Page 1

d.SIGN

IPS

®

Instructions for Use

Page 2

Table of Contents

3 IPS d.SIGN

6 Composition

7 IPS d.SIGN – Product overview

8 IPS d.SIGN – Description of the assortments

8 IPS d.SIGN Basic Kits

10 IPS d.SIGN Trial Kit

11 IPS d.SIGN Deep Dentin Kits

12 IPS d.SIGN Margin Kits

13 IPS d.SIGN Bleach Kit

14 IPS d.SIGN Impulse 1 Kit

15 IPS d.SIGN Impulse 2 Kit

16 IPS d.SIGN Gingiva Kit

1

6 IPS d.SIGN Essence Kit

17 IPS d.SIGN Stains Kit

17 IPS d.SIGN Shade Kit

IPS d.SIGN – Liquids

18

20 IPS d.SIGN – Shade selection

21 IPS d.SIGN – Layering diagrams

21 IPS d.SIGN Chromascop layering diagram

22 IPS d.SIGN A–D layering diagram

I

2

2

24 Functional support of the veneering ceramic

25 Framework design for ceramic shoulders

25 Framework stability

26 Framework design for bridges

27 Design of bridge pontics

27 Interface between metal and ceramic

28

28 Starting situation

28 Fabricating the framework

30 Oxide firing

32 1

33

34 1

36 2

37 1

41 2

42 Preparing the restoration for glaze firing

43

45

PS d.SIGN – Framework design

3

Alloys

3

d.SIGN – Instructions for Use

IPS

st

opaquer firing

nd

2

opaquer fi

st

shoulder firing

nd

shoulder firing

st

dentin and incisal firing

nd

dentin and incisal firing

Stain and char

ring

Glaze fi

ring

acterization firing

47

IPS d.SIGN – Corrective firings (Add-on)

48 Correct use of IPS d.SIGN Cervical Dentin D2/D3

49 IPS d.SIGN –

50 Feel the difference – feel IPS d.SIGN

52 A look over the shoulder

62 IPS d.SIGN –

Chromascop

62

A–D

64

66 Independent of any shade system

Firing parameters

Materials combination tables

2

Page 3

d.SIGN

IPS

®

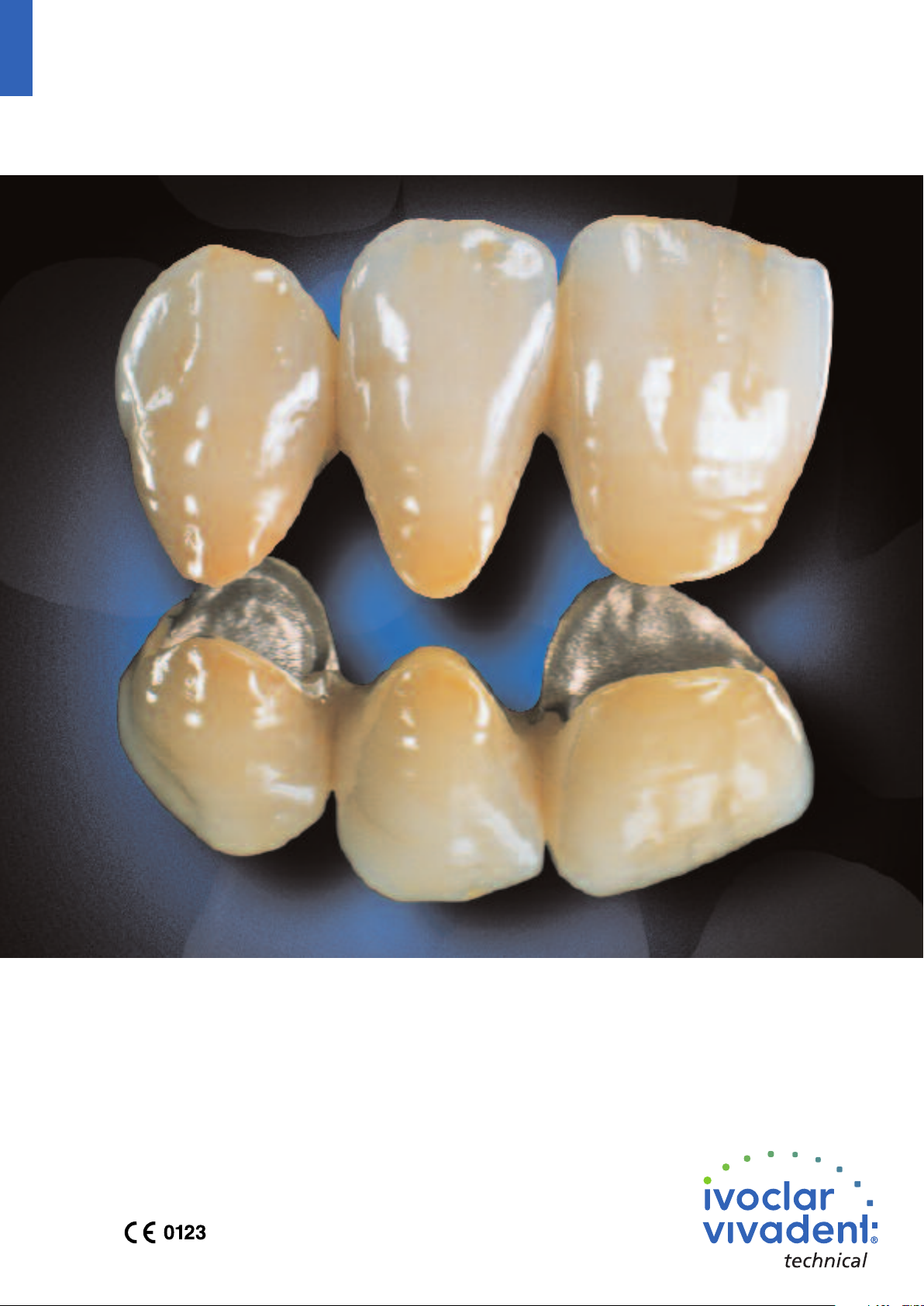

The requirements for functionality and

esthetic appearance of ceramic restorations

a

re continuously rising. To meet these requi-

a

rements manufacturers are faced with the

challenge of developing materials that satisfy

the needs of experienced ceramists, by

ffering them a multitude of design

o

possibilities, and less experienced users by

enabling them to have a successful start in

the field of porcelain-fused-to-metal

restorations. In order to give a high end

eramic the ease of handling that customers

c

expect, the range of indications of IPS d.SIGN

was given top priority during the

development phase.

With a well designed basic assortment and

the various additional assortments of

IPS d.SIGN, beginners and specialists alike

will have all the materials they need to

restore lost tooth structure in a true-tonature, highly aesthetic fashion. IPS d.SIGN is

a material suitable for basic types of restorations, as well as restorations having

sophisticated morphological structures. In

this way, all the demands placed on the

material prior to its development have been

fully met.

With IPS d.SIGN, highly aesthetic restorations

that are virtually undetectable among their

natural counterparts may be fabricated by

easy, efficient layering of the material.

Moreover, expert ceramists are provided with

a comprehensive range of additional

materials.

The shades of IPS d.SIGN are based on the

Chromascop and A–D shade guides. Shade

tabs fired from the actual material are

supplied with each assortment.

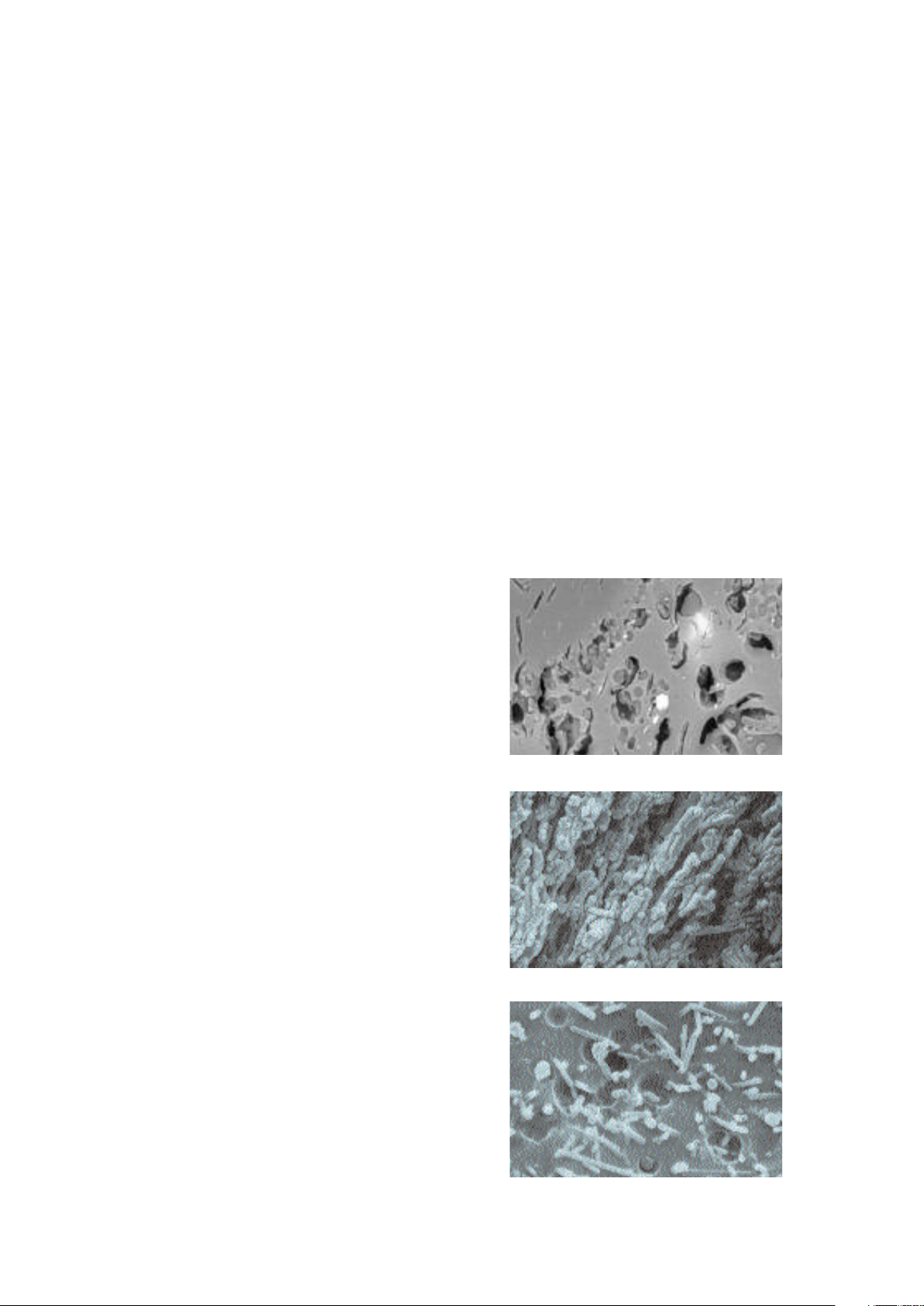

Fluorapatite leucite glassceramic

PS d.SIGN fluorapatite leucite glass-ceramic

I

has been developed taking nature as the

standard, with the most important properties

of natural teeth serving as models. The main

norganic component of a natural tooth are

i

apatite crystals, in which hydroxyl and sometimes carbonate groups are embedded. In

addition to this composition, IPS d.SIGN

fluorapatite glass-ceramics also contains

uoride ions that provide the material with a

fl

very high chemical resistance. Moreover, the

above mentioned compositions results in

IPS d.SIGN demonstrating exceptional optical

properties, which is yet another distinct

advantage of this new type of glass-ceramic

material. Increased brightness and brilliance,

clearly enhanced stability of shade, and trueto-nature fluorescence are the results of

these development efforts.

