Page 1

CH-9101 Herisau/Switzerland

Tel. +41 71 353 85 85

Fax +41 71 353 89 01

E-Mail sales@metrohm.ch

Internet http://www.metrohm.ch

774 Oven Sample Processor

Instructions for use

Program version 5.774.0010

8.774.1043

2005.07 dm

Page 2

Page 3

Table of contents

Page

1 Overview 1

1.1 Application range___________________________________________ 1

1.2 Application possibilities_____________________________________ 1

1.3 Instrument description ______________________________________ 3

1.3.1 Oblique view from the right-hand side ......................................... 3

1.3.2 Oblique view from left-hand side.................................................. 4

1.3.3 Rear view....................................................................................... 5

1.3.4 The socket strip (rear panel):........................................................ 5

1.3.5 Guide head ................................................................................... 6

1.3.6 Sample rack.................................................................................. 6

1.3.7 Sample vials.................................................................................. 7

2 Installation 8

2.1 Setting up the instrument____________________________________ 8

2.2 Power supply ______________________________________________ 8

2.3 Safety considerations ______________________________________ 10

2.4 Arranging the accessories__________________________________ 11

2.4.1 Connecting the keyboard ........................................................... 11

2.4.2 Equipping the guide head ..........................................................12

2.4.3 Adjusting the sample rack .......................................................... 12

2.4.4 Adjusting the needle position .....................................................13

2.4.5 Installation of the tubing system and the drying flask................ 14

2.4.6 Installation of the measuring cell ................................................ 15

2.5 Integration ________________________________________________ 15

2.5.1 Remote connections................................................................... 16

2.5.2 External bus connections ...........................................................19

2.5.3 Serial connection (RS232) .......................................................... 20

2.5.4 Connecting a printer ................................................................... 21

3 Introduction 23

3.1 Configuration _____________________________________________ 23

3.1.1 Basic settings ............................................................................. 23

3.1.2 Oven settings.............................................................................. 24

3.1.3 Rack definitions .......................................................................... 25

3.1.4 Dosing units ................................................................................ 26

3.1.5 RS232 interface........................................................................... 27

3.1.6 Lock keyboard functions ............................................................28

3.2 Manual operation __________________________________________ 30

3.3 Methods and Sequences ___________________________________ 33

3.3.1 Designing a method ................................................................... 33

3.3.2 LEARN mode and TRACE function ............................................ 34

3.3.3 Process control........................................................................... 35

3.3.4 POWER-UP methods.................................................................. 36

4 Oven control and gas flow 37

4.1 Oven control ______________________________________________ 37

4.2 Gas flow __________________________________________________ 38

4.3 KF Moisture determination _________________________________ 40

Page 4

Table of contents

5 Detailed description 43

5.1 The display ________________________________________________43

5.2 The keyboard ______________________________________________44

5.3 Menu organization _________________________________________62

5.4 Command reference________________________________________76

5.5 Printing reports ____________________________________________ 85

5.6 Sample racks ______________________________________________89

5.7 Dosimats and Dosinos______________________________________92

5.8 Remote Interface ___________________________________________97

5.9 Operation via RS232 Interface______________________________101

5.10 The remote control tree ___________________________________106

5.11 Description of the remote control commands _______________116

5.12 Properties of the RS232 Interface __________________________131

Page

5.2.1 Individual key functions .............................................................. 45

5.2.2 Data entry ................................................................................... 59

5.2.3 Text Entry .................................................................................... 60

5.3.1 Configuration .............................................................................. 63

5.3.2 Parameters ................................................................................. 68

5.3.3 User Defined Methods ............................................................... 75

5.5.1 Automatic reports ....................................................................... 88

5.5.2 Manual reports............................................................................ 88

5.9.1 General rules ............................................................................ 101

5.9.2 Calling up Objects ................................................................... 102

5.9.3 Triggers..................................................................................... 103

5.9.4 Status and Error Messages...................................................... 103

5.9.5 Error Messages, Errors............................................................. 104

5.10.1 Overview ................................................................................. 106

5.10.2 &Mode .................................................................................... 106

5.10.3 &Config................................................................................... 108

5.10.4 &Info ....................................................................................... 109

5.10.5 &Setup .................................................................................... 112

5.10.6 &UserMeth.............................................................................. 113

5.10.7 &Assembly.............................................................................. 113

5.10.8 &Diagnose.............................................................................. 115

5.11.1 &Mode … ............................................................................... 116

5.11.2 &Config … .............................................................................. 119

5.11.3 &Info …................................................................................... 122

5.11.4 &Setup … ............................................................................... 125

5.11.5 &UserMeth …......................................................................... 127

5.11.6 &Assembly …......................................................................... 128

5.11.7 &Diagnosis … ........................................................................ 130

5.12.1 Data Transfer Protocol ........................................................... 131

5.12.2 Handshake ............................................................................. 131

5.12.3 Pin Assignment....................................................................... 135

5.12.4 What to do if Data Transfer fails? ........................................... 136

Page 5

Table of contents

Page

6 Appendix 137

6.1 Error messages __________________________________________ 137

6.2 Technical data____________________________________________ 140

6.3 Maintenance and servicing ________________________________ 142

6.3.1 Maintenance / service............................................................... 142

6.3.2 Servicing / care ......................................................................... 142

6.4 Diagnosis ________________________________________________ 143

6.4.1 General ..................................................................................... 143

6.4.2 Preparing the instrument ..........................................................144

6.4.3 Main memory (RAM)................................................................. 145

6.4.4 Display ......................................................................................145

6.4.5 Keypad...................................................................................... 146

6.4.6 Remote interface....................................................................... 146

6.4.7 RS232 interface......................................................................... 147

6.4.8 External bus interface ...............................................................147

6.4.9 Beeper....................................................................................... 148

6.4.10 Rack code recognition............................................................ 148

6.5 Initialise data memory_____________________________________ 149

6.6 Validation / GLP __________________________________________ 152

6.7 Warranty and Conformity__________________________________ 154

6.7.1 Warranty.................................................................................... 154

6.7.2 EU Declaration of Conformity ................................................... 155

6.7.3 Certificate of Conformity and System Validation...................... 156

6.8 Accessories______________________________________________ 157

7 Index 159

Page 6

Page 7

1.1 Application range

1 Overview

1.1 Application range

The Metrohm 774 Oven Sample Processor is a very versatile instrument. It

has been specially designed for laboratory use and can be used for a wide

range of applications. It provides an essential service when large numbers

of samples have to be processed in which the samples require to be

heated and/or whenever it is necessary to remove moisture or organic solvents from solids or liquids by the application of heat.

The construction of the 774 Oven Sample Processor has been principally

based on the determination of moisture by the oven method. The sample

heated in the oven block releases its moisture as water vapor which is

transferred to a measuring cell in a stream of gas. The moisture determination in the cell can be carried out either coulometrically or volumetrically according to Karl Fischer.

This method is becoming increasingly popular wherever moisture determinations have to be carried out in matrices which interfere with the moisture

determination process or which release their moisture only with great difficulty.

Its comprehensive range of communications possibilities means that it

cannot just work together with the wide range of Metrohm titrators, meters

and dosing instruments via its parallel remote interface and its serial RS232

interface, but that it can also control or be controlled by any instrument

which is equipped with a suitable communications interface. These abilities

mean that it is predestined for automation tasks in a modern laboratory,

even within highly integrated laboratory data systems.

1.2 Application possibilities

Despite its comprehensive range of commands and numerous configuration possibilities the 774 Oven Sample Processor, with its capability of

managing operator-defined methods, offers an uncomplicated operation

system which is suitable for routine use.

The standard methods for routine tasks which we supply together with the

instrument can be used without any further ado. After a short familiarization

period the operators can alter them to suit their own requirements and store

them in the instrument. In this way the 774 Oven Sample Processor can

774 Oven Sample Processor, Instructions for use

1

Page 8

1 Overview

also be used for demanding special applications as well as for routine

tasks.

The operating sequences for processing individual samples can be freely

defined within wide limits. The same applies to the start and final sequences, which always need to be carried out once before the start and

once at the end of a sample series.

A learning mode is provided for the creation of operating sequences; with

its help command parameters can be set manually.

The standard sample rack offers place for 36 sample vials (22 mm x 38

mm). Freely definable "special beaker" positions can also be defined. These

are used for positioning conditioning beakers, which can be selected in

each part-sequence, on the rack.

2

774 Oven Sample Processor, Instructions for use

Page 9

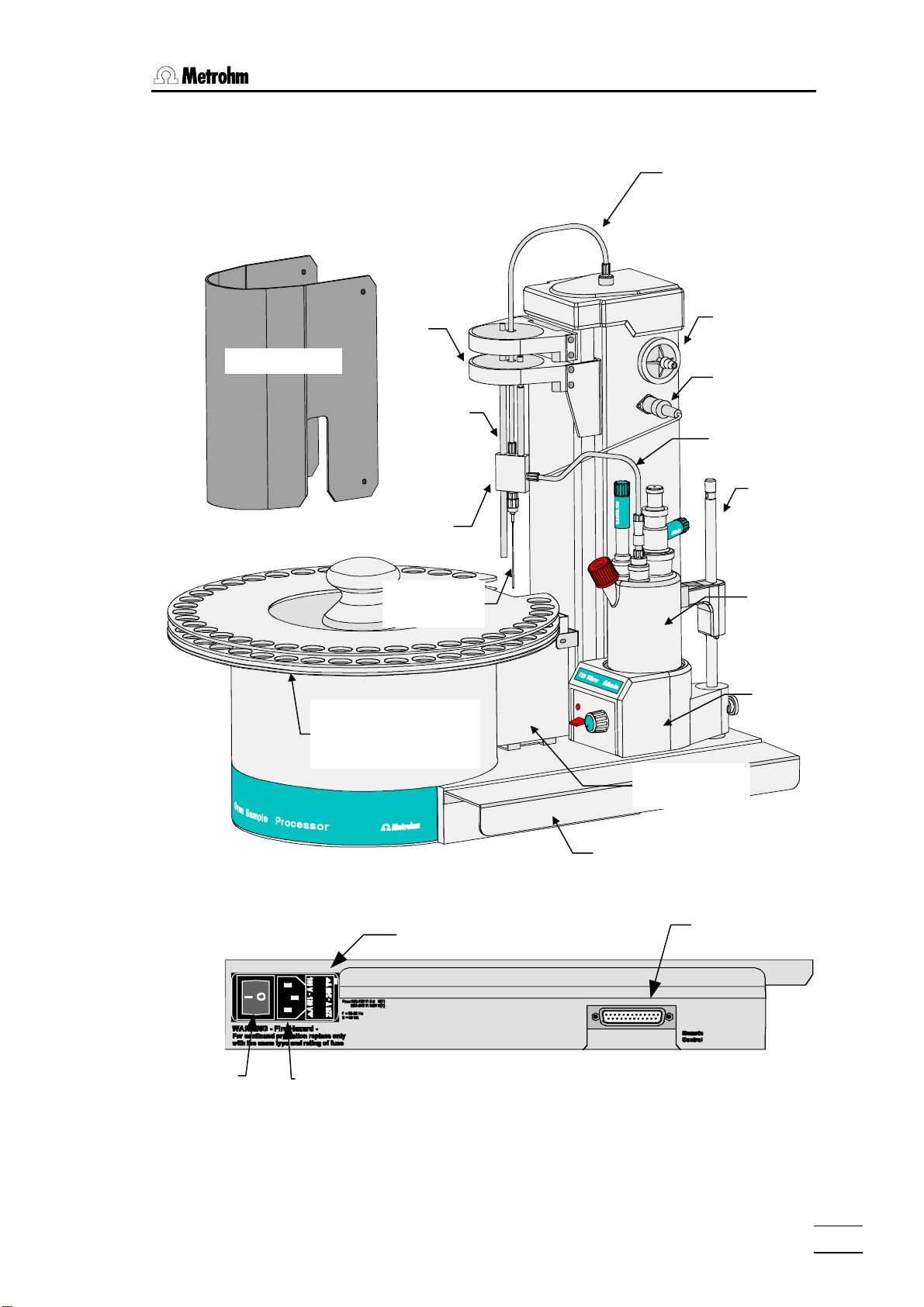

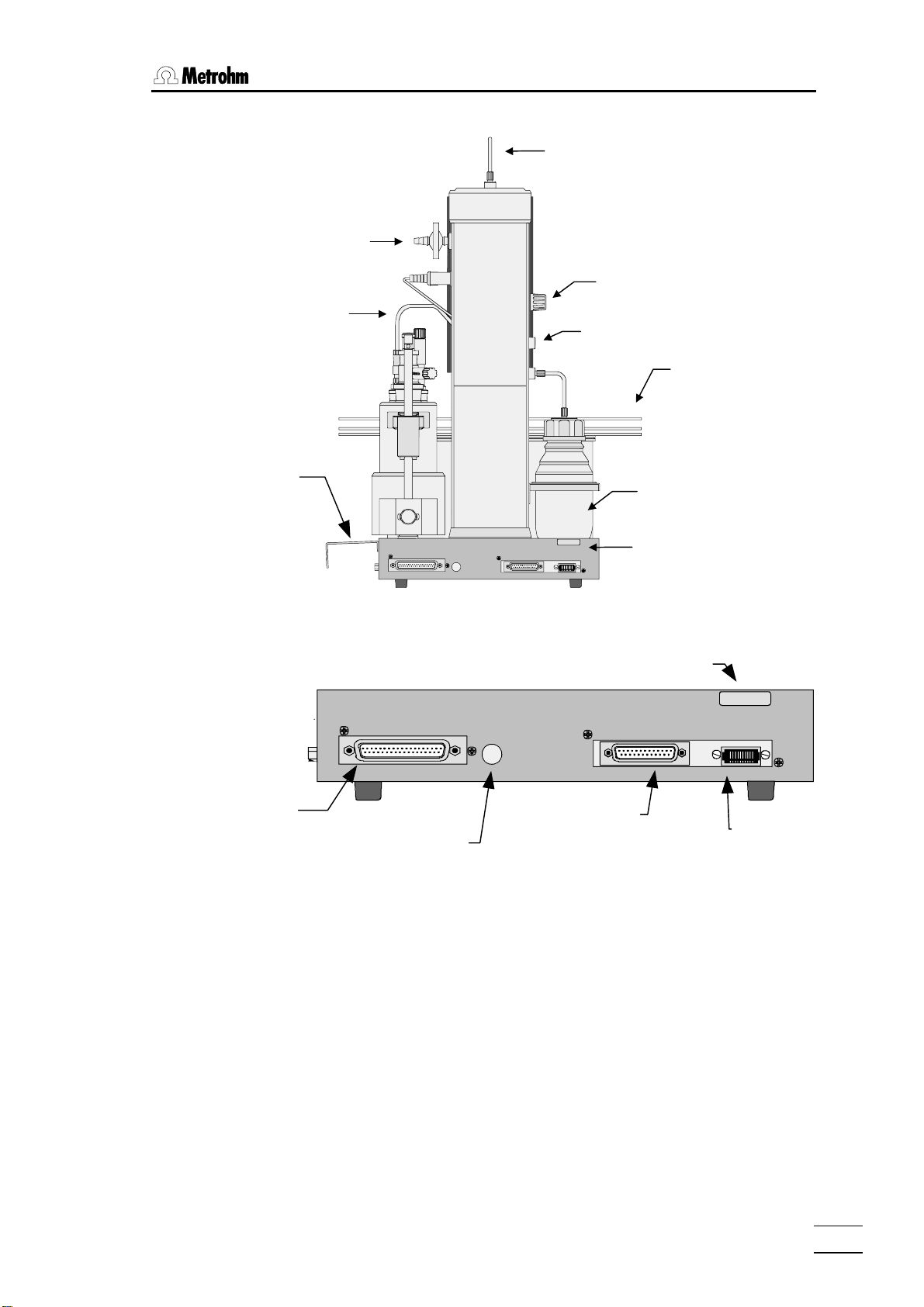

1.3 Instrument description

A

1.3 Instrument description

1.3.1 Oblique view from the right-hand side

equipped with Coulometer cell

Gas supply

Protective cover

Sample rack with 36

places (including conditioning position)

