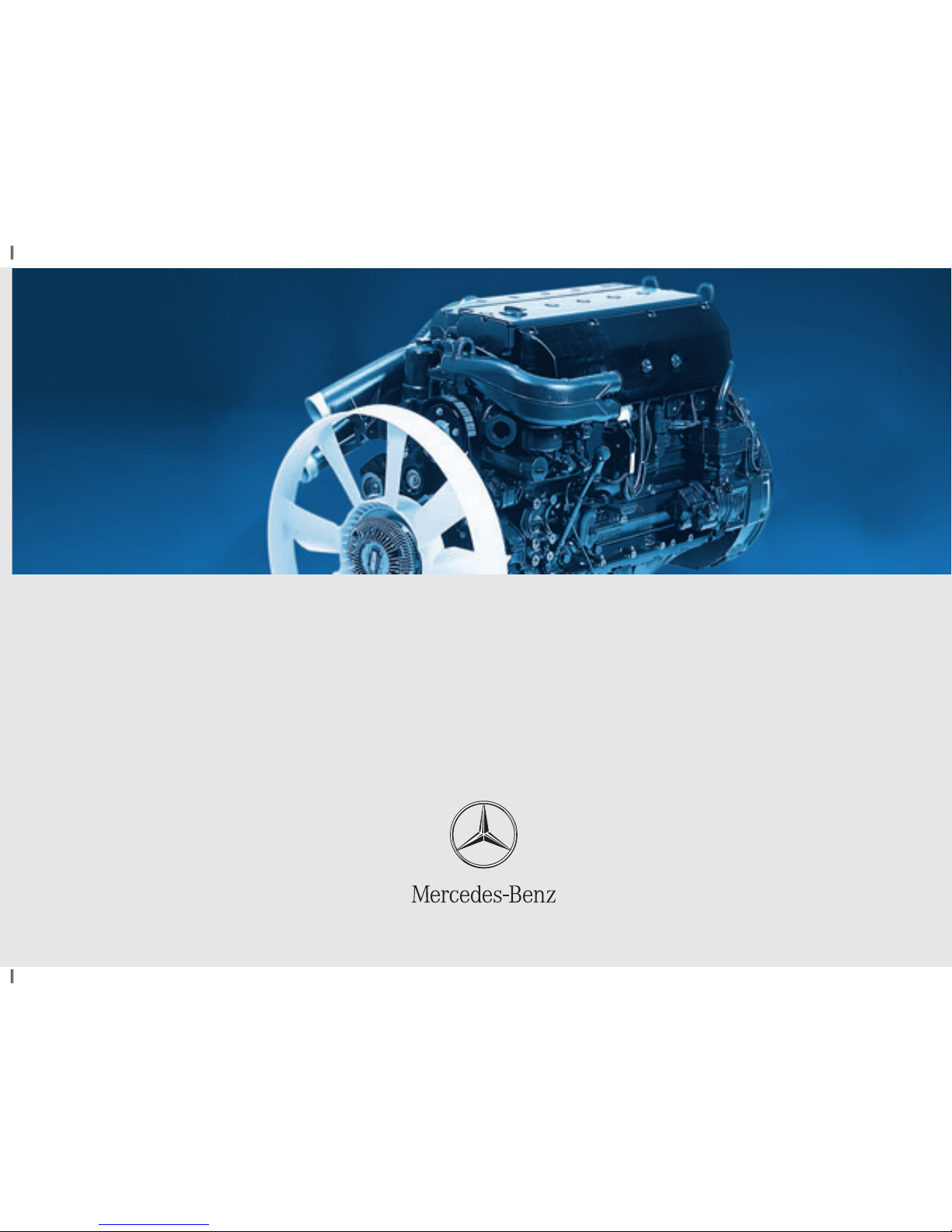

Mercedes-Benz OM 904 LA, OM 926 LA, OM 906 LA Operating Instructions Manual

Bild in der Größe

215x70 mm einfügen

Operating Instructions

OM 904 LA – OM 906 LA – OM 926 LA

EU Level III A (EU 97/68/EC)

EPA TIER 3 (US EPA 40 CFR Part 89)

Symbols

* Optional equipment

G Warning

H Environmental note

! Possible vehicle damage

i Tip

Action required

Sequence of actions (several

)

Continuation symbol

Continuation symbol for a warning

page Page reference

-> Term in the glossary of technical

terms

Display

Displays in the multi-function

display

Internet

Further information about

Mercedes-Benz vehicles and

about DaimlerChrysler AG can be

found on the following websites:

www.mercedes-benz.com

www.daimlerchrysler.com

Editorial office

You are welcome to forward any queries

or suggestions you may have regarding

these Operating Instructions to the

technical documentation team at the

following address:

DaimlerChrysler AG, Abt. SVI, HPC: E124,

70546 Stuttgart, Germany

As at: 01.12.2005

Not to be reprinted, translated or

otherwise reproduced, in whole or in

part, without the written permission

of DaimlerChrysler AG.

Thank you for choosing this

Mercedes-Benz engine.

Make sure that you read the Operating Instructions before using the engine for the

first time. This will help you to make optimum use of the engine and avoid endangering yourself and others.

Since the scope of delivery varies depending on each specific order, the equipment

of your engine may differ from certain

descriptions and illustrations in these

Operating Instructions. These Operating

Instructions also describe items of optional equipment where their operation requires explanation.

DaimlerChrysler reserves the right to make

changes to design, equipment and technology. You cannot, therefore, base any

claims on the data, illustrations or descriptions in these Operating Instructions.

Your nearest Mercedes-Benz Service

Centre will be happy to assist you further

should you have any more queries.

The Operating Instructions and Maintenance Booklet are an integral part of the

engine. You should therefore always keep

them with the engine and pass them on to

the new owner if you sell it.