SEM – Conventional feldspar cer

amic

Comprehensive Treatment

System

Ivoclar V

comprehensive treatment system that

consists of the following components:

– Alloys

– Veneering ceramic

– Cementation system

This system was developed with the objective

that all of the materials should be coordinated with each other so that optimum results

are achieved. The IPS d.SIGN fluorapatite

leucite ceramic is an innovative ceramic

material that of

and application. These properties of

IPS d.SIGN are based on its new material

specifications. What does that means in

practical work?

ivadent pr

ovides you with a

fers new ways of pr

ocessing

al tooth

SEM – Natur

SEM (after surface etching) – IPS d.SIGN

3

Page 4

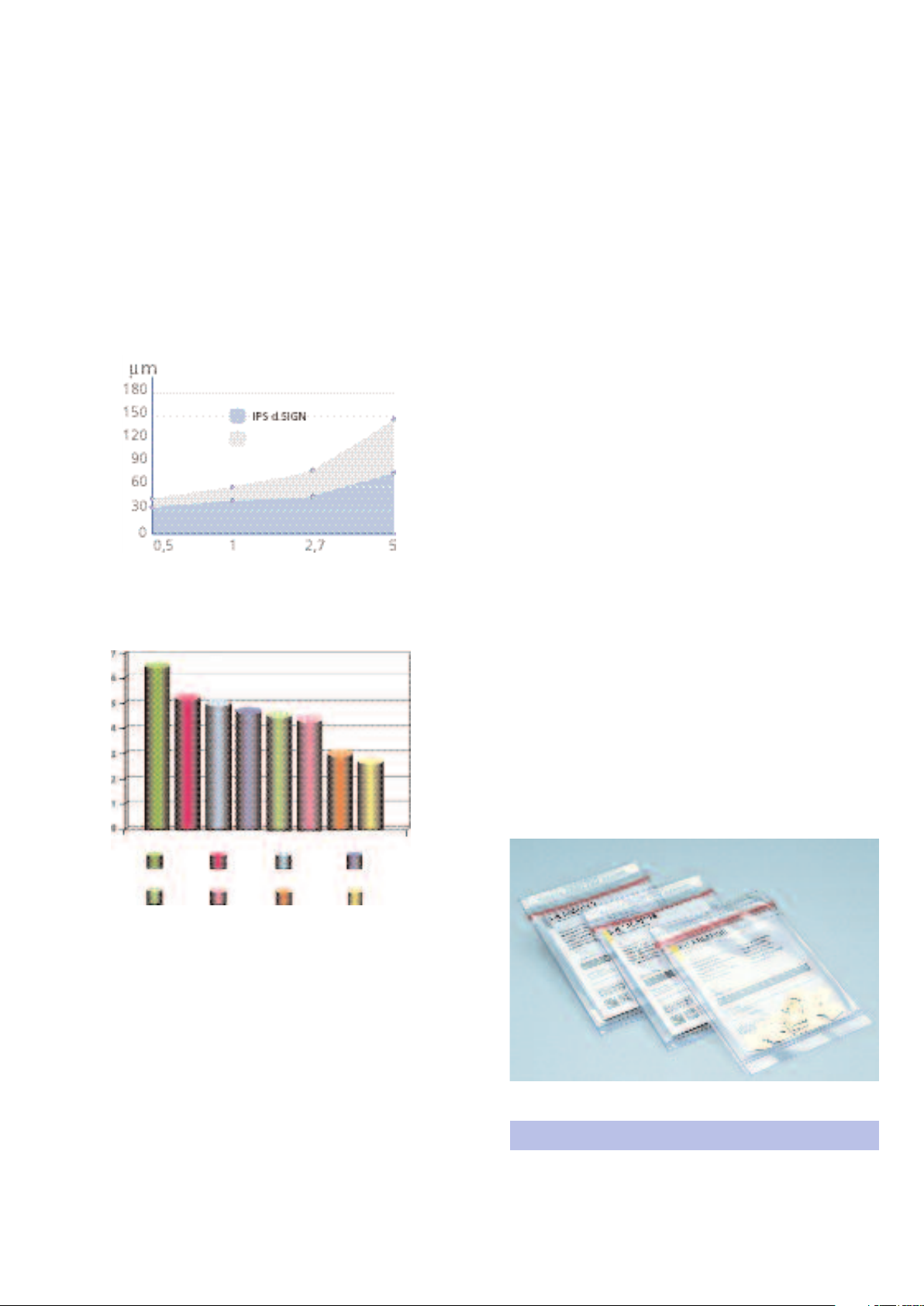

Another property that this new type of

urface structure exhibits is excellent

s

olishability and limited abrasion to opposing

p

natural tooth structure. The IPS d.SIGN

materials demonstrate outstanding stability

and are fired at temperatures below

00 °C/1652 °F.

9

Feldspar ceramic

n vitro-equivalent years

I

Alloys

Each metal supported restoration starts with

the fabrication of a metal framework. For

hat purpose, various IPS d.SIGN alloys are

t

available. The IPS d.SIGN alloy selection

ranges from high gold alloys and goldreduced alloys to base metal alloys. These

alloys meet the international requirements of

SA and ADA and were developed in

I

combination with IPS d.SIGN.

The coefficient of thermal expansion (CTE) is

a significant parameter for dental materials.

t is vitally important to ensure the thermal

I

compatibility between alloy and ceramic

material. In the 25–500 °C temperature

range, the CTE values of the IPS d.SIGN

alloys range between 13.8 and

14.8 x 10

composition. The coefficient of thermal

expansion of the IPS d.SIGN ceramic is

12.0–12.6 x 10

-6K-1

, depending on the alloy's

6

1

-

-

K

.

Vertical abrasion to the enamel of the antagonist.

Internal investigation, R&D Ivoclar Vivadent AG (1998)

Abrasion to antagonist enamel

2

mm

Ceramic A

Ceramic E

This bar diagram depicts the abrasion to antagonist enamel compared to other

amic materials

dental cer

Sorensen,

A.

John

Ceramic B Ceramic C Ceramic D

Enamel IPS

DMD

.

PhD (1999)

,

Ceramic F

d.SIGN

The IPS d.SIGN alloys

– IPS d.SIGN 98 (high gold)

– IPS d.SIGN 96 (high gold)

– IPS d.SIGN 91 (gold-reduced)

– IPS d.SIGN 84 (palladium-based)

– IPS d.SIGN 67 (palladium-based)

– IPS d.SIGN 59 (palladium-based)

– IPS d.SIGN 53 (palladium-based)

– IPS d.SIGN 30 (chrome-cobalt)

– IPS d.SIGN 15 (nickel-chrome)

The compatibility of the IPS d.SIGN ceramic

and IPS d.SIGN alloys was thor

oughly tested.

When using other alloys, please ask your

alloy manufacturer if they are compatible

with IPS d.SIGN ceramic.

The product range may vary from country to country.

4

Page 5

Cementation

Variolink

®

Esthetic Resin Cements

Multilink

®

Universal Resin Cement

Vivaglass®CEM

Glass ionomer Cement

C

ement

Variolink®Veneer Variolink®II Multilink®Automix Vivaglass®CEM PL

C

uring Mode Light-cure Light/Dual-cure Dual-cure Self-cure

Cementation Method Adhesive: Adhesive: Adhesive: Conventional

Syntac or Excite Syntac or Excite DSC Multilink Primer A/B

total-etch total-etch self-etch

IPS d.SIGN

––

33

Select an appropriate cementation material

rom the Ivoclar Vivadent range of products.

f

ybrid ionomer and glass ionomer cements

H

(Vivaglass

for conventional cementation and offer a

number of advantages such as:

–

– High translucency

– High radiopacity

– Continuous fluoride release

– Aesthetic advantages for ceramic

– Minimum solubility

®

CEM), for example, are suitable

Low expansion

houlders

s

Please observe the corresponding Instructions for Use

3 recommended product combination

– not recommended/combination impossible

5

Page 6

Indication

– Metal-ceramic veneers

Veneers on refractory dies

–

Contraindication

– If patients are known to be allergic to any of the ingre-

dients of IPS d.SIGN, the

material should not be used.

Composition

The IPS d.SIGN glass-ceramic materials and liquids

contain the following main components:

– IPS d.SIGN ceramic materials

iO

50–65 wt.%

S

:

2

K

, Na

dditional contents are: Al

A

Li

O, ZrO2and pigments

2

2O3

,

O

2

– Opaquer pastes, Stains, and glazing materials

lso contains 25–40 wt. % glycols

a

, CaO, P

O

2

2O5

F,

,

Important processing

restrictions

– Mixing with other metal-ceramic powders (e.g.

IPS Classic

– Mixing with metal-free veneering ceramic powders (e.g.

IPS Empress

– Use of liquids or separating agents other than the ones

provided with the IPS d.SIGN assortments.

– Mixing of IPS d.SIGN materials in powder form (e.g.

Dentin, Incisal, etc.) with

IPS d.SIGN paste materials (e.g. Shades, Stains).

– Firing of IPS d.SIGN onto incompatible alloys

®

, IPS InLine®)

®

, IPS e.max®)

Important note

– Ceramic furnaces of other manufacturers often feature

opening mechanisms different from that of Ivoclar

Vivadent

furnaces. Therefore, the firing conditions may also differ.

Make sure to take these varying firing conditions into

account when working with IPS d.SIGN.

Warning

– Finishing ceramic restorations results in grinding dust.

Avoid inhalation. Use

suction equipment or protective masks.

– IPS d.SIGN Opaquer Liquid, 15 ml

Components: Polymer, butylene glycol, and glycerine

– IPS d.SIGN Build-Up Liquid, 60 ml and 250 ml

Components: Water, butylene glycol, and additives

– IPS d.SIGN Glaze and Stain Liquid, 15 ml

Components: Butylene glycol

– IPS d.SIGN Margin Build-Up Liquid, 60 ml

Components: Water, cellulose derivative

– IPS Margin Sealer, 20 ml

Components: Wax dissolved in hexane

– IPS Model Sealer, 50 ml

Components: Ethyl acetate, nitro-cellulose, softener

– IPS Ceramic Separating Liquid, 15 ml

Componets: Paraffin oil

6

Page 7

d.SIGN – Product overview

IPS

Opaquer pastes, intensive opaquer pastes, dentin, incisal, transparent,

dd-on, and glazing materials, as well as all the necessary liquids. The Kit also

Basic Kit

a

ontains a materials shade guide for the most popular Chromascop shades.

c

Chromascop

A–D

eep Dentin Kit

D

Margin Kit

Bleach Kit

Basic Kit

Deep Dentin Kit

Margin Kit

Deep dentin materials in the 10 most popular Chromascop shades. They are

M

add-on, and glazing materials, as well as all the necessary liquids. The Kit also

Margin materials in the 8 most popular A-D shades and 4 intensive materials

sed to intensify the chroma in layers of limited thickness.

u

argin materials in the 10 most popular Chromascop shades and 4 intensive

materials for special effects. 1 margin add-on material is used for final

The ultra-light shades enable optimum integration of the r

leached environment. 2 opaquers, 2 margin materials, 4 dentin materials,

b

paquer pastes, intensive opaquer pastes, dentin, incisal, transparent,

O

contains a materials shade guide for the most popular A–D shades.

eep dentin materials in the 7 most popular A-D shades. They are used to

D

for special effects. 1 margin add-on material is used for final adjustment of

djustment of the ceramic shoulder.

a

estoration in a

1 incisal material.

intensify the chroma in layers of limited thickness.

the ceramic shoulder.

Bleach Kit BL

Impulse Kit 1

Impulse Kit 2

Gingiva Kit

Essence Kit

any shade system

Assortments independent of

Stains Kit

Shade Kit

Four accurately coordinated shades meet the highest demands related

15 r

ranging from Mamelon to Opal materials facilitate the application

14 ready-mixed Impulse materials based on the inspiration and philosophies

of renowned experts, such as Enrico Steger, Donald F. Cornell,

5 true-to-natur

each patient situation in combination with the 4 gingival modifiers.

4 ceramic stains in powder form. They may be applied alone or mixed with

14 intensive stains in paste form to r

7 dentin stains in paste form for subsequent shade adjustments

to contemporary “white aesthetics”.

eady-mixed individual fluorapatite leucite ceramic materials

of true-to-nature effects.

and Dr. Robert R. Winter.

e gingival materials that can be individually used for

other materials.

oduce natural characteristics

on the ceramic surface.

of IPS d.SIGN r

epr

estorations.

7

Page 8

d.SIGN – Description of the

IPS

assortments

IPS d.SIGN Basic Kits

d.SIGN Basic Kit A–D

IPS d.SIGN Basic Kit Chromascop

IPS d.SIGN Dentin

IPS

IPS d.SIGN Incisal

The apatite glass-ceramic material is

distinguished for its lifelike appearance.

Apatite is also a component of natural teeth

and supports the light optical properties,

such as translucency, brightness, and light

scattering. Page 48 contains a detailed

description on the use of Cervical Dentin

D2/D3.

