Page 1

Before using this Compact Static Eliminator, be sure to

thoroughly read this Instruction Manual.

After you are finished with this Instruction Manual, be

sure to store it in a safe place for quick reference.

High-performance Micro Static Eliminatior

Instruction Manual

SJ-M

96M10103

1

Page 2

Preface

This document describes handling, method of operation and precautions when using the Compact

Spot-type Static Eliminator SJ-M 300 Series. Before you start to use the SJ-M 300 Series, be sure to

thoroughly read this document in order to make full use and safely use its functions.

Store this document in a safe place so that you can retrieve it whenever necessary.

■ Symbols

This manual uses the following symbols to alert you to important information.

Be sure to read this information.

Failure to follow these instructions may lead to death or serious injury.

Failure to follow these instructions may lead to injury.

Failure to follow these instructions may lead to product damage (product

malfunction, etc.).

Provides additional information on precautions and restrictions that must be

followed in operation.

Provides additional information on proper operation.

Indicates useful information or information that aids understanding of text descriptions.

Indicates a reference item or page to be referred to in this manual or a separate manual.

DANGER

WARNING

CAUTION

Important

Note

Tip

Safety Precautions

■ General Precautions

• At startup and during operation, be sure to monitor the functions and

performance of the SJ-M Series.

• We recommend that you take substantial safety measures to avoid any

damage in the event that a problem occurs.

• Do not modify the SJ-M Series or use it in any way other than described in

the specifications. The functions and performance of products used or

modified in this way cannot be assured.

• When the SJ-M Series is used in combination with other instruments,

functions and performance may be degraded, depending on operating

conditions and the surrounding environment. Use the SJ-M after fully

studying the effect of combined use with other instruments.

• Do not use the SJ-M Series for the purpose of protecting the human body.

■ SJ-M Series Handling Precautions

The SJ-M Series is a high-voltage product that is not designed in an explosion-proof structure. Pay

attention to the following when using the SJ-M Series.

•

To prevent electric shock and to ensure accurate static elimination, be sure

to connect a Class D earth (maximum resistance of 100 Ohms).

•

The power cable supplied with the exclusive power supply (SJ-U2) is a 125 V

rated power cable. When connecting a power supply that exceeds this power

rating to the SJ-M Series, the user must prepare a power cable having

adequate voltage rating. If a power cable that does not meet the voltage

rating is used, this may cause electric shock, fire or malfunction.

•

Do not use this product in locations where there is the risk of ignition or

explosion from flammable solvents or dirt and dust.

•

High voltage is applied to this product. Prevent it from being splashed with

water, oil, or flammable solvents. Failure to do so may cause insulation

breakdown, which will result in electric shock or malfunction.

•

Do not bring your fingers, tools, wire or other metallic objects near this

product. Doing so may cause electric shock or malfunction.

•

Protect the area around the tip of the Static Elimination Head with silicon,

fluoro-resin or other highly ozone-resistant resin. Ozone that is generated

may cause the metal or resin on the SJ-M Series to rust, corrode or

deteriorate.

The ozone generated from this product may adversely affect the human

body. For this reason, do not use the SJ-M Series in closed spaces. Be sure

to use the SJ-M Series in a well-ventilated location. Also, do not bring your

face close to the Static Elimination Head. The ozone generated from this

product might be painful to your nose or throat.

•

Do not use this product in locations where sudden changes in temperature

or condensation are likely to occur.

•

Do not operate this product with wet hands. Doing so may cause electric

shock.

•

Before starting inspection or maintenance, be sure to turn the power OFF.

Failure to do so might result in electric shock or malfunction.

•

During maintenance, do not directly touch the electrode probe. Doing so may

cause personal injury.

•

If any malfunction is observed in this product, immediately turn it OFF, and

contact your nearest agent. You should never repair this product yourself.

Doing so may cause electric shock or malfunction.

CAUTION

WARNING

• Do not touch the electrode probe with a tool or other hard object. Damage to

the electrode probe will prevent static elimination performance from being

fully demonstrated, and cause accidents or malfunction.

• When this product is used for a long period of time, the electrode probe

become dirty due to the adhesion of dust and dirt. If the ion level alarm

indicator or condition alarm indicator lights, clean the electrode probe. If the

product is used with the electrode probe in a dirty or dusty state, the static

elimination performance can no longer be fully demonstrated, resulting in

accidents or malfunction. We recommend periodically cleaning the

electrode probe (as a guideline, once every two weeks in a regular operating

environment though this depends on the installation conditions).

• Do not drop or subject this product to shock. Doing so might result in

accident or malfunction.

• Use this product for static elimination only. Do not use it for other purposes.

• When installing the SJ-M Series, observe the minimum bending radius of all

provided cables. Also, do not install the SJ-M with the cables deformed by

staples or other objects. Doing so might cause the SJ-M to malfunction.

■ Power Supply Precautions

• Use a DC power supply with rated 24 V output.

• Noise applied to the power supply may cause this product to malfunction. If

this happens, install an insulated transformer.

• When using a switching regulator, be sure to connect a Class D earth to the

Frame Ground terminal.

■ Grounding Precautions

• To ensure safety and appropriate static elimination, be sure to ground this

product.

• Be sure to connect a Class D earth (maximum resistance of 100 Ohms)

■ Air Purge Function Precautions

• Be sure to use air of pressure to 0.2 MPa. Use outside of the rated air

pressure range might result in accidents or malfunction.

• Be sure to supply clean or dry air of temperature –20°C or more through a

filter of mesh size about 0.01μm. Moisture or oil contained in the air or

nitrogen may cause discharge inside the Static Elimination Head, which

may result in accidents or malfunction.

CAUTION

CAUTION

CAUTION

CAUTION

■ SJ-M Series Warning label

A WARNING label is affixed on the SJ-M Series to ensure safety. Read the description on this

WARNING label to ensure correct use of the SJ-M Series.

■ Installation Precautions

Avoid installing the SJ-M Series in the following locations as this may cause

accidents.

• Locations directly subject to vibration and shock

• Locations subject to ambient temperature outside of the 0°C to +40°C range

• Locations subject to ambient humidity outside of the 35 to 65%RH range

(condensation not allowed)

• Locations subject to sudden changes in temperature

• Locations subject directly to blasts from air conditioners

• Locations subject to volatile or flammable substance, solvents or corrosive

gases

• Locations subject to large amounts of dirt, and dust, salt, iron and oil smoke

• Locations that may be splashed with water, oil or chemical mist

• Locations where strong magnetic and electrical fields are generated

■ About Warm-up

After turning the SJ-M Series ON, leave it for about 20 minutes to allow the ion

balance to stabilize.

WARNING labels in Japanese, German, French, Italian and Chinese (Simplified) are provided.

Use them as necessary.

CAUTION

Note

1

Page 3

■ Other Precautions

•

Be sure to read the WARNINGS and CAUTIONS described in each of the

items in this Instruction Manual.

•

This Static Eliminator has a built-in EEPROM. Do not turn the Static

Eliminator OFF during the setup.

Refer to the following illustration to install the SJ-M300.

●Provide enough space between the static elimination bar and surrounding

walls as shown in the figures below.

●If a number of SJ-M300 units are used in combination, make a proper

distance between adjacent static elimination bars.

• Do not install the Static Elimination Head at locations where moving parts of

other equipment and machinery may place stress on the cable.

CAUTION

CAUTION

20mm

min.

20mm

min.

20mm min.

30mm

min.

30mm

min.

Side-to-side installation

300mm

min.

Face-to-face installation

100mm

min.

Precautions on Regulations and Standards

■ CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of the

applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in the Member State of

European Union.

● EMC Directive (2004/108/EC)

• Applicable standard EMI: 61326-1(evaluated according to EN55011 Group 1, Class A)

EMS: 61326-1

• Be sure to provide a ground when installing the SJ-M Series.

• The length of cable (power lead and I/O leads) must be less than or equal to 30 m.

Remarks:

These specifications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of EMC Directive. The manufacturer of the end-product is

solely responsible for the compliance on the end-product itself according to EMC Directive.

● Low-Voltage Directive (2006/95/EC)

• Applicable Standard : EN61010-1

• Overvoltage category I

• Use this product under pollution degree 2.

• Use the power supply for the SJ-M Series, that satisfies the requirements of the Limited Power

Source specifications stipulated in EN60950-1 and certified by European third-party certification

organization, or a Keyence Corporation AC adapter (SJ-U2). The specifications of the AC adapter

(SJ-U2) are as follows.

When connecting to an SJ-U2, be sure to use a power cable compliant with European standards.

Applicable standard: EN60950-1

Overvoltage category II

Pollution degree 2

• Be sure to provide a ground when installing the SJ-M Series.

