Kenmore Elite 42 Italian-Design Wall-Mounted Range Hood, Elite 36 Italian-Design Wall-Mounted Range Hood, Elite Large Flue Extension, Elite 30 Italian-Design Wall-Mounted Range Hood Installation Guide

E L l T

an e

use & Care / installation Manual

pana

Manual de uso y cuidado /instalaci6n

Models

Modelos

233.52303200 (3o"wide/ 76,2cm de ancho)

233.52363200 (36" wide/91,4 cm de ancho)

233.52423200 (42" wide/106,7 cm de ancho)

J

0

u

m

t_

0

Sears, Roebuck and Co,, Hoffman Estates, HL60179 U,S,A, www,sears,com

WARNING WARNING

SUITABLE FOR USE IN HOUSEHOLD

COOKING AREA.

TO REDUCETHE RISK OF FIRE, ELECTRICAL

SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended by

the manufacturer. If you have questions, corn

tact the manufacturer at the address or tele_

phone number listed in the warranty.

2. Before servicing or cleaning unit, switch power

off at service pane! and lock service panel to

prevent power from being switched on

accidentally. When the service disconnecting

means cannot be locked, securely fasten a

prominent warning device, such as a tag, to

the service panel.

3. Installation work and electrical wiring must be

done by a qualified person(s) in accordance

with all applicable codes and standards, includ-

ing fire=rated construction codes and stare

dards.

4. Sufficient air is needed for proper combustion

and exhausting of gases through the flue (chim_

ney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment

manufacturer's guidelines and safety stare

dards such as those published by the National

Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and

the local code authorities.

5. When cutting or drilling into wail or ceiling, do

not damage electrical wiring and other hidden

utilities.

6. Ducted fans must always be vented to the out-

doors.

7. Do not use this unit with any solid=state speed

control device.

8. To reduce the risk of fire, use only steel

ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

A. Neverleavesurface units unattended athighsettings.

Boilovers cause smoking and greasy spillovers that

mayignite.Heatoils slowlyon lowormedium settings.

B. AIwaysturn hood ON when cooking athigh heat or

whencooking flaming foods.

C. Cleanventilating fans frequently. Grease should not

beallowed to accumulate on fan or filter.

D. Useproper pansize.Always usecookwareappropriate

for the size of the surface element.

TO REDUCE THE RtSK OF INJURY TO PER-

SONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close=fitting lid,

cookie sheet, or metal tray, then turn off the

burner. BE CAREFULTO PREVENT BURNS.

Ifthe flames do not go out immediately, EVACU=

ATE AND CALLTRE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN =You may

be burned.

3. DO NOT USE WATER, including wet dishcloths

or towe!s =vio!ent steam explosion will result.

4. Use an extinguisher ONLY" if:

A. You know you have a C!ass ABC extim

guisher and you already know how to op=

erate it.

B. The fire is small and contained in the area

where it started.

C. The fire department is being called.

D. "Youcan fight the fire with your back to an

exit.

* Based on "Kitchen Fire Safety Tips" pub=

lished by NFPA.

CAUTION

1. To reduce risk of fire and to properly exhaust air,

be sure to duct air outside. Do not vent exhaust

air into spaces within wails or ceilings or into

attics, crawl spaces, or garages.

2. Take care when using cleaning agents or

detergents.

3. Avoid using food products that produce flames

under the Range Rood.

4. For general ventilating use only. Do not use to

exhaust hazardous or explosive materials and

vapors.

5. To avoid motor bearing damage and noisy and/

or unba!anced impellers, keep drywa!l spray,

construction dust, etc. off power unit.

6. Your hood motor has a thermal over!oad which

will automatically shut off the motor ifitbecomes

overheated.The motor will restart when it cools

down. If the motor continues to shut off and

restart, have the hood serviced.

7. For best capture of cooking impurities, the

bottom of the hood should be a minimum of 24"

and a maximum of 30" above the cooking sur=

face.

