Mitsubishi Electronics Q64TCRTBWN, Q64TCRTN, Q64TCTTBWN, Q64TCTTN User Manual

MELSEC-Q Temperature Control Module

User's Manual

-Q64TCTTN

-Q64TCTTBWN

-Q64TCRTN

-Q64TCRTBWN

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " CAUTION" and " WARNING".

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

WARNING

● Outputs may remain on or off due to a failure of a component such as a transistor in an output circuit.

Configure an external circuit for monitoring output signals that could cause a serious accident.

● Do not write any data to the "system area" and "write-protect area" (R) of the buffer memory in the

intelligent function module. Also, do not use any "use prohibited" signal as an input or output signal

from the intelligent function module to the programmable controller CPU.

Doing so may cause malfunction of the programmable controller system.

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

1

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the user's

manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

● To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module.

Failure to do so may result in damage to the product.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in

the system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant chapter in this manual.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

2

[Wiring Precautions]

CAUTION

● Individually ground the shielded cables of the programmable controller with a ground resistance of

100 or less.

Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when the terminal screw comes

loose, resulting in failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

3

[Startup and Maintenance Precautions]

CAUTION

● Do not touch any terminal while power is on.

Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws or module fixing screws.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

Undertightening can cause drop of the component or wire, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Do not disassemble or modify the module.

Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module.

Failure to do so may cause the module to fail or malfunction.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in

the system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant chapter in this manual.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

● Before handling the module, touch a grounded metal object to discharge the static electricity from the

human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

4

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions; i) where any

problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious

accident; and ii) where the backup and fail-safe function are systematically or automatically

provided outside of the PRODUCT for the case of any problem, fault or failure occurring in the

PRODUCT.

(2) MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT. ("Prohibited

Application") Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

5

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi MELSEC-Q series programmable controllers.

This manual describes the operating procedures, system configuration, parameter settings, functions, programming,

and troubleshooting of the Q series temperature control module

Q64TCTTN/Q64TCTTBWN/Q64TCRTN/Q64TCRTBWN (hereafter abbreviated as Q64TCN).

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-Q series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to the actual system, ensure the applicability and

confirm that it will not cause system control problems.

Relevant modules: Q64TCTTN, Q64TCTTBWN, Q64TCRTN, Q64TCRTBWN

.

● Operating procedures are explained using GX Works2. When using GX Developer or GX Configurator-CT, refer to the

following.

Page 378, Appendix 3

● In the Temperature Control Module User's Manual (SH-080121) for the Q64TCTT, Q64TCTTBW, Q64TCRT, and

Q64TCRTBW, buffer memory addresses are written in hexadecimal. In this manual, the addresses are written in decimal

using Intelligent function module device (Un\G).

• SH-080121: Temperature process value (PV) (buffer memory address: 9

• SH-080989ENG: CH Temperature process value (PV) (Un\G9 to Un\G12)

Although differently expressed, the buffer memory areas have the same address as long as they are used for the same

functions.

to CH)

H

6

COMPLIANCE WITH EMC AND LOW VOLTAGE

DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated

into other machinery or equipment, certain measures may be necessary. Please refer to one of the following

manuals.

• QCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the CPU module or base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage

Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to one of the manuals listed

under (1).

7

RELEVANT MANUALS

(1) CPU module user's manual

Manual name

<manual number (model code)>

QCPU User's Manual

(Hardware Design, Maintenance and Inspection)

<SH-080483ENG, 13JR73>

QnUCPU User's Manual

(Function Explanation, Program Fundamentals)

<SH-080807ENG, 13JZ27>

Qn(H)/QnPH/QnPRHCPU User's Manual

(Function Explanation, Program Fundamentals)

<SH-080808ENG, 13JZ28>

(2) Operating manual

Manual name

<manual number (model code)>

GX Works2 Version 1 Operating Manual (Common)

<SH-080779ENG, 13JU63>

GX Developer Version 8 Operating Manual

<SH-080373E, 13JU41>

Description

Specifications of the hardware (CPU modules, power supply

modules, base units, extension cables, and memory cards), system

maintenance and inspection, troubleshooting, and error codes

Functions, methods, and devices for programming

Description

System configuration, parameter settings, and online operations

(common to Simple project and Structured project) of GX Works2

Operating methods of GX Developer, such as programming,

printing, monitoring, and debugging

8

Memo

9

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CHAPTER 1 OVERVIEW 17

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2 The PID Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3 About the PID Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

1.3.1 Operation method and formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.3.2 The Q64TCN actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.3.3 Proportional action (P-action). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.3.4 Integral action (I-action) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.3.5 Derivative action (D-action) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.3.6 PID action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CHAPTER 2 SYSTEM CONFIGURATION 29

2.1 Applicable Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2 Using the Q64TCN with Redundant CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.3 How to Check the Function Version and Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.4 Precautions for System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CHAPTER 3 SPECIFICATIONS 38

3.1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1.1 Type of usable temperature sensors, temperature measurement range, resolution,

and effect from wiring resistance of 1 ohm

3.1.2 Sampling cycle and control output cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.1.3 Number of parameters to be set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.2 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.3 I/O Signals Transferred to/from the CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3.1 I/O signal list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.3.2 Details of input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.3.3 Details of output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.4 Buffer Memory Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3.4.1 Q64TCN buffer memory assignment list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3.4.2 Details of the buffer memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CHAPTER 4 FUNCTIONS 162

4.1 Control Mode Selection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

4.2 Control Output Setting at CPU Stop Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

4.3 Control Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

10

4.4 Manual Reset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

4.5 Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

4.6 Auto Tuning Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

4.7 Simple Two-degree-of-freedom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

4.8 Derivative Action Selection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

4.9 Setting Change Rate Limiter Setting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

4.10 Moving Averaging Process to a Temperature Process Value (PV). . . . . . . . . . . . . . . . . . . . . 191

4.11 Temperature Process Value (PV) Scaling Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

4.12 Alert Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

4.13 RFB Limiter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

4.14 Sensor Correction Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

4.15 Auto-setting at Input Range Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

4.16 Input/output (with Another Analog Module) Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

4.17 ON Delay Output Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

4.18 Self-tuning Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

4.19 Peak Current Suppression Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

4.20 Simultaneous Temperature Rise Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

4.21 Forward/Reverse Action Selection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

4.22 Loop Disconnection Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .253

4.23 During AT Loop Disconnection Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

4.24 Proportional Band Setting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

4.25 Cooling Method Setting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

4.26 Overlap/Dead Band Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

4.27 Temperature Conversion Function (Using Unused Channels) . . . . . . . . . . . . . . . . . . . . . . . .262

4.28 Heater Disconnection Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

4.29 Output Off-time Current Error Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

4.30 Buffer Memory Data Backup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

4.31 Error History Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

4.32 Module Error History Collection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

4.33 Error Clear Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .275

CHAPTER 5 SETTINGS AND THE PROCEDURE BEFORE OPERATION 276

5.1 Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .276

5.2 Settings and the Procedure before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

5.3 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

5.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .287

5.4.1 Wiring precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

5.4.2 External wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

5.4.3 Heater disconnection detection wiring and setting example for three-phase heater . . . . . . 296

5.5 Unused Channel Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .297

CHAPTER 6 VARIOUS SETTINGS 298

6.1 Addition of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .298

6.2 Switch Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

11

6.3 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300

6.4 Auto Refresh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303

6.5 Auto Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

6.6 Sensor Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .305

CHAPTER 7 PROGRAMMING 306

7.1 Programming Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .306

7.2 When Using the Module in a Standard System Configuration . . . . . . . . . . . . . . . . . . . . . . . .307

7.2.1 Standard control (such as auto tuning, self-tuning, and error code read) . . . . . . . . . . . . . . 307

7.2.2 Standard control (peak current suppression function, simultaneous temperature rise

function)

