Kohler 24RCL User Manual

Operation

Residential/Light Commercial Generator Sets

Model:

24RCL

Controller:

RDC2

TP-6905 6/14

California Proposition 65

WARNING

Engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Product Identification Information

Product identification numbers determine service parts. Record the product identification numbers in the spaces below immediately after unpacking the products so that the numbers are readily available for future reference. Record field-installed kit numbers after installing the kits.

Controller Identification

Record the controller description from the generator set operation manual, spec sheet, or sales invoice.

Controller Description

Generator Set Identification Numbers

Record the product identification numbers from the generator set nameplate(s).

Model Designation

Specification Number

Serial Number

Accessory Number |

|

Accessory Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine Identification

Record the product identification information from the engine nameplate.

Manufacturer Model Designation Serial Number

2 |

TP-6905 6/14 |

Table of Contents

Product Identification Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions and Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 1 Service Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 2 Generator Set Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 |

Operating Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

2.2 |

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

2.3 |

Exercising the Generator Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

2.4 |

Generator Set Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

|

2.4.1 |

Local Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

2.4.2 |

Automatic Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

2.4.3 |

Remote Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

2.4.4 |

Engine Start Crank Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

2.4.5 |

Engine Cooldown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

2.4.6 |

Automatic Operation with Model RXT Transfer Switch . . . . . . . . . . . . . . |

16 |

|

2.4.7 |

Automatic Operation with Model RDT or RSB Transfer Switches . . . . . |

17 |

2.5 |

Exercise |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

2.5.1 |

Unloaded Cycle Exercise with Complete System Diagnostics . . . . . . . . |

17 |

|

2.5.2 |

Unloaded Full-Speed Exercise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

2.5.3 |

Loaded Full-Speed Exercise (with RXT only) . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

2.5.4 |

Shutdown During Exercise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

2.5.5 |

Power Failure During Exercise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

2.5.6 |

Exerciser Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

2.5.7 |

Setting the Exerciser at Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

2.5.8 |

Changing the Exercise Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

2.6 |

Faults . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

2.6.1 |

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

2.6.2 |

Shutdowns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

2.6.3 |

ATS Communication Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

2.6.4 |

Resetting the Controller after a Fault Shutdown . . . . . . . . . . . . . . . . . . . . |

22 |

|

2.6.5 |

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

2.7 |

Model RXT Transfer Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

|

2.7.1 |

Source Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

2.7.2 |

ATS Control Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

2.7.3 |

Time Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

2.7.4 |

ATS Load Control Relay Time Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

Section 3 RDC2 Controller Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

||

3.1 |

RDC2 Generator Set/Transfer Switch Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

3.2 |

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

3.2.1 |

Controller Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

3.2.2 |

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

3.2.3 |

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

3.3 |

Controller Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

3.4 |

Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

3.5 |

Changing Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

3.6 |

Controller Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

3.7 |

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

3.8 |

Overview Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

3.9 |

Engine Metering Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

3.10 |

Generator Metering Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

|

3.11 |

Generator Set Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

TP-6905 6/14 |

Table of Contents 3 |

Table of Contents, continued

3.12 |

Genset Run Time Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

3.13 |

Genset System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

|

3.14 |

ATS Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

|

3.15 |

ATS Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

3.16 |

Date and Time Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

|

3.17 |

Networking Information Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|

|

3.17.1 |

Networking Status Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

3.17.2 |

Networking Configuration Submenu (OnCue Plus Password) . . . . . . . . |

44 |

|

3.17.3 |

RBUS Information Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

3.17.4 |

Remote Devices Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

3.18 |

Programmable Interface Module (PIM) Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

3.19 |

Load Control Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

Section 4 Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

||

4.1 |

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

4.2 |

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

4.3 |

Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

|

4.3.1 |

Oil Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

4.3.2 |

Oil Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

4.3.3 |

Oil Additions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

4.3.4 |

Oil and Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

4.4 |

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

|

4.5 |

Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

|

4.6 |

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

|

|

4.6.1 |

Checking and Filling Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

|

4.6.2 |

Cooling System Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

4.6.3 |

Draining Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

4.6.4 |

Flushing and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

4.6.5 |

Filling Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

4.7 |

Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

|

4.8 |

Battery . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

59 |

4.9 |

Storage Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

60 |

|

Section 5 Troubleshooting . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

5.1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

5.2 |

USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

5.3 |

Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

5.4 |

Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

|

5.4.1 |

Load Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

5.4.2 |

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

5.4.3 |

Controller Internal Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

5.5 |

Generator Set Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

|

5.6 |

Controller Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

|

Appendix A Abbreviations . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

4 Table of Contents |

TP-6905 6/14 |

Safety Precautions and Instructions

IMPORTANT SAFETY INSTRUCTIONS.

Electromechanical equipment, including generator sets, transfer switches, switchgear, and accessories, can cause bodily harm and pose life-threatening danger when improperly installed, operated, or maintained. To prevent accidents be aware of potential dangers and act safely. Read and follow all safety precautions and instructions. SAVE THESE INSTRUCTIONS.

This manual has several types of safety precautions and instructions: Danger, Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a hazard that will cause severe personal injury, death, or substantial property damage.

WARNING

Warning indicates the presence of a hazard that can cause severe personal injury, death, or substantial property damage.

CAUTION

Caution indicates the presence of a hazard that will or can cause minor personal injury or property damage.

NOTICE

Notice communicates installation, operation, or maintenance information that is safety related but not hazard related.

Safety decals affixed to the equipment in prominent places alert the operator or service technician to potential hazards and explain how to act safely. The decals are shown throughout this publication to improve operator recognition. Replace missing or damaged decals.

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before working on the generator set. Remove the negative (--) lead first when disconnecting the battery. Reconnect the negative (--) lead last when reconnecting the battery.

