Page 1

Operation and Safety Manual

Keep this manual with the machine at all times.

Model(s)

DVL &

DVSP

Series

P/N - 3121135

September 27, 2005

Page 2

Page 3

FOREWORD

FOREWORD

This manual is a ve ry important too l! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions

and operating procedures essential for the safe and proper machine operation for its int ended purpose.

Due to continuous pro du ct imp ro v em en ts , JLG Industries, Inc. re se rv es th e right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

Other Publications Available:

Service and Maintenance Manual .......................................................3121136

Illustrated Parts Manual (ANSI/CSA) ...................................................3121137

Illustrated Parts Manual (CE)...............................................................3121839

3121135 – JLG Lift – a

Page 4

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert yo u to the

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid poss ibl e injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL

DECAL WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

DECAL WILL HAVE AN ORANGE BACKGROUND.

RESULT IN SERIOUS INJURY OR DEATH. THIS

RESULT IN SERIOUS INJURY OR DEATH. THIS

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL

HAVE A YELLOW BACKGROUND.

RESULT IN MINOR OR MODERATE INJURY. IT MAY

IMPORTANT

INDICATES PROCEDURES ESSENTIAL FOR SAFE OPERATION.

THIS DECAL WILL HAVE A GREEN BACKGROUND.

b – JLG Lif t – 3121135

Page 5

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETY-RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR

THIS PRODUCT.

IMPORTANT

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES, INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE UPDATED AND ACCURATE.

IMPORTANT

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN

ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRO DUCT.

FOR :

•Accident Reporting

•Product Safety Publications

•Current Owner Updates

•Questions Regarding Product Safety

•Standards and Regulatio ns Compliance Information

•Questions Rega rd in g Special Product Applica t io ns

•Questions Regarding Product Modifications

CONTACT :

Product Safety and Reliability Department

JLG Industries , Inc.

1 JLG Drive

McConnellsburg, PA 17233

or Your Local JLG Office

(See addresses on back cover of manual)

In USA:

Toll Free: 877-JLG-SAFE

877-554-7233

Outside USA:

717-485-5161

E-mail: ProductSafety@JLG . com

3121135 – JLG Lift – c

Page 6

REVISION LOG

October 1, 2001 – Original Issue of Manual

November 19, 2001 – Manual Revised

December 13, 2001 – Manual Revised

February 22, 2002 – Manual Revised

October 29, 2002 – Manual Revised

January 22, 2003 – Manual Revised

February 18, 2003 – Manual Revised

August 9, 2004 – Manual Revised

May 6, 2005 - Manual Revised

July 25, 2005 – Manual Revised

September 27, 2005 – Manual Revised

REVISION LOG

d – JLG Lif t – 3121135

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . a

SAFETY ALERT SYMBOL S AN D SAFETY SIGNAL WORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . b

REVISION LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . d

SECTION 1 - SAFETY PRECAUTIONS

1.1 GENER AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 PRE-OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Operator Training And Knowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Workplace Inspec t i on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 OPERA TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Trip and Fall Hazar d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Electrocutio n Ha z ard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Tipping Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Crushing And Collision Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 TOWING, LIFTING, AND HAULING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

SECTION 2 - PREPA RATION AND INS PECTION

2.1 PERSONNEL TRAI NIN G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Operator Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Training Supervis ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Operator Respon s ibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2- 1

2.2 PREPARATION, IN S PECTION, AND MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 PRE-START INSP ECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.4 DAILY WALK-AROUND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 FUNCTION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

SECTION 3- MACHINE CONTROLS, INDICATORS AND OPERATION

3.1 GENER AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2 MACHINE DESCRI P TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 MACHINE OPERATIO N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Getting Start e d. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.4 BATTERY CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Battery Low Voltage Warning Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

To Charge Batter ie s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Battery Chargi ng Status Indicat ors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.5 GROUND CONTROL STATION - OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Main Power Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Emergency Stop/Shut Down Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Master Disconnec t Switch - (EE Option Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Brake Release But t on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Platform Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Platform Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Manual Descent Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Machine Status LCD Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

LCD Display Fault Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3121135 – JLG Lift – i

Page 8

TABLE OF CONTENTS

3.6 GROUND CO N TROL STATION - PROGRAMMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Programming Lev e l s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Operator Programming Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Activating Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Entering Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Programming Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Selecting Progr ammable Item to Adju s t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Adjusting Progr ammable Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.7 PLATFORM CONTROL CONSOLE OPERATION -

(MACHINES SERIAL NUMBER - 0130007616 TO PRESENT) . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 11

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Platform On/Off Key Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Platform Eme rgency Stop/Shu t Down Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Platform Control Display Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Drive/Lift Mode Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Horn Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 13

Joystick Function Enable Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Multifunction Joystick Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Drive Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Lift Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Drive Speed Setting Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.8 PLATFORM CONTROL CONSOLE OPERATION -

(MACHINES BEFORE SERIAL NUMBER - 0130007616) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

At Ground Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Emergency Sto p/Shut-Down But t on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Battery Charg e /Fault Code LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Driving Machi ne. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Adjusting Maxi mum Drive Speed Cont r ol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -17

Elevating/Lowering the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.9 PARKI N G M ACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.10 PROGAMMABLE SECURITY LOCK (PSL™) (DVL/DVSP - OPTION) . . . . . . . . . . . . . . . . . . . . . .3-18

PSL™ Box and Ground Control Locati ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Machine Power Up u s ing the PSL™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Machine Power Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Changing the Operator’s Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3.11 PLATFORM CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

StockPicking Platform Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.12 FA L L PRO TECTION - LANYARD ATTACHMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 2 1

3.13 QUICK-CHANGE PLA T FO RM MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Platform Rem ov al. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Platform Inst al l ation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.14 OBSTRUCTION SENSIN G SY STEM (DVSP - OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 2 2

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

OSS Pre-Start Ins pe ction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.15 TRANSPORTING, LIFTING AND TIE DOWN PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Truck Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Machine Tie-D own. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Crane Hook Acce s sory (DVL Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Fork-Lift Truck Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.16 RUG CA R RIER ACCESSORY (DVSP - OPTION). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 2 5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

ii – JLG Lift – 3121135

Page 9

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Hanging a Rug using the Rug Carrier Accessory Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Removing a Rug using Rug Carrier Accessory Arm s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3.17 STOCK-PICKER HANGER ACCESSORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Loading and Transporting an Item using the Hanger Accessory. . . . . . . . . . . . . . . . . . . . .3-27

SECTION 4 - EMERGENCY PROCEDURES

4.1 GENERAL INFORMATI O N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Operator Unabl e to C ont rol Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Platform Caught Overhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.3 INCIDENT NOTIFICA TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

SECTION 5- GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

5.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 GENERAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Machine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Electrical Spec ifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Platform Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Machine Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Serial Number Lo c at i ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3 OPERATOR MAINTE N AN CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

TABLE OF CONTENTS

SECTION 6 - INSPECTION AND REPAI R LOG

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

2-1. Daily Walk-Around Inspection for DVL/DVSP Machines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

3-1. Battery Charger Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2. Ground Control Stat ion. (Machine Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3-3. Platform Control Console (Machines Serial Number - 0130007616 to Present) . . . . . . . . . . . . . .3-11

3-4. Platform Control Display Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3-5. Platform Control Console (Machines Before Serial Number - 0130007616) . . . . . . . . . . . . . . . . .3-15

3-6. PSL™ Switch & Groun d Control Station Locations - At Rear of Machi ne .. . . . . . . . . . . . . . . . . . .3-18

