Page 1

FOREWORD

This manual contains safety information, set-up instructions, operating instructions, and maintenance procedures,

for the Model MT8 Header Transporter. Your new MT8 Header Transporter allows you to transport MD draper

headers (combine or windrower) with the M Series Windrower, truck, or combine (three-axle only). The

Transporter can be towed at highway speeds.

CAREFULLY READ ALL THE MATERIAL PROVIDED BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE, OR

USE THE MACHINE.

Use this manual as your first source of information about the Transporter. If you follow the instructions given in

this manual, your Transporter will work well for many years. Use this manual in conjunction with your M Series

Self-Propelled Windrower and D Series Draper Header manuals.

Use the Table of Contents to guide you to specific areas. Review the Table of Contents to familiarize yourself

with how the material is organized.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your dealer if you

need assistance, information, or additional copies of this manual.

RECORD THE SERIAL NUMBER OF THE TRANSPORTER IN THE SPACE BELOW.

_______________________________

Serial Number plate is located on the right side of the main beam near the front of the Transporter.

Form 169365 Issue – May 2008

Page 2

Page 3

TABLE OF CONTENTS

SECTION G ................................................GENERAL INFORMATION

SECTION UA ................................................. SETUP INSTRUCTIONS

SECTION OM .................................................OPERATOR’S MANUAL

Form 169365 Issue – May 2008

Page 4

Page 5

SECTION G – GENERAL INFORMATION

SECTION G – GENERAL INFORMATION

Section Contents

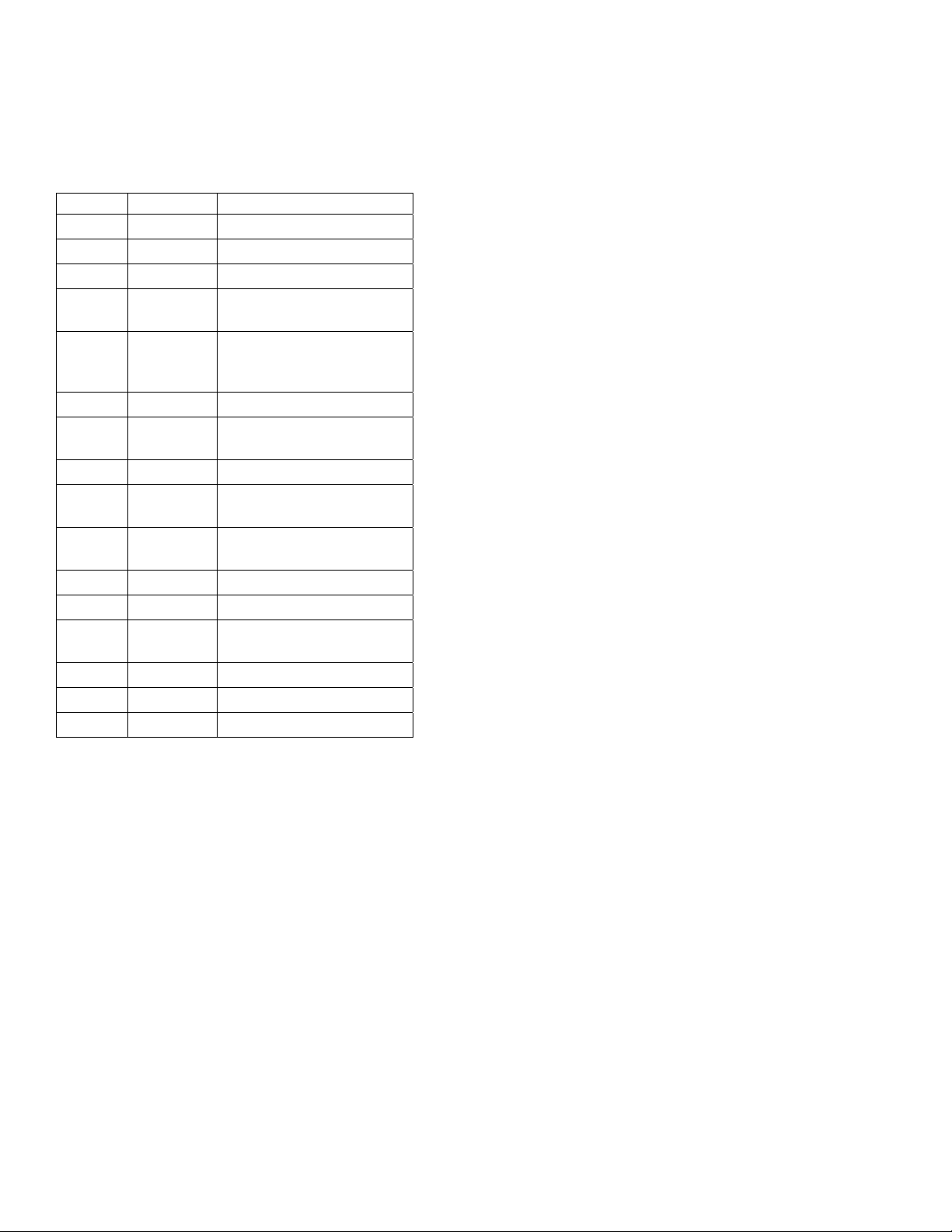

ITEM DESCRIPTION PAGE G-

1

SAFETY .........................................................................................................................................................1

1.1 SAFETY ALERT SYMBOL ......................................................................................................................1

1.2 SIGNAL WORDS .....................................................................................................................................1

1.3 SAFETY INSTRUCTIONS .......................................................................................................................2

2 RECOMMENDED TORQUES.......................................................................................................................5

2.1 GENERAL ................................................................................................................................................5

2.2 SAE BOLTS .............................................................................................................................................5

2.3 METRIC BOLTS.......................................................................................................................................5

3 ENGLISH/METRIC EQUIVALENTS..............................................................................................................6

Form 169365 Issue – May 2008

Page 6

Page 7

SECTION G – GENERAL INFORMATION

1 SAFETY

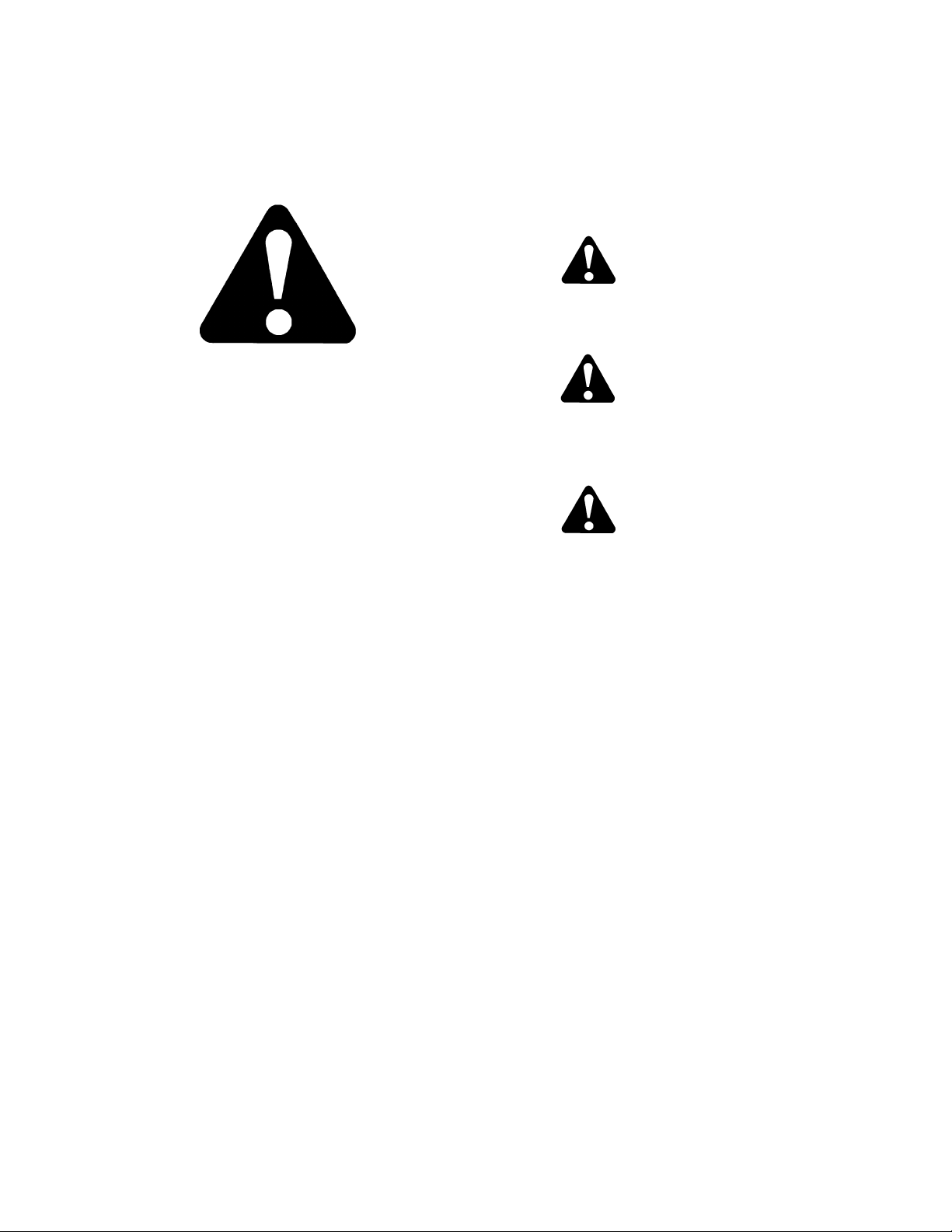

1.1 SAFETY ALERT SYMBOL

This safety alert symbol indicates important

safety messages in this manual and on safety

signs on the machine.

This symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Carefully read and follow the safety message

accompanying this symbol.

1.2 SIGNAL WORDS

Note the use of the signal words DANGER,

WARNING, and CAUTION with safety

messages. The appropriate signal word for each

message has been selected using the following

guidelines:

DANGER

Indicates an imminently hazardous

situation that, if not avoided, will result in

death or serious injury.

WARNING

Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious injury. It is also used to alert

against unsafe practices.

CAUTION

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It is also used as a

reminder of good safety practices.

WHY IS SAFETY IMPORTANT TO YOU?

ACCIDENTS DISABLE AND KILL

ACCIDENTS COST

ACCIDENTS CAN BE AVOIDED

1.3 SAFETY SIGNS

• Keep safety signs clean and legible at all

times.

• Replace safety signs that are missing or

become illegible.

• If original parts on which a safety sign was

installed are replaced, be sure the repair

part also bears the current safety sign.

• Safety signs are available from your Dealer

Parts Department.

1.3.1 Safety Sign Installation

a. Be sure the installation area is clean and dry.

b. Decide on the exact location before you remove

the decal backing paper.

c. Remove the smaller portion of the split backing

paper.

d. Place the sign in position and slowly peel back

the remaining paper, smoothing the sign as it is

applied.

e. Small air pockets can be smoothed out or

pricked with a pin.