Disabling the generator set. Accidental starting can cause severe injury or death. Before working on the generator set or equipment connected to the set, disable the generator set as follows:

(1)Press the generator set off/reset button to shut down the generator set.

(2)Disconnect the power to the battery charger, if equipped. (3) Remove the battery cables, negative (--) lead first. Reconnect the negative (--) lead last when reconnecting the battery. Follow these precautions to prevent the starting of the generator set by the remote start/stop switch.

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and clothing. Battery acid may cause blindness and burn skin.

WARNING

Explosion.

Can cause severe injury or death. Relays in the battery charger cause arcs or sparks.

Locate the battery in a well-ventilated area. Isolate the battery charger from explosive fumes.

Battery electrolyte is a diluted sulfuric acid. Battery acid can cause severe injury or death. Battery acid can cause blindness and burn skin. Always wear splashproof safety goggles, rubber gloves, and boots when servicing the battery. Do not open a sealed battery or mutilate the battery case. If battery acid splashes in the eyes or on the skin, immediately flush the affected area for 15 minutes with large quantities of clean water. Seek immediate medical aid in the case of eye contact. Never add acid to a battery after placing the battery in service, as this may result in hazardous spattering of battery acid.

Battery acid cleanup. Battery acid can cause severe injury or death.

Battery acid is electrically conductive and corrosive. Add 500 g (1 lb.) of bicarbonate of soda (baking soda) to a container with 4 L (1 gal.) of water and mix the neutralizing solution. Pour the neutralizing solution on the spilled battery acid and continue to add the neutralizing solution to the spilled battery acid until all evidence of a chemical reaction (foaming) has ceased. Flush the resulting liquid with water and dry the area.

Battery gases. Explosion can cause severe injury or death. Battery gases can cause an explosion. Do not smoke or permit flames or sparks to occur near a battery at any time, particularly when it is charging. Do not dispose of a battery in a fire. To prevent burns and sparks that could cause an explosion, avoid touching the battery terminals with tools or other metal objects. Remove all jewelry before servicing the equipment. Discharge static electricity from your body before touching batteries by first touching a grounded

TP-6905 6/14 |

Safety Precautions and Instructions |

5 |

metal surface away from the battery. To avoid sparks, do not disturb the battery charger connections while the battery is charging. Always turn the battery charger off before disconnecting the battery connections. Ventilate the compartments containing batteries to prevent accumulation of explosive gases.

Battery short circuits. Explosion can cause severe injury or death.

Short circuits can cause bodily injury and/or equipment damage. Disconnect the battery before generator set installation or maintenance. Remove all jewelry before servicing the equipment. Use tools with insulated handles. Remove the negative (--) lead first when disconnecting the battery. Reconnect the negative (--) lead last when reconnecting the battery. Never connect the negative (--) battery cable to the positive (+) connection terminal of the starter solenoid. Do not test the battery condition by shorting the terminals together.

Engine Backfire/Flash

Fire

WARNING

Fire.

Can cause severe injury or death.

Do not smoke or permit flames or sparks near fuels or the fuel system.

Servicing the fuel system. A flash fire can cause severe injury or death.

Do not smoke or permit flames or sparks near the carburetor, fuel line, fuel filter, fuel pump, or other potential sources of spilled fuels or fuel vapors. Catch fuels in an approved container when removing the fuel line or carburetor.

Servicing the air cleaner. A sudden backfire can cause severe injury or death. Do not operate the generator set with the air cleaner removed.

Combustible materials. A fire can cause severe injury or death.

Generator set engine fuels and fuel vapors are flammable and explosive. Handle these materials carefully to

minimize the risk of fire or explosion. Equip the compartment or nearby area with a fully charged fire extinguisher. Select a fire extinguisher rated ABC or BC for electrical fires or as recommended by the local fire code or an authorized agency. Train all personnel on fire extinguisher operation and fire prevention procedures.

Exhaust System

WARNING

Carbon monoxide.

Can cause severe nausea, fainting, or death.

The exhaust system must be leakproof and routinely inspected.

Generator set operation. Carbon monoxide can cause severe nausea, fainting, or death. Carbon monoxide is an odorless, colorless, tasteless, nonirritating gas that can cause death if inhaled for even a short time. Avoid breathing exhaust fumes when working on or near the generator set. Never operate the generator set inside a building. Never operate the generator set where exhaust gas could seep inside or be drawn into a potentially occupied building through windows, air intake vents, or other openings.

Carbon monoxide symptoms. Carbon monoxide can cause severe nausea, fainting, or death. Carbon monoxide is a poisonous gas present in exhaust gases. Carbon monoxide is an odorless, colorless, tasteless, nonirritating gas that can cause death if inhaled for even a short time. Carbon monoxide poisoning symptoms include but are not limited to the following:

D Light-headedness, dizziness

DPhysical fatigue, weakness in joints and muscles

DSleepiness, mental fatigue, inability to concentrate

or speak clearly, blurred vision D Stomachache, vomiting, nausea

If experiencing any of these symptoms and carbon monoxide poisoning is possible, seek fresh air immediately and remain active. Do not sit, lie down, or fall asleep. Alert others to the

possibility of carbon monoxide poisoning. Seek medical attention if the condition of affected persons does not improve within minutes of breathing fresh air.

Carbon monoxide detectors. Carbon monoxide can cause severe nausea, fainting, or death. Install carbon monoxide detectors on each level of any building adjacent to the generator set. Locate the detectors to adequately warn the building’s occupants of the presence of carbon monoxide. Keep the detectors operational at all times. Periodically test and replace the carbon monoxide detectors according to the manufacturer’s instructions.

Fuel System

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling, storing, and using fuels.