8. Two installers are recommended because of the

large size and weight of this hood.

9. Please read specification !abel on product for

further information and requirements.

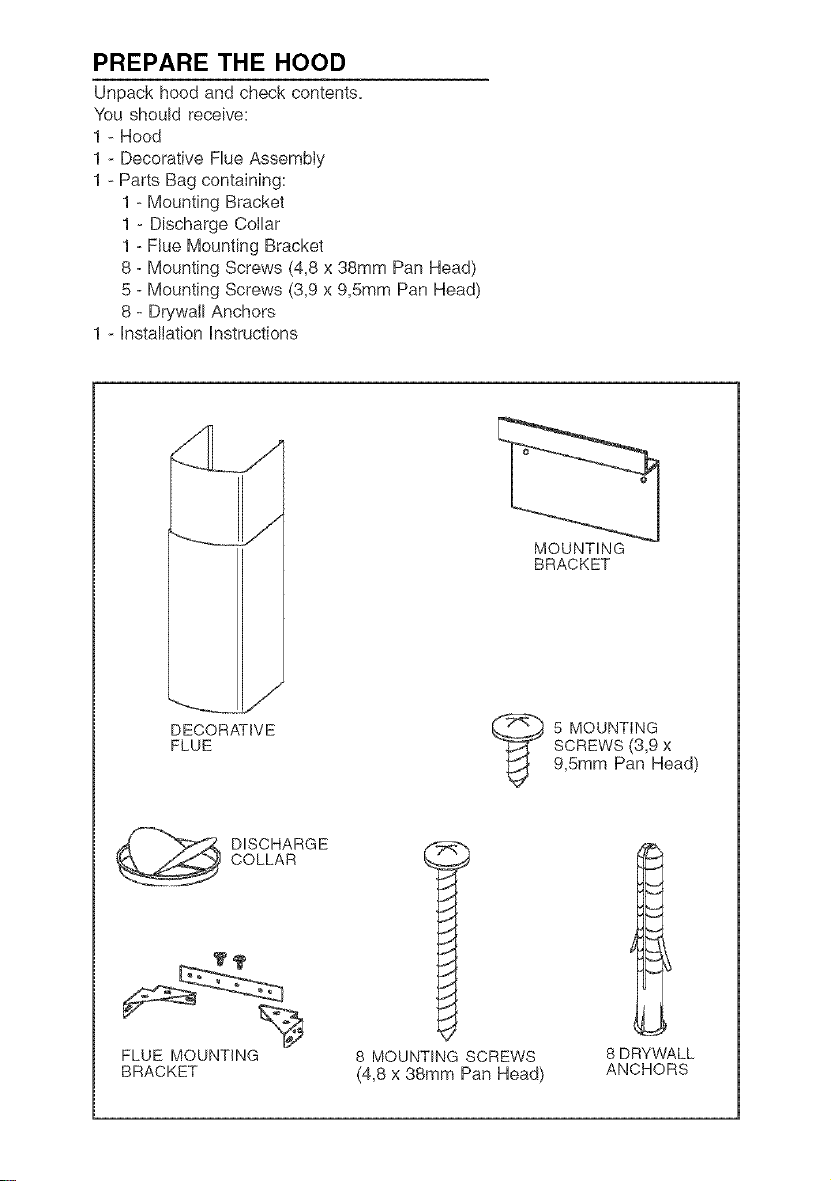

PREPARE THE HOOD

Unpack hood and check contents_

You should receive:

1 - Hood

1 - Decorative Flue Assembly

1 - Parts Bag containing:

1 - Mounting Bracket

1 - Discharge Collar

1 - Flue Mounting Bracket

8 - Mounting Screws (4,8 x 38mm Pan Head)

5 - Mounting Screws (3,9 x 9,Smm Pan Head)

8 - Drywall Anchors

1 - Installation Instructions

MOUNTING

BRACKET

DECORATIVE

FLUE

_ ISCHARGE

COLLAR

FLUE MOUNTING

BRACKET

_ 5 MOUNTING

SCREWS (3,9 x

9,Smm Pan Head)

