Page 1

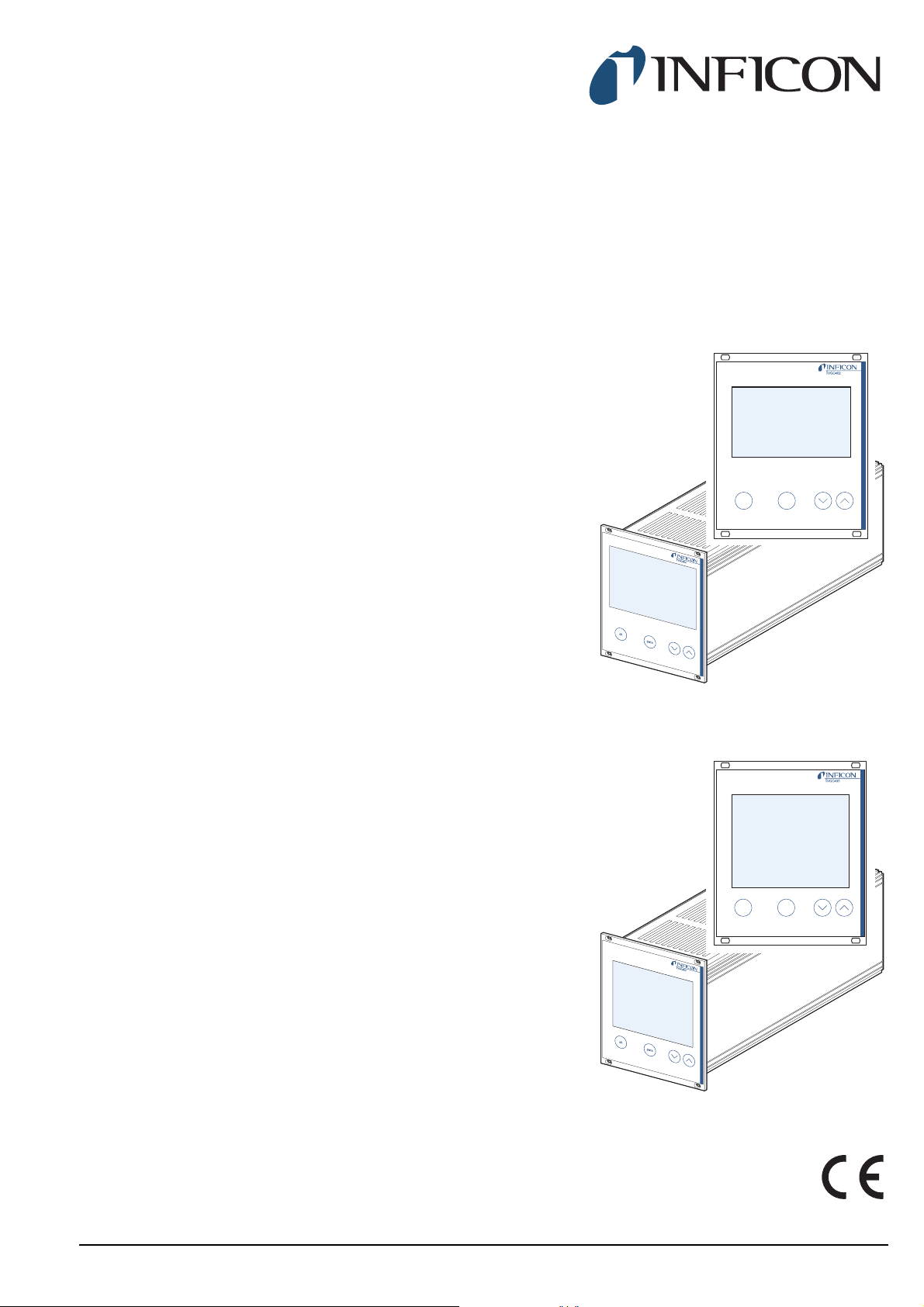

Operating Manual

parach

parach

Incl. EC Declaration of Conformity

VGC402

Two-Channel Measurement and Control Unit

VGC403

Three-Channel Measurement and Control Unit

tinb07e1-e 2011-07 1

Page 2

Contents

1 Introduction

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Part number . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.2 Firmware version . . . . . . . . . . . . . . . . . . . . . . 4

1.1.3 Type label . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 Liability and warranty . . . . . . . . . . . . . . . . . . . 4

1.3 Product versions . . . . . . . . . . . . . . . . . . . . . 4

1.4 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4.1 Personnel qualifications . . . . . . . . . . . . . . . . . 5

1.4.2 Illustration of residual dangers . . . . . . . . . . . . 5

1.4.3 General safety instructions . . . . . . . . . . . . . . 5

1.4.4 Disconnecting device . . . . . . . . . . . . . . . . . . . 6

2 Technical data

2.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Mechanical data. . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Ambience . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Mains connection. . . . . . . . . . . . . . . . . . . . . 7

3.3.6 CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.7 RS232C . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Operation

4.1 Front panel . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.2 Control buttons. . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Switching on and off . . . . . . . . . . . . . . . . . 16

4.2.1 Switching on. . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Switching off. . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.3 Waiting time . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Operating modes . . . . . . . . . . . . . . . . . . . . 16

4.4 Measurement mode . . . . . . . . . . . . . . . . . . 17

4.4.1 Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.3 Control button functions . . . . . . . . . . . . . . . . 17

4.5 Parameter mode. . . . . . . . . . . . . . . . . . . . . 19

4.5.1 Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5.2 Parameter groups . . . . . . . . . . . . . . . . . . . . 19

4.5.3 Basic operation . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Sensor connections . . . . . . . . . . . . . . . . . . . . 8

2.3.2 Sensor supply . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.3 Measuring technique . . . . . . . . . . . . . . . . . . . 8

2.4 Switching functions. . . . . . . . . . . . . . . . . . . 8

2.4.1 Switching function relay . . . . . . . . . . . . . . . . . 9

2.4.2 Error signal relay . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.1 Analog output. . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.2 Recorder output . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.3 Computer interface . . . . . . . . . . . . . . . . . . . . 9

2.6 Scope of delivery . . . . . . . . . . . . . . . . . . . . . 9

3Installation

3.1 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Mechanical installation . . . . . . . . . . . . . . . 10

3.2.1 Desktop unit . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Control panel mounted. . . . . . . . . . . . . . . . . 10

3.2.3 Mounting the unit in a rack. . . . . . . . . . . . . . 11

3.3 Connecting . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.1 Back side of the device . . . . . . . . . . . . . . . . 11

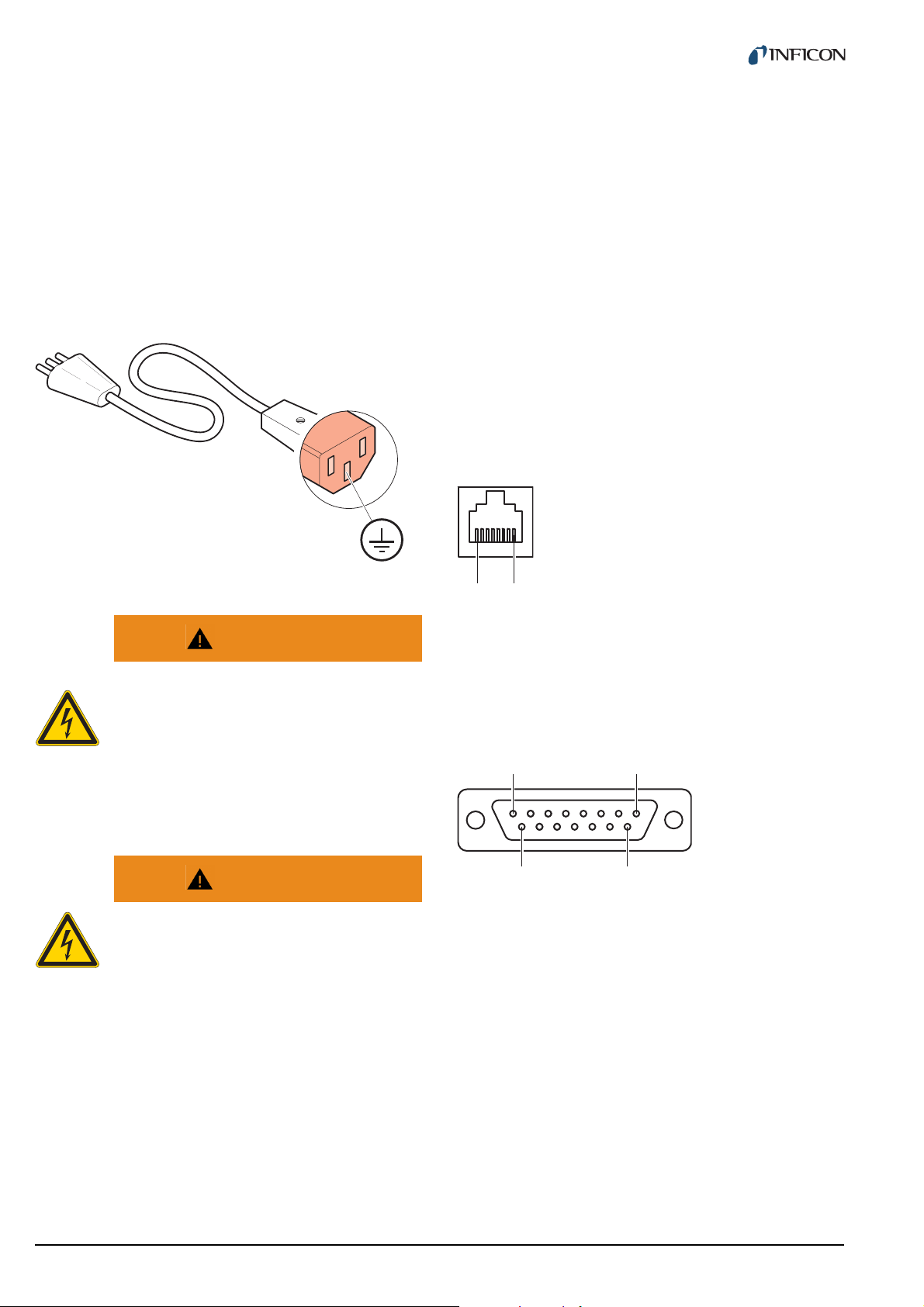

3.3.2 Mains connection . . . . . . . . . . . . . . . . . . . . . 12

3.3.3 Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.4 SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.5 RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Parameter

5.1 Switching function parameters (PArA SP)21

5.1.1 Fundamental terms . . . . . . . . . . . . . . . . . . . 21

5.1.2 Configuring switching functions . . . . . . . . . . 22

5.1.3 Adjustment range. . . . . . . . . . . . . . . . . . . . . 22

5.2 Sensor parameters (PArA SEn). . . . . . . . . 23

5.2.1 Measurement filter (FiLt) . . . . . . . . . . . . . . . 23

5.2.2 Gas type (GAS) . . . . . . . . . . . . . . . . . . . . . . 24

5.2.3 Measuring range (FS) . . . . . . . . . . . . . . . . . 24

5.2.4 Offset (oFS) . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2.5 Degas function (dEGAS) . . . . . . . . . . . . . . . 25

5.2.6 Sensor activation (S-on) . . . . . . . . . . . . . . . 25

5.2.7 Switch-on threshold (t-on) . . . . . . . . . . . . . . 25

5.2.8 Sensor deactivation (S-oFF) . . . . . . . . . . . . 25

5.2.9 Switch-off threshold (t-off) . . . . . . . . . . . . . . 26

5.2.10 Emission (EMi) . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.11 Filament selection (FiL) . . . . . . . . . . . . . . . . 26

5.2.12 Pirani range extension (PrE) . . . . . . . . . . . . 26

5.3 General parameters (PArA GEn) . . . . . . . . 27

5.3.1 Unit of measurement (unit) . . . . . . . . . . . . . 27

5.3.2 Baud rate (bAud) . . . . . . . . . . . . . . . . . . . . . 27

5.3.3 Display format (diGit) . . . . . . . . . . . . . . . . . . 27

5.3.4 Default parameters (dEF). . . . . . . . . . . . . . . 27

5.3.5 Recorder output (Ao) . . . . . . . . . . . . . . . . . . 27

5.3.6 Error signal relay (Err-r) . . . . . . . . . . . . . . . . 29

5.4 Test parameters (PArA tESt) . . . . . . . . . . . 29

2 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 3

5.4.1 Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4.2 Firmware version (Pnr) . . . . . . . . . . . . . . . . 29

5.4.3 Watchdog control (dt-C). . . . . . . . . . . . . . . . 29

5.4.4 Torr lock (tr-L) . . . . . . . . . . . . . . . . . . . . . . . 30

5.4.5 Parameter setup lock (LoC) . . . . . . . . . . . . . 30

5.4.6 RAM test (rA-t). . . . . . . . . . . . . . . . . . . . . . . 30

5.4.7 EPROM test (EP-t). . . . . . . . . . . . . . . . . . . . 30

5.4.8 EEPROM test (EE-t) . . . . . . . . . . . . . . . . . . 30

5.4.9 Display test (di-t) . . . . . . . . . . . . . . . . . . . . . 30

5.4.10 A/D converter signal (Ad-S). . . . . . . . . . . . . 30

5.4.11 A/D converter ID (Ad-i) . . . . . . . . . . . . . . . . 31

5.4.12 I/O test (io-t). . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4.13 RS232C test (rS-t) . . . . . . . . . . . . . . . . . . . . 31

