Page 1

Empress®System

IPS

Empress®Esthetic

IPS

Instructions for Use

Page 2

Table of Contents

IPS Empress Esthetic – Product Information 4

Material

Uses

Composition

Ingot concept

Product overview and description

Product Information

Practical

working steps

Accessories, auxiliaries and equipment

IPS Empress Esthetic – Practical working steps 17

Preparation guidelines and minimum thicknesses

Shade determination

Cementation

IPS Empress Esthetic – Inlays / Onlays / Crowns – stained / glazed 21

Model and die preparation

Wax-up

Sprueing

Investing

Preheating

Calibration

Pressing

Divesting

Removing the pressed object / finishing

Fabricating the die using IPS Natural Die Material

Stain and Glaze firing

Subsequent adjustments

IPS Empr

Wall and layering thicknesses

Preparing the model and dies

W

Cut-back technique

Preparing for veneering

W

Incisal fi

Fabrication of IPS Empress Esthetic restorations in the laboratory

General

Information

Finishing and preparing for stain and characterization firing

Stain and Characterization fi

Glaze fi

Subsequent adjustments

IPS Empress Esthetic – General Information 45

Preparing for cementation

Press parameters

Firing parameters

Combination tables

ess Esthetic – Veneers / Anterior Crowns – Cut-back and layered

ax-up

ring

ash fi

ring

ring

ring

36

2

Page 3

®

Empress

IPS

Nearly 20 years ago, IPS Empress revolutionized the processing of ceramic and thanks

to its many advantages, such as aesthetics, IPS Empress has been established as the

“benchmark”. More then 33 million restorations fabricated of IPS Empress throughout

the world and the use of “IPS Empress” as a synonym for all-ceramics speak for the

durable life-like appearance, the ongoing success, and the high quality standard of the

material.

In addition to the tried-and-tested PRESS technology, the CAD/CAM technology has

also developed in the area of all-ceramics. In order to supply the “benchmark” for this

technology as well, the future IPS Empress System will comprise products for both

processing technologies. You will be able to benefit from roughly 20 years of clinical

experience and convincing aesthetics, irrespective of whether the restorations were

fabricated with the PRESS or CAD/CAM technique.

IPS Empress Esthetic is available for the PRESS technology, while IPS Empress CAD

is used in the CAD/CAM technology. Both products consist of the highly aesthetic,

leucite-reinforced glass-ceramic that has been clinically tried-and-tested for many years.

The two ceramics are characterized by excellent strength values and outstanding aesthetic appearance. They may thus be used for the fabrication of fully anatomic singleunit restorations, such as inlays, onlays, veneers, and crowns.

– the Original

Both products may subsequently be stained and/or glazed using IPS Empress

Universal Shades/Stains, or individually veneered using the IPS Empress Esthetic

Veneer layering ceramic.

In this way, the IPS Empress System will remain synonymous for highly aesthetic, fully

anatomical all-ceramic restorations, irrespective of the processing technology.

PRESS

Technology

Empress

IPS

CAD / CAM

Technology

Empress CAD

IPS

Esthetic

Empress

IPS

Esthetic Veneer

Empress

IPS

Universal Shade/Stains

3

Page 4

Empress Esthetic –

IPS

Product Information

Material

IPS Empress Esthetic is used for the fabrication of highly aesthetic

single-tooth restorations by means of the PRESS technique.

IPS Empress Esthetic ingots are made of a leucite-reinforced glassceramic which consists of a glass and a crystal phase. Leucite crystals

of a few microns evenly grow in a multi-stage process directly from

the amorphous glass phase. During the fabrication of the ingots, the

semi-finished product in powder form is pressed to ingots in a fully

automated process, which enables a maximum of homogeneity.

Given the difference in the coefficients of thermal expansion (CTE)

between the glass phase and the crystal phase (leucite), cooling after

sintering produces compressive stress in the glass phase. This

mechanism results in an increase in strength and enables IPS Empress

Esthetic to achieve a flexural strength of 160 MPa.

This type of material has been successful as well as proven for almost

20 years. The pressed restorations feature excellent accuracy of fit

and a homogeneous surface. Subsequently, the restorations may be

stained using IPS Empress Universal Stains and/or individually

veneered using IPS Empress Esthetic Veneer.

CTE (100–400°C) [10-6/K] 16.6

-6

C) [10

CTE (100–500

Flexural str

Fracture toughness [MPa m

Vickers hardness [MPa] 6200

Chemical solubility [

*accor

°

ength (biaxial) [MPa]* 160

ding to ISO

g/cm

µ

6872

/K]

0.5

] 1.3

2

]*

17.5

25

4

Page 5

Uses

ndications

I

IPS Empress Esthetic ingots can be used for the following adhesively cemented restorations.

– Inlays

– Onlays

– Veneers

– Anterior crowns

– Posterior crowns

– Implant superstructures for single-tooth restorations (anterior and posterior region)

For further processing of IPS Empress Esthetic restorations, users have the following options:

– Aesthetic characterization and glazing of fully anatomical restorations using IPS Empress Universal

Shades, Stains, and Glaze pastes.

– Aesthetic veneering in the incisal third of reduced restorations (veneers and anterior crowns) using

IPS Empress Esthetic Veneer and additional staining and glazing

Contraindications

– Bridge reconstructions

– Conventional cementation

– Very deep, subgingival preparations

– Patients with severely reduced residual dentition

– Bruxism

– Fully (circularly) veneered anterior crowns using IPS Empress Esthetic Veneer

– Veneering of posterior crowns

Important processing restrictions

Failure to observe the following restrictions may compromise the success achieved with IPS Empress

Esthetic:

– The fully anatomical IPS Empress Esthetic restorations must not fall below the required minimum

thickness

– The reduced IPS Empress Esthetic restorations must not fall below the required minimum thickness

Observe the extent of the layering area in the cut-back technique

–

– The maximum layer thickness of IPS Empress Esthetic Veneer layering materials must not be exceeded

– IPS Empress Esthetic restorations must not be stained and veneered using materials other than

ess Esthetic Veneer

IPS Empr

– IPS Empress Esthetic restorations must not be stained and glazed using materials other than

IPS Empress Universal Shades, Stains, and Glaze

Combination with metal-ceramic systems (e.g. IPS d.SIGN)

–

– Powder materials must not be mixed with paste materials

– Do not use investment materials and press furnaces from other manufacturers

Side effects

If patients ar

not be used.

e known to be allergic to any of the ingr

edients of IPS Empress Esthetic, the material should

5

Page 6

Composition

– IPS Empress Esthetic Ingots

Components: SiO

Additional contents: K2O, Al2O3, Na2O, CaO, B2O3, TiO2, CeO2and pigments

– IPS Empress Esthetic Veneer

Components: SiO

Additional contents: Al2O3, K2O, Na2O, CaO, oxides and pigments

– IPS Empress Universal Shades, Stains and Glaze Paste

Components: Oxides, glycerine, butandiol, poly(vinylpyrrolidone)

– IPS Empress Esthetic Veneer Build-Up Liquid

Components: water, butandiol, chloride

– IPS Empress Universal Glaze and Stain Liquid

Components: Butandiol

– IPS Natural Die Material

Components: Polyester urethane dimethacrylate, paraffin oil, SiO2and copolymers

– IPS Natural Die Material Separator

Components: Wax dissolved in hexane

2

2

– IPS PressVEST Investment Material Powder

Components: SiO2(quartz powder), MgO and NH4H2PO

4

– IPS PressVEST Investment Material Liquid 1000 ml

Components: Colloidal silicic acid in water

IPS Empr

–

Components: SiO2(quartz powder), MgO and NH4H2PO

ess Esthetic Speed Investment Material Powder

4

– IPS Empress Esthetic Speed Investment Material Liquid 500 ml

Components: Colloidal silicic acid in water

– IPS Ceramic Etching Gel

Components: Hydrofluoric acid

Warnings

– Butandiol is irritating – avoid contact with skin and eyes and do not inhale the vapours.

– Hexane is highly flammable and detrimental to health. Avoid contact with skin and eyes. Do not

inhale the vapours and keep away from sources of ignition.

– Do not inhale ceramic grinding dust during processing - use suction equipment and a face mask.

– Etching gel contains hydrofluoric acid. Avoid contact with skin, eyes, and clothing at any time, since

the material is highly toxic and corrosive. The etching gel is intended for professional use only and

must not be applied intra-orally (in the oral cavity).

