Page 1

BeneVision TMS60

Telemetry Monitoring System

Service Manual

Page 2

Page 3

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray)

owns the intellectual property rights to this product and this manual. This manual may

refer to information protected by copyrights or patents and does not convey any license

under the patent rights of Mindray, nor the rights of others. Mindray does not assume any

liability arising out of any infringements of patents or other rights of third parties.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the

written permission of Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rent, adaptation and translation of this

manual in any manner whatsoever without the written permission of Mindray is strictly

forbidden.

, and are the registered trademarks or trademarks

owned by Mindray in China and other countries. All other trademarks that appear in this

manual are used only for editorial purposes without the intention of improperly using

them. They are the property of their respective owners.

This posting serves as notice under 35 U.S.C.§287(a) for Mindray patents:

http://www.mindrayna.com/patents.

For this manual, the issued Date is January 2019 (Version: 4.0).

© 2015-2019 Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights reserved

WARNING

Federal Law (USA) restricts this device to sale by or on the order of a

physician or other practitioner licensed by U.S. state law to use or

order the use of this device..

NOTE

This manual describes all features and options. The equipment may not

have all of them. Contact Mindray service department for any questions.

BeneVision TMS60 Service Manual I

Page 4

Manufacturer’s Responsibility

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be

liable for errors contained herein nor for incidental or consequential damages in

connection with the furnishing, performance, or use of this manual.

Mindray is responsible for the effects on safety, reliability and performance of this

product, only if:

All installation operations, expansions, changes, modifications and repairs of

this product are conducted by Mindray authorized personnel;

The electrical installation of the relevant room complies with the applicable

national and local requirements;

The product is used in accordance with the instructions for use.

WARNING

This manual is for biomedical engineers or technicians responsible for

troubleshooting, repairing, and maintaining the telemetry monitoring

system.

II BeneVision TMS60 Service Manual

Page 5

Return Policy

In the event that it becomes necessary to return a unit to Mindray, follow the instructions

below.

1. Obtain a return authorization.

Contact the Mindray Service Department and obtain a Mindray Customer Service

Authorization Number. The Mindray Customer Service Authorization Number must

appear on the outside of the shipping container. Return shipments will not be accepted if

the Mindray Customer Service Authorization Number is not clearly visible. Please provide

the model number, serial number, and a brief description of the reason for return.

2. Freight policy

The customer is responsible for freight charges when this product is shipped to Mindray

for service (including any relevant customs fees or other freight related charges).

3. Return address

Please send the part(s) or equipment to the address offered by Customer Service

Department.

BeneVision TMS60 Service Manual III

Page 6

Contact Information

Manufacturer: Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address: Mindray Building, Keji 12th Road South, High-tech Industrial

park, Nanshan, Shenzhen 518057,P.R.China

Website: www.mindray.com

E-mail Address: service@mindray.com

Tel : +86 755 81888998

Fax: +86 755 26582680

Distributor: Mindray DS USA, Inc.

Address: 800 MacArthur Boulevard, Mahwah, New Jersey 07430, USA

Tel : 1.800.288.2121, 1.201.995.8000

Website: http://www.mindraynorthamerica.com/

IV BeneVision TMS60 Service Manual

Page 7

Contents

1 Safety .................................................................................................................. 1-1

1.1 Safety Information ...................................................................................................................... 1-1

1.1.1 Warnings ........................................................................................................................... 1-2

1.1.2 Cautions ............................................................................................................................ 1-2

1.1.3 Notes ................................................................................................................................. 1-2

1.2 Equipment Symbols ................................................................................................................... 1-3

2 Principles .................................................................................................................... 2-1

2.1 System Operating Principle ...................................................................................................... 2-1

2.2 Hardware Operating Principles ............................................................................................... 2-2

2.2.1 Transmitter Principle ..................................................................................................... 2-2

2.2.2 Overview .......................................................................................................................... 2-2

2.2.3 Receiver ............................................................................................................................ 2-3

2.2.4 Central Monitoring System (CMS) ............................................................................. 2-5

2.2.5 Central Charger ............................................................................................................... 2-5

2.3 Software Principles ..................................................................................................................... 2-8

2.3.1 Transmitter Software System ...................................................................................... 2-8

2.3.2 Receiver System Software ............................................................................................ 2-9

3 Receiver Physical Views .............................................................................................. 3-1

3.1 Front View ..................................................................................................................................... 3-1

3.2 Rear View ....................................................................................................................................... 3-2

3.3 Restoring Latest Configuration Automatically .................................................................... 3-3

4 BP10 Physical Views ................................................................................................... 4-1

4.1 Front View ..................................................................................................................................... 4-1

4.2 Side View ....................................................................................................................................... 4-2

4.3 Top Vie w ........................................................................................................................................ 4-3

5 Central Charger Physical Views .................................................................................. 5-1

5.1 Front View ..................................................................................................................................... 5-1

5.2 Rear View ....................................................................................................................................... 5-1

6 Maintenance ............................................................................................................... 6-1

6.1 Recommended Maintenance and Test Frequency ............................................................. 6-2

6.2 Parameter Tests ............................................................................................................................ 6-3

6.2.1 ECG Test s .......................................................................................................................... 6-3

6.2.2 Resp Test ........................................................................................................................... 6-4

6.2.3 SpO2 Tes t ........................................................................................................................... 6-5

6.2.4 NIBP Tests ......................................................................................................................... 6-6

6.3 Miscellaneous Tests .................................................................................................................... 6-9

BeneVision TMS60 Service Manual 1

Page 8

6.3.1 Visual Inspection ............................................................................................................ 6-9

6.3.2 Power-On Te st ................................................................................................................. 6-9

6.3.3 Nurse Call Test ................................................................................................................. 6-9

6.3.4 Electric Safety Test....................................................................................................... 6-10

6.3.5 Network Print Test ....................................................................................................... 6-10

6.3.6 Battery Check ............................................................................................................... 6-10

6.3.7 Tests in Service Menu ................................................................................................. 6-10

7 Service Menu .............................................................................................................. 7-1

7.1 Entering the Service Menu ....................................................................................................... 7-1

7.2 Performing Software Update ................................................................................................... 7-1

7.3 Service Log ................................................................................................................................... 7-1

7.4 Fa cto ry Test ................................................................................................................................... 7-1

7.4.1 Device Test ....................................................................................................................... 7-1

7.4.2 Screen Test ....................................................................................................................... 7-2

7.4.3 Tou ch Scr een Te st ........................................................................................................... 7-2

7.4.4 Keys Test ........................................................................................................................... 7-2

7.4.5 Sound & Light Test ......................................................................................................... 7-3

7.4.6 USB Interface Test .......................................................................................................... 7-3

7.4.7 System Watchdog Test .................................................................................................. 7-3

7.4.8 MO Module Watchdog Test ......................................................................................... 7-3

7.4.9 Bluetooth Module Test.................................................................................................. 7-4

7.4.10 Processing Method ...................................................................................................... 7-4

7.5 Checking System Software Version ........................................................................................ 7-5

8 Troubleshooting ......................................................................................................... 8-1

8.1 Telemetry Monitoring System Problems ............................................................................... 8-1

8.1.1 Troubleshooting Tools .................................................................................................. 8-1

8.1.2 Technical Alarm Messages ........................................................................................... 8-1

8.1.3 Error Codes ...................................................................................................................... 8-3

8.1.4 Other Failures .................................................................................................................. 8-7

8.1.5 Failure Examinations ..................................................................................................... 8-9

8.2 Central Charger Problems ...................................................................................................... 8-25

9 Parts ........................................................................................................................... 9-1

9.1 Transmitter (P/N 115-029485-00/115-047566-00).............................................................. 9-1

9.1.1 Exploded View of Main Unit ........................................................................................ 9-1

9.2 Receiver (P/N 115-029486-00) ................................................................................................. 9-5

9.2.1 Exploded View of Receiver ........................................................................................... 9-5

9.2.2 Front Cover Assembly of Receiver ............................................................................. 9-8

9.2.3 Power Assembly of Receiver ....................................................................................... 9-9

9.2.4 Amplifying and Branching Assembly of Receiver (P/N 0152-30-39691) ...... 9-10

9.2.5 Active Antenna (P/N 115-059711-00) .................................................................... 9-11

9.2.6 4-Channel Receiver Module Assembly (P/N 115-029487-00) .......................... 9-12

9.3 Power Injector (P/N 115-035637-00) ................................................................................... 9-13

9.4 Signal Switching Box (P/N 115-020216-00) ....................................................................... 9-14

2 BeneVision TMS60 Service Manual

Page 9

9.5 BP 10 (P/N 115-047557-00) .................................................................................................... 9-15

9.5.1 BP10 Front Housing Assembly................................................................................. 9-15

9.5.2 BP10 Rear Housing Assembly .................................................................................. 9-16

9.5.3 BP10 Main Unit ............................................................................................................ 9-17

9.6 Exploded View of Central Charger (PN:115-030108-00) ................................................ 9-18

9.7 Miscellaneous: .......................................................................................................................... 9-19

A Electrical Safety Inspection ....................................................................................... A-1

A.1 Power Cord Plug ........................................................................................................................ A-1

A.2 Device Enclosure and Accessories ........................................................................................ A-2

A.3 Device Labeling ......................................................................................................................... A-2

A.4 Scheduled Electrical Safety Inspection ............................................................................... A-2

A.5 Electrical Safety Inspection after Repair ............................................................................. A-2

A.6 Electrical Safety Inspection Form ......................................................................................... A-3

BeneVision TMS60 Service Manual 3

Page 10

This page intentionally left blank.

4 BeneVision TMS60 Service Manual

Page 11

1 Safety

1.1 Safety Information

WARNING

Indicates a potential hazard or unsafe practice that, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potential hazard or unsafe practice that, if not avoided, could

result in minor personal injury or product/property damage.

NOTE

Provides application tips or other useful information to ensure that you

get the most from your product.

BeneVision TMS60 Service Manual 1-1

Page 12

1.1.1 Warnings

WARNING

There is high voltage inside the system. Never disassemble the system

before it is disconnected from the AC power source.

The system must be connected to a properly installed power outlet with

protective earth contacts only. If the installation does not provide for a

protective earth conductor, disconnect it from the power line.

To completely disconnect the power supply, unplug the power cord.

To avoid the electric shock, disassemble the central charger after the

central charger is disconnected from the AC power source for five minutes

la ter.

Dispose of the package material, observing the applicable waste control

regulations and keeping it out of children’s reach.

1.1.2 Cautions

CAUTION

Make sure that no electromagnetic radiation interferes with the

performance of the system when preparing to carry out performance tests.

Mobile phone, X-ray equipment or MRI devices are a possible source of

interference as they may emit higher levels of electromagnetic radiation.

Before connecting the system to the power line, check that the voltage and

frequency ratings of the power line are the same as those indicated on the

system’s label or in this manual.

Protect the system from damage caused by drop, impact, strong vibration

or other mechanical force during servicing.

1.1.3 Notes

NOTE

Refer to Operator’s Manual for detailed operation and other information.

1-2 BeneVision TMS60 Service Manual

Page 13

1.2 Equipment Symbols

See TMS60 Telemetry Monitoring System/TM80 Telemetry Monitor Operator’s Manual

for information about the symbols used on this product and its packaging.

BeneVision TMS60 Service Manual 1-3

Page 14

This page intentionally left blank.