6 Computer interface

6.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1.1 Connection. . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1.2 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Communication . . . . . . . . . . . . . . . . . . . . . 32

6.2.1 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2.2 Sending (Host --> Unit) . . . . . . . . . . . . . . . . 32

6.2.3 Receiving (Unit --> Host) . . . . . . . . . . . . . . . 33

6.2.4 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2.5 Number formats . . . . . . . . . . . . . . . . . . . . . . 33

6.2.6 Continuous transmission of measurements. 33

6.3.31 TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.32 TEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.33 TID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.34 TIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.35 TKB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.36 TLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3.37 TRA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3.38 TRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3.39 UNI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3.40 WDT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7 Maintenance and service

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.1 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2 Program transfer mode . . . . . . . . . . . . . . . 45

7.2.1 Preparations and selection . . . . . . . . . . . . . 45

7.2.2 Program transfer . . . . . . . . . . . . . . . . . . . . . 45

7.2.3 Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.2 CAO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.3 CAF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.4 Calibrating the unit . . . . . . . . . . . . . . . . . . . . 46

6.3 Mnemonics . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.2 AOM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.3 BAU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.4 COM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.5 COR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.6 DCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.7 DGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.8 ERA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.9 ERR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.10 EUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.11 FIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.12 FSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.13 FUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.14 GAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.15 HVC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.16 ITR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.17 LOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.18 OFC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.19 OFD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.20 PNR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.21 PR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.22 PRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.23 PRX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.24 RES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.25 SAV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.26 SC1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3.27 SP1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3.28 SPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3.29 TAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.30 TDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8 Troubleshooting

8.1 Fault indication . . . . . . . . . . . . . . . . . . . . . 48

8.2 Error messages . . . . . . . . . . . . . . . . . . . . . 48

8.3 Technical support . . . . . . . . . . . . . . . . . . . 48

9 Storage and disposal

9.1 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix

Conversion tables . . . . . . . . . . . . . . . . . . . 50

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Linear measures . . . . . . . . . . . . . . . . . . . . . 50

Temperature . . . . . . . . . . . . . . . . . . . . . . . . 50

Default parameters . . . . . . . . . . . . . . . . . . 51

Literature . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

ETL Certification . . . . . . . . . . . . . . . . . . . . 55

EC Declaration of Conformity. . . . . . . . . . 55

tinb07e1-e 2011-07 Vacuum Gauge Controller 3

Page 4

1 Introduction

Model:

PN:

SN:

V Hz W

1.1 Validity

1.1.1 Part number

This document applies to the following products:

Part number Product

398-020 VGC402

398-021 VGC403

The part number can be found on the type label which is

attached to one side of the unit.

1.1.2 Firmware version

This Operating Manual is based on the firmware version

302-534-D.

If the unit does not work as described, please check if it

is equipped with this firmware version. See Chapter 5.4.2

Firmware version (Pnr), 29.

1.1.3 Type label

There is a type label attached to one side of the unit. In

all communication with INFICON, please state the information on the type label. For this purpose you may want

to copy the information into the space provided below:

1.2 Intended use

The VGC402 and VGC403 Vacuum Gauge Controller is

a display and control unit for vacuum gauges made by

INFICON.

It is used together with vacuum gauges of the PSG, PCG,

PEG, MPG, CDG, BPG, BCG and HPG series and is

used for total pressure measurements. The vacuum

gauges must be operated in accordance with their

respective operating manuals.

In the following, the VGC402 or VGC403 Vacuum Gauge

Controller will be referred to as «Vacuum Gauge Controller».

1.2.1 Liability and warranty

INFICON assumes no liability and the warranty becomes

null and void if the end user or third parties

• Disregard the information in this document

• Use the product in a non-conforming manner

• Make any kind of alterations (modifications, repair

work, etc.) to the product

• Use the product with accessories not listed in the corresponding product documentation

We reserve the right to make technical changes without

prior notice. The figures are non-committal.

1.3 Product versions

The Vacuum Gauge Controller is available in two different versions: VGC402 and VGC403. The two products

differ from each other with regard to:

• Number of channels

Fig. 1-1 Type label (example)

4 tinb07e1-e 2011-07 Vacuum Gauge Controller

• Number of switching functions

• Power consumption

• Weight

See Chapter 2 Technical data, 7.

This Operating Manual describes both the VGC402 and

the VGC403.

Page 5

1.4 Safety

1.4.1 Personnel qualifications

All work described in this document may only be carried

out by persons who have suitable technical training and

the necessary experience or who have been instructed

by the end user of the product.

1.4.3 General safety instructions

For all work you are going to do, adhere to the applicable

safety regulations.

Also observe all safety notes given in this document and

forward the information to all other users of the product.

In particular, pay attention to the following safety notes:

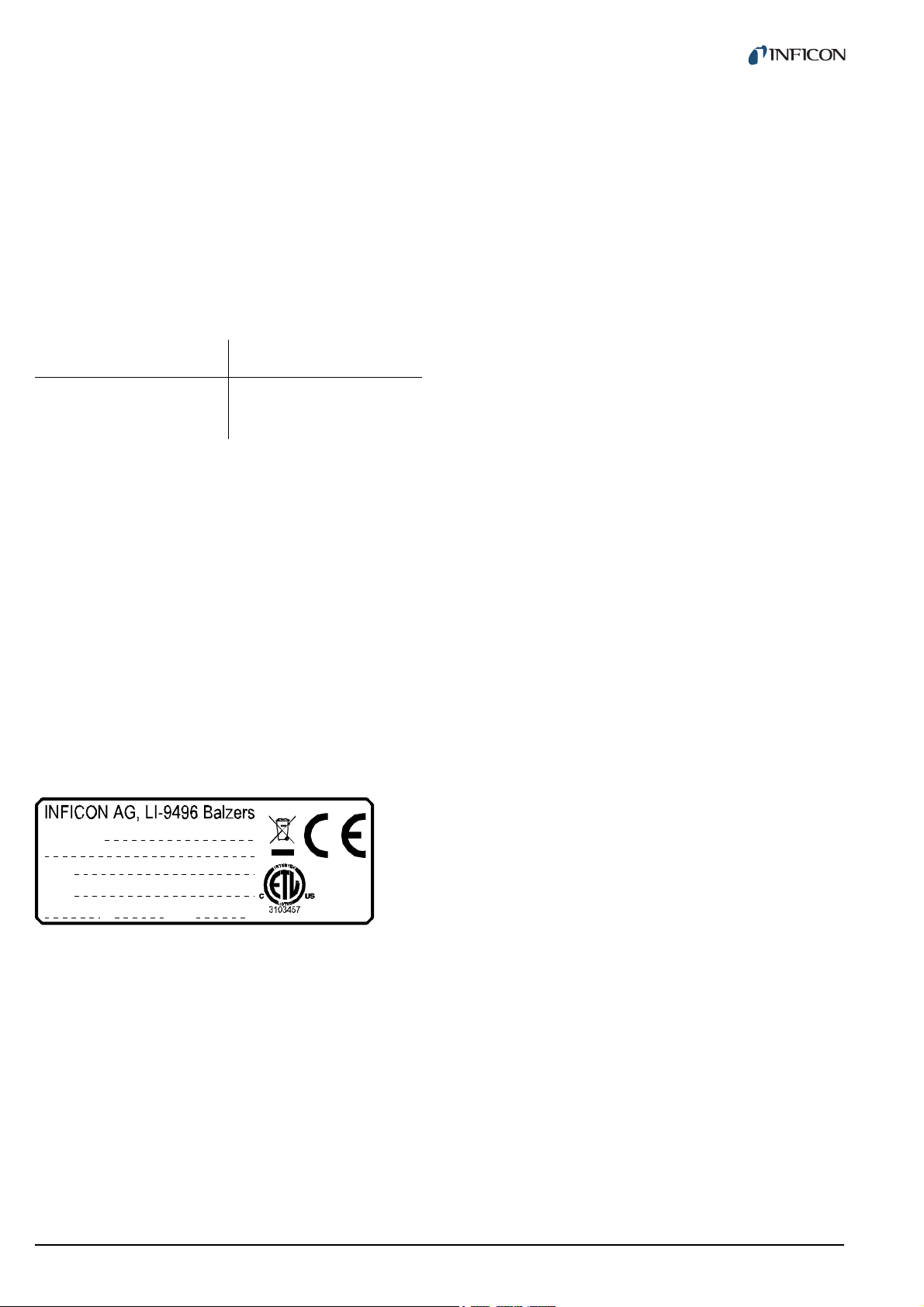

1.4.2 Illustration of residual dangers

This Operating Manual illustrates safety notes concerning residual dangers as follows:

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or severe injury.

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or severe injury.

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

moderate or minor injury or in property damage.

DANGER

Mains power.

The Vacuum Gauge Controller contains parts

which are connected to the mains supply.

Make sure that no objects enter through the

louvers of the unit. Keep the unit dry. Do not

open the unit.

NOTE:

A note such as this one indicates particularly important, but not safety-relevant information.

Fig. 1-2 Do not insert objects through louvers and keep unit dry

WARNING

Improper use.

Improper use can damage the Vacuum

Gauge Controller.

Use the Vacuum Gauge Controller only as intended by the manufacturer. See Chapter 1.2

Intended use, 4.

tinb07e1-e 2011-07 Vacuum Gauge Controller 5

Page 6

WARNING

A

Improper installation and operation data.

Improper installation and operation data may

damage the Vacuum Gauge Controller.

Strictly adhere to the stipulated installation

and operation data.

1.4.4 Disconnecting device

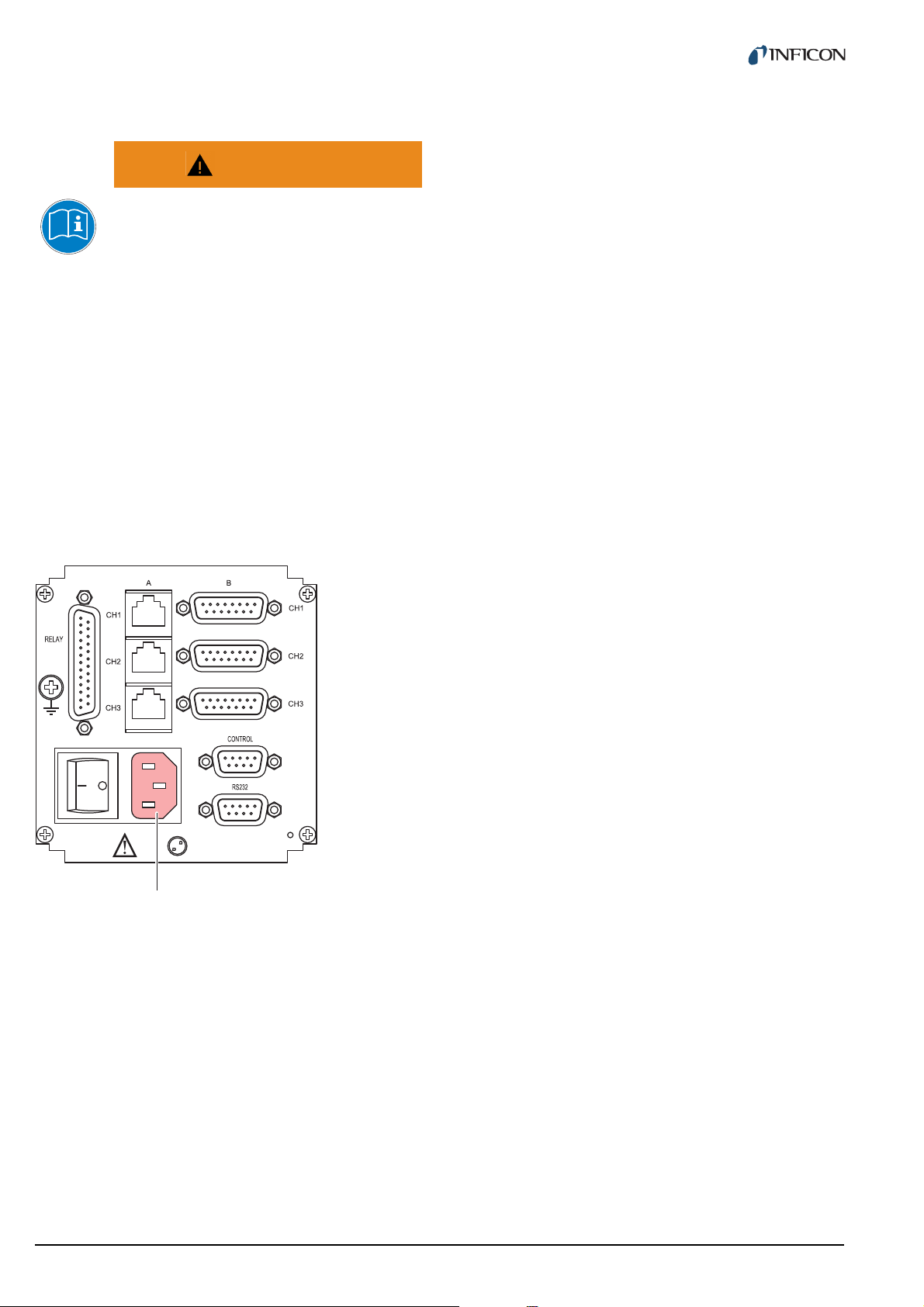

The Vacuum Gauge Controller is equipped with a disconnecting device according to EN 61010-1.