6

Page 7

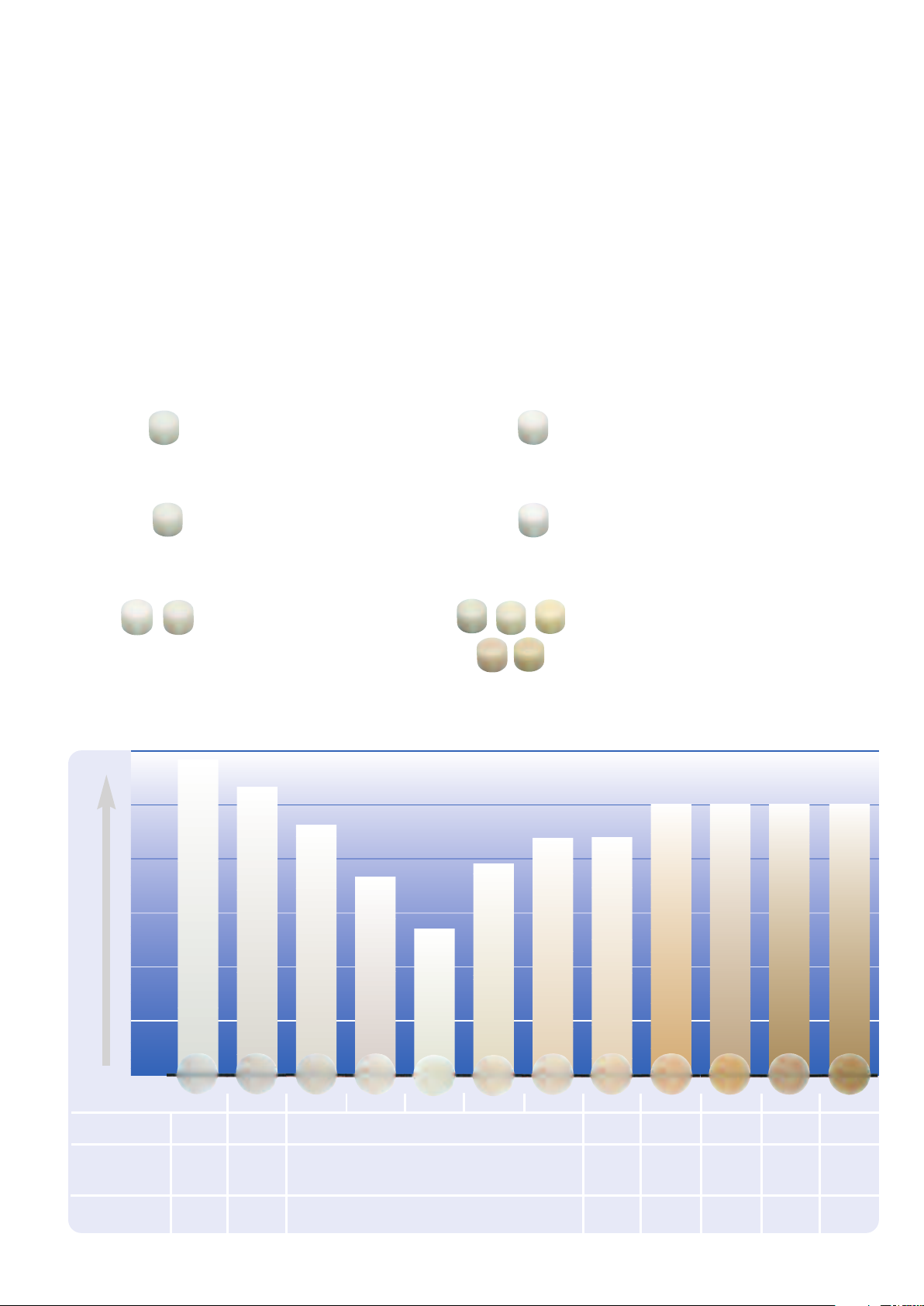

Ingot concept

IPS Empress Esthetic ingots are available in 12 shades and 7 levels of translucency to fulfil even the most discerning

requirements.

Non-shaded ingots are supplied in 5 levels of opacity: E T1, E T2, E O1, E O2 and E O3. The IPS Empress Esthetic TC ingots

are slightly shaded to reduce the need for characterization. In addition, 3 further shades are available, which are ideal for

the veneering technique. The E TC0, E O1 and E O3 ingots can be used for cases in which a bright shade effect is desired,

e.g. with a very bright tooth shade or after bleaching.

Translucency

E T1: Inlays and onlays

For older patients with very translucent

glassy residual dentition.

E T2: Inlays and onlays

For younger patients with a residual

dentition that features a low opacity.

E O1, E OC1: Crowns and veneers

For patients with a residual dentition

that features a medium opacity.

E O2: Crowns and veneers

For patients with a residual dentition

that features a very high opacity.

E O3: Crowns and veneers

For patients with a residual dentition

that features a very high opacity and

for matching bleached teeth.

E TC0 – E TC5: Inlays, onlays,

crowns and veneers

The shades of the IPS Empress Esthetic

Translucent Colour ingots are coordinated with the Chromascop shade

guide. They can be combined with AD shades.

Opacity

Chromascop

A–D Shades

Bleach BL

E T1 E T2 E O1 E O2 E O3 E OC1 E TC0 E TC1 E TC2 E TC3 E TC4 E TC5

110-140

A1, A2,

B1,

BL1, BL2, BL3, BL4

7

C1

B2,

210-240

A3, A3.5,

A4,

D3

310-340

B3, B4,

D4

410-440

C2, C3,

C4

510-540

–

Page 8

Product overview and description

IPS Empress Esthetic Basic Kit

The IPS Empress Esthetic Basic Kit contains all the ingots, as well as

the necessary accessories. The Basic Kit is supplied in the new material cabinet and can be supplemented with any other Ivoclar

Vivadent all-ceramic assortment, e.g. IPS e.max.

Delivery form:

IPS Empress Esthetic Basic Kit

– 12x 5 IPS Empress Esthetic ingots;

Farben T1, T2, O1, O2, O3, OC1, TC0, TC1, TC2, TC3, TC4, TC5

– 2x IPS Empress ring base; size 100 g and 200 g

– 2x IPS Empress ring gauge; size 100 g and 200 g

–

2x IPS Silicone Ring; size 100 g and 200 g

– 2x IPS Sprue Guide; size 100 g and 200 g

– 1x 2 IPS Empress Alox plungers

– 1x 12 g IPS Object Fix

– 1x IPS UniTray

– 1x IPS Empress Esthetic Ingots shade guide

IPS Empress Veneer Kit

The IPS Empress Veneer Kit comprises a selection of the most

popular wash pastes and layering materials for the veneering (cutback technique) of IPS Empress restorations (Esthetic and CAD). With

the wash pastes, an excellent and homogeneous bond with the

estoration is achieved. The leucite-r

educed r

r

materials feature incisal-like fluorescence and a true-to-nature

opalescence. The additional wash pastes and layering materials

e indicated on the materials shade guide

available as Refi

supplied with the Kit.

Delivery form:

IPS Empress Veneer Kit

6x 1 g IPS Empr

–

Shades: neutral, low value, high value, MM light-salmon,

MM yellow-orange, MM red-orange

6x 20 g IPS

–

Shades: Incisal Opal LT, Incisal Opal MT, Incisal Opal HT, Incisal

white, Transpa neutral, Transpa blue

1x 20 g IPS

–

– 1x 60 ml IPS Empress Esthetic Veneer Build-Up Liquid

– 1x 3 g IPS Empress Universal Glaze Paste

1x 15 ml IPS Empress Universal Glaze and Stain Liquid

–

– 1x 12 g IPS Object Fix

– 1x IPS Empress Esthetic Veneer Material Shade Guide

Various accessories

–

lls ar

ess Esthetic V

Empress Esthetic Veneer;

Empress Add-On 770°C/1418°F

eneer Wash Pastes;