7.2.3 When performing the heating-cooling control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

7.3 When Using the Module on the Remote I/O Net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .344

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

CHAPTER 8 TROUBLESHOOTING 359

8.1 Before Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .359

8.2 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .359

8.3 Checks Using LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .361

8.3.1 When the RUN LED flashes or turns off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

8.3.2 When the ERR. LED turns on or flashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

8.3.3 When the ALM LED turns on or flashes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

8.4 Checks Using Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .363

8.4.1 When Module READY flag (Xn0) does not turn on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

8.4.2 When Write error flag (Xn2) is on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

8.4.3 When Hardware error flag (Xn3) is on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

8.4.4 When the auto tuning does not start (CH Auto tuning status (Xn4 to Xn7) does not

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

turn on)

8.4.5 When the auto tuning does not complete (CH Auto tuning status (Xn4 to Xn7) stays on

and does not turn off)

8.4.6 When the self-tuning does not start (CH Auto tuning status (Xn4 to Xn7) does not

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

turn on)

8.4.7 When E2PROM write failure flag (XnA) is on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

8.4.8 When CH Alert occurrence flag (XnC to XnF) is on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

8.5 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .366

8.5.1 When the temperature process value (PV) is abnormal . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

8.6 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .367

8.7 Alarm Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .370

8.8 Check the Q64TCN Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

APPENDICES 374

Appendix 1 Addition and Change of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .374

Appendix 1.1 Additional function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Appendix 1.2 Change of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Appendix 2 Comparison of the Q64TCN with the Q64TCTT, Q64TCTTBW, Q64TCRT, and

Q64TCRTBW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

375

Appendix 2.1 Compatibility between the Q64TC and Q64TCN. . . . . . . . . . . . . . . . . . . . . . . 377

Appendix 3 When Using GX Developer and GX Configurator-TC. . . . . . . . . . . . . . . . . . . . . . . . . .378

Appendix 3.1 GX Developer operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

Appendix 3.2 GX Configurator-TC operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

Appendix 4 Online Module Change Procedure (When Using GX Developer) . . . . . . . . . . . . . . . . . 386

Appendix 4.1 Precautions on online module change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

Appendix 4.2 Conditions for online module change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

Appendix 4.3 Operations when performing an online module change . . . . . . . . . . . . . . . . . . 390

Appendix 4.4 Online module change procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Appendix 4.5 When GX Configurator-TC was used for the initial setting . . . . . . . . . . . . . . . . 392

Appendix 4.6 When a sequence program was used for the initial setting . . . . . . . . . . . . . . . . 396

Appendix 5 Online Module Change Procedure (When Using GX Works2) . . . . . . . . . . . . . . . . . . .401

Appendix 5.1 Precautions on online module change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Appendix 5.2 Online module change conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Appendix 5.3 Operations of when performing an online module change . . . . . . . . . . . . . . . . 403

Appendix 5.4 Online module change procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Appendix 5.5 When parameters were configured using GX Works2 . . . . . . . . . . . . . . . . . . . 405

Appendix 5.6 When the initial settings were configured using a sequence program . . . . . . . . . 410

Appendix 6 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .416

INDEX 418

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

13

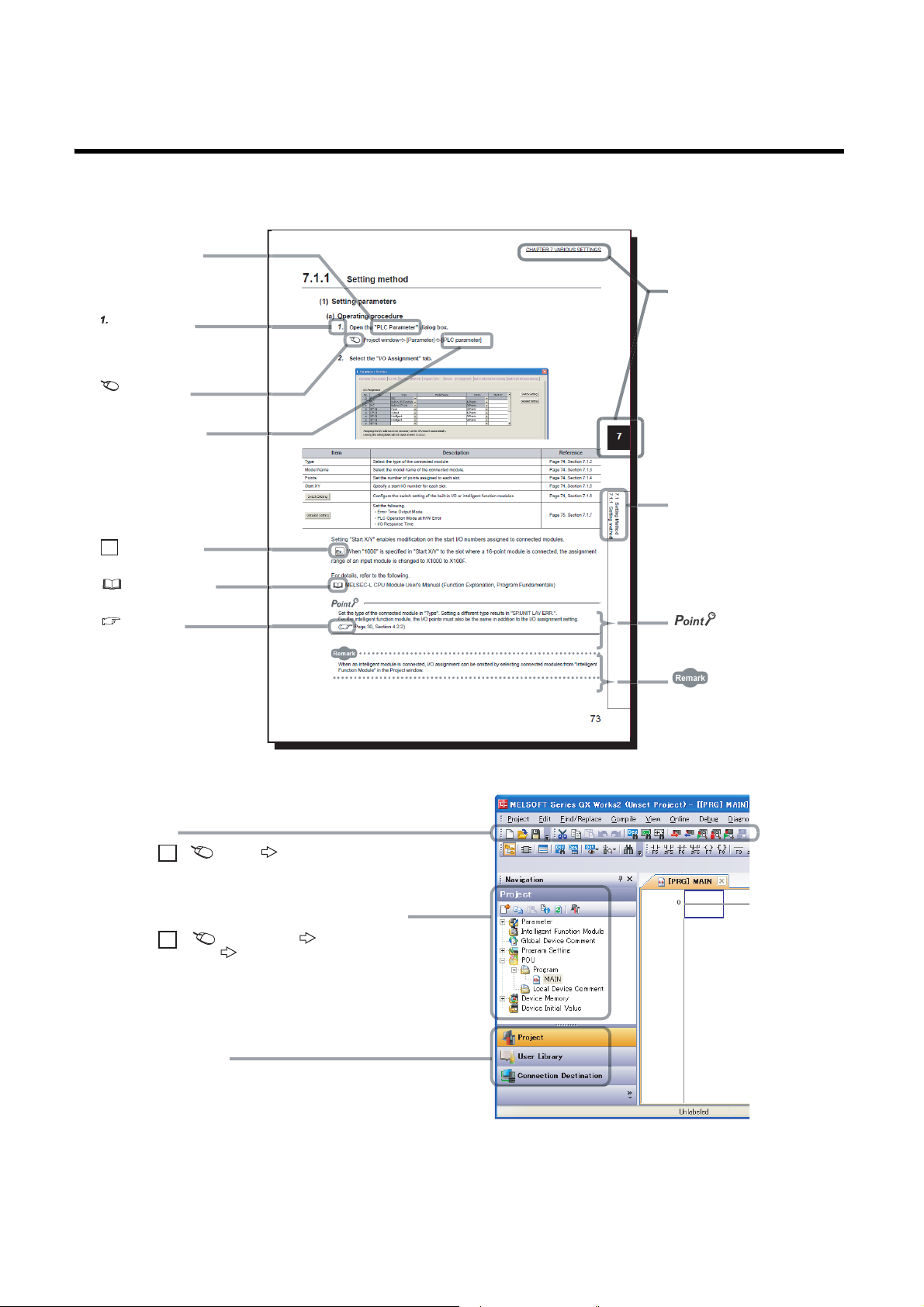

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

*1 The mouse operation example is provided below.

