Page 1

FD75

FlexDraper

®

Combine Header

Operator ’s Manual

169894 Revision A

Original Instruction

The harvesting specialists worldwide.

Page 2

FD75 FlexDraper®FlexDraper®Header for Combines

Published: July, 2014

Page 3

Declaration of Conformity

169894

i

Revision A

Page 4

Introduction

This instructional manual contains information on the FD75 FlexDraper®and the CA25 Combine Adapter. It must

be used in conjunction with your combine operator's manual.

TheFD75FlexDraper

cut conditions, whether cutting on or above the ground, using a three-piece flexible frame to closely follow ground

contours.

CAREFULLYREAD ALLTHE MATERIALPROVIDED BEFOREATTEMPTINGTO UNLOAD, ASS EMBLE , OR USE

THE MACHINE.

Use this manual as your first source of information about the machine. If you follow the instructions given here,

your header will work well for many years. If you require more detailed service information, a technical manual is

available from your MacDon Dealer.

The Table of Contents and Index will guide you to specific areas of this manual. Study the Table of Contents to

familiarize yourself with how the info rmation is organized.

Keep thismanual handy for frequentreference and to pass

on to new Operators or Owners. A storage case for this

manual is located inside the header left endshield.

Call your MacDon Dealer if you need assistance,

information, or additional copies of this manual.

NOTE:

Keep your

The most

from our

our Deal

(login r

®

is specially designed as a “straight cut” header and is equipped to work well in all straight

MacDon publications up-to-date.

current version can be downloaded

website (www.macdon.com)orfrom

er-only site (https://portal.macdon.com)

equired).

Figure 1: Manual Storage Location

169894

i

i

Revision A

Page 5

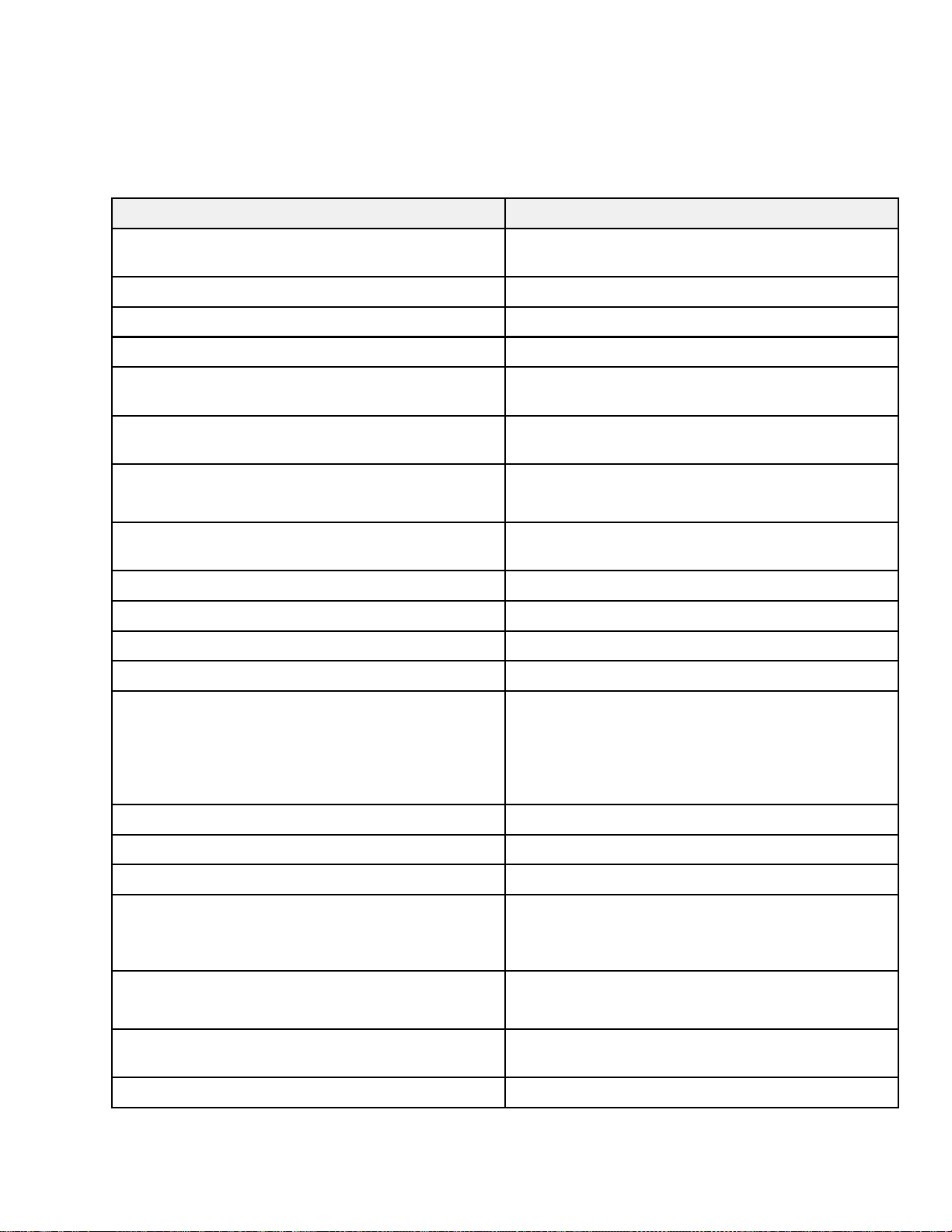

List of Revisions

The following

Summary of Change Refer To

Note regarding access to updated manuals added to

Introduction

25 ft. FD75 deleted

Specificat

CA25 oil change interval revised Changing Oil in Header Drive Gearbox, page 273

Optimizing the header for straight combining canola

section added

Wing Float procedure revised

Operating in flex mode and in rigid mode sections

added

John Deere combine coupler attachment procedure

revised

nal attachments section updated

Optio

lists the changes from the previous version (169595 Revision D) of this document.

Introduction, page ii

All locations

ions table revised

3 Specifica

4.6.3 OptimizingHeader for Straight CombiningCanola,

page 48

6.14 Che

page 390

Operating In Flex Mode, page 143

Operating In Rigid Mode, page 144

5.3.1 Attaching Header to John Deere Combine, page

198

8Opti

tions, page 27

cking and Adjusting Header Wing Balance,

ons and Attachments, page 415

Cutting on the ground section revised Cutting On the Ground, page 55

Header Float section revised 4.7.3 Header Float, page 137

AHHC section reorganized 4.7.2 Auto Header Height Control, page 56

7.5 Reel Speed, page 146

4.

7.6 Ground Speed, page 147

el Speed, Ground Speed, Draper Speed and Knife

Re

eed sections revised

Sp

References to HC10 Hay Conditioner deleted

CR Feeder Deflector section revised 5.5.3 CR Feeder D eflectors, page 220

Multicoupler topic deleted Various locations

Installing and removing flighting extensions, feed

deflectors, and stripper bars moved to Maintenance

and Servicing.

Auger to Plan Clearance, and Auger Drive Chain

Tension revised

Major changes to Knife and Knife Drive sections

4.

7.7 Draper Speed, page 148

4.

.7.8 Knife Speed, page 150

4

All locations

6.7.6 Flighting Extensions, p age 298

6.10 Adapter Stripper Bars and Feed Deflectors, page

332

6.7 Auger, page 286

6.7.2 Adjusting Auger Drive Chain Tension, page 287

Various locations including 6.8 Knife and Knife Drive,

page 300

Knife hold-down clearances revised Knife Hold-Downs, page 309

169894

ii

i

Revision A

Page 6

Installing knife drive box revised Installing Knife Drive Box, page 317

Header Draper Tracking section revised 6.11.4 Adjusting Header Draper Tracking, page 337

Wing Balance section revised

General text and formatting revision s to improve

readability

Revision Page added

6.14 Checkin

page 390

Various locations throughout

List of Revisions, page iii

g and Adjusting Header Wing Balance,

Figure titles added and revised Various locations throughout

169894

v

i

Revision A

Page 7

Model and Serial Number

Record the mod

wheel option (

NOTE:

Draper Heade

Header Model:

Serial Numb

Year:

The serial

drive moto

Combine Adapter

Adapter

if installed) on the lines below.

Right Hand (RH) and Left Hand (LH) designations are determined from the operator’s position, facing

forward.

r

er:

number plate (A) is located beside the knife

r on the left hand endsheet.

Model:

el nu mber, serial number, and model year of the header, combine adap ter, and transport/stabilizer

Figure 2: Header

Serial Number:

Year:

The serial number plate (A) is located on the underside

of the reservoir at the right end.

Speed Transport/Stabilizer Wheel Option

Slow

Serial Number:

r:

Yea

The serial number plate (A) is located on the right hand

axle assembly.

