Page 1

Operating

M

a

r

m

a

n

5

l

G

o

n

Incl. EU Declar

anual

ation of Confor

ity

Singl

Cont

VGC50

e-Ch

ol U

1, VGC

nne

its

02, V

, Tw

C503

-Channel & Th

ree-Chan

el

tina96e1-b (20

16-12)

1

Page 2

Prod

u

V

f

n

T

T TIf

f

o

V

U

W

A

c

-

-

-

e

t

t

l

g

e

N

c

o

m

m

t

5

o

e

a

a

-

C

-

t

h

h

n

a

e

n

U

c

t

s

5

t

o

c

m

a

a

o

t

alid

ct Identi

ity

ication

I

all communi

n

meplate:

his document

398

398

398

he part numb

ations with I

Spe

applies to pr

481

482

483

er (Mod.-No.)

FICON, plea

imen namepl

ducts with p

(VGC501, Single

(VGC502, Two-

(VGC503, Three

can be found

e specify th

te

rt numbers:

Channel Control

hannel Control U

Channel Control

on the produ

information

Unit)

nit)

Unit)

t nameplate.

n the produc

his manual is

your unit doe

uipped with

e

not indicated

I

rrespond to

c

GC501 (Sing

nit) by analo

e reserve th

ll dimensions

based on fir

s not work as

he above fir

otherwise in

he unit VGC

e-Channel C

y.

right to mak

are indicated

ware version

described in

ware version

he legends, t

03 (Three-C

ntrol Unit) a

technical ch

in mm.

V1.04.

his documen

(→ 58).

e illustration

annel Control

d to the VGC

nges withou

, please che

in this docu

Unit). They

02 (Two-Ch

prior notice.

k that it is

ent

pply to the

nnel Control

2

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 3

Intended Use

Scope of Delivery

The Control Units VGC501, VGC502 and VGC503 are used together with

INFICON gauges for total pressure measurement. All products must be operated in

accordance with their respective operating manuals.

The scope of delivery consists of the following parts:

1× Control Unit

1× Power cord (country-specific)

1× Rubber bar

2× Rubber feet

4× Collar screws

4× Plastic sleeves

1× CD-ROM (manuals, tools, …)

1× EU Declaration of Conformity

1× Installation Manual

tina96e1-b (2016-12) VGC501_VGC502_VGC503.om 3

Page 4

Contents

Product Identification 2

Validity 2

Intended Use 3

Scope of Delivery 3

Contents 4

1 Safety 6

1.1 Symbols Used 6

1.2 Personnel Qualifications 6

1.3 General Safety Instructions 7

1.4 Liability and Warranty 7

2 Technical Data 8

3 Installation 12

3.1 Installation, Setup 12

3.1.1 Rack Installation VGC501 12

3.1.2 Rack Installation VGC502, VGC503 15

3.1.3 Installation in a control panel 16

3.1.4 Use as Desk-Top Unit 17

3.2 Mains Power Connector 18

3.3 Gauge Connectors CH 1, CH 2, CH 3 19

3.4 CONTROL Connector VGC501 21

3.5 CONTROL Connector VGC502, VGC503 22

3.6 RELAY Connector VGC502, VGC503 22

3.7 Interface Connector USB Type B 24

3.8 Interface Connector USB Type A 24

3.9 Interface Connector Ethernet 25

4 Operation 26

4.1 Front panel 26

4.2 Turning the VGC50x On and Off 28

4.3 Operating Modes 28

4.4 Measurement Mode 31

4.5 Parameter Mode 33

4.5.1 Switching Function Parameters 34

4.5.2 Gauge parameters 38

4.5.3 Gauge Control 46

4.5.4 General Parameters 50

4.5.5 Test Parameters 58

4.5.6 Data Logger Mode 61

4.5.7 Parameter Transfer Mode 63

5 Communication Protocol (Serial Interface) 65

5.1 Data Transmission 66

5.2 Communication Protocol 67

5.3 Mnemonics 68

5.4 Measurement Mode 70

5.5 Switching Function Parameters 76

5.6 Gauge Parameters 77

5.7 Gauge Control 84

5.8 General Parameters 85

5.9 Data Logger Parameters 91

5.10 Parameter Transfer 92

5.11 Test Parameters 92

5.12 Further 97

5.13 Example 98

6 Maintenance 99

7 Troubleshooting 100

8 Repair 101

9 Accessories 101

10 Storage 101

11 Disposal 101

4 tina96e1-b (2016-12) VGC501_VGC502_VGC503.om

Page 5

Appendix 102

A: ConversionTables 102

B: Firmware Update 103

C: Ethernet Configuration 106

C 1: Connect the VGC50x to a Network 106

C 2: Connect the VGC50x to a Computer 107

C 3: Ethernet Configuration Tool 107

D: Literature 110

ETL Certification 112

EU Declaration of Conformity 113

For cross-references within this document, the symbol (→ XY) is used; for cross-

references to further documents listed under ‘Literature’, use is made of the symbol

(→ [Z]).

tina96e1-b (2016-12) VGC501_VGC502_VGC503.om 5

Page 6

1

S

S

S

F

P

U

r

b

l

s

a

I I I

m

A

h

i

A

n

W

n

a

n

e

s

n

e

e

r

t

a

e

d

y

y

y

a

n

o

n

o

y

D

m

n

n

l

e

d

n

o

h

o

1.1

afety

ymbols

ymbols for

sed

esidual risk

D

NGER

urther sym

ols

nformation o

nformation o

nformation o

inor equipm

The

The

The

Pre

preventing

ARNING

preventing

C

ution

correct han

ent damage.

lamp / displa

lamp / displa

lamp / displa

s the key (ex

ny kind of ph

xtensive equi

ling or use.

is lit.

flashes.

is off.

mple: para

sical injury.

pment and e

isregard can

eter key).

vironmental

lead to malfu

amage.

ctions or

1.2

ersonne

Qualific

tions

Do

<

……> Lab

Skill

ll work desc

ave suitable

nstructed by

ot press any

ling

d person

ibed in this d

technical trai

he end-user

key.

el

cument may

ing and the

f the product

only be carri

ecessary exp

d out by pers

erience or w

ns who

o have been

6

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 7

C

1.3 Gen

e

u

n

y

W

c

o

t

e

t

E

a

o

R

w

d

e

t

e

i

f

o

n

g

i

d

e

a

n

t

m

(

s

e

y

n

t

i

o

s

,

p

i

e

n

e

g

u

t

n

r

e

s

p

d

a

t

o

Instr

ral Safet

ctions

Adhere

work yo

to the applic

u are going t

ble regulatio

do and cons

s and take th

der the safet

necessary

instructions

recautions fo

n this docum

all

nt.

DANGER

Disco

necting dev

ice

The dis

user.

To disc

DANGE

Contact

introduce

Make sur

trate into

onnecting d

nnect the un

: mains volta

ith live parts

or any liqui

no objects

he equipmen

vice must be

t from the m

e

s extremely h

s penetrate i

nter through

.

readily identif

ins supply, y

azardous wh

to the unit.

he louvers a

iable by and

u must unplu

n any object

d no liquids

asily reache

the mains c

are

ene-

by the

ble.

1.4 Liabi

lity and

arranty

Disconn

acc. to

Commu

INFICO

user or

• disre

• use t

• mak

• use t

men

ecting device

N 61010-1

nicate the sa

N assumes n

third parties

gard the infor

he product in

any kind of i

he product wi

ation.

ety instructio

liability and

mation in this

a non-confor

nterventions

th accessorie

s to all other

he warranty i

document

ing manner

modifications

not listed in

users.

s rendered n

, alterations e

the correspo

ll and void if

c.) on the pr

ding product

he end-

duct

docu-

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

7

Page 8

2 Technical Data

Mains specifications

Ambience

Gauge connections

Gauge supply

Voltage 100 … 240 V (ac) ±10%

Frequency 50 … 60 Hz

Power consumption

VGC501

VGC502

VGC503

≤45 W

≤65 W

≤90 W

Overvoltage category II

Protection class 1

Connection European appliance connector IEC 320 C14

Temperature

Storage

Operation

–20 … +60 °C

+ 5 … +50 °C

Relative humidity ≤80% up to +31 °C,

decreasing to 50% at +40 °C

Use indoors only

max. altitude 2000 m NN

Pollution degree II

Degree of protection IP30

Number

VGC501

VGC502

VGC503

Gauge connections per channel

1

2

3

RJ45 (FCC68), 8-pin (→ 20)

D-Sub, 15-pin, female (→ 20)

(connected in parallel)

Compatible gauges

Pirani PSG400, PSG400-S, PSG100-S, PSG101-S,

PSG500, PSG500-S, PSG502-S, PSG510-S,

PSG512-S, PSG550, PSG552, PSG554

Pirani / Capacitance PCG400, PCG400-S, PCG550, PCG552,

PCG554

Cold cathode PEG100, MAG500, MAG504

Cold cathode / Pirani MPG400, MPG401, MPG500, MPG504

Hot ionization / Pirani BPG400, BPG402, HPG400

Capacitance CDG020D, CDG025, CDG025D,

CDG025D-X3, CDG045, CDG045-H,

CDG045D, CDG045D2, CDG045Dhs,

CDG100, CDG100D, CDG100D2,

CDG100Dhs, CDG160D, CDG200D

Hot ionization / Capacitance /

BCG450

Pirani

Voltage +24 V (dc) ±5%

Ripple <±1%

Current 0 … 1 A (per channel)

Power 25 W (per channel)

Fuse protection 1.5 A (per channel) with PTC element, self-

resetting after turning the unit off or disconnecting the gauge. The supply conforms to the

grounded protective extra low voltage requirements.