Lift

Guide rod

(adjust-

Guide head

Double

hollow needle

ir inlet filter

Connection for

outlet heater

Outlet heater /

transfer hose

Support rod

Coulometer cell

with generatorand indicator

electrode

Magnetic stirrer

The socket strip:

Mains switch

Fuse holder

Mains connection

Oven with

protective jacket

Plug cover

Remote

interface

774 Oven Sample Processor, Instructions for use

3

Page 10

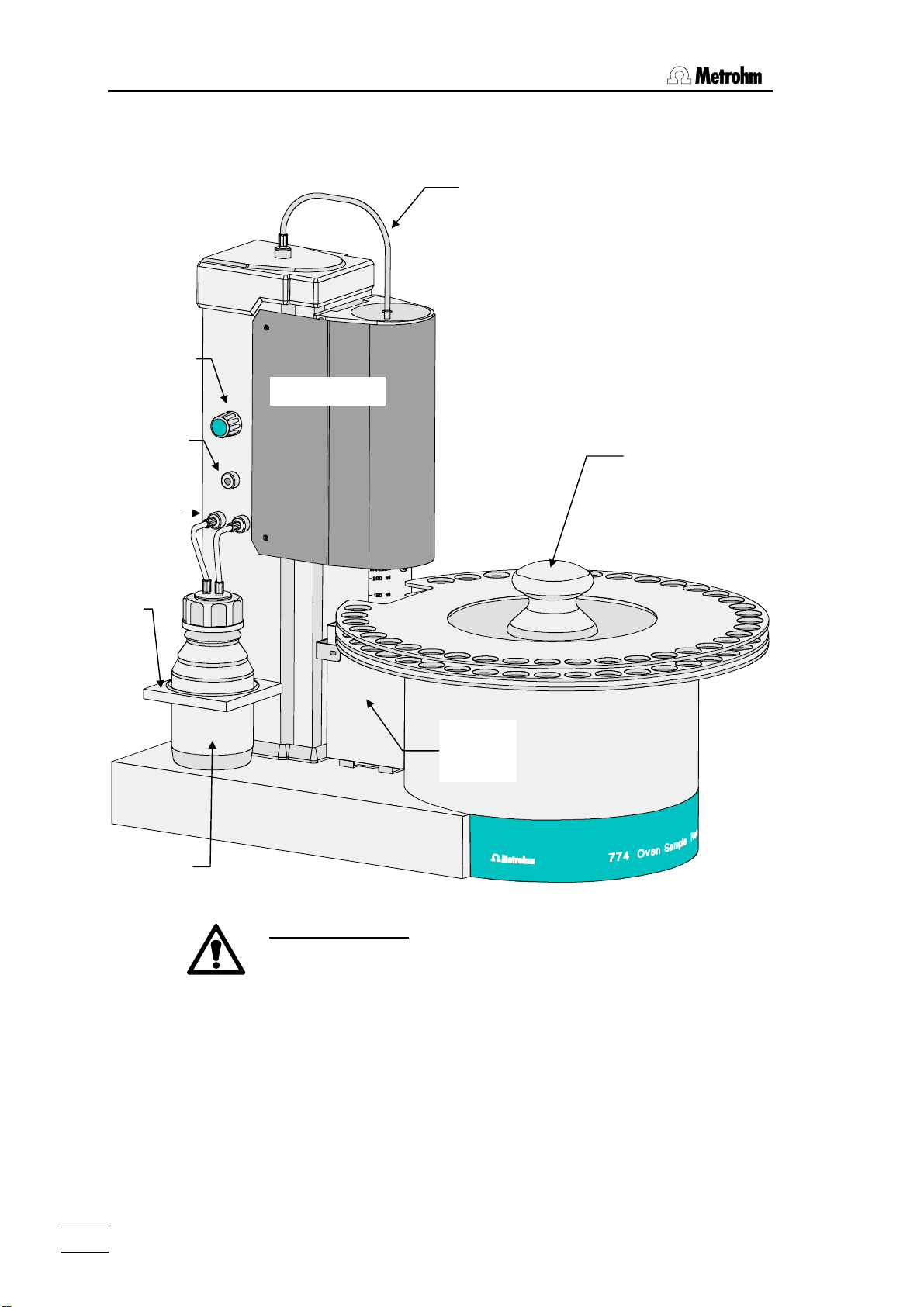

1 Overview

j

1.3.2 Oblique view from left-hand side

with protective cover in position

Flow regulator

Protective cover

Gas supply

Inert gas

Drying flask

connections

Holder for

drying flask

Drying flask with

molecular sieve

inlet

Sample rack

with grip

Oven with

protective

acket

Safety information:

The protective cover and the plug cover have to be in position for

safety reasons.

The plug cover prevent spilt solvents or chemicals from adversely

affecting the connections and interfaces.

4

774 Oven Sample Processor, Instructions for use

Page 11

1.3 Instrument description

p

/

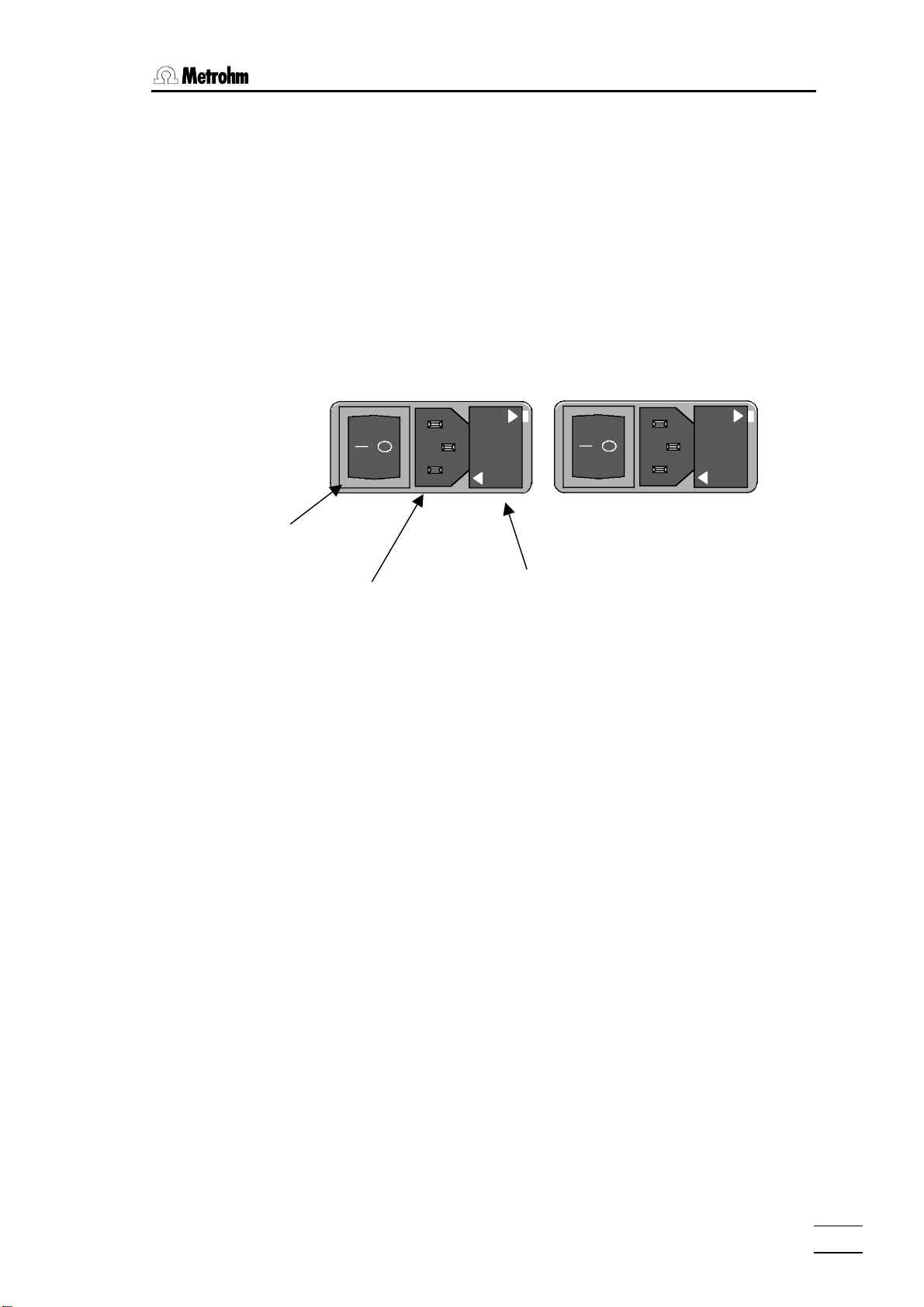

1.3.3 Rear view

Air inlet filter

Outlet heater

transfer tube

Plug

cover

Gas supply

Flow regulator

Inert gas inlet

Sample rack

Drying flask

External Bus

Address

1.3.4 The socket strip (rear panel):

External Bus

Address

External bus

connection

External bus

address

selector

The 'External Bus' address must be set to 0 (zero).

