MacDon FlexDraper FD1, FM100, FlexDraper FD145, FlexDraper FD130, FlexDraper FD135 Operator's Manual

...Page 1

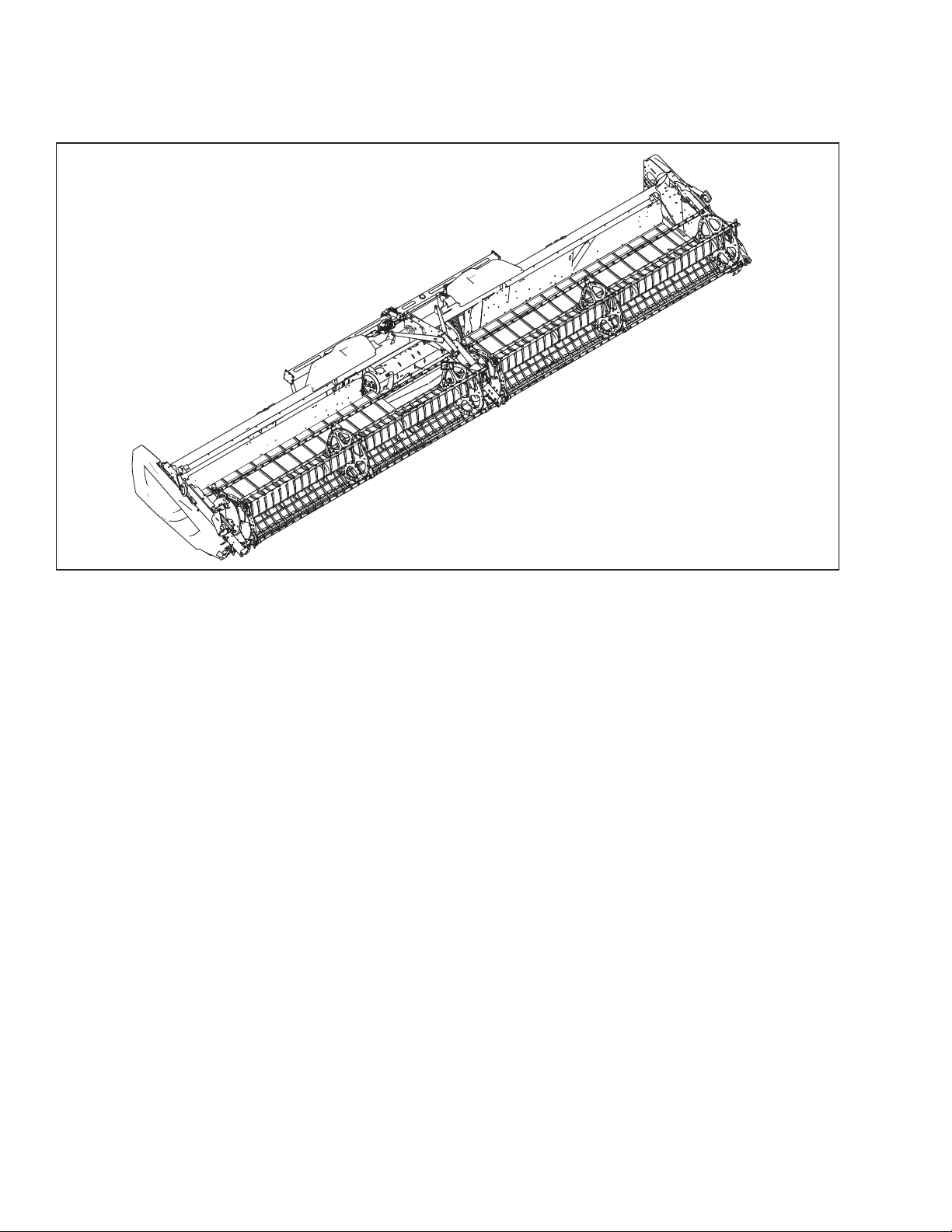

FD1 Series

FlexDraper

®®

Combine Header

Operator ’s Manual

214683 Revision A

2019 Model Year

Original Instruction

Featuring MacDon FLEX-FLOAT Technology™

The harvesting specialists.