3-7. PSL™ Switch Controls & Indicators.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3-8. OSS Transducer Sens or Array Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3-9. OSS - Pre-Start Inspection of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3-10. Crane Hook Accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3-11. Forklift Truck Lifting Pockets and Machine Tie Down Bar Locations. . . . . . . . . . . . . . . . . . . . . . .3-24

3-12. DVL Series Decal Ins t all at ion Chart - (See Table 3-5 for Specification ). . . . . . . . . . . . . . . . . . . . .3-28

3-13. DVSP Decal Instal la t ion Chart - (See Table 3-6. for Specificatio n) . . . . . . . . . . . . . . . . . . . . . . . .3-30

3121135 – JLG Lift – iii

Page 10

TABLE OF CONTENTS

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Minimum Safe Approach Distance (M .S.A.D.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2-1 Inspect ion and Maintenance Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

3-1 DVL And DVSP - Mac hi ne Operating Spe cifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3-2 Battery Low Voltage Warning Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3-3 LCD Display - Ope r ating Fault Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3-4 DVL/DVSP Ground Control Station - Level 3 - Programmable Settings and Factory Presets. . . .3-8

3-5 DVL Series - Dec a l Installation Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

3-6 DVSP Decal Installation Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

5-1 Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5-2 Lubrication Int e rvals for Variou s Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

6-1 Inspection an d Re pair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

iv – JLG Lift – 3121135

Page 11

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper

and safe machine usage and mainten ance. For proper

machine use, it is mandatory that a daily routine is established based on the content of this manual. A maintenance program, using the information provided in this

manual and the Service and Maintenance Manual, must

also be established by a qualified person and must be followed to ensure that the machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine

should not accept operating responsibility until t his manual has been read, training is accomplished, and operation of the machine has been completed under the

supervision of an e xperienced and qu al ified operator.

If there are any questions with regard to safety, training,

inspection, maintenance, application, and operation,

please contact JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAF ETY PRECAUTI ONS LISTED

IN THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

1.2 PRE-OPERATION

Operator Training And Knowledge

•Read and understand this manual before operating the

machine.

• Do not operate this ma chine until complete training is

performed by aut horized persons.

• Only authorized and qualified personnel can operate

the machine.

•Read, understand, and obey all DANGERS, WARNINGS, CAUTIONS, and operatin g instruc tions on th e

machine and in t hi s m an ual.

•Use the machine in a manner which is within the scope

of its intended application set by JLG.

•All operating personnel must be familiar with the emergency controls and emergency operation of the

machine as specified in this man ual.

• Read, understand, and obey all applicable employer,

local, and governmental regulations as they pertain to

operation of the machine.

Workplace Inspection

•The operator is to take safety measures to avoid all hazards in the work area prior to machine operation.

• Do not operate or raise the platform while on trucks,

trailers, railway cars, floating vessels, scaffolds or other

equipment unless approved in writing by JLG.

•This machine can be operated in temperatures of 0° F

to 104° F (-20° C to 40° C). Consult JLG for operation

outside this range.

Machine Inspection

•Before machine operation, perform inspections and

functional checks. Refer to Section 2 of this manual for

detailed inst r uctions.

•Do not operate this machine until it has been serviced

and maintained according to requirements specified in

the Service and Maintenance Manual.

3121135 – JLG Lift – 1-1

Page 12

SECTION 1 - SAFETY PRECAUTIONS

•Ensure all safety devices are operating properly . Modifi cation of these devices is a safety violation.

MODIFICATIO N OR ALTE RATION OF AN AERI AL WORK PL ATFORM SHALL BE MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER

• Do not operate any machine on which the safety or

instruction pl acards or decals are missing or ille gible.

• Avoid any build up of debris on platform floor. Keep

mud, oil, grease, and other slippery substances fro m

footwear and platform fl oor.

1.3 OPERATION

General

• Do not use the machine for any purpose other than

positioning personnel, their tools and equipment, or for

hand stock pick i ng.

•Never operate a machine that is not working properly. If

a malfunction occurs , s hut down the machine.

•Never slam a control switch or lever through neutral to

an opposite direction. Always return switch to neutral

and stop before moving the switch to the next function.

Operate controls with slow and even pressure.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform, except in an emergency .

•Do not carry materials directly on platform railing unless

approved by JLG.

• Always ensure that power tools are properly stowed

and never left hanging by their cord from the platform

work area.

•Fully lower mast assembly and shut off all power before

leaving machine.

•When performing welding operations at elevation, precautions must be taken to protect all machine components from contact with weld splatter or molten metal.

•Battery fluid is highly corrosive. Avoid contact with skin

and clothing at all times.

•Charge batteries on in a well ventilated area.

Trip and Fall Hazard

• JLG Industries, Inc. recommends that the operator in

the platform wear a full body harness with a lanyard

attached to an authorized lanyard anchorage point. For

further informa tion regard ing fall pr otection requ irements on JLG products, contact JLG Industries, Inc.

•Before operating the machine, make sure all railing and

gates are fastened in their proper position.

•Keep both feet firmly positioned on the platform floor at

all times. Never use ladders, boxes, steps, planks, or

similar items on platform to provide additional reach.

•Never use the mast assembly to enter or leave the platform.

•Use extreme caution when entering or leaving platform.

Ensure that the mast assembly is fully lowered. Face

the machine when entering or leaving the platform.

Always maintain “three point contact” with the machine,

using two hands and one foot or two feet and one hand

at all times during entry and exit.

•Platform-to-s tructure transfers at elevated positions are

discouraged. Where transfer is necessary, enter/exit

through the gate only with the platform within 1 foot

(0.3m) of a safe and secure structure. 100% tie-off is

also required in this situation utilizing two lanyards.

One lanyard must be attached to the platform with the

second lanyard attached to the structure. The lanyard

connected to the platform must not be disconnected

until such time the transfer to the structure is safe and

complete.

1-2 – JLG Lift – 3121135

Page 13

SECTION 1 - SAFETY PRECAUTIONS

Electrocution Hazard

Table 1-1. Minimum Safe Approach Distance (M.S.A.D.)

VOLTAGE RANGE

(PHASE TO PHASE)

0-50KV 10 (3)

Over 50KV to 200KV 15 (5)

Over 200KV to 350KV 20 (6)

Over 350KV to 500KV 25 (8)

Over 500KV to 750KV 35 (11)

Over 750KV to 1000KV 45 (14)

NOTE: This Minim um Safe Approach D istance shall apply

except where employer , local, or governmental regulations are more stringent.

Maintain a clearance of at least 10 ft (3m) between any

part of the machine and its occupants, their tools, and

their equipment f rom any el ectrical line or ap paratu s carrying up to 50,000 volts. One foot (0.3m) additional clearance is required for every additional 30,000 volts or less.

The minimum safe approach distance may be reduced if

insulating barriers are installed to prevent contact, and if

the barriers are rated for the voltage of the line being

guarded. These barriers shall not be part of (or attached

to) the machine. The minimum safe approach distance

shall be reduced to a distance within the designed working dimensions of the insulating barrier. This determination shall be made by a qualified person in accordance

with employer, local, or governmental requirements for

work practices near energized equipment.

MINIMUM SAFE APPROACH

DISTANCE - Feet (m)

Tipping Hazard

•The user should be familiar with the surface before driving. Do not exceed the allo wable sidesl ope and grade

while driving.