1-1 Features of the SJ-M Series

This section describes an outline of the functions, the features of the SJ-M Series.

Outline of the SJ-M Series

■ Pulse AC method

The SJ-M Series uses a pulse AC method that generates + and – charged air ions from a single

electrode probe. This system ensures a maximum ion level per unit time, which in turn high-speed static

elimination. The SJ-M Series also automatically controls the level of + and – ions generated matched to

the charged state of the target object. This enables high-speed and high-precision static elimination

suited to installation conditions.

■ I.C.C. (Ion Current Control) method

This control method calculates the charged level of the target object by sensing the state of ion current

that arises due to the potential difference between the electrode on the Static Elimination Head and

GND. Optimum static elimination matched to the state of the target object can be performed by rapidly

supplying the optimum ions suited to the polarity and charged level of the target object.

■ Versatile frequency settings

A variety of frequencies can be set for the SJ-R. This allows optimal static elimination according to the

distance and the strength of the electric charge of the target.

■ Ion monitor functions

●

Charge monitor

The integrated ion monitor allows you to learn how much the target object is charged by + or – ions.

This monitor also allows you to confirm at a glance how static elimination is being performed.

● Ion level monitor

The ion level currently being generated by the Static Elimination Head is monitored at all times so that

drops in the generated ion level can be diagnosed on the unit. The generated ion level is indicated by

LEDs and an alarm can be output when the generated ions fall below a certain level. This allows you to

monitor the influence of a dirty electrode probe in advance.

"Ion Monitor Functions" (page 8)

Target without

static charge

Eliminates electricity

from positively

charged target

Eliminates electricity

from negatively

charged target

Target: 0V Target: Positively charged Target: Negatively charged

1-1

Features of the SJ-M Series

■ Alarm output functions

●

Alarm output functions

An indicator blinks and an alarm signal is output, for example, when internal circuits are damaged or

abnormal discharging occurs. When an alarm signal is output, generation of ions is forcibly stopped.

● Ion level alarm output function

An indicator lights and an alarm signal is output when the level of generated ions drops due to a dirty

electrode probe, for example.

● Condition alarm output function

An indicator lights and an alarm signal is output when static elimination performance is impaired.

"Alarm Output Functions" (page 8)

■ Abnormal discharge detection function

Abnormal discharge caused by condensation on the electrode probe tip or adhesion of debris is

detected. When abnormal discharge is detected, ion generation is forcibly stopped to prevent trouble at

an early stage.

"Abnormal Discharge Detection Function" (page 8)

■ Ion balance adjustment function

The ion balance zero point can be fine-adjusted.

"Ion Balance Adjustment Function" (page 7)

■ Static elimination stop function

Static elimination only can be turned ON/OFF with the device still powered. This is achieved by shorting

the 0V terminal with the static elimination stop input terminal on the Controller Unit (I/O terminal

section) or by holding down the two ion balance adjustment keys simultaneously for about one second.

"Static Elimination Stop Function" (page 8)

■ Air purge function

Dirt can be prevented from sticking to the electrode probe on the SJ-M030 by attaching a joint to the air

duct of the Static Elimination Bar and supplying clean dry air from the air compressor. This also extends

the static elimination range.

"Air Purge Function" (page 9)

2

Page 4

1-2

Checking the Contents of the Package

The package contains the following components and accessories. Before you start using the SJ-M

Series, make sure that the package contains everything that it is supposed to contain. A Replacement

Electrode Unit and other accessories are available as options.

"Appendices - List of Options" (page 13)

Package Contents

Options

WARNING labels (Japanese, German, French, Italian and Chinese

(Simplified)) *

* Use as necessary.

CompactSpot-typeStatic Eliminator

Instruction Manual

SJ-M Series

Before using this Compact Static Eliminator, be sure to

thoroughly read this Instruction Manual.

After you are finished with this Instruction Manual, be

sure to store it in a safe place for quick reference.

CompactSpot-typeStatic Eliminator

Instruction Manual

SJ-M

96M1533

Controller Unit (SJ-M300)Static Elimination Bar

Instruction Manual

SJ-M030/070 Series Mounting Fixture

1set

Flat-blade

screwdriver

Earth lead

AC Adapter SJ-U2

Extension cable SJ-C3

(3m cable, can be extended to 9m)

Tungsten electrode probe for SJ-M030/070 (set of 4 pieces) OP-42213

Silicon electrode probe for SJ-M030/070C (set of 4 pieces) OP-42214

Tungsten electrode probe for SJ-M030/070G (set of 4 pieces) OP-51644

Tungsten electrode probe for SJ-M030/070V (set of 4 pieces) OP-75352

Silicon electrode probe for SJ-M030/070VC (set of 4 pieces) OP-75353

*

For details of the AC cable, contact the

KEYENCE sales office in your district.

1-3 Names and Functions of Parts

This section describes the names and functions of parts on the SJ-M Series.

Static Elimination Bar

● SJ-M030/070 Series

(2)

(3)

(4)

(1)

(1) Electrode probe

Ion charge is emitted from the tip of this probe.

(2) Air duct

Supplies clean dry air.

(3) High-voltage cable

Ambient operating temperature: 0 to +40°C

Minimum bending radius 30 mm

(4) Drive unit

Manages body information of the Static

Elimination Bar or drives the Bar.

1-3

Names and Functions of Parts

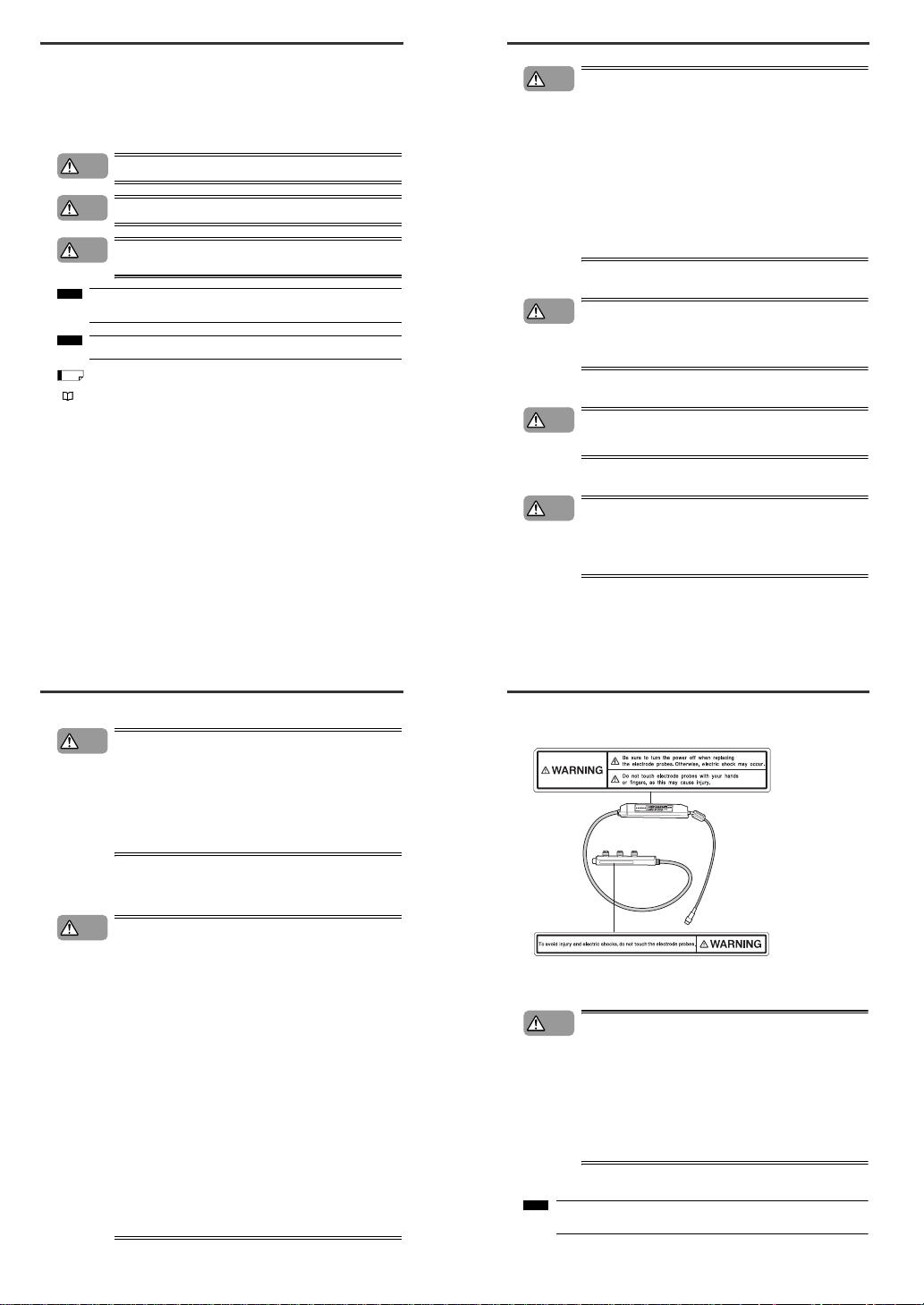

Controller Unit (operation/display section)

Enlarged view of display section

Terminal plate cover

Lights when the charged level of the target object is

displayed.