einforced layering

8

Page 9

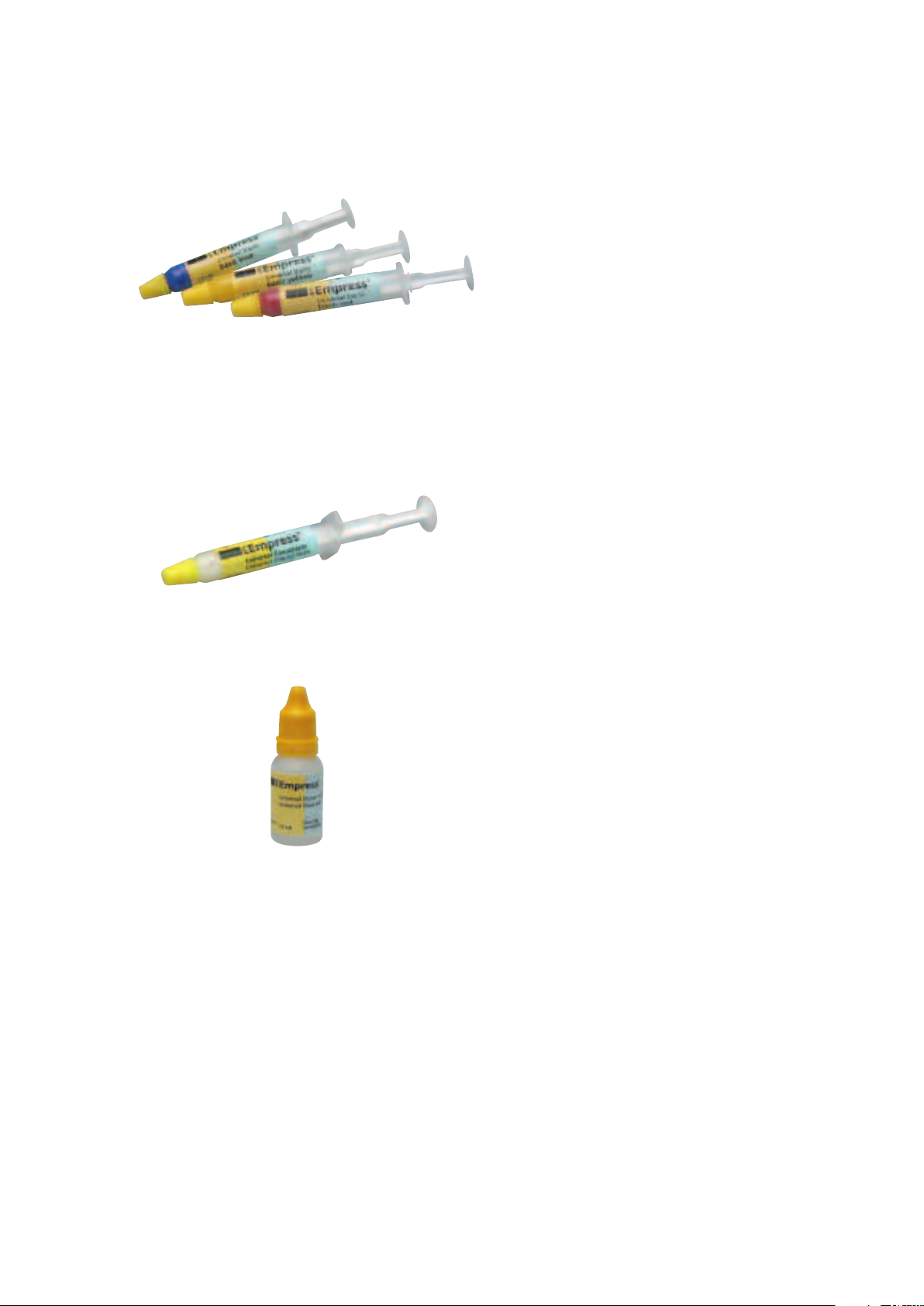

IPS Empress Universal Shade/Stains Kit

A–D and Chromascop)

(

The IPS Empress Universal Shade/Stains Kits comprise a selection of

the most popular Dentin and Intensive stains. The stains are suitable

to apply surface characterizations. For the final glazing of the

IPS Empress restorations, a smooth and fine-grained glazing paste

is provided.

Delivery form:

IPS Empress Universal Shade/Stains Kit A–D

– 6x 3 g IPS Empress Universal Shade;

Shades: A1, A2/A3/A3.5, B1, B2/B3/B4, C1/C2, D2/D3

– 2x 3 g IPS Empress Universal Shade Incisal;

Shades: I1, I2

– 5x 1 g IPS Empress Universal Stains;

Shades: white, orange, mahogany, khaki, maroon

– 1x 3 g IPS Empress Universal Glaze Paste

– 1x 15 ml IPS Empress Universal Glaze and Stain Liquid

– Various accessories

IPS Empress Esthetic Veneer Wash Pastes

Given the 2 : 1 effect of the wash pastes, i.e. bonding and

characterization in one step, highly aesthetic restorations can be

fabricated very efficiently.

The Wash Paste neutral produces the direct bond to the reduced

restorations and is always applied first on the restoration; it enables

a homogeneous bond.

Delivery form:

IPS Empress Universal Shade/Stains Kit Chromascop

– 6x 3 g IPS Empress Universal Shade;

Shades: 110/120, 130, 140/210, 220/230, 310, 410/420

– 2x 3 g IPS Empress Universal Shade Incisal;

Shades: I1, I2

– 5x 1 g IPS Empress Universal Stains;

Shades: white, orange, mahogany, khaki, maroon

– 1x 3 g IPS Empress Universal Glaze Paste

– 1x 15 ml IPS Empress Universal Glaze and Stain Liquid

– Various accessories

Delivery form:

1x 1 g IPS Empr

–

Subsequently, the reduced restorations are individually characterized

using the 5 Standard Wash Pastes. Ideal shade gradations permit

individualized characterizations of the highest order.

Delivery form:

– 5x 1 g IPS Empress Esthetic Wash Paste;

Shades: low value, high value, MM light-salmon,

MM yellow-orange, MM reddish-orange

The 5 standar

the 5 Wash-Paste Modifiers or the neutral paste.

Delivery form:

5x 1 g IPS Empr

–

Shades: Modifi

Modifier basic yellow, Modifier basic red

ess Esthetic Wash Paste neutral

d wash pastes may then be individually shaded using

ess Esthetic Wash Paste;

er copper

, Modifi

er orange, Modifi

er sky blue,

9

Page 10

IPS Empress Esthetic Veneer Incisal Opal

These opalescent materials are available in three different gradations

(low, medium, and high translucency). They feature an incisal-like

fluorescence and true-to-nature opalescence. The high stability and

excellent modelling properties permit detailed layering of life-like

incisal edges. The opalescent effect demonstrates high firing stability

and is thus clearly visible even after several firing cycles.

Delivery form:

– 3x 20 g IPS Empress Esthetic Veneer Incisal Opal;

hades: low translucent, medium translucent, high translucent

S

IPS Empress Esthetic Veneer Incisal

These Incisal materials are available in 6 shade nuances and are used

for additional characterizations in the incisal area.

Delivery form:

– 6x 20 g IPS Empress Esthetic Veneer Incisal;

Shades: white, grey, orange, edge, yellow, orange-pink

IPS Empress Esthetic Veneer Transpa

The Transparent materials in 2 shade nuances are used for the trueto-nature reproduction of transparent areas, particularly in the

incisal third.

Delivery form:

– 2x 20 g IPS Esthetic Veneer Transpa;

Shades: blue, neutral

IPS Empress Esthetic Veneer Chroma Modifier

These materials support the shade intensity of the reduced

estoration and are available in shades 110/A1 and 210/A3.

r

Delivery form:

– 2x 20 g IPS Empress Esthetic Veneer Chroma Modifier;

Shades: 110/A1, 210/A3

IPS Empr

ess Esthetic Veneer Brightener

Used to incr

Delivery form:

– 1x 20 g IPS Empress Esthetic Veneer Brightener

10

ease the brightness value.

Page 11

IPS Empress Add-On 770°C/1418°F

IPS Empress Add-On 770 °C/1418 °F is a low-fusing add-on material

for subsequent adjustment, e.g. proximal and occlusal contact

points, of IPS Empress Esthetic and IPS Empress CAD restorations.

Delivery form:

– 1x 20 g IPS Empress Add-On 770°C/1418°F

IPS Empress Esthetic Veneer Build-Up Liquid

The Build-Up Liquid is used to mix the IPS Empress Esthetic Veneer

materials and the IPS Empress Add-On corrective material. Since

build-up liquids contain various organic additives that do not fire

without leaving residue at the used firing temperatures and thus

may cause discolouration, only the IPS Empress Esthetic Veneer

Build-Up Liquid must be used.

Delivery form:

– 1x 60 ml IPS Empress Esthetic Veneer Build-Up Liquid

IPS Empress Universal Shade

The IPS Empress Universal Shades are available in 9 A–D and

15 Chromascop shades. They are used for the exact reproduction of

the A-D and Chromascop shades.

Delivery form:

– 9x 3 g IPS Empress Universal Shade;

A–D shades: A1, A2/A3/A3,5, A4, B1, B2/B3/B4, C1/C2, C3/C4,

D2/D3, D4

– 15x 3 g IPS Empress Universal Shade;

Chromascop shades: 110/120, 130, 140/210, 220/230, 240, 310,

320, 330, 340, 410/420, 430/440, 510, 520, 530, 540

IPS Empress Universal Shade Incisal

These 2 pastes are especially suitable for fully anatomical

restorations. They are used to imitate the incisal area and provide

the incisal third with optical translucency and an in-depth effect.

Delivery form:

– 2x 3 g IPS Empress Universal Shades Incisal;

Shades: I1, I2

11

Page 12

IPS Empress Universal Stains

These intensive stains are available in 14 different shades. They are

used to reproduce natural characteristics. With the three

complementary shades basic blue, basic red, and basic yellow,

the shades can be individually adjusted.

Delivery form:

– 14x 1 g IPS Empress Universal Stains;

Shades: white, mahogany, khaki, orange, grey, vanilla, crackliner,

olive, yellow, black, maroon, basic red, basic blue, basic yellow

IPS Empress Universal Glaze Paste

IPS Empress Universal Glaze Paste is used to apply the final glaze to

IPS Empress restorations. The glazing paste demonstrates a smooth,

fine-grained consistency and thus permits easy and quick application

of the glazing material layer.

Delivery form:

– 1x 3 g IPS Empress Universal Glaze Paste

IPS Empress Universal Glaze and Stain Liquid

The IPS Empress Universal Glaze and Stain Liquid is used to adjust

the consistency of all materials in paste form (Wash pastes, Shades,

Stains, and Glaze). No other liquid may be used for this purpose,

since those liquids contain various organic additives that do not fire

without leaving r

may result in discolouration.

Delivery form:

– 1x 15 ml IPS Empress Universal Glaze and Stain Liquid

esidue at the defi

ned firing temperatures, which

12

Page 13

Accessories, auxiliaries and equipment

IPS Natural Die Material

The light-curing IPS Natural Die Material simulates the shade of the

prepared tooth and thus is the optimum basis for true-to-nature

shade match with the oral situation during fabrication of the allceramic restorations. The IPS Natural Die Material Kit comprises

9 shades. The shade arrangement was newly designed. The

assortment contains all the shade variants necessary for the

fabrication of life-like all-ceramic restorations.

