Page 1

SQC-222

Thin Film CoDeposition Controller

User’s Guide

Version 3.08

© Copyright Sigma Instruments, Inc. 2002 - 2006

Σ

Σ

ΣΣ

Sigma

instruments

Page 2

Safety Information

Read this manual before installing, operating, or servicing equipment. Do not install

substitute parts, or perform any unauthorized modification of the product. Return the

product to Sigma Instruments for service and repair to ensure that safety features are

maintained.

Safety Symbols

WARNING: Calls attention to a procedure, practice, or condition that could

possibly cause bodily injury or death.

CAUTION: Calls attention to a procedure, practice, or condition that could

possibly cause damage to equipment or permanent loss of data.

Refer to all manual Warning or Caution information before using this product

to avoid personal injury or equipment damage.

Hazardous voltages may be present.

Earth ground symbol.

Chassis ground symbol.

Equipotential ground symbol.

Page 3

Warranty Information

This Sigma Instruments product is warranted against defects in material and

workmanship for a period of 2 years from the date of shipment, when used in

accordance with the instructions in this manual. During the warranty period, Sigma

Instruments will, at its option, either repair or replace products that prove to be

defective.

Limitation of Warranty

Defects from, or repairs necessitated by, misuse or alteration of the product, or any

cause other than defective materials or workmanship are not covered by this warranty.

NO OTHER WARRANTIES ARE EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILIT Y AND FITNESS

FOR A PARTICULAR PURPOSE. UNDER NO CIRCUMSTANCES SHALL SIGMA

INSTRUMENTS BE LIABLE FOR CONS EQUENTIAL OR OTHER DAMAGES

RESULTING FROM A BREACH OF THIS LIMITED WARRANTY, OR OTHERWISE.

Return Policy

The purchaser may return this product in new condition within 30 days after shipment

for any reason. In case of return, purchaser is liable and responsible for all freight

charges in both directions.

Sigma Instruments

120 Commerce Drive, Unit 1

Fort Collins, CO 80524 USA

970-416-9660

970-416-9330 (fax)

Page 4

Table of Contents

Chapter 1 Quick Start

1.0 Introduction...................................................................................................... 1-1

1.1 Front Panel...................................................................................................... 1-1

1.2 Rear Panel.......................................................................................................1-2

1.3 System Connections........................................................................................1-3

1.4 Installation....................................................................................................... 1-4

1.5 Menus.............................................................................................................. 1-5

1.6 Thin Film Process Overview............................................................................1-7

1.7 Building a Process........................................................................................... 1-8

1.8 Depositing a Film............................................................................................. 1-11

Chapter 2 Operation

2.0 Introduction...................................................................................................... 2-1

2.1 Definitions........................................................................................................ 2-1

2.2 Defining a Film.................................................................................................2-1

2.3 Defining a Process.......................................................................................... 2-5

2.4 Sensor Setup................................................................................................... 2-7

2.5 Source Setup................................................................................................... 2-10

2.6 Running a Process..........................................................................................2-11

2.7 Loop Tuning.....................................................................................................2-15

2.8 Troubleshooting............................................................................................... 2-17

Chapter 3 Menus

3.0 Introduction...................................................................................................... 3-1

3.1 Main Menu 1.................................................................................................... 3-2

3.2 Main Menu 2.................................................................................................... 3-3

3.3 Main Menu 3.................................................................................................... 3-4

3.4 Quick Setup Menu........................................................................................... 3-5

3.5 Process Menu..................................................................................................3-7

3.6 Layer Menus.................................................................................................... 3-9

3.7 Cut/Copy Menu................................................................................................3-12

3.8 Film Menu........................................................................................................ 3-14

3.9 System Parameters Menu...............................................................................3-21

3.10 PLC I/O........................................................................................................... 3-26

Page 5

Chapter 4 Maintenance & Installation

4.0 Introduction...................................................................................................... 4-1

4.1 Cleaning.......................................................................................................... 4-1

4.2 Software Upgrades.......................................................................................... 4-2

4.3 Option Card Installation................................................................................... 4-3

4.4 Half-Rack Adapter...........................................................................................4-3

4.5 Full Rack Adapter............................................................................................ 4-4

Chapter 5 Communications

5.0 Introduction...................................................................................................... 5-1

5.1 SQC-222 Comm Program ...............................................................................5-1

5.2 Protocol........................................................................................................... 5-1

5.3 Commands......................................................................................................5-2

Appendix

A. Material Parameters

B. Specifications

C. I/O Connections

D. Handheld Remote Controller

E. Declaratio n of Conformity

Page 6

Page 7

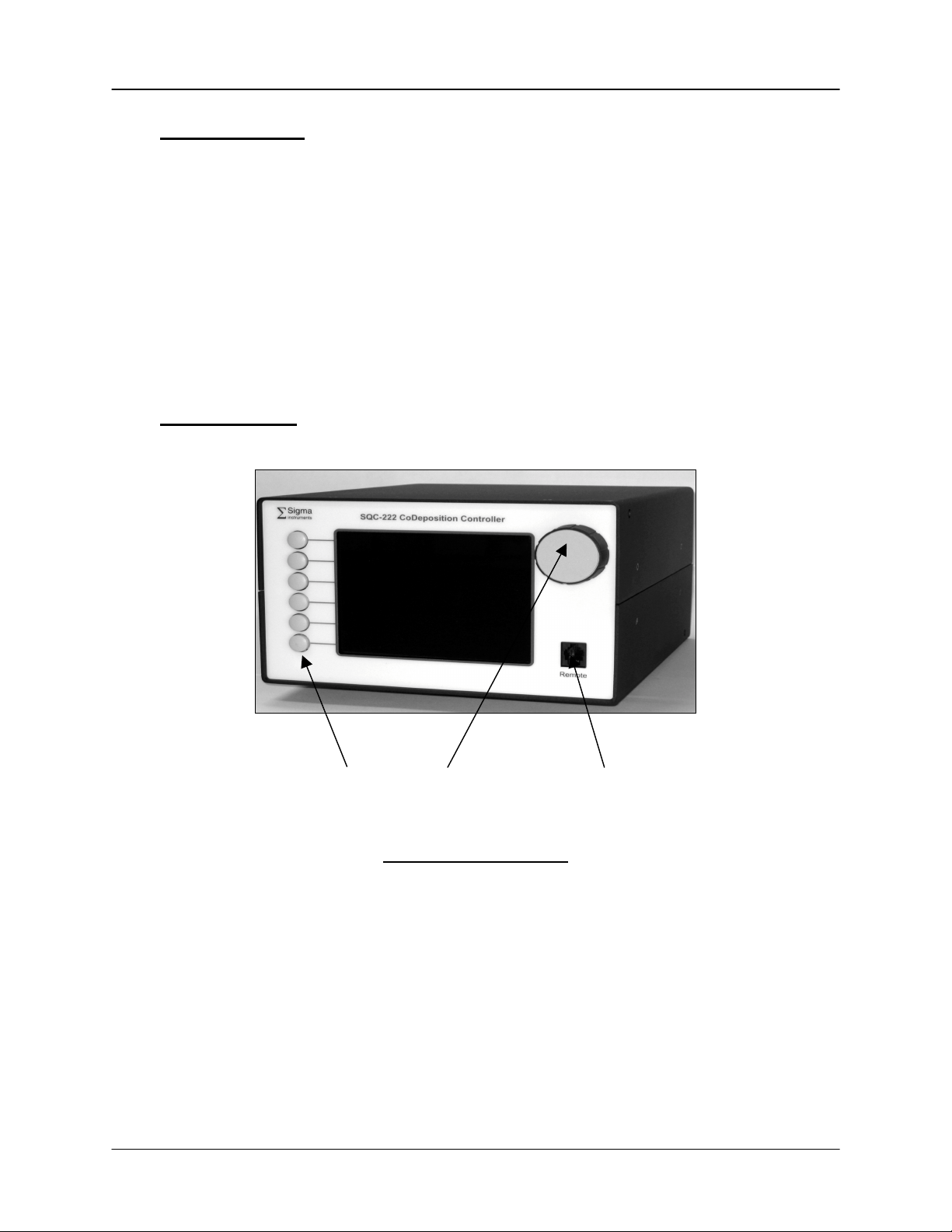

Chapter 1 Quick Start

1.0 Introduction

The SQC-222 is a multi-channel quartz crystal monitor and deposition controller. It

measures two 1 MHz to 6 MHz quartz crystal sensors, and controls up to two

evaporation sources. Eight process control relays, and eight digital inputs are easily

configured to support a broad range of external functions, including source pocket

rotation. The number of sensors, outputs, and digital I/O can be doubled with an

optional expansion card.

This chapter will aid you in the initial setup and operation of your system . Plea se re view

the entire manual for detailed operational, programming, and safety information.

1.1 Front Panel

SoftKeys Control Knob Remote Jack

Front Panel Controls

SoftKeys Provide access to instrument operations and setup menus.

The functions of the SoftKeys change to adapt to different

operations and are displayed on the left of the screen.

Control

Knob

Remote

Jack

Used to adjust values and select menu items. Pushing the

control knob stores the current setting and moves to the next.

Connection jack for the optional handheld remote controller.

See Appendix D.

1-1

Page 8

Chapter 1 Quick Start

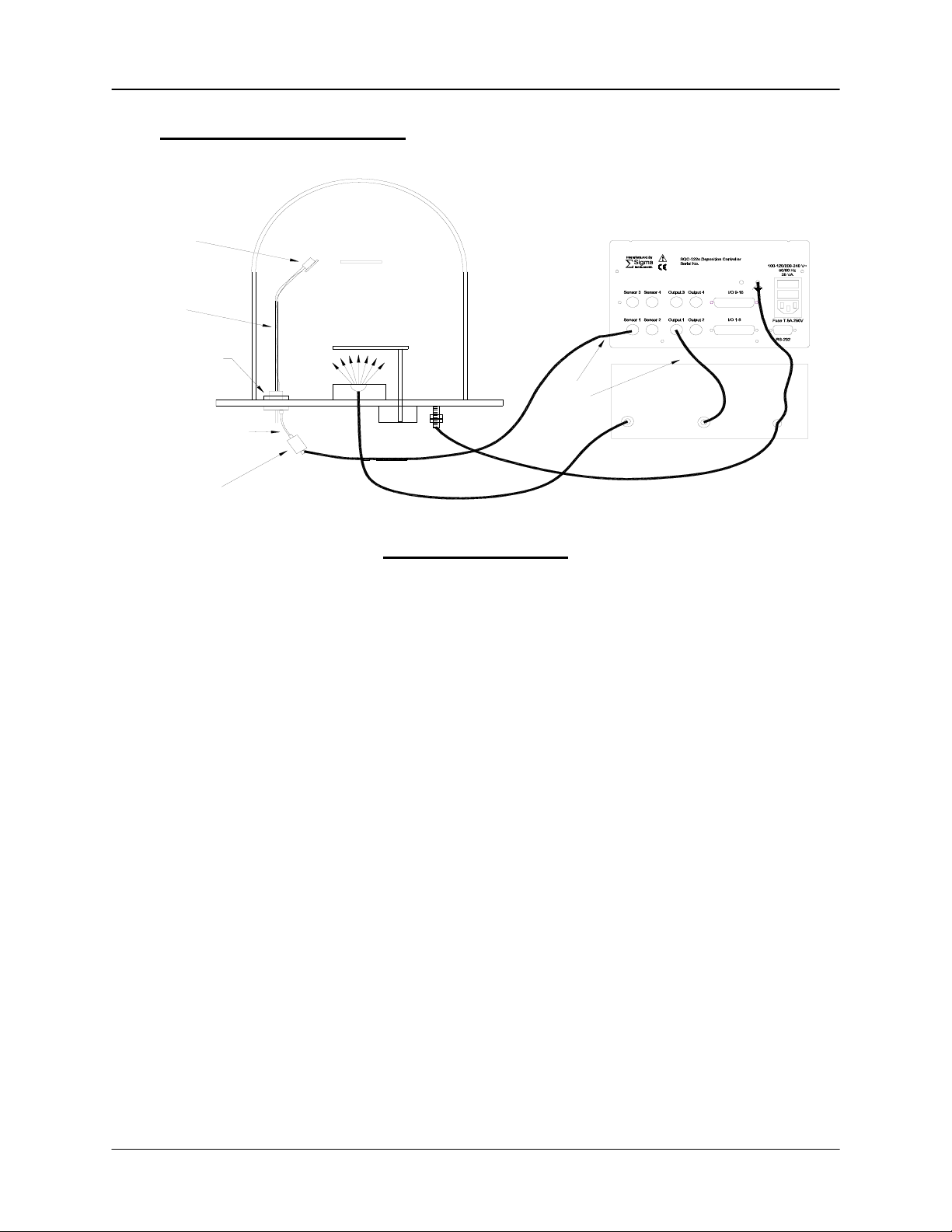

1.2 Rear Panel

Manufactured By

Sigma

Σ

instruments

Sensor 3 Sensor 4 Output 3 O utput 4

Sensor 1 Sensor 2 Output 1 O utput 2

SQC-222 D eposition Controller

Serial No.