8 MOUNTING SCREWS

(4,8 x 38mm Pan Head)

t;

8 DRYWALL

ANCHORS

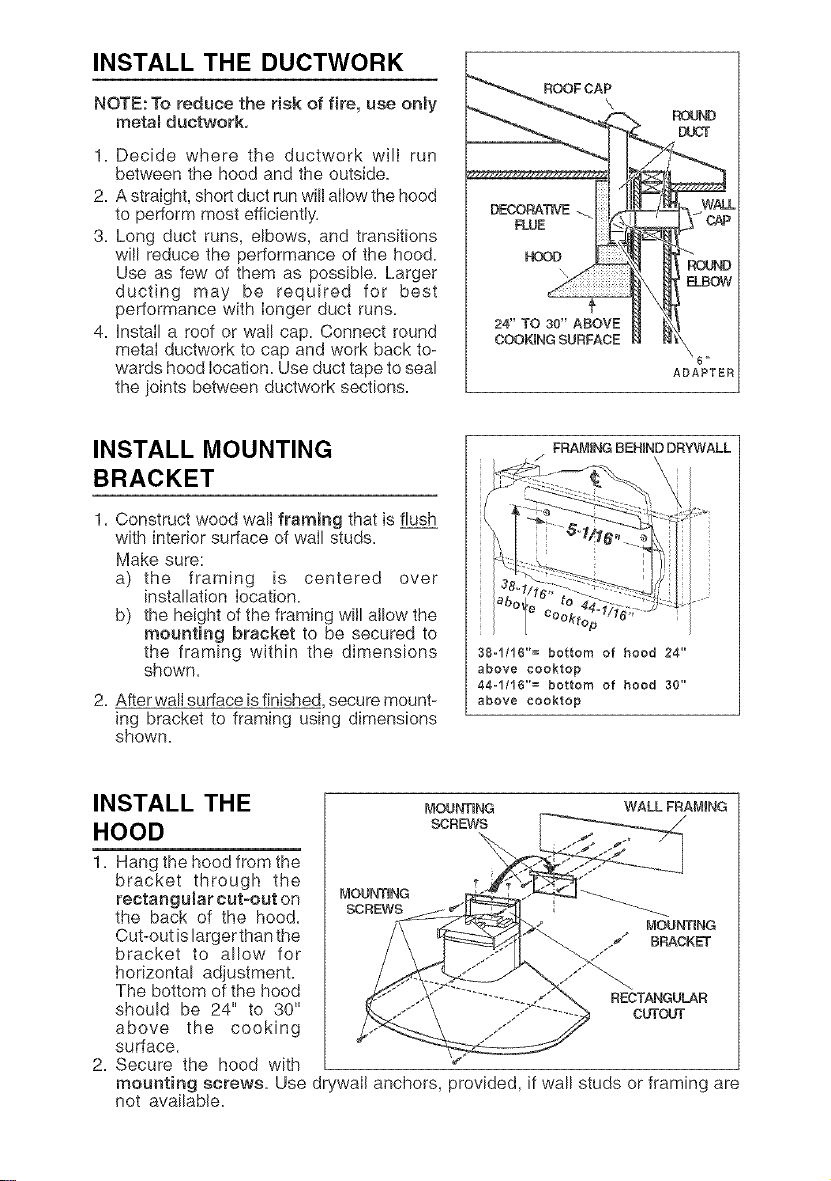

INSTALL THE DUCTWORK

NOTE: To reduce the risk of fire, use only

metal ductwork,

1. Decide where the ductwork will run

between the hood and the outside.

2. A straight, short duct run will allow the hood

to perform most efficiently.

3. Long duct runs, elbows, and transitions

wilI reduce the performance of the hood.

Use as few of them as possible. Larger

ducting may be required for best

performance with longer duct runs.