8 tina96e1-b (2016-12) VGC501_VGC502_VGC503.om

Page 9

g

Operation

Measurement values

Switching functions

Switching function relays

Error signal

Front panel

VGC501

VGC502, VGC503

via 3 keys

via 4 keys

Remote control via USB type B interface

via Ethernet interface

Measurement ranges

Measurement error analog

Gain error

depending on gauges (→ [1] … [27])

≤0.01% F.S. (typical)

≤0.10% F.S. (over temperature range, time)

Offset error ≤0.01% F.S. (typical)

≤0.10% F.S. (over temperature range, time)

Measurement rate analog ≥100 / s

Display rate ≥10 / s

Filter time constant

Slow

Normal

Fast

= 0.02 Hz)

8 s (f

g

800 ms (f

160 ms (f

= 0.2 Hz)

g

= 1 Hz)

Measurement units mBar, hPa, Torr, Pa, Micron, V

Offset correction for linear gauges

Calibration factor 0.10 … 10.00

A/D converter resolution 0.001% F.S.

(the measurement values of BPG, HPG, BCG

and CDGxxxD are transmitted digitally)

Number

VGC501

VGC502

VGC503

2

4 (user-assignable)

6 (user-assignable)

Reaction delay ≤10 ms, if switching threshold close to meas-

urement value (for larger differences consider

filter time constant)

Adjustment range

depending on gauge (→ 36, 37)

Hysteresis ≥1% F.S. for linear gauges,

≥10% of measurement value for logarithmic

gauges

Contact type floating changeover contact

Load max. 60 V(dc), 30 W (ohmic)

30 V(ac), 1 A (ohmic)

Service life

Mechanical

Electrical

Contact positions

Connector

VGC501 (CONTROL)

8

cycles

1×10

5

1×10

cycles (at max. load)

→ 23

D-Sub appliance connector, male, 15-pin

(pin assignment → 21)

VGC502, VGC503 (RELAY) D-Sub appliance connector, female, 25-pin

(pin assignment → 22)

Number 1

Reaction time ≤10 ms

tina96e1-b (2016-12) VGC501_VGC502_VGC503.om 9

Page 10

Error signal relay

Analog outputs

Recorder output

(VGC502, VGC503 only)

USB Type A interface

USB Type B interface

Ethernet interface

Contact type floating normally open contact

Load max. 60 V(dc), 0.5 A, 30 W (ohmic)

30 V(ac), 1 A (ohmic)

Service life

Mechanical

Electrical

Contact positions

Connector

VGC501 (CONTROL)

8

cycles

1×10

5

1×10

cycles (at max. load)

→ 23

D-Sub appliance connector, male, 15-pin

(pin assignment → 21)

VGC502, VGC503 (RELAY)

D-Sub appliance connector, female, 25-pin

(pin assignment → 22)

Number

VGC501

VGC502

VGC503

1

2 (1 per channel)

3 (1 per channel)

Voltage range –5 … +14.5 V (dc)

If no gauge is connected, +14.5 V (dc) is output

Deviation from display value ±20 mV

Output resistance

Measuring signal vs. pressure

CONTROL connector

VGC501

<50 Ω

depending on gauge (→ [1] … [27])

D-Sub appliance connector, male, 15-pin

(pin assignment → 21)

VGC502, VGC503 D-Sub appliance connector, male, 9-pin

(pin assignment → 22)

Number

1

Voltage range 0 … +10 V (dc)

Resolution 1 mV

Accuracy ±20 mV

Internal resistance

<50 Ω

Measuring signal vs. pressure programmable

CONTROL connector D-Sub appliance connector, male, 9-pin

(pin assignment → 22)

Protocol FAT file system

file handling in ASCII format

Protocol ACK/NAK, ASCII with 3-character mnemonics

Data format bi-directional data flow, 1 start bit, 8 data bits,

1 stop bit, no parity bit, no handshake

Transmission rate 9600, 19200, 38400, 57600, 115200

Protocol ACK/NAK, ASCII with 3-character mnemonics,

Data format bi-directional, 1 start bit, 8 data bits, 1 stop bit,

no parity bit, no handshake

Transmission rate 9600, 19200, 38400, 57600, 115200

IP Address

DHCP (default) or manual setting (→ 106)

MAC Address readable via "MAC" parameter

10 tina96e1-b (2016-12) VGC501_VGC502_VGC503.om

Page 11

C

Dimens

V

1

V

2

o

1

2

3

o

a

ions [mm]

GC50

Use

Weight

GC50

For inc

VGC50

VGC50

VGC50

, VGC503

rporation int

1

a rack or control panel or

0.85 kg

1.10 kg

1.14 kg

s a desk-top unit

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

11

Page 12

n

o

a

VG

T

TDw

n

e

e

t

mope

i

o

h

sacc

k

u

a

p

n

h

o

G

t

u

a

a

e

G

c

e

a

a

d

G

p

b

u

n

s

t

a

g

g

w

h

o

n

s

a

m

n

a

o

p

c

a

p

a

b

i

C

o

-

3 I

3.1 I

3.1.1

stallati

nstallatio

Rack Inst

n

n, Setup

llation

C501

he unit is suit

d

sk-top unit.

he unit is des

IN 41 494. F

ith it.

Th

unit may onl

trai

ning and the

the

end-user of t

d for incorp

Pu

ting a produc

tre

ely hazardo

ration and m

igned for inst

r this purpos

Skilled

DAN

ersonnel

y be installed

ecessary ex

e product.

ration into a 1

ER

which is visi

s. If the prod

ke sure it is

llation into a

, four collar

by persons

erience or w

9" rack or a c

ly damaged i

ct is visibly d

ot inadverte

9" rack chas

crews and pl

ho have suit

o have been

ontrol panel

nto operation

amaged do n

tly put into o

sis adapter a

stic sleeves

ble technical

instructed by

r for use as a

can be ex-

ot put it into

eration.

cording to

re supplied

Guide rail

I

order to red

b

ly equip the r

DA

NGER: prote

If t

e product is i

cla

s of the rack

ording to the

Ta

e appropriat

the

protection cl

ce the mech

ck chassis a

DAN

ER

tion class of

nstalled in a r

(protection a

EN 60204-1 r

measures fo

ss.

nical strain o

apter with a

uide rail

he rack

ck, it is likely

ainst foreign

gulations for

the rack to

the front pa

uide rail.

to lower the

bodies and w

switching ca

eet the spec

el of the VG

rotection

ter) e.g.

inets.

fications of

50x, prefera

12

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 13

C

Mou

n

a

S

h

c

e

e

c

a

d

d

l

c

b

a

a

t

t

,

m

ting height

Heig

t 2

Rack instal

ation

Height 3

Heig

ht 2 rack ch

Height

ssis adapte

2 rack chassi

r

s adapter (→

ecure the ra

Th

be

Ra

Hei

, 13)

k chassis ad

maximum a

xceeded an

k chassis ada

ht 2

Height 3

pter in the ra

missible am

the air circul

ter

rack chassis

ck frame.

ient tempera

tion must no

dapter (→

ure (→ 8)

be obstructe

14)

ust not

d.

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

13

Page 14

w

e

w

o

w

h

1

C

r

c

p

m

a

c

a

c

a

k

r

e

d

r

A

p

a

t

v

e

m

h

p

e

e

s

l

o

t

Height 3 rack chassis a

dapter

Slide th

… and fa

supplied

F

or incorporati

o collar scre

t

Secure

VGC501 int

sten the VG

with it.

n into a 19"

s and plasti

the rack ada

o the adapter

501 to the ra

ack chassis

sleeves) is a

ter in the rac

…

k chassis ad

dapter, heigh

ailable (Acc

frame.

pter using th

t 3, an adapt

ssories →

screws

r panel (incl.

101).

Mount t

VGC50

The maxi

be exceed

Rack ch

Height 3

he adapter p

1 using the s

um admissib

ed and the ai

ssis adapte

nel as upper

rews supplie

dapter

(Height 2

e ambient te

circulation m

xtension to t

with the ada

anel

to height 3)

perature (→

ust not be ob

he front pane

pter panel.

8) must no

tructed.

of the

14

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 15

C

k

VGC

o

5

S

u

t

4

r

b

C

h

f

p

R

d

h

g

c

e

r

n

c

2

s

s

a

r

H

d

k

c

f

a

r

p

a

w

s

h

h

t

n

p

t

n

5

lide the VG

501 into the r

ck chassis a

eight 3

dapter …

3.1.2 Rac

Guid

Installati

502, VGC

e rail

n

03

The uni

DIN 41

with it.