0000/ 00 00

Type 1.774._

RS 232 Keyboard

Made by Met rohm Herisa u Switzerl and

Serial number

Serial

RS 232 interface

Rear socket

stri

Type 1.774. _

RS 232

Made by Metrohm Heri sau Switz erland

0000/ 00 00

Keyboard

Keyboard

connection

774 Oven Sample Processor, Instructions for use

5

Page 12

1 Overview

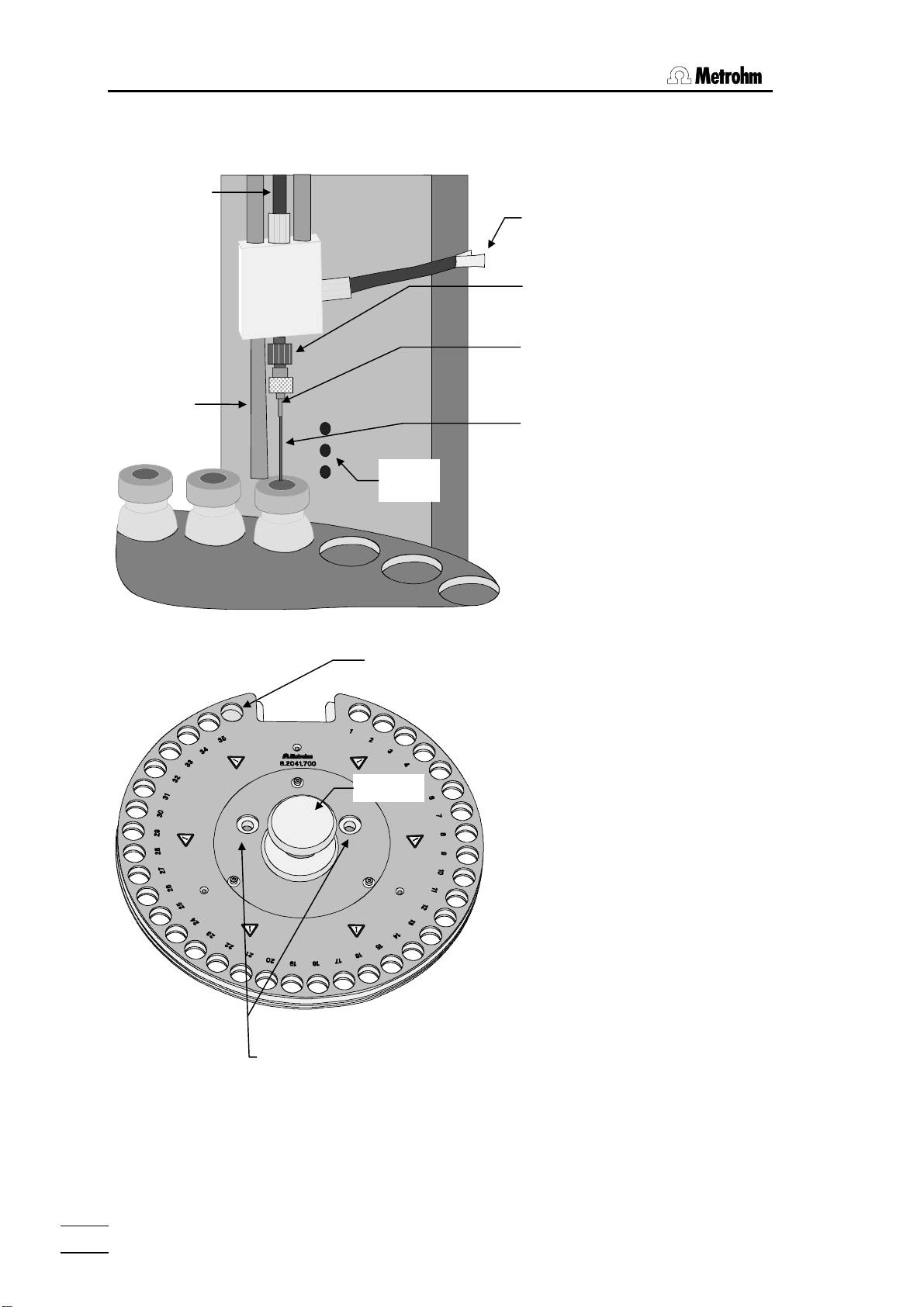

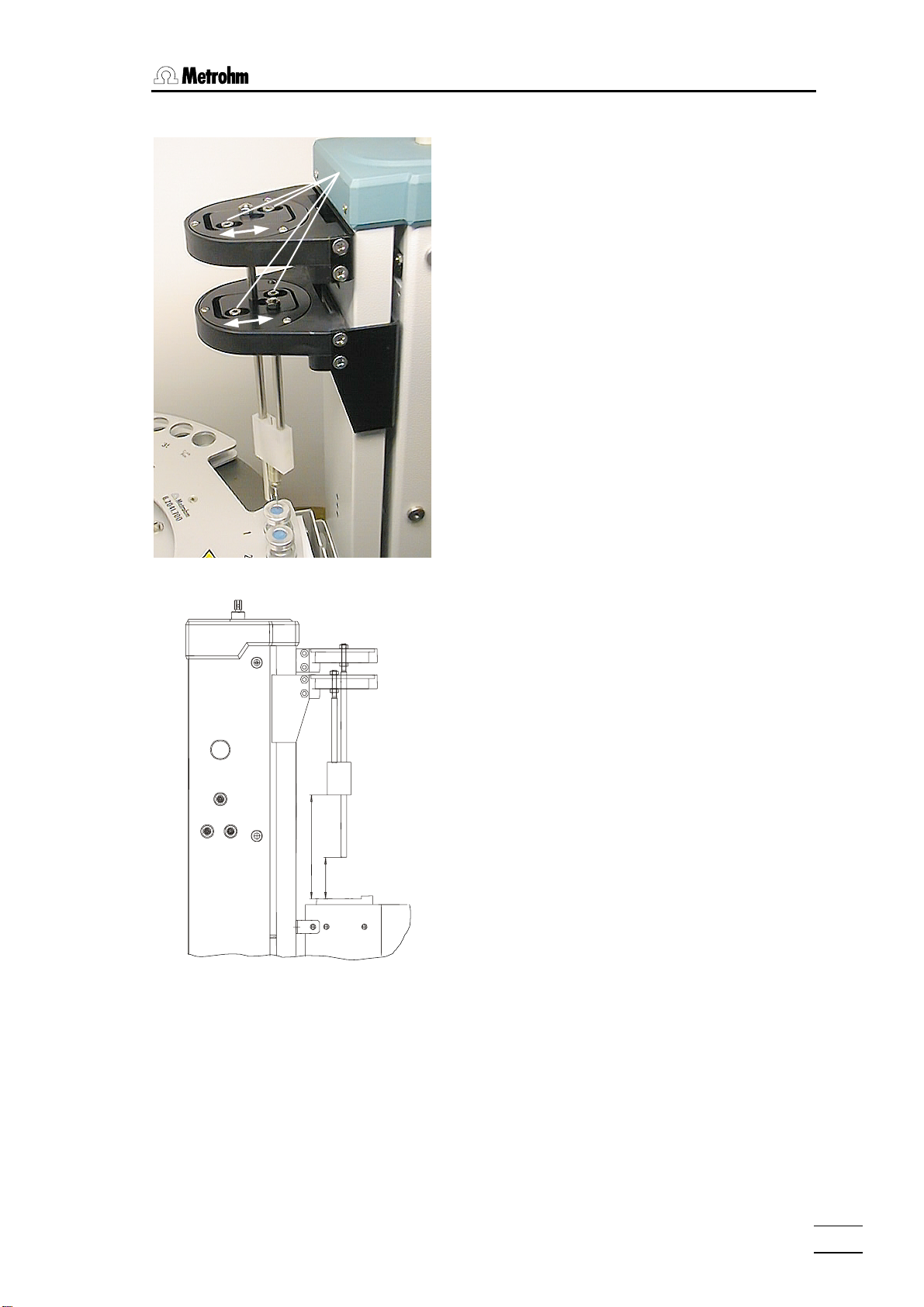

(

1.3.5 Guide head

Gas supply

(gas inlet)

Guide rod

(adjustable)

Infrared

sensors

Heated transfer hose

(outlet heating)

Needle adapter

made of PEEK

Hollow needle with

Luer connection

exhaust)

Hollow needle

(injection needle)

The tower of the 774 Oven Sample

Processor is equipped with infrared

beaker sensors which detect the

presence of a vial in front of the

tower. This "beaker test" is carried

out after every MOVE command.

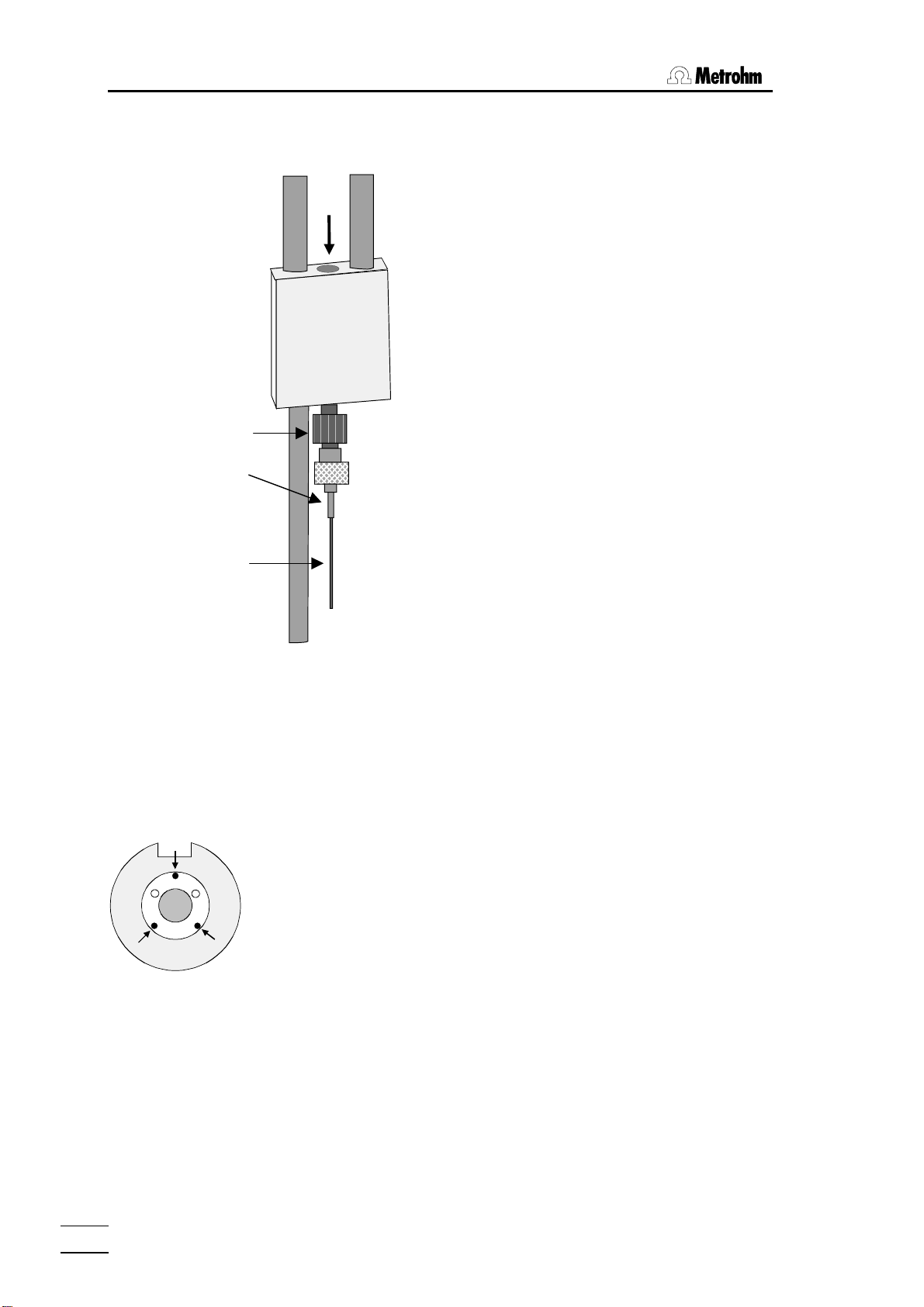

1.3.6 Sample rack

Special position 1 (for conditioning vial)

.

d

on

C

.

os

P

Grip

Openings for

guide bolts

Warning!

If sample vials on the racks have just been processed

they could have a temperature above 200°C!

The removable sample rack offers

space for 35 sample vials and a conditioning vessel. A snap-in mechanism

ensures that the rack base is blocked

when the rack is removed so that no

sample vials can fall out. When the

rack is replaced this block is removed

so that the upper part of the rack with

the sample vials can be rotated.

The rack can only be exchanged in the

base position (recess in front of the

tower). The sample rack is moved to

the base position by pressing the

<RACK> key.

When replacing the rack take care that

it is positioned correctly. The guide

bolts of the turntable must be located

in the openings provided for them in

the sample rack. The recess of the

rack must surround the oven block.

6

774 Oven Sample Processor, Instructions for use

Page 13

1.3 Instrument description

When the sample rack is positioned the rod magnets on the base of the

rack are read in automatically. The arrangement of the magnets defines the

rack code, which is allocated to an internal position table with whose help

the 774 Oven Sample Processor recognizes the arrangement of the vial positions on the rack.

The above arrangement corresponds to the magnet code 000001.

1.3.7 Sample vials

The sample rack (order no. 6.2041.700) is intended for use with sample vials (order. no. 6.2419.000) with 21 mm outer diameter. Only these vials

guarantee optimal heat transfer between the oven block and the sample.

Use only septum seals with a PTFE insert (order. no. 6.1448.050), as these

are exposed to high temperatures. The sample vials must be tightly sealed

by using the septum closure crimpers.

Closures which are not sufficiently tight can cause significant errors in the

results. Closures which are not mounted properly may cause damage to

the injection needle.

774 Oven Sample Processor, Instructions for use

7

Page 14

2 Installation

2 Installation

2.1 Setting up the instrument

Packaging

The 774 Oven Sample Processor is supplied with the accessories in separate special packages designed to ensure maximum protection. These contain shock-absorbing foam linings. As only these special packages guarantee damage-free transport of the instrument, it is essential you store them in

a safe place.

Control

Immediately following delivery, check that the consignment is complete and

undamaged (compare with delivery note and accessories list in the Instructions for Use, page 155). In case of damage see "Warranty", page 154.

Setting up

The 774 Oven Sample Processor is a rugged instrument and may be used

in rough environments such as laboratories and manufacturing plants. It

must not be exposed to a corrosive atmosphere.

If the sample changer is operated in a rough environment, regular maintenance is strongly recommended.

2.2 Power supply

Follow these instructions to connect the 774 Oven Sample Processor to the power supply. Ensure that the instrument is never operated with incorrect voltage ratings and/or with fuses of an incorrect

rating, otherwise there is a fire hazard!

Setting the instrument supply voltage

Before switching on the 774 Oven Sample Processor for the first time,

check that the line voltage set on the instrument (see next page) matches

the local power supply voltage. If this is not the case, change the voltage

setting as follows:

• Disconnect line cable

Unplug the 774 Oven Sample Processor.

Remove fuse holder

Using a screw driver, loosen the fuse holder and pull it out.

774 Oven Sample Processor, Instructions for use

8

Page 15

2.2 Power supply

Power switch

• Checking and replacing fuse

Carefully remove the built-in fuse and check its specifications. (The position of the fuse in the fuse holder is marked by the white arrow printed

next to the supply voltage):

2.0 A (slow) ord. no. U.600.0019

• Replace fuse

Replace fuse if necessary and reinsert it in the fuse holder.

• Insert the fuse holder

Insert the fuse holder according to the appropriate supply voltage. The

white arrow besides the desired voltage has to point towards the white

block mark printed on the fuse holder's panel (see below).

220 – 240 V

100 – 120 V

100

-

120 V

240 V

-

220

220 - 240 V

Power plug Fuse holder

100 - 120 V

774 Oven Sample Processor, Instructions for use

9

Page 16

2 Installation

2.3 Safety considerations

• Do not operate the 774 Oven Sample Processor without protective covers.

The plug cover protects the connectors from spillage. Organic solvents

are always a potential serious fire hazard.

The protective cover of the guide head prevents the access to the stroke

path of the injection needle. Never get your hand beneath the protective

cover while operating the instrument.

• If you work with inflammable samples the 774 Oven Sample Processor

has to be operated under a safety hood. In addition to that you have to

use nitrogen or another inert gas instead of the integrated air pump. See

chapters 2.2.4 and 4.2.

• Always wear safety goggles while working with the 774 Oven Sample

Processor.

The oven can reach 250 °C and more. The heating block is covered by

a protective jacket. Keep your hands off the heated oven or the sam-

ple in work. Do not reach under the protective cover.

Caution! Just after processing sample vials may be hot, too. Even parts of

the sample rack can reach elevated temperature up to 60 °C.

• Allow the sample vials to cool off before removing vials from the rack or

detaching the sample rack .

The 774 Oven Sample Processor may be used for sample processing with

extraction methods at higher temperatures. These kinds of method require

special safety precautions.

Before working with inflammable organic solvents read the relevant

safety sheets or consult common accessible safety literature.

• Do not heat organic solvents to their flash point!

• Use nitrogen or another inert gas.

If failure or malfunctioning occurs during operation of the 774 Oven Sample

Processor, it is recommended to first search for the cause with the help of

the diagnostic functions (see Instructions for Use, page 143). If this is of no

help in rectifying the disorder or the cause of the malfunction cannot be

identified, the Metrohm Service Department should be consulted.

774 Oven Sample Processor, Instructions for use

10

Page 17

2.4 Arranging the accessories

If opening the instrument is unavoidable, the following safety precautions

are to be strictly adhered to:

Before opening the instrument disconnect it from all electrical

sources. Make sure that the power plug has been pulled out.

Only in exceptional cases should the instrument be opened while it is

switched on. Because parts that conduct current are exposed in this case,

this should only be undertaken by an expert who is acquainted with the associated dangers.

Electronic components are sensitive to static electricity and can be destroyed by discharge. Before touching any components inside the instrument, both the person and his tools should be grounded by grasping a

grounded object (for example: a metallic part of the casing of the instrument or a radiator) in order to eliminate any static electricity.

When peripheral instruments are connected to the 774 Oven Sample Processor, the sample changer and the instruments to be connected have to be

switched off, otherwise all instruments could suffer damage.

If it becomes apparent that the instrument can no longer be operated safely

it must not be used at all.

2.4 Arranging the accessories

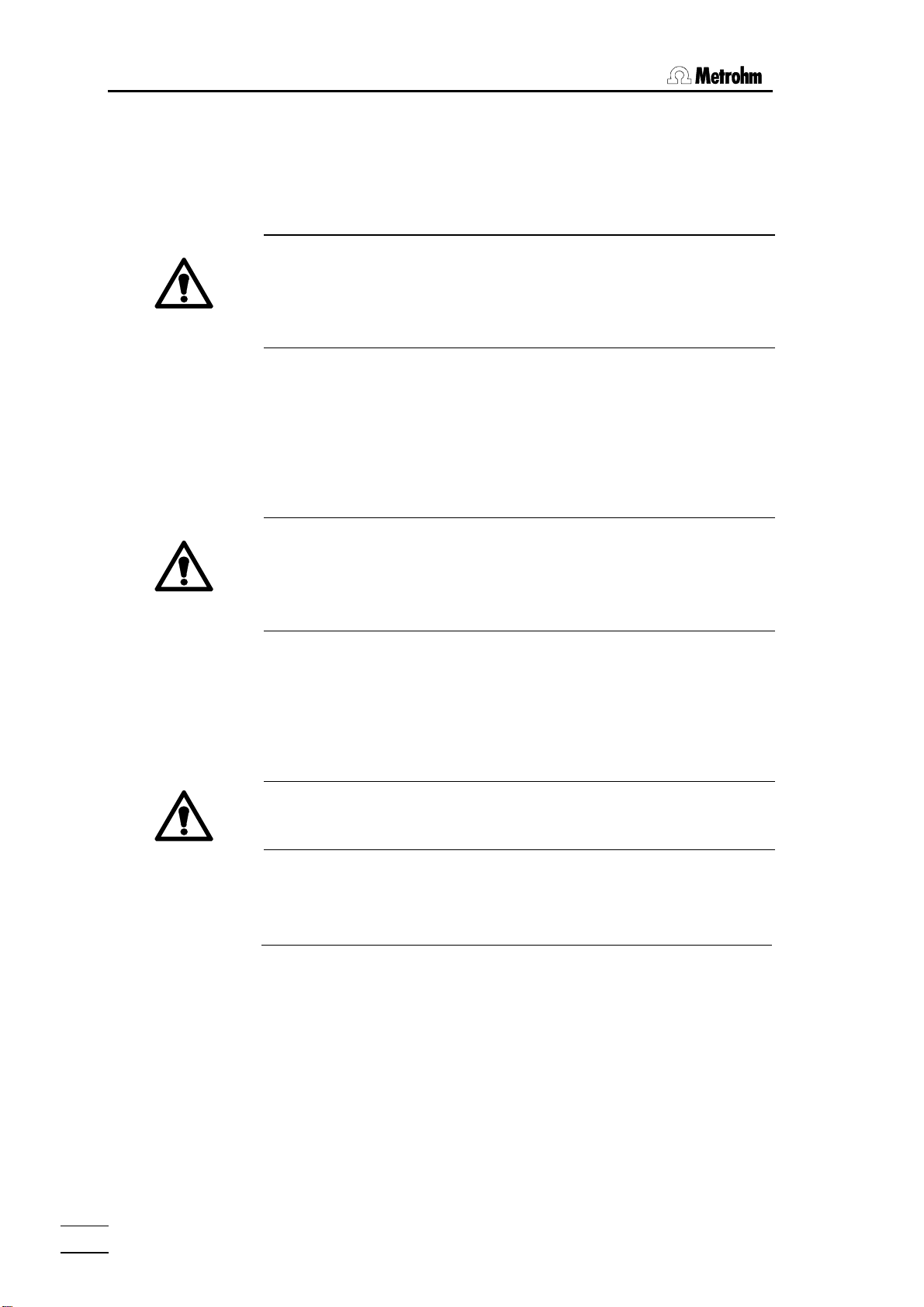

2.4.1 Connecting the keyboard

The keyboard is connected to the

keyboard socket at the rear of the

sample changer. To disconnect

press the plug together slightly on

both sides.