4. install a roof or wall cap. Connect round

metal ductwork to cap and work back to-

wards hood location. Use duct tape to seal

the joints between ductwork sections.

24" TO 30" ABOVE

COOKING SURFACE

ROUND

@

, !\ _D

=BOW

6"

ADAPTER

INSTALL MOUNTING

BRACKET

1=Construct wood wall framing that is flush

with interior surface of wail studs.

Make sure:

a) the framing is centered over

installation location.

b) the height of the framing wilI allow the

mounting bracket to be secured to

the framing within the dimensions

shown.

2. Afterwall surface is finished secure mount-

ing bracket to framing using dimensions

shown.

FRAMING BEHIND DRYWALL

38oi/16"= bottom of hood 24"

above eooktop

44o1/16"= bottom of hood 30"

above eooktop

INSTALL THE

HOOD

1. Hang the hood from the

bracket through the

rectangular cut-out on

the back of the hood.

Cut-out islarger than the

bracket to allow for

horizontal adjustment.

The bottom of the hood

should be 24" to 30"

above the cooking

surface.

2. Secure the hood with

mounting screws. Use dr

not available.

MOUNTENG WALL FRAMING

SCREWS

MOUN_NG

SCREWS

MOUN_NG

y'° BRACKET

RECTANGULAR

CUTOUT

fwalI anchors, provided, if wall studs or framing are

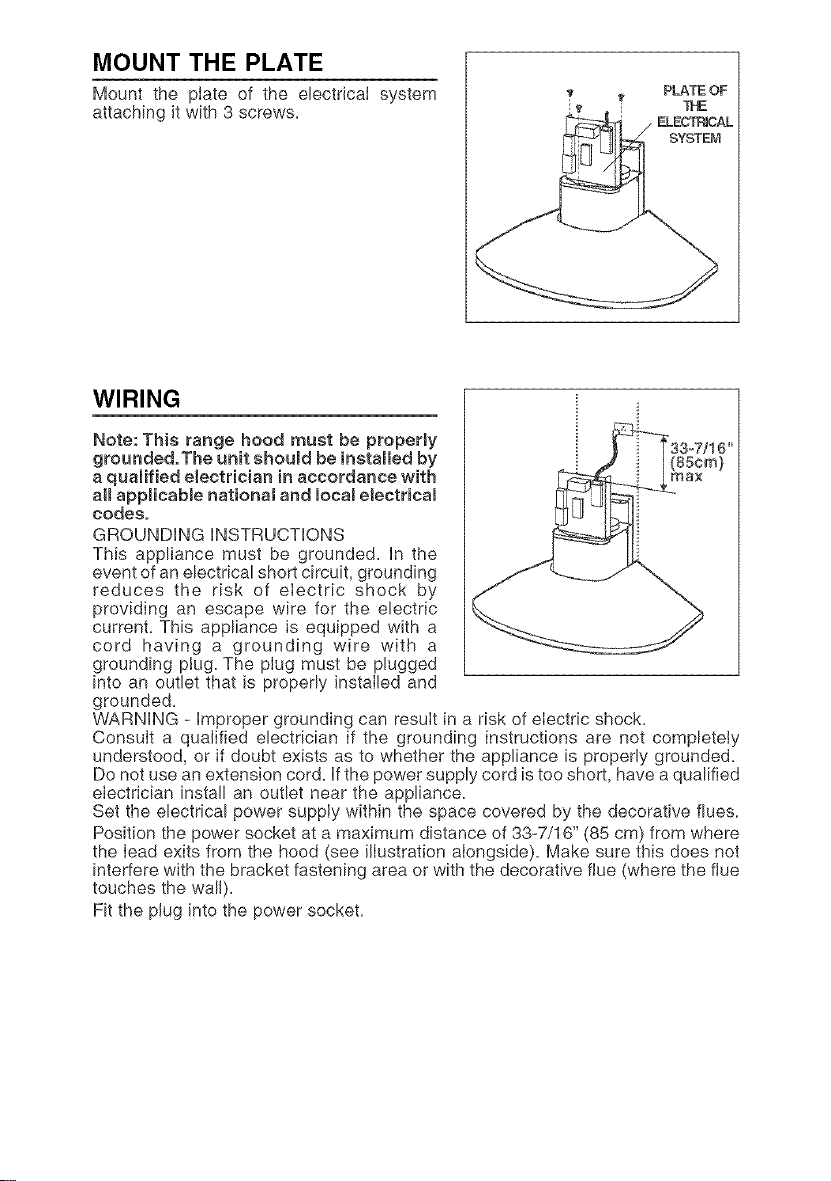

MOUNT THE PLATE

Mount the plate of the electricaI system

attaching it with 3 screws,

PLATE OF

ELECTF_AL

SYSTEM

WIRING

Note: This range hood must be properly

grounded.The unit shoumd be installed by

a qualified electrician in accordance with

all appHcabme national and mocalelectricam

codes.

GROUNDING INSTRUCTIONS

This appliance must be grounded, In the

event of an electrical short circuit, grounding

reduces the risk of electric shock by

providing an escape wire for the electric

current, This appliance is equipped with a

cord having a grounding wire with a

grounding plug, The plug must be plugged

into an outlet that is properly instaIled and

grounded,

WARNING - Improper grounding can result in a risk of electric shock,

ConsuIt a qualified electrician if the grounding instructions are not completely

understood, or if doubt exists as to whether the appliance is properly grounded,

Do not use an extension cord, If the power supply cord is too short, have a qualified

eIectrician install an outlet near the appliance,

Set the electrical power supply within the space covered by the decorative flues,

Position the power socket at a maximum distance of 33-7/16" (85 cm) from where

the Iead exits from the hood (see ilIustration aiongside), Make sure this does not

interfere with the bracket fastening area or with the decorative flue (where the flue