The six IPS d.SIGN Incisal materials (S1–S3

and TS1-TS3) demonstrate a shade gradation

similar to that of natural incisal ar

dinated with the

materials ar

Chromascop and the A–D shade guides (see

Materials Combination Tables on page 62 ff).

e coor

eas. The

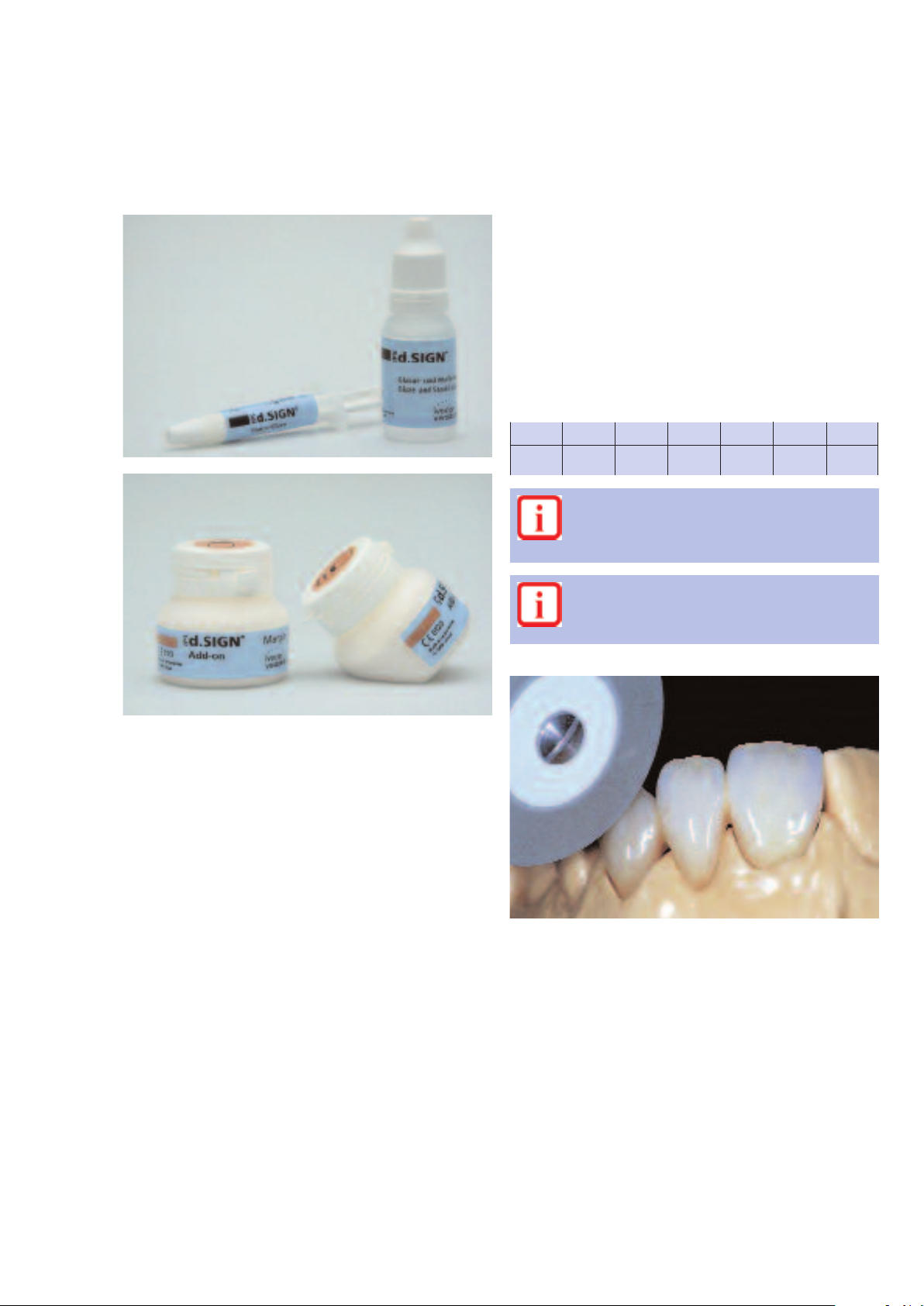

IPS d.SIGN Add-On

This add-on material with its medium incisal

opacity can be used alone or mixed with

other IPS d.SIGN layering materials. Observe

a mixing ratio of max. 1:1.

8

Page 9

IPS d.SIGN Opaquer

Opaquer pastes in the most

popular shades. The

aterials demonstrate

m

excellent stability and

outstanding masking

capabilities, even when

applied in thin layers (see

lso Material Combination

a

Table on page 62 ff).

Delivery form

Chromascop

IPS d.SIGN Basic Kit

– 10 IPS d.SIGN Opaquers, 3 g each

Shades: 130, 140, 210, 220, 230, 310, 410, 420, 430,

510

– 4 IPS d.SIGN Intensive Opaquers, 3 g each

Shades: white, purple, brown, incisal

– 10 IPS d.SIGN Dentin materials, 20 g each

Shades: 130, 140, 210, 220, 230, 310, 410, 420, 430,

510

– 3 IPS d.SIGN Incisal materials, 20 g each

Gradations: S1, S2, S3

– 1 IPS d.SIGN Transparent material, neutral, 20 g

– 1 IPS d.SIGN Glaze, 3 g

– 1 IPS d.SIGN Add-On material, 20 g

– 1 IPS d.SIGN Opaquer liquid, 15 ml

– 2 IPS d.SIGN Build-up liquid (Medium and Optimum 2),

60 ml

1 IPS d.SIGN Glaze and Stain liquid, 15 ml

–

– 1 IPS Model Sealer, 50 ml

– 1 IPS Ceramic Separating Liquid, 15 ml

– 1 IPS d.SIGN Opaquer material shade guide

– 1 IPS d.SIGN Dentin material shade guide

1 IPS d.SIGN Incisal material shade guide

–

– 1 Chromascop shade guide

IPS d.SIGN Glaze

PS d.SIGN Glaze and Stain Liquid

I

life-like lustre can be

A

chieved easily and

a

conveniently with IPS d.SIGN

Glaze in combination with

the IPS d.SIGN Glaze and

taine liquid.

S

A–D

IPS d.SIGN Basic Kit

– 8 IPS d.SIGN Opaquers, 3 g each

Shades: A2, A3, A3.5, B2, B3, C3, D2, D3

– 4 IPS d.SIGN Intensive Opaquers, 3 g each

Shades: white, purple, brown, incisal

– 8 IPS d.SIGN Dentin materials, 20 g each

Shades: A2, A3, A3.5, B2, B3, C3, D2, D3

– 1 IPS d.SIGN Cervical Dentin D2/D3

– 3 IPS d.SIGN Incisal materials, 20 g each

Gradations: TS1, TS2, TS3

– 1 IPS d.SIGN Transparent material, neutral, 20 g

– 1 IPS d.SIGN Glaze, 3 g

– 1 IPS d.SIGN Add-on material, 20 g

– 1 IPS d.SIGN Opaquer liquid, 15 ml

– 2 IPS d.SIGN Build-up liquid (Medium and Optimum 2),

60 m

– 1 IPS d.SIGN Glaze and Stain liquid, 15 ml

– 1 IPS Model Sealer, 50 ml

– 1 Ceramic Separating Liquid, 15 ml

1 IPS d.SIGN Opaquer material shade guide A–D

–

– 1 IPS d.SIGN Dentin material shade guide A–D

– 1 IPS d.SIGN Incisal material shade guide A–D

The IPS d.SIGN Basic Kits contain the most popular shades and are suitable for

oducing the most popular basic tooth shades without any difficulties. In this

epr

r

way, rarely used shades do not increase the initial investment but are available as

refills.

Refills

IPS d.SIGN Opaquer, 3 g each

–

Shades: 110, 120, 130, 140, 210, 220, 230, 240, 310,

320, 330, 340, 410, 420, 430, 440, 510, 520, 530, 540

– IPS d.SIGN Opaquer F, 1 g

IPS d.SIGN Dentin material, 20 g each / 100 g each /

–

250 g each; Shades: 110, 120, 130, 140, 210, 220, 230,

240, 310, 320, 330, 340, 410, 420, 430, 440, 510, 520,

530, 540

– IPS d.SIGN Incisal material, 20 g each / 100 g each /

250 g each; Gradations: S1, S2, S3

ent material, neutral, 20 g each /

– IPS d.SIGN T

100 g each / 250 g each

ranspar

Refills

– IPS d.SIGN Opaquer, 3 g each

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2, D3, D4

–

IPS d.SIGN Opaquer F, 1 g

– IPS d.SIGN Dentin materials, 20 g each / 100 g each /

250 g each; Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4,

C1, C2, C3, C4, D2, D3, D4

IPS d.SIGN Cervical Dentin D2/D3

–

– IPS d.SIGN Transparent Incisal material, 20 g each / 100 g

-S3

-S2, T

each / 250 g each; Gradations: T

9

-S1, T

Page 10

IPS d.SIGN Trial Kit

IPS d.SIGN Trial Kit

Delivery form

Chromascop

IPS d.SIGN Trial Kit

– 1 IPS d.SIGN Opaquer, 3 g; Shade: 210

– 1 IPS d.SIGN Dentin, 3 g; Shade: 210

– 1 IPS d.SIGN Incisal, 3 g; Gradation: S2

– 1 IPS d. SIGN Deep Dentin, 3 g; Shade: 210

– 1 IPS d.SIGN Margin, 3 g; Shade: 210

- 1 IPS d.SIGN Transpa, 3 g; Shade: neutral

– 1 IPS d.SIGN Occlusal Dentin, 3 g; Shade: orange

– 2 IPS d.SIGN Effect, 3 g each; Shades: 1, 3

– 1 IPS d.SIGN Mamelon, 3 g; Shade: light

– 1 IPS d.SIGN Glaze, 3 g

– 1 IPS d.SIGN Build-up liquid Medium, 5 ml

– 1 IPS d.SIGN Glaze and Stain liquid, 5 ml

1 IPS d.SIGN Margin Build-Up liquid, 5 ml

–

– 1 Material shade guide

A–D

IPS d.SIGN Trial Kit

– 1 IPS d.SIGN Opaquer, 3 g; Shade: A33

– 1 IPS d.SIGN Dentin, 3 g; Shade: A3

– 1 IPS d.SIGN Incisal, 3 g; Gradation: TS2

– 1 IPS d. SIGN Deep Dentin, 3 g; Shade: A3

– 1 IPS d.SIGN Margin, 3 g; Shade: A3

- 1 IPS d.SIGN Transpa, 3 g; Farbe: neutral

– 1 IPS d.SIGN Occlusal Dentin, 3 g; Farbe: orange

– 2 IPS d.SIGN Effect, 3 g each; Shades: 1, 3

– 1 IPS d.SIGN Mamelon, 3 g; Shade: light

– 1 IPS d.SIGN Glaze, 3 g

1 IPS d.SIGN Build-Up liquid Medium, 5 ml

–

– 1 IPS d.SIGN Glaze and Stain liquid, 5 ml

– 1 IPS d.SIGN Margin Build-Up liquid, 5 ml

– 1 Material shade guide

10

Page 11

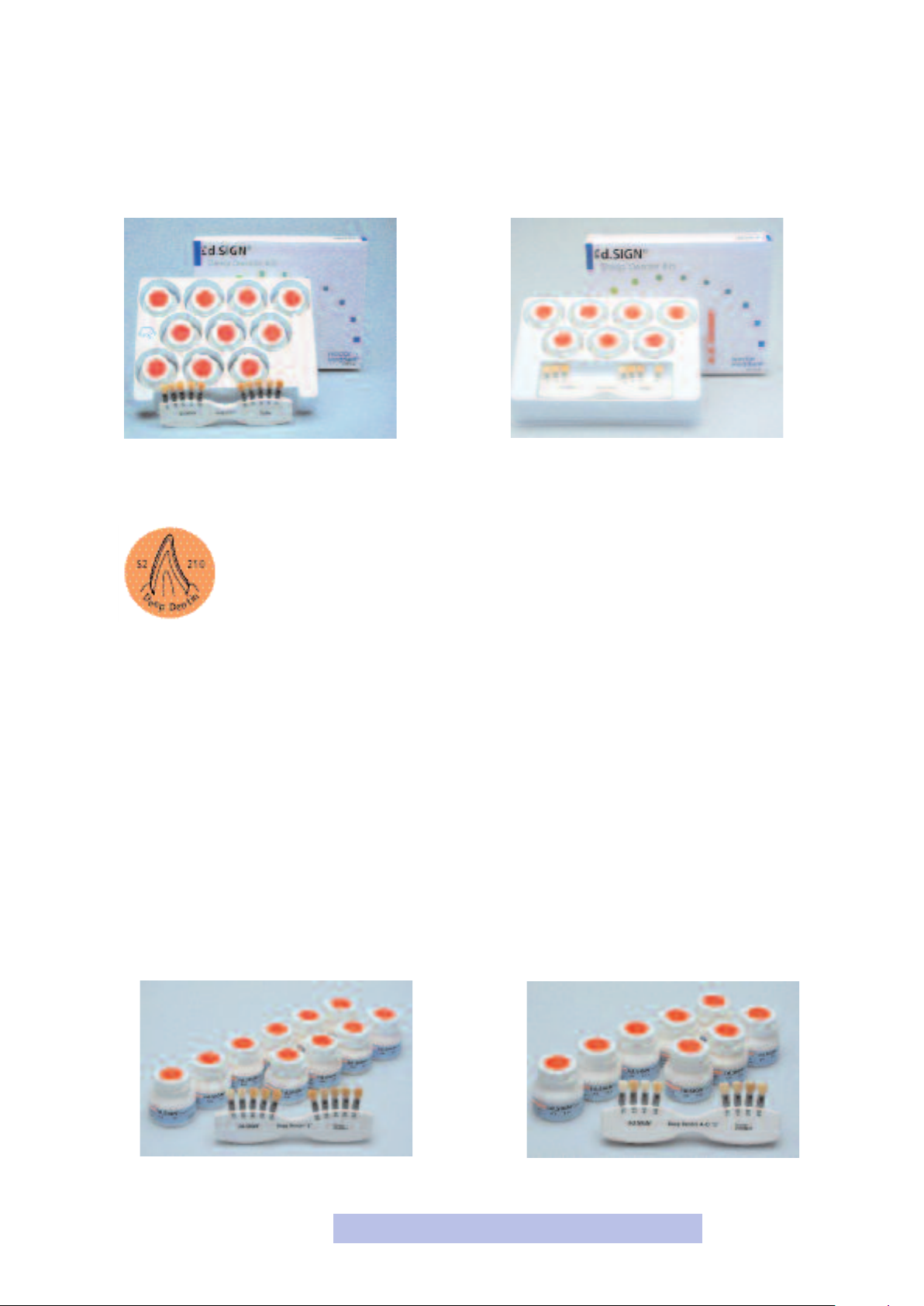

IPS d.SIGN Deep Dentin Kits

IPS d.SIGN Deep Dentin

With the IPS d.SIGN Deep Dentin materials,

restorations that demonstrate true-to-nature

shade effects can be achieved even with

limited layer thicknesses. Particularly if space

is limited, IPS d.SIGN Deep Dentin materials

can be used to intensify the chroma

(see 'Materials Combination Table' on page

62 ff).

