john deere POWERTECH 8.1 L Technical Manual

POWERTECH 8.1 L

Diesel Engines

Base Engine

TECHNICAL MANUAL

POWERTECH 8.1 L Diesel Engines —

Base Engine

CTM86 15JUL05 (ENGLISH)

For complete service information also see:

POWERTECH 8.1 L Diesel |

|

Engines—Mechanical Fuel Systems . . . . . . |

CTM243 |

POWERTECH 6.8 L & 8.1 L Diesel |

|

Engines—Level 3 Electronic Fuel Systems |

|

with Bosch In-Line Pump . . . . . . . . . . . . . . . |

CTM134 |

POWERTECH 8.1 L Diesel Engines—Level 9 |

|

Electronic Fuel Systems with Denso In-Line |

|

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

CTM255 |

Electronic Fuel Injection Systems . . . . . . . . |

CTM68 |

OEM Engine Accessories . . . . . . . . . . . . . . . |

CTM67 |

Alternators and Starting Motors . . . . . . . . . . |

CTM77 |

John Deere Power Systems

LITHO IN U.S.A.

Introduction

Foreword

This manual is written for an experienced technician. Essential tools required in performing certain service work are identified in this manual and are recommended for use.

This manual (CTM86) covers only the base engine. It is one of five volumes on 8.1 L engines. The following four companion manuals cover fuel system repair and diagnostics:

•CTM243—Mechanical Fuel Systems

•CTM134—Level 3 Electronic Fuel Systems

•CTM255—Level 9 Electronic Fuel Systems

•CTM68—Electronic Injection Fuel Systems

Other manuals will be added in the future to provide additional information on electronic fuel systems as needed.

This manual covers the base engine for all 8.1L engines, including emission non-certified, Tier I certified, and Tier II certified (esn 200,000 — ).

Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text of the manual.

This is the safety-alert symbol. When you see this symbol on the machine or in this manual, be alert to the potential for personal injury.

This is the safety-alert symbol. When you see this symbol on the machine or in this manual, be alert to the potential for personal injury.

Use this component technical manual in conjunction with the machine technical manual. An application listing in the introduction identifies engine-models/applications. See the machine technical manual for information on engine removal and installation, and gaining access to engine components.

Information is organized in sections and groups for the various components requiring service instruction. At the end of the book are summary listings of all

applicable essential tools, service equipment, and other materials needed to do the job, service parts kits, specifications, wear tolerance, and torque values.

Before beginning repair on an engine, clean the engine and mount on a repair stand. (See CLEAN ENGINE in Group 010 and see MOUNT ENGINE ON REPAIR STAND in Group 010..)

This manual contains SI Metric units of measure followed immediately by the U.S. Customary units of measure. Most hardware on these engines is metric sized.

Some components of this engine may be serviced without removing the engine from the machine. Refer to the specific machine technical manual for information on components that can be serviced without removing the engine from the machine and for engine removal and installation procedures.

Read each block of material completely before performing service to check for differences in procedures that apply to the engine model number you are working on. If only one procedure is given, that procedure applies to all the engines in the manual.

Component Technical Manuals are concise service guides for specific components. Component technical manuals are written as stand-alone manuals covering multiple machine applications.

Fundamental service information is available from other sources covering basic theory of operation, fundamentals of troubleshooting, general maintenance, and basic types of failures and their causes.

CALIFORNIA PROPOSITION 65 WARNING: Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

|

DPSG,OUO1004,912 –19–15JUN99–1/1 |

CTM86 (15JUL05) |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=2

Introduction

John Deere Dealers

The changes listed below make your CTM obsolete. Repair, operation, and diagnostics are now covered in five manuals. Discard CTM86 dated 06JUL99 and replace with the following new manuals:

•CTM86—Base Engine

•CTM243—Mechanical Fuel Systems

•CTM134—Level 3 Electronic Fuel Systems

•CTM255—Level 9 Electronic Fuel Systems

•CTM68—Electronic Fuel Injection Systems

Also, copy these pages and route through your Service Department.

SECTION 01, GROUP 001 (Engine Identification)

•Updated engine model designation chart.

•Updated engine application charts.

SECTION 01, GROUP 002 (Fuels, Lubricants, and

Coolants)

•Updated engine oil and coolant application guidelines.

SECTION 02, GROUP 010 (Engine Rebuild)

•Updated engine disassembly sequence.

•Updated engine assembly sequence.

•Updated sealant application guidelines.

SECTION 02, GROUP 020 (Cylinder Head and Valves Repair and Adjustment Serial Number ( —199,999)

•Repair procedures for cylinder head and valves on engines with serial number ( —199,999) are covered in this group.

SECTION 02, GROUP 021 (Cylinder Head and Valves Repair and Adjustment Serial Number (200,000— )

•Repair procedures for cylinder head and valves on engines with serial number (200,000— ) are covered in this group.

SECTION 02, GROUP 050 (Camshaft and Timing Gear Train Repair and Adjustment)

•Eliminated procedure to check valve lift. Use appropriate procedure from Group 020 or Group 021.

•Revised specifications for installation of crankshaft gear-driven auxiliary drive.

•Revised procedure for installation of thrust washer and timing gear cover.

SECTION 02, GROUP 060 (Lubrication System

Repair and Adjustment)

• Added information for top-load oil filter.

SECTION 02, GROUP 070 (Cooling System Repair

and Adjustment)

•Added belt routing diagrams.

•Revised procedure for installation of coolant pump.

SECTION 02, GROUP 080 (Air Intake and Exhaust System Repair and Adjustments)

•Revised procedure for turbocharger inspection techniques.

•Eliminated procedure for adjusting turbocharger wastegate actuator.

•Revised specifications for installing turbocharger.

SECTION 02, GROUP 090 (Fuel System Repair and

Adjustments)

NOTE: Repair procedures for fuel systems have been have been moved to Section 02, Group 090 in the three following technical manuals:

•CTM243—Mechanical Fuel Systems

•CTM134—Level 3 Electronic Fuel Systems

•CTM255—Level 9 Electronic Fuel Systems

SECTION 02, GROUP 100 (OEM Starting and

Charging Systems)

|

DPSG,OUO1004,898 –19–19MAY99–1/2 |

CTM86 (15JUL05) |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=3

Introduction

• Starting and charging systems are covered in this |

• |

CTM243—Mechanical Fuel Systems |

new group. |

• |

CTM134—Level 3 Electronic Fuel Systems |

|

• |

CTM255—Level 9 Electronic Fuel Systems |

SECTION 03, GROUP 120 (Base Engine Operation)

•Base engine theory of operation is covered in this new group.

NOTE: Fuel system theory of operation has been moved to Section 03 in the three following technical manuals:

SECTION 05 (Tools and Other Materials)

•All essential tools, service tools, dealer fabricated tools, and other materials listed throughout this manual are consolidated in this section for ease of reference.