New items in the assortment are as follows:

– 1 shade for the imitation of bleached preparations (ND1)

– 1 shade for the imitation of intensively shaded secondary dentin

(ND 6)

– 1 shade for the imitation of severely discoloured / devitalized

preparations (ND 9)

The arrangement and designations of the IPS Natural Die shades compared to the IPS Empress Die shades is as follows:

Natural Die Material

IPS

ND 1

ND 2

ND 3

ND 4

ND 5

ND 6

ND 7

ND 8

ND 9

IPS Empress Die Material

Delivery form:

IPS Natural Die Material Kit

– 9x 8 g IPS Natural Die Material,

Shades: ND 1, ND 2, ND 3, ND 4, ND 5, ND 6, ND 7, ND 8, ND 9

– 1x 20 ml IPS Natural Die Material Separator

– 8x 10 IPS Condensers

– 8x 10 IPS Condenser Tips

2x Universal Holders

–

– 1x IPS Natural Die Shade Guide

–

St 9

St 1

IPS Sprue Guide

The IPS Sprue Guide helps check the correct sprueing of the objects

essed on the ring base.

to be pr

Delivery form:

– IPS Sprue Guide 100 g

– IPS Sprue Guide 200 g

IPS Empr

The investment ring system is used to sprue the contour

tions. The 100-g investment ring system is used for individual

restorations, whereas the 200-g ring system is suitable for several

single-tooth restorations. Due to the different diameters of the

pr

system is only suitable for materials from the IPS Empress System.

ess Investment Ring System

essed ingots and Alox plungers, the IPS Empr

ed restora-

ess investment ring

St 2

St 3

–

St 8

St 5

–

Delivery form:

– IPS Empress Investment Ring System 100 g

(3x ring base, 3x ring gauge)

– IPS Empress Investment Ring System 200 g

3x ring base, 3x ring gauge)

13

Page 14

IPS Silicone Rings

– IPS Silicone Ring, small, for the IPS Empress and IPS e.max

investment ring system 100 g

– IPS Silicone Ring, big, for the IPS Empress and IPS e.max

investment ring system 200 g

Delivery form:

– IPS Silicone Ring small 100 g

– IPS Silicone Ring big 200 g

IPS Empress Esthetic Speed Investment Material

The phosphate-bonded Esthetic Speed investment material is

suitable for the indication range of IPS Empress Esthetic and is

composed of powder and liquid.

IPS Empress Esthetic Speed investment material helps achieve highquality press results in no time at all. The investment material allows

quick heating and the fabrication of accurately fitting inlays, onlays,

veneers and crowns.

Delivery form:

– 25x 100 g IPS Empress Esthetic Speed Investment Material

Powder

– 1x 0.5 l IPS Empress Esthetic Speed Liquid

IPS PressVEST

Alternatively, the IPS PressVEST investment material can be used. It is

an optimized, phosphate-bonded investment material for the

conventional heating technique (over night) and consists of powder

and liquid. It ensures highly accurate press results and can be used

with the following Ivoclar Vivadent pressed ceramics in the EP 500

EP 600 and EP 600 Combi press furnaces:

– IPS Empress Esthetic

– IPS e.max Press

– IPS e.max ZirPress

– IPS Empress Cosmo

For detailed information on processing please refer to the

IPS PressVEST Instructions for Use.

Delivery form:

IPS PressVEST Investment Material, 2.5 kg

– 25x 100 g IPS PressVEST Investment Material Powder

– 1x 0.5 l IPS PressVest Liquid

IPS PressVEST Investment Material, 5 kg

– 50x 100 g IPS PressVEST Investment Material Powder

– 1x 1 l IPS PressVEST Liquid

14

Page 15

Investment tongs

The investment tongs ensure safe working with the investment

rings. They are used to place the ingots and AlOx plungers into the

investment ring before the press procedure is started.

Delivery form:

– 1x Investment Tongs

IPS UniTray

The IPS UniTray is a universal firing tray that has been designed to

accommodate objects to be fired, or pressed ingots and AlOx

plungers. If the IPS UniTray is used in a ceramic furnace, the

restorations are placed in the furnace using the enclosed metal pins.

Delivery form:

– 1x IPS UniTray

– 3x 4 Metal Pins

IPS Object Fix

IPS Object Fix is an auxiliary firing paste to support all-ceramic

restorations during firing. The paste is used for easier securing of

the restorations on the metal pins of the honey-comb firing tray.

Due to its consistency, IPS Object Fix is easy to apply and convenient

emove after fi

to r

Delivery form:

– 1x 12 g IPS Object Fix

ring.

EP 600/EP 600 Combi

The EP 600 furnace is ideally coordinated with the IPS Empress and

IPS e.max pressed ceramics. The furnace delivers excellent press

results due to the electronic press drive, automatic temperature

calibration, as well as a fast and easy operation by means of the

graphic display and menu controls. The EP 600 Combi is a

combination of a press and ceramic furnace, which unites the

advantages of the EP 600 with those of a high-quality ceramic

furnace. The furnace is ideal for both pressing ceramics of the

IPS Empress and IPS e.max systems and firing layering ceramics,

such as IPS Empress Esthetic Veneer.

Delivery form:

EP 600 Basic Equipment

– EP 600

Power Cor

–

d

EP 600 Combi Basic Equipment

– EP 600

Power Cor

–

d

15

Page 16

Programat®P300

The new Programat P300, which is reduced to the essentials, is an

inspiration due to its cost-effectiveness. Furthermore, it features a

convincing and easy operating concept. A simple menu structure

with clearly arranged symbols guides the user during the application

of the programs. The furnace is equipped in the factory with preset

programs for IPS e.max, IPS d.SIGN, IPS InLine, and the IPS Empress

System and it convinces users with its modern, timeless design.

Delivery form:

rogramat P300 Basic Equipment

P

Programat P300

–

– Power Cord, Vacuum Hose, Calibration Test Package,

Programat Firing Tray Kit

Programat®P500

Optimum firing results for glazing materials, stains, and ceramic

materials can be achieved with the user-friendly Programat P500

ceramic furnace. This new ceramic furnace combines high-tech and

design. The combination of the membrane-sealed keypad and the

large, clearly-arranged graphic display with touch function facilitate

operation. The homogeneous heat emission due to the new muffle

technology, the easy, precise and automatic temperature calibration,

as well as the 300 firing programs make the P500 and indispensable

companion in the laboratory.

Delivery form:

Programat P500 Basic Equipment

– Programat P500

– Power Cord, Vacuum Hose, Calibration Test Package (ATK2),

Programat Firing Tray Kit, USB Download Cable, USB Stick

ogramat

Pr

IPS®Ceramic Etching Gel

IPS Ceramic Etching Gel is used to pr

surfaces on ceramic restorations in the composite cementation

technique. It enhances the bonding effect between the luting

composite and the ceramic surface. IPS Ceramic Etching Gel is

exclusively intended for professional use and must not be applied in

the oral cavity.

Advantages

– Usable in conjunction with most glass-ceramic materials

– No environmental pollution due to neutralization

Contraindications

– Application in the oral cavity

– Enamel etching of natural teeth

– Use in conjunction with oxide ceramics

Delivery form:

IPS Ceramic Etching Gel Kit

1x 5 ml IPS Ceramic Etching Gel

–

– 1x 30 g Neutralization Powder

– 1 Measuring Spoon

oduce retentive bonding

16

Page 17

Empress Esthetic –

IPS

Practical Working Steps

Preparation guidelines and minimum thicknesses

Successful results with IPS Empress Esthetic can only be achieved if the guidelines below and minimum layer thicknesses

are strictly observed.

Inlays and onlays

Static and dynamic antagonist contacts must be taken into consideration. The preparation margins must not be located on

centric antagonist contacts.

A preparation depth of at least 1.5 mm and an isthmus width of at least 1.5 mm must be observed in the fissure area.

Prepare the proximal box with slightly diverging walls and observe an angle of 100 - 120° between the proximal cavity

walls and the pr

support by the proximal shoulder, marginal ridge contacts should be avoided. Round out internal edges in order to prevent

stress concentration within the ceramic material. Eliminate the proximal contacts on all sides. Do not prepare slice-cuts or

feather edges.

ospective proximal inlay surfaces. For inlays with pronounced, convex cavity walls without adequate

For onlays, provide at least 2 mm of space in the cusp areas. On the vestibular side, the shoulder should be prepared with

°) to improve the aesthetic appearance of the transitions between the ceramic material and the tooth.

-30

a chamfer (10

Partial cr

enamel is severely undermined.

°

e indicated if the pr

owns ar

eparation margin is less than appr

oximately 0.5 mm away fr

om the cusp tip, or if the

Dimensions in mm

Dimensions in mm

17

Page 18

Full crown

Anterior and posterior crown

The anatomical shape is evenly reduced while observing the given minimum thicknesses. A circumferential shoulder is

prepared with rounded inner edges or a chamfer. The width of the circular shoulder or chamfer should be ≥ 1 mm. The

incisal/occlusal third of the crown is reduced by approximately 1.5 mm. The incisal or occlusal part should be reduced by

approximately 2 mm.

OR

Dimensions in mm

Veneer

If possible, the preparation should be entirely located in the enamel, either without involving reduction of the incisal edge

or traditional preparation involving reduction of the incisal edge. The incisal preparation margins should not be located in

the area of the abrasion surfaces.