IPS d.SIGN Deep Dentin Kit A–DIPS d.SIGN Deep Dentin Kit Chromascop

Delivery form

Chromascop

IPS d.SIGN Deep Dentin Kit

– 10 IPS d.SIGN Deep Dentin materials, 20 g each

Shades: 130, 140, 210, 220, 230, 310, 410, 420, 430, 510

– 1 IPS d.SIGN Deep Dentin material shade guide

Refill

– IPS d.SIGN Deep Dentin material, 20 g each

Shades: 110, 120, 130, 140, 210, 220, 230, 240, 310,

320, 330, 340, 410, 420, 430, 440, 510, 520, 530, 540

– IPS d.SIGN Deep Dentin '2' material shade guide

A–D

IPS d.SIGN Deep Dentin Kit

– 7 IPS d.SIGN Deep Dentin materials, 20 g each

Shades: A2, A3, A3.5, B2, B3, C3, D2/D3

– 1 IPS d.SIGN Deep Dentin material shade guide

Refill

– IPS d.SIGN Deep Dentin material, 20 g each

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2/D3, D4

– IPS d.SIGN Deep Dentin '2' material shade guide A-D

The various pr

ange may vary fr

oduct r

om country to country

11

.

Page 12

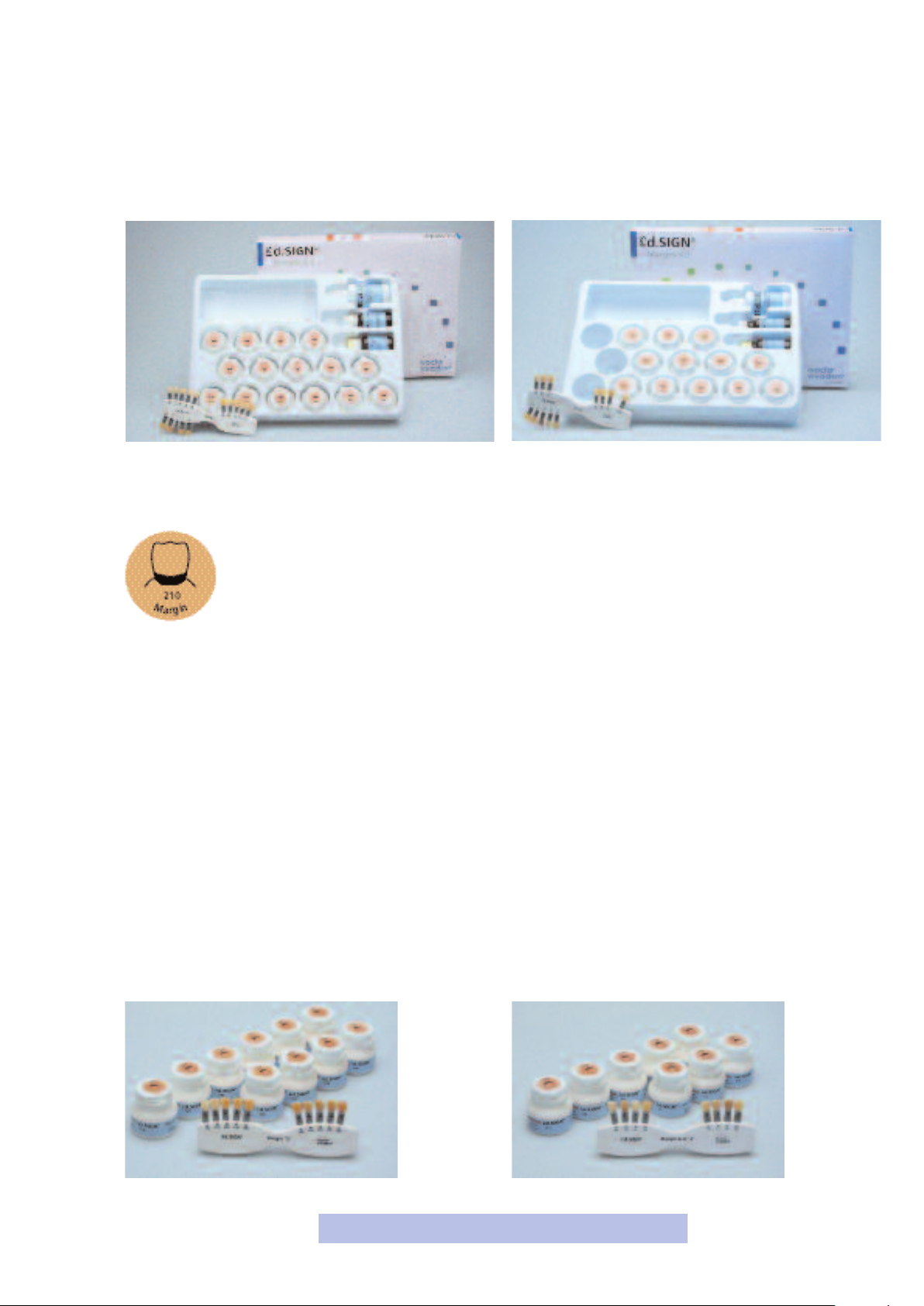

IPS d.SIGN Margin Kits

d.SIGN Margin Kit Chromascop

IPS

IPS d.SIGN Margin

The IPS d.SIGN Margin material permits the

design of a ceramic shoulder. They are

available in Chromascop and A–D shades.

Additionally, there are 4 Intensive Margin

materials to achieve special effects. The

Delivery form

Chromascop

IPS d.SIGN Margin Kit

– 10 IPS d.SIGN Margin materials, 20 g each

Shades: 130, 140, 210, 220, 230, 310, 410, 420, 430, 510

– 4 IPS d.SIGN Intensive Margin material, 20 g each

Shades: yellow

1 IPS d.SIGN Margin Add-On material, 20 g

–

– 1 IPS d.SIGN Margin Build-Up liquid, 60 ml

– 1 IPS d.SIGN Margin Separating liquid, 20 ml

1 IPS d.SIGN Ceramic separating liquid with brush, 15 ml

–

– 1 IPS d.SIGN Margin material shade guide

, orange, orange-pink, opaque

d.SIGN Margin Kit A–D

IPS

Margin Add-On material is used for

subsequent adjustments of the shoulder

area and the corresponding accuracy of fit (see

'Materials Combination Table' on

page 62 ff).

A–D

IPS d.SIGN Margin Kit

– 7 IPS d.SIGN Margin materials, 20 g each

Shades: A2, A3, A3.5, B2, B3, C3, D2/D3

– 4 IPS d.SIGN Intensive Margin materials, 20 g each

Shades: yellow, orange, orange-pink, opaque

– 1 IPS d.SIGN Margin Add-On material, 20 g

– 1 IPS d.SIGN Margin Build-Up liquid, 60 ml

1 IPS d.SIGN Margin Separating liquid, 20 ml

–

– 1 IPS d.SIGN Ceramic separating liquid with brush, 15 ml

1 IPS d.SIGN Margin material shade guide

–

Refill

IPS d.SIGN Margin material, 20 g each

–

Shades: 110, 120, 130, 140, 210, 220, 230, 210, 320,

330, 340, 410, 420, 430, 440, 510, 520, 530, 540

– IPS d.SIGN Margin '2' material shade guide

The various pr

oduct r

Refill

– IPS d.SIGN Margin material, 20 g each

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2/D3, D4

– IPS d.SIGN Margin '2' material shade guide A-D

ange may vary fr

12

om country to country

.

Page 13

IPS d.SIGN Bleach Kit

Delivery form

IPS d.SIGN Bleach

he ultra-light shades enable

T

ptimum integration of the

o

restoration in a bleached

environment (see 'Materials

Combination Table' on

page 62 ff).

IPS d.SIGN Bleach Kit

2 IPS d.SIGN Opaquers, 3 g each

–

Shades: 010/020, 030/040

– 2 IPS d.SIGN Margin materials, 20 g each

Shades: 010/020, 030/040

– 4 IPS d.SIGN Dentin materials, 20 g each

Shades: 010, 020, 030, 040

– 1 IPS d.SIGN Transparent-Incisal material, 20 g, T-S1

– IPS d.SIGN Bleach material shade guide

IPS d.SIGN Bleach Kit BL

Four accurately coor

demands related to contemporary “white aesthetics” (see

page 67 Combination table).

dinated shades meet the highest

Delivery form

IPS d.SIGN Bleach Kit BL

–

2 IPS d.SIGN Opaquer 3 g each; Shades: BL1/BL2, BL3/BL4

– 4 IPS d.SIGN Dentin 20 g each; Shades: BL1, BL2, BL3, BL4

– IPS d.SIGN Incisal, 20 g; Shade: BL

IPS d.SIGN Margin 20 g each; Shade: BL1, BL4*

–

IPS d.SIGN Deep Dentin 20 g each; Shades: BL1, BL4*

–

– IPS d.SIGN Add-On, 20 g; Shade: BL

IPS d.SIGN/IPS InLine material shade guide BL

–

– Shade guide Bleach BL

IPS d.SIGN Bleach Refill

– IPS d.SIGN Deep Dentin

material, 20 g

Shade 010

Refill

– All products are also available as Refill

* The Margin and Deep Dentin materials are only available in

shades BL1 and BL4. Shades BL2 and BL3 can be achieved

by mixing the materials as following:

BL2: 2/3 BL1 : 1/3 BL4

BL3: 1/3 BL1 : 2/3 BL4

13

Page 14

IPS d.SIGN Impulse 1 Kit

5 ready-mixed individual fluorapatite leucite ceramic

1

materials ranging from Mamelon to Opal materials facilitate

the application of true-to-nature effects.

IPS d.SIGN Occlusal Dentin

The Occlusal Dentin materials are available in

two different shades. They are used to

provide the basic shade for occlusal surfaces

and to intensify the chroma (see 'Materials

Combination Table' on page 66).

IPS d.SIGN Mamelon

The Mamelon materials are available in three

different shade gradations. They demonstrate

high opacity and optimum masking

capabilities even when applied in very thin

layers. Depending on the working habits of

the user, the material is applied in thin stripes

on reduced dentin. In this way, an

individualized appearance of the incisal third

can be achieved (see 'Materials Combination

Table' on page 66).

IPS d.SIGN Ef

fect

Users may chose between six shade

gradations of the IPS d.SIGN Ef

Starting with Effect 1, which demonstrates

true-to-nature opalescence in conjunction

with high translucency, the value gradually

increases from Effect 2 to Effect 5. In

contrast, the violet material reduces the

value in the incisal area (see 'Material

Combination Table' on page 66).

fect materials.

IPS d.SIGN Transparent

The Transparent materials are available in

three shade nuances. They are suitable to

reproduce shaded, transparent areas,

particularly in the incisal third (see 'Materials

Combination Table' on page 66).

IPS d.SIGN Incisal Edge

This material is used to achieve what is

known as the 'halo effect', which is caused

in natural teeth by light refraction at the

incisal edge (see 'Materials Combination

able' on page 66).