SECTION 06 (Specifications)

•CTM243—Mechanical Fuel Systems

•CTM134—Level 3 Electronic Fuel Systems • All repair, test, and diagnostic specifications listed

• CTM255—Level 9 Electronic Fuel Systems |

|

throughout this manual are consolidated in this |

|

• |

section for ease of reference. |

SECTION 04, GROUP 150 (Observable Diagnostics |

Updated bolt and cap screw torque values. |

|

and Tests) |

• |

Updated General OEM specifications. |

|

• |

Updated dynamometer specifications. |

• Base engine observable diagnostics and tests are |

• |

Updated turbocharger boost specifications |

covered in this new section/group. |

|

|

NOTE: Fuel system diagnostics and testing has been |

|

|

moved to Section 04 in the three following |

|

|

technical manuals: |

|

|

DPSG,OUO1004,898 –19–19MAY99–2/2

CTM86 (15JUL05) |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=4

Introduction

About this Manual

This component technical manual (CTM) covers the base engine for POWERTECH 8.1 L (494 cu. in.) diesel engines produced in Waterloo, Iowa. This manual’s coverage includes: emissions non-certified, emissions certified Tier I, and emissions certified Tier II (esn 200,000 — ) engines

This manual is a complete revision of CTM86 (06JUL99). Replace earlier manual with the following new manuals:

•CTM86 — POWERTECH 8.1 L Diesel Engines—Base Engine

•CTM243 — POWERTECH 8.1 L Diesel Engines— Mechanical Fuel Systems

•CTM134 — POWERTECH 6.8 L & 8.1 L Diesel Engines—Level 3 Electronic Fuel Systems with Bosch In-Line Pump

•CTM255 — 8.1 L Diesel Engines—Level 9 Electronic Fuel Systems with Denso In-Line Pump

•CTM68 —Electronic Fuel Injection Systems

Direction of engine crankshaft rotation in this manual is referenced as clockwise, as viewed from the rear of the engine. Front of engine is fan drive end.

Read each procedure completely before performing any service.

IMPORTANT: For repair, diagnostics, and testing procedures on the fuel system, refer to the companion manuals:

•CTM243 — POWERTECH 8.1 L Diesel

Engines—Mechanical Fuel Systems

•CTM134 — POWERTECH 6.8 L & 8.1 L

Diesel Engines—Level 3 Electronic Fuel Systems with Bosch In-Line Pump

•CTM255 — 8.1 L Diesel Engines— Level 9 Electronic Fuel Systems with Denso In-Line Pump

•CTM68 —Electronic Fuel Injection Systems

POWERTECH is a registered trademark of Deere & Company |

DPSG,OUO1004,913 –19–15JUN99–1/1 |

CTM86 (15JUL05) |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=5

Introduction

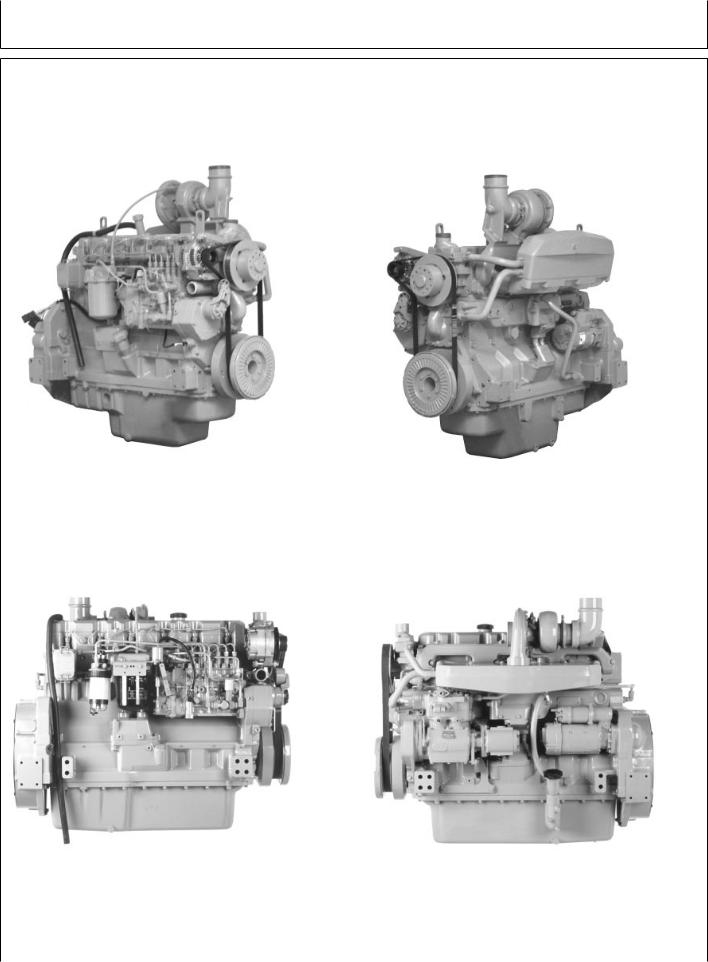

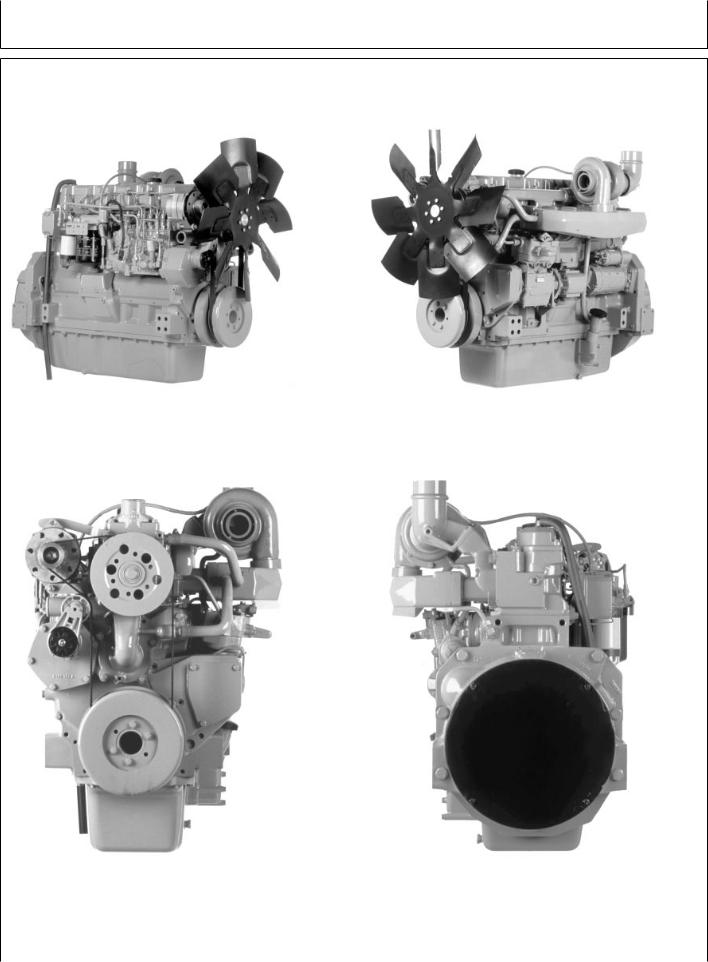

Identification Views Serial Number ( —199,999) Non Emissions Certified, and Tier I Emissions Certified Engines