Lights when the ion emission level is being displayed.

Indicates the charged level of the target object.

Also, indicates the ion emission level.

Used for adjusting the ion balance and for selecting setting

items.

Lights when an alarm occurs.

Lights when the ion emission level has fallen below the set

value due to dirt or wear of the electrode probe.

Lights when the charged level of the target object is high

and static cannot be completely eliminated.

Used for determining setting items and for switching the

display.

Used for switching the frequency.

Ion balance

indicator

Ion level

indicator

Ion monitor

keys

key

Alarm indicator

Ion level alarm indicator

Condition alarm indicator

Ion balance indicator

Ion level indicator

Ion monitor

keys

Alarm indicator

Ion level alarm indicator

Condition alarm indicator

key

Rotary switch

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(9) Rotary switch

FREQ

1-3

Names and Functions of Parts

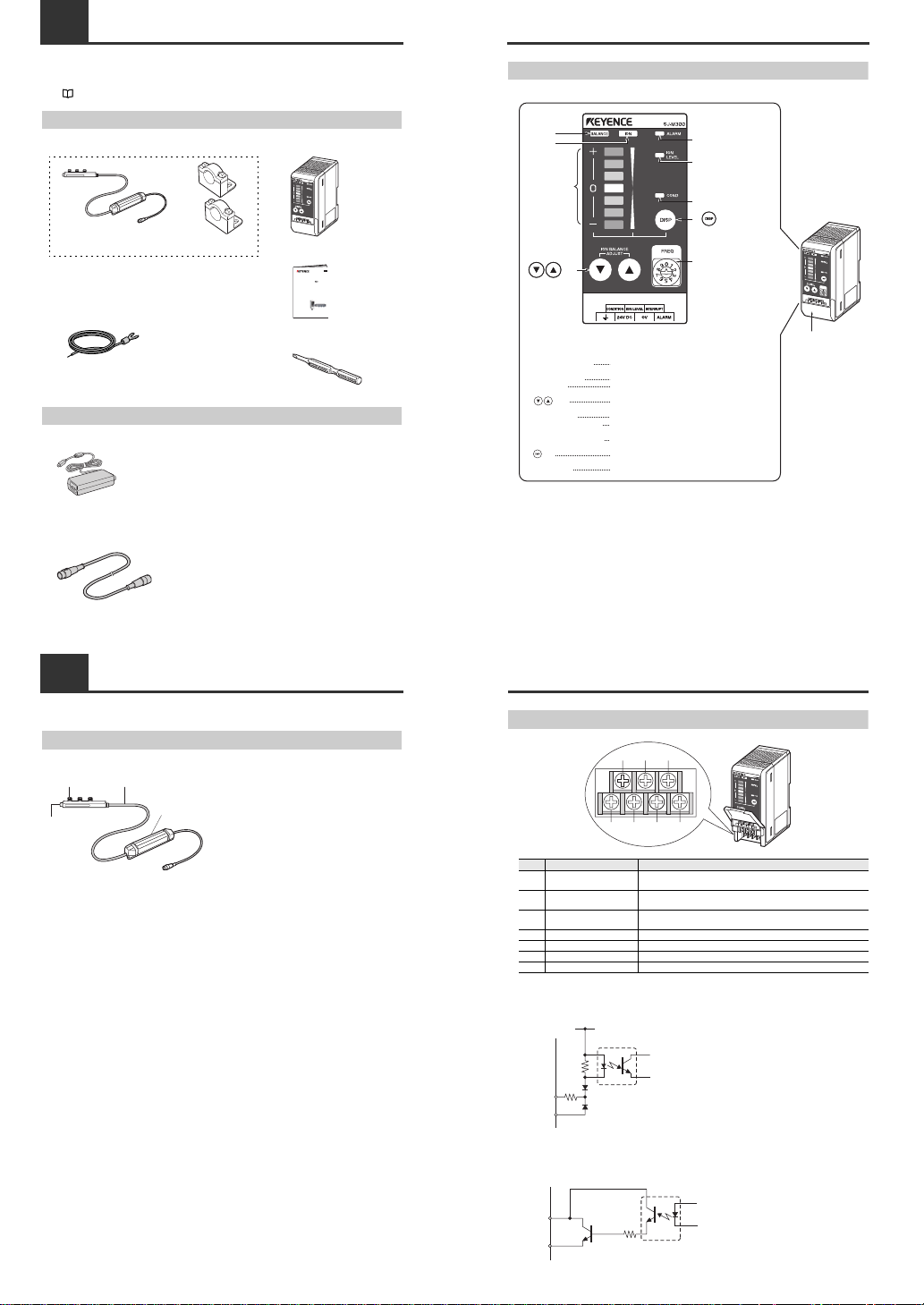

Controller Unit (I/O terminal section)

■ Input circuit diagram

■ Output circuit diagram

Number

Name Function

(1)

Condition alarm output

terminal

Outputs when static elimination performance is influenced by excessive

charge.

(2)

Ion level alarm output

terminal

Outputs when the ion emission level drops.

(3)

Static elimination stop input

terminal

Static elimination can be turned ON/OFF by shorting this terminal with

(6).

(4) Ground terminal Be sure to connect a Class D earth (maximum resistance of 100 Ohms).

(5) DC power terminal 24 VDC ±10%

(6) 0V terminal 0V for power and 0V for I/O

(7) Alarm output terminal Outputs when an alarm occurs.

(1)

(4) (5) (6) (7)

(2) (3)

+24V

3kΩ

INPUT( (3) )

0V( (6) )

Input a no-voltage contact (relay, etc.)

or NPN open collector to INPUT and 0V.

[ (3) (static elimination stop input)]

OUT

DC40V

100mA

0V( (6) )

Open collector output

[ (2) (ion level alarm output), (1) (condition alarm output), (7) (alarm output)]

3

Page 5

2-1 Before Installation

This section describes the static elimination performance of the SJ-M100/200 Series.

Before you install the SJ-M100/200 Series, fully calculate the distance between the Static Elimination

Head up to the target object and the time required for static elimination.

About Static Elimination Performance

■ Static elimination speed and operating distance

The SJ-R Series offers a variety of frequency settings to enable flexible static elimination according to

the location and application.

See "Frequency setting" (page 6).

The following graphs show typical examples of the relationship of static elimination speed, operating

distance, and frequency settings for the SJ-R Series. Use the graphs to select the appropriate static

elimination setting.

■

Operation time vs. operating distance

Static elmination

speed

Location

Operating

distance(mm)

Recommended

frequency (Hz)

High-speed

Low-speed

Production lines of films or sheets

(Short distance)

50–300 50, 30

Clean bench (Middle distance) 300–1000 10, 8, 5

On ceiling of clean room (Long distance) 1000–2000 3, 1

Model: SJ-M030/030C

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The 150 x 150 mm plate monitor (20pF) is used.

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The 150 x 150 mm plate monitor (20pF) is used.

Under the downward air flow of 0.3 m/sec.

Model: SJ-M070/070C

50Hz

30Hz

25

20

15

10

5

30

Charged level (V)

Time (secs)

0

0 50 100 150 200 250 300

8Hz

5Hz

1Hz

50

60

40

30

20

10

0

0

400

600 800

1000

1200

1400

1600200

Charged level (V)

Time (secs)

0

2

4

6

8

10

12

14

16

18

20

0 50 100 150 200 250 300

Operating distance (mm)

Operating time (sec.)

50Hz

30Hz

0

5

10

15

20

25

30

35

0 200 400 600 800 1000 1200 1400 1600

Operating distance (mm)

Operating time (sec.)

8Hz

5Hz

1Hz

2-1

Before Installation

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The 150 x 150 mm plate monitor (20pF) is used.

The downward air flow of 0 m/sec

3 NL/min (1 electrode) air purge

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The 150 x 150 mm plate monitor (20pF) is used.

Under the downward air flow of 0.3 m/sec.

3 NL/min (1 electrode) air purge

Model: SJ-M030G

Model: SJ-M070G

50Hz

30Hz

4

3

2

0

0150 100 150 200 250 300

3.5

2.5

1.5

0.5

Operating time (sec.)

