Page 1

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

775 Dosimat

Instructions for Use

8.775.1013

2005.06 ti/dm

Page 2

Page 3

Content

Content

1 Overview ...................................................................................................................2

2 Error messages, troubleshooting............................................................................4

2.1 Special messages and error messages ..................................................................... 4

2.2 Diagnosis ................................................................................................................... 5

2.3 RAM initialisation......................................................................................................... 8

2.4 Releasing a locked spindle with insertd Exchange Unit.............................................9

3 Appendix.................................................................................................................10

3.1 Technical specifications............................................................................................ 10

3.2 Warranty and certificates .......................................................................................... 12

3.2.1 Warranty ............................................................................................................. 12

3.2.2 Certificate of Conformity and System Validation................................................ 13

3.3 Scope of delivery and ordering designations ........................................................... 15

Index...........................................................................................................................16

775 Dosimat

Page 4

Page 5

Overview

Explanation of symbols:

< > means "key", e.g. <GO> means key "GO"

DOS.....0.000 ml means "display"

775 Dosimat

1

Page 6

Overview

1 Overview

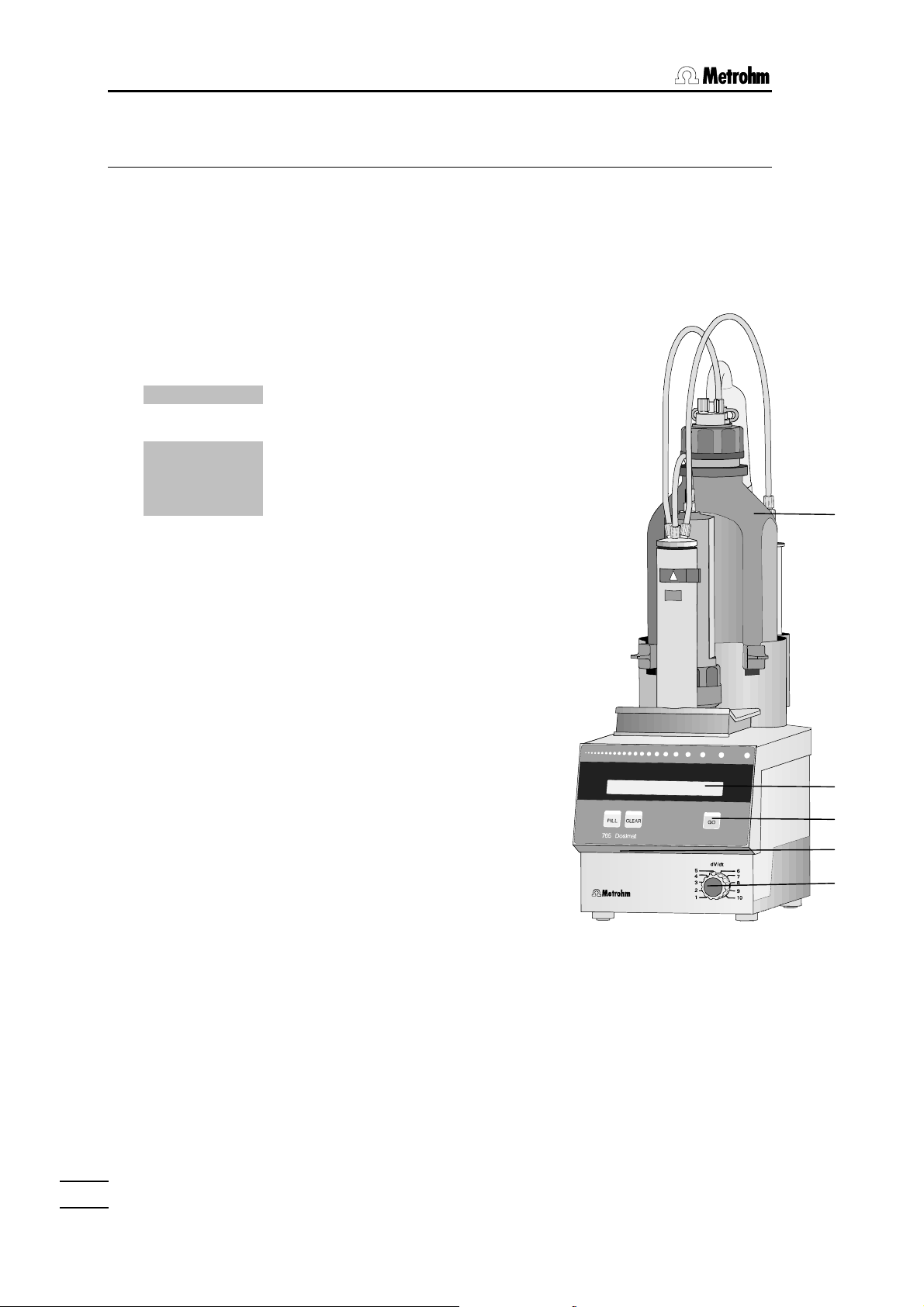

Front view of instrument:

1 Exchange unit

Choose the volume of the Exchange unit in such a

way that a volume between 10...100% of the nominal

volume is expelled.

2 Display

The 16 digit display shows all important information:

DOS 3.456 ml Mode (DOS = dosing) and dosed

DOS ↑ 3.456 ml The piston is moving upwards.

DOS ↓ 3.456 ml The piston is moving downwards.

DOS → 3.456 ml The cock is turned to the right.

DOS ← 3.456 ml The cock is turned to the left.