| <![if ! IE]> <![endif]>–UN–05JAN98 |

<![if ! IE]> <![endif]>–UN–05JAN98 |

| <![if ! IE]> <![endif]>RG7362 |

<![if ! IE]> <![endif]>RG7363 |

8.1 L Diesel Engine Right Front View (Engines —199,999) |

8.1 L Diesel Engines Left Front View (Engines —199,999) |

| <![if ! IE]> <![endif]>–UN–05JAN98 |

<![if ! IE]> <![endif]>–UN–05JAN98 |

| <![if ! IE]> <![endif]>RG7385 |

<![if ! IE]> <![endif]>RG7387 |

8.1 L Diesel Engines Right Side View (Engines —199,999) |

8.1 L Diesel Engines Left Side View (Engines —199,999) |

|

RG,RG34710,4001 –19–14DEC00–1/2 |

CTM86 (15JUL05) |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=6

Introduction

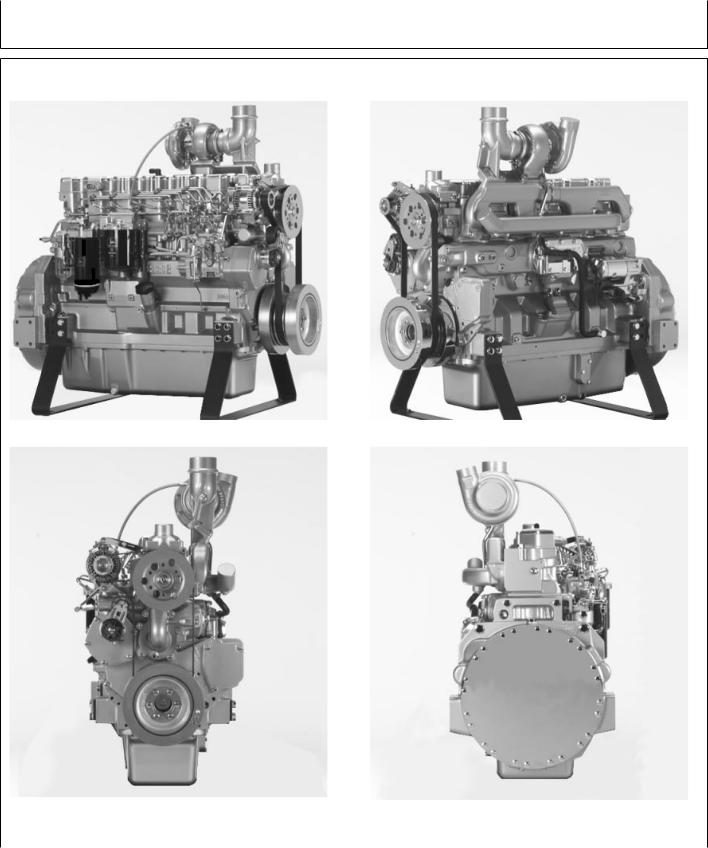

| <![if ! IE]> <![endif]>–UN–20JUN00 |

<![if ! IE]> <![endif]>–UN–20JUN00 |

| <![if ! IE]> <![endif]>RG7388 |

<![if ! IE]> <![endif]>RG7386 |

8.1 L Diesel Engine Right Front View (Engines —199,999) |

8.1 L Diesel Engine Left Front View (Engines —199,999) |

| <![if ! IE]> <![endif]>–UN–05JAN98 |

<![if ! IE]> <![endif]>–UN–05JAN98 |

| <![if ! IE]> <![endif]>RG7383 |

<![if ! IE]> <![endif]>RG7384 |

8.1 L Diesel Engine Front View (Engines —199,999) |

8.1 L Diesel Engine Rear View (Engines —199,999) |

|

RG,RG34710,4001 –19–14DEC00–2/2 |

CTM86 (15JUL05) |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=7

Introduction

Identification Views Serial Number (200,000— ) Tier II Emissions Certified Engines

| <![if ! IE]> <![endif]>–UN–13DEC00 |

<![if ! IE]> <![endif]>–UN–31OCT00 |

| <![if ! IE]> <![endif]>RG11511 |

<![if ! IE]> <![endif]>RG11512 |

8.1 L Diesel Engine Right Front View (Engines 200,000— ) |

8.1 L Diesel Engines Left Front View (Engines 200,000— ) |

| <![if ! IE]> <![endif]>–UN–31OCT00 |

<![if ! IE]> <![endif]>–UN–31OCT00 |

| <![if ! IE]> <![endif]>RG11513 |

<![if ! IE]> <![endif]>RG11514 |

8.1 L Diesel Engine Front View (Engines 200,000— ) |

8.1 L Diesel Engine Rear View (Engines 200,000— ) |

|

RG,OUOD007,4002 –19–01NOV00–1/1 |

|

|

CTM86 (15JUL05) |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=8

Contents

SECTION 01—General

Group 000—Safety

Group 001—Engine Identification

Group 002—Fuels, Lubricants and Coolant

SECTION 02—Repair and Adjustments

Group 010—Engine Rebuild

Group 020—Cylinder Head and Valves Repair and Adjustment S. N. ( —199,999)

Group 021—Cylinder Head and Valves Repair and Adjustment S. N. (200,000— )

Group 030—Cylinder Block, Liners, Pistons, and Rods Repair and Adjustment

Group 040—Crankshaft, Main Bearings and Flywheel Repair and Adjustment

Group 050—Camshaft and Timing Gear Train Repair and Adjustment

Group 060—Lubrication System Repair and Adjustment

Group 070—Cooling System Repair and Adjustment Group 080—Air Intake and Exhaust System Repair

and Adjustment

Group 100—OEM Starting and Charging Systems Repair and Adjustment

SECTION 03—Theory of Operation

Group 120—Base Engine Operation

SECTION 04—Diagnostics

Group 150—Observable Diagnostics and Tests

SECTION 05—Tools and Other Materials

Group 170—Repair Tools and Other Materials

Group 180—Diagnostic Service Tools

Group 190—Dealer Fabricated Service Tools

SECTION 06—Specifications

Group 200—Repair and General OEM

Specifications

Group 210—Diagnostic Specifications

All information, illustrations and specifications in this manual are based on the latest information available at the time of publication. The right is reserved to make changes at any time without notice.