Form 169365 G-1 Issue– May 2008

Page 8

SECTION G – GENERAL INFORMATION

1.3.2 Safety Sign Locations

#188405

Form 169365 G-2 Issue– May 2008

Page 9

SECTION G – GENERAL INFORMATION

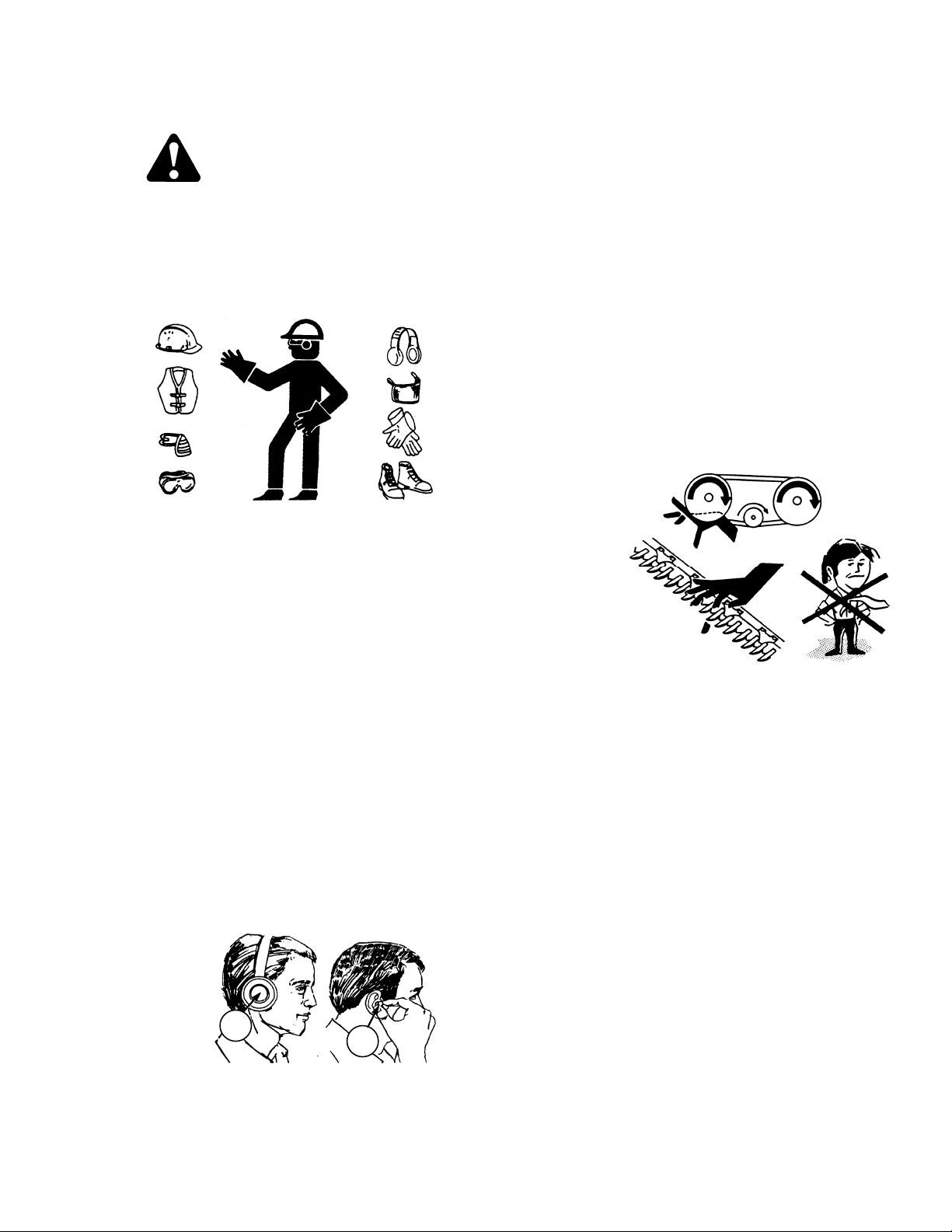

1.4 SAFETY INSTRUCTIONS

CAUTION

The following are general farm safety

precautions that should be part of your

operating procedure for all types of

machinery.

Protect yourself.

• Provide a first-aid kit for use in case of

emergencies.

• Keep young children away from machinery at

all times.

• Be aware that accidents often happen when

the operator is tired or in a hurry to get

finished. Take the time to consider the safest

way. Never ignore warning signs of fatigue.

• Wear close-fitting clothing and cover long

hair. Never wear dangling items such as

scarves or bracelets.

• Keep hands, feet, clothing and hair away

from moving parts. Never attempt to clear

obstructions or objects from a machine while

the engine is running.

• Keep all shields in place. Never alter or

remove safety equipment. Make sure

driveline guards can rotate independently of

the shaft and can telescope freely.

• When assembling, operating and servicing

machinery, wear all the protective clothing

and personal safety devices that COULD be

necessary for the job at hand. Don't take

chances.

• You may need:

o a hard hat.

o protective shoes with slip resistant soles.

o protective glasses or goggles.

o heavy gloves.

o wet weather gear.

o respirator or filter mask.

o hearing protection. Be aware that

prolonged exposure to loud noise can

cause impairment or loss of hearing.

Wearing a suitable hearing protective

device such as ear muffs (A) or ear plugs

(B) protects against objectionable or loud

noises.

• Use only service and repair parts made or

approved by the equipment manufacturer.

Substituted parts may not meet strength,

design, or safety requirements.

• Replace any caution, warning, danger, or

instructional safety decal that is unreadable

or is missing. See paragraph for location of

decals.

• Do not modify the machine. Unauthorized

modifications may impair the function and/or

safety and affect machine life.

• Do not allow persons to operate or assemble

this unit until they have developed a

thorough understanding of safety

precautions and how it works.

(continued next page)

A

Form 169365 G-3 Issue– May 2008

B

Page 10

SECTION G – GENERAL INFORMATION

• Stop engine and remove key from ignition

before leaving operator's seat for any

reason. A child or even a pet could engage

an idling machine.

• Keep the area used for servicing machinery

clean and dry. Wet

or oily floors are

slippery. Wet spots

can be dangerous

when working with

electrical

equipment. Be

sure all electrical

outlets and tools

are properly

grounded.

• Use adequate light

for the job at hand.

• Keep machinery clean. Do not allow oil or

grease to accumulate on service platforms,

ladders or controls. Clean machines before

storage.

• Never use gasoline, naphtha or any volatile

material for cleaning purposes. These

materials may be toxic and/or flammable.

• When storing machinery, cover sharp or

extending components to prevent injury from

accidental contact.

Form 169365 G-4 Issue– May 2008

Page 11

SECTION G – GENERAL INFORMATION

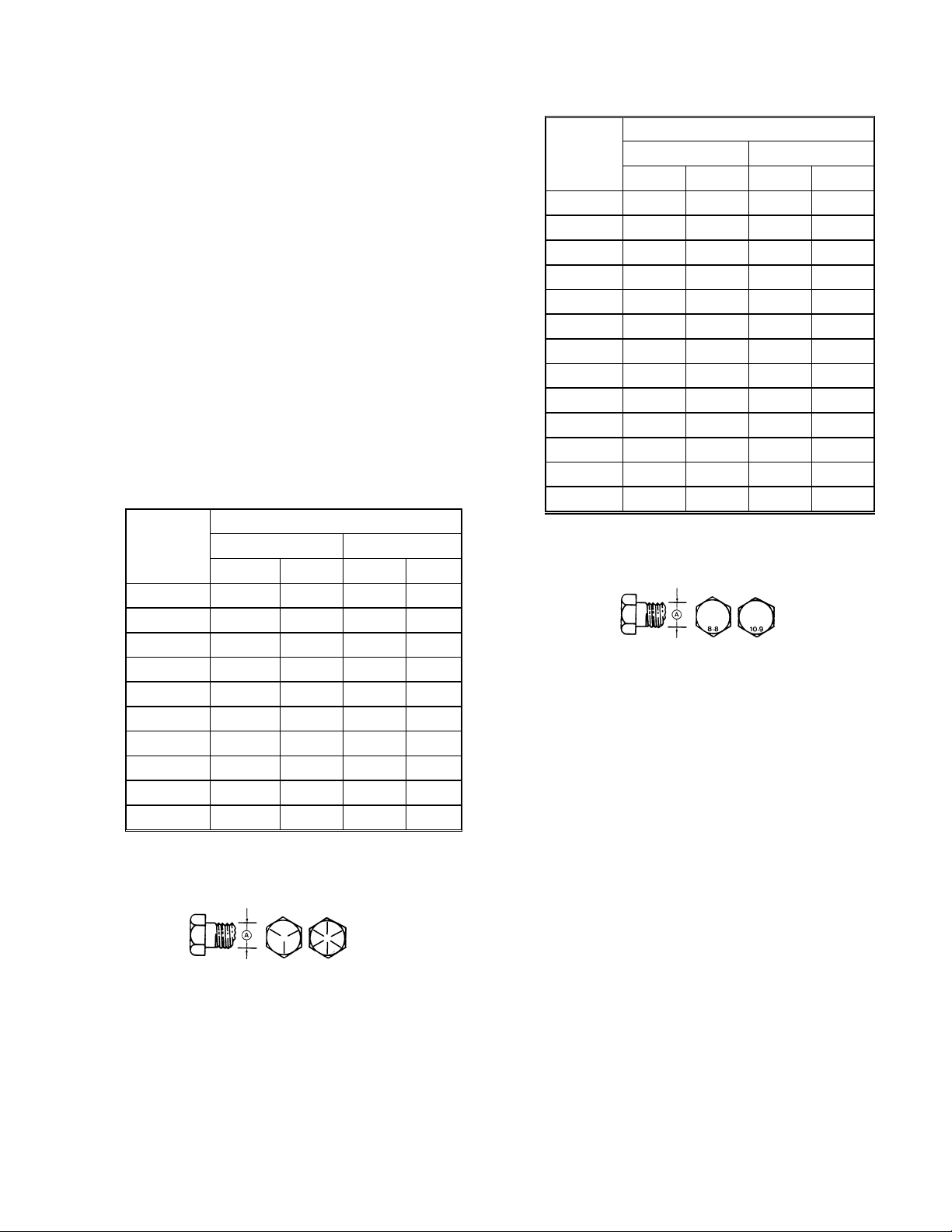

2 RECOMMENDED TORQUES

2.1 GENERAL

The tables shown below give correct torque

values for various bolts and capscrews.

• Tighten all bolts to the torques specified in

chart unless otherwise noted throughout this

manual.

• Check tightness of bolts periodically, using

bolt torque chart as a guide.

• Replace hardware with the same strength

bolt.

• Torque figures are valid for non-greased or

non-oiled threads and heads unless

otherwise specified. Do not grease or oil

bolts or capscrews unless specified in this

manual. When using locking elements,

increase torque values by 5%.

2.2 SAE BOLTS

NC BOLT TORQUE *

BOLT

DIA. "A"

1/4" 9 12 11 15

5/16" 18 24 25

3/8" 32 43 41

7/16" 50 68 70 95

1/2" 75 102 105 142

9/16" 110 149 149 202

5/8" 150 203 200 271

3/4" 265 359 365 495

7/8" 420 569 600 813

1" 640 867 890 1205

* Torque categories for bolts and capscrews are identified by

their head markings.

SAE 5 SAE 8

lbf-ft N·m lbf-ft N·m

34

56

2.3 METRIC BOLTS

NC BOLT TORQUE *

BOLT

DIA. "A"

M3 0.4 0.5 1.3 1.8

M4 2.2 3 3.3 4.5

M5 4 6 7 9

M6 7 10 11 15

M8 18 25 26 35

M10 37 50 52 70

M12 66 90 92 125

M14 103 140 148 200

M16 166 225 229 310

M20 321 435 450 610

M24 553 750 774 1050

M30 1103 1495 1550 2100

M36 1917 2600 2710 3675

* Torque categories for bolts and capscrews are identified by

their head markings.

8.8 10.9

lbf-ft N·m lbf-ft N·m

10.9

8.8

SAE-8

SAE-5

Form 169365 G-5 Issue– May 2008

Page 12

SECTION G – GENERAL INFORMATION

3 ENGLISH/METRIC

EQUIVALENTS

ENGLISH FACTOR SI UNITS (METRIC)

acres x 0.4047 = hectares (ha)

ft/min x 0.3048 = meters/min (m/min)

ft/s x 0.3048 = meters/sec (m/s)

gal

(US)

US

gal/min

(gpm)

hp x 0.7457 = kilowatts (kW)

in.3 x 16.3871

lbf x 4.4482 = Newtons (N)

lbf-ft or

ft-lb

lbf-in.

or in-lbf

mph x 1.6063 = kilometers/hour (km/h)

oz. x 29.5735 = milliliters (ml)

pint

(US)

psi x 6.8948 = kilopascals (kPa)

psi x 0.00689 = megapascals (MPa).

qt. (US) x 0.9464 = liters (L)

x 3.7854 = liters (L)

x 3.7854 = liters/min (L/min)

= cubic centimeters (cm

or cc)

x 1.3558 = Newton meters (N·m)

x 0.1129 = Newton meters (N·m)

x 0.4732 = liters (L)

3

Form 169365 G-6 Issue– May 2008

Page 13

SECTION UA – UNLOADING AND SETUP

Section Contents

ITEM DESCRIPTION PAGE UA-

STEP 1.