The disconnecting device is located at the back of the

Vacuum Gauge Controller. See Fig. 1-3, 6.

The disconnecting device must be readily identifiable and

easily reached by the user.

In order to disconnect the Vacuum Gauge Controller from

mains, you must unplug the mains cable.

Fig. 1-3 Back side of the VGC403

A Disconnecting device

6 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 7

2 Technical data

106.3

91.4

3.5

122.5

128.5

103

110

285

204.5

2.5

2.1 General data

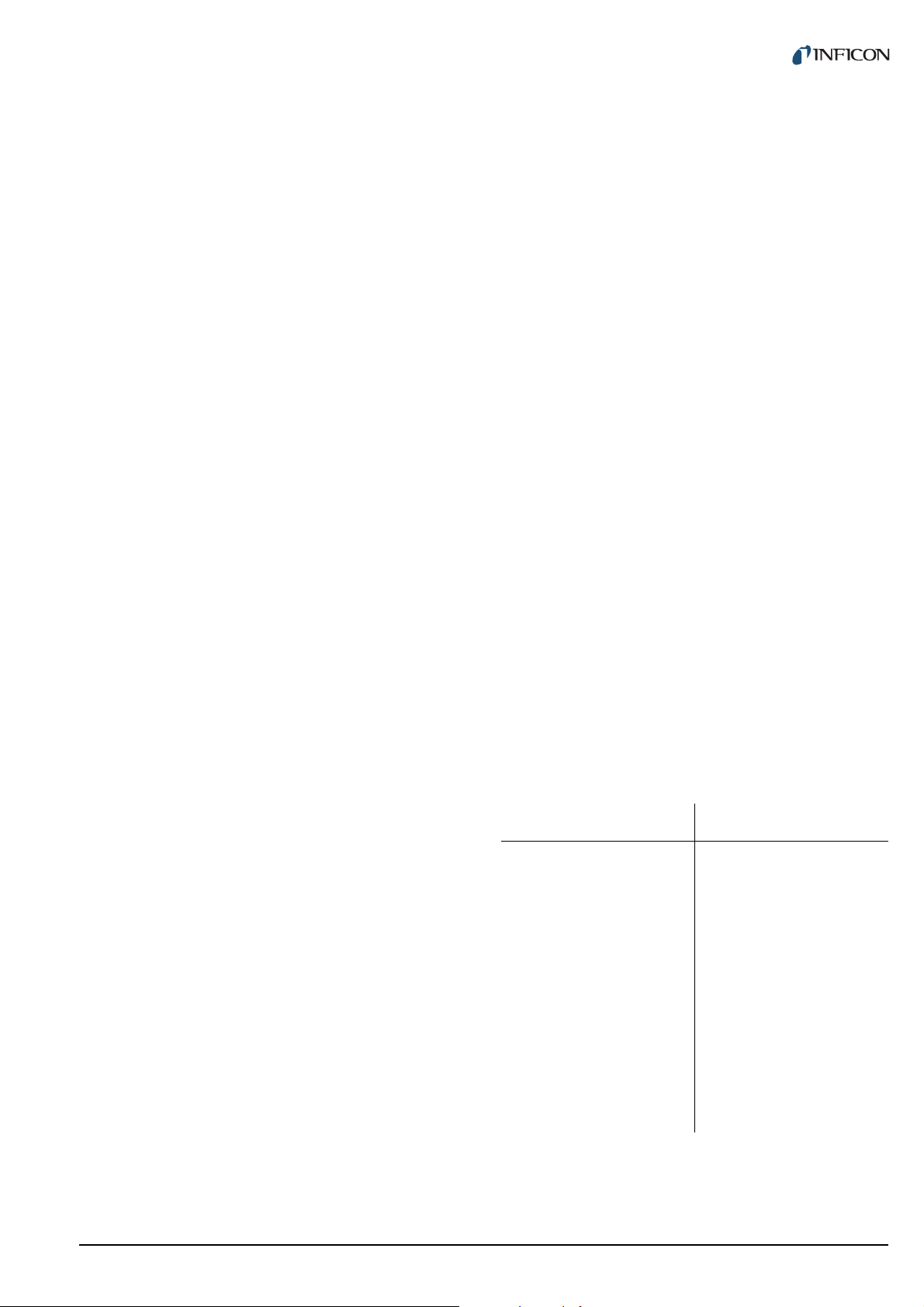

2.1.1 Mechanical data

Dimensions Width: 106.3 mm

Height: 128.5 mm (3 HE)

Depth: 207 mm

See Fig. 2-1, 7

Weight VGC402:

1.04 kg

VGC403:

1.16 kg

Use Desktop unit

Control panel mounted

Mounting the unit in a rack

2.1.2 Ambience

Temperature Storage: -20… +60 °C

Operation: +5…+50 °C

Relative humidity Max. 80 % (bis 31 °C),

decreasing to

max. 50 % (above 40 °C)

Use Indoors only

Altitude max. 2000 m NN

Pollution degree II

Protection type IP20

2.1.3 Operation

Manually Via 4 control buttons on the

front panel

Remote control Via RS232C interface

Fig. 2-1 Dimensions (in mm)

2.2 Mains connection

Voltage 90…250 VAC

Frequency 50…60 Hz

Power consumption VGC402:

Max. 45 W

VGC403:

Max. 65 W

Overvoltage category II

Protection class 1

Connection European appliance con-

nector IEC 320 C14

tinb07e1-e 2011-07 Vacuum Gauge Controller 7

Page 8

2.3 Channels

2.3.3 Measuring technique

2.3.1 Sensor connections

Number of channels VGC402: 2

VGC403: 3

Sensor connections per

channel

Compatible sensors Pirani:

RJ45 (FCC 68)

D-Sub, 15 pins, female

(connected in parallel)

PSG400, PSG400-S,

PSG100-S, PSG101-S,

PSG500, PSG500-S,

PSG502-S, PSG510-S,

PSG512-S, PSG550,

PSG552, PSG554

Pirani / Capacitance:

PCG400, PCG400-S,

PCG550, PCG552, PCG554

Cold cathode:

PEG100

Cold cathode / Pirani:

MPG400, MPG401

Capacitance:

CDG025, CDG025D,

CDG045, CDG045D,

CDG100, CDG100D,

CDG160D

Hot ionization / Pirani:

BPG400, BPG402

HPG400

Hot ionization / Pirani /

Capacitance: BCG450

Measuring ranges Sensor dependent

Error of measurement Gain error:

≤ 0.005 % FS

Offset error:

≤ 0.01 % FS

-1

Measuring rate 50 s

Display rate 10 s

Filter time constant Slow:

Unit of measurement mbar, Pa, Torr, Micron

Possible adjustments Linear sensors (CDG):

A/D converter Resolution > 16 bit

NOTE:

The measurements of the BPG/BCG/HPG/CDGxxxD

are transferred digitally.

-1

Approx. 1.0 s (f

Normal (nor):

Approx. 0.3 s (f

Fast:

Approx. 0.06 s (f

Zero-adjust

Logarithmic sensors (PSG,

PCG, PEG, MPG, BPG,

BCG, HPG):

Fixed correction factors for

, Ar, H2, or a variable cor-

N

2

rection factor in the range

0.10…9.99

= 0.16 Hz)

g

= 0.53 Hz)

g

= 2.65 Hz)

g

2.3.2 Sensor supply

2.4 Switching functions

Voltage +24 VDC ±5 %

Current 500 mA

(750 mA short-time)

Fuse 900 mA via PTC element

Self-resetting after switching

the unit off or unplugging the

sensor.

The supply meets the

requirements of a ground

protective extra low voltage

(SELV).

8 tinb07e1-e 2011-07 Vacuum Gauge Controller

Number of switching

functions

Assignment Can be configured any way

Delay time Filter time constant depen-

Adjustment range Sensor dependent

Hysteresis Linear sensors (CDG): ≥ 1

VGC402: 4

VGC403: 6

dent

% FS

Logarithmic sensors (PSG,

PCG, PEG, MPG, BPG,

BCG, HPG):

≥ 10 % of measurement

Page 9

2.4.1 Switching function relay

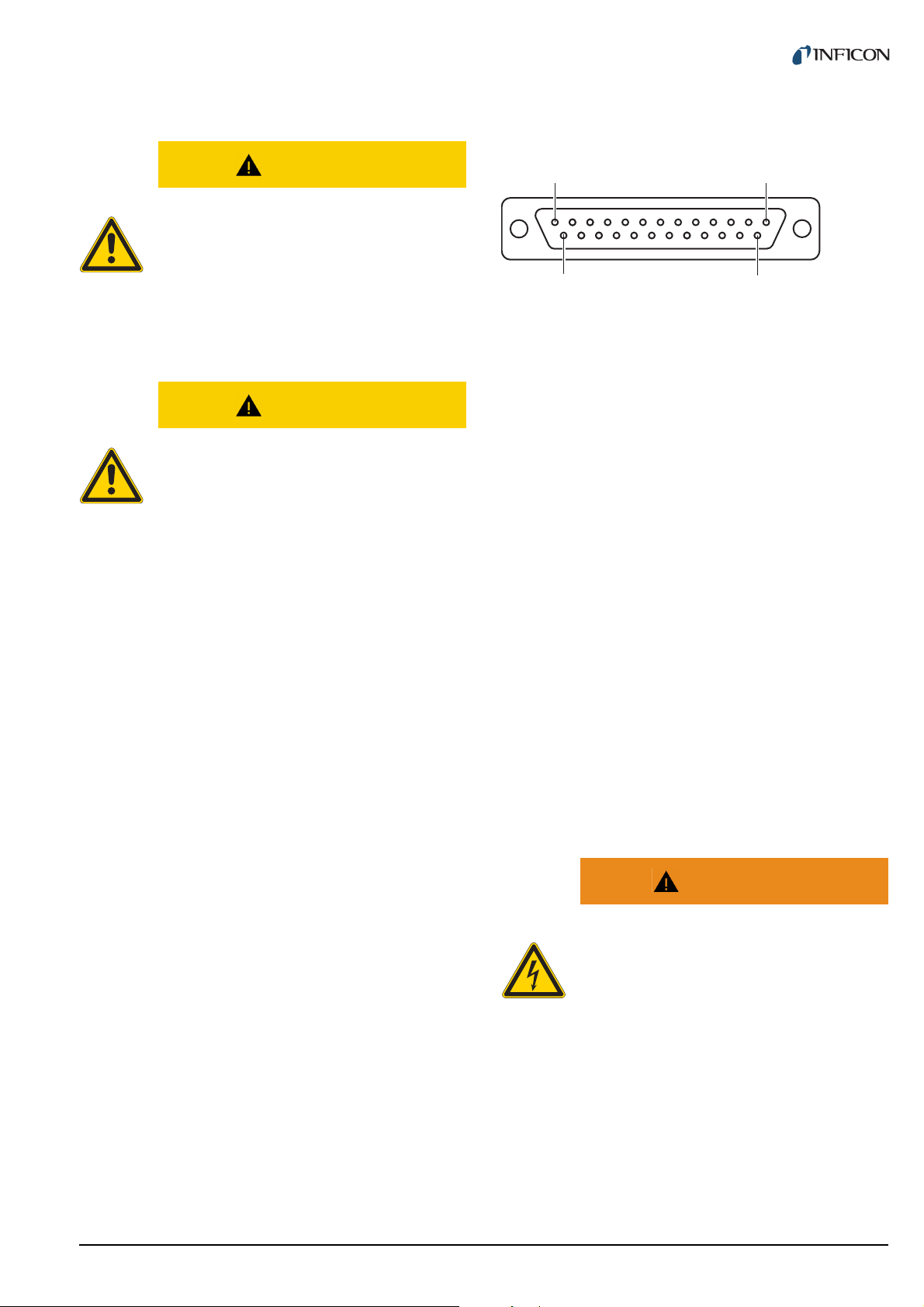

2.5.2 Recorder output

Contact type Change-over contact, float-

ing

Load (ohmic) Max. 60 VDC, 0.5 A

Max. 30 VAC, 1 A

Lifetime Mechanical:

Connection D-sub, 25 pins, female.

7

cycles

10

Electrical:

5

cycles at maximum load

10

See Fig. 3-8, 13.