I/O 9-16

I/O 1 - 8

100-120/200-240 V~

50/60 Hz

25 VA

Fuse T.5A 250V

RS-232

Rear Panel Connections

Sensor 1 & 2 Connects to quartz crystal sensor (see next section).

Output 1 & 2 Connects the SQC-222 output to your evaporation supply

control input (see next section).

I/O (1-8) Connects 8 relays and 8 digital inputs to external equipment for

process control. See Appendix C for connections.

RS-232 Connects to a computer for programming and data acquisition.

Also used for the PLC I/O option.

Sensor 3 & 4,

Output 3 & 4,

Increases the number of input, output, and digital I/O

connections when the optional expansion card is installed.

I/O 9-16

Measurement ground terminal useful for common system and

cable grounding.

1-2

Page 9

Chapter 1 Quick Start

Power Input and

Fuse

Connects to mains power. The SQC-222 automatically detects

mains voltages of 100-120 and 200-240VAC, 50/60 Hz

ARNING: For continued protection, replace fuses with the

W

proper type and rating.

WARNING: Use removable power cords only of the specified

type and rating, attached to a properly grounded receptacle.

1-3

Page 10

Chapter 1 Quick Start

1.3 System Connections

Sensor

In-V ac

Cable

Feedthrough

Source

Shutter

Evaporation Supply

Output Control Input

6" BNC Cable

O s cillat o r

BNC

Cables

Ground Wire

System Components

Sensor Holds the quartz crystal used to measure rate and thickness.

Crystals must be replaced occasionally.

In-Vac Cable A coaxial cable that connects the sensor to the feedthrough.

Feedthrough Provides isolation between vacuum and atmosphere for

electrical and cooling lines.

6” BNC Cable Provides a flexible connection from the feedthrough to the

oscillator. Keep this cable as short as possible.

Oscillator Contains the electronics to operate the quartz crystal. Total

cable length to the crystal should be under 40”.

Sensor Input

BNC Cable

Control Output

BNC Cable

Connects the oscillator to the SQC-222 input. Lengths up to

100’ are acceptable.

Connects the SQC-222 output to the evaporation source’s

control voltage input. Keep the length below 10’.

Ground Wire A wire, typically braided, that connects the vacuum system to

the SQC-222 ground terminal. Important for noise rejection.

1-4

Page 11

Chapter 1 Quick Start

1.4 Installation

WARNING: Care should be exercised to route SQC-222 cables as far as practical from

other cables that carry high voltages or generate noise. This includes other line voltage

cables, wires to heaters that are SCR-controlled, and cables to source power supplies

that may conduct high transient currents during arc down conditions.

Rack

Installation

Power

Connection

Sensor Input

Connections

Source Output

Connections

Digital I/O

Connections

The SQC-222 occupies a 5.25” high, half-rack space. An

optional installation kit is available to adapt to a full rack (see

Chapter 4). Install the unit in a 19” rack with the supplied

hardware.

The SQC-222 automatically detects mains voltages of 100-120

and 200-240VAC, 50/60Hz .

WARNING: Verify that the power cable provided is connected to

a properly grounded mains receptacle.

Connect the BNC cables and oscillators from your vacuum

chamber feedthrough to the desired SQC-222 sensor inputs.

See the previous section for cabling details.

Connect the BNC cables from the SQC-222 output connectors

to your evaporation supply control input. Consult your Power

Supply operator’s manual for control input wiring instructions.

Refer to Appendix C for details on wiring digital I/O to the SQC222 Relay I/O connectors. Appendix C also covers I/O wiring

with the optional PLC.

Computer

Connection

If you would like to use the Windows software to collect data or

program the SQC-222, attach a 9 pin straight-thru cable from

the RS-232 connector to your computer’s serial port. A cable

is supplied with the SQC-222.