COPYRIGHT 2005

DEERE & COMPANY

Moline, Illinois

All rights reserved

A John Deere ILLUSTRUCTION Manual

Previous Editions

Copyright 1994,1997,1999, 2001, 2003, 2004

01

02

03

04

05

06

INDX

CTM86 (15JUL05) |

i |

POWERTECH 8.1 L Diesel Engines — Base Engine

080305

PN=1

Contents

01

02

03

04

05

06

INDX

CTM86 (15JUL05) |

ii |

POWERTECH 8.1 L Diesel Engines — Base Engine

080305

PN=2

01

Section 01

General

Contents

Page

Group 000—Safety . . . . . . . . . . . . . . . . . . . .01-000-1

Group 001—Engine Identification

Engine Model Designation. . . . . . . . . . . . . . . .01-001-1

Engine Serial Number Plate Information . . . . .01-001-2

Engine Option Code Label . . . . . . . . . . . . . . .01-001-3

Engine Application Chart (John Deere

Agricultural Equipment) . . . . . . . . . . . . . . . .01-001-3

Engine Application Chart (John Deere

Construction Equipment) . . . . . . . . . . . . . . .01-001-6

Engine Application Chart (OEM) (Outside

Equipment Manufacturers) . . . . . . . . . . . . . .01-001-6

Group 002—Fuels, Lubricants and Coolant

Diesel Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .01-002-1

Bio-Diesel Fuel . . . . . . . . . . . . . . . . . . . . . . . .01-002-2

Lubricity of Diesel Fuel . . . . . . . . . . . . . . . . . .01-002-3

Dieselscan Fuel Analysis. . . . . . . . . . . . . . . . .01-002-3

Diesel Engine Break-In Oil . . . . . . . . . . . . . . .01-002-4

Diesel Engine Oil . . . . . . . . . . . . . . . . . . . . . .01-002-5

Extended Diesel Engine Oil Service

Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . .01-002-6

Alternative and Synthetic Lubricants . . . . . . . .01-002-6

Mixing of Lubricants . . . . . . . . . . . . . . . . . . . .01-002-7

Oilscan and Coolscan . . . . . . . . . . . . . . . . . . .01-002-7

Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .01-002-8

Diesel Engine Coolant. . . . . . . . . . . . . . . . . . .01-002-9

Diesel Engine Coolants, Supplemental

Additive Information . . . . . . . . . . . . . . . . . .01-002-11

Testing Diesel Engine Coolant . . . . . . . . . . .01-002-12

Replenishing Supplemental Coolant

Additives (SCAs) Between Coolant

Changes . . . . . . . . . . . . . . . . . . . . . . . . . .01-002-13

Operating in Warm Temperature Climates . .01-002-14

Flush and Service Cooling System . . . . . . . .01-002-15

Disposing of Coolant . . . . . . . . . . . . . . . . . . .01-002-16

CTM86 (15JUL05) 01-1 POWERTECH 8.1 L Diesel Engines — Base Engine

080305

PN=1

Contents

01

CTM86 (15JUL05) 01-2 POWERTECH 8.1 L Diesel Engines — Base Engine

080305

PN=2

Handle Fluids Safely—Avoid Fires

When you work around fuel, do not smoke or work near heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn spontaneously.

Group 000

Safety

01

000

1

<![if ! IE]><![endif]>TS227 –UN–23AUG88

DX,FLAME –19–29SEP98–1/1

Handle Starting Fluid Safely

Starting fluid is highly flammable.

Keep all sparks and flame away when using it. Keep starting fluid away from batteries and cables.

To prevent accidental discharge when storing the pressurized can, keep the cap on the container, and store in a cool, protected location.

Do not incinerate or puncture a starting fluid container.

<![endif]> TS1356 –UN–18MAR92

TS1356 –UN–18MAR92

DX,FIRE3 –19–16APR92–1/1

CTM86 (15JUL05) |

01-000-1 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=13

Safety

01

000 Handling Batteries Safely

2

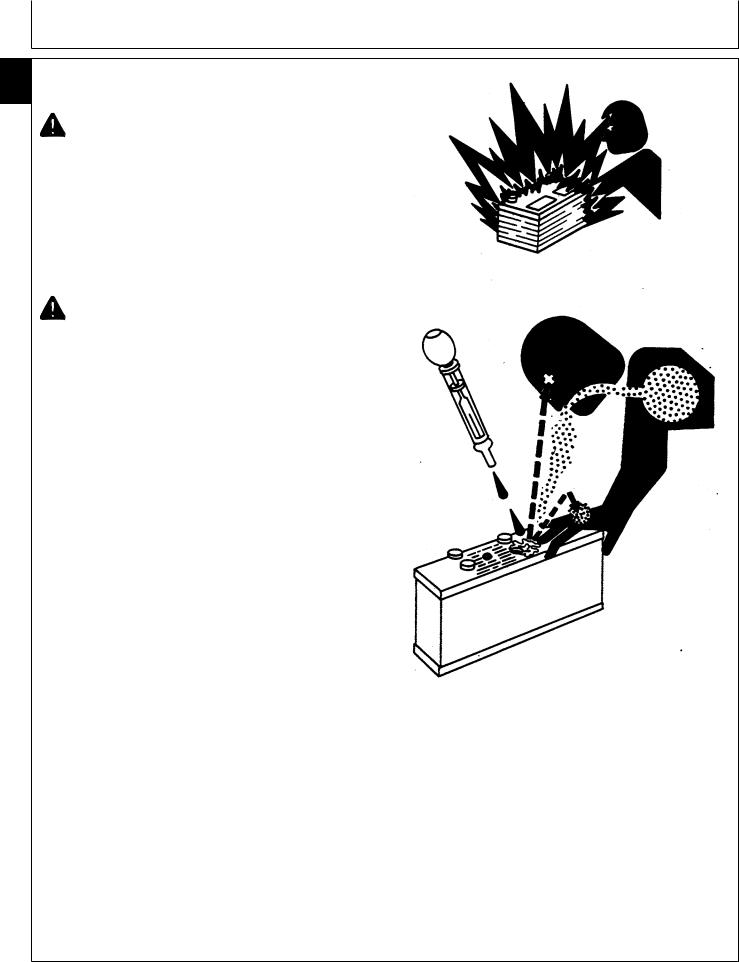

CAUTION: Battery gas can explode. Keep sparks and flames away from batteries. Use a flashlight to check battery electrolyte level.

Never check battery charge by placing a metal object across the posts. Use a voltmeter or hydrometer.

Always remove grounded (-) battery clamp first and replace it last.

CAUTION: Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin, eat holes in clothing, and cause blindness if splashed into eyes.

Avoid the hazard by:

1.Filling batteries in a well-ventilated area.

2.Wearing eye protection and rubber gloves.

3.Avoiding breathing fumes when electrolyte is added.

4.Avoiding spilling or dripping electrolyte.

5.Use proper jump start procedure.

If you spill acid on yourself:

1.Flush your skin with water.

2.Apply baking soda or lime to help neutralize the acid.

3.Flush your eyes with water for 15—30 minutes. Get medical attention immediately.

If acid is swallowed:

1.Do not induce vomiting.

2.Drink large amounts of water or milk, but do not exceed 2 L (2 quarts).

3.Get medical attention immediately.

WARNING: Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

CTM86 (15JUL05) |

01-000-2 |

<![endif]>TS204 –UN–23AUG88

<![if ! IE]><![endif]>TS203 –UN–23AUG88

DPSG,OUO1004,2758 –19–11MAY00–1/1

POWERTECH 8.1 L Diesel Engines — Base Engine

080305

PN=14

Safety

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

01

000

3

–UN–23AUG88 TS291 DX,FIRE2 –19–03MAR93–1/1

Avoid High-Pressure Fluids

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

<![endif]> X9811 –UN–23AUG88

X9811 –UN–23AUG88

DX,FLUID –19–03MAR93–1/1

CTM86 (15JUL05) |

01-000-3 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=15

Safety

01

000 Wear Protective Clothing

4

Wear close fitting clothing and safety equipment appropriate to the job.