1-4 BeneVision TMS60 Service Manual

Page 15

2 Principles

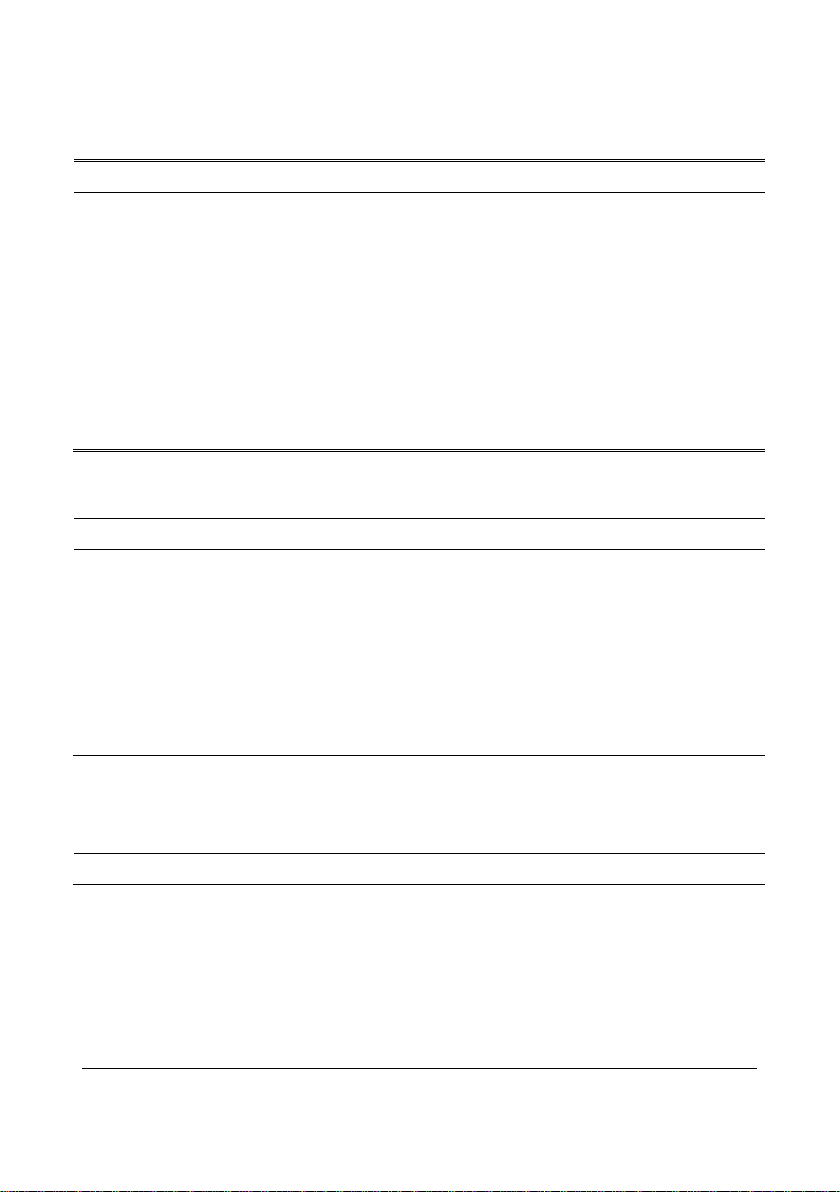

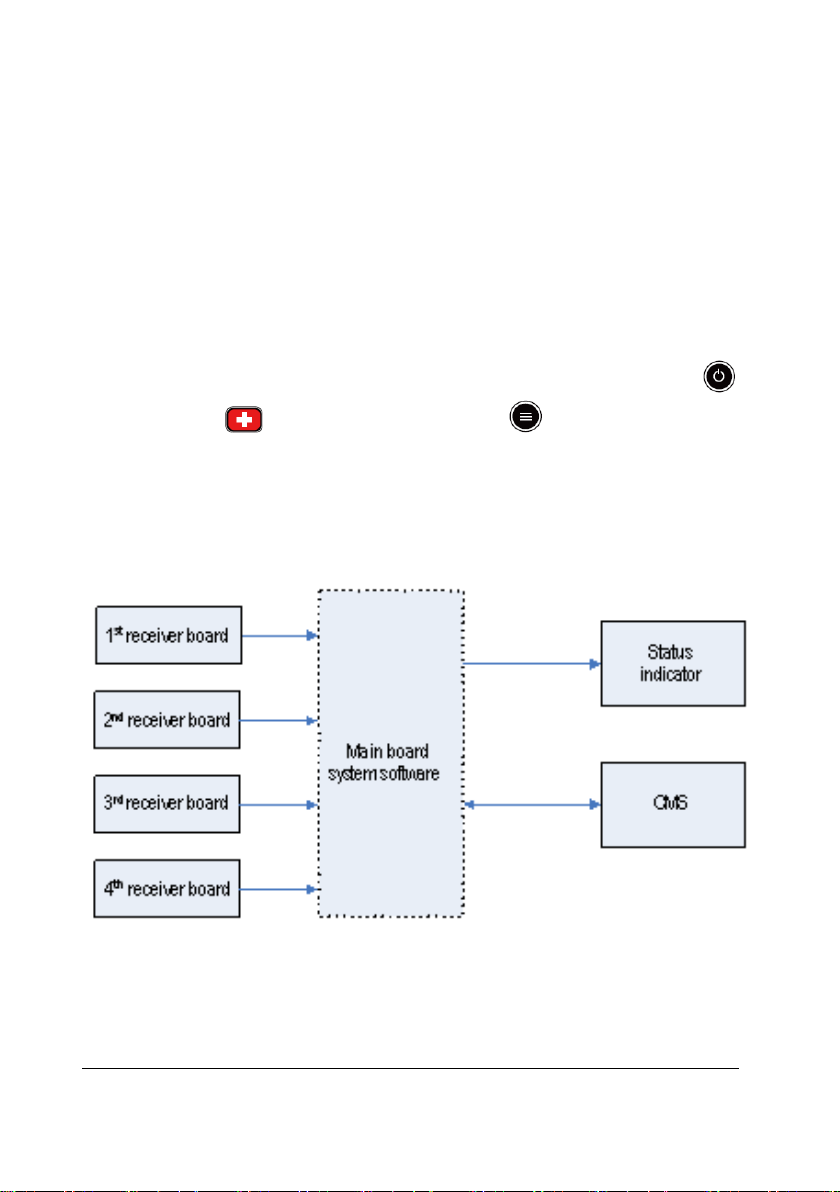

2.1 System Operating Principle

TMS60 is a digital telemetry monitoring system consisting of the transmitter (TD60), the

receiver (RC60), the antenna array. The transmitter sends the patient’s physiological

information to the receiver, which then transmits the information to the Central

Monitoring System (CMS) for analysis, displaying, storage and printing. The transmitter is

attached to the patient, whereas the receiver is used together with the CMS. TMS60

telemetry monitoring system is intended to monitor and display a fixed set of parameters

including ECG, Resp, SpO

module, SpO

The following is a simple illustration:

module, and NIBP module are optional.

2

, N IB P, HR and PR under hospital environments. The Resp

2

Figure 2-1 TMS60 Telemetry Monitoring System Diagram

NOTE

The distance between the TD60 and the antenna should be at least one

meter.

BeneVision TMS60 Service Manual 2-1

Page 16

WMTS IC

TCXO

12.8

M

LDO

Match

LPF

PLL

MCU

ECG circuit

SpO2

connector

ECG

leadwire

Externally

connecting with

SpO2

module

Power

Circuit

Display and

Control Module

Bluetooth

module

Antenna

NIBP module

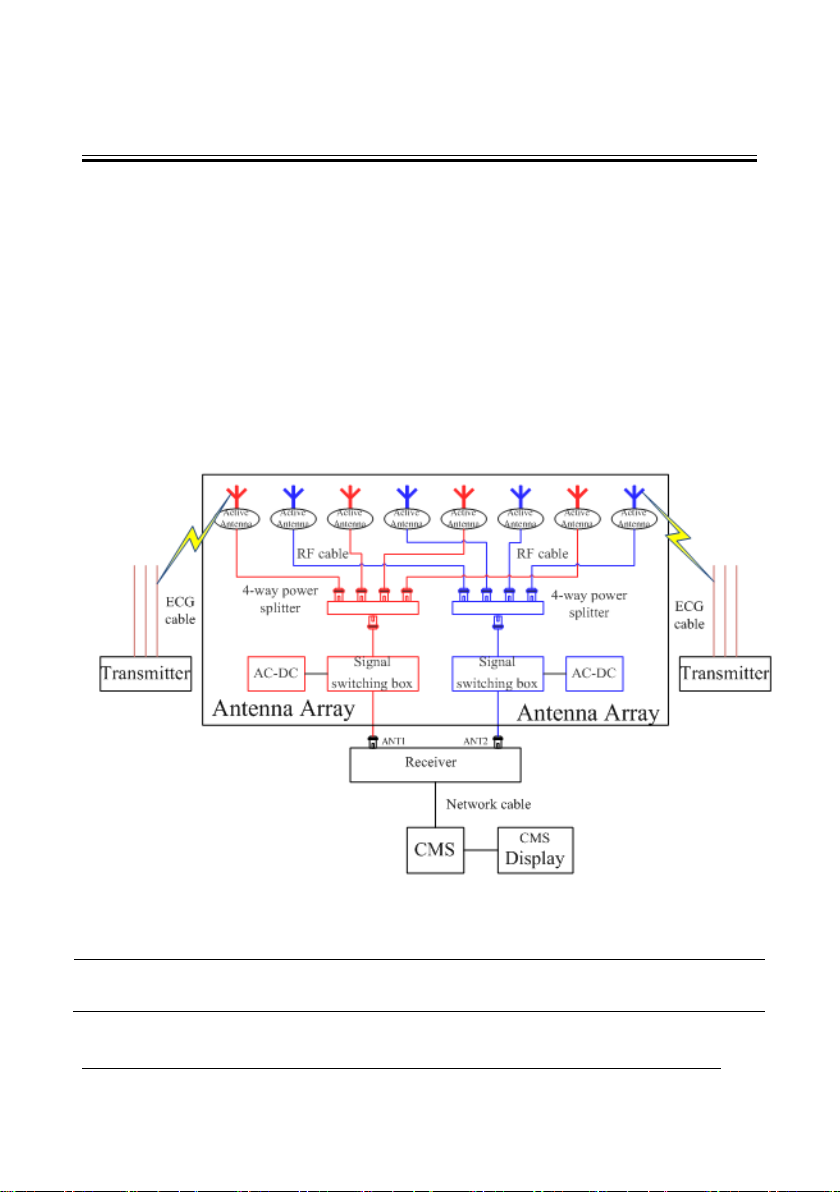

2.2 Hardware Operating Principles

2.2.1 Transmitter Principle

Figure 2-2 Transmitter Principle Diagram

2.2.2 Overview

The transmitter mainly consists of the MCU, ECG circuit, SpO2 connector, WMTS circuit,

Bluetooth module, Power Circuit, and Display and Control Module.

The ECG circuit provides the amplified ECG signals, which supports 3-lead and 5-lead

modes.

SpO

module is externally connected to the transmitter.

2

WMTS circuit is to send ECG data, SpO2 data and status information out .The shielding

layer of the ECG lead is the transmitter antenna.

Bluetooth module is used to transfer configuration between the transmitters.

The Display and Control Module consists of a LCD, a touch screen, a LED indicator, a

speaker, and three keys. It is used to display ECG, SpO

etc, and allow users to control transmitter.

2-2 BeneVision TMS60 Service Manual

waveforms and transmitter status,

2

Page 17

The MCU circuit is the core of the transmitter, enabling the following functions:

Button signal detection

SpO

connector

2

Status detection, such as ECG overload detection, lead off detection, PACE

detection, etc.

