Page 1

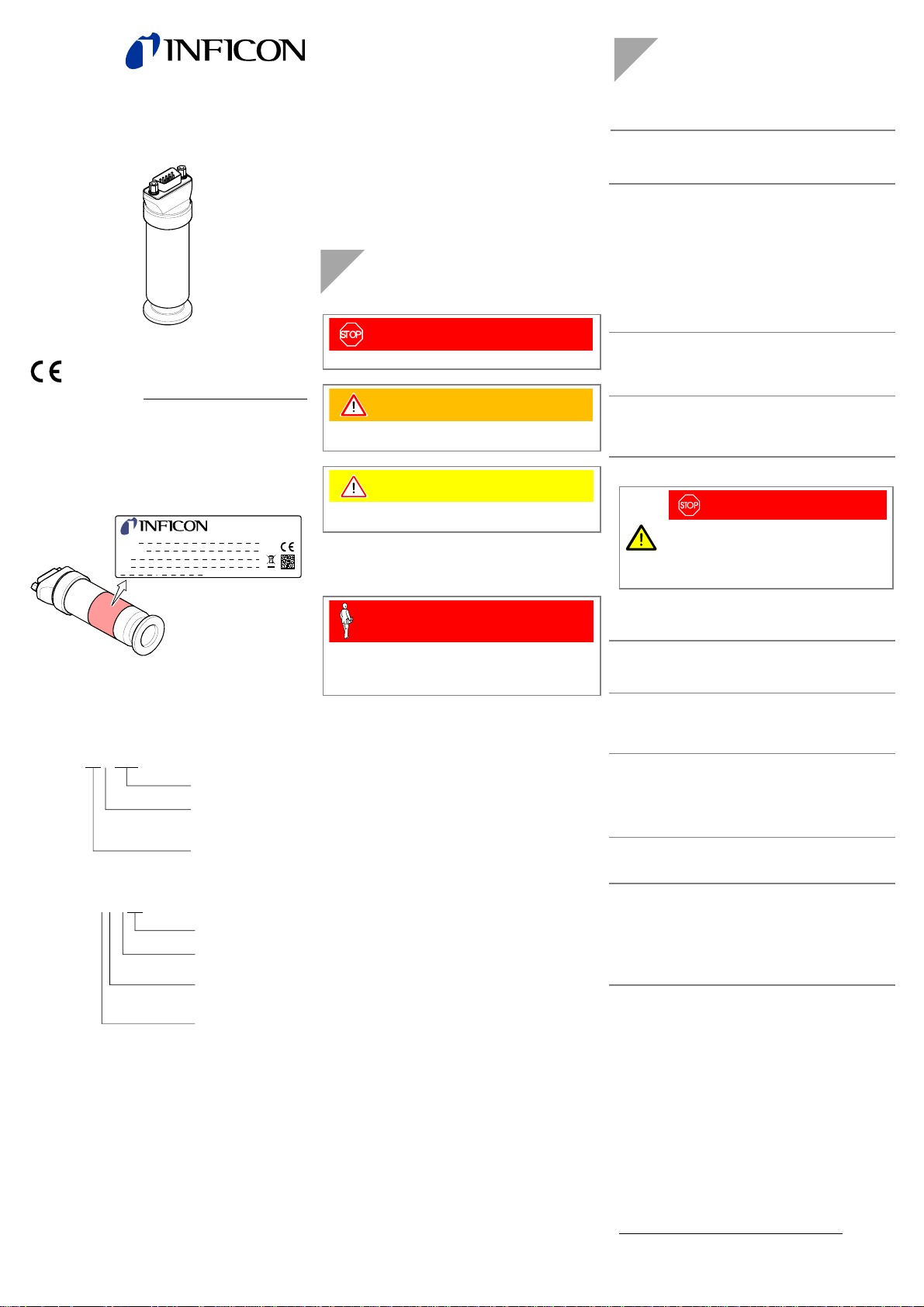

Vacuum Switch

VSA200, VSD200

Operating Manual

Product Identification

In all communications with INFICON, please specify the information on the product nameplate. For convenient reference copy that information into the space provided below.

Validity

This document applies to products with the following part

numbers:

VSA200

3SA1-xxx-xxx0

VSD200

3SD1-Mxx-xxx0

The part number (PN) can be taken from the product nameplate.

If not indicated otherwise in the legends, the illustrations in

this document correspond to the vacuum switch with vacuum

connection DN 16 ISO-KF. They apply to vacuum switches

with other vacuum connection by analogy.

We reserve the right to make technical changes without prior

notice.

All dimensions in mm.