2.4.2 Error signal relay

Number 1

Delay time ≤ 20 ms

Contact type Change-over contact, float-

ing

Load (ohmic) Max. 60 VDC, 0.5 A

Max. 30 VAC, 1 A

Lifetime Mechanical:

7

cycles

10

Electrical:

5

cycles at maximum load

10

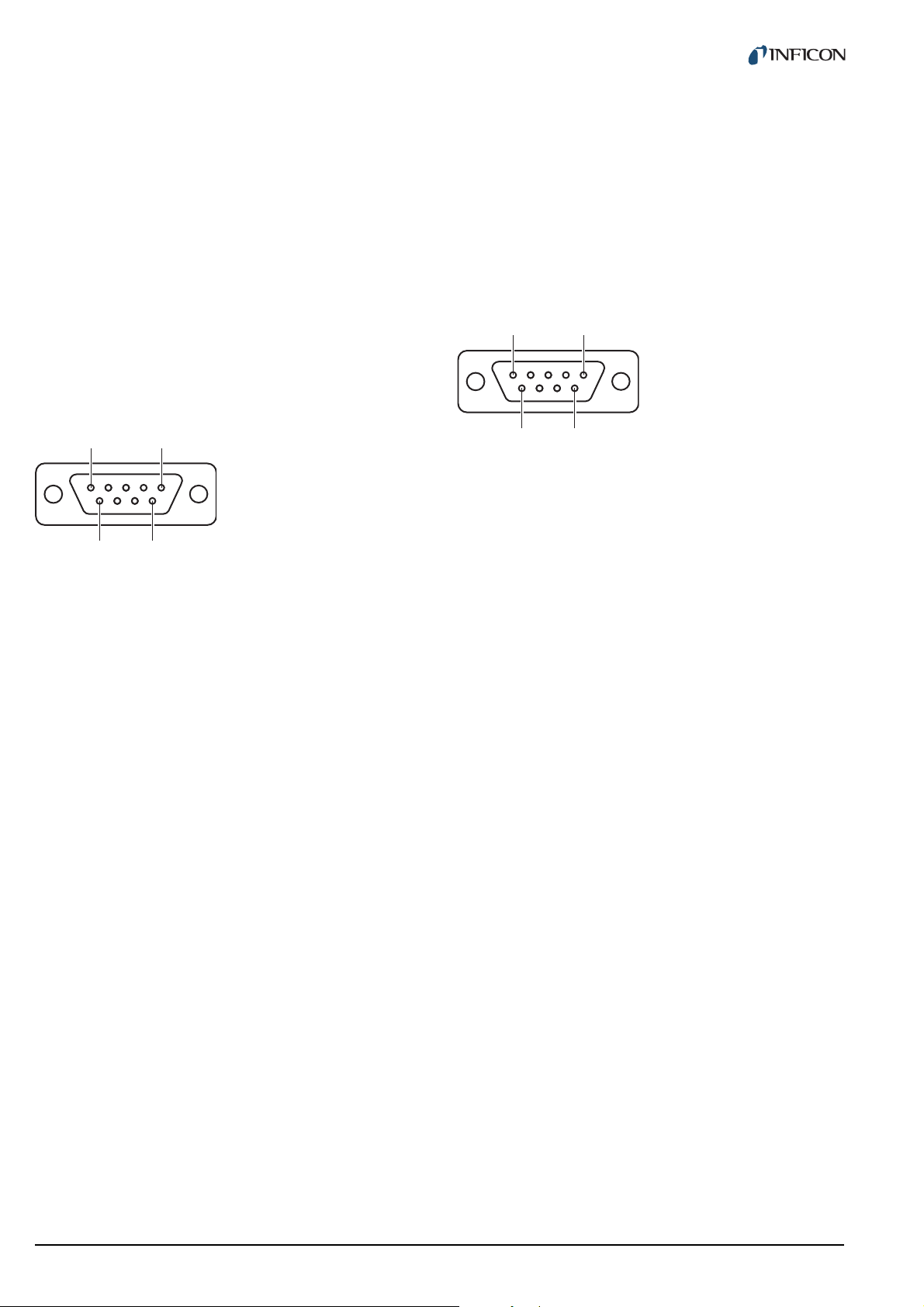

Number 1

Voltage range 0…10 VDC

Resolution 1 mV

Accuracy ± 20 mV

Internal resistance 3300 Ω

Relation between

voltage and pressure

Connection D-Sub, 9 pins, male.

Programmable

See Fig. 3-9, 14.

2.5.3 Computer interface

Default RS232C

Protocol ACK/NAK

ASCII with 3-character mnemonics. Bidirectional data

flow.

Signals Only TXD and RXD used

Baud rate 9600, 19200, 38400

Connection D-Sub, 9 pins, female.

See Fig. 3-10, 14.

Connection D-sub, 25 pins, female.

See Fig. 3-8, 13.

2.5 Outputs

2.5.1 Analog output

Number 1 per channel

Voltage range 0…10 VDC

Deviation from

displayed value

Internal resistance 47 Ω

Relation between

voltage and pressure

Connection D-Sub, 9 pins, male.

± 50 mV

Sensor dependent

See Fig. 3-9, 14.

2.6 Scope of delivery

Designation Number

Vacuum Gauge Controller

Mains cable 1

Rubber strip

Rubber feet

Collar screws

Plastic sleeves

CD-ROM manual 1

EC Declaration of Conformity

Installation manual 1

1

1

2

4

4

1

tinb07e1-e 2011-07 Vacuum Gauge Controller 9

Page 10

3 Installation

105

91.4

122.5

112

M3 (ø3.5)

3.1 Unpacking

1 Visually inspect the transport packaging for signs

of external damage

2 Unpack the Vacuum Gauge Controller and put the

packaging material aside

NOTE:

Keep the packaging material for later use. The Vacuum Gauge Controller must be stored and transported

in the original packaging material only.

3 Examine the Vacuum Gauge Controller for com-

pleteness

4 Visually inspect the Vacuum Gauge Controller for

signs of damage

WARNING

Damaged product.

Putting a damaged product into operation can

be extremely dangerous.

Never attempt to put a damaged product into

operation. Secure the damaged product from

unintended operation. Send a damage report

to the haulage company or the insurer.

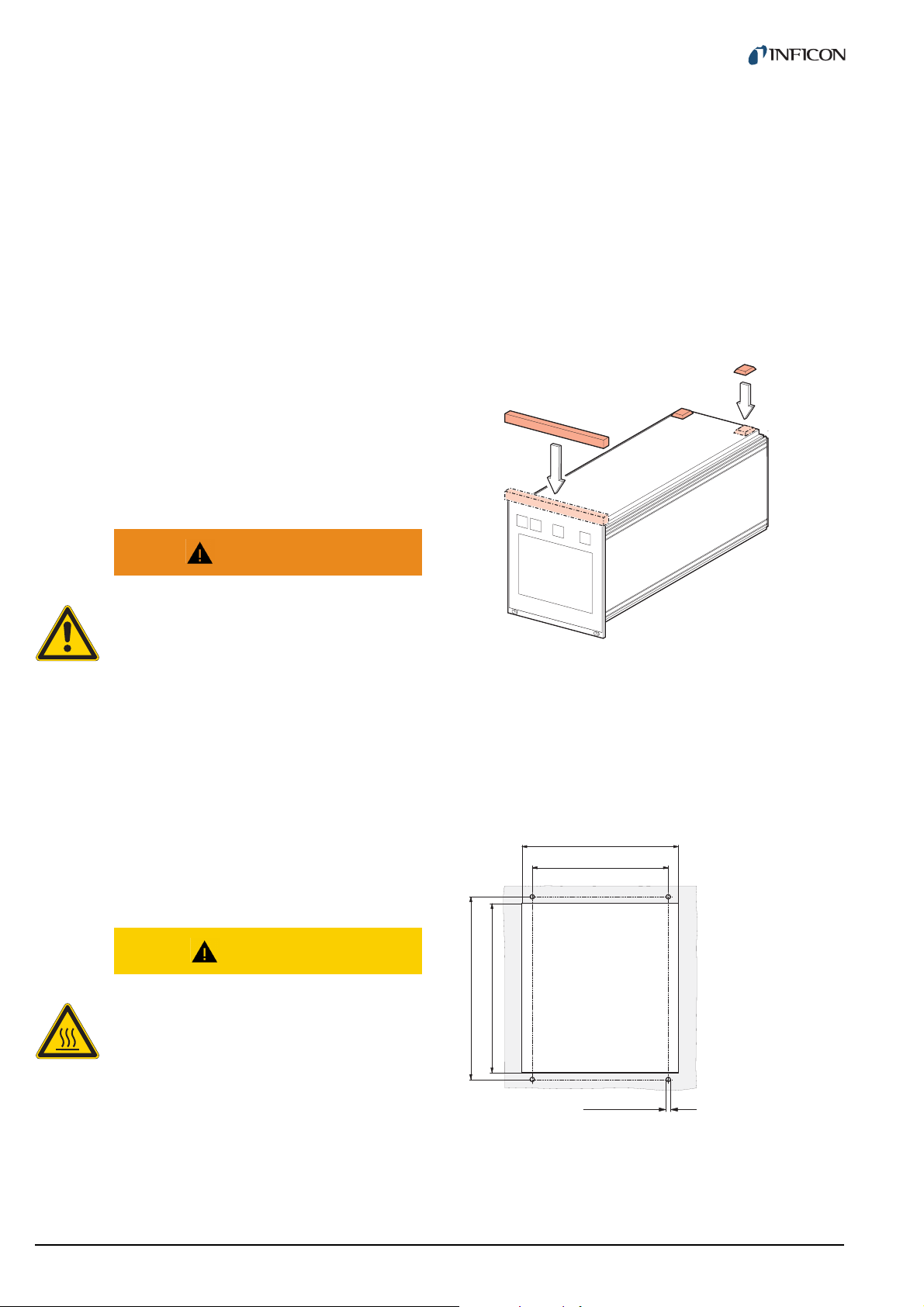

1 Turn the Vacuum Gauge Controller upside down

as shown in Fig. 3-1, 10

2 Push the supplied rubber strip onto the lower edge

of the front panel

3 Stick the supplied rubber feet to the bottom of the

casing

Fig. 3-1 Using the product as a desk-top unit

4 Turn the Vacuum Gauge Controller back to normal

orientation and place it on the required location

3.2 Mechanical installation

The Vacuum Gauge Controller can be used as follows:

As a desk-top unit, mounted in a control panel, or

mounted in a 19" rack. In each of these cases you must

pay attention to the following safety note:

CAUTION

Too high ambient temperature.

Exceeding the maximum permitted ambient

temperature may damage the unit.

Make sure that the maximum permitted ambient temperature is not exceeded and that the

air can flow freely through the louvers. Do not

expose the unit to direct sunlight.

3.2.1 Desktop unit

In order to use the Vacuum Gauge Controller as a desktop unit, proceed as follows:

3.2.2 Control panel mounted

In order to mount the unit in a control panel, the following

cutout is required:

Fig. 3-2 Control panel cutout (in mm)

1 Insert the Vacuum Gauge Controller into the cutout

2 Fasten the unit with four M3 screws

10 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 11

NOTE:

A

B

C

D

EFGH

I

J

K

In order to reduce the strain on the front panel it is

recommended to support the bottom of the unit.

3.3 Connecting

3.3.1 Back side of the device

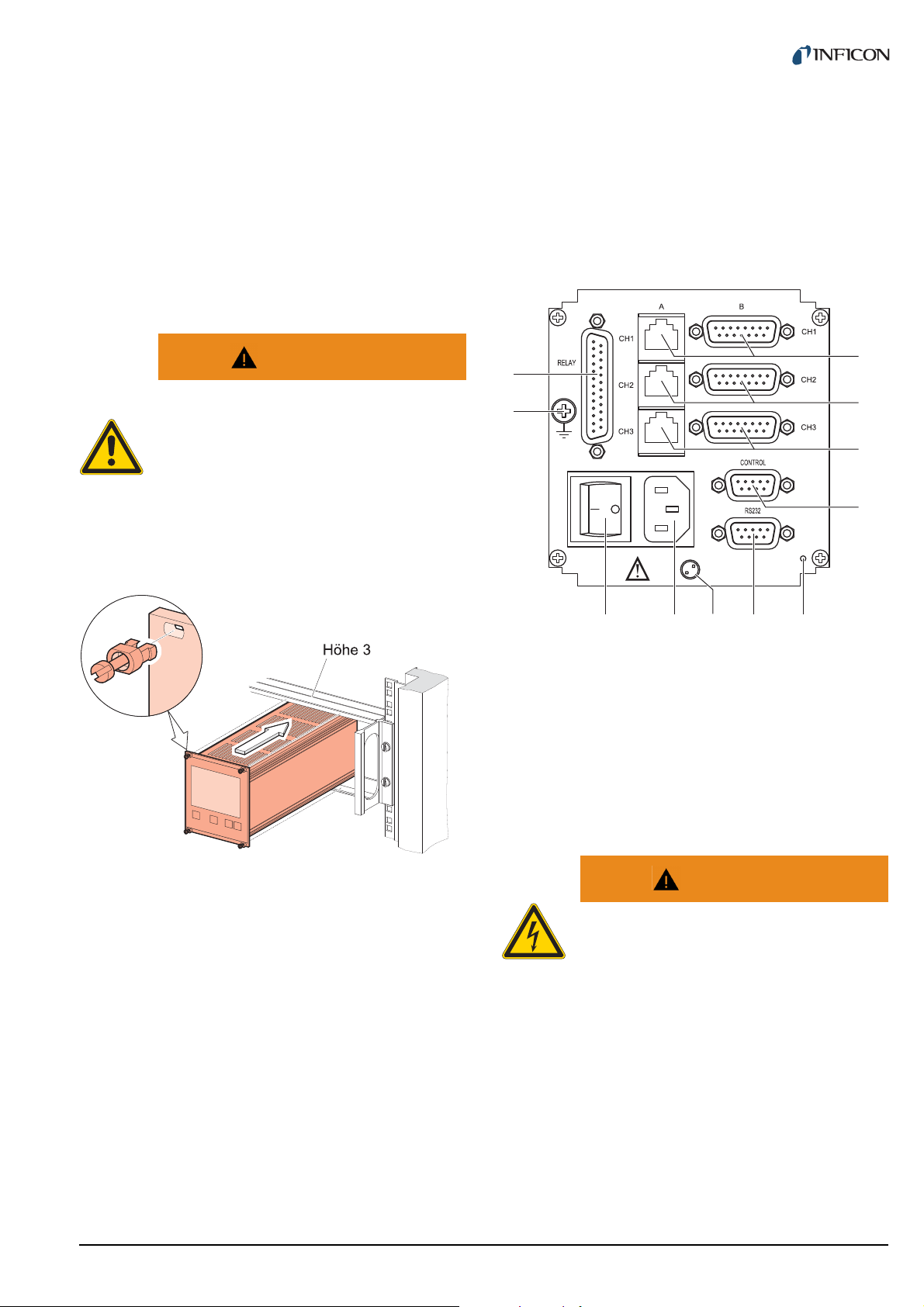

3.2.3 Mounting the unit in a rack

The Vacuum Gauge Controller is designed for installation

into a rack chassis adapter according to DIN 41 494 (19",

3 HE). For this purpose, 4 collar screws and 4 plastic

sleeves are supplied with the unit.