STEP 2. CONFIGURE THE TRANSPORTER ..............................................................................................2

STEP 3. SET UP COMBINE HITCH – THREE-AXLE ONLY ........................................................................8

STEP 4. PRE-DELIVERY CHECK ................................................................................................................9

STEP 5. LUBRICATE THE TRANSPORTER................................................................................................9

UNLOAD TRANSPORTER .............................................................................................................1

A. ONE-AXLE..................................................................................................................................2

B. TWO-AXLE .................................................................................................................................3

C. THREE-AXLE..............................................................................................................................4

D. TRANSPORTER ADJUSTMENT PROCEDURES.....................................................................5

I. CUTTERBAR SUPPORTS ....................................................................................................5

II. MOVING REAR AXLES.........................................................................................................5

III. ADJUSTING AXLE SPACING – TWO & THREE AXLE........................................................6

IV. BUMPER................................................................................................................................7

V. FRONT AND REAR SUPPORTS – TWO & THREE AXLE...................................................7

A. TIRE PRESSURE .......................................................................................................................9

B. WHEEL BOLT TORQUE ............................................................................................................9

C. LIGHTS.......................................................................................................................................9

D. BRAKES......................................................................................................................................9

E. BREAKAWAY SWITCH ..............................................................................................................9

F. MANUALS...................................................................................................................................9

Form 169365 Issue– May 2008

Page 14

Page 15

SECTION UA – UNLOADING AND SETUP

STEP 1. UNLOAD TRANSPORTER

CAUTION

To avoid injury to bystanders from being

struck by machinery, do not allow persons

to stand in unloading area.

CAUTION

Equipment used for unloading must meet

or exceed the requirements specified

below. Using inadequate equipment may

result in vehicle tipping or machine

damage.

g. Check for shipping damage and missing parts.

LIFTING VEHICLE

Min. Lifting

Capacity *

Min. Fork Length

* At 48 inches (1220 mm) from back end of

forks.

IMPORTANT

Forklifts are normally rated for a load

located 24 inches (610 mm) ahead of

back end of the forks. To obtain the

forklift capacity at 48 inches (1220 mm),

check with your forklift distributor.

5000 lb. (2270 kg)

60 inches (1524 mm)

CAUTION

Never use the axle or any portion of the

suspension to lift or support the

transporter. This will damage the axle and

lead to premature failure.

a. Remove hauler's tie down straps and chains.

b. Attach sling(s) to transporter. Locate slings on

transporter to ensure it is lifted evenly.

CAUTION

If transporter is not supported properly, it

will have a tendency to rotate as it is lifted,

and may cause serious injury, or damage

adjacent equipment.

c. Approach transporter with forklift or equivalent

from either side of hauling equipment. Attach

slings to lifting device with chains.

d. Lift transporter off trailer bed and back up until

unit clears trailer. Slowly lower to 6 inches (150

mm) from ground.

e. Take to storage or set-up area.

f. Set transporter down securely on level ground.

Form 169365 UA-1 Issue – May 2008

Page 16

SECTION UA – UNLOADING AND SETUP

”

STEP 2. CONFIGURE THE

TRANSPORTER

The transporter must be set up to carry a

specific size and type of header. Refer to

applicable section for each model of transporter.

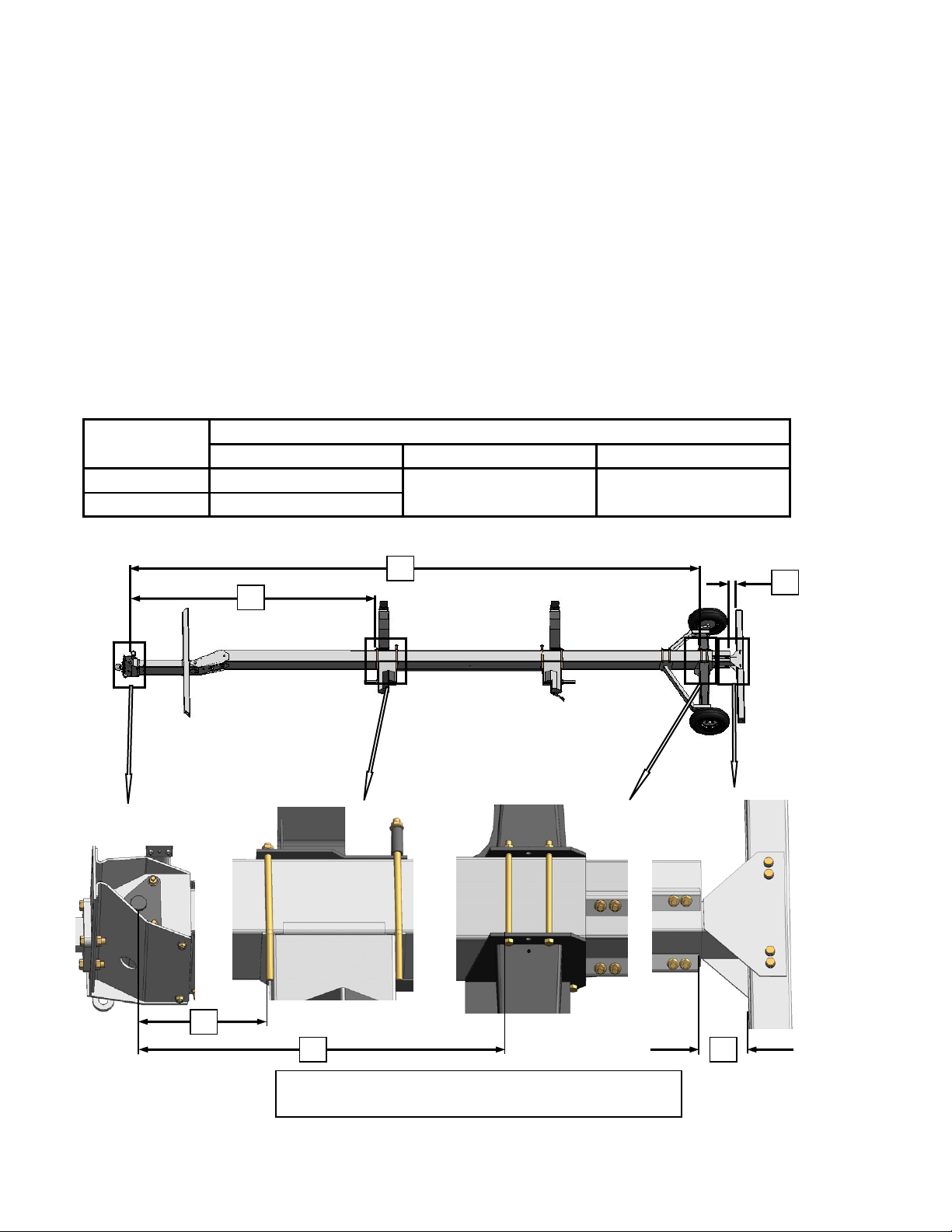

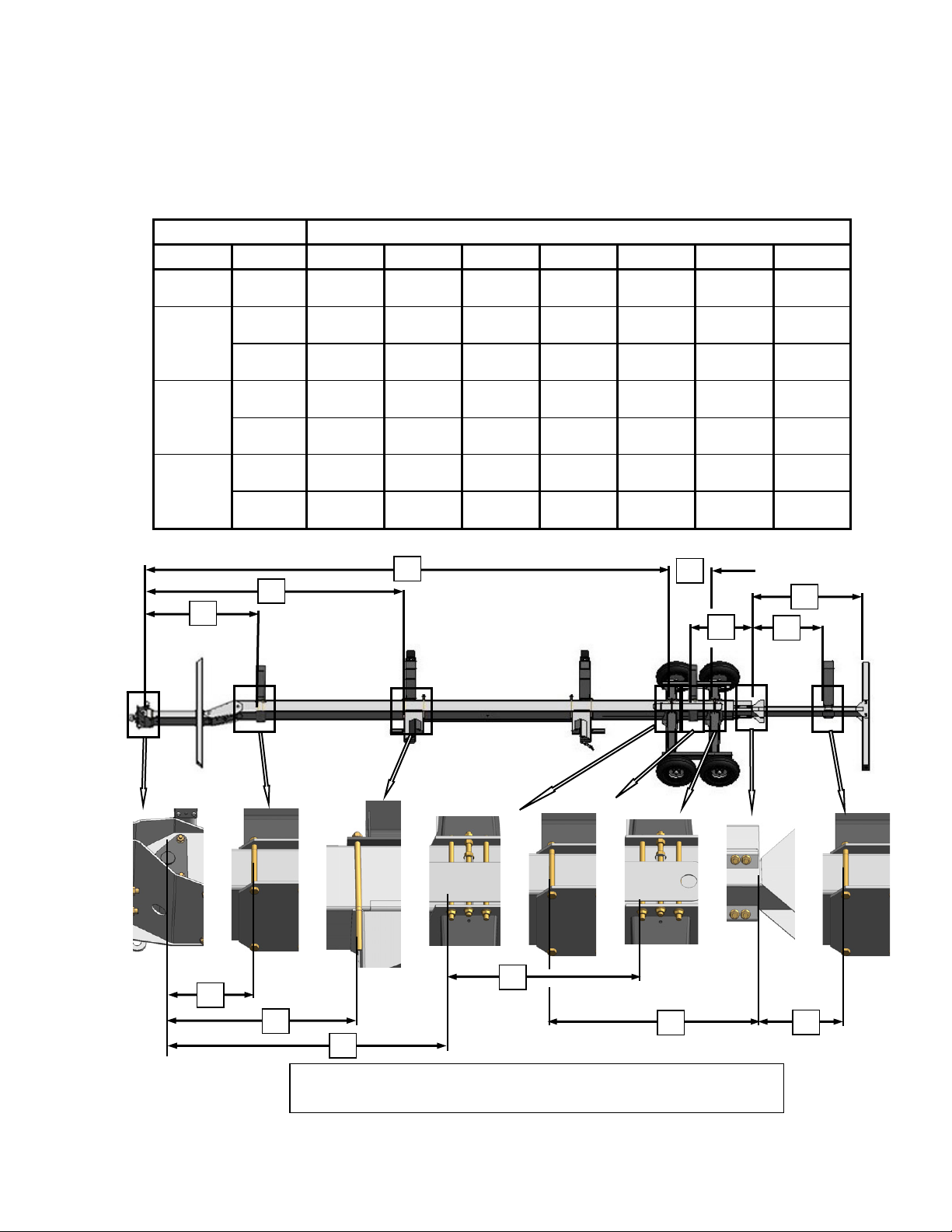

A. ONE-AXLE

The one-axle transporter is designed to carry D Series 25 ft, and 30 ft windrower headers using a truck or an

M Series windrower tractor. Determine the header that the transporter will carry and set up the transporter in

accordance with the following table: Refer to paragraph D, TRANSPORTER ADJUSTMENT PROCEDURES

for instructions.

IMPORTANT

The one-axle transporter is not designed to carry a 30 ft combine header. Do not exceed 5400 lb

(2452 kg) header weight. Ensure attachments and header weight conform.

D SERIES

HEADER SIZE

25’

30’

A B C

181.8 (4618)

162.1 (4118)

A

DIMENSION inches (mm)

423.1 (10747) 4.84 (123)

B

C

A

B C

NOTE

Dimensions “A” and “B

Form 169365 UA-2 Issue – May 2008

are to forward edge of bolts.