1-5

Page 12

Chapter 1 Quick Start

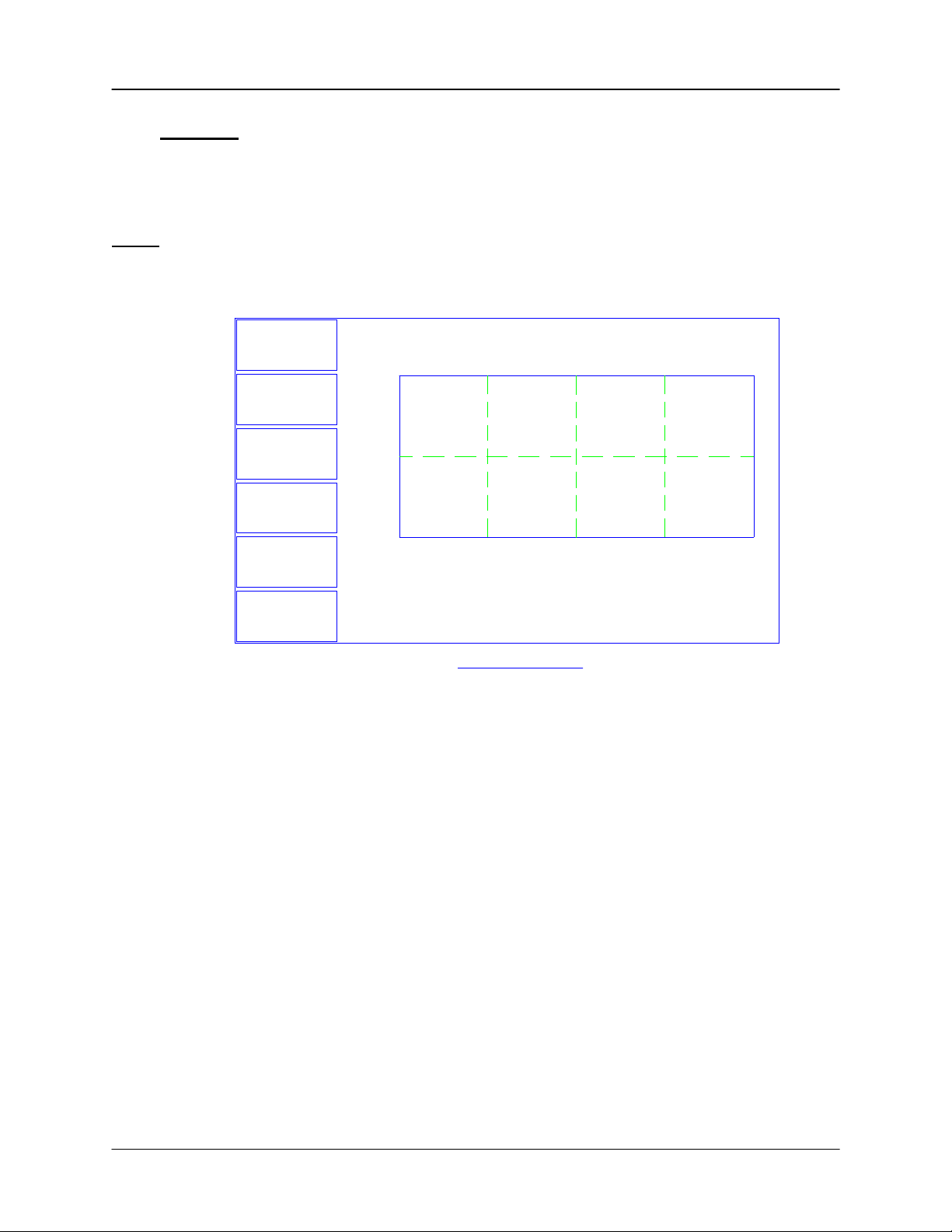

1.5 Menus

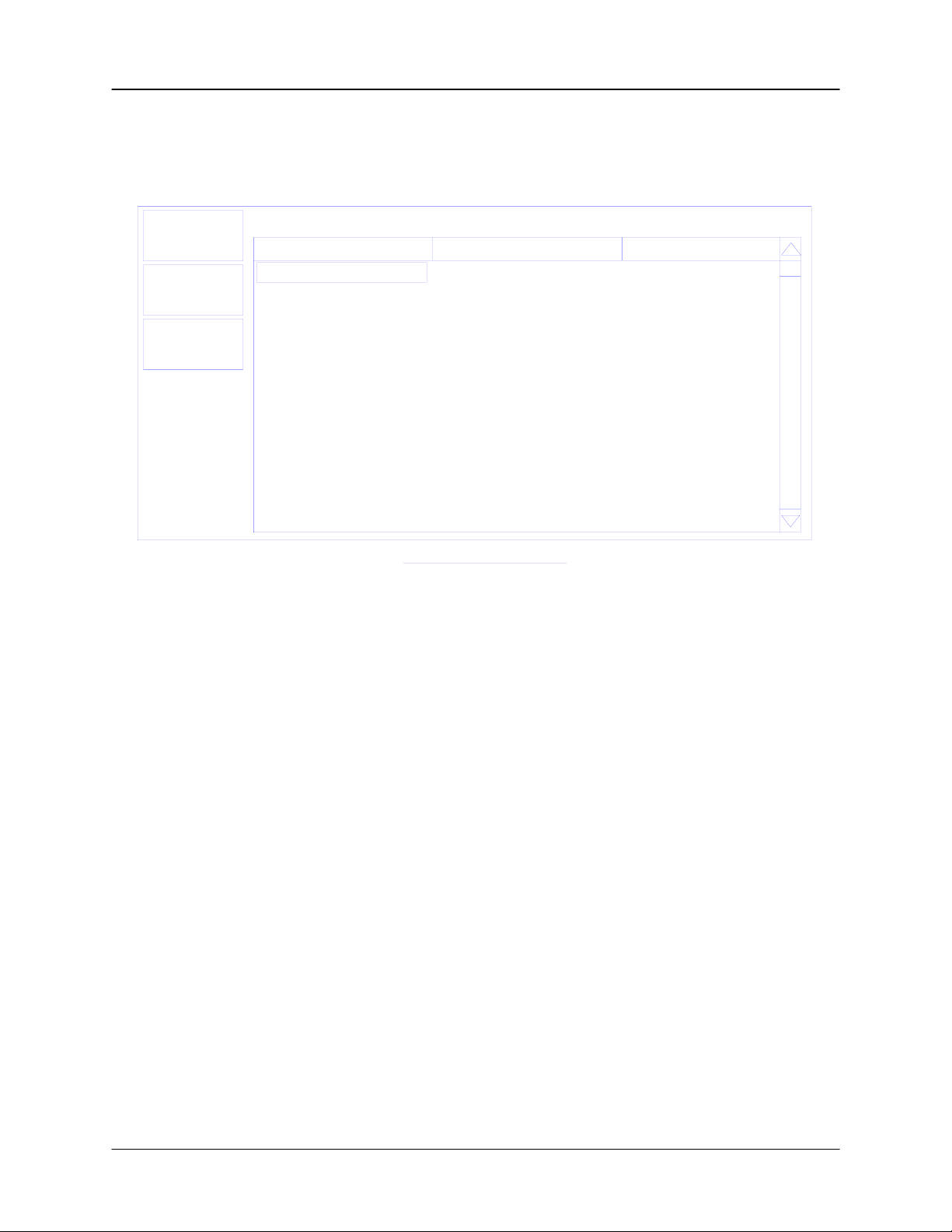

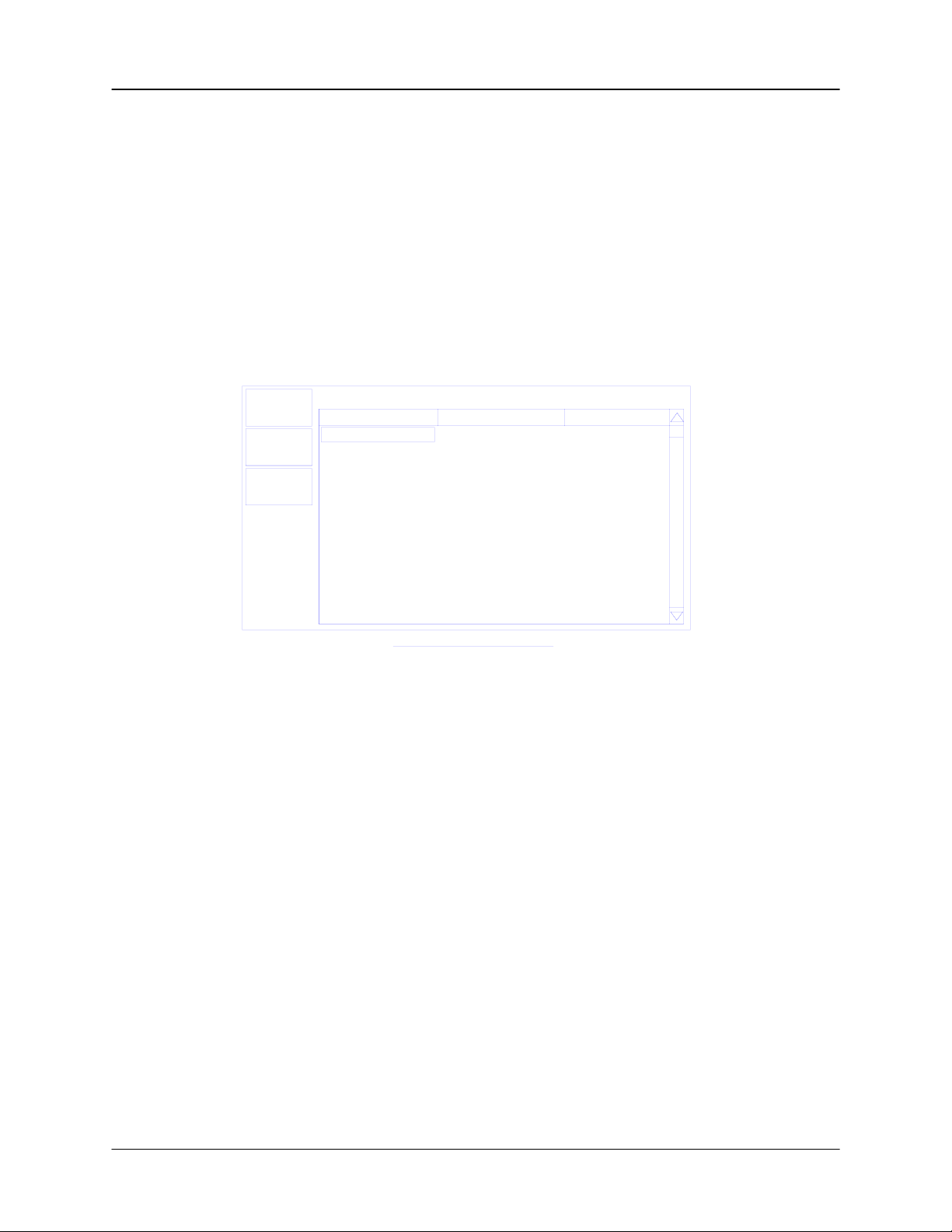

At power up the SQC-222 briefly displays initialization and version information, then the

Main screen.

Note: If you are prompted for a password, use the switches along the left of the screen

to enter the password. The top switch is “1”, the bottom switch is “6.” See the System

Parameters section of this manual for password setup information.

Next

Menu

Process 1 : Layer 1 of 1 Run # :0

Stopped

Power (% vs. Time)

100.0

0:00:00

Quick

Edit

Auto /

Manual

50.0

Zero

0.0

Next

Layer

Start

Out#

1

2

3

4

0.0

R a te (A /S )

0.00

0.00

0.00

0.00

6.2

12.5

Dev(%)

00.0

00.0

00.0

00.0

18.8

Thick(kA )

0.000

0.000

0.000

0.000

25.0

Pow(%)

0.0

0.0

0.0

0.0

M a in S c r ee n

The first line of the Main screen shows the name of the currently selected process.

After the process name are the layer that will run when the Start SoftKey is pushed, and

the total number of layers in the process. Further to the right is the number of times this

process has been run.

The second line of the Main screen is a status line. It displays the current phase of the

deposition cycle, and other status or error messages. When the process is running, the

right side of this line shows the process elapsed time.

Three graphs are possible: rate, rate deviation, and output power. The graphs scale the

vertical axis and scroll the horizontal axis based on the data displayed.

Below the graph are two lines that show deposition readings (four lines if the option card

is installed). This section shows current rate, rate deviation, thickness, and output

power as shown above. Alternatively it can show measured rate and thickness versus

rate and thickness setpoints.

1-6

Page 13

Chapter 1 Quick Start

The six SoftKey legends along the left side of the screen will change, depending on the

status of the process and the functions you select. Press Next Menu to display

alternate main screen menus:

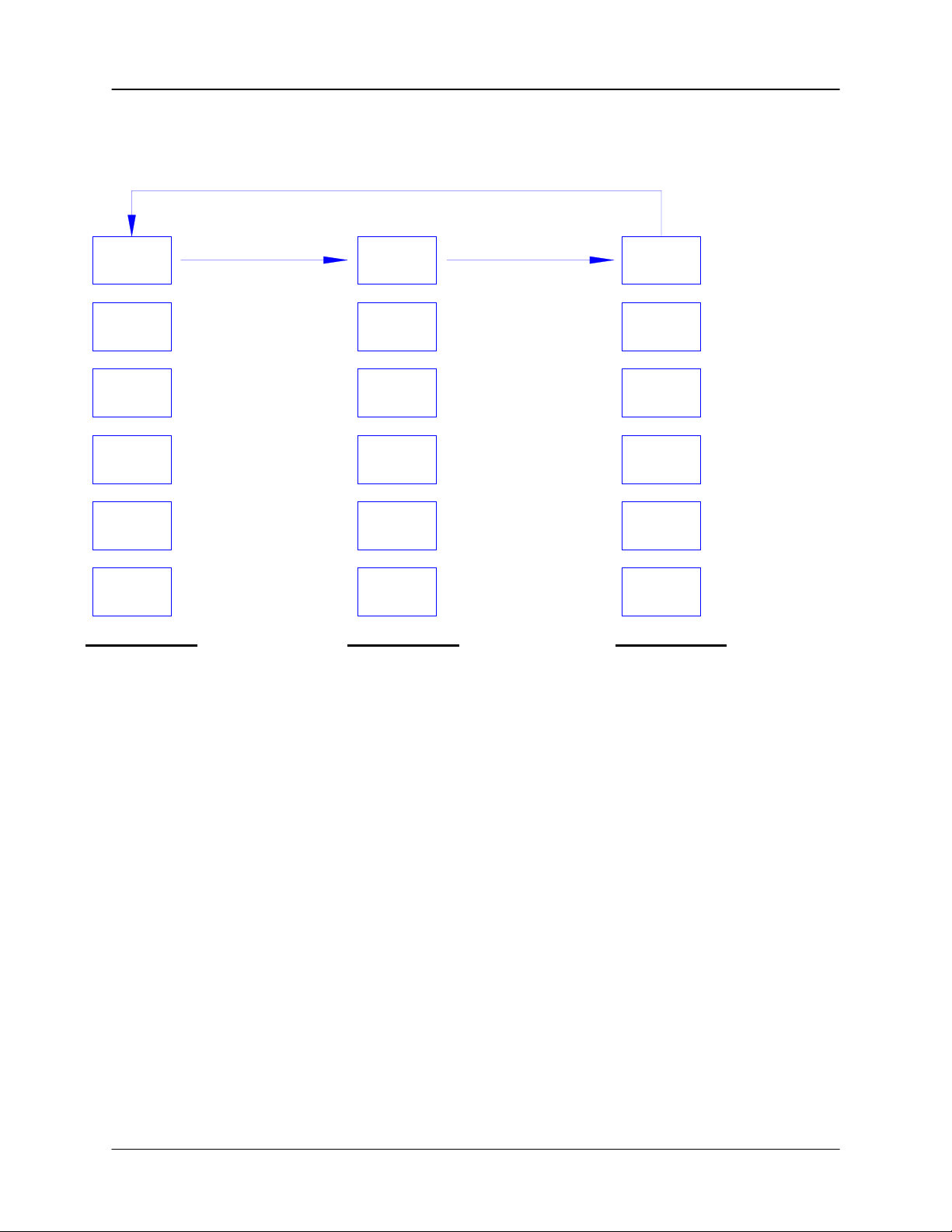

Main Menu 1 Main Menu 2 Main Menu 3

Next

Menu

Quick

Edit

Auto /

Manual

Zero

Next

Layer

Start

Selec t th e n ext la yer

Main Menu 1

Access the most

comm only edited

setting s.

Switch between PID

and Manual power

control.

Zero the thickness

reading on all

channels.

in the process.

Start or Stop the

selected layer.

Next

Menu

Next

Graph

Next

Display

Sensor

Info

Next

Layer

Start

Third menu available only

when process is stopped.

Switch graph between

Main Menu 2

rate, deviation, and

power.

Switch the readout

below the graph.

Dis p lay d eta ile d

sensor information.

Selec t th e n ext la yer

in the process.

Start or Abort the

process.

Next

Menu

Process

Menu

Film

Menu

System

Params

Start

Create or edit process

Create or edit films to

Main Menu 3

layers .

be used as layers.

Modify instrument

related se tting s.

Start the selected

layer.

Because Main Menu 3 provides access to functions that can completely redefine a

process, it is available only when the process is not running.

Spend some time now moving between the three menus. Pay particular attention to the

effects that the Main Menu 2 selections have on the displa y. W e will cover the setu p

parameters of Main Menu 3 in the Building a Process section.