Operating distance (mm)

8Hz

5Hz

1Hz

25

30

20

15

10

5

0

0

400

600 800

1000

1200

1400

1600200

Charged level (V)

Time (secs)

0

0.5

1

1.5

2

2.5

3

3.5

4

0 50 100 150 200 250 300

Operating distance (mm)

Operating time (sec.)

50Hz

30Hz

0

2

4

6

8

10

12

14

16

0 200 400 600 800 1000 1200 1400 1600

Operating distance (mm)

Operating time (sec.)

8Hz

5Hz

1Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The 150 x 150 mm plate monitor (20pF) is used.

The downward air flow of 0 m/sec

1 NL/min (1 electrode) air purge

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The 150 x 150 mm plate monitor (20pF) is used.

Under the downward air flow of 0.3 m/sec.

1 NL/min (1 electrode) air purge

Model: SJ-M030V/030VC

Model: SJ-M070V/070VC

50Hz

30Hz

20

18

16

14

12

10

8

6

4

2

0

0 50 100 150

200

250

300

Charged level (V)

Time (secs)

8Hz

5Hz

1Hz

50

60

40

30

20

10

0

0

400

600 800

1000

1200

1400

1600200

Charged level (V)

Time (secs)

0

2

4

6

8

10

12

14

16

18

20

0 50 100 150 200 250 300

Operating distance (mm)

Operating time (sec.)

50Hz

30Hz

0

10

20

30

40

50

60

0 200 400 600 800 1000 1200 1400 1600

Operating distance (mm)

Operating time (sec.)

8Hz

5Hz

1Hz

2-1

Before Installation

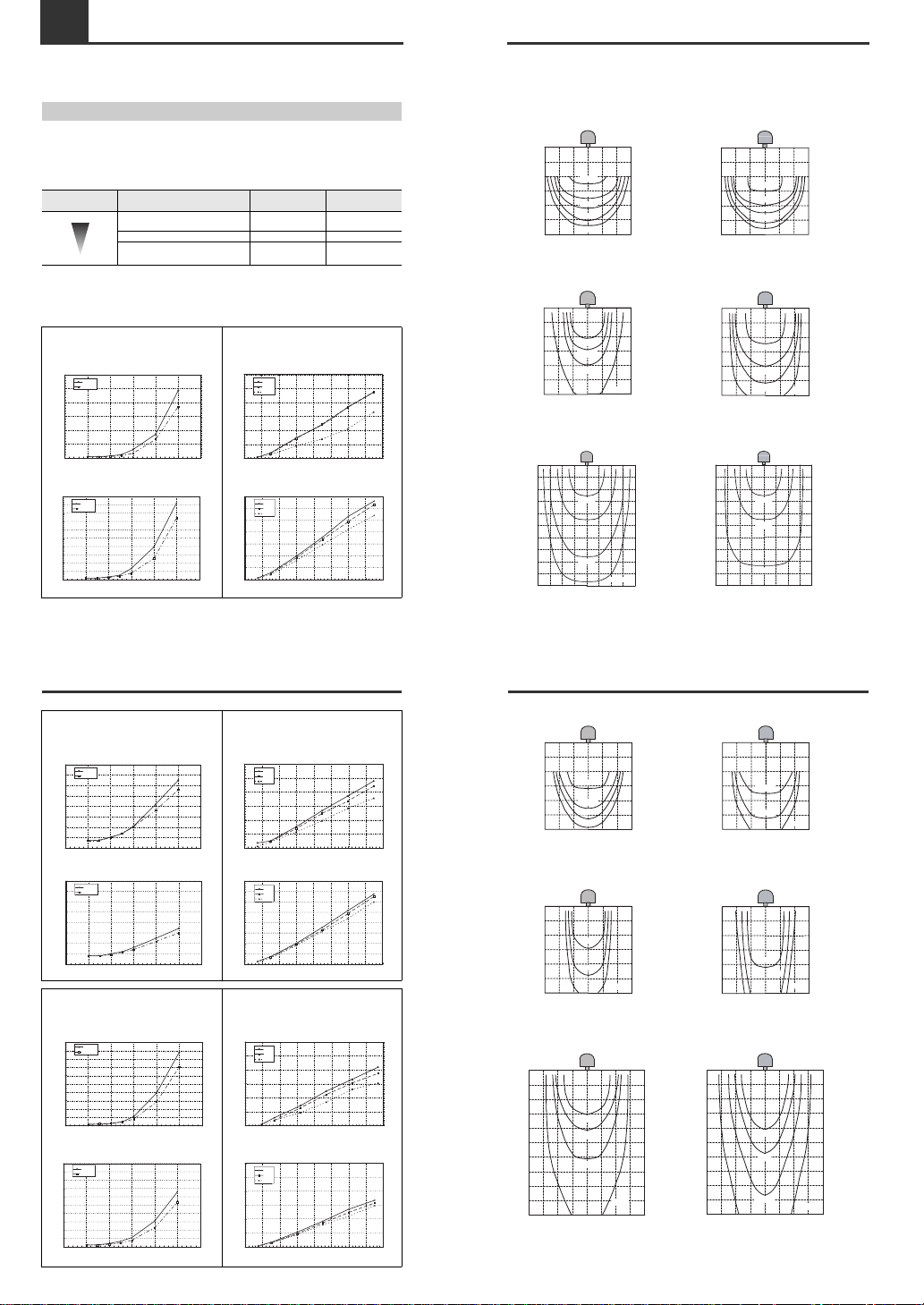

■ Operating area and operation time

The following graphs show typical examples of the relationship between the time required to eliminate

the target's static charge and the operating distance from the target to the static elimination bar.

Use the graphs to select the appropriate static elimination setting.

Model: SJ-M030/030C

At the time of frequency 50 Hz

Model: SJ-M070/070C

At the time of frequency 50 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge: 0 NL/min

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge: 0 NL/min

At the time of frequency 8 Hz At the time of frequency 8 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 0 NL/min

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 0 NL/min

At the time of frequency 1 Hz At the time of frequency 1 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 0 NL/min

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 0 NL/min

50100150

50

100

150mm

50 100 150mm

0.4sec

0.6sec

0.8sec

1.2sec

1.5sec

50100150

50

100

150mm

50 100

150mm

0.4sec

0.6sec

0.8sec

1.2sec

1.5sec

150300450

300

600

900mm

150 300

450mm

5sec

10sec

15sec

30sec

150300450

300

600

900mm

150 300

450mm

5sec

10sec

15sec

20sec

300450600 150 450300150 600mm

300

600

900

1200

1500mm

4sec

20sec

30sec

300450600 150 4503001 50 600mm

300

600

900

1200

1500mm

4sec

10sec

20sec

2-1

Before Installation

Model: SJ-M030G

At the time of frequency 50 Hz

Model: SJ-M070G

At the time of frequency 50 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge: 3 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge: 3 NL/min (1 electrode)

At the time of frequency 8 Hz At the time of frequency 8 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 3 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 3 NL/min (1 electrode)

At the time of frequency 1 Hz At the time of frequency 1 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 3 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 3 NL/min (1 electrode)

50100150

50

100

150mm

50 100 150mm

0.4sec

0.8sec

0.6sec

1.0sec

50100150

50

100

150mm

50 100 150mm

0.4sec

0.6sec

0.8sec

50100150

50

100

150mm

50 100 150mm

5sec

15sec

10sec

50100150

50

100

150mm

50 100 150mm

5sec

15sec

10sec

300450600 150 450300150 600mm

300

600

900

1200

1500mm

20sec

10sec

6sec

4sec

300450600 150 450300150 600mm

300

600

900

1200

1500mm

4sec

10sec

20sec

6sec

4

Page 6

2-1

Before Installation

Model: SJ-M030V/030VC

At the time of frequency 50 Hz

Model: SJ-M070V/070VC

At the time of frequency 50 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge: 1 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±3000 V to ±300 V is measured.

The downward air flow: 0 m/sec

The air purge: 1 NL/min (1 electrode)

At the time of frequency 8 Hz At the time of frequency 8 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 1 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 1 NL/min (1 electrode)

At the time of frequency 1 Hz At the time of frequency 1 Hz

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 1 NL/min (1 electrode)

Measurement conditions:

The time required to eliminate the static charge of the

target from ±5000 V to ±500 V is measured.

The downward air flow: 0.3 m/sec

The air purge: 1 NL/min (1 electrode)

50100150

50

100

150mm

50 100 150mm

0.4sec

0.6sec

1.0sec

1.5sec

2.0sec

50100150

50

100

150mm

50 100 150mm

0.4sec

0.6sec

1.0sec

1.5sec

2.0sec

150300450

300

600

900mm

150 300 450mm

10sec

15sec

30sec

5sec

150300450

300

600

900mm

150 300 450mm

10sec

15sec

30sec

5sec

300450600 150 450300150 600mm

300

600

900

1200

1500mm

20sec

30sec

10sec

6sec

4sec

300450600 150 450300150 600mm

300

600

900

1200

1500mm

20sec

30sec

10sec

4sec

2-1

Before Installation

■ Proper static elimination

To e ns ure proper static elimination, consider the following points.