Figure 3: Adapter

169894

igure 4: Transport/Stabilizer Option

F

v

Revision A

Page 8

Page 9

TABLE OF CONTENT

S

Declaration of Conformity.................................................................................................................. i

Introduction......................................................................................................................................ii

Listof Revisions..............................................................................................................................iii

Model and Serial Number................................................................................................................. v

1 Safety.................................................................................................................................................... 1

1.1 Safety Alert Symbols........................................................................................................................1

1.2 Signal Words................................................................................................................................... 2

1.3 General Safety ................................................................................................................................3

1.4 Maintenance Safety......................................................................................................................... 5

1.5 HydraulicSafety.............................................................................................................................. 6

1.6 Tire Safety....................................................................................................................................... 7

1.7 Safety Signs.................................................................................................................................... 8

1.7.1 Installing Safety Decals ............................................................................................................ 8

1.8 Safety DecalLocations .................................................................................................................... 9

1.9 Interpreting Safety Signs................................................................................................................ 13

2 Reference............................................................................................................................................ 21

2.1 Definitions..................................................................................................................................... 21

2.2 Component Identification................................................................................................................ 23

2.2.1 FD75 FlexDraper

®

.................................................................................................................. 23

2.2.2 CA25Combine Adapter.......................................................................................................... 24

3 Specifications ..................................................................................................................................... 27

4 Operation............................................................................................................................................ 31

4.1 Owner/Operator Responsibilities..................................................................................................... 31

4.2 Operational Safety......................................................................................................................... 32

4.2.1 Header Safety Props.............................................................................................................. 32

4.2.2 ReelSafetyProps.................................................................................................................. 33

Engaging Reel SafetyProps............................................................................................ 33

Disengaging Reel Safety Props ....................................................................................... 34

4.2.3 Endshields............................................................................................................................. 35

Opening Endshields........................................................................................................ 35

Closing Endshields ......................................................................................................... 36

Removing Endshields ..................................................................................................... 37

Installing Endsh ields ....................................................................................................... 38

AdjustingEndshields....................................................................................................... 39

4.2.4 Linkage Covers...................................................................................................................... 40

Removing Linkage Covers............................................................................................... 40

Installing Linkage Covers ................................................................................................ 41

4.2.5 Daily Start-Up Check.............................................................................................................. 42

4.3 Break-in Period.............................................................................................................................. 43

4.4 Shutdown Procedure ..................................................................................................................... 44

4.5 Cab Controls................................................................................................................................. 45

4.6 Header Setup ................................................................................................................................ 46

4.6.1 Header Attachments ............................................................................................................... 46

4.6.2 Header Settings..................................................................................................................... 47

4.6.3 Optimizing Headerfor Straight CombiningCanola.................................................................... 48

AdjustingFeed AugerSprings ......................................................................................... 48

4.6.4 ReelSettings ......................................................................................................................... 49

4.7 Header Operating Variables ........................................................................................................... 51

4.7.1 Cutting Height........................................................................................................................ 51

Cutting OffThe Ground................................................................................................... 51

Cutting On the Ground.................................................................................................... 55

4.7.2 AutoHeaderHeightControl ....................................................................................................56

Height Sensor OutputVoltage Range – CombineRequirements ........................................ 58

169894

ii

v

Revision A

Page 10

TABLE OF CONTENT

S

AGCO6 and 7 Series Combines ..................................................................................... 61

CaseIH 2300/2500 Combines......................................................................................... 68

CaseIH 7010/8010, 7120/8120/9120, and 7230/8230/9230 Combines............................... 70

Gleaner R62/R72 Combines............................................................................................ 77

Gleaner R65/R75 Combines............................................................................................ 80

JohnDeere 50 Series Combines ..................................................................................... 89

JohnDeere 60 Series Combines ..................................................................................... 92

JohnDeere 70 Series Combines ..................................................................................... 98

JohnDeere S Series Combines......................................................................................104

Lexion 500 Series Combines..........................................................................................112

Lexion 700 Series Combines.......................................................................................... 122

New Holland Combines..................................................................................................128

Sensor Operation...........................................................................................................136

4.7.3 Header Float.........................................................................................................................137

Checking andAdjusting Header Float ............................................................................. 138

Locking/Unlocking Header Float..................................................................................... 142

Locking/Unlocking Header Wings....................................................................................143

OperatingIn Flex Mode..................................................................................................143

OperatingIn Rigid Mode.................................................................................................144

4.7.4 Header Angle........................................................................................................................145

Controlling Header Angle ............................................................................................... 146

4.7.5 ReelSpeed...........................................................................................................................146

Optional Reel Drive Sprockets........................................................................................147

4.7.6 Ground Speed......................................................................................................................147

4.7.7 Draper Speed.......................................................................................................................148

AdjustingSide Draper Speed..........................................................................................148

AdjustingFeed Draper Speed.........................................................................................149

4.7.8 Knife Speed ..........................................................................................................................150

Checking Knife Speed....................................................................................................151

4.7.9 ReelHeight...........................................................................................................................151

4.7.10 Reel Fore-AftPosition ...........................................................................................................152

AdjustingReel Fore-Aft Position.....................................................................................152

Repositioning Fore-AftCylinders.....................................................................................153

4.7.11 ReelTinePitch......................................................................................................................156

Choosing a ReelCam Setting......................................................................................... 156

AdjustingReel Cam.......................................................................................................158

4.7.12 Crop Dividers........................................................................................................................159

Removing Crop Dividers from Header withLatch Option ..................................................159

Removing Crop Dividers from Header without Latch Option..............................................160

Installing Crop Dividers on Header with Latch Option .......................................................160

Installing Crop Dividers on Header without Latch Option...................................................162

4.7.13 Crop Divider Rods.................................................................................................................163

Removing Crop Divider Rods .........................................................................................164

Using Rice Dividers........................................................................................................164

4.8 Leveling the Header......................................................................................................................165

4.9 Unplugging Cutterbar ....................................................................................................................167

4.10 Unplugging Adapter......................................................................................................................168

4.11 Upper Cross Auger (UCA).............................................................................................................169

4.11.1 Removing Beater Bars...........................................................................................................169

4.11.2 Installing Beater Bars ............................................................................................................170

4.12 Transporting Header ....................................................................................................................171

4.12.1 Transporting Header on Combine........................................................................................... 171

4.12.2 Towing ..................................................................................................................................171

AttachingHeaderto Towing Vehicle................................................................................172

169894

iii

v

Revision A

Page 11

TABLE OF CONTENT

S

Towing the Header ......................................................................................................... 172

4.12.3 Convertingfrom Transport to FieldPosition............................................................................. 173

Removing Tow-Bar ........................................................................................................173

Storing Tow-Bar.............................................................................................................174

Moving Front(Left)Wheels into Field Position................................................................. 175

Moving Rear (Right) Wheels intoField Position................................................................177

4.12.4 Convertingfrom Field to TransportPosition............................................................................. 179

Moving Front(Left)Wheels into Transport Position .......................................................... 179

Moving Rear (Right) Wheels intoTransport Position.........................................................181

AttachingTow-Bar..........................................................................................................184

4.13 Storage ........................................................................................................................................187

5 Header Attachment/Detachment ........................................................................................................189

5.1 Adapter Setup ..............................................................................................................................189

5.1.1 Using Flighting Extensions.....................................................................................................189

5.1.2 Using Stripper Bars...............................................................................................................189

5.1.3 AdjustingAuger Speed..........................................................................................................190

5.2 CaseIH Combines........................................................................................................................191

5.2.1 AttachingHeaderto Case IH Combine ...................................................................................191

5.2.2 DetachingHeader from Case IH Combine..............................................................................195

5.3 John Deere Combines .................................................................................................................. 198

5.3.1 AttachingHeaderto John Deere Combine ..............................................................................198

5.3.2 DetachingHeader from John Deere Combine.........................................................................201

5.4 Lexion Combines..........................................................................................................................205

5.4.1 AttachingHeaderto LexionCombine......................................................................................205

5.4.2 DetachingHeader from Lexion Combine.................................................................................209

5.5 New HollandCombines .................................................................................................................213

5.5.1 AttachingHeaderto New Holland CR/CX Combine.................................................................213

5.5.2 DetachingHeader from New Holland Combine........................................................................216

5.5.3 CR Feeder Deflectors............................................................................................................ 220

5.6 AGCOCombines..........................................................................................................................221

5.6.1 AttachingHeaderto AGCO Combine......................................................................................221

5.6.2 DetachingHeader from AGCO Combine.................................................................................226

5.7 Attachingand Detaching Header FromAdapterand Combine .........................................................230

5.7.1 DetachingHeader from Adapter and Combine........................................................................230

5.7.2 AttachingHeaderto Adapter and Combine .............................................................................235

6Maint

6.1 Prepa

6.2 Maint

6.

enance and Servicing................................................................................................................241

ration for Servicing...............................................................................................................241

enance Specifications...........................................................................................................242

6.2.

6.2.

6.2.

6.2

6.

3

6.

6.