1-7

Page 14

Chapter 1 Quick Start

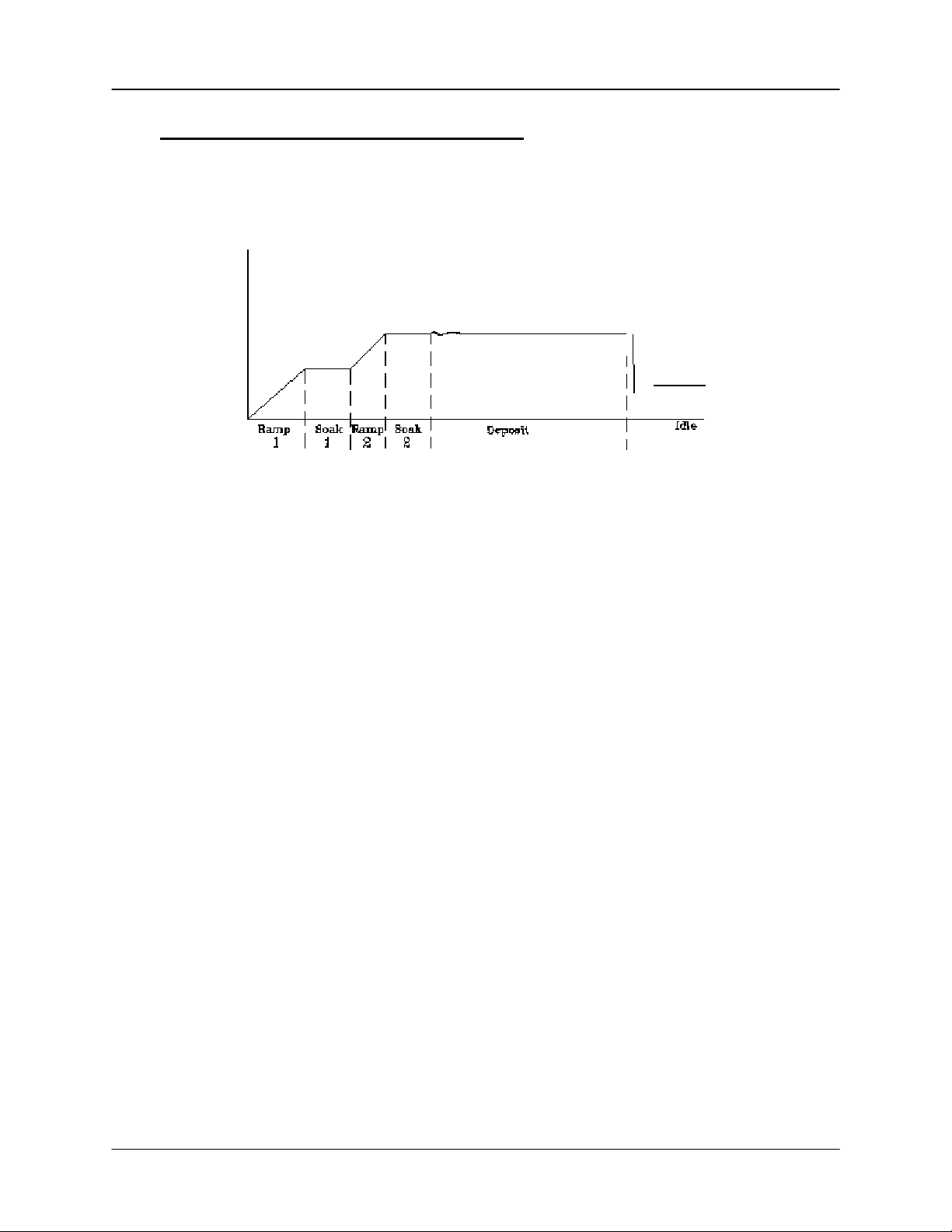

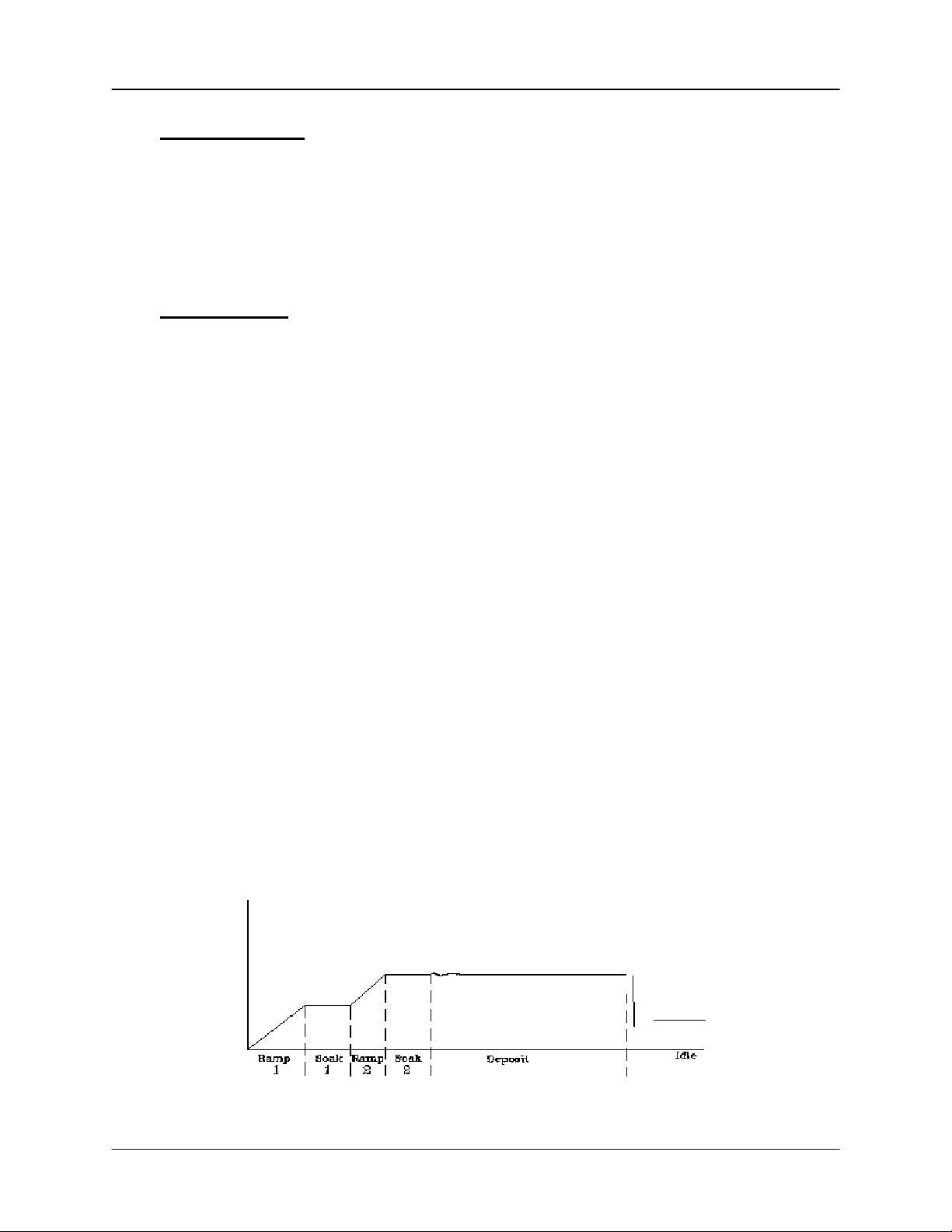

1.6 Thin Film Deposition Overview

The SQC-222 stores the recipes, and provides the operating functions, required to

control thin film deposition processes. A typical thin film deposition cycle is shown

below.

The cycle can be broken into three distinct phases:

• Pre-conditioning (ramp/soak)

• Deposition

• Post-conditioning (feed/idle)

During pre-conditioning, power is supplied in steps to prepare the evaporation source

for deposition. Once the material is near the desired deposition rate, material

deposition begins.

During deposition, the PID loop adjusts the evaporation source power as required to

maintain the desired rate. In CoDeposition multiple films can be deposited

simultaneously.

When the desired thickness is reached, the evaporation source is set to idle power. At

this point the process may be complete, or deposition of another layer may begin.

1-8

Page 15

Chapter 1 Quick Start

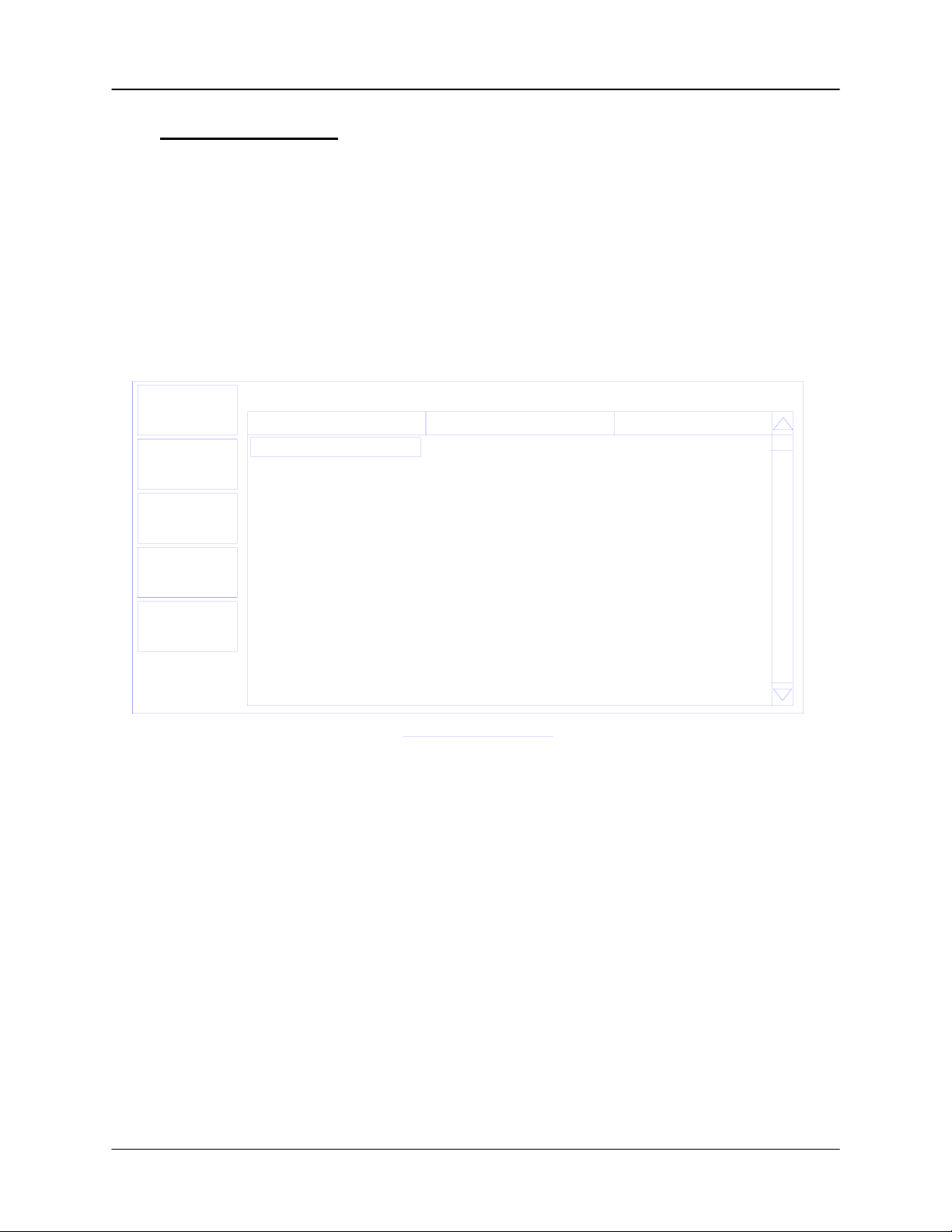

1.7 Building a Process

This section presents a brief guide to building and running a simple one layer process.

Chapter 2 covers instrument operation in much greater detail.