Prolonged exposure to loud noise can cause impairment or loss of hearing.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises.

Operating equipment safely requires the full attention of the operator. Do not wear radio or music headphones while operating machine.

<![endif]>TS206 –UN–23AUG88

DX,WEAR –19–10SEP90–1/1

Service Machines Safely

Tie long hair behind your head. Do not wear a necktie, scarf, loose clothing, or necklace when you work near machine tools or moving parts. If these items were to get caught, severe injury could result.

Remove rings and other jewelry to prevent electrical shorts and entanglement in moving parts.

Work In Ventilated Area

Engine exhaust fumes can cause sickness or death. If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension.

If you do not have an exhaust pipe extension, open the doors and get outside air into the area

–UN–23AUG88 TS228 DX,LOOSE –19–04JUN90–1/1

–UN–23AUG88 TS220 DX,AIR –19–17FEB99–1/1

CTM86 (15JUL05) |

01-000-4 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=16

|

|

Safety |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Work in Clean Area |

|

|

|

01 |

|

|

|

|

000 |

||

|

|

|

|

|

5 |

Before starting a job: |

|

|

|

|

|

|

|

|

|

||

• |

Clean work area and machine. |

|

|

|

|

• |

Make sure you have all necessary tools to do your job. |

|

<![if ! IE]> <![endif]>–UN–18OCT88 |

|

|

• |

Have the right parts on hand. |

|

|

|

|

|

|

|

|

||

• |

Read all instructions thoroughly; do not attempt |

|

|

|

|

|

shortcuts. |

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>T6642EJ |

|

|

|

|

DX,CLEAN |

–19–04JUN90–1/1 |

|

|

|

|

|

|

|

Install Fan Guards |

|

|

|

|

|

Rotating cooling system fans can cause serious injury. |

|

|

|

||

Keep fan guards in place at all times during engine |

|

|

|

|

|

operation. Wear close fitting clothes. Stop the engine and |

|

|

|

||

be sure fan is stopped before making adjustments or |

|

<![if ! IE]> <![endif]>–UN–21SEP89 |

|

||

connections, or cleaning near the front of the engine. |

|

|

|||

|

|

|

|||

|

|

|

|

<![if ! IE]> <![endif]>TS677 |

|

|

|

|

Rotating Fan |

|

|

|

|

|

OUOD006,000009D |

–19–04DEC02–1/1 |

|

|

|

|

|

|

|

Avoid Hot Parts |

|

|

|

|

|

Avoid skin contact with exhaust manifolds, turbochargers |

|

|

|

||

and mufflers. Keep flammable materials clear of the |

|

|

|

|

|

turbocharger. |

|

|

|

|

|

External dry exhaust parts become very hot during |

|

|

<![if ! IE]> <![endif]>–UN–23AUG88 |

|

|

exhaust manifolds may reach 600°C (1112°F) under full |

|

|

|||

operation. Turbochargers may reach temperatures as high |

|

|

|

||

as 500°C (932°F) under full load, and naturally aspired |

|

|

|

||

load. This may ignite paper, cloth or wooden materials. |

|

<![if ! IE]> <![endif]>TS271 |

|

||

Parts on engines that have been at full load and reduced |

|

|

|||

to no load idle will maintain approximately 150°C (302°F). |

Hot Surface |

|

|

||

|

|

|

OUOD006,000009E |

–19–04DEC02–1/1 |

|

CTM86 (15JUL05) |

01-000-5 |

POWERTECH 8.1 L Diesel Engines — Base Engine |

|||

|

|

|

|

080305 |

|

PN=17

Safety

01

000 Remove Paint Before Welding or Heating

6

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated by welding, soldering, or using a torch.

Remove paint before heating:

•Remove paint a minimum of 100 mm (4 in.) from area to be affected by heating. If paint cannot be removed, wear an approved respirator before heating or welding.

•If you sand or grind paint, avoid breathing the dust. Wear an approved respirator.

•If you use solvent or paint stripper, remove stripper with soap and water before welding. Remove solvent or paint stripper containers and other flammable material from area. Allow fumes to disperse at least 15 minutes before welding or heating.

Do not use a chlorinated solvent in areas where welding will take place.

Do all work in an area that is well ventilated to carry toxic fumes and dust away.

Dispose of paint and solvent properly.

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near pressurized fluid lines, resulting in severe burns to yourself and bystanders. Do not heat by welding, soldering, or using a torch near pressurized fluid lines or other flammable materials. Pressurized lines can accidentally burst when heat goes beyond the immediate flame area.

<![endif]>TS220 –UN–23AUG88

DX,PAINT –19–24JUL02–1/1

–UN–15MAY90 TS953 DX,TORCH –19–10DEC04–1/1

CTM86 (15JUL05) |

01-000-6 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=18

Safety

Illuminate Work Area Safely

Illuminate your work area adequately but safely. Use a portable safety light for working inside or under the machine. Make sure the bulb is enclosed by a wire cage. The hot filament of an accidentally broken bulb can ignite spilled fuel or oil.

Use Proper Lifting Equipment

Lifting heavy components incorrectly can cause severe injury or machine damage.

Follow recommended procedure for removal and installation of components in the manual.

Construct Dealer-Made Tools Safely

Faulty or broken tools can result in serious injury. When constructing tools, use proper, quality materials and good workmanship.

Do not weld tools unless you have the proper equipment and experience to perform the job.

CTM86 (15JUL05) |

01-000-7 |

01

000

7

–UN–23AUG88 TS223 DX,LIGHT –19–04JUN90–1/1

–UN–23AUG88 TS226 DX,LIFT –19–04JUN90–1/1

<![if ! IE]><![endif]>LX1016749 –UN–01JUL97

Construct Dealer-Made Tools Safely

DPSG,OUO1004,899 –19–19MAY99–1/1

POWERTECH 8.1 L Diesel Engines — Base Engine

080305

PN=19

Safety

01

000 Practice Safe Maintenance

8

Understand service procedure before doing work. Keep area clean and dry.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet , and clothing from power-driven parts. Disengage all power and operate controls to relieve pressure. Lower equipment to the ground. Stop the engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be raised for service work.

Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine.

On towed implements, disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine.

Use Proper Tools

Use tools appropriate to the work. Makeshift tools and procedures can create safety hazards.

Use power tools only to loosen threaded parts and fasteners.

For loosening and tightening hardware, use the correct size tools. DO NOT use U.S. measurement tools on metric fasteners. Avoid bodily injury caused by slipping wrenches.

Use only service parts meeting John Deere specifications.