If the target is in contact with metallic objects (grounding

conductor), the static charge of the target is not completely

eliminated.

Install the SJ-M Series in a location in which the target is not in

contact with any metallic objects (such as a grounding conductor).

If the film or sheet is an electrical insulator, only the static

electricity on the surface exposed to the static elimination bar

is eliminated.

To eliminate the static electricity on both surfaces, use another

SJ-M unit on the other side.

Precautions for installation

■ Locations

Refer to the following illustration to install the SJ-M Series.

• Provide enough space between the static elimination bar and surrounding

walls as shown in the figures below.

•

When mounting the SJ-M Series, use the provided mounting bracket,

otherwise an accident or malfunction may result.

Target (film or sheet)

Metal roller

NG

OK

OK

• Install the static elimination bar in a

location that allow easy maintenance

access (to replace or clean parts).

Note

CAUTION

20mm

min.

20mm

min.

20mm min.

30mm

min.

30mm

min.

2-1

Before Installation

■ Interference

The Static Elimination Head may not function properly if there is a conductor (earthed body) located

nearby or if two or more units are used close to each other. In such an installation, refer to the figure

below and maintain the indicated distance between the conductor (earthed body). If a conductor (earthed

body) is located inside the distances indicated below, adjust using the ion balance manual setup.

"Ion Balance Adjustment Function" (page 7)

If two SJ-R units are used, refer to the following illustration and separate the static elimination bars

properly.

The interference distance between the conductive object and the static elimination bar and that

between the static elimination bars located in parallel are specified, on condition that the target is

located at the following distances under a down flow of 0.3 m/s.

The interference distance between the static elimination bars located face to face is specified under no

wind flow.

Frequency (Hz) Operating distance (mm)

50 50

30 150

10 300

8 600

5 900

3 1200

1 1500

20mm

min.

20mm

min.

20mm min.

30mm

min.

30mm

min.

Side-to-side installation

300mm

min.

Face-to-face installation

100mm

min.

2-2 Connection and Installation

This section describes how to connect and install the Static Elimination Head and Controller Unit.

Installing the SJ-M Series

■ Installing the Static Elimination Bar

●

Install the static elimination bar in the desired location.

Adjust the angle of the mounting brackets so that the

static elimination bar is properly secured at the desired

angle. Tap M4 screw holes at the appropriate location

and secure the static elimination bar using M4 screws.

• Do not allow any objects to contact the static elimination bar after

installation, as this may lead to product breakdown.

• When installing the SJ-M Series, observe the minimum bending radius of all

provided cables. Also, do not install the SJ-M Series with the cables

deformed by staples or other objects. Doing so might cause the SJ-M Series

to malfunction.

● When the mounting fixture is used:

When installing the drive unit, prepare tapped

mounting holes, and install the drive unit at a tightening

torque of 1 Nm or less (M4 screws: 1 Nm or less).

The M3 screws and bundling band for fastening the

mounting fixture must be prepared separately.

Make a space of 30 mm or more around the drive unit. Otherwise, the unit may

be damaged.

■ Installing the Controller unit

Mount the Controller Unit on the DIN rail.

M4 screws

M4 taps

In case of the side mounting, use the

ion balance adjustment function to

adjust the ion balance again.

( page 7)

Note

CAUTION

M4 Tap

CAUTION

FREQ

5

Page 7

2-2

Connection and Installation

Connecting Cables

When you have finished installing the Static Elimination Bar, connect the earth lead, Static Elimination

Head connector cable and power supply.

■ Connecting the earth lead

Open the terminal plate cover on the Controller

Unit, and connect the earth lead to the GND

connection terminal.

Be sure to connect a Class D earth (maximum

resistance of 100 Ohms).

To prevent electric shock and to ensure accurate static elimination, be sure to

connect a Class D earth (maximum resistance of 100 Ohms).

■ Connecting the cable

Connect the Static Elimination Bar

connector cable to the Controller Unit.

Connect this cable with the power

turned OFF.

When installing the Controller Unit

away from the Static Elimination Bar,

use the optional extension cable (SJC3).

■ Connecting the power supply

Connect the power supply according to either

of the following methods.

24 VDC power supply

Connect a 24 VDC output power supply

having sufficient power capacity margin to the

power terminals (terminals (5) and (6))

"Controller Unit (I/O terminal section)" (page

3)

Be sure to connect

a Class D earth

(maximum resistance

of 100 Ohms).

WARNING

Match and connect

the end of the connector

cable to the inlet on the

Controller Unit.

To 24 VDC

power supply

To 24 VDC

power supply

2-2

Connection and Installation

AC adapter (SJ-U2)

Connect the AC adapter to the connector on the side of

the Controller Unit.

The AC adapter is available as an option.

3-1 SJ-M Series Operations

This section describes operation of the SJ-M Series.

Setup Flow

The setup flow for setting up the SJ-M Series is as follows.

■ When the SJ-M Series is turned ON for the first time

■ Moving between modes

Modes on the SJ-M series change as follows.

The unit starts up in the Run mode after the power is turned ON or after static elimination is

stopped.

1 Frequency setting

2 Function setting

Set and change

functions

in each mode.

<Run mode> <Select mode>

<Ion Balance Manual Adjustment mode>

<Setup mode>

One lit Blink alternately Blink alternately fast

Press for

a short time.

"BALANCE" lit

Hold down for

at least 1 second.

Hold down for

at least 1 second.

Hold down and

simultaneously

for at least 1 second.

Tip

3-1

SJ-M Series Operations

Frequency setting

A frequency is set with the FREQ switch in the SJ-M Series.

For frequency settings in detail, see "About Static Elimination Performance" (page 4).

When the frequency changes, the ion balance adjustment value (see page 7) is

initialized. Adjust the ion balance again.

FREQ switch setting number Frequency

0 50Hz

1 30Hz

2 10Hz

38Hz

45Hz

53Hz

61Hz

7 Continuous positive ion generation

8 Continuous negative ion generation

9

Output terminal test mode. All output of alarm, ion level alarm,

condition alarm is ON. Static elimination stops.

FREQ

0

1

2

3

4

5

6

7

8

9

The illustration shows that the

FREQ switch is set to 0.

Note

6

Page 8

3-1

SJ-M Series Operations

Run Mode

Regular static elimination operation is performed in the Run mode.

The following functions are available in the Run mode.

●Ion monitor functions

"Ion Monitor Functions" (page 8)

●Alarm output functions

"Alarm Output Functions" (page 8)

●Confirmation of ion balance adjustment values

Select Mode

In this mode, select the setting items to change in the Setup mode

Setup Mode

In this mode, change the settings of the items selected in the Select mode.

A

B

C

D

Blink alternately

1

424

3

Operations in the Select mode

Press for a short time:

Enters the Setup mode for the currently selected item.

Hold down for at least 1 second:

Exits the Select mode, and returns to the Run mode.

: Move the cursor up and down.

On the ion monitor, the currently selected items are lit (green), and the items

whose defaults have been changed are lit (red).

Items that satisfy both of these conditions blink red and green alternately.

The following describes each of the items in the Select mode:

:

Ion level alarm, sensitivity setting

:

Condition alarm, sensitivity setting

:I.C.C. ON/OFF

:

Initialization of settings

1

424

3

Blink alternately fast

Operations in the Setup mode

:Applies the setting at the selected conditions.

:Move the cursor up and down.

The following describes each of the items in the Setup mode:

424

3

3-1

SJ-M Series Operations

■ Ion level alarm sensitivity setup

Sets the sensitivity at which the ion level alarm is output.

(1) High sensitivity (red): Alarms are easily output.

(2) Medium sensitivity (orange):

(3) Low sensitivity (green): Alarms are not easily output.

(4) No sensitivity (red): Alarms are easily output.

Default is “Low sensitivity.”

"Ion level alarm output function (ION LEVEL)" (page 8)

■ Condition alarm sensitivity setup

Sets the sensitivity at which the condition alarm is output.

(1) High sensitivity (red): Alarms are easily output.

(2) Medium sensitivity (orange):

(3) Low sensitivity (green): Alarms are not easily output.

(4) No sensitivity (red): Alarms are easily output.

Default is “Low sensitivity.”

"Condition alarm output function (COND)" (page 8)

①

②

③

④

Blin

k

Tip

①

②

③

④

Blin

k

Tip

3-1

SJ-M Series Operations

■ I. C. C. ON/OFF Setting

Advance to the

I.C.C. ON/OFF

setting from the Select mode in

page 7, and select either of the followings.