The fuel system. Explosive fuel vapors can cause severe injury or death. Vaporized fuels are highly explosive. Use extreme care when handling and storing fuels. Store fuels in a well-ventilated area away from spark-producing equipment and out of the reach of children. Never add fuel to the tank while the engine is running because spilled fuel may ignite on contact with hot parts or from sparks. Do not smoke or permit flames or sparks to occur near sources of spilled fuel or fuel vapors. Keep the fuel lines and connections tight and in good condition. Do not replace flexible fuel lines with rigid lines. Use flexible sections to avoid fuel line breakage caused by vibration. Do not operate the generator set in the presence of fuel leaks, fuel accumulation, or sparks. Repair fuel systems before resuming generator set operation.

Explosive fuel vapors can cause severe injury or death. Take additional precautions when using the following fuels:

6 |

Safety Precautions and Instructions |

TP-6905 6/14 |

Propane (LP)—Adequate ventilation is mandatory. Because propane is heavier than air, install propane gas detectors low in a room. Inspect the detectors per the manufacturer’s instructions.

Natural Gas—Adequate ventilation is mandatory. Because natural gas rises, install natural gas detectors high in a room. Inspect the detectors per the manufacturer’s instructions.

Gas fuel leaks. Explosive fuel vapors can cause severe injury or death. Fuel leakage can cause an explosion. Check the LP vapor gas or natural gas fuel system for leakage by using a soap and water solution with the fuel system test pressurized to 6--8 ounces per square inch (10--14 inches water column). Do not use a soap solution containing either ammonia or chlorine because both prevent bubble formation. A successful test depends on the ability of the solution to bubble.

Hazardous Noise

CAUTION

Hazardous noise.

Can cause hearing loss.

Never operate the generator set without a muffler or with a faulty exhaust system.

Engine noise. Hazardous noise can cause hearing loss. Generator sets not equipped with sound enclosures can produce noise levels greater than 105 dBA. Prolonged exposure to noise levels greater than 85 dBA can cause permanent hearing loss. Wear hearing protection when near an operating generator set.

Hazardous Voltage/

Moving Parts

DANGER

Hazardous voltage.

Will cause severe injury or death.

Disconnect all power sources before opening the enclosure.

WARNING

Hazardous voltage. Moving parts. Can cause severe injury or death.

Operate the generator set only when all guards and electrical enclosures are in place.

WARNING

Hazardous voltage.

Backfeed to the utility system can cause property damage, severe injury, or death.

If the generator set is used for standby power, install an automatic transfer switch to prevent inadvertent interconnection of standby and normal sources of supply.

DANGER

Hazardous voltage.

Will cause severe injury or death.

This equipment must be installed and serviced by qualified electrical personnel.

CAUTION

Welding the generator set.

Can cause severe electrical equipment damage.

Never weld components of the generator set without first disconnecting the battery, controller wiring harness, and engine electronic control module (ECM).

WARNING

Airborne particles.

Can cause severe injury or blindness.

Wear protective goggles and clothing when using power tools, hand tools, or compressed air.

Grounding electrical equipment. Hazardous voltage can cause severe injury or death. Electrocution is possible whenever electricity is present. Ensure you comply with all applicable codes and standards. Electrically ground the generator set, transfer switch, and related equipment and electrical circuits. Turn off the main circuit breakers of all power sources before servicing the equipment. Never contact electrical leads or appliances when standing in water or on wet ground because these conditions increase the risk of electrocution.

Disconnecting the electrical load. Hazardous voltage can cause severe injury or death. Disconnect the generator set from the load by turning off the line circuit breaker or by disconnecting the generator set output leads from the transfer switch and heavily taping the ends of the leads. High voltage transferred to the load during testing may cause personal injury and equipment damage. Do not use the safeguard circuit breaker in place of the line circuit breaker. The safeguard circuit breaker does not disconnect the generator set from the load.

TP-6905 6/14 |

Safety Precautions and Instructions |

7 |

Welding on the generator set. Can cause severe electrical equipment damage. Before welding on the generator set perform the following steps: (1) Remove the battery cables, negative (--) lead first. (2) Disconnect all engine electronic control module (ECM) connectors. (3) Disconnect all generator set controller and voltage regulator circuit board connectors.

(4) Disconnect the engine batterycharging alternator connections.

(5) Attach the weld ground connection close to the weld location.

Connecting the battery and the battery charger. Hazardous voltage can cause severe injury or death.

Reconnect the battery correctly, positive to positive and negative to negative, to avoid electrical shock and damage to the battery charger and battery(ies). Have a qualified electrician install the battery(ies).

Short circuits. Hazardous voltage/current can cause severe injury or death. Short circuits can cause bodily injury and/or equipment damage. Do not contact electrical connections with tools or jewelry while making adjustments or repairs. Remove all jewelry before servicing the equipment.

Engine oil pan heater. Hazardous voltage can cause severe injury or death. The engine oil pan heater can cause electrical shock. Disconnect power to the engine oil pan heater and allow to cool before working on the oil pan heater electrical connections.

Electrical backfeed to the utility. Hazardous backfeed voltage can cause severe injury or death. Install a transfer switch in standby power installations to prevent the connection of standby and other sources of power. Electrical backfeed into a utility electrical system can cause severe injury or death to utility personnel working on power lines.

Servicing the generator set when it is operating. Exposed moving parts can cause severe injury or death.

Keep hands, feet, hair, clothing, and test leads away from the belts and pulleys when the generator set is running. Replace guards, screens, and covers before operating the generator set.

Hot Parts

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap, stop the generator set and allow it to cool. Then loosen the pressure cap to relieve pressure.

WARNING

Hot engine and exhaust system. Can cause severe injury or death.

Do not work on the generator set until it cools.