touches the wall),

Fit the plug into the power socket,

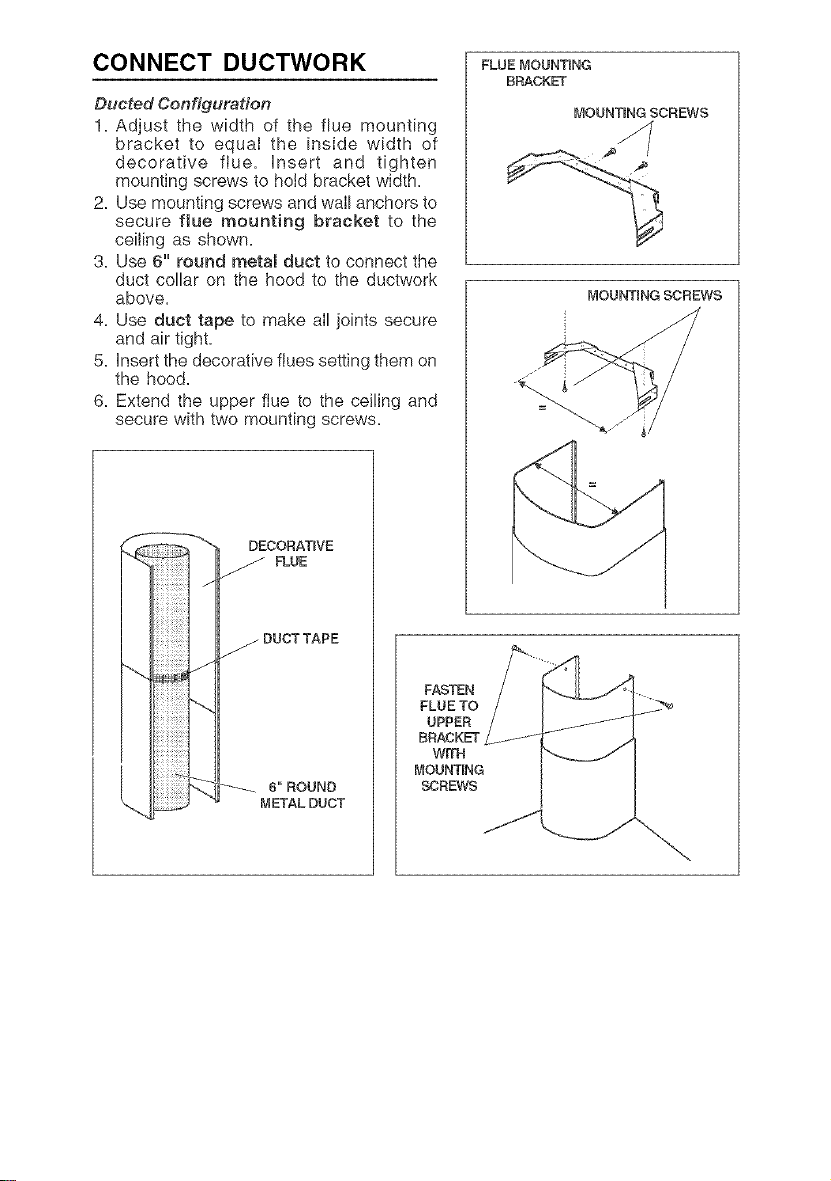

CONNECT DUCTWORK FLUEMOUNTtNG

BRACKET

Ducted Configuration

1. Adjust the width of the flue mounting

bracket to equal the inside width of

decorative flue. insert and tighten

mounting screws to hold bracket width.

2. Use mounting screws and wall anchors to

secure flue mounting bracket to the

ceiling as shown.

3. Use 6" round metal duct to connect the

duct collar on the hood to the ductwork

above.

4. Use duct tape to make alI joints secure

and air tight.

5. Insert the decorative flues setting them on

the hood.

6. Extend the upper ftue to the ceiling and

secure with two mounting screws.