1

2

3

.4

2.5

intenanceRequirements...........................................................................................................257

Ma

3.1

3.2

ersion Chart.................................................................................................................. 243

Conv

mmended Fluids and Lubricants..................................................................................... 244

Reco

ue Specifications ............................................................................................................244

Torq

olt Torque Specifications....................................................................................... 244

SAE B

ic Bolt Specifications ...............................................................................................247

Metr

ic Bolt Specifications Bolting into Cast Aluminum ......................................................249

Metr

re-Type Hydraulic Fittings..........................................................................................249

Fla

ing Boss (ORB)Hydraulic Fittings (Adjustable)..........................................................251

O-R

ing Boss (ORB)Hydraulic Fittings (Non-Adjustable)...................................................253

O-R

ing Face Seal (ORFS) Hydraulic Fittings ................................................................... 254

O-R

talling a Roller Ch ain.........................................................................................................255

Ins

stalling a Sealed Bearing .................................................................................................... 256

In

intenanceSchedule/Record...............................................................................................258

Ma

eak-In Inspection...............................................................................................................260

Br

169894

x

i

Revision A

Page 12

TABLE OF CONTENT

S

6.3.3 Preseason/Annual Service.....................................................................................................260

6.3.4 End of Season Service..........................................................................................................260

6.3.5 Checking Hydraulic Hoses andLines......................................................................................262

6.3.6 Lubrication and Servicing.......................................................................................................262

Service Intervals ............................................................................................................263

Greasing Procedure.......................................................................................................270

Lubricating AugerDrive Chain........................................................................................271

Lubricating Header Drive Gearbox.................................................................................. 272

6.4 Hydraulics....................................................................................................................................274

6.4.1 Reservoir..............................................................................................................................274

Checking OilLevel......................................................................................................... 274

Adding Oil.....................................................................................................................275

Changing Oil.................................................................................................................275

6.4.2 Changing OilFilter ................................................................................................................276

6.5 Electrical......................................................................................................................................278

6.5.1 ReplacingLight Bulbs............................................................................................................278

6.6 Header Drive................................................................................................................................279

6.6.1 Removing Driveline ...............................................................................................................279

6.6.2 Installing Driveline .................................................................................................................280

6.6.3 Removing Driveline Guard.....................................................................................................281

6.6.4 Installing Driveline Guard.......................................................................................................283

6.6.5 AdjustingTension on Gearbox Drive Chain .............................................................................285

6.7 Auger...........................................................................................................................................286

6.7.1 AdjustingAuger to Pan Clearance .......................................................................................... 286

6.7.2 AdjustingAuger Drive ChainTension......................................................................................287

6.7.3 Removing Auger DriveChain ................................................................................................. 288

6.7.4 Installing Auger Drive Chain...................................................................................................292

6.7.5 Auger Tines ..........................................................................................................................294

Removing Feed Auger Tines .......................................................................................... 294

Installing Feed Auger Tines............................................................................................296

ReplacingAuger Tine Guides .........................................................................................297

6.7.6 FlightingExtensions..............................................................................................................298

Installing Flighting Extensions......................................................................................... 298

Removing Flighting Extensions .......................................................................................299

6.8 Knife and Knife Drive....................................................................................................................300

6.8.1 ReplacingKnife Section.........................................................................................................300

6.8.2 Removing Knife.....................................................................................................................302

6.8.3 Removing Knifehead Bearing.................................................................................................302

6.8.4 Installing Knifehead Bearing...................................................................................................303

6.8.5 Installing K nife ......................................................................................................................303

6.8.6 Spare Knife...........................................................................................................................304

6.8.7 Knife Guards.........................................................................................................................304

AdjustingKnife Guards...................................................................................................305

ReplacingPointed Guards on a Single-Knife Header........................................................305

ReplacingPointed Guards on a Double-Knife Header ......................................................306

ReplacingStub Guards on a Single-Knife Header ............................................................ 307

ReplacingStub Guards on a Double-Knife Header...........................................................308

Knife Hold-Downs .......................................................................................................... 309

6.8.8 Knife Drive Belt..................................................................................................................... 311

Removing Knife DriveBelt (Non-Timed)..........................................................................311

Installing Knife Drive Belt................................................................................................312

Tensioning Knife Drive Belts...........................................................................................313

6.8.9 Knife Drive Box.....................................................................................................................314

Mounting Bolts...............................................................................................................314

169894

x

Revision A

Page 13

TABLE OF CONTENT

S

Removing Knife DriveBox.............................................................................................. 314

Removing Knife DriveBox Pulley .................................................................................... 316

Installing Knife Drive B o x Pulley...................................................................................... 317

Installing Knife Drive B ox................................................................................................317

Changing Oilin Knife Drive Box ...................................................................................... 320

6.8.10 Knifehead Shield ................................................................................................................... 320

Installing Knifehead Shield ............................................................................................. 321

6.9 Adapter FeedDraper....................................................................................................................322

6.9.1 ReplacingAdapter Feed Draper.............................................................................................322

6.9.2 AdjustingFeed Draper Tension ..............................................................................................323

6.9.3 Adapter Drive Roller..............................................................................................................324

Removing Adapter FeedDraperDrive Roller................................................................... 324

Installing Adap ter Feed Draper Drive Roller.....................................................................326

ReplacingAdapterDrive Roller Bearing .......................................................................... 326

6.9.4 Adapter Idler Roller ...............................................................................................................328

Removing Adapter FeedDraperIdler Roller....................................................................328

ReplacingAdapterFeed Draper IdlerRollerBearing........................................................329

Installing Adap te r Feed Draper Idler Roller ......................................................................330

6.10 Adapter Stripper Bars an d Feed Deflectors.....................................................................................332

6.10.1 Installing Stripper Bars...........................................................................................................332

6.10.2 Removing Stripper Bars .........................................................................................................332

6.10.3 Replacing Feed Deflectors ..................................................................................................... 333

6.11 Header Drapers............................................................................................................................334

6.11.1 Removing SideDraper..........................................................................................................334

6.11.2 Installing S id e Draper ............................................................................................................335

6.11.3 Adjusting Side DraperTension ...............................................................................................336

6.11.4 Adjusting Header Draper Tracking..........................................................................................337

6.11.5 Adjusting Deck Height...........................................................................................................339

6.11.6 Draper RollerMaintenance....................................................................................................340

Inspecting DraperRollerBearing ....................................................................................340

SideDraperDeck Idler Roller.........................................................................................341

SideDraperDrive Roller.................................................................................................343

6.12 Reeland Reel Drive......................................................................................................................348

6.12.1 Reel Clearance to Cutterbar...................................................................................................348

Measuring Reel Clearance.............................................................................................348

AdjustingReel Clearance ............................................................................................... 350

6.12.2 Reel Frown...........................................................................................................................350

AdjustingReel Frown.....................................................................................................351

6.12.3 Centering theReel ................................................................................................................352

Centeringthe Reel......................................................................................................... 352

6.12.4 Reel Drive Chain...................................................................................................................352

AdjustingChain Tension on Double ReelDrive................................................................352

ReplacingChain on Double ReelDrive............................................................................354

6.12.5 Reel Drive Sprocket ..............................................................................................................359

ReplacingReel Drive Sprocket on Double Reel ...............................................................359

6.12.6 Reel Drive U-Joint.................................................................................................................362

Removing U-Joint..........................................................................................................363

Installing U-Joint............................................................................................................364

6.12.7 Reel Drive Motor...................................................................................................................366

Removing Double ReelDrive Motor ................................................................................ 366

Installing Double Reel Drive Motor ..................................................................................368

6.12.8 Reel Speed Sensor ...............................................................................................................370

ReplacingJohn DeereReel Speed Sensor- Double Reel.................................................370

ReplacingLexion 500/700SeriesReel Speed Sensor - Double Reel.................................371

169894

i

x

Revision A

Page 14

TABLE OF CONTENT

S

ReplacingAGCO Reel Speed Sensor - DoubleReel........................................................372

6.12.9 Reel Tines............................................................................................................................373

Removing Steel Tines....................................................................................................374

Installing Steel Tines......................................................................................................374

Removing Plastic Fingers............................................................................................... 375

Installing Plastic Fingers.................................................................................................375

6.12.10 TineTubeBushings...............................................................................................................376

Removing Bushings from 5-, 6- or 9-Bat Reels................................................................ 376

Installing Bushings on 5-, 6- or 9-Bat Reels .....................................................................379

6.12.11 Reel Endshields....................................................................................................................384

ReplacingEndshield...................................................................................................... 384

ReplacingSupport......................................................................................................... 385

6.13 Transport System(Optional)..........................................................................................................387

6.13.1 Checking Wheel Bolt Torque..................................................................................................387

6.13.2 Checking AxleBolt Torque.....................................................................................................388

6.13.3 Checking Tire Pressure .........................................................................................................388

6.14 Checking andAdjusting Header Wing Balance...............................................................................390

6.14.1 Checking WingBalance.........................................................................................................390

6.14.2 Adjusting Wing Balance.........................................................................................................395

7 Troubleshooting.................................................................................................................................399

7.1 Crop Loss at Cutterbar..................................................................................................................399

7.2 Cutting Action and Knife Components ............................................................................................ 401

7.3 Reel.............................................................................................................................................404

7.4 Header and Drapers .....................................................................................................................406

7.5 Cutting Edible Beans ....................................................................................................................410

8 Options

8.1 O ptions

8.1.1 Cutterb

8.1.2 Divide

8.1.3 Draper

8.1.4 Draper

8.1.5 Europe

8.1.6 CA25 Fe

8.1.7 Knife

8.1.8 Lodge

8.1.9 Reel E

8.1.1

8.1.1

8.1.

8.1.

8.1.

8.1.

8.1.

8.1.

8.1

and Attachments ..................................................................................................................415

and Attachments..............................................................................................................415

ar Plastic Wear Strips................................................................................................. 415

r LatchKit .................................................................................................................... 415

Deflector (Narrow)...................................................................................................... 416

Deflector (Wide).........................................................................................................416

an Adapter SealKit.....................................................................................................416

ed Auger Flighting .................................................................................................... 417

headShield...................................................................................................................417

d Crop Reel Finger Kit .................................................................................................. 417

ndshield Kit.................................................................................................................418

12

13

14

15

16

17

.18

0

1

PR15 T

Rice D

Rock

Shor

Stab

Stab

Stub

Uppe

Ver

ine Tube Reel Conversion Kit......................................................................................418

ivider Rods ................................................................................................................. 418

Retarder.......................................................................................................................419

t Brace Kit For Center Reel Arm ...................................................................................... 419

ilizer Wheels ..................................................................................................................419

ilizer/Slow Speed Transport Whee ls.................................................................................420

Guard Conversion Kit .................................................................................................... 420

r CrossAuger (UCA) .....................................................................................................421

tical Knife Mounts.............................................................................................................421

9 Unloading and Assembly ...................................................................................................................423

Index ..................................................................................................................................................425

169894

ii

x

Revision A

Page 15

1Safety

1.1 Safety Alert Symbols

This safety alert symbol indicates important safety

messages in this manual and on safety signs on

the header.