In orde

prefera

and fasten t

…

pplied with th

s

is designed

494. For this

DANGE

If the pro

class of t

accordin

Take app

the prote

to reduce th

ly equip the

e adapter pa

e VGC501.

or installation

urpose, four

DANGER

: protection cl

uct is installe

e rack (prote

to the EN 60

opriate mea

tion class.

mechanical

ack chassis

el to the rac

into a 19" ra

collar screws

ass of the rac

in a rack, it

tion against

04-1 regulati

ures for the r

train on the f

dapter with a

chassis ada

k chassis ad

and plastic sl

k

is likely to lo

oreign bodie

ons for switc

ck to meet t

ront panel of

guide rail.

ter using the

pter accordi

eves are su

er the protec

and water) e

ing cabinets.

e specificatio

he VGC502/

screws

g to

plied

ion

.g.

s of

03,

Guide

il

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

15

Page 16

Height 3 ra

c

o

t

e

w

h

saccTak

h

p

m

p

5

G

c

e

a

n

a

k

r

k

h

t

a

g

m

r

m

p

i

m

w

m

n

t

s

n

p

a

b

i

s

e

d

e

o

t

s

k chassis a

dapter

Secure

the rack ada

ter in the rac

frame.

Slide th

The maxi

be exceed

Rack ch

Height 3

VGC502/50

um admissib

ed and the ai

ssis adapte

3 into the rac

e ambient te

circulation m

chassis ada

perature (→

ust not be ob

pter …

8) must no

tructed.

3.1.3

Installati

panel

VGC501

n in a con

rol

… and fa

supplied

F

or mounting t

sten the ada

with the VGC

DA

NGER: prote

e product is i

If t

cla

s of the rack

ording to the

e appropriat

the

protection cl

e VGC501 i

DAN

ter panel to t

02/503.

ER

tion class of

nstalled in a r

(protection a

EN 60204-1 r

measures fo

ss.

to a control p

The

ture (

circul

e rack chass

he rack

ck, it is likely

ainst foreign

gulations for

the rack to

anel, the follo

aximum ad

8) must

tion must no

s adapter usi

to lower the

bodies and w

switching ca

eet the spec

wing cut-out i

issible ambi

ot be excee

t be obstruct

g the screw

rotection

ter) e.g.

inets.

fications of

required:

nt tempera-

ed and the ai

d.

r

16

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 17

C

C

0

T

u

S

u

u

p

S

v

c

C

t

C

c

C

t

s

c

o

t

p

c

n

u

)

m

p

n

e

G

…

i

e

b

G

a

u

r

r

d

p

VG

502, VGC5

3

For red

support

…

For mo

quired:

cing the me

the unit.

lide the VG

and secure i

nting the VG

hanical strain

501 into the

with four M3

502/503 int

on the front

ut-out of the

or equivalent

a control pa

anel of the V

ontrol panel

screws.

el, the follow

C501, prefe

ng cut-out is

ably

e-

For red

bly sup

cing the me

ort the unit.

lide the VG

hanical strain

502/503 into

The maxim

ture (→ 8

circulation

on the front

he cut-out of

m admissibl

) must not be

ust not be o

anel of the V

the control p

ambient tem

exceeded an

structed.

C502/503,

nel …

pera-

the air

refera-

…

and secure i

3.1.4 Use

tina96e1-b (2016-12) VG

as Desk-

501_VGC502_VGC503.om

op Unit

The VG

adhesi

C50x may al

e rubber feet

with four M3

o be used as

and a slip-on

or equivalent

a desk-top u

rubber bar ar

screws.

it. For this p

supplied wit

rpose, two se

h it.

lf-

17

Page 18

e

T

w

f

e

s

oeveUsepow

h

p

s

v

o

r

1

d

e

G

o

n

r

e

o

o

d

t

o

h

c

e

t

c

a

e

o

m

o

a

n

t

m

e

u

u

n

a

i

c

d

o

e

)

3.2 Mains Power Conn

ctor

Stick th

… and

he unit is sup

ith your syste

The s

fuse-p

two supplie

lip the suppli

DA

NGER: line v

rrectly groun

Inc

nt of a fault.

only a 3-co

er connecto

gro

und. The prot

out protectiv

wit

plied with a p

m, use your

cket must be

rotected with

0 A

max

DAN

rubber feet

d rubber bar

ER

ltage

ded products

ductor power

may only be

ection must n

ground.

wer cord. If t

wn, suitable

the rear par

Select a lo

maximum

exceeded (

(→ 8).

onto the bott

can be extre

cable with pr

lugged into

t be nullified

e mains con

able with pro

t of the botto

ation where t

mbient temp

e.g. due to s

m edge of th

ely hazardo

tective grou

socket with

by an extens

ector is not

ective groun

plate …

he admissibl

rature is not

n irradiation)

front panel.

s in the

d. The mains

protective

on cable

ompatible

(3×1.5 mm

3

.

I

the unit is in

nd turned on

a

talled in a sw

ia a central

tching cabin

istributor.

t, the mains v

oltage should

be supplied

18

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 19

C

Groun

d

g

,

c

1

r

t

v

n

i

n

h

a

a

M

o

R

g

s

n

1

n

r

a

e

b

H

v

0

G

p

p

r

t

s

c

e

nth

epr

o

a

n

o

c

c

(

m

e

e

u

m

d

d Connectio

n

On the

connec

stand.

ear of the un

ed via a grou

t is a screw e

d conductor,

abling the V

e.g. with the

C50x where

protective gr

necessary to

und of the pu

be

p

3.3 Gau

CH 2

e Conne

CH 3

tors CH

,

Protecti

groundi

ve

ng

For eac

h channel the

parallel:

• one

• one

RJ45 applian

D-Sub applia

Connect t

cable set

(electrom

(→ 8).

re are two co

ce connector,

ce connecto

e gauge to th

vailable from

gnetic comp

Caution

Do

(int

nections ava

female, 8-pin

, female, 15-

e CH 1, CH 2

us (

→

sales li

tibility) senso

ot unfasten

is screw

rnal ground

rotection)

ilable which

(CH A)

in (CH B)

or CH 3 con

terature) or y

cable. Use

re connected

ector via a s

ur own, scre

ompatible ga

in

nsor

ned

ges

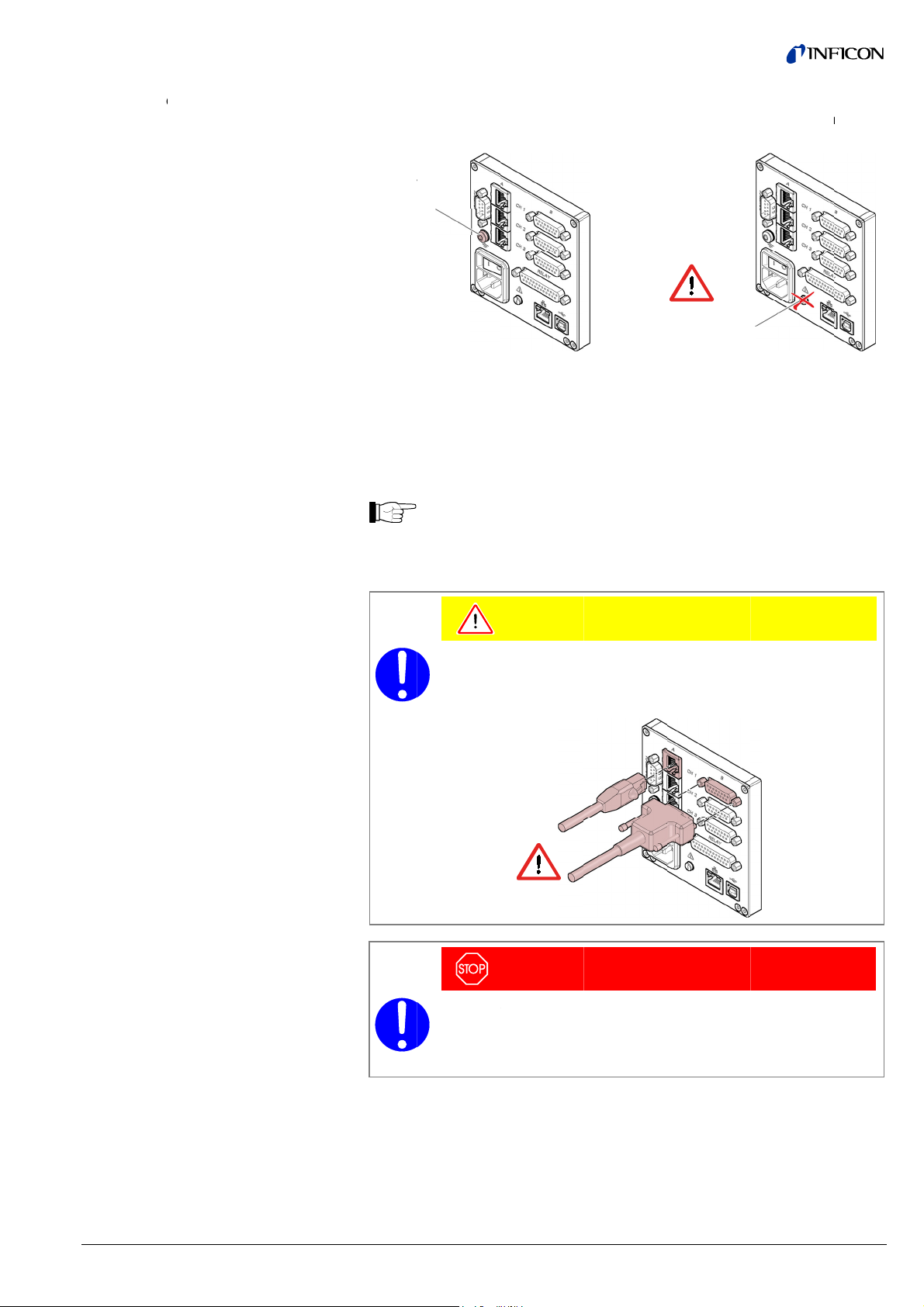

Caution:

Only one

(connecti

damaged

ultiple conn

sensor may

n CH A or C

.

ction

e connected

B). Otherwi

o each of the

e the conne

channels

ted sensors

ay be

only at once

DANGER

DANGE

Accordin

hazardou

Only con

: Hazardous

to EN 6101

.

ect a protecti

oltage

, voltages ex

e low voltag

eeding 30 V

(PELV).

ac) or 60 V (

c) are

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

19

Page 20

P

C

in assignm

e

A

e

A

e

H

P

P

n

n

p

p

n

n

n

uHV_HV_

n

n

n

uHV_

p

p

n

p

nRxD

e

e

i

i

0

0

o

H 3

pplianc

pplianc

nt CH 1, C

socket RJ4

socket D-S

2,

5

ub

in assignmen

ppliance con

a

Pin Sig

1

2

3

4

5

6

7

8

in assignmen

ppliance con

a

t of the femal

ectors:

al

Sup

ply

ply common

Sup

Sig

al input

Ide

tification

Sig

al common

us

Stat

L

H / HV_EMI

t of the femal

ectors:

8-pin RJ45

+24 V (dc)

GND

(measuring s

15-pin D-Su

gnal 0 … +1

b

V (dc))

Pin Sig

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

al

status

EMI

al input

Sig

us

Stat

H / HV_EMI

ply common

Sup

n.c.

Deg

as

Sup

ply

n.c.

tification

Ide

ply

Sup

Sig

al common

TxD

ssis

Cha

(measuring s

GND

+24 V (dc)

+24 V (dc)

gnal 0 … +1

V (dc))

20

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 21

C

3.4 CON

T

VGC5

s

n

n

t

i

c

s

o

g

h

R

g

s

n

e

p

p

u

rthr

n

f

G

o

u

rthr

G

g

m

e

l

G

c

u

v

0

+

w

f

u

e

w

f

1

u

a

o

n

c

e

f

t

e

a

(

s

h

i

s

o

d

s

h

d

t

s

d

e

p

m

ROL Co

01

nector

This co

the floa

for cold

nector allow

ing contacts

cathode gau

the user to r

f the error re

es PEG/MA

ad the meas

ay, and activ

).

uring signal,

te or deactiv

valuate the s

te the gauge

ate of

(only

Pin as

signment

Pin ass

applian

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Connect t

rear of the

e peripheral

unit using yo

cable.

DANGER

DANGE

Accordin

hazardou

Only con

gnment of th

e connector:

Signal

Analog out

Analog out

Switching f

HV_H o

o

+24 V (dc),

Chassis =

Error signa

Switching f

Chassis =

: Hazardous

to EN 6101

.

ect a protecti

male 15-pin

ut –5 …

ut GND

nction 1

P

essure above

eshold or po

su

pply turned o

+24 V

f 0 V

200 mA

ND

N

error

nction 2

P

essure above

eshold or po

su

pply turned o

ND

omponents t

r own, scree

oltage

, voltages ex

e low voltag

D-Sub

13 V (dc)

er

f

se-protected

F

s

lf-resetting a

C

NTROL con

a

grounded pro

er

f

the CONTR

ed (electrom

eeding 30 V

(PELV).

at 300 mA w

ter power off

nector. Meet

tective extra l

agnetic comp

ac) or 60 V (

Pres

ure bellow

thres

old

th PTC elem

the requirem

or power sup

Error

turne

off

Pres

ure bellow

thres

old

L connector

r pulling the

w voltage.

on the

atibility)

c) are

nt,

ents of

ly

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

The analo

than ±20

output (pin

V.

) differs from

the displaye

value by no

ore

21

Page 22

3.5

C

V

P

R

V

L

V

e

o

V

t

T

P

Tse

L

p

s

e

V

chazOnl

n

n

l

l

eHV_HV_

l

o

e

_

e

f

i

f

h

c

g

n

t

s

p

G

r

p

9

V

V

t

p

y

o

n

b

u

n

g

v

+

+

+

6

n

n

e

n

t

h

O

e

V

m

T

s

E

m

n

c

6

v

e

o

o

m

o

d

)

t

ONTRO

GC502,

Connec

GC503

or

he CONTRO

•

Analog out

•

Recorder o

to one of th

•

HV-EMI. U

and off. Th

On = +24

Off = 0 V

connection

uts for the si

utput. This is

e three chan

ed to switch

signal level

ontains the f

nals of the i

programma

els.

he high-vacu

are:

llowing signa

dividual chan

le analog ou

m circuit of t

l pins:

nels.

tput which ca

e PEG/MAG

be assigne

gauges on

in assignm

nt

Con

in assignmen

a

ppliance con

Pin Sig

1

2

3

4

5

6

7

8

9

nect the peri

rear

of the unit us

cabl

e.

DA

NGER: Haza

Ac

ording to EN

ardous.

y connect a

t of the male

ector:

al

Ana

log output 1

Ana

log output 3

Scr

ening GND

EMI 3

EMI 1

log output 2

Ana

order output

Rec

Scr

ening GND

HV

EMI 2

DAN

heral compo

ing your own,

ER

dous voltage

61010, volta

rotective low

-pin D-Sub

–5 …

–5 …

–5 …

0 … +

ents to the C

screened (el

es exceeding

oltage (PEL

13 V (dc)

13 V (dc)

13 V (dc)

10 V (dc)

ONTROL con

ctromagneti

30 V (ac) or

).

nector on the

compatibility

0 V (dc) are

The

3.6

22

ELAY C

GC502,

nnector

GC503

he switching

veral relays

a

llows utilizing

tential-free (

p

Con

analog outpu

than ±20 m

mor

unctions and

nside of the

the relay con

loating).

nect the peri

of t

e unit using

cabl

e.

ts (pins 1, 2,

.

the error mo

acuum Gaug

acts for switc

heral compo

our own, scr

) differ from t

itoring syste

e Controller.

ing purpose

ents to the R

ened (electro

he displayed

influence th

he RELAY c

. The relay c

LAY connec

magnetic co

tina96e1-b (2016-12)

alues by no

state of

nnection

ntacts are

or on the rea

patibility)

VGC501_VGC502_VGC503.

r

m

Page 23

C

s

c

i

a

R

g

s

n

e

n

u

rthr

u

rthr

u

rthr

u

rthr

u

rthr

u

rthr

rtur

r

v

0

w

f

w

f

w

f

w

f

w

f

w

f

s

g

u

e

r

c

e

f

a

(

s

h

s

h

s

h

s

h

s

h

s

h

r

i

f

e

r

d

e

n

DANGER

Pin as

Conta

signment,

t positions

Pin ass

D-Sub

Pin

4

5

6

8

9

10

11

12

13

16

17

18

19

20

21

22

23

24

3

15

14

25

1, 7

2

DANGE

Accordin

hazardou

Only con

gnment of th

ppliance con

Signal

Switching f

Switching f

Switching f

Switching f

Switching f

Switching f

Error signa

Supply for

+24 V (dc),

GND

n.c.

: Hazardous

to EN 6101

.

ect a protecti

female 25-pi

ector:

nction 1

P

essure above

eshold or po

su

pply turned o

nction 2

P

essure above

eshold or po

su

pply turned o

nction 3

P

essure above

eshold or po

su

pply turned o

nction 4

P

essure above

eshold or po

su

pply turned o

nction 5

essure above

P

eshold or po

su

pply turned o

nction 6

P

essure above

eshold or po

su

pply turned o

E

ror or power

ned off

elays with hi

200 mA

oltage

, voltages ex

e low voltag

n

er

f

er

f

er

f

er

f

er

f

er

f

upply

her switching

F

se-protected

s

lf-resetting a

in

the RELAY

p

otective extr

eeding 30 V

(PELV).