DECORATIVE

FLUE

j DUCTTAPE

6"ROUND

METALDUCT

MOUNTENG SCREWS

MOUNTING SCREWS

FASTEN

FLUETO

UPPER

BRACKET

WrrH

MOUNTING

SCREWS

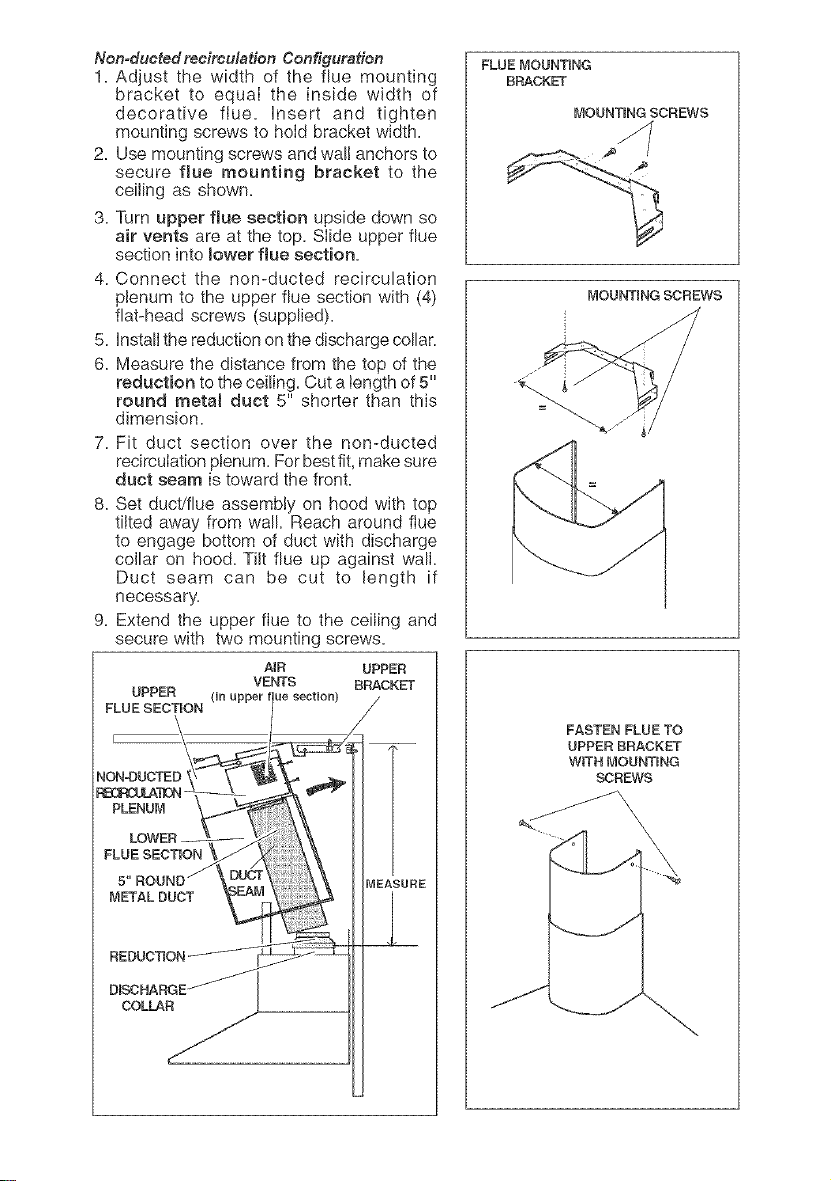

Nomductedrecirculation Configuration

1. Adjust the width of the flue mounting

bracket to equal the inside width of

decorative flue. insert and tighten

mounting screws to hold bracket width.

2. Use mounting screws and wall anchors to

secure flue mounting bracket to the

ceiling as shown.

3. Turn upper flue section upside down so

air vents are at the top. Slide upper flue

section into mowerflue section.

4. Connect the non-ducted recirculation

plenum to the upper flue section with (4)

fiat-head screws (supplied).

5. Install the reduction on the discharge collar.

6. Measure the distance from the top of the

reduction to the ceiling. Cut a iength of 5"

round metal duct 5" shorter than this

dimension.

7. Fit duct section over the non-ducted

recirculation plenum. For bestfit, make sure

duct seam is toward the front.

8. Set duct/flue assembly on hood with top

tilted away from wall Reach around flue

to engage bottom of duct with discharge

collar On hood. TiNtflue up against wall.

Duct seam can be cut to length if

necessary.

9. Extend the upper flue to the ceiling and

secure with two mounting screws.

UPPER

FLUE SECTION

AIR UPPER

VENTS BRACKET=

(nnupper Je sectnon)