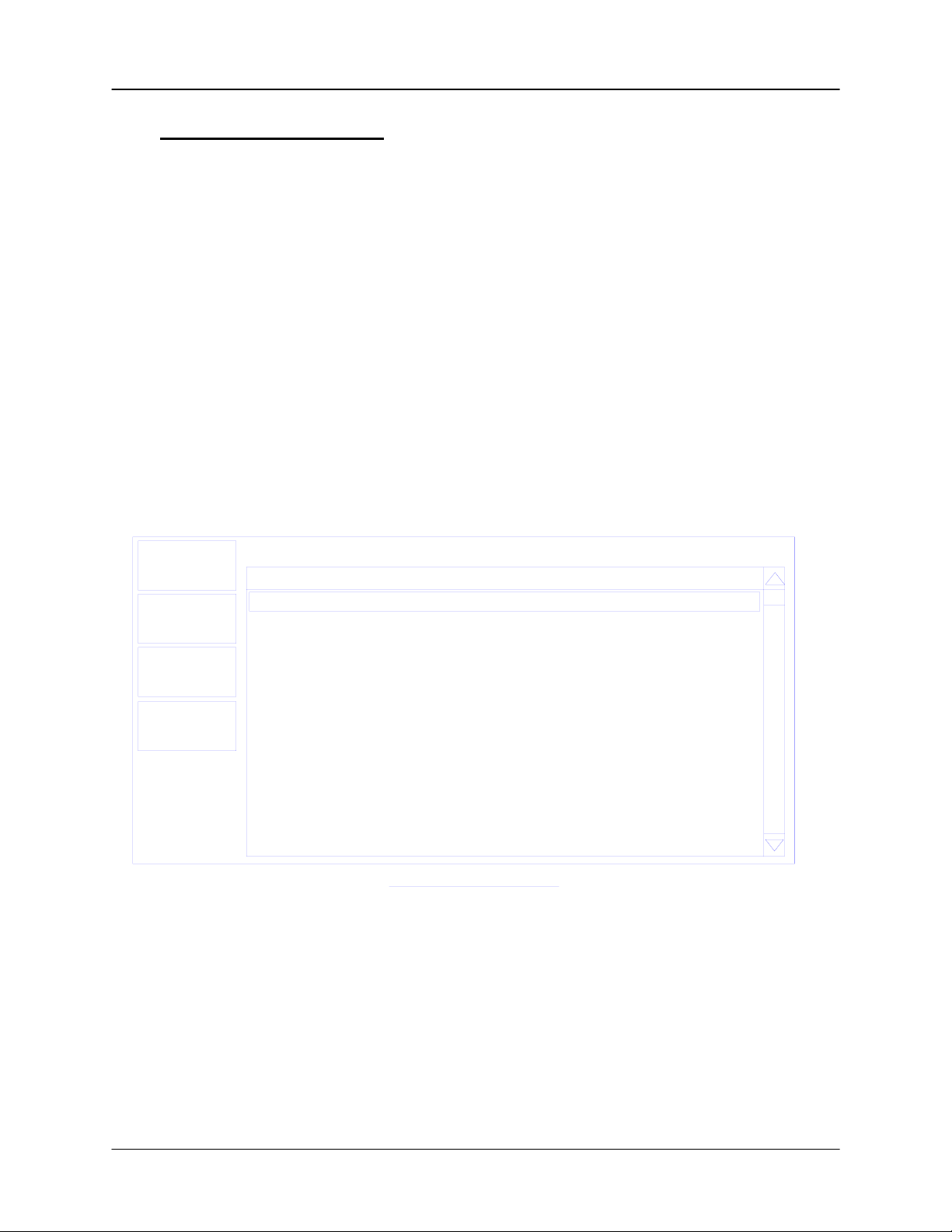

Create a

Film

M a in

Screen

Prev

Menu

Edit

Delete

A film is a material to be deposited, and its associated

deposition settings. Initially the list of films may be empty.

Press Next Menu until the Film Menu SoftKey is displayed.

Press Film Menu to view a list of stored films. Turn the setting

knob to scroll to an entry in the list that is currently labeled

<Empty>.

Press the Create SoftKey to create a default film at that

location. Note the film number that you just created. For now,

accept the default film parameters.

Press Main Screen to return to the main screen.

Process 1

S c ro ll film s w ith k n o b .

1. Film 1

2. Film 2

3. Film 3

4 . F ilm 4

5. Film 5

6. Film 6

7 . F ilm 7

8. Film 8

9. Film 9

10. Film 10

11. Film 11

12. Film 12

13. Film 13

F ilm Se le c t Me n u

Now that we are sure that at least one film exists, we will build a simple single layer

process using that film.

1-9

Page 16

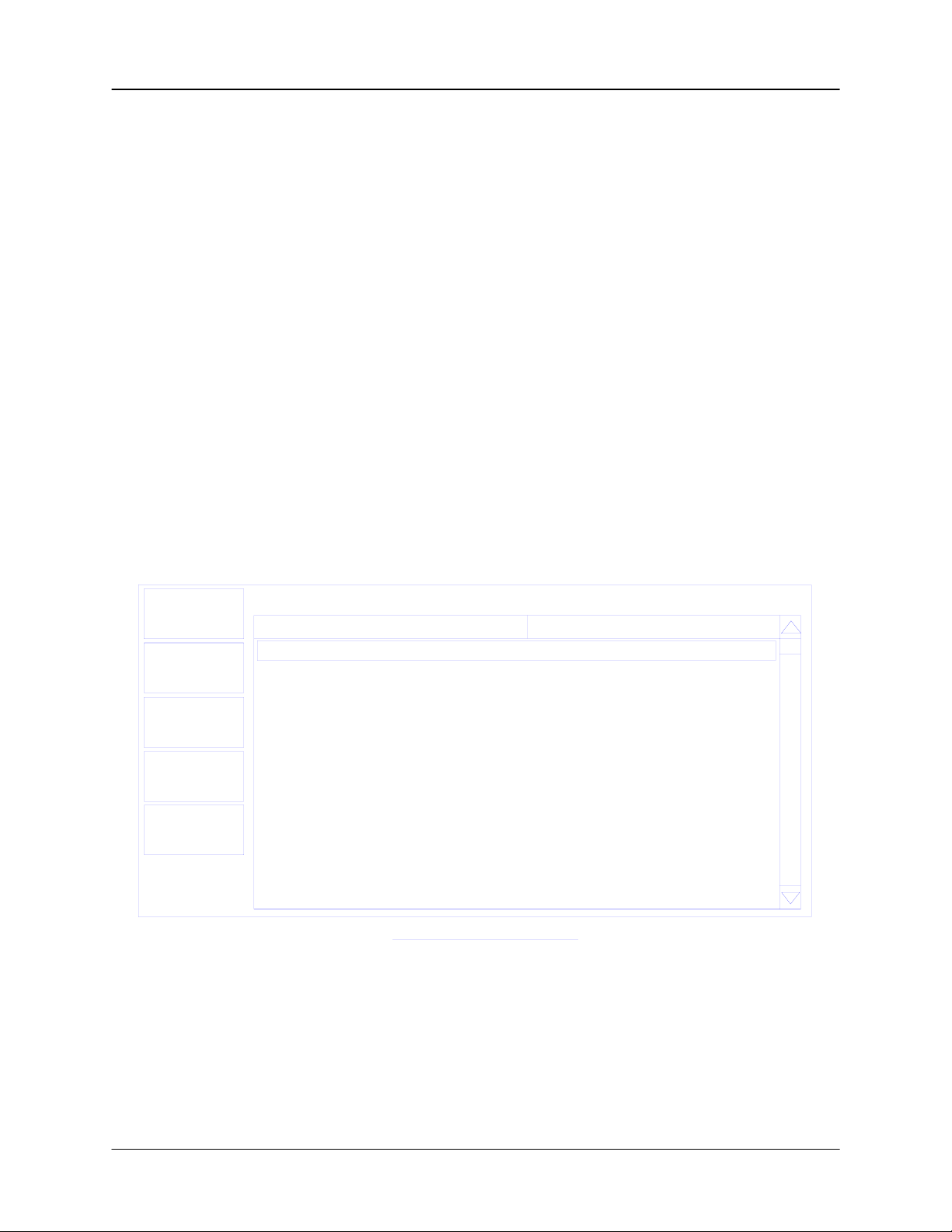

Chapter 1 Quick Start

Select

Process

Edit

Process

Insert

Layer

Press the Process Menu SoftKey to view a list of processes.

Turn the setting knob to scroll to an entry in the list that is

labeled <Empty>.

Press the Create SoftKey to create a default process at that

location.

Press the Select SoftKey to make the selection the active

process.

Press the Edit SoftKey to view a list of layers in the selected

process. The layers list should be blank.

Press Insert Layer, then scroll down the list of films to the film

you just created.

Press Insert Normal to insert the selected film as Layer 1.

The display returns to the Layer Select menu.

To

Ma in

Prev

Menu

Edit

Cut /

Paste

Insert

Layer

P ro c e ss 2 5 -> L a ye r 1 -> F ilm 1

Layer

Layer1

Layer S elect Menu

F ilm

F ilm 1

A process consists of one or more layers. Each layer can have a different film, or even

multiple films (CoDeposition). For this example, we will stop with only a single layer.

1-10

Page 17

Chapter 1 Quick Start

Edit

Layer

To

Main

Prev

Menu

Edit

With Layer 1 selected, press Edit to display the Layer Edit

menu for Layer 1.

Process 1 -> Layer 1 -> Film 1

Parameter Value Units

In it R a te 1 0 .0 A /s

Fnl T hk

Tim e Setpoint

Thickness Lim it

Start M ode

Output

Max. Power 90.0

S le w R a te

Sensor 1

Sensor 2

Sensor 3

Sensor 4

Ramp1

0.100

0:00:00 h:m m:ss

0.000

Manual

Out1

90.0

On

Off

Off

Off

Disabled

Layer Edit M enu

k/A

kA

A u to /M a n .

O ut1/O u t2

%

%

O n/O ff

O n/O ff

O n/O ff

O n/O ff

En/Dis

Edit Menu

Operation

Edit

Layer 1

To edit a setting in any menu, turn the control knob to scroll to

the desired setting, then press the Edit SoftKey. The cursor

moves to the setting value, and the SoftKey functions change

to show:

Next: Store the parameter and move to next parameter for

editing.

Cancel: Stop editing and return the selected parameter to its

previous value.

Enter: Stop editing and save values for selected pa rameter.

In Edit mode, adjust the control knob to set the desired

parameter value.

Spend some time navigating through the Layer 1 parameters

and editing values. When you are comfortable, be sure your

values for Layer 1 match those shown above.

Press Main Menu to return to the Main Screen.

We have completed the design of a single layer process.

1-11

Page 18

Chapter 1 Quick Start

1.8 Depositing a Film

Note: You can simulate the steps below, without actually depositing a film, by going to

the System Params Menu and selecting Simulate Mode ON. Simulate mode is useful

for testing processes before applying power to the evaporation supply. See Section 3.6

for detailed System Parameters Menu information.

Verify Sensor

Operation

Show

Power Graph

Verify Output

Operation

Press Next Menu until the Sensor Info option is shown.

Press Sensor Info to display the quartz sensor readings.

Sensor 1 should be ON and display a % life of over 50%. If

not, check your sensor connections (Section 1.3), and refer to

Min/Max Frequency (Section 3.6).

Press Exit to return to the main screen.

Press the Next Graph SoftKey until the graph shows Power (%

vs. Time).

Press the Next Menu SoftKey until the Auto/Manual SoftKey is

displayed. Now press Auto/Manual until Manual/Auto is

displayed. Press Start to begin deposition in manual mode.