ECG data processing

MWTS circuit control and Baseband signal generation

Bluetooth module control

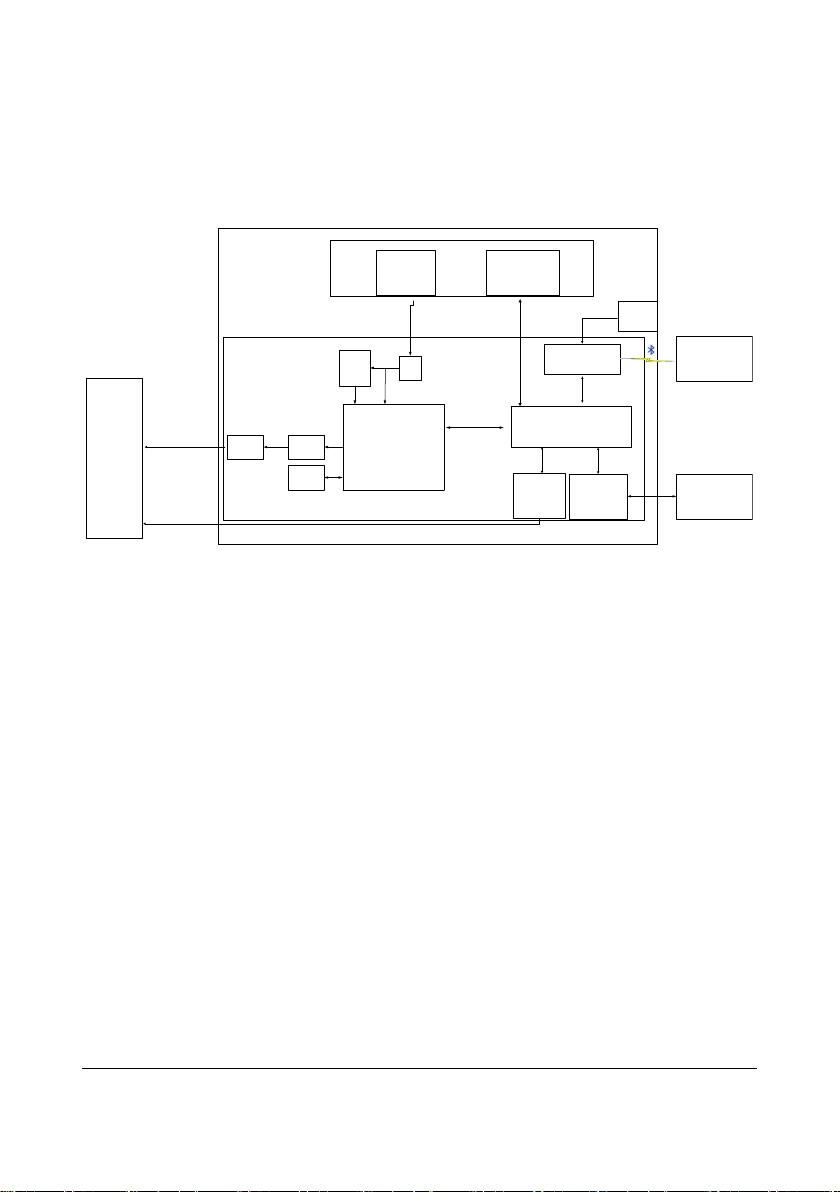

2.2.3 Receiver

2.2.3.1 Principle Diagram

Figure 2-3 Receiver Principle Diagram

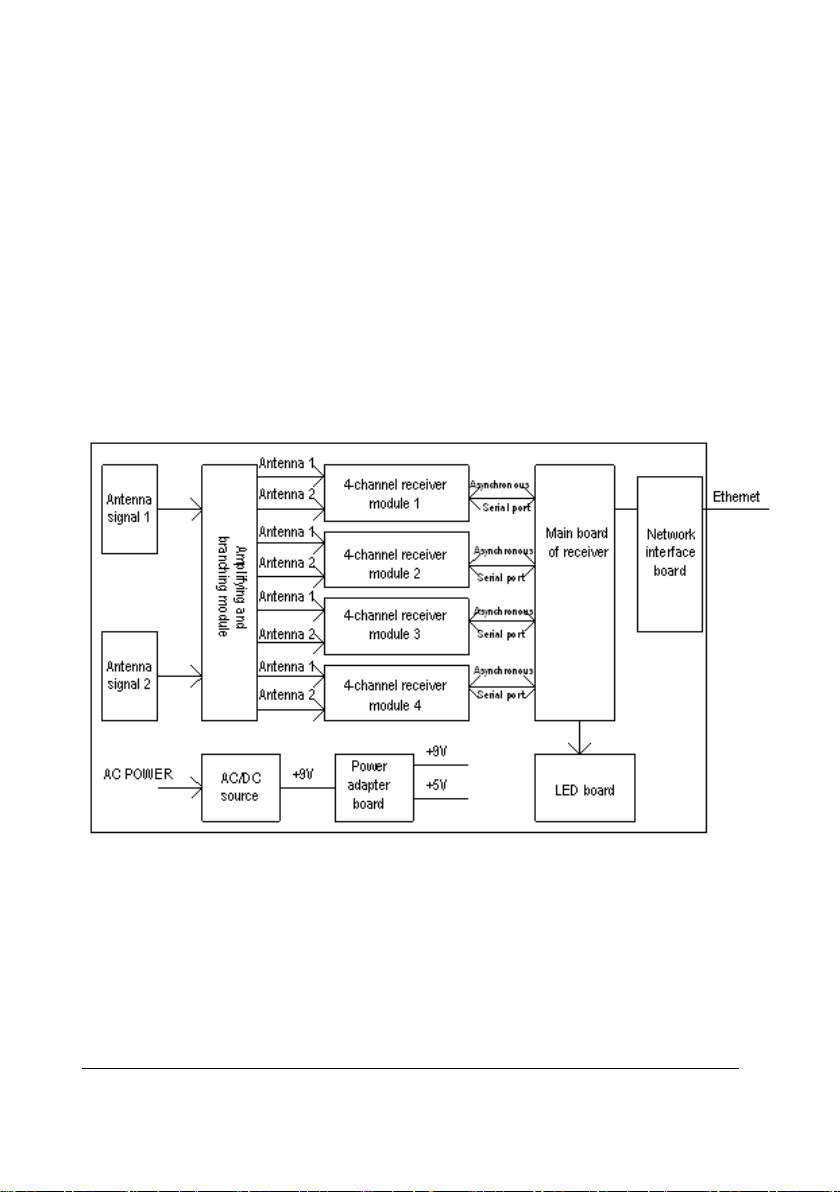

The receiver comprises the AC/DC power source, power adapter board, amplifying and

branching module, 4-channel receiver, LED board, main control board and network

interface board.

BeneVision TMS60 Service Manual 2-3

Page 18

2.2.3.2 AC/DC Source

The AC/DC source is to convert the externally inputted AC source into a 9V DC by means

of isolation. The inputted AC voltage range is from 90V to 264V, and the outputted

voltage/current is 9V/6.5A.

2.2.3.3 Power Adapter Board

The power adapter board is to drop the 9V DC coming from the AC/DC source to a 5V DC

and then output it with the 9V DC.

2.2.3.4 Amplifying and Branching Module

The amplifying and branching module is to amplify, filter and branch RF signals. The

module allows two amplifying, filtering & branching circuits with circuit parameters in full

symmetry. Each circuit amplifies, filters and branches the RF signals received by its

corresponding antenna and then outputs 4 channels of RF signals. Therefore, there are a

total of 8 channels of RF signals, which are then sent to the 4-channel receiver for

processing. The 9V DC linearly drops down to an 8V DC, which then goes to the

amplifying and branching module. The antenna array is shared by all receiving modules.

Therefore, in order to compensate for the branching attenuation of the signal, a LNA (low

noise amplification) is added before the branch divider. Besides, to avoid that the LNA is

blocked by strong out-band signal interference, filtering circuits shall be added in front of

and behind the LNA.

2.2.3.5 4-Channel Receiver

The 4-channel receiver divides the two channels of antenna signals coming from the

amplifying and branching module into four channels of RF signals through the 4-channel

branch divider. The MCU of the 4-channel receiving board will estimate the received

signal strength (RSSI) and then select the corresponding antenna signals through the

antenna switch. The selected signals will be respectively sent to the receiving modules for

filtering, amplifying, mixing, filtering and demodulating. The demodulated 4-channel

analog signals will then be sent to the MCU system for clock and data regenerating. The

regenerated data is packed by CPU and then delivered via the asynchronous serial port to

the main control board for processing. The 9V DC linearly drops down to an 8V DC, which

is then stabilized into a 5V and a 3.5 V supplying power for the 4-channel receiver.

2.2.3.6 Main Control Board

After receiving the data coming from the 4-channel receiving board, the main control

board will pack them and then delivers them to theCMS through the Ethernet. The

speaker of the main control board will give a short beep when the initialization is over,

and will beep continuously when an initialization failure or a hardware fault occurs.

2-4 BeneVision TMS60 Service Manual

Page 19

1

2.2.3.7 LED Board

The LED board has two green LEDs, respectively indicating the power status and the

communication status of the receiving module.

2.2.3.8 Network Interface Board

The interface between the main control board and Ethernet consists of the network

isolating transformer and interface connector.

2.2.4 Central Monitoring System (CMS)

BeneVision Central Monitoring System comprises powerful system software and

high-performance computer components. It constructs a monitoring network by

connecting monitors and telemetry transmitters. By collecting, processing, analysing and

outputting the information coming from monitors and telemetry transmitters, the CMS

can achieve centralized monitoring over multiple patients so as to greatly promote the

efficiency and quality of the monitoring work.

The CMS is capable of connecting up to 32 telemetry transmitters.

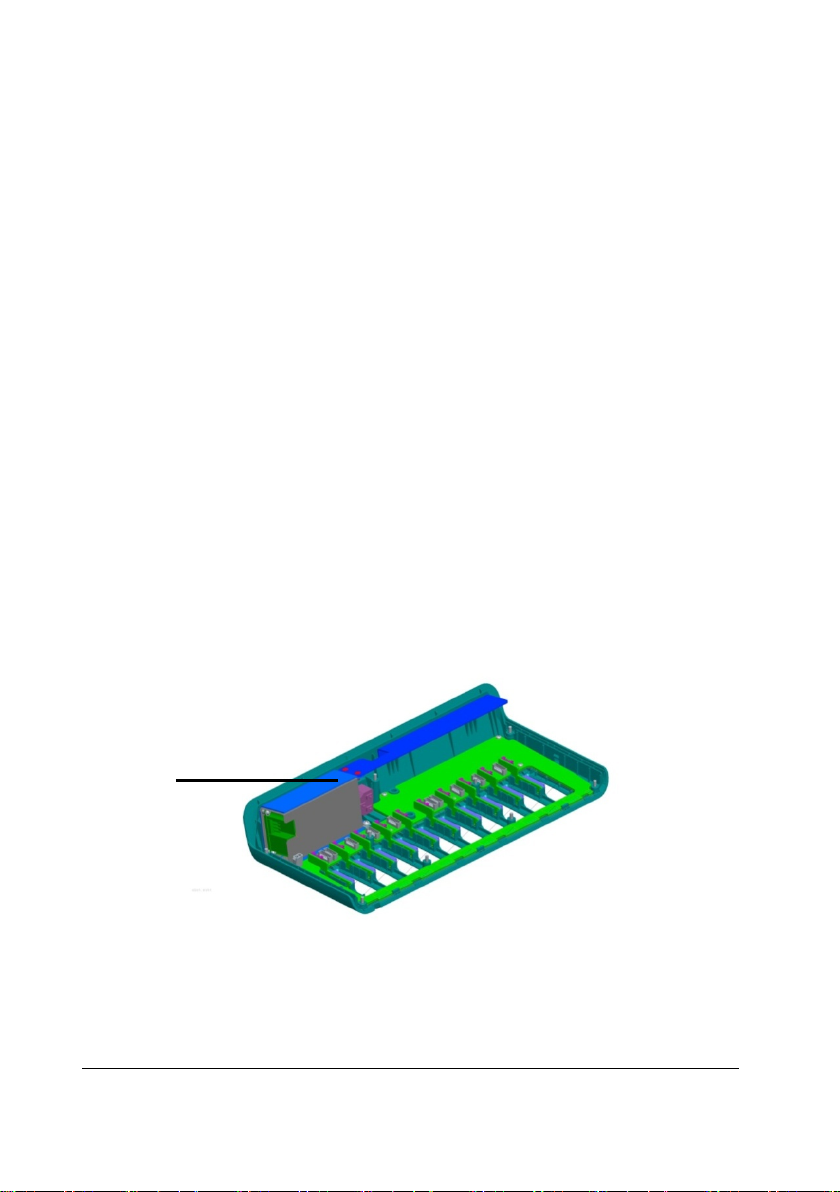

2.2.5 Central Charger

The central charger inner structure consists of three boards, as shown in Figure 2-4:

BeneVision TMS60 Service Manual 2-5

Page 20

2

3

Figure 2-4 Central Charger Inner Structure

1. AC-DC board (one)

Switching the AC circuit to the DC circuit.