(1)

I.C.C. O N

(green) (Default)

(2)

I.C.C. O FF

(red)

■ Initialization of settings

Returns settings to their defaults.

(1) Press , or for a short time:

Returns to the Select mode without initializing the settings.

(2) Hold down for at least one second:

Initializes the settings and returns to the Select mode.

When settings are initialized, the ion monitor indication moves

towards both ends of the display.

①

②

Blin

k

Blin

k

When the I.C.C. OFF is selected, the ion level

alarm will not be output correctly. Ion level

monitor indication is not available, either.

Important

①

Blin

k

Tip

3-1

SJ-M Series Operations

Ion Balance Manual Adjustment Mode

In this mode, you can adjust the zero point, the point for reference for the I.C.C. function.

Ion Balance Adjustment Function

The SJ-M Series automatically senses the charged level of the target body by the I.C.C. function to

automatically control the generated amount (balance) of plus and minus ions.

The zero point, the point for reference for the I.C.C. function, is adjusted before the SJ-M Series is

shipped from the factory. However, in some environments, the zero point sometimes drifts. If this

reference zero point drifts, adequate static elimination cannot be maintained. For this reason, you need

to adjust the zero point again by “Ion Balance Adjustment Function”.

Do not turn the power OFF while the ion balance is being adjusted (about 1

minute).

■ Setting the ion balance

1 Hold down for at least one second to enter the ion

balance manual adjustment mode.

The ion balance indicator blinks.

2 Set the ion balance using .

The LED on the ion monitor corresponding to the set value lights.

CAUTION

Key Function

Key Shifts the zero point in the + direction.

Key Shifts the zero point in the – direction.

Hold down for a

t

least 1 second.

1

7

Page 9

3-1

SJ-M Series Operations

3 Press to end ion balance setup.

Holding down for about

one second when setting the

ion balance clears the preset

ion balance zero point and

returns the ion balance to its

default setting.

Blink fast

The mode changes to the Run mode.

After you have finished setting up the ion balance, the ion

balance indicator will blink fast fo r about max. three minites,

indicating that the ion balance setup is being written to memory.

After you have finished setting up the ion

balance, do not change the ambient

environment for about 1 minute. If you do, the

zero point sometimes cannot be set accurately.

Note

Note

During this operation,

the ion monitor indication

moves towards both ends

of the display.

3-2 Ion Monitor Functions

This section describes the ion monitor functions of the SJ-M Series.

Ion monitor functions are enabled in the Run mode.

Ion Monitor Functions

The charged level of the target object and the level of ions generated from the static elimination head

are indicated on the ion monitor.

The ion monitor indication can be switched by .

■ Charge monitor

This monitor indicates the charged and decharged

states of the target object.

The indication of this monitor fluctuates towards the

+ and – sides according to the charged level. The

further the indication is away from the center LED,

the larger the charged level. When static elimination

is completed, the indication returns to the center

LED so that you can easily tell how static

elimination is progressing.

The ion balance indicator lights when the charge

monitor is operating.

■ Ion level monitor

This monitor indicates the level of ions being

generated by the Static Elimination Head.

The level of plus ions being generated is indicated

on the upper side, while the level of minus ions is

indicated on the lower side. The further the

indication is away from the center LED, the larger

the level of ions. In a state where ions are being

sufficiently generated, both ends of this monitor light

(green).

The ion balance indicator lights when the ion level

monitor is operating.

Ion level monitor indication is not available when I.C.C. is OFF.

When I.C.C. is OFF, the ion balance indicator and ion level indicator light.

Red

Orange

Orange

Green

Orange

Orange

Red

Green

Green

Orange

Red

Orange

Green

Green

Max.

+ ion

Min.

Min.

- ion

Max.

Note

3-3 Alarm Output Functions

This section describes the alarm output functions of the SJ-M Series.

Alarm Output Functions

■ Alarm output function (ALARM)

The alarm indicator blinks (red) and an alarm signal

(control output (N.C.)) is output, for example, when

internal circuits are damaged or abnormal discharging

occurs. When an alarm signal is output, static

elimination is forcibly stopped.

Alarm output turns ON even in a static elimination

stopped state (including forced static elimination stop).

■ Ion level alarm output function (ION LEVEL)

The ion level alarm indicator lights and an alarm signal

(control output (N.O.)) is output when the level of

generated ions drops due to a dirty or worn electrode

probe, for example. When an alarm signal is output,

static elimination is not stopped.

Alarm output can be adjusted in three stages

according to the level of ions generated.

The default setting for the ion level alarm sensitivity

setting is Low.

The ion level alarm serves as a guideline for learning

when to perform maintenance on the electrode probe.

As static elimination is continued, be sure to turn the

power OFF before starting maintenance on the

electrode probe.

The ion level alarm output function is enabled in the

Run mode.

"Ion level alarm sensitivity setup" (page 7)

■ Condition alarm output function (COND)

The condition alarm output indicator lights and an

alarm signal (control output (N.O.)) is output when

static elimination performance is influenced by an

excessive charge on the target object. When an alarm

signal is output, static elimination is not stopped.

Alarm output can be adjusted in three stages

according to the installation environment. The default

setting for the condition alarm sensitivity setting is

Low.

The ion level alarm output function is enabled in the

Run mode.

"Condition alarm sensitivity setup" (page 7)

3-4 Other Functions

This section describes the abnormal discharge detection and static elimination stop functions of the SJM Series.

Abnormal Discharge Detection Function

To prevent trouble, the generation of ions is stopped when abnormal discharging caused by

condensation on the electrode probe tips or adhesion of debris, for example, is detected. At this time,

the alarm indicator and ion monitor blink to inform you that an abnormality has occurred. For details of

the indicated state on the Controller Unit (operation/display section), see "During an alarm (level 2)"

( page 13).

Static Elimination Stop Function

Static elimination only can be turned OFF in a powered ON state by two methods: by shorting the static

elimination stop input and 0V terminals on the Controller Unit (I/O terminal section), or by holding down

on the Controller Unit (operation/display section) simultaneously for about one second.

When static elimination stop input has been performed on the Controller Unit (operation/display

section), this state can be canceled by holding down simultaneously for about one second.

For details on indication states on the Controller Unit (operation/display section) when static elimination

stop input is canceled, see "Static elimination stop input (operation/display section)" ( page 13).

■ Static elimination stop input

Static elimination is stopped by either of the following methods.

By operation on the Controller Unit (I/O terminal section):

Short the static elimination stop input and 0V

terminals to stop static elimination.

The center LED of the ion monitor blinks (red).

"Controller Unit (I/O terminal section)" (p age

3)

To 24 VDC

power supply

To 24 VDC

power supply

8

Page 10

3-4

Other Functions

By operation on the Controller Unit (operation/display section):

Hold down simultaneously for about one

second to stop static elimination.

The three center LEDs of the ion monitor blink

(red).

Air Purge Function

Supplying clean air through the air duct on both ends of the static elimination bar will prevent the dust

accumulation on the electrode probes (SJ-M0

*

0G/V type). The air purge widens the static elimination

area and increases the speed of static elimination as well.

* The air pressure indicates the pneumatic value at the route of the joint.

Use clean air or dry air of temperature –25°C, and of mesh size of about 0.01 μm.

When supplying air to the SJSJ-G, SJ-V/VC Series, you can use the active carbon filter to decrease

the dust accumulation on the electrode probes.

• Be sure to limit the air pressure to 0.2 MPa. Exceeding this limit may cause

accidents or malfunction.

• Be sure to use clean air, dry air as the air for supplying to the Static

Elimination Head. Moisture or oil contained in the air or nitrogen may cause

discharge inside the Static Elimination Head, which may result in accidents

or malfunction.

■ Relationship between air pressure and air flow with different bar lengths

The relationship between air pressure and air flow varies depending on the length of the static

elimination bar.

Refer to the typical example below to select the appropriate air supply device (compressor) that will

supply sufficient air flow.

Hold down for

at least 1 second.

CAUTION

50

60

40

30

20

10

0

0

0.05

0.1 0.15 0.2

Charged level (V)

Time (secs)

SJ-M030

SJ-M030C

SJ-M030G

SJ-M030V

SJ-M030VC

0.05 0.1 0.15 0.2

SJ-M070/070C

SJ-M070G

SJ-M070V/070VC

120

100

80

60

40

20

0

0

Air pressure(MPa)

Air flow(Nl/min)

3-4

Other Functions

■ Relationship between operating time and operating distance with different

air pressure

The relationship between operating time and operating distance varies depending on the air pressure.

Refer to the typical example on the right to select the appropriate air pressure.