Page 17

SECTION UA – UNLOADING AND SETUP

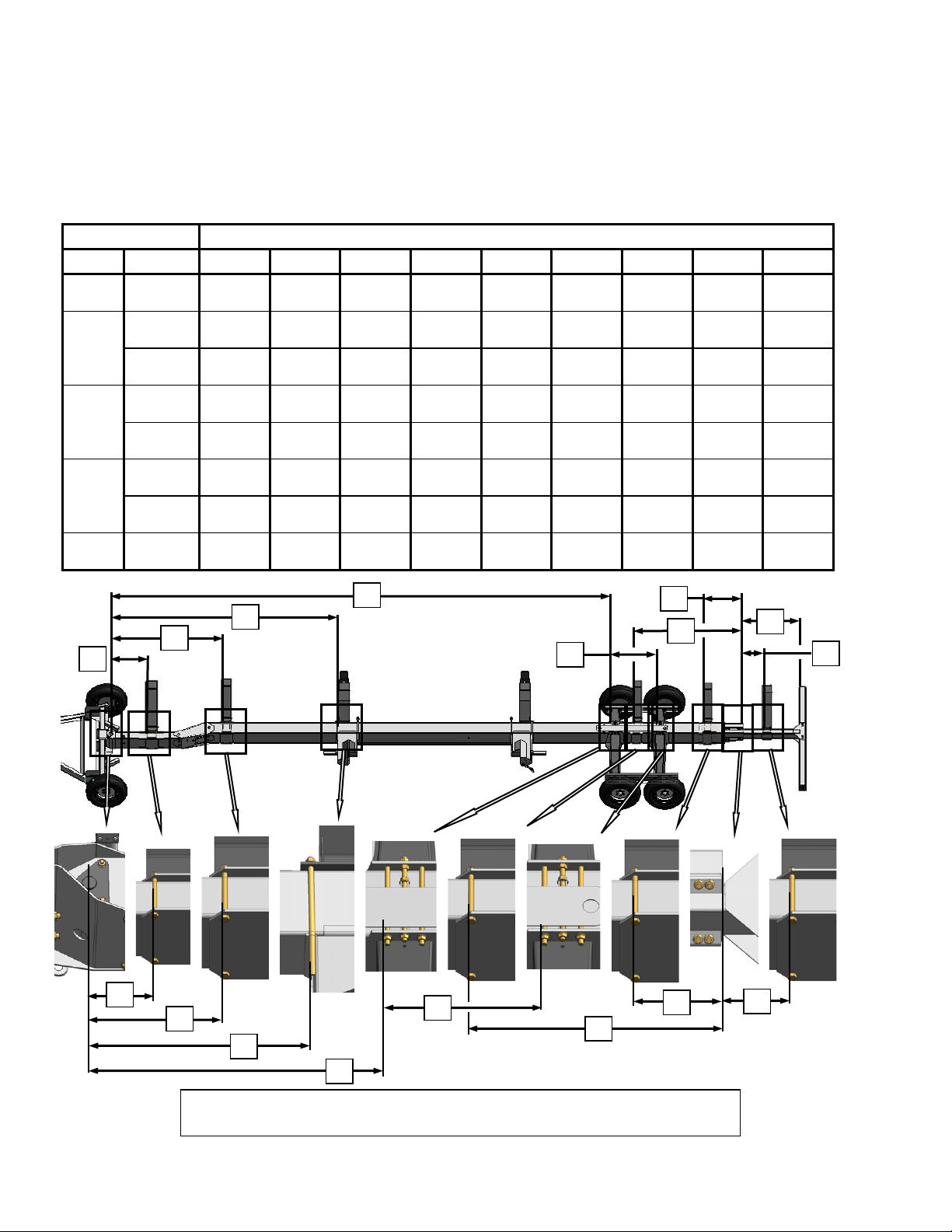

B. TWO-AXLE

The two-axle transporter is designed to carry D Series and FD Series 25 ft, 30 ft, 35 ft, and 40 ft windrower

and combine headers using a truck or an M Series windrower tractor. Determine the header that the

transporter will carry and set up the transporter in accordance with the following table. Refer to paragraph D,

TRANSPORTER ADJUSTMENT PROCEDURES for instructions.

HEADER DIMENSION inches (mm)

SIZE

25’ D

30’

35’

40’

MODEL A B C D E F G

D

FD

D

FD

D

FD

No

Support

No

Support

92.0

(2338)

86.7

(2202)

78.4

(1922)

82.8

(2102)

78.8

(2002)

226.9

(5763)

203.1

(5160)

189.2

(4806)

228.7

(5808)

203.3

(5163)

229.3

(5823)

229.8

(5836)

393.4

(9992 0

393.4

(9992)

393.4

(9992 0

385.5

(9792)

367.8

(9343)

393.4

(9992 0

378.3

(9610)

31.5

(800)

31.5

(800)

31.5

(800)

39.4

(1000)

39.4

(1000)

31.5

(800)

31.5

(800)

No

Support

No

Support

No

Support

30.2

(768)

9.33

(237)

40.8

(1037)

60.5

(1537)

5.67

(144)

15.0

(380)

6.6

(168)

56.9

(1445)

43.9

(1114)

100.0

(2540)

100.4

(2549)

No

Support

No

Support

38.4

(976)

No

Support

No

Support

No

Support

No

Support

A

A

B

B

C

C

D

F

G

E

D

G

E

NOTE

Dimensions “A”, “B”, “C”, “D”, “E”, & “H” are to forward edge of bolts.

Form 169365 UA-3 Issue – May 2008

Page 18

SECTION UA – UNLOADING AND SETUP

,

C. THREE-AXLE

The three-axle transporter is designed to carry D Series and FD Series 25 ft, 30 ft, 35 ft, 40 ft, and 45 ft

windrower and combine headers using either a truck, a M Series windrower tractor, or a combine. Determine

the header that the transporter will carry and set up the transporter in accordance with the following table.

Refer to paragraph D, TRANSPORTER ADJUSTMENT PROCEDURES, for adjustment instructions.

HEADER DIMENSION inches (mm)

SIZE MODEL A B C D E F G H J

25’ D

30’

35’

40’

45’

A

D

FD

D

FD

D

FD

D

B

No

Support

No

Support

No

Support

19.5

(495)

19.5

(495)

19.5

(495)

19.5

(495)

19.5

(495)

C

No

Support

No

Support

2402

No

Support

No

Support

No

Support

No

Support

No

Support

191.5

(4863)

187.5

(4763)

189.2

(4805)

140.3

(3563)

138.3

(3513)

167.8

(4263)

167.8

(4263)

191.5

(4852)

D

385.5

(9792)

382.1

(9705)

393.4

(9992)

297.1

(7547)

302.9

(7693)

341.3

(8670)

318.1

(8080)

385.5

(9792)

No

Support

No

Support

No

Support

47.1

(1197)

49.1

(1247)

No

Support

No

Support

No

Support

31.5

(800)

31.5

(800)

31.5

(800)

39.4

(1000)

39.4

(1000)

31.5

(800)

31.5

(800)

31.5

(800)

F

No

Support

No

Support

943

No

Support

No

Support

No

Support

No

Support

No

Support

E

G

5.2

(133)

5.2

(133)

5.2

(133)

5.2

(133)

5.2

(133)

37.8

(960)

37.8

(960)

91.4

(2322)

No

Support

No

Support

No

Support

No

Support

No

Support

1.9 (48)

1.9 (48)

63.1

(1602)

H

J

A

B

F

E

G

J

C

D

NOTE

Dimensions “A”

Form 169365 UA-4 Issue – May 2008

“B”, “C”, “D”, “E”, “F”, “G”, & “J” are to forward edge of bolts.

Page 19

SECTION UA – UNLOADING AND SETUP

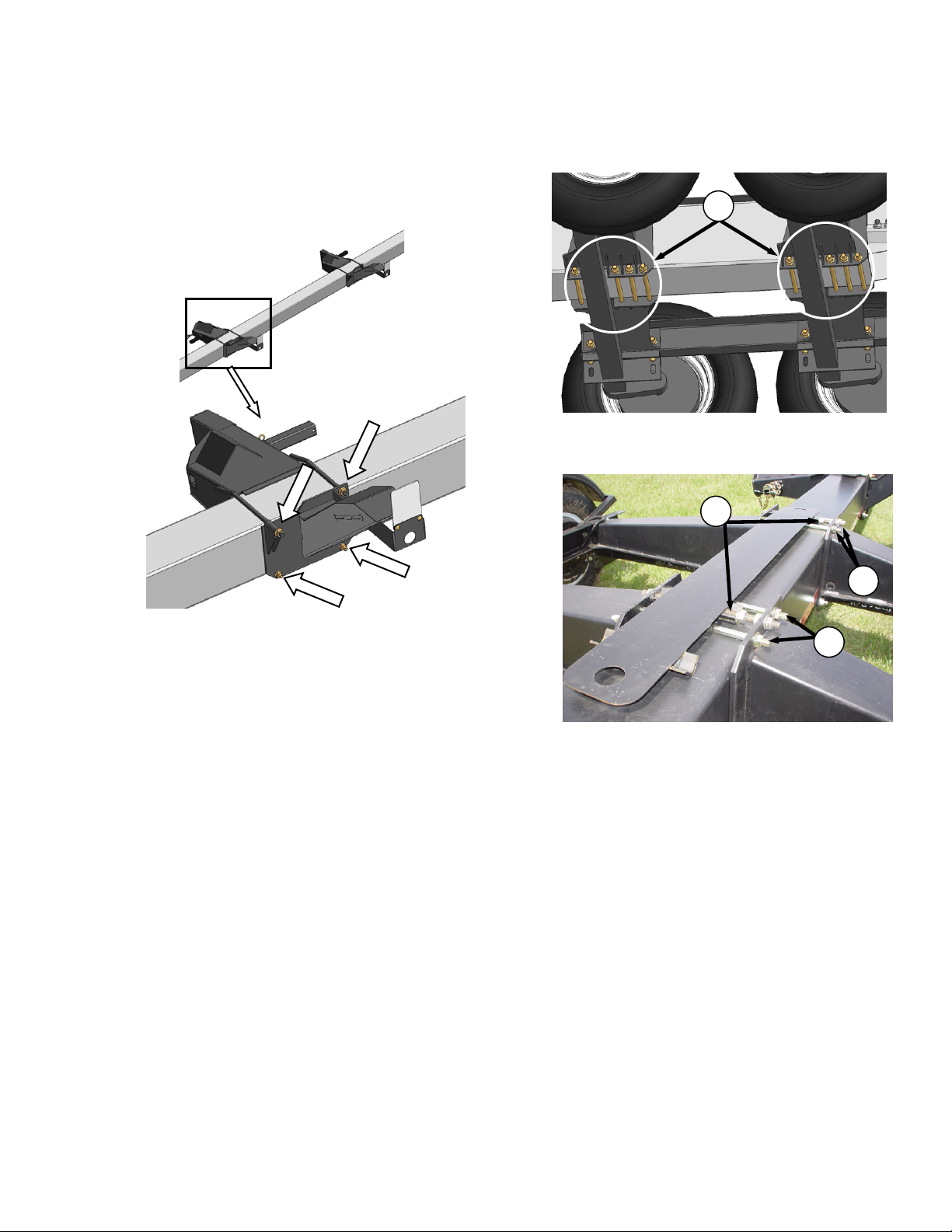

D. TRANSPORTER ADJUSTMENT

PROCEDURES

I. CUTTERBAR SUPPORTS

II. MOVING REAR AXLES

Two & Three Axle Transporter Only

A

a. Loosen four lower bolts (A) on each axle

support.

C

B

a. Loosen four nuts on each support.

b. Slide both supports to specified location (see

previous page).

NOTE

Supports are joined by a tie angle and

move together to maintain correct

spacing.

c. Re-tighten nuts. Ensure supports are evenly

clamped onto main beam.

B

b. Loosen two bolts (B) on each axle support

topside.

c. Loosen outer nuts on both adjuster rods (C).

d. Turn inner nuts on both adjuster rods (C) so that

left and right frames separate approximately 3

mm from main beam.

e. Slide tandem axle assembly to desired location.

Holes are provided on adjuster plate for

attaching a winch or come-along.

NOTE

Ensure winch pulls adjuster plate straight

to avoid binding.

f. Tighten inner nuts on adjuster rods (C) against

adjuster plate.

g. Retighten all nuts and bolts. Ensure supports

are evenly clamped onto main beam.

