Mitsubishi VS-50XH70S SETUP MANUAL

DLPTM Display Wall Cube /

LCD Display Wall

Seventy Series

Set-up Manual

REV. 1.3

January 29, 2010

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table of Contents |

|

|||

1 |

OVERVIEW............................................................................................................................................................. |

4 |

||||||||||||||||

|

1.1 |

Product lineup ................................................................................................................................................................................ |

4 |

|||||||||||||||

|

1.1.1 |

Main Products ............................................................................................................................................................................. |

4 |

|||||||||||||||

|

1.1.2 |

Optional products...................................................................................................................................................................... |

5 |

|||||||||||||||

|

1.2 |

Flowchart.......................................................................................................................................................................................... |

6 |

|||||||||||||||

|

1.3 |

Basic operation............................................................................................................................................................................... |

8 |

|||||||||||||||

|

1.3.1 |

Remote control unit................................................................................................................................................................... |

8 |

|||||||||||||||

|

1.3.2 |

Operation mode ......................................................................................................................................................................... |

9 |

|||||||||||||||

|

1.3.3 |

Menus.......................................................................................................................................................................................... |

10 |

|||||||||||||||

|

1.4 |

Control panel................................................................................................................................................................................. |

12 |

|||||||||||||||

2 |

CUBE INSTALLATION ( |

CUBE |

)............................................................................................................................. |

|

|

|

|

|

|

|

13 |

|||||||

|

2.1 |

Safety precaution......................................................................................................................................................................... |

13 |

|||||||||||||||

|

2.2 |

Preparation .................................................................................................................................................................................... |

14 |

|||||||||||||||

|

2.2.1 |

Accessories ................................................................................................................................................................................. |

14 |

|||||||||||||||

|

2.2.2 |

Input boards installation........................................................................................................................................................ |

14 |

|||||||||||||||

|

2.2.3 Front attachment in 80” cabinet .......................................................................................................................................... |

15 |

||||||||||||||||

|

2.3 |

Engine embedding ..................................................................................................................................................................... |

16 |

|||||||||||||||

|

2.3.1 |

|

Rear |

............................................................................................................................................................................................ |

|

|

|

|

|

|

|

|

|

|

|

16 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

2.3.2 |

|

Front |

.......................................................................................................................................................................................... |

|

|

|

|

|

|

|

|

|

|

17 |

|||

|

2.4 |

Cube stacking ............................................................................................................................................................................... |

18 |

|||||||||||||||

|

2.4.1 |

Screen demounting ................................................................................................................................................................. |

18 |

|||||||||||||||

|

2.4.2 Base stands and cubes assembling ..................................................................................................................................... |

19 |

||||||||||||||||

|

2.4.3 Screen mounting and open/close ( |

Front |

) ........................................................................................................................ |

20 |

||||||||||||||

|

2.4.4 |

Screen gaps adjustment......................................................................................................................................................... |

21 |

|||||||||||||||

|

2.4.5 Fixing to the wall and floor .................................................................................................................................................... |

22 |

||||||||||||||||

3 LCD PANEL INSTALLATION ( |

LCD |

)..................................................................................................................... |

|

23 |

||||||||||||||

|

3.1 |

Safety precaution......................................................................................................................................................................... |

23 |

|||||||||||||||

|

3.2 |

Preparation .................................................................................................................................................................................... |

24 |

|||||||||||||||

|

3.2.1 |

Accessories ................................................................................................................................................................................. |

24 |

|||||||||||||||

|

3.2.2 |

Input boards installation........................................................................................................................................................ |

24 |

|||||||||||||||

|

3.3 |

Mounting........................................................................................................................................................................................ |

24 |

|||||||||||||||

|

3.3.1 For using commercial wall mount brackets ...................................................................................................................... |

24 |

||||||||||||||||

|

3.3.2 For using optional wall mount frame (BR-XM70KK)........................................................................................................ |

26 |

||||||||||||||||

|

3.3.3 |

Arrangement ............................................................................................................................................................................. |

27 |

|||||||||||||||

|

3.3.4 Wall mount frame attaching................................................................................................................................................. |

28 |

||||||||||||||||

|

3.3.5 |

Preliminary internal cabling.................................................................................................................................................. |

28 |

|||||||||||||||

|

3.3.6 |

LCD panel mounting ............................................................................................................................................................... |

29 |

|||||||||||||||

|

3.3.7 Panel open / close..................................................................................................................................................................... |

29 |

||||||||||||||||

|

3.3.8 |

Panel gap adjustment............................................................................................................................................................. |

30 |

|||||||||||||||

|

3.3.9 IR receiver (R-XM70IR) attaching.......................................................................................................................................... |

31 |

||||||||||||||||

4 |

ADJUSTMENT...................................................................................................................................................... |

32 |

||||||||||||||||

|

4.1 |

Initial setting.................................................................................................................................................................................. |

32 |

|||||||||||||||

|

4.1.1 |

Connecting................................................................................................................................................................................. |

32 |

|||||||||||||||

|

4.1.2 |

Dipswitch setting...................................................................................................................................................................... |

33 |

|||||||||||||||

|

4.1.3 |

Power-on .................................................................................................................................................................................... |

33 |

|||||||||||||||

|

4.1.4 |

Focus adjustment ( |

Cube |

)...................................................................................................................................................... |

|

|

|

|

33 |

|||||||||

|

4.1.5 |

Wallaby....................................................................................................................................................................................... |

34 |

|||||||||||||||

|

4.2 |

System memory setting (basic)............................................................................................................................................... |

36 |

|||||||||||||||

|

4.2.1 |

Basic adjustment items........................................................................................................................................................... |

36 |

|||||||||||||||

|

4.2.2 |

System memory saving........................................................................................................................................................... |

37 |

|||||||||||||||

|

4.3 |

Geometry adjustment ( |

Cube |

|

) ................................................................................................................................................ |

|

38 |

|||||||||||

|

4.3.1 |

6-axis adjustment .................................................................................................................................................................... |

38 |

|||||||||||||||

|

4.3.2 |

Mirror correction....................................................................................................................................................................... |

41 |

|||||||||||||||

|

4.4 |

Color balance adjustment......................................................................................................................................................... |

43 |

|||||||||||||||

|

4.4.1 |

Preparation................................................................................................................................................................................ |

43 |

|||||||||||||||

|

4.4.2 SENSOR GAIN adjustment ( |

LCD |

) ......................................................................................................................................... |

43 |

||||||||||||||

|

4.4.3 |

BLACK LEVEL adjustment ....................................................................................................................................................... |

44 |

|||||||||||||||

2Seventy Series Set-up Manual

|

4.4.4 |

CSC adjustment ........................................................................................................................................................................ |

44 |

|||||||||||||||||||||

|

4.4.5 Light source output adjustment ( |

LED |

, |

LCD |

) |

.................................................................................................................... 45 |

||||||||||||||||||

|

4.4.6 |

WHITE BALANCE adjustment ................................................................................................................................................ |

46 |

|||||||||||||||||||||

|

4.4.7 |

GRADATION adjustment......................................................................................................................................................... |