774 Oven Sample Processor, Instructions for use

11

Page 18

2 Installation

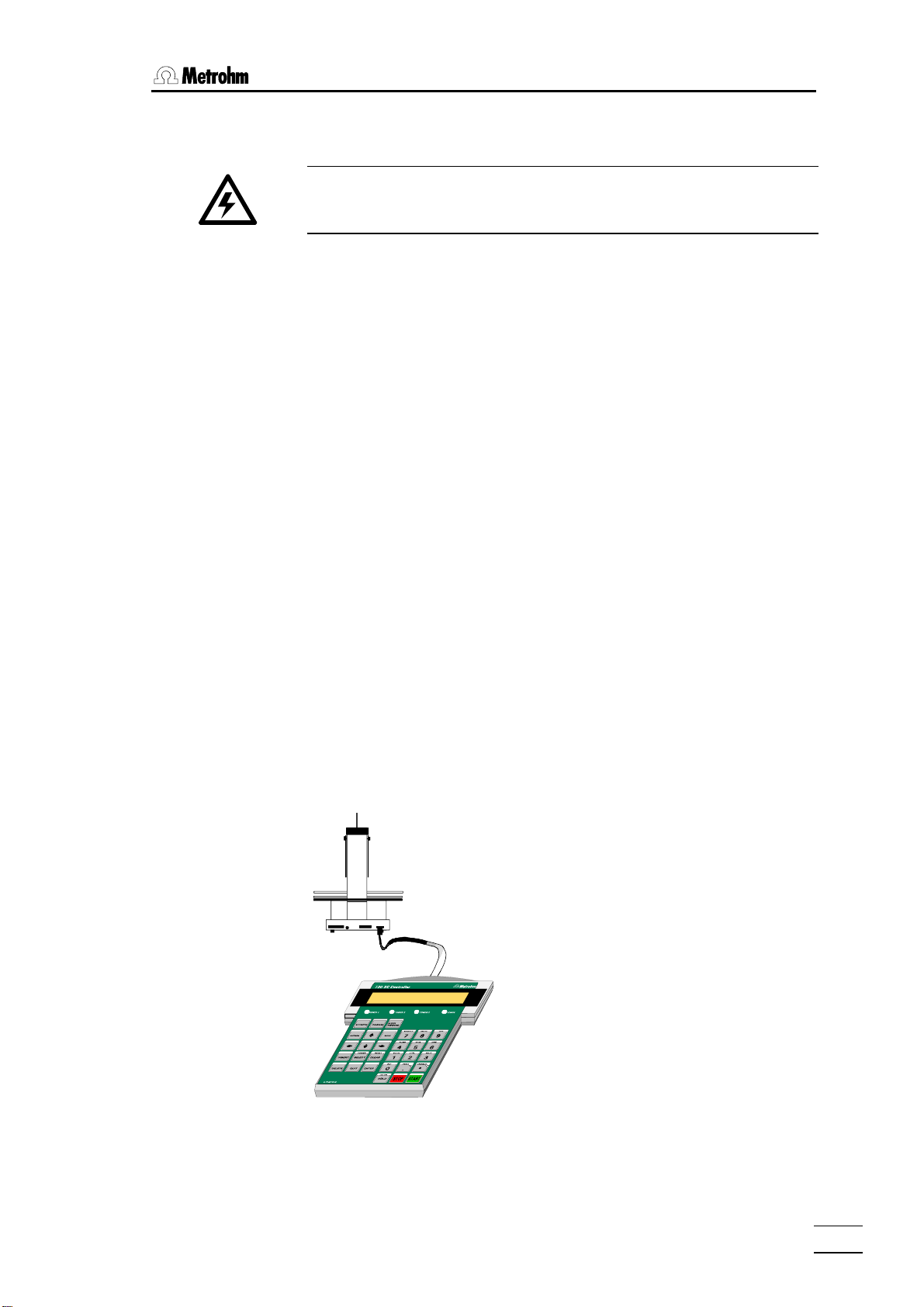

2.4.2 Equipping the guide head

• Screw the needle adapter (6.1808.150) onto the

bottom of the guide head.

• Attach the outlet hollow needle (6.2816.060) to the

Luer connection of the needle adapter.

• Carefully introduce the hollow injection needle

Guide head

Needle adapter

Hollow outlet

needle

Hollow injection

needle

(6.2816.050) into the guide head from above (see

arrow). Pull the needle downwards to the full extent.

• Now lead the gas inlet (6.1805.470) through the

lift head from above and screw it onto the guide

head (see arrow). Connect the other end of the

tubing to the gas outlet opening on the top of the

tower. Take care that the connections are tight.

If necessary, the injection needle may be lifted by attaching

the PTFE spacer ring (that is supplied with) to the needle.

If you wish to avoid the penetration of the sample by the

needle, you may lift the injection needle by the use of two

different M6/M8 adapters (order no. 6.1808.040 and

6.1808.090). The injection needle must only puncture the

vial's seal by a few milimeters.

2.4.3 Adjusting the sample rack

• Check the positioning of the sample rack. After switching on the 774

Oven Sample Processor place the rack on the instrument and let it move

to the first sample position by pressing the <Í> key. The circular

opening of sample position 1 of the rack must coincide with the opening

of the oven block beneath it.

• If this is not the case then loosen the three Allen screws (see diagram) on

the sample rack. Carefully adjust the upper part of the rack and then retighten the Allen screws.

• Now place a sample vial with a septum cap closure in sample position 2

and press the <Í> key again. By carefully pressing the <Ð> key to

lower the lift it is now possible to check whether the penetration needle

correctly penetrates the center of the sample vial septum and that the vial

is pressed down into the oven opening without tilting.

Warning!

Do not lower the needle too far. It must not contact the base of the vial and

become bent.

• Press the <RACK> key in order to return the sample rack and lift to the

starting position.

• Readjust the sample rack, if necessary.

774 Oven Sample Processor, Instructions for use

12

Page 19

2.4 Arranging the accessories

2.4.4 Adjusting the needle position

In addition to the adjustment of the sample rack, the

Allen screws

position of the needle (radial positioning) may be

adjusted.

After the adjustment of the sample rack proceed as

follows:

1. Place a sealed beaker under the needle.

2. Lower the needle on to the seal.

3. Loosen the Allen screws of the sliding de-

4. Position the needle in the centre of the seal.

5. Fasten the sliding devices.

6. Press <RACK>. The instrument moves to

7. Remove rack.

vices.

initial position.

Positioning the needle

±1,5

111

±1

44

Distances of the guide head and rod

(in mm)

8. Check the distances according to the drawing on the right and adjust if necessary.

774 Oven Sample Processor, Instructions for use

13

Page 20

2 Installation

2.4.5 Installation of the tubing system and the drying flask

A stream of gas with a constant flow rate is required to transfer the moisture

which is released when the sample is heated to a measuring vessel. You

can either use the built-in pump to supply air or use an inert gas such as nitrogen for this purpose.

Inert gas connection

Connect the inert gas to the 'Air/N

the instrument. Make sure that the pressure in the supply line is less than 1

bar. The inert gas should be dried by passing it through the drying flask.

The flow rate is measured and monitored by the 774 Oven Sample Processor. A solenoid valve is used to switch the gas flow on and off.

Air supply from the built-in pump

A stream of air can be used for the determination of chemically and thermally stable samples. The pump built into the tower of the 774 Oven Sample Processor provides a sufficiently large and stable flow rate.

It is essential that the flow of gas is dried and filtered. If the pump is used

the air is drawn in through the right-hand side of the instrument. A dust filter

(6.2724.010) should be mounted on the 'Inlet filter' connection. The gas is

dried by mounting a drying flask on the left-hand side of the instrument, as

shown in the drawing alongside.

Gas flow

The drying flask is filled with molecular sieve and the outlet tube

(6.1821.050) with its filter is fitted to the drying flask insert (6.1602.140).

2 in

Air/N

Screw the completely assembled insert onto the drying flask and attach the

two tubing connections (6.1805.520, 7 cm long) to the drying flask cap.

Place the flask in the drying flask holder and then attach the free ends of

from to

the tubing connections to the corresponding connections on the tower of

the 774 Oven Sample Processor. The tubing connected to the inlet tube in

Drying flask

the drying flask is connected to the left-hand connection marked 'from

Drying flask'. The carrier gas will stream into the head space of the flask

and penetrate the molecular sieve. Then it can stream up inside the outlet

tube and enter the tower's gas tubings via the 'from Drying flask' connector'.

The filling of the drying flask must be replaced from time to time. The interval

may vary depending on the length of use, moisture content of the gas and

atmospheric humidity. Read the information given on the label of the molecular sieve container for more details.

in' connection on the left-hand side of

2

774 Oven Sample Processor, Instructions for use

14

Page 21

2.5 Integration

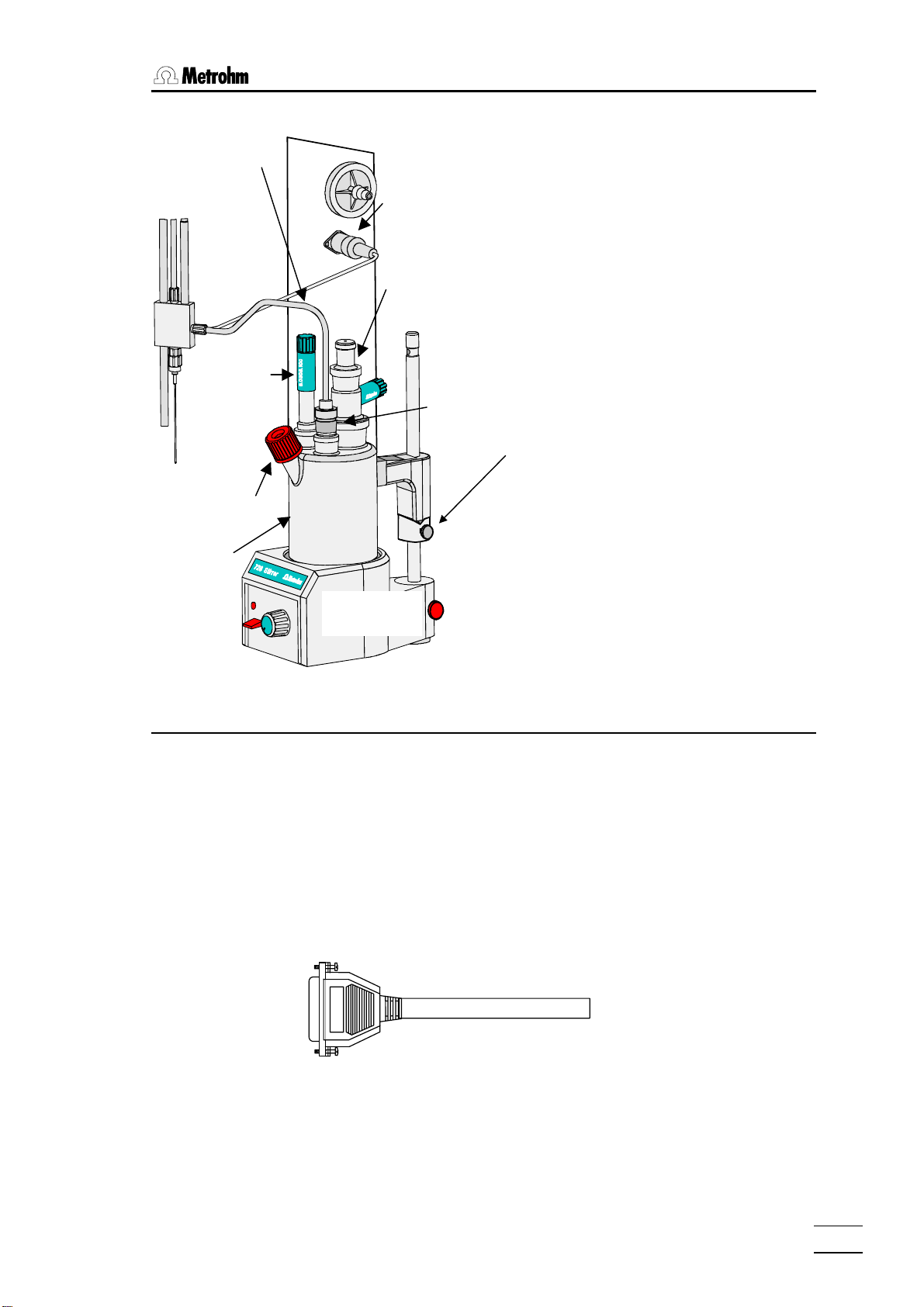

2.4.6 Installation of the measuring cell

Transfer hose with

outlet heating

Indicator

electrode

Septum

stopper

6.1464.320

Titration vessel

Connection for

outlet heating

r

e

t

a

e

h

t

l

e

u

t

O

Generator

electrode with

drying tube

728 Magnetic

stirrer

Stopper with

6.1446.170 O-ring

Example: 6.1464.320 Coulometer titration vessel

Install the necessary accessories as shown in

the diagram alongside.

The fastening screws can be used to permanently fix the whole assembly in position.

If you wish to automate the reagent changing

process (aspiration and dosing) then the Coulometer titration vessel with two side-mounted

threaded openings (6.1465.320) should be

used.

If volumetric KF determinations are to be carried out a suitable titration vessel should be

selected (see Metrohm accessories catalog)

together with the KF titration vessel upper part

(6.1414.030). Instead of the 6.1446.170 stopper use the nipple and O-ring of the

6.2730.030 stopper to introduce the transfer

hose into the titration vessel.