Form 169365 UA-5 Issue – May 2008

Page 20

SECTION UA – UNLOADING AND SETUP

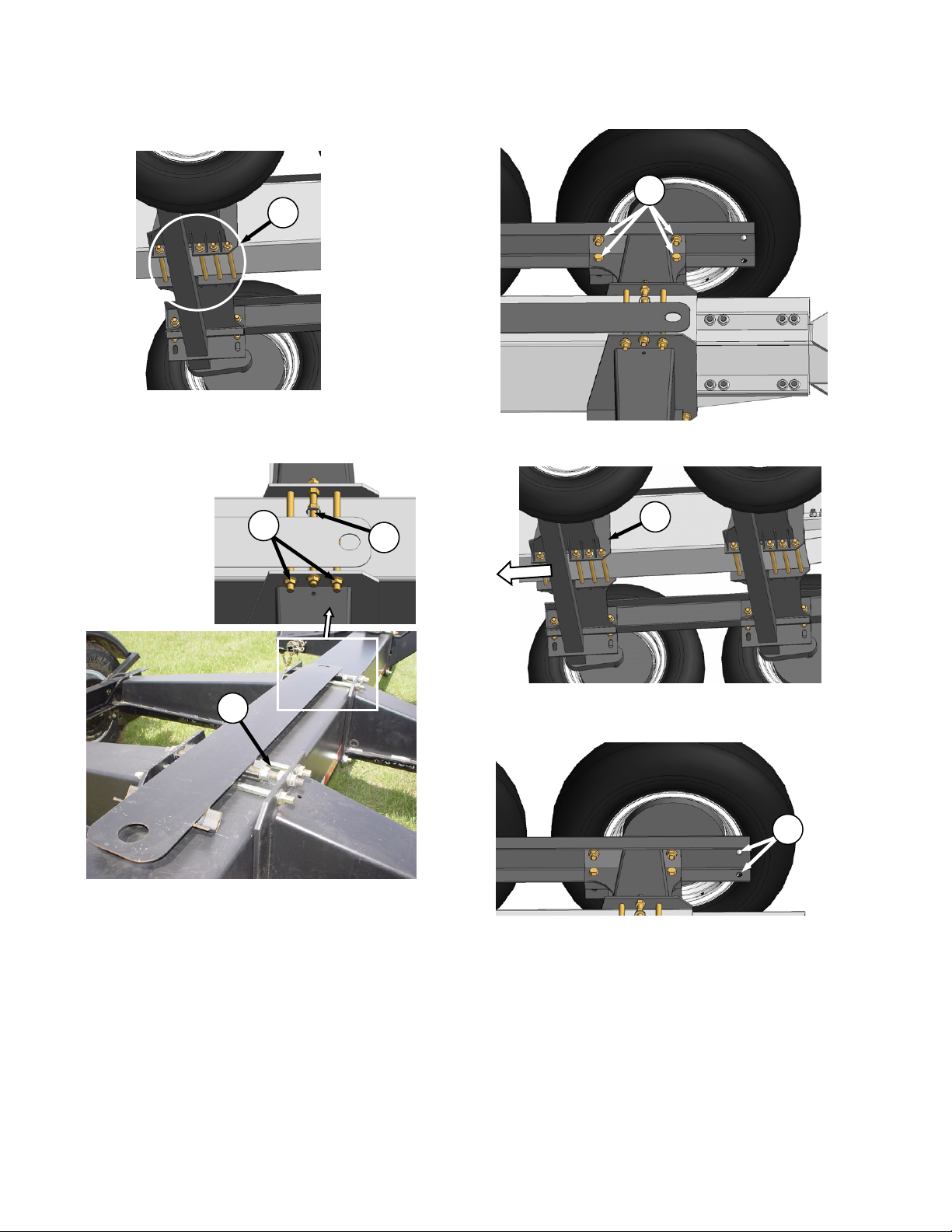

III. ADJUSTING AXLE SPACING – TWO &

THREE AXLE

D

a. Loosen four bolts (D) on underside of axle to be

moved.

f. Remove the four bolts (H) on both sides of rear

H

axle mount (J).

E

G

b. Loosen two bolts (E) on topside of forward axle.

c. Loosen outer nuts on the forward axle adjuster

rod (F).

d. Turn inner nuts on adjuster rod (F) so that left

and right frames separate slightly from main

beam.

e. Remove adjuster rod (G) on rear axle.

F

J

g. Slide axle to new location and line up rear axle

mounting holes (K).

K

h. Re-install four bolts removed at step e. on both

sides of rear axle mount and tighten.

i. Re-install adjuster rod (G) in adjuster plate and

tighten.

j. Tighten all remaining nuts.

Form 169365 UA-6 Issue – May 2008

Page 21

SECTION UA – UNLOADING AND SETUP

IV. BUMPER

A

a. Loosen eight nuts (A) on bumper clamps.

b. Slide bumper (B) to specified location (see

previous page).

c. Re-tighten nuts. Ensure nuts are evenly

tightened.

B

V. FRONT AND REAR SUPPORTS – TWO &

THREE AXLE

D

C

FRONT SUPPORT SHOWN – REAR SUPPORT SIMILAR

a. Loosen four bolts (C) on support (D).

b. Slide support to desired location and retighten

bolts. Ensure supports are evenly clamped onto

main beam.

Form 169365 UA-7 Issue – May 2008

Page 22

SECTION UA – UNLOADING AND SETUP

STEP 3. SET UP COMBINE HITCH

– THREE-AXLE ONLY

The combine hitch can be configured in two

lengths depending on the combine and header

size. The longer hitch is for combines where

there is insufficient clearance between the rear

of the combine and the header reel when

rounding corners.

CAUTION

Towing the transporter with a truck when

the combine hitch is installed is not

recommended for highway travel. If

necessary, a pintle type hitch should be

installed on the truck and the transporter

combine hitch (p/n 113566) in place of the

clevis type hitch.

a. Detach tow-bar from storage position on

transporter.

A

E

e. Install receptacle bracket (E) onto lugs on hitch

with hardware provided.

f. Attach wiring receptacle to bracket with

hardware provided.

G

C

D

B

b. Ensure stop-bolt (A) is installed.

c. Position combine tow-bar (B) inside channel (C)

under existing hitch in either long or short

location. Illustration shows long setup.

d. Install two bolts and castle nuts (D) to secure

combine hitch to channel. Secure castle nuts

with cotter pins.

D

g. Secure wiring to lugs on hitch with clamps and

hardware provided at four locations (G).

h. Connect plug from transporter to receptacle on

combine hitch.

Form 169365 UA-8 Issue – May 2008

Page 23

SECTION UA – UNLOADING AND SETUP

STEP 4. PRE-DELIVERY CHECK

Perform the final checks and adjustments as

listed on the "Pre-Delivery Checklist" (yellow

sheet attached to back of this instruction) to

ensure the machine is field-ready. Refer to the

pages for detailed instructions as indicated on

the checklist.

The completed checklist should be retained

either by the operator or the dealer.

A. TIRE PRESSURE

a. Check tire pressure on all tires. Correct

pressure is 65 psi (448 kPa).

B. WHEEL BOLT TORQUE

1

6

b. Drive slowly forward and apply brakes. Observe

if electric brakes on transporter are operational.

c. There should be no sensation of the transporter

pushing or pulling the tow vehicle.

D. LIGHTS

a. Check function of running lights, signal lights,

hazard lights, and brake lights.

E. BREAKAWAY SWITCH

4

2

a. Check wheel bolt torque on all wheels. Correct

torque is 90-120 ft-lbf (122-163 N·m).

3

5

C. BRAKES

a. Hitch transporter to towing vehicle and connect

transporter wiring harness to towing vehicle.

FRONT VIEW – COVER OPEN

IMPORTANT

Center pin on towing vehicle electrical

receptacle must not be energized,

otherwise the transporter brakes will be

activated. Re-wire receptacle if

necessary.

a. Check breakaway switch operation by firmly

pulling on pin in breakaway switch. The brakes

should activate when the pin is pulled.

F. MANUALS

a. The owner’s manual storage case is located

near the front of the transporter on the right side.

b. Check that it is mounted securely.

c. Store this manual and other applicable

documents in storage case.

STEP 5. LUBRICATE THE

TRANSPORTER

Refer to SECTION OM, Paragraph 4.2,

Lubricating the Transporter

Form 169365 UA-9 Issue – May 2008

Page 24

Page 25

SECTION OM – OPERATOR’S INSTRUCTIONS

Section Contents

ITEM DESCRIPTION PAGE OM-

1

COMPONENT IDENTIFICATION..................................................................................................................3

2 SPECIFICATIONS AND WEIGHT DATA ......................................................................................................4

2.1 SPECIFICATIONS ...................................................................................................................................4

2.2 TRANSPORTER WEIGHT AND TONGUE WEIGHT DATA ...................................................................5

3 OPERATION..................................................................................................................................................6

3.1 OWNER/OPERATOR RESPONSIBILITIES............................................................................................6

3.2 OPERATIONAL SAFETY.........................................................................................................................6

3.3 FIRST USE ..............................................................................................................................................6

3.4 TOWING ONE-AXLE AND TWO-AXLE TRANSPORTERS WITH M SERIES WINDROWER

TRACTOR .........................................................................................................................................................7

3.4.1 Attaching Adapter Hitch to Windrower Tractor ...........................................................................7

3.4.2 Hookup to Windrower Adapter Hitch...........................................................................................8

3.4.3 Unhook From Windrower Adapter Hitch .....................................................................................9

3.4.4 Unhook From Windrower Leaving Adapter Hitch on Transporter...............................................9

3.5 TOWING ONE-AXLE AND TWO-AXLE TRANSPORTERS WITH TRUCK..........................................11

3.5.1 Hookup to Truck........................................................................................................................11

3.5.2 Unhooking from Truck...............................................................................................................12

3.6 TOWING THREE-AXLE TRANSPORTER WITH M SERIES WINDROWER TRACTOR.....................13

3.6.1 Transporter Hookup to Windrower Adapter Hitch.....................................................................13

3.6.2 Unhook From Windrower Leaving Adapter Hitch on Transporter.............................................14

3.6.3 Windrower Hookup to Adapter Hitch on Transporter................................................................15

3.6.4 Transporter Unhook From Windrower Adapter Hitch ...............................................................15

3.7 TOWING THREE-AXLE TRANSPORTER WITH COMBINE ................................................................16

3.7.1 Hookup To Combine .................................................................................................................16

3.7.2 Unhook From Combine.............................................................................................................17

3.8 TOWING THREE-AXLE TRANSPORTER WITH TRUCK.....................................................................18

3.8.1 Hookup to Truck........................................................................................................................18

3.8.2 Unhook from Truck....................................................................................................................18

3.9 LOADING D SERIES WINDROWER HEADER ONTO TRANSPORTER.............................................19

3.9.1 Prepare the Header...................................................................................................................19

3.9.2 Prepare the Transporter............................................................................................................20

3.9.3 Loading Procedure....................................................................................................................20

3.9.4 Engage Cutterbar Tie-downs ....................................................................................................21

3.9.5 Attach Header Anchor Chain ....................................................................................................23

3.10 UNLOADING D SERIES WINDROWER HEADER ...............................................................................24

3.11 LOADING D AND FD SERIES COMBINE HEADER.............................................................................26

3.11.1 Prepare the Header and Transporter........................................................................................26

3.11.2 Loading Procedure....................................................................................................................27

3.12 UNLOADING D AND FD SERIES COMBINE HEADER .......................................................................29

3.13 ATTACHING/DETACHING CA20 COMBINE ADAPTER ......................................................................30

3.14 STORAGE..............................................................................................................................................30

4 MAINTENANCE...........................................................................................................................................31

4.1 RECOMMENDED SAFETY PROCEDURES.........................................................................................31

4.2 LUBRICATING THE TRANSPORTER ..................................................................................................31

4.2.1 Lubricants..................................................................................................................................31

4.2.2 Lubricant Storage......................................................................................................................31

4.2.3 Greasing Requirements ............................................................................................................31

4.3 WHEELS AND TIRES............................................................................................................................32

4.3.1 Wheel Nuts................................................................................................................................32

4.3.2 Wheel - Removal/Installation ....................................................................................................32

4.3.2.1 Removal .................................................................................................................................................. 32

4.3.2.2 Installation ............................................................................................................................................... 33