The display of the status

important for very slow dosings where movements of

the piston cannot be clearly identified.

3 Operating keys at the Dosimat

<FILL> Filling of the dosing cylinder.

<CLEAR> Resetting of the volume display to 0.

<GO> Dosing goes on as long as <GO> is

pressed.

4 Setting of display contrast

5 Analogue setting of dosing rate

Position 1 = lowest rate

Position 10 = highest rate

volume. Dosimat is in stand-by

position

↑ resp.↓ are specially

1

2

3

4

5

775 Dosimat

2

Page 7

Overview

Rear view of instrument:

6 Identification plate

Indication of model, series and serial number.

7 Indication of power voltage

Make sure the current has been adapted correctly

before Dosimat is switched on.

8 Connection for external dosing contact

E.g. 6.2107.000 push button cable.

9 Power connection

In power supply systems, in which strong HF

interferences (transients) are superimposed on the

power voltage, the 775 Dosimat should be

connected via an additional power line filter, e.g.

METROHM 615 model.

The main cables supplied with the instrument are

three-core and equipped with a plug with an earthing

pin. If a different plug has to be fitted, the

yellow/green lead must be connected to the

protective earth. Each break in the earthing inside or

outside the instrument can make it a hazard.

When the instrument is opened or if parts of it are

removed, certain components may be live if the

instrument is connected to the power line. The power

cable must therefore always be unplugged when

certain adjustments are made or parts replaced.

10 Earthing socket

The 775 Dosimat must be grounded correctly and

effectively, if necessary through the separate

earthing socket.

11 Connection for stirrer

In general a Magnetic Stirrer (forms a complete

titrating stand). Other stirrers may be connected as

well, e.g. a METROHM Rod Stirrer. Supply voltage

output: +9 V DC (I ≤ 200 mA).

12 Power switch

Switching on and off Dosimat.

Made by Metrohm

Herisau Switzerland

1.775.

Nr.

230/240 V

220 V

117 V

100 V

f = 50-60 Hz

S = 15 VA

E

on

off

D

11 7612 10 98

775 Dosimat

3

Page 8

2.1. Special messages and error messages

2 Error messages, troubleshooting

2.1 Special messages and error messages

error 1 Check sum error in PROM.

Remedy: Call Metrohm-Service.

error 2 RAM-check: Error in on-chip-RAM.

Remedy: Call Metrohm-Service.

error 3 RAM-check: Error in off-chip-RAM.