FLUE SECTION

METAL DUCT

COLLAR

FLUE MOUNTING

BRACKET

MOUNTENG SCREWS

MOUNTING SCREWS

FASTEN FLUE TO

UPPER BRACKET

WiTH MOUNTING

SCREWS

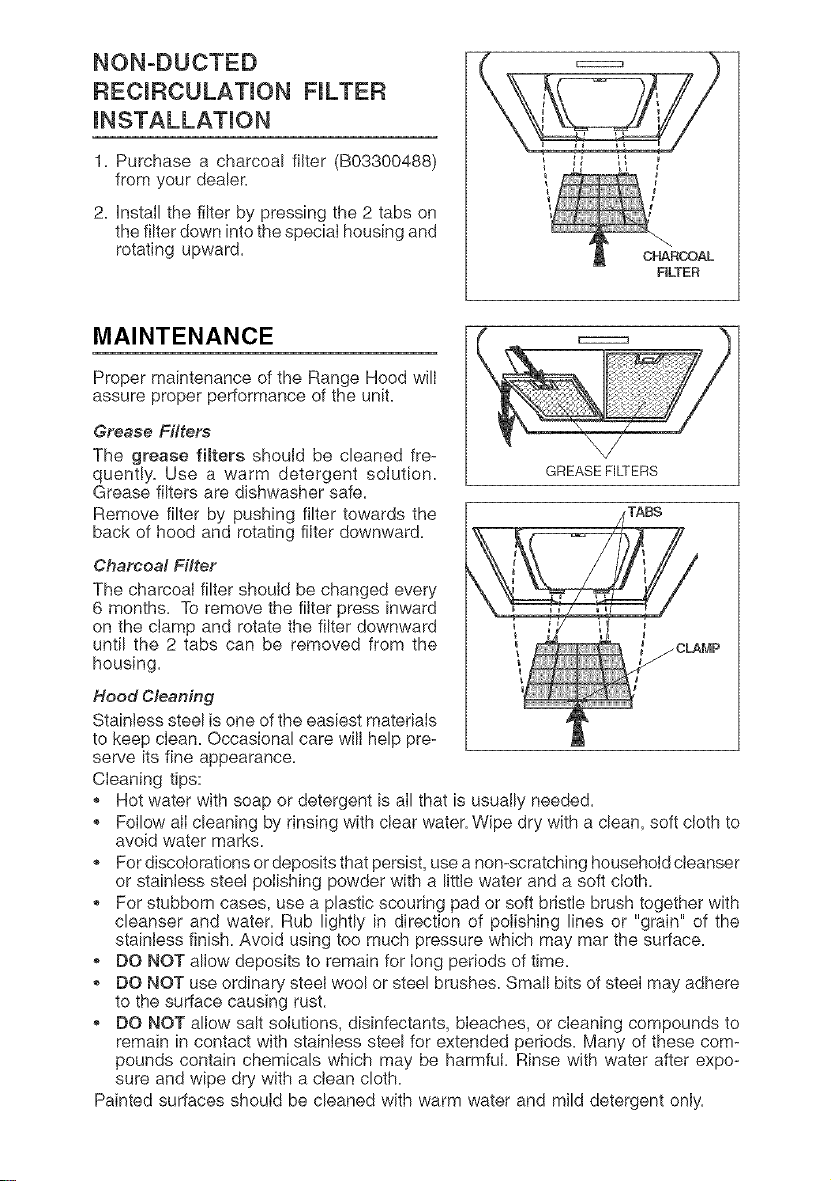

NON°DUCTED

RECmRCULATmON FILTER

mNSTALLATmON

1. Purchase a charcoal filter (B03300488)

from your dealer.

2. InstalI the filter by pressing the 2 tabs on

the filter down into the speciaI housing and

rotating upward.

FILTER

MAINTENANCE

Proper maintenance of the Range Hood wilI

assure proper performance of the unit.

Grease Filters

The grease filters should be cleaned fre-

quently. Use a warm detergent solution.

Grease filters are dishwasher safe.

Remove filter by pushing filter towards the

back of hood and rotating filter downward.

Charcoal Filter

The charcoal filter should be changed every

6 months. To remove the fiiter press inward

on the clamp and rotate the filter downward

until the 2 tabs can be removed from the

housing.

GREASE FILTERS

Hood Cleaning

Stainless steel is one of the easiest materiaIs

to keep clean. Occasional care will help pre-

serve its fine appearance.

Cleaning tips:

, Hot water with soap or detergent is all that is usually needed.

,FoIIow alI cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth to

avoid water marks.

, For discolorations or deposits that persist, use a non-scratching household cteanser

or stainless steel polishing powder with a little water and a soft cloth.

, For stubborn cases, use a plastic scouring pad or soft bristle brush together with

cleanser and water. Rub lightly in direction of polishing lines or "grain" of the

stainless finish. Avoid using too much pressure which may mar the surface.

,, DO NOT allow deposits to remain for long periods of time.

*, DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere

to the surface causing rust.

,, DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to

remain in contact with stainless steel for extended periods. Many of these com e

pounds contain chemicals which may be harmfui. Rinse with water after expo-

sure and wipe dry with a clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

Loading...

Loading...