WARNING

Lower protection class of the rack.

If the product is installed in a rack, it is likely

to lower the protection class of the rack (protection from foreign bodies and water) e.g.

according to the EN 60204-1 regulations for

switching cabinets.

Take appropriate measures to restore the required protection class of the rack.

Fig. 3-4, 11 shows the back side of the VGC403. The

connection for channel 3 (Pos. C) is not available in the

VGC402.

Fig. 3-4 Back side of the VGC403

A Sensor connection, channel 1

B Sensor connection, channel 2

C Sensor connection, channel 3

D CONTROL connection

E Switch for program transfer mode

F RS232C connection

G Mains connection / disconnecting device

HMains switch

I Ground screw

J RELAY connection

K Screw for internal protective conductor. Do not loosen this screw!

Fig. 3-3 Mounting the unit in a rack

WARNING

NOTE:

In order to reduce the strain on the front panel it is

recommended to equip the rack chassis adapter with

a guide rail.

NOTE:

Screw for internal protective conductor.

The internal protective conductor is connected to the casing with a screw (Pos. K).

Do not turn or loosen this screw.

For safe and easy installation of heavy rack chassis

adapters, it is recommended to equip the rack frame

with slide rails.

1 Fasten the rack chassis adapter in the rack

2 Insert the Vacuum Gauge Controller into the rack

chassis adapter

The configuration of the available connections is

described in the following sections.

3 Fasten the Vacuum Gauge Controller with the sup-

plied collar screws and plastic sleeves to the rack

chassis adapter

tinb07e1-e 2011-07 Vacuum Gauge Controller 11

Page 12

3.3.2 Mains connection

1

8

1

8

9

15

3.3.3 Ground

The mains connection (Fig. 3-4, 11, Pos. G) is

designed for a mains cable which contains a European

appliance connector on the device side.

A mains cable is supplied with the unit. If the plug is not

compatible with your wall socket, you have to get a suitable mains cable:

• Three-conductor cable with protective ground

2

• Conductor cross-section 3 × 1.5 mm

Fig. 3-5 Three-conductor cable with protective ground (example)

or larger

The ground screw (Fig. 3-4, 11, Pos. I) can be used to

connect the Vacuum Gauge Controller with the protective

ground of the pumping station.

1 If required: Connect the protective ground of the

pumping station with the ground screw. Use a protective conductor.

3.3.4 SENSOR

The SENSOR connection is used to connect the sensors.

For each channel, there are two connections available

which are connected in parallel: An 8-pin RJ45 appliance

socket and a 15-pin D-Sub appliance socket. See

Fig. 3-4, 11, Pos. A…C.

Pin assignment

WARNING

Mains power.

Improperly grounded devices can be extremely dangerous in the event of a fault.

Use three-wire mains or extension cables

with protective ground only. Plug the mains

cable into wall sockets with protective ground

only.

WARNING

No mains fuse.

The Vacuum Gauge Controller is not

equipped with a mains fuse.

The wall socket must be protected with a fuse

(max. 10 A).

1 Connect the European appliance connector of the

mains cord with the mains connection of the unit

Fig. 3-6 SENSOR appliance socket (RJ45)

1 +24 VDC

2PGND

3 Signal

4 Ident

Fig. 3-7 SENSOR appliance socket (D-Sub, 15-pin)

1 EMI-Status

2 Signal

3 Status

4 HV_EMI

5PGND

6n.c.

7 Degas

8 Supply

5 Signal-GND

6 Status

7HV_L

8 HV_EMI

9n.c.

10 Ident

11 Supply_CDG

12 Signal-GND

13 RXD

14 TXD

15 Chassis

2 Connect the plug of the mains cable with the wall

socket

NOTE:

If the unit is installed in a switching cabinet, the

mains power can be supplied via a switchable central

power distributor.

12 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 13

CAUTION

1

13

14

25

Improper sensor.

Sensors which are not designed for use with

the Vacuum Gauge Controller may damage

the unit.

Operate the Vacuum Gauge Controller with

proper sensors only. See Chapter 2.3.1 Sensor connections, 8.

CAUTION

Multiple connection.

Only one sensor may be connected to each of

the channels. Otherwise the connected sensors will be damaged.

Never connect more than one sensor per

channel.

Connecting

1 Channel 1: Connect the sensor with to the CH1-A

or CH1-B connection. Use a shielded 1:1 cable.

2 Channel 2: Connect the sensor with to the CH2-A

or CH2-B connection. Use a shielded 1:1 cable.

3 Channel 3: Connect the sensor with to the CH3-A

or CH3-B connection. Use a shielded 1:1 cable.

3.3.5 RELAY

The switching functions and the error monitoring system

influence the state of several relays inside of the Vacuum

Gauge Controller. The RELAY connection (Fig. 3-4,

11, Pos. J) allows to utilize the relay contacts for

switching purposes. The relay contacts are potential-free

(floating).

Pin assignment

Fig. 3-8 RELAY appliance socket (D-Sub, 25-pin)

1GND

2n.c.

3 Error break contact (NC)

4 SP 1 break contact (NC)

5 SP 1 common contact

(COM)

6 SP 1 make contact (NO)

7GND

8 SP 2 break contact (NC)

9 SP 2 common contact

(COM)

10 SP 2 make contact (NO)

11 SP 3 break contact (NC)

12 SP 3 common contact

(COM)

13 SP 3 make contact (NO)

n.c. not connected

COM common contact

NC break contact (normally closed)

NO make contact (normally open)

14 Error make contact (NO)

15 Error common contact

(COM)

16 SP 4 break contact (NC)

17 SP 4 common contact

(COM)

18 SP 4 make contact (NO)

19 SP 5 break contact (NC)

20 SP 5 common contact

(COM)

21 SP 5 make contact (NO)

22 SP 6 break contact (NC)

23 SP 6 common contact

(COM)

24 SP 6 make contact (NO)

25 +24 VDC, 200 mA. Meets

the requirements of a ground

protective extra low voltage

(SELV)

NOTE:

Pin 25 is used for supplying relays with a higher

breaking capacity. The supply contact is protected at

200 mA with a PTC element. The element is self-resetting when switching the unit off or unplugging the

RELAY connector.

WARNING

Hazardous voltage.

Voltages above 60 VDC or 30 VAC pose a

shock hazard.

The RELAY connection may be used for

switching voltages of max. 60 VDC or 30 VAC

only. These voltages must meet the requirements of a ground protective extra low voltage (SELV).

1 Connect the peripheral components with the

RELAY connection. Use a shielded connection

cable.

tinb07e1-e 2011-07 Vacuum Gauge Controller 13

Page 14

3.3.6 CONTROL

1

5

6 9

1

5

6

9

3.3.7 RS232C

The CONTROL connection (Fig. 3-4, 11, Pos. D) contains the following signal pins:

• Analog outputs for the signals of the individual channels

• Recorder output. This is a programmable analog output which can be assigned to one of the three channels.

• HV-EMI. Used to switch the high-vacuum circuit of the

PEG sensor on and off. The signal levels are: On =

+24 V. Off = 0 V. See Reference [7].

Pin assignment

Fig. 3-9 CONTROL appliance plug (D-Sub, 9-pin)

1 Analog output 1

2 Analog output 3

3GND

4 HV-EMI 3

5 HV-EMI 1

6 Analog output 2

7 Recorder output

8GND

9 HV-EMI 2

1 Connect the peripheral components with the CON-

TROL connection. Use a shielded connection

cable.

The RS232C serial interface (Fig. 3-4, 11, Pos. F)

allows remote control of the unit via a computer or a terminal. See Chapter 6 Computer interface, 32.

In addition, the interface may be used for firmware

updates. See Chapter 7.2 Program transfer mode, 45.

Pin assignment

Fig. 3-10 RS232C appliance socket (D-Sub, 9-pin)

1 n.c. / SUP

2TXD

3RXD

4n.c.

5GND

6DSR

7n.c.

8CTS

9GND

1 Connect the serial interface of the computer with

the RS232C connection. Use a shielded cable.

NOTE:

Use a serial extension cable with a 9-pin plug and a

9-pin socket. The cable must not contain any crossed

wires.

NOTE:

The analog outputs (pins 1, 2, 6) differ from the displayed values by no more than ±50 mV.

14 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 15

4Operation

parach

ABC

D

E

F

G

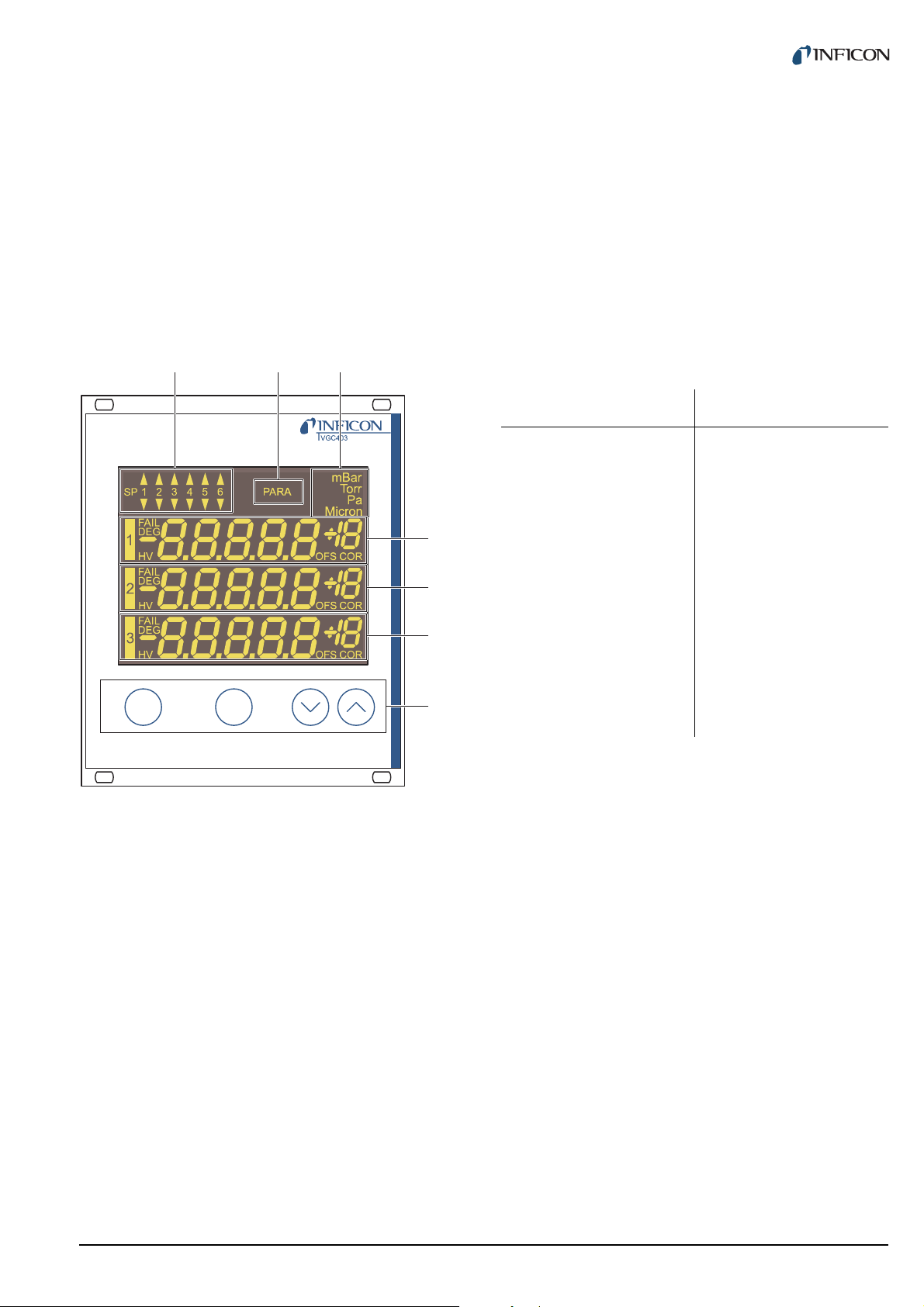

4.1 Front panel

Fig. 4-1, 15 shows the front panel of the VGC403. The

VGC402 is not equipped with the switching points SP5

and SP6 (Pos. A) and the display for the channel 3 (Pos.