Pres

thres

Pres

thres

Pres

thres

Pres

thres

Pres

thres

Pres

thres

No e

power

at 200 mA w

ter turning of

connector. M

low voltage

ac) or 60 V (

ure below

old

ure below

old

ure below

old

ure below

old

ure below

old

ure below

old

ror

th PTC elem

the VGC50x

ets the grou

equirements.

c) are

nt,

or pull-

ded

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

23

Page 24

3.7 I

U

U

C

C

r

r

T

V

U

Tfr

w

U

c

u

t

p

o

g

c

o

f

i

d

t

c

e

k

o

t

o

o

B

r

c

a

r

c

a

k

o

nterface

SB Type

onnecto

B

he USB Type

GC50x via a

Con

the

B interface c

omputer (e.

nect the USB

nit using a s

nnector facil

. firmware up

interface con

reened (elec

tates direct c

ate, parame

ector to the

romagnetic c

mmunication

er saving (re

connecto

mpatibility)

with the

d/write)).

on the rear o

able.

f

3.8 I

nterface

SB Type

onnecto

A

SB Type B

he USB Type

ont of the uni

are update,

SB Type A

Con

unit.

A interface c

and is used

arameter sav

nect the USB

nnector with

or the conne

ng (read/writ

memory stic

master functi

tion of a US

), data logge

to the conne

nality is situ

memory stic

).

ctor on th

ted on the

(e.g. firm-

front of the

24

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 25

C

3.9 Inte

e

e

o

n

h

e

t

o

s

h

e

r

c

a

t

a

e

n

c

s

e

V

a

m

c

e

n

Eth

rface Co

rnet

nector

The Et

puter.

ernet interfac

e allows dire

t communicat

ion with the

GC50x via a

om-

Gre

Yell

n LED

w LED

Ethern

Link or

Status

LED fla

Connect t

t

ransmit LED.

r packet det

hes or flicke

e Ethernet c

Indicates tha

ct LED. Indic

s, data are b

ble to the co

a hardware

tes the statu

ing transmitt

nector on

onnection h

the rear of th

s been establ

of the trans

d.

ission. Whe

unit.

ished.

this

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

25

Page 26

O

F

D

n

e

C

a

S

m

a

9

2

e

e

e

V

0

e

m

m

t

u

o

4

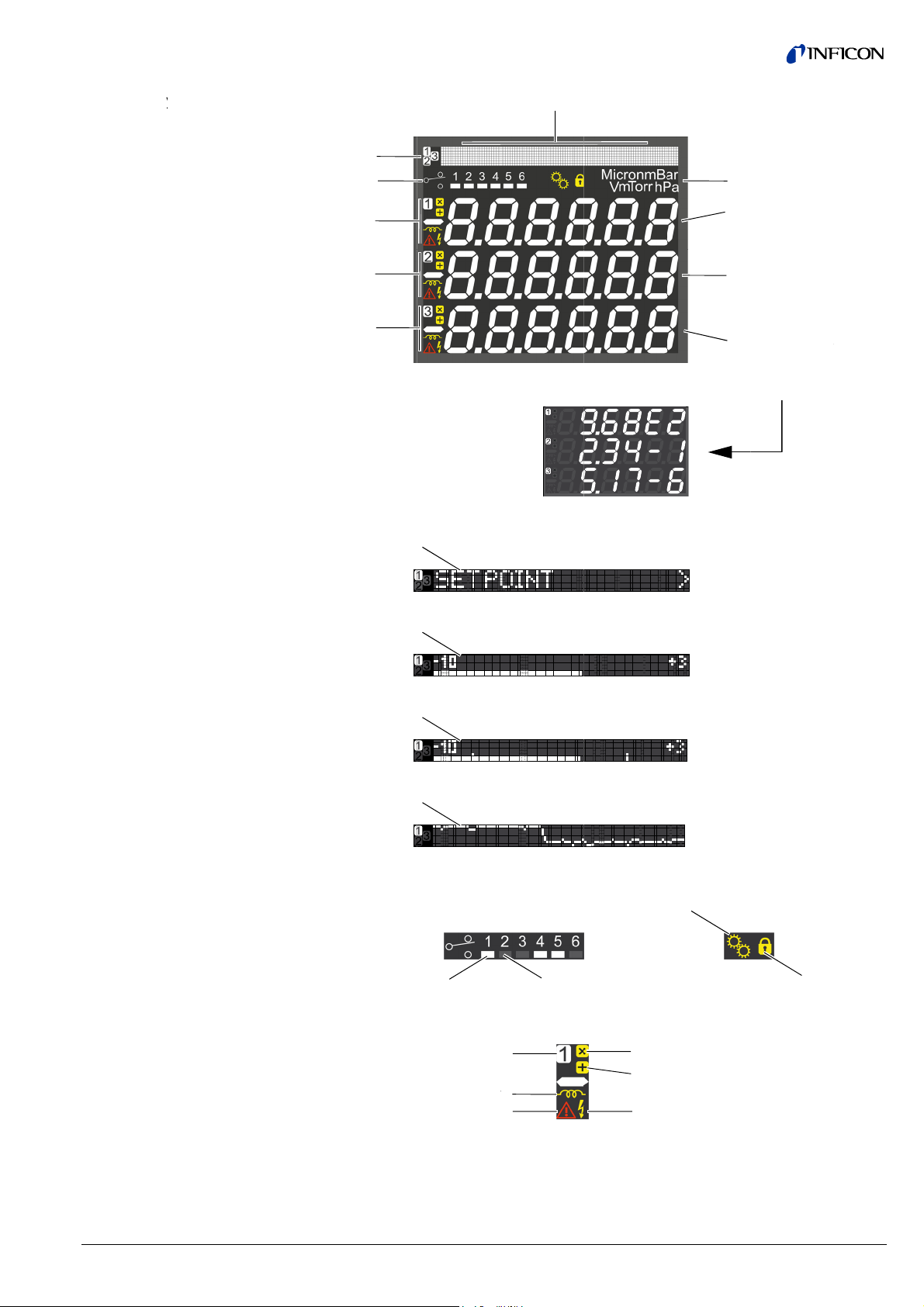

4.1

peratio

ront pan

l

Display

USB

connector

VGC502

VGC501

Operator k

GC5

ys

3

isplay VG

501

et points, par

St

tus measure

meter mode,

keylock

ent channel

.68×102 corr

.34×10-1 corr

Paramete

sponds to

sponds to

Display

Operator k

USB

connecto

r or bar graph

ys

r

Pressure

Measure

Measure

floating po

nential sta

nit

ent channel:

ent value in

int or expo-

us

26

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 27

C

Displa

y

m

o

u

y

V

a

e

n

a

n

a

a

s

n

e

n

n

n

0

0

e

p

p

r

n

R

(

d

d

d

o

e

a

e

y

v

o

r

e

e

v

eMe

anenPreMe

e

anen

c

o

eMe

a

o

a

e

a

e

a

e

VGC502,

Mea

Set poi

Status me

Status me

Status me

GC503

urement cha

ts, parameter

surement cha

surement cha

surement cha

nel 1

mode,

ylock

k

nel 1

nel 2

nel 3

9.68×1

02 correspon

P

rameter or ba

s to

graph

ssure unit

M

asurement ch

asurement val

flo

ting point or

nnel 1:

ue in

xpo-

tial status

asurement ch

M

asurement val

flo

ting point or

nnel 1:

ue in

xpo-

tial status

M

asurement ch

asurement va

flo

ting point or

ne

ntial status

nnel 3:

lue in

xpo-

Para

Set p

keyloc

eter, bar gr

ints, param

k

ph

ter mode,

2.34×1

5.17×1

Param

Bar gra

Bar gra

Pressu

Set poi

-1

correspon

-6

correspon

ter

h

h with set p

e vs. time, tr

ts 1 … 6

s to

s to

int

nd

Param

ter mode acti

ated

elay on

Relay off

Keylock

n

Meas

specifi

rement cha

cally

nel

Measu

VG

rement chann

C502/503 onl

Degas acti

Err

Calib

l

ration factor a

Offs

t active

tive

e

High

vacuum sens

r active

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

27

Page 28

4.2

T

a

T

T

O

h

V

V

x

T

T(o

A

T

T

t

5

a

c

e

e

t

p

5

t

e

w

m

p

c

g

n

n

t

e

e

p

a

s

g

t

m

r

e

e

r

a

u

a

S

a

o

a

T

s

DAT

o

t

h

t

d

h

a

g

t

s

→

p

d

SENSOR

CON

o

RAL

→

LOGGER

SETUP

h

e

x

ETPOINT

>

→

>

e

→

>

>

o

u

e

o

)

o

urning t

nd Off

urning the

e VGC50

GC50x on

On

he power swi

urn the VGC

r centrally, vi

if

the unit is in

ch is on the r

0x on with th

a a switched

orporated in

ar of the uni

power switc

ower distribu

rack).