T

Delivery form

IPS d.SIGN Impulse 1 Kit

2 IPS d.SIGN Occlusal Dentin materials, 20 g each

–

Shades: orange, brown

– 3 IPS d.SIGN Mamelon materials, 20 g each

Shades: light, yellow-orange, salmon

– 6 IPS d.SIGN Effect materials, 20 g each

Gradation: Ef

violet

– 3 IPS d.SIGN Transparent materials, 20 g each

Shades: blue, brown-grey, orange-grey

1 IPS d.SIGN Incisal Edge material, 20 g

–

– 1 IPS d.SIGN Impulse 1 material shade guide

fect 1, Ef

fect 2, Ef

fect 3, Effect 4, Effect, 5,

14

Page 15

IPS d.SIGN Impulse 2 Kit

14 ready-mixed Impulse materials based on the inspiration

and philosophies of renowned experts, such as Enrico Steger,

onald F. Cornell, and Dr. Robert R. Winter.

D

IPS d.SIGN Brilliant Dentin

In order to highlight the shade of certain

areas of the tooth, IPS d.SIGN Brilliant

Dentin is applied on the opaquer in very thin

layers. These special dentin materials

demonstrate outstanding opacity and colour

saturation (see 'Material Combination Table'

on page 66).

IPS d.SIGN Palatinal Dentin

These dentin materials have been especially

developed for use in palatal areas where

space is limited. They only need to be

covered with Incisal materials and provide

the required colour saturation for the palatal

fossa (see 'Materials Combination Table' on

page 66).

IPS d.SIGN Insert

IPS d.SIGN Insert materials are mainly used in

incisal ar

incisal and dentin materials for shade

characterization purposes. With Insert grey, a

true-to-nature in-depth effect can be

achieved (see 'Materials Combination Table'

on page 66).

IPS d.SIGN Special Incisal

These two special incisal materials may either

be mixed with IPS d.SIGN Incisal materials to

modify and intensify the shade or applied

directly (see 'Materials Combination Table' on

page 66).

eas and are applied between the

IPS d.SIGN Inter Incisal

This special incisal material is used when high

brightness values in the incisal area are

needed or to increase the brightness value in

the incisal third when space is limited. It can

be applied alone or mixed with other

materials (see 'Materials Combination Table'

on page 66).

IPS d.SIGN Cervical Incisal

These very transparent cervical incisal

materials are used to achieve true-to-nature

effect of depth in the cervical third. In

contrast to conventional Transparent

materials, these special materials

demonstrate a strong white fluorescence (see

'Materials Combination Table' on page 66).

Delivery form

IPS d.SIGN Impulse 2 Kit

– 3 IPS d.SIGN Brilliant Dentin materials, 20 g each

Shades: yellow, orange, white

2 IPS d.SIGN Palatinal Dentin material, 20 g each

–

Shades: yellow, red

2 IPS d.SIGN Insert materials, 20 g each

–

Shades: orange, grey

– 2 IPS d.SIGN Special Incisal materials, 20 g each

Shades: yellow, grey

1 IPS d.SIGN Inter Incisal material, 20 g

–

Shade: white-blue

– 4 IPS d.SIGN Cervical Incisal materials, 20 g each

Shades: yellow

– IPS d.SIGN Impulse 2 material shade guide

, orange-pink, khaki, orange

15

Page 16

IPS d.SIGN Gingiva Kit

Delivery form

IPS d.SIGN Gingiva Kit

– 1 IPS d.SIGN Gingiva Opaquer, 3 g

– 5 IPS d.SIGN Gingiva materials, 20 g each

Gradations: G1, G2, G3, G4, G5

– 4 IPS d.SIGN Gingiva Modifiers, 20 g each

Gradations: GM1, GM2, GM3, GM4

– IPS d.SIGN Gingiva material shade guide

IPS d.SIGN Gingiva and Gingiva Modifier

These special Gingiva materials are used in

combination with the Gingiva Modifiers

epending on the individual situation of the

d

atient. The shade gradations range from

p

orange to reddish to bluish (see 'Materials

Combination Table' on page 67).

IPS d.SIGN Essence Kit

Delivery form

IPS d.SIGN Essence Kit

– 1 IPS d.SIGN Essence, 1 g, orange

– 1 IPS d.SIGN Essence, 1 g, yellow

– 1 IPS d.SIGN Essence, 1 g, grey

– 1 IPS d.SIGN Essence, 1 g, brown

– 1 IPS d.SIGN Glazing and Staining liquid, 15 ml

IPS d.SIGN Essence materials are ceramic stains in powder

form that may be mixed with IPS d.SIGN layering materials in

der to intensify the shade. Furthermore, IPS d.SIGN Essence

or

can be used for surface characterizations to repr

special characteristics of the natural tooth (see 'Materials

Combination Table' on page 67)

oduce the

16

Page 17

IPS d.SIGN Stains Kit

Delivery form

IPS d.SIGN Stains Kit

– 1 IPS d.SIGN Stains, 1 g, white

– 1 IPS d.SIGN Stains, 1 g, mahogany

– 1 IPS d.SIGN Stains, 1 g, khaki

– 1 IPS d.SIGN Stains, 1 g, orange

– 1 IPS d.SIGN Stains, 1 g, grey

– 1 IPS d.SIGN Stains, 1 g, vanilla

– 1 IPS d.SIGN Stains, 1 g, crackliner

– 1 IPS d.SIGN Stains, 1 g, olive

IPS d.SIGN Stains

– 1 IPS d.SIGN Stains, 1 g, yellow

1 IPS d.SIGN Stains, 1 g, black

–

– 1 IPS d.SIGN Stains, 1 g, maroon

– 1 IPS d.SIGN Stains, 1 g, basic blue

– 1 IPS d.SIGN Stains, 1 g, basic red

– 1 IPS d.SIGN Stains, 1 g, basic yellow

– 1 IPS d.SIGN Glaze, 3 g

– 1 IPS d.SIGN Glaze and Stain liquid, 15 ml

hese intensive stains in

T

aste form are available in

p

14 different shades. They are

used to reproduce natural

characteristics on the

eramic surface. With the

c

three primary colours basic

blue, basic red, and basic

yellow, custom shades may

be developed (see 'Materials

Combination Table' on

page 67).

IPS d.SIGN Shade Kit

Delivery form

IPS d.SIGN

– 1 IPS d.SIGN Shade 1, 3 g

– 1 IPS d.SIGN Shade 2, 3 g

– 1 IPS d.SIGN Shade 3, 3 g

1 IPS d.SIGN Shade 4, 3 g

–

Combination table

IPS d.SIGN Shade

Shade Kit

IPS d.SIGN Shade

These 7 dentin stains in

paste form make shade

adjustments to IPS d.SIGN

restorations possible. They

are coordinated with the

20 Chromascop shades and

the 16 A–D shades (see

'Materials Combination

able' on page 67).

T

– 1 IPS d.SIGN Shade 5, 3 g

– 1 IPS d.SIGN Shade 6, 3 g

– 1 IPS d.SIGN Shade 7, 3 g

1

2

3

4

5

6

7

Chromascop

A–D Shades

110, 120,

130

A1, B1, B2

140, 210,

220, 230,

240

A2, A3,

A3,5

310, 320,

330

B3, B4, D4

17

340, 540,

A4

410, 420

C1, D2, D3

430, 440,

510

C2, C3, C4

520, 530

Page 18

d.SIGN – Liquids

IPS

IPS d.SIGN Opaquer Liquid, 15 ml

his liquid is used to adjust

T

the consistency of IPS d.SIGN

Paste Opaquer materials. Do

not excessively dilute the

paste opaquer with the

paquer liquid.

o

Components: Polymer,

butylene glycol, and

glycerine

The Opaquer Liquid must not be used to mix

opaquers, as it is the case in power/liquid opaquer

systems.

IPS d.SIGN Margin Build-Up Liquid, 60 ml

Use to mix the IPS d.SIGN

Margin materials.

Components: Water,

cellulose derivative

IPS d.SIGN Glaze and Stain Liquid, 15 ml

This liquid is used to adjust

the consistency of IPS d.SIGN

Stains, IPS d.SIGN Shade,

IPS d.SIGN Essence, and

IPS d.SIGN Glaze.

Components: Butylene

glycol

Warning

Butylene glycol is irritating. Avoid contact. Do not

inhale vapours.

IPS d.SIGN Build-Up Liquid Medium, 60 and 250 ml

This liquid is suitable for

ixing IPS d.SIGN materials

m

or most layering techniques

f

and restorations. The BuildUp Liquid Medium is particularly suitable for technicians

ho prefer a longer working

w

time and enhanced stability

of IPS d.SIGN. In this way,

IPS d.SIGN may be processed

in smaller increments, with-

ut the constant need of

o

moistening. Given the longer

working time than with the

Build-Up Light, a longer

closing time (pre-drying time)

IPS d.SIGN Build-Up Liquid Light, 60 and 250 ml

This liquid is suitable for

mixing IPS d.SIGN materials

that will be used for smaller

restorations or when smaller

amounts of material are

needed for 2nd dentin and

incisal firings (corrective

firing). The Build-Up Liquid

Light is suitable for those

who prefer a drier working

consistency, thus avoiding

the need for constant

blotting since the liquid

evaporates much quicker

this way, IPS d.SIGN can be

IPS d.SIGN Build-Up Liquid Premium, 60 and 250 ml

This liquid is suitable for

mixing IPS d.SIGN materials

that will be used for

fabricating larger restorations

where a longer working time

and smooth consistency is

desired. The Build-Up Liquid

Premium is suitable for

technicians who prefer a

long working time and moist

material coupled with high

stability. In this way,

IPS d.SIGN can be pr

without the need for

constant moistening. Since

the material stays moist for a

longer period of time

controlled blotting is

18

. In

ocessed

is required for the firing

ocedure.

pr

Components: Water,

butylene glycol, and

additives

easily manipulated with an

instrument.

Components: Water,

butylene glycol, and

additives

equired as well as a longer

r

closing time (pre-drying

time) for the firing

procedure.

Components: Water,

butylene glycol-chloride

solution

Page 19

PS d.SIGN Build-Up Liquid Optimum 1,60 and 250 ml

I

xcellently suitable for

E

mixing IPS d.SIGN, with its

outstanding firing behaviour

and lowest possible

hrinkage. The materials are

s

easily suctioned off and

condensed and are

particularly suitable for the

manual reduction of

aterials with the help of

m

instruments.

IPS Margin Sealer, 20 ml

his separating liquid is used

T

to seal the gypsum die when

fabricating a ceramic

shoulder with IPS d.SIGN

Margin materials.

Components: Wax dissolved

in hexane

Components: Water, polyethylene glycol (PEG), and

additives

IPS d.SIGN Build-Up Liquid Optimum 2, 60 and 250 ml

Excellently suitable for

mixing IPS d.SIGN, with its

properties that support the

build-up, as well as the

optimized firing properties

with low shrinkage. This

liquid is particularly suitable

for targeted material

application without

continuous suction.

Components: Water, polyethylene glycol (PEG), and

additives

Warning:

Hexane is highly flammable and detrimental to

health. Avoid contact of the material with skin and

eyes. Do not inhale the vapours. Keep the material

away from open fire.

IPS Model Sealer, 50 ml

This separator is used to seal

the pontic tissue areas and

interproximal contact area

when working with

IPS d.SIGN layering materials.

The IPS Model Sealer closes

the pores of the gypsum and

prevents the moisture in the

ceramic material from being

absorbed by the gypsum.

Components: Ethyl acetate,

nitro-cellulose, softener

Warning

Ethyl acetate is highly flammable

away from open fire. Do not inhale the vapours.

. Keep material

IPS Ceramic Separating Liquid, 15 ml

This Separating Liquid is

used on areas that have

been sealed with either the

IPS Margin Sealer Liquid or

the IPS

Model Sealer

. Use of

this liquid will ensure a clean

separation between the

ceramic material and the

gypsum model and/or die.

Components: Paraffin oil

Other build-up liquids or separating liquids must

not be used.

They may contain or

that do not burnout at the firing temperatures

used for IPS d.SIGN and leave a residue that will

cause discolor

19

ation in the cer

ganic additives

amic.