This symbol means:

• ATTENTION!

• BECOME ALERT!

• YOUR SAFETY IS INVOLVED!

Carefully read and follow the safety message

accompanying this symbol.

Why is safety important to you?

• Ac cidents disable and kill.

• Accidents cost.

• Accidentscanbeavoided.

Figure 1.

1: Safety Sym bol

169894

1

Revision A

Page 16

SAFETY

1.2 Signal Words

Three signal words, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. The

appropriate signal word for each situation has been selected using the following guidelines:

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death, or serious injury.

WARNING

Indicates a pote

mayalsobeused

ntially hazardous situation that, if not avoided, could result in death, or serious injury. It

to alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor, or moderate injury. It

may be used to alert against unsafe practices.

169894

2

Revision A

Page 17

SAFETY

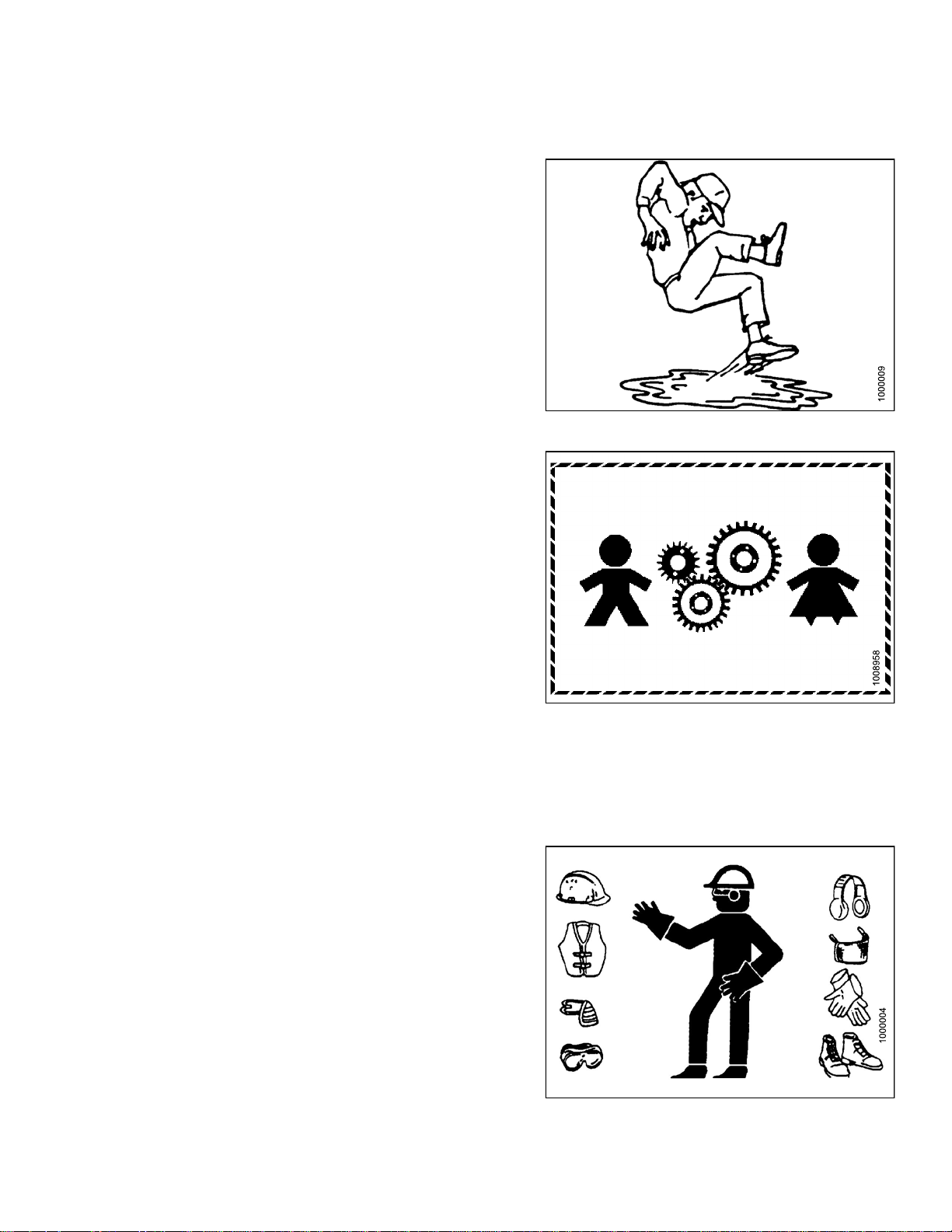

1.3 General Safety

CAUTION

The following are general farm safety precautions

that should be part of your operating procedure for

all types of machinery.

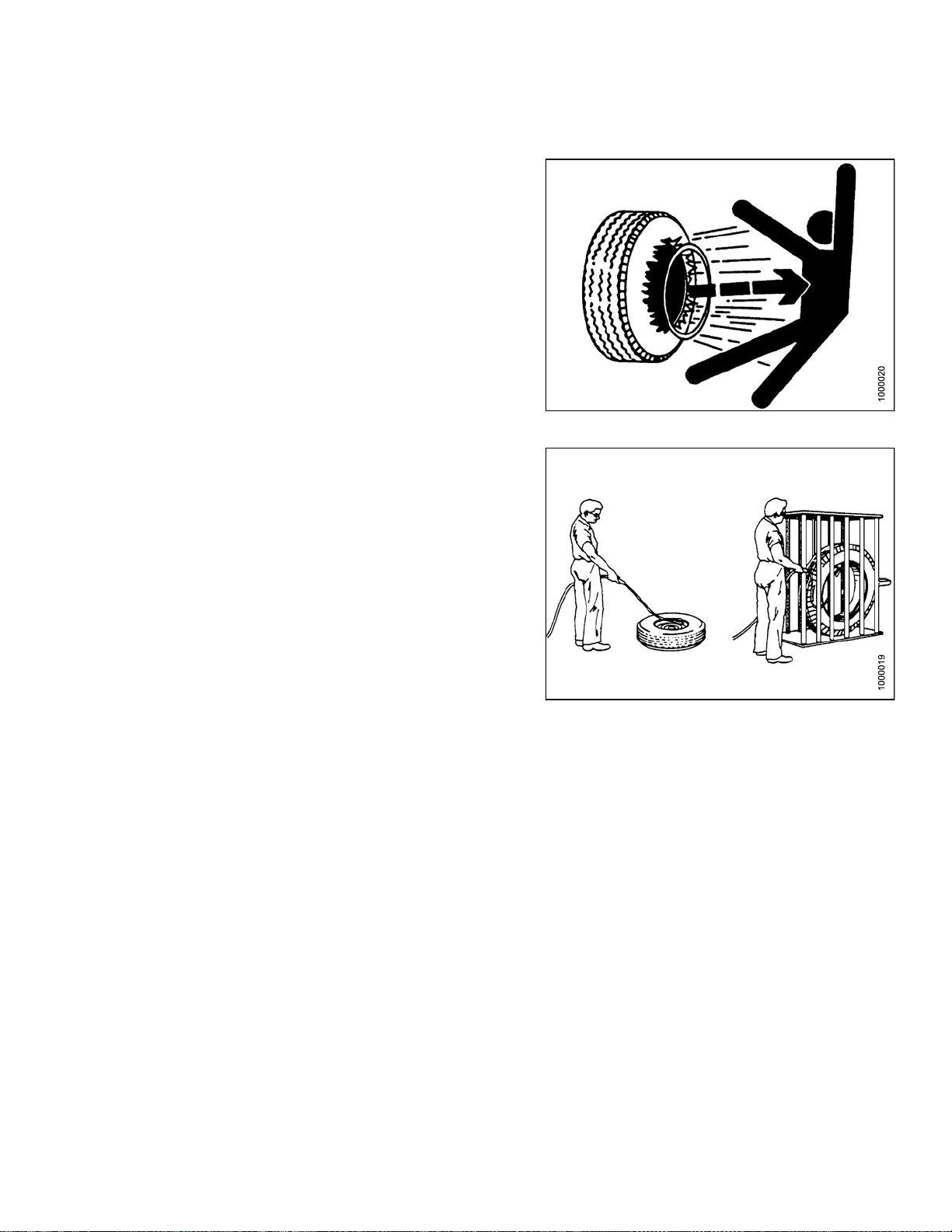

Protect yourself

• When assembling, operating, and servicing machinery,

wear all the protective clothing and personal safety

devices that COULD be necessary for the job at hand.

Don’t take chances.

• You may need:

– A hard hat

– Protective footwear with slip resistant soles

– Protective glasses or goggles

– Heavy gloves

– Wet weather gear

– A respirator or filter mask

– Hearing protection

Be aware that exposure to loud noise can cause

impairment or loss of hearing. Wearing suitable

hearing protection devices such as ear muffs or ear

plugs. These will help protect against objectionable

or loud noises.