Page 2

FD1 Series FlexDraper®Header

1016679

Published: June 2018

Page 3

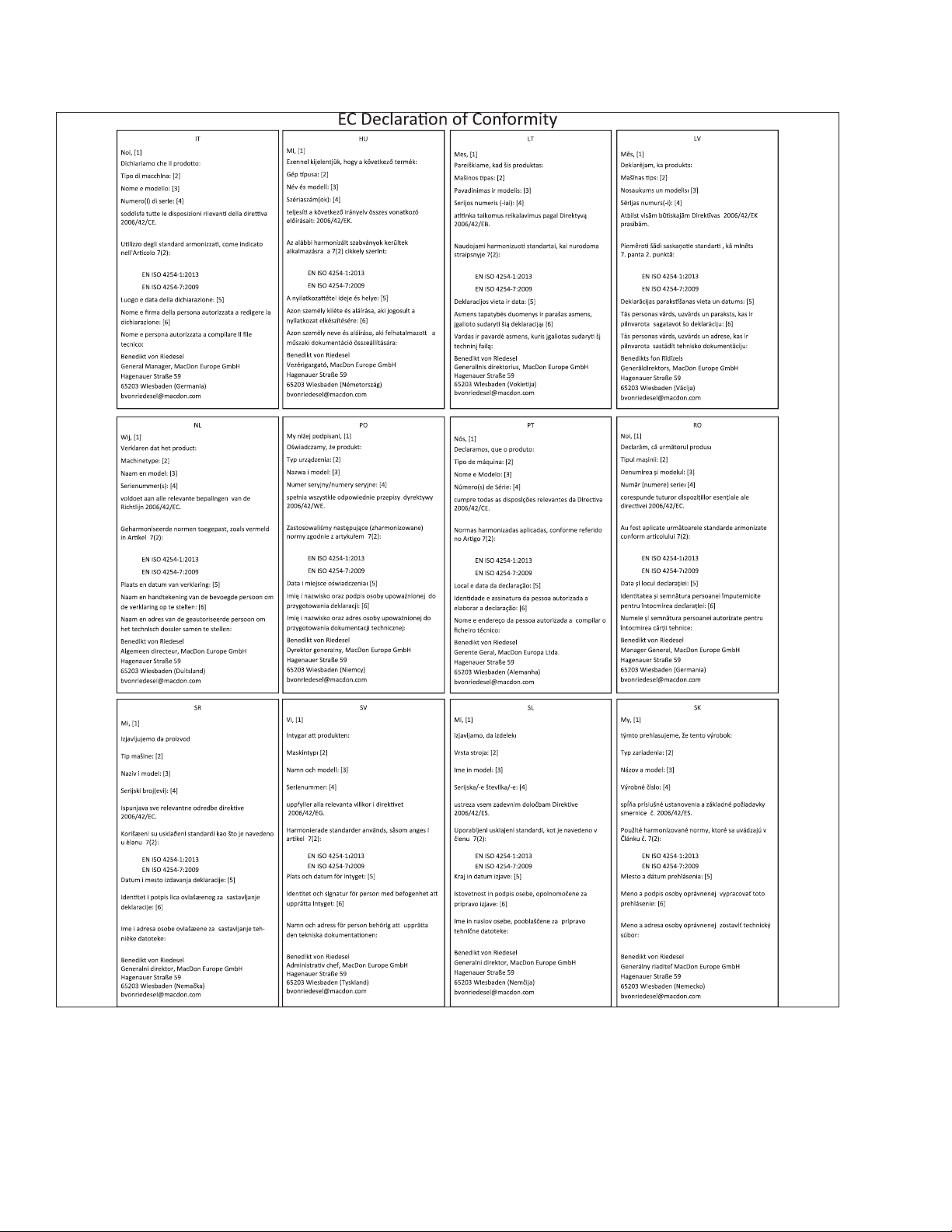

Declaration of Conformity

1026043

214683 i Revision A

Page 4

1026044

214683 ii Revision A

Page 5

1026045

214683 iii Revision A

Page 6

1026044

214683 iv Revision A

Page 7

Introduction

This instructional manual contains information on the FD1 Series FlexDraper®and the FM100 Combine Float

Module. It must be used in conjunction with your combine operator's manual.

®

The FD1 Series FlexDraper

above the ground, using a three-piece flexible frame to closely follow ground contours. The FM100 Combine Float

Module is used to attach an FD1 Series FlexDraper

Carefully read all the material provided before attempting to use the machine.

Use this manual as your first source of information about the machine. If you follow the instructions provided, your

header will work well for many years. If you require more detailed service information, a technical manual is

available from your MacDon Dealer.

MacDon provides warranty for Customers who operate and maintain their equipment as described in this manual.

A copy of the MacDon Industries Limited Warranty Policy, which explains this warranty, should have been provided

to you by your Dealer. Damage resulting from any of the following conditions will void the warranty:

• Accident

• Misuse

• Abuse

• Improper maintenance or neglect

• Abnormal or extraordinary use of the machine

is specially designed to work well in all straight cut conditions, whether cutting on or

®

to most makes and models of combines.

• Failure to use the machine, equipment, component, or part in accordance with the manufacturer’s instructions

The following conventions are used in this document:

• Right and left are determined from the operator’s position. The front of the header faces the crop; the back of

the header attaches to the combine.

• Unless otherwise noted, use the standard torque values provided in Chapter 8.1 Torque Specifications, page

577.

When setting up the machine or making adjustments, review and follow the recommended machine settings in all

relevant MacDon publications. Failure to do so may compromise machine function and machine life and may result

in a hazardous situation.

The Table of Contents and Index will guide you to specific areas of this manual. Study the Table of Contents to

familiarize yourself with how the information is organized.

214683 v Revision A

Page 8

1024245

A

Keep this manual handy for frequent reference and to pass

on to new Operators or Owners. A manual storage case (A)

is located inside the header left endshield.

Call your MacDon Dealer if you need assistance,

information, or additional copies of this manual.

NOTE:

Keep your MacDon publications up-to-date. The most

current version can be downloaded from our website

(www.macdon.com) or from our Dealer-only site

(https://portal.macdon.com) (login required).

This document is available in English, Czech, German,

French, Portuguese, Russian, and Ukrainian.

Figure 1. Manual Storage Location

214683 vi Revision A

Page 9

List of Revisions

Summary of Change Refer To

Updated Declaration of Conformity for model

year 2019.

Added Ukrainian to the list of languages available.

Added FM100 safety decal locations. 1.7 Safety Decal Locations, page 8

Added safety decal MD #252996. 1.8 Understanding Safety Signs, page 13

Updated illustrations of endshield hinge plate. Added

note to ensure hinge arm is installed in outboard hole

on the hinge bracket.

Updated illustrations to show transport lights.

Revised the high voltage limit adjustment instructions.

Added topic.

Added step and image showing the header

control switch.

Added settings for HEIGHT/TILT RESPONSE and

AUTO HEIGHT OVERRIDE.

Declaration of Conformity, page i

Introduction, page v

• Removing Endshields, page 36

• Installing Endshields, page 37

Repositioning Fore-Aft Cylinders on Non-EuropeanConfigured Headers with Multi-Crop Rapid Reel

Conversion Option, page 108

Adjusting Voltage Limits: One-Sensor System, page

131

Replacing Float Indicator Cable, page 135

Calibrating Auto Header Height Control (Case IH 5130/

6130/7130, 5140/6140/7140), page 146

Calibrating the Auto Header Height Control (Case

Combines with Version 28.00 or Higher Software),

page 160

Added settings specific to the two-sensor system.

Added steps to set center link to D, unlock float, and

lock wings.

Added steps for calibrating feeder house speed.

Removed unnecessary steps involving header float;

these steps are not applicable to reel height sensor

calibration.

Deleted note with link to height sensor adjustment; the

note isn’t relevant to feeder house speed calibration.

Added step to lock wings before calibration.

• Setting up the Header on the Combine Display

(Case IH 5130/6130/7130; 5140/6140/7140), page

142

• Calibrating the Auto Header Height Control

(Case IH 7010/8010, 7120/8120/9120,

7230/8230/9230, 7240/8240/9240), page 156

• Calibrating the Auto Header Height Control (Case

Combines with Version 28.00 or Higher Software),

page 160

Calibrating the Auto Header Height Control (Case

Combines with Version 28.00 or Higher Software),

page 160

Calibrating the Auto Header Height Control (John

Deere S and T Series), page 215

Calibrating Reel Height Sensor (John Deere S and T

Series), page 227

Calibrating Feeder House (John Deere S7 Series),

page 236

Calibrating the Auto Header Height Control (CLAAS

600 and 700 Series), page 251

214683 vii Revision A

Page 10

Added topics.

• Calibrating Reel Height Sensor (CLAAS 600 and

700 Series), page 258

• Adjusting Auto Reel Height (CLAAS 600 and 700

Series), page 260

Revised caution statement about reduced header

stability when cornering.

• Removed mentions of discontinued flighting

bundles B6215 and B6216.

• Updated feed auger illustrations.

Updated feed auger illustrations.

• Added changing oil in header drive gearbox (first 50

hours only).