Contents

i Please also refer to the index ( page 113)

Introduction

Protection of the environment . . . . . 5

Operating safety . . . . . . . . . . . . . . . . . 6

Correct use . . . . . . . . . . . . . . . . . . . 7

1At a glance

OM 904 LA overview . . . . . . . . . . . . 10

OM 906 LA/OM 926 LA

overview . . . . . . . . . . . . . . . . . . . . . . 14

Location of sensors . . . . . . . . . . . . . 18

Engine number . . . . . . . . . . . . . . . . . 20

2 Before commissioning

General information . . . . . . . . . . . . . 22

Type designation . . . . . . . . . . . . . . 22

Engine data card . . . . . . . . . . . . . . 22

Description of the engine . . . . . . . 23

Engine brake*/constantly-open

throttle valves* . . . . . . . . . . . . . . . 24

Flame-start system* . . . . . . . . . . . 25

Grid heater* . . . . . . . . . . . . . . . . . . 26

Telligent

®

engine system . . . . . . . . 27

Transport and installation . . . . . . . . 31

3Safety

Safety precautions . . . . . . . . . . . . . . 34

Staff qualifications . . . . . . . . . . . . . . 35

Conversion parts and

modifications to the engine . . . . . . . 36

Safety/emergency running

programs . . . . . . . . . . . . . . . . . . . . . . 37

Genuine Mercedes-Benz parts . . . . . 38

4Operation

Starting the engine for

the first time . . . . . . . . . . . . . . . . . . . 40

Preparation . . . . . . . . . . . . . . . . . . 40

Starting the engine for

the first time . . . . . . . . . . . . . . . . . 42

Starting the engine . . . . . . . . . . . . 45

Monitoring engine operation . . . . . . 48

Charge current . . . . . . . . . . . . . . . . 48

Oil pressure . . . . . . . . . . . . . . . . . . 48

Telligent

®

engine system . . . . . . . . 49

Flame-start system* . . . . . . . . . . . 49

Grid heater* . . . . . . . . . . . . . . . . . . 50

Stopping the engine . . . . . . . . . . . . . 51

Contents

Winter operation . . . . . . . . . . . . . . . . 52

Cleaning/protective treatment . . . 54

Cleaning the engine . . . . . . . . . . . . 54

Cleaning the cooling system . . . . . 55

Protective treatment . . . . . . . . . . . 57

Service products . . . . . . . . . . . . . . . . 58

Diesel fuels . . . . . . . . . . . . . . . . . . 59

FAME fuels . . . . . . . . . . . . . . . . . . . 61

Engine oils . . . . . . . . . . . . . . . . . . . 63

Coolant . . . . . . . . . . . . . . . . . . . . . 64

5 Maintenance

Maintenance instructions . . . . . . . . 68

Work schedule overview . . . . . . . . . 69

Maintenance service . . . . . . . . . . . 69

Additional work . . . . . . . . . . . . . . . 69

Additional work with every

third maintenance service . . . . . . . 69

Work schedules . . . . . . . . . . . . . . . . . 70

Engine: checking for leaks and

general condition . . . . . . . . . . . . . . 70

Lines and hoses on the engine:

checking for leaks and general

condition . . . . . . . . . . . . . . . . . . . . 70

Engine: oil change and filter

replacement . . . . . . . . . . . . . . . . . . 71

Adjusting the valve clearance . . . . 74

Fuel prefilter: cleaning the filter

element . . . . . . . . . . . . . . . . . . . . . 78

Heated fuel prefilter with water

separator*: replacing

the filter element . . . . . . . . . . . . . . 79

Replacing the fuel filter

element . . . . . . . . . . . . . . . . . . . . . 80

Intake pipe between air cleaner

and engine: checking for leaks

and general condition . . . . . . . . . . 83

Poly-V-belt: checking condition . . . 83

Engine brake*: checking

condition and setting . . . . . . . . . . . 87

Engine cooling system: checking

and correcting the fluid level

and the antifreeze/

corrosion inhibitor . . . . . . . . . . . . . 88

Cooling and heating system:

checking for leaks and general

condition . . . . . . . . . . . . . . . . . . . . 89

Renewing coolant . . . . . . . . . . . . . 92

6 Practical advice

Malfunctions, causes

and solutions . . . . . . . . . . . . . . . . . . . 96

Jump-starting . . . . . . . . . . . . . . . . . . 104

7 Technical data

Engine data . . . . . . . . . . . . . . . . . . . 106

Test values and adjustment

values . . . . . . . . . . . . . . . . . . . . . . . . 110

Tightening torques . . . . . . . . . . . . . 111

8 Glossary and index

Index . . . . . . . . . . . . . . . . . . . . . . . . . 113

5

Introduction

Protection of the environment

Environmental note H

DaimlerChrysler’s declared policy is one of

integrated environmental protection. This

policy starts at the root causes and encompasses in its management decisions all the

consequences for the environment which

could arise from production processes or

the products themselves.

The objectives are for the natural resources

which form the basis of our existence on this

planet to be used sparingly and in a manner

which takes the requirements of both nature

and humanity into account.

Operate the engine in an environmentally responsible manner and you will help to protect the environment.

Fuel consumption and engine wear depend

on the operating conditions.

Therefore:

do not warm up the engine at idle speed

switch off the engine during periods in

stationary traffic

monitor fuel consumption

carry out the specified maintenance

work regularly

6

Introduction

Operating safety

The operating safety of an engine primarily

depends on its proper installation into the

complete system (e.g. vehicle, machine,

etc.). However, as the operator, you also

have a direct influence on the safe operation of the engine.

Some of the requirements for operating

the engine safely can be met by adhering

to the specified maintenance intervals and

ensuring that the required maintenance

work is carried out correctly.

However, the safe functioning of the engine also depends on correct operation,

which includes, for instance, checking the

engine oil level at regular intervals.

Risk of accident G

Engine damage arising from incorrect operation could result in an accident.

Therefore, observe the notes on operating

the engine in these Operating Instructions.

Risk of accident G

Maintenance work that is carried out incorrectly or not at all, and the failure to observe

the specified maintenance intervals, may reduce the service life of the engine and cause

engine damage, which could result in an accident.

Therefore, observe the notes on engine

maintenance in these Operating Instructions.

7

Introduction

Operating safety

The engine is only designed for installation

in accordance with the specifications defined in the contract.

The manufacturer of the end product is

personally responsible for the complete

system, and in particular for the correct installation and compatibility of this engine

with the rest of the system.

The engine must not be modified.

DaimlerChrysler accepts no responsibility

for damage caused as the result of modifications.

Correct use of the engine includes adhering to these Operating Instructions, adhering to the maintenance intervals and

performing maintenance work correctly in

accordance with these Operating Instructions.

Risk of accident G

Work incorrectly carried out on electronic

components and their software could impair

the functioning of these components. Since

the electronic systems are networked, this

might also affect systems that have not

been modified.

For this reason, always have work on, or

modifications to, electronic components

carried out at a qualified specialist workshop.