14

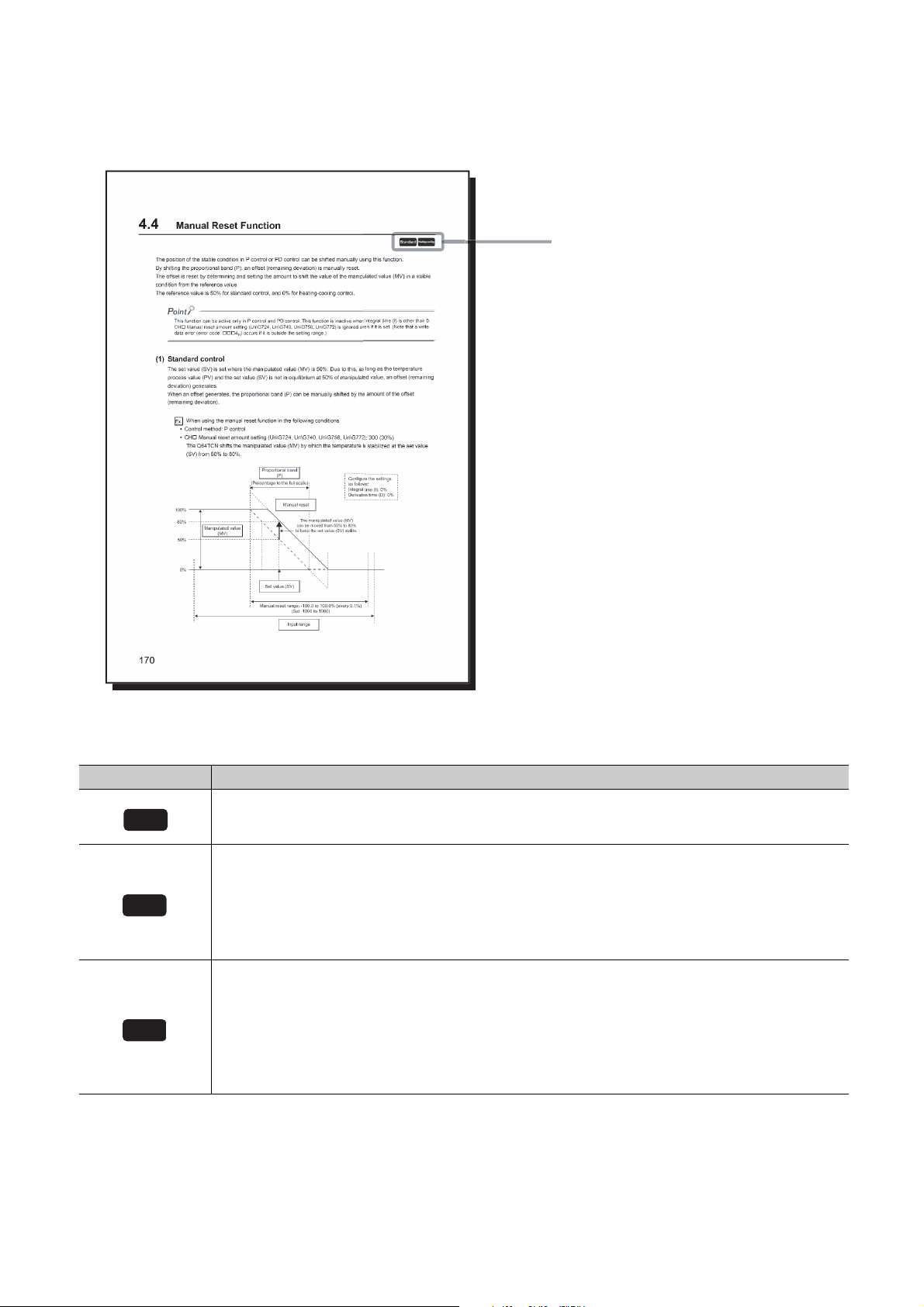

Pages describing buffer memory areas and functions are organized as shown below.

These icons indicate control modes

that can be used.

Common

Standard

Heating-cooling

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

The following table describes the meaning of each icon.

Icon Meaning

This icon means that the buffer memory area or function can be used in all control modes.

This icon means that the buffer memory area or function for temperature control can be used in the standard

control.

The buffer memory area and function can be used in the following control modes and channels:

• CH1 to CH4 in the standard control

• CH3 and CH4 in the mix control (normal mode)

• CH3 and CH4 in the mix control (expanded mode)

This icon means that the buffer memory or function for temperature control can be used in the heating-cooling

control.

The buffer memory area and function can be used in the following control modes and channels:

• CH1 and CH2 in the heating-cooling control (normal mode)

• CH1 to CH4 in the heating-cooling control (expanded mode)

• CH1 in the mix control (normal mode)

• CH1 and CH2 in the mix control (expanded mode)

15

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

Q64TCTTN The abbreviation for the Q64TCTTN temperature control module

Q64TCTTBWN

Q64TCRTN The abbreviation for the Q64TCRTN temperature control module

Q64TCRTBWN

Q64TCN A generic term for the Q64TCTTN, Q64TCTTBWN, Q64TCRTN, and Q64TCRTBWN

PID constants A generic term for the proportional band (P), integral time (I), and derivative time (D)

Temperature sensor A generic term for thermocouples and platinum resistance thermometers

Control method

Control mode

Fixed value action The operating status of when the set value (SV) is fixed

Full scale

Ramp action The operating status of when the set value (SV) is constantly changed

Number of loops

QCPU Another term for the MELSEC-Q series CPU module

Redundant CPU A generic term for the Q12PRHCPU and Q25PRHCPU

External input The abbreviation for input from connectors for external devices

External output The abbreviation for output to connectors for external devices

Programming tool A generic term for GX Works2 and GX Developer

GX Works2

GX Developer

GX Configurator-TC

Buffer memory

The abbreviation for the Q64TCTTBWN temperature control module with the

disconnection detection function

The abbreviation for the Q64TCRTBWN temperature control module with the

disconnection detection function

A generic term for two-position control, P control, PI control, PD control, and PID

control

A generic term for the standard control, heating-cooling control (normal mode),

heating-cooling control (expanded mode), mix control (normal mode), and mix control

(expanded mode)

A full input range. For example, when the selected input range is

-200.0°C to 400.0°C, the full scale is 600.0.

The number of feedback control systems (closed-loop control systems) that can be

configured using one module. Under the standard control, one loop consists of one

input and one output. Under the heating-cooling control, one loop consists of one input

and two outputs.

The product name of the software package for the MELSEC programmable

controllers

A setting and monitoring tool added in GX Developer (for temperature control

modules)

The memory of an intelligent function module used to store data (such as setting

values and monitored values) for communication with a CPU module

PACKING LIST

The following items are included in the package of this product.

Model Item name Quantity

Q64TCTTN Q64TCTTN temperature control module 1

Q64TCTTBWN Q64TCTTBWN temperature control module with the disconnection detection function 1

Q64TCRTN Q64TCRTN temperature control module 1

Q64TCRTBWN Q64TCRTBWN temperature control module with the disconnection detection function 1