Incl. EC Declaration of Conformity

tina65e1 (2011-01)

Model:

Set point:

PN:

SN:

V W

Set-point value

Flange

Setpoint value

Flange

LI-9496 Balzers

1 ⇒ DN 16 ISO-KF

C

⇒

4 VCR male

4 VCR female

D

⇒

Unit

F5 ⇒ 1000

G6 ⇒ 1100 mbar

Sign

A ⇒ +

B ⇒ –

1 ⇒ DN 16 ISO-KF

C

⇒

D

⇒

Unit

5

⇒

6 ⇒ mbar

4 VCR male

4 VCR female

Torr

Torr

Intended Use

The vacuum switches have been designed for the use in

vacuum systems as absolute pressure switch (VSA200) or as

differential pressure switch (VSD200) in different measurement ranges.

Trademark

VCR® Swagelok Marketing Co.

Safety

Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead

to malfunctions or minor equipment damage.

Personnel Qualifications

Skilled personnel

All work described in this document may only be carried out

by persons who have suitable technical training and the

necessary experience or who have been instructed by the

end-user of the product.

General Safety Instructions

• Adhere to the applicable regulations and take the necessary precautions for the process media used.

Consider possible reactions between the materials and the

process media.

• Adhere to the applicable regulations and take the necessary precautions for all work you are going to do and consider the safety instructions in this document.

• Before beginning to work, find out whether any vacuum

components are contaminated. Adhere to the relevant regulations and take the necessary precautions when handling contaminated parts.

Communicate the safety instructions to all other users.

Liability and Warranty

INFICON assumes no liability and the warranty becomes null

and void if the end-user or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of interventions (modifications, alterations

etc.) on the product

• use the product with accessories not listed in the product

documentation.

The end-user assumes the responsibility in conjunction with

the process media used.

Gauge failures due to contamination or wear and tear, are not

covered by the warranty.

Technical Data

Measurement range

VSA200 (absolute)

VSD200 (relative to atm) -100 … +50 mbar, Torr

Setpoint (setting range)

VSA200

VSD200 -99 … +46 mbar, Torr

Switching contact changeover contact, floating

Hysteresis 2 % above setpoint

Contact rating

Switching

characteristics

1)

Accuracy ≤0.5 % F.S.

Resolution 10 bit

Switching frequency 0.5 Hz

Response time ≤45 ms

Temperature effect on zero

and span

Long-term stability ≤±0.5 % F.S. / a

Effect supply voltage ≤±0.005 % F.S. / V

Starting time 1 s

Service live

Electronic

Relay

Supply

DANGER

The vacuum switch may only be connected to

power supplies, instruments or control devices

that conform to the requirements of a grounded

extra-low voltage (SELV). The connection to the

vacuum switch has to be fused.

Supply voltage +14 … +30 VDC

Current consumption ≤15 mA

Power consumption ≤0.5 W

Electrical connection D-Sub, 9 pin, male

Cable 6 pin plus shielding

Cable length ≤100 m (8×0.14 mm

Materials exposed to

vacuum

Housing

Diaphragm

Internal volume

DN 16 ISO-KF

®

4 VCR

Admissible pressure (abs.)

Admissible temperatures

VSA200

VSD200

Operation

Storage

Relative humidity ≤80 at temperatures up to

Use indoors only, altitude up to

Mounting orientation any

Degree of protection IP40

1100 mbar (F.S.)

1000 Torr (F.S.)

30 … 1060 mbar

20 … 970 Torr

30 V, 1 A DC

125 V, 0.3 A AC

Low Trip Point

≤±0.02 % F.S. / 1K

8

>1×10

cycles

25'000 h

6

>3×10

cycles

1.4571, 1.4404

1.4435

3

2.81 cm

3

0.93 cm

5 bar

2 bar

0 … +70 °C

–40 … +80

≤+31 °C, decreasing to 50

at +40 °C

4000 m NN

2

)

1)

The switching characteristics and the setpoint can be

programmed via the serial interface (pin 6, 7, 8).