•Provideafirs

• Keep a fire ext

fire extingui

its proper us

• Keep young c

all times.

t aid kit for use in case of emergencies.

inguisher on the machine. Be sure the

sher is properly maintained. Be familiar with

e.

hildren away from the machinery at

Figure 1.2

Figure 1.3: Safety Equipment

: Safety Equipment

•Beawaretha

Operator is

time to cons

signs of fa

169894 3 Revision A

t accidents often happen when the

tiredorinahurrytogetfinished. Take the

ider the safest way. Never ignore warning

tigue.

Figure 1.4: Safety Equipment

Page 18

SAFETY

•Wearclosefitting clothing and cover long hair. Never

wear dangling items such as scarves or bracelets.

• Keep all shields in place. Never alter or remove safety

equipment. Make sure driveline guards can rotate

independently of the shaft and can telescope freely.

• Use only serviceand repair parts,made, or approvedby

the equipment manufacturer. Substituted parts may not

meet strength, design, or safety requirements.

• Keep hands, feet, clothing, and hair away from moving

parts. Neve r attempt to clear obstructions or objects,

from a machine while the engine is running.

•DoNOT modify the machine. Non-authorized

modifications may impair machine function and/or

safety. It may also shorten the machine’s life.

Figure 1.5: Safety around Equipment

• Stop the engineand remove the keyfrom ignition before

leaving operator ’s seat for any reason. A child or even

a pet could engage an idling machine.

• Keep the area used for servicing machinery clean and

dry. Wet or oily floors are slippery. Wet spots can be

dangerous when working with electrical equipment.

Be sure all electrical outlets and tools are properly

grounded.

• Keep work area well lit.

• Keep machinery clean. Straw and chaff, on a hot

engine, are a fire hazard. Do NOT allow oil or grease to

accumulate on service platforms, ladders, or controls.

Clean machines before storage.

• Never use gasoline, naphtha, or anyvolatile material for

cleaningpurposes. These materialsmay be toxic and/or

flammable.

• When storing machinery, cover sharp or extending

components to prevent injury from accidental contact.

Figure 1.6: Safety around Equipment

Figure 1.7: Safety around Equipment

169894

4

Revision A

Page 19

SAFETY

1.4 Maintenance Safety

To ensure your safety while maintaining the machine:

• Review the operator’s manual and all safety items

before operation and/or maintenance of the machine.

• Place all controls in Neutral, stop the engine, set the

park brake, remove the ignition key, and wait for all

moving parts to stop before servicing, adjusting, and/or

repairing.

• Follow good shop practices:

– Keep service area clean and dry.

– Be sure electrical outlets and tools are

properly grounded.

– Use adequate light for the job at hand.

• Relieve pressure fromhydraulic circuitsbefore servicing

and/or disconnecting the machine.

• Befo re applying pressure to a hydraulic system , make

sureall components are tight and that steellines, hoses,

and couplings are in good condition.

Figure 1.8: Safety around Equipment

• Keep hands, feet, clothing, and hair away from all

moving and/or rotating parts.

• Clear the area of bystand ers especially children w hen

carrying out any maintenance and repairs or when

making any adjustments.

• Install transport lock or place safety stands under the

frame before working under the header.

• If more than one person is servicing the machine at the

same time, be aware that rotating a driveline or other

mechanically driven component by hand (for example,

accessing a lube fitting) will cause drive components in

other areas (belts, pulleys, and knife) to move. Stay

clear of driven components at all times.

• Wear protective gea

• Wear heavy gloves w

r when working on the machine.

hen working on knife components.

Figure 1.9: Eq

uipment NOT Safe for Children

Figure 1.10: Saf

169894 5 Revision A

ety Equipment

Page 20

SAFETY

1.5 Hydraulic Safety

• Always place all hydraulic controls in Neutral

before dismounting.

• Make sure that all components in the hydraulic system

are kept in good condition and clean.

• Replace any worn, cut, abraded, flattened, or crimped

hoses and steel lines.

•DoNOT attempt any makeshift repairs to the hydraulic

lines, fittings,or hosesby usingtapes, clamps,cements,

or welding. The hydraulic system operates under

extremely high pressure. Such makeshift repairs will fail

suddenly and create a hazardous and unsafe condition.

Figure 1.11: Checking Hydraulic Leaks

•Wearprope

for a highcardboar

and ident

•Ifinjure

hydrauli

Serious

hydraul

• Before applying pressure to a hydraulic system, make

sure all components aretight andthat steel lines,hoses,

and couplings are in good condition.

r hand and eye protection when searching

pressure hydraulic leak. U se a piece of

d a s a backstop instead of hands to isolate

ify a leak.

d by a concentrated high-pressure stream of

c fluid, seek medical attention immediately.

infection or toxic reaction can develop from

ic fluid piercing the skin.

Figure

1.12: Hydraulic Pressure Hazard

ure 1.13: Safety Glasses

Fig

169894 6 Revision A

Page 21

SAFETY

1.6 Tire Safety

• Failure to followproper procedures when mountinga tire

on a wheel or rim can produce an explosion that may

result in serious injury or death.

•DoNOT attempt to mount a tire unless you have the

proper training and equipment.

• Haveaqualified tire dealer or repair service perform

required tire maintenance.

Figure 1.14: Over-Inflated Tire

Figure 1.15: Safely Filling a Tire with Air

169894

7

Revision A

Page 22

SAFETY

1.7 Safety Signs

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or

become illegible.

• If original parts on which a safety sign was installed are

replaced, be sure the repair part also bears the current

safety sign.

• Safety signs are available from your Dealer

Parts Department.

1.7.1 Installing Safety Decals

Figure 1.16: Operator’s Manual Decal

To instal

1. Clean and

2. Decide on

3. Remove t

4. Place th

5. Prick sm

l a safety decal, follow these steps:

e sign in position and slowly peel back the remaining paper, smoothing the sign as it is applied.

dry the installation area.

the exact location before you remove the decal backing paper.

he smaller portion of the split backing paper.

all air pockets with a pin and smooth out.