Slowly turn the control knob to increase the control voltage to

your evaporation supply. Verify that the Power(%) reading for

Output 1 (lower right, below graph) approximates the actual

output of your evaporation supply. If not, check your hookup

(Section 1.3), and refer to Scale Voltage (S ecti on 3.6) .

Caution: Observe the output power versus your evaporation

supply’s actual output. If there is a problem, press the Stop

SoftKey immediately.

Enter

Auto Mode

Please take time to review the remainder of this manual for detailed operational,

programming, and safety information.

Press the Next Menu key until the Manual/Auto SoftKey is

shown. Press Manual/Auto to change the SoftKey display to

Auto/Manual. This places the output under PID deposition

control.

Press Stop at any time to halt deposition and set output power

to zero.

1-12

Page 19

Chapter 1 Quick Start

1-13

Page 20

Chapter 2 Operation

2.0 Introduction

This chapter describes common tasks associated with operating the SQC-222. It

assumes that you understand basic operation of the menus and parameter setup as

described in Chapter 1. Detailed definitions of each parameter can be found under the

appropriate menu description in Chapter 3.

2.1 Definitions

Several terms will be used repeatedly throughout this manual. It is important that you

understand each of these terms.

Material: A physical material to be deposited. A database of approximately 100

materials is stored in the SQC-222, and additional materials may be added using the

setup software. Three parameters completely define a material: Name, Density, and ZFactor. A table of common materials, their density, and Z-Factor is listed in Appendix A.

Film: A film describes in detail how a material will be deposited. It includes the material

definition and all of the preconditioning, deposition, and post conditioning variables

necessary to accurately deposit the materi al. Bec ause th e film de fini ti on does not

include rate and thickness information, a single film can be used in several different

layers and processes. The SQC-222 stores up to 25 films.

Layer: Layers are the basic building blocks of processes. A layer consists of a film and

the thickness and rate setpoints for that stage of the process. Layers also define which

outputs and sensors will be used at that point in the process. Codeposition of multiple

films occurs when more than one output is active during a layer.

Process: A process is a sequence of layers to be deposited. The SQC-222 can store

up to 25 processes, consisting of a total of 400 layers.

Phase: A step in the deposition cycle. Preconditioning phases include Ramp 1, Soak 1,

Ramp 2, Soak 2. Deposit phases include indexer rotate, shutter delay, deposition, and

deposition rate ramps. Post conditioning phases include Feed Ramp, Feed, and Idle

Power.

2-1

Page 21

Chapter 2 Operation

2.2 Defining a Film

A film is a material to be deposited, plus all of its associated setup parameters. Keep in

mind that a film can be used in multiple layers, or even multiple processes. Editing a

film’s parameters will cause changes to every location where the film is used.

To define a film, press Next Menu until Film Menu is shown (Menu 3). Press Film

Menu. A list of 25 films (or <Empty>) will be displayed. To define a new film, scroll to

<Empty> and press Create. A new Film# is added to the list of existing films (you can

use the SQC-222 setup software later to assign descriptive film names). Press Edit to

display the parameters fo r this film.

To

Main

Prev

Menu

Edit

F ilm

Conds.

Deposit

Controls

P ro c e s s 1 Editin g : F ilm 1

Parameter Value Units

P Term 50 None

I T e rm

D Term 0.0 Sec.

F ilm T oolin g

Pocket

C rystal Qu ality

Crys t a l Stability

Xtal Fail M ode

Material

Density

Z Factor

0.7

100

None

Disabled

Disabled

Halt

Aluminum

2.73

1.08

F ilm E d it M e n u

Sec.

%

gm/cc

P Term is the proportional gain, that is the % process rate change divided by the %

input power change. The I Term (integral) sums the rate deviations over time to more

accurately achieve the rate setpoint. The D Term (derivative) speeds response to

sudden changes in rate. Volumes have been written on determining the proper PID

settings. See the section on Loop Tuning later in this chapter for a common PID loop

tuning procedure. Start with P=25, I=.5, D=0.

Film Tooling adjusts for differences in actual versus measured thickness for this film

(material). This parameter is seldom used, but can adjust for material specific

dispersion patterns. See Xtal Tooling in the System Par a meters menu for the more

commonly used tooling correction.

Pocket selects the source pocket used for this film. This parameter requires that the I/O

Setup section of the System Parameters me nu be pr og r am med for pocket rel ay s .

2-2

Page 22

Chapter 2 Operation

The next chapter covers Crystal Quality, Stability, and Fail Mode. For initial operation

leave Quality and Stability disabled, and Fail Mode set to Halt.

With Material highlighted, press Edit to scroll through the list of available materials.

Select the desired material and press Enter. You could also change the Density and ZFactor for the selected material, but it is unlikely those values are wrong. To add a new

material or edit the name of an existing material, you must use the SQC-222 setup

software.

Film conditioning adjusts the output power level to achieve a desired material state

before and after deposition. Press Film Conds to enter the film conditioning menu.

To

M a in

Prev

Menu

Edit

Process 1 Editing: Film 1

Param eter Value Un its

Ramp1 Power

Ramp1 T ime

Soak1 Time

Ramp2 Power

Ramp2 T ime

Soak2 Time

Feed Power

Ramp Time

Feed Time

Idle Powe r

Ramp Time

Film C onditioning Menu

25.0 %

0:00:10

0:00:05 h:mm:ss

50.0

0:00:05

0:00:05

0.0

0:00:00

0:00:00

0.0

0:00:00

h:mm:ss

%

h:mm:ss

h:mm:ss

%

h:mm:ss

h:mm:ss

%

h:mm:ss

Ramp1 starts at 0% power and increases the power during Ramp1 Time to the Ramp 1

power level. Set the Ramp 1 Power and Time to gradually bring the material to a near

molten state. Set the Soak 1 Time to a value that will allow the material to

homogeneously achieve that state. Ramp 2 is used to slowly bring the material to a

power level that nearly matches the desired deposition power. Use Soak 2 to hold the

material at that level until deposition (i.e. rate control) begins.

If you use wire feed to replenish material after deposition, set the Feed Power and times

as required. The idle conditioning phase typically ramps output power back toward zero

at the end of a process.

From the Film Conds menu, press Prev Menu to return to the main Film Params menu.

2-3

Page 23

Chapter 2 Operation

Now press Deposit Controls. The Deposit Controls menu contains parameters that

modify operation during the deposition phase.

Process 1 Editing: Film 1

To

Main

Prev

Menu

Edit

Shutter delay causes the SQC-222 to delay opening the shutter until the process has

stabilized at the desired deposition rate. Capture is the % rate deviation that must be

achieved to open the shutter and go to the Deposit phase. Shutter delay is the

maximum amount of time to wait for capture to be achieved. Set Shutter Delay and

Capture to zero to disable this feature.

Parameter Value Units

Shutter Delay

Capture

Control Error

Setting

Error

Rate Sampling

Setting

0:00:00 h:mm:ss

0.0

(Ignore, Stop, Hold)

Stop

0.0

(Cont, Time, Acc based)

Continuous

Deposition Controls Menu

%

%

%

During co-deposition, the SQC-222 waits for all films to achieve capture before moving

to the deposit phase. If any film fails to achieve rate capture within its programmed

shutter delay time, an error occurs.

If the SQC-222 is unable to maintain the desired deposition rate (for example, out of

material or a bad sensor), one of three actions is possible. Keep trying (Ignore), set

power to zero to halt deposition (Stop), or maintain constant power (Hold) and

extrapolate thickness from the last good rate reading. Until your process is known and

stable, it is best to leave the Control Error setting on Ignore.

Rate sampling can extend sensor life in high rate processes. Select Cont (continuous)

to disable rate sampling. A Time selection closes the shutter for a fixed time, then

opens the shutter for a fixed time to sample the rate. Acc Based (accuracy based)

sampling closes the shutter for a fixed time, then opens the shutter until the desired rate

is achieved. Rate Sampling assumes a very stable process!

2-4

Page 24

Chapter 2 Operation

2.3 Defining a Process

To define a process, press Next Menu until the Process Menu SoftKey is shown. Press

Process Menu. A list of 25 processes (or <Empty>) will be displayed. To define a new

process, scroll to <Empty> and press Create. A new Process# is added to the list of

existing processes (use the SQC-222 setup software to assign descriptive process

names).

Press Select, then Edit to display the sequence of layers and films that comprise the

selected process.

To add a layer, scroll to the desired location in the layer sequence, and press Insert

Layer. Select a film from the list and press Insert Normal to insert a new layer. Layers

are always inserted at the selected layer. The selected layer and subsequent layers will

be shifted down.

Hint: When building a process it may be easiest to add a “dummy” last layer and keep

inserting above that layer. When the process is complete, delete the “dummy” layer.

To add a film to an existing layer so that materials will be codeposited, highligh t the

layer after the desired codeposition layer. Press Insert Layer, select the desired film,

then press Insert CoDep. The codeposited film will be inserted in the layer above the

selected layer, and indented to show that it is a codeposition film.

The display below shows two films being codeposited with Film1, then a fourth film

being deposited as an additional layer. While layers are always numbered sequentially,

the films are sequential only for this example. Any film can be used in any layer.

To

Ma in

Prev

Menu

Edit

Cut /

Paste

Insert

Layer

P ro c e ss 2 5 -> L a ye r 1 -> F ilm 1

Layer

Layer1

L a y e r2

L a y e r3

Layer4

F ilm

F ilm 1

F ilm 2

F ilm 3

F ilm 4

Layer S elect M enu

2-5

Page 25

Chapter 2 Operation

To delete a layer, highlight it in the Layer Select menu and press Cut/Paste.

On the Cut/Paste menu, press Cut to remove the layer. Press Prev Menu to return to

the Layer Select menu.

To

Main

Prev

Menu

Copy

Cut

P ro c e ss 2 5 -> L a ye r 1 -> F ilm 1

Layer

Layer1

L a y e r2

L a y e r3

Layer4

Cu t/Paste Menu

F ilm

F ilm 1

F ilm 2

F ilm 3

F ilm 4

To move or duplicate a layer, highlight it in the Layer Select menu and press Cut/Paste.

On the Cut/Paste menu, press Cut to remove the layer. A copy of the layer is

automatically saved to copy/paste memory. Press Copy to save a copy to memory

without removing the layer. Without leaving the Cut/Past menu, highlight the layer that

you want to insert the cut layer above and press Paste Normal or Paste CoDep.

Operations on the Cut/Past menu can be repeated several times. Each cut operation

overwrites the cut/paste memory. Pressing Prev Menu on the Cut/Past menu returns to

the Layer Select menu. The contents of copy/paste memory are lost!

Note: Once a film is assigned to a process layer, you cannot change the film. Instead,

cut the layer, then insert a new layer and select the desired film.

2-6

Page 26

Chapter 2 Operation

2.4 Defining a Layer

To edit a Process Layer, press Process Menu. Select the desired process, then press

Edit. Finally, select the desired layer and press Edit.

To

Main

Prev

Menu

Edit

Process 1 -> Layer 1 -> Film 1

Parameter Value Units

In it R a te 1 0 .0 A /s

Fnl Thk

Tim e Setpoint

Thickness Lim it

Start Mode

Output

Max. Power 90.0

S le w R a te

Sensor 1

Sensor 2

Sensor 3

Sensor 4

Ramp1

0.100

0:00:00 h:mm :ss

0.000

Manual

Out1

90.0

On

Off

Off

Off

Disabled

k/A

kA

A u to /M a n .

O ut1/O u t2

%

%

O n/O ff

O n/O ff

O n/O ff

O n/O ff

En/Dis

Layer Edit M enu

Initial Rate and Final Thickness are the main process setpoints for the film used in this

layer. Time Setpoint and Thickness Limit are secondary values that will activate a rela y

when they are reached.