.

tor,

4.3

urning the

perating

GC50x off

Modes

fter power on

automaticall

•

identifies th

•

•

activates th

•

switches to

•

adapts the

connected).

urn the VGC

d

istributor, if th

Wai

corr

he VGC50x

•

Measureme

for displayin

•

Parameter

for displayin

− Switchin

for enter

− Gauge

for enter

− Gauge

for enter

− General

for enter

− Test pro

for runni

− Data log

for loggi

− Parame

for savin

, the VGC50x

y performs a

connected

parameters

he Measure

arameters if

0x off with th

e unit is incor

at least 10 s

ctly initialize

orks in the fo

nt mode

g measurem

ode

g and editing

g function pa

ing and displ

arameter gro

ing and displ

ontrol group

ing and displ

parameter gr

ing and displ

gram group

ng internal te

ger mode

g measurem

er transfer m

g (read/write)

…

elf-test

auges

hat were in e

ent mode

equired (if a

power switc

orated in a r

before turnin

itself.

llowing opera

nt values or

parameters (

ameter grou

ying threshol

p

ying gauge p

-

ying gauge c

up

GENE

ying general

t programs (

A

ent data (→

de

parameters (

fect before t

ifferent gaug

(or centrally

ck).

the VGC50

ing modes:

tatuses (→

33)

S

s (→ 34)

rameters (

ntrol param

arameters (

58)

>

61)

63)

e last power

was previo

, via a switch

on again in

31)

>

38)

ters (→ 46

50)

ff

sly

d power

rder for it to

28

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 29

C

VGC5

0

Ba

FSR

1

rgraph

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

29

Page 30

V

GC502, VGC503

B

p

FSR

o

argra

30

tina96e1-b (2016-12) VGC501_VGC502_VGC503.

m

Page 31

C

4.4 Mea

s

A

g

e

5

h

M

h

e

y

s

e

a

e

u

e

n

n

d

d

t

p

n

n

d

d

q

a

T

ali

b

HAND

w

n

r

h

s

o

m

w

n

r

d

s

p

n

e

a

a

e

s

F

e

a

EMISS

o

a

e

i

n

e

e

i

c

o

t

n

h

l

M

H

n

d

y

d

HAND

s

M

0

h

n

o

h

a

G

n

e

h

e

e

d

m

e

m

y

o

m

s

s

n

h

t

v

n

i

w

n

n

djust

Chan

chann

(VGC

Turnin

urement

ing bar grap

ing measur

l

02/503 onl

g the gauge

ode

ment

)

on/off

Measur

• a b

• a m

• stat

If requir

Certain

set to

S

Availabl

Pira

Pira

Col

Col

Hot

Cap

Hot

ment mode i

r graph (if re

asurement v

s messages

ed a bar grap

gauges can

-ON

e for the follo

ni

ni / Capacita

cathode

cathode / Pi

ionization / Pi

acitance

ionization / Pi

s the standar

uired)

lue for each

for each mea

h may be dis

he unit alter

nd three. Th

ghts up.

e turned on

ing gauges:

ce

ani

rani

rani / Capacit

Press k

Gauge

word O

operating m

measuremen

urement cha

layed (→ 5

ates between

number of t

nd off manua

(→

48).

nce

y for >1 s:

witches off. I

F is displaye

ode of the V

nnel

5).

measureme

e selected m

lly, provided t

(PSG)

(PCG)

(PEG,

MAG)

(MPG)

(BPG,

HPG)

(CDG)

(BCG)

channel

stead of a m

.

C50x with di

t channels o

asurement c

e gauge con

asurement

play of

e, two

annel

rol is

alue the

Switc

ing the emi

sion on / off

For cer

sensor

Availabl

Pira

Pira

Col

Col

Hot

Cap

Hot

ain gauges t

arameter is

Switching

2.4×10-2

e for the follo

ni

ni / Capacita

cathode

cathode / Pi

ionization / Pi

acitance

ionization / Pi

Press k

Gauges

a status

e emission c

et to

n the emissi

bar.

ing gauges:

ce

ani

rani

rani / Capacit

Press k

The em

the Pira

measur

sensor.

Press k

The em

the hot

solid.

y for >1 s:

switches on.

message ma

n be switche

n is only pos

(PSG)

(PCG)

(PEG,

(MPG)

(BPG4

(CDG)

nce

(BCG)

y for >1 s:

ssion is switc

i or CDG se

ment value

y for >1 s:

ssion is switc

athode ioniz

Instead of th

y be displaye

on and off

(→ 45).

sible if the pr

MAG)

2 only)

hed off. The

sor is displa

f the hot cath

hed on. The

tion sensor i

measureme

.

anually, prov

ssure is belo

easurement

ed instead of

de ionizatio

easurement

displayed a

t value

ded the

value of

the

value of

d lid

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

31

Page 32

M

DidCm

easureme

n

h

g

0

0

2

/

0

a

0

a

n

n

0

5

0

u

e

t

f

n

P

e

C

e

G

n

G

n

p

c

c

3

C

d

b

e

e

f

t

P

a

g

l

G

0

a

n

n

e

othdi

P

PPM

B

B

H

B

C

CCn

n

C

u

r

g

MAG

100

Vx

10

v

n

e

m

e

S

m

e

3

o

t range

isplaying t

entification

hanging to

ode

e gauge

Pirani

(PSG40

PSG50

PSG55

Pirani

(PCG40

Cold c

(PEG10

Cold c

(MPG40

Hot io

Hot io

(BCG45

Linear

(CDG02

CDG04

Linear

(CDG02

CDG10

No ga

Gaug

the Parame

auge

, PSG400-S, PS

-S, PSG502-S, P

, PSG554)

Capacitanc

, PCG400-S, P

thode gaug

, MAG500, MA

thode / Pira

0, MPG401, MP

ization / Pira

ization / Ca

)

gauge (capa

0D, CDG025, CD

Dhs, CDG100, C

gauge (capa

5D, CDG025D-X

D, CDG100D2,

ge connecte

connected,

er

I

the unit is op

dicated.

i

ossible caus

•

negative dr

•

activated o

Firs

100-S, PSG101

G510-S, PSG51

gauge

G550, PCG552,

504)

i gauge

500, MPG504)

i gauge

acitance / Pir

itance, analo

G045,CDG045-H

DG100Dhs)

itance, digita

, CDG045D, CD

DG160D, CDG2

ut not identifi

erated with li

s:

ift

fset correctio

, select the r

P

-S, PSG500,

2-S, PSG550,

CG554)

(BPG400)

(BPG402)

(HPG400)

ani gauge

g)

,

)

045D2,

0D)

ble

→

ear gauges (

.

quired meas

ress keys for

F

r the measu

e connected

splayed for 6

xxx

xxx

/

xxx

DGxxx

DGxxxD

xxxD

oSENSOR

oIDENT.

33

DG), negati

rement chan

0.5 … 1 s:

ement chann

auge is auto

s:

xxx

.xx

MBAR

MBAR

I

I

I

I

I

I

I

I

I

V

F

I

I

e pressures

el with k

l in question

matically iden

rsion during

R during 3 s

ay be

y.