•Do not elevate platform or d rive with platform elevated

while on a slope, o r on an uneven or soft surface.

•Before driving on floors, bridges, trucks, and other surfaces, check allowable capacity of the surfaces.

•Never exceed the maximum platform capacity. Distribute loads evenly on platform floor.

• Keep the chassis of the machine a minimum of 2 ft.

(0.6m) from holes, bumps, drop-offs, obstructions,

debris, conce al ed holes, and othe r pot e ntial hazards at

the ground level.

•Never attempt to use the machine as a crane. Do not

tie-off machine to any adjacent structure.

• Do not increase the platform size with unauthorized

deck extensions or attachments, increasing the area

exposed to wind will decrease stability.

•If mast assembly or platform is caught so that one or

more wheels are off the ground, the operator must be

removed before attem pting t o free th e machi ne. Use

cranes, forklift trucks, or other appropri ate eq uipment to

stabilize ma chine and remove pe r s onnel.

3121135 – JLG Lift – 1-3

Page 14

SECTION 1 - SAFETY PRECAUTIONS

Crushing And Collision Hazard

•Personal protection equipment must be worn by all

operating an d ground personnel.

•Check work area clearances above, on sides, and bottom of platform while driving and lifting or lowering platform.

• During operation, keep all body parts inside platform

railing.

• Always post a lookout when driving in areas where

vision is obstructed.

•Keep non-operating personnel at least 6 ft. (1.8m) away

from machine dur ing all driving operations.

• Limit travel speed according to conditions of ground

surface, congestion, visibility, slope, location of personnel, and other factors ca using ha zards of collision or

injury to personnel.

• Be aware of stopping distances in all drive speeds.

•Do not drive at high speeds in restricted or close quarters or when driving in revers e .

•Exercise extreme caution at all times to prevent obstacles from striki ng or interfe ring w ith op erating contr ols

and persons in the pl atform.

• Ensu re that ope rators of o ther overh ead and flo or level

machines are awar e of the aerial work platfor m’s pr esence. Disconnect power to overhead cranes.

• Warn personnel not to work, stand, or walk under a

raised platform. Position barricades on floor as necessary.

1.4 TOWING, LIFTING, AND HAULING

•Never allow personnel in platform while towing, lifting,

or hauling.

•This machine should not be towed, except in the event

of emergency, malfunction, power failure , or loading/

unloading. Refer to the Emergency Procedures Section

of this manual for emergency towing procedures.

•Ensure platform is fully retracted and completely empty

of tools prior to towing, lifting or hauling.

• Do no t assist a stuck or disabled machine by pus hing

or pulling except by pulling at the chassis tie-down

bars.

•When lifting machine with a forklift, positio n forks on ly at

designated areas of the machine. Lift with a forklift of

adequate capa city.

•Refer to the Machine Operation section of this manual

for lifting informatio n.

1-4 – JLG Lift – 3121135

Page 15

SECTION 2 - PREPARATION AND INSPECTION

SECTION 2. PREPARATION AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is

necessary that it be operated and maint ained only by

trained personnel.

Persons under the influence of drugs or alcohol or who

are subject to seizures, dizziness or loss of physical control must not operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform

and at the ground, emergency controls and safety

systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of

the machine to recognize a malfunction.

6. The safest means to operate the machine where

overhead obstructions, other moving equipment,

and obstacles, depressions, holes, drop-offs are

present.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified

person in an open area free of obstructions until the

trainee has developed the ability to safely control and

operate the machine.

Operator Responsibility

The operator must be instructed tha t he/she has the

responsibility and authority to shut down the machine in

case of a malfunction or other unsafe condition of either

the machine or the job site.

NOTE: The Manufacturer o r Dis tr ibuto r wil l provi de q ualif ied

people for training assistance with the first unit(s)

delivered and fro m th at ti me forward as requested by

the user or his/her personnel.

3121135 – JLG Lift – 2-1

Page 16

SECTION 2 - PREPARATION AND INSPECTION

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

The following table covers the periodic machine inspections and maintenance recommended by JLG Industries,

Inc. Consult local regulations for further requirements for

aerial work platforms. The frequency of inspections and

maintenance must be in creased as nece ssary when th e

machine is used in a harsh or hostile environment, if the

machine is used with increased fre quency, or if the

machine is used in a severe manner.

Table 2-1. Inspection and Maintenance Table

TYPE FREQUENCY

Pre-Start

Inspection

Pre-Delivery

Inspection

(See Note)

Frequent

Inspection

Annual Machine

Inspection

Preventative

Maintenance

Before using each day; or

whenever there’s an Operator change.

Before each sale, lease, or rental delivery. Owner, Dealer, or User Qualified JLG

In service for 3 months or 150 hours, whichever

comes first; or;

Out of service for a period of more than 3 months; or

Purchased used.

Annually, no later than 13 months from the date of

prior inspection.

At intervals as specified in the Service and Maintenance Manual.

IMPORTANT

JLG INDUSTRIES, INC. RECOGNIZES A QUALIFIED JLG

MECHANIC AS A PERSON WH O HAS SUCCESSFULLY COMPLETED THE JLG SERVICE TRAINING SCHOOL FOR THE SPECIFIC JLG PRODUCT MODEL.

PRIMARY

RESPONSIBILITY

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or User Qualified JLG

SERVICE

QUALIFICATION

Mechanic

Mechanic

Mechanic

Mechanic

REFERENCE

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

2-2 – JLG Lift – 3121135

Page 17

SECTION 2 - PREPARATION AND INSPECTION

2.3 PRE-START INSPECTION

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil,

fuel, or battery fluid) or foreign objects. Report any

leakage to the proper maintenance personnel.

2. Decals and Placards – Check all for cleanliness

and legibility. Make sure no decals or placards are

missing. Make sure all illegible decals and placards

are cleaned or replaced. (Reference "Decal Installa-

tions" in Section 3).

3. Operators and Safety Manuals – Make sure a copy

of the Operator and Safety Manual, EMI Safety Manual (Domestic only), and ANSI Ma nual of Responsibilities (Domestic only) is enclosed in the weather

resistant storage conta i ner.

4. Daily Walk-Around Inspection – (See Section 2.4)

5. Battery – Charge as required.

6. Hydraulic Oil – Check the hydraulic oil level.

NOTE: Check Service Manual for instructions and hydraulic

oil specification bef ore add ing. DO NOT OVERFILL.