DaimlerChrysler recommends that you use

a Mercedes-Benz Service Centre for this

purpose as it has the necessary specialist

knowledge and tools for the work required.

Correct use

8

9

1

At a glance

OM 904 LA overview

OM 906 LA/OM 926 LA overview

Location of sensors

Engine number

10

At a glance

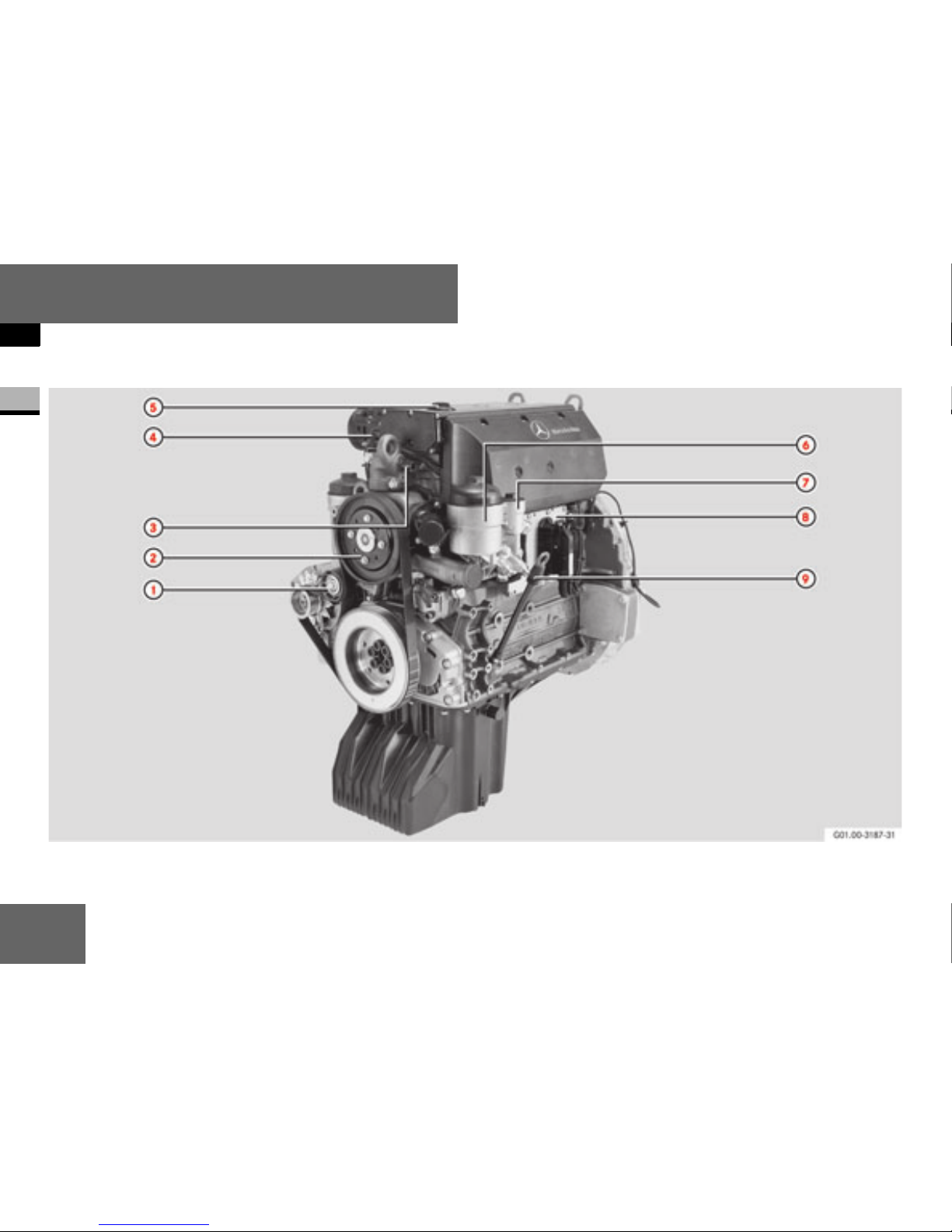

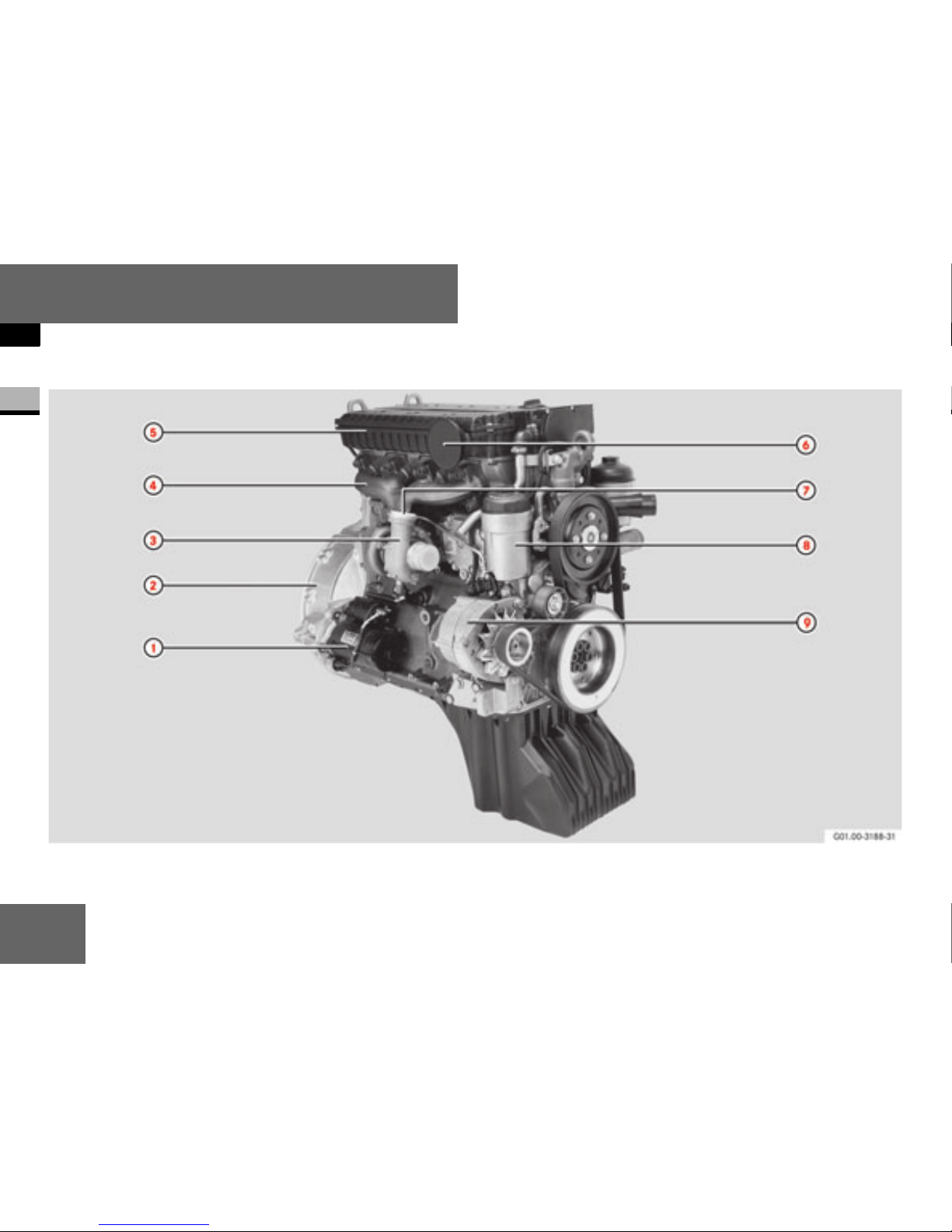

OM 904 LA overview

1

11

At a glance

OM 904 LA overview

1

1 Poly-V-belt tensioning pulley

2 Coolant pump

3 Coolant line heater supply*

4 Crankcase breather

5 Oil filler opening