Servicing the alternator. Hot parts can cause severe injury or death.

Avoid touching the alternator field or exciter armature. When shorted, the alternator field and exciter armature become hot enough to cause severe burns.

Servicing the exhaust system. Hot parts can cause severe injury or death. Do not touch hot engine parts. The engine and exhaust system components become extremely hot during operation.

Servicing the engine oil pan heater. Heated components can cause severe injury. The oil pan heater will rapidly become hot when energized. Do not touch the oil pan heater while it is hot. Disconnect power to the engine oil pan heater and allow to cool before servicing it or nearby parts.

Notice

NOTICE

Canadian installations only. For standby service connect the output of the generator set to a suitably rated transfer switch in accordance with Canadian Electrical Code, Part 1.

NOTICE

Electrostatic discharge damage.

Electrostatic discharge (ESD) damages electronic circuit boards. Prevent electrostatic discharge damage by wearing an approved grounding wrist strap when handling electronic circuit boards or integrated circuits. An approved grounding wrist strap provides a high resistance (about 1 megohm), not a direct short, to ground.

8 |

Safety Precautions and Instructions |

TP-6905 6/14 |

Introduction

This manual provides operation instructions for Model 24RCL and 30RCLH residential/light commercial generator sets equipped with the RDC2 generator set/transfer switch controller.

This generator set is approved for use in stationary applications in locations served by a reliable utility power source. Have the generator set installed by an authorized Kohler distributor/dealer or service technician. Refer to the Installation Manual for installation instructions.

Information in this publication represents data available at the time of print. Kohler Co. reserves the right to change this publication and the products represented without notice and without any obligation or liability whatsoever.

Read this manual and carefully follow all procedures and safety precautions to ensure proper equipment operation and to avoid bodily injury. Read and follow the Safety Precautions and Instructions section at the beginning of this manual. Keep this manual with the equipment for future reference.

The equipment maintenance requirements are very important for safe and efficient operation. Inspect the parts often and perform required maintenance at the prescribed intervals. Obtain service from an authorized Kohler distributor/ dealer or service technician to keep equipment in top condition.

GM91044--MA2

Figure 1 Model 24RCL Generator Set

Nameplate

Figure 2 shows a typical generator set nameplate. Copy the model, serial, and specification numbers from the nameplate into the spaces provided in the product information section on the inside front cover of this manual. See the service view in Section 1 for the nameplate location.

GM12070

Figure 2 Nameplate, Typical

TP-6905 6/14 |

Introduction |

9 |

List of Related Literature

Figure 3 identifies related literature available for the generator sets covered in this manual. Only trained and qualified personnel should install or service the generator set.

Literature Type |

Part Number |

|

|

Specification Sheet, 24RCL |

G4-228 |

|

|

Specification Sheet, 30RCLH |

G4-230 |

|

|

Installation Manual, Generator Set |

TP-6906 |

|

|

Operation Manual, KG2204 Engine |

TP-6901 |

|

|

Service Manual, Generator Set |

TP-6907 |

|

|

Service Manual, KG2204 Engine |

|

Mechanical |

TP-6902 |

|

|

Service Manual, Engine ECM |

|

Diagnostics |

TP-6903 |

|

|

Parts Catalog, KG2204 Engine |

TP-6904 |

|

|

Parts Catalog, 24RCL and 30RCLH |

|

Generator Set |

TP-6908 |

|

|

Installation Instructions, Load Control |

|

Module (LCM) |

TT-1574 |

|

|

Installation Instructions, Programmable |

|

Interface Module (PIM) |

TT-1584 |

|

|

Operation Manual, OnCuet Plus |

|

Software |

TP-6928 |

|

|

Operation/Installation Manual, RXT ATS |

TP-6807 |

|

|

Operation/Installation Manual, RDT ATS |

TP-6345 |

|

|

Installation Manual, RSB Transfer Switch |

TP-6486 |

|

|

Operation Manual, RSB Transfer Switch |

TP-6487 |

Figure 3 Related Literature

10 Introduction |

TP-6905 6/14 |

Service Assistance

For professional advice on generator set power requirements and conscientious service, please contact your nearest authorized Kohler distributor or dealer.

D Consult the Yellow Pages under the heading Generators—Electric.

D Visit the Kohler Power Systems website at KohlerPower.com.

DLook at the labels and stickers on your Kohler product or review the appropriate literature or documents included with the product.

D Call toll free in the US and Canada 1-800-544-2444.

DOutside the US and Canada, call the nearest regional office.

Headquarters Europe, Middle East, Africa

(EMEA)