169894 8 Revision A

Page 23

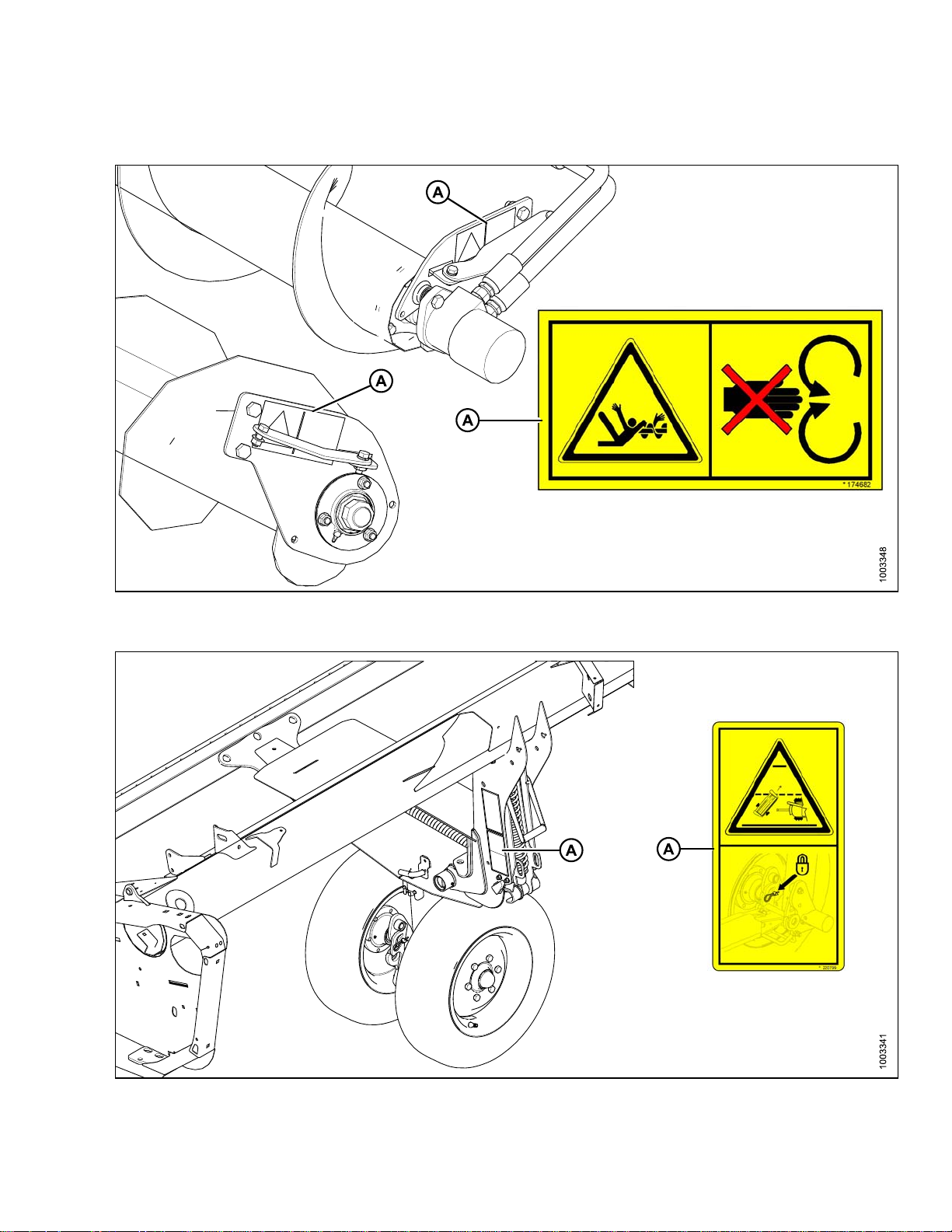

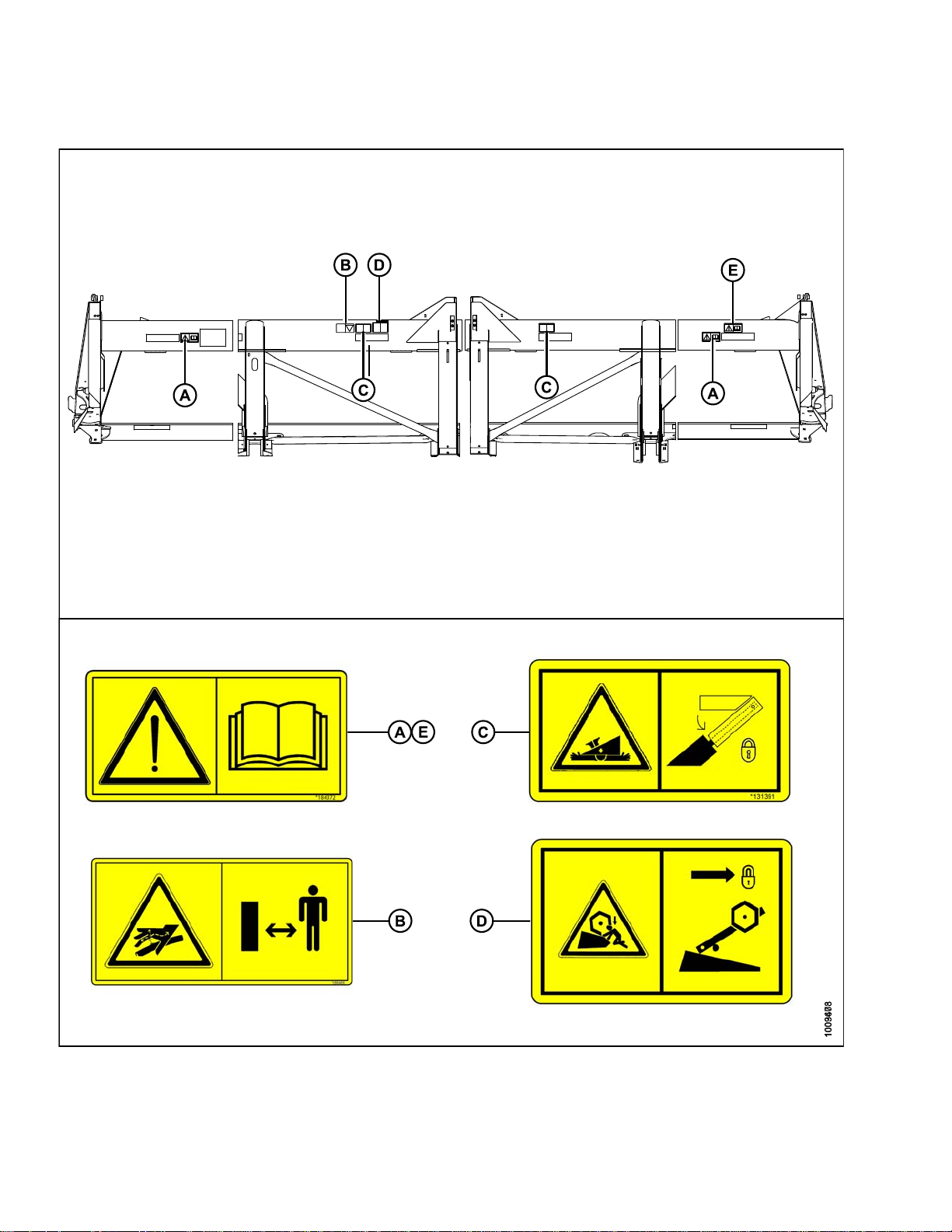

1.8 Safety Decal Locations

SAFETY

Figure 1

A - MD #174682

.17: Upper Cross Auger

Figure 1.18: Slow Speed Transport

D #220799

A-M

169894 9 Revision A

Page 24

SAFETY

Figure 1.19: Slow Speed Transport Tow-Bar

A - MD #220797 B - MD #220798

Figure 1.20: Vertical Knife

A - MD #174684

169894 10 Revision A

Page 25

SAFETY

Figure 1.21: Endsheets, Reel Arms, Backsheet

A - MD #131393 B - MD #174632 C - MD #184371 D - MD #184371 (DK Only)

E - MD #131392 (2 PLC’s) F - MD #131391 (2 PLC’s) G - MD #174436 H - MD #184371 (DK 2 PLC’s)

169894

1

1

Revision A

Page 26

SAFETY

Figure 1.22: Back Tube

A - MD #184372 B - MD #166466 C - MD #131391

D - MD #131392 E - MD #184372 (Split Frame)

169894

2

1

Revision A

Page 27

SAFETY

1.9 Interpreting Safety Signs

Inthe safetysignexplanations below, (a)refers to thetop or

left position panel, (b) refers to the bottom or right position

of the safety decal depending on decal orientation.

NOTE:

If there are more than two panels in a decal, the

lettering will continue downward or to the right,

depending on decal orientation.

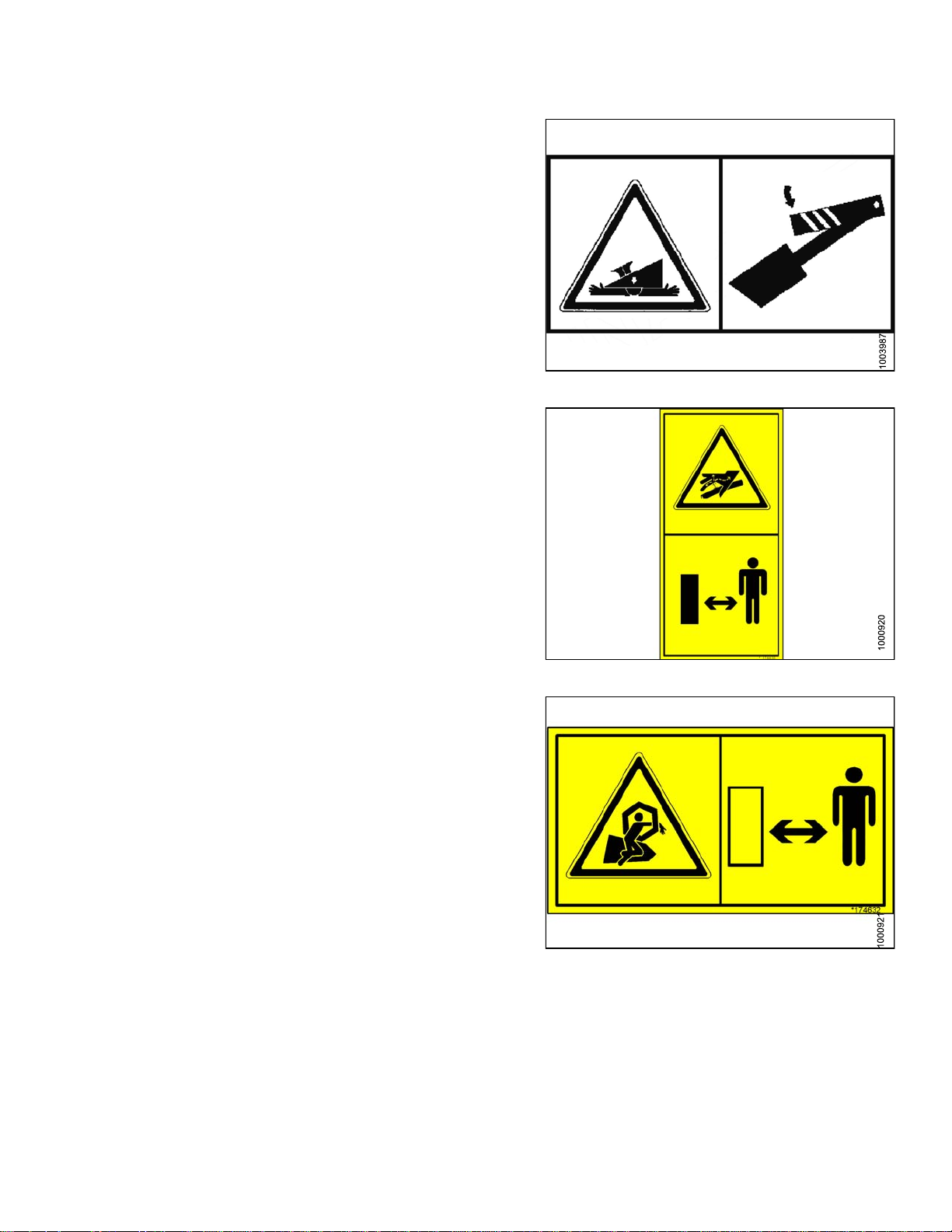

1. MD #131391

a. Crushing hazard.

b. DANGER

• Rest header on ground or engage safety props

before going under unit.

2. MD #131392

a. Crushing hazard.

b. WARNING

• To avoid injury from fall of raised reel; fully

raise reel, stop the engine, remove the key,and

engage safety prop on each reel support arm

before working on or under reel.

• Refer to header operator’s manual.