6 Fuel filter

7 Fuel prefilter

8 MR (engine control) unit

9 Dipstick

12

At a glance

OM 904 LA overview

1

13

At a glance

OM 904 LA overview

1

1 Starter motor

2 Flywheel housing

3 Exhaust gas turbocharger

4 Exhaust manifold

5 Charge-air housing

6 Charge-air pipe connection from the

intercooler

7 Charge-air pipe connection to the

intercooler

8 Oil filter

9 Alternator

14

At a glance

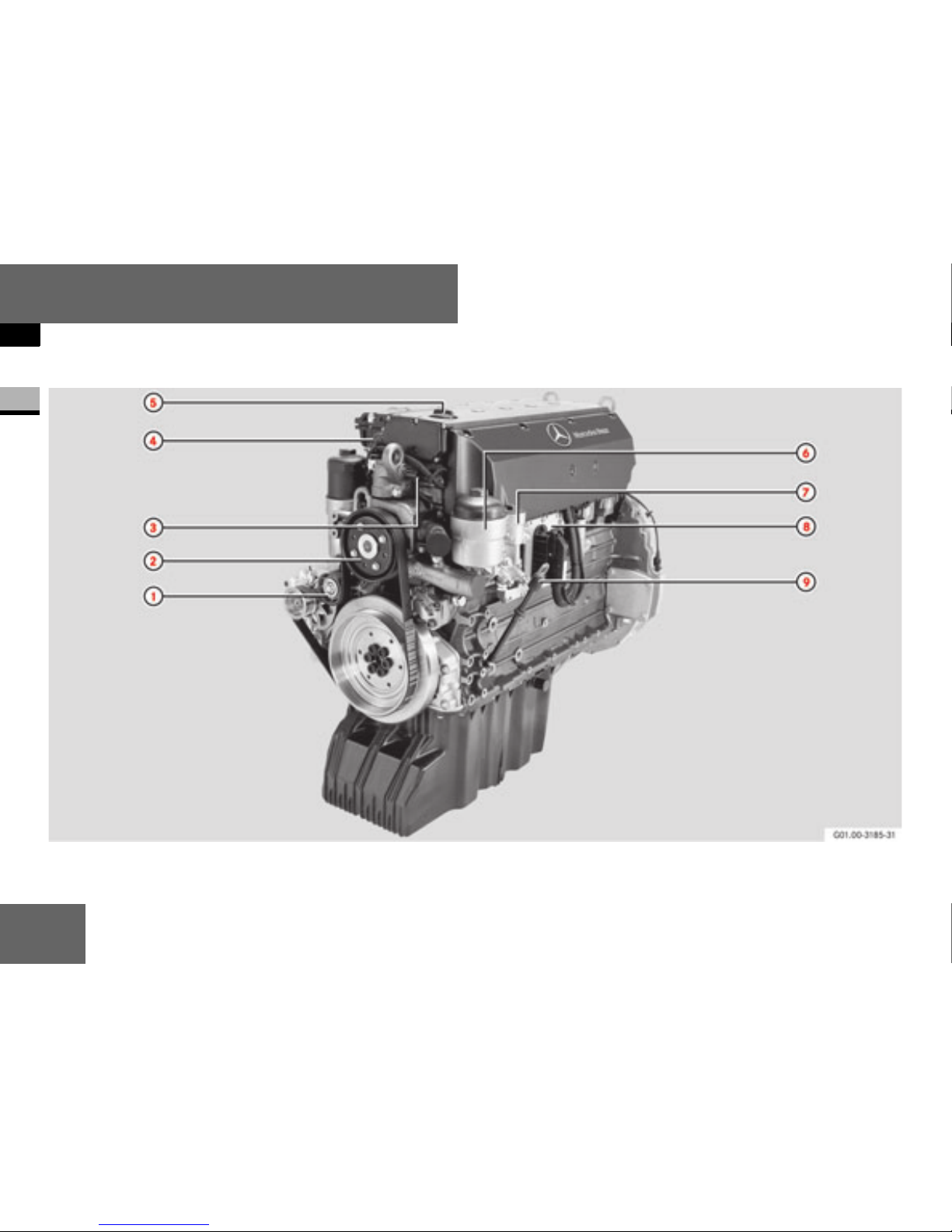

OM 906 LA/OM 926 LA overview

1

15

At a glance

OM 906 LA/OM 926 LA overview

1

1 Poly-V-belt tensioning pulley