46 |

|||||||||||||||||||||

|

4.4.8 |

TARGET COLOR ( |

Lamp |

).......................................................................................................................................................... |

|

|

|

|

|

|

|

46 |

||||||||||||

|

4.4.9 |

SENSOR ....................................................................................................................................................................................... |

47 |

|||||||||||||||||||||

|

4.5 |

System memory setting (custom).......................................................................................................................................... |

48 |

|||||||||||||||||||||

|

4.6 |

Input memory setting ................................................................................................................................................................ |

54 |

|||||||||||||||||||||

|

4.6.1 |

Basic setting............................................................................................................................................................................... |

54 |

|||||||||||||||||||||

|

4.6.2 |

Custom setting.......................................................................................................................................................................... |

56 |

|||||||||||||||||||||

|

4.6.3 |

Input memory saving .............................................................................................................................................................. |

58 |

|||||||||||||||||||||

|

4.6.4 Input memory calling / deleting ........................................................................................................................................... |

58 |

||||||||||||||||||||||

|

4.7 |

Display memory setting ............................................................................................................................................................ |

59 |

|||||||||||||||||||||

|

4.7.1 |

Available layouts ...................................................................................................................................................................... |

59 |

|||||||||||||||||||||

|

4.7.2 |

Layout patterns setting........................................................................................................................................................... |

60 |

|||||||||||||||||||||

|

4.7.3 |

Display memory saving.......................................................................................................................................................... |

63 |

|||||||||||||||||||||

|

4.7.4 Display memory calling / deleting ....................................................................................................................................... |

63 |

||||||||||||||||||||||

5 |

MAINTENANCE ................................................................................................................................................... |

64 |

||||||||||||||||||||||

|

5.1 |

Lamp replacement ( |

Lamp |

)...................................................................................................................................................... |

|

|

|

|

|

|

64 |

|||||||||||||

|

5.1.1 |

Safety precaution ..................................................................................................................................................................... |

64 |

|||||||||||||||||||||

|

5.1.2 |

Procedure ................................................................................................................................................................................... |

65 |

|||||||||||||||||||||

|

5.1.3 Auto-lamp changing function ( |

Changer |

)........................................................................................................................ |

66 |

||||||||||||||||||||

|

5.2 |

Error indication............................................................................................................................................................................. |

67 |

|||||||||||||||||||||

|

5.2.1 |

On-screen indicator ( |

Cube |

) .................................................................................................................................................. |

|

|

67 |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

5.2.2 |

Status indicator ( |

Cube |

).......................................................................................................................................................... |

|

|

|

67 |

||||||||||||||||

|

5.2.3 |

Side indicator ( |

LCD |

) |

................................................................................................................................................................ |

|

|

|

|

68 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

5.2.4 |

Internal temperature warning ( |

LED |

).................................................................................................................................. |

68 |

|||||||||||||||||||

|

5.3 |

Cleaning.......................................................................................................................................................................................... |

69 |

|||||||||||||||||||||

|

5.4 |

Securing for delivery ( |

Cube |

) ................................................................................................................................................... |

69 |

|||||||||||||||||||

|

5.5 |

Resetting......................................................................................................................................................................................... |

69 |

|||||||||||||||||||||

|

5.6 |

About LCD panels ( |

LCD |

)........................................................................................................................................................... |

70 |

|||||||||||||||||||

6 |

.................................................................................................................................................SPECIFICATIONS |

|

|

71 |

||||||||||||||||||||

|

6.1 |

Available input signals ............................................................................................................................................................... |

71 |

|||||||||||||||||||||

|

6.2 |

Menu trees ..................................................................................................................................................................................... |

72 |

|||||||||||||||||||||

|

6.2.1 |

On-screen menus ..................................................................................................................................................................... |

72 |

|||||||||||||||||||||

|

6.2.2 |

Wallaby menu ........................................................................................................................................................................... |

75 |

|||||||||||||||||||||

|

6.3 |

Connectors / switches spec...................................................................................................................................................... |

81 |

|||||||||||||||||||||

7 |

REVISION HISTORY............................................................................................................................................. |

82 |

||||||||||||||||||||||

* The symbol Changer, Front, etc. refers to lamp changer, front access models etc.

REV 1.3 3

lineup Product

1 Overview

1.1 Product lineup

1.1.1 Main Products

Cubes Cube

A variety of cubes can be configured by combining engine units, cabinets, screen units and optional products.

With lamps Lamp

Size |

Access |

Resolution |

|

|

Lamp |

Combined name |

Engine unit |

Cabinet |

Screen unit |

|||||||||

|

|

|

|

|

|

SXGA+ |

|

|

|

|

|

|

VS-50PH70U |

VS-PH70U |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Changer |

|

|

|

|

|

||

|

|

Rear |

|

|

|

|

|

|

|

|

|

VS-50XH70U |

VS-XH70U |

S-5070CA |

SC-5070U |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

XGA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50” |

|

|

|

|

|

|

|

|

|

|

|

Single |

|

VS-50XL70U |

VS-XL70U |

|

|

|

|

|

|

|

|

SXGA+ |

|

|

|

|

|

|

VS-50PHF70U |

VS-PH70U |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Changer |

|

|

|

|

|

||

|

|

Front |

|

|

|

|

|

|

|

|

VS-50XHF70U |

VS-XH70U |

S-5070CAF |

SC-5070UF |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

XGA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single |

|

VS-50XLF70U |

VS-XL70U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

SXGA+ |

|

|

|

|

|

|

VS-60PH70U |

VS-PH70U |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Changer |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Rear |

|

|

|

|

|

|

|

|

|

VS-60XH70U |

VS-XH70U |

S-6070CA |

SC-6070U |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

XGA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60” |

|

|

|

|

|

|

|

|

|

|

|

Single |

|

VS-60XL70U |

VS-XL70U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SXGA+ |

|

|

|

|

|

|

VS-60PHF70U |

VS-PH70U |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Changer |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Front |

|

|

|

|

|

|

|

|

VS-60XHF70U |

VS-XH70U |

S-6070CAF |

SC-6070UF |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

XGA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single |

|

VS-60XLF70U |

VS-XL70U |

|

|

|

|

|

|

|

|

|

SXGA+ |

|

|

|

|

|

|

VS-67PH70U |

VS-PH70U |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Changer |

|

|

|

|

|

||

|

|

Rear |

|

|

|

|

|

|

|

|

|

VS-67XH70U |

VS-XH70U |

S-6770CA |

SC-6770U |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

XGA |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

67” |

|

|

|

|

|

|

|

|

|

|

|

Single |

|

VS-67XL70U |

VS-XL70U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SXGA+ |

|

|

|

|

|

|

VS-67PHF70U |

VS-PH70U |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Changer |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Front |

|

|

|

|

|

|

|

|

VS-67XHF70U |

VS-XH70U |

S-6770CAF |

SC-6770UF |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

XGA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single |

|

VS-67XLF70U |

VS-XL70U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PH75 |

|

|

VS-80PH75U |

VS-PH75U |

|

|

|

|

Rear |

|

|

|

SXGA+ |

|

|

|

|

|

|

|

|

||||

80” |

|

|

|

|

|

high brightness changer |

S-8070CA |

SC-8070B |

||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

Changer |

|

VS-80PH70U |

VS-PH70U |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•The product names marked in red may be delivered with the projection engine and for 50” also the screen, already installed. 67” and 80” models always have the screen shipped separately.