Figure 1.23: MD #131391

Figure 1.24: MD #131392

169894 13 Revision A

Page 28

3. MD #131393

a. Reel hazard.

b. WARNING

• To avoid in jury from fall of raised re el; fully

raise reel, stop the engine, remove the key, and

engage safety prop on each reel support arm

before working on or under reel.

• Refer to header operator’s manual.

4. MD #166466

a. High pressure oil hazard.

b. WARNING

Do not go near leaks.

SAFETY

Figure 1.25: MD #131393

• High pressure oil easily punctures skin causing

serious injury, gangrene, or death.

• If injured, seek emergency medical help.

Immediate surgery is required to remove oil.

• Do not use finger or skin to check for leaks.

• Lower load or relieve hydraulic pressure before

loosening fittings.

5. MD #174432

a. Reel hazard.

b. WARNING

• To avoid in jury from fall of raised re el; fully

raise reel, stop the engine, remove the key, and

engage m echanical lock on each reel support

arm before working on or under reel.

• See operator’s manual.

Figure 1.26: MD #166466

Figure 1.27: MD #174432

169894

4

1

Revision A

Page 29

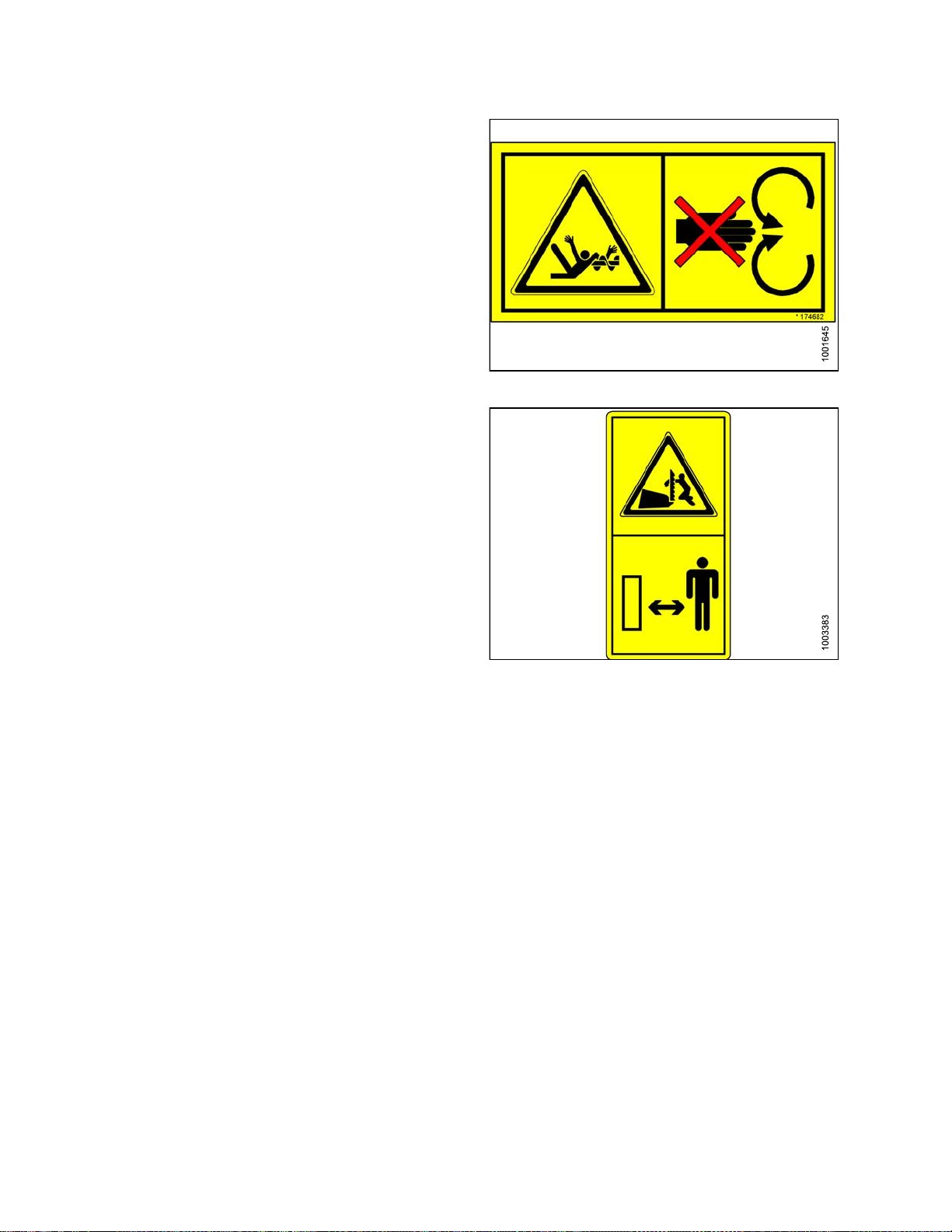

6. MD #174434

a. Header hazard.

b. DANGER

• Rest header on ground or engage mechanical

locks before going under unit.

7. MD #174436

a. High pressure oil hazard.

b. WARNING

Do not go near leaks.

SAFETY

Figure 1.28: MD #174434

• High pressure oil easily punctures s kin causing

serious injury, gangrene, or death.

• If injured, seek emergency medical help.

Immediate surgery is required to remove oil.

• Do not use finger or skin to check for leaks.

• Lower load or relieve hydraulic pressure before

loosening fittings.

8. MD #174632

a. Reel entanglement hazard.

b. CAUTION

• To avoid injury from entanglement with rotating

reel, stand clear of header while machine

is running.

Figure 1.29: MD #174436

Figure 1.30: MD #174632

169894 15 Revision A

Page 30

9. MD #174682

a. Auger entanglement hazard.

b. CAUTION

• To avoid injury from entanglement with rotating

auger, stand clear of header while machine

is running.

10. MD #174684

a. Sharp component hazard.

b. CAUTION

• Wear heavy canvas or leather gloves when

working with knife.

SAFETY

Figure 1.31: MD #174682

• Be sure no one is near the vertical knife when

removing or rotating knife.

Figure 1.32: MD #174684

169894 16 Revision A

Page 31

11. MD #184372

a. General hazard pertaining to machine operation

and servicing.

b. CAUTION

To avoid injury or death from improper or unsafe

machine operation:

• Read theoperator’s manualand follow allsafety

instructions. If you do not have amanual, obtain

one from your Dealer.

• Do not allow untrained persons to operate

the machine.

SAFETY

• Review safety instructions with all

Operators annually.

• Ensure that all safety signs are installed

and legible.

• Make certain everyone is clear of machine

before starting engine and during operation.

• Keep riders off the machine.

• Keep all shields in place and stay clear of

moving parts.

• Disengage header drive, put transmission in

Neutral, and wait for all movement to stop

before leaving operator’s position.

• Shut off the engine and remove the key from

ignition before servicing, adjusting, lubricating,

cleaning, or unplugging machine.

• Engage safety props to prevent lowering

of raised unit before servicing in the

raised position.

• Use slow moving vehicle emblem and flashing

warning lights when operating on roadways

unless prohibited by law.

Figure 1.33: MD #184372

12. MD #184422

a. Keep shields in place hazard.

b. WARNING

• Toavoid injury, stop the engine and remove the

key before opening power drive system shield.

• Keep all shields in place.

169894

Figure 1.

7

1

34: MD #184422

Revision A

Page 32

13. MD #190546

a. Slippery surface.

b. WARNING

Do not place foot.

• Do not use this area as a step or platform.

• Failure to comply could result in serious injury

or death.

14. MD #193147

a. Transport/roading hazard.

b. WARNING

• Ensure tow-bar lock mechanism is locked.

SAFETY

Figure 1.35: MD #190546

Figure 1.36: MD #193147

169894 18 Revision A

Page 33

15. MD #194521

a. Auger entanglement hazard.

b. CAUTION

• To avoid injury from entanglement with rotating

auger, stand clear of header while machine

is running.

c. General hazard pertaining to machine operation

and servicing

d. CAUTION

• Read the operator’s manual and follow safety

instructions. If you do not have amanual, obtain

one from your Dealer.

• Do not allow untrained persons to operate

the machine.

• Review safety instructions with all

Operators annually.

• Ensure that all safety signs are installed

and legible.

SAFETY

• Make certain everyone is clear of machine

before starting engine and during operation.

• Keep riders off the machine.

• Keep all shields in place and stay clear of

moving parts.

• Disengage header drive, put transmission in

Neutral, and wait for all movement to stop

before leaving operator’s position.

• Stop the engine and remove the key from

ignition before servicing, adjusting, lubricating,

cleaning, or unplugging machine.

• Engage locks to prevent lowering of header or

reel before servicing in the raised position.

• Use slow moving vehicle emblem and flashing

warning lights when operating on roadways

unless prohibited by law.

Figure 1.

37: MD #194521

169894 19 Revision A

Page 34

16. MD #220797

a. Tipping hazard in transport mode.

b. WARNING

• Read the operator’s manual for more

information on potential tipping or roll-over of

header while transporting.

17. MD #220798

a. Loss of control hazard in transport.

b. CAUTION

• Do not tow the header with a dented or

otherwise damaged tow pole (the circle with the

red X shows a dent in the pole).

SAFETY

Figure 1.38: MD #220797

• Consult the operator’s manual for

more information.

18. MD #220799

a. Transport/roading hazard.

b. WARNING

• Ensure tow-bar lock mechanism is locked.