2 Coolant pump

3 Coolant line heater supply*

4 Crankcase breather

5 Oil filler opening

6 Fuel filter

7 Fuel prefilter

8 MR (engine control) unit

9 Dipstick

16

At a glance

OM 906 LA/OM 926 LA overview

1

17

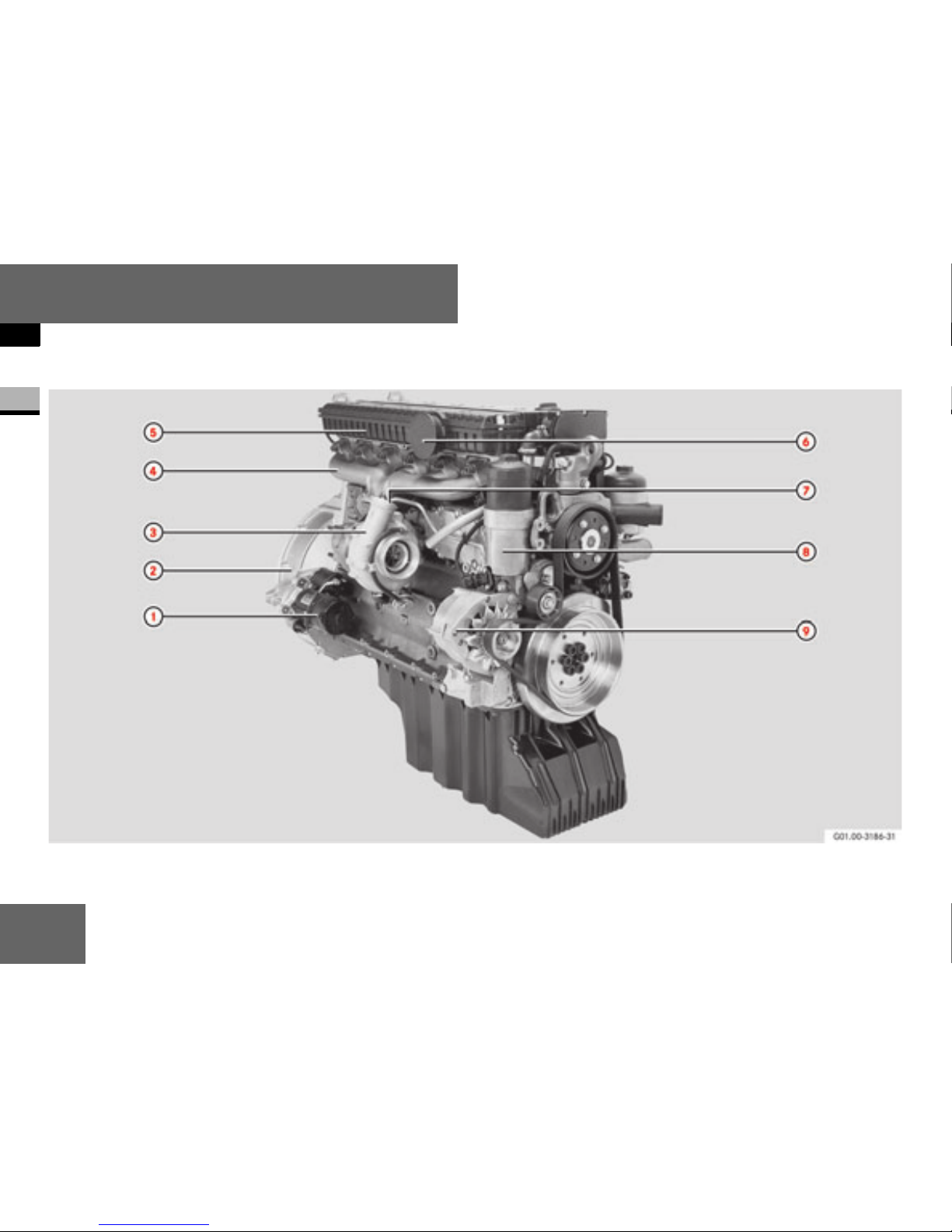

At a glance

OM 906 LA/OM 926 LA overview

1

1 Starter motor

2 Flywheel housing

3 Turbocharger with wastegate valve

4 Exhaust manifold

5 Charge-air housing

6 Charge-air pipe connection from the

intercooler

7 Charge-air pipe connection to the

intercooler

8 Oil filter

9 Alternator

18

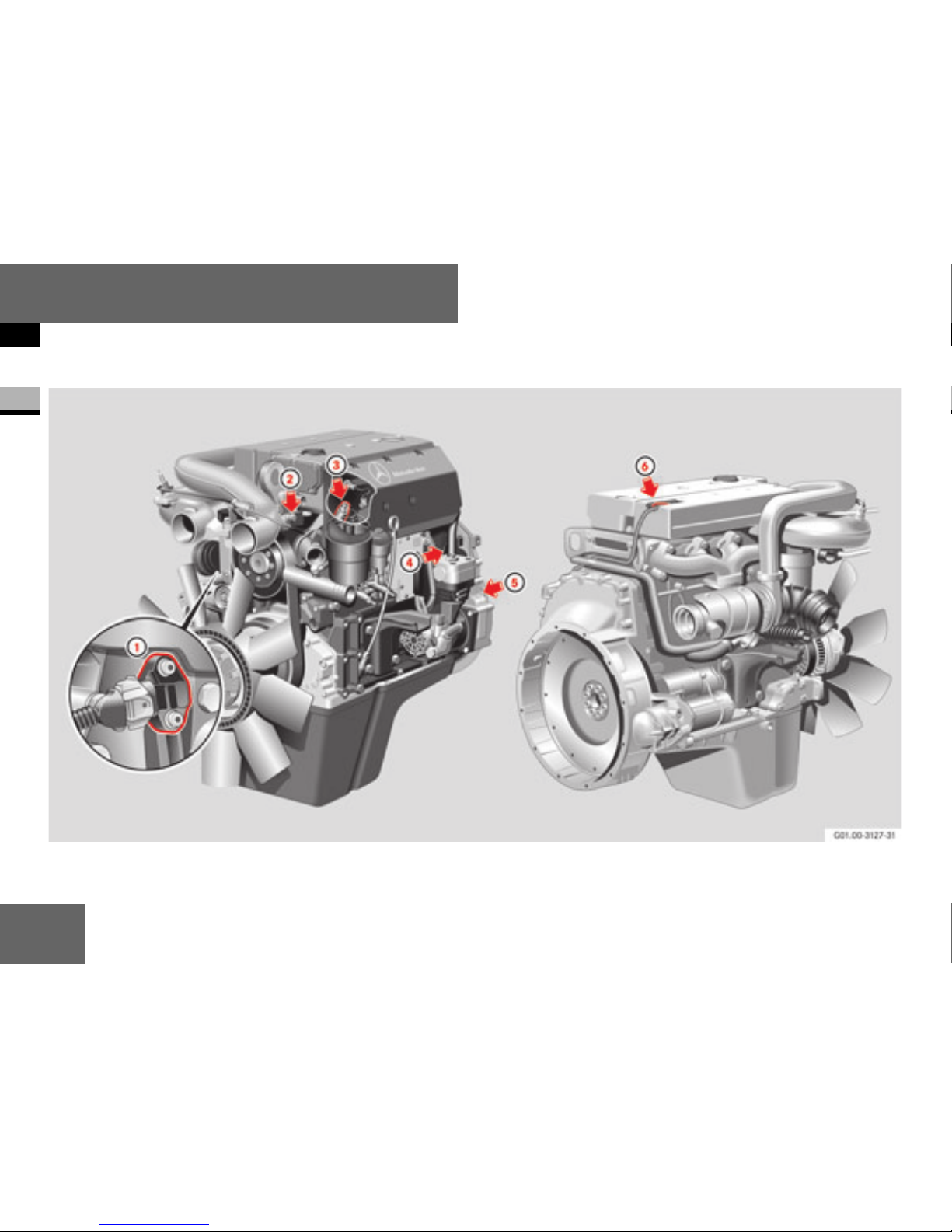