Q64TCTTN/RTN-U-HW Before Using the Product 1

16

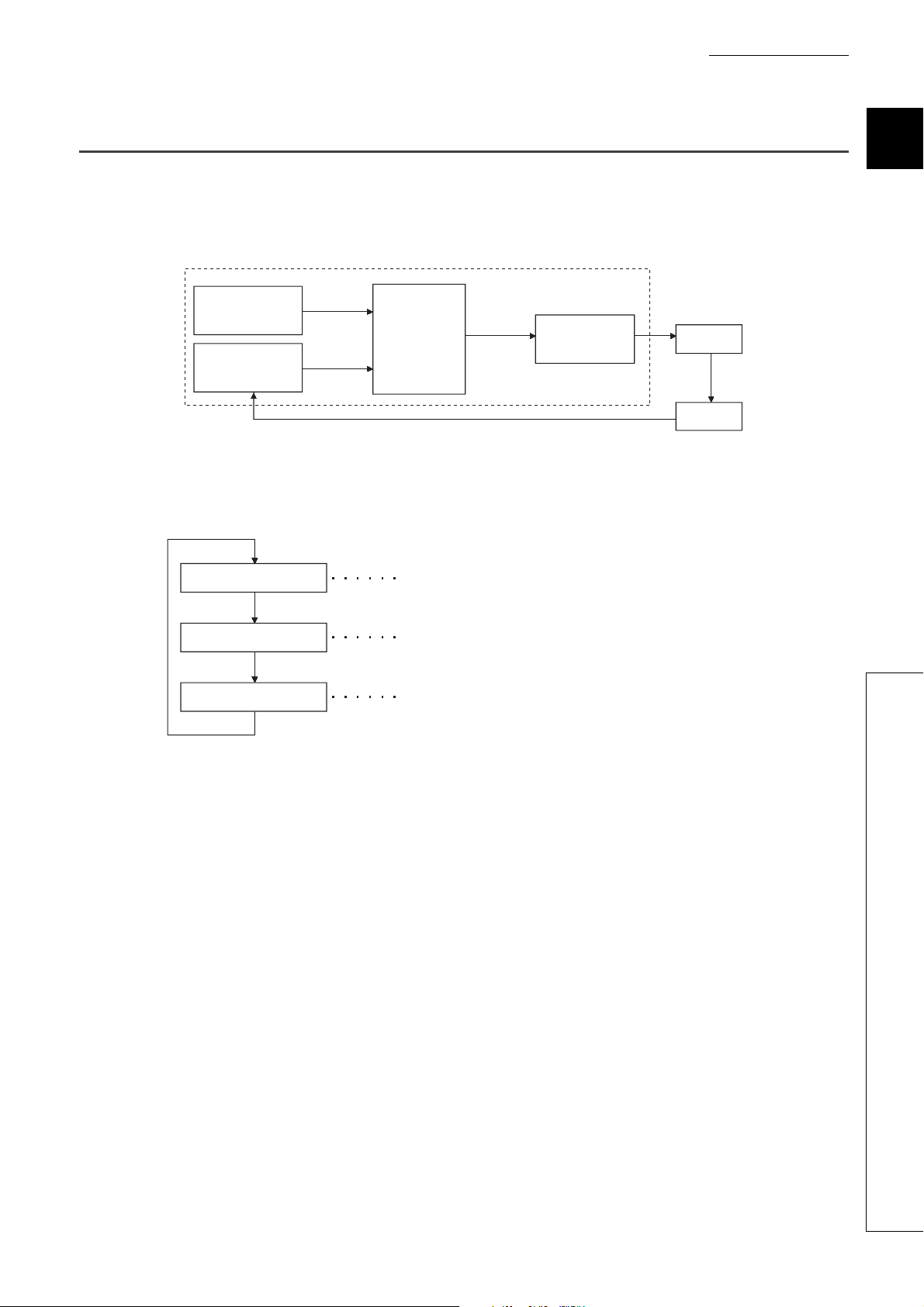

CHAPTER 1 OVERVIEW

Buffer memory

Programmable

controller CPU Q64TCTTN, Q64TCRTN

Initial

setting

(To instruction)

Set value (SV)

Set value (SV)

PID

operation

Temperature

process

value (PV)

Temperature

process

value (PV)

Manipulated

value (MV)

Manipulated

value (MV)

Temperature

Device to be

controlled

Input from temperature sensor

Transistor output

(ON/OFF pulse)

CH1

CH4

CH4

CH4

CH1

CH1

CH1

CH1

CH

Temperature

process value (PV)

(Un\G9 to Un\G12)

CH

Manipulated value

(MV)

(Un\G13 to Un\G16)

CH

Set value

(SV) setting

(Un\G34, Un\G66,

Un\G98, Un\G130)

This chapter describes the overview of the Q64TCN.

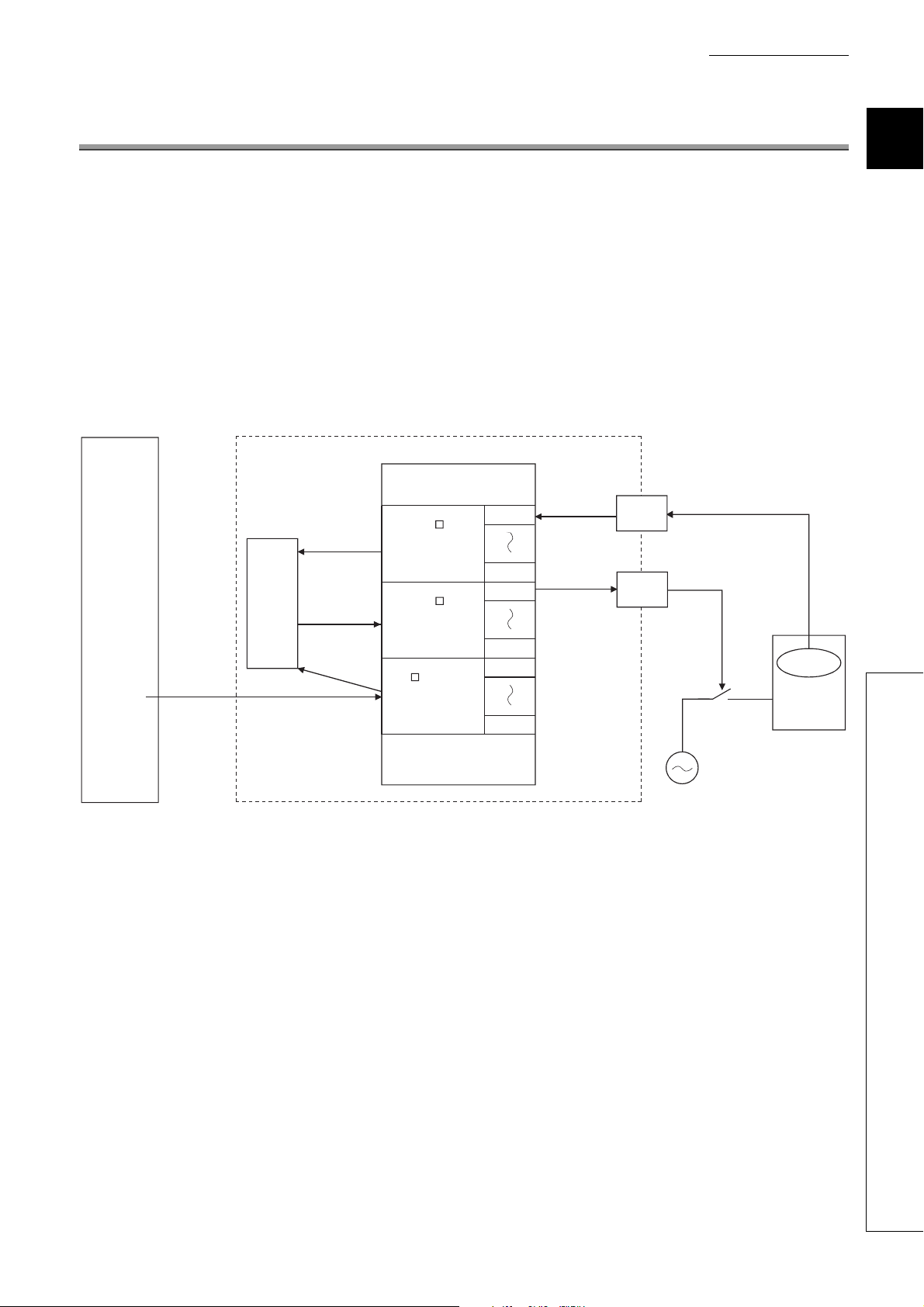

(1) The Q64TCTTN and Q64TCRTN

• The Q64TCTTN and Q64TCRTN perform PID operation to reach the target temperature based on input from

an external temperature sensor. The modules control temperature by transistor output.

• The Q64TCTTN and Q64TCRTN possess the auto tuning function by which proportional band (P), integral

time (I) and derivative time (D) for PID operation are automatically set.

• The Q64TCTTN accepts type K, J, T, B, S, E, R, N, U, L, PL II, and W5Re/W26Re thermocouples. The

Q64TCRTN accepts type Pt100 and JPt100 platinum resistance thermometers.