2. Main board (one)

Including the charge circuit, MCU, and LED indicator.

3. Battery interface board (10)

Switching the circuit from the battery contact terminal to the main board.

Three kinds of wires connect with those boards:

AC-DC socket + wire (P/N 0651-20-76879)

The wire connects the AC socket and the AC-DC board.

Main board wire (P/N 009-003327-00)

The wire connects the AC-DC board and the main board.

Battery interface board wires (10) (P/N 009-003325-00)

The wires connect the main board and the battery interface boards.

2-6 BeneVision TMS60 Service Manual

Page 21

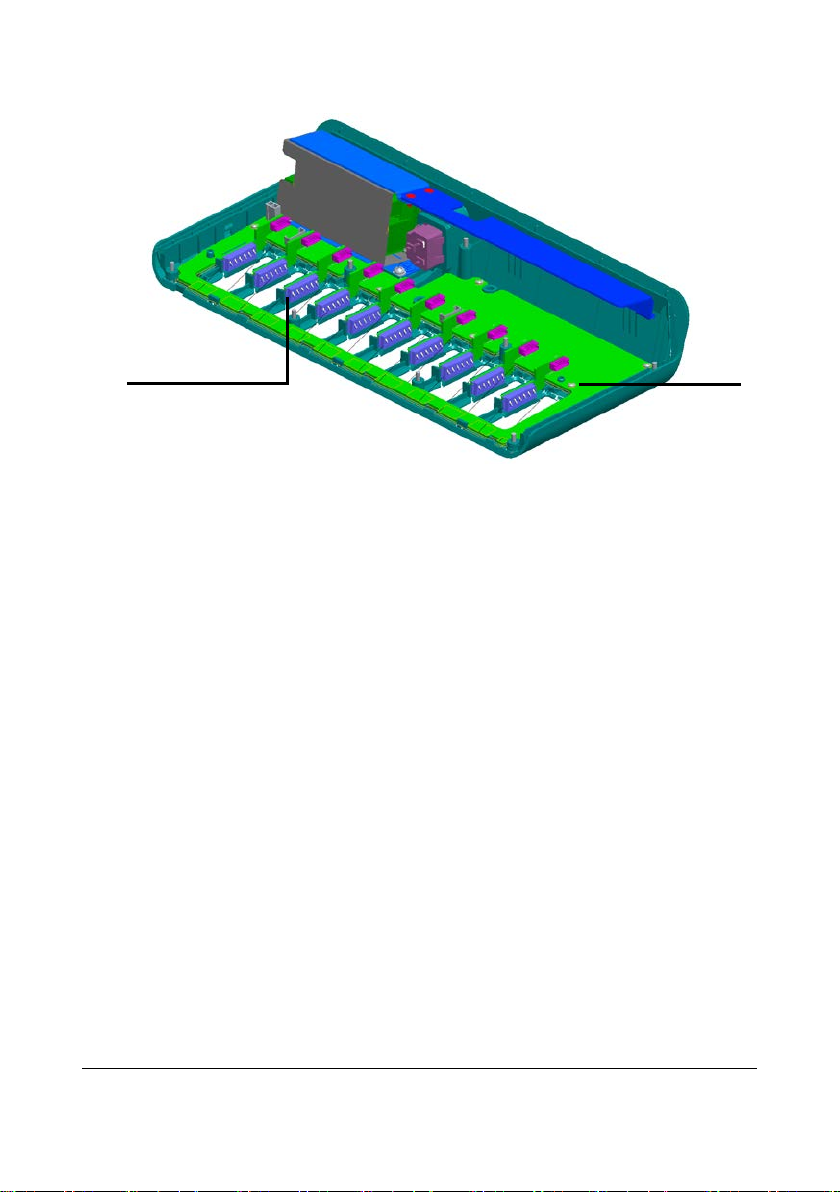

Main board

AC-DC socket

MCU power supply

circuit

Charge Circuit (10)

EN Circuit

Charge

voltage

selecting

circuit

Charge current

selecting circuit

NTC detection

circuit

Battery switch board

socket

MCU (10)

LED control

Burning upgrade

I2C access

EN control

Charge voltage

control

Charge current

control

Battery-LED

circuit (10)

AC-LED

circuit

AC-DC

board

Main

board

wire

Battery

interface

board wire

(10)

Battery

interface board

(10)

Battery interface

socket Battery contact

terminal

DC-DC

MOS Switch

circuit

voltage AD

detect

MOS switch

control

BeneVision TMS60 Service Manual 2-7

Figure 2-5 Central Charger Hardware Boards and Wires

Page 22

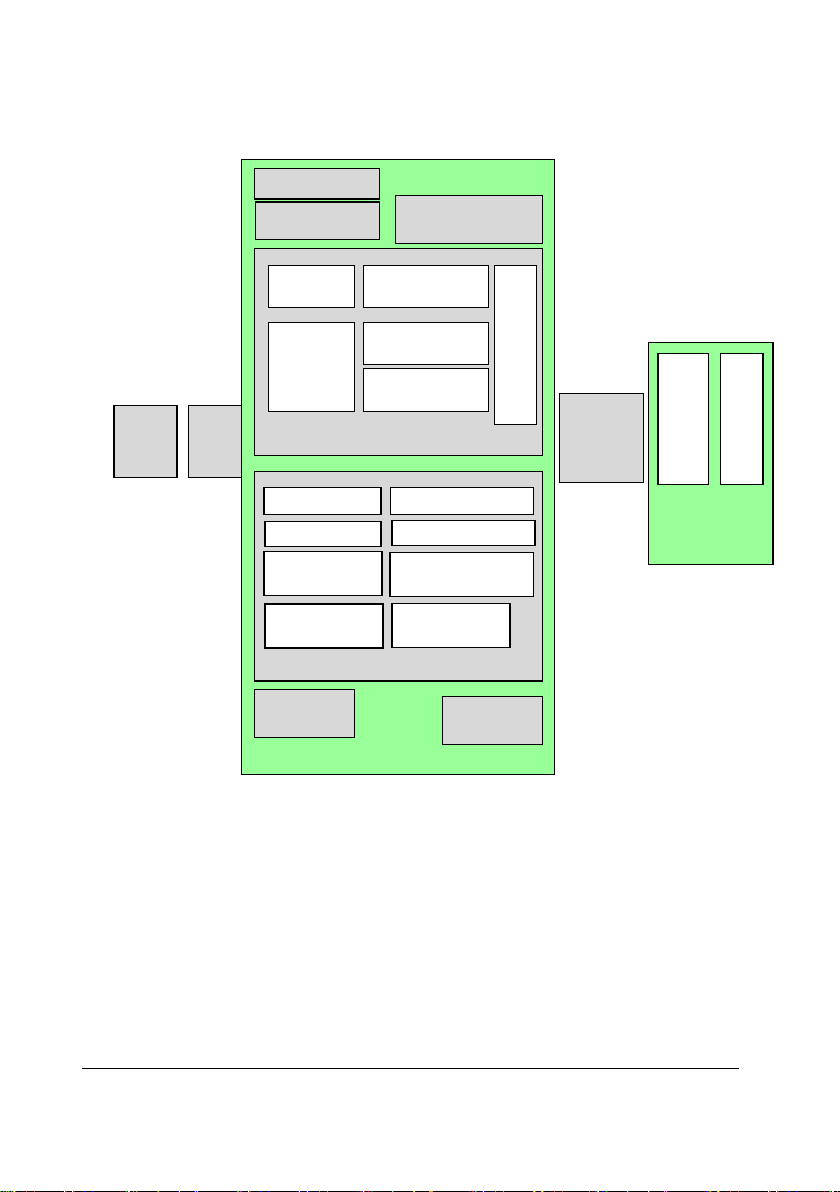

Transmitter Software

System

ECG Circuit

SpO2 Module

Display Unit

Toucher

Power Hard Key

Menu Hard Key

Nurse Call Hard Key

Patient

Signal

User

Serial Port

Speaker

Alarm Light

Battery

Central Monitoring

System

RF Module

2.3 Software Principles

2.3.1 Transmitter Software System

2.3.1.1 Overview

Figure 2-6 Interfacing Diagram between the Transmitter Single-Chip Software and

Peripherals

Inside the solid frame is the transmitter software system (hereinafter called the software

system), and outside the solid frame are the inputs and outputs of the software system.

The patient’s ECG data are inputted into the software system by means of sampling.

The external SpO

and the collected SpO

CMS and external SpO

serial port. The user commands and online upgrade files of the transmitter software are

inputted into the software system through this serial port.

Patient calls can be inputted into the software system through the nurse call button. The

pa t i e nt ’s ECG and SpO

by the software system and then transmitted to the RF module. In addition, the indicator

and speaker are also controlled by the software system.

module communicates with the transmitter through the serial port,

2

data are inputted into the software system via the serial port. The

2

module communicate with the transmitter through the same

2

parameter signals and the transmitter’s status data are processed

2

2-8 BeneVision TMS60 Service Manual

Page 23

2.3.1.2 Transmitter System Task

The transmitter collects the patient’s ECG and SpO2 signals, and then detects the pace

pulse, SpO

and other status information in them by amplifying and digitalizing them,

2

and finally sends the detected information to the receiver through wireless channels.

The transmitter supports the auto detection of 3-lead or 5-lead leadwire, lead off

detection and PACE detection. It also supports the external SpO

connector, through which the CMS can perform the parameter configuration and

SpO

2

module through the

2

online software upgrade to the transmitter.

The transmitter also enables these functions including battery voltage detection,

hardware button detection including the Power On/Off and Display On/Off button ,

Nurse Call button , Main menu/Main screen button . Besides, it supports

audible and visual alarms and enables the standby mode, sleep mode, and lock screen

mode.