At a glance

Location of sensors

1

OM 904 LA (OM 906 LA/OM 926 LA

comparable)

19

At a glance

Location of sensors

1

1 Combined oil temperature/pressure

sensor

2 Coolant temperature sensor

3 Fuel temperature sensor

4 TDC sensor (on the camshaft sprocket)

5 Crankshaft position sensor (on the

flywheel)

6 Combined charge-air pressure/

temperature sensor

20

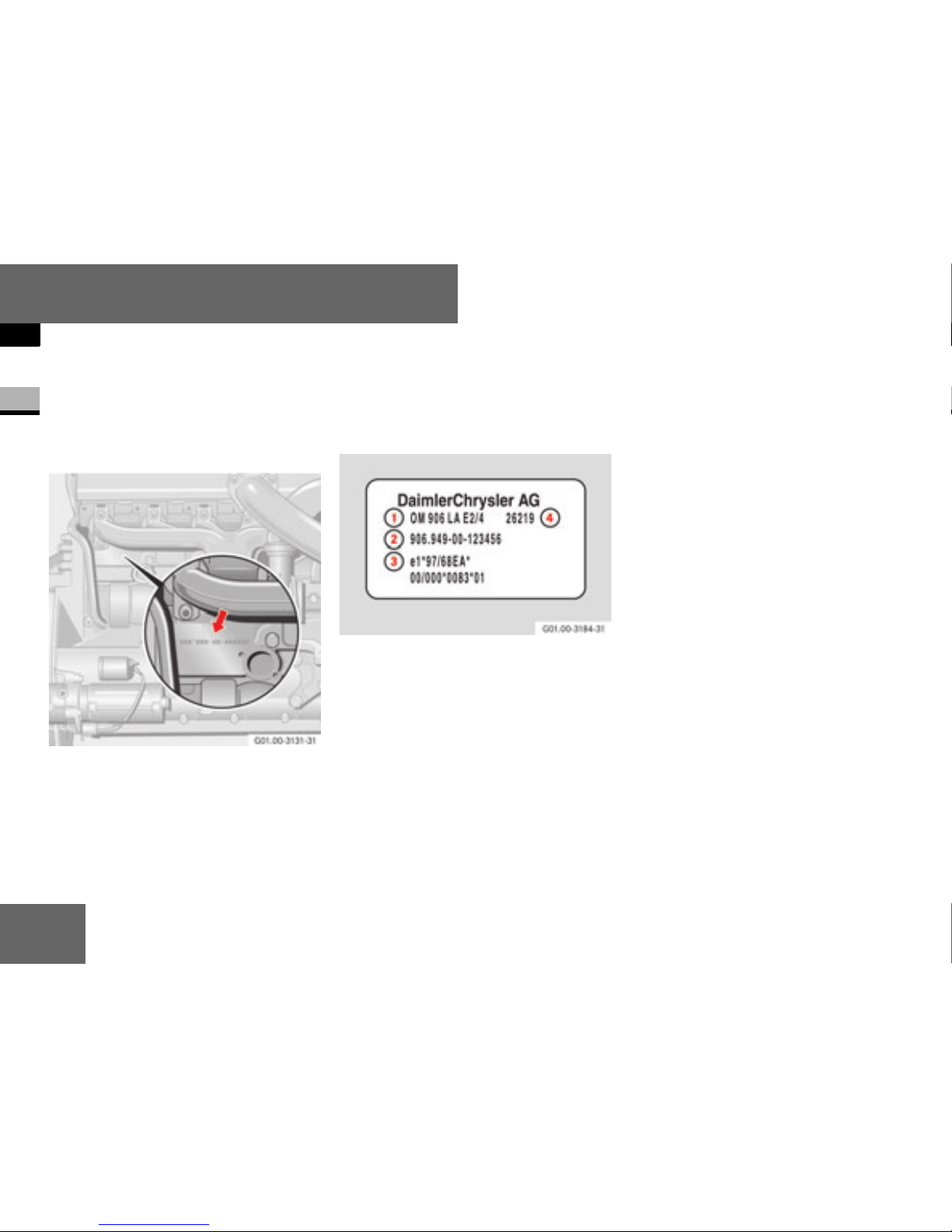

At a glance

Engine number

1

Location

The engine number is located on the rear

right-hand side, beneath the exhaust manifold (arrow).