Kohler Power Systems Netherlands B.V. Kristallaan 1

4761 ZC Zevenbergen The Netherlands Phone: (31) 168 331630 Fax: (31) 168 331631

Asia Pacific

Power Systems Asia Pacific Regional Office Singapore, Republic of Singapore

Phone: (65) 6264-6422 Fax: (65) 6264-6455

China

North China Regional Office, Beijing

Phone: (86) 10 6518 7950

(86) 10 6518 7951

(86) 10 6518 7952

Fax: (86) 10 6518 7955

East China Regional Office, Shanghai

Phone: (86) 21 6288 0500

Fax: (86) 21 6288 0550

India, Bangladesh, Sri Lanka

India Regional Office

Bangalore, India

Phone: (91) 80 3366208

(91) 80 3366231

Fax: (91) 80 3315972

Japan, Korea

North Asia Regional Office

Tokyo, Japan

Phone: (813) 3440-4515

Fax: (813) 3440-2727

Latin America

Latin America Regional Office

Lakeland, Florida, USA

Phone: (863) 619-7568

Fax: (863) 701-7131

TP-6905 6/14 |

Service Assistance 11 |

Notes

12 Service Assistance |

TP-6905 6/14 |

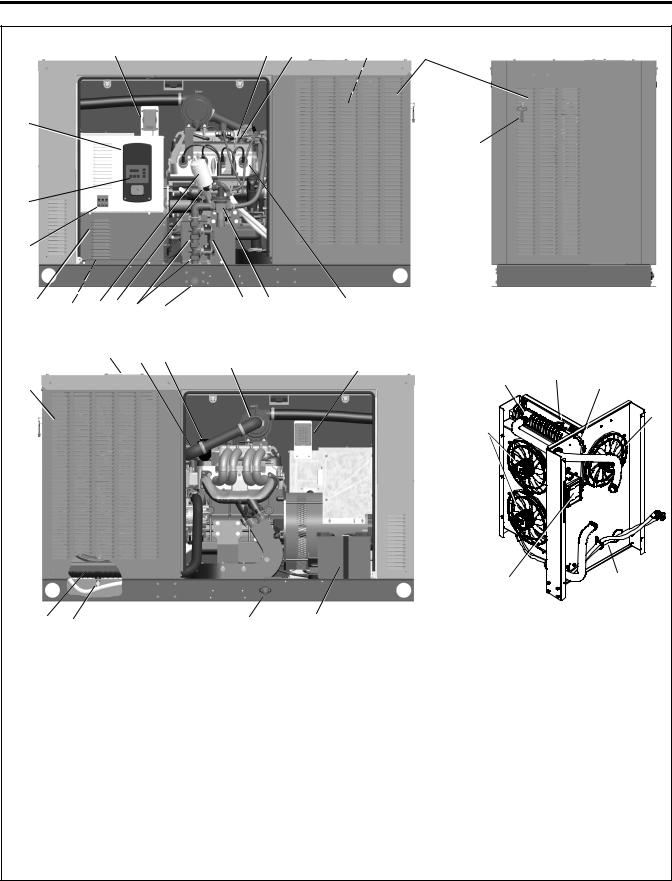

Section 1 Service Views

19 |

1 |

2 |

18

17

16

15

14 |

13 |

12 11 |

10 |

9 |

21 22 23

20

28 27

8 7 SERVICE SIDE

24

26 25 NON-SERVICE SIDE

1.Oil check (dipstick)

2.Oil fill location (on valve cover)

3.See cooling system detail

4.Exhaust outlet

5.Enclosure locking tool (shipping location only)

6.Spark plugs

7.EPR (electronic fuel pressure regulator)

8.Engine ECM

9.Fuel inlet (1 in. NPT)

10.Fuel solenoid valves (qty. 2 shown)

11.Oil cooler adapter (model 30RCLH only)

12.Lube oil filter

13.Customer load lead access

14.Customer connection access panel

15.Line circuit breaker

16.Generator set master control buttons (on RDC2 controller)

17.Nameplate location

3 4

5

6

19 |

30 |

31 |

|

|

32 |

||

|

|

||

|

|

|

|

|

|

|

29 |

|

29 |

|

|

34 |

33 |

GM90230

ADV-8641

Cooling System Detail

18.RDC2 controller

19.Fan fuses

20.Cooling air inlet (remove this panel to access coolant drain)

21.Access to coolant fill

22.Air-fuel mixer

23.Throttle body

24.Air cleaner

25.Battery

26.Oil Drain

27.Coolant drain

28.Oil cooler (model 30RCLH only)

29.Fans (qty. 3)

30.Radiator

31.Pressure cap (engine coolant fill)

32.Coolant overflow tube

33.Oil cooler hoses (model 30RCLH only)

34.Coolant overflow bottle

Figure 1-1 24RCL and 30RCLH Service Views for Maintenance

TP-6905 6/14 |

Section 1 Service Views 13 |

Notes

14 Section 1 Service Views |

TP-6905 6/14 |

Section 2 Generator Set Operation

2.1 Operating Area

WARNING

Carbon monoxide.

Can cause severe nausea, fainting, or death.

The exhaust system must be leakproof and routinely inspected.

Carbon monoxide symptoms. Carbon monoxide can cause severe nausea, fainting, or death. Carbon monoxide is a poisonous gas present in exhaust gases. Carbon monoxide is an odorless, colorless, tasteless, nonirritating gas that can cause death if inhaled for even a short time. Carbon monoxide poisoning symptoms include but are not limited to the following:

D Light-headedness, dizziness

DPhysical fatigue, weakness in joints and muscles

DSleepiness, mental fatigue, inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms and carbon monoxide poisoning is possible, seek fresh air immediately and remain active. Do not sit, lie down, or fall asleep. Alert others to the possibility of carbon monoxide poisoning. Seek medical attention if the condition of affected persons does not improve within minutes of breathing fresh air.

Generator set operation. Carbon monoxide can cause severe nausea, fainting, or death. Carbon monoxide is an odorless, colorless, tasteless, nonirritating gas that can cause death if inhaled for even a short time. Avoid breathing exhaust fumes when working on or near the generator set. Never operate the generator set inside a building. Never operate the generator set where exhaust gas could seep inside or be drawn into a potentially occupied building through windows, air intake vents, or other openings.

Keep the generator set area clear. Maintain at least 0.9 m (3 ft.) of clearance on all sides of the generator set. Verify that there are no windows, air vents, or other openings in the building within 1.5 m (5 ft.) of the generator set exhaust outlet in any direction.

Notice

Do not locate patios, decks, play areas, or animal shelters near the generator set. Keep items such as lawn furniture, toys, sports equipment, and all combustible materials away from the generator set exhaust outlet. Remind family members, children, and visitors to use caution near the generator set.

Generator sets connected to automatic transfer switches start automatically during exercise periods and power outages. Some generator set components become hot when the generator set is running and remain hot for a time after the generator set shuts down.