• Added lubricating center draper roller bearings

(every 50 hours).

• Added checking draper roller bearings for heat

(every 200 hours)

Towing the Header, page 291

4.1 Float Module Feed Auger Configurations, page 307

• 5.7.2 Checking Auger Drive Chain Tension, page

421

• 5.7.3 Adjusting Auger Drive Chain Tension, page

423

• 5.7.4 Removing Auger Drive Chain, page 424

• 5.7.5 Installing Auger Drive Chain, page 426

5.3.1 Maintenance Schedule/Record, page 385

Added checking and adjusting finger timing

instructions.

Revised topic—No adjustment is required if spring

retainers are within +6 to –3 of flush and feed draper is

tracking properly.

Updated torque value for center reel arm brace bolts.

Updated illustration to show new bolt orientation.

Updated reel speed sensor illustrations.

Updated load range D tire pressure to 75 psi.

Added topics.

• Checking Auger Finger Timing, page 434

• Adjusting Auger Finger Timing, page 435

5.10.2 Adjusting Feed Draper Tension, page 468

5.15.3 Centering Double Reel, page 507

• Replacing AGCO (Challenger, Gleaner, and

Massey Ferguson) Sensor, page 538

• Replacing John Deere Reel Speed Sensor, page

540

5.17.3 Checking Tire Pressure, page 544

• 6.4.6 Center Skid Shoes Kit, page 554

• 6.5.9 European Combine Upper Cross Auger

(UCA), page 559

214683 viii Revision A

Page 11

Model and Serial Number

1020884

A

1020665

A

Record the model number, serial number, and model year of the header, combine float module, and

transport / stabilizer wheel option (if installed) in the spaces provided.

NOTE:

Right and left designations are determined from the operator’s position, facing forward.

®®

FlexDraper

Header Model:

Serial Number:

Year:

The serial number plate (A) is located in the upper corner

on the left endsheet.

Header

Figure 2. Header, Left Side Endshield

Combine Float Module

Float Module

Model:

Serial Number:

Year:

The serial number plate (A) is located at the top left side

of the float module.

Figure 3. Float Module

214683 ix Revision A

Page 12

1005072

A

Slow Speed Transport / Stabilizer Wheel Option

Serial Number:

Year:

The serial number plate (A) is located on the right axle

assembly.

Figure 4. Transport/Stabilizer Option

214683 x Revision A

Page 13

TABLE OF CONTENTS

Declaration of Conformity............................................................................................................................ i

Introduction...............................................................................................................................................v

List of Revisions ...................................................................................................................................... vii

Model and Serial Number.......................................................................................................................... ix

Chapter 1: Safety .................................................................................................................................... 1

1.1 Safety Alert Symbols ............................................................................................................................1

1.2 Signal Words .......................................................................................................................................2

1.3 General Safety.....................................................................................................................................3

1.4 Maintenance Safety .............................................................................................................................5

1.5 Hydraulic Safety...................................................................................................................................6

1.6 Safety Signs ........................................................................................................................................7

1.6.1 Installing Safety Decals ...............................................................................................................7

1.7 Safety Decal Locations.........................................................................................................................8

1.8 Understanding Safety Signs................................................................................................................ 13

Chapter 2: Product Overview ............................................................................ ................................ 19

2.1 Definitions .........................................................................................................................................19

2.2 Specifications ....................................................................................................................................21

2.3 Component Identification ....................................................................................................................25

®

2.3.1 FD1 Series FlexDraper

2.3.2 FM100 Float Module..................................................................................................................26

............................................................................................................25

Chapter 3: Operation ...........................................................................................................................29

3.1 Owner/Operator Responsibilities.........................................................................................................29

3.2 Operational Safety .............................................................................................................................30

3.2.1 Header Safety Props .................................................................................................................30

3.2.2 Reel Safety Props .....................................................................................................................31

Engaging Reel Safety Props......................................................................................................31

Disengaging Reel Safety Props .................................................................................................32

3.2.3 Endshields................................................................................................................................33

Opening Endshields..................................................................................................................33

Closing Endshields ...................................................................................................................34

Checking and Adjusting Endshields ...........................................................................................35

Removing Endshields ...............................................................................................................36

Installing Endshields .................................................................................................................37

3.2.4 Linkage Covers.........................................................................................................................37

Removing Linkage Covers ........................................................................................................37

Installing Linkage Covers ..........................................................................................................38

3.2.5 Daily Start-Up Check .................................................................................................................39

3.3 Break-in Period..................................................................................................................................40

3.4 Shutting down the Combine ................................................................................................................41

3.5 Cab Controls .....................................................................................................................................42

214683 xi Revision A

Page 14

TABLE OF CONTENTS

3.6 Header Setup ....................................................................................................................................43

3.6.1 Header Attachments..................................................................................................................43

3.6.2 Header Settings ........................................................................................................................ 43

3.6.3 Optimizing Header for Straight Combining Canola .......................................................................54

Checking and Adjusting Feed Auger Springs .............................................................................. 54

3.6.4 Reel Settings ............................................................................................................................56

3.7 Header Operating Variables................................................................................................................58

3.7.1 Cutting off the Ground ...............................................................................................................58

Adjusting Stabilizer / Slow Speed Transport Wheels ....................................................................59

Adjusting Stabilizer Wheels .......................................................................................................60

3.7.2 Cutting on the Ground ............................................................................................................... 62

Adjusting Inner Skid Shoes .......................................................................................................62

Adjusting Outer Skid Shoes.......................................................................................................63

3.7.3 Header Float............................................................................................................................. 64

Checking and Adjusting Header Float ........................................................................................64

Locking/Unlocking Header Float ................................................................................................ 69

Locking/Unlocking Header Wings .............................................................................................. 70

Operating in Flex Mode.............................................................................................................70

Operating in Rigid Mode............................................................................................................ 71

3.7.4 Checking and Adjusting Header Wing Balance ............................................................................ 73

Checking Wing Balance ............................................................................................................73

Adjusting Wing Balance ............................................................................................................79

3.7.5 Header Angle............................................................................................................................81

Adjusting Header Angle from Combine.......................................................................................83

3.7.6 Reel Speed............................................................................................................................... 89

Optional Reel Drive Sprockets...................................................................................................89

3.7.7 Ground Speed ..........................................................................................................................90

3.7.8 Draper Speed ...........................................................................................................................91

Adjusting Header Draper Speed ................................................................................................92

Feed Draper Speed ..................................................................................................................93

3.7.9 Knife Speed Data ...................................................................................................................... 94

Checking Knife Speed ..............................................................................................................95

3.7.10 Reel Height............................................................................................................................. 95

Checking and Adjusting Reel Height Sensor..... ..........................................................................96