Remedy: Call Metrohm-Service.

error 4 RAM-check: Error in on- and off-Chip-RAM.

Remedy: Call Metrohm-Service.

error 5 Check sum error in off-chip-RAM.

Remedy: RAM has to be re-initialized: Switch Dosimat off.

Press <FILL> during switching it on again. Display shows

"RAM init.". Press <GO>. Display shows "RAM init. passed".

<CLEAR> leads to basic program.

no exch. unit! Exchange unit is not (properly) mounted.

Exit: Mount Exchange unit properly.

775 Dosimat

4

Page 9

2.2 Diagnosis

2.2 Diagnosis

2.2.1 General

The 775 Dosimat is a very precise and dependable feeding instrument.

Thanks to its rugged construction, it is highly unlikely that external mechanical or electrical influences will have any adverse effect on its functions.

Although a fault in the instrument can not be excluded with certainty, the

possibility is greater that malfunctions are caused by wrong operation or

handling, through improper connections and the operation with third-party

devices.

Whatever the case, it is always advisable to localise the fault with the diagnostic tests, which can be performed quickly and simply. The customer

need call Metrohm service only when the instrument really has a fault. Further, he can use the results of the specific diagnostic function to provide the

service engineer with much more precise information.

In the case of inquiries, always quote the serial number on model plate (see

page 3) and if applicable the error message.

Procedure

The diagnostic menu listed in section 2.2.2 shows all components for which

detailed instructions (diagnostic steps) are available for checking the functionality.

In the case of a possible malfunction, we advise you to perform either the

corresponding diagnostic step or all diagnostic steps as a routine check on

the instrument.

The reactions of the Dosimat to the instructions must be compared with the

descriptions in the diagnostic step. If the Dosimat do not show the expected reaction ("No" case), the appropriate diagnostic step must be repeated to exclude operating errors. However, it is highly probable that repeated wrong reactions indicate a malfunction.

Equipment required:

3.496.0070 Dummy-exchange unit (or exchange units if possible with different cylinder

6.2107.000 Push-button cable or ordinary test lead with 4 mm banana plugs

-.---.---- Stop watch or watch with second hand.

volumes).

775 Dosimat

5

Page 10

2.2. Diagnosis

2.2.2 Summary

2.2.3 RAM-test ............................................................................6

2.2.4 Diagnosis of spindle zero and cock changeover..............6

2.2.5 Diagnosis of spindle drive .................................................7

2.2.3 RAM-test

1.

Power off.

2.

Remove exchange unit.

3.

Disconnect all cables at rear, except mains cable.

4.

Power on and simultaneously press key <CLEAR> and keep pressed until

5.

6.

RAM test

<GO>

The processor now checks the RAM of the Dosimat, without affecting the content. The exclamation (!) appears when the test is positive. The test can be continued at will. If no fault is found, the following appears:

RAM test ! (exclamation mark is flashing)

The test is broken off with <CLEAR> (Depress the key only until the dotted pattern appears)

no exch. unit!

2.2.4 Diagnosis of spindle zero and cock changeover

1.

Power off.

2.

Insert exchange unit.

3.

Power on.

4.

5.

Dosimat fills.

Remove exchange unit.

To check the spindle zero.

The spindle must be 0.2 - 0.6 mm below the edge of the mounting plate (see Fig. 1).

The link piece of the cock coupling must be parallel to the side walls of the Dosimat (see Fig. 2).

Fig. 1 Fig. 2

0.2 - 0.6 mm

775 Dosimat

6

Page 11

2.2 Diagnosis

2.2.5 Diagnosis of spindle drive

1.

Insert exchange unit and put the burette tip into a collecting receptacle.

2.

Connect push-button cable 6.2107.000 (if available).

3.

Knob 'dV/dt' fully to the right.

4.

Press feed button 6.2107.000 (if not available, <GO>) all the time until the piston

rod reaches the top position and simultaneously measure the time from start to

stop.

5.

The running time of the spindle is 18 ... 22 s.