CHAPTER 1 OVERVIEW

1

17

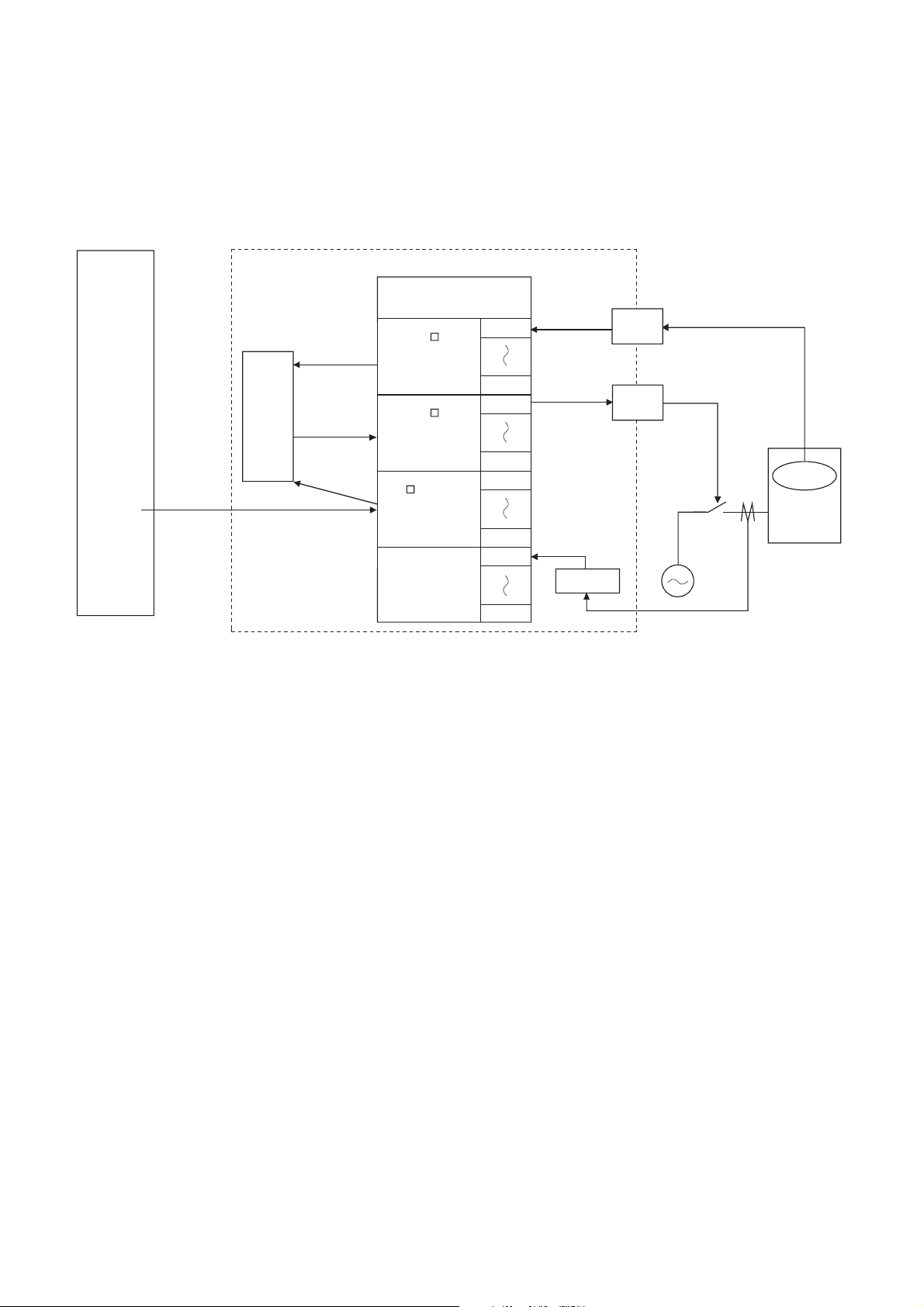

(2) The Q64TCTTBWN and Q64TCRTBWN

Buffer memory

Programmable

controller CPU

Initial

setting

(To instruction)

Set value (SV)

Set value (SV)

PID

operation

Temperature

process

value (PV)

Manipulated

value (MV)

Manipulated

value (MV)

Temperature

Device to be

controlled

Input from temperature sensor

Transistor output

(ON/OFF pulse)

CH1

CH4

CH4

CH4

CH1

CH1

CH1

CH1

Q64TCTTBWN, Q64TCRTBWN

CH4

CH1

Current

sensor

Disconnection

detection

Alarm

Temperature

process

value (PV)

CH

Temperature

process value (PV)

(Un\G9 to Un\G12)

CH

Manipulated value

(MV)

(Un\G13 to Un\G16)

CH

Set value

(SV) setting

(Un\G34, Un\G66,

Un\G98, Un\G130)

The Q64TCTTBWN and Q64TCRTBWN are Q64TCTTN and Q64TCRTN-based modules which possess an

additional function to detect heater disconnection using input from external current sensors.

18

CHAPTER 1 OVERVIEW

1.1 Features

(1) Optimum temperature adjustment control (PID control)

• The Q64TCN performs temperature adjustment control automatically when the user simply sets PID

constants necessary for PID operation: proportional band (P), integral time (I), derivative time (D), and

temperature set value (SV). No special instruction is necessary to perform PID control.

• Using the auto tuning function or self-tuning function enables the PID constants to be set automatically.

Complicated PID operational expressions to determine PID constants are not necessary.

(2) Selection of control mode

A control mode can be selected from the standard control (heating or cooling), heating-cooling control (heating

and cooling), or mix control (combination of the standard control and heating-cooling control).

(3) Four loops on one module

The maximum of four loops of temperature adjustment control can be performed simultaneously. In addition, loop

control can be performed using analog modules on the base unit or the network; input from an A/D converter

module or output to a D/A converter module can be processed.

(4) Simultaneous temperature rise of multiple loops

Temperatures of multiple loops can be adjusted to simultaneously reach the set value of each; temperatures are

controlled evenly without any partial heat exaggeration. This function saves energy and cost.

1

(5) Suppression of peak current

Current flows into a heater can be suppressed by controlling output so that each channel's output does not turn

on at the same time as other channels.

This function saves energy and cost.

(6) RFB limiter function

The RFB (Reset feed back) limiter suppresses overshoot which is liable to occur at a startup or when a

temperature process value (PV) is increased.

(7) Correction of temperature process value (PV)

The difference between the temperature process value (PV) and actual temperature can be corrected easily

using the following functions.

• Normal sensor correction (one-point correction) function: Corrects the difference by setting the rate of

correction value to the full scale of the input range.

• Sensor two-point correction function: Corrects the difference based on the inclination of the line on the two

points set in advance.

• Primary delay digital filter setting: Smoothens transient noise, and absorbs drastic change.

(8) E2PROM for backing up set values

The set values in the buffer memory, such as the setting related to PID control, can be stored into E2PROM for

data backup. The values do not need to be reset after turning the power on from off or releasing the CPU module

from its reset status.

Using the test function of the programming tool to write data directly to the buffer memory, the minimum

sequence program required is "LD**" + "OUT Yn1".

1.1 Features

19

(9) Detection of disconnection

Heater disconnection can be detected easily by the loop disconnection detection function.

The Q64TCTTBWN and Q64TCRTBWN can detect the disconnection of a heater accurately.

(10)Easy setting by GX Works2

Sequence program can be reduced by configuring the default setting or auto refresh setting on the screen. Also,

the setting status or operating status of the module can be checked easily.

20

CHAPTER 1 OVERVIEW

Set value data

storage area

Temperature

process value

data storage area

PID operation

Manipulated

value data storage

area

Temperature

sensor

Control

object

Q64TCN

Set value

(SV)

Temperature

process

value (PV)

Manipulated

value (MV)

Import a signal from the temperature sensor and write it to the temperature

process value data storage area as a temperature process value (PV).

Perform PID operation using the Set value (SV)/temperature process

value (PV) values in the set value/temperature process value data

storage area.

Convert manipulated value (MV) obtained by the PID operation to

transistor-output on time and output it.

Read the temperature

process value (PV)

Perform PID operation

Output the manipulated

value (MV)

1.2 The PID Control System

(1) PID control system

The following figure shows a system of when performing the PID control.

(2) PID control procedure

The PID control is performed in the following procedure.