Replacing Reel Height Sensor...................................................................................................98

3.7.11 Reel Fore-Aft Position .............................................................................................................. 99

Adjusting Reel Fore-Aft Position .............................................................................................. 100

Repositioning Fore-Aft Cylinders on Non-European-Configured Headers....................................101

Repositioning Fore-Aft Cylinders on European-Configured Headers........................................... 104

Repositioning Fore-Aft Cylinders on Non-European-Configured Headers with Multi-Crop Rapid

Reel Conversion Option..............................................................................................108

3.7.12 Reel Tine Pitch ...................................................................................................................... 111

Reel Cam Settings.................................................................................................................. 111

Adjusting Reel Cam ................................................................................................................ 113

3.7.13 Crop Dividers ........................................................................................................................ 115

Removing Crop Dividers with Latch Option from Header............................................................ 115

Removing Crop Dividers without Latch Option from Header ....................................................... 116

Installing Crop Dividers with Latch Option onto Header.............................................................. 116

Installing Crop Dividers without Latch Option onto Header ......................................................... 118

214683 xii Revision A

Page 15

TABLE OF CONTENTS

3.7.14 Crop Divider Rods ................................................................................................................. 119

Removing Crop Divider Rods .................................................................................................. 120

Installing Crop Divider Rods .................................................................................................... 120

Rice Divider Rods...................................................................................................................121

3.7.15 Setting Auger Position ...........................................................................................................121

3.8 Auto Header Height Control (AHHC)..................................................................................................124

3.8.1 Sensor Operation....................................................................................................................125

3.8.2 Sensor Output Voltage Range – Combine Requirements ...........................................................126

10 Volt Adapter (MD #B6421) – New Holland Combines Only .................................................... 126

Manually Checking Voltage Range: One-Sensor System ........................................................... 127

Manually Checking Voltage Range: Two-Sensor System ........................................................... 129

Adjusting Voltage Limits: One-Sensor System ..........................................................................131

Adjusting Voltage Limits: Two-Sensor System.... .......................................................................131

Replacing the Auto Header Height Control (AHHC) Sensor (One-Sensor System)....................... 133

Replacing Float Indicator Cable ............................................................................................... 135

3.8.3 Case IH 5088/6088/7088 Combines ......................................................................................... 139

Calibrating the Auto Header Height Control (Case IH 5088/6088/7088) ...................................... 139

Setting the Sensitivity of the Auto Header Height (Case IH 5088/6088/7088)...............................140

3.8.4 Case IH 5130/6130/7130 and 5140/6140/7140 Mid-Range Combines......................................... 142

Setting up the Header on the Combine Display (Case IH 5130/6130/7130;

5140/6140/7140)........................................................................................................142

Checking Voltage Range from Combine Cab (Case IH 5130/6130/7130;

5140/6140/7140)........................................................................................................144

Calibrating Auto Header Height Control (Case IH 5130/6130/7130, 5140/6140/7140) .................. 146

Setting Preset Cutting Height (Case 5130/6130/7130, 5140/6140/7140) ..................................... 147

3.8.5 Case IH 7010/8010, 7120/8120/9120, 7230/8230/9230 and 7240/8240/9240 Combines .............. 150

Checking Voltage Range from the Combine Cab (Case 8010)....................................................150

Setting Header Controls (Case 8010).......................................................................................153

Checking Voltage Range from the Combine Cab (Case IH 7010/8010, 7120/8120/9120,

7230/8230/9230, 7240/8240/9240).............................................................................. 153

Calibrating the Auto Header Height Control (Case IH 7010/8010, 7120/8120/9120,

7230/8230/9230, 7240/8240/9240).............................................................................. 156

Calibrating the Auto Header Height Control (Case Combines with Version 28.00 or Higher

Software)................................................................................................................... 160

Checking Reel Height Sensor Voltages (Case IH) .....................................................................164

Setting Preset Cutting Height (Case 7010/8010, 7120/8120/9120, 7230/8230/9230,

7240/8240/9240)........................................................................................................165

3.8.6 Challenger and Massey Ferguson 6 and 7 Series Combines ......................................................166

Checking Voltage Range from the Combine Cab (Challenger and Massey Ferguson) .................. 166

Engaging the Auto Header Height Control (Challenger and Massey Ferguson) ........................... 168

Calibrating the Auto Header Height Control (Challenger and Massey Ferguson).......................... 169

Adjusting the Header Height (Challenger and Massey Ferguson) ............................................... 171

Adjusting the Header Raise/Lower Rate (Challenger and Massey Ferguson) .............................. 171

Setting the Sensitivity of the Auto Header Height Control (Challenger and Massey

Ferguson).................................................................................................................. 172

3.8.7 Gleaner R65/R66/R75/R76 and S Series Combines .. ................................................................ 173

Checking Voltage Range from the Combine Cab (Gleaner R65/R66/R75/R76 and Pre-2016

S Series) ................................................................................................................... 173

Engaging the Auto Header Height Control (Gleaner R65/R66/R75/R76 and Pre-2016

S Series) ................................................................................................................... 175

214683 xiii Revision A

Page 16

TABLE OF CONTENTS

Calibrating the Auto Header Height Control (Gleaner R65/R66/R75/R76 and Pre-2016

S Series) ................................................................................................................... 177

Turning off the Accumulator (Gleaner R65/R66/R75/R76 and Pre-2016 S Series) ....................... 178

Adjusting the Header Raise/Lower Rate (Gleaner R65/R66/R75/R76 and Pre-2016

S Series) ................................................................................................................... 179

Adjusting Ground Pressure (Gleaner R65/R66/R75/R76 and Pre-2016 S Series) .. ...................... 179

Adjusting the Sensitivity of the Auto Header Height Control (AHHC) (Gleaner

R65/R66/R75/R76 and Pre-2016 S Series) ..................................................................180

Troubleshooting Alarms and Diagnostic Faults (Gleaner R65/R66/R75/R76 and Pre-2016

S Series) ................................................................................................................... 181

3.8.8 Gleaner S9 Series Combines ................................................................................................... 183

Setting up the Header (Gleaner S9 Series) ...............................................................................183

Setting up Reel Settings (Gleaner S9 Series)............................................................................ 188

Setting up Automatic Header Controls (Gleaner S9 Series).. ...................................................... 189

Calibrating the Header (Gleaner S9 Series) ..............................................................................192

Operating Header (Gleaner S9 Series).....................................................................................195

Header In-Field Settings .........................................................................................................196

3.8.9 John Deere 60 Series Combines .............................................................................................. 197

Checking Voltage Range from the Combine Cab (John Deere 60 Series)....................................197

Calibrating the Auto Header Height Control (John Deere 60 Series) ...........................................200