Page 20

d.SIGN – Shade selection

IPS

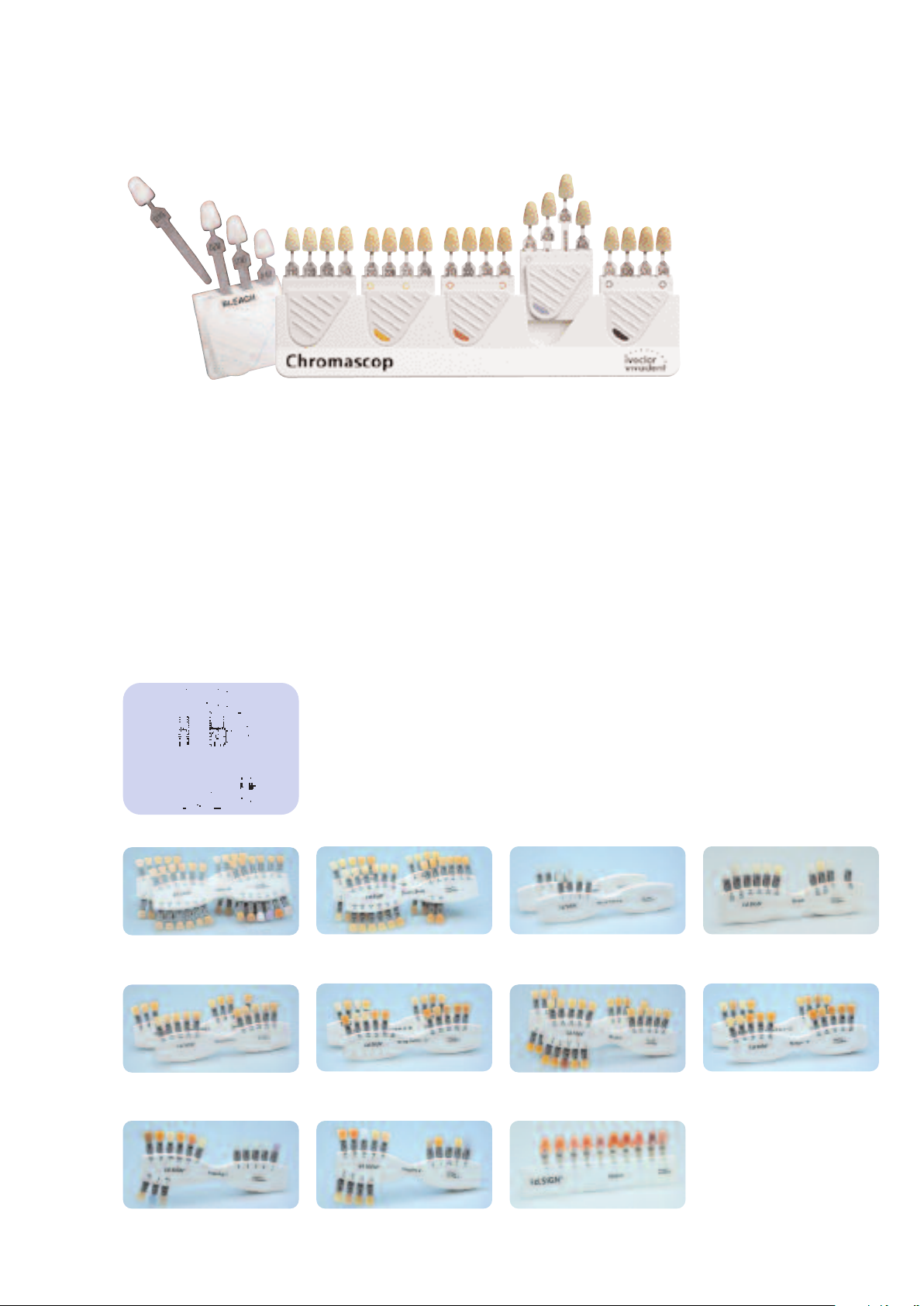

The Chromascop shade guide represents the shade standard for Ivoclar Vivadent products.

With the logical arrangement of the individual shades, the Chromascop permits exact and

ficient shade determination. The 20 shades are divided into five detachable shade groups.

ef

IPS d.SIGN material shade guides

The shade guides fired from original materials are also an integrated part of the IPS d.SIGN

product system. For reasons of light refraction, the new shade tabs have been given an

anatomical shape and a certain surface structure. On the reverse side, the teeth are smooth,

i.e. without any texture whatsoever, which facilitates shade comparison with the prepared die

and shaded cementation media. The smooth side of shade tabs may be individually ground

to determine the layering. The shade tabs are fired from original materials under laboratorytype conditions. In this way, they correspond with the desired result.

IPS d.SIGN Opaquer material shade guide

Chromascop and A–D

IPS d.SIGN Deep Dentin material shade guide

Chromascop and

A–D

IPS d.SIGN Dentin material shade guide

Chromascop and A–D

IPS d.SIGN Deep Dentin '2' material shade guide

Chromascop and Deep Dentin

A–D '2'

IPS d.SIGN Incisal/Transparent material shade guide

Chromascop and

IPS d.SIGN Margin material shade guide

Chromascop and A–D

A–

IPS d.SIGN Bleach material shade guide

IPS d.SIGN Margin '2' material shade guide

Chromascop and Margin

A–D '2'

IPS d.SIGN Impulse 1 material shade guide

Chromascop and A–D

IPS d.SIGN Impulse 2 material shade guide

Chromascop and

A–D

IPS d.SIGN Gingiv

Chromascop and

20

a material shade guide

A–D

Page 21

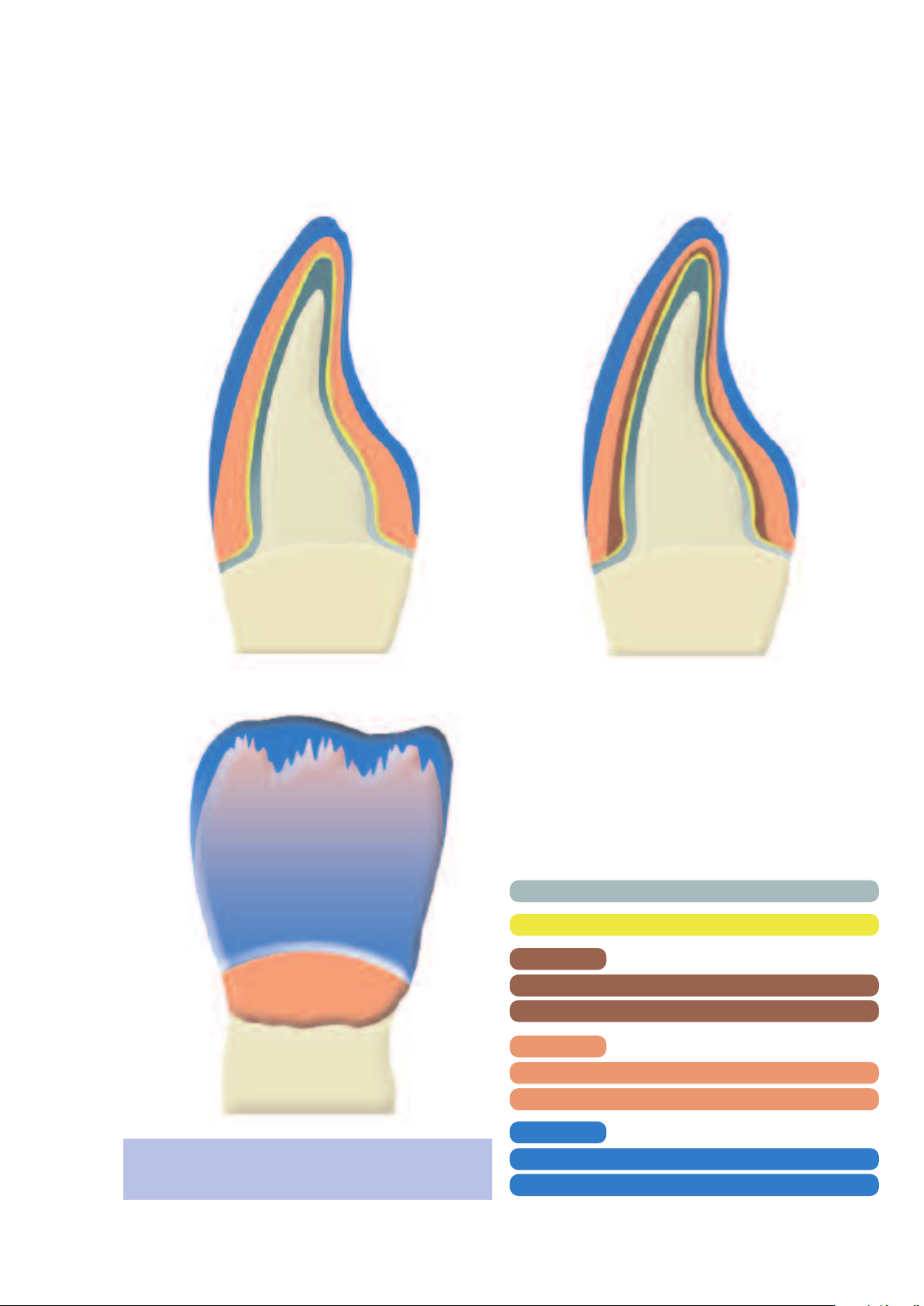

d.SIGN – Layering diagram

IPS

Chromascop – ideal space

Chromascop – limited space

the incisal material extends up to

In Chromascop layering

the cervical third. The indications on the right are reference

values.

,

Framework

Opaquer

Deep Dentin

cervical

incisal

Dentin

cervical

incisal

Incisal

cervical

incisal

21

ideal

space

0.3 mm

0.1 mm

–

–

1.0 mm

0.7 mm

0.2 mm

0.5 mm

limited

space

0.3 mm

0.1 mm

0.3 mm

0.1 mm

0.5 mm

0.3 mm

0.1 mm

0.4 mm

Page 22

A–D – ideal space

A–D – limited space

the incisal material extends to the center of

In A–D layering

the cervical third. The indications on the right are reference

values.

,

Framework

Opaquer

Deep Dentin

cervical

incisal

Dentin

cervical

incisal

Incisal

cervical

incisal

22

ideal

space

0.3 mm

0.1 mm

–

–

0.9 mm

0.7 mm

0.2 mm

0.5 mm

limited

space

0.3 mm

0.1 mm

0.3 mm

0.1 mm

0.5 mm

0.3 mm

0.1 mm

0.4 mm

Page 23

d.SIGN – Framework design

IPS

crowns

4

/

3

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

–

–

–

–

Telescope and

conus crowns

Root canal

posts

l

l

l

l

–

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

–

l

–

l

–

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Ceramic crowns

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Long span

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Alloy

Implant Series

Callisto Implant 78

IS-85

IS-64

allisto Implant 60

C

High gold content

Brite Gold

Brite Gold XH

Golden Ceramic

Aquarius Hard

Aquarius

IPS d.SIGN 98

Y

Aquarius XH

Y-Lite

Sagittarius

IPS d.SIGN 96

Reduced gold content

IPS d.SIGN 91

W

W-5

Lodestar

W-3

Evolution Lite

Palladium based

Capricorn 15

IPS d.SIGN 84

d.SIGN 67

IPS

Spartan Plus

IPS d.SIGN 59

d.SIGN 53

IPS

Ni based

Pisces Plus

4all

IPS d.SIGN 15

Co based

IPS d.SIGN 30

Inlays

–

–

–

–

l

l

–

l

l

l

–

–

–

–

l

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Onlays

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

–

–

–

–

bridges

Short span

bridges

l

l

l

l

–

–

l

–

l

–

l

l

l

l

l

l

l

l

l

l

l

–

l

l

l

l

l

l

l

l

l

l

Implant

l

l

l

l

–

–

–

–

–

l

–

l

–

l

–

l

–

l

l

l

–

l

l

l

l

l

l

–

–

–

l

Partial dentures

Superstructures

l

l

l

l

–

–

–

l

–

l

–

l

l

l

–

l

l

l

l

l

–

l

l

l

l

l

l

l

–

–

l

oduct lines may vary fr

The pr

om country to country.

When designing frameworks to be veneered with ceramic materials, the following

parameters have to be observed:

1. Functional support of the veneering ceramic

2. Framework design for porcelain shoulders

3. Framework stability

4. Framework design for bridges

5. Design of bridge pontics

6. Interface between metal and ceramic

23

Page 24

1. Functional support of the veneering ceramic

tress peaks, which may cause delamination or cracks. Sharp

The framework should reflects the shape of the tooth in a

reduced form. The framework should be designed in such a

way that it supports the cusps so that an even layer of the

eneering ceramic can be used in the cusp/fissure area. In

v

this way, the masticatory forces are exerted on the framework rather than on the veneering ceramic. Furthermore,

the framework should not have any sharp angles or edges

see diagram), so that the masticatory forces do not cause

(

Anterior crowns

correct wrong

s

angles or edges should be rounded in the wax-up so that

the minimum framework thickness is not compromised. The

wall thickness of the metal framework for single crowns

after finishing should be at least 0.3 mm and 0.5 mm for

ridge abutments (see diagram). For further information,

b

please refer to the Instructions for Use of the alloy being

used.