the type of

tified and

s, then

32

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 33

C

4.5 Para

m

n

g

a

d

e

r

a

o

e

t

u

t

a

s

e

e

n

o

e

u

h

i

n

u

t

b

c

g

g

e

a

a

T

u

n

e

r

n

s

e

→

6

e

h

o

a

→

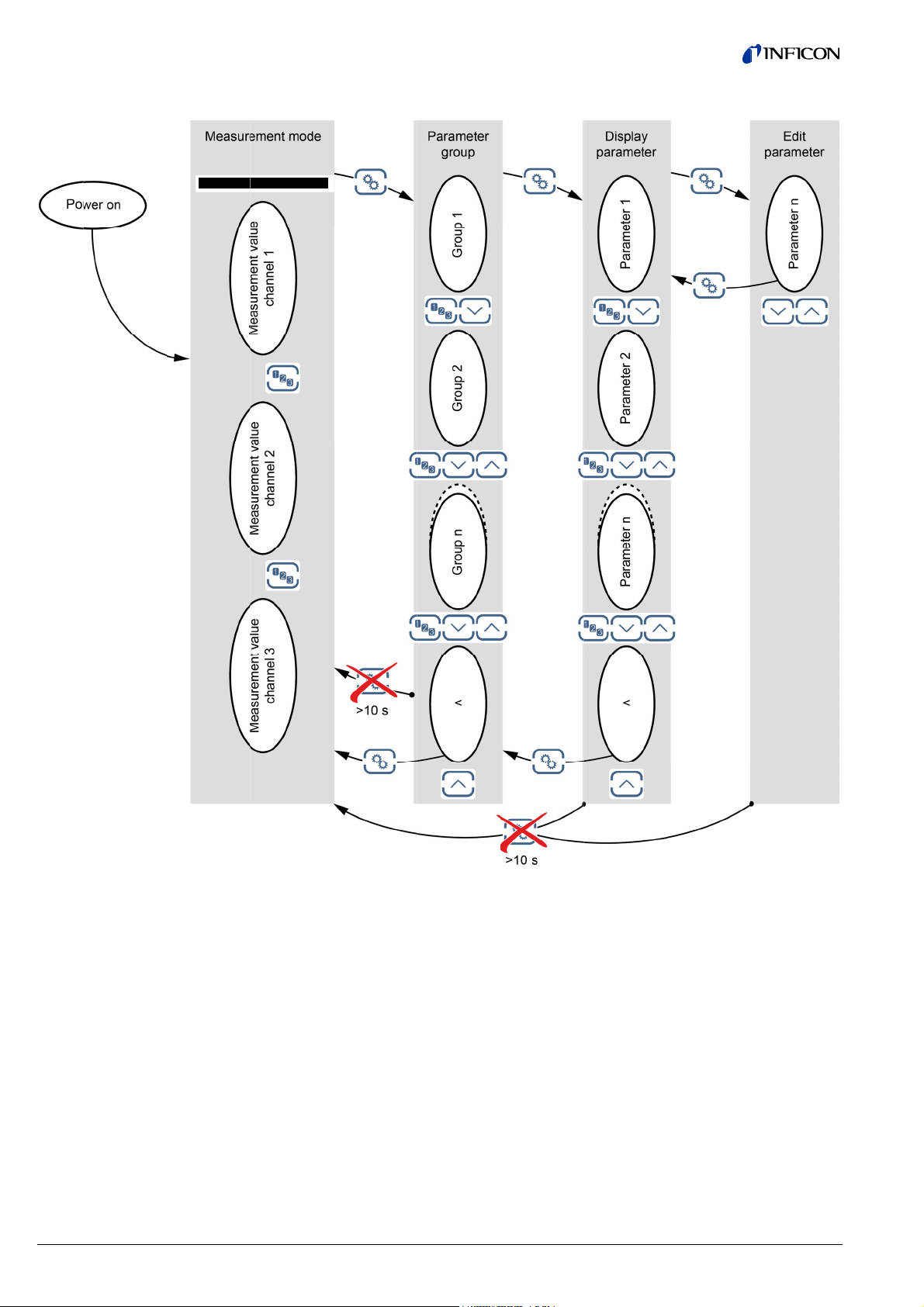

Select

eter Mo

ing a param

e

ter group

The Pa

as well

operati

ameter mod

s for testing

n the individ

is used for di

he VGC50x

al parameter

Unit switch

meter mod

displayed i

Select

group

splaying, edit

nd for saving

are divided i

s from meas

. The respec

place of the

Swit

Gau

Gau

Gen

Test

Dat

Par

ing and enteri

measureme

nto groups.

rement mod

ive paramete

bar graph.

hing functio

e parameter

e control →

ral paramet

parameters

logger →

meter transf

ng parameter

t data. For e

to para group is

parameters

→ 38

46

rs → 50

58

1

r → 63

values

se of

34

Readi

param

Editin

in a p

g a parame

eter group

and saving

rameter gro

ter in a

a paramete

up

Confirm gr

up

Confirm th

parameter.

he value flas

es and can n

ow be

edited.

Edit the val

e.

Save the c

ange and ret

rn to read m

de.

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

33

Page 34

4.5.1 Switching Function

Parameters

Parameters in this group

SETPOINT >I The switching function parameter group is used for

displaying, editing and entering threshold values and

assigning the two (VGC501), four (VGC502) or six

(VGC503) switching functions to a measurement

channel.

SP1-CH I Configuration of switching function 1

SP1-L I Switching function 1 lower threshold

SP1-H I Switching function 1 upper threshold

SP2-CH I Configuration of switching function 2

SP2-L I Switching function 2 lower threshold

SP2-H I Switching function 2 upper threshold

SP3-CH I Configuration of switching function 3

(VGC502/503 only)

SP3-L I Switching function 3 lower threshold

(VGC502/503 only)

SP3-H I Switching function 3 upper threshold

(VGC502/503 only)

SP4-CH I Configuration of switching function 4

(VGC502/503 only)

SP4-L I Switching function 4 lower threshold

(VGC502/503 only)

SP4-H I Switching function 4 upper threshold

(VGC502/503 only)

SP5-CH I Configuration of switching function 5

(VGC503 only)

SP5-L I Switching function 5 lower threshold

(VGC503 only)

SP5-H I Switching function 5 upper threshold

(VGC503 only)

SP6-CH I Configuration of switching function 6

(VGC503 only)

SP6-L I Switching function 6 lower threshold

(VGC503 only)

SP6-H I Switching function 6 upper threshold

(VGC503 only)

< I One level back

The VGC501 has two, the VGC502 has four and the VGC503 has six, switching

functions with two adjustable thresholds each. The status of the switching functions

is displayed on the front panel and can be evaluated via the floating contacts at the

CONTROL, respectively RELAY connector.

• VGC501: CONTROL connector (→ 21)

• VGC502, VGC503: RELAY connector (→ 22)

34 tina96e1-b (2016-12) VGC501_VGC502_VGC503.om

Page 35

C

c

n

m

m

n

m

e

m

t

SP1

h

p

e

u

e

u

e

t

½

d

DISAB

r

e

d

d

e

w

e

e

b

c

d

a

w

.

Sele

Editi

para

ting a para

g and savi

eter

eter

g the

The na

e.g.:

Select

parame

e of the para

er value are

-CH

Switc

ing function 1 tu

arameter. Th

meter and th

isplayed.

I

ned off

value flash

currently val

s and can no

id

be

edited.

Press k

The val

Press k

The val

Save th

y for <1 s:

e is increase

y for >1 s:

e is increase

change and

d/decreased

d/decreased

return to rea

y 1 incremen

ontinuously.

mode.

t.

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

We recom

or the low

end setting

r threshold

he upper thr

decade belo

shold ½ dec

the upper, t

de above the

hreshold limit

lower,

35

Page 36

Configuring a switching

function

Limits of the lower switching

thresholds

SP1-CH I Configuring a switching function.

SP1-CH 1 I Switching function 1 is assigned to

Value

channel 1

SP1-CH 2 I Switching function 1 is assigned to

channel 2

(VGC502/503 only)

SP1-CH 3 I Switching function 1 is assigned to

channel 3

(VGC503 only)

SP1-CH DISABLED I Switching function 1 is factory-deactivated

SP1-CH ENABLED I Switching function 1 is always turned on

The lower and the upper threshold of a switching function are always

assigned to the same channel. The last assignment is valid for both

thresholds.

SP1-L I The lower threshold (Setpoint low) defines the

Value

pressure at which the switching function is

activated when the pressure is dropping.

e.g.: SP1-L 5.00-4 I gauge dependent.

If another gauge type is connected, the

VGC50x automatically adjusts the switching

threshold if required.

PSGxxx I

PCGxxx I

PEG100/MAGxxx I

MPGxxx I

BPG400 I

BPG402 I

HPG400 I

BCG450 I

CDGxxx I

CDGxxxD I

SPx-L min. SPx-L max.

-3 *)

1×10

1×10

1×10

1×10

1×10

1×10

-3 *)

-9

-9

-8

-8

-6

-8

= SPx-H max.

2×10

2×10

F.S. / 1000

F.S. / 1000

all values in mbar, GAS=nitrogen

*)

2×10-4 mbar if RNG-EXT (Pirani range extension) is activated (→ 51)

The minimum hysteresis between the upper and lower switching

threshold amounts to at least 10% of the lower threshold (logarithmic

gauges) or 1% of the full scale value (linear gauges). The upper

threshold is if necessary automatically adjusted to a minimum

hysteresis. This prevents unstable states.

36 tina96e1-b (2016-12) VGC501_VGC502_VGC503.om

Page 37

Limits of the upper switching

thresholds

SP1-H I The upper switching threshold (Setpoint high)

Value

defines the pressure at which the switching

function is deactivated when the pressure is

rising.

e.g.: SP1-H 1500 I gauge dependent.

If another gauge type is connected, the

VGC50x automatically adjusts the threshold

if required.

PSGxxx I

PCGxxx I

PEG100/MAGxxx I

MPGxxx I

BPG400 I

BPG402 I

HPG400 I

BCG450 I

CDGxxx I

CDGxxxD I

SPx-H min. SPx-H max.

3

1×10

1.5×10

-2

1×10

3

1×10

3

1×10

= SPx-L min.

1×10

1×10

3

3

1.5×10

F.S.

F.S.

3

3

all values in mbar, GAS=nitrogen

The minimum hysteresis between the upper and lower switching

threshold amounts to at least 10% of the lower threshold (logarithmic

gauges) or 1% of the full scale value (linear gauges). This prevents

unstable states.

tina96e1-b (2016-12) VGC501_VGC502_VGC503.om 37

Page 38

4.5.2 Gauge parameters

Parameters in this group

SENSOR >I The sensor parameter group is used for displaying,

entering and editing parameters of the connected

gauges.

DEGAS I Cleaning the electrode system.

FSR I Measurement range linear gauges.

FILTER I Measurement value filter.

OFFSET I Offset correction.

GAS I Correction factor for other gases.

COR I Offset correction.

HV-CTRL I Activating / deactivating high vacuum measurement

circuit.

EMISSION I Emission.

FILAMENT I Filament selection.

DIGITS I Display resolution.

< I One level back.

Some parameters are not available for all gauges and thus not always displayed.