Turning the Accumulator Off (John Deere 60 Series) .................................................................201

Setting the Sensing Grain Header Height to 50 (John Deere 60 Series) ......................................202

Setting the Sensitivity of the Auto Header Height Control (John Deere 60 Series) ........................ 203

Adjusting the Threshold for the Drop Rate Valve (John Deere 60 Series) .................................... 204

3.8.10 John Deere 70 Series Combines ............................................................................................ 205

Checking Voltage Range from the Combine Cab (John Deere 70 Series)....................................205

Calibrating Feeder House Speed (John Deere 70 Series) ..........................................................208

Calibrating the Auto Header Height Control (John Deere 70 Series) ...........................................208

Setting the Sensitivity of the Auto Header Height Control (John Deere 70 Series) ........................ 210

Adjusting the Manual Header Raise/Lower Rate (John Deere 70 Series) .................................... 211

3.8.11 John Deere S and T Series Combines.....................................................................................212

Checking Voltage Range from the Combine Cab (John Deere S and T Series)............................212

Calibrating the Auto Header Height Control (John Deere S and T Series).................................... 215

Setting the Sensitivity of the Auto Header Height Control (John Deere S and T Series) ................ 218

Adjusting the Manual Header Raise/Lower Rate (John Deere S and T Series)............................. 219

Setting Preset Cutting Height (John Deere S and T Series)........................................................ 220

Calibrating Feeder House Fore-Aft Tilt Range (John Deere S and T Series) ................................ 222

Checking Reel Height Sensor Voltages (John Deere S and T Series) .........................................225

Calibrating Reel Height Sensor (John Deere S and T Series) .....................................................227

3.8.12 John Deere S7 Series Combines............................................................................................ 230

Setting up Header (John Deere S7 Series) ...............................................................................230

Checking Voltage Range from the Combine Cab (John Deere S7 Series) ................................... 234

Calibrating Feeder House (John Deere S7 Series) ....................................................................236

Calibrating Header (John Deere S7 Series) .............................................................................. 239

3.8.13 CLAAS 500 Series Combines.................................................................................................242

Calibrating the Auto Header Height Control (CLAAS 500 Series)................................................242

Setting Cutting Height (CLAAS 500 Series) .............................................................................. 244

Setting the Sensitivity of the Auto Header Height Control (CLAAS 500 Series) ............................246

Adjusting Auto Reel Speed (CLAAS 500 Series) .......................................................................248

3.8.14 CLAAS 600 and 700 Series Combines.. .................................................................................. 251

Calibrating the Auto Header Height Control (CLAAS 600 and 700 Series)...................................251

Setting Cutting Height (CLAAS 600 and 700 Series).................................................................. 254

214683 xiv Revision A

Page 17

TABLE OF CONTENTS

Setting the Sensitivity of the Auto Header Height Control (CLAAS 600 and 700 Series)................ 255

Adjusting Auto Reel Speed (CLAAS 600 and 700 Series) . .........................................................256

Calibrating Reel Height Sensor (CLAAS 600 and 700 Series) .................................................... 258

Adjusting Auto Reel Height (CLAAS 600 and 700 Series) ..........................................................260

3.8.15 New Holland Combines (CR/CX Series—Pre-2015 Model Year) ............................................... 261

Checking Voltage Range from the Combine Cab (New Holland).................................................261

Setting up Auto Header Height Control (New Holland CR/CX Series) . ........................................264

Calibrating the Auto Header Height Control (New Holland CR/CX Series) ...................................265

Adjusting Header Raise Rate (New Holland CR/CX Series) .......................................................268

Setting the Header Lower Rate (New Holland CR/CX Series).....................................................268

Setting the Sensitivity of the Auto Header Height Control (New Holland CR/CX Series)................269

Setting Preset Cutting Height (New Holland CR/CX Series) .......................................................270

3.8.16 New Holland Combines (CR Series—Model Year 2015 and Later) ............................................271

Checking Voltage Range from the Combine Cab (New Holland CR Series) ................................. 271

Setting up Auto Header Height Control (New Holland CR Series) ...............................................274

Calibrating the Auto Header Height Control (New Holland CR Series).........................................277

Checking Reel Height Sensor Voltages (New Holland) .............................................................. 280

Setting Preset Cutting Height (New Holland CR Series – 2015 and Later) ................................... 281

Setting Maximum Work Height (New Holland CR Series) ........................................................... 283

Configuring Reel Fore-Aft, Header Tilt, and Header Type (New Holland CR Series) .....................284

3.9 Leveling the Header ......................................................................................................................... 286

3.10 Unplugging the Cutterbar................................................................................................................ 288

3.11 Unplugging the Float Module...........................................................................................................289

3.12 Transporting the Header . ...............................................................................................................290

3.12.1 Transporting Header on Combine ...........................................................................................290

3.12.2 Towing..................................................................................................................................290

Attaching Header to Towing Vehicle ......................................................................................... 291

Towing the Header..................................................................................................................291

3.12.3 Converting from Transport to Field Position .............................................................................292

Removing Tow-Bar ................................................................................................................. 292

Storing the Tow-Bar ................................................................................................................293

Moving Front (Left) Wheels into Field Position .......................................................................... 295

Moving Rear (Right) Wheels into Field Position.........................................................................296

3.12.4 Converting from Field to Transport Position .............................................................................298

Moving Front (Left) Wheels into Transport Position ...................................................................298

Moving Rear (Right) Wheels into Transport Position ..................................................................300

Attaching Tow-Bar ..................................................................................................................303

3.13 Storing the Header ......................................................................................................................... 306

Chapter 4: Header Attachment/Detachment................................................................................ 307

4.1 Float Module Feed Auger Configurations ........................................................................................... 307

4.1.1 Converting from Ultra Narrow Configuration or Narrow Configuration to Medium

Configuration....................................................................................................................310

4.1.2 Converting from Wide Configuration to Medium Configuration .................................................... 313

4.1.3 Converting from Medium Configuration or Wide Configuration to Narrow Configuration ................315

4.1.4 Converting from Ultra Narrow Configuration to Narrow Configuration ..........................................317

4.1.5 Converting from Medium Configuration to Wide Configuration .................................................... 318

4.1.6 Converting from Ultra Narrow or Narrow Configuration to Wide Configuration .............................. 320

214683 xv Revision A

Page 18

TABLE OF CONTENTS

4.1.7 Optional Modification to Wide Configuration ..............................................................................322

4.1.8 Converting from Medium Configuration or Wide Configuration to Ultra Narrow

Configuration....................................................................................................................323

4.1.9 Converting from Narrow Configuration to Ultra Narrow Configuration ..........................................327

4.2 Float Module Setup .......................................................................................................................... 331