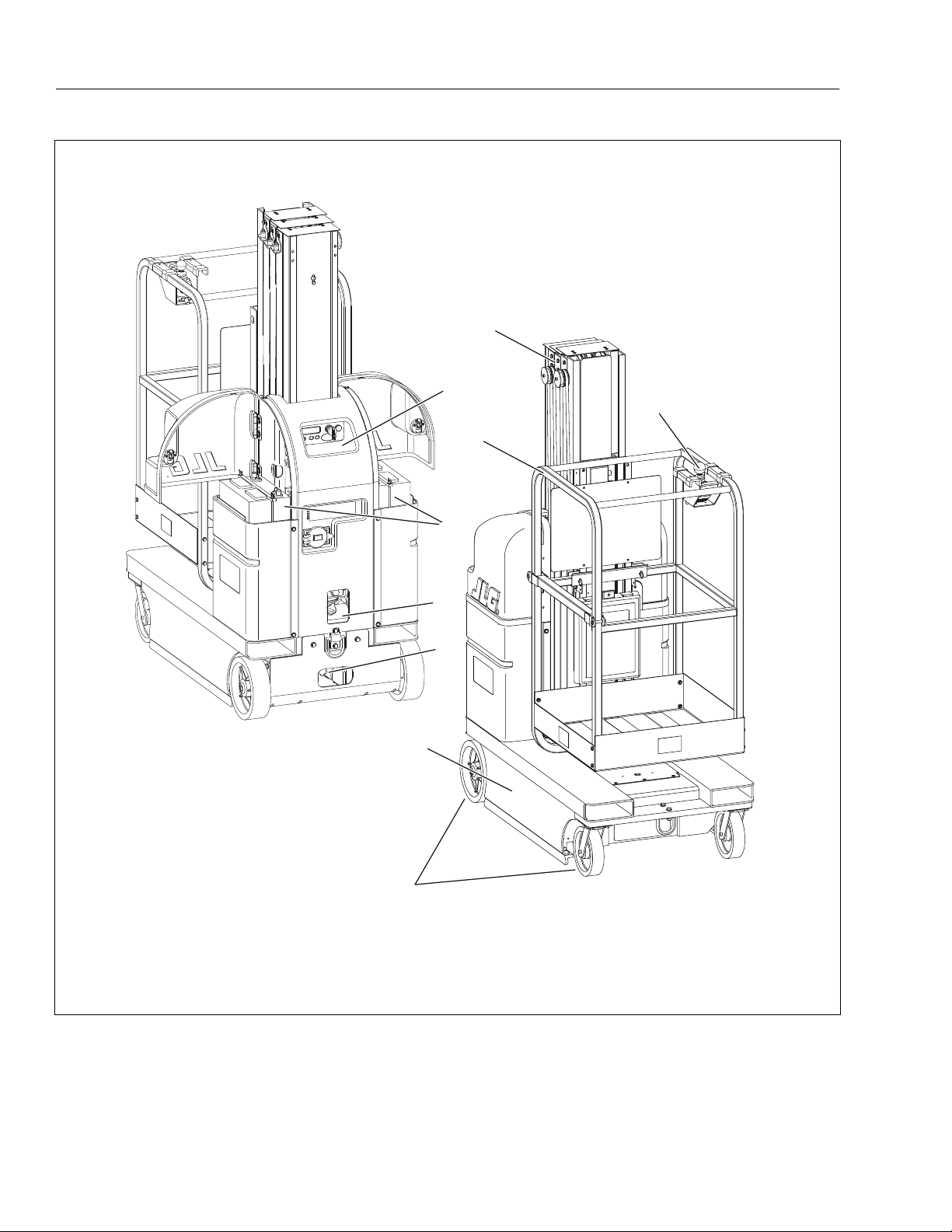

2.4 DAILY WALK-AROUND INSPECTION

Begin the “Walk-Around Inspection” at item one (1) as

noted on the diagram. Continue around machine check

each item in sequence for th e conditions lis ted in the f ollowing check list.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS

“OFF” DURING “WALK-AROUND INSPECTION”.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE

BEEN CORRECTED.

IMPORTANT

DO NOT OVERLOOK VISUAL INSP ECTION OF THE BASE FRAME

UNDERSIDE. CHECK THIS AREA FOR OBJECTS OR DEBRIS

WHICH COULD CAUSE EXTENSIVE MACHINE DAMAGE.

NOTE: On all components, make sure there are no loose or

missing parts, that they are securely fastened, and

that no visible damage, leaks or excessive wear

exists in addition to any other criteria mentioned.

1. Drive and Caster Wheels - Check for any debris

stuck to or around wheels.

FILL TO LINE

on Hydraulic

Reservoir

indicates the

proper level for

hydraulic oil.

7. Funct ion Che ck – Check all machine controls for

operation. (See Section 2.5)

If optional equipment is installed on this machine refer to

Section 3 for specific Pre-Start Inspection and Operation

instructions.

2. Base Frame - Check pot-hole-protection system

components; check for loose wires or cables dangling below the base.

3. Manual Descent Control Valve - See note above.

4. Motor/Pump/Reservoir Unit - No evidence of

hydraulic leaks. Hydraulic oil level should be filled

level with the full line.

5. Batteries - Battery cables; no corrosion.

6. Platform Assembly and Gate - Quick-Change platform mounting and mounting pins; DVSP - platform

fasteners; platform railings; entry bar or gate in

proper working or der.

7. Platform Control Console - Platform control; plac-

ards secure and legible; emergency stop switch

reset for operation; Control markings legible.

8. Ground Control Station - Main Power Selector

Switch operable; placards secure and legible; emergency stop switch operates properly.

9. Mast Assembly - Mast sections; slide pads; mast

chains; sequencing cables; platform control and

power cables (on side of mast); power cables properly tensioned and seated in sheaves; cable

sheaves rotating freely.

3121135 – JLG Lift – 2-3

Page 18

SECTION 2 - PREPARATION AND INSPECTION

9

8

7

6

5

4

3

2

1

Figure 2-1. Daily Walk-Around Inspection for DVL/DVSP Machines.

1. Drive and Caster Wheels 4. Motor/Pump/Reservoir Unit 7. Platform Control Console

2. Base Frame 5. Batteries (Open Cover Doors) 8. Ground Control Station

3. Manual Descent Control Valve 6. Platform Assembly 9. Mast Assembly

2-4 – JLG Lift – 3121135

Page 19

SECTION 2 - PREPARATION AND INSPECTION

2.5 FUNCTION CHECK

Once the “Walk-Around” Inspection is c omplete , perfor m

a function check of all systems in an area free o f o verhead

and ground level obstructions. Refer to Section 3 for more

specific operating instructions.

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF

THE MACHINE IMMEDIATELY! REPORT THE PROBLEM TO THE

PROPER MAINT ENANCE PERS ONNEL. DO NO T OPERATE THE

MACHINE UNTIL IT IS DECLARED SAFE FOR OPERATION.

Perform a Function Check as follows:

1. From the ground controls with no load in the platform:

a. Operate ground control functions, platform lift

up and lift down.

NOTE: Ensure Pot-Hole-Protection device is fully engaged

(both bars down) when the platform is elevated .

b. Ensure that all machine functions are disabled

when the Emergency Stop Button is activated.

c. Check Manual Descent Control valve is operat-

ing properly.

2. From the platform control console:

a. Ensure that the control console is properly

mounted and secure.

b. Raise and lo wer p l atfo rm 2 ft. to 3 ft. (.61m to .92

m) several times. Check for smooth elevation

and lowering of pl atform.

c. Operate all functions and check all limit and cut-

out switches.

d. Ensure that all machine functions are disabled

when the Emergency Stop Button is activated.

3. With platform in the transport (stowed) positio n:

a. Drive the machine on a grade, not to exceed the

rated grade ability, and stop to ensure the

brakes hold.

b. Check the 1.5 degree tilt sensor alarm to ensure

proper operation.

3121135 – JLG Lift – 2-5

Page 20

SECTION 2 - PREPARATION AND INSPECTION

This page intentionally left blank.

2-6 – JLG Lift – 3121135

Page 21

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

SECTION 3. MACHINE CONTROLS, INDICATORS AND OPERATION

Table 3-1. DVL And DVSP - Machine Operating Specifications

15DVL 20DVL 15DVSP 20DVSP

Maximum Occupants: 1

Maximum W ork Load (Capacity) :

(DVL-Std. Platform / DVSP - Stockpicker Platform)

Maximum T r avel Grade (Gradeabilit y):

(Platform STOWED ONL Y)

Maximum T ravel Grade (Side Slope):

(Platform STOWED ONL Y)

500 lb.