The extent of the incisal reduction depends on the desired translucency of the incisal area to be built up. The more

transparent the incisal edge of the intended veneer, the more pronounced the reduction should be. The incisal edge must

be reduced by at least 1 mm. By preparing orientation grooves using a depth marker, controlled enamel reduction can be

achieved. The minimum preparation thickness is ≥ 0.6 - 1 mm, depending on the preparation technique selected.

Dissolution of the proximal contacts is not required. Discoloured teeth may require more preparation. In the cervical area,

epar

pr

e a chamfer

.

Dimensions in mm

18

Page 19

Shade determination

The correct tooth shade is the basis for a restoration with a life-like appearance. After tooth cleaning, the tooth shade

of the non-prepared tooth and/or the adjacent teeth is determined. Individual characteristics have to be taken into

consideration when determining the tooth shade. If a crown preparation is planned, for example, the cervical shade should

also be determined. In order to achieve the best possible true-to-nature results, shade determination should be carried out

at daylight. Furthermore, the patient should not wear clothes of intensive colours and/or lipstick. Basically, it has to be kept

in mind that the final shade of the restoration is the result of the following individual shades:

– Die shade

– Shade of the ingot

– Shade of the layering ceramic

– Shade of the cementation material

IPS Natural Die Material

In order to facilitate the reproduction of the tooth shade, the shade

of the prepared tooth can be determined with the help of the

IPS Natural Die Material shade guide. This facilitates the fabrication

of the all-ceramic restoration and the individual characteristics of the

preparation may also be taken into consideration. By deterimining the

shade of the pr

restorations may be checked during the individual fabrication steps.

IPS Empr

With the IPS Empress Esthetic shade guide, the shade of the ingot

to be used can already be determined in the dental practice. In

addition, the shade guide may be used to select the suitable pr

ingot and layering materials in the laboratory. The shade tabs have

been fired and pressed from original materials under laboratory

conditions and, ther

epared tooth, the shade and brightness value of the

ess Esthetic Shade Guide

essed

efore, correspond with the final result.

19

Page 20

Cementation

For cementation, the IPS Empress Esthetic restoration must be conditioned. For this

purpose, the completed restoration is etched with IPS Ceramic Etching Gel and

subsequently silanated using Monobond-S.

Total Etch

For the preparation of adhesive cementation with Variolink II/

Variolink Veneer, Total Etch is used. It is an enamel etching and dentin

conditioning gel used during the adhesive cementation of all-ceramic

restorations.

For the adhesive cementation of IPS Empress Esthetic restorations, you may choose

between tried-and-tested luting composites from Ivoclar Vivadent. Adhesive

cementation achieves an excellent bond between the preparation and the restoration.

®

riolink

Va

(Variolink II, Variolink Veneer)

Veneers

Inlays

Onlays

Partial crowns

Anterior and posterior crowns

ariolink

V

®

II

3

3

3

3

3

The dual-curing luting composite Variolink II has been used for more

than ten years and in over 20 million restorations. It is the world's

leading highly aesthetic material concept. Numerous awards as the

best product in the category of adhesive luting composites and

excellent results from clinical long-term studies are testimony to this

success.

ariolink

V

Pur

®

eneer

V

ely light-curing luting composite in 7 "Value" shades for the

adhesive cementation of translucent all-ceramic restorations with a

layer thickness of < 2.0 mm (veneers, inlays, onlays).

®

Multilink

(Multilink, Multilink Automix)

––

3

3

3

3

indicated

3

aindicated

contr

––

Multilink®Automix

The universal, self-curing (with light-curing option) resin based luting

cement Multilink offers a broad range of indications and produces

very high adhesive strength on all material surfaces. Together with

the self-etching Primer, which is applied as a simple preliminary layer

on enamel and dentin, Multilink is processed quickly and efficiently.

20

Page 21

Empress Esthetic –

IPS

Processing Procedure

IPS Empress Esthetic Inlays / Onlays / Crowns – stained/glazed

Model and die preparation

abricate a working model with removable die segments as usual. The application of a sealer is recommended to harden

F

he surface and to protect the stone die. However, the sealer layer must not result in any changes of the dimensions of the

t

stone die.

Subsequently, the spacer is applied as described below. Please be aware of the fact that the expansion of the investment

materials is coordinated with this procedure.

– For inlays/onlays, the spacer is applied in up to 3 layers and up to the preparation margin.

– For single crowns, the spacer is applied in two layers up to max. 1 mm from the preparation margin (spacer application

9–11 µm per layer).

– Two sealer layers are also applied up to max. 1 mm from the preparation margin for veneers.

Applying the spacer

for inlay/onlay

preparation

Up to three layers of spacer are applied to inlays/onlays.

The surfaces are covered up to the preparation margin.

for crown

preparation

Two layers of spacer are applied up to max. 1 mm from

the preparation margin. This measure helps prevent

undesired friction.

for veneer

preparation

Two layers of spacer are applied up to max. 1 mm from

the preparation margin.

21

Page 22

Wax-up

Fabricate a fully anatomical, functional wax-up for the Esthetic technique. You can use any organic waxes that burn out

without leaving residue. Please observe the following notes for contouring:

– Observe the stipulated minimum wall thicknesses.

– Exact contouring of the restoration, particularly in the area of the preparation margins, is indispensable. Do not over-

contour, since this would require time-consuming and risky fitting procedures.

– Possible occlusal relief must be taken into consideration as early as during the wax-up, since the final firing of Shades,

Stains and Glaze also results in added surface dimension.

Waxed up posterior crown Waxed up inlays

Sprueing

Always place the sprues in the direction of flow of the ceramic and at the thickest part of the wax-up in order to achieve

unimpeded flow of the viscous ceramic material. The 100-g or 200-g investment ring base is selected depending on the

number of objects to be invested and their wax weight.

The following guidelines are recommended to determine the proper wax weight:

– Weigh the IPS Empress investment ring base (seal the opening of the ring base with wax).

– Position the objects to be pressed on the ring base and attach them with wax. Weigh again.

– The difference between the two values is the weight of the wax used.

– Remove excess separating material prior to investing.

The following sprueing guidelines must be observed:

Investment ring system

Wax wire ø

e length

ax wir

W

Length wax wire including object

Sprueing angle to the wax object

Sprueing angle to the investment ring base

Design of the attachment points

Distance between objects

Distance to the silicone ring

Important

Inlays, onlays, veneers, single crowns

100 g

max. 1 ingot; max. 0.6 g wax weight

200 g

max. 2 ingots; up to max. 1.4 g wax weight

2.5–3 mm

min. 3 mm, max. 8 mm

max. 15 – 16 mm

axial

°

45–60

rounded and slightly tapered; no sharp angles or edges

min. 3 mm

min. 10 mm

A dummy object must be invested with very small single

wax objects in order to activate the abort criterion of the

EP 500/EP 600/EP 600 Combi furnace.

22

Page 23

Correct sprueing:

max. 6-8 mm

45–60°

max. 15 –16 mm

max. 6-8 mm

45–60°

<6 mm

45–60°

6 mm

45–60°

max. 15 –16 mm

max. 15 –16 mm

max. 15 –16 mm

max. 6-8 mm

45–60°

6 mm

45–60°

max. 15 –16 mm

max. 15 –16 mm

45–60°

45–60°

45–60°

Maximum sprueing height

The sprue and wax pattern should not be longer than 15–16 mm. Observe a 45–60° angle.

Provide sprues in the direction of flow of the ceramic material.

Always attach the sprue to the thickest part of the wax pattern.The internal surface of the wax pattern points outwards.

The attachment points of the sprues must be rounded. Observe an angle of 45 - 60°.

23

Page 24

<6 mm

45–60°

max. 15 –16 mm

mind. 10 mm

mind. 10 mm

Ring gauge

min. 10 mm

min. 10 mm

min. 10 mm

The distance between the wax patterns to be pressed and the IPS Silicone Ring/ring gauge

must be at least 10 mm. This applies to all the above diagrams.

Checking the sprueing

The IPS Sprue Guide will help you to easily check the correct sprueing of the objects to be pressed on

the investment ring base. By turning the IPS Sprue Guide on the investment ring base, the required

distance to the silicone ring, the proper height, as well as the sprueing angle can be quickly checked.

Checking the position of the wax patterns by means of the IPS Sprue Guide.

24

Page 25

Investing

Investing is carried out with either IPS PressVEST or IPS Empress Esthetic Speed. The corresponding

IPS Silicone Ring with matching ring gauge is used for that purpose.

Please refer to the Instructions for Use of the corresponding investment material regarding the detailed

processing parameters. The following procedure is recommended:

– Do not apply a debubblizer to the wax objects.

– Mix investment material. The investment material contains quartz powder. Therefore, the inhalation of

dust must be avoided.

Use a suitable instrument for the fine investment of the cavity. Make sure that the delicate wax

–

argins are not damaged.

m

– Carefully position the IPS Silicone Ring on the investment ring base without damaging the wax

objects. The IPS Silicone Ring must sit flush on the investment ring base.

– Subsequently, carefully fill the investment ring with investment material up to the marking and posi-

tion the ring gauge with a hinged movement.

– Allow the investment material to set without manipulating the investment ring.

– Do not use IPS PressVEST for investment over the weekend to prevent crystallization.

Use the IPS Silicone Ring for investment. Pour the investment material slowly and carefully. Avoid the

formation of bubbles.