2.2 Prestart Checklist

To ensure continued satisfactory operation perform the following checks or inspections before or at each startup, as designated, and at the intervals specified in the service schedule. In addition, some checks require verification after the unit starts.

Air Cleaner. Check for a clean and installed air cleaner element to prevent unfiltered air from entering the engine.

Air Inlets. Check for obstructions that could block the flow of cooling air. Keep the air intake area clean. Do not leave rags, tools, or debris on or near the generator set.

Battery. Check for tight battery connections. Consult the battery manufacturer’s instructions regarding battery care and maintenance.

Coolant Level. Check the coolant level according to the cooling system maintenance information.

Drive Belt. Check the belt condition of the water pump and battery charging alternator belt.

Carbon Monoxide Detectors. Check for the installation and operation of carbon monoxide (CO) detectors on each level of any building near the generator set.

Oil Level. Maintain the oil level at or near, not over, the full mark on the dipstick.

TP-6905 6/14 |

Section 2 Generator Set Operation 15 |

2.3 Exercising the Generator Set

Operate the generator set without load every week or every other week for 20 minutes. Perform all of the prestart checks before starting the exercise procedure. See Section 2.5 for instructions to set the automatic exerciser.

2.4 Generator Set Operation

2.4.1Local Starting and Stopping

Start: Press the RUN button to immediately start the generator set.

Stop: Press the OFF button. The engine stops.

Run the generator set with no load for at least 2 minutes to ensure adequate engine cooldown.

2.4.2Automatic Starting and Stopping

An automatic transfer switch monitors the utility power and signals the generator set to start when utility power is lost. The ATS then transfers the load to the generator set.

When utility power is restored, the transfer switch transfers the load back to utility, runs the generator set with no load to cool down the engine, and then stops the generator set engine. The electric fans continue to run for two minutes after the engine shuts down to evacuate the engine compartment.

2.4.3Remote Starting and Stopping

A remote switch connected to terminals 3 and 4 can be used to start and stop the generator set. Close the switch to start and run the generator set. Open the switch to stop the generator set.

Run the generator set with no load for at least 2 minutes to ensure adequate engine cooldown.

2.4.4Engine Start Crank Cycle

The controller attempts to start the generator set three times (three crank cycles, 15 seconds crank and 15 seconds off). If the generator set does not start in three attempts, the system shuts down on an overcrank fault. See Section 2.6.

Pressing the OFF button during the crank cycle stops the cranking. No other buttons are acknowledged during the crank cycle.

2.4.5Engine Cooldown

The engine cooldown time delay allows the engine to run after the loads have been removed.

The engine cooldown time delay is set to 5 minutes. The engine stops before the cooldown time delay expires if the temperature drops below the cooled-down temperature level, or if the temperature rises above the high limit during the cooldown cycle.

The electric fans continue to run for two minutes after the engine shuts down to evacuate the engine compartment.

If a transfer switch other than the Model RXT is used, an additional engine cooldown time delay may be programmed on the transfer switch. To allow the smart engine cooldown on the RDC2 controller to operate most efficiently, set the cooldown time on the transfer switch controller to zero or the minimum time allowed. Refer to the instructions provided with the transfer switch for more information.

2.4.6Automatic Operation with Model RXT Transfer Switch

The Model RXT transfer switch connects to the RDC2 controller through the ATS interface board on the transfer switch. Also see Section 2.7, Model RXT Transfer Switch Operation.

The RDC2 controller must be in AUTO mode for automatic transfer switch operation.

Automatic Start

The RDC2 controller receives utility source voltage sensing data from the Model RXT transfer switch.

1.If the utility source voltage falls below an acceptable level, the controller starts the engine start time delay.

2.If the utility source is not restored before the time delay expires, the generator set starts.

3.After the Normal-to-Emergency time delay, the ATS is signaled to transfer the load to the emergency source.

16 Section 2 Generator Set Operation |

TP-6905 6/14 |

Automatic Stop

1.When the utility source is restored, the Emergency-to-Normal time delay starts.

2.When the Emergency-to-Normal time delay expires, the load is transferred to the utility.

3.The generator set stops.

2.4.7Automatic Operation with Model RDT or RSB Transfer Switches

If a Kohler Model RDT or RSB transfer switch is used, the engine start contacts from the ATS must be connected to engine start leads 3 and 4 on the generator set.

The RDC2 generator set controller must be in AUTO mode to respond to remote start/stop signals from an ATS or remote switch. Press the AUTO button on the RDC2 controller to put the generator set into automatic mode.

Automatic Start

The engine start contacts on the ATS close to signal the generator set to start, and remain closed while the generator set is running.

Automatic Stop

The engine start contacts on the ATS open to signal the generator set to stop.

2.5 Exercise

The RDC2 controller can be set to automatically run the generator set at the same time and day every week or every other week. Exercising the generator set every week or every two weeks is required in order to keep the engine and alternator in good operating condition.

Three exercise modes are available: unloaded cycle, unloaded full speed, and loaded full speed. See Sections 2.5.1 through 2.5.3 for information about the exercise modes. A loaded exercise can be set at the RDC2 controller only if a Model RXT transfer switch is connected.

Note: With the RDT and RSB transfer switches, it is possible to have two exercise settings (one unloaded exercise set at the generator set controller, and another exercise set at the ATS controller). If the exercise times overlap, the ATS exercise setting takes priority.

If a Model RDT or RSB transfer switch is used, refer to the instructions provided with the transfer switch to set a loaded exercise at the ATS, if desired.