Figure 1.39: MD #220798

Figure 1.40: MD #220799

169894 20 Revision A

Page 35

2 Reference

2.1 Definitions

The following terms and acronyms may be used in this manual.

Term

AHHC Automatic H

API American Petroleum Institute.

ASTM American S

Bolt

Center-link

CGVW Combined vehicle gross weight.

D-Series header

DK

DKD

DDD Doubl

DR Double reel.

eries header MacDon FlexDraper

FD-S

Finger tight

FFFT

Definition

eader Height Control

ociety of Testing and Materials.

A headed and externally threaded fastener that is designed to be paired with a nut.

Ahydraul

and the ma

MacDon rigid draper header.

Double

Double-knife drive.

Finger tight is a reference position w here sealing surfaces or components are

making contact with each other and the fitting has been tightened to a point where

the fitting is no longer loose.

Flats from finger tight.

ic cylinder or manually adjustable turnbuckle type link between the header

chine to which it is attached. It is used to change header angle.

knife.

e draper drive.

®

header.

L

GS

GVW Gross vehicle weight.

Hard joint

Header A machine that cuts crop and feeds it into an attached combine.

Hex key

HDS Hydraulic deck shift.

hp Horsepower.

ISC Intermediate Speed Control.

JIC

Knife

n/a

Nut An internally threaded fastener that is designed to be paired with a bolt.

ound speed lever.

Gr

A joint made with the use of a fastener where the joining materials are

highly incompressible.

A hex key or Allen key (also known by various other synonyms) is a tool of

hexagonal cross-section used to drive bolts and screws that have a hexagonal

socket in the head (internal-wrenching hexagon drive).

Joint Industrial Council: a standards body that developed the standard sizing and

shape for original 37° flared fitting.

A cutting device which uses a reciprocating cutter. Also called a s ickle.

Not applicable.

169894

1

2

Revision A

Page 36

REFERENCE

Term

NPT

ORB

ORFS

PTO Power Take

RoHS (Reduction of

Hazardous Substances)

Definition

National Pipe

on NPT fittings

Thread: a style of fitting used for low pressure port openings. Threads

are uniquely tapered for an interference fit.

O-ring boss: a style o f fitting commonly used in port opening on manifolds, pumps

and motors.

O-ring face seal: a style of fitting commonly used for connecting hoses and tubes.

This style of fitting is also commonly called ORS, which stands for O-ring seal.

-Off.

A directive by the European Union to restrict the use of certain hazardous

substances (such as hexavalent chromium used in some yellow zinc platings).

SAE Society Of Automotive Engineers.

Screw

A headed

forms it

and externally threaded fastener that threads into preformed threads or

s own thread in one of the mating parts.

SDD Single draper drive.

Self-Propelled (SP)

Windrower

SK Singl

Self-propelled machine consisting of a power unit with a header.

eknife.

SKD Single-knife drive.

Soft joint

A joint made with the use of a fastener where the joining materials are compressible

or experience relaxation over a period of time.

spm

okes per minut e.

Str

SR Single reel.

actor

Tr

Truck

Timed knife drive

ricultural type tractor.

Ag

A four-wheel highway/road vehicle weighing no less than 7500 lbs (3400 kg).

Synchronized motion applied at the cutterbar to two separately driven knives from a

single hydraulic motor.

Tension Axial load placed on a boltor screw, usually measured in pounds (lb) or Newtons (N).

TFFT

Torque

Turns from finger tight.

The product of a force X lever arm length, usually measured in foot-pounds (ft·lbf)

or Newton-meters (N·m).

A tightening procedure where the fitting is assembled to a precondition (finger

Torque angle

tight) and then the nut is turned further a number of degrees or a number of flats to

achieve its final position.

Torque-tension

UCA

Untimed knife drive

Washer

The relationship between the assembly torque applied to a piece of hardware and

the axial load it induces in the bolt or screw.

Upper cross auger.

Unsynchronized motion applied at the cutterbar to two separately driven knives

from a single hydraulic motor or two hydraulic motors.

A thin cylinder with a hole or slot located in the center and is to be used as a spacer,

load distribution element, or a locking mechanism.

Windrower

169894

Power unit of a self-propelled header.

2

2

Revision A

Page 37

REFERENCE

2.2 Component Identification

2.2.1 FD75 FlexD raper

®

Figure 2.1: FD75 FlexDraper®Components

A - Wing Float Linkage

D - Transition Pan

G - Endshield H - Knife Drive J - Crop Divider

K - Reel Endshield L - Pick-up Fingers M - Pick-up Reel

N - Reel Cam

B - Center-Link C - Center Reel Arm Prop Handle

E - Reel

Fore-Aft Cylinder

F-Reel

Lift Cylinder

169894 23 Revision A

Page 38

REFERENCE

2.2.2 CA25 Com

bine Adapter

Figure 2.2: Header Side of CA25 Combine Adapter

A-FeedA

D - Hydraulic Reservoir

G - Feed Draper

uger

B - Header Float Springs C - Center-Link

E - Gearbox F - Header Support Arm

169894

4

2

Revision A

Page 39

REFERENCE

Figure 2.3: Combine Side of CA25 Combine Adapter

A - Adapter Gearbox B - Hydraulic Compartment Cover C - Reservoir Oil Level Sight Glass

D - Center-Link E - Header Height Control Indicator

G - Torque Wrench

H-Header

Float Lock

F - Transition Frame

J - Side Draper Speed Control

169894 25 Revision A

Page 40

Page 41

3 Specifications

| FD75 | CA25 | Attachments

O

S: standard /

CUTTERBAR

Effective Cutting Width (distance between crop divider points)

30 ft header 30 ft. (360 in. [9144 mm]) S

: optional (factory installed) / OD: optional (dealer installed) / -: not available

F

FD75

35 ft head

er

35 ft. (42

0 in. [10668 mm])

40 ft header 40 ft. (480 in. [12192 mm]) S

45 ft header 45 ft. (540 in. [13716 mm]) S

Cutterb

ar Lift Range

Varies W

ith Combine Model

Knife

Single Knife Drive (all sizes): One hydraulic motor with V-belt to one heavy duty (MD) knife

drive box

le Knife Drive (40, 45 ft only, untimed): Two hydraulic motors with banded-belts, to two

Doub

y duty (MD) knife drive boxes.

heav

O

O

Knife Stroke 3 in. (76 mm) S

0–1400 spm

30 ft.

ngle Knife Speed (strokes per minute)

Si

35

ft.

40 ft.

Double Knife Speed (strokes per minute) 40, 45 ft.

nife Sections

K

120

1100–1300 spm

1050–1200 spm

1100–1400 spm

Over-serrated / Solid / Bolted / 9 serrations per inch S

Knife Overlap at Center (Double Knife Headers) 1/8 in. (3 mm) S

Guards and Hold-Downs

S

S

F

F

S

S

S

S

Guard: Pointed / Forged / Double Heat Treated (DHT)

Hold-Down: Sheet Metal / Adjustment Bolt

Guard Angle (Cutterbar on Ground)

Center-Link Retracted

Center-Link Extended

2.0 Degrees

7.4 Degrees

CONVEYOR (Draper) and DECKS

Draper W idth

41-19/32 in. (1057 mm) S

Draper Drive Hydraulic

Draper Speed: CA25 (Combine Adapter) Controlled 0–464 fpm (141 m/min.) S

Delivery Opening Width 73-19/32 in. (1870 mm) S

169894

7

2

S

S

S

S

Revision A

Page 42

PR15 PICK-UP REEL

SPECIFICATIONS

FD75

Quantity of Tine Tubes

Center Tube D

iameter

5-, 6-, or 9-ti

8 in. (203 mm) S

ne tubes

Factory-Set 31-1/2 in. (800 mm) S

Finger Tip Radius

Effective

Reel Diameter (via cam profile)

Finger Length

Adjustment Range

30-3/16 – 31-1/2 in.

(766–800 mm)

65 in. (165

0mm)

11 in. (290 mm) S

Finger Spacing (staggered on alternate bats) 6 in. (150 mm) S

Reel Drive Hydraulic

Reel Speed (adjustable from cab, varies with combine model)

0–67 rpm

FRAME and STRUCTURE

Field Mode

Cut W i

15-1/

dth +

8 in. (384 mm)

(A) Long Dividers

Header

Width

Transport Position - reel

Installed

(refer to figure 3.1:

Header Width, page 28)

106 in. (2684 mm)

fore-aft fully retracted

(shortest center-link)

(B) Long Dividers

Removed

(refer to figure 3.1:

98 in. (2500 mm)

Header Width, page 28)

S

S

S

S

S

-

-

Figure 3.1: Header Width

169894 28 Revision A

Page 43

ATTACHMENTS

SPECIFICATIONS

CA25 Combine A

Feed Draper

dapter

Width

Speed

Width

78-11/16 in. (2000 mm) S

350–400 fpm

(107–122 m/min)

65-5/16 in.

(1660 mm)

Outside Diameter 22 in. (559 mm) S

Feed Auger

Oil Reservoir Capacity

Oil Type

Driveline

Overall Length

1

Case, New Holland

Deere, Lexion,

John

AGCO

Minimum (Compressed) 38-3/16 in. (970 mm)

Mini

Tube Diameter

Speed (va

combine m

ries with

odel)

14 in. (356 mm) S

150 rpm

16 US Gallons

(60 Litres)

15W40

Maximu

m (Extended)

6 in. (1230 mm)

48-7/1

Maximum (Extended) 49-11/16 in. (1262 mm)