Start Mode controls operation in multi layer processes. In Auto Start the layer starts

immediately on completion of the previous layer. Manual Start waits for a user signal

via the front panel, RS-232, or digital input to start the layer. Don’t confuse this Manual

Start mode with the Manual Power SoftKey function.

The Output entry assigns the layer/film parameters to a specific SQC-222 rear panel

output. The layer and film parameters for power, preconditioning, PID settings, etc. will

be applied to the selected output. Assign the Max Power and Slew Rate appropriate for

this material and your power supply. For now, set both to 100%. Set them to lower

values if you find that small power changes cause excessively large changes in

deposition rate.

The SQC-222 can use multiple sensors to measure a film’s deposition rate and

thickness. If multiple sensors are selected, an average of the sensors is used. Set

each sensor that will be used to measure this film to ON.

Rate Ramps allow the PID controlled deposition rate to change over time, under PID

control. Each rate ramp has a starting thickness, an elapsed time to ramp to the new

rate, and a new rate setpoint. Each process layer can have up to two rate ramps.

2-7

Page 27

Chapter 2 Operation

2.5 Sensor Setup

Sensor setup involves selecting the sensor(s) to be used, setting the Min/Max crystal

frequencies, and adjusting the Tooling Factor.

In the System Params menu, Max Frequency is the initial frequency of a new crystal,

typically 6.0e+06 Hz (6 MHz). Due to manufacturing tolerances, some crystals may

oscillate above 6MHz initially, which would be detected a s a senso r error. S etting the

Max Frequency slightly above the nominal value, to say 6.1 MHz will avoid this problem.

Min Frequency is the frequency where the SQC-222 will flag a sensor as bad. For a

6 MHz crystal, the Min Frequency is typically 5 MHz. Crystal failure is often predicted

by periods of “mode hopping,” where the crystal briefly makes an abrupt change in

frequency, or stops oscillating altogether. Some materials will cause crystals to fail or

mode hop well before 5 MHz. It is good practice to set the Min Frequency to a value

that indicates crystal failure in you process well before crystals actually fail.

To better determine impending crystal failure, Crystal Quality and Stability parameters

are also available for each Film. See Chapter 3, Film Menus, for more information on

setting Crystal Quality and Stability.

Sensor Tooling and System Tooling (System Params menu) adjusts for the difference

in measured deposition rate between the sensor and the substrate being coated.

Substrate

Substrate

Tooling

Over 100%

In the left illustration above, the sensor will measure less rate o r thickness than is

actually deposited on the substrate because of its positio ning. In the right illustration,

the sensor will measure high. Tooling is the ratio of the actual substrate deposition rate

or thickness, to that measured by the sensor.

Tooling

Under 100%

Let’s assume that at the end of deposition the sensor measures a thickness of 1.000

kA. But, suppose the actual substrate is deposited to 1.100 kA thickness (as

2-8

Page 28

Chapter 2 Operation

determined by some other means, such as a stylus profilometer). Then the tooling for

this sensor would be:

(1.100 / 1.000) x 100 = 110

A simple rule to remember is: If the rate/thickness reading is low, then increase the

tooling value. If the rate/thickness reading is high, then lower the tooling value.

Xtal Tool 1 and 2 adjust the tooling for each individual sensor. It is particularly important

when using sensor averaging to balance multiple sensors so that their measurements

match. System Tooling applies to the overall Rate and Thickness measurements of all

sensors. It is sometimes used to adjust for some systematic difference in the actual vs.

measured readings. In general, Crystal Tooling (Xtal Tool 1 and 2) should be used

instead.

Multi Xtal Count sets the number of crystals in a multi-crystal sensor head. For a

standard single or dual sensor head, leave the value at 0.

Once the sensor parameters are set, test your sensor setup to assure reliable readings

at the SQC-222. Press Next Menu until the Sensor Info option is shown, then press

Sensor Info.

Any connected sensor (whether programmed On or Off) should display its frequency

and % remaining life, as defined by Min and Max Frequency setup. For a new sensor,

the value should be near 100%. If the % Life is 0.00% or jumps around, check your

cabling and the installation of the sensor in its holder.

Sigma supplies a small 5.5 MHz “test crystal adapter” with each oscillator. If the % Life

reading is not correct, remove the 6” BNC that is connected to your feedthrough at the

oscillator. Connect the test crystal and adapter to the oscillator connector labeled

Feedthrough. For a typical setup of 6 MHz Max Frequency and 5 MHz Min Frequency,

the % Life display should be near 50%.

Sensors are assigned to each Layer, as described in the Chapter 3, Layer Edit.

More information on locating system and sensor problems is described in the

Troubleshooting section, later in this chapter.

2-9

Page 29

Chapter 2 Operation

2.6 Source Setup

The SQC-222 controls deposition rate by varying the control voltage to an external

evaporation (source) supply.

The SQC-222 output voltage range is set in the Systems Params menu. For the

supply connected to each output, set the Scale to the control voltage that corresponds

to 100% output on the source supply. The SQC-222 uses 0 volts as 0% output, and the

programmed value as 100% output. Scale values from –10 volts to 10 volts are

possible.

If you find that very small changes in control voltage yield large changes in deposition

rate, you can lower the Scale value to decrease the dynamic range. Also, each Film

has a Max Power and Slew Rate parameter that may be used to customize response to

that film.

2-10

Page 30

Chapter 2 Operation

2.7 Running a Process

Once a Process is defined with the desired Layers, and the sensors and source supply

are properly connected, the deposition process is ready to run. This section describes

the steps to select, start, and stop a process.

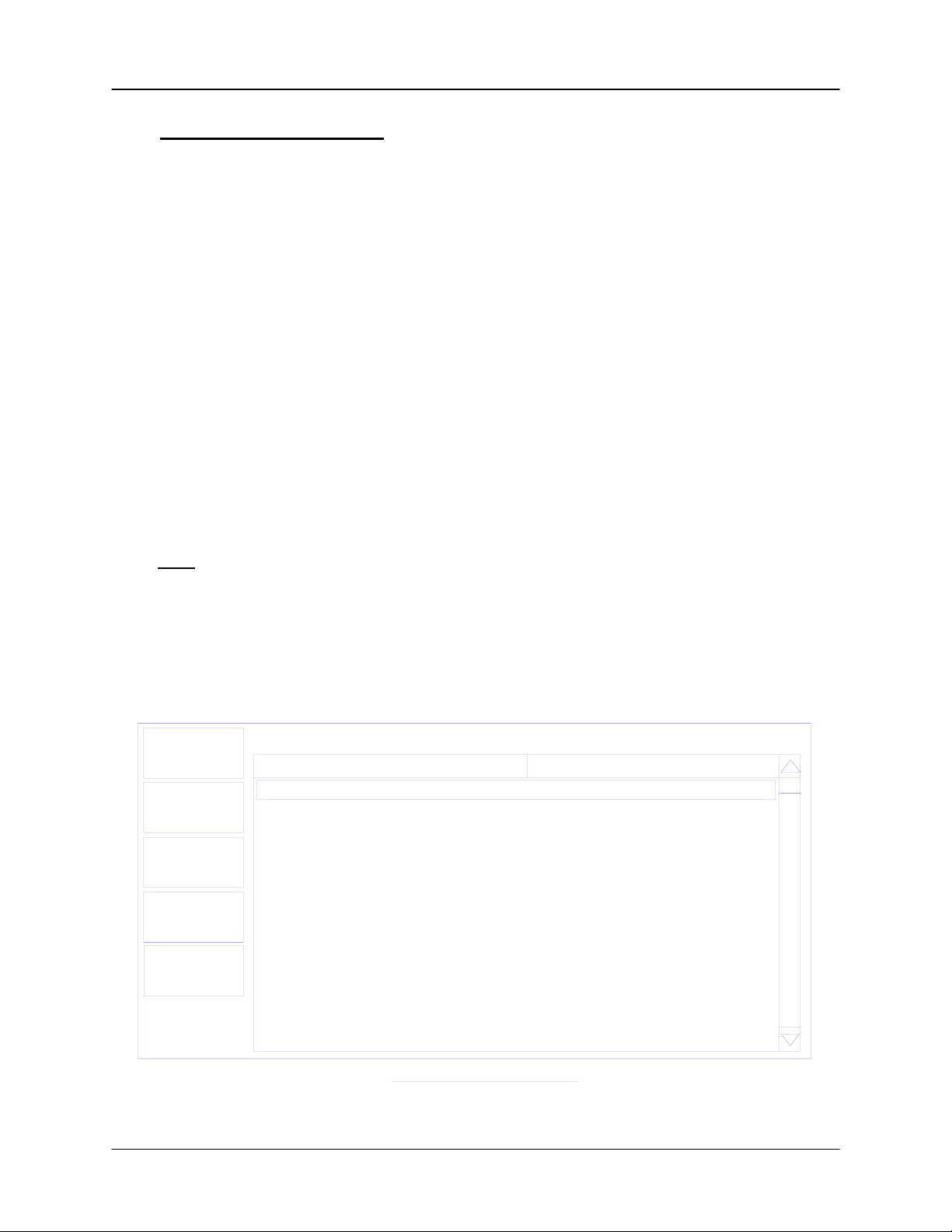

There are three Main Menu screens while the process is stopped (two when it is

running). Pressing the Next Menu SoftKey accesses the three screens. Next Menu is

the first SoftKey in each of the three menus. Likewise, Start/Stop is the last SoftKey on

each Main Menu. Main Menu 1 displays the SoftKeys used to control the process.

Next

Menu

Process 1 : Layer 1 of 1 Run # :0

Stopped

Power (% vs. Tim e)

100.0

0:00:00

Quick

Edit

Auto /

Manual

50.0

Zero

0.0

Next

Layer

Start

Out#

1

2

3

4

0.0

R a te (A /S )

0.00

0.00

0.00

0.00

6.2

12.5

Dev(%)

00.0

00.0

00.0

00.0

18.8

Thick(kA)

0.000

0.000

0.000

0.000

25.0

Pow(%)

0.0

0.0

0.0

0.0

M a in S c re e n

The Quick Edit SoftKey (available while the process is running) provides easy access

to the most commonly set process parameters.

To

Main

Edit

Next

Layer

Process 1 --> Layer 1 --> Film 1

Parameter Value Units

Init Rate 0.2 A/s

Fnl Thk

P Term 70 None

I Term

D Term

Max. Powe r

Slew Rate

Material

Density

Zfactor 1.00

3.0

0.1

0.0

99.0

99.0

Aluminum

2.73

kA

Sec.

Sec.

%

%

gm/cm^2

Quick Edit Menu

Press Next Layer and Prev Layer on the Quick Edit screen to review each layer.

Press To Main to return to the Main screen.

2-11

Page 31

Chapter 2 Operation

Next

Menu

Process 1 : Layer 1 of 1 Run # :0

Stopped

Power (% vs. Time)

100.0

0:00:00

Quick

Edit

Auto /

Manual

50.0

Zero

0.0

Next

Layer

Start

Out#

1

2

3

4

0.0

R a te (A /S )

0.00

0.00

0.00

0.00

6.2

12.5

Dev(%)

00.0

00.0

00.0

00.0

18.8

Thick(kA )

0.000

0.000

0.000

0.000

25.0

Pow(%)

0.0

0.0

0.0

0.0

M a in S c r ee n

The Auto/Manual key alternates between Automatic (PID) output control and Manual

(user) output control. In Manual mode, the SQC-222 immediately starts the deposition

phase for the current layer, whether the process was stopped or running. However, the

PID loop is disabled and the front panel control knob controls output power.