Location of the engine number on the righthand side of the engine

Information on the engine

As well as the name of the manufacturer,

the following data is listed:

Information on the engine

1 Engine model designation

2 Engine number

3 Type approval number

4 Engine group

21

2

Before commissioning

General information

Transport and installation

22

Before commissioning

General information

2

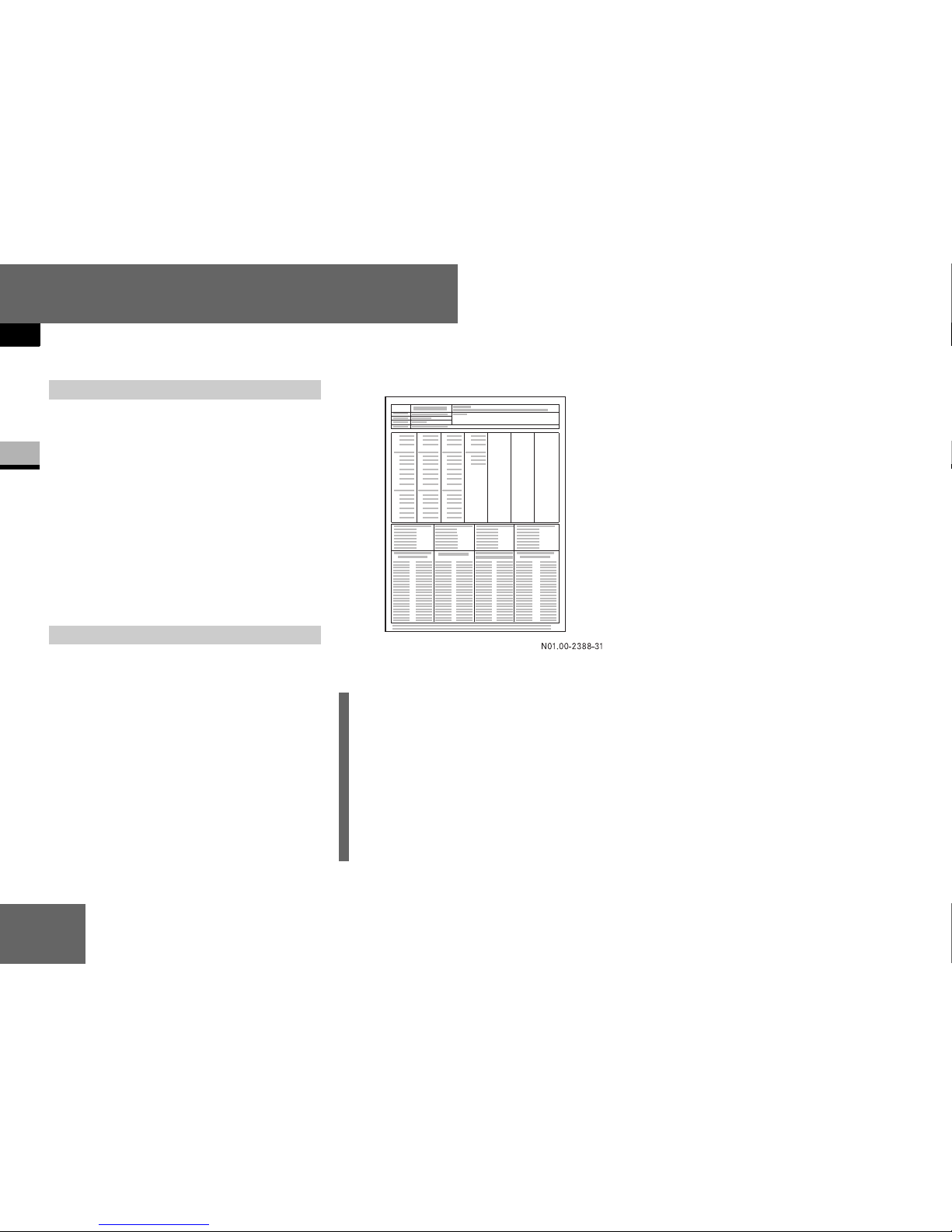

The engine data card (A4 sheet) forms an

integral part of the documents belonging

to the engine and should always be kept

with the Maintenance Booklet. It contains

details about the engine, including special

equipment.

The engine data card must be produced for

the procurement of genuine parts.

Engine data card

Type designation

OM 9XX L A

OM Oil engine

(diesel engine)

9XX Engine model

L Intercooler

A Exhaust gas

turbocharger

Engine data card

i

The engine data card describes the

scope of delivery from the

DaimlerChrysler factory; later changes

to the scope of delivery are not recorded on the data card.

Always keep the engine data card with

the Maintenance Booklet.

23

Before commissioning

General information

2

The OM 904 LA (four cylinder) and

OM 906 LA/OM 926 LA (six cylinder) engines are water-cooled 4-stroke direct injection diesel engines.

The cylinders are arranged in-line. Each

cylinder has two inlet valves and one outlet

valve.

Each cylinder has a separate fuel-injection

pump (unit pump) with a short high-pressure fuel injection line to the multi-hole

nozzle located in the centre of the combustion chamber. The unit pumps are mounted directly on the crankcase and driven by

the camshaft.

The engines are fitted with a turbocharger

and intercooler as standard. The engine

can be equipped with an engine brake* as

an option (throttle valve and constantlyopen throttle valves*).

The engines produce particularly low emissions. Injection start, injection period and

injection quantity are controlled fully electronically.

The control system consists of an engine

control unit mounted on the engine, the

MR (engine control) module and the application-dependent FR (drive control) unit or

the ADM adaptation module. All these control units are interconnected via the Controller Area Network (CAN).