2.5.1Unloaded Cycle Exercise with Complete System Diagnostics

An unloaded cycle exercise runs the generator set without signalling the transfer switch to transfer the electrical load from the utility source to the generator set. The Unloaded Cycle exercise with diagnostics is the recommended exercise mode and is the factory-default exercise setting.

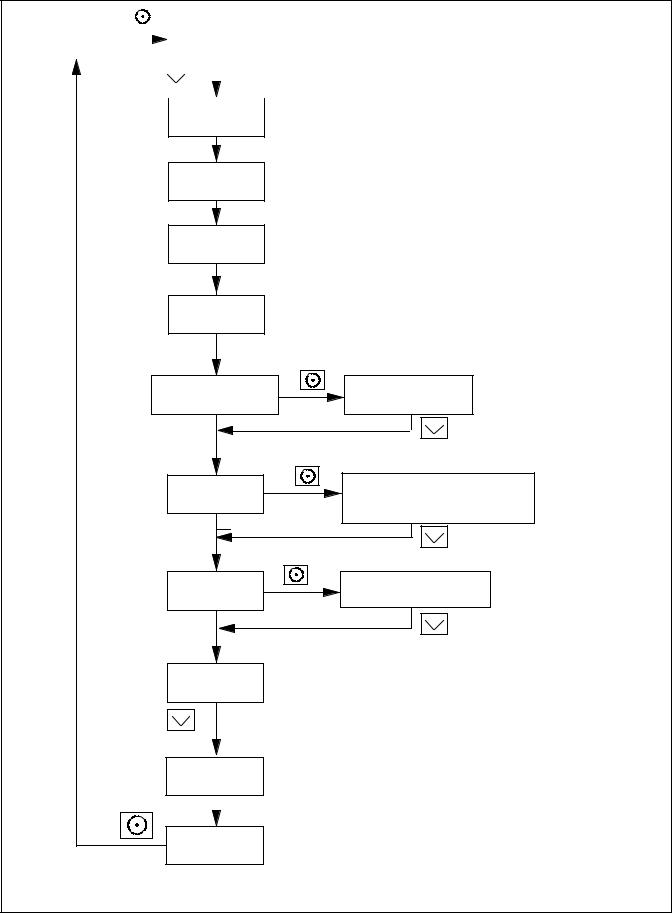

The Unloaded Cycle exercise runs the engine for 20 minutes in the cycle shown in Figure 2-1 and described below.

DRuns at reduced speed for 10 minutes to warm up and exercise the engine.

D Ramps up and runs at full speed for 3 minutes. Engine diagnostics are performed during this full-speed portion of the cycle, which provides the best test of engine and alternator power backup capability. Diagnostic tests at full speed can identify potential problems with the power output and alert the operator before an emergency event.

D Ramps down and runs at reduced speed for 5 minutes to cool down the engine before shutting down automatically.

Speed, RPM |

|

3 min. |

|

|

1 min. |

1 min. |

|

Engine |

10 min. |

|

5 min. |

|

|

||

|

Engine |

Full-Speed |

Cooldown |

|

Exercise |

Diagnostics |

|

Figure 2-1 Unloaded Exercise Cycle

System Diagnostics

During the unloaded cycle exercise, the controller monitors the following data. The controller display indicates an unloaded exercise run during the diagnostics, unless a fault is detected as described below.

TP-6905 6/14 |

Section 2 Generator Set Operation 17 |

D ATS connection. The controller verifies that the Model RXT ATS interface board is connected.

DBattery voltage. Battery voltage is checked before exercise to verify engine starting capability. Battery voltage provides a measurement of battery health. If the controller detects low battery voltage, low battery or low charging battery is displayed and the exercise does not start.

D Coolant level check. The coolant level is checked.

D Communication integrity tests. J1939, RBUS, Ethernet, and USB are monitored for messages indicating that the controller and wiring are reliable.

DEngine speed. Engine speed is measured at low speed and full speed. An overspeed or underspeed condition will result in a fault condition and shutdown.

D Generator output frequency and voltage.

Operating the generator at full speed allows the RDC2 controller to check the output power for correct voltage, frequency, and stability. When the engine is running at full speed, the controller verifies that the voltage and frequency are within acceptable limits. A fault message is displayed if the voltage or frequency is out of range.

D Oil pressure. Oil pressure is verified to ensure proper lubrication of critical engine components. Pressure is monitored at both low and full speeds. If the oil pressure is low, low oil pressure is displayed and the generator set shuts down.

2.5.2Unloaded Full-Speed Exercise

The unloaded full speed exercise runs the generator set at full speed for 20 minutes without transferring the load.

To set an unloaded full speed exercise, follow the procedure in Figure 2-3 and select Exercise Mode: Unloaded Full.

2.5.3Loaded Full-Speed Exercise (with RXT only)

A loaded exercise starts the generator set, ramps up to full speed, and then transfers the electrical load from the utility source to the generator set. The load is transferred back to the utility source before the generator set shuts down.

Note: With a loaded exercise, power to the building is lost for up to 10 seconds during load transfer.

For a loaded exercise controlled by the RDC2 controller, a Model RXT transfer switch must be connected to the

generator set. To set a loaded exercise, follow the procedure in Section 2.5.8 and select Exercise Type: Loaded.

For a loaded exercise with a transfer switch other than a Kohlerr Model RXT, program the exercise at the transfer switch controller. Refer to the transfer switch operation manual for instructions.

2.5.4Shutdown During Exercise

The following advanced diagnostic operation applies to RDC2 controllers with firmware versions 5.04 and higher.

If the generator set shuts down on a fault during an exercise, the controller will try to restart the engine. If the engine starts, the generator set will run at full speed for two minutes and then stop. The event history will show Advanced Diagnostic Active. The exercise schedule is maintained.