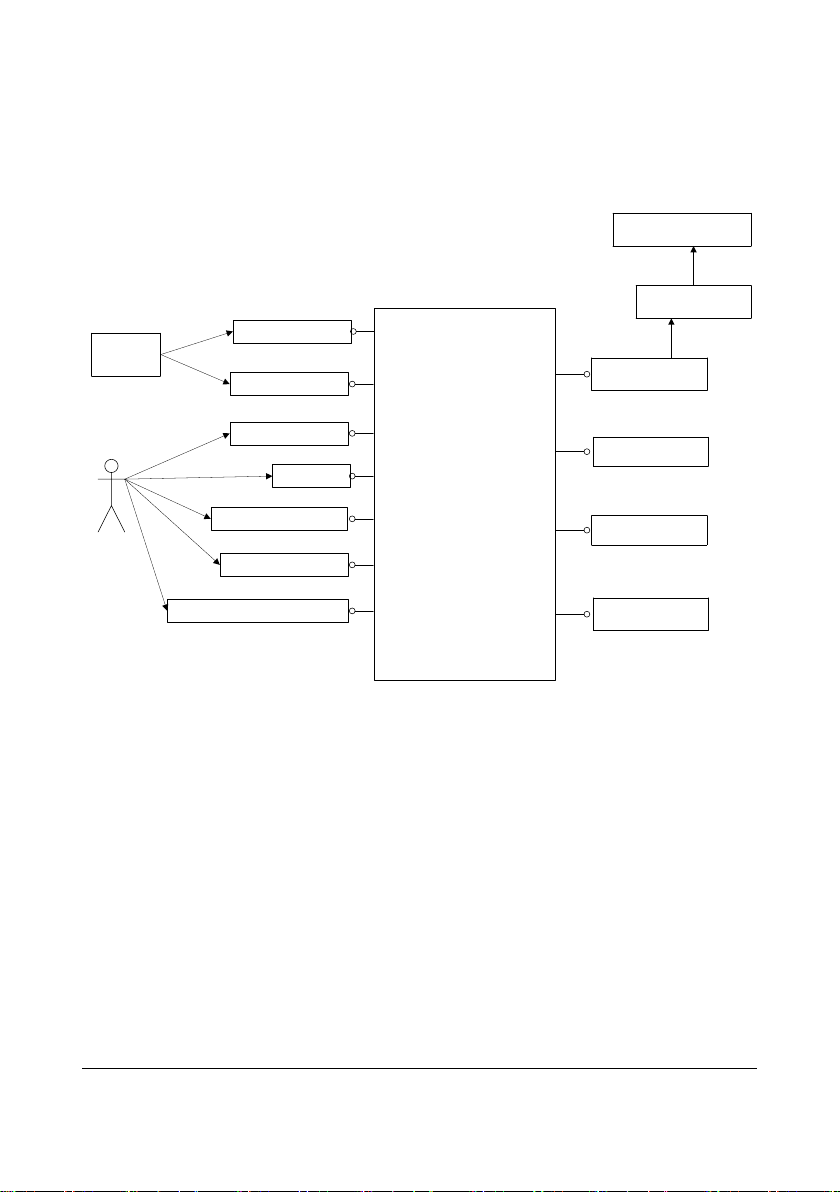

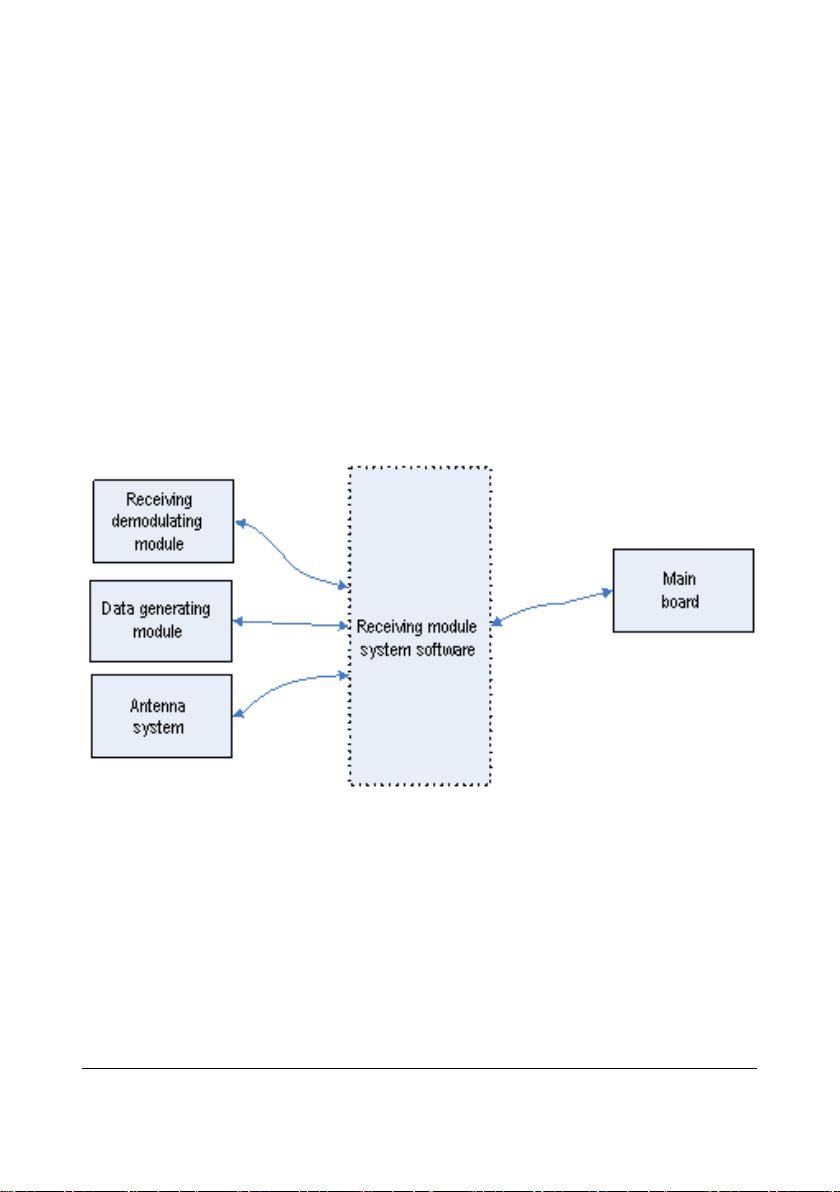

2.3.2 Receiver System Software

2.3.2.1 Overview

Figure 2-7 Receiver system software diagram

Inside the dashed frame is the system software of the main control board (hereinafter

called the software system), and outside the dashed frame is the inputs and outputs of

the software system. The data coming from the 4-channel receiver are sent to the

software system through the serial port.

BeneVision TMS60 Service Manual 2-9

Page 24

The main control board and receiver controller communicate through the serial port. The

main control board directly controls the LED indicator through the I/O port and

communicates with the CMS through the Ethernet.

2.3.2.2 Receiver System Task

The receiver receives data from boards, descrambles data, analyses the integrity of data,

generates relevant alarm messages and sends them together with data to the CMS.

Through the receiving controller, the receiver obtains and controls the operating status of

the receiving demodulator, including the operating frequency and signal strength of the

demodulator. After detecting the operating status, the receiver will give prompt

information through the communication status indicator.

2.3.2.3 Overview of the 4-Channel Receiver Software

Figure 2-8 Diagram for the 4-Channel Receiver Software

Inside the dashed frame is the receiving module control software (hereinafter call

software system), and outside the dashed frame are the inputs and outputs of the

software system. Through the serial port and signal line, the software system

communicates with the receiving demodulator, resolves the data coming from the

data-generating module and controls the antenna system via switch. Besides, it also

communicates with the main control board via the serial port.

2-10 BeneVision TMS60 Service Manual

Page 25

2.3.2.4 4-Channel Receiver Software Task

The 4-channel receiver mainly undertakes the following tasks:

Recover and resolve the wireless transmission space protocol;

Configure frequency for the 4-channel receiver on the receiving board;

Collect the RSSI from the 4-channel receiver on the receiving board;

Select antenna according to the received signal strength;

Collect the status information of the 4-channel receiver on the receiving board;

Carry out the communication with the main control board.

BeneVision TMS60 Service Manual 2-11

Page 26

This page intentionally left blank.

2-12 BeneVision TMS60 Service Manual

Page 27

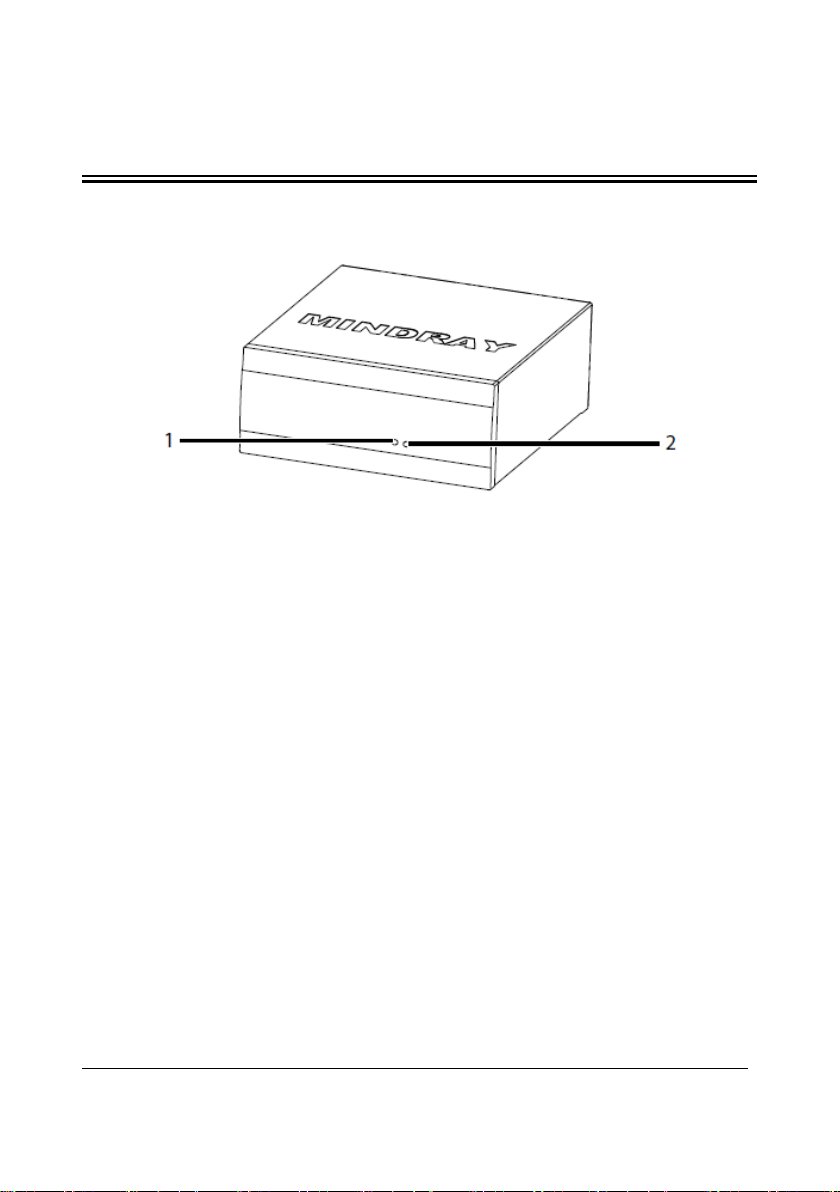

3 Receiver Physical Views

3.1 Front View

Figure 3-1 Receiver Front View

1. Communications indicator

Flashes periodically: communications is occurring.

On: communications is not occurring.

Off: there is a startup failure or hardware failure.

2. Power indicator

On: the receiver is powered on.

Off: the receiver is powered off.

BeneVision TMS60 Service Manual 3-1

Page 28

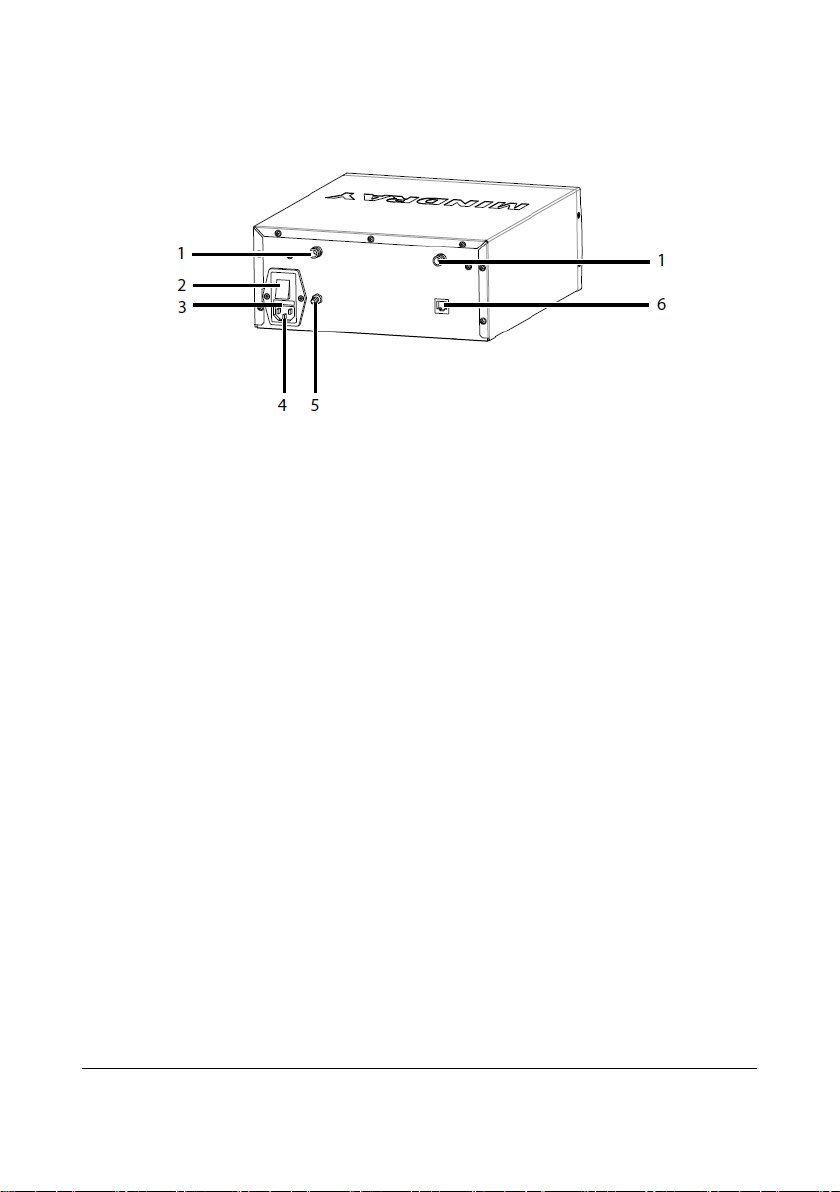

3.2 Rear View

Figure 3-2 Receiver Rear View

1. Antenna connectors

The receiver has two antenna connectors. Each connector connects an antenna

cable.