CTM86 (15JUL05) |

01-000-8 |

<![endif]>TS218 –UN–23AUG88

DX,SERV –19–17FEB99–1/1

<![if ! IE]><![endif]>TS779 –UN–08NOV89

DX,REPAIR –19–17FEB99–1/1

POWERTECH 8.1 L Diesel Engines — Base Engine

080305

PN=20

Safety

Dispose of Waste Properly

Improperly disposing of waste can threaten the environment and ecology. Potentially harmful waste used with John Deere equipment include such items as oil, fuel, coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids. Do not use food or beverage containers that may mislead someone into drinking from them.

Do not pour waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth’s atmosphere. Government regulations may require a certified air conditioning service center to recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste from your local environmental or recycling center, or from your John Deere dealer.

01

000

9

<![if ! IE]><![endif]>TS1133 –UN–26NOV90

DX,DRAIN –19–03MAR93–1/1

Live With Safety

Before returning machine to customer, make sure machine is functioning properly, especially the safety systems. Install all guards and shields.

–19–07OCT88 TS231 DX,LIVE –19–25SEP92–1/1

CTM86 (15JUL05) |

01-000-9 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=21

Safety

01

000

10

CTM86 (15JUL05) |

01-000-10 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=22

Group 001

Engine Identification

Engine Model Designation

JOHN DEERE ENGINE MODEL—6081

John Deere engine model designation includes number of cylinders, displacement in liters, aspiration, user code, and application code. For example:

6081 HRW01 Engine

6 ............................................................................ |

Number of cylinders |

8.1 ............................................................................... |

Liter designation |

H .................................................................................... |

Aspiration code |

RW ........................................................................................ |

User code |

01 ............................................................................... |

Application Code |

Aspiration Code |

|

T ............................................................ |

Turbocharged, no aftercooling |

A ...................................... |

Turbocharged and coolant-to-air aftercooled |

H ............................................. |

Turbocharged and air-to-air aftercooled |

User Code |

|

CQ ................................................................ |

S.L.C. Horizontina (Brazil) |

DW ........................................................................................ |

Davenport |

F ............................................ |

OEM (Original Equipment Manufacturer) |

FF ........................................ |

Kernersvill Deere-Hitachi (North Carolina) |

FM ..................................................................................... |

OEM Marine |

H ............................................................................................. |

Harvester |

N ......................................................................................... |

Des Moines |

RW ......................................................................... |

Waterloo (Tractors) |

T ................................. |

Dubuque, and Cameco (Thibodaux, Louisiana) |

TJ ......................................................... |

Ontario (Canada) - Timberjack |

Z ...................................................................... |

Zweibrucken (Germany) |

Application Code |

|

001, etc. ..... |

See ENGINE APPLICATION CHART, later in this Group |

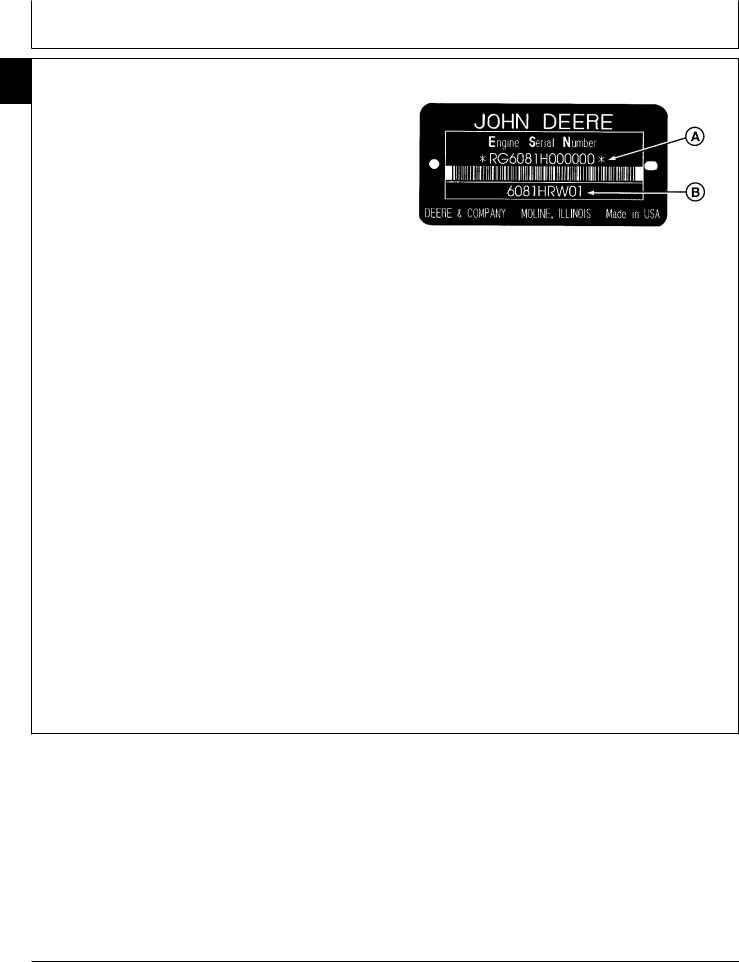

Engine Serial Number Plate

A—Engine Serial Number

B—Engine Model Designation

01

001

1

<![if ! IE]><![endif]>RG7010 –UN–26NOV97

RG,RG34710,1021 –19–23OCT97–1/1

CTM86 (15JUL05) |

01-001-1 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=23

Engine Identification

01

001

2

Engine Serial Number Plate Information

IMPORTANT: The engine serial number plate can be easily destroyed. Remove the plate or record the information elsewhere, before “hot tank” cleaning the block.

Engine Serial Number (A)

Each engine has a 13-digit John Deere engine serial number identifying the producing factory, engine model designation, and a 6-digit sequential number. The following is an example:

RG6081H000000 |

|

RG ........................................................ |

Factory code producing engine |

6081H ........................................................... |

Engine model designation |

000000 .......................................................... |

Sequential serial number |

Factory Code |

|

RG .............................................................. |

Waterloo Engine Works |

Engine Model Designation |

|

6801H .................................... |

(See ENGINE MODEL DESIGNATION.) |

Sequential Number |

|

000000 .......................................................... |

6-digit sequential number |

The engine serial number plate is located either on the right-hand side of engine between the oil filter base and fuel injection pump (viewed from flywheel end) or on the left-hand side of the engine directly above the starter motor.

Engine Application Data (B)

The second line of information on the engine serial number plate identifies the engine/Deere machine or OEM relationship. SeeENGINE APPLICATION CHART later in this group.