Form # 169365 Issue – May 2008

Page 26

SECTION OM – OPERATOR’S MANUAL

4.3.3 Tires ..........................................................................................................................................34

4.3.3.1 Inflation ....................................................................................................................................................34

4.3.3.2 Wear ........................................................................................................................................................34

4.4 ELECTRICAL.........................................................................................................................................35

4.4.1 Lights ........................................................................................................................................35

4.4.1.1 Tail/Brake/Signal Replacement................................................................................................................35

4.4.1.2 Clearance Lights ......................................................................................................................................35

4.4.1.3 Red Light Bar ...........................................................................................................................................35

4.4.1.4 License Plate Light...................................................................................................................................35

4.4.2 Electric Brakes ..........................................................................................................................35

4.4.2.1 Wiring.......................................................................................................................................................35

4.4.2.2 Brake Adjustment.....................................................................................................................................35

4.4.2.3 Breakaway Battery...................................................................................................................................36

4.5 MAINTENANCE SCHEDULE................................................................................................................37

5 TROUBLESHOOTING.................................................................................................................................39

Form # 169254 OM-2 Issue – April 2008

Page 27

SECTION OM – OPERATOR’S MANUAL

1 COMPONENT IDENTIFICATION

CUTTERBAR SUPPORT

HEADER LEG SUPPORT

BREAKAWAY SYSTEM BATTERY

MANUAL CASE

CUTTERBAR TIE-DOWN

GUIDE

COMBINE HITCH

TRACTOR/TRUCK HITCH BREAKAWAY SWITCH

CUTTERBAR TIE-DOWN

THREE-AXLE TRANSPORTER

BUMPER

CUTTERBAR SUPPORT

CUTTERBAR TIE-DOWN

HEADER LEG SUPPORT

LIGHTBAR

BREAKAWAY SWITCH

HEIGHT ADJUSTABLE PINTLE HITCH

ONE AND TWO-AXLE TRANSPORTER

Form # 169365 OM-3 Issue – May 2008

Page 28

SECTION OM – OPERATOR’S MANUAL

2 SPECIFICATIONS AND WEIGHT DATA

2.1 SPECIFICATIONS

ITEM

AXLES

MAX GROSS TRANSPORT WEIGHT

LENGTH

WIDTH

TREAD WIDTH

WEIGHT

MINIMUM HITCH LOAD

TIRES

Pressure 65 psi (448 kPa)

MT8-1 MT8-2 MT8-3

One Two Three

8000 lb (3620 kg) 12000 lb (5430 kg) 14000 lb (6335 kg)

467 in. (11866 mm)

2613 lb (1182 kg) 3255 lb (1473 kg) 3755 lb (1699 kg)

2000 lb (905 kg) 3000 lb (1375 kg) <100 lb. (45 kg)

SPECIFICATION

468-563 in.

(11891-14301 mm)

100.75 in. (2560 mm)

88 in. (2235 mm)

ST225/75 R15 LR D

580-617 in.

(14730-15673 mm)

MAX HEADER SIZE

SUSPENSION

ADJUSTABLE CUTTERBAR SUPPORTS

TOWING VEHICLE

TOWING SPEED

BRAKES

FENDERS

30 ft D Series 40 ft D or FD Series 45 ft D or FD Series

Flex Torsion Axle

Two Two Two or Three

Truck, M Series Windrower Tractor

(See Note 2)

Highway

Electric Drum on All Wheels (See Note 4)

Each Wheel

Truck, M Series

Windrower Tractor,

Combine

(See Note 3)

NOTES:

1. Specifications and design are subject to change without notice or obligation to revise previously sold

units.

2. Ensure that truck and truck hitch are rated for maximum gross weight and maximum hitch load.

Hitch loads require a suitably sized truck.

3. Ensure that truck and truck hitch are rated for maximum gross weight.

4. Requires electric brake controller to be installed in truck.

Form # 169365 OM-4 Issue – May 2008

Page 29

SECTION OM – OPERATOR’S MANUAL

2.2 TRANSPORTER WEIGHT AND TONGUE WEIGHT DATA

IMPORTANT: Weights are estimated and owner should check transporter weight when loaded. Weights will

vary significantly depending on header options, (number of reel bats, steel versus plastic fingers etc)

HEADER

SIZE MODEL GROSS TONGUE GROSS TONGUE GROSS TONGUE

25’

D Wind

7995 (3630)

ONE-AXLE TWO-AXLE THREE-AXLE

3179

(1443)

D Comb Do Not Use

30’

D Wind

D Comb

7945

(3607)*

3418

(1552)

FD

D

35’

FD

Do Not Use

D

40’

FD

45’ D

* Do not exceed 5400 lb (2452 kg) header weight. Ensure attachments and header weight conform.

WEIGHT pounds (kilograms)

9764 (4433)

max

9805 (4451)

2718 (1234)

max

3471 (1576)

max

10864

(4932)

11259

3918 (1779)

max

(5112)

10984

(4987)

11421

3661 (1662)

max

(5185)

11489

(5216)

11706

3245 (1473)

max

(5314)

Do Not Use

3743 (1699)

max

11750

(5334) max

11912

(5408) max

12197

(5537) max

12650

(5743)

<500 (227)

Weight

Transfer

Springs Not

Engaged

Form # 169365 OM-5 Issue – May 2008

Page 30

SECTION OM – OPERATOR’S MANUAL

3 OPERATION

3.1 OWNER/OPERATOR

RESPONSIBILITIES

CAUTION

• It is your responsibility to read and

understand this manual completely

before operating the mower

conditioner. Contact your dealer if an

instruction is not clear to you.

• Follow all safety messages in the

manual and on safety signs on the

machine.

• Remember that YOU are the key to

safety. Good safety practices protect

you and the people around you.

• Review the manual and all safety

related items with all operators

annually.

• Be alert for other operators not using

recommended procedures or not

following safety precautions. Correct

these mistakes immediately, before an

accident occurs.

• Do not modify the machine.

Unauthorized modifications may impair

the function and/or safety and affect

machine life.

• The safety information given in this

manual does not replace safety codes,

insurance needs, or laws governing

your area. Be sure your machine meets

the standards set by these regulations.

3.2 OPERATIONAL SAFETY

Follow these safety precautions:

CAUTION

• Follow all safety and operational

instructions given in your towing

vehicle Operator's Manual. If you do

not have a manual, get one from your

dealer and read it thoroughly.

• Never move the unit until you are sure

all bystanders have cleared the area.

• Stop towing vehicle engine and remove

key before adjusting the transporter. A

child or even a pet could engage the

drive.

• Check for excessive vibration and

unusual noises. If there is any

indication of trouble, shut down the

towing vehicle and inspect the

transporter. Follow proper shutdown

procedure:

o engage tractor brake

o disengage PTO

o turn off engine and remove key

• Operate only in daylight or good

artificial light.

• Do not carry passengers on equipment.

• Pick the most level possible route when

towing the transporter across fields.

Avoid edges of ditches, gullies, and

steep hills.

• Be extra careful when working on

inclines.

• Manoeuvre towing vehicle at safe

speeds.

• Avoid loose gravel, rocks, and holes;

they can be dangerous for equipment

operation or movement.

• Allow for transporter length when

turning.

• Ensure towing vehicle is capable of

towing the transporter when empty or

when loaded with a header. Refer to

SECTION OM, Paragraph 2,

Specifications for gross transport

weights.

• To avoid bodily injury and or machine

damage caused by loss of control:

o Reduce transport speed for slippery

or rough conditions.

o Obey all highway traffic regulations

in your area when transporting on

public roads.

3.3 FIRST USE

After attaching transporter to towing vehicle for

the first time, drive slowly, watching and

listening FROM THE OPERATOR'S SEAT for

unusual towing behavior or steering control

problems.

CAUTION

Before investigating an unusual sound or

attempting to correct a problem, shut off

engine, engage parking brake and

remove key.

a. Tighten any loose hardware after the first

5 hours operation. Refer to SECTION G,

Paragraph 2, Recommended Torques.

Form # 169365 OM-6 Issue – May 2008

Page 31

SECTION OM – OPERATOR’S MANUAL

3.4 TOWING ONE-AXLE AND TWOAXLE TRANSPORTERS WITH M

SERIES WINDROWER TRACTOR

The one-axle and two-axle MT8 Header

Transporters can be towed with the MacDon M

Series Windrower Tractor provided that the

MacDon Transporter Adapter Hitch (B5247) is

attached to the tractor.

CAUTION

Towing the Transporter without a header

on the Transporter is not recommended

because of the lack of sufficient weight

on the tractor drive wheels for safe

operation of the tractor.

b. Start tractor and lower windrower lift legs fully

and approach hitch.

c. Line up legs with pockets in hitch and drive

forward until legs fully engage hitch.

CAUTION

If necessary to tow the Transporter

without a header on the Transporter, do

not operate tractor at typical road speed.

Proceed with caution.

3.4.1 Attaching Adapter Hitch to

Windrower Tractor

a. Remove clevis pins from hitch.

d. Rotate stops against legs and insert clevis

pins. Secure with hairpins.

e. Attach safety chain on hitch to center link

mounting bracket on tractor frame. Leave

some slack in chain to allow hitch to be raised

to maximum height of lift linkage. Secure

chain with locking device.

f. Connect wiring harness from hitch to tractor.

Form # 169365 OM-7 Issue – May 2008

Page 32

SECTION OM – OPERATOR’S MANUAL

3.4.2 Hookup to Windrower Adapter Hitch

a. Open pintle on adapter hitch.

b. Start tractor and activate header lift cylinders

on tractor to lower tractor hitch.

c. Slowly approach transporter hitch with tractor

and line up pintle with hitch ring on transporter.

d. Activate header lift cylinders on tractor until

pintle engages hitch ring on transporter. Raise

slightly to take weight of the hitch jack.

e. Stop tractor engine and remove key.

i. Plug in wiring harnesses at tractor hitch and

transporter.

f. Close pintle lock and insert locking pin.

g. Route safety chains through tractor hitch frame

and connect under frame. Ensure hook safety

latches are closed.

h. Turn jack handle to retract jack. Remove pin

from jack and rotate jack to transport position.

Secure jack with pin.

j. Attach breakaway switch lanyard to tractor

adapter hitch.

k. Start tractor and raise header lift legs to full

height (towing mode).

l. Stop tractor engine and remove key.

m. Engage header lift cylinder stops. See tractor

operator’s manual.

n. Remove blocks if used, from transporter

wheels.

Form # 169365 OM-8 Issue – May 2008

Page 33

SECTION OM – OPERATOR’S MANUAL

3.4.3 Unhook From Windrower Adapter

Hitch

a. Stop tractor engine and remove key.

b. Block the transporter wheels to prevent

transporter from moving.

c. Remove pin that holds jack in storage location

on transporter frame. Rotate jack to working

position and re-insert pin to secure jack.

d. Lower jack to the ground. Use a wooden block

if ground is soft.

g. Disconnect breakaway switch lanyard from

windrower hitch.

h. Disconnect electrical plug on windrower hitch.

i. Disengage tractor lift cylinder locks.

j. Start tractor engine and activate header lift

cylinders to lower the hitch and disengage

pintle ring on transporter.

3.4.4 Unhook From Windrower Leaving

Adapter Hitch on Transporter

The following procedure is the normal method

for unhooking the transporter from the

windrower tractor.

e. Remove safety chains from windrower hitch.

f. Remove locking pin from pintle and raise pintle

lock.

a. Stop tractor engine and remove key.

b. Block the transporter wheels to prevent

transporter from moving.

c. Remove pin that holds jack in storage location

on transporter frame. Rotate jack to working

position and re-insert pin to secure jack.

d. Lower jack to the ground. Use a wooden block

if ground is soft.

e. Disengage tractor lift cylinder locks.

f. Start tractor engine and activate header lift

cylinders to lower the adapter hitch onto blocks

or the ground.

(continued next page)

Form # 169365 OM-9 Issue – May 2008

Page 34

SECTION OM – OPERATOR’S MANUAL

g. Stop engine and remove key.

h. Disconnect wiring harness at tractor.

k. Start tractor and back away from hitch.

l. Re-install clevis pins into hitch boots.

i. Remove safety chain from tractor and store on

hitch.

j. Remove clevis pins from tractor legs and set

aside.