2. Power switch

Place the switch to “┃” to turn the receiver on. Place the switch to “〇” to turn

the receiver off.

3. Fuse holder

You can open the cover to replace the fuse.

4. AC power input connector

5. Equipotential grounding terminal

When the receiver and other device are to be used together, their equipotential

grounding terminals should be connected together to eliminate the potential

difference.

6. Network connector

A standard RJ45 connector that connects the receiver to the central monitoring

system.

3-2 BeneVision TMS60 Service Manual

Page 29

WARNING

Only use the approved power cord with the grounded mains plug to firmly

connect the receiver to a grounded AC mains socket. Never refit the mains

plug to fit an ungrounded AC mains socket.

Do not use the Multiple Portable Socket Outlets (MPSO) or AC mains

extension cords. Use an IEC 60601-1 approved isolation / separation

transformer, otherwise, it may result in leakage current. Insure that the

sum of the individual ground leakage currents does not exceed the

allowable limits.

3.3 Restoring Latest Configuration Automatically

To prevent the changes from losing in case of a sudden power failure, the device, such as

the receiver or the BeneVision CMS, stores the configuration in real time. The saved

configuration is the latest configuration.

The device restores the latest configuration if it restarts within 60 seconds after the power

failure. And the device will restore the default configuration rather than the latest

configuration if it restarts 120 seconds after the power failure. The device may load either

the latest configuration or the default configuration if it restarts from 60-120 seconds

after the power failure.

BeneVision TMS60 Service Manual 3-3

Page 30

This page intentionally left blank.

3-4 BeneVision TMS60 Service Manual

Page 31

1 7 6 5 4

2

3

4 BP10 Physical Views

4.1 Front View

1. Display

2. Confirmation key

When the desired option is highlighted, press this key to select or activate the

corresponding function.

3. Main menu key

Press this key to turn to the main menu.

4. NIBP start/stop key

When NIBPmeasurement is in process, press this key to stop the

proceeding NIBP measurement.

When NIBP measurement is not performed, press this key to start an NIBP

measurement.

5. Down key

Press this key to move down along the column of menu options or configuration

choices.

BeneVision TMS60 Service Manual 4-1

Page 32

1 1 2

3

6. Return key

Press this key to return to the previous menu and save the settings.

Press this key to switch between two main screens.

7. Up key

Press this key to move up along the column of menu options or configuration

choices.

4.2 Side View

1. Power On/Off key

When BP10 is powered off, press this key to turn BP10 on.

When BP10 is powered on, press and hold this key to display the power off

confirmation menu.

If the screen display is on, press this key to turn the display off.

2. Mindray Patient Area Network (MPAN) key

When BP10 is disconnected from the MPAN, press this key to begin the

bluetooth pairing process.

When BP10 is connected with the MPAN , press this key to unpair any

connected bluetooth devices.

You can also set up the MPA N communication in the main menu.

3. USB port

This port is used for software upgrade.

4-2 BeneVision TMS60 Service Manual

Page 33

NIBP cuff connector: connect the NIBP hose.

4.3 Top Vie w

For further details about the BP10 NIBP module, refer to the BP10 NIBP Module

Operator’s Manual (P/N 046-011008-00).

BeneVision TMS60 Service Manual 4-3

Page 34

FOR YOUR NOTES

4-4 BeneVision TMS60 Service Manual

Page 35

1

5 Central Charger Physical Views

5.1 Front View

Figure 4-1 Central Charger Front Vi ew

1. Charging slot

2. AC power indicator

Off: No AC power supply connected, or the AC-DC board is abnormal.

Green: AC power supply is connected.

3. LED indicators: indicates the charging status for the corresponding charging slot.

5.2 Rear View

Figure 4-2 Central Charger Rear View

1. AC power socket

For further details about the central charger such as how to mount the central charger

and how to charge and remove batteries, refer to the BeneVision Central Charger

Operator’s Manual (P/N 046-007059-00).

BeneVision TMS60 Service Manual 5-1

Page 36

This page intentionally left blank.

5-2 BeneVision TMS60 Service Manual

Page 37

6 Maintenance

To ensure that the telemetry monitoring system always functions normally, qualified

service personnel should perform regular inspection, maintenance and test. This chapter

provides a checklist of the testing procedures for the telemetry monitoring system with

recommended test equipment and frequency. The service personnel should perform the

testing and maintenance procedures as required and use appropriate test equipment.

The testing procedures provided in this chapter are intended to verify that the telemetry

monitoring system meets the performance specifications. If the telemetry monitoring

system fails to perform as specified in any test, repairs or replacement must be done to

correct the problem. If the problem persists, contact our Customer Service Department.

CAUTION

All tests should be performed by qualified service personnel only.

Care should be taken to change the settings in the Maintenance menu to

avoid loss of data.

Service personnel should acquaint themselves with the test tools and

make sure that test tools and cables are applicable.

BeneVision TMS60 Service Manual 6-1

Page 38

Visual inspection

When first installed or reinstalled.

1. When first installed or reinstalled

transmitter components

Performance test

Calibration

Pressure check

Leakage test

1. After the transmitter or central charger

as needed

1. When first installed.

replaced.

1. When first installed.

2. Whenever a battery is replaced.

Once every two months or when the

noticeably shorter.

6.1 Recommended Maintenance and Test Frequency

Check/Maintenance Item Frequency

Power-on test

ECG test

Resp test Performance test

SpO2 test

NIBP test

Nurse call test

Electrical safety tests

Network print test

Functionality test

Battery check

Performance test

2. Following any repairs or replacement of

1. If the user suspects that the measurement

is incorrect.

2. Following any repairs or replacement of

relevant module.

3. At least once every two years.

Note: NIBP test should be performed at least

once a year.

If the user suspects that the measurement is

incorrect.

2. Performed at least once every two years or

2. Whenever the printer is serviced or

lithium-ion battery’s run time becomes

falls off.

6-2 BeneVision TMS60 Service Manual

Page 39

6.2 Parameter Tes ts

6.2.1 ECG Tests

6.2.1.1 ECG Performance Test

Tool required:

Medsim 300B patient simulator recommended

Follow this procedure to perform the test:

1. Connect the patient simulator with the ECG module using an ECG cable.

2. Set the patient simulator as follows: ECG sinus rhythm, HR=80 bpm with the

amplitude as 1mV.

3. Check the ECG waves are displayed correctly without noise and the displayed HR

value is within 80±1 bpm.

4. Disconnect each of the leads in turn and observe the corresponding lead off

message displayed on the screen.

5. Set that the simulator outputs paced signals and set

Check the pace pulse marks on the transmitter’s screen.

6.2.1.2 ECG Calibration

The ECG signal may be inaccurate due to hardware or software problems. As a result, the

ECG wave amplitude becomes greater or smaller.

Tool required:

Vernier caliper

To verify the ECG waveform amplitude:

1. In the main menu, select Parameter Setup.

2. Select ECG.

3. Set Filter to Monitor.

4. Return to the main menu and select Maintenance.

5. Input the maintenance passcode.

6. Tap Accept.

7. In the Maintenance menu, select General.

8. Enable Calibrate ECG. A square wave appears on the screen and the message ECG

Calibrating is displayed in the technical alarm area of the transmitter’s screen.

Compare the amplitude of the square wave with the wave scale. The difference

should be within 5%.

9. After completing the verification, disable Calibrate ECG. If necessary, you can print

out the square wave and wave scale through the recorder and then measure the

difference.

Paced to Yes on the transmitter.

BeneVision TMS60 Service Manual 6-3

Page 40

6.2.2 Resp Test

6.2.2.1 Enabling Resp Functionality

Before performing the Resp performance test, you need to enable the Resp functionality.

Follow this procedure to enable the Resp functionality:

1. After powering on the TD60, press to enter the main menu of the transmitter.

2. Select Maintenance→input the maintenance passcode→tap Accept→select

Service.

3. Input the passcode.

4. Tap Accept.

5. Enable Support Resp.

6. Return to the main menu.

7. Select Maintenance→input the maintenance passcode→tap Accept→select

General.

8. Enable Resp.

6.2.2.2 Resp Performance Test

Tools required:

Medsim300B patient simulator

1. Connect the patient simulator to the TD60 using an ECG cable and set lead II as the

respiration lead.

2. Configure the simulator as follows: lead II as the respiration lead, base impedance

line as 500 Ω; delta impedance as 1 Ω, respiration rate as 20 rpm.

3. Verify that the Resp wave is displayed without any distortion and the displayed Resp

value is within 20±1 rpm.

NOTE

The Resp functionality for the TMS60 telemetry monitoring system is

supported by the CMS whose version is 03.00 or above.

6-4 BeneVision TMS60 Service Manual

Page 41

6.2.3 SpO

Test

2

Tool required:

None

Follow this procedure to perform the test:

1. Connect an adult SpO

sensor to the SpO2 connector of the transmitter.

2

2. In the main menu, select Patient Info and set Patient Category to Adult on the

transmitter

3. Measure SpO

on your finger. (Assume that you stay healthy)

2

4. Check the Pleth wave and PR reading on the screen and make sure that the

displayed SpO

5. Remove the SpO

is within 95%-100%.

2

sensor from your finger and make sure that an alarm of SpO

2

2

Sensor Off is triggered.

Measurement accuracy verification:

The accuracy of Masimo and Nonin SpO2 modules has been verified in human

experiments by comparing with arterial blood sample reference measured with a

CO-oximeter. Pulse oximeter measurements are statistically distributed and about

two-thirds of the measurements are expected to come within the specified accuracy

range compared to CO-oximeter measurements.

NOTE

A functional tester cannot be used to assess the accuracy of a pulse

oximeter monitor. However, it can be used to demonstrate that a particular

pulse oximeter monitor reproduces a calibration curve that has been

independently demonstrated to fulfill a particular accuracy specification.

BeneVision TMS60 Service Manual 6-5

Page 42

BP10

Tubing

Balloon

Rigid vessel

Connector for NIBP cuff

Manometer

6.2.4 NIBP Tes ts

Perform NIBP accuracy test and leakage test at the BP10.

NOTE

The NIBP functionality for the TMS60 telemetry monitoring system is

supported by the CMS whose version is 03.00 or above.

6.2.4.1 NIBP Accuracy Test

Tools required:

T-shape connector

Appropriate tubing

Balloon pump

Rigid Vessel with volume 500 ± 25 ml

Reference manometer (calibrated with accuracy equal to or greater than 1

mmHg)

Follow this procedure to perform the test:

1. Connect the equipment as shown below.

2. Before inflation, the reading of the manometer should be 0. If not, turn off the

balloon pump to let the whole airway open to the atmosphere. Turn on the balloon

pump after the reading is 0.

3. On the main menu of the BP10, select System→Maintenance→NIBP Accuracy

Test.

6-6 BeneVision TMS60 Service Manual

Page 43

4. Check the manometer values and the values displayed on the BP10. Both should be

0mmHg.

5. Raise the pressure in the rigid vessel to 50 mmHg with the balloon pump. Then, wait

for 10 seconds until the measured values become stable.

6. Compare the manometer values with the values displayed on the BP10. The

difference should be 3 mmHg. If it is greater than 3 mmHg, contact your service

personnel.

7. Raise the pressure in the rigid vessel to 200 mmHg with the balloon pump. Then,

wait for 10 seconds until the measured values become stable and repeat step 6.

NOTE

You can use an NIBP simulator to replace the balloon pump and the

reference manometer to perform the test.