25

Page 26

Preheating

After the stipulated setting time of the respective investment material (IPS PressVEST or IPS Empress Esthetic Speed), the

investment ring is prepared for preheating as follows:

– Remove the ring gauge and ring base with a turning movement,

– Carefully push the investment ring out of the IPS Silicone Ring.

– Remove rough spots on the bottom surface of the investment ring with a plaster knife and check the 90° angle.

– Investment material residue must not enter the sprues. Blow into the sprues if necessary.

– If several investment rings are preheated together, mark them with the respective ingot shade.

Setting time

Temperature of the preheating

furnace

Preheating temperature

Position of the investment ring in

the furnace

IPS Empress Esthetic Ingots

IPS Empress Alox Plunger

Important

IPS PressVEST

min. 60 min.

Room temperature

850°C (1562 °F)

Towards the rear wall; tipped with the

opening facing down

Always preheat

Always preheat

IPS Empress Esthetic Speed

min. 30 min., max. 45 min.

850 °C (1562 °F); switch on

preheating furnace in time

850°C (1562 °F)

Towards the rear wall; tipped with the

opening facing down

Always preheat

Always preheat

If several Speed investments are

required, they should be invested with

a time difference and placed in the

preheating furnace at intervals of

approximately 20 minutes. When

placing the investment rings in the

preheating furnace, make sure that the

nace temperatur

fur

e does not dr

op too

much. The indicated holding time starts

when the preheating temperature is

reached again.

Position the IPS Empress Esthetic ingots and AlOx plungers on the IPS UniTray. Place the investment rings and IPS UniTray with AlOx plungers and ingots in the preheating

furnace

In order to ensure smooth working procedures in the laboratory on a daily basis, impeccable functioning of the infrastructure and the preheating furnaces is essential. This includes their maintenance, cleaning with a vacuum cleaner in a

cool state as well as regular checks of the temperature controls and heating elements, etc. by the manufacturer.

26

.

Page 27

Calibration

The furnace must be regularly calibrated to achieve optimum press results. Calibrate the EP 500 with the Temperature

Checking Set 2 and the EP 600 with the Automatic Temperature Checking Set 1.

EP 500

1. Switch on the EP 500 and allow the furnace to heat up to the stand-by-temperature of 700 °C/

1292 °F. Hold this temperature for at least 30 minutes.

2. Select a program for the staining technique T=1075 °C/1967 °F. Run the program with the furnace empty. After

activation of the holding time H=20 min., which the EP500 does automatically,

interrupt the program after 15 minutes (set timer) by pressing the STOP key twice.

If you fail to interrupt the program, the ER16 error message appears. Rectify this error by following the instructions

given on the corresponding list of error messages. Allow the furnace to cool until the stand-by-temperature of

700 °C/1292 °F has been reached with the furnace head closed. Hold this temperature for at least 30 minutes.

3. Place the calibration set on the honey-combed firing tray in order to ensure the appropriate height (temperature

range) in the furnace.

4. Conduct the calibration using the Temperature Checking Set 2.

EP 600

1. Place the melting sample in the ceramic base.

2. Tighten the contact pin to secure the melting sample.

Important: Do not use tweezers or tongs. Apply slight pressure to secure the melting sample in place.

3. Select the calibration program in the 'Miscellaneous' menu. The furnace head opens.

4. Remove the firing plate from the furnace and place it on the cooling plate using the firing tongs.

5. Place the calibration tray in the holes for the Automatic Temperature Checking Set ATK 1 in the stone lining.

6. Slightly press the calibration tray into place with the firing tongs until you feel it click into place.

7. Start the calibration program

8. Once the program is completed, remove the calibration sample from the furnace using the tongs and allow it to cool.

Contraindication:

Do not pull at the melting sample. The ceramic base may fracture when you do so.

9. Replace the firing tray and select the firing program. The furnace head closes automatically.

10. Once it is cooled, disassemble the calibration sample.

11. Use a new melting sample for the next calibration procedure and start with item 1.

27

Page 28

Pressing

Before the preheating cycle for the investment ring has ended, the following preparations for pressing must be carried out:

– Switch on the press furnace in time to ensure that the self-test and preheating phase are completed.

– Select the press program for IPS Empress Esthetic and the respective investment ring size (EP 600/EP 600 Combi).

– Place the ingots and AlOx plungers in the investment ring and position it quickly (in less than 1 min.) in the furnace.

– Do not use the IPS e.max AlOx Plunger Separator. The press temperature of the IPS Empress Esthetic ingots of 1075 °C/

1967 °F is too high for the separator to be effective.

Once the preheating cycle has been completed, remove the investment ring from the preheating furnace and proceed as

ollows:

f

Place the hotIPS Empress Esthetic ingot – in the required shade of the tooth (see material combination table) – into the

–

hot investment ring.

– Place the hot AlOx plunger into the hot investment ring.

– Place the completed investment ring central the hot press furnace.

– Press START to start the selected program.

100 g investment ring

Number of ingots

IPS Empress Esthetic Ingots

IPS Empress Alox-Kolben

Place the hot IPS Empress Esthetic ingot in the investment ring.

ess parameters for the IPS Empress Esthetic Ingots

Pr

EP 500

Small and large investment ring

EP 600/EP

600 Combi

Small and large investment ring

B

°

700

1292

B

700°C

1292°F

C

F

°

tÚ

60°C

108°F

t

60°C

108°F

max. 1 ingot

hot ingot

hot plunger

Ú

T

°

1075

°

1967

T

1075°C

1967°F

200 g investment ring

max. 2 ingots

hot ingot

hot plunger

Place the

hot AlOx plunger into the investment ring.

H

C

F

20’

H

20’

V

1

°

500

°

932

V

1

500°C

932°F

C

F

V

1075

1967

V

1075°C

1967°F

Pressure

2

C

°

°

2

5 bar

F

A

m

µ

250

28

Page 29

Position the investment ring in the press furnace Place the investment ring on the cooling grid

Remove the investment ring from the furnace immediately after the program is completed and close the furnace. Place the

investment ring on the cooling grid and allow it to cool to room temperature. The grid ensures quick and even cooling of

the investment ring and prevents undesired heat accumulation.

Divesting

After cooling to room temperature (after approximately 60 minutes), the investment ring may show cracks. These cracks

developed (immediately around the AlOx plunger) during cooling as a result of the different CTEs of the various materials

(AlOx plunger, investment material, and pressed materials). They do not compromise the press result.

– Mark the length of the AlOx plunger on the cooled investment ring.

– Separate the investment ring using a separating disk. This predetermined breaking point enables reliable separation of

the AlOx plunger and the ceramic material.

– Break the investment ring at the predetermined breaking point using a plaster knife.

– Rough divestment is carried out with glass polishing beads at 4 bar (60 psi) pressure.

– For fine divestment, only 2 bar (30 psi) pressure is applied.

not use Al2O3for rough or fine divestment

– Do

When divesting the object, blast fr

–

om the dir

and observe the appropriate distance in order not to damage the object margins.

The investment material contains quartz powder

–

dust.

– Use Al

to clean the AlOx plunger from any ceramic residue.

2O3

ection indicated in the schematic below

. Therefore avoid any inhalation of

Separate the investment ring using a separating disk and break it at the predetermined breaking point.

29

Mark the length of the AlOx plunger

Page 30

Rough divestment is carried out with glass polishing beads at 4 bar (60 psi) pressure.

When divesting the object, blast from the direction indicated in the schematic at the top. Note:Blast from the incisal and/or occlusal direction, if possible.

Fine divestment is carried out with glass polishing beads at 2 bar (30 psi) pressure.

Removing the pressed object / finishing

The following procedure is recommended to finish IPS Empress Esthetic restorations:

– Wet the area to be ground and use a fine diamond disk to cut the sprues.

– Prevent overheating of the ceramic material. Low speed and light pressure is recommended.

– Smooth out the attachment points of the sprues.

– Remove the spacer prior to placing the pressed object on the die.

– Place the restoration on the die, check contact points and carefully adjust.

– Make sure that the minimum thicknesses are maintained even after finishing.

– Clean the restoration under running water or with steam before characterization.

– It is not necessary to blast the restoration with Al2O3prior to further processing.

Divested objects

The sprues are cut with a fine diamond disk.

30

Page 31

The anatomical, functionally waxed-up restoration is accurately reproduced in ceramic. Apply surface structures with suitable grinders..

Fabricating the die using IPS Natural Die Material

The light-curing IPS Natural Die Material simulates the shade of the prepared tooth. A control die is fabricated using the

selected shade. This control die represents the optimum basis for a true-to-nature shade reproduction of the given oral

situation.

– Coat the inner surfaces of the ceramic restorations with IPS Natural Die Material Separator and allow it to react for a

short time.

– Apply the IPS Natural Die Material in the corresponding shade to the inner surfaces of the restoration using the

IPS Condenser and adapt so that the entire inner surface is coated and filled.

– Completely fill the restoration cavity and insert an IPS Die Holder into the material and adapt excess material around the

holder. Make sure that the Die Material is well adapted to the restoration margins and that no gaps are present.

– Polymerize the IPS Natural Die Material die with a commercial polymerization light, e.g. Lumamat 100, for 60 seconds.

– After polymerization, the die can be finished and smoothed, if required.