General rules:

• Dosimat fills automatically.

• Spindle and cock must move in regular speed (observe sound!)

• In the filling position the cock coupling must turn the lever of the exchange unit blamelessly to the

left stop (almost without play and without jamming).

Repeat point 4. and now measure the filling time until the spindle stops at the

lower end.

The running time (filling time) of the spindle is 18 ... 22 s.

6.

Knob 'dV/dt' fully to the left.

7.

<CLEAR>

8.

DOS 0.000 ml

Press feed button 6.2107.000 (if not available, <GO>) all the time and simultaneously measure the time, until, depending on the exchange unit, the volume in the

table below is reached.

1 ml: 0.02 ml

5 ml: 0.1 ml

10 ml: 0.2 ml

20 ml: 0.4 ml

50 ml: 1 ml

9.

The time must be 14 ... 24 s.

<FILL>

DOS 0.000 ml

775 Dosimat

7

Page 12

2.3. RAM-initialisation

2.3 RAM-initialisation

In rare cases, it is possible that major interference signals such as line spikes and lightning can have an adverse influence on the contents of the data memory. If the contents

of the data memory are undefined, this is indicated after “power on“ with ‘error 5'. The

keyboard is then blocked, no entering is possible until the RAM is initialised again.

1.

Disconnect all cables at rear, except mains cable.

2.

Power off and wait 5 s.

3.

Power on and simultaneously press key <FILL> and keep pressed until

4.

5.

RAM init.

<GO>

RAM init. passed

<CLEAR>

DOS 0.000 ml

Dosimat fills.

The RAM-initialisation overwrites the data present in the User-Memory with the standard data.

775 Dosimat

8

Page 13

2.4 Releasing a locked spindle

2.4 Releasing a locked spindle

with inserted Exchange Unit

The burette drive may very occasionally jam at the top or bottom end of the cylinder. If

jamming occurs at the top or when the drive is out of function, the Exchange Unit can no

longer removed. In this case, it is necessary to proceed as follows:

2 screws (M4 countersunk)

Fig. 3

1.

Disconnect instrument from power supply!

2 screws (M3 fillister head)

knob

edge of bench

2.

Remove control knob.

3.

Place instrument over edge of bench to allow the M3 screws to be removed.

4.

Remove M4 screws.

5.

Lift off top part of instrument together with Exchange Unit in the manner shown by

the arrow.

The electronic circuits are now accessible!

On no account touch these!

6.

Remove spindle from mechanical stop by turning the large gear wheel. (In case

that the motor is inoperative, position spindle by hand to zero position.)

775 Dosimat

9

Page 14

3.1. Technical specifications

3 Appendix

3.1 Technical specifications

Exchange units 1, 5, 10, 20, 50 mL burette cylinder volumes,

preferably with flat cock for automatic cock changeover

Resolution 10'000 pulses per 100% of burette volume

Exactitude Metrohm dosimats and exchange units meet the requirements

of ISO/EN/DIN Standard 8655-3 "Piston-operated volumetric

apparatus – Part 3: Piston burets" and DIN Standard 12 650.

Limits according to ISO/EN/DIN 8655-3

Cylinder

volume

1 mL ± 0.6% ± 6 µL ± 0.1% ± 1 µL

5 mL ± 0.3% ± 15 µL ± 0.1% ± 5 µL

10 mL ± 0.3% ± 20 µL ± 0.07% ± 7 µL

20 mL ± 0.2% ± 40 µL ± 0.07% ± 14 µL

50 mL ± 0.2% ± 100 µL ± 0.05% ± 25 µL

Dispensing time for 100% of burette cylinder volume

20 s ... app. 17 min

Display LCD, 16 characters

Material

Cabinet Polybutylene terephthalate (PBTP)

Key cover Polycarbonate (PC)

Ambient temperature Nominal functional range +5... +40°C

Safety specifications Designed and tested in accordance to IEC-Publication 1010,

Max. permissible system. error

Metrohm agencies throughout the world offer you the possibility of checking the accuracy of your exchange units and Dosimats locally and also of certifying them. If the dosing cylinder

and/or piston of an exchange unit are replaced then we recommend that an accuracy check is carried out.