1

1.2 The PID Control System

21

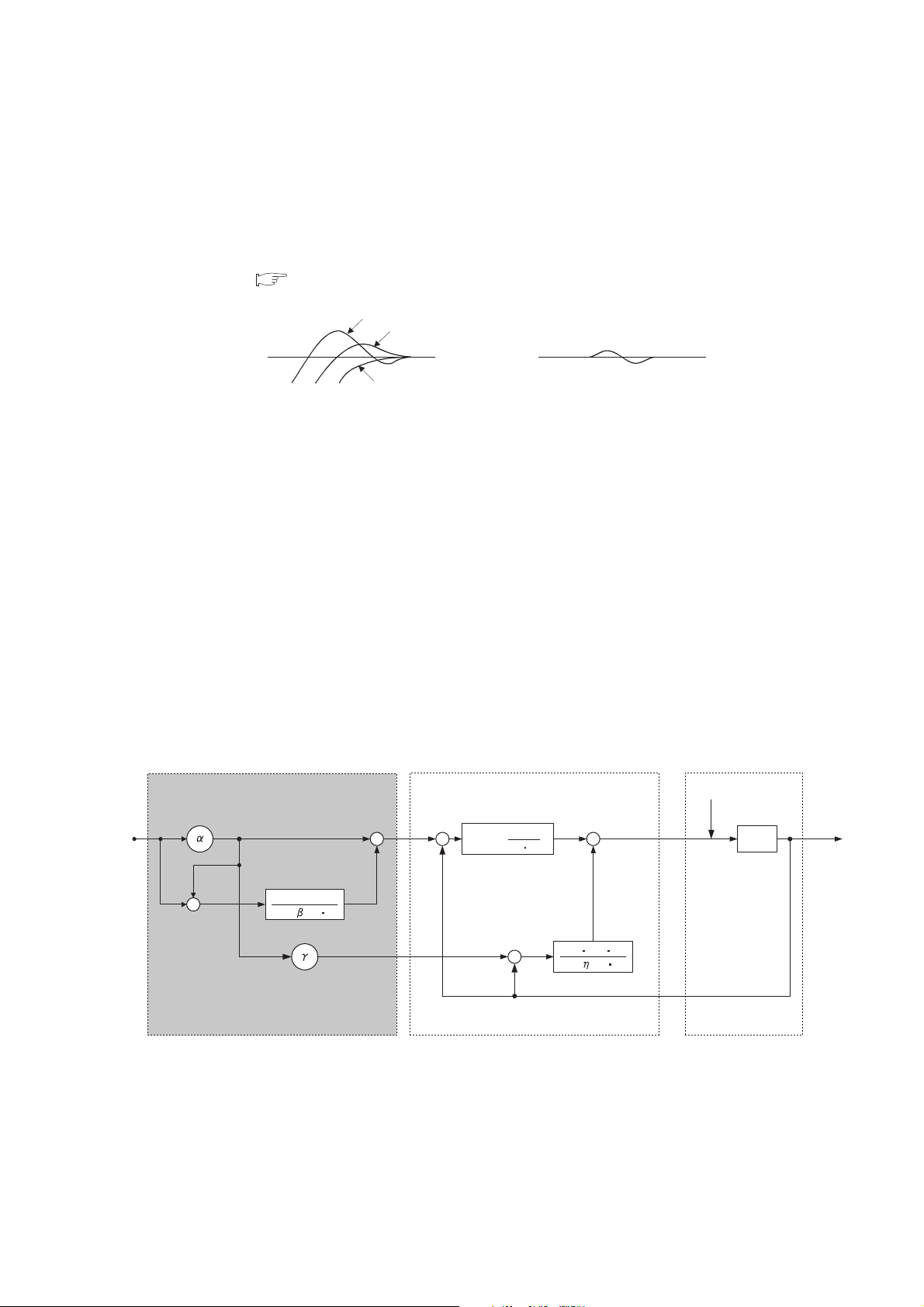

(3) PID control (simple two-degree-of-freedom)

PID control

Object to be

controlled

Disturbance D

1

1 + T

I s

1 + TD s

KP TD s

1

T

I s

KP (1 + )

Added function for two-degree-of-freedom

Manipulated

value (MV)

Set value

(SV)

G(s)

Temperature

process value (PV)

-

+

-

+

+

+

+

+

+

-

The Q64TCN operates in "simple two-degree-of-freedom". In this form of PID control, parameters are simplified

compared to the two-degree-of-freedom PID control.

In the simple two-degree-of-freedom, the module controls the target subject using not only PID constants but also

the control response parameter. The parameter can be set to "fast", "normal", or "slow". This setting enables the

form of "response to the change of the set value (SV)" to change maintaining "response to the disturbance" in a

good condition. ( Page 188, Section 4.7)

Fast

Normal

Set value

(SV)

Slow

Response to the change

of the set value (SV)

The following explains the difference between the one-degree-of-freedom PID control, two-degree-of-freedom

PID control, and simple two-degree-of-freedom PID control.

(a) One-degree-of-freedom PID control and two-degree-of-freedom PID control

• General PID control is called one-degree-of freedom PID control. In the one-degree-of freedom PID

control, when PID constants to improve "response to the change of the set value (SV)" are set, "response

to the disturbance" degrades. Conversely, when PID constants to improve "response to the disturbance"

are set, "response to the change of the set value (SV)" degrades.

• In the two-degree-of-freedom PID control, a manipulated value (MV) is determined considering the set

value (SV) or variations. In this form of PID control, "response to the change of the set value (SV)" and

"response to the disturbance" can be compatible with each other.

Set value

(SV)

Response to the disturbance

(b) Two-degree-of-freedom PID control and simple two-degree-of-freedom PID control

The following figure is a block diagram of the two-degree-of-freedom PID control.

By setting , , and above properly, optimum control can be achieved.

Note that required parameter settings increase and PID constants can hardly be auto-set by the auto tuning

function for complete two-degree-of-freedom PID control. Therefore, the Q64TCN operates in the simple two-

degree-of-freedom PID control for which parameters are simplified.

22

CHAPTER 1 OVERVIEW

Remark

Q64TCN

Control object

Slow

Normal

Fast

1

Disturbance D

G(s)

K

P TD s

1

TD s

Temperature

process value (PV)

Laplace transform conversion

DerivativeProportional gain

Integral time

Derivative time

Set value (SV)

K

P (1 )

Control response

parameters

TI s

KP

TI

TD

s

Manipulated

value (MV)

Sampling cycle

Incomplete derivative output

Temperature process value (PV)

Derivative time

Derivative

MV

n MVn 1

TD

(PV

n 1 PVn)