4.2.1 Using Auger Flighting ..............................................................................................................331

4.2.2 Using Stripper Bars .................................................................................................................331

4.3 Case IH Combines ...........................................................................................................................332

4.3.1 Attaching Header to Case IH Combine......................................................................................332

4.3.2 Detaching Header from Case IH Combine.................................................................................337

4.4 AGCO (Challenger, Gleaner, and Massey Ferguson) Combines ..........................................................340

4.4.1 Attaching Header to a Challenger, Gleaner, or Massey Ferguson Combine.................................. 340

4.4.2 Detaching Header from a Challenger, Gleaner, or Massey Ferguson Combine............................. 345

4.5 John Deere Combines ......................................................................................................................348

4.5.1 Attaching Header to John Deere Combine ................................................................................ 348

4.5.2 Detaching Header from John Deere Combine ...........................................................................352

4.6 CLAAS Combines ............................................................................................................................355

4.6.1 Attaching Header to CLAAS Combine....................................................................................... 355

4.6.2 Detaching Header from CLAAS Combine.................................................................................. 360

4.7 New Holland Combines ....................................................................................................................363

4.7.1 Attaching Header to New Holland CR/CX Combine....................................................................363

4.7.2 Detaching Header from New Holland CR/CX Combine...............................................................367

4.7.3 CR Feeder Deflectors..............................................................................................................371

4.8 Attaching and Detaching Header from Float Module ........................................................................... 372

4.8.1 Detaching Header from Float Module........................................................................................ 372

4.8.2 Attaching Header to Float Module.............................................................................................377

Chapter 5: Maintenance and Servicing .........................................................................................383

5.1 Preparing Machine for Servicing........................................................................................................ 383

5.2 Maintenance Specifications ..............................................................................................................384

5.2.1 Installing a Sealed Bearing.......................................................................................................384

5.3 Maintenance Requirements .............................................................................................................. 385

5.3.1 Maintenance Schedule/Record ................................................................................................ 385

5.3.2 Break-In Inspection ................................................................................................................. 388

5.3.3 Preseason Servicing ............................................................................................................... 388

5.3.4 End-of-Season Service............................................................................................................389

5.3.5 Checking Hydraulic Hoses and Lines........................................................................................390

5.3.6 Lubrication and Servicing.........................................................................................................390

Service Intervals.....................................................................................................................390

Greasing Procedure................................................................................................................ 399

Lubricating Reel Drive Chain ...................................................................................................400

Lubricating Auger Drive Chain .................................................................................................402

Lubricating Header Drive Gearbox ........................................................................................... 404

214683 xvi Revision A

Page 19

TABLE OF CONTENTS

5.4 Hydraulics ....................................................................................................................................... 407

5.4.1 Checking Oil Level in Hydraulic Reservoir .................................................................................407

5.4.2 Adding Oil to Hydraulic Reservoir .............................................................................................408

5.4.3 Changing Oil in Hydraulic Reservoir .........................................................................................409

5.4.4 Changing Oil Filter ..................................................................................................................410

5.5 Electrical System ............................................................................................................................. 411

5.5.1 Replacing Light Bulbs.............................................................................................................. 411

5.6 Header Drive ...................................................................................................................................412

5.6.1 Removing Driveline .................................................................................................................412

5.6.2 Installing Driveline ...................................................................................................................413

5.6.3 Removing Driveline Guard ....................................................................................................... 414

5.6.4 Installing Driveline Guard.........................................................................................................416

5.6.5 Adjusting Gearbox Drive Chain Tension ....................................................................................418

5.7 Auger..............................................................................................................................................419

5.7.1 Adjusting Auger to Pan Clearance ............................................................................................419

5.7.2 Checking Auger Drive Chain Tension........................................................................................421

5.7.3 Adjusting Auger Drive Chain Tension ........................................................................................423

5.7.4 Removing Auger Drive Chain ................................................................................................... 424

5.7.5 Installing Auger Drive Chain..................................................................................................... 426

5.7.6 Using Auger Flighting ..............................................................................................................428

5.7.7 Auger Fingers ......................................................................................................................... 428

Removing Feed Auger Fingers ................................................................................................429

Installing Feed Auger Fingers ..................................................................................................431

Checking Auger Finger Timing.................................................................................................434

Adjusting Auger Finger Timing.................................................................................................435

5.8 Knife ............................................................................................................................................... 437

5.8.1 Replacing Knife Section ...........................................................................................................437

5.8.2 Removing Knife ...................................................................................................................... 438

5.8.3 Removing Knifehead Bearing...................................................................................................439

5.8.4 Installing Knifehead Bearing.....................................................................................................440

5.8.5 Installing Knife ........................................................................................................................ 440

5.8.6 Spare Knife.............................................................................................................................441

5.8.7 Knife Guards...........................................................................................................................441

Adjusting Knife Guards ...........................................................................................................441

Replacing Pointed Guards.......................................................................................................443

Replacing Stub Guards ...........................................................................................................446

Checking Pointed Guard Hold-Downs ...................................................................................... 447

Adjusting Hold-Downs with Pointed Guards..............................................................................448

Adjusting Hold-Down at Double-Knife Center Pointed Guard .....................................................449

Checking and Adjusting Stub Guard Hold-Downs......................................................................450

Adjusting Hold-Downs with Stub Guards .................................................................................. 451

5.8.8 Knifehead Shield.....................................................................................................................452

Installing Knifehead Shield ......................................................................................................453

5.9 Knife Drive System...........................................................................................................................454

5.9.1 Knife Drive Box .......................................................................................................................454

214683 xvii Revision A

Page 20

TABLE OF CONTENTS

Checking Knife Drive Box........................................................................................................454

Checking Mounting Bolts.........................................................................................................455

Removing Knife Drive Box.......................................................................................................456

Removing Knife Drive Box Pulley.............................................................................................458

Installing Knife Drive Box Pulley.. .............................................................................................458

Installing Knife Drive Box ........................................................................................................459

Changing Oil in Knife Drive Box .... ........................................................................................... 461

5.9.2 Knife Drive Belts .....................................................................................................................462

Knife Drive Belts.....................................................................................................................462

5.10 Feed Draper ..................................................................................................................................466

5.10.1 Replacing Feed Draper..........................................................................................................466

5.10.2 Adjusting Feed Draper Tension...............................................................................................468

5.10.3 Feed Draper Drive Roller ....................................................................................................... 469

Removing Feed Draper Drive Roller......................................................................................... 469

Installing Feed Draper Drive Roller .......................................................................................... 472

Replacing Feed Draper Drive Roller Bearing ............................................................................ 473