Premolar crowns

Molar cr

owns

correct wrong

correct wrong

24

Page 25

2. Framework design for porcelain shoulders

When fabricating porcelain shoulders, make sure that the

ramework is supported by the prepared tooth rather than

f

he veneer. To achieve this the framework is reduced exactly

t

to the inner edge of the chamfer or shoulder preparation. In

this way, functional support of the framework by the

prepared tooth is achieved. A framework that accuractly fits

he prepared tooth is essential in order to keep the ceramic

t

material from getting on the inner surface of the framework.

correct

3. Framework stability

The dimensions of the interproximal connector greatly

influences the stability of the restoration during the

laboratory procedure as well as the clinical long-term success

after cementation. Therefore, the dimension of the

connector area must be adequate for the alloy being used.

This is especially important if a bio-alloy or high-gold alloy is

to be used.

wrong

Double the width of the

connector

= double the stability

Single connector width

= single stability

Double the height of the

connector at single width

= eightfold the stability

25

Page 26

4. Framework design for bridges

Frameworks veneered with ceramic materials are subject to

thermal stress during the firing procedures and to

masticatory stress after cementation. Therefore, the

orresponding forces must be transferred to the framework

c

rather than the veneer. In particular, adequate framework

thickness must be ensured in the connector area between

the abutment and the pontic in bridge reconstructions.

he design of the framework must meet the visual,

T

unctional and periodontal hygiene requirements of the

f

patient. A functional wax-up reduced to allow space for

the ceramic material is the optimum prerequisite. During the

laboratory procedures the framework is repeatedly exposed

to high temperatures. These firing temperatures may cause

the framework to distort and compromise the accuracy of fit

if it has not been properly designed and the required

hickness observed. A scallop-type design with interproximal

t

reinforcement will provide the necessary strength needed to

avoid deformation of the framework. Also, this type of

proper framework design (e.g. with cooling grooves) will

ensure even cooling of the restoration once it is removed

rom the porcelain furnace after firing. This is particularly

f

important if bio-alloys or high-gold alloys are used. The

corresponding failures can be prevented as described under

point 1.

n order to ensure proper oral hygiene with bridges, the

I

design of the interdental areas should be given special

attention. Adequate opening of the interdental area should

be considered when designing the framework without

creating black triangles. In this way, periodontal hygiene may

be performed using interdental brushes and dental floss.

correct

ect

corr

wrong

26

Page 27

5. Design of bridge pontics

Bridge pontics are designed taking aesthetic and functional

aspects into account, as well as oral hygiene. The area of the

pontic that contacts the alveolar ridge should be made of

eramic. In order to ensure adequate stability between

c

Bridge pontic design – ovate pontics Bridge pontic design – saddle-type pontics

bridge pontic and the bridge abutments, a palatal and/or

ingual scallop is recommended. Furthermore, to ensure even

l

cooling of the bridge pontic that absorbs the most heat,

additional cooling grooves are advantageous.

6. Interface between metal and ceramic

The interface between the metal framework and the venee

ring ceramic must be clearly defined and, if possible,

incorporate a right angle finish line. The juncture between

the metal framework and the veneering ceramic must not

be located in the contact area nor on surfaces involved in

masticatory functions. Furthermor

interface in the marginal area does not come into contact

e, make sure that the

with the gingiva, particularly if a tapered crown margin is

designed (e.g. no metal margin and no ceramic shoulder).

In this way, irritation of the gingiva can be prevented. The

interface in the interdental area should be designed in such

a way that cleaning of these difficult-to-access areas is

possible.

27

Page 28

d.SIGN – Instructions for Use

IPS

Starting situation

Fabricate a master model or a model with detachable

segments on the basis of the impression in the usual manner.

t is advisable to apply a sealer to harden the surface to

I

protect the die from abrasion. The application of a sealer

must not cause any changes in the dimension of the die.

After that, a spacer may be applied in the usual manner.

A model with detachable segments is used as the basis.

Fabricating the framework

When fabricating the framework, make sure that the

minimum wall thickness

rowns and 0.5 mm for bridge abutments. These dimensions

c

are the prerequisite for the stability of the metal framework

and the durable bond between the metal and ceramic

material. If the stipulated framework and connector

dimensions are not observed, stress within the material may

ause delamination of the ceramic material and distortion of

c

the framework.

Recommended procedure

. Complete modelling of the anatomical tooth shape

1

2. Reduce to make room for the veneering materials

3. Waxing of the contact points and connector areas

4. Checking the occlusal and proximal contact points

after finishing is 0.3 mm for single

Dies isolated with a sealer, followed by a spacer layer.

28

Page 29

Contouring

he framework reflects the reduced anatomical tooth shape

T

see 'Functional support of the veneering ceramic' on page

(

24). In this way, the ceramic material may be applied in even

layers and is adequately supported. For that purpose, the

properties of the different alloys (e.g. firing stability) must be

aken into consideration.

t

– Undersized metal frameworks result in increased

hrinkage of the veneering ceramic and require

s

additional corrective firings.

– If the metal framework is too small, the veneering

ceramic is not adequately supported, which may lead to

cracks and delamination, particularly in very thick ceramic

layers.

Finishing the metal framework

he cast metal framework is finished using tungsten carbide

T

etal burs or ceramic-bonded grinding instruments. The

m

marginal area of the framework is reduced up to the inner

edge of the chamfer or shoulder preparation (labial or

circular) to make room for the ceramic shoulder.

– Use reduced pressure when working with softer

alloys.

– Work in one direction only to avoid overlapping and

inclusions in the metal surface.

– Do not use diamond grinding instruments. Diamond

particles may be trapped in the alloy and cause bubbles

in the cer

amic material during firing.

The frameworks are contoured according to the static requirements…

... and the properties of the alloy used.

ameworks are finished using tungsten carbide metal burs…

Cast metal fr

... or ceramic-bonded grinding instruments.

29

Page 30

Oxide firing

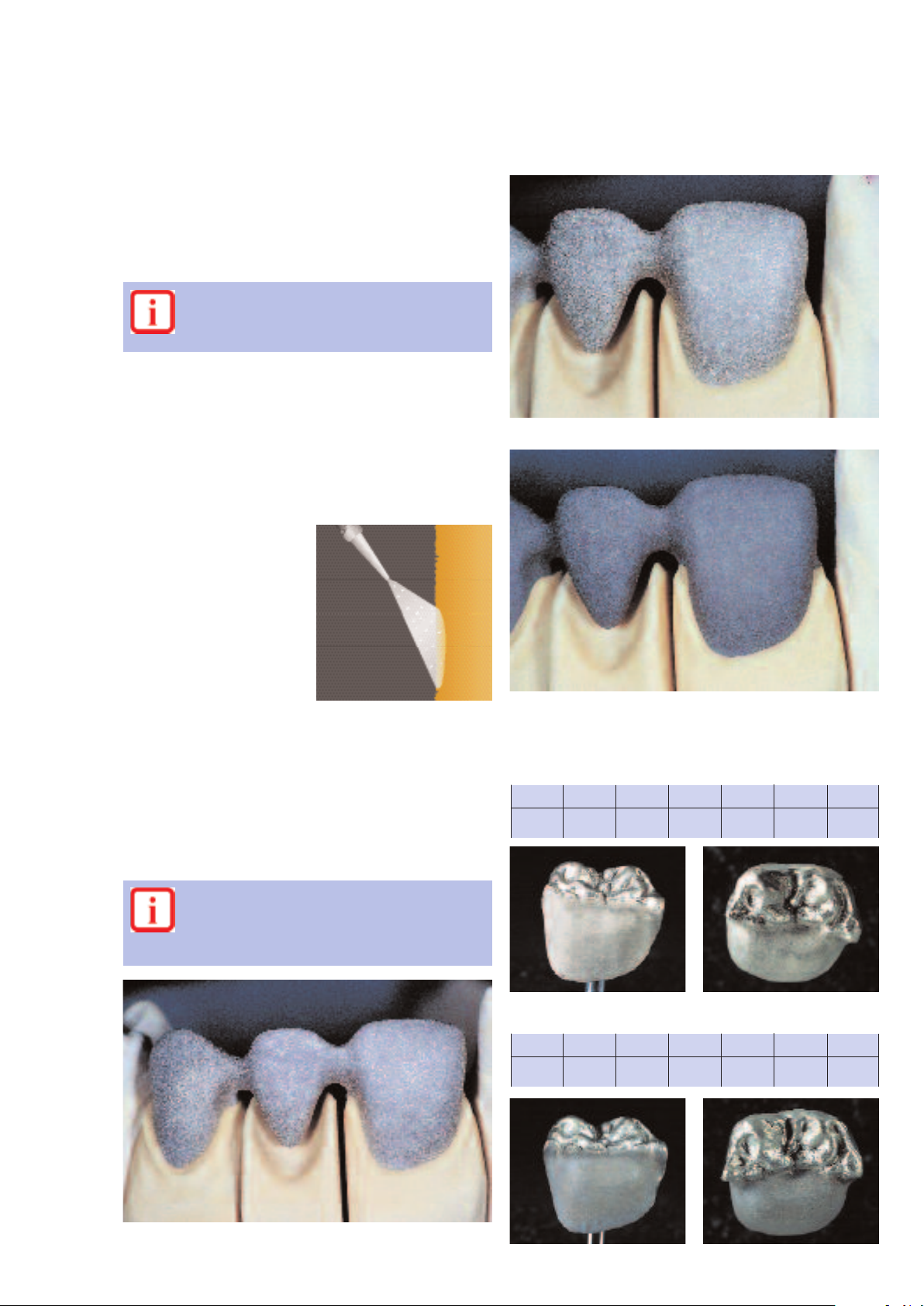

After grinding, carefully blast the framework with type

80–100 aluminium oxide (Al

edium). When using IPS d.SIGN alloys, the required

m

pressure is 1.5–2.0 bar.

Use only disposable, pure Al2O3to blast the alloy

surface. Observe the Instructions for Use of the

corresponding alloy manufacturer.

Blasting improves the mechanical bond. It results in the

object surface being roughened and considerably enlarged.

In order to prevent inclusions of blasting medium residue in

the ceramic, we recommend blasting the alloys with the

indicated pressure while keeping the nozzle at a flat angle to

the object surface. A contaminated metal surface may result

in the formation of bubbles during ceramic firing.

Schematic diagram of the

blasting direction

Correct angle for blasting the

alloy surface.

). (Ivoclar Vivadent special jet

2O3

... thoroughly cleaned, ...

Before the oxidation firing, clean the metal framework using

a brush under running water. Then, thoroughly clean it with

steam or in the ultrasonic cleaner. Allow the framework to

dry after cleaning. Oxidize the framework according to the

. Provide ample

instructions given by the alloy manufactur

support for the framework on the fi

er

ring tray

. This is

particularly important for long-span bridges. After oxidation,

carefully check the framework for porosity or irregular oxide

layer. Applied corr

W

ections if necessary.

hen conditioning the frameworks, the instructions

of the alloy manufacturer must be observed at all

times. Oxidation is carried out according to the

instructions of the alloy manufacturer.

.

.. and oxidized according to the instructions of the alloy manufacturer.

Correctly oxidized IPS d.SIGN alloys

Firing parameters for the oxide firing of IPS d.SIGN 98

T

925°C

1697°F

B

403°C

757°F

S

1 min.

1 min.

t

80°C

144°F

H

Ú

5 min.

5 min.

V

–

–

V

1

2

–

–

Firing parameters for the oxide firing of IPS d.SIGN 96

950

1742

T

B

C

°

°

°

403

F

757

S

C

1 min.

F

°

1 min.

80

144

t

°

H

Ú

C

5 min.

F

°

5 min.

450

842

V

V

1

C

°

°

2

°

950

F

1742

C

F

°

After grinding, the framework is carefully blasted with type 100 aluminium oxide Al

2O3

,….

30

Page 31

Firing parameters for the oxide firing of IPS d.SIGN 91

010°C

1

850°F

1

T

4

7

B

03°C

57°F

S

min.

1

min.

1

8

1

t

0°C

44°F

H

Ú

min.

5

min.

5

4

8

V

1

50°C

42°F

010°C

1

850°F

1

V

2

Firing parameters for the oxide firing of IPS d.SIGN 53

010°C

1

850°F

1

T

4

7

B

03°C

57°F

S

min.

1

min.

1

8

1

t

0°C

44°F

H

Ú

0 min.

1

0 min.

1

V

–

–

V

1

2

–

–

Firing parameters for the oxide firing of IPS d.SIGN 84

T

1010°C

1850°F

B

403°C

757°F

S

1 min.

1 min.

t

80°C

144°F

H

Ú

5 min.

5 min.

