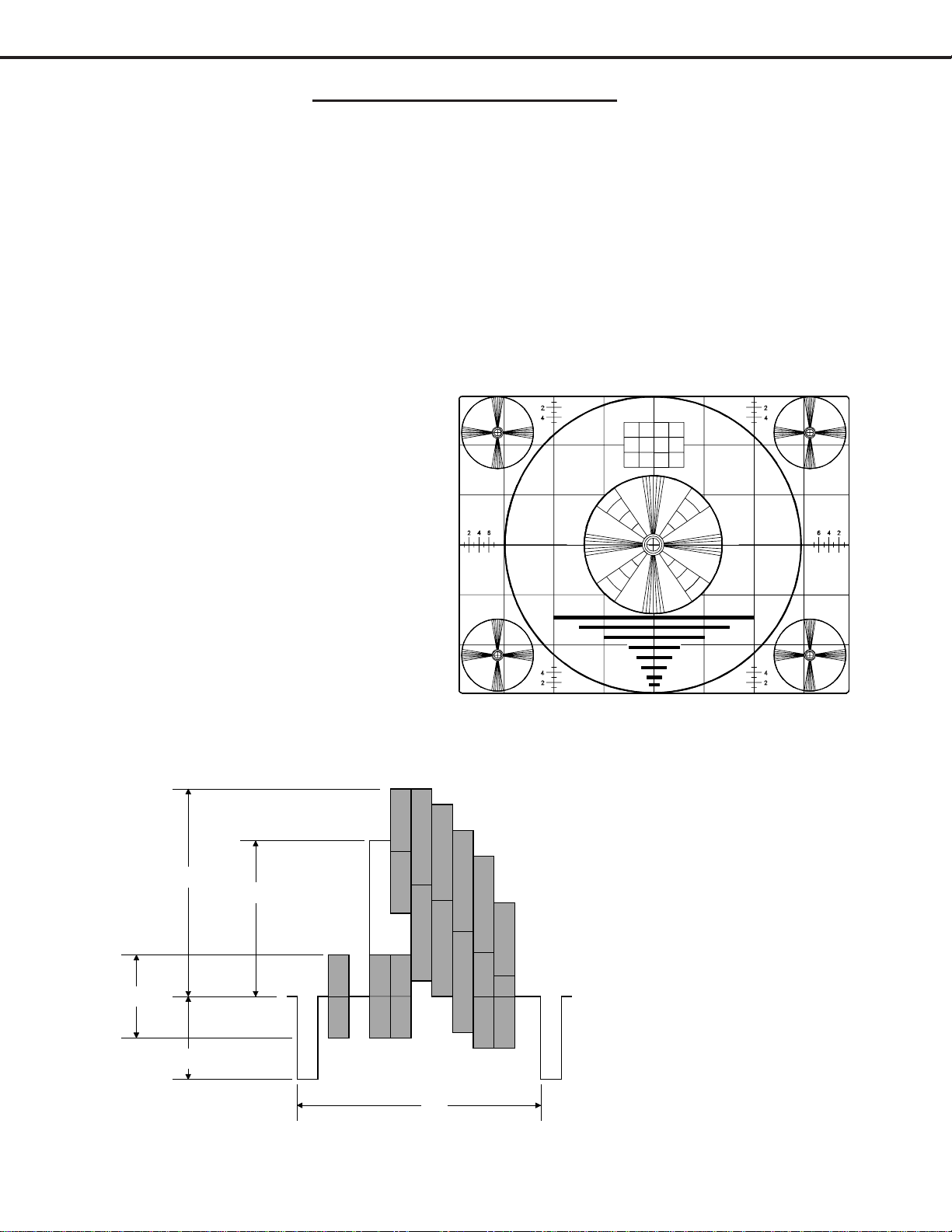

2. Test Signal

A. Monoscope Signal

Note: If you do not have

a monoscope signal source,

connect the unit to a VCR

and play a Monoscope

*alignment tape.

(* Part Number: 859C568060)

B. Color Bar Signal

Use the color bar signal shown

below, unless otherwise specified

in this manual.