(230 kg)

350 lb.

(160 kg)

20%

5°

500 lb.

(230 kg)

400 lb.

(180 kg)

Machine Height (Platform Stowed) 78 in. (198cm)

Maximum Vertical Platform Height: 15 ft. (4.57 m) 19.5 ft. (5.94 m) 15 ft. (4.57 m) 19.5 ft. (5.94 m)

Maximum Wheel Load (Per Wheel): 800 lb. (360 kg)

Maximum Drive Speeds (Operator Variabl e): 0.5 - 2 mph (0.8 - 3.2 kph)

Max. Platform Speeds (w/Max. Load): Plat-

20 sec. 22.5 sec. 20 sec. 22.5 sec.

form Up:

Platform Down: 15 - 21 sec. 21 - 26 sec. 15 - 21 sec. 21 - 26 sec.

Gross Machine Weight

(Standard Equipment/Platform Empty):

2,105 lb.

(955 kg)

2,105 lb.

(955 kg)

2,150 lb.

(975 kg)

2,150 lb.

(975kg)

3121135 – JLG Lift – 3-1

Page 22

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.1 GENERAL

IMPORTANT

THE MANUFACTURER HAS NO DIRECT CONTROL OVER

MACHINE APPLICATION AND OPERATION. THE USER AND

OPERATOR ARE RESPONSIBLE FOR CONFORMING WITH GOOD

SAFETY PRACTICES.

This section provides the necessary information needed

to understand control function and oper ation.

3.2 MACHINE DESCRIPTION

The JLG DVL and DVSP Model Lifts are electric self-propelled machines with an aerial work platform mounted to

an elevating aluminum mast mechanism. The personnel

lift’s intended purpose is to provide personnel access to

areas above ground level. The DVSP model lift is intended

for stock picking pur poses in retail store s or wa rehouses.

The primary control station is located in the platform.

From the Platform Control Console the operator can drive

the machine and raise or lower the platform.

The controls of the programmable Ground Control Station

are to be used during machine power-up, machine maintenance or in case of emergency should the operator in

the platform be unable to lower the platform.

Vibrations emitted by these machines are not hazar dous

to an operator working in the platform.

The continuous A-Weighted sound pressure level at the

work platform is less than 70db (A).

3.4 BATTERY CHARGING

DVL and DVSP machines are equipped with an AC voltage input/DC voltage output battery charger. The charger

automatically terminates charging when the batteries

reach full capaci ty.

NOTE: The machine’s platform drive function is disabled

when the battery charger is plugged into an AC

receptacle.

1

Figure 3-1. Battery Charger Location.

1. Battery Charger

NOTE: Machines built to the UL-EE electrical specification

(option) include additional controls and design features. These controls are labeled as (EE Only).

3.3 MACHINE OPERATION

Getting Started

The following control conditions must be met before the

machine can be operated from either the G round or Platform Controls.

• The batteries contain enough voltage to operate the

machine.

• The Main Power Selector Switch on the Gound Control

Station must be se t for eith er Grou nd C ontrol Mode or

Platform Control Mode.

• Both Emergency Stop Switches, one on the Ground

Control Station the other on the Platform Contr ol Console must be in the RESET position.

• If equipped, the On/Off Key Switch on the Platform

Console must be set to the ON position.

2

3

1

Battery Charger Fron t Panel

1. 120V/5 Amp Breaker 3. 240V/5 Amp Breaker

2. AC Input Voltage Selector

3-2 – JLG Lift – 3121135

Page 23

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

Battery Low Voltage Warning Indicators

The Platform Control Console and Ground Control Station indicate battery low voltage at three (3) Warning Levels.

Table 3-2. Battery Low Voltage Warning Indicators.

IMPORTANT: The 3 Levels of Battery Low Voltage Warning indication will only activate on Ground Control Modules with version 29 or later Ground

Control Module software (implemented 8/2004). However, machines with earlier versions of software must follow the same LED/BAR indicator

guidelines and battery charging cycles to maximize battery life.

WARNING

LEVEL

LEVEL-1 • 3 LEDs/BARS Flashing with

PLATFORM CONTROL LED GROUND CONTROL LCD

INDICATOR LOCATION

RESULT

an audible beep.

• Machine will Operate - No

ACTION REQUIRED TO

CLEAR FAULT

Charge b atteries to a level o f four

(4) LEDs/BARS or more before

operating.

Control Functions Locked

Out.

LEVEL-2 • 2 LEDs/BARS Flashing with

an audible beep.

• Platform Lift-UP Function is

Locked Out.

LEVEL-3 • 1 LED/BAR Flashing with an

audible beep.

•Drive and Platform Lift-UP

Functions Locked Out.

Charge batteries for a minimum

of four (4) continuous hours or

eight (8) LEDs/BARS lit before

operatin g. (a)

Charge batteries for a minimum

of four (4) continuous hours or

eight (8) LEDs/BARS lit before

operatin g. (a)

NOTE: (a) To maximize battery life, it is recommended that the factory supplied batteries be charged continuously for a minimum of 4 hours or

until 8 bars are lit on the ground station LCD Display be fore operating the machine. When drain ed to Warning Level 2 or 3, batteries

must be charged until 8 ba rs are lit on the ground station LCD display to clear the fault code.

To Charge Batteries

1. Park machine in a well ventilated area near an AC voltage electrical outlet.

2. Check the AC voltage selector switch on front of the

battery charger is set to correct local AC voltage.

NOTE: The batteries on DVL/DVSP machines require

approximately five (5) hours to fully charge when

drained to LOW BATTERY VOLTAGE warning on the

Ground Control Module LCD display.

Battery Charging Status Indicators

The battery charging status indica tors are located just

above the Charger AC input receptacle on the center

cover section at the rear of the machine. (See Figure 3-2.)

When first plugged in, the charger runs through a selfdiagnostic test, lighting the LEDs in sequence, then charging will begin.

+

-

CHARGE COMPLETE

GREEN (TOP) LED ON

100% Complete

3. Plug a h eavy duty

+

-

AC extensio n cord

into the Charger

AC Input Receptacle on the center

rear cover of the

machine.

+

-

+

-

+

-

+

-

CHARGING

AMBER (MIDDLE) LED ON

Charge Incomplete

CHARGING PROBLEM

RED (BOTTOM) LED ON

Consult Troubleshooting Section

of the Serv ice Manual.

3121135 – JLG Lift – 3-3

Page 24

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.5 GROUND CONTROL STATION OPERATION

(See Figure 3-2.)

NOTE: If equipped with optional Programmable Security

Lock (PSL) see Section 3.10 for additional instructions.

Main Power Selector Switch

Set the Main Power Selector

Switch to Ground Control Mode at

the Ground Control Station

Emergency Stop/Shut Down Button

POWER OFF

PUSH IN To Engage

Emergency Stop

Brake Release Button

PUSH and RELEASE TO DISENGAGE Brakes

PUSH and RELE A S E AGAIN TO ENGAGE Brakes

NOTE: The brakes only DISENGAGE (electrically) when the

joystick control is moved off center during driving or

are manually DISENGAGED (electrically) using the

the Brake Release Button.

If the machine’s batteries are completely depleted of

electrical charge the brakes cannot be released

manually.