Form # 169365 OM-10 Issue – May 2008

Page 35

SECTION OM – OPERATOR’S MANUAL

3.5 TOWING ONE-AXLE AND TWOAXLE TRANSPORTERS WITH

TRUCK

CAUTION

• To avoid bodily injury and/or machine

damage caused by loss of control:

• Check tire condition and pressure prior

to transporting.

• Connect hitch to towing vehicle with a

proper hitch pin with a spring locking

pin or other suitable fastener.

• Attach hitch chain to towing vehicle.

Adjust chain length to remove all slack

except what is needed for turns.

• Ensure wiring is properly connected

and lights and brakes are working

correctly

b. Open pintle and lower transporter hitch onto

truck hitch with jack.

c. Raise jack fully. Remove pin from jack and

rotate to storage location. Secure with pin.

d. Close pintle lock and secure with lynch pin.

CAUTION

Ensure towing vehicle is capable of

handling transporter tongue weight and

gross weight to ensure adequate braking

performance and control.

a. Refer to paragraph 2.2 TRANSPORTER

WEIGHT AND TONGUE WEIGHT DATA for

transporter gross weights and tongue weights.

IMPORTANT

Tongue weight is higher on one and twoaxle transporters than other trailers

because wheels are located to provide

clearances for loading and unloading

procedures.

3.5.1 Hookup to Truck

b. Back up truck to align pintle with transporter

hitch.

a. Shut off truck engine and remove key.

e. Attach safety chains to truck and plug in the

electrical connector to truck receptacle.

FRONT VIEW – COVER OPEN

IMPORTANT

Center pin on towing vehicle electrical

receptacle must not be energized,

otherwise the transporter brakes will be

activated. Re-wire receptacle if

necessary.

(continued next page)

Form # 169365 OM-11 Issue – May 2008

Page 36

SECTION OM – OPERATOR’S MANUAL

f. Check that transporter lights and brakes are

functioning.

g. Attach breakaway lanyard to truck hitch.

3.5.2 Unhooking from Truck

a. Park transporter on level ground.

b. Shutoff truck engine and remove key.

c. Block the transporter wheels.

d. Disconnect electrical plug from truck and store

on transporter.

e. Remove safety chains and breakaway switch

lanyard from truck and store on transporter.

f. Remove lynch pin from pintle and open pintle.

g. Remove pin securing jack in storage position

and rotate jack to working position. Secure

with pin. Place wooden block under jack if

ground is soft.

h. Lower jack to raise transporter hitch ring clear

of truck pintle.

i. Drive truck away from transporter.

Form # 169365 OM-12 Issue – May 2008

Page 37

SECTION OM – OPERATOR’S MANUAL

3.6 TOWING THREE-AXLE

TRANSPORTER WITH M SERIES

WINDROWER TRACTOR

3.6.1 Transporter Hookup to Windrower

Adapter Hitch

CAUTION

Significant weight transfer to tractor is

required for steering and braking in

transport. See tractor operators manual.

d. Slowly approach transporter hitch with tractor

and line up pintle with hitch ring on transporter.

e. Stop tractor engine and remove key.

f. Lift transporter hitch onto tractor pintle hitch.

g. Close pintle lock and insert locking pin.

h. Route safety chains through tractor hitch frame

and connect under frame. Ensure hook safety

latches are closed.

a. Open pintle on tractor hitch.

b. Remove two pins and washers on weight

transfer spring assembly and store in holes in

frame.

c. Start tractor and activate header lift cylinders

to lower tractor hitch to ground.

i. Attach breakaway switch lanyard to tractor

hitch.

j. Retrieve electrical plug from transporter and

connect to receptacle on tractor hitch.

CAUTION

If necessary to tow the Transporter

without a header on the Transporter, do

not operate tractor at typical road speed.

Proceed with caution.

(continued next page)

Form # 169365 OM-13 Issue – May 2008

Page 38

SECTION OM – OPERATOR’S MANUAL

IMPORTANT

If transporter is being moved without a

header on it, do not re-install pins in

weight transfer assembly. Store pins in

holes in frame.

k. If header is on transporter, re-insert pins and

washers in slotted holes weight transfer

assembly.

l. Start tractor and raise header lift legs to full

height (towing mode).

m. Stop tractor engine and remove key.

n. Engage header lift cylinder stops. See tractor

operator’s manual.

o. Remove blocks if used, from transporter

wheels.

f. Disconnect wiring harness at tractor.

g. Remove safety chain from tractor and store on

hitch.

3.6.2 Unhook From Windrower Leaving

Adapter Hitch on Transporter

The following procedure is the normal method

for unhooking the transporter from the

windrower tractor.

a. Stop tractor engine and remove key.

b. Block the transporter wheels to prevent

transporter from moving.

c. Disengage header lift cylinder stops.

d. Start tractor and activate header lift cylinders

to lower hitch to ground.

e. Stop engine and remove key.

h. Remove clevis pins from tractor legs and set

aside.

i. Start tractor and back away from hitch.

j. Re-install clevis pins into hitch boots.

Form # 169365 OM-14 Issue – May 2008

Page 39

SECTION OM – OPERATOR’S MANUAL

3.6.3 Windrower Hookup to Adapter Hitch

on Transporter

Refer to paragraph 3.4.1 Attaching Adapter

Hitch to Windrower Tractor.

3.6.4 Transporter Unhook From

Windrower Adapter Hitch

a. Stop tractor engine and remove key.

b. Block the transporter wheels to prevent

transporter from moving.

c. Disengage header lift cylinder stops.

d. Start tractor and activate header lift cylinders

to lower hitch to ground.

h. Remove safety chains from adapter hitch and

store on transporter hitch.

e. Remove two pins and washers on weight

transfer spring assembly and store in holes in

frame.

i. Lift transporter hitch off tractor adapter pintle

hitch.

f. Disconnect breakaway switch lanyard from

adapter hitch and store on transporter.

g. Disconnect electrical plug on adapter hitch.

Form # 169365 OM-15 Issue – May 2008

Page 40

SECTION OM – OPERATOR’S MANUAL

3.7 TOWING THREE-AXLE

TRANSPORTER WITH COMBINE

Only a three-axle transporter can be towed

with a combine when equipped with the

combine towing hitch assembly.

3.7.1 Hookup to Combine

a. If combine hitch not already installed, refer to

SECTION UA. UNLOADING AND SETUP,

Step 3. Set Up Combine Hitch.

IMPORTANT

Ensure hitch allows sufficient clearance

between combine and header reel.

Adjust hitch if required. Refer to

SECTION UA, Step 3. Set Up Combine

Hitch.

b. Extend the tongue as follows to assist in

hitching to the combine.

4. Lower latch so that forward pin rests on

tongue.

c. Start combine and slowly back up so that

tongue slides back into the tow-bar.

d. Continue to back up until latch re-engages the

tongue.

e. Stop combine engine and remove key.

1. Remove pin in tow-bar latch.

2. Lift latch to disengage tongue.

3. Pull tongue to align with combine hitch

and connect to combine. Refer to

combine Operator’s Manual for

instructions on towing equipment with

the combine.

f. Re-install pin in latch to lock tongue.

g. Attach safety chains to combine.

h. Connect transporter electrical plug to combine

receptacle.

(continued next page)

Form # 169365 OM-16 Issue – May 2008

Page 41

SECTION OM – OPERATOR’S MANUAL

NOTE

Receptacle on combine must be a seven

circuit RV type connector.

FRONT VIEW – COVER OPEN

IMPORTANT

Center pin must not be energized.

i. Attach breakaway switch lanyard to combine.

j. Remove blocks from transporter wheels if

applicable.

3.7.2 Unhook From Combine

a. Park transporter on level ground.

b. Shutoff combine engine and remove key.

c. Block the transporter wheels.

d. Disconnect breakaway switch lanyard from

combine.

e. Disconnect electrical plug from combine and

store on transporter.

f. Remove safety chains and breakaway switch

lanyard from combine and store on transporter.

g. Disconnect transporter hitch from combine.

h. Drive combine away from transporter.

Form # 169365 OM-17 Issue – May 2008

Page 42

SECTION OM – OPERATOR’S MANUAL

3.8 TOWING THREE-AXLE

TRANSPORTER WITH TRUCK

CAUTION

Ensure towing vehicle is capable of

handling transporter tongue weight and

gross weight to ensure adequate braking

performance and control.

3.8.1 Hookup to Truck

a. Refer to paragraph 2.1 TRANSPORTER

WEIGHT AND TONGUE WEIGHT DATA for

transporter gross weights and tongue weights.

b. Back up truck to align pintle with transporter

hitch.

c. Shut off truck engine and remove key.

IMPORTANT

Center pin on towing vehicle electrical

receptacle must not be energized,

otherwise the transporter brakes will be

activated. Re-wire receptacle if

necessary.

g. Check that transporter lights and brakes are

functioning.

h. Attach breakaway lanyard to truck hitch.

d. Open pintle and lift transporter hitch onto truck

hitch.

e. Close pintle lock and secure with lynch pin.

f. Attach safety chains to truck and plug in the

electrical connector to truck receptacle.

3.8.2 Unhook from Truck

a. Park transporter on level ground.

b. Shutoff truck engine and remove key.

c. Block the transporter wheels.

d. Disconnect electrical plug from truck and store

on transporter.

e. Remove safety chains and breakaway switch

lanyard from truck and store on transporter.

f. Remove lynch pin from pintle and open pintle.

g. Lift transporter hitch off truck hitch.

h. Drive truck away from transporter.

Form # 169365 OM-18 Issue – May 2008

Page 43

SECTION OM – OPERATOR’S MANUAL

3.9 LOADING D SERIES WINDROWER

HEADER ONTO TRANSPORTER

a. Set up transporter to suit your header. Refer

to Step 2. Configuring The Transporter in

SECTION UA. UNLOADING AND SETUP.

b. Block the transporter wheels.

3.9.1 Prepare the Header

a. Raise the stabilizer wheels on header as

follows:

C

B

A

D

1. Support wheel weight by lifting slightly

with one hand on handle (A), and pull up

on handle (B) to release lock.

2. Lift wheel with handle (A) to uppermost

position and engage support channel

into slot (C) in upper support.

3. Push down on handle (B) to lock.

b. The right hand stabilizer wheel on 35 ft

headers needs to be removed prior to loading

onto two-axle and three-axle transporters.

1. Remove clevis pin (D) securing axle to

axle support.

2. Remove wheel assembly (E) and reinstall clevis pin in axle or axle support.

3. Store wheel assembly on header deck or

in truck bed.

c. If towing on road or highway with truck,

remove and store the crop dividers in location

provided on end sheet. Refer to header

Operator’s Manual.

E

d. If loading header for the first time, remove the

two leg guides and hardware that are secured

to the transporter left center support. Discard

bolt and nut.

e. Install leg guides on header as follows:

LH LEG

RH LEG

1. Raise header fully, shut down windrower

engine and remove key.

2. Engage both header lift cylinder stops.

3. Locate leg guides on outboard side of

both center legs on header. Secure

each guide with four bolts and nuts.

Form # 169365 OM-19 Issue – May 2008

Page 44

SECTION OM – OPERATOR’S MANUAL

3.9.2 Prepare the Transporter

a. Ensure both cutterbar tie-downs on transporter

are in the down position and the transporter is

cleared of tools or other debris that may

damage the header.

3.9.3 Loading Procedure

a. Disengage header lift cylinder stops and start

windrower.

b. Approach transporter from left hand side, lining

up the mid-point of the header (center-link)

with the mid-point of the two center supports

on the transporter.

NOTE

Orange or red marking tape on the

transporter frame identifies the mid-point

between the center cutterbar supports.

Tape may need to be relocated

depending on header configuration.

Refer to SECTION UA. Step 2.

Configuring the Transporter.

TIP

Mark the center guard with fluorescent

paint/marker or equivalent to assist in

lining up header with transporter. The

b. Remove hairpin on left support tube and slide

support tube to inboard side of support. Reinstall hairpin.

c. Remove hairpin to remove chain from storage

position on support tube.