<![endif]>RG7010 –UN–26NOV97

Engine Serial Number Plate

A—Engine Serial Number

B—Engine Application Data

RG,RG34710,1022 –19–19MAY99–1/1

CTM86 (15JUL05) |

01-001-2 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=24

|

|

Engine Identification |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine Option Code Label |

|

|

|

|

01 |

|

|

|

|

|

001 |

||

|

|

|

|

|

|

3 |

|

|

|

|

<![if ! IE]> <![endif]>–UN–14AUG00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>RG11074 |

|

|

|

|

Option Code Label |

|

|

|

|

In addition to the serial number plate, later OEM |

factory. When in need of parts or service, furnish your |

|

||||

engines have an engine option code label affixed to |

authorized servicing dealer or engine distributor with |

|

||||

the rocker arm cover. These codes indicate which of |

these numbers. |

|

|

|

||

the engine options were installed on your engine at the |

|

|

|

|

||

|

|

|

|

DPSG,OUO1004,900 |

–19–19MAY99–1/1 |

|

|

|

|

|

|

||

Engine Application Chart (John Deere |

|

|

|

|

||

Agricultural Equipment) |

|

|

|

|

|

|

Machine Model |

|

|

|

|

|

|

DES MOINES—COTTON PICKERS & SPRAYERS |

|

|

|

|

|

|

9970 |

Cotton Picker ............................................................. |

6081AN001 |

|

|

|

|

9976 |

Cotton Picker .................................................... |

6081HN001, 003 |

|

|

|

|

9986 |

Cotton Picker ............................................................ |

6081HN003 |

|

|

|

|

4920 |

Sprayer ...................................................................... |

6081HN005 |

|

|

|

|

HARVESTER—COMBINES |

|

|

|

|

|

|

9510 |

Low Power Combine ................................................. |

6081HH001 |

|

|

|

|

9510 |

High Power Combine ................................................ |

6081HH002 |

|

|

|

|

9550 |

Low Power Combine ................................................. |

6081HH008 |

|

|

|

|

9550 |

High Power Combine ................................................ |

6081HH009 |

|

|

|

|

9610 |

Combine .................................................................... |

6081HH003 |

|

|

|

|

9650 and 9650CTS Combine ............................................ |

6081HH010 |

|

|

|

|

|

9650 |

CTS-(Europe) Combine ............................................ |

6081HH011 |

|

|

|

|

9650 |

STS Combine ............................................................ |

6081HH006 |

|

|

|

|

9750 |

STS Combine ............................................................ |

6081HH005 |

|

|

|

|

CTS II Combine (Europe-1998 Model Year ...................... |

6081HH003 |

|

|

|

|

|

CTS II Combine (Europe-1999 Model Year) ..................... |

6081HH004 |

|

|

|

|

|

CTS II Combine (North America) ....................................... |

6081HH003 |

|

|

|

|

|

Amadus Peanut Combine .................................................. |

6081HH007 |

|

|

|

|

|

|

|

|

Continued on next page |

RE38635,000003B |

–19–18JUL05–1/3 |

|

CTM86 (15JUL05) |

01-001-3 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

||||

|

|

|

|

|

080305 |

|

PN=25

|

|

|

|

Engine Identification |

|

|

|

|

|

|

|

|

|

|

01 |

|

|

|

|

001 |

WATERLOO—TRACTORS |

|

|

|

4 |

7710 |

Tractor .............................................. |

6081TRW01, 03, 05, 07, 09 |

|

|

7810 |

Tractor |

6081TRW02, 04, 06, 08, 10, 11 |

|

|

||||

|

7710/7810 Tractor ................................................ |

6081HRW43 (Tier II) |

||

|

7820 |

Tractor ...................................................................... |

|

6081HRW41 |

|

7920 |

Tractor ...................................................................... |

|

6081HRW42 |

|

8100 |

Tractor ...................................................................... |

|

6081HRW06 |

|

8200 |

Tractor ...................................................................... |

|

6081HRW07 |

|

8300 |

Tractor ...................................................................... |

|

6081HRW08 |

|

8400 |

Tractor ................................................................ |

|

6081HRW01, 04 |

|

8100T (Tracks) Tractor ..................................................... |

|

6081HRW10 |

|

|

8200T (Tracks) Tractor ..................................................... |

|

6081HRW02 |

|

|

8300T (Tracks) Tractor ..................................................... |

|

6081HRW09 |

|

|

8400T (Tracks) Tractor ..................................................... |

|

6081HRW03 |

|

|

8110 |

Tractor ...................................................................... |

|

6081HRW11 |

|

8210 |

Tractor ...................................................................... |

|

6081HRW13 |

|

8310 |

Tractor ...................................................................... |

|

6081HRW15 |

|

8410 |

Tractor ...................................................................... |

|

6081HRW17 |

|

8110T (Tracks) Tractor ..................................................... |

|

6081HRW12 |

|

|

8210T (Tracks) Tractor ..................................................... |

|

6081HRW14 |

|

|

8310T (Tracks) Tractor ..................................................... |

|

6081HRW16 |

|

|

8410T (Tracks) Tractor ..................................................... |

|

6081HRW18 |

|

|

8120/8220 Wheel/Tracks (W/T)Tractor |

............................. |

6081HRW23 |

|

|

8120/8220 Front Suspended Axle North America ............ |

6081HRW31 |

||

|

8120/8220 Front Suspended Axle Region II .................... |

6081HRW32 |

||

|

8320 |

W/T Tractor .............................................................. |

|

6081HRW25 |

|

8320 |

Front Suspended Axle North America ..................... |

6081HRW33 |

|

|

8320 |

Front Suspended Axle Region II |

............................. |

6081HRW34 |

|

8420W CIS Tractor (Wheels Only) ................................... |

|

6081HRW26 |

|

|

8420 |

W/T Tractor .............................................................. |

|

6081HRW27 |

|

8420 |

Front Suspended Axle Tractor North America ........ |

6081HRW35 |

|

|

8420 |

Front Suspended Axle Tractor Region II ................. |

6081HRW36 |

|

|

8520 |

W/T Tractor .............................................................. |

|

6081HRW28 |

|

8520 |

Front Suspended Axle Tractor North America ........ |

6081HRW37 |

|

|

8520 |

Front Suspended Axle Tractor Region II ................. |

6081HRW38 |

|

|

9100 |

4-Wheel Drive Tractor .............................................. |

|

6081HRW05 |

|

9120 |

4-WD Wheels Tractor .............................................. |

|

6081HRW30 |

Continued on next page |

RE38635,000003B –19–18JUL05–2/3 |

CTM86 (15JUL05) |

01-001-4 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=26

Engine Identification

|

|

|

|

01 |

ZWEIBRUCKEN—COMBINES/FORAGE HARVESTERS |

|

001 |

||

2256 |

Combine ............................................................. |

6081HZ003, 007 |

|

5 |

2258 |

Combine |

6081HZ002, 05 |

|

|

|

|

|||

2264 |

Combine ..................................................................... |

6081HZ002 |

|

|

2266 |

Combine ..................................................................... |

6081HZ001 |

|

|

2268 |

Combine ..................................................................... |

6081HZ006 |

|

|

9640/9640HM ...................................................................... |

6081HZ009 |

|

|

|

9640/9640HM & 9850/9850HM Combine ............................................... |

|

|

||

................................................................. |

|

6081HZ017 (replaces HZ009) |

|

|

9680/9680HM Combine ...................................................... |

6081HZ011 |

|

|

|

9780/9780HM Combine ...................................................... |

6081HZ012 |

|

|

|

9680/9680HM & 9780/9780HM Combine ............................................... |

|

|

||

................................................. |

6081HZ019 (replaces HZ011 & HZ012) |

|

|

|

9660/9660HM Combine ...................................................... |

6081HZ010 |

|

|

|

9660/9660HM Combine ......................... |

6081HZ018 (replaces HZ010) |

|

|

|

6650 |

Self-Propelled Forage Harvester |

............................... 6081HZ004 |

|

|

7200 |

Self-Propelled Forage Harvester |

. 6081HZ013 (European Model) |

|

|

7200 |

Self-Propelled Forage Harvester |

................................................... |

|

|

...................................................... |

6081HZ016 (North American Model) |

|

|

|

S.L.C. HORIZONTINA (BRAZIL)—COMBINES |

|

|

||

1185A Combine ................................................................. |