F).

Pressure unit

The top right corner (Pos. C) of the display indicates the

pressure unit: mbar, Torr, Pa, or Micron.

Channels

There is a separate display area for each of the available

channels (Pos. D, E, F). From the left to the right, this

area displays the following information:

Display Significance

1, 2, 3 Channel number

FAIL (flashing) Error

DEG (illuminated) Degas function is acti-

vated

HV (illuminated) High-vacuum circuit is

activated

+18

-8.8.8.8.8

Measurement or status

message

OFS (illuminated) Offset correction is acti-

vated

Fig. 4-1 Front panel of the VGC403

A Switching function indicator

B Parameter mode

C Pressure unit

D Display area for channel 1

E Display area for channel 2

F Display area for channel 3

G Control buttons

4.1.1 Display

Switching functions

The top left corner (Pos. A) of the display indicates the

switching function states. An illuminated triangle above a

number indicates that the pressure is above the lower

threshold value. An illuminated triangle below a number

indicates that the pressure is below the upper threshold

value. See Fig. 5-1, 21.

Parameter mode

The PARA indicator (Pos. B) is illuminated when the unit

is set to the parameter mode.

COR (illuminated) Gas type correction is

activated

4.1.2 Control buttons

CH

The CH button is used to select a channel. This may be

necessary e.g. if you want to switch a particular sensor on

or off, or if you want to modify the sensor parameters. The

number of the currently selected channel is flashing for a

few seconds.

PARA

The PARA button is used to select the parameter mode.

The PARA indicator (Pos. B) is illuminated and you can

modify various parameters. See Chapter 4.5 Parameter

mode, 19.

Arrow buttons (DOWN/UP)

The arrow buttons are required for entering data in the

parameter mode. Pressing one of these buttons will

decrease or increase the currently displayed value. In the

following, these buttons will be referred to as DOWN and

UP, respectively.

tinb07e1-e 2011-07 Vacuum Gauge Controller 15

Page 16

4.2 Switching on and off

4.3 Operating modes

4.2.1 Switching on

1 Switch the mains switch on. See Fig. 3-4, 11,

Pos. H.

After switching on, the Vacuum Gauge Controller will perform the following actions:

•Self test

• Identify all sensors

• Restore the previously set parameters

• Activate measurement mode

• Adapt parameters (if a sensor type has changed

meanwhile)

4.2.2 Switching off

1 Switch the mains switch off. See Fig. 3-4, 11,

Pos. H.

4.2.3 Waiting time

CAUTION

Delay time.

The Vacuum Gauge Controller can be set to one of the

following operating modes:

Measurement mode

The measurement mode is the standard operating mode.

It displays the pressure readings of the sensors. In case

of an error, a status message is displayed instead. See

Chapter 4.4 Measurement mode, 17.

Parameter mode

The parameter mode gives you access to various parameters. You can check the parameter settings or modify

them using the arrow buttons. This allows you to configure the Vacuum Gauge Controller. See Chapter 4.5

Parameter mode, 19.

Program transfer mode

The program transfer mode is used to transfer the latest

version of the firmware to the Vacuum Gauge Controller.

See Chapter 7.2 Program transfer mode, 45.

After switching off, the Vacuum Gauge Controller requires approximately 10 seconds to

initialize again.

Wait for at least 10 seconds before you switch

the Vacuum Gauge Controller on again.

NOTE:

If the Vacuum Gauge Controller has been installed in

a control panel or a rack, it can also be switched on

and off via the central power distributor.

16 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 17

4.4 Measurement mode

parach

parach

parach

4.4.3 Control button functions

4.4.1 Selection

The Vacuum Gauge Controller automatically selects the

measurement mode after it has been switched on.

When the unit is set to the parameter mode, it will automatically return to the measurement mode if no button is

pressed for 10 seconds.

4.4.2 Description

The measurement mode is the standard operating mode.

It displays the pressure readings of the sensors. A status

message is displayed if the pressure exceeds the permissible range. See Tab. 4-1, 17.

Display Pressure

Er Hi Significantly above the permissible

range

The FAIL indicator flashes

The error signal relay switches

Reading In the permissible range

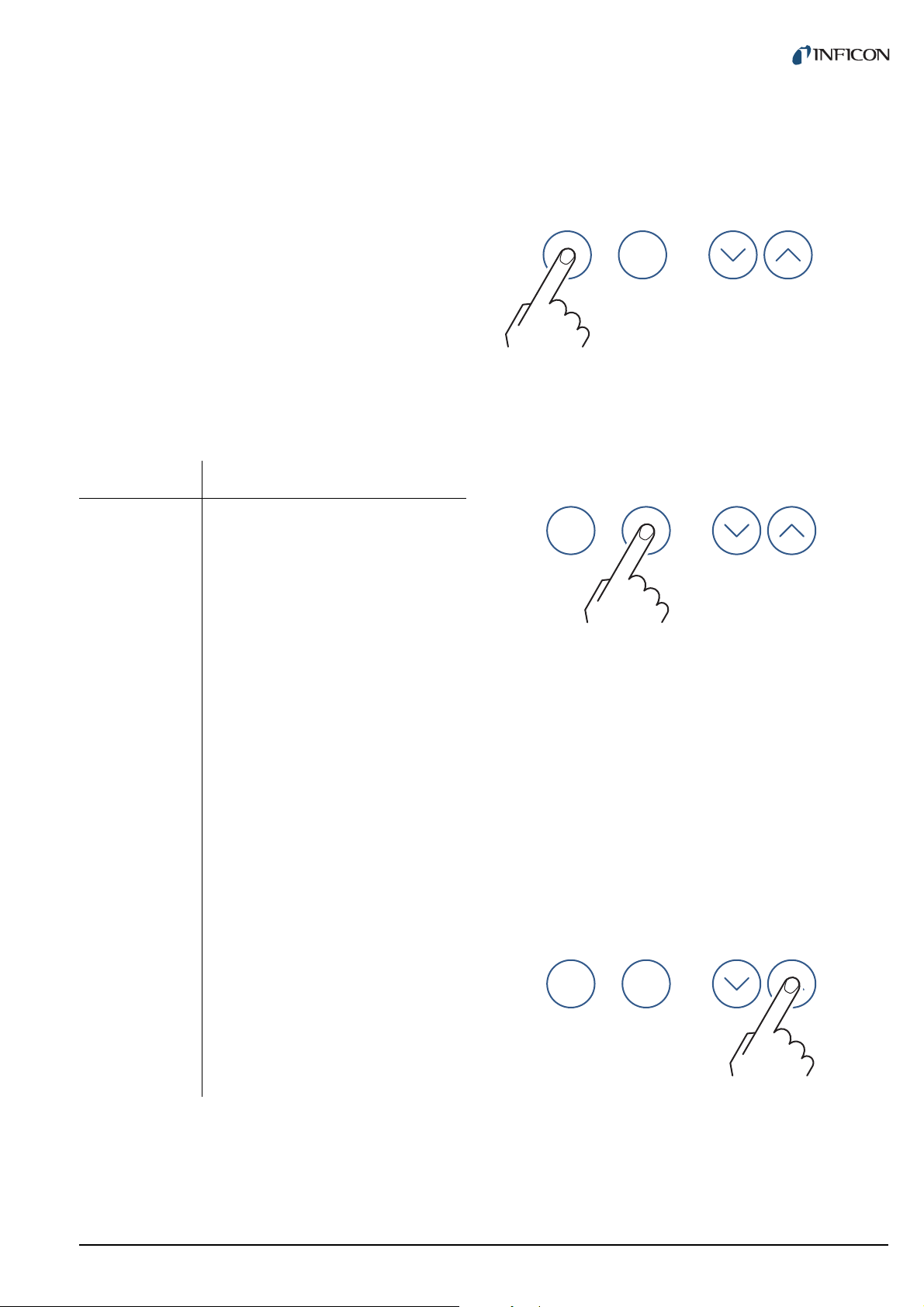

4.4.3.1 Selecting a channel

1 Press the CH button

Fig. 4-2 Pressing the CH button

The unit selects the next channel. The number of the

selected channel is flashing for a few seconds.

4.4.3.2 Selecting parameter mode

1 Press the PARA button

Er Lo Significantly below the permissible

range

The FAIL indicator flashes

The error signal relay switches

Er x Error message of BPG400/HPG

x = Error code (High-Byte)

Er xx Error message of BCG, BPG402

xxH = Error code

noSEn See Tab. 4-2, 18

noid See Tab. 4-2, 18

oFF See Tab. 5-14, 30

Hot See Chapter 5.2.6, 25

SELF See Chapter 5.2.8, 25

CH 1 See Chapter 5.2.8, 25

CH 2 See Chapter 5.2.8, 25

CH 3 See Chapter 5.2.8, 25

LoC See Chapter 5.4.5, 30

Tab. 4-1 Display when in measurement mode

Channels which are not connected to a sensor display

noSEn. This status message disappears after approximately two minutes.

Fig. 4-3 Pressing the PARA button

The unit changes to the parameter mode. See

Chapter 4.5 Parameter mode, 19. It will automatically

return to the measurement mode if no button is pressed

for 10 seconds.

4.4.3.3 Switching high-vacuum circuit on

The high-vacuum circuit of the following sensors can be

switched on manually: PEG.

For this purpose the sensor control must be set to HAnd.

See Chapter 5.2.6 Sensor activation (S-on), 25.

1 Press the CH button to select the required channel

2 Keep the UP button pressed for approximately 1

second

Fig. 4-4 Press the UP button for 1 second

The sensor on the selected channel is switched on. The

HV indicator is illuminated. The display shows the pressure reading or a status message. See Tab. 4-1, 17.

tinb07e1-e 2011-07 Vacuum Gauge Controller 17

Page 18

4.4.3.4 Switching degas function on

parach

parach

4.4.3.7 Identifying a sensor

The degas function of the following sensors can be

switched on manually: BPG, BCG.

1 Press the CH button to select the required channel

2 Keep the UP button pressed for approximately 1

second. See Fig. 4-4, 17.

The degas function of the sensor on the selected channel

is switched on. The DEG indicator is illuminated.

4.4.3.5 Switching high-vacuum circuit off

The high-vacuum circuit of the following sensors can be

switched off manually: PEG.

For this purpose the sensor control must be set to HAnd.

See Chapter 5.2.8 Sensor deactivation (S-oFF), 25.

1 Press the CH button to select the required channel

2 Keep the DOWN button pressed for approximately

1 second

1 Keep the UP and DOWN buttons pressed for

approximately 1 second

Fig. 4-6 Press the UP and DOWN buttons for 1 second

The display area of the individual sensor shows the connected sensors. See Tab. 4-2, 18.

Display Significance

PSG Pirani gauge (PSG)

PCG Combined gauge

Pirani / Capacitance (PCG)

PEG Cold cathode gauge (PEG)

MPG Combined gauge

Cold cathode / Pirani (MPG)

Fig. 4-5 Press the DOWN button for 1 second

The sensor on the selected channel is switched off. The

HV indicator is dark. The display shows the status oFF.

4.4.3.6 Switching degas function off

The degas function of the following sensors can be

switched off manually: BPG, BCG.

1 Press the CH button to select the required channel

2 Keep the DOWN button pressed for approximately

1 second. See Fig. 4-5, 18.

The degas function of the sensor on the selected channel

is switched off. The DEG indicator is dark.

CDG Capacitive analog gauge, linear

(CDG025, CDG045, CDG100)

CDG d Capacitive digital gauge, linear

(CDG025D, CDG045D, CDG100D,

CDG160D)

bPG Combined gauge

Hot ionization / Pirani (BPG400)

bPG2 Combined gauge

Hot ionization / Pirani (BPG402)

bCG Combined gauge

Hot ionization / Pirani / Capacitance

HPG Combined gauge

Hot ionization / Pirani (HPG)

noSEn No sensor found

noid No sensor identification found

Tab. 4-2 Sensor identification

NOTE:

In the case of BPG/BCG/HPG sensors, the software

version number of the sensor is also shown (e.g.

1.20).

18 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 19

4.5 Parameter mode

4.5.1 Selection

Pressing the PARA button switches from the measurement mode to the parameter mode. The PARA indicator

is illuminated.

When the unit is set to the parameter mode, it will automatically return to the measurement mode if no button is

pressed for 10 seconds. The PARA indicator is dark.

4.5.2 Parameter groups

The parameter mode gives you access to various parameters. You can check the parameter settings or modify

them using the arrow buttons. This allows you to configure the Vacuum Gauge Controller.

Tab. 4-3, 19 shows all available parameters.

Parameter

group

PArA

SP

PArA

SEn

Parameter

SP1-L

SP1-H

SP2-L

SP2-H

SP3-L

SP3-H

SP4-L

SP4-H

SP5-L

SP5-H

SP6-L

SP6-H

FiLt

GAS

FS

oFS

dEGAS

S-on

S-oFF

EMi

FiL

PrE

Parameter

group

PArA

tESt

Tab. 4-3 Parameter groups and their parameters

The available parameters are subdivided into the following parameter groups:

Switching function parameters (PArA SP)

These parameters are used to assign pressure dependent switching functions to the channels. The switching

points 5 and 6 are only available in the VGC403. See

Chapter 5.1 Switching function parameters (PArA SP),

21.