Page 2

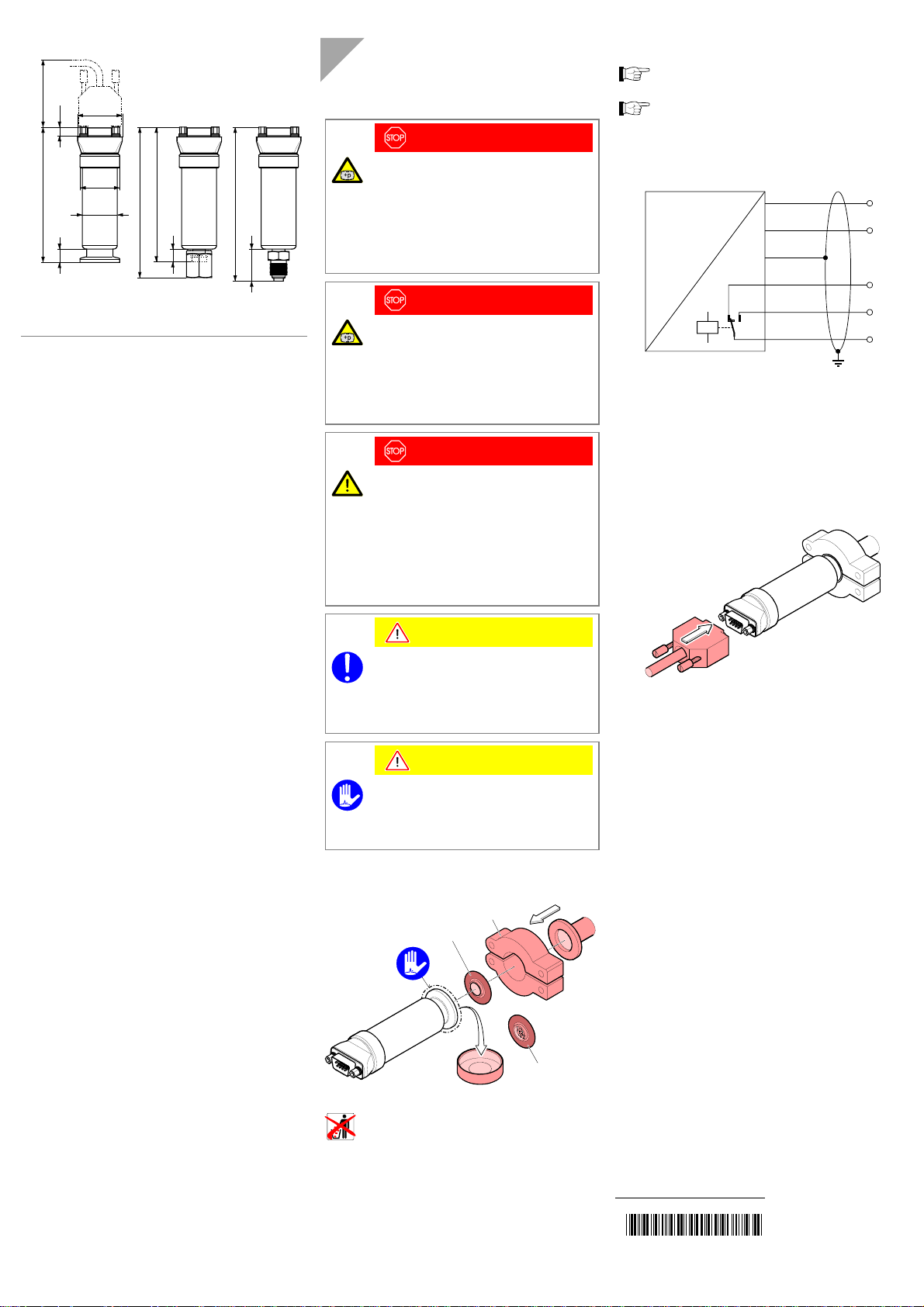

Dimensions [mm]

≈60

5.5

34

ø30

101.5

ø26.5

117

104.5

10

DN 16 ISO-KF

Weight

9

4 VCR

female

≈140 g

Installation

Vacuum Connection

DANGER

DANGER: overpressure in the vacuum system

>1 bar

Injury caused by released parts and harm

caused by escaping process gases can result if

117.5

24.2

4 VCR

male

clamps are opened while the vacuum system is

pressurized.

Do not open any clamps while the vacuum system is pressurized. Use the type of clamps which

are suited to overpressure.

DANGER

DANGER: overpressure in the vacuum system

>2.5 bar

KF connections with elastomer seals (e.g.

O-rings) cannot withstand such pressures. Process media can thus leak and possibly damage

your health.

Use O-rings provided with an outer centering

ring.

DANGER

DANGER: protective ground

Incorrectly grounded products can be extremely

hazardous in the event of a fault.

The gauge must be electrically connected to the

grounded vacuum chamber. This connection

must conform to the requirements of a protective

connection according to EN 61010:

®

• VCR

connections fulfill this requirement.

• For gauges with a KF connection, use a con-

ductive metallic clamping ring.