You can use an appropriate cylinder and a cuff instead of the rigid

vessel.

6.2.4.2 NIBP Leakage Test

NOTE

You should perform NIBP accuracy test and make sure the test result is

pass prior to NIBP leakage test.

Tools required:

NIBP cuff for adult patient

Appropriate tubing

Cylinder

Follow this procedure to perform the test:

1. Set Patient Category to Adult.

2. Connect the NIBP cuff with the NIBP connector on the monitor.

3. Apply the cuff to the cylinder as shown below.

BeneVision TMS60 Service Manual 6-7

Page 44

Cylinder

Air tubing

Cuff

Connector for NIBP cuff

BP10

4.

On the main menu of the BP10, select System→Maintenance→NIBP Leakage Test.

The NIBP parameter area displays Leakage Testing….

5. The cuff automatically deflates after 20s, which means NIBP leakage test is

completed. If no message is displayed in the NIBP parameter area, it indicates that

the system has no leakage. If the message NIBP Pneumatic Leak is displayed, it

indicates that the system may have a leakage. In this case, check if all connections

are good and the cuff and tubing have no leakage. Perform the test again after

making sure all connections are good and the cuff and tubing have no leakage.

You can either perform a manual leakage test:

1. Perform Steps 1 to-4 in the NIBP Accuracy Test section.

2. Raise the pressure in the rigid vessel to 250 mmHg with the balloon pump. Then,

wait for 5 seconds to let the measured values becoming stable.

3. Record the current pressure value and meanwhile use a time counter to count time.

Then, record the pressure value after counting to 60s.

4. Compare the two values and make sure the difference should not be greater than 6

mmHg.

6-8 BeneVision TMS60 Service Manual

Page 45

6.3 Miscellaneous Tests

6.3.1 Visual Inspection

Perform a visual inspection before the equipment is first used every day. Verify that the

equipment meets the following requirements:

The housing and display screen are free from cracks or other damages.

All keys function properly.

Connectors are not loose, cracked, or bent and cables have no cuts, nicks, or

fraying.

ECG leadwires are securely connected with the equipment.

Battery pack is installed and has sufficient charge.

Chest electrodes are free from cracks and limb electrodes can properly clamp.

6.3.2 Power-O n Te st

This test is to verify that the transmitter can power up correctly.

Follow this procedure to perform the test:

1. Install a lithium-ion rechargeable battery pack or AA batteries into the transmitter’s

battery compartment.

2. Press the Power on/off key to turn on the transmitter. The cyan alarm light will

momentarily turn on to indicate that the device is starting.

When the boot screen appears, the device sounds a beep, and the alarm light serially

turns red, yellow, cyan, and then off. This indicates that the alarm system functions

correctly. When the boot screen disappears, the main screen displays and the device

finishes starting.

WARNING

Check that visual and auditory alarm signals are presented correctly when

the equipment is powered on. Do not use the equipment for any

monitoring procedure on a patient if you suspect the equipment is not

working properly or if the equipment is mechanically damaged. Contact

your service personnel or Mindray.

6.3.3 Nurse Call Test

Follow this procedure to perform the test:

1. Press the nurse call button on the transmitter.

2. Observe corresponding display on the CMS. If a nurse call icon appears, it indicates

that the nurse call test passes.

BeneVision TMS60 Service Manual 6-9

Page 46

6.3.4 Electric Safety Test

Refer to A Electrical Safety Inspection for details.

6.3.5 Network Print Test

Follow this procedure to perform the test:

1. Power on the transmitter.

2. Connect the transmitter to the CMS wirelessly.

3. Press to enter the main menu of the transmitter or swipe your finger up from

the bottom of the main screen to display the quick keys area.

4. Select Print.

5. Verify that the network printer shall print out a report correctly.

6.3.6 Battery Check

Refer to 11 Battery in BeneVision TMS60 Telemetry Monitoring System Operator’s

Manual (P/N 046-007056-00) for methods to check battery status and verify battery

supply specifications.

6.3.7 Tests in Service Menu

Refer to 6 Service Menu for test items in the service menu.

6-10 BeneVision TMS60 Service Manual

Page 47

7 Service Menu

In the Service menu, you can update TD60 software, check the service log, perform the

factory test, and check the system software version.

7.1 Entering the Service Menu

1. Press to enter the main menu

2. Select Maintenance.

3. Input the passcode, and then tap Accept.

4. Select Service.

5. Input the passcode, and then tap Accept.

7.2 Performing Software Update

Software upgrade must be performed by Mindray. Please contact Mindray for software

upgrade.

7.3 Service Log

The service log stores and displays the error codes.

To check the service log, select Service Log in the Service menu.

For details on the error codes, refer to 7.1.3 Error Codes.

7.4 Factory Test

To enter the Factory Test menu, select Factory Test from the Service menu.

7.4.1 Device Test

The option is to do the device self-test.

1. In the Factory Test menu, select Device Test.

2. Tap Start.

The device self-tests including device test, MO module test, and Bluetooth module

test start.

BeneVision TMS60 Service Manual 7-1

Page 48

The test results will correspondingly display to the right of the test. If the test fails, refer to

6.4.10 Processing Method.

7.4.2 Screen Test

This option is to test the screen.

1. In the Factory Test menu, select Screen Test.

2. Tap the screen in turn.

If the screen color turns red, green, cyan, white, and then off, tap Pass. If the screen color

is not displayed in this way, tap Fail.

If the test fails, refer to 6.4.10 Processing Method.

7.4.3 Touch Screen Test

This option is to test the touch screen.

1. In the Factory Test menu, select Touch Screen Test.

2. Touch the white blank screen, and move around.

If a touch line appears on the screen, tap Pass.

If a touch line does not appear on the screen, tap Fail. If the test fails, refer to 6.4.10

Processing Method.

7.4.4 Keys Te st

This option is to test the hard keys.

1. In the Factory Test menu, select Keys Test.

2. Press each key to test.

Press and the screen displays “Power Key is Pressed Shortly”; or keep

pressing and the screen displays “Power Key is Pressed Long”.

Press and the screen displays “Nurse Call Key is Pressed”.

Press and the screen displays “Menu Key is Pressed”.

3. Tap Pass to finish the keys test.

If any key test fails, refer to 6.4.10 Processing Method.

7-2 BeneVision TMS60 Service Manual

Page 49

7.4.5 Sound & Light Test

This option is to test speaker, and red, yellow, cyan LEDs.

1. In the Factory Test menu, select Sound & Light Test.

2. Select Sound Test. If the speaker sounds, tap Pass.

3. Select Red Light Test. If the red light flickers, tap Pass.

4. Select Yellow Light Test. If the yellow light flickers, tap Pass.

5. Select Cyan Light Test. If the cyan light flickers, tap Pass.

7.4.6 USB Interface Test

This option is to test USB interface.

1. Insert a USB drive.

2. In the Factory Test menu, select USB Interface Test.

If the test is completed successfully, tap Pass. If it fails, refer to 6.4.10 Processing Method.

NOTE

The upgrade tools kit (Dubhe) P/N 115-033434-00 is required to perform

the USB interface test.

7.4.7 System Watchdog Test

This option is to test the system watchdog.

1. In the Factory Test menu, select System Watchdog Test.

2. Tap Yes. Then, the device will be restarted. If the test fails, refer to 6.4.10 Processing

Method.

7.4.8 MO Module Watchdog Test

This option is to test the MO module watchdog.

1. In the Factory Test menu, select MO Module Watchdog Test.

2. Tap Ye s. The device will be restarted. If the test fails, refer to 6.4.10

Processing Method.

BeneVision TMS60 Service Manual 7-3

Page 50

7.4.9 Bluetooth Module Test

This option is to test the Bluetooth module. Two or more TD 60 devices are required for

this test. To show the test procedures clearer, we use two TD 60 devices which are called

as TD 60-2 and TD 60-1 hereinafter.

1. For TD 60-2, in the Factory Test menu, select Bluetooth Module Test.

2. For TD 60-1, in the Maintenance menu, select Defaults and then select Import

Device Settings.

3. Slide the MPAN on/off switch of TD 60-2 to right. Then, TD 60-2 starts searching

devices.

4. Tap Connect when TD 60-1 was found. When they are connected successfully, the

connection status on the right of TD 60-1 will be changed to Connected, as shown in

Figure 6-1.

Figure 6-1 Example of Bluetooth Module Test Screen

If the test fails, refer to 6.4.10 Processing Method.

7.4.10 Processing Method

If the factory test fails, please contact your service personnel or Mindray.

7-4 BeneVision TMS60 Service Manual

Page 51

7.5 Checking System Software Version

In the Service menu, select System Software Version.

The screen displays the software version of development as follows:

Format: xx.xx.xx.xx.

Compile Time: Month day, year

BeneVision TMS60 Service Manual 7-5

Page 52

This page intentionally left blank.

7-6 BeneVision TMS60 Service Manual

Page 53

Low Battery

The battery charge of the

Replace the battery of the

No RF signal (The

1. The battery charge of the

1. Check if the battery charge of

CMS.

RF interference

(The transmitter

1. The transmitter signal is

weak.

1. Check if the Patient is at the

edge of the coverage area or

8 Troubleshooting

8.1 Telemetry Monitoring System Problems

The section describes the troubleshooting about the transmitter, and the receiver.

8.1.1 Troubleshooting Tools

Receiver

Transmitter

8.1.2 Technical Alarm Messages

Alarm

Message

Possible Cause Processing Method

transmitter is to be depleted.

receiver does not

receive valid

data for

consecutive 5

seconds)

BeneVision TMS60 Service Manual 8-1

2. The transmitter in the

3. The patient is out of the

4. There is an error in the

5. The transmitter is not

6. The receiver frequency is

7. There is an IP addresses

transmitter is to be

depleted.

dormant status.

antenna array coverage

area.

antenna array.

connected with the ECG

cable.

not paired with the

transmitter frequency.

conflict.

transmitter.

the transmitter is depleted.

2. Check if the corresponding

transmitter is in dormant

status.

3. Check if the patient is out of

the coverage area.

4. Check if there is an error in the

antenna array. Refer to 7.1.5.1

Determining RF Signal

Interference and 7.1.5.2 Low

RSSI Signal Check for details.

5. Check if the transmitter is

connected with the ECG cable

properly.

6. Check if the receiver frequency

configuration that is

consistent with the

transmitter.

7. Reset the IP addresses at the

Page 54

receives three

2. There is RF interference

in an elevator. Remove behind

for details.

Wrong Channel

1. The channel name for

1. Reset the channel name at the

the frequency.

Receiver Offline

1. The receiver is not

1. Check if the receiver is

SpO2 No Pulse

The SpO2 sensor failed to

Check the patient’s condition and

sensor.

Transmitter key

The transmitter detects that a

10 seconds.

Check if the key is pressed by a

Receiver Fault

An error occurred to the

receiver.

Restart the receiver.

MPAN

The MAPN is disconnected.

1. Enable the MPAN switch.

to each other.

NIBP Cuff or

The NIBP airway may leak air.

1. Verify that the cuff is properly

not leak air.

NIBP Timeout

Time is out.

over 120 seconds.

Check the patient’s condition and

Replace the cuff.

Alarm

Message

consecutive

wrong frames.)

Possible Cause Processing Method

around.

the transmitter is

incorrect.

2. The receiver receives the

data sent from some

other transmitter which

does not belong to the

system.

3. The same frequency is

allocated to different

transmitters.

powered on.

2. The receiver cannot be

connected to the CMS.

obtain pulse signal.

a reinforced concrete wall.

2. Check for RF Interference.

Refer to 7.1.5.1 Determining

RF Signal Interference and

7.1.5.2 Low RSSI Signal Check

CMS.

2. Check if there is another

telemetry monitoring system

in the vicinity. Re-configure

the frequency. Refer to 7.1.5.3

Programming Telemetry

Packs for details.

3. Check the frequencies of all

the transmitters. If duplicated

frequency exists, re-allocate

powered on;

2. Check if the network cable is

properly connected.

change the sensor application site.

If the error persists, replace the

error

Disconnected

Airway Leak

8-2 BeneVision TMS60 Service Manual

key has been pressed for over

The measurement time is

foreign object or jammed.