Completely fi

ation with IPS Natur

Coat the inner surfaces of the cer

ation cavity and insert an IPS Die Holder into the material and adapt excess material around the holder.Then, polymerize with a commercial polymerization light.

ll the restor

amic restor

al Die Material Separator and allow it to react for a short time.

31

Page 32

Stain and Glaze firing

The IPS Empress Universal Shades/Stains and Glaze have been especially developed for the ceramic materials of the

IPS Empress System from Ivoclar Vivadent. They can be used for the following techniques:

– IPS Empress Esthetic

– IPS Empress CAD

– IPS Empress 2 Layering Technique

– IPS Empress 2 / IPS Eris for E2 Layering Technique

After cleaning the restoration, the Stain and Glaze firing is carried out. Basically, there are two options:

Optional

Version A – 2-in-1 Technique

First, the glaze paste is applied, followed by the stains, which are applied on the unfired glaze layer.

Step 1 – Application of the glaze material:

– Extrude IPS Empress Universal Glaze from the syringe and thin the material to the desired consistency using IPS Empress

Universal Glaze and Stain Liquid.

– Apply the glazing material on the entire outer surfaces of the restoration.

– The glazing material must not come into contact with the inner aspects of the restoration.

– Too thin glazing material layers result in an unsatisfactory gloss.

– Avoid pooling and too thick glazing material layers.

Step 2 – Application of Shades/Stains:

– Extrude IPS Empress Universal Shade or Stains from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid.

- Apply the mixed Shade/Stains material directly into the unfired glazing material layer.

– Intensify the corresponding dentin shade in the cervical and occlusal areas using IPS Empress Universal Shades.

– To imitate the incisal area and translucency in the incisal third, use IPS Empress Universal Shade Incisal.

– Apply individualized effects and characterizations using IPS Empress Universal Stains materials.

After staining and glazing, the Stain and Glaze fi

ring is conducted in a compatible ceramic furnace (e.g. Programat

®

P500).

The following points should be observed when placing the restoration in the furnace and setting the firing parameters:

– Place the restorations on the metal pins using a small amount of IPS Object Fix and position them on the honey-comb

ring tray .

fi

– As an alternative, the restorations can be supported with a firing pillow. Due to their lower position in the firing

chamber, the restorations are exposed to less heat. Therefore, in order to achieve the desired gloss, the holding time

must be extended to up to 2 minutes.

Firing parameters for Stain and Glaze fi

IPS Empress Esthetic with IPS Empress Universal

2-in-1 Technique

Stain and Glaze fi

B = Stand-by temperature °C / °F

Closing time/minutes

S =

Temperature increase rate °C/min. / °F/min.

t

Ú =

ring 403°C 6' 100°C 790°C 1–2' 450°C 789°C

ring

(note the temperature control)

B S tÚ T H V

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

1

T = Firing temperature °C / °F

H = Holding time / min.

= Vacuum-on temperature °C / °F

V

2

acuum-off temperature

V

V

=

C /

°

1

F

°

V

2

32

Page 33

Version B

Step 1 – Application of Shades/Stains:

– First, apply a small amount of IPS Empress Universal Glaze and Stain Liquid to assess the shade. This will provide better

wetting of the stains.

– Extrude IPS Empress Universal Shade or Stains from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid.

– Apply the mixed Shades/Stain material.

– Intensify the corresponding dentin shade in the cervical and occlusal areas using IPS Empress Universal Shades.

– To imitate the incisal area and translucency in the incisal third, use IPS Empress Universal Shade Incisal.

– Apply individualized effects and characterizations using IPS Empress Universal Stains materials.

Starting situation

Occlusal area:

Shade 130

Incisal area:

Shade I1

Fissure:

Stains orange

After staining and glazing, the Stain and Glaze firing is conducted in a compatible ceramic furnace (e.g. Programat P500).

The following points should be observed when placing the restoration in the furnace and setting the firing parameters:

– Place the restorations on the metal pins using a small amount of IPS Object Fix and position them on the honey-comb firing tray .

– As an alternative, the restorations can be supported with a firing pillow. Due to their lower position in the firing chamber, the

restorations are exposed to less heat. Therefore, in order to achieve the desired gloss, the holding time must be extended to up to

2 minutes.

– More intensive shades are achieved by repeated staining, rather than by applying thicker layers.

Firing parameters for Stain and Characterization firing (note the temperature control)

IPS Empress Esthetic with IPS Empress Universal

Stain and Characterization fi

B = Stand-by temperature °C / °F

S = Closing time/minutes

Ú = Temperature increase rate °C/min. / °F/min.

t

ring 403°C 6' 100°C 790°C 1–2' 450°C 789°C

B S tÚ T H V

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

T = Firing temperature °C / °F

H = Holding time / min.

V1= Vacuum-on temperature °C / °F

2

V

= Vacuum-off temperature °C / °F

1

2

V

33

Page 34

Step 2 – Application of the glazing material:

– Extrude IPS Empress Universal Glaze from the syringe and thin the material to the desired consistency using IPS Empress

Universal Glaze and Stain Liquid.

– Apply the glazing material on the entire outer surfaces of the restoration.

– The glazing material must not come into contact with the inner aspects of the restoration.

– Too thin glazing material layers result in an unsatisfactory gloss.

– Avoid pooling and too thick glazing material layers.

Evenly apply IPS Empress Universal Glaze on the entire outer surfaces of the restoration. Place the restorations on the honey-comb firing tray using IPS Object Fix

Completed IPS Empress Esthetic restorations, stained and glazed.

and metal pins and fire.

After applying the glazing material, the glaze firing is conducted in a compatible ceramic furnace (e.g. Programat P500).

The following points should be observed when placing the restoration in the furnace and setting the firing parameters:

– Place the restorations on the metal pins using a small amount of IPS Object Fix and position them on the honey-comb

firing tray .

– As an alternative, the restorations can be supported with a firing pillow. Due to their lower position in the firing

chamber, the restorations are exposed to less heat. Therefore, in order to achieve the desired gloss, the holding time

must be extended to up to 2 minutes.

Firing parameters for Glaze firing (note the temperature control)

ess Esthetic with IPS Empress Universal

IPS Empr

B

St

Ú T

H V

1 V2

Glaze firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

6' 180°F 1454°F 1–2' 842°F 1453°F

F

°

757

B = Stand-by temperature °C / °F

S = Closing time/minutes

t

Ú = Temperature increase rate °C/min. / °F/min.

T = Firing temperature °C / °F

H = Holding time / min.

1

= Vacuum-on temperature °C / °F

V

2

= Vacuum-off temperature °C / °F

V

34

Page 35

ptional

O

Subsequent adjustments

After completion, additional adjustment (e.g. contact points) may become necessary. For that purpose,

IPS Empress Add-On 770 °C/1418 °F is available.

Processing:

– Before the adjustment, the restoration must be free from dirt and grease. For that purpose, blast the areas to be

adjusted with Al2O3(Type 100) at max. 0.5 bar pressure and thoroughly clean the restoration using the steam jet.

– Mix IPS Empress Add-On 770 °C / 1418 °F with IPS Empress Esthetic Veneer Build-Up Liquid to a workable consistency.

ake sure that the add-on material and liquid are evenly mixed so that an optimum firing result can be achieved.

M

Apply the mixed add-on material on the cleaned, desired areas using a brush and slightly blot them with an absorbent

–

cloth.

– Position the adjusted restoration on the firing tray and fire in the ceramic furnace.

– After firing, manually polish the supplemented areas to a high gloss.

Adjust the proximal contact points

Firing parameters for the Corrective firing

IPS Empress Esthetic with B S tÚ T H V

IPS Empress Add-On 770°C/1418°F

Corrective firing 403°C 4' 60°C 770°C 2' 450°C 769°C

757°F 4' 108°F 1418°F 2' 842°F 1417°F

B = Stand-by temperature °C / °F

S = Closing time/minutes

t

Ú = Temperature increase rate °C/min. / °F/min.

T = Firing temperature °C / °F

H = Holding time / min.

1

= Vacuum-on temperature °C / °F

V

2

= Vacuum-off temperature °C / °F

V

1

2

V

35

Page 36

IPS Empress Esthetic Veneers / Anterior Crowns – Cut-back and layered

Wall and layering thicknesses

In order to individualize restorations in the incisal area so that they correspond with their natural model, the IPS Empress

Esthetic restoration is additionally veneered using opalescent IPS Empress Esthetic Veneer ceramic materials. The cut-back

technique is very efficient if the fully anatomical anterior crown or the veneer are first designed according to the definite

final shape. After that, the incisal third is reduced and subsequently provided with an individualized aesthetic veneer.

The following wall and layering thicknesses have to be observed:

Veneer

Layer thickness =

Minimum thickness

of the restoration

after the

corresponding

reduction

= 0.5 mm

.5–1.0 mm

0

0.5 mm

0.5 mm

approx.

Anterior cr

Layer thickness =

Limited layering area: labial,

incisal third

Fully anatomical, pressed veneer and anterior crown, which are reduced in the incisal area.

Minimum thickness

of the restoration

after the

corresponding

reduction

= 0.5 mm

own

.5–1.0 mm

0

0.5 mm

.5 mm

0

approx.

Limited layering area: labial,

incisal third

eparing the model and the dies

Pr

Fabricate a working model with r

application of a sealer is r

emovable die segments as usual. The

ecommended to har

den the surface and to pr

otect

the stone die. However, the sealer layer must not result in any changes of the

dimensions of the stone die.