T

D

MVn 1

MV

PV

T

D

TD

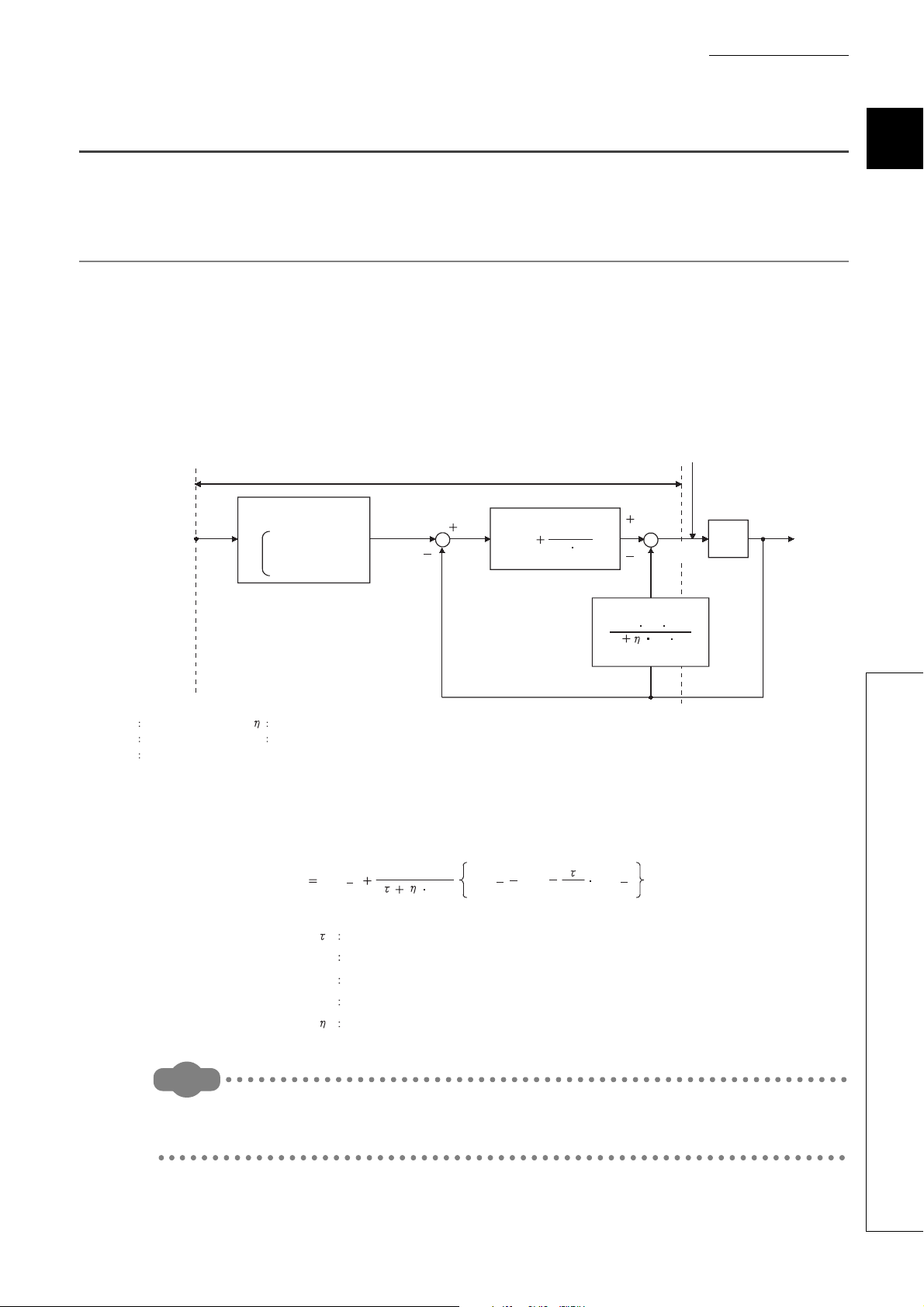

1.3 About the PID Operation

The Q64TCN can perform PID control in process-value incomplete derivation.

1.3.1 Operation method and formula

The PID control in process-value incomplete derivation is an operation method which puts a primary delay filter on

input from a derivative action and eliminate high-frequency noise component in order to perform a PID operation on

the deviation (E).

(1) Algorithm of PID control in process-value incomplete derivation

The algorithm of PID control in process-value incomplete derivation is shown below.

1

(2) Formula

The formula used for the Q64TCN is shown below.

The PID control in process-value derivation is an operation method which uses the process value (PV) for the derivation

section in order to perform a PID operation. Not using deviation for the derivation section, drastic output change due to a

derivative action is reduced when deviation varies along with the setting value change.

23

1.3 About the PID Operation

1.3.1 Operation method and formula

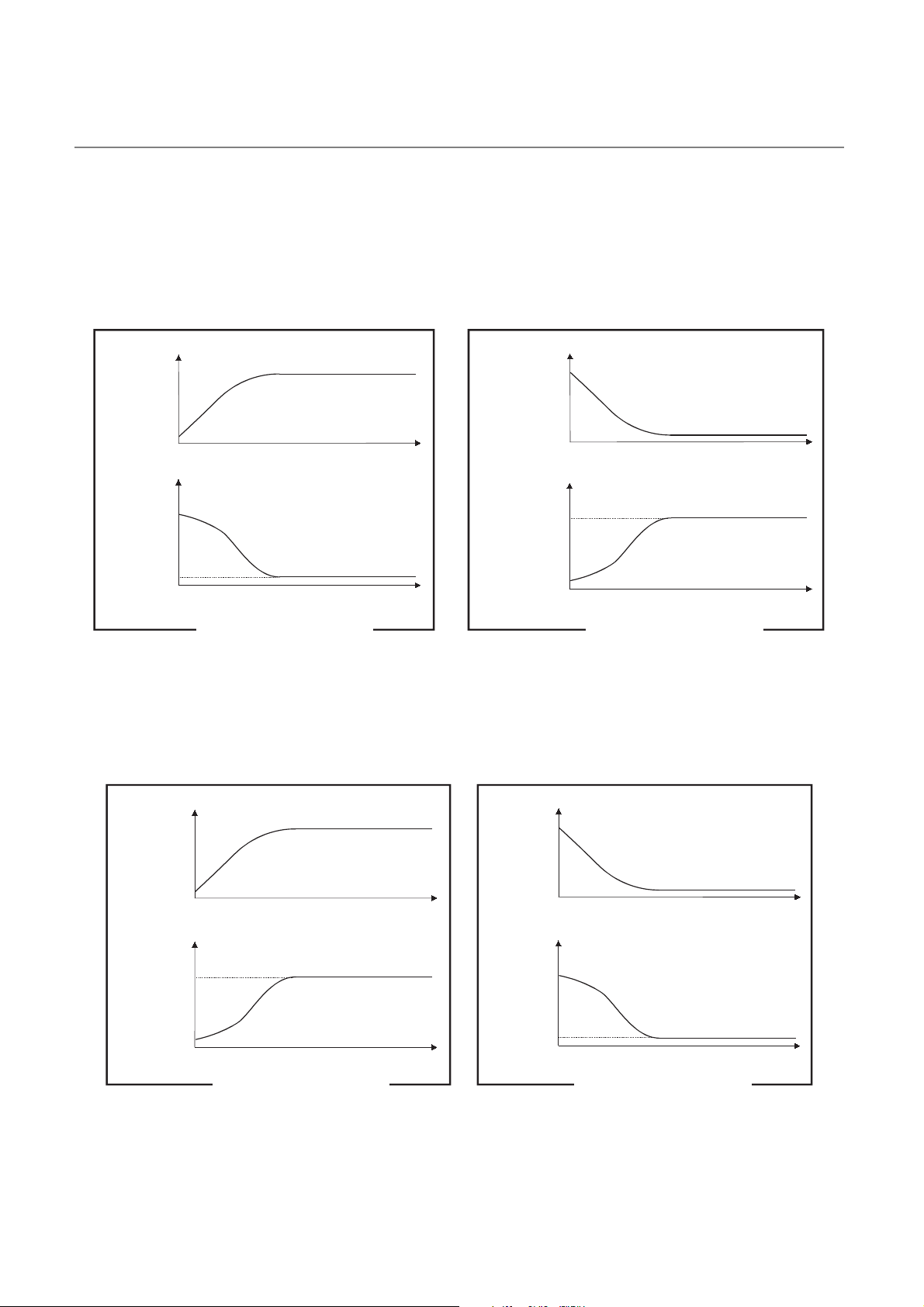

1.3.2 The Q64TCN actions

Manipulated

value

Manipulated

value

Temperature Temperature

Time

Time

Time

Time

Set value < Starting temperature Set value > Starting temperature

Set

value

Set

value

Manipulated

value

Temperature

Time

Time

Time

Time

Manipulated

value

Temperature

Set

value

Set value > Starting temperature Set value < Starting temperature

Set

value

The Q64TCN performs PID operations in forward actions and reverse actions.

(1) Forward action

In a forward action, the manipulated value (MV) is increased when the temperature process value (PV) increases

from the set value (SV).