39 40 41 42 44 44

→

45 45 45

46

PSGxxx I

PCGxxx I

PEG100/MAGxxx I

MPGxxx I

BPG400 I

BPG402 I

Available for

HPG400 I

BCG450 I

CDGxxx I

CDGxxxD I

DEGAS I

− −

− −

− −

− −

−

−

− −

−

−

−

FSR I

FILTER I

OFFSET I

GAS I

COR I

HV-CTRL I

EMISSION I

FILAMENT I

DIGITS I

− − −

− − −

− −

− − −

− − −

−

− − −

−

− − −

− − −

−

−

−

−

−

−

−

−

−

−

−

38 tina96e1-b (2016-12) VGC501_VGC502_VGC503.om

Page 39

C

Deg

a

n

m

n

m

t

c

n

n

d

d

DEGAS

s

.

s

w

/

n

r

/

OFF

c

a

k

a

e

e

h

g

s

M

p

h

m

n

s

u

d

a

7

o

a

o

e

.

s

)

o

y

n

r

i

s

s

Conta

instabili

the ele

ination depo

ies of the me

trode system

its on the ele

asurement v

trode system

lues. The de

of hot catho

as function f

e gauges ma

cilitates clea

cause

ing of

Editi

para

g and savi

eter

g a

Availabl

Pira

Pira

Col

Col

Hot

Hot

Cap

Hot

The dega

BPG402 g

e for the follo

ni

Capacita

ni

cathode

cathode / Pi

ionization / Pi

ionization

Pi

acitance

ionization / Pi

DEGAS

DEGAS ON

process wor

auges: The D

ing gauges:

ce

ani

rani

rani

rani / Capacit

I

I

I

Start D

180 sec

s only at pre

gas function

(PSG)

(PCG)

(PEG,

(MPG)

(BPG)

(HPG)

(CDG)

nce

(BCG)

Value

Normal o

Degas: T

heated to

bombard

system is

180 s.

gas. Duratio

nds (may al

sures below

acts only up

MAG)

eration (Deg

e electron c

≈700 °C by e

ent and the

thus cleaned

of the Dega

o be aborted

.2×10-6 mba

n the active f

s blocked)

llection grid i

lectron

lectrode

Duration =

function

.

.

lament.

Abort D

Save c

gas.

ange and ret

rn to read m

de.

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

39

Page 40

Measuring range (F.S.) of

linear gauges

For linear analog gauges, the full scale (F.S.) value has to be defined on the basis

of the connected gauge type. For linear digital gauges and logarithmic gauges it is

automatically recognized.

Available for the following gauges:

Pirani

(PSG)

Pirani / Capacitance (PCG)

Cold cathode

Cold cathode / Pirani

Hot ionization / Pirani

Capacitance

Hot ionization / Pirani / Capacitance

FSR I

Value

(PEG, MAG)

(MPG)

(BPG, HPG)

(CDG)

(BCG)

e.g. FSR 1000 MBAR I 0.01 mbar, 0.02 mbar, 0.05 mbar

0.01 Torr, 0.02 Torr, 0.05 Torr

0.10 mbar, 0.25 mbar, 0.50 mbar

0.10 Torr, 0.25 Torr, 0.50 Torr

1 mbar, 2 mbar, 5 mbar

1 Torr, 2 Torr, 5 Torr

10 mbar, 20 mbar, 50 mbar

10 Torr, 20 Torr, 50 Torr

100 mbar, 200 mbar, 500 mbar

100 Torr, 200 Torr, 500 Torr

1000 mbar, 1100 mbar

1000 Torr

2 bar, 5 bar, 10 bar, 50 bar

A conversion table can be found in the

Appendix (→ 102).

40 tina96e1-b (2016-12) VGC501_VGC502_VGC503.om

Page 41

Measurement value filter

The measurement value filter permits a better evaluation of unstable or disturbed

measuring signals.

The measurement value filter does not affect the analog output

(→ 22).

FILTER I

FILTER OFF I No measurement value filter

FILTER FAST I Fast:

Value

The VGC50x responds quickly to fluctuations in the measurement value. As a result,

it will respond faster to interference in the

measured values.

Pressure p

FILTER NORMAL I Normal (factory setting):

FILTER SLOW I Slow:

Time t

Good relationship between response and

sensitivity of the display and the switching

function to changes in the measured values.

Pressure p

Time t

The VGC50x does not respond to small

changes in measured values. As a result, it

will respond more slowly to changes in the

measured values.

Pressure p

Time t

tina96e1-b (2016-12) VGC501_VGC502_VGC503.om 41

Page 42

Offset corr

e

Tva

A

T

O

W

p

d

d

o

o

e

e

e

o

OFFSE

OFFSE

o

e

d

a

/ C

:

v

e

OFF

a

R

t

T

e

w

c

s

s

hmen

e

e

e

a

e

t

o

n

d

s

e

u

i

m

s

r

m

e

o

.

controller

ction of the

he offset valu

lue.

vailable for th

Pirani

Pirani / Ca

Cold catho

Cold catho

Hot ionizati

Capacitanc

Hot ionizati

he offset corr

the display

the display

the analog

e is displaye

e following g

acitance

e

e / Pirani

on / Pirani

e

on / Pirani

ction affects

d measurem

d threshold

outputs at th

I

and readjust

uges:

apacitance

nt value

alue of the s

CONTROL

Wert

I Off

d according

(PSG)

(PCG)

(PEG, MAG)

(MPG)

(BPG, HPG)

(CDG)

(BCG)

itching functi

onnector (→

et correction

o the actual

ns

21, 22)

factory-deact

easurement

ivated

e.g.

hen offset c

a

tual measur

9.53

P

S

rrection is ac

ment value.

I Off

ress key for >

e offset valu

T

v

lue is accept

eset the offs

ave change a

ivated, the s

his allows m

et correction

in t

e relevant u

t)

1.5 s:

is readjuste

d as new off

t value.

nd return to r

ved offset val

asuring relat

activated (di

its of measu

(the actual

et value).

ad mode.

ue is subtract

ive to a refer

play

e-

easurement

d from the

nce pressure

42

tina96e1-b (2016-12)

VGC501_VGC502_VGC503.

m

Page 43

C

Zero

G

n

n

d

d

OFFSE

t

w

/

n

r

z

d

OF

s

g

t

n

a

a

j

y

o

M

H

s

s

e

v

s

e

v

s

a

m

p

h

m

adjustment of a digital

CD

Availabl

Pira

Pira

Col

Col

Hot

Cap

Hot

First adjus

e for the follo

ni

ni

Capacita

cathode

cathode / Pi

ionization / Pi

acitance

ionization / Pi

the gauge a

ing gauges:

ce

ani

rani

rani / Capacit

d then the c

(PSG)

(PCG)

(PEG,

(MPG)

(BPG,

(CDG)

nce

(BCG)

ntroller.

MAG)

HPG)

When the

deactivate

ero of the g

.

uge is readju

ted, the offs

t correction

ust be

e.g.

OFFSET

I

Value

I

Zero adju

tment deacti

Lit

as long as

ated

olid after >1.

key remains

5 s and

ressed

Press >

Zero ad

.5 s:

ustment of th

e digital CDG

.

After adju

measuring

several di

ting the zero

resolution of

its are displa

oint, a zero

the CDG (noi

ed.

alue is displ

e, drift), a ze

yed. Due to t

ro with plus/

e

inus

tina96e1-b (2016-12) VG

501_VGC502_VGC503.om

43

Page 44

Correction factor GAS

The correction factor GAS allows

• the measured value to be calibrated for the preset gases N

, Ar, H2, He, Ne, Kr

2

and Xe, or

• manual input of the correction factor for other gases (COR).

→ Characteristic curves in [1] … [16].

This parameter is not available for the unit of measurement: Volt.

Available for the following gauges:

Pirani

(PSG) <1 mbar

Only for pressures

Pirani / Capacitance (PCG) <1 mbar

Cold cathode

Cold cathode / Pirani

Hot ionization / Pirani

(PEG, MAG)

(MPG) <1×10-3 mbar

(BPG) <1×10-3 mbar

Hot ionization / Pirani (HPG)

Capacitance (CDG)

Hot ionization / Pirani / Capacitance

GAS I

GAS N2 I Gas: nitrogen / air (factory setting)

GAS AR I Gas: argon

Value

(BCG) <1×10-3 mbar

Calibration factor COR

GAS H2 I Gas: hydrogen

GAS HE I Gas: helium

GAS NE I Gas: neon

GAS KR I Gas: krypton

GAS XE I Gas: xenon

GAS COR I Calibration factor for other gases by

manually entering parameter COR

The calibration factor COR allows the measured value to be calibrated for other

gases (→ characteristic curve in [1] … [16]). This parameter is effective in the

entire measurement range of the gauge.

Precondition: Parameter "GAS COR" is set (except capacitance gauges).

This parameter is not available with the measurement unit: Volt.

Available for the following gauges:

Pirani

(PSG)

Pirani / Capacitance (PCG)

Cold cathode

Cold cathode / Pirani