Description of the engine

24

Before commissioning

General information

2

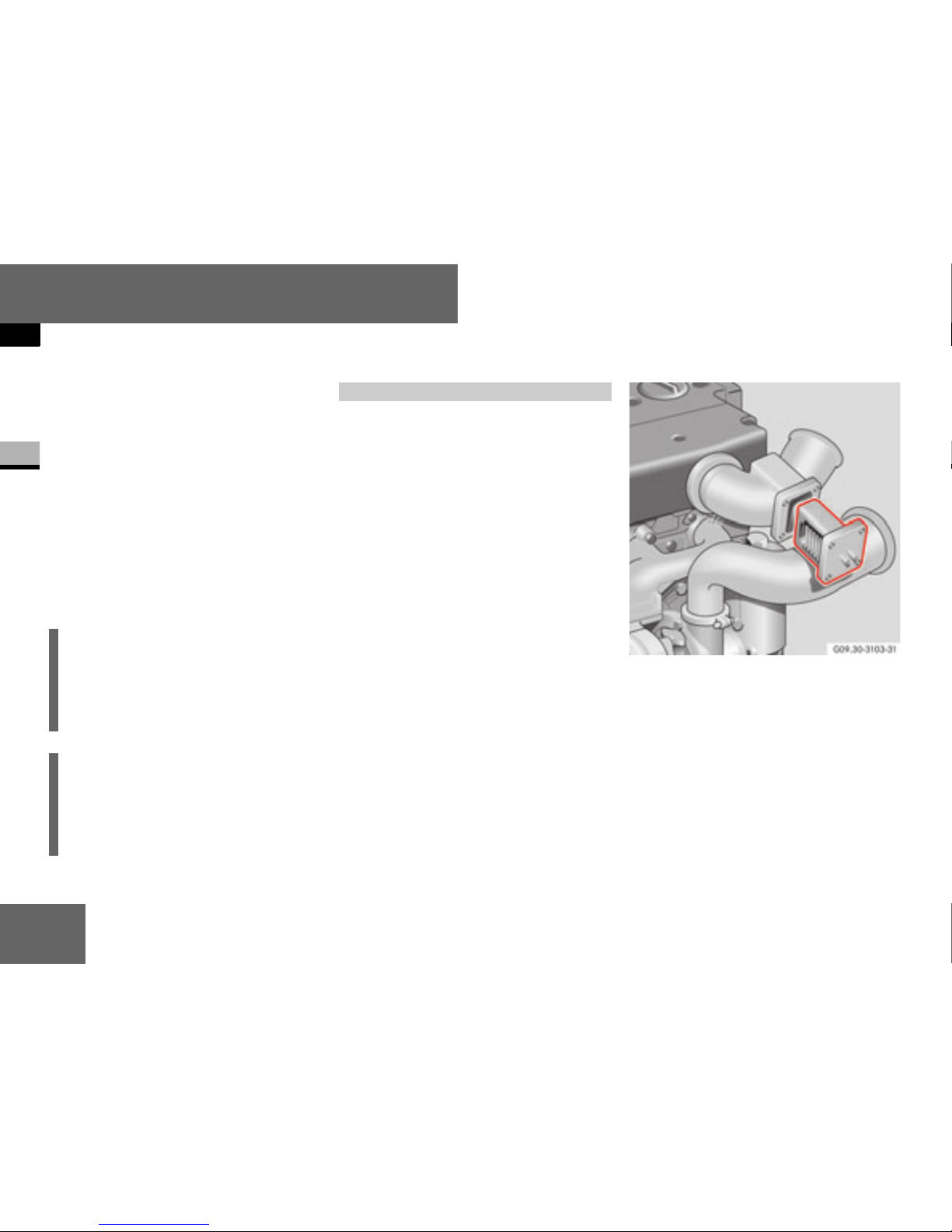

To increase the braking power, the engine

can be equipped with an exhaust brake

valve on the exhaust gas turbocharger in

conjunction with constantly-open throttle

valves on the cylinders.

Whereas exhaust gas backpressure, acting

through the exhaust brake valves, can be

used to increase the braking power, the

constantly-open throttle valves cause a

reduction of compression in the power

stroke (3rd stroke), leaving compression

(2nd stroke) practically unaffected.

The constantly-open throttle valves are

valves in the cylinder head. When open,

they connect the combustion chamber to

the exhaust duct, which generates the required decompression in the power stroke.

Constantly-open throttle valves on the

4-cylinder engine

When the engine brake is engaged, the

constantly-open throttle valves are opened

pneumatically on the 4-cylinder engine and

hydraulically on the 6-cylinder engine. At

the same time, the exhaust brake valve on

the exhaust gas turbocharger is closed.

Engine brake*/constantly-open

throttle valves*

i

Hydraulic constantly-open throttle

valves

The constantly-open throttle valves are

not actuated in the lower engine speed

range between 900 and 1,300 rpm or if

the engine oil temperature is less than

40 °C.

Observe these restrictions during operation.

25

Before commissioning

General information

2

The engine brake is controlled by the FR

(drive control) unit ( page 29) or the

ADM.

The engine brake always remains deactivated at engine speeds of below 900 rpm

to prevent the engine from stalling. The engine brake is also automatically deactivated if the position sensor is triggered (e.g. if

the accelerator pedal is depressed).

The flame-start system is a cold-start aid

for when ambient temperatures are low. It

reduces the emissions of white smoke

once the engine has been started. The

starter motor and battery are also protected as a result of the shorter start-up time.

Flame-start system

A flame glow plug is fitted in the charge

pressure pipe of the intercooler. Fuel can

be ignited at this flame glow plug. The fuel

is supplied to the flame glow plug via a solenoid valve with a dosing nozzle.

Flame-start system indicator lamp

(example)

i

In the emergency running program

(constant engine speed), the engine

brake can only be activated in overrun

mode at an increased engine speed.

The engine brake is automatically deactivated again once a constant engine

speed has been reached.

Flame-start system*

26

Before commissioning

General information

2

Following the preglow time, which is dependent on the ambient temperature

(maximum 20 seconds), the flame-start

system is activated and the flame-start

system indicator lamp goes out.

Once the engine has been started, the

flame-start system is supplied with fuel by

the fuel pump.

The flame-start system is only enabled if

the engine is started within 30 seconds of

the flame-start system indicator lamp going out.

The grid heater is a cold-start aid for low

ambient temperatures. A heating strip integrated in the intercooler charge pressure

pipe preheats the charge air. The starter

motor and battery are also protected as a

result of the shorter start-up time.

The tendency of the engine to emit white

smoke after it has been started is reduced

by a subsequent heating time of up to

180 seconds.

Grid heater

i

If the flame-start system indicator lamp

does not go out after more than 20 seconds, there is a malfunction in the

flame-start system.

i

For operation at low ambient temperatures, see also the “Diesel fuels”

( page 59) and “Coolant”

( page 64) sections.

Grid heater*

27

Before commissioning

General information

2

The engine has a fully electronic control

system, which, in addition to the engine

and associated sensors, also comprises:

an MR (engine control) unit and

an FR (drive control) unit and/or other

vehicle-specific control units, e.g. ADM

Both are interconnected via a CAN (Controller Area Network) line, on which all the

necessary data/information is exchanged.

The engine control monitors itself as well

as the engine. A safety and emergency running program is selected automatically,

depending on the malfunctions/system

failures that occur ( page 37).

MR (engine control) unit (mounted on

the engine)

The MR (engine control) unit is mounted on

the left-hand side of the engine.

MR (engine control) unit

The MR (engine control) unit processes

data from the drive control unit or the

ADM, indicating for example the position

of the position sensor (accelerator pedal),

the engine brake* or engine start/stop,

etc.

Telligent® engine system

Loading...

Loading...