Fastening screws

2.5 Integration

Cables

Connecting peripheral instruments to the 774 Oven Sample Processor requires Metrohm cables. Otherwise safe data transmission may not be

guaranteed.

Remark:

Metrohm cables are labeled with the type of the instrument which they may

be connected with and optionally with the particular socket. Look at the cable ends. For example:

All instruments have to be switched off before they are connected.

Otherwise the instruments could be damaged.

Titrino B

692 / 712 / 713

774 Oven Sample Processor, Instructions for use

15

Page 22

2 Installation

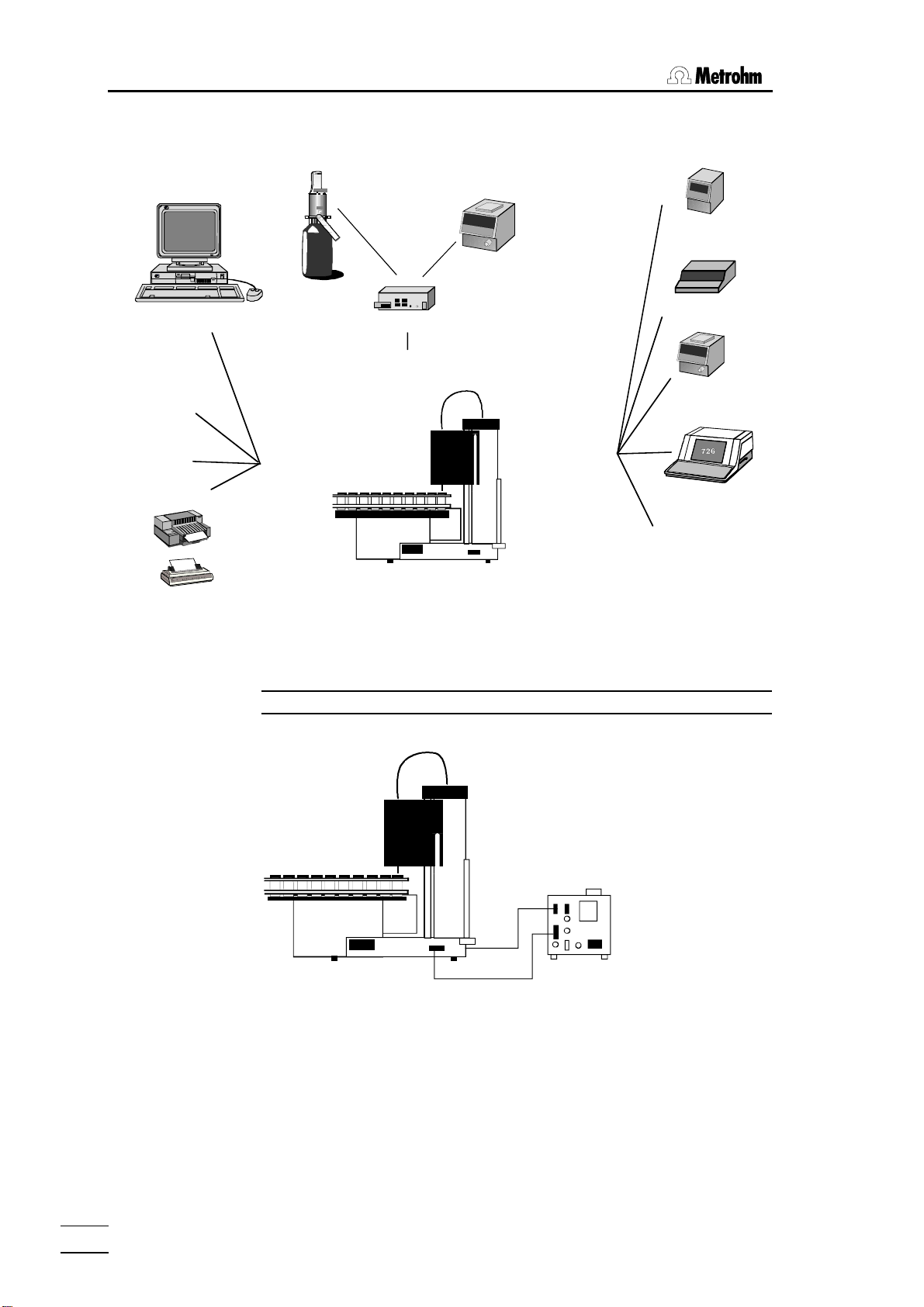

The 774 Automation System

700 Dosino 685 Dosimat

756 Coulometer

684

737

701

...

784

PC software

Metrohm-

instruments

729

729 Dosimat Interface

External Bus

Coulometer

Titrino

family

other

instruments

printers

Seiko

Citizen

Epson

HP

IBM

…

RS 232

774

774 Oven Sample Processor

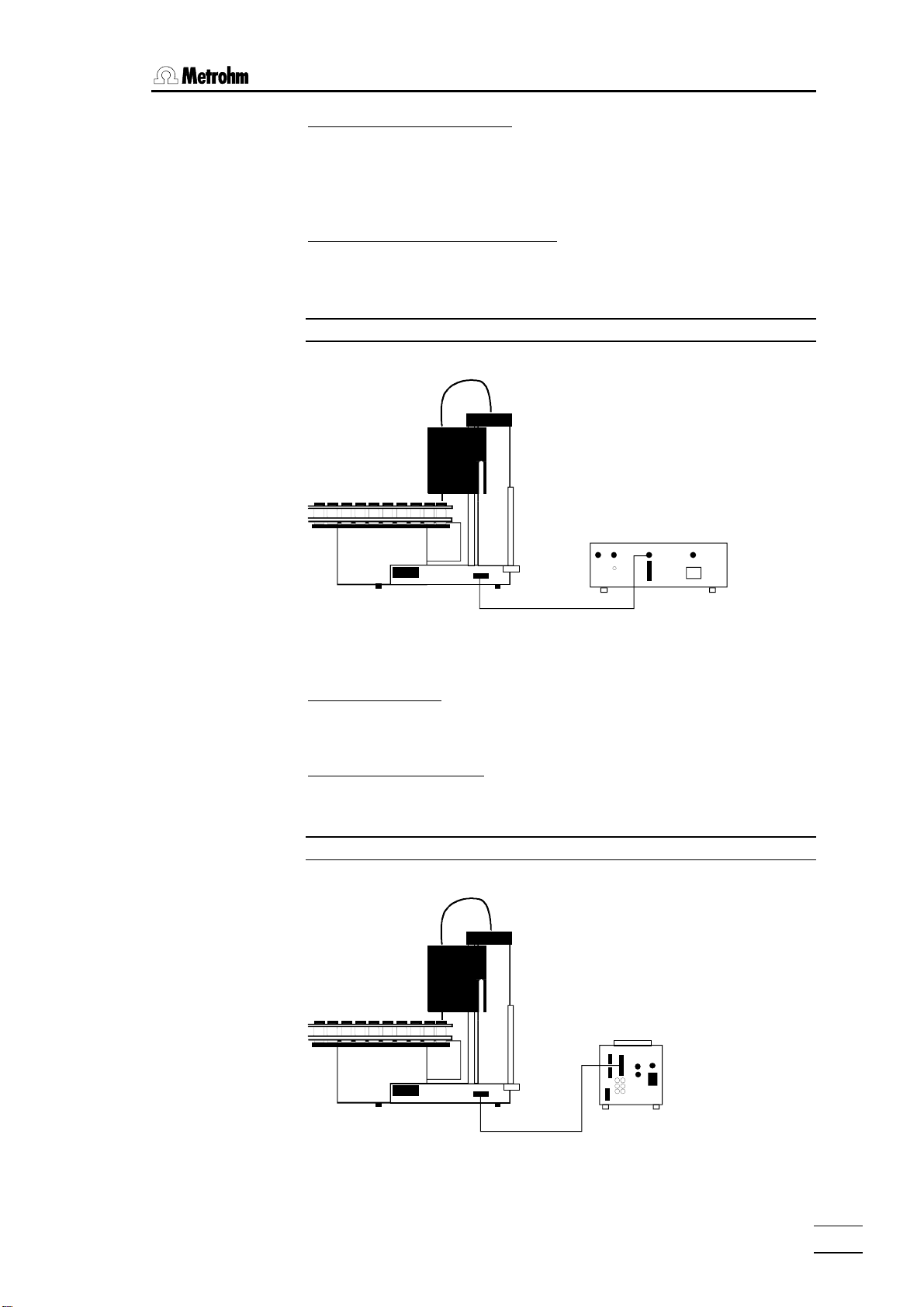

2.5.1 Remote connections

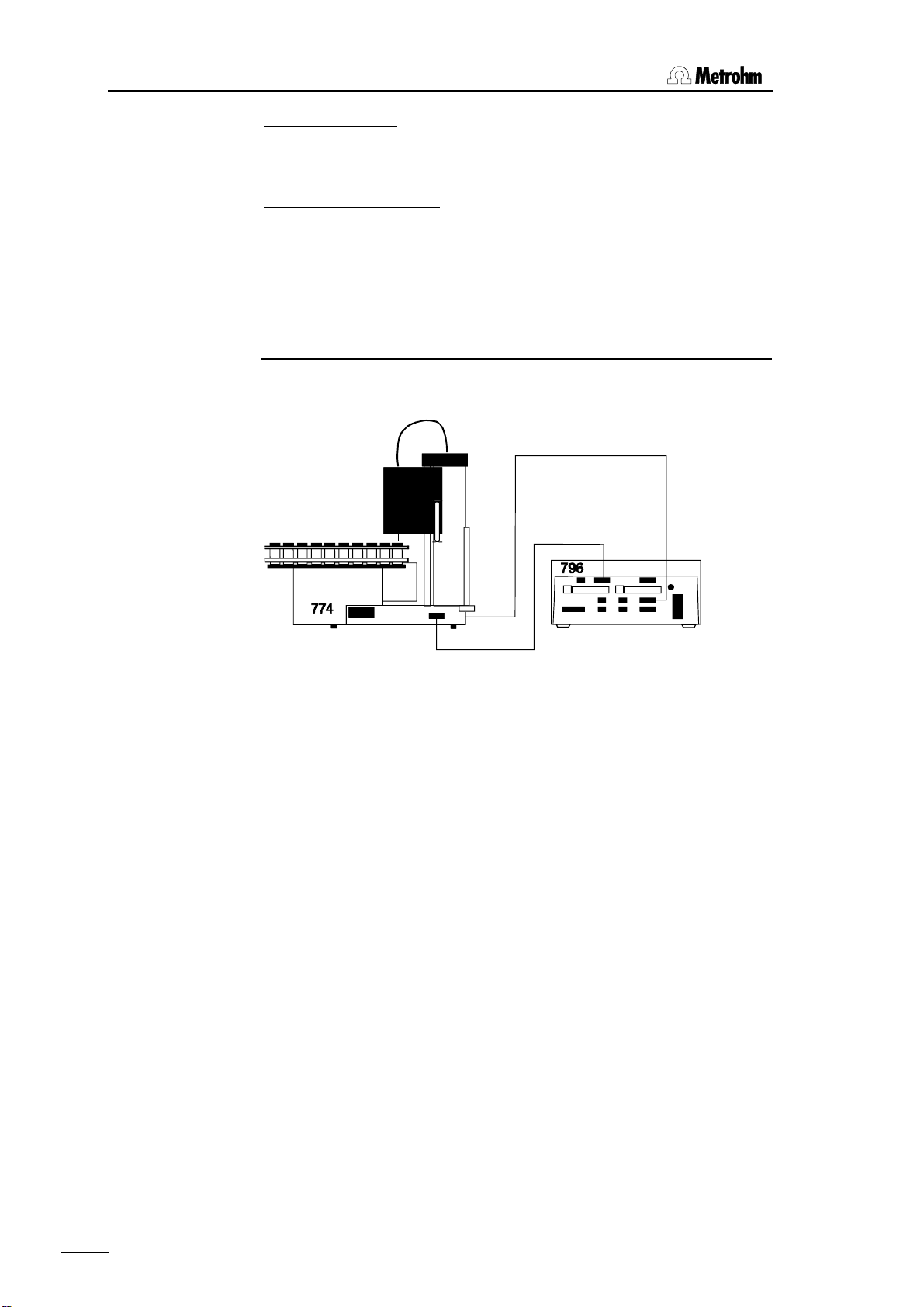

774 Oven Sample Processor — 756 Coulometer

for coulometric determinations

Remote

726 Titroprocessor

other

instruments

6.2125.110

cable (RS232)

774

756

6.2141.020

cable (remote)

Control of the 756 Coulometer is carried out via the control lines of the remote connection.

While a sequence is being processed the 774 Oven Sample Processor can,

via the serial RS232 interface, cause the 756 Coulometer to load a particular method. When drawing up a report the 756 Coulometer automatically

obtains the temperature of the 774 Oven Sample Processor via the RS232

connection.

774 Oven Sample Processor, Instructions for use

16

Page 23

2.5 Integration

Control commands of the 774:

CTL:Rm : START Gerät1 starts Coulometer

CTL:Rm : *************1 "

CTL:RS &U.R.N loads a method in the Coulometer

CTL:RS "774BLANK"..$G here e.g. "774BLANK"

Scanning the remote lines of the 774:

SCN:Rm : **0**010 waits for 'cond. ready'

SCN:Rm : *****000 waits for end of determination

774 Oven Sample Processor — 737 Coulometer

for coulometric determinations

774

737

6.2141.000 cable (remote)

The 737 Coulometer is completely controlled via the remote lines.

Control commands:

CTL:Rm: *********1**** starts Coulometer with

CTL:Rm: *********0**** a start impulse

Scanning via remote lines:

SCN:Rm : 10000100 waits for 'cond. ready'

774 Oven Sample Processor — 7xx Titrino

for volumetric KF titrations

774

774 Oven Sample Processor, Instructions for use

6.2141.020

cable (remote)

758

17

Page 24

2 Installation

Control commands:

CTL:Rm : START Gerät1 starts Titrino

CTL:Rm : ***********1** advance impulse / ENTER

Scanning via remote lines:

SCN:Rm : ****1000 waits for end of titration (EOD-impulse)

SCN:Rm : *****010 waits for 'cond. ok'

In principle it is possible to use an additional RS232 connection to automatically load a particular method in the Titrino while a sequence is being

processed. Please refer to the example of the remote connection given for

the 756 Coulometer on the previous page.

774 Oven Sample Processor — 796 Titroprocessor

for volumetric KF titrations

6.2125.110

cable (RS232)

6.2141.020

cable (remote)

or

If connected to a 774 Oven Sample Processor the 796 Titroprocessor takes

over the functions of the control instrument itself (Master). The communication between the 774 Oven Sample Processor and the 796 Titroprocessor

can be solved in any manner.

If a remote connection is used (6.2141.020 cable) the input and output lines

0…7 can be used as required. However, it is then not possible to start a

774 Oven Sample Processor method. See page 79ff for the communication

commands.

A serial RS232 connection between the 796 Titroprocessor and the 774

Oven Sample Processor has the advantage that the Titroprocessor as control unit can access all internal functions except starting or loading a

method in the 774 Oven Sample Processor. Please refer to the description

of the Metrohm remote language and the 774 remote control tree on page

98ff.