4Seventy Series Set-up Manual

With LED light source LED

Size |

Access |

Resolution |

Combined name |

Engine unit |

Cabinet |

Screen unit |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SXGA+ |

|

VS-50PE70U |

VS-PE70U |

|

|

||

|

|

Rear |

|

|

|

|

S-5070CA |

SC-5070U |

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

50” |

|

|

|

|

|

|

XGA |

|

VS-50XE70U |

VS-XE70U |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SXGA+ |

|

VS-50PEF70U |

VS-PE70U |

|

|

||

|

|

Front |

|

|

|

S-5070CAF |

SC-5070UF |

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

XGA |

|

VS-50XEF70U |

VS-XE70U |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

SXGA+ |

|

VS-60PE70U |

VS-PE70U |

|

|

||

|

|

Rear |

|

|

|

|

S-6070CA |

SC-6070U |

|||||

|

|

|

|

|

|

|

|

|

|

||||

60” |

|

|

|

|

|

|

XGA |

|

VS-60XE70U |

VS-XE70U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SXGA+ |

|

VS-60PEF70U |

VS-PE70U |

|

|

||

|

|

Front |

|

|

|

S-6070CAF |

SC-6070UF |

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

XGA |

|

VS-60XEF70U |

VS-XE70U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

SXGA+ |

|

VS-67PE70U |

VS-PE70U |

|

|

||

|

|

Rear |

|

|

|

|

S-6770CA |

SC-6770U |

|||||

|

|

|

|

|

|

|

|

|

|

||||

67” |

|

|

|

|

|

|

XGA |

|

VS-67XE70U |

VS-XE70U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SXGA+ |

|

VS-67PEF70U |

VS-PE70U |

|

|

||

|

|

Front |

|

|

|

S-6770CAF |

SC-6770UF |

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

XGA |

|

VS-67XEF70U |

VS-XE70U |

|

|

|

LCD panel LCD

VS-L46XM70U

lineup Product

1.1.2 Optional products

The main products are not equipped with any input ports. Arrange optional input boards according to input signals to be displayed.

|

Optional products |

Product names |

Applicable main products |

|||||

|

Input boards |

VC-B70D2 (for digital inputs) |

|

|

|

|

||

|

|

VC-B70V2 (for video inputs) |

|

|

|

|

||

|

|

VC-B70G2 (for analog inputs) |

|

|

|

|

||

|

|

VC-B70DC (for daisy chain) |

|

|

|

|

||

|

|

VC-B70SD1 (for SDI/HD-SDI input) |

|

|

|

|

||

|

Wireless / wired |

R-XL50TX |

Common |

|||||

|

remote control unit |

|

|

|

|

|

|

|

|

Motorized adjustment tool |

S-A70E |

|

|

|

|

||

* |

|

|

|

|

|

|

|

|

|

Motor units |

S-MA70E |

|

|

|

|

||

|

for screen / mirror * |

|

|

|

|

|

|

|

|

Power cord (3m) |

JC-PC3MA (for North America) |

|

|

|

|

||

|

|

JC-PC3ME (for Europe) |

Common |

|||||

|

|

JC-PC3MC (for China) |

|

|

|

|

||

|

Spare lamps |

S-70LA (standard) |

|

|

|

|

||

|

|

S-75LA (for |

PH75 |

) |

|

|

|

|

|

|

For |

Lamp |

|

||||

|

Spare color wheels |

S-703CW (3 segments) |

|

|||||

|

|

|

|

|

||||

|

|

S-704CW (4 segments) |

|

|

|

|

||

|

Spare LED light source |

|

|

|

|

|

|

|

|

S-70LE |

For |

LED |

|

|

|||

|

module |

|

||||||

|

|

|

|

|

|

|

|

|

|

Wall mount frame |

BR-XM70KK |

|

|

|

|

||

|

For |

LCD |

|

|

||||

|

IR receiver |

R-XM70IR |

|

|

||||

|

|

|

|

|

||||

The combination of S-A70E and S-MA70E can be applied to the wall mount frame, which can adjust the gaps between panels electrically.

REV 1.3 5

Flowchart

1.2 Flowchart

Installation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cube |

|

|

|

|

LCD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

For |

(page 13) |

|

For |

(page 23) |

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input boards installation (page 14) |

|

Input boards installation (page 24) |

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

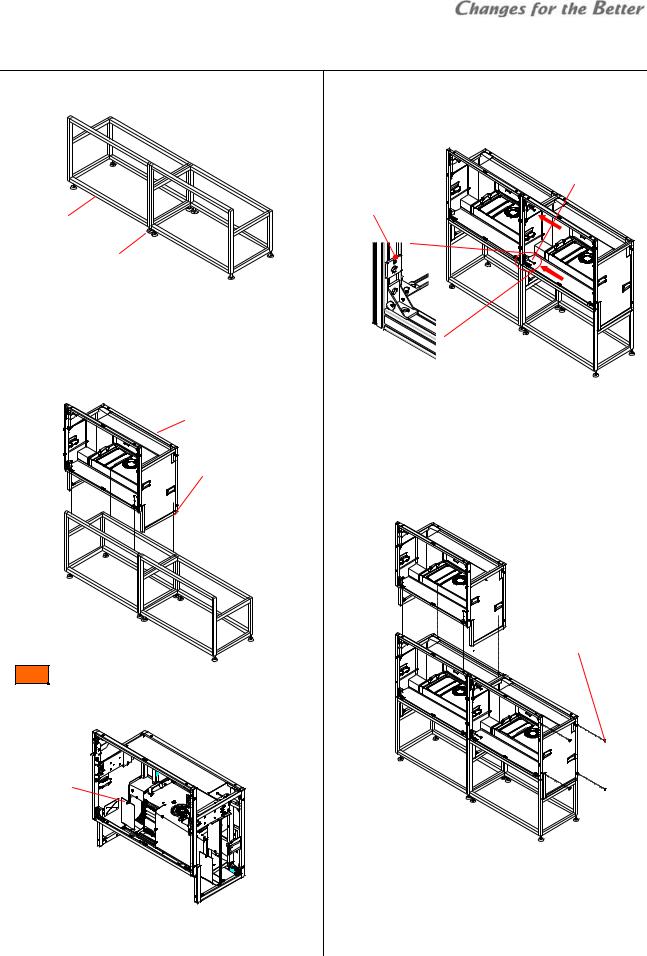

Engine embedding (page 16) |

|

Wall mount frame attaching (page 26) |

Cube stacking (page 18) |

|

LCD panel mounting (page 29) |

Screen gap adjustment (page 21) |

|

LCD panel gap adjustment (page 30) |

( Go to next page)