Size of characters: 4.84 x 8.01 mm

Storage, transport - 40... +60°C

safety class I. This manual contains some information and

warnings which have to be followed by the user to ensure safe

operation and to retain apparatus in safe condition.

Max. permissible random error

775 Dosimat

10

Page 15

3.1 Technical specifications

Power supply

Voltage 100, 117, 220, 230/240 V ± 10% (adjustable)

Frequency 50... 60 Hz

Consumption 15 VA

Fuse Thermal fuse (100°C)

Dimensions

Dosimat with Exchange unit

Width 150 mm

Height 450 mm

Depth 275 mm

Weight

Dosimat app. 2,9 kg

775 Dosimat

11

Page 16

3.2. Warranty and certificates

3.2 Warranty and certificates

3.2.1 Warranty

The warranty regarding our products is limited to rectification free of

charge in our workshops of defects that can be proved to be due to

material, design or manufacturing faults which appear within 12

months from the day of delivery. Transport costs are chargeable to

the purchaser.

For day and night operation, the warranty is valid for 6 months.

Glass breakage in the case of electrodes or other glass parts is not

covered by the warranty. Checks which are not a result of material or

manufacturing faults are also charged during the warranty period.

For parts of outside manufacture insofar as these constitute an appreciable part of our instrument, the warranty stipulations of the

manufacturer in question apply.

With regard to the guarantee of accuracy, the technical specifications in the Instructions for Use are authoritative.

Concerning defects in material, construction or design as well as the

absence of guaranteed features, the purchaser has no rights or

claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment

or if the goods show signs of transport damage after unpacking, the

carrier must be informed immediately and a written damage report

demanded. Lack of an official damage report releases METROHM

from any liability to pay compensation.

If any instruments and parts have to be returned, the original packaging should be used if at all possible. This applies above all to instruments, electrodes, burette cylinders and PTFE pistons. Before

embedding in wood shavings or similar material, the parts must be

packed in a dustproof package (for instruments, use of a plastic bag

is imperative). If open assemblies are enclosed in the scope of delivery that are sensitive to electromagnetic voltages (e.g. data interfaces etc.) these must be returned in the associated original protective packaging (e.g. conductive protective bag). (Exception: assemblies with built-in voltage source belong in a non-conductive protective packaging). For damage which arises as a result of noncompliance with these instructions, no warranty responsibility whatsoever will be accepted by METROHM.

775 Dosimat

12

Page 17

3.2 Warranty and certificates

3.2.2 Certificate of Conformity and System Validation

This is to certify the conformity to the standard specifications for electrical appliances and

accessories, as well as to the standard specifications for security and to system validation

issued by the manufacturing company.

Name of commodity: 775 Dosimat

System software: Stored in ROMs

Name of manufacturer: Metrohm Ltd., Herisau, Switzerland

This Metrohm instrument has been built and has undergone final type testing according

to the standards:

Electromagnetic compatibility: Emission

EN50081-1/92, EN55022/class B,

EN55011/class B Generic emission

Electromagnetic compatibility: Immunity

EN50082-1/92 Immunity

IEC1000-4-2/95 (level 4), NAMUR/93 Static discharge

IEC801-3, ENV50140/93+ENV50204/93 (level 2) Radiated rf electromag.field immunity

IEC801-4, IEC1000-4-4/95 (level 3) El.fast transient requirements

IEC801-5, IEC1000-4-5/95 (level 2/3) "Surges" immunity

NAMUR/93 Paragr. 3.2.2., IEC1000-4-11/94 Voltage dips, short interruptions

Security specifications

IEC1010 class1, EN61010 class1, UL3101-1, EN60947:IP31

The technical specifications are documented in the instruction manual.

The system software, stored in Read Only Memories (ROMs) has been validated in connection with standard operating procedures in respect to functionality and performance.