A forward action is used for cooling control.

(2) Reverse action

In a reverse action, the manipulated value is increased when the temperature process value (PV) decreases from

the set value (SV).

A reverse action is used for heating control.

24

CHAPTER 1 OVERVIEW

E

Time

Time

Deviation

(E)

Manipulated

value (MV)

K

P E

Set value

(SV)

Set value

(SV)

Temperature process value (PV) Temperature process value (PV)

Offset

TimeTime

Offset

1.3.3 Proportional action (P-action)

A proportional action is an action to obtain the manipulated value (MV) proportional to the deviation (difference

between the set value (SV) and the process value (PV)).

(1) Proportional gain

In a proportional action, the relationship between changes in the deviation (E) and the manipulated value can be

expressed in the following formula:

MV = K

P•E

where Kp is a proportional constant and is called proportional gain. The manipulated value (MV) varies in the

range from -5.0% to 105.0%.

The following table describes the difference of actions depending on the value of Kp, proportional gain.

Condition Proportional action

Kp is a small value The control action slows down.

Kp is a large value

The following figure shows a proportional action of step responses where the deviation (E) is a fixed value.

The control action speeds up, though the temperature process value (PV) tends to

fluctuate around the set value.

1

(2) Offset

The certain amount of difference generates between the temperature process value (PV) and the set value (SV)

is called an offset (remaining deviation).

In an proportional action, an offset (remaining deviation) generates.

1.3 About the PID Operation

1.3.3 Proportional action (P-action)

25

1.3.4 Integral action (I-action)

An integral action is an action which continuously changes the manipulated value (MV) to eliminate the deviation (E)

when there is any.

The offset caused by a proportional action can be eliminated.

In an integral action, the time from a deviation occurrence until when the manipulated value (MV) of the integral action

becomes equals to that of the proportional action is called integral time, and is indicated as TI.

The following table describes the difference of actions depending on the value of T

Condition Integral action

TI is a small value

I is a large value The integral effect gets small, and time to eliminate the offset gets long.

T

The integral effect gets large, and time to eliminate the offset gets short.

Though, the temperature process value (PV) tends to fluctuate around the set value.

The following figure shows an integral action of step responses where the deviation (E) is a fixed value.

I, integral time.

Deviation

(E)

Manipulated

value (MV)

T

I

Time

K

P E

Time

E

Manipulated value of the Proportional action + Integral action

Manipulated value of the Integral action

Manipulated value of the Proportional action

An integral action is used as a PI action in combination with a proportional action, or PID action in combination with a

proportional and derivative actions.

An integral action cannot be used by itself.

26

CHAPTER 1 OVERVIEW

E

Manipulated value of the Proportional action

T

D

Time

Time

Deviation

(E)

Manipulated

value (MV)

K

P E

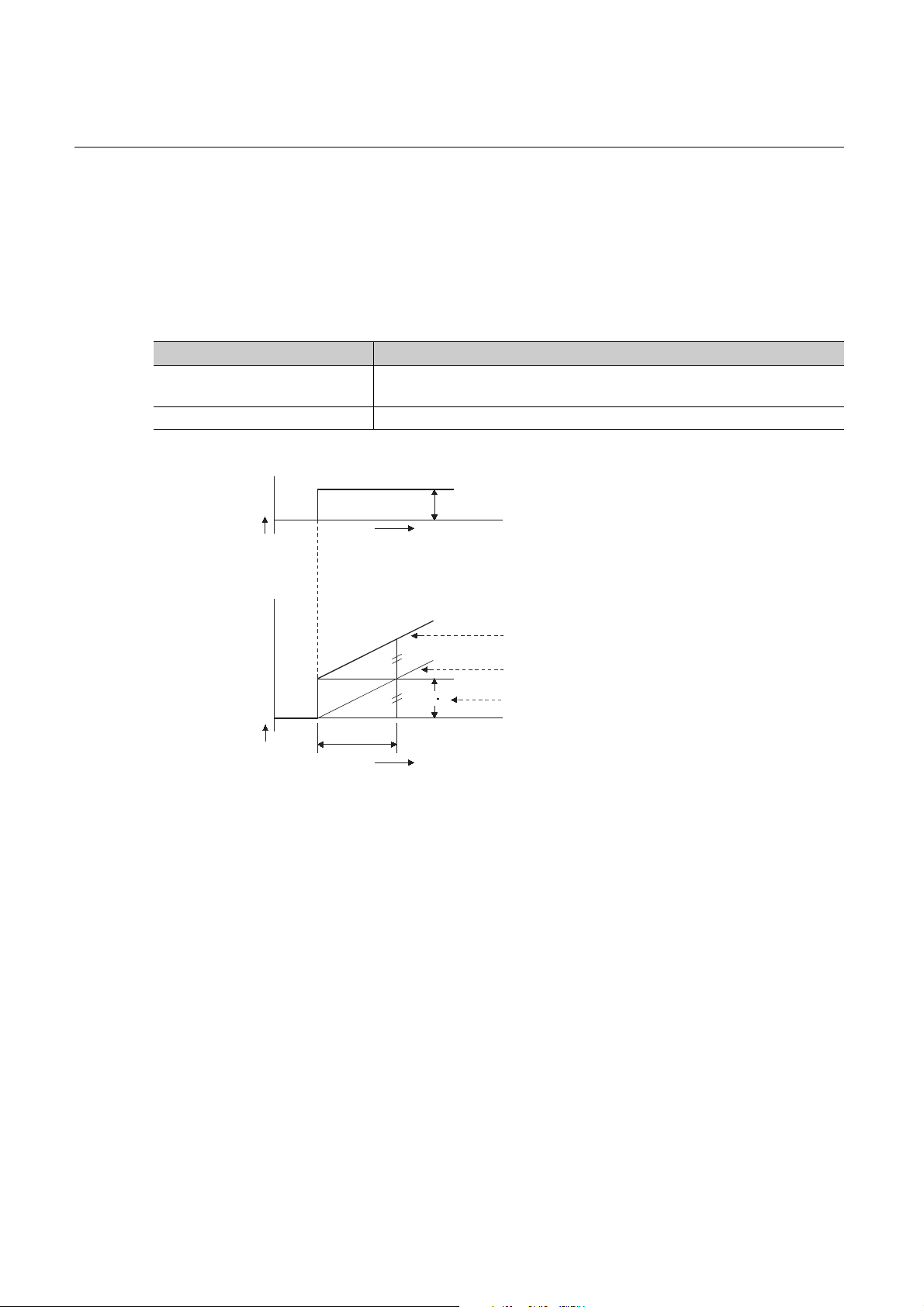

1.3.5 Derivative action (D-action)

A derivative action adds the manipulated value (MV) proportional to the rate of change to eliminate the deviation (E)

when it occurs.

A derivative action can prevent the control target from changing significantly due to disturbance.

In a derivative action, the time from a deviation occurrence until when the manipulated value (MV) of the derivative

action becomes equals to that of the proportional action is called derivative time, and is indicated as TD.

The following table describes the difference of actions depending on the value of T

Condition Derivative action

TD is a small value The derivative effect gets small.

The derivative effect gets large.

T

D is a large value

Though, the temperature process value (PV) tends to fluctuate around the set value

in short cycles.

The following figure shows a derivative action of step responses where the deviation (E) is a fixed value.

D, derivative time.

1

A derivative action is used as a PD action in combination with a proportional action, or PID action in combination with

a proportional and integral actions.

A derivative action cannot be used by itself.

1.3 About the PID Operation

1.3.5 Derivative action (D-action)

27

1.3.6 PID action

PID action

I action

P action

D action

PI action

Deviation

(E)

Manipulated

value (MV)

Time

Time

A PID action performs control using the manipulated value (MV) calculated by merging the proportional action, integral

action, and derivative action.

The following figure shows a PID action of step responses where the deviation (E) is a fixed value.

28

Loading...

Loading...