In Manual Mode, you will usually display the Rate Graph, an d manually adjust the

output power to achieve the desired deposition rate. It is easy to exceed a layer’s Final

Thickness in Manual mode, so watch the Thickness reading carefully. Manual mode is

particularly useful for determining preconditioning power levels, and loop tuning.

Moving from Manual mode to Auto mode places the SQC-222 into automatic (PID)

control. The PID control loop will try to achieve ra te setpoint, so there may be a rapid

change in output power.

Note: Don’t confuse the Manual/Auto power SoftKey with a layer’s Manual and Auto

Start. Manual/Auto Start modes are a Layer setup parameter that tells the SQC-222 to

wait for operator intervention before starting a Layer.

The Zero SoftKey can be used to zero the thickness reading at any time. It is not

normally needed, since the SQC-222 automatically zeroes the thickness at the

beginning of each layer. However, it is useful when simulating a process, and when

operating in Manual mode.

Next Layer moves the starting point for the Start SoftKey to the next layer, wrapping

back layer 1 at the end of the process.

The last SoftKey on this menu is used to Start and Stop the deposition cycle. Press

Start to start the layer shown on the first line of the screen at the preconditioning phase.

2-12

Page 32

Chapter 2 Operation

Press Stop to halt the current layer. You can restart the current layer pressing Start.

Press Next Layer, then Start, to start any other process layer.

Note: It is best (and safest!) to place the SQC-222 in Simulate mode when a process is

first run. If the bottom SoftKey does not show Start Simulate, press System Params

and turn Simulate Mode ON.

Enough preliminaries, let’s start the process!

Press Start to start deposition. If the first layer Start mode was programmed as

Manual, you will need to press the Start Layer SoftKey now to start the layer.

Next

Menu

Process 1 : Layer 1 of 1 Run # :1

Soak 2

Power ( % vs. Time)

100.0

0:25:00

Quick

Edit

Auto /

Manual

50.0

Zero

0.0

Start

Layer

Start

Out#

1

2

3

4

0.0

Rate(A/S)

1.20

0.00

0.00

0.00

6.2

12.5

Dev( %)

00.0

00.0

00.0

00.0

18.8

Thick(kA)

0.085

0.000

0.000

0.000

25.0

Pow( %)

75.0

0.0

0.0

0.0

Preconditioning

The process starts with the first layer preconditioning phase. When preconditioning is

complete, the deposition phase begins. The deposition phase ends when Final

Thickness is reached for the layer, then Feed and Idle phases run (if programmed).

If the second layer is Auto Start, its cycle begins immediately when the first layer is

complete. If the second Layer is Manual Start, or it’s the last layer in the process, the

process halts and waits for operator intervention.

2-13

Page 33

Chapter 2 Operation

While the process is running, a Stop Layer SoftKey is shown (see above). Pressing

Stop Layer temporarily halts the current Layer.

Next

Menu

Process 1 : Layer 1 of 1 Run # :1

Layer Stopped

R a t e (A/s v s . T im e )

10.0

0:42:00

Quick

Edit

Auto /

Manual

5.0

Zero

0.0

Next

Layer

Start

Out#

1

2

3

4

0.0

R a te (A /S )

4.91

0.00

0.00

0.00

6.2

12.5

Dev(%)

- 1.8

00.0

00.0

00.0

18.8

Thick(kA )

0.095

0.000

0.000

0.000

25.0

Pow(%)

75.0

0.0

0.0

0.0

Layer Stopped

Start repeats the stopped layer, beginning with preconditioning. Next Layer allows you

to select another layer to start.

Note: Pressing the Abort SoftKey on Main Menu 2 at any time completely aborts the

process.

Spend some time in Simulate mode verifying that the process sequences through each

phase of each layer as expected. If not, use the Quick Setup, Process, and Film menus

to make corrections.

Because the process is being “simulated,” some parameters will not be correct for your

process (particularly PID). However, you can become familiar with the effect of each

parameter in this simulated process. Also practice using the Next Menu options,

especially Auto/Manual modes.

Once you have verified the process in Simulate Mode, you may return to the System

Params menu and turn Simulate OFF to start testing your process. Use the next

section to finalize the loop PID settings.

2-14

Page 34

Chapter 2 Operation

2.8 Loop Tuning

This section will help you adjust your control loop PID parameters to achieve a stable

deposition process. Keep in mind that there is no “best” way to determine PID

parameters, and no one set of settings that are best.

Set System Parameters: Be sure that the output Scale and crystal Min/Max Frequency

parameters are accurate for your system. All Tooling parameters are best set to 100%

for now. A Period of .25 seconds is also a good starting point. Simulate should be

OFF.

Create a One-Layer Test Process: Create a new film with all default values. Create a

new process that has the new film as its only layer, and select it as the current process.

In the Quick Setup menu set Init Rate to your desired rate and Final Thickness to a

large value, say 10X your desired Final Thickness. Select the proper Sensor(s), Output,

and Material. Set Max Power to 100% and Slew Rate to 100%.

Test the Setup: Press Auto/Manual to start the layer in Manual mode. Slowly turn the

control knob to a power of 10%, and verify that your power supply output is about 10%

of full scale. Continue to turn the control knob until a Rate(A/s) above 0 is shown.

Again, verify that the power supply output agrees with the SQC-222 Power(%) reading.

If the readings don’t agree, check your wiring and process setup. In particular, verify

that the System Parameters output scale agrees with your power supply input

specifications.

Determine Open Loop Gain: Slowly adjust the control knob until the Rate(A/s) reading

approximately matches your desired rate (Init Rate in the Quick Setup menu). Record

the desired rate Power(%) reading as PWRDR. Slowly lower the power until the

Rate(A/s) reading is just at (or near) zero. Record the zero rate Power(%) reading as

PWR0R.

Determine Open Loop Response Time: Calculate 1/3 of your desired rate (RATE

and 2/3 of the desired rate (RATE

Rate(A/s) matches RATE

. Get ready to record the loop’s response to an input

1/3

change. Quickly adjust Power(%) to PWR

reading to reach RATE

. You may want to do this several times to get an average

2/3

) for this layer. Slowly increase the power until

2/3

. Measure the time for the Rate (A/s)

DR

1/3

),

response time reading. Displaying the Rate graph will also help. Twice the measured

time is the step response time, TIMESR. TIMESR is typically .7 to 1.5 seconds for EBeam evaporation, 5 to 20 seconds for ther mal ev ap or ation.

Return the output power to 0%, then press Manual/Auto to return to Auto mode. Follow

these steps to set the loop PID parameters:

Set PID Values: In the Quick Setup menu set P=25, I= TIME

, D=0. Exit the Quick

SR

Setup menu. Press Start and observe the Power graph. The power should rise from

0%, and stabilize near PWRDR with little ringing or overshoot. If there is more than

2-15

Page 35

Chapter 2 Operation

about 10% overshoot, lower the P Term. If the time to reach PWRDR is very slow,

increase the P Term. A lower I Term will increase response time, a higher value will

eliminate ringing and setpoint deviations. It is unlikely you will need any D Term.

Continue to Start the process and adjust PID until steady-state response is smooth and

the step response is reasonably controlled. You don’t need to totally eliminate ringing

during the step if the steady-state response is smooth, preconditioning will minimize

step changes.

Set Preconditioning: The power level you recorded as PWR0R is the power where

deposition just begins. That’s a good value for Ramp 1 power in the Film Conds menu.

PWRDR, or slightly less, is a good value for Ramp 2 Power. This will eliminate a large

step change when entering the deposition phase.

Once PID terms are established for a material, they will typically be similar for other

materials. Only the P Term and preconditioning power levels may need adjustment.

2-16

Page 36

Chapter 2 Operation

2.9 Troubleshooting

Most SQC-222 problems are caused by defective crystals or improper film setup,

particularly incorrect PID settings for the control loop. Follow the procedures below to

identify and correct common problems.

2.9.1 No Readings, or Erratic Readings from Sensors:

Disconnect the deposition source supply. This eliminates the possibility that a noisy

source, or poor loop tuning, are causing an unstable PID loop.

Verify that the sensors, oscillator and cab ling are connected as shown in Section 1.5.

Assure that a good ground connection has been made to the SQC-222 chassis.

Replace the quartz crystal. Crystals sometimes fail unexpectedly, or exhibit erratic

frequency shifts before total failure. Depending on the material, crystals may fail well

before the typical 5 MHz value. If you find that crystals consistently fail early, you may

want to set Min Frequency in the System Menu to a value higher then 5 MHz.

In the System Menu, assure that Simulate Mode is OFF, and Frequency Min/Max are

set properly for your crystals (typically Freq Min=5.0 MHz, Freq Max=6.0 MHz). Some

manufacturer's crystals exceed 6MHz when new. Setting Frequency Max to 6.1 MHz

will correct that problem, with no bearing on instrument accuracy.

Press Film Menu, Edit, and assure that the proper sensors are enabled. Press Exit to

Main, then Next Menu until the Sensor Info SoftKey shows. Press Sensor Info to show

sensor Frequency and % Life.

While not depositing, observe the % Life display for each active sensor. The value

should be stable, between 20% and 100%.

If the % Life reading is zero or unstable: Recheck the wiring from the sensor to the

SQC-222, and verify that the SQC-222 is properly grounded. Also check that the

crystal is seated properly in the sensor head.

Swap the sensor to the other SQC-222 input. If both SQC-222 inputs show zero or

unstable readings, the problem is almost certainly a wiring or sensor problem.

If the % Life is less than 50%: Replace the crystal and assure that % Life is near

100%, very stable. If % Life is not near 100%, check the Frequency Min/Max limits.

If the problem is not corrected: Referring to Section 1.5, disconnect the 6” M/F BNC

cable from the external oscillator module. A 5.5 MHz test crystal and BNC barrel

adapter is supplied with each oscillator. Attach the test crystal to the oscillator

Sensor connector. The display should read about 5.5 MHz, very stable. If not,

contact Sigma Instruments technical support.

2-17

Page 37

Chapter 2 Operation

When the frequency reading is stable, reconnect the source supply. Start the

deposition process in Manual mode with 0% power. The % Life readings should remain

stable.

Slowly raise the % Power until a rate reading is displayed above the graph. As material

is deposited on the crystal, the % Life reading should remain stable, or drop slowly and

consistently. If not, check your source supply for erratic output. Also assure that the

sensor is not too close to the source (particularly in sputtering).

2.9.2 Incorrect Rate or Thickness Measurement:

First, complete the procedures in Section 2.9.1 to assure reliable sensor operation.

Set the Xtal Tooling as described in the System Menu section of Chapter 3. Incorrect

Xtal Tooling values will cause consistently low or high rate/thickness values for every

material.

Once the Xtal Tooling is set, set Film Tooling in the Film Menu to 100% unless you are

certain that another value is needed for a specific film.

Verify that the Density and Z-Factor values match those in the Materials Parameters

Appendix. If the material is not listed, check a materials handbook. Density has a

significant effect on rate/thickness calculations.

Z-Factor corrects for stresses as a crystal is coated. If readings are initially accurate,

but deteriorate as crystal life drops below 60-70%, you need to adjust the Z-Factor or

replace crystals more frequently. The relationship between Z-Factor and Acoustic

Impedance is discussed in the Materials Appendix.

2.9.3 Poor Rate Stability:

First, be sure that a stable rate can be achieved in Manual mode, as explained in

Section 2.9.1. Once a stable rate is achieved in Manual mode, follow the Loop Tuning

procedures of Section 2.8.

2-18

Page 38

Chapter 2 Operation

2-19

Page 39

Chapter 3 Menus

3.0 Introduction

Three menus on the Main Screen control SQC-222 operation. The SoftKeys associated

with each of these menus leads to sub menus. This chapter describes the function of

each setting in each menu. It is arranged by Main Screen menus, then by major sub

menus.