CAUTION

DO NOT MANUALLY DISENGAGE T HE BRAKES UNLESS

MACHINE IS SETTING ON A LEVEL SURFACE OR MACHINE IS

FULLY RESTRAINED.

Platform Up

PUSH IN TO ELEVATE Platform

RELEASE TO STOP ELEVATING

POWER ON

TURN CLOCKWISE

and RELEASE To Reset

Emergency Stop

Master Disconnect Switch - (EE Option Only)

POWER ON

Lever is pointing

-

-

xxxxxxx

straight out towards left

side of machine.

POWER OFF

Lever is TURNED

COUNTERCLOCKWISE towards decal.

Platform Down

PUSH IN TO LOWER Platform

RELEASE TO STOP LOWERING

Manual Descent Control Valve

PUSH-IN TO

LOWER Platform

RELEASE TO STOP Platform

Descent

3-4 – JLG Lift – 3121135

Page 25

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

11

1

-

xxxxxxx

5

4

-

-

6

7

+

+

2

3

8

FILL TO LINE

9

10

Figure 3-2. Ground Control Station. (Machine Rear View)

1. Machine Status LCD Display 5. Platform Up 9. Hydraulic Oil Reservoir

2. Main Power Selector Switch 6. Platform Down 10. Manual Descent Control Valve

3. Emergency Stop 7. Battery Char ging Status Indicators 11. Master Power Disconnect Switch (UL - EE Only)

4. Brake Release 8. Charger A/C Input Receptacle

3121135 – JLG Lift – 3-5

Page 26

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Machine Status LCD Display

At power-up and during operation the LCD display on the

Ground Control Module displays the current machine

operating status. The following illustration explains the

symbol indication s.

1

00000.0

3

2

00

4

In the LCD Display Symbols illustration item (2), the Function Display or Function Disabled Indicators will vary as

shown followi ng:

DRIVE Disabled

LIFT UP Disabled

LIFT DOWN Disabled

Both LIFT UP and LIFT DOWN

Disabled

Drive Speed Cut-Back (Turtle) Mode

Engaged (When Platform is Elevated)

00

5

LCD Display Symbols

1. Battery Charge Indicator (BCI)

2. Function Display or Function Disabled Indicators

3. Hour Meter Display

4. Fault Code Indicator

5. Fault Text Message Display (a)

Note: (a) When an Fault Code is indicate d the LC D sc reen will

alternate between the text and symbol display modes.

Battery Charger (AC) Plugged In

LCD Display Fault Conditions

Table 3-3, LCD Display - Operating Fault Conditions show

common LCD display Fault i ndications wh ich may occur

during operation and are usually caused by either an erro r

in machine operation or a work area condition. These

fault conditions can usually be corr ected by the ope rator

and do not require a qualified mechanic to repair.

IMPORTANT

AFTER A FAULT CONDITION IS CORRECTED THE MACHINE

POWER MAY NEED TO BE RECYCLED TO RESET THE GROUND

CONTROL STATION.

3-6 – JLG Lift – 3121135

Page 27

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

Table 3-3. LCD Display - Operating Fa ult Conditions

PLATFORM

FAULT

CODE

CONSOLE

LED FAULT

CODE

LCD SYMBOL SCREEN LCD TEXT SCREEN

——

00000.0

—— NONE

00000.0

——

00000.0

——

00000.0

02 2

00000.0

02

03 2

00000.0

03

04 3

00000.0

04

13 6

00000.0

13

17 7

00000.0

17

32 7

00000.0

32

33 2

00000.0

33

34 —

35 —

FAULT DESCRIPTION/

MACHINE CONDITION

Brakes Released

(DRIVE Disabled)

Charger AC Plugged In

DRIVE Disabled

Obstruction Sensor System

(Platform Elevated)

LIFT DOWN Disabled

Programmable Security

Lock Password

Left PHP Bar UP

(Platform Elevated)

02

DRIVE and Lift UP Disabled

Right PHP Bar UP

(Platform Elevated)

03

DRIVE and Lift UP Disabled

Tilt Condition

(Platform Elevated)

04

DRIVE and Lift UP Disabled

Traction Module

Over T emperature

13

(DRIVE Disabled)

Ground Control Module

Over T emperature

17

(Machine Stopped)

Pump Motor Over Current

(LIFT UP Disabled)

32

Both PHP Bars UP

DRIVE and Lift UP Disabled

33

Aux. #1 - Platform Gate

Open or No Pressure on the

Platform Enable switch.

Aux. #1 - Platform Enable

switch depressed during

Machine Power-up.

LOOK FOR THIS

T o Engage Brakes - Press

Brake Release Button on

Ground Contr ol Station

Unplug Charger AC Power

Cord

Obstruction Under Platform

or Sensor Defective

Enter Code on PSL Ke ypad

to Powe r-Up Machi ne

Lower Platform and Ch eck

the Left Pot Hole Protection

Bar

Lower the Platform and

Check the Right P ot Hole

Protection Bar

Lower the Platform and

Drive off the Tilt Condition

Allow Dri ve System T ract ion

Module to Cool Before

Operating

Allow Ground Control

Module to Cool Before

Operating

Platform Load Over Capacity

Check for Object Blocking

Both the Left and Right PHP

Bars

Close Platform G ate or

Depress Platform Enable

switch during machine

operation.

Do Not Press on P latform

Enable switch during

Machine P ower -Up.

NOTE: The fault conditi ons sh own above are fault cond itions whic h the O perato r may be able t o resol ve. Should a fault

occur and be displayed on the LCD screen which cannot be corrected at the Operator’s level, the problem must

be referred to a quali fied m echan ic. A comp le te tab le o f Fault Codes is listed in the TroubleSh ooting Sectio n of the

Service and Maintenance Manual.

3121135 – JLG Lift – 3-7

Page 28

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.6 GROUND CONTROL STATION PROGRAMMING

General

The DVL/DVSP mach ine Ground Control Stat ion allows

on-board prog r amming of various co mponent and cont rol

function personality settings.

Programming may be required under circumstances such

as:

• Optional equipment has been added to the machine in

the field and a function must be enabled before operation.

• Customizing the machine to fit a specific application,

such as changing the LCD display language.

Programming Levels

There is one (1) password protected programming level

available to the Operator:

• Level-3: Operator’s Settings -

Level-3 Password: 33271

Operator Programming Mode

In the Operator Level Programming Mode the following

items are shown on the main menu (See Table 3-4 f o r S et-

ting Range and Default Factory Setting):

•Tilt Sensor

•Program

•Tilt Sensor

Allows viewing current tilt sensor individual X and Y

direction degree reading.

•Program

Allows programm ing of the items shown in Table 3-4,

the following is a brief explanation of each programming item.

NOTE: There are two produc tion modules available at this

time, one for North/South American and European

languages, and one for Asian languages. All programmable items between these modules are identical with the excepti on of lang uage selection.

• Back To Main - When selected, will return to main

level menu.

• Set Language - Selects the language that text on

the LCD screen will be displ aye d.

• Set Sleep Time - Allows setting the length of time

the machine will remain powered up without control

input before po we r ing itself down.

• Set Polarity of Keypad Code - Turns on or off the

Programmable Security Lock switch circuit, if

equipped.

• Enable Detection of Horn Open Circuit - Enables

horn electrical circuit to be turned on (YES) or off

(NO) if machine is equipped with a horn.

Table 3-4. DVL/DVSP Ground Control Station - Level 3 - Programmable Settings and Factory Presets.