2. Put the TD60 and BP10 closer

connected.

2. 2. Verify that the airway does

NIBP connections.

Page 55

Power off and then on

Power off and then on

board.

Power off and then on

board.

1. The SpO

abnormal.

1. Replug the SpO

1. The Bluetooth

module is

1. Power off and

8.1.3 Error Codes

Error

Code

001

002 ECG ASIC Init Err

Message Displayed

on the Screen

Module Selftest

Err(0xff)

Possible Cause Processing Method

the transmitter to see if

The parameter board

MCU is faulty.

the fault disappears. If

the fault persists,

change the parameter

board.

the transmitter to see if

The ECG ASIC chip is

faulty.

the fault disappears. If

the fault persists,

change the parameter

003 ECG ASIC 3.3V Err

004 SPO2 Init Err

006 Bluetooth Init Err

BeneVision TMS60 Service Manual 8-3

The power supply for

the parameter board

is abnormal.

module is faulty.

2

2. The SpO

2

module is not

supported by

the transmitter.

3. The SpO

2

connection

circuit of the

transmitter is

firmware is

abnormal.

2. The Bluetooth

firmware is

faulty.

3. The power

supply for the

Bluetooth

the transmitter to see if

the fault disappears. If

the fault persists,

change the parameter

module.

2

2. Replace with a

SpO

module

2

supported by the

transmitter.

3. Replace the SpO

2

connection circuit

or the parameter

board.

then on the

transmitter to see

if the fault

disappears.

2. Upgrade the

Bluetooth

firmware.

3. Replace the

parameter board.

Page 56

abnormal.

1. Reinstall batteries

batteries.

1. Battery voltage

abnormal.

1. Replace with new

1. Move the

parameter board.

1. Power off and

parameter board.

1. RTC battery is

1. Replace the RTC

The main control

EEPROM is faulty.

Replace the parameter

An error occurred

1. Move the

Error

Code

Message Displayed

on the Screen

008 Battery Comm Err

011 Power 2.5V Err(0xff)

020 ECG Selftest(0xff )

Possible Cause Processing Method

1. Batteries are not

installed

properly.

2. The battery

contacts inside

the battery

compartment of

the transmitter

are damaged or

distorted.

3. Batteries are

faulty.

is low.

2. The power

supply circuit of

the parameter

board is

per instructions in

Operator’s

Manual.

2. Check that the

battery contacts

are not depressed.

If they are

depressed, pull

the battery

contacts to the

original positions.

3. Replace with new

batteries.

2. Replace the

parameter board

with a known

good one.

transmitter away

The ECG detection

circuit is abnormal.

from interference

sources and then

restart it.

2. Replace the

021 Module Watchdog Err

103 RTC Comm Err

104 E2PROM Err

105 ECG Init Err

8-4 BeneVision TMS60 Service Manual

The watchdog circuit

on the parameter

board is abnormal.

low.

2. RTC chip is

faulty.

while initializing the

then on the

transmitter.

2. Replace the

battery.

2. Replace the

parameter board.

board.

transmitter away

Page 57

parameter board

from interference

parameter board.

1. Move the

parameter board.

1. Move the

parameter board.

1. Move the

parameter board.

Error

Code

Message Displayed

on the Screen

106 ECG Comm Stop

107 ECG Comm Abnormal

Possible Cause Processing Method

ECG.

sources and then

restart it.

2. Replace the

transmitter away

from interference

sources and then

Communication

between the

parameter board and

the main control

board is abnormal.

restart it.

2. Check the FPC

connection

between the

parameter board

and the main

control board.

3. Replace the

transmitter away

from interference

sources and then

Communication

between the

parameter board and

the main control

board is abnormal.

restart it.

2. Check the FPC

connection

between the

parameter board

and the main

control board.

3. Replace the

108 ECG COMM Err

BeneVision TMS60 Service Manual 8-5

Communication

between the

parameter board and

the main control

board is abnormal.

transmitter away

from interference

sources and then

restart it.

2. Check the FPC

connection

between the

parameter board

and the main

control board.

3. Replace the

Page 58

1. Move the

module.

1. Move the

module.

1. Move the

module.

1. Move the

module.

The parameter board

Replace the parameter

Communication

control board is

1. Move the

restart it.

Error

Code

Message Displayed

on the Screen

109 SPO2 Init Err

110 SPO2 Comm Stop

111

SPO2 Comm

Abnormal

Possible Cause Processing Method

transmitter away

from interference

An error occurred

while initializing the

SpO

module.

2

sources.

2. Replug the SpO

module.

3. Replace with a

known good SpO

transmitter away

Communication

between the SpO

module and the

transmitter is

abnormal.

2

from interference

sources.

2. Replug the SpO

module.

3. Replace with a

known good SpO2

transmitter away

Communication

between the SpO

module and the

transmitter is

abnormal.

2

from interference

sources.

2. Replug the SpO

module.

3. Replace with a

known good SpO

2

2

2

2

2

112 SPO2 Comm Err

114 Module Init Err

115 Module Comm Err

8-6 BeneVision TMS60 Service Manual

Communication

between the SpO

module and the

transmitter is

abnormal.

MCU is abnormal.

between the

parameter board

MCU and the main

2

2. Replug the SpO

3. Replace with a

board.

transmitter away

from interference

sources.

2

module.

known good SpO2

transmitter away

from interference

sources and then

Page 59

abnormal.

2. Check the FPC

parameter board.

1. Power off and

control board.

The receiver

1. Bad network cable

1. Replug the network cable of

same network segment.

The telemetry

CMS.

1. Incorrect network cable

1. Check the network cable

Error

Code

116 Main Board Selftest Err

Message Displayed

on the Screen

8.1.4 Other Failures

Symptom Possible Cause Processing Method

cannot connect

to network.

2. The IP address of the

Possible Cause Processing Method

The main board

selftest error

connection

receiver is set incorrectly.

connection

between the

parameter board

and the main

control board.

3. Replace the

then on the

transmitter.

2. Replace the main

the receiver and make sure

that it is connected securely.

2. Connect the receiver to the

PC via a network cable. The

PC is installed with a

telemetry configuration tool.

Change the receiver IP

address and confirm the

change at the PC side. If the IP

address of the CMS is set to

DHCP, the IP address of the

receiver should be set to

DHCP. If the IP address of the

CMS is set to a static IP, the IP

address of the receiver should

be set to a static IP in the

monitoring

system cannot

connect to the

network of the

BeneVision TMS60 Service Manual 8-7

connection.

2. Incorrect IP address

setting

connection.

2. Configure correct IP address.

Page 60

The CMS does

1. The SpO

module is not

SpO2 module.

1. Connect the SpO

module to

module with a new one.

ECG noise

ECG waveforms are

Check that the electrodes are

electric device.

ECG signal

The transmitter detects that

1. Check if patient has excessive

Low signal

The signal of theCMS (average

Check if the ECG cable is firmly

The AC power

1. The receiver is not

1. Check if the receiver is

on.

Transmitter or

The battery charge of the

Replace the battery of the

The TD60 and

When the TD60/TM80 and

blocked by the patient’s body.

Put the TD60 and BP10 closer.

Symptom Possible Cause Processing Method

not display the

SpO

data.

2

saturation

intensity

connected to the

2

transmitter.

2. There may be error in the

overlapped with the noise

interference.

ECG signal saturation or

overload.

value) is less than -75dBm.

the transmitter.

2

2. If there is an error in the SpO

module, replace the SpO

2

properly attached, the leadwires

are secured properly, and the

patient does not come into

contact with any ungrounded

movement.

2. Check if the electrodes are in

good contact with the skin.

3. Check if the electrodes

operating time is over the

electrode service life.

connected to the transmitter.

1.

2

indicator on the

receiver is off.

SpO2 module

2. The receiver is power off.

transmitter is to be depleted.

restarting

repeatedly.

BP10 are prone

to offline.

BP10 are secured to the

patient, signals may be

8-8 BeneVision TMS60 Service Manual

connected to the power.

connected to the power.

2. Check if the receiver sounds a

beep when turn the receiver

transmitter.

Page 61

8.1.5 Failure Examinations

8.1.5.1 Determining RF Signal Interference

1. Connect a receiver to the antenna array.

2. Turn on the telemetry monitoring system and the CMS. Ensure that the

telemetry monitoring system works normally.

3. Remove the battery of interference transmitter; make sure its RSSI in the

telemetry window of the CMS is not higher than 130 (-105dBm). If the RSSI is

higher than 130 (-105dBm), use the CMS configuration tool to scan all of the

frequencies, and choose a frequency, of which the signal is lower than

-105dBm, and program it to the interference transmitter.

Method to enter the telemetry window of the CMS (version earlier tha

03.00) : select the System Setup button→select the Admin Setup button

→select the Telemetry tab→select the Frequency Setup section

Method to enter the telemetry window of the CMS (version 03.00 or

above) : select the system menu area in the upper left corner

of the CMS screen to enter the System Setup menu→enter the passcode

→select the Telemetry tab→enter the passcode→select the OK button

4. If there is more than one transmitter with interference, resolve each transmitter

one by one according to step 2.

Figure 8-1 Example of Telemetry Tab in the CMS (Version Earlier than 03.00)

BeneVision TMS60 Service Manual 8-9

Page 62

Figure 8-2 Example of Telemetry Tab in the CMS (Version 03.00 or Above)

8.1.5.2 Low RSSI Signal Check

1. When a transmitter has a low signal strength indication, access the “Telemetry”

tab and check the RSSI to see if it is low.

2. Choose a known good transmitter whose RSSI is above-75dBm.

3. Program the known good transmitter to the frequency of the suspected bad

transmitter and vice versa.

4. If the low RSSI follows the transmitter, the transmitter is defective. If the low

RSSI stays with the channel, the receiver board is defective.

8-10 BeneVision TMS60 Service Manual

Page 63

LAN2

(Hospital NetWork)

LAN

(Patient NetWork)

DP2 Monitor2

DP1 Montor1

DP3 Monitor3

Audio

COM2

(Paging)

COM 1

(Recorder/Programming)

DVI Monitor4

USB 2.0(Keyboard/Mouse/USB module devices

USB 3.0(Keyboard/Mouse/USB module devices

Redundant Power

8.1.5.3 Programming Telemetry Packs

Programming Telemetry Packs at the CMS (Version Earlier than 03.00)

1. Connect one end of the dedicated programming cable to the serial port 1 (COM1) on

the CMS, and the other end to the SpO

connector on the transmitter.

2

Figure 8-3 CMS Host Rear View

2. At the CMS, select System Setup and then select Admin Setup. After entering a

passcode, tap OK to enter the “Admin Setup” win d o w.

3. Select the Telemetry tab, and then select Frequency Setup. The “Telemetry” tab

displays as shown in Figure 8-4.

BeneVision TMS60 Service Manual 8-11

Page 64

Figure 8-4 Example of Telemetry Tab in the CMS (Version Earlier than 03.00)

4. View the transmitter SN number, and remember the last eight digitals, such as

12345678.

5. In the “Frequency Setup” field, select the desired transmitter name, such as

“TEL-0001”, from the “Monitor Name” column.

6. Tap Program to display the “Program” window as shown in Figure 8-5.

8-12 BeneVision TMS60 Service Manual

Page 65

Figure 8-5 Example of Program Window in the CMS (Version Earlier than 03.00)

7. In the “Frequency” input field, enter the frequency as desired.

8. Tap OK to start programming.

NOTE

The power is 23. Do not change the power level.

9. After the programming succeeds, the prompt message “Frequency setup completed

successfully” displays.

10. Tap OK to close the dialog. So far the programming of a pair of transmitter and

receiver is finished.

If you want to program another pair of transmitter and receiver, repeat the above

step 6-10.

BeneVision TMS60 Service Manual 8-13

Page 66

LAN2

(Hospital NetWork)

LAN

(Patient NetWork)

DP2 Monitor2

DP1 Montor1

DP3 Monitor3

Audio

COM2

(Paging)

COM 1

(Recorder/Programming)

DVI Monitor4

USB 2.0(Keyboard/Mouse/USB module devices