6Seventy Series Set-up Manual

Adjustment (page 32)

Initial setting (page 32) |

|

Connecting |

|

Dipswitch setting |

|

Power-on |

A1 |

Focus adjustment Cube |

|

Basic system memory setting (page 36)

Unit ID assignment |

|

|

|

ID 1 |

ID 2 |

||

IP address assignment |

|||

MASTER |

SLAVE |

||

H. / V. LOCATION |

|||

H=1, V=1 |

H=2, V=1 |

||

(IMAGE FLIP) |

|

|

|

(SYSTEM SYNC) |

|

|

|

ID 3 |

ID 4 |

||

|

|||

|

SLAVE |

SLAVE |

|

|

H=1, V=2 |

H=2, V=2 |

|

|

|

|

Geometory adjustment (page 38) (Cube)

6-axis adjustment Mirror correction

Color balance adjustment (page 43)

Sensor gain adjustment LCD (BLACK LEVEL)

CSC

LED POWER gain LED

BACKLIGHT DIMMER gain LCD (WHITE BALANCE) GRADATION

TARGET COLOR Lamp

SENSOR

ID 1 |

ID 2 |

ID 3 |

ID 4 |

Custom system memory setting (page 48)

LAMP POWER / FRAME LOCK / REDUNDANCY / AMP. GAIN etc.

Input signal adjustment (page 54) |

|

|

|

layout pattern adjustment (page 59) |

|

|

|

Input port selection |

|

|

Input signal allocation |

|

MEMORY SCAN |

H=1, V=1 |

H=2, V=1 |

Position / size setting |

|

H. / V. POSITION |

Crop / zoom setting |

|||

|

|

|||

CLOCK PHASE |

|

|

Priority order setting |

|

AMP. GAIN |

|

|

etc. |

|

etc. |

H=1, V=2 |

H=2, V=2 |

|

|

|

|

Flowchart

Finish

REV 1.3 7

operation Basic

1.3 Basic operation

The cubes can be operated with the remote control unit or control software, “Wallaby” (page 34).

1.3.1 Remote control unit

In Cube, face the remote control toward the screen on each cube to control. Or facing to the MASTER cube (page 33) directs other cubes. In LCD, face to the IR receptor on the left side of the panel or to the optional IR receiver (page 31).

It can control the imaging monitors (cubes or LCD panels) also through the cable supplied with the remote control.

Buttons |

In normal |

|

In advanced mode |

|||||||||||||

mode |

|

In menu off |

|

|

|

|

|

In menu on |

||||||||

|

|

|

|

|

|

|

||||||||||

POWER |

Switch between power-on and standby state |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Status |

|

Status information (press-and-hold for advanced information) |

|||||||||||||

DISPLAY *1 |

information |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Switch the contents on the status indicator *2 |

Cube |

|

|

|

|

|

|

|

|

|

|

|

|

||

MUTE *1 |

- |

|

Screen mute |

|

|

|

Screen mute |

|||||||||

|

Status bar off (on test patterns) |

|

|

|

(Window mute) *3 |

|||||||||||

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INPUT SELECT menu |

|

|

|

- |

|

|

|

||||||

INPUT A |

- |

|

WINDOW PRIORITY menu (press-and-hold) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Light path calibration with [INPUT A] + [ESC] +[2-digit unit ID] |

Lamp |

|

|||||||||||

INPUT B |

- |

|

INPUT MEMORY menu |

|

|

|

- |

|

|

|||||||

Manual lamp change with [INPUT B] + [ESC] +[2-digit unit ID] ( |

Changer |

) *2 |

|

|

||||||||||||

|

|

|||||||||||||||

VIDEO |

- |

|

SENSOR DATA window with [VIDEO] + [DISPLAY] |

LCD |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

SENSOR GAIN: AUTO ADJ. window with [VIDEO] + [ESC] |

LCD |

|

|||||||||||

MEM LIST |

- |

|

MEMORY CALL menu |

|

|

|

- |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEST |

- |

|

Internal test patterns *4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MENU1 |

- |

|

TOP menu |

|

|

|

Simple menu display |

|||||||||

MENU2 |

- |

|

DISPLAY MEMORY menu |

|

|

|

- |

|

|

|

||||||

|

|

|

|

|

|

|

|

|||||||||

|

SYSTEM MEMORY menu (press-and-hold) |

|

|

|

||||||||||||

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ESC |

information |

Cancel, exit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|||||||||||||

|

On-screen indicator off (available in light source off) |

Cube |

|

|||||||||||||

ENTER |

- |

|

Enter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Up/down |

- |

|

- |

|

|

|

Menu select, |

|||||||||

arrows |

|

|

|

|

cursor up/down |

|||||||||||

|

|

|

|

|

|

|||||||||||

Left/right |

- |

|

- |

|

|

|

Option select, |

|||||||||

arrows |

|

|

|

|

value change |

|||||||||||

|

|

|

|

|

|

|||||||||||

R, G, B |

- |

|

Primary color mute/display *5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

numbers |

- |

|

Remote ID input after [FUNC] |

|

|

|

|

|

|

|

|

|

|

|

|

|

Recall display memory by number |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

NORMAL |

Switch between normal and advanced mode |

|

|

|

Value reset |

|||||||||||

FUNC |

- |

|

Remote ID switch *6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Slide switch |

- |

|

Switch the function between [DISPLAY] and [MUTE] |

|||||||||||||

*1. The slide switch switches the function between [DISPLAY] and [MUTE]. *2. It is available even in standby state and blowout mode (page 49).

*3. Specified window image will be muted off/on during DISPLAY > WINDOW 1 – 6 menu display. *4. Every press of the button switches the test patterns to be displayed.

*5. Regardless of ID setting, the R / G / B button mutes (switches off) the red / green / blue color for the monitors. When muted / un-muted monitors are mixed in a display wall, pressing R / G / B may just alternate the effect. To un-mute all of the monitors, press and hold the R / G / B button.

*6. Number keys specify the ID number, or left/right buttons change the number by 1 and up/down buttons by 10.

8Seventy Series Set-up Manual

1.3.2 Operation mode

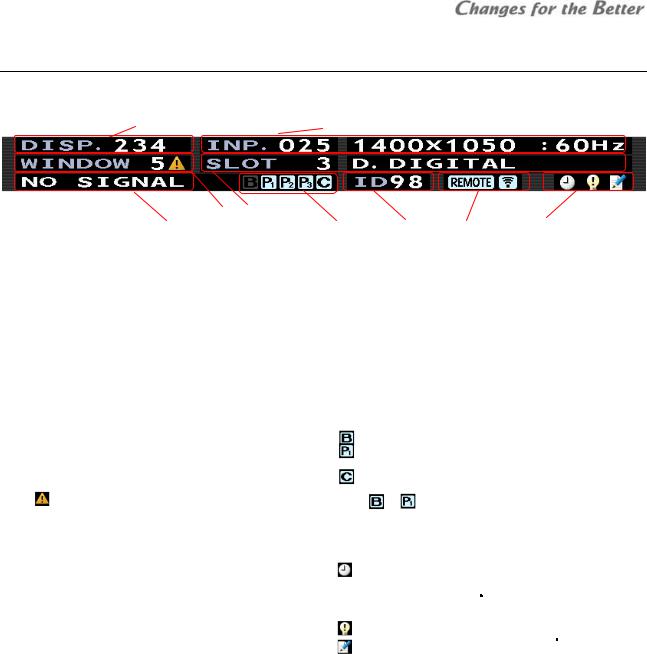

For remote control, the monitors have 2 operation modes: “normal mode” and “advanced mode”. The normal mode is for usual operation and advanced mode for set-up and adjustment. [NORMAL] button switches the modes when there is no adjustment menu on screen. This status bar is shown on screen in the advanced mode.