V

1

450°C

842°F

V

2

1010°C

1850°F

Firing parameters for the oxide firing of IPS d.SIGN 67

1010

1850°

T

B

C

°

°

403

F

757°

S

C

1 min.

F

1min.

80

144°

t

°

H

Ú

C

5 min.

F

5 min.

V

1

–

–

V

2

–

–

Firing parameters for the oxide firing of IPS d.SIGN 30

T

925°C

697°F

1

B

403°C

57°F

7

S

1 min.

min.

1

80°C

44°F

1

t

H

Ú

5 min.

min.

5

V

1

450°C

42°F

8

V

925°C

697°F

1

2

Firing parameters for the oxide firing of IPS d.SIGN 15

T

950°C

1742°

B

403°C

F

757°

S

1 min.

F

1 min.

t

80°C

144°

H

Ú

1 min.

F

1 min.

V

–

–

V

1

2

–

–

Firing parameters for the oxide firing of IPS d.SIGN 59

T

1010°C

1850°F

B

403°C

757°F

S

1 min.

1 min.

t

80°C

144°F

H

Ú

10 min.

10 min.

V

1

–

–

V

2

–

–

Explanation of firing parameter symbols

T = Top temperature B = Low temperature

= Dry time

S

t = heat rate of climb

Ú

V

= Vacuum start temperature V2= Vacuum off temperature

1

oduct lines may vary fr

The pr

hold time a top temperatur

=

H

om country to country

.

Some alloy types require pickling after oxide firing

and/or blasting of the oxide layer (observe instruc-

After that,

tions of the alloy manufactur

er).

thoroughly clean the framework with steam or in

the ultrasonic bath. Oxidation can be considered a

'cleaning firing' and is also used to check the

quality of the framework surface.

31

e

Page 32

1stopaquer firing (wash firing)

Extrude the desired amount of the ready-to-use opaquer

paste from the syringe and mix thoroughly. Unlike with

owder/liquid systems, the opaquer paste

p

excessively mixed with opaquer liquid. The opaquer liquid

exclusively used to adjust the consistency of the paste

is

opaquer and to rewet dried opaquer that has been used

several times. Caution: Do not excessively dilute the paste

paquer with the opaquer liquid. Do not dilute the material

o

with water.

Extrude opaquer from the syringe and mix thoroughly.

ust not be

m

Make sure to smooth out any roughness on the metal surface.

e with powder/liquid

Unlik

the opaquer paste

,

systems

must not be excessively

mixed with opaquer liquid.

Apply the first opaquer layer (wash) thinly using a brush.

Smooth out any r

oughness on the metal surface since the

wash is the most important connection between the metal

oxide surface and the ceramic.

Apply wash in a thin layer.

Firing parameters for the 1st opaquer firing

(wash firing)

T

900°C

1652°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

Ú

1 min.

1 min.

450°C

842°F

Important

If furnaces from other manufacturers are used,

s have to be adjusted accor

these par

ameter

V

V

1

2

899°C

1650°F

dingly.

Apply the first opaquer layer (wash) thinly using a brush.

Subsequently

32

, the restoration is fired using the stipulated firing parameters.

Page 33

2ndopaquer firing

Apply the second opaquer layer in such a way that the metal

framework is entirely covered with opaquer, i.e. as much as

ecessary and as little as possible.

n

For each individual situation, five ready-mixed Intensive

Opaquers are available to meet exacting, aesthetic

requirements. The Intensive Opaquers are applied before the

second opaquer firing in the desired areas (e.g. in the

ervical, incisal, occlusal, or palatal area).

c

Subsequently, the restoration is fired using the stipulated firing parameters.

nd

Apply the 2

opaquer layer so that it covers the entire framework.

TIP:

To enhance in-depth fluorescence and to improve the bond

between the ceramic and opaquer, the applied,

unfired opaquer surface may be sprinkled

with the desir

ed shade of IPS d.SIGN

Margin material. Carefully blow off any

excess materials after a short reaction time

of the IPS d.SIGN Mar

gin powder on the

opaquer surface.

Firing parameters for the 2ndopaquer firing

T

890°C

1634°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

Ú

1 min.

1 min.

V

1

450°C

842°F

Important

If furnaces of other manufactur

ers are used,

these

parameters have to be adjusted accordingly. The

temperature increase for the 2nd opaquer firing

C/144 °F / min.

must not be below 80

°

V

889°C

1632°

Fired opaquer layer on the model with detachable segments.

The fired opaquer should have a silky-mat

appearance (egg-shell gloss). The appearance of the

fired opaquer can be compared with the

corresponding material shade guide. If the gloss is

too high, the firing temperature of the 2ndopaquer

firing may be reduced to the firing temperature of

the subsequent fi

2

ring

.

33

Page 34

IPS d.SIGN Opaquer F

For more in-depth fluorescence.

rd

s a 3

A

Apply the IPS d.SIGN Opaquer F as a very thin, third opaquer

layer and fire separately.

Important: dilute the paste opaquer with an adequate

amount of IPS d.SIGN Opaquer Liquid.

Mix with current IPS d.SIGN opaquers:

Mix up to 20 % of Opaquer F with the conventional

IPS d.SIGN Opaquer before the second layer is applied.

Firing parameters for the IPS d.SIGN Opaquer F

ring:

fi

1stshoulder firing

A porcelain shoulder can be fabricated on the metal framework after the opaquer firing if the necessary space has been

rovided during finishing. First, isolate the gypsum die with

p

IPS Margin Sealer. Once this material has dried, apply

IPS Ceramic Separating Liquid.

T

890°C

1634°F

IPS d.SIGN

Opaquer

B

403°C

757°F

S

6 min.

6 min.

Opaquer F

as a thin, third

opaquer layer

t

80°C

144°F

H

Ú

1 min.

1 min.

V

1

450°C

842°F

Up to 20%

mixed Opaquer F

889°C

1632°

V

2

Isolate the model die using IPS Margin Sealer and IPS Ceramic Separating Liquid.

After that, generously apply the IPS d.SIGN Margin material

in the desired tooth shade in the cervical area in the shape of

a drop (i.e. the outer surface of the ceramic material is given

a convex design) and dry. For aesthetically exacting work,

four intensive Margin materials are available. They may either

be mixed or applied alone.

correct

wrong

34

Page 35

ip:

T

When designing a ceramic shoulder (particularly for

bridges), the Margin material may be applied higher up in

the proximal areas. This will reduce interdental shrinkage

uring the subsequent dentin and incisal firings.

d

Apply IPS d.SIGN Margin material generously in the cervical area in the shape of a drop…

Firing parameters for the 1

90°C

8

634°F

1

T

4

7

B

03°C

57°F

S

min.

6

min.

6

Important

f furnaces from other manufacturers are used,

I

these parameters have to be adjusted accordingly.

t

s

shoulder firing

6

1

t

0°C

08°F

H

Ú

min.

1

min.

1

50°C

4

8

V

42°F

V

1

89°C

8

632°F

1

2

... and dry.

Fire the restoration using the firing parameters for the 1

st

Sinter shrinkage of the shoulder after the 1

shoulder firing.

st

shoulder firing.

Carefully remove the framework with the applied and dried shoulder material from the die.

35

Page 36

2ndshoulder firing

After the firing, the shoulder may have to be slightly adjusted

by grinding. The accuracy of fit (sinter shrinkage) has to be

eestablished by means of a 2nd shoulder firing. Use the

r

same Margin materials as for the 1st shoulder firing for that

purpose. First, however, isolate the die again with

IPS Ceramic Separating Liquid. Then, supplement the missing

areas by carefully applying the shoulder material in the space

esulting from the 1

r

optimum accuracy of fit of the ceramic shoulder. After that,

complete the shoulder, dry, carefully remove the framework

from the die, and place it on the firing tray.

st

houlder firing, thus providing

s

Firing parameters for the 2

90°C

8

634°F

1

T

4

7

B

03°C

57°F

S

min.

6

min.

6

Important

f furnaces of other manufacturers are used, these

I

parameters have to be adjusted accordingly.

d

n

shoulder firing

6

1

t

0°C

08°F

H

Ú

min.

1

min.

1

50°C

4

8

V

42°F

V

1

89°C

8

632°F

1

2

A

pply the shoulder material ...

... to reestablish the cervical accuracy of fit of the shoulder.

The restoration is fired using the firing parameters for the 2ndshoulder firing.

ramework with fired ceramic shoulder.

F

Any necessary adjustments of the cer

may be carried out using IPS d.SIGN Margin AddOn material. The use of this material is explained

under 'Corr

ective Firing' on page 47.

amic shoulder

Framework with applied and dried shoulder material.

36

Page 37

1stdentin and incisal firing

Before layering the Dentin and Incisal materials, sealing the

model is a very important step. In this way, the ceramic

aterial is prevented from drying out or sticking to the

m

model. Use the IPS Model Sealer and the IPS Ceramic

Separating Liquid to seal and lubricate the gypsum die and

the adjoining areas of the model.

Use the IPS Model Sealer and the IPS Ceramic Separating Liquid to seal and lubricate the gypsum die and

the adjoining areas of the model.

Five different IPS d.SIGN build-up liquids are available, which

are used according to the individual requirements (see page

18 for a detailed description). Depending on the type of

build-up liquid used, various closing times are possible.

To achieve an optimum bond between the ceramic materials

nd the opaquer surface, apply the ceramic material in small

a

ncrements, particularly in the cervical and interdental areas

i

(for bridges) and slightly roughen it. In this way, the adaption

of the Deep Dentin or Dentin materials on the opaquer

surface is enhanced.

IPS d.SIGN Deep Dentin

In order to achieve true-to-nature shade effects

in areas where space is limited, IPS d.SIGN

eep Dentin materials are used. They are

D

directly applied on the opaquer layer. For

pontics and crowns margins thinning

towards the metal, Deep Dentin material of

the appropriate tooth shade is applied in the

cervical or basal area to enhance the shade.

Recommended drying times:

IPS d.SIGN mixed with

ox. 4–5 minutes

Build-Up Liquid Light

appr

Build-Up Liquid Medium approx. 6–7 minutes

Build-Up Liquid Premium approx. 8–9 minutes

Build-Up Liquid Optimum 1 approx. 6–7 minutes

Build-Up Liquid Optimum 2

approx. 6–7 minutes

The recommended drying times depend on how

much moisture was absorbed by the ceramic and

on whether or not the restorations was predried.

For large restorations, such as bridges and implant superstructures, the number of corrective firings can be reduced

by conducting a pr

or dentin material.

eliminary fi

When using this technique apply the

ring using either Deep Dentin

Deep Dentin or dentin material in areas where maximum

e this material using

sintering shrinkage is anticipated.

st

the 1

dentin and incisal firing parameters.

Fir

Deep Dentin layering to enhance the shade in the cervical area.

IPS d.SIGN Dentin, Incisal, and T

ranspar

ent materials

Next, outline the mamelon area with a layer of

Dentin material. Individually. Another option

is to contour the fully anatomical shape of

the tooth. If this procedure is used, the

contour

own has to be r

ed cr

educed in the

labial, incisal-mesial, and distal areas. The

mamelon shape is, once again, only outlined.

Irrespective of the method used, make sure

ovide adequate space for the

to pr

subsequent application of the Incisal and

Transparent materials.

IPS d.SIGN Essence

IPS d.SIGN Essence ceramic stains

may be added to any IPS d.SIGN

layering materials for

characterization. The mixing ratio

depends on the desired shade

effect of the layering material.

While IPS d.SIGN Stains and Shades ar

e only suitable for

surface characterization, IPS d.SIGN Essence stains may be

used for both intensifying the shade of the layering material

and surface characterization of the fired restoration.

37

Page 38

Labial layering

The fully anatomical shape contoured with dentin material …..

….is reduced to provide adequate space for the subsequent application of the incisal material.

…..using Mamelon materials salmon and light.

Completion of the incisal third using opalescent materials (Effect 1)….

Individual and easy build-up of the incisal area …..

….and Special Incisal or Insert materials

38

.

Page 39

Palatal layering

In the labial area, the restoration is completed using Incisal and ……

…..Transparent materials by means of over-contouring the labial….

The palatal fossa of the restoration is covered with Palatal Dentin material.

The marginal ridges are lined with Dentin material.

….and incisal areas.

Then, the tuberculum and the marginal ridges are covered with Incisal and Transparent materials.

39

Page 40

O

nce the contact points have been provided, the bridge restorations…..

– Basically, a prolonged pre-drying time is

advantageous: The required period is approx.

10 minutes on the cooling tray. If slow-

vaporating liquids (Build-Up Liquid Premium) are used,

e

this drying period is very important

– Provide adequate support for bridges on the firing tray.

Position the firing tray in the furnace only after the head

–

has completed its opening sequence (once the buzzer has

sounded).

Firing parameters for the 1stdentin and incisal firing

T

70°C

8