774 Oven Sample Processor, Instructions for use

18

Page 25

2.5 Integration

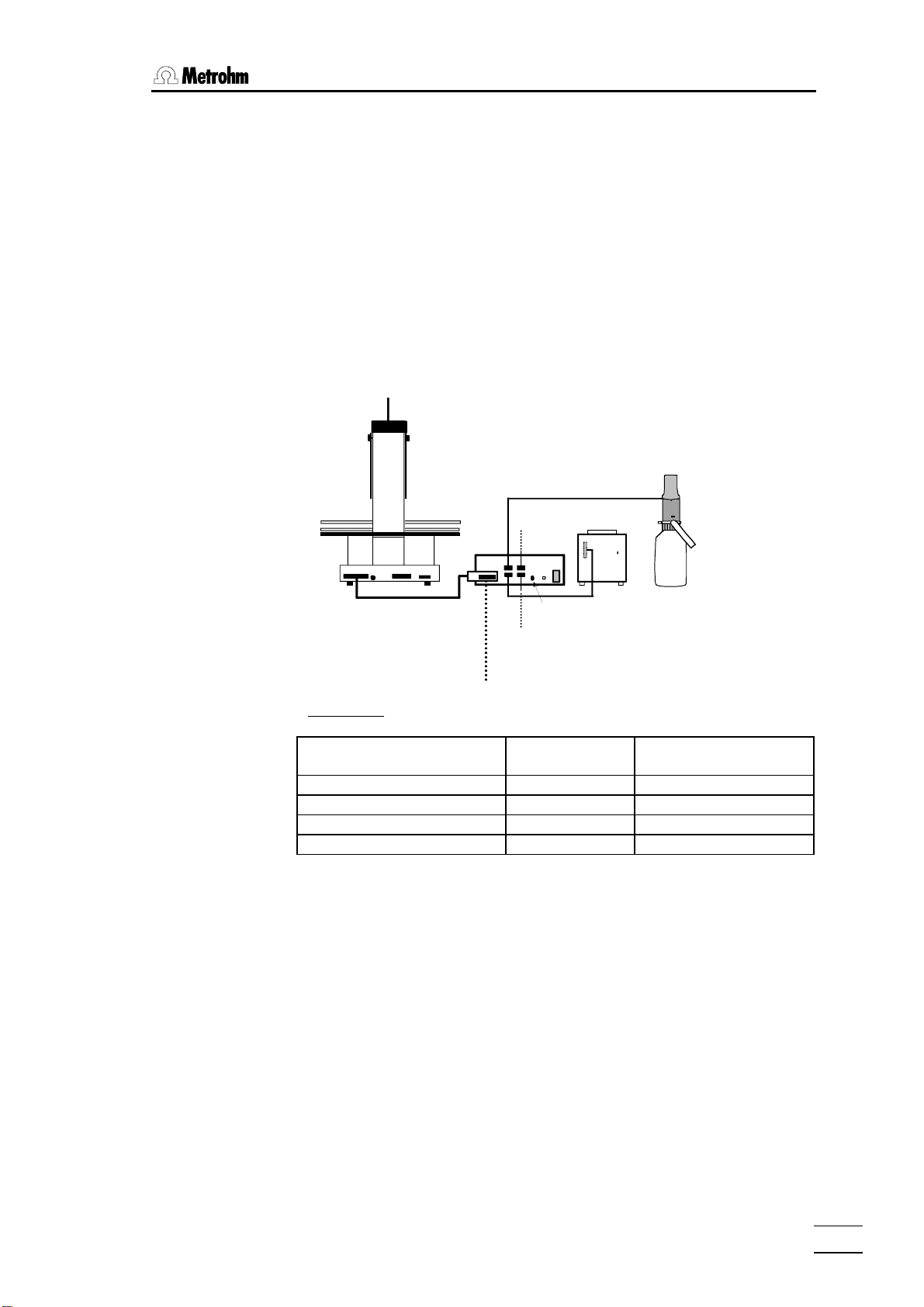

2.5.2 External bus connections

If a KF Titrino or a Coulometer which does not support automatic solvent

changing is connected to the 774 Oven Sample Processor then this can be

carried out with the help of a 700 Dosino. 685 Dosimats can also be used

for the addition of solvents. 700 Dosinos or 685 Dosimats are connected to

the 774 Oven Sample Processor via the so-called 'External Bus'.

A 729 Dosimat interface can be used to connect up to 4 dosing devices to

the 'External Bus' interface. Up to 3 Dosimat interfaces can be switched in

line (cascaded) and equipped with further dosing instruments. The instrument address must always be set correctly at the interfaces. In this way it is

possible to operate up to 12 dosing instruments directly with the 774 Oven

Sample Processor with the aid of the DOS command.

Dos. 1

685

Dos. 2

6.2134.000 cable

774

6.2135.000 cable

729

Dos. 4

Dos. 3

EBus

address 1

Addresses:

'External Bus'-

address

774 Oven Sample Processor 0

1st interface 1 Dos. 1 … Dos. 4

2nd interface 2 Dos. 5 … Dos. 8

3rd interface 3 Dos. 9 … Dos. 12

700

Dosing instrument

774 Oven Sample Processor, Instructions for use

19

Page 26

2 Installation

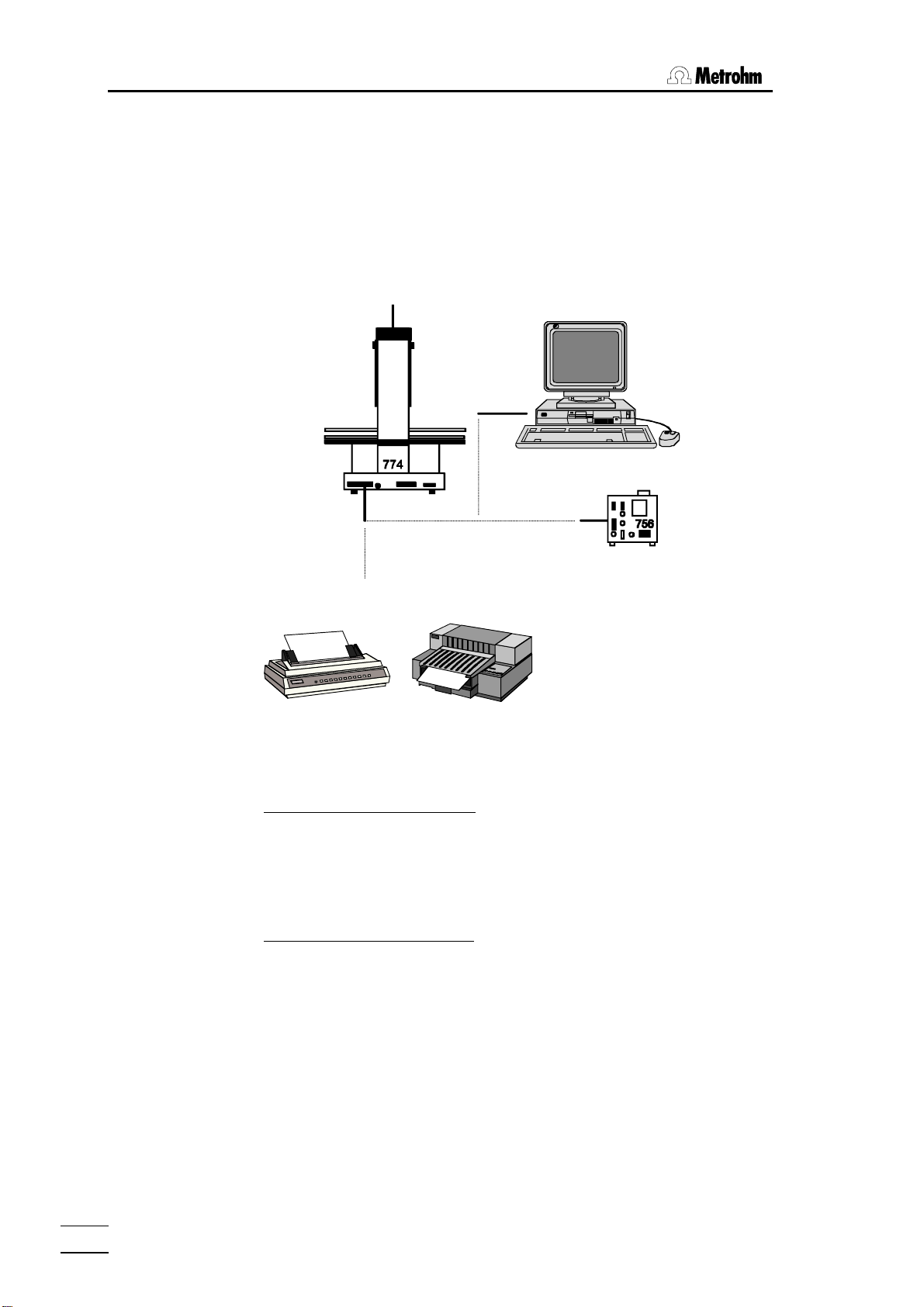

2.5.3 Serial connection (RS232)

Many different instruments may be connected via the serial RS232 interface. In addition to all Metrohm instruments that support the Metrohm remote control language (see page 101ff) any printer with serial interface (or

parallel interface and parallel/serial converter) or a personal computer (PC)

may be connected. Any other measuring instrument may be controlled via

RS232 interface, as long as it supports serial data transmission.

6.2125.060 cable

Printer cables see page. 20f

In order to guarantee safe data transmission, it is important to set the same

RS232 interface parameters correctly for both instruments connected (see

page 21f).

Control commands (examples):

CTL:RS &M;$G starts a Metrohm instrument

CTL:RS &M;$S stops a Metrohm instrument

PRINT: config

Scanning input data (example):

SCN:RS : *R" waiting for readiness of a Metrohm instru-

Information about the settings and cables required for connecting a printer

is given in the following section.

prints a configuration report to a printer or

PC

ment

774 Oven Sample Processor, Instructions for use

20

Page 27

2.5 Integration

2.5.4 Connecting a printer

Printers with the following printer emulations may be connected:

IBM IBM Proprinter and printers with IBM emulation

Epson Epson printers and printers with Epson emulation

Seiko Seiko printer DPU-411/414

Citizen Citizen printer IDP560 RS

HP

HP printers and compatibles with HP PCL3 emulation

If you connect a printer not listed in the following table, be sure that it is able

to emulate Epson or IBM Proprinter mode.

Use the 6.2125.050 cable for connecting a printer with built-in serial interface. Printers with parallel interface require the 2.145.0300 serial/parallel

converter and 6.2125.020 cable.

Before connecting a printer to the RS232 interface, switch off the

774 Oven Sample Changer.

The parameters of the RS232 interface are accessible in the configuration

menu under '>RS232 settings'.

The following table lists the information necessary for connecting a printer:

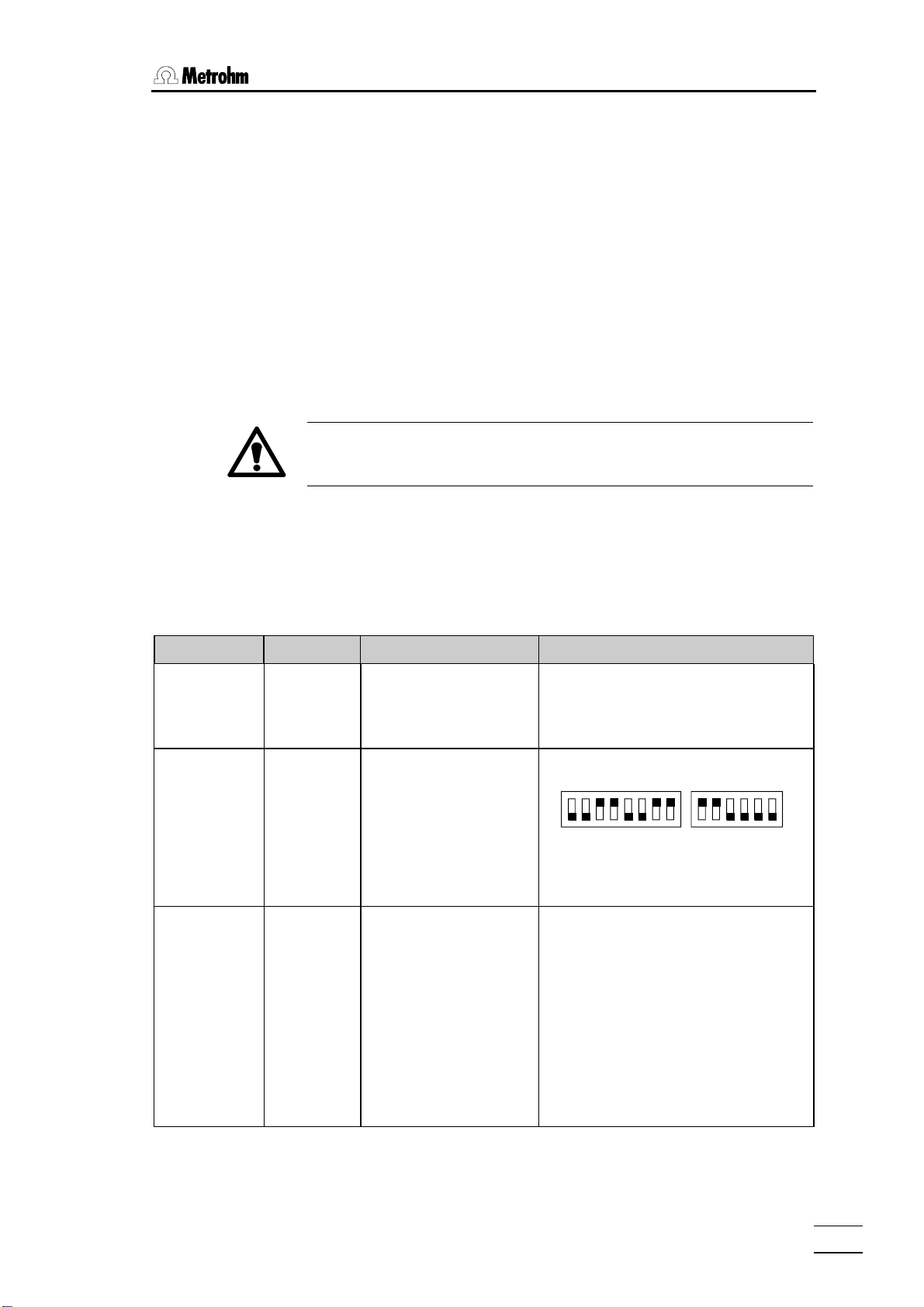

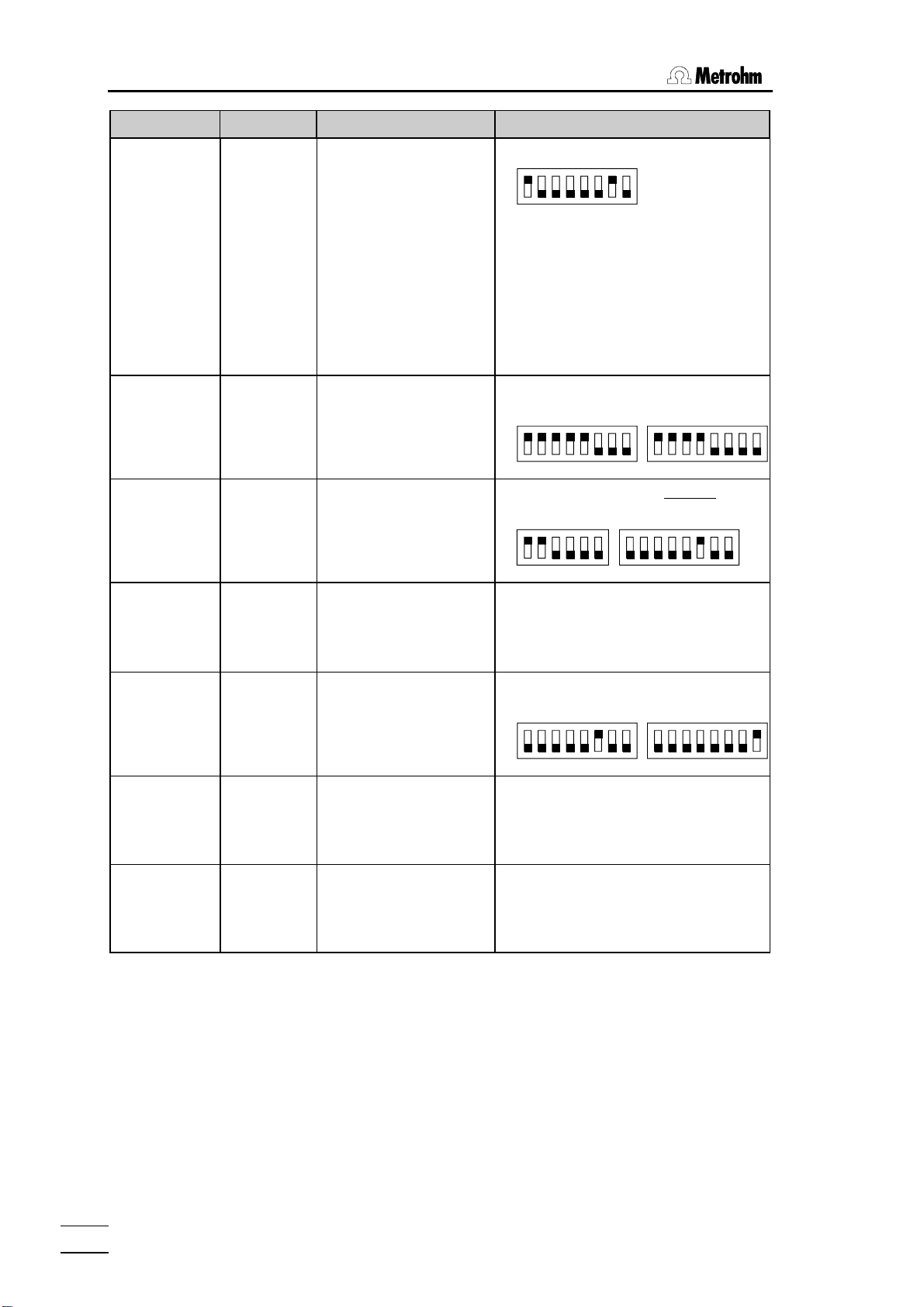

Printer type Cable RS232 Settings Settings on Printer

IBM Proprinter 6.2125.050

Seiko

6.2125.020

DPU-411

Seiko

6.2125.130

DPU-414

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: IBM

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: Seiko

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: Seiko

see printer manual

DIP switch settings:

DIP01 DIP02

on

off

12345678

The 7-bit ASCII character is set automatically to the specific national character set

according to the selected dialog language.

Recommended DIP switch settings

Dip SW-1 Dip SW-2 Dip SW-3

1 OFF ON ON

2 ON OFF ON

3 ON ON ON

4 OFF ON ON

5 ON ON OFF

6 OFF ON ON

7 ON OFF ON

8 ON OFF ON

The 7-bit ASCII character is set automatically to the specific national character set

according to the selected dialog language.

123456

774 Oven Sample Processor, Instructions for use

21

Page 28

2 Installation

Printer type Cable RS232 Settings Settings on Printer

Citizen

IDP560-RS

6.2125.050

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set:Citizen

DIP switch settings:

on

off

12345678

The 7-bit ASCII character is altered to the

specific national character set by setting

the jumpers J1 and J2 as follows:

J1 J2 character set

open open USA

closed closed Great Britain

closed. open France

open closed Germany

No Spanish character set available

(French may be best).

Epson

6.2125.040

with 6-pole

round plug

Epson

6.2125.050

with additional

serial interface

#8148

Epson LX-300 6.2125.050

HP Deskjet

with built-in

serial interface

6.2125.050

or cable 25pole neg. /

9-pole pos.

(e.g. HP

C2933A)

HP Laserjet

with built-in

serial interface

cable 25pole neg. /

9-pole pos.

(e.g. HP

C2933A)

HP Deskjet /

Laserjet

with parallel

interface

6.2125.020

+ serial/

parallelconverter

2.145.0300

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: Epson

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: Epson

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: Epson

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: HP

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: HP

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

character set: HP

DIP switch settings:

SW1 SW2

on

off

12345678

12345678

DIP switch settings on the Interface:

SW1 SW2

on

off

123456

12345678

see printer manual

DIP switch settings :

A B

on

off

12345678

12345678

see printer manual

see printer manual*

* character set PC-8 is required.

PCL3 command: esc(10U

774 Oven Sample Processor, Instructions for use

22

Page 29

3.1 Configuration

3 Introduction

3.1 Configuration

The 774 Oven Sample Processor must be configured correctly before it is

used for the first time. This includes both the basic settings with the oven

settings and the configuration of the sample rack and the peripheral devices which are connected. All these settings are accessible via the configuration menu which can be opened with the <CONFIG> key. It is arranged in various submenus according to subject. Navigating (selecting the

individual settings) in the menu is carried out with the cursor keys (<Ð>,

<Ï>) and is also possible with the <HOME>, <END> and <ENTER>

keys. Submenus and main menus are exited with the <QUIT> key. In

many menu entries the <SELECT> key can be used to select the required

entry from a list of entries. These menu items are marked with a colon (:).

Further details are given on page 58.

When the configuration has been altered a RESET should be carried out

with <CLEAR> or the oven sample changer should be switched off and

on in order to ensure that the alterations become effective.

3.1.1 Basic settings

The basic settings which can be set in the submenu '>auxiliaries' include:

• dialog language

• display contrast

• beeper on/off for warnings

• Instrument identifier (instrument name or identification)

• program version

• maximum lift height and way

• beaker sensor on/off.

dialog

The dialog language can be selected from 'deutsch, english, français,

español'.

display contrast

The display contrast can be set on a scale from 0 (low contrast) to 7 (high

contrast).

beeper on/off

With error messages or when a value has been entered and not confirmed

with <ENTER> (and as a result is not accepted) then an acoustic signal is

produced. This signal can be switched off.

774 Oven Sample Processor, Instructions for use

23

Page 30

3 Introduction

device label

In order to be able to identify each particular laboratory instrument unambiguously (required by GLP) the sample changer can be given an 8-character

identifier made up of letters and/or numbers. Text input is described on

page 59.

program version

The program version (instrument software) cannot be altered. It is shown in

the configuration menu for information.

max. lift way

The maximum lift way is an important safety entry. If a correct entry is made

this ensures that the lift with the working head cannot be moved down too

far; this could cause damage to the needle or the sample vessel. The lowest lift position to be reached can be entered in mm (measured from the

upper stop position).

A convenient way of determining this position is to set the required height

manually (normal state) with the <Ð> and <Ï> keys. The configuration

menu is then opened and the current lift position in the display can be accepted in the menu entry 'max. lift way' with the <CLEAR> key.

Important: the entered value only becomes effective after a RESET or

when the instrument is switched off and then on again.

beaker sensor

The tower of the 774 Oven Sample Processor is equipped with an infraredbeaker sensor which detects the presence of a sample vial in front of the

tower. If the beaker sensor is switched on then this test will be carried out

after each MOVE command.

This entry also only becomes effective after a RESET or when the instrument is switched off and then on again.

3.1.2 Oven settings

The basic settings for the oven affect the various temperatures.

initial temperature

Entry of an initial temperature means that the oven is heated up to the set

temperature immediately after the 774 Oven Sample Processor is switched

on. The initial temperature can also be used as a parameter for the

HEATER command. (HEATER:init°C)

max. temperature

The maximum temperature is used as a safety setting. The entered value

cannot be exceeded. If the oven reaches the maximum temperature during

heating up then an error message is produced and the oven heating is

switched off. This emergency stop prevents the sample from being overheated.

temp. correction

The temperature correction allows the temperature control to be adjusted.

This can compensate for any temperature difference which may occur between the oven temperature and the sample temperature. The temperature

correction has a direct effect on the temperature control. The temperature

which is displayed is always the corrected oven temperature.

24

774 Oven Sample Processor, Instructions for use

Page 31

3.1 Configuration

3.1.3 Rack definitions

The 774 Oven Sample Processor is supplied with the standard rack for 35

samples. The rack positions for this rack (Rack 1) are already preconfigured. Sample position 36 is reserved for a conditioning beaker.

If different configurations are to be defined for the same type of rack then

the individual racks must be allocated different codes and the stud magnets on the base of each sample rack arranged accordingly.

This means that a particular sample rack can be designated for use with a

particular application and that the use of the wrong rack can be avoided by

the automatic rack code recognition feature.

rack number

Up to 32 different rack configurations can be stored in the sample changer.

rack code

The rack code is used for automatic rack recognition. A particular code can

only be issued once. The standard racks supplied by Metrohm are already

predefined with a code (see page 90). The rack code consists of a 6-place

binary pattern made up of the numbers 0 or 1 which must coincide with the

arrangement of the stud magnets. Number ‘1’ stands for an inserted magnet, ‘0’ means that no magnet has been inserted. 63 different codes are

possible (000001 to 111111).

Magnet inserted

rack type

work position

In this

example the code is:

000110

base of rack

The rack type indicates an internal table of positions, in which the angles of

rotation of the beaker positions are defined. Metrohm racks use the following type name pattern:

MXX-Y (XX = number of sample beakers, Y = special code: 0 for 1-row,

1 for 2-row and 2 for 3-row standard racks)

e.g. M36-0 is a 1-row Metrohm standard rack with 36 sample positions.

The correct setting of the working position is very important. This is the lift

height which is to be used with the corresponding sample rack. It should be

selected so that the working head is standing in the optimal position. The

working position is given in mm (from the upper stop position).

A convenient way of determining this position is to set the required height

manually (normal state) with the <Ð> and <Ï> keys. This is done by

placing a sealed sample vessel on the oven and moving the lift carefully

downwards until the needle penetrates the septum and the lower rim of the

septum closure coincides with the upper rim of the oven opening.

The keyboard can then be used to open the configuration menu and the

current lift position in the display can be accepted in the menu entry 'work

position' with the <CLEAR> key.

774 Oven Sample Processor, Instructions for use

25

Page 32

3 Introduction

shift position

The sample rack can only be rotated when the lift is at or above the shift

position height.

The shift position should therefore be selected so that safe rotation of the

sample rack is always possible, i.e. it must be impossible to damage either

the needle or the rack when the rack is rotated. Please note that the conditioning vessel is slightly higher than the other sample vessels.

The value can also be entered manually or accepted automatically, as described for the work position - see above.

rinse position

The rinsing position defines a further height setting, which is used for conditioning, i.e. penetration into the conditioning vessel. See the exemplary

methods given in the 774 Tutorial.

The value can also be entered manually or accepted automatically, as described for the work position - see above.

special position

The special position can be used to define a further lift height.

No commands are linked with the defined lift positions. In principle they can

therefore be used with any lift heights which are to be stored.

special beakers (in sub-menu special positions)

Up to 8 special beaker positions can be defined for each sample rack; in a

normal method procedure these are not regarded as sample beakers. Special beakers can be deliberately selected at any time. For example, they can

be used as conditioning beakers. See the exemplary methods in the 774

Tutorial.

The special beakers 'Spec.1' to 'Spec.8' can each be allocated a beaker

position from 1 up to [number of sample positions]. Position 0 stands for

"not defined". Special beakers are preferably set at higher rack positions in

order to be able to start the series of samples at position 1. In the standard

rack for the 774 Oven Sample Processor position 36 is already defined as a

special position for the conditioning vessel and should not be altered.

3.1.4 Dosing units

dosing unit

max. rate

26

In order to be able to additionally automate the dosing-in of auxiliary solutions or aspiration from the measuring cell it is possible to connect up to 12

dosing instruments to the 774 Oven Sample Processor via 729 Dosimat interfaces. The 685 Dosimats and 700 Dosinos can be used for this.

The maximum dosing and filling rates as well as the tubing dimensions of

the inlet tubing can be defined for each dosing instrument.

Dosing unit for which the parameters are to be entered

(1–12, see page 65f).

This value represents the maximum permissible dosing and filling speed

(mL/min) of the dosing unit. Depending on the viscosity of the medium to

be dosed in, this value should be selected so that as rapid a dosing as

possible is selected; however, the buret must still be filled without any problems and free from any air bubbles. The max. rate is an absolute limit; it

cannot be exceeded even during manual dosing.

774 Oven Sample Processor, Instructions for use

Page 33

3.1 Configuration

tubing lengths and diameters

These values are only relevant for the 700 Dosino. As this has the ability to

prepare the complete tubing system automatically for dosing, i.e. to rinse

the tubings and fill them with dosing solution, the particular tubing lengths

and (inner) diameters must be entered. The necessary rinsing volumes are

then calculated automatically.

The settings for dosing units mentioned above must be carried out for all 4

ports of the 700 Dosino (inlets and outlets 1–4).

3.1.5 RS232 interface

Either a printer (for protocolling the instrument settings and methods) or a

PC for controlling the Oven Sample Processor can be connected to the

RS232 interface.

It is also possible to communicate with other Metrohm instruments (e.g.

Coulometer via Metrohm remote control language) and possibly instruments from other manufacturers via the interface.

The necessary transmission parameters which must be matched to those

of the instrument to be connected are:

baud rate, data bit, stop bit, parity and handshake.

For data communication with PCs, Metrohm instruments and instruments

from other manufacturers the parameter 'Send to: IBM' must be set. The

other parameters should remain set to the standard values or the settings

should be adapted to those of the corresponding peripheral unit.

Connection of a printer: see page 21.

Data reception can be switched on and off with 'control via RS: on'. If the

remote control is switched off then data can no longer be received, but reports can still be printed out.

774 Oven Sample Processor, Instructions for use

27

Page 34

3 Introduction

3.1.6 Lock keyboard functions

Particular areas of the operator dialog can be made inaccessible to untrained operators by locking individual dialog areas or keys. In this way the

accidental overwriting of a method or even the alteration of parameters can

be prevented.

The menu '>keyboard options' for the corresponding functions is opened

by holding down the <CONFIG> key when the Oven Sample Processor is

switched on. Alternatively this can be done by triggering a reset with

<CLEAR> and then pressing the <CONFIG> key within 0.4 seconds.

This menu can even be accessed when the complete keyboard has previously been locked.