1 |

2 |

|

3 |

4 |

|

|

|

Normal mode |

5 |

6 |

7 |

8 |

9 |

|

|

|

|

|

|

Following operations are available in normal mode. |

|

|

|

||

Button |

Function |

|

|

|

|

[POWER] |

Switch between power-on and standby state |

|

|

|

|

[DISPLAY] |

Status information, switch the contents on the status indicator |

|

|

|

|

[ESC] |

Status information off |

|

|

|

|

[NORMAL] |

Switch between normal and advanced mode |

|

|

|

|

Numbers |

Recall a display memory (page 63) by 3-digit number. Press 001 for display memory 1. |

|

|||

Advanced mode

Monitor adjustments such as color balance and input signal adjustments should be done in advanced mode.

Status bar

|

No. |

|

Description |

No. |

|

Description |

|

|

|

|

|

||

1 |

|

Selected display memory number (page 59) |

|

|

Redundancy (page 51) and color-key (page 50) setting, status |

||||||||

|

|

|

• |

: BOARD REDUNDANCY mode |

|||||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

• |

: PORT REDUNDANCY mode (The number shows the slot |

||||||

|

|

|

Input memory number (page 54) and its comment on the |

|

|

||||||||

2 |

|

6 |

|

|

number) |

|

|

|

|

|

|||

|

|

|

foreground window |

|

|

• |

: COLOR-KEY mode |

||||||

|

|

|

Foreground window number |

|

|

||||||||

3 |

|

|

|

These indicators are shown when the function is set ON. The color of |

|||||||||

|

icon is shown when the window is displayed in space |

|

|

indicator |

or |

changes to yellow when the signal is switched. |

|||||||

|

|

|

coordinates on another monitor. |

7 |

|

Unit ID number |

|

|

|

|

|

||

4 |

|

Slot number and input port on foreground window |

8 |

|

Remote ID indicator |

|

|

|

|

|

|||

|

|

* It is shown when remote controlling is available by remote ID setting. |

|||||||||||

|

|

|

|

|

|

||||||||

|

|

|

Image status |

|

|

Monitor status |

|

|

|

|

|

||

|

|

|

• Test pattern name: in internal test pattern displaying |

|

|

• |

: In waiting time for lamp calibration (page 52) or for initial sensor |

||||||

|

|

|

• SCREEN MUTE: in screen mute |

|

|

||||||||

|

|

|

|

|

|

data obtaining (page 47) ( |

Lamp |

). |

|

|

|||

|

|

|

• WINDOW MUTE: One of the windows is mute. |

|

|

|

|

|

|||||

|

|

|

|

|

|

The |

operation |

will be completed in 5 minutes and then the |

|||||

|

|

|

• NO SIGNAL: no signal on the foreground window |

|

|

|

|||||||

5 |

|

9 |

|

|

indication will disappear. |

||||||||

|

|

|

|

||||||||||

|

|

|

|

|

|

• |

: The spare lamp status is not “NEW” ( |

Changer |

). |

||||

|

|

|

|

|

|

• |

: Adjustment values have been changed. |

||||||

|

|

|

|

|

|

|

* It appears when a value is changed automatically by internal |

||||||

|

|

|

|

|

|

|

process as well as changed by remote control. |

||||||

operation Basic

Remote ID

An individual monitor can be controlled remotely. Specify it with [FUNC] button followed by 2-digit unit ID number. Specifying 00 means that all monitors will be controlled. To control only ID 1 monitor, press [FUNC] + [0] + [1].

•Arrow keys after [FUNC] can also specify the ID. Left/right buttons change the ID by 1 and up/down buttons by 10. Press [ENTER] button to confirm.

•Remote ID switch is available even when the menus are on displayed on the screen.

Test patterns

[TEST] button shows internal test patterns. Every press cycles through the patterns in the following order. Full-bit white -> Crosshatch -> Adjustment white -> Gradation -> Color bar -> Test pattern off -> (Full-bit white)

REV 1.3 9

operation Basic

1.3.3 Menus

Basic menu operations

•The up/down arrow buttons on the remote control move the yellow cursor to select menus.

•The left/right arrow buttons change the value in a menu with left/right triangle marks.

•In a menu with “>” mark on the right, [ENTER] button shows its lower layer menu. [ESC] button restores the original upper menu.

•In a menu with an enter mark on the right, [ENTER] button confirms or executes the menu.

•When values are changed in a menu,  mark appears. Save the change according to the necessity.

mark appears. Save the change according to the necessity.

-In WINDOW PRIORITY menu, the mark appears when an input memory in any of the windows is changed.

-In INPUT MEMORY menu, the mark appears when an input memory in the top window is changed.

•In the menu displaying, [MENU1] button changes the menu GUI to the simple one. The image area behind the menu can be observed widely. Re-pressing the same button restores the original menu.

TOP menu

The TOP menu is displayed by [MENU1] button on the remote control in the advanced mode. Starting from the menu, which is the top of the menu tree, lower menus can be choosen.

•Allocated short-cut buttons directly access each menu not-through the TOP menu.

INFORMATION menu

It shows various status information on screen. Short-cut: [DISPLAY] button

1 and 2 in SIGNAL column represent with or without signals on each input port (The signal from the SDI input board is shown only in 1). In the case of the daisy chain board, it shows following signals.

1: digital in, 2: analog in, 3: video in, D: digital out

Lamp

LED

LCD

•Menus are not displayed when the monitors are controlled by Wallaby.