Sensor parameters (PArA SEn)

These parameters concern the sensor on the currently

selected channel only. There is an individual set of

parameters for each channel. See Chapter 5.2 Sensor

parameters (PArA SEn), 23.

General parameters (PArA GEn)

These parameters are used for general configuration of

the unit. The parameters affect all channels. See

Chapter 5.3 General parameters (PArA GEn), 27.

Test parameters (PArA tESt)

This parameter group is used to check individual system

functions. The parameter group is not required during

normal operation. For this reason it must be accessed in

a special way. See Chapter 5.4 Test parameters (PArA

tESt), 29.

Parameter

Pnr

dt-C

tr-L

LoC

rA-t

EP-t

EE-t

di-t

Ad-S

Ad-i

CALib

io-t

rS-t

PArA

GEn

tinb07e1-e 2011-07 Vacuum Gauge Controller 19

unit

bAud

diGit

dEF

Ao

Err-r

Page 20

4.5.3 Basic operation

Starting at the measurement menu, you can select and

modify a specific parameter as follows:

1 Press the CH button to select the required channel.

(This is only necessary if you want to modify a sensor parameter.)

2 Press the PARA button

• The parameter menu is selected

• The PARA indicator is illuminated

3 Use the arrow buttons to select the required

parameter group

• The name of the parameter group is displayed

4 Press the PARA button to select the required

parameter

• The name and the value of the parameter are

displayed

5 Use the arrow keys (and the CH button, if neces-

sary) to modify the parameter value

• The value of the parameter is changed

6 Repeat the steps 4 and 5 to change further param-

eters of the same parameter group

The unit returns to the measurement mode after the last

parameter of a parameter group has been accessed.

Parameter modifications are effective immediately, and

they are saved in the EEPROM automatically.

20 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 21

5 Parameter

p

t

SP-H

SP-L

NO

COM

NC

NO

COM

NC

NO

COM

NC

5.1 Switching function

parameters (PArA SP)

This parameter group allows you to configure the switching functions. The following switching function parameters are available in the VGC402:

• SP1-L

• SP1-H

• SP2-L

• SP2-H

• SP3-L

• SP3-H

• SP4-L

• SP4-H

In addition, the VGC403 is equipped with the following

switching function parameters:

• SP5-L

• SP5-H

• SP6-L

• SP6-H

upper threshold value. This means that the common

contact of the relay is connected to the make contact.

Hysteresis

In the pressure range between the two threshold values,

the previous relay state is maintained. The relay does not

switch in this range, and the relay state depends on the

pressure curve history. See Fig. 5-1, 21.

5.1.1 Fundamental terms

Switching functions

The VGC402 is equipped with four relays which switch in

dependance of the measured pressure. The relay contacts are potential-free and can be used for switching via

the RELAY connection. See Chapter 3.3.5 RELAY, 13.

In this context we speak of the switching functions 1 … 4.

The VGC403 contains a total of six switching function

relays, i.e. the switching functions 1 … 6 are available in

this unit.

Fig. 5-1 Behaviour of a switching function when the pressure

changes

pPressure

tTime

NO make contact (normally open)

COM common contact

NC break contact (normally closed)

The region between the threshold values generates a

hysteresis (lag) between activating and deactivating of

the relay. The hysteresis prevents the switching function

from rapidly switching on and off when the pressure is

close to one of the threshold values.

Threshold values

The switching behavior of the individual relays is determined by two parameters each: The lower threshold

value and the upper threshold value of the switching function.

• Lower threshold value SP-L:

The lower threshold value is responsible for activating

the assigned switching function. The relay switches

on as soon as the pressure falls below the lower

threshold value. This means that the common contact

of the relay is connected to the make contact.

• Upper threshold value SP-H:

The upper threshold value is responsible for deactivating the assigned switching function. The relay

switches off as soon as the pressure rises above the

tinb07e1-e 2011-07 Vacuum Gauge Controller 21

Page 22

5.1.2 Configuring switching functions

5.1.3 Adjustment range

Prerequisite: The parameter group SP-P is selected

1 Press the PARA button to select the required

parameter

• The name and the value of the parameter are

displayed

2 Use the CH button to assign the switching function

to a channel

• The switching functions can be assigned to the

channels any way

• The two threshold values of the switching function are always assigned to the same channel

3 Use the arrow buttons to modify the threshold

value

• The value of the parameter is changed

4 Repeat the steps 1 to 3 to change further parame-

ters of the same parameter group

Adjustment range of the lower threshold value

The lower threshold value of a switching function can be

set in the following pressure range:

Sensor

SP-L min.

[mbar]

PSG 2 × 10

PCG 2 × 10

PEG 1 × 10

MPG 5 × 10

-3

*) 5 × 102

-3

*) 1.5 × 103

-9

1 × 10-2

-9

5 × 10

SP-L max.

[mbar]

2

CDG/CDG d FS/1000 FS

bPG/bPG2 1 × 10

HPG 1 × 10

bCG 1 × 10

Tab. 5-1 Adjustment range of the lower threshold values

*) 2 × 10-4 mbar if

PrE

is activated (see Chapter 5.2.12, 26)

-8

5 × 102

-6

1 × 103

-8

1.5 × 10

3

Adjustment range of the upper threshold value

The upper threshold value of a switching function can be

set in the following pressure ranges:

Sensor

SP-H min.

[mbar]

PSG 1.1 SP-L 5 × 10

PCG 1.1 SP-L 1.5 × 10

PEG 1.1 SP-L 1 × 10

MPG 1.1 SP-L 5 × 10

SP-H max.

[mbar]

2

3

-2

2

CDG/CDG d SP-L + 0.01 FS FS

bPG/bPG2 1.1 SP-L 5 × 10

HPG 1.1 SP-L 1 × 10

bCG 1.1 SP-L 1.5 × 10

Tab. 5-2 Adjustment range of the upper threshold values

2

3

3

This means that the hysteresis amounts to 10 % of the

lower threshold value (logarithmic sensors) or to 1 % of

the full-scale range (linear sensors) at least. If another

sensor type is connected to a channel, the respective

threshold values will be adjusted automatically if necessary.

22 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 23

5.2 Sensor parameters (PArA SEn)

p

t

p

t

p

t

There is an individual set of sensor parameters for each

channel. Select the required channel before you change

to the parameter menu and modify the sensor parameters.

The number of available parameters depends on the sensor type which is connected to the selected channel. See

Tab. 5-3, 23.

Sensor

FiLt

GAS

FS

oFS

dEGAS

S-on

S-oFF

EMi

FiL

PSG 99 9

PCG 99 9

PEG 99 99

MPG 99

CDG 999

CDG d 999

FASt

Fast. The Vacuum Gauge Controller responds quickly to

signal changes. This makes it rather sensitive to signal

noise.

PrE

Fig. 5-2 Measurement with filter set to FASt (example)

nor

Normal. This is the default setting. It offers a good compromise between the response time and the sensitivity to

noise.

bPG 99

bPG2 9999

bCG 999

HPG 9

Tab. 5-3 Available sensor parameters

5.2.1 Measurement filter (FiLt)

The measurement filter improves measurements when

the signal is noisy or disturbed. The filter affects the readings on the display, the RS232C output, the recorder output, and the switching functions. The analog outputs,

however, are not affected.

The filter can be set to one of the following values:

Fig. 5-3 Measurement with filter set to nor (example)

SLo

Slow. The Vacuum Gauge Controller responds slowly to

signal changes. This makes it less sensitive to signal

noise. This setting is recommended for precise comparison measurements.

Fig. 5-4 Measurement with filter set to SLo (example)

tinb07e1-e 2011-07 Vacuum Gauge Controller 23

Page 24

5.2.2 Gas type (GAS)

Sensors are normally calibrated for a measurement in

nitrogen or in air. The GAS parameter is used to configure

the channel to other gas types.

Display Significance

n2 Nitrogen or air. No correction of any

kind is required.

Ar Argon. The pressure reading is

determined utilizing a correction factor for argon. COR is illuminated.

H2 Hydrogen. The pressure reading is

determined utilizing a correction factor for hydrogen. COR is illuminated.

Cor Other gases. The pressure reading

is determined utilizing a variable

correction factor. COR is illuminated.

Tab. 5-4 GAS parameter settings

Cor

If you want to perform pressure measurements in a gas

type without a fixed correction factor, you may multiply

the pressure reading with a variable correction factor. To

this end proceed as follows:

1 Set the GAS parameter to Cor

2 Press the PARA button

• The correction factor is displayed

3 Use the arrow buttons the modify the correction

factor

• The value of the parameter is changed

• The COR indicator is illuminated

You can adjust the correction factor of a sensor in the

range 0.10… 9.99. The setting 1.00 returns the uncorrected pressure reading.

NOTE:

The gas type correction is effective only for the following pressures: p < 10

sor), p < 10 mbar (PCG sensor), p < 1 mbar (BCG

sensor).

-2

mbar (BPG/HPG/MPG sen-

5.2.3 Measuring range (FS)

Linear sensors (CDG) require specification of the fullscale range. You can set this value using the cursor buttons. The following values are available:

• 0.01 mbar

• 0.01 Torr, 0.02 Torr, 0.05 Torr

• 0.10 mbar, 0.25 mbar, 0.50 mbar

• 0.10 Torr, 0.25 Torr, 0.50 Torr

• 1 mbar, 2 mbar, 5 mbar

• 1 Torr, 2 Torr, 5 Torr

• 10 mbar, 20 mbar, 50 mbar

• 10 Torr, 20 Torr, 50 Torr

• 100 mbar, 200 mbar, 500 mbar

• 100 Torr, 200 Torr, 500 Torr

• 1000 mbar, 1100 mbar

• 1000 Torr

• 2 bar, 5 bar, 10 bar, 50 bar

5.2.4 Offset (oFS)

When the offset correction is activated, a previously

specified offset value will be subtracted from each pressure reading. This allows to conveniently measure the

relative pressure with respect to a reference pressure.

The offset correction affects the readings on the display,

the RS232C output, the recorder output, and the switching functions. The analog outputs, however, are not

affected.

Establishing an offset value and activating the offset

correction

1 Select the oFS parameter

2 Keep the UP button pressed for approximately 2

seconds

• The current pressure reading becomes the new

offset value

• The offset correction is activated

• The OFS indicator is illuminated

Deactivating the offset correction

1 Select the oFS parameter

2 Press the DOWN button

• The offset correction is deactivated

• The display shows oFF

• The OFS indicator is dark

Activating the offset correction

1 Select the oFS parameter

2 Press the UP button

• The offset correction is activated

• The OFS indicator is illuminated

NOTE:

Always deactivate the offset correction before adjusting the offset of a sensor.

24 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 25

Adjusting the zero point of a digital CDG

1 Select the oFS parameter

2 Keep the DOWN button pressed for approximately

2 seconds

• The zero point of the sensor is adjusted

• The OFS indicator is illuminated after >2 s and

as long as the button is being pressed

NOTE:

First adjust the sensor, then the Vacuum Gauge Controller.

NOTE:

After adjusting the zero point, a zero value is displayed. Due to the measuring resolution of the CDG

(noise, drift), a zero with plus/minus several digits are

displayed.

5.2.5 Degas function (dEGAS)

Ionization sensors with a hot cathode are sensitive with

regard to depositions on the electrodes. These depositions can cause signal fluctuations.

The dEGAS function is to bakeout and thereby clean the

electrode system of the sensor. See Reference [11].

Hot

Hot start. The sensor automatically switches on when the

unit is switched on. After a power failure the measurement will be resumed automatically.

CH 1

By channel 1. The subsequent parameter t-on is used to

specify the switch-on threshold. The sensor is switched

on when the pressure on channel 1 falls below the switchon threshold.

CH 2

By channel 2. The subsequent parameter t-on is used to

specify the switch-on threshold. The sensor is switched

on when the pressure on channel 2 falls below the switchon threshold.

CH 3

By channel 3. This setting is only available if the unit is

equipped with three channels. The subsequent parameter t-on is used to specify the switch-on threshold. The

sensor is switched on when the pressure on channel 3

falls below the switch-on threshold.

5.2.7 Switch-on threshold (t-on)

BPG402 gauge:

The dEGAS function only affects the currently active filament. See Reference [15].

Activating the degas function

1 Select the dEGAS parameter

2 Press the UP button

• The degas function is activated

• The display shows on

• The DEG indicator is illuminated

The cleaning process takes approximately 3 minutes.

Then the degas function switches off automatically. You

may also deactivate this function manually.

Deactivating the degas function

1 Select the dEGAS parameter

2 Press the DOWN button

• The degas function is deactivated

• The display shows oFF

• The DEG indicator is dark

5.2.6 Sensor activation (S-on)

This parameter determines how the sensor is switched

on. The sensor activation can be set to one of the following values:

HAnd

Manually. The sensor can be switched on by pressing the

UP button. See Chapter 4.4.3.3 Switching high-vacuum

circuit on, 17.

This parameter is only available if the sensor activation

parameter is set to CH 1, CH 2 or CH 3. See Chapter 5.2.6

Sensor activation (S-on), 25.