6081ACQ01 |

|

|

|

|

|

RE38635,000003B |

–19–18JUL05–3/3 |

|

CTM86 (15JUL05) |

01-001-5 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=27

Engine Identification

01

001

6

Engine Application Chart (John Deere

Construction Equipment)

Machine Model |

|

DAVENPORT |

|

644G Loader ..................................................................... |

6081HDW04 |

644H Loader ..................................................................... |

6081HDW05 |

644H-MH Loader ................................................... |

6081HDW06 (Tier I) |

644H-MH Loader .................................................. |

6081HDW08 (Tier II) |

724J Loader ......................................................... |

6081HDW09 (Tier II) |

740G/748G/748G II/748G III Skidder ............................... |

6081TDW01 |

770C (Late)/770CH/772CH Motor Grader ........................ |

6081HDW01 |

770C Motor Grader (Early) ............................................... |

6081HDW03 |

870C/872CH Motor Grader ............................................. |

6081HDW013 |

DUBUQUE |

|

762B Series II Scraper ........................................................ |

6081AT001 |

850C Series II Crawler Dozer (822868— ) ........................ |

6081AT002 |

850J Crawler Dozer ................................................. |

6081HT006 Tier II |

BELL EQUIPMENT - SOUTH AFRICA |

|

250D/300D Articulated Truck .............................................. |

6081HT003 |

L2006/L2306 Bell Loaders .................................................. |

6081HT007 |

DEERE-HITACHI (CANADA) |

|

2054 Logger (based on JD200 Excavator) ......................... |

6081HT053 |

2554 Logger (based in JD230 Excavator ........................... |

6081HT054 |

DEERE-HITACHI (JAPAN) |

|

330/370 Logger (based on JD330 Excavator) .................... |

6081HT002 |

WOODSTOCK, ON. (TIMBERJACK) & THIBODAUX, LA. (CAMECO) |

|

660D Skidder ...................................................................... |

6081ATJ02 |

530B/535 Log Loader ................................................... |

6081ATJ01, 03 |

608B Feller Buncher .............................................. |

6081HTJ07 (Tier II) |

608S Feller Buncher .............................................. |

6081HTJ08 (Tier II) |

1710 Forwarder ................................................................... |

6081HTJ02 |

1270 Harvester .................................................................... |

6081HTJ03 |

2500 Cane Harvester .......................................................... |

6081HT801 |

RG41183,0000024 –19–25JAN01–1/1

Engine Application Chart (OEM) (Outside

Equipment Manufacturers)

Application |

Engine Model |

OEM Engine (Tier I Emissions Certified) |

........................ 6081TF001 |

OEM Engine (Tier I Emissions Certified) ............................ |

6081AF001 |

OEM Engine (Tier I Emissions Certified) ............................ |

6081HF001 |

Marine Engine .................................................................... |

6081AFM01 |

OEM Engine (Tier II Emissions Certified) ........................... |

6081HF070 |

|

RG41183,000003A –19–28FEB01–1/1 |

|

CTM86 (15JUL05) |

01-001-6 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

|

080305 |

|

PN=28

|

|

Group 002 |

|

|

|

Fuels, Lubricants and Coolant |

|

|

|

|

|

|

|

|

|

Diesel Fuel |

|

|

01 |

|

|

002 |

|

|

|

|

1 |

Consult your local fuel distributor for properties of the |

Fuel lubricity should pass a minimum of 3100 gram |

|

|

|

|||

diesel fuel available in your area. |

load level as measured by the BOCLE scuffing test. |

|

|

In general, diesel fuels are blended to satisfy the low |

Sulfur content: |

|

|

temperature requirements of the geographical area in |

• |

|

|

which they are marketed. |

Sulfur content should not exceed 0.5%. Sulfur |

|

|

|

• |

content less than 0.05% is preferred. |

|

Diesel fuels specified to EN 590 or ASTM D975 are |

If diesel fuel with sulfur content greater than 0.5% |

|

|

recommended. |

|

sulfur content is used, reduce the service interval for |

|

|

• |

engine oil and filter by 50%. |

|

In all cases, the fuel shall meet the following |

DO NOT use diesel fuel with sulfur content greater |

|

|

properties: |

|

than 1.0%. |

|

Cetane number of 40 minimum. Cetane number |

DO NOT mix used engine oil or any other type of |

|

|

greater than 50 is preferred, especially for |

lubricant with diesel fuel. |

|

|

temperatures below -20°C (-4°F) or elevations above |

|

|

|

1500 m (5000 ft). |

|

|

|

Cold Filter Plugging Point (CFPP) below the |

|

|

|

expected low temperature OR Cloud Point at least |

|

|

|

5°C (9°F) below the expected low temperature. |

|

|

|

|

|

RG41165,0000071 –19–13MAR01–1/1 |

|

CTM86 (15JUL05) |

01-002-1 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=29

Fuels, Lubricants and Coolant

01

002 Bio-Diesel Fuel

2

Consult your local fuel distributor for properties of the bio-diesel fuel available in your area.

Bio-diesel fuels may be used ONLY if the bio-diesel fuel properties meet the latest edition of ASTM PS121, DIN 51606 or equivalent specification.

It has been found that bio-diesel fuels may improve lubricity in concentrations up to a 5% blend in petroleum diesel fuel.

When using a blend of bio-diesel fuel, the engine oil level must be checked daily when the air temperature is -10°C (14°F) or lower. If the oil becomes diluted with fuel, shorten oil change intervals accordingly.

IMPORTANT: Raw pressed vegetable oils are NOT acceptable for use for fuel in any concentration in John Deere engines.

These oils do not burn completely, and will cause engine failure by leaving deposits on injectors and in the combustion chamber.

A major environmental benefit of bio-diesel fuel is its ability to biodegrade. This makes proper storage and handling of bio-diesel fuel especially important. Areas of concern include:

•Quality of new fuel

•Water content of the fuel

•Problems due to aging of the fuel

Potential problems resulting from deficiencies in the above areas when using bio-diesel fuel in concentrations above 5% may lead to the following symptoms:

•Power loss and deterioration of performance

•Fuel leakage

•Corrosion of fuel injection equipment

•Coked and/or blocked injector nozzles, resulting in engine misfire

•Filter plugging

•Lacquering and/or seizure of internal components

•Sludge and sediments

•Reduced service life of engine components

RG41183,0000046 –19–18DEC01–1/1

CTM86 (15JUL05) |

01-002-2 POWERTECH 8.1 L Diesel Engines — Base Engine |

|

080305 |

PN=30

Loading...

Loading...