10 Seventy Series Set-up Manual

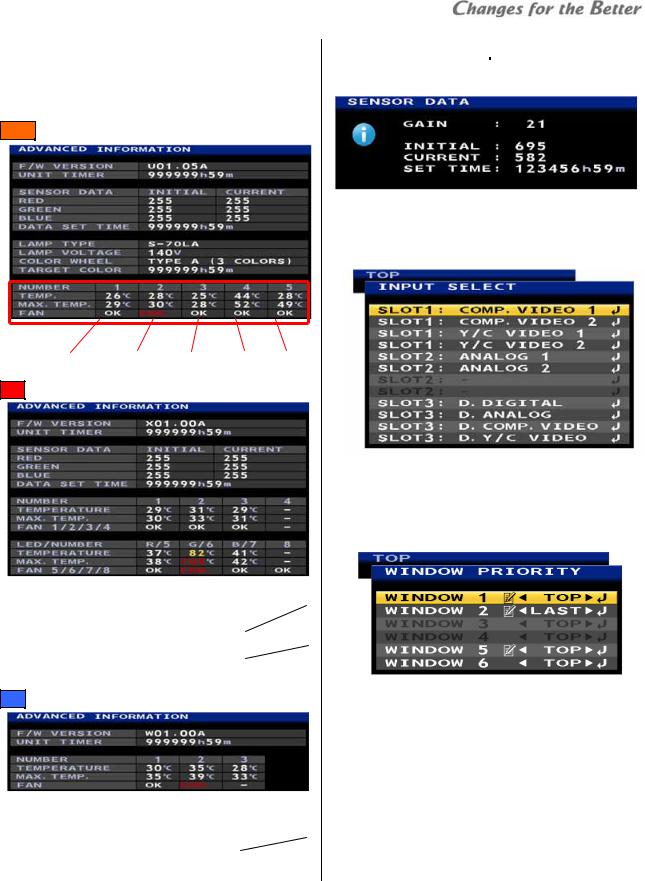

ADVANCED INFORMATION menu

Pressing-and-holding [DISPLAY] button on the status information displays the advanced information. The NUMBER section shows temperetures and fan status in the following positions.

Lamp

Power PCB 1 Power PCB 2 DLPTM chip Lamp A Lamp B

LED

|

|

No. |

1 |

|

2 |

|

3 |

|

4 |

|

|||||

|

|

Temp. |

|

Power PCB 1 |

Power PCB 2 |

|

DLPTM |

|

|

|

|||||

|

|

/ fan |

|

|

chip |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

No. |

|

|

5 |

|

|

6 |

|

|

7 |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Temp. |

|

Red LED |

Green LED |

|

Blue LED |

|

|

|

|||||

|

|

Fan |

|

|

Green LED 1 |

|

|

Green LED 2 |

|||||||

|

|

|

|

|

|

|

|

|

|

||||||

LCD

No. |

1 |

2 |

3 |

Temp. |

Power PCB 1 |

Power PCB 2 |

Sensor PCB |

Fan |

Fan 2 (left) * |

Fan 2 (right) * |

|

* Seen from the panel front

SENSOR DATA menu |

LCD |

|

Basic |

|

Pressing [VIDEO] + [DISPLAY] button in the advanced |

||||

|

||||

mode shows the light sensor data. |

operation |

|||

|

|

|

||

INPUT SELECT menu

It can select input ports to be adjusted (page 54). Selected input signal will be displayed on top. Short-cut: [INPUT A] button

WINDOW PRIORITY menu

It can set the window overlay priority order. The designated window will be displayed on top or last behind other windows.

Short-cut: Press-and-hold [INPUT A] button

It shows the priority order list and can set the order all together, unlike PRIORITY menu (page 62) in display memory which should enter in each window menu to set. To save the order, enter DISPLAY MEMORY menu and save in a display memory (page 63).

The  mark appears when an input memory in the window is changed. To save the change, move the window priority to the top and save the input memory.

mark appears when an input memory in the window is changed. To save the change, move the window priority to the top and save the input memory.

REV 1.3 11

panel Control

MEMORY CALL menu

Registered input memories / display memories can be called (page 58, 63).

Short-cut: [MEM LIST] button

INPUT MEMORY menu

It can set input signals. See on page 54 for detail. The setting can be memorized in 128 input memories. Short-cut: [INPUT B] button

DISPLAY MEMORY menu

It can set display layout patterns. See on page 59 for detail. The setting can be memorized in 256 display memories.

Short-cut: [MENU2] button

SYSTEM SETTING menu

It can set an entire monitor / screen condition. See on page 36 and 48 for detail. One condition is memorized in the monitor.

Short-cut: Press-and-hold [MENU2] button.

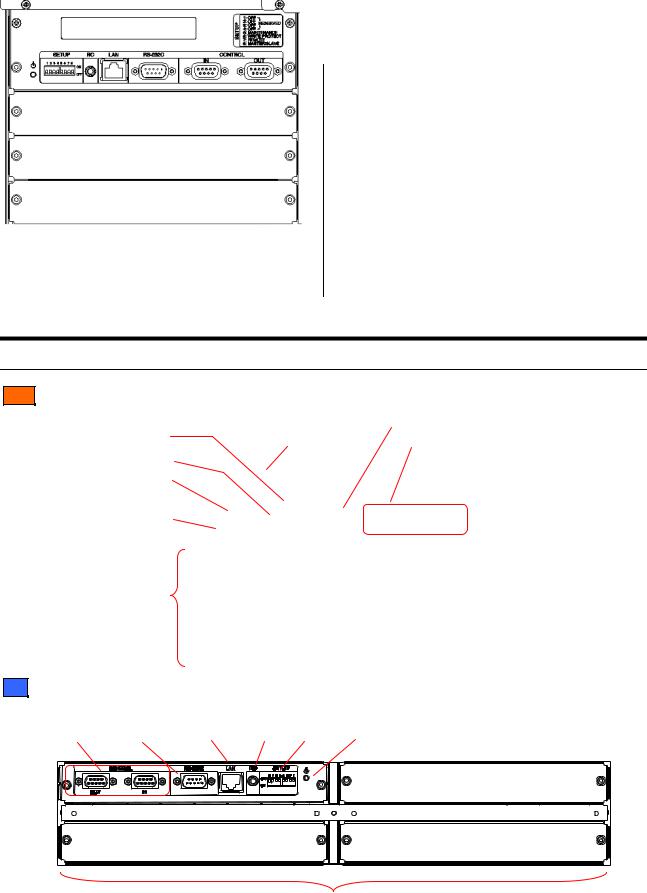

1.4 Control panel

The control panel has the following functions.

Cube

Network port (page 32)

Wired remote port (page 8)

Dipswitches

(page 32)

Standby switch (page 33)

Input board slots (page 15)

|

RS-232 port (page 32) |

Status indicator” |

Control ports (page 32) |

(page 66) |

Slot 1

Slot 2

Slot 3

LCD

Control |

RS-232 |

Network |

Wired remote |

Dipswitches |

Standby |

|

ports |

port |

port |

port |

(page |

32) |

switch |

(page 32) |

(page 32) |

(page 32) |

(page 8) |

|

|

(page 33) |

|

|

|

|

|

|

Slot 1 |

|

Slot 3 |

|

|

|

|

Slot 2 |

|

|

|

Input |

board |

slots |

(page 24) |

12 Seventy Series Set-up Manual

2 Cube installation (Cube)

2.1 Safety precaution

This product requires special installation to prevent falling or toppling. This should be done by installation specialists.

This product requires special installation to prevent falling or toppling. This should be done by installation specialists.

Be sure to read this manual and the user’s manual for your safety before starting assembly or installation.

Be sure to read this manual and the user’s manual for your safety before starting assembly or installation.

Be sure to use supplied accessories for assembly or installation.

Be sure to use supplied accessories for assembly or installation.

Attach all the screws and fixtures specified in this manual securely.

Attach all the screws and fixtures specified in this manual securely.

Reinforce the wall surface and floor so that it can support the total weights of the products permanently and resist earthquakes, possible vibrations, and external forces.

Reinforce the wall surface and floor so that it can support the total weights of the products permanently and resist earthquakes, possible vibrations, and external forces.

Ensure that the safety factor is more than 10 (or ensure that the total bolts can bear ten times the weight of products and the brackets).

Ensure that the safety factor is more than 10 (or ensure that the total bolts can bear ten times the weight of products and the brackets).

Inspect the mounting fixings more than once in a year as needed.

Inspect the mounting fixings more than once in a year as needed.

Do not use the product near a heater or in a humid, dusty or smoky location.

Do not use the product near a heater or in a humid, dusty or smoky location.

Do not install the product with its intakes, exhaust slots and ventilation holes blocked. The unit may overheat and cause a fire or breakdown.

Do not install the product with its intakes, exhaust slots and ventilation holes blocked. The unit may overheat and cause a fire or breakdown.

Rear |

Front |

Be careful not to pinch your fingers while sliding the screen holding arms (Front).

Be careful not to pinch your fingers while sliding the screen holding arms (Front).

Be sure that a lighting or sunlight does not leak into the screens.

Be sure that a lighting or sunlight does not leak into the screens.

Be sure to mount/demount the screen by 2 or more people. These works may be perilous particularly on a height or a narrow scaffold.

Be sure to mount/demount the screen by 2 or more people. These works may be perilous particularly on a height or a narrow scaffold.

Handling instructions for 80” screen

Because 80” screens are large and heavy, the screens should be held carefully.

•To prevent the screen from damage or breakage, carry the screen by two or more people.

•Hold the short sides of the screen frame or the corners when picking up the screen. Holding the center of the long sides of the frame (between labels) may damage the screen edge due to its heavy weight.

•Do not lay the screen with face up on the floor or table. The screen frames may not support the heavy and large screen surface.

REV 1.3 13

precaution Safety

Preparation

LED Safety LED

The LED engines are CLASS 2 LED products.

An exposure hazard may exist only if the protective housing is removed.

Do not look into the LED light directly.

Do not look into the LED light directly.

Do not lens the LED light at anyone.

Do not lens the LED light at anyone.

Looking at the LED light directly may damage eyesight.

Looking at the LED light directly may damage eyesight.

Use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

• Specification of the LEDs

|

LED |

|

|

Wave length |

|

|

Pulse width |

|

|

Maximum |

|

|

|

|

|

|

|

|

illumination power |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Red |

623 nm |

|

234 μs |

|

41.24 mW |

|||||

|

Green |

525 nm |

349 μs |

26.43 mW |

|||||||

|

Blue |

462 nm |

218.3 μs |

|

34.76 mW |

||||||

•The LED light irradiation window is the projection lens on the upper-center of the engine products.

2.2 Preparation

2.2.1 Accessories

•Remove desiccant taped on the products. (no desiccant in engine integrated cubes)

•Remove a shipping protection sheet tucked in the lamp replacement door (page 65).

• Make sure that all of the following items are supplied. |

• Prepare following tools. |

Supplied accessories |

Q’ty per unit |

|||

Hex socket head bolts (M6) |

8 |

(12 for 80”) |

||

Flat washers (for M6) |

8 |

(12 for 80”) |

||

Spring washers (for M6) |

8 |

(12 for 80”) |

||

Seals for Joint holes |

1 |

|

||

Control cable |

1 |

|

||

User’s manual |

1 |

|

||

|

|

|

|

|

Cable ties ( |

Front |

) |

6 |

(50”), 10 (60”, 67”) |

Necessary tools

Hex keys 2mm, 2.5mm, 3mm, 4mm, 5mm

Phillips screwdrivers #0, #2

Level

Stepladder

Spacers (for screen gaps)

Wrenches (for base stands)

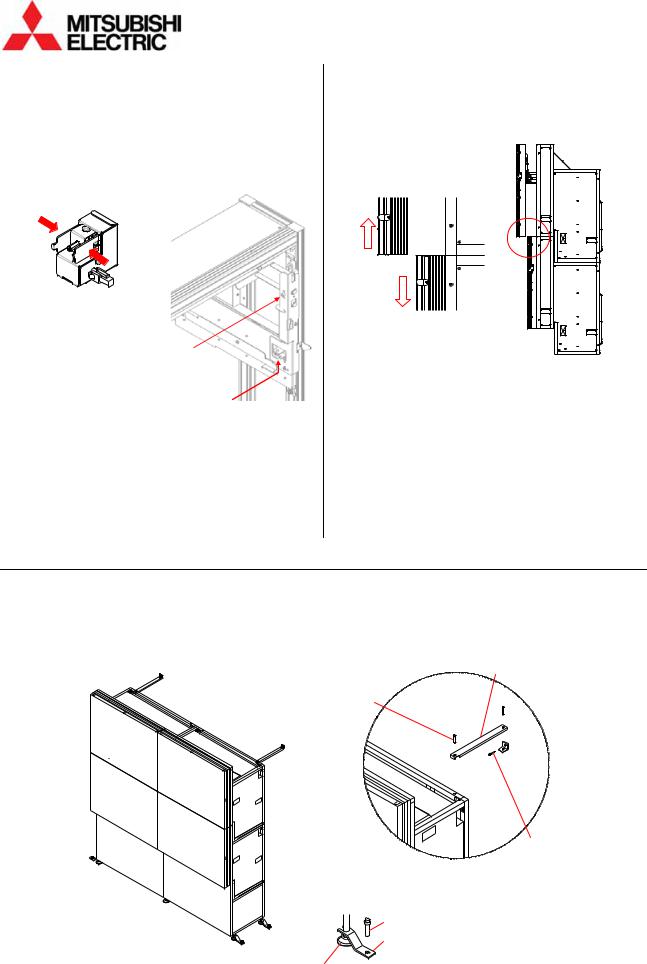

2.2.2 Input boards installation

Install input boards into the slots according to input signal configurations.

•Be sure to turn off the main power switch before installation.

•In Front, open the screen unit (page 20). The input

board slots are located inside the cubes.

1Unscrew the 2 screws on the slots evenly with a hex key (2.5mm) to remove the cover panels.

Screws

Cover panels

Input board slots

2 Insert input boards into the slots along their guide rails.

3 Firmly fix the boards until the end by evenly and alternately tightening the screws on both sides removed in the step 1 (suggested torque: 0.7Nm). For uninstalling the boards, reverse the procedure.

14 Seventy Series Set-up Manual

2.2.3 Front attachment in 80” cabinet

This work is normally unnecessary.

When you pass the cubes through a narrow gate or door, you can shorten the depth of the 80” cabinet by separating the front attachment.

1 Remove the nylon washer with “C” shape on each screen fixing bolt.

Screen fixing |

|

bolt |

|

Nylon |

|

washer |

Front |

|

|

|

attachment |

2 Pull out the 4 screen fixing bolts from rear. Be sure not to drop the washers attached to the tip of the bolts.

Washer

3 Unscrew 4 hexagon socket head bolts (5mm) to detach the front attachment.

Front attachment

Hexagon socket head bolt

4 After passing through, reverse the procedure to restore.

•Inside the front attachment, there are 4 connecting plates which can be used as additional cube connecting holes when making a curved display wall. Prepare proper bolts, nuts and washers to connect the cubes together through these holes. Unlike other connecting plates on the main cabinet (page 19), there is no castle nut inside the attachment.

Connecting plate

Preparation

REV 1.3 15

embedding Engine

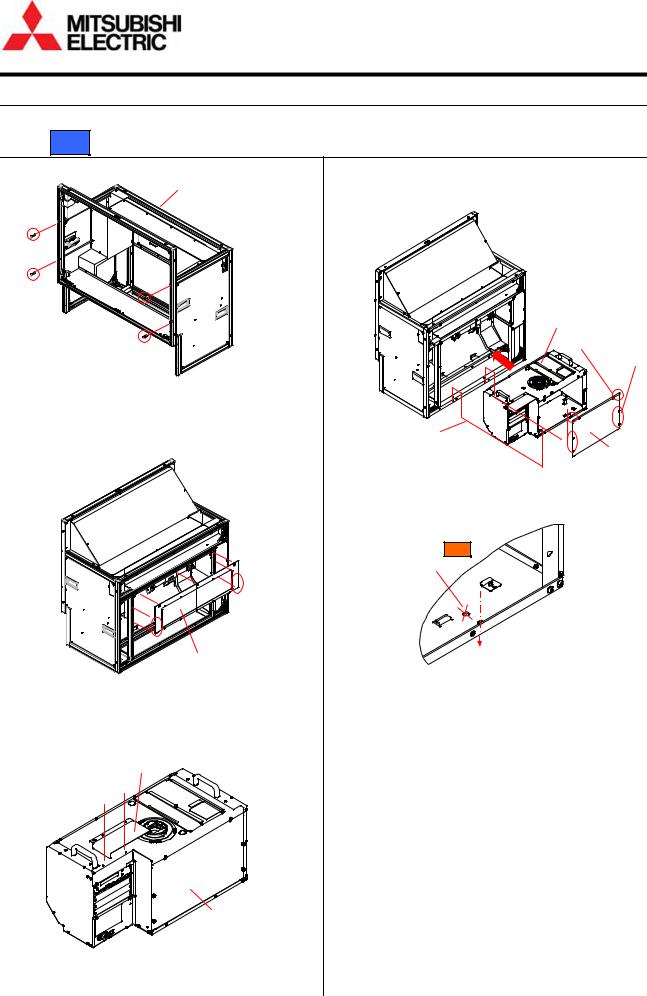

2.3 Engine embedding

Embed the engine units before cube installation (page 18) for separately supplied units.

2.3.1 Rear

1 Remove 4 bolt caps from the cabinet.

Cabinet

Bolt caps

2Loosen screws on the bottom edges of the rear panel and lift the panel to remove.

•Three screws on the top edge are hooks and need not to be loosened.

Rear panel

3 Attach a chassis cover, which is supplied with the cabinet, on the top panel of the engine unit with 2 screws.

4Remove the rear panel of the engine unit.

Loosen 2 screws on the top edge, release 4 latches and lift the panel to remove.

Engine unit

2 screws

4 latches

2 hex socket bolts

Rear panel

5Insert the engine unit into the cabinet fully and fix it with supplied 2 hex socket head bolts on both sides.

Holes for Front |

(not in use) |

2 hex socket bolts |

(on left and right sides) |

Bottom of engine unit |

6Put back the rear panels on both the engine unit and the cabinet.

Chassis cover

Engine unit

16 Seventy Series Set-up Manual

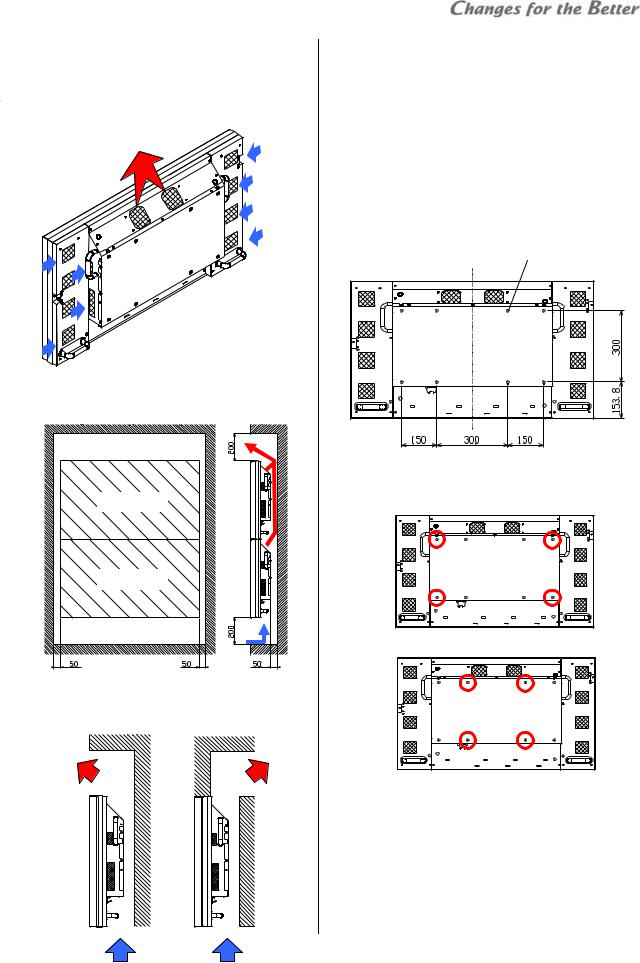

2.3.2 Front

1Loosen screws on the rear panel and lift the panel to remove. There is no need to unscrew them.

For 50”: Loosen 2 “A” screws and unscrew 7 “B” screws. There is no need to unscrew “A” screws.

A

A

B

B

B

B

A

B

B B

2Remove the rear panel of the engine unit.

Loosen 2 screws on the top edge, release 4 latches and lift the panel to remove.

2 screws

4 latches

Engine unit

Rear panel

2 hex socket bolts

3Insert the engine unit into the cabinet fully and fix 2 metal brackets, which are supplied with the cabinet, with 2 screws each.

Bracket shape for 50"

2 brackets

4Fix the engine with supplied 2 hex socket head bolts on both sides.

Holes for Rear

(not in use)

2 hex socket bolts

Bottom of engine unit

5Put back the rear panels of both the engine unit and the cabinet.

•The engine unit can be embedded from the screen side as well.

1In the same manner as above step 3, fix the 2 metal brackets from the rear side.

2Put the engine unit in the cabinet from the front side. Be careful not to touch the mirror.

3 Fix the bottom of the engine unit on the cabinet in the same manner as above step 4.

4 Put back the rear panel of the engine unit.

REV 1.3 17

embedding Engine