If the engine does not start, the shutdown message will be displayed. Correct the fault condition and reset the fault as described in Section 2.6.

2.5.5Power Failure During Exercise

If the utility power is lost during an unloaded exercise, the ATS transfers to the emergency source, the exercise is ended and the control remains in the AUTO mode.

If the utility power is lost during a loaded exercise, the exercise is ended. The ATS remains in the emergency position and the control goes into the AUTO mode.

The generator set continues to run and supply power to the load for the duration of the utility power outage. When Utility power is restored, the ATS will re-transfer to the utility source through normal timing sequences.

2.5.6Exerciser Reset

To reset the exerciser to run at a different day and/or time or to change the exercise mode, follow the procedure in Section 2.5.7 to change the exerciser settings.

2.5.7Setting the Exerciser at Power-up

When power is connected to the controller, you will be prompted to set the date, time, and exercise schedule.

1.At power--up, the date is displayed with the year flashing. Use the up or down arrow key to step to the current year.

18 Section 2 Generator Set Operation |

TP-6905 6/14 |

2.Press Select button to save the year and move to the month.

3.Use the arrow and select buttons to set the month and the day.

4.The time is displayed with the hour flashing. Use the up or down arrow key to step to the current hour and am or pm setting.

Note: Check the am/pm setting displayed. If pm is displayed and you need to change it to am, use the down arrow button to step down in time until the correct hour and am are displayed.

5.Press the Select button to save the hour and move to minutes.

6.Use the up or down arrow button to change the minutes.

7.Press Select to save the time and move to the next screen.

8.Next Exercise is displayed. Use the up, down, and select buttons to set the exercise time and date. Be sure to set a time and date in the future.

9.Press Select. The controller exits the exercise menu.

10.Press the Auto button and verify that the AUTO LED is lit. The generator set must be in automatic mode for the exercise to run as scheduled.

The exercise will run every 7 days at the same time, starting on the date set. To change the exerciser to run every other week or on a different day and time, use the following procedure.

2.5.8Changing the Exercise Setting

Set the date and time on the controller before setting the exercise schedule. Set the exerciser to automatically run the generator set for 20 minutes every week or every two weeks. Follow the procedure below and see the flowchart in Figure 2-3 to set the exercise time and date, mode, and frequency.

Procedure to Change the Exercise Setting

1. Press the AUTO button on the controller.

2.Press the Select button to go to the main menu. See Figure 2-2.

3.Press the down arrow button to step to the Genset System menu.

4.Press the Select button to enter the Genset system menu. See Figure 2-3.

5.Use the down arrow button to step to the next Exercise menu.

6.Press the Select button. The setting flashes to show that it can be changed. For example, the hour flashes to show that the hour can be changed.

7.Press the UP or Down arrow buttons to change the setting.

8.Press the Select button to save the setting and move to the next. For example, save the hour setting and move to minutes.

9.Repeat steps 5 through 8 to change the next item on the line until the desired settings are displayed.

10.Press Select to save after all settings have been selected. Settings will stop flashing.

11.If the generator set is connected to a Kohlerr Model RXT transfer switch, the exercise can be changed to a loaded exercise. Set the Exercise Mode to loaded full speed, unloaded full speed, or unloaded cycle as shown in Figure 2-3.

12.Set the exercise frequency (weekly or every two weeks). Weekly exercises are recommended.

13.Press the down arrow button to step to the Return menu. Press the Select button to return to the main menu.

14.Check that the AUTO LED is lit. The generator set must be in automatic mode for the exercise to run as scheduled.

After a scheduled exercise run, the next exercise time and date will be updated automatically based on the Exercise Frequency setting.

Other transfer switches: For a loaded exercise with a transfer switch other than a Kohlerr Model RXT, program the exercise at the transfer switch controller. Refer to the transfer switch operation manual for instructions.

TP-6905 6/14 |

Section 2 Generator Set Operation 19 |

Status |

Overview ----> |

|

|

|

Displays |

1.2 h |

|

|

|

|

Engine |

----> |

ATS |

----> |

|

Metering |

|

Configuration |

|

|

Generator----> |

Date |

----> |

|

|

Metering |

|

and Time |

|

|

Genset |

----> |

Network |

----> |

|

Information |

Information |

||

|

Genset |

----> |

PIM |

----> |

|

Run Time |

|

Status |

|

|

Genset |

----> |

Load |

----> |

|

System |

|

Control |

|

|

ATS |

----> |

Event Log----> |

|

|

Status |

|

|

|

tp6810

Figure 2-2 RDC2 Main Menu

20 Section 2 Generator Set Operation |

TP-6905 6/14 |

|

|

|

|

|

|

|

|

|

Genset |

----> |

|

|

|

|

System Voltage: |

||

|

|

|

|

|

|

|||

System |

|

|

|

|

|

|

240 V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

System Freq:

60 Hz

VR Voltage Adj:

240.0V

System Phase:

Single

System Battery:

12 V

Next Exercise * |

Next Exercise |

HR:MN PM MM/DD/YY |

HR:MN PM MM/DD/YY |

See Section 2.5.8, Changing

the Exercise Setting

Exercise Mode: |

Exercise Mode: |

|

|

||

Unloaded Cycle |

None/Unloaded Full Sp/ |

|

Unloaded Cycle/Loaded Full SP |

||

|

Exercise Freq:

Weekly

Exercise Freq:

Weekly/Every Other Week

Meas. System:

English

Contrast: |

|

50 |

|

<---- Return |

|

* If the exerciser has not been set, No Exercise Sch will be displayed. |

tp6809 |

|

|

Figure 2-3 Procedure to Set the Exerciser |

|

TP-6905 6/14 Section 2 Generator Set Operation 21

Loading...

Loading...