Model: SJ-M030/030C Model: SJ-M070/070C

Model: SJ-M030G Model: SJ-M070G

* 9NL/min is minimum air flow to get a CAB effect.

* 21NL/min is minimum air flow to get a CAB effect.

Model: SJ-M030V/030VC Model: SJ-M070V/070VC

* 3NL/min is minimum air flow to get a ACAB effect.

* 7NL/min is minimum air flow to get a ACAB effect.

0

1

2

3

4

5

6

7

8

9

10

0 50 100 150 200 250 300 350

Operating distance (mm)

Operating time (sec.)

No air

0.001MPa

0.01MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0 50 100 150 200 250 300 350

Operating distance (mm)

Operating time (sec.)

No air

0.001MPa

0.01MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0 50 100 150 200 250 300 350

Operating distance (mm)

Operating time (sec.)

No air

9NL/min

0.02MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0 50 100 150 200 250 300 350

Operating distance (mm)

Operating time (sec.)

No air

21NL/min

0.02MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0 50 100 150 200 250 300 350

Operating distance (mm)

Operating time (sec.)

3NL/min

0.05MPa

0.2MPa

0

1

2

3

4

5

6

7

8

9

10

0 50 100 150 200 250 300 350

Operating distance (mm)

Operating time (sec.)

7NL/min

0.05MPa

0.2MPa

3-4

Other Functions

■ Air supply method

As shown in the following figure, remove the screwwhich closes the air duct on the edge of the Static

Elimination Bar first. Then, attach a joint to the air duct and supply air.

• Be sure to limit the tightening torque to 2 N·m (20 kgf·cm) or less.

Otherwise, an accident or product breakdown may occur.

• Be sure to supply only clean, dry air. The use of improper air may cause an

accident or product breakdown.

● R ecommended joint

The recommended joint is the tube fitting(tube diamete: I6 mm, I8 mm) manufactured by Pisco Co..

CAUTION

Tube

Rc1/8

Joint for end unit

R1/8

Tube diameter I 6 mm : PC6-01SUS

Tube diameter I 8 mm : PC8-01SUS

3-4

Other Functions

I.C.C. Setting

The I.C.C. (Ion Current Control) can be turned on and off.

Turning off the I.C.C. allows the ion balance adjustment function to generate positive and negative ions

at a fixed ratio.

①

②

Either of them lit Blink alternately

Hold down

for at least

1 second

Hold down for at

least 1 second

simultaneously

<Run mode> <Select mode>

Change

Blink

Blink

Change the 4th LED from the top in the Select mode.

Press for a short time : advances to the Setup mode

of the selected item

Hold down for at least 1 second: exits the Select mode and

returns to the Run mode

: moves the cursor up and

down

On the ion monitor, the currently selected items are lit in green and the

items whose default have been changed are lit in red.

I.C.C. is set at ON by default setting.

Items that satisfy both of these conditions blink in red and green

alternately.

Advance to the I.C.C. ON/OFF setting from the Select mode in page 7,

and select either of the followings.

(1) I.C.C. ON (green) (Default)

(2) I.C.C. OFF (red)

When the I.C.C. OFF is selected, the ion level

alarm will not be output correctly. Ion level

monitor indication is not available, either. In the

Run mode, only the charge monitor is operating,

and the ion balance indicator and ion level

indicator light.

Important

9

Page 11

4-1 About Maintenance

Maintenance must be performed periodically to ensure that the static elimination performance of the

SJ-M Series is fully demonstrated. Maintenance personnel should thoroughly read the descriptions

under "Safety Precautions" ( page 1), and perform maintenance paying attention to the following

points.

About Maintenance

•

The SJ-M Series uses high voltage. Before starting maintenance, be sure to

turn the power OFF. Failure to do so might result in electric shock or

malfunction.

•

Do not directly touch the electrode probe. Take

care not to touch these probes even if the

power is turned OFF. Directly touching these

probes may cause personal injury.

When the SJ-M Series is used for a long period of time, the electrode probe becomes dirty due to the

adhesion of dust and dirt.

If the ion level alarm indicator lights, clean the electrode probe. If the electrode probe is used in a dirty

or dusty state, static elimination performance can no longer be fully demonstrated, resulting in

accidents or malfunction. We recommend periodically cleaning the electrode probe (as a guideline,

once every two weeks in a regular operating environment though this depends on the installation

conditions).

If cleaning the electrode probe does not improve the static elimination performance, or the ion level

alarm indicator frequently lights, replace the electrode probe.

If I.C.C. is set to OFF, the ion level alarm can not be judged correctly.

WARNING

Important

4-2

Performing Maintenance on the Electrode probe

When the SJ-M Series is used for a long period of time, the electrode probe becomes dirty due to the

adhesion of dust and dirt.

If the electrode probe is used in a dirty or dusty state, static elimination performance can no longer be

fully demonstrated, resulting in accidents or malfunction. Be sure to periodically perform maintenance

on the electrode probe.

Performing Maintenance on the Electrode probe

• At the time of maintenance, turn the SJ-M Series OFF.

• Do not directly touch the electrode probe with your hands. Doing so may

cause personal injury. Pay attention to this when performing maintenance

on the electrode probe.

■ How to clean the electrode probe

Clean the electrode probe gently with a cotton

wool bud moistened with alcohol.

■ How to replace the electrode probe

If the static elimination performance of an electrode probe does not recover or the ION LEVEL indicator

is lit frequently after cleaning, the life of the electrode probemay be expired. In that case, replace the

electrode probe.

Use the tungsten electrode probe as spares for SJ-G Series.

Replace all the remaining electrode probes along with the bad one, regardless of whether the

remaining electrode probes are still in serviseable condition or not.

WARNING

5-1 Timing Charts

This section provides timing charts for SJ-M Series.

■ Ion generation control timing chart

Indicator states when static elimination is OFF

Normal static elimination OFF

<during static elimination stop

input (terminal)>

The center LED of the ion monitor blinks (red).

■ Input response timing chart

Normally ON Normally OFF Normally ON Forced OFF Normally ON Normally OFF Normally ON

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (controller)

ON

OFF

Ion emission state

Unit indicator

Emitting

No emissions

Alarm output

ON

OFF

Forced OFF Forced OFFNormally ONNormally OFF

Max. 15 ms Max. 1 s

Static elimination

stop input (unit)

ON

OFF

Ion emission

state

Emitting

No emissions

Normal static elimination OFF <during

static elimination stop input (controller)>

The three center LEDs of the ion monitor

blink (red).

5-1

Timing Charts

■ Ion level alarm output timing chart

■ Condition alarm output timing chart

■ Alarm output timing chart

Power

ON

OFF

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (controller)

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output (N.C.)

ON

OFF

Ion emission

Emitting

No emissions

Ion level indicator

Max. 15s

Blinking

OFF

Ion level alarm

output (N.O.)

ON

OFF

When the ion level al arm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

perform maintenance on the electrode

probe.

For details on electrode probe

maintenance, see "Perfor

ming

Maintenance on the Electrode probe"

(page 10).

Power

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output (N.C.)

ON

OFF

Ion emission

Emitting

No emissions

Condition indicator

Blinking

OFF

Condition alarm

output (N.O.)

ON

OFF

Max. 15s

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (controller)

ON

OFF

When the condition alarm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

improve the installation environment.

Power

ON

OFF

Static elimination

stop input

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output (N.C.)

ON

OFF

Ion emission

Emitting

No emissions

Max. 15s

When the alarm is output, the normal

state can be restored by perfor ming

one of the two available restore

methods depending on the cause of

alarm output.

For details on how to restore the

normal state, see “Durin

g an alarm

(levels 1, 2)” ( page 13).

10

Page 12

5-2 Specifications

This section provides the specifications of the SJ-M300 Series.

■ Static Elimination Bar/Controller Unit

*1: The following conditions were applied for measurement.

Please inquire for ion balance in operating distance 50mm (50 Hz) of a V,VC type separately.

*2: The effective length represents the operating area at an operating distance of 50 mm.

*3: The total length represents the length of the model with a mounting bracket attach.

■ AC adapter

* The power cable supplied with SJ-U2 is 125V rated power voltage.

Model

Static Elimination Bar

SJ-M030/030C/030G/

030V/030VC

SJ-M070/070C/070G/

070V/070VC

Controller Unit SJ-M300

Voltage application method Pulse AC

Applied voltage ±5.5 kV

Rated output voltage ±6 kV

Ion balance control method I.C.C. method

Ion balance *1 ±30 V

Air purge supply pressure 0.2 MPa max.

Control input

Static elimination stop input

No-voltage input

Control output

Alarm output

NPN open collector

100 mA 40 V or less

Ion level alarm output

Condition alarm output

Rating

Power voltage 24 VDC ±10%

Current consumption 450 mA max.