The individual keyboard areas which can be locked are:

whole keyboard

In routine operation where only a single method is used it may be necessary to prevent manual manipulation. For this reason it is possible to lock

(almost) all keyboard keys. The <START>, <STOP> and <CLEAR/ RE-

SET> keys are always accessible so that starting and interrupting methods

is always possible. If the Oven Sample Processor is operated with PC software this may also be necessary. In this case it is possible to do without the

keyboard and to remove it completely.

'lock keyboard: on' locks all keyboard keys (exceptions: see above).

lock configuration

The basic configuration can be protected against overwriting. All settings of

the configuration menu are no longer accessible.

'lock configuration: on' locks the <CONFIG> key.

lock parameters

If operator-defined methods are normally used then it may be necessary to

ensure that the stored method parameters cannot be altered. The parameter menu can therefore be made inaccessible.

'lock parameters: on' locks the <PARAM>key.

lock method memory functions

Preventing the accidental deletion of stored methods makes sense. The deletion of methods should only be possible after deliberately switching off the

locking function.

'>user methods' + <ENTER> opens the submenu for locking method

memory functions.

'lock method recall: on' locks method loading.

'lock method store: on' locks method saving.

'lock method delete: on' locks method deletion.

28

774 Oven Sample Processor, Instructions for use

Page 35

lock display

3.1 Configuration

If the Oven Sample Processor is to be operated solely by external control

software (see above) then the display for manual operation can be

switched off.

'lock display: on' locks the display.

774 Oven Sample Processor, Instructions for use

29

Page 36

3 Introduction

3.2 Manual operation

As an introduction only those basic manual control functions which are

necessary for preparing the sample changer for processing a series of

samples are described here.

Only a few keys are required.

For further commands and details please refer to page 61ff and page 74ff.

Shift sample rack / position samples

The <Í> and <Î> keys can be used to rotate the sample rack one

position to the left (counterclockwise) or right (clockwise).

The MOVE function can be used to position a particular sample vessel on

the oven. Apart from the numerical rack position, <SELECT> can also be

used to enter the position defined as the current sample (SAMPLE command) or the special beaker 1 to 8.

Example:

MOVE : sample <ENTER>

MOVE : spec.1 <ENTER>

MOVE : 5 <ENTER>

Important:

For safety reasons it is only possible to rotate the rack when the lift is at or

above the shift position height.

The <Ï> and <Ð> keys move the lift upwards and downwards respectively. The lowest possible lift position is defined under the configuration

parameter 'max. lift way'.

The <HOME> key is used to return the lift to the resting position (0 mm),

i.e. to the upper stop position.

<END> moves the lift to the predefined working position (see pages 65

and 77).

The LIFT function can be used to move the lift to a particular position. As

well as the exact position in mm (0 –100 mm), a previously defined position can be selected with <SELECT> (rest pos = 0 mm, working, rinsing,

shift pos, special).

Example:

LIFT : work <ENTER>

LIFT : shift pos <ENTER>

LIFT : 50 mm <ENTER>

MOVE

8

Move lift

HOME

LIFT

9

END

30

774 Oven Sample Processor, Instructions for use

Page 37

3.2 Manual operation

Set sample position

SAMPLE

The SAMPLE function is used to set the current sample position. It defines

the first sample beaker for the following series of samples.

7

4

5

DOS

6

The FLOW function is used for switching the pump or inert gas solenoid

valve on and off. <SELECT> is used to select the parameters for this

command from the two possibilities. The first parameter of the command

defines whether the pump (i.e. air as gas flow) or the solenoid valve for

other gases is to be switched on. The current gas flow rate is shown directly in the display .

Example:

FLOW: pump : ON

FLOW: valve : OFF

<STOP> is used to switch off the pump (or valve) again, provided that

nothing else has been defined under 'Manual stop options', see page 74.

The HEATER function is used for controlling the oven temperature. The first

parameter of the command defines the oven temperature, the second

parameter sets the heating-up time, i.e. the time in which the defined temperature is to be reached. If the defined temperature is lower than the current oven temperature then the oven unit will be automatically cooled. The

current oven temperature is always shown in the display.

Example:

HEATER:init°C min (=heat up to initial temperature)

HEATER: 130°C 15 min

The DOS function is used to control the connected dosing instruments.

Both positive and negative volumes can be dosed.

Apart from entering the volume to be dosed, <SELECT> can be used to

select additional functions of the particular dosing instrument:

- Filling the cylinder (fill),

- Change dosing unit initialization (change),

- Prepare the tubing system (prepare),

- Empty the tubing system and the cylinder (empty),

- Eject the cylinder contents (eject),

- Adjust, i.e. remove the play between dosing piston and spindle before

aspiration or filling the cylinder (adjust),

- Compensate for the play between dosing piston and spindle before

dosing (level).

Pump / Valve

FLOW

Oven control

HEATER

Dosing units

(=heat to 130°C within 15 minutes)

774 Oven Sample Processor, Instructions for use

31

Page 38

3 Introduction

The first parameter of the DOS command represents the number of the

dosing instrument (1–12), the second parameter the function or volume to

be dosed.

Example:

DOS: 2 <ENTER> 4.51 ml <ENTER>

DOS: 2 <ENTER> <SELECT> ... fill <ENTER>

Interface monitoring

SCAN

1

Operate interfaces

CTRL

2

The SCAN function is used for monitoring the serial RS232 and the remote

interfaces. In this way it is possible to check the communication of the 774

Oven Sample Processor with other instruments. The interface can be selected with the <SELECT> key and must then be confirmed with <EN-

TER>.

If the Remote interface is selected then the logical condition of input lines

0…8 is displayed as a bit pattern (1=active, 0=inactive). If the RS232

interface is selected then the received character strings are shown.

Example:

SCN:Rm :00000001 (= e.g. Coulometer is 'ready')

SCN:RS $d

The CTRL function is used to operate the serial RS232 and remote interfaces. In this way it is possible to check the communication of the 774

Oven Sample Processor with other instruments. It is therefore possible to

transmit a remote command as a character string to a connected instrument via the RS232 interface or to individually activate or deactivate remote lines Output 0…13.

The interface can be selected with the <SELECT> key and must then be

confirmed with <ENTER>.

If the RS232 interface is selected then any character string can be entered;

this will be transmitted after confirmation with the <ENTER> key.

If the remote interface is selected then a 14-place bit pattern can be defined which then defines the required logical conditions of remote lines

0…14. (1=active, 0=inactive, * =do not alter current condition). The

<SELECT> key can be used to select predefined bit patterns to cover the

most frequently required tasks (see also page 98ff). Setting the lines (static

signals) is carried out after pressing the <ENTER> key.

Example:

SCN:RS $d (=status query of Coulometer)

CTL:Rm :************01 (=start Coulometer or Titrino)

CTL:Rm : START device1 (=start Coulometer or Titrino)

(= status query of Coulometer)

32

774 Oven Sample Processor, Instructions for use

Page 39

3.3 Methods and Sequences

3.3 Methods and Sequences

3.3.1 Designing a method

A method is made up of the following components:

• number of samples to be processed

• run sequences (start, sample and final sequences)

• Definition of the various instrument settings (report definitions, sample

changer settings, time-out settings, gas flow settings, dosing unit definitions, manual stop options)

For details about instrument settings please refer to page 67ff.

Sequences

A sequence is a series of commands which are carried out in the defined

order when a series of samples is being processed. Functions for controlling the oven temperature, gas flow, lift and for moving the turntable are

available. External instruments (titrators, Coulometers, Dosimats, etc.) can

be controlled by efficient commands. In a sequence the further settings for

the individual instrument components and dosing units (700 Dosino or

685 Dosimat) can also be defined or altered.

Processing a sample series is carried out in three phases. These are:

Start sequence: Command sequence which is carried out once at

the start of the series.

Sample sequence: Command sequence which is carried out for

each sample.

Final sequence: Command sequence which is carried out once at

the end of the series.

Course of a method

number

of samples

<START>

start sequence final sequence

774 Oven Sample Processor, Instructions for use

sample sequence

normal state

33

Page 40

3 Introduction

Sequences are created in the submenus '>start sequence', '>sample

sequence' and '>final sequence'; these can be accessed via the pa-

rameter menu (press <PARAM>).

A sequence is arranged in lines. If a command is entered a new line containing this command will be appended to the line which is currently shown.

The line number can be seen in the display. 99 lines are possible per sequence.

A line is deleted by pressing <DELETE>. The following lines move up one

position.

A new line can be inserted at a later date by using <INSERT>. This inserts

an empty line before the line which is currently shown. The following lines

move down one position.

The commands which are available as a second function on the numeric

block of the keyboard can also be used in a command sequence. These

are almost the same commands which are used for manual operation.

However, in a sequence these may possess other or further selection possibilities.

During the course of a method it is possible to alter all entries in the 'con-

figuration' and 'parameters' menus. With a few exceptions (see page 23ff)

these alterations directly affect the course of the method.

Care should be taken in making alterations to the method sequences. These

can be edited "live" (including inserting or deleting a command line); however, the TRACE and LEARN functions are not available. It is therefore not

possible to test out the edited function. This means that it is easy to produce

illogical or critical command sequences which create an error situation and

compel a sample series to be aborted.

3.3.2 LEARN mode and TRACE function

As when editing a method it is easiest to determine the parameters of a

command interactively, i.e. by manual operation, certain commands are

"adaptive". When editing a sequence the LEARN mode makes it possible to

carry out particular sample changer commands by manual operation. In

this way the resulting parameter (e.g. the lift position or the status of the input lines of the remote interface) can be included in the actual command

line. The LEARN function can be used repeatedly. If times or volumes are

"learned" then this means that the values will always be added together.

Procedure for creating methods:

• Enter a command or select an existing command line

• Press the <LEARN / HOLD> key

• the function starts, the "LEARN"-LED lights up

• press the <LEARN / HOLD> key

• function is stopped, the "LEARN"-LED blinks

• use the <ENTER> key to accept the value (or start the LEARN

function again)

• The "LEARN"-LED goes out, edit the next command line

34

774 Oven Sample Processor, Instructions for use

Page 41

3.3 Methods and Sequences

The LEARN function is available for the following commands:

Command Adaptive parameter Type of function

LIFT Lift position in mm absolute

WAIT pause time in seconds additive

DOS Dosing volume in mL additive

SCN Rm Status of the 8 remote lines "live" value

SCN RS Received character string "live" value

TRACE function

The "TRACE" function is a valuable aid for processing a complete sequence

or method, or excerpts, step-by-step for test purposes. Each command line

in a sequence can be carried out directly by pressing the <START> key.

When the action is finished the following command line is displayed.

"Tracing" can be used directly after the entry of a command line or at any

time after the parameter menu has been opened and a sequence has been

selected.

3.3.3 Process control

<START> is used to start a method from the normal state. If not interrupted manually and if no unexpected errors occur the sample series will be

processed properly and terminated with the final sequence. The sample

sequence is carried out several times according to the entry in 'No. of samples', starting with the sample beaker which has been defined as 'SAM-

PLE'.

If the sample series is interrupted with <STOP> the Oven Sample Processor immediately returns to the normal state. Unprocessed samples are not

taken into account; the final sequence is not carried out. If settings for this

occurrence have been entered under '>manual stop' then the corresponding actions or commands will be carried out via the interface in order to

stop the connected instruments as well or to carry out other actions.

The sample series can also be interrupted with <HOLD>. The command

which is currently active is immediately terminated. <START> can be used

to continue the method with the following command in the sequence which

is active. Connected peripheral units are not stopped with the <HOLD>

key. In the 'HOLD' condition the current oven temperature is maintained.

<CLEAR> interrupts a sample series when the currently active sequence

has ended (soft termination). The sample which is currently being processed will be processed to the end.

<QUIT> terminates the command currently being carried out and starts

the next command line of the sequence.

If errors occur during a sample series then a corresponding error mes-

sage will appear; this must be confirmed with <QUIT>. The sample

changer then goes to the HOLD status (see above). When the error has

been remedied <START> can be used to continue or, if necessary,

<STOP> can be used to terminate the sample series completely.

If the gas flow limits are exceeded or undercut this does not interrupt the

method sequence. The gas flow can be corrected manually with the gas

flow regulator.

774 Oven Sample Processor, Instructions for use

35

Page 42

3 Introduction

3.3.4 POWER-UP methods

When the 774 Oven Sample Processor is switched on the sample rack and

the guide head move to their rest positions. In order to condition the complete carrier gas tubing system when the instrument is switched on a

"POWER-UP" method can be used. This method is automatically started

when the instrument is switched on.

Create a method containing a command sequence which is to be carried

out when the 774 Oven Sample Processor is switched on and save this

method under the name "POWERUP" (see page 75).

In the 774 Oven Sample Processor tutorial you will find a list of the exemplary methods stored in

the instrument as standard together with comments about them.

36

774 Oven Sample Processor, Instructions for use

Page 43

4.1 Oven control

4 Oven control and gas flow

In addition to the essential sample changer features, such as rotating the

sample rack and raising and lowering the lift, the 774 Oven Sample Processor also has a controllable sample heating block and a gas supply device.

This means that it is extremely suitable for applications in which moisture or

solvent vapors are to be driven out of a sample at an increased temperature and transferred to a measuring cell in a stream of carrier gas. The 774

Oven Sample Processor together with the Metrohm Coulometer or a

Metrohm KF Titrator and the suitable KF measuring cell form the ideal analytical system for the determination of water in samples which cannot be titrated directly or only with great difficulty according to the conventional Karl

Fischer method.

4.1 Oven control

The oven heating block of the 774 Oven Sample Processor consists of a

solid aluminium block with a chromium steel jacket surrounding the sample

chamber. The sample chamber is intended for 22 mm x 38 mm sample vials and allows samples of up to approx. 8 g to be heated up to 250 °C in a

very short time. The heating rate is up to 15 °C/min, depending on the temperature range. The built-in fan quickly cools the oven down and supports

the accurate temperature control of the oven block.

The temperature control of the oven is functionally separate from the other

(sample changer) functions of the 774 Oven Sample Processor, i.e. the set

oven temperature remains constant (background control), even when other

functions or commands are carried out.

The required oven temperature can be set in three different ways:

• Initial temperature

tion menu of the 774 Oven Sample Processor. As soon as the instrument is switched on the temperature control is activated and the oven

heats up to the required (initial) temperature. The value of the initial temperature remains stored in the instrument and can be used by the manual HEATER function or the programmable HEATER command.

<CONFIG> key

Configuration

>oven settings

initial temperature 110°C

– an initial temperature can be set in the configura-

• Manual HEATER function – the oven temperature can be set manually to

any required value. When the <HEATER> key has been pressed the

required temperature and the duration of the heating-up phase can be

entered. If no heating-up time is entered then the full heating power will

be used to reach the required temperature as quickly as possible; this

temperature is then maintained.

<HEATER> key

HEATER: 110°C 10 min or

HEATER:init°C min

774 Oven Sample Processor, Instructions for use

37

Page 44

4 Oven control and gas flow

• Programmable HEATER command – the HEATER command can be

used as a part step in the processing sequence of a method. This

means that it is possible to alter the program-controlled oven temperature whenever this is necessary. If the HEATER command is used the

heating-up period can be freely selected so that it is possible to carefully

warm up a sensitive sample. Temperature profiles or ramps within a sequence can be followed by repeated use of the HEATER command.

This allows the realization of complex applications, e.g. the determination of surface moisture and the water of crystallization content of solid

samples in the same run.