Caution

Power Connection

Make sure the vacuum connection is properly made

(→ "Vacuum Connection").

Before connecting or disconnecting the product, turn

off the control system.

n If no sensor cable is available, make one according to

the following diagram.

p

9

U

Pin 1 Supply common, GND

Pin 2 Supply +14V ... 30 V

Pin 3 Relay n.o.

Pin 4 Relay common

Pin 5 Relay n.c.

Pin 6 Internal common RxD

Pin 7 Internal common TxD

Pin 8 Internal common (com)

Pin 9 Housing (Chassis Ground)

o Connect the cable to the vacuum switch.

2

UB+

1

–

U

B

5

NC

3

NO

4

C

Caution: vacuum component

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

Remove the protective lid and install the product to the vacuum system.

Clamp

Seal with centering ring

Keep the protective lid.

or

Seal with

centering ring

and filterProtective lid

Original: German tina65d1 (2011-01)

t i na65e1

(2011-01)

Page 3

Operation

The product is ready for operation as soon as it has been

installed.

The gauge is factory calibrated while "standing upright". Due

to changing the mounting orientation, a low zero drift could

occur (0.05 % F.S.).

Setpoint, Switching Characteristics

The setpoint can be read and set to any pressure within the

setting range of the vacuum switch with the communication

software (

→ [1]).

The switching characteristics of the setpoint can be programmed with the communication software (

Low Trip Point (default)

If the pressure in the vacuum system is lower than the setpoint, the relay is closed.

Measurement signal

(Pressure p)

Setpoint

Off

→ [1]).

t

n

e

m

e

r

u

s

a

e

M

Hysteresis

(2% of threshold)

Threshold value

OffOn

e

u

l

a

v

Time t

Deinstallation

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

n Vent the vacuum system.

o Put the vacuum switch out off operation.

p Unplug the sensor cable.

Before connecting or disconnecting the pro-

duct, turn off the control system.

Maintenance, Repair

Under clean operating conditions, the product requires no

maintenance.

The product is factory calibrated while "standing upright". Due

to long time operation, contamination, or operation in other

mounting orientation a zero adjustment may become

necessary.

We recommend returning the product to your local

INFICON service center for service.

Vacuum switch failures due to contamination or

wear and tear are not covered by the warranty.

INFICON assumes no liability and the warranty becomes null

and void if any repair work is carried out by the end-user or

third parties.

Returning the Product

WARNING

WARNING: forwarding contaminated products

Contaminated products (e.g. radioactive, toxic,

caustic or microbiological hazard) can be detrimental to health and environment.

Products returned to INFICON should preferably

be free of harmful substances. Adhere to the forwarding regulations of all involved countries and

forwarding companies and enclose a duly completed declaration of contamination

*)

Form under www.inficon .com

Products that are not clearly declared as "free of harmful substances" are decontaminated at the expense of the customer.

Products not accompanied by a duly completed declaration of

contamination are returned to the sender at his own expense.

*)

.

q Remove the vacuum switch from the vacuum system

and install the protective lid.

Schutzkappe

Page 4

Disposal

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

WARNING

N

WARNING: substances detrimental to the environment

Products or parts thereof (mechanical and electric components, operating fluids etc.) can be detrimental to the environment.

Dispose of such substances in accordance with

the relevant local regulations.

Separating the components

After disassembling the product, separate its components

according to the following criteria:

• Contaminated components

Contaminated components (radioactive, toxic, caustic, or

biological hazard etc.) must be decontaminated in accordance with the relevant national regulations, separated

according to their materials, and disposed of.

• Other components

Such components must be separated according to their

materials and recycled.

Accessories

Ordering number

Communication adapter with USB

connector (2 m)

303-336

Further Information

[1] www.inficon.com

Communication software VSA200, VSD200

EC Declaration of Conformity

Products

We, INFICON, hereby declare that the equipment mentioned below complies with the provisions of the Directive relating to electromagnetic compatibility 2004/108/EC.

Vacuum Switch

VSA200, VSD200

Standards

Harmonized and international/national standards and specifications:

• EN 61326-1:1997 + A1:1998 + A2:2001 + A3:2003

(EMC requirements for electrical equipment for measurement,

control and laboratory use)

Manufacturer / Signatures

INFICON AG, Alte Landstraße 6, LI-9496 Balzers

17 January 2010 17 January 2010

Dr. Urs Wälchli

Managing Director

Alex Nef

Product Manager

LI–9496 Balzers

Liechtenstein

Tel +423 / 388 3111

Fax +423 / 388 3700

reachus@inficon.com

www.inficon.com

Loading...

Loading...