The features of the system software are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS certificate of the quality system ISO 9001 for quality

assurance in design/development, production, installation and servicing.

Herisau, May 14, 1998

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

775 Dosimat

13

Page 18

3.2. Warranty and certificates

Ionenanalytik • Analyse des ions • Ion analysis • Análisis iónico

775 Dosimat

EU- Declaration of Conformity

The company Metrohm AG, Herisau, Switzerland, certifies herewith, that the following

instrument:

775 Dosimat

meets the CE mark requirements of EU Directives 89/336/EWG and 73/23/EWG.

Source of specifications:

EN 50081-1 Electromagnetic compatibility, basic specification Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement and control

equipment

Description of apparatus:

Dispensing unit for titrating and dosing tasks.

Herisau, May 20, 1998

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

775 Dosimat

14

Page 19

3.3 Scope of delivery and ordering designations

3.3 Scope of delivery and ordering designations

Dosimat 775 ......................................................................................2.775.0010

including the following accessories:

1 Push button cable ............................................................................................ 6.2107.000

1 Key for Exchange units......................................................................................6.2739.010

1 Exchange Unit with 20 mL glass cylinder ...................................................... 6.3026.220

1 Power cable with cable socket, type CEE(22), V

Cable plug to customer's specifications

type SEV 12 (Schweiz...).................................................................................. 6.2122.020

type CEE(7), VII (Deutschland...) ..................................................................... 6.2122.040

type NEMA/ASA (USA...) ................................................................................. 6.2122.070

1 Instructions for Use for Dosimat 775................................................................. 8.775.1013

Options

Accessories to separate order and on payment of extra charge:

806 Exchange Unit 6.3026.xxx

Buret unit for Metrohm Dosimats, Titrinos, Titrandos; with glass cylinder, PCTFE/PTFE flat

cock and built-in data chip

806 Exchange Unit with 1 mL glass cylinder........................................................ 6.3026.110

806 Exchange Unit with 5 mL glass cylinder........................................................ 6.3026.150

806 Exchange Unit with 10 mL glass cylinder...................................................... 6.3026.210

806 Exchange Unit with 20 mL glass cylinder...................................................... 6.3026.220

806 Exchange Unit with 50 mL glass cylinder...................................................... 6.3026.250

Ceramic flat cock.................................................................................................. 6.1542.010

Stirrer and working equipment

728 Magnetic stirrer.............................................................................................. 2.728.0040

Magnetic stirring bars, length

12 mm........................................................................................................... 6.1903.010

16 mm........................................................................................................... 6.1903.020

25 mm........................................................................................................... 6.1903.030

802 Rod stirrer ...................................................................................................... 2.802.0010

Electrode holder ................................................................................................. 6.2021.020

775 Dosimat

15

Page 20

Index

Index

Keys are marked with < >, display texts are in bold characters.

A

Accessories........................................15

Arrows ..................................................2

C

CE sign............................................... 14

Certificate ...........................................13

<CLEAR>............................................ 2

Connection

Power .............................................3

Stirrer ...............................................3

D

Delivery............................................... 15

Diagnose............................................ 5ff

Dosing.................................................. 2

Dosing key ...........................................3

Dosing rate...........................................2

E

Earthing ................................................ 3

error X ................................... 4

Error messages.................................... 4

Exchange unit..................................... 15

Expelling rate........................................ 2

F

<FILL> ................................................2

Filling rate.............................................2

G

<GO>.................................................. 2

I

Initializing.............................................. 8

ISO quality system .............................13

N

no exch.unit! ................................... 4

O

Ordering designations ....................... 15

P

Power

Connection ..................................... 3

Switch .............................................3

Voltage ............................................ 3

R

RAM-Initializing .................................... 8

Rate...................................................... 6

S

Scope of delivery ............................... 15

Stirrer connection................................. 3

Stirrer ................................................. 15

T

Technical specifications .................... 10

W

Warranty............................................. 12

775 Dosimat

16

Loading...

Loading...