The t-on parameter is used to specify a switch-on threshold. The sensor is switched on when the pressure on the

respective channel falls below the switch-on threshold.

5.2.8 Sensor deactivation (S-oFF)

This parameter determines how the sensor is switched

off. The sensor deactivation can be set to one of the following values:

HAnd

Manually. The sensor can be switched off by pressing the

DOWN button. See Chapter 4.4.3.5 Switching high-vacuum circuit off, 18.

SELF

Self control. The subsequent parameter t-off is used to

specify the switch-off threshold. The sensor is switched

off when the pressure at the sensor exceeds the switchoff threshold.

CH 1

By channel 1. The subsequent parameter t-off is used to

specify the switch-off threshold. The sensor is switched

off when the pressure on channel 1 exceeds the switchoff threshold.

CH 2

By channel 2. The subsequent parameter t-off is used to

specify the switch-off threshold. The sensor is switched

tinb07e1-e 2011-07 Vacuum Gauge Controller 25

Page 26

off when the pressure on channel 2 exceeds the switchoff threshold.

Display Significance

CH 3

By channel 3. This setting is only available if the unit is

equipped with three channels. The subsequent parameter t-off is used to specify the switch-off threshold. The

sensor is switched off when the pressure on channel 3

exceeds the switch-off threshold.

5.2.9 Switch-off threshold (t-off)

This parameter is only available if the sensor deactivation

parameter is set to CH 1, CH 2 or CH 3. See Chapter 5.2.8

Sensor deactivation (S-oFF), 25.

The t-off parameter is used to specify a switch-off threshold. The sensor is switched off when the pressure on the

respective channel exceeds the switch-off threshold.

5.2.10 Emission (EMi)

This parameter defines the rules for switching the emission on.

Display Significance

on Range extension:

• Display down to 5 × 10

• Setpoint adjustment range

down to 2 × 10

Tab. 5-7 PrE parameter values

-4

mbar

-5

mbar

Auto Emission is switched on and off by

the sensor electronics

MAn Emission is switched on and off

manually

Tab. 5-5 EMi parameter values

5.2.11 Filament selection (FiL)

This parameter defines the rules for selecting the active

filament.

Display Significance

Auto The sensor alternately selects one

of the two filaments

Fil 1 Filament 1 ist active

Fil 2 Filament 2 ist active

Tab. 5-6 FiL parameter values

5.2.12 Pirani range extension (PrE)

Extend the display and the setpoint adjustment range.

Display Significance

oFF Normal operation

26 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 27

5.3 General parameters (PArA GEn)

These parameters are used for general configuration of

the unit. The parameters affect all channels.

5.3.1 Unit of measurement (unit)

Unit of measurement for pressure values. The unit affects

displayed pressure readings, threshold values, etc.

NOTE:

The diGit parameter has no effect on CDG sensors.

NOTE:

When PrE is enabled, the display of PSG and PCG

gauges in the pressure range p < 10

duced by one digit.

-4

mbar is re-

5.3.4 Default parameters (dEF)

Reset all parameters to the default values (factory settings). Please note that this action cannot be undone.

Display Significance

bAr Pressure unit mbar or bar

torr Pressure unit Torr

PASC Pressure unit Pascal

uC Pressure unit Micron

Tab. 5-8 unit parameter values

The unit of measurement is indicated on the display. See

Fig. 4-1, 15, Pos. C. For information on common pressure units refer to Section «Conversion tables», 50.

NOTE:

The pressure unit «Torr» can be locked. In this case

torr is not available for selection. See Chapter 5.4.4

Torr lock (tr-L), 30.

5.3.2 Baud rate (bAud)

Transfer rate of the RS232C interface.

Display Significance

Proceed as follows to reset the parameters:

1 Select the dEF parameter

2 Press both the UP and the DOWN button at the

same time

• The display shows SEt

• All parameters are reset to the default values

5.3.5 Recorder output (Ao)

The recorder output is a programmable analog output.

The recorder output voltage is a function of the pressure

on the sensor. The relation between the pressure and the

voltage is called the characteristic curve of the output. It

can be selected.

Modifying parameter

1 Select the Ao parameter

2 Use the CH button to assign the recorder output to

a channel

3 Use the arrow buttons to select the characteristic

curve of the output

• The value of the parameter is changed

9600 9600 Baud

19200 19200 Baud

38400 38400 Baud

Tab. 5-9 bAud parameter values

5.3.3 Display format (diGit)

Number of digits shown in the display.

Display Significance

2 Two digits

-1

e.g. 2.5

3 Three digits

e.g. 2.47

Tab. 5-10 diGit parameter values

tinb07e1-e 2011-07 Vacuum Gauge Controller 27

or 370

-1

or 373

Characteristic curves

Fundamentally we have to distinguish between logarithmic and linear characteristic curves. A logarithmic characteristic curve is useful if the pressure range covers several orders of magnitude in the measurement. In this case

it is appropriate to take the logarithm of the pressure and

then scale the result in a suitable manner.

A linear characteristic curve is useful if the pressure

range covers only a few orders of magnitude in the measurement. In this case the recorder output voltage is proportional to the pressure value. You can specify which

pressure value will result in the maximum output voltage.

The available characteristic curves will be described in

the following. In each case it is shown how to calculate

the pressure p (in mbar) from the recorder output voltage

U (in volts).

Page 28

LoG

Logarithmic representation of the entire measuring

range.

LoG +0

Logarithmic representation of a part of the measurement

range (2.5 V/decade).

Sensor Pressure (in mbar)

PSG p = 10^[U/(10/7) - 4]

PCG p = 10^[U/(10/7) - 4]

PEG p = 10^[U/(10/7) - 9]

MPG p = 10^[U/(10/12) - 9]

CDG/CDG d p = 10^[U/(10/4) - 4] * FS

bPG/bPG2 p = 10^[U/(10/12) - 9]

bCG p = 10^[U/(10/12) - 9]

HPG p = 10^[U/(10/9) - 6]

LoG A

Logarithmic representation of the entire measuring range

(compatible with VGC012, VGC023, VGC032).

Sensor Pressure (in mbar)

PSG p = 10^[U/(10/6) - 3]

PCG p = 10^[U/(10/7) - 4]

PEG p = 10^[U/(9/7) - 9 - 7/9]

MPG p = 10^[U/(10/11) - 8]

CDG/CDG d p = 10^[U/(10/4) - 4] * FS

bPG p = 10^[(U - 7.75)/0.75]

bPG2 p = 10^[U - 8]

Sensor Pressure (in mbar)

All types p = 10^[U/(10/4) - 4]

LoG +3

Logarithmic representation of a part of the measurement

range (2.5 V/decade).

Sensor Pressure (in mbar)

All types p = 10^[U/(10/4) - 1]

LoGC1

Logarithmic representation matched to the following sensor combination:

• PSG on channel 1

• PEG on channel 2

Sensor Pressure (in mbar)

PSG + PEG p = 10^[U/(10/12) - 9]

LoGC2

Logarithmic representation matched to the following sensor combination:

• CDG on channel 1

• CDG on channel 2

This characteristic curve is only useful if the sensors have

different measuring ranges. The total measuring range of

the sensor combination is represented logarithmically in

the range 0…10 V.

bCG p = 10^[(U - 7.75)/0.75]

HPG p = 10^[U/(10/9) - 6]

LoGC3

Logarithmic representation matched to the following sensor combination:

LoG -6

Logarithmic representation of a part of the measurement

range (2.5 V/decade).

• CDG on channel 1

• CDG on channel 2

• CDG on channel 3

This characteristic curve is only useful if the sensors have

Sensor Pressure (in mbar)

different measuring ranges. The total measuring range of

the sensor combination is represented logarithmically in

All types p = 10^[U/(10/4) - 10]

LoG -3

Logarithmic representation of a part of the measurement

range (2.5 V/decade).

Sensor Pressure (in mbar)

All types p = 10^[U/(10/4) - 7]

the range 0…10 V.

NOTE:

The three sensors must be sorted with regard to their

measuring range (FS). The sort order may be increasing or decreasing.

Lin n

Linear representation. U = 10 V is equivalent of p = 10

n

mbar. The exponent n may be any integer value in the

range -10… +3.

28 tinb07e1-e 2011-07 Vacuum Gauge Controller

Page 29

Sensor Pressure (in mbar)

All types p = U/10 * 10

iM221

Logarithmic representation of the IM221 controller (1

V/decade) U = 8 V is equivalent of p = 10

n

-2

mbar.

5.4 Test parameters (PArA tESt)

This parameter group is intended for test and service purposes. It is used to examine additional system data, to set

basic system parameters, and to check individual system

functions.

The parameter group tESt is not required for normal operation. For this reason it is not accessible normally.

Controller Pressure (in mbar)

IM221 p = 10^[U - 10]

LoGC4

Logarithmic representation of 12 decades (0.83 V /

decade) matched to the following sensor combination:

• PCG on channel 1

• BPG402 on channel 2

Sensor Pressure (in mbar)

PCG+BPG402 p = 10^[U/(10/12) - 9]

U = 10 V is equivalent of p = 1000 mbar. The switching

point between the sensors is 10

PM411

Nonlinear characteristic curve of the output as with the

PM411 board.

-2

mbar.

5.3.6 Error signal relay (Err-r)

The Err-r parameter is used to specify what kind of error

will trigger the error signal relay.

Display Significance

ALL All errors

no SE Device errors

5.4.1 Selection

When switching on

The parameter group tESt becomes available if you

switch on the Vacuum Gauge Controller as follows:

1 Press the PARA button and keep it pressed

2 Switch the mains switch on. See Fig. 3-4, 11,

Pos. H.

• The Vacuum Gauge Controller is switched on

• The parameter group tESt is selected

• The PARA indicator is illuminated

During normal operation

During normal operation it is also possible to activate the

parameter group tESt from the measurement mode:

1 Press the PARA button

• The parameter menu is selected

• The PARA indicator is illuminated

2 Keep the UP and DOWN buttons pressed for

approximately 5 seconds

• The firmware version is displayed

• The parameter group tESt is selected

NOTE:

When the parameter group tESt is selected, the Vacuum Gauge Controller will not automatically return to

the measurement mode. In order to return to the measurement mode, press the PARA button repeatedly

until all test parameters have been run through.

CH 1 Sensor 1 and device errors

CH 2 Sensor 2 and device errors

CH 3 Sensor 3 and device errors

Tab. 5-11 Err-r parameter values

5.4.2 Firmware version (Pnr)

Displays the firmware version number. The last character

represents the modification index.

Example: 302-534-D

5.4.3 Watchdog control (dt-C)

Behavior of the system monitoring system (watchdog

control) in the event of an error.

Display Significance

Auto An error message from the watch-

dog control is acknowledged automatically after 2 seconds

tinb07e1-e 2011-07 Vacuum Gauge Controller 29

Page 30

Display Significance

oFF An error message from the watch-

dog control must be acknowledged

by the user

Tab. 5-12 dt-C parameter values

5.4.7 EPROM test (EP-t)

Test the program memory.

Press the UP button to start the test.

Display Significance

run Test is running

5.4.4 Torr lock (tr-L)

This parameter affects the general parameter unit. When

the lock is activated, the unit of measurement «Torr» cannot be selected. See Chapter 5.3.1 Unit of measurement

(unit), 27.

Display Significance

oFF Unit of measurement «Torr» can be

selected

on Unit of measurement «Torr» cannot

be selected

Tab. 5-13 tr-L parameter values

5.4.5 Parameter setup lock (LoC)

This parameter affects the parameter mode. When the

lock is activated, the user can inspect but not modify

parameter values.

Display Significance

oFF Parameters can be inspected and

modified

on Parameters can be inspected only

Tab. 5-14 LoC parameter values

PASS Test completed without errors

Err Test completed and errors detected.

A four-digit checksum is displayed.

Tab. 5-16 EPROM test

Please contact your local INFICON service center if the

test fails repeatedly.

5.4.8 EEPROM test (EE-t)

Test the parameter memory.

Press the UP button to start the test.

Display Significance

run Test is running

PASS Test completed without errors

Err Test completed and errors detected

Tab. 5-17 EEPROM test

Please contact your local INFICON service center if the

test fails repeatedly.

5.4.9 Display test (di-t)

Test the display. In this test all segments of the display

are illuminated simultaneously at first. Then the individual

segments of the display are activated one after the other.

5.4.6 RAM test (rA-t)

Test the main memory. Press the UP button to start the

test.

Display Significance

run Test is running

PASS Test completed without errors

Err Test completed and errors detected

Tab. 5-15 RAM test

Please contact your local INFICON service center if the

test fails repeatedly.

30 tinb07e1-e 2011-07 Vacuum Gauge Controller

Press the UP button to start the test.

5.4.10 A/D converter signal (Ad-S)

Display the A/D converter output signal (in volts) for each

of the channels. When applying a reference voltage to the

input signal pin of the SENSOR connection, this allows

you to check the A/D converters of the respective channel. See Chapter 3.3.4 SENSOR, 12.

NOTE:

When the signal input is not connected, a quickly

fluctuating value is displayed because of the high

measurement sensitivity of the unit.

Press the UP button to start the test.

Page 31

5.4.11 A/D converter ID (Ad-i)

For each channel, display a signal (in volts) which is