Form # 169365 OM-20 Issue – May 2008

center guard is at the mid-point of the

header opening.

(continued next page)

Page 45

SECTION OM – OPERATOR’S MANUAL

c. Slowly continue forward until the guards touch

the white plastic stops on the transporter.

Lower header as required so that the white

plastic stops remain visible from the operator’s

station.

d. Slowly lower header onto transporter cutterbar

supports.

IMPORTANT

Header should rest firmly in and against

the support pockets.

g. Lower reel fully and retract to aft position.

h. Shutdown windrower and remove key.

i. Disconnect reel and header drive hydraulics

and store on tractor. Refer to header

operator’s manual.

j. Disengage header float springs and disconnect

center link. Refer to tractor operator’s manual.

e. Back up slightly until cutterbar guard tips

approximately line up with the top plate on the

cutterbar support.

k. Remove the two pins securing header boots to

tractor.

l. Start windrower and back away from header.

3.9.4 Engage Cutterbar Tie-downs

CAUTION

Cutterbar tie-downs must be engaged

before transporting header. Failure to do

so may result in header shifting on

transporter and damage to header or

transporter.

f. Continue to lower header until leg guides

contact supports at rear of header and header

is resting fully on the transporter.

Form # 169365 OM-21 Issue – May 2008

a. Remove lynch pin from storage location on

lever.

(continued next page)

Page 46

SECTION OM – OPERATOR’S MANUAL

b. Position hook onto cutterbar lower edge.

c. Pull lever to lock hook onto cutterbar. The tie-

down is an over-center locking system and

should require a firm pull to lock the hook.

d. Re-install lynch pin in lever to lock into

position.

e. If the cutterbar tie-down does not latch

properly, adjust as follows:

1. Check that header is properly positioned

on transporter.

3. Back-off the two nuts below pivot with

the lever in the up position.

4. Position tie-down with hook firmly

engaging the cutterbar. Tighten the two

attachment bolts.

5. Lower lever and tighten nuts slightly.

6. Raise lever. Lever should over-center

2. Loosen the two tie-down attachment

bolts.

with a firm pull. Adjust nuts as required.

7. Repeat above steps 2 to 6 for other tiedown.

Form # 169365 OM-22 Issue – May 2008

Page 47

SECTION OM – OPERATOR’S MANUAL

3.9.5 Attach Header Anchor Chain

a. If first use, undo bolt to remove retaining plate

at end of chain.

b. Install retaining plate in keyhole slot in header

RH leg with bolt removed in previous step. Do

not fully tighten as plate must be able to

swivel.

c. Swivel retaining plate and install chain in

keyhole slot. Tighten bolt on plate to secure

chain in slot.

Form # 169365 OM-23 Issue – May 2008

Page 48

SECTION OM – OPERATOR’S MANUAL

3.10 UNLOADING D SERIES

WINDROWER HEADER

a. Block the transporter wheels.

f. Remove pins from header boots.

b. Loosen bolt on anchor chain retaining plate

and swivel plate off chain.

c. Remove chain from slot.

d. Remove lynch pins from both cutterbar tie-

downs and push levers down to disengage

hooks from cutterbar.

g. Rotate latch on centerlink to down position.

h. Approach header with windrower tractor and

line up lift legs with header boots.

i. Continue forward so that tractor legs engage

header boots.

(continued next page)

e. Store lynch pin in hole provided on lever.

Form # 169365 OM-24 Issue – May 2008

Page 49

SECTION OM – OPERATOR’S MANUAL

j. Connect center link as follows:

MECHANICAL LINK – M150

1. Loosen nut and rotate barrel to adjust

length so that link lines up with header

bracket.

2. Install pin and secure with cotter pin.

3. Tighten nut against barrel. A slight tap

with a hammer is sufficient.

HYDRAULIC LINK – M200 STD, M150 OPTION

1. Activate header tilt cylinder switches in

tractor to position center link cylinder so

that it can connect to header.

n. Install pins into tractor legs to secure header

boots onto legs.

o. Back slowly away from transporter.

2. Push down on rod end of link cylinder

until hook engages pin on header and is

locked.

NOTE

If optional auto-connect system is

installed, activate link lift cylinder from in

the cab to lower center link onto header.

k. Activate header lift cylinders on tractor to lift

header slightly. Ensure that centerlink

securely engages pin on header. Raise

header fully.

l. Shutdown tractor engine and remove key.

m. Engage lift cylinder locks on tractor.

p. Secure anchor chain to transporter support

with hairpin.

q. Re-install stabilizer wheel and crop dividers

onto header.

Form # 169365 OM-25 Issue – May 2008

Page 50

SECTION OM – OPERATOR’S MANUAL

3.11 LOADING D AND FD SERIES

COMBINE HEADER

a. Set up transporter to suit your header. Refer

to Step 2. Configuring The Transporter in

SECTION UA. UNLOADING AND SETUP.

b. Block the transporter wheels.

3.11.1 Prepare the Header and Transporter

a. Raise the stabilizer wheels on header as

follows:

C

B

E

d. If loading header for the first time, remove the

two leg guides and hardware that are secured

to the transporter center support. Discard bolt

and nut.

e. Install leg guides on header as follows:

1. Raise header fully, shut down combine

engine and remove key.

2. Engage both header lift cylinder stops.

Refer to combine operator’s manual.

A

D

1. Support wheel weight by lifting slightly

with one hand on handle (A), and pull up

on handle (B) to release lock.

2. Lift wheel with handle (A) to uppermost

position and engage support channel

into slot (C) in upper support.

3. Push down on handle (B) to lock.

b. The right hand stabilizer wheel on 35 ft

headers needs to be removed prior to loading

onto two-axle and three-axle transporters.

1. Remove clevis pin (D) securing axle to

axle support.

2. Remove wheel assembly (E) and reinstall clevis pin in axle or axle support.

3. Store wheel assembly on header deck or

in truck bed.

c. If towing on road or highway with truck,

remove and store the crop dividers in location

provided on end sheet. Refer to header

Operator’s Manual.

RH LEG

LH LEG

3. Insert four bolts in each leg from inside.

NOTE

If necessary, use a pry bar to allow

installation of bolts into leg.

(continued next page)

Form # 169365 OM-26 Issue – May 2008

Page 51

SECTION OM – OPERATOR’S MANUAL

f. Locate leg guides on bolts and secure with

nuts.

g. Ensure both cutterbar tie-downs on transporter

are in the down position and the transporter is

cleared of tools or other debris that may

damage the header.

3.11.2 Loading Procedure

a. Disengage header lift cylinder stops and start

combine.

b. Approach transporter from left hand side, lining

up the mid-point of the header (center-link)

with the mid-point of the two center supports

on the transporter.

NOTE

Orange or red marking tape on the

transporter frame identifies the mid-point

between the center cutterbar supports.

Tape may need to be relocated

depending on header configuration.

Refer to SECTION UA. Step 2.

Configuring the Transporter.

TIP

Mark the center guard with fluorescent

paint/marker or equivalent to assist in

lining up header with transporter. The

center guard is at the mid-point of the

header opening.

c. Slowly continue forward until the guards touch

the white plastic stops on the transporter.

Lower header as required so that the white

plastic stops remain visible from the operator’s

station.

(continued next page)

Form # 169365 OM-27 Issue – May 2008

Page 52

SECTION OM – OPERATOR’S MANUAL

d. Slowly lower header onto transporter cutterbar

supports.

e. Back up slightly until cutterbar guard tips

approximately line up with the top plate on the

cutterbar support.

f. Continue to lower header until leg guides

contact supports at rear of header and the

header is resting fully on the transporter.

IMPORTANT

Header should rest firmly in and against

the support pockets.

RIGID HEADER – LH SUPPORT

RIGID HEADER – RH SUPPORT

FLEX HEADER – LH SUPPORT

FLEX HEADER – RH SUPPORT

g. Detach header/adapter from combine. Refer

to CA20 Combine Adapter Operator’s Manual.

h. Engage cutterbar tie-downs. Refer to

paragraph 3.9.4 Engage Cutterbar Tie-downs.

i. Attach header anchor chain. Refer to

paragraph 3.9.5 Attach Header Anchor Chain.

Form # 169365 OM-28 Issue – May 2008

Page 53

SECTION OM – OPERATOR’S MANUAL

3.12 UNLOADING D AND FD SERIES

COMBINE HEADER

a. Block the transporter wheels.

e. Leave lever in lowered position and store lynch

pin in hole provided on lever.

f. Attach combine to header/adapter. Refer to

CA20 Combine Adapter Operator’s Manual.

g. Activate header lift cylinders on combine to lift

header off transporter.

h. Back slowly away from transporter.

b. Loosen bolt on anchor chain retaining plate

and swivel plate off chain.

c. Remove chain from slot.

d. Remove lynch pins from both cutterbar tie-

downs and push levers down to disengage

hooks from cutterbar.

i. Secure anchor chain to transporter support

with hairpin.

j. Re-install stabilizer wheel (if removed) and

crop dividers onto header.

Form # 169365 OM-29 Issue – May 2008

Page 54

SECTION OM – OPERATOR’S MANUAL

3.13 ATTACHING/DETACHING CA20

COMBINE ADAPTER

The combine and CA20 Combine Adapter may

be detached from the header and then reattached with the header loaded on the MT8

transporter. Refer to the CA20 Combine

Adapter Operator’s Manual for instructions.

3.14 STORAGE

Do the following at the end of each operating

season:

a. Clean the transporter thoroughly.

CAUTION

Never use gasoline, naphtha or any

volatile material for cleaning purposes.

These materials may be toxic and/or

flammable.

b. Store in a dry, protected place if possible.

c. Repaint all worn or chipped painted surfaces to

prevent rust.

d. Apply grease to exposed threads, and sliding

surfaces of components.

e. Check for worn components and repair.

f. Check for broken components and order

replacements from your dealer. Attention to

these items right away will save time and effort

at beginning of next season.

g. Replace or tighten any missing or loose

hardware. Refer to SECTION G, Paragraph 2,

Recommended Torques.

Form # 169365 OM-30 Issue – May 2008

Page 55

SECTION OM – OPERATOR’S MANUAL

4 MAINTENANCE

4.1 RECOMMENDED SAFETY

PROCEDURES

• Park on level surface when possible.

Block wheels securely if windrower is

parked on an incline.

• Follow all safety procedures in Section

G, Paragraph 1, Safety Instructions.

4.2 LUBRICATING THE

TRANSPORTER

4.2.1 Lubricants

LUBRICANT SPEC DESCRIPTION USE

Grease SAE Multi-

Purpose.

High Temp.

Extreme Pressure

(EP). 0-1% Max

Molybdenum

Disulphide (NLGI

Grade 2).

Lithium Complex

Base.

Base Oil Viscosity

of 190-250 CST @

40C.

As Required

Unless

Otherwise

Specified.

4.2.2 Lubricant Storage

a. Use clean containers to handle all lubricants.

b. Store in an area protected from dust, moisture,

and other contaminants.

4.2.3 Greasing Requirements

Refer to Paragraph 4.5 Maintenance Schedule

for lubrication intervals.

b. Inject grease until bearings are fully packed

with grease.

c. Replace rubber end cap.

a. Remove rubber end cap to expose grease

zerk.

Form # 169365 OM-31 Issue – May 2008

Page 56

SECTION OM – OPERATOR’S MANUAL

4.3 WHEELS AND TIRES

DANGER

Stop engine and remove key from ignition

before leaving operator's seat for any

reason. A child or even a pet could

engage an idling machine.

4.3.1 Wheel Nuts

1

6

3

4

5

2

4.3.2 Wheel - Removal/Installation

DANGER

Stop engine and remove key from ignition

before leaving operator's seat for any

reason. A child or even a pet could

engage an idling machine.

4.3.2.1 Removal

IMPORTANT

If transporter is not attached to towing

vehicle, block transporter wheels to

prevent movement.

a. Loosen wheel nuts slightly.

NOTE

Minimum jack capacity – 5000 lb (2270

kg).

IMPORTANT

Check and tighten wheel nuts after the