Level-3: Operator Progr ammable Setti ngs On LCD Disp lay: YES =

LEVEL PROGRAMMABLE ITEM

3 Back to Main — Return to Main Menu

3 Set Language

NOTE: There are two production modules available at this

time, one for Nor th/South Americ an and European

Languages, and one for Asian Languages.

3 Set Sleep Time 5 MINS 0 - 60 MINS

3 Set Polari ty of the Keyp ad Code L OW HIGH/L OW

3 Enable Detection of Horn Open Circuit NO (a) YES/NO

3 Enable Detection of Beacon Open Circuit NO (a) YES/NO

3 Forward Alarm Disable NO YES/NO

3 OSS Diagnostics NO YES/NO

Notes: (a) DVSP Models this feature is standard equipment and preset to YES at factory.

FACTORY

PRESET

1 1 - English 6 - Italian

2 - German 7 - Swedish

3 - Dutch 8 - Brazilian Portuguese

4 - French 9 - Finnish

5 - Spanish

2 1 - English 3 - Japanese

2 - Chinese

NO =

!

✕

SETTING RANGE

HIGH =

LOW =

↑

↓

3-8 – JLG Lift – 3121135

Page 29

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

• Enable Detection of Beacon Open Circuit -

Enables mast/base beacon strobe electrica l circuits

to be turned on (YES) or off (NO) if machine is

equipped with either or both beacon strobes.

• Forward A larm Disable - When turned on (YES) will

disable the alarm wh e n dr iving forward.

• OSS Diagnostics - When turned on (YES) will cause

the controller LCD to continuously display the

Obstruction Sensing System (OSS) Diagnostics until

turned back off (NO)...... .the machine wil l function

normally, but only the OSS Diagnostics screen will

display until this setting is re-set to the off (NO) position.

Activating Programming Mode

NOTE: If machine does not power up, check that both the

Ground Control Station - Emergency Stop Button,

and the Platform Control Console - Emergency Stop

Button, are in the RESET position.

Also if machine is equipped with the (PSL) Programmable Security Lock option, see Section 3.5 of this

Operators Manual for additional machine power-up

steps.

Entering Password

4

00000

1

1. The Brake Release button (1) moves the box from left

to right to select which digit to change.

2. Platform UP button (2) increases the numerical digit.

3. Platform DOWN button (3) decreases the numerical

digit.

4. Change all five digits (4) to match password level,

then press the Brake Release button (1) again.

23

2

1

1. W ith machine power OFF, press and hold the Brake

Release Button (1) on the Ground Control Station.

2. While holding the Brake Release Button in, power

machine up by turning the Main Power Selector

Switch (2), to either the Ground Control or Platform

Control Mode.

3. Release the Brake Release Button (1) after machine is

powered up. The LCD display should now display five

zeros, one wit h a box around . Continue to n ext step

Entering Password.

Programming Mode Selection

2

3

1. Use Platform UP/DOWN buttons (1) to move the

selection box (2) up or down to select item to program.

2. Press the Brake Release button (3) to enter selected

mode then move on to Selecting Programmable Item

to Adjust.

1

3121135 – JLG Lift – 3-9

Page 30

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Selecting Programmable Item to Adjust Adjusting Programmable Setting

2

1. Use the Platform UP/DOWN buttons (1) to scroll

through the list of programmable items available to

your programming level.

2. Once a programmable item to be adjusted is selected,

press the Brake Release button (2) to enter that settings’ adjustment mode.

1

2

1. Adjust the programmable setting using the Platform

UP/DOWN buttons (1), see Table 3-4 for range of settings for that item.

2. Once parameter is set for the programmable item,

press the Brake Release button (2), this will enter the

parameter and return you to the Programmable Settings Menu.

TO EXIT Programming Mode after adjusting programmable settings, power machine down w ith either the

Main Power Selector Switch or Emergency Stop Button.

1

3-10 – JLG Lift – 3121135

Page 31

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

8

3.7 PLATFORM CONTROL CONSOLE OPERATION - (MACHINES SERIAL NUMBER 0130007616 TO PRESENT)

1. On/Off Key Switch -

7

6

5

4

3

(See page 3-12)

2. Emergency Stop/Shut D own Button (See page 3-12)

3. Functio n Enable Lever - (on front of joystick)

(See page 3-13)

4. Multifunction Joystick Control (See page 3-13)

5. Drive Speed Setting Selector Switch (See page 3-14)

6. Platform Control Display Panel (See page 3-12)

7. Horn Button - (See page 3-13)

8. Drive/Lift Mode Selector Switch -

(See page 3-13)

Figure 3-3. Platform Control Console -

(Machines Serial Number - 0130007616 to Present)

General

The following conditions must be met before the machine

can be operated from the platform control console:

• Ground Control Station - Main Power Selector Switch

must be set to PLATFORM CONTROL MODE.

• Ground Control Station - Emergency Stop/Shut Down

Button must be in the RESET position (POWER ON).

NOTE: See Section 3.5 on page 3-4, for Ground Control

Station operation.

• Platform Console - On/Off Key Switch must be set to

the ON position.

• Platform Console - Emergency Stop/Shut Down Button

must be in the RESET po sition (POWER ON).

2

1

• If equipped with the OPTIONAL - PSL (Programmable

Security Lock) it must be set to the ON position.

NOTE: See Section 3.10 on page 3-18, for locati on a nd PSL

instructions.

NOTE: SLEEP MODE - During operation if no control func-

tions have been activated for 10 minutes (default

programmable setting), the ground control module

will power the machine down to conserve battery

power. Cycle power back on using either the main

power selector switch (key) or the emergency stop/

power down button either on the platform controller

or on the ground control station.

3121135 – JLG Lift – 3-11

Page 32

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Platform On/Off Key Switch

1

2

Set the ON/OFF Key Switch to th e OFF posi tion to pow er

machine down.

NOTE: If necessary, when machine is not in use, remove

key from platform key switch to disabl e machi ne from

unauthorized use.

NOTE: During operation the operator in the platform can

prevent unauthorized control of the machine (from

the Ground Control Station) by either switching the

On/Off Key to the OFF position, or activating the

Emergency Stop Button on the platform control console.

At the Platform Control Cons ole Set the On/Off Key Switch to th e

ON position (2) to operate

machine.

1. OFF Position

2. ON Position

Platform Control Display Panel

1

4

3

Figure 3-4. Platform Control Display Panel.

1. Battery Charge/Flash Code LEDS

2. Drive Mode Indicator

3. Lift Mode Indicator

4. Drive Speed Setting

Indicator

2

Platform Emergency Stop/Shut Down Button

NOTE: The Platform and Ground Control Station Emer-

gency Stop/Shut Down Buttons must both be in the

RESET position to operate machine.

POWER OFF

PUSH IN TO ENGAGE

Emergency Stop

POWER ON

TURN CLOCKW ISE

and RELEASE to

RESET Emergency Stop

1. Battery Charge/Flash Code Indicator LEDS

On normal pow er-up and operation this series of ten

(10) LEDs visually indicates the amount of charge

remaining in the batteries.

The number of LEDs lit will change depending on the

level of charge in the batteries.

• (+) All Three (3) GREEN LEDs lit up indicate maxi-

mum battery charge.

• Four (4) YELLOW LEDs indicate a two thirds to one

third battery charge remaining.

• (–) Three (3) RED LED’s lit indicate minimum battery

charge remaining. The mach ine will continue to

operate at this charge level but will begin to indicate

low battery voltage warning indicators.