Environmental

resistance

Operating ambient

temperature

0 to +40°C

Operating ambient

humidity

35 to 65%RH, No condensation

Effective length *2 164 mm 324 mm

Total length *3 220 mm 380 mm

Weight

Static elimination bar Approx. 600 g Approx. 720 g

Controller Approx. 300 g

Model(Static

elimination bar)

SJ-M030/070 SJ-M030C/070C SJ-M030G/070G SJ-M030V/070V

SJ-M030VC/070VC

Air purge None None

(3 NL/min)/

1 electrode

(1 NL/min)/

1electrode

(1 NL/min)/

1electrode

Downward air flow 0.3m/s

Operating distance 50mm(50Hz), 600mm(8Hz), 1500mm(1Hz)

Model SJ-U2

Rating

Rated input 100 to 240 VAC (50/60 Hz)

Rated output 24 VDC 2.65 A

Environmental resistance

Operating ambient temperature 0 to +35°C

Operating ambient humidity 20 to 80%, No condensation

Weight Approx. 250 g

5-3 External Dimensions

This section presents the external dimensions of the SJ-M Series.

■ Body

Static Elimination Bar

At the time of

front installation

46 (SJ-M030/030C/030G)

41 (SJ-M030V/030VC)

26.5

5.5

29

26

43 40 40

220

200

At the time of

side installation

(17.5)

Rc1/8

17.5

28.5 (SJ-M030/030C/030G)

23.5 (SJ-M030V/030VC)

(17.5)

240(P=40x6)

5.5

26.5

43

380

360

At the time of

side installation

Rc 1/8

46(SJ-M070/070C/070G)

41(SJ-M070V/070VC)

28.5(SJ-M070/070C/070G)

23.5(SJ-M070V/070VC)

17.5

29 26

At the time of

front installation

15 mm dia.

51

3

18

2-4.4 mm dia.(thru hole)

191

181

24

30

2.5

11.5

5

131

5

8.5

6 mm dia. cable length

300mm (min. bend radius 18)

10 mm dia.cable length 800mm

min. bend radius 30

35

5-3

External Dimensions

Controller Unit SJ-M300

Mounting Fixture detail

■ Extension cable (SJ-C3)

■ AC adapter (SJ-U2)

* For details of the AC cable, contact the KEYENCE sales office in your district.

50

120

5

70

32

76

46

36

89

37

26

13

hole for self-tapping

screw(2-M3)

(screw hole depth= 6mm)

5

4

28

18

18

11

4

27.5

17.5

29

6 mm dia.

cable length 3 m

49

15.5

51

15

(37.5)

7

ø16

(10.3)

(16.3)

(12.5)

(14)

28

ø3.5

1800

114.5

50.5

1 Troubleshooting

This appendix describes trouble that may occur during use of the SJ-M Series and how to remedy this

trouble. Check the following table before sending in your SJ-M Series for repair.

Symptom Check Item Remedy

No indication on ion

monitor

Is the power cable connected

properly?

Connect the power cable correctly.

Is a power supply within specification

being used?

Use a power supply that is within

specification.

Static elimination is

not performed.

Is the electrode probe worn or dirty?

Perform maintenance on the electrode probe

or replace the Electrode Unit.

Is static elimination stop currently

set?

Cancel static elimination stop input on the SJM Series.

Is the abnormal discharge detection

function operating?

Check the Static Elimination Bar for any

conductive substances (e.g. oil droplets).

Static elimination is

not performed

properly.

Are conductors or other Static

Eliminators located nearby the Static

Eliminator?

Move the Static Eliminator away from

conductors or other static eliminators nearby.

The ion level alarm is

output/indicated.

Is the electrode probe worn or dirty?

Perform maintenance on the electrode

probes or replace the Static Elimination Bar.

Are conductive o

bjects located in

the

surrounding area?

Check the installation state.

"Locat

ions"(page 5)

The condition alarm is

output/indicated.

Are static elimination target objects

having a very high charged level

located nearby the Static

Eliminators?

Increase the number of connected static

eliminators.

Is the electrode probe worn or dirty?

Perform maintenance on the electrode

probes or replace the Static Elimination Bar.

The alarm indicator

lights.

–

Check “During an alarm (levels 1, 2)”

( page13) in this Instruction Manual.

Control output is not

output correctly.

Is output wired correctly?

Check the output circuit and wiring, and

connect correctly.

Static elimination stop

input is not input

correctly.

Is input wired correctly?

Check the input circuit and wiring, and

connect correctly.

Do not know meaning

of indicators.

–

Chec

k "Table of Indicated States" ( page

12) in this Instruction Manual.

11

Page 13

2 Table of Indicated States

This appendix describes the various indicated states of the SJ-M Series.

■ Indicated states when the power is turned ON

Lit State Description

The charged level indication, ion level

indication, the alarm indicator, ion level

alarm indicator, and condition alarm

indicator light (red).

The ion monitor LEDs fluctuate upward

and downward.

When the power is turned ON, the charged level indication, ion

level indication, the alarm indicator, ion level alarm indicator and

condition alarm indicator light (red). After this indication state

continues for about two seconds, the ion monitor LEDs fluctuate

upward and downward, and static elimination is then started.

After static elimination starts, the charged level or ion level is

indicated.

2

Table of Indicated States

■ Mode indications (except when the power is turned ON)

Lit State Mode Desc ription

Either of the ion balance or ion level

indicators is lit.

Run mode

The SJ-M Series is operating in the Run mode. For

details on other indications, see the following.

"Indications in the Run mode" (page 12)

The ion balance indicator is blinking.

Ion Balance

Manual

Adjustment mode

For details on other indications in the Ion Balance

Manual Adjustment mode, see the following.

"Ion Balance Manual Adjustment Mode" (page

7)

The ion balance indicator is blinking fast.

End of ion

balance manual

adjustment (Run

mode)

The SJ-M Series is storing the setup information

after ion balance manual adjustment. Though the

SJ-M Series is operating in the Run mode, it cannot

enter the Select mode yet.

"Ion Balance Manual Adjustment Mode" (page 7)

The ion balance indicator and ion level

indicator blink alternately.

Select mode

For details on other indications in the Select mode,

see the following.

"Select Mode" (page 7)

The ion balance indicator and ion level

indicator blink alternately fast.

Setup mode

For details on other indications in the Setup mode,

see the following.

"Select Mode" (page 7)

Both the ion balance indicator and ion

level indicators are out.

Other

Static elimination is not being performed. For

details on other indications, see the following.

"Other indications" (page 13)

2

Table of Indicated States

■ Indications in the Run mode

Lit State Description

One of the ion monitor LEDs and the ion

balance indicator light (red).

Charged level indication

This indicates the charged level of the target object. When there

is a plus charged object, the LEDs on the upper side (+ side)

light, and when there is a minus charged object, the LEDs on the

lower side (– side) light according to the charged level.

One each of the plus and minus side

LEDs of the ion monitor, and the ion level

indicator light (red).

Ion level indication

This indicates the level of ions that are being generated by the

SJ-M Series.

Charged level indication or ion level

indication

Display selection

The display switches to the charged level indication when (DISP)

is pressed while the ion level is indicated.

When the charged level is indicated, the display switches to the

ion level indication.

The ion balance indicator lights, and one

of the ion monitor LEDs blinks.

Ion balance manual setup confirmation

If the device is not in an ion balance manual setup state, you can

confirm the ion balance manual setup by pressing either of the

ion balance adjustment keys. During confirmation, the ion

monitor LEDs blink in one of the following three colors:

Orange: The LED blinks (orange) at the position corresponding

to the setup state when ion b

alance manual setup is

be

ing performed. (Sometimes the center LED also is

lit.)

Red: The LED at t

he edge of the side (+ or –) that was set

blinks (red) when the set value was set to MAX during

ion balance manual setup.

Green: The center LED blinks (green) for the duration that the

ion balance adjustment key is held down when ion

balance manual setup is not being performed.

Hold down for

less than 1 second.

2

Table of Indicated States

The condition alarm indicator lights (red).

Condition alarm

The condition alarm indicator lights (red) when the ion balance

has deteriorated influenced by the installation environment.

The ion level alarm indicator lights (red).

Ion level alarm

The ion level alarm indicator lights (red) when the generated ion

level falls below the preset level.

The ion balance indicator and ion level

indicator light (red).

I. C. C. OFF

While I.C.C. shows OFF, the ion balance indicator and ion level

indicator continue to light (red).

Lit State Description

12

Page 14

2

Table of Indicated States

■ Other indications

Lit State Description

The center LED of the ion monitor blinks

(red).

Static elimination stop input (I/O terminal section)

The center LED of the ion monitor blinks (red) when the static