5.10.4 Feed Draper Idler Roller.........................................................................................................475

Removing Feed Draper Idler Roller ..........................................................................................475

Installing Feed Draper Idler Roller............................................................................................476

Replacing Feed Draper Idler Roller Bearing.............................................................................. 477

5.11 Lowering Float Module Feed Deck Pan ............................................................................................479

5.12 Raising Float Module Feed Deck Pan .............................................................................................. 481

5.13 Float Module Stripper Bars and Feed Deflectors...............................................................................482

5.13.1 Removing Stripper Bars.........................................................................................................482

5.13.2 Installing Stripper Bars........................................................................................................... 483

5.13.3 Replacing Feed Deflectors on New Holland CR Combines .......................................................483

5.14 Header Drapers .............................................................................................................................485

5.14.1 Removing Side Drapers.........................................................................................................485

5.14.2 Installing Side Drapers ...........................................................................................................486

5.14.3 Adjusting Draper Tension ....................................................................................................... 488

5.14.4 Adjusting Header Draper Tracking ..........................................................................................490

5.14.5 Adjusting Deck Height ........................................................................................................... 492

5.14.6 Header Draper Roller Maintenance.........................................................................................494

Inspecting Draper Roller Bearing .. ........................................................................................... 494

Draper Deck Idler Roller..........................................................................................................494

Draper Deck Drive Roller ........................................................................................................ 497

5.15 Reel ..............................................................................................................................................502

5.15.1 Reel Clearance to Cutterbar...................................................................................................502

Measuring Reel Clearance ...................................................................................................... 502

Adjusting Reel Clearance........................................................................................................ 505

5.15.2 Reel Frown ...........................................................................................................................506

Adjusting Reel Frown..............................................................................................................506

5.15.3 Centering Double Reel...........................................................................................................507

5.15.4 Reel Fingers .........................................................................................................................507

Removing Steel Fingers..........................................................................................................507

Installing Steel Fingers............................................................................................................508

Removing Plastic Fingers.

.......................................................................................................509

214683 xviii Revision A

Page 21

TABLE OF CONTENTS

Installing Plastic Fingers .........................................................................................................510

5.15.5 Tine Tube Bushings............................................................................................................... 511

Removing Bushings from Five-, Six-, or Nine-Bat Reels............................................................. 511

Installing Bushings on Five-, Six-, or Nine-Bat Reels .................................................................516

5.15.6 Reel Endshields ....................................................................................................................523

Replacing Reel Endshields......................................................................................................523

Replacing Reel Endshield Supports .........................................................................................525

5.16 Reel System .................................................................................................................................. 526

5.16.1 Reel Drive Cover...................................................................................................................526

Removing Reel Drive Cover .................................................................................................... 526

Installing Reel Drive Cover ...................................................................................................... 527

5.16.2 Reel Drive Chain Tension....................................................................................................... 528

Loosening Reel Drive Chain ....................................................................................................528

Tightening Reel Drive Chain ....................................................................................................528

5.16.3 Reel Drive Sprocket............................................................................................................... 530

Removing Reel Drive Sprocket ................................................................................................530

Installing Reel Drive Sprocket..................................................................................................531

5.16.4 Double-Reel U-Joint .............................................................................................................. 532

Removing Double-Reel U-Joint . .............................................................................................. 532

Installing Double-Reel U-Joint .................................................................................................533

5.16.5 Reel Drive Motor ................................................................................................................... 534

Removing Reel Drive Motor.. ...................................................................................................534

Installing Reel Drive Motor ..... .................................................................................................534

5.16.6 Replacing Drive Chain on Double Reel ..... ..............................................................................535

5.16.7 Replacing Drive Chain on Single Reel.....................................................................................537

5.16.8 Replacing Reel Speed Sensor................................................................................................538

Replacing AGCO (Challenger, Gleaner, and Massey Ferguson) Sensor ..................................... 538

Replacing John Deere Reel Speed Sensor...............................................................................540

Replacing CLAAS 400 Series Reel Speed Sensor ....................................................................540

Replacing CLAAS 500/700 Series Reel Speed Sensor .............................................................. 541

5.17 Transport System (Optional) ........................................................................................................... 542

5.17.1 Checking Wheel Bolt Torque .................................................................................................. 542

5.17.2 Checking Axle Bolt Torque .....................................................................................................543

5.17.3 Checking Tire Pressure.......................................................................................................... 544

Chapter 6: Options and Attachments............................................................................................545

6.1 Float Module.................................................................................................................................... 545

6.1.1 Hillside Extension Kit ............................................................................................................... 545

6.2 Reel................................................................................................................................................ 546

6.2.1 Multi-Crop Rapid Reel Conversion Kit ....................................................................................... 546

6.2.2 Reel Arm Extension Kit (European-configured Headers Only).....................................................546

6.2.3 Lodged Crop Reel Finger Kit .................................................................................................... 547

6.2.4 PR15 Tine Tube Reel Conversion Kit ........................................................................................547

6.2.5 Reel Endshield Kit................................................................................................................... 547

6.2.6 Tine Tube Reinforcing Kit.........................................................................................................548

6.3 Cutterbar.........................................................................................................................................549

214683 xix Revision A

Page 22

TABLE OF CONTENTS

6.3.1 Cutterbar Wearplate ................................................................................................................ 549

6.3.2 Knifehead Shield.....................................................................................................................549

6.3.3 Extended Center Filler ............................................................................................................. 550

6.3.4 Rock Retarder.........................................................................................................................550

6.3.5 Stub Guard Conversion Kit.......................................................................................................550

6.3.6 FD1 Series Vertical Knife Mounts and Double Vertical Knife Hose Kits ........................................551

6.3.7 Vertical Knife Plumbing Kits .....................................................................................................551

6.3.8 Roto-Shear Completion Package ............................................................................................. 551

6.4 Header............................................................................................................................................ 552

6.4.1 Divider Latch Kit.. ....................................................................................................................552

6.4.2 Stabilizer Wheels ....................................................................................................................552

6.4.3 Secondary Stabilizer Wheel .....................................................................................................553

6.4.4 Stabilizer Wheels and Slow Speed Transport Package...............................................................553

6.4.5 Backsheet Extension Kit ..........................................................................................................554

6.4.6 Center Skid Shoes Kit..............................................................................................................554

6.5 Crop Delivery................................................................................................................................... 555

6.5.1 FM100 Dual Auto Header Height Control (AHHC) Sensor Kit......................................................555

6.5.2 FM100 Feed Auger Flighting .................................................................................................... 555

6.5.3 In-Cab Draper Speed Control (ICDSC) Kit................................................................................. 556

6.5.4 Draper Deflector (Narrow)........................................................................................................556