Subsequently, the spacer is applied as described below. Please be aware of the

fact, that the expansion of the investment material is coor

e.

ocedur

pr

dinated with this

– For anterior crowns, the spacer is applied in two layers up to max. 1 mm

from the preparation margin (spacer application 9–11 µm per layer).

wo sealer layers ar

T

–

e also applied up to max. 1 mm fr

om the preparation

margin for veneers.

36

Sealer and spacer applied on the prepared model.

Page 37

Wax-up

A fully anatomical wax-up should be fabricated for veneer restorations. You can use any organic waxes that burn out

without leaving residue. Also, ensure a wall thickness of at least 0.5 mm. For better distinction, a basic wax in a different

colour can be used.

For better distinction, a basic wax in a different colour is recommended. Fully anatomical wax-up.

Veneers with sprues in place. Sprued veneers on the 200-g investment ring system.

For the processing steps on investment, preheating, pressing and divesting/separation, as well as die fabrication with

IPS Natural Die Material, please refer to pages 25–31.

Once the restoration has been pressed using the

ess Esthetic ingot selected accor

IPS Empr

individual patient situation, they ar

ding to the

e placed on the

corresponding working model.

Veneers on the working model after finishing.

37

Page 38

Cut-back technique

Fabricate a silicone key to prepare the restorations for individualization with IPS Empress Esthetic Veneer. Subsequently, the

cut-back is carried out. The fully anatomically pressed veneers are reduced in the incisal third. For that purpose, use

ceramic-bonded grinding instruments or diamonds.

The following points must be observed:

– Too much pressure and excess heat development during grinding must be prevented.

– Refrain from designing too extreme mamelons with undercuts.

– Check the cut-back by means of the silicone key.

The minimum wall thickness of the pressed IPS Empress Esthetic restorations of 0.5 mm must be observed.

–

Fabricate a silicone key before conducting the cut-back.

Check the cut-back by means of the silicone key, observe the minimum

wall thickness of 0.5 mm.

Refrain from designing too extreme mamelons with undercuts.

Limit the cut-back to the incisal third.

Preparing for veneering

Blast the outer surfaces of the ceramic restoration carefully with Al2O3(Type 100) at max. 0.5 bar pressure and clean

oughly with the steam jet. Befor

thor

e veneering, the restorations must be free of dirt and grease.

Blast the restor

ation with

2O3

Al

ype 100) at 0.5 bar pressure

(T

.

Clean the restor

ation with steam prior to w

ash firing.

38

Page 39

Wash firing

Conduct the wash firing using the IPS Empress Esthetic Veneer Wash Pastes. Apply the wash pastes thinly and cover the

entire restoration. The IPS Empress Esthetic Veneer Wash Paste neutral is always applied first on the restoration and

enables a homogenous bond to the IPS Empress Esthetic material. Subsequently, the reduced restorations are individually

characterized, if required, using the Standard Wash Pastes and Wash Paste Modifiers. The wash pastes must be fired

separately. If required, the pastes can be slightly diluted using IPS Empress Universal Glaze and Stain Liquid.

neutral low value high value MM

6 Standard Wash Pastes for individual internal characterizations

Examples of the wash pastes applied on the restorations.

light-salmon

MM

yelloworange

MM

reddish-

orange

Modifier

copper

Modifier

orange

5 Wash Pastes Modifiers permit individual shading of the

Modifier

sky blue

Standard Wash Pastes

Modifier

basic yellow

Modifier

basic red

Place the objects on the honey-comb firing tray by using IPS Object Fix and fire.

Firing parameters for the Wash firing (note the temperature control)

IPS Empress Esthetic Veneer B S tÚ T H V

Wash Pastes

ash firing 403°C 4' 60°C 840°C 2' 450°C 839°C

W

F

°

C /

B = Stand-by temperature

S = Closing time/minutes

t

Ú = Temperature increase rate °C/min. / °F/min.

°

T = F

H = Holding time / min.

F 4' 108°F 1544°F 2' 842°F 1543°F

°

757

iring temperature

F

°

C /

°

1

acuum-on temperature

V

=

V

2

V

= Vacuum-off temperature °C / °F

39

1

F

°

C /

°

2

V

Page 40

Incisal firing

The IPS Empress Esthetic Veneer layering materials are used to complete the anatomical shape and to achieve the

individual aesthetics of the restorations. The materials are mixed with the IPS Empress Esthetic Build-Up Liquid. If required,

a second incisal firing is conducted with the same firing program.

Incisal

T = high

H

anslucent

tr

Veneer 11 after wash firing.

Incisal

pal

O

pal

O

T = medium

M

anslucent

tr

Incisal

pal

O

T = low

L

anslucent

tr

ranspa

T

blue

Transpa

eutral

n

Incisal

dge

e

Incisal

hite

w

Incisal

rey

g

Incisal

range

o

Incisal

ellow

y

Incisal

range-

o

p

ink

Chroma

odifier

M

10/A1

1

Chroma

odifier

M

10/A3

2

Brightener

.

The layered structure should be slightly bigger than the final shape.

Apply the IPS Empress Esthetic

eneer Incisal materials

V

Firing parameters for the 1stand 2ndIncisal firing (note the temperature control)

IPS Empress Esthetic Veneer B S tÚ T H V

Incisal

°C 4' 60°C 830°C 2' 450°C 829°C

1stand 2ndIncisal fi

B = Stand-by temperature °C / °F

Closing time/minutes

S =

t

Ú = Temperature increase rate °C/min. / °F/min.

ring

403

F

°

757

T = Firing temperature °C / °F

H = Holding time / min.

4'

108°F 1526°F 2' 842°F 1525°F

1

= Vacuum-on temperature °C / °F

V

2

acuum-off temperature

V

V

=

40

°C / °F

After incisal firing.

1

2

V

Page 41

Finishing and preparing for Stain and Characterization firing

Before the stain and characterization firing, the restoration has to be finished as follows::

– Finish the restoration using diamonds and give it a true-to-nature shape and surface structure, such as growth lines and

convex/concave areas.

– Areas that should exhibit a higher gloss after glaze firing can be smoothed out and prepolished using silicone disks.

– If gold and/or silver dust was used to visualize the surface texture, the restoration has to be thoroughly cleaned with

steam. Make sure to remove all gold or silver dust in order to avoid any discolouration.

The shape of the veneers can be checked with the help of the silicone key and a colour varnish.

Finish the restoration with diamonds and give it a true-to-nature shape and surface structure.

Finished restorations ready for stain and characterization firing.

41

Page 42

Stain and Characterization firing

Once the restoration has been cleaned with steam, the Stain and Characterization firing is conducted. First, apply a thin

coat of IPS Empress Universal Glaze and Stain Liquid to the surface of the restoration to evaluate the shade of the

restoration more clearly. Subsequently, apply the stains.

The following working procedure should be observed:

– Extrude IPS Empress Universal Shade/Stains from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid.

– Apply the Shade and Stains.

– Intensify the dentin shade in the cervical and central crown third using the respective Shade material.

– More intensive shades are achieved by repeated staining and firing, rather than by applying thicker layers.

– Apply individualized effects and characterizations using IPS Empress Universal Stains materials.

– After staining, the stain and characterization firing is conducted in a compatible ceramic furnace (e.g. Programat P500).

Apply IPS Empress Universal Shade and Stains

Firing parameters for the Stain and Characterization firing (note the temperature control)

and komplettieren und analog den Brennparametern brennen.

IPS Empress Universal Shade/Stains B S tÚ T H V

Zahnform mit dem 2.

Stain and Characterization firing 403°C 6' 100°C 790°C 1–2' 450°C 789°C

B = Stand-by temperature °C / °F

S = Closing time/minutes

t

Ú = Temperature increase rate °C/min. / °F/min.

Br

757°F 6' 180°F 1454°F 1–2' 842°F 1453°F

1

T = Firing temperature °C / °F

H = Holding time / min.

= Vacuum-on temperature °C / °F

V

2

= Vacuum-off temperature °C / °F

V

1

2

V

42

Page 43

Glaze firing

– Extrude IPS Empress Universal Glaze from the syringe and thin the material to the desired consistency using IPS Empress

Universal Glaze and Stain Liquid.

– Apply the glazing material on the entire outer surfaces of the restoration.

– The glazing material must not come into contact with the inner aspects of the restoration.

– Too thin glazing material layers result in an unsatisfactory gloss.

– Avoid pooling and too thick glazing material layers.

– Place the restorations on the metal pins using a small amount of IPS Object Fix and position them on the honey-comb

firing tray .

As an alternative, the restorations can be supported with a firing pillow. Due to their lower position in the firing

–

hamber, the restorations are exposed to less heat. Therefore, in order to achieve the desired gloss, the holding time

c

must be extended to up to 2 minutes.

– After staining, the glaze firing is conducted in a compatible ceramic furnace (e.g. Programat P500).

Apply IPS Empress Universal Glaze

Firing parameters for Glaze firing (note the temperature control)

IPS Empress Universal Glaze B S tÚ T H V1 V2

Glaze fi

ring 403°C 6' 100°C 790°C 1–2' 450°C 789°C

B = Stand-by temperature °C / °F

S = Closing time/minutes

emperature increase rate