NOTE: For more information on Battery Warning Level Indi-

cators See “Battery Low Voltage Warning Indicators”

on page 3-3.

This set of ten (10) LEDs will also indicate a flash (fault)

code if operating problems are detected by the

Ground Control Station.

NOTE: LED Flash (Fault) Code indications that can be cor-

rected by the operator are shown on Table 3-3 on

page 3-7, this section of the manual.

3-12 – JLG Lift – 3121135

Page 33

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

2. Drive Mode Indicator

When the Drive/Lift Mode Selector Switch is set to

DRIVE MODE the round LED indicator on that portion

of the display panel will light up indicating the DRIVE

Mode active.

3. Lift Mode Indicator

When the Drive/Lift Mode Selector Switch is set to LIFT

MODE the round LED indicator on that portion of the

display panel will light up indicating the LIFT Mode

active.

4. Drive Speed Setting Indicator

The five (5) GREEN LEDs on the top of this indicator

display the drive speed setting with the TURTLE (on

the left) representing the MINIMUM speed setting and

the RABBIT (on the right) representing the MAXIMUM

speed setting.

Drive/Lift Mode Selector Switch

Drive/Lift Mode

Selector Switch

1 2

1. LIFT Mode

2. DRIVE Mode

Horn Button

When the machine is

powered on, pressing

this button will sound

the Horn.

Joystick Function Enable Lever

Joystick Function

Enable Lever

The Function Enable lever on

the front of the joystick control, must be engaged and

held in during any joystick

operation.

PUSH the rocker

switch to se lect mode

of operation.

Whichever mode is

selected the appropriate LED indicat or on

the display panel

below will light up

showing which mode

has been activated for

joystick operation.

IMPORTANT:

The selected mode

will only remain

active for 5 seconds if the function

is not op erated.

Multifunctio n Joystick Contro l

The joystick will operate the following machine functions:

•Drive

•Platform Lift Up and Down

NOTE: Use the Drive/Lift Mode Selector Switch to select

which function the joystick will operate.

The selected operating mode will only remain active

for 5 seconds if the function is not operated.

Remember to press and hold the joystick function

enable lever to operate any joystick functions.

WARNING

WHEN DRIVING WITH PLATFORM LOWERED, DO NOT ATTEMPT

TO DRIVE MACHINE UP A RAMP (GRA DE) OF GREA TER THAN

FIFTEEN PER CENT (15%).

DRIVING WITH PLATFORM ELEVATED IS RESTRICTED TO A

SMOOTH, FIRM AND LEVEL SURFACE WITHIN 1.5 DEGREES OF

LEVEL IN AN Y DI RE CT ION .

3121135 – JLG Lift – 3-13

Page 34

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Drive Mode

WARNING

1. Activate the Drive

Mode using the Drive/

Lift Mode Selector

switch.

1

Within 5 seconds of activation - ENGAGE and HOLD

the JOYSTICK ENABLE

LEVER then move the joystick in the desired direction

of travel. Drive power is

applied proportionally the

further the joystick is

moved off center .

THE GROUND CON TROL STATION CONTAINS A 1.5 DEGREE

TILT ALARM, IF THE TILT ALARM HAS BEEN AC TIVATED, THE

PLATFORM WILL NOT ELEVATE. ALSO IF THE TILT ALARM HAS

BEEN ACTIVATED WHEN THE PLATFORM IS ELEVATED, T HE

DRIVE AND LIFT UP FUNCTIONS WILL BE DISABLED UNTIL THE

PLATFORM IS COMPLETELY LOWERED, THEN DRIVEN OFF T HE

TILT CONDITION.

Drive Speed Setting Controls

NOTE: When the platform is elevated the maximum drive

speed is automatically cut-back to 1/4th the speed

when the platform is fully lowered. The Ground Control Module-LCD screen will display a turtle when in

this mode, See page 3-6 - Ground Control - LCD

Status Display in this section of the manual.

Lift Mode

2

3

1. Activate the Lift Mode

using the Drive/Lift

Mode Selector switch.

2. Platform LIFT DOWN

Direction

3. Platform LIFT UP

Direction

Within 5 seconds of activation - ENGAGE and HOL D the

JOYSTICK EN ABLE LEVER

then move the joystick in the

direction of LIFT (3) OR

LOWER (2).

Drive Speed Setting

Selector Switch

1. Selector Switch (on top

of joystick)

Each PRESS on this side of

the switch will DECREASE

maximum drive speed.

(FEWER LEDs Lit up on the

1

Drive Speed Indicator .)

Each PRESS on this side of

the switch will INC REA S E

maximum drive speed.

(MORE LEDs Lit up on the

Drive Speed Indicator.)

3-14 – JLG Lift – 3121135

Page 35

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

1

3.8 PLATFORM CONTROL CONS OLE OPERATION - (MACHINES BEFORE SERIAL NUMBER -

0130007616)

4

5

2

3

6

Figure 3-5. Platform Control Console -

(Machines Before Serial Number - 0130007616

7

8

9

1. Battery Charge/Fault Code (LEDs) 4. Increase Max. Drive Speed 7. Platform Function (Enable)

2. Max. Drive Speed Setting (LEDs) 5. Horn 8. Joystick with Enable Button

3. Decrease Max. Drive Speed 6. Drive Function (Enable) 9. Emergency Stop

At Ground Control Station Emergency Stop/Shut-Down Button

Set the Main Power Selector

Switch to Platform Control

Mode at the Ground Control

Station. (See Figure 3-2.)

3121135 – JLG Lift – 3-15

POWER OFF

PUSH IN TO ENGAGE

Emergency Stop

POWER ON

TURN CLOCKW ISE

and RELEASE TO RESET

Emergency Stop

Page 36

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Battery Charge/Fault Code LED Indicator

–+

On normal power-up and operation this series of LEDs

visually indicates the amount of charge left in the batteries.

• (+) GREEN LEDs lit indicate maximum charge.

• (–) RED LED’s lit indicate minimum charge remaining.

• The number of LEDs lit will change depending on the

level of charge in the batteries.

If battery voltage falls below 16.8 volts a fault condition will

occur and the machine will stop operating. The batteries

will need recharged.

NOTE: LED Fault Code indications are in Table 3-3, LCD

Display - Operating Fault Conditions, this section of

the manual.

Driving Machine

WARNING

WHEN DRIVING WITH PLATFORM LOWERED, DO NOT ATTEMPT

TO DRIVE MACHINE UP A RAMP (GRA DE) OF GREA TER THAN

TWENTY PER CENT(20%), AS TIPPING COULD OCCUR.

®

POINT G

S

E

E

T

R

1. Enter the platform.

POINT & GO

The Joystick can be

moved in any direction

off center.

Drive Power is applied

proportionally the further the Joystick is

moved off center.

2. PRESS and RELEASE the

Drive Function Button. The

flashing LED indicates the

function is active. The function

remains active 3 to 4 seconds.

3. While the Drive Function is

active. PRESS and HOLD the

enable button on top the joystick

POINT G

4. Move the joystick in the

desired direction of travel. TO

STOP the machine return the

joystick back to center.

3-16 – JLG Lift – 3121135

Page 37

SECTION 3 - MAC HINE CONTROLS, INDICATORS AND OPERATION

Adjusting Maximum Drive Speed Co ntrol

NOTE: When the platform is elevated the maximum drive