6.5.5 Draper Deflector (Wide) ........................................................................................................... 557

6.5.6 Stripper Bars...........................................................................................................................557

6.5.7 Auger Dent Repair Kit..............................................................................................................558

6.5.8 Upper Cross Auger (UCA) ....................................................................................................... 558

6.5.9 European Combine Upper Cross Auger (UCA) ..........................................................................559

6.5.10 Rice Divider Rods..................................................................................................................559

Chapter 7: Troubleshooting.............................................................................................................561

7.1 Crop Loss at Cutterbar .....................................................................................................................561

7.2 Cutting Action and Knife Components ............................................................................................... 564

7.3 Reel Delivery ...................................................................................................................................567

7.4 Header and Drapers.........................................................................................................................570

7.5 Cutting Edible Beans........................................................................................................................ 572

Chapter 8: Reference .........................................................................................................................577

8.1 Torque Specifications .......................................................................................................................577

8.1.1 Metric Bolt Specifications......................................................................................................... 577

8.1.2 Metric Bolt Specifications Bolting into Cast Aluminum ................................................................ 579

8.1.3 Flare-Type Hydraulic Fittings... .................................................................................................580

8.1.4 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable) .................................................................... 581

8.1.5 O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable).............................................................583

8.1.6 O-Ring Face Seal (ORFS) Hydraulic Fittings .............................................................................584

8.1.7 Tapered Pipe Thread Fittings ...................................................................................................585

214683 xx Revision A

Page 23

TABLE OF CONTENTS

8.2 Conversion Chart.............................................................................................................................586

8.3 Unloading and Assembly .................................................................................................................. 587

Index.......................................................................................................................................................589

Recommended Fluids and Lubricants ............................................................. Inside Back Cover

214683 xxi Revision A

Page 24

Page 25

1 Safety

1000915

1.1 Safety Alert Symbols

This safety alert symbol indicates important safety

messages in this manual and on safety signs on

the machine.

This symbol means:

• ATTENTION!

• BECOME ALERT!

• YOUR SAFETY IS INVOLVED!

Carefully read and follow the safety message

accompanying this symbol.

Why is safety important to you?

• Accidents disable and kill

• Accidents cost

• Accidents can be avoided

Figure 1.1: Safety Symbol

214683 1 Revision A

Page 26

SAFETY

1.2 Signal Words

Three signal words, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. Signal

words are selected using the following guidelines:

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. It

may also be used to alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It

may be used to alert against unsafe practices.

214683 2 Revision A

Page 27

1000004

1000005

1010391

SAFETY

1.3 General Safety

CAUTION

The following are general farm safety precautions that

should be part of your operating procedure for all types

of machinery.

Protect yourself.

• When assembling, operating, and servicing machinery,

wear all protective clothing and personal safety devices

that could be necessary for job at hand. Do NOT take

chances. You may need the following:

• Hard hat

• Protective footwear with slip-resistant soles

• Protective glasses or goggles

• Heavy gloves

• Wet weather gear

• Respirator or filter mask

• Be aware that exposure to loud noises can cause hearing

impairment or loss. Wear suitable hearing protection

devices such as earmuffs or earplugs to help protect

against loud noises.

Figure 1.2: Safety Equipment

Figure 1.3: Safety Equipment

• Provide a first aid kit for use in case of emergencies.

• Keep a fire extinguisher on the machine. Be sure fire

extinguisher is properly maintained. Be familiar with its

proper use.

• Keep young children away from machinery at all times.

• Be aware that accidents often happen when Operator is

tired or in a hurry. Take time to consider safest way.

Never ignore warning signs of fatigue.

Figure 1.4: Safety Equipment

214683 3 Revision A

Page 28

1000007

1000008

1000009

SAFETY

• Wear close-fitting clothing and cover long hair. Never

wear dangling items such as scarves or bracelets.

• Keep all shields in place. NEVER alter or remove safety

equipment. Make sure driveline guards can rotate

independently of shaft and can telescope freely.

• Use only service and repair parts made or approved by

equipment manufacturer. Substituted parts may not meet

strength, design, or safety requirements.

• Keep hands, feet, clothing, and hair away from moving

parts. NEVER attempt to clear obstructions or objects

from a machine while engine is running.

• Do NOT modify machine. Unauthorized modifications

may impair machine function and/or safety. It may also

shorten machine’s life.

Figure 1.5: Safety around Equipment

• To avoid bodily injury or death from unexpected startup of

machine, ALWAYS stop the engine and remove the key

from the ignition before leaving the operator’s seat for

any reason.

• Keep service area clean and dry. Wet or oily floors are

slippery. Wet spots can be dangerous when working with

electrical equipment. Be sure all electrical outlets and

tools are properly grounded.

• Keep work area well lit.

• Keep machinery clean. Straw and chaff on a hot engine is

a fire hazard. Do NOTallow oil or grease to accumulate

on service platforms, ladders, or controls. Clean

machines before storage.

• NEVER use gasoline, naphtha, or any volatile material for

cleaning purposes. These materials may be toxic and/or

flammable.

• When storing machinery, cover sharp or extending

components to prevent injury from accidental contact.

Figure 1.6: Safety around Equipment

Figure 1.7: Safety around Equipment

214683 4 Revision A

Page 29

1000009

1008958

1000004

SAFETY

1.4 Maintenance Safety

To ensure your safety while maintaining machine:

• Review operator’s manual and all safety items before

operation and/or maintenance of machine.

• Place all controls in Neutral, stop the engine, set the park

brake, remove the ignition key, and wait for all moving

parts to stop before servicing, adjusting, and/or repairing.

• Follow good shop practices:

– Keep service areas clean and dry

– Be sure electrical outlets and tools are properly

grounded

– Keep work area well lit

• Relieve pressure from hydraulic circuits before servicing

and/or disconnecting machine.

• Make sure all components are tight and that steel lines,

hoses, and couplings are in good condition before

applying pressure to hydraulic systems.

Figure 1.8: Safety around Equipment

• Keep hands, feet, clothing, and hair away from all

moving and/or rotating parts.

• Clear area of bystanders, especially children, when

carrying out any maintenance, repairs, or adjustments.

• Install transport lock or place safety stands under frame

before working under machine.

• If more than one person is servicing machine at same

time, be aware that rotating a driveline or other

mechanically-driven component by hand (for example,

accessing a lubricant fitting) will cause drive components

in other areas (belts, pulleys, and knives) to move. Stay

clear of driven components at all times.

• Wear protective gear when working on machine.

• Wear heavy gloves when working on knife components.

Figure 1.9: Equipment NOT Safe for Children

Figure 1.10: Safety Equipment

214683 5 Revision A

Page 30

1001205

1001207