MODELS: WS-48313 / WS-48413 / WS-55313 / WS-55413 / WS-65313 / WS-65413

Page 21

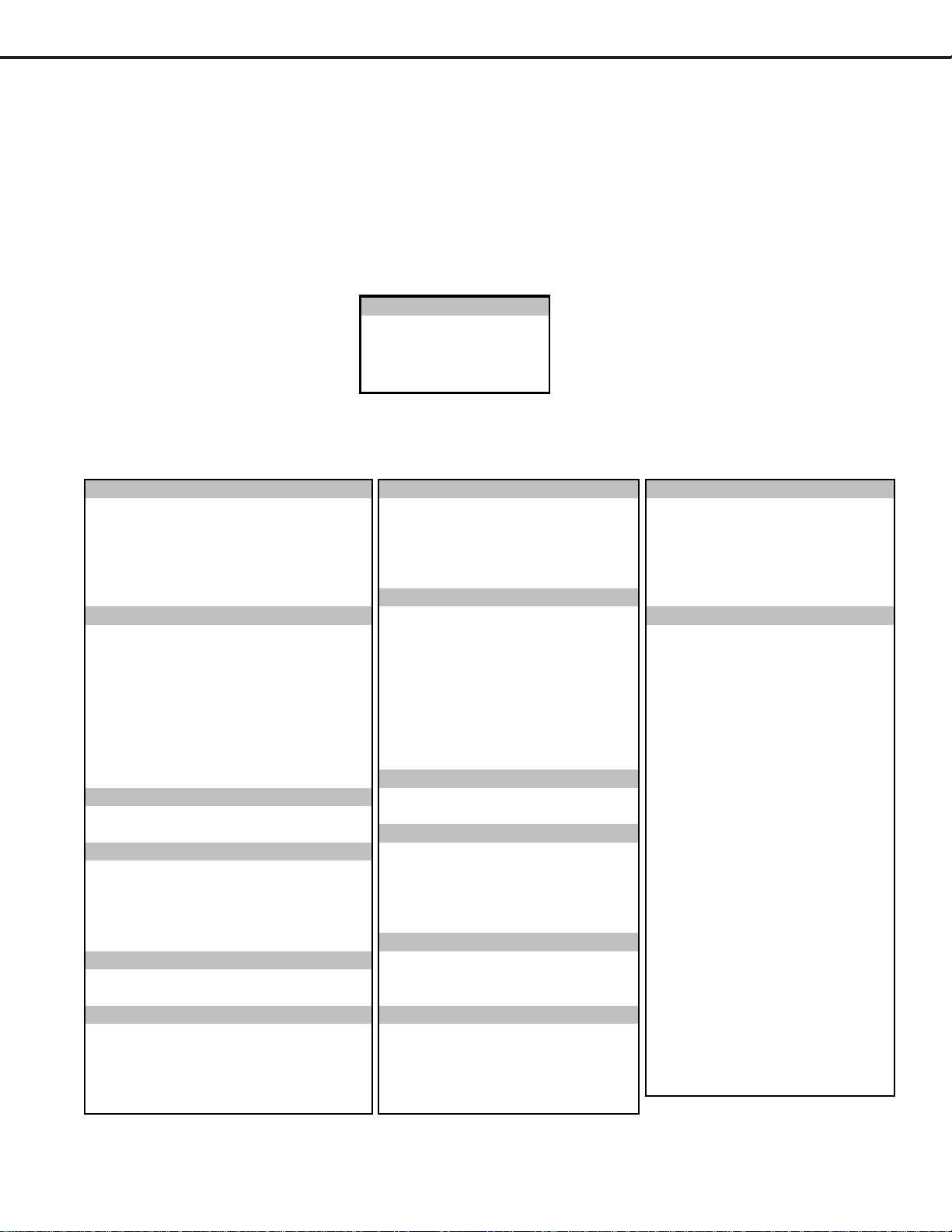

3. Initial Setup

A. Option Menu Setup

Follow the steps below for the initial set-up:

1. Select the "MENU" display by pressing the "MENU" button once.

2. Press the number buttons "0", "3", "7", "0" in sequence to select the "OPTION MENU" display.

3. Press the "ADJUST" button to select "INITIAL."

4. Press "ENTER."

NOTE: At this time channel 3 is automatically selected.

B. Default Settings

MENU-0-3-7-0

OPTION MENU

Initial

Power Restore :OFF

DTV Port :Auto

Direct Key Mod :OFF

Memorize Channels Ant-A Air Lock by Time Off Magenta 50%

Input Assignment (V22) Lock Time N/A Red 50%

NetCommand® IR Setup (V22+) Unlock Time N/A Yell o w 50%

Clock Front Button Lock Off Green 50%

Language English V-Chip Cyan 50%

Energy Mode Low Blue 50%

V-Chip Off

Antenna-A On TV Rating TV-PG A/V Memory Reset Ant A

Antenna-B On FV-Fantasy Violence Allow TV Speakers (Internal) On

DTV YPrPb D-Sexual Dialog Allow Audio Output Variable

Component-1 Comp-1 L-Adult Language Allow

Component-2 C omp-2 S-Sexual Situati o n Allow TV Bass 50%

Input-1 Input-1 V-Violence Allow TV Treble 50%

Input-2 Input-2 Movie Rating PG TV Balance 50%

Input-3 Input-3 Programs Not Rated Allow TV Surround Off

MonLink M onLink TV Listen To Stereo

V-Chip Start Time 12:00am TV Level Sound Off

Language English V-Chip Stop Time 12:00am VIDEO SETTINGS

NetCommand

®

IR Setup

TV Contrast 100%

CLOCK M enu Color Balance TV Brightness 50%

Clock Setting Manual Timer TV Sharpness 50%

Clock Time --:-- Convergence TV Color 50%

Set Day Sunday Video Mute On TV Tint 50%

Time Zone N/A Black Enhancement On TV Color Temp High

Daylig ht Savings Time N /A TV Video Noise Standard

CAPTIONS Menu Ant-A Auto Color Correction Off TV Film Mode (Auto) On

Closed Captions In Mute PerfectColor™ TV VSM (V22+ Only) On

CC Background Gray Reset Color for Ant-A TV Volume 30%

CHANNEL EDIT Menu TIMER Menu PIP Source Ant A Ch 3

Antenna ANT-A Timer Off PIP Position Lower Right

Channel 003 Set Time 12:00 am POP Position Right Half

Memory Deleted Set Day Everyd ay

Format

Stretch

Name N/A Input Ant-A PIP/POP Format Dble Win

SQV N/A Channel 003

V-CHIP Hours

COLOR BALANCE Menu

V-CHIP LOCK Menu

V-CHIP Menu

ADVANCED FEATURES Menu

MAIN MENU DEFAULT SETTINGS

AUDIO/VIDEO SETTINGS Menu

PerfectColor™

AUDIO SETTINGS

SETUP Menu

INPUT ASSIGNMENT Menu (V2 2)

Welcome to NetCommand® IR (V22+)

Loading...

Loading...