Mitsubishi Electric RV-1A, RV-2AJ Specifications Manual

MITSUBISHI ELECTRIC

MITSUBISHI ELECTRIC

MELFA

Industrial Robots

Specifications Manual

RV-1A/RV-2AJ Series

Art. no.: 132309 05 07 2002 BFP-A8050-F

MITSUBISHI ELECTRIC INDUSTRIAL AUTOMATION

MITSUBISHI ELECTRIC INDUSTRIAL AUTOMATION

Safety Precautions

Safety Precautions

Always read the following precautions and the separate "Safety Manual" before starting use of the robot to learn the required measures to be taken.

|

|

CAUTION |

All teaching work must be carried out by an operator who has received special training. |

|

|||

|

|

||

|

|

|

(This also applies to maintenance work with the power source turned ON.) |

|

|

|

→ Enforcement of safety training |

|

|

CAUTION |

For teaching work, prepare a work plan related to the methods and procedures of oper- |

|

|

||

|

|

||

|

|

||

|

|

|

ating the robot, and to the measures to be taken when an error occurs or when restart- |

|

|

|

ing. Carry out work following this plan. (This also applies to maintenance work with the |

|

|

|

power source turned ON.) |

|

|

|

→ Preparation of work plan |

|

|

WARNING |

Prepare a device that allows operation to be stopped immediately during teaching work. |

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

(This also applies to maintenance work with the power source turned ON.) |

|

|

|

→ Setting of emergency stop switch |

|

|

CAUTION |

During teaching work, place a sign indicating that teaching work is in progress on the |

|

|

||

|

|

||

|

|

||

|

|

|

start switch, etc. (This also applies to maintenance work with the power source turned |

|

|

|

ON.) |

|

|

|

→ Indication of teaching work in progress |

WARNING

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

Provide a fence or enclosure during operation to prevent contact of the operator and robot.

→ Installation of safety fence

Establish a set signaling method to the related operators for starting work, and follow this method.

→ Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign indicating that maintenance work is in progress on the start switch, etc.

→ Indication of maintenance work in progress

|

|

CAUTION |

Before starting work, inspect the robot, emergency stop switch and other related |

|

|||

|

|

||

|

|

|

devices, etc., and confirm that there are no errors. |

|

|

|

→ Inspection before starting work |

The points of the precautions given in the separate "Safety Manual" are given below. Refer to the actual "Safety Manual" for details.

CAUTION Use the robot within the environment given in the specifications. Failure to do so could lead to a drop or reliability or faults. (Temperature, humidity, atmosphere, noise environ- ment, etc.)

CAUTION Use the robot within the environment given in the specifications. Failure to do so could lead to a drop or reliability or faults. (Temperature, humidity, atmosphere, noise environ- ment, etc.)

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

WARNING

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

Transport the robot with the designated transportation posture. Transporting the robot in a non-designated posture could lead to personal injuries or faults from dropping.

Always use the robot installed on a secure table. Use in an instable posture could lead to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise source, positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable. Failure to observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the rated load or tolerable torque. Exceeding these values could lead to alarms or faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to observe this could lead to personal injuries or damage if the object comes off or flies off during operation.

Securely ground the robot and controller. Failure to observe this could lead to malfunc- tioning by noise or to electric shock accidents.

Indicate the operation state during robot operation. Failure to indicate the state could lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure the pri- ority right for the robot control. Failure to observe this could lead to personal injuries or damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do so could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation before starting automatic operation. Failure to do so could lead to interference with peripheral devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic operation, the door is locked or that the robot will automatically stop. Failure to do so could lead to personal injuries.

Never carry out modifications based on personal judgments, or use non-designated maintenance parts.

Failure to observe this could lead to faults or failures.

When the robot arm has to be moved by hand from an external area, do not place hands or fingers in the openings. Failure to observe this could lead to hands or fingers catching depending on the posture.

CAUTION Do not stop the robot or apply emergency stop by turning the robot controller's main power OFF.

CAUTION Do not stop the robot or apply emergency stop by turning the robot controller's main power OFF.

If the robot controller main power is turned OFF during automatic operation, the robot accuracy could be adversely affected.

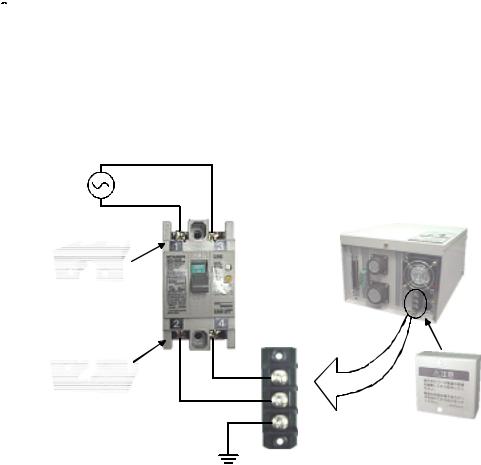

C.Precautions for the basic configuration are shown below.(When CR1-571 is used for the controller.)

CAUTION Provide an earth leakage breaker that packed together on the primary power supply of the controller as protection against electric leakage. Confirm the set- ting connector of the input power supply voltage of the controller, if the type which more than one power supply voltage can be used. Then connect the power supply.

CAUTION Provide an earth leakage breaker that packed together on the primary power supply of the controller as protection against electric leakage. Confirm the set- ting connector of the input power supply voltage of the controller, if the type which more than one power supply voltage can be used. Then connect the power supply.

Failure to do so could lead to electric shock accidents.

Power supply *RV-1A/2AJ series and RP-1AH/3AH/5AH series: Single phase 90-132VAC, 180-253VAC. *Except the above: Single phase 180-253VAC.

Rear side of controller

Earth leakage breaker

(NV)

Cover

Terminal

Cover

Terminal cover

Protective earth terminal

(PE)

■ Revision history

Date of print |

Specifications No. |

Details of revisions |

|

|

|

|

|

|

2000-02-08 |

BFP-A8050Z |

First print |

|

|

|

2000-04-05 |

BFP-A8050 |

Formal style |

|

|

|

2000-06-09 |

BFP-A8050-A |

The power supply voltage of CR1 controller was corrected |

|

|

|

2001-03-12 |

BFP-A8050-B |

Error in writing correction. |

|

|

|

2002-01-23 |

BFP-A8050-C |

LNG, RLNG and MESNGLSW parameters were added. |

|

|

Error in writing correction. |

|

|

|

2002-04-01 |

BFP-A8050-D |

CR1-MB (controller protction box) was added. |

|

|

Error in writing correction. |

|

|

|

2002-06-03 |

BFP-A8050-E |

RV-1AC-SB, RV-2AJC-SB was added. |

|

|

Error in writing correction. |

|

|

|

2002-07-05 |

BFP-A8050-F |

The description of input/output circuit terminal was corrected. |

|

|

Error in writing correction. |

|

|

|

|

|

|

■ Introduction

The "RV-1A" and "RV-2AJ" are compact industrial robots developed with Mitsubishi's advanced technology. These robots respond to users needs for compact and flexible production facilities generated due to the recent diffusion of compact and highly accuracy products such as personal computer related devices, information termi- nal devices and compact electronic devices for mounting on vehicles, and due to shorter product life cycles.

However, to comply with the target application, a work system having a well-balanced robot arm, peripheral devices or robot and hand section must be structured.

When creating these standard specifications, we have edited them so that the Mitsubishi robot's characteristics and specifications can be easily understood by users considering the implementation of robots. However, if there are any unclear points, please contact your nearest Mitsubishi branch or dealer.

Mitsubishi hopes that you will consider these standard specifications and use our robots.

In this manual, the specifications regarding the robot arm are given in Page 5, "2 Robot arm" and following, and the specifications regarding the controller are given in Page 38, "3 Controller" and following. Refer to the correspond- ing sections for details on the specifications, options and maintenance parts, etc.

Note:

No part of this manual may be reproduced by any means or in any form, without prior consent from Mitsubishi.

The contents of this manual are subject to change without notice.

The specifications values are based on Mitsubishi standard testing methods.

The information contained in this document has been written to be accurate as much as possible. Please inter- pret that items not described in this document "cannot be performed.".

Please contact your nearest dealer if you find any doubtful, wrong or skipped point.

|

Contents |

|

|

|

Page |

1 General configuration .................................................................................................................................................................... |

1-1 |

|

1.1 Structural equipment ............................................................................................................................................................. |

1-1 |

|

1.1.1 Standard structural equipment .................................................................................................................................. |

1-1 |

|

1.1.2 Shipping special specifications ................................................................................................................................... |

1-1 |

|

1.1.3 Options ................................................................................................................................................................................. |

1-1 |

|

1.1.4 Maintenance parts ........................................................................................................................................................... |

1-1 |

|

1.2 |

Contents of the structural equipment ............................................................................................................................ |

1-2 |

1.2.1 Robot arm ........................................................................................................................................................................... |

1-2 |

|

1.3 |

Controller .................................................................................................................................................................................... |

1-3 |

1.4 |

Contents of the Option equipment and special specification .............................................................................. |

1-4 |

2 Robot arm ........................................................................................................................................................................................... |

2-5 |

|

2.1 |

Standard specifications ........................................................................................................................................................ |

2-5 |

2.2 |

Definition of specifications .................................................................................................................................................. |

2-6 |

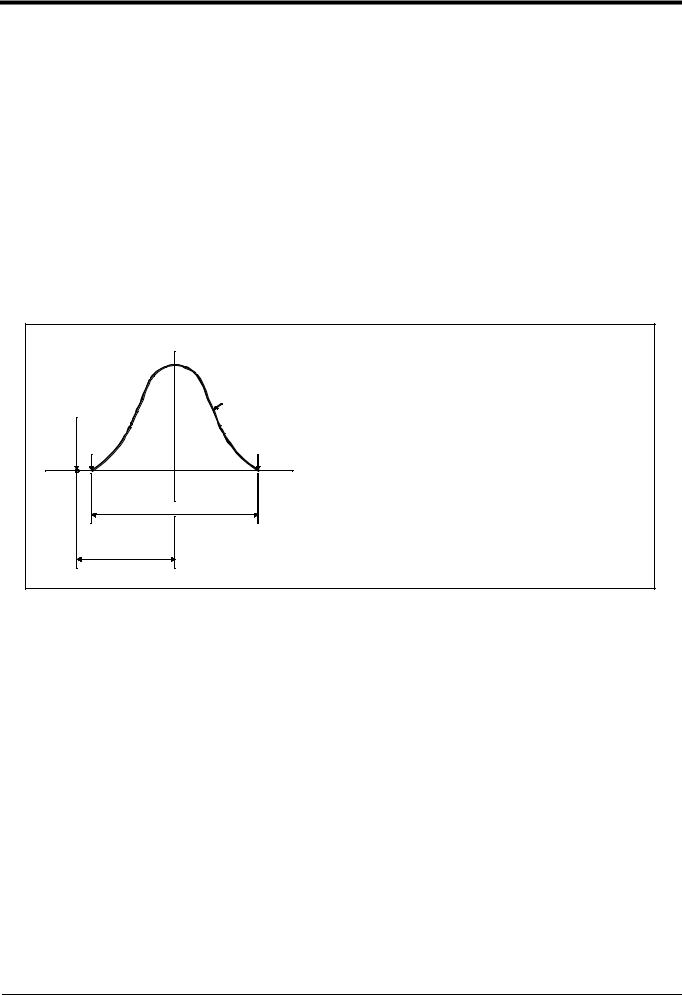

2.2.1 Pose repeatability and distance accuracy ............................................................................................................ |

2-6 |

|

2.2.2 Rated load (mass capacity) ......................................................................................................................................... |

2-7 |

|

2.2.3 Protection specifications and working environment ......................................................................................... |

2-8 |

|

|

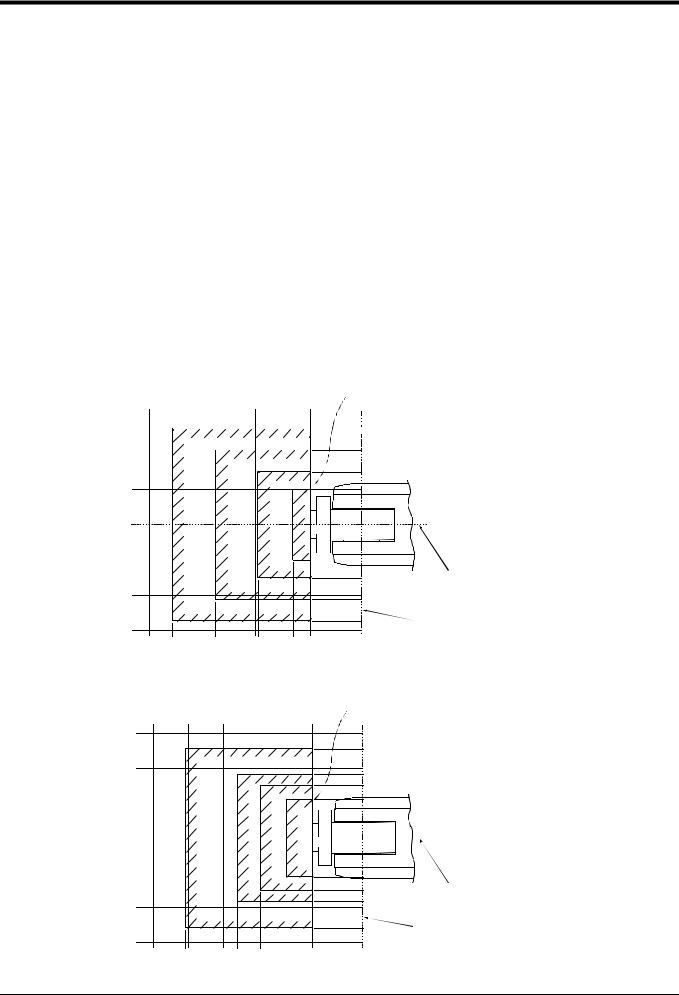

(1) Types of protection specifications ...................................................................................................................... |

2-8 |

2.2.4 Clean specifications ........................................................................................................................................................ |

2-9 |

|

|

(1) Types of clean specifications ................................................................................................................................. |

2-9 |

2.3 |

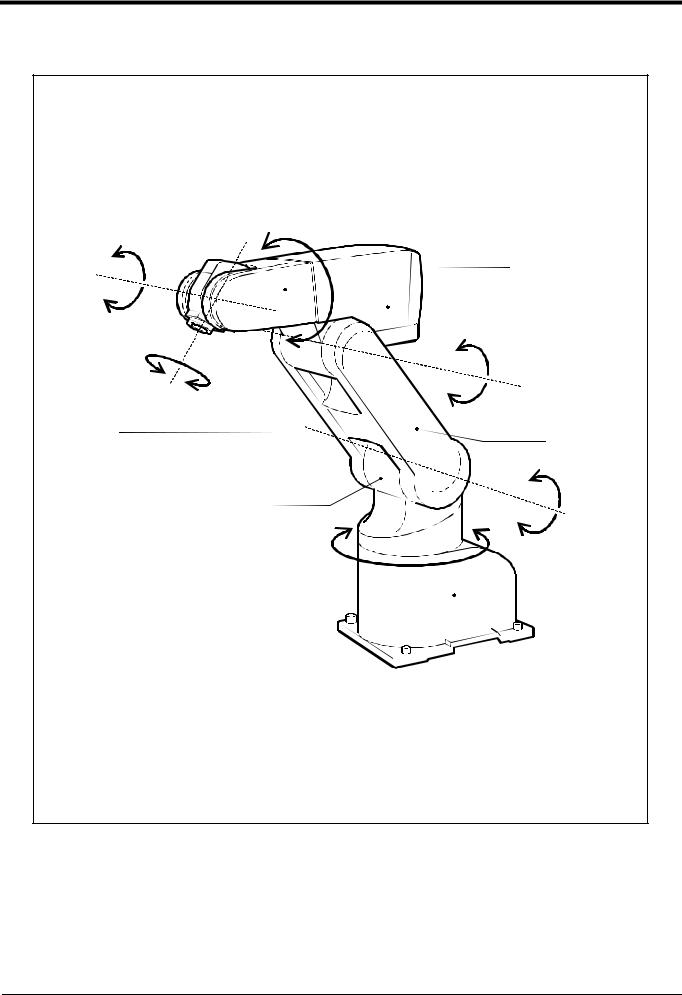

Names of each part of the robot .................................................................................................................................... |

2-10 |

2.4 |

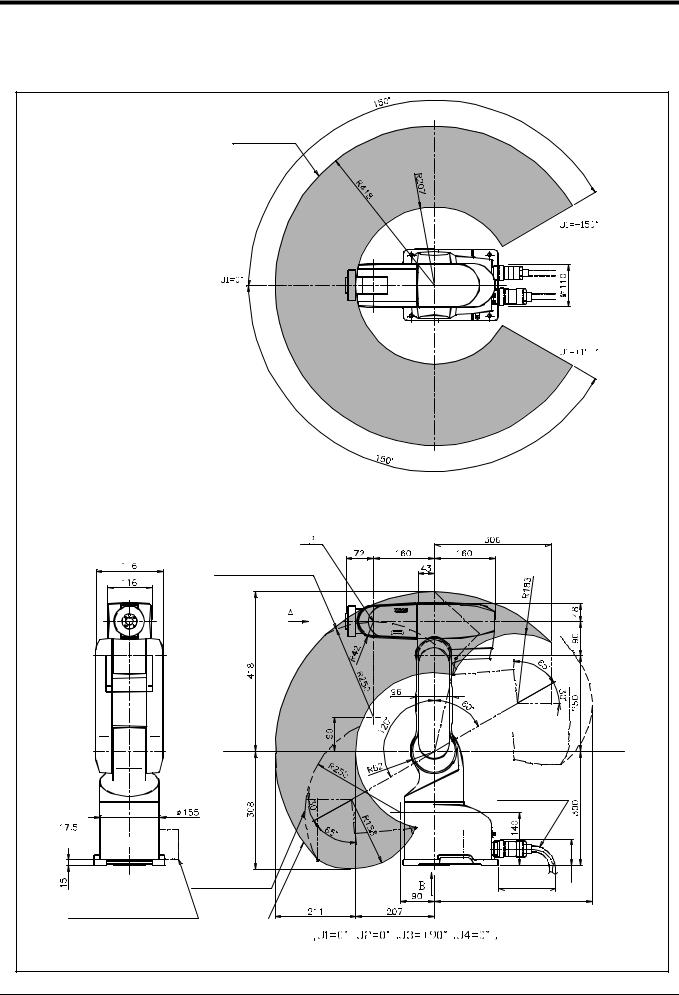

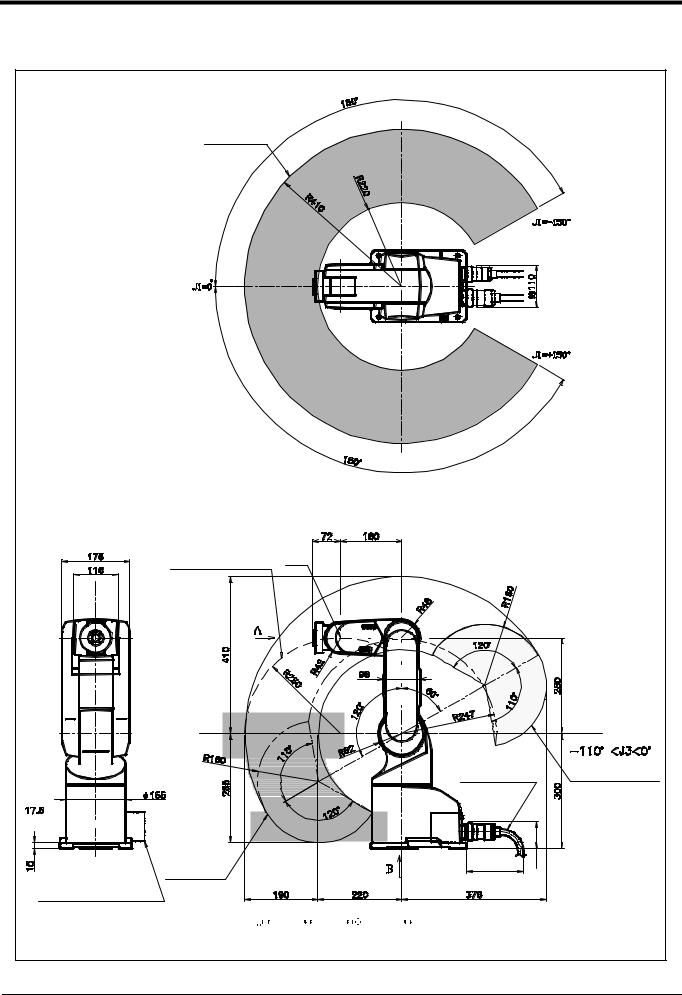

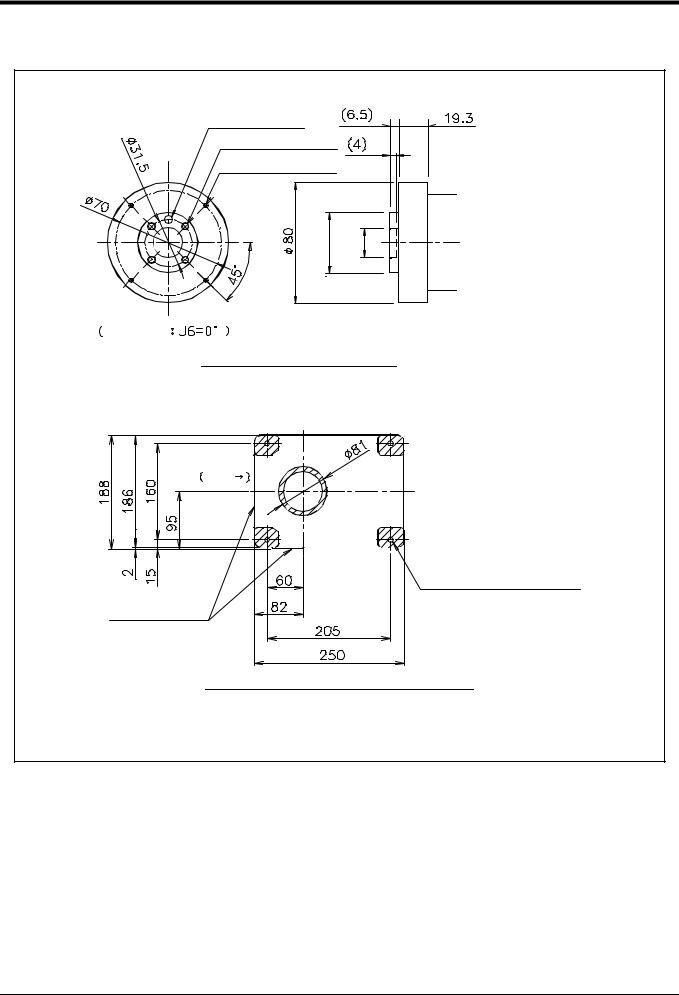

Outside dimensions Operating range diagram ........................................................................................................ |

2-11 |

|

(1) RV-1A/1AC-SB ........................................................................................................................................................ |

2-11 |

|

(2) RV-2AJ/2AJC-SB ................................................................................................................................................... |

2-12 |

|

(3) Mechanical interface and Installation surface of RV-1A/2AJ, RV-1AC-SB/2AJC-SB .......... |

2-13 |

2.5 |

Tooling ........................................................................................................................................................................................ |

2-14 |

2.5.1 Wiring and piping for hand .......................................................................................................................................... |

2-14 |

|

|

(1) RV-1A/2AJ (General environment) .................................................................................................................. |

2-14 |

|

(2) RV-1AC-SB/2AJC-SB (Clean specification) .............................................................................................. |

2-15 |

2.5.2 Internal air piping ............................................................................................................................................................ |

2-16 |

|

2.5.3 Internal wiring for the pneumatic hand output cable ...................................................................................... |

2-16 |

|

2.5.4 Internal wiring for the hand check input cable .................................................................................................. |

2-16 |

|

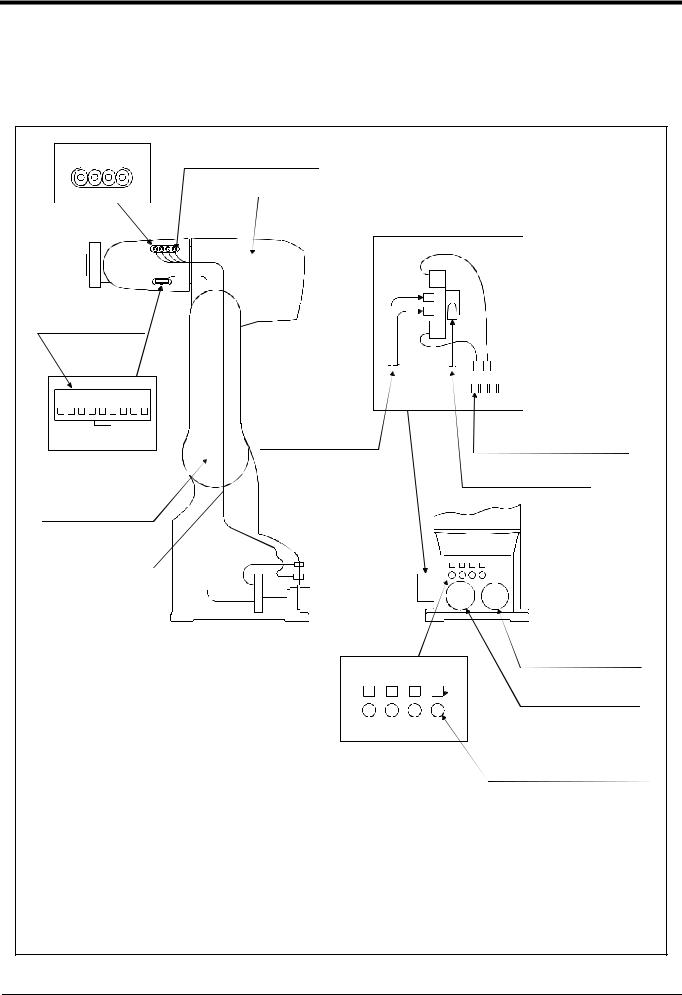

2.5.5 Wiring and piping system diagram for hand ......................................................................................................... |

2-17 |

|

|

(1) RV-1A/2AJ (General environment) .................................................................................................................. |

2-17 |

|

(2) RV-1AC-SB/2AJC-SB (Clean specification) .............................................................................................. |

2-19 |

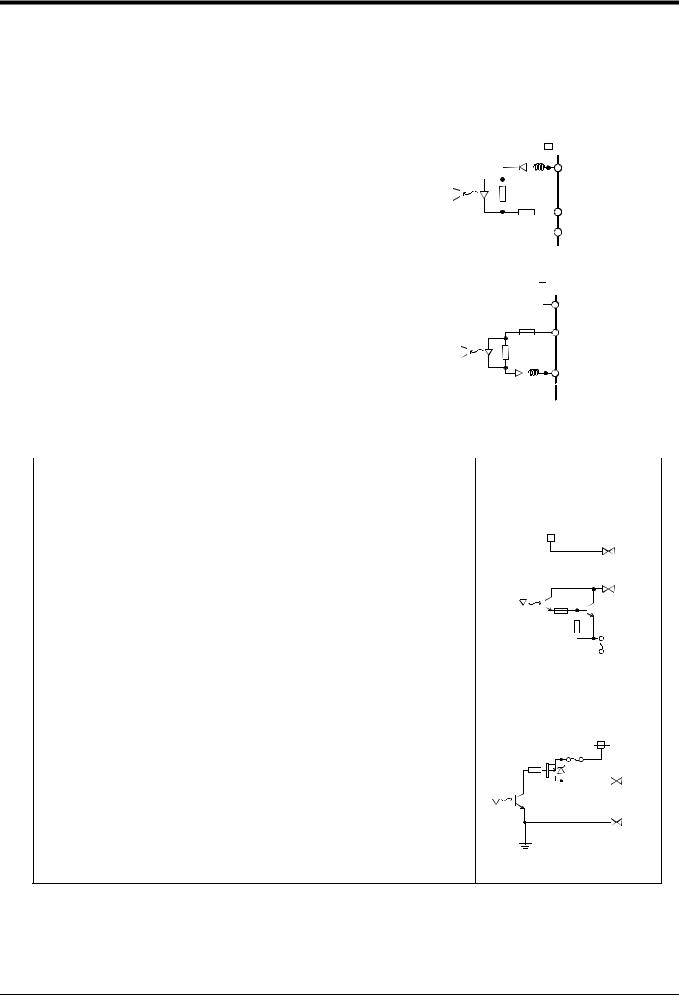

2.5.6 Electrical specifications of hand input/output .................................................................................................. |

2-21 |

|

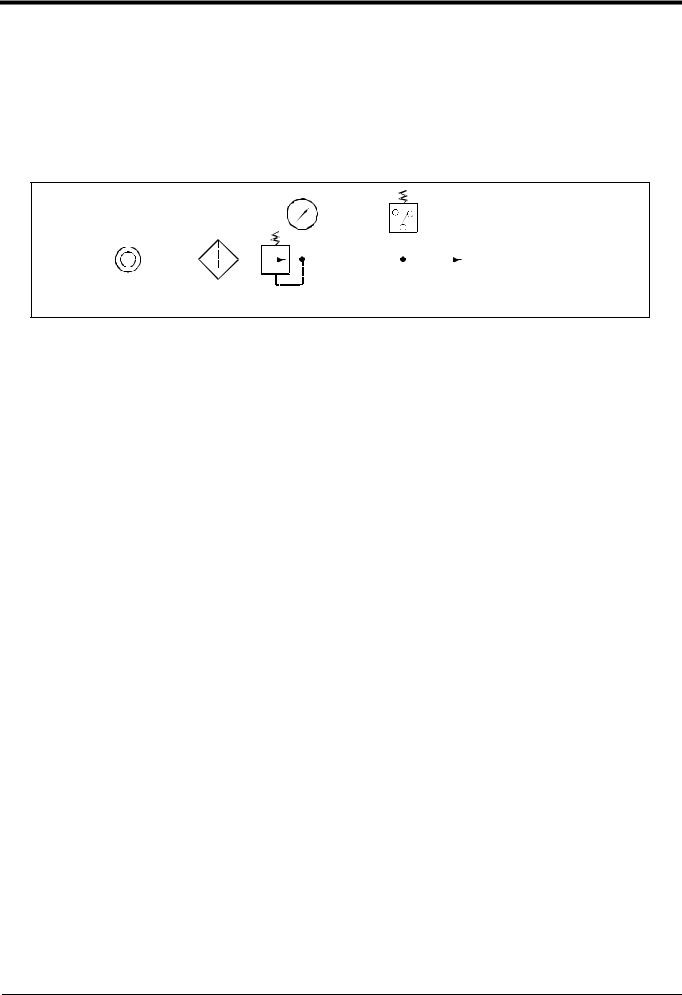

2.5.7 Air supply circuit example for the hand ............................................................................................................... |

2-22 |

|

2.6 |

Shipping special specifications, options, and maintenance parts ...................................................................... |

2-23 |

2.6.1 Shipping special specifications ................................................................................................................................. |

2-23 |

|

|

(1) Machine cable extension ........................................................................................................................................ |

2-24 |

2.7 |

Options ....................................................................................................................................................................................... |

2-26 |

|

(1) Motorized hand set ................................................................................................................................................... |

2-27 |

|

(2) Pneumatic hand set .................................................................................................................................................. |

2-29 |

|

(3) Solenoid valve set ..................................................................................................................................................... |

2-31 |

|

(4) Hand input cable ........................................................................................................................................................ |

2-33 |

|

(5) Hand output cable ..................................................................................................................................................... |

2-34 |

|

(6) Hand curl tube ............................................................................................................................................................ |

2-35 |

|

(7) Hand adapter ............................................................................................................................................................... |

2-36 |

2.8 |

Maintenance parts ................................................................................................................................................................. |

2-37 |

3 Controller .......................................................................................................................................................................................... |

3-38 |

|

3.1 |

Standard specifications ...................................................................................................................................................... |

3-38 |

3.1.1 Standard specifications ............................................................................................................................................... |

3-38 |

|

3.1.2 Protection specifications and operating supply ................................................................................................ |

3-39 |

|

3.2 |

Names of each part .............................................................................................................................................................. |

3-40 |

3.3 |

Outside dimensions/Installation dimensions .............................................................................................................. |

3-42 |

i

|

|

|

Page |

3.3.1 Outside dimensions ...................................................................................................................................................... |

3-42 |

||

3.3.2 Installation dimensions ................................................................................................................................................ |

3-43 |

||

3.4 |

External input/output ......................................................................................................................................................... |

3-44 |

|

3.4.1 Types .................................................................................................................................................................................. |

3-44 |

||

3.4.2 Explanation ....................................................................................................................................................................... |

3-44 |

||

3.5 |

Dedicated input/output ...................................................................................................................................................... |

3-45 |

|

3.6 |

Emergency stop input/output ......................................................................................................................................... |

3-47 |

|

3.6.1 Connection of the external emergency stop ..................................................................................................... |

3-47 |

||

3.6.2 Door switch function ................................................................................................................................................... |

3-48 |

||

3.7 |

Parallel input/output unit .................................................................................................................................................. |

3-49 |

|

3.8 |

Options ...................................................................................................................................................................................... |

3-53 |

|

|

(1) Teaching pendant (T/B) ........................................................................................................................................ |

3-54 |

|

|

(2) |

Pneumatic hand interface ..................................................................................................................................... |

3-57 |

|

(3) |

Controller protection box ...................................................................................................................................... |

3-59 |

|

(4) |

Expansion option box .............................................................................................................................................. |

3-62 |

|

(5) |

Parallel I/O unit ......................................................................................................................................................... |

3-64 |

|

(6) |

External I/O cable .................................................................................................................................................... |

3-72 |

|

(7) |

Personal computer cable ....................................................................................................................................... |

3-74 |

|

(8) |

Personal computer support software/Personal computer support software mini ....................... |

3-76 |

3.9 |

Maintenance parts ................................................................................................................................................................ |

3-78 |

|

4 Software |

........................................................................................................................................................................................... |

4-79 |

|

4.1 |

List of commands ................................................................................................................................................................. |

4-79 |

|

|

(1) The procedure of robot language selection ................................................................................................... |

4-79 |

|

|

(2) |

MELFA-BASIC commands ..................................................................................................................... |

........ 4-80 |

|

(3) |

MOVEMASTER commands ................................................................................................................................... |

4-82 |

4.2 |

List of parameters ................................................................................................................................................................ |

4-85 |

|

|

(1) List of parameters .................................................................................................................................................... |

4-85 |

|

|

(2) |

Change the display language / .............................................................................. |

4-87 |

5 Safety ...................................................................................................................... |

.......................................................................... |

5-88 |

|

5.1 |

Safety ........................................................................................................................................................................................ |

5-88 |

|

5.1.1 Self-diagnosis stop functions .................................................................................................................................. |

5-88 |

||

5.1.2 External input/output signals that can be used for safety protection measures ............................. |

5-88 |

||

5.1.3 Precautions for using robot ...................................................................................................................................... |

5-89 |

||

5.1.4 Safety measures for automatic operation .......................................................................................................... |

5-89 |

||

5.1.5 Safety measures for teaching .................................................................................................................................. |

5-89 |

||

5.1.6 Safety measures for maintenance and inspections, etc. ............................................................................. 5-89 |

|||

5.1.7 Examples of safety measures .................................................................................................................................. |

5-90 |

||

5.2 |

Working environment ........................................................................................................................................................... |

5-91 |

|

5.3 |

Precautions for handling .................................................................................................................................................... |

5-91 |

|

6Appendix .............................................................................................................................................................................. |

|

Appendix-92 |

|

Appendix 1 Specifications discussion material ........................................................................................... |

Appendix-92 |

||

ii

1General configuration

1 General configuration

1.1 Structural equipment

Structural equipment consists of the following types.

1.1.1 Standard structural equipment

The following items are enclosed as a standard. (1) Robot arm

(2)Controller

(3)Machine cable

(4)Robot arm installation bolts

(5)Instruction manual, Safety manual

(6)Guarantee card

1.1.2 Shipping special specifications

Part of the standard structural equipment is changed at the time of factory shipment. Consequently, kindly con- firm the delivery date.

To make changes to the specifications after shipment, service work must be performed at the work site or the robot must be returned for service.

1.1.3 Options

Installation is possible after shipment. Customer needs to perform the installation work.

1.1.4 Maintenance parts

Consumable parts and spare parts for maintenance use.

For items not listed, contact the dealer where you made your purchase.

Structural equipment 1-1

1General configuration

1.2 Contents of the structural equipment

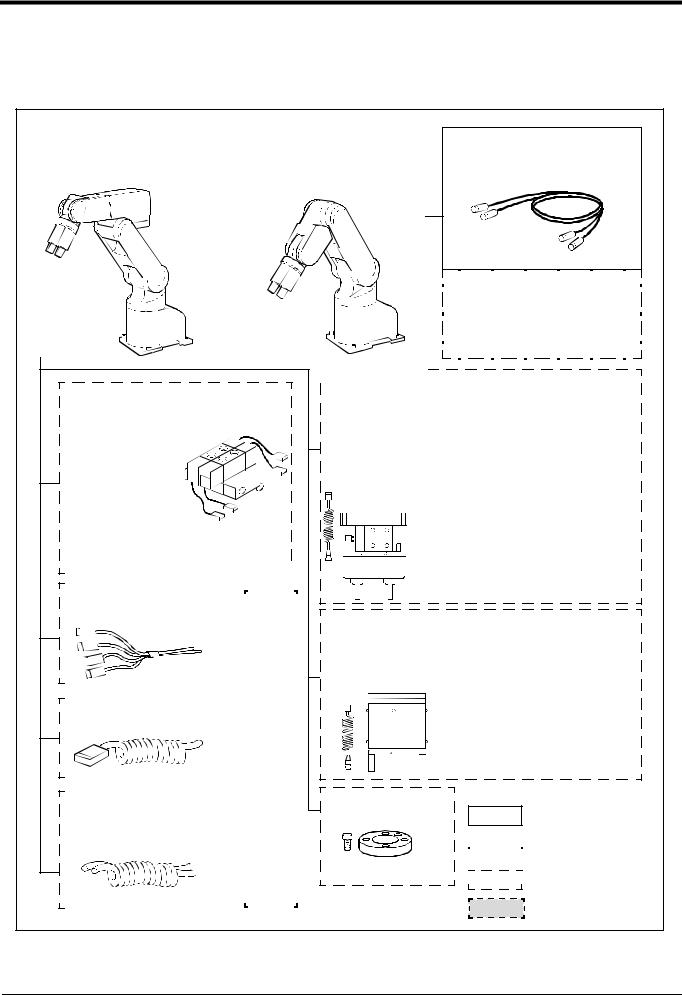

1.2.1 Robot arm

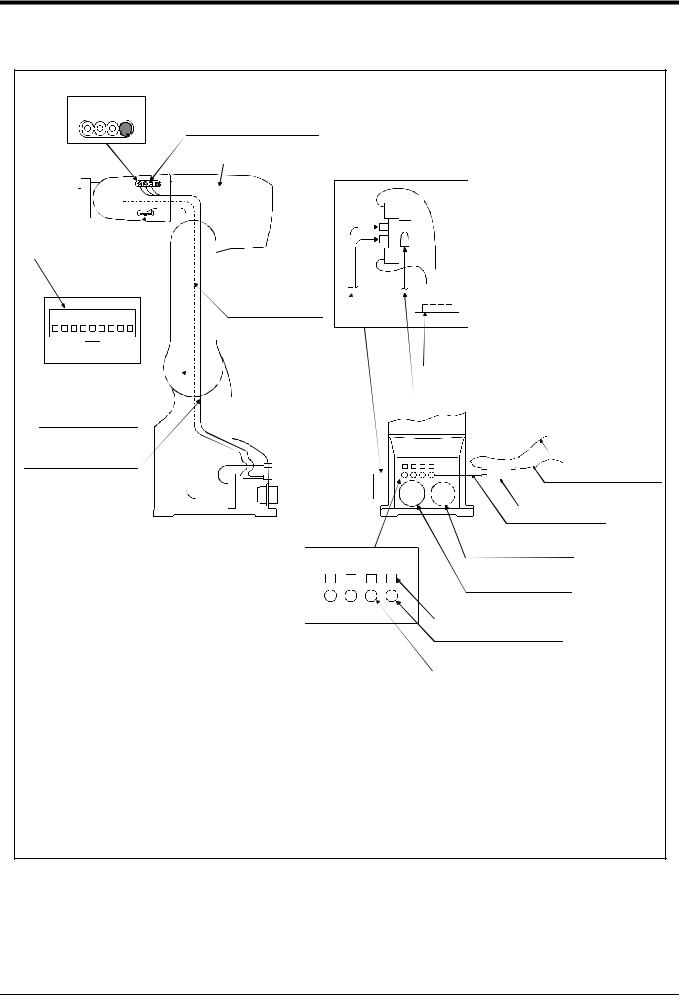

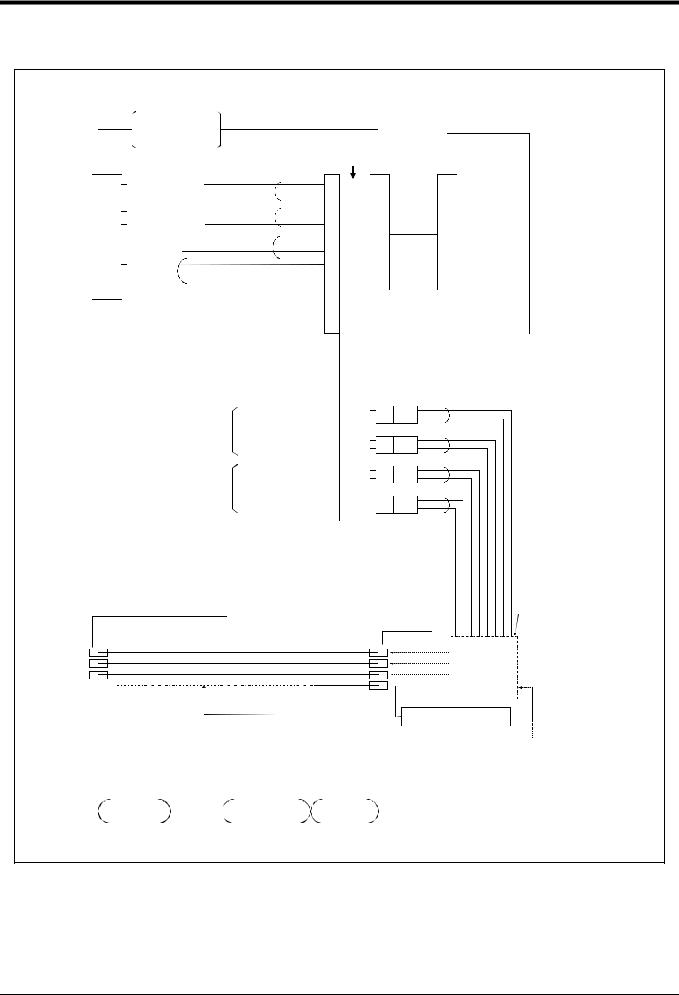

The list of structural equipment is shown in Fig. 1-1.

Vertical six-axis |

|

Vertical five-axis |

||||||||||||

RV-1A:General environment |

|

multiple-jointed type |

||||||||||||

RV-1AC-SB:Clean specification |

|

RV-2AJ:General environment |

||||||||||||

|

|

RV-2AJC-SB:Clean specification |

||||||||||||

|

or |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Machine cable fixed type 5m |

1A-5CBL-1 |

Machine cable |

Fixed type:1A- □□ CBL-1 |

Flexed type:1A- □□ LCBL-1 |

Note) □□ refer the length.

Refer to section "1.4" for datails.

Solenoid valve set <sink type>

1 set: 1E-VD01

2 set: 1E-VD02

<source type>

1 set: 1E-VD01E2 set: 1E-VD02E

With installation bolts.

Note) Not clean specification

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hand output cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

1E-GR35S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

parts |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

manufactured |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

1A-HC20 |

|

|

|

|

||||||||||||||||||||||||||||||||||||

Hand input cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

customer- |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

Hand curl tube |

|

|

|

|

|

|

|

|

hand |

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

1 set, 2pc. 1E-ST0402C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

2 set, 4pc. 1E-ST0404C |

|

|

|

|

|

|

|

|

Pneumatic |

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig.1-1 Structural equipment (Robot arm)

Pneumatic hand set

4A-HP01(sink type)/4A-HP01E (source type)

The set consists of the following parts.

Pneumatic hand |

1A-HP01/1A-HP01E |

Solenoid valve set (1 pc.) 1E-VD01/1E-VD01E |

|

Curl cable |

1A-GHCD/1A-GHCD |

Hand curl tube |

1A-ST0402C/1A-ST0402C |

Pneumatic hand I/F |

2A-RZ365/2A-RZ375 |

Hand adapter |

1A-HA01/1A-HA01 |

With installation bolts.

Note) Not clean specification

Motorized hand set 4A-HM01 |

|

||||||

Motorized hand |

1A-HM01 |

||||||

Curl cable |

1A-GHCD |

||||||

Motorized hand I/F |

2A-RZ364 |

||||||

Hand adapter |

1A-HA01 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With

With installation bolts.

installation bolts.

Note) Not clean specification

Note) Not clean specification

Hand adapter1A-HA01

With installation bolts.

Caution

Standard configuration

equipment

Special shipping

Special shipping

specifications

specifications

Option

Option

Prepared by customer |

1-2 Contents of the structural equipment

1General configuration

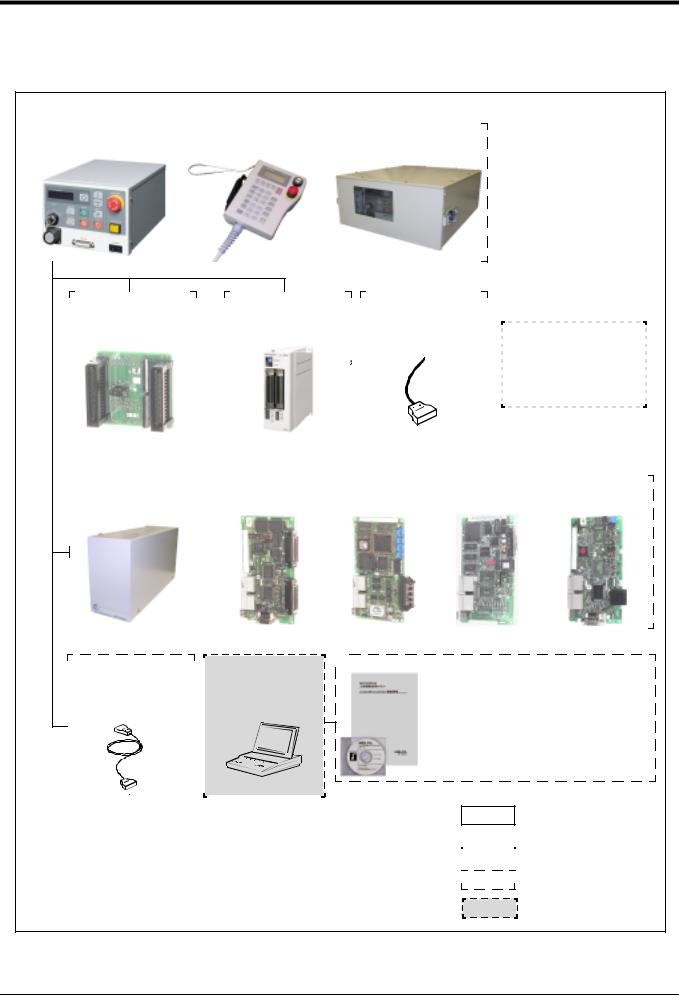

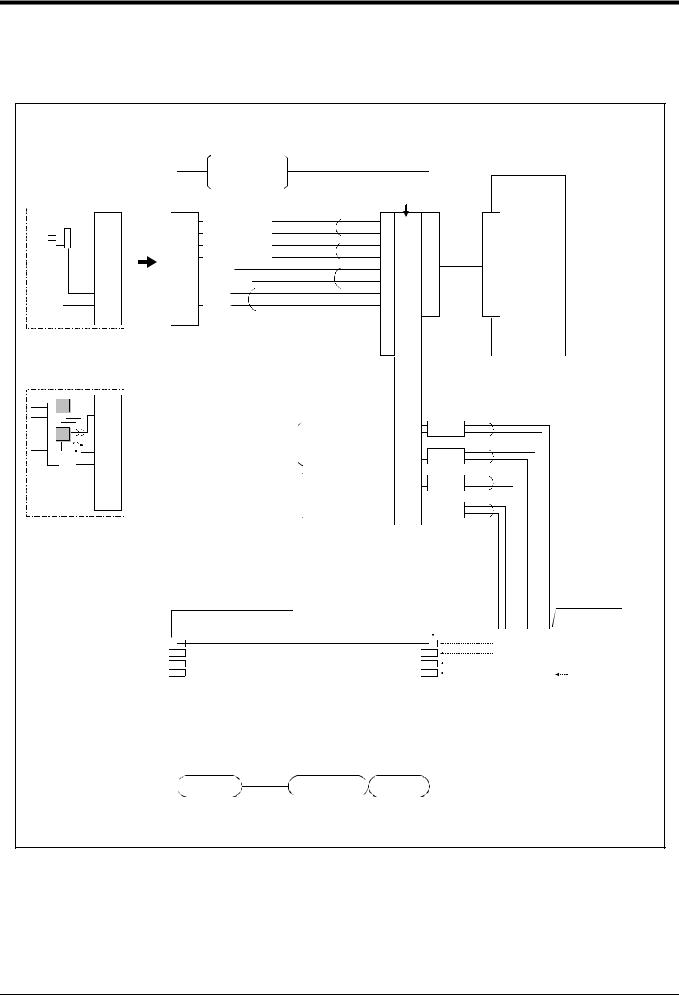

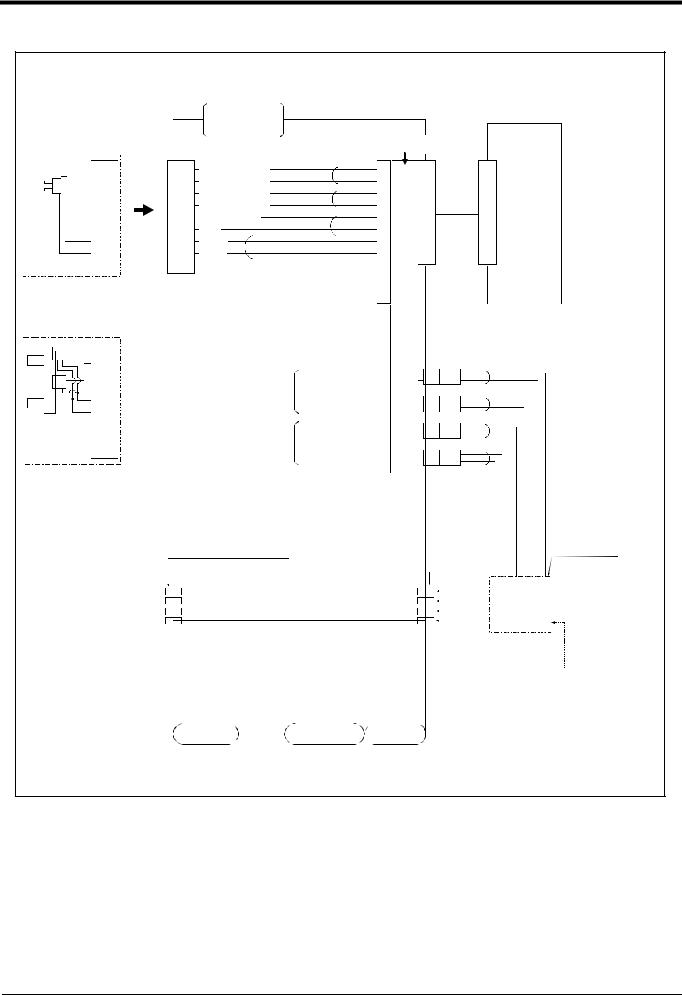

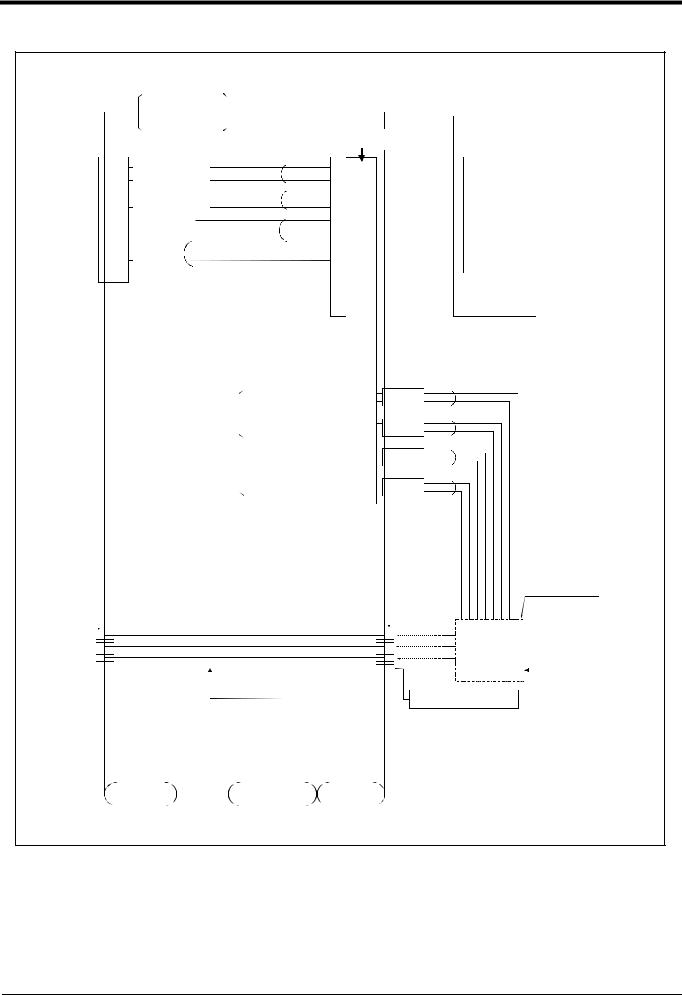

1.3 Controller

The devices shown below can be installed on the controller.

Controller |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

CR1-571 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

Teaching pendant(T/B) |

|

|

|

|

|

Controller protection box |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

R28TB |

|

|

|

|

|

CR1-MB |

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic I/F |

|

|

|

Parallel I/O unit |

|

|

|

|

External I/O cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

2A-RZ365 (Sink) |

|

|

|

2A-RZ361 (Sink) |

|

|

|

|

2A-CBL05(5m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

2A-RZ375 (Source) |

|

|

|

2A-RZ371 (Source) |

|

|

|

|

2A-CBL15(15m) |

|

|

|

PLC(Programmable |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Logic Controller) |

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

External device |

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Prepared by customer |

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Expansion option box |

|

|

Extended serial I/F |

|

|

CC-LINK I/F |

|

|

|

|

ETHERNET I/F |

|

Additional axis I/F |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CR1-EB3 |

|

|

2A-RZ581E |

|

|

2A-HR575E |

|

|

|

|

2A-HR533E |

|

2A-RZ541E |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Personal computer |

|

Personal computer |

||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

|

cable |

|

Prepared |

|||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||

|

RS-MAXY-CBL |

|

by customer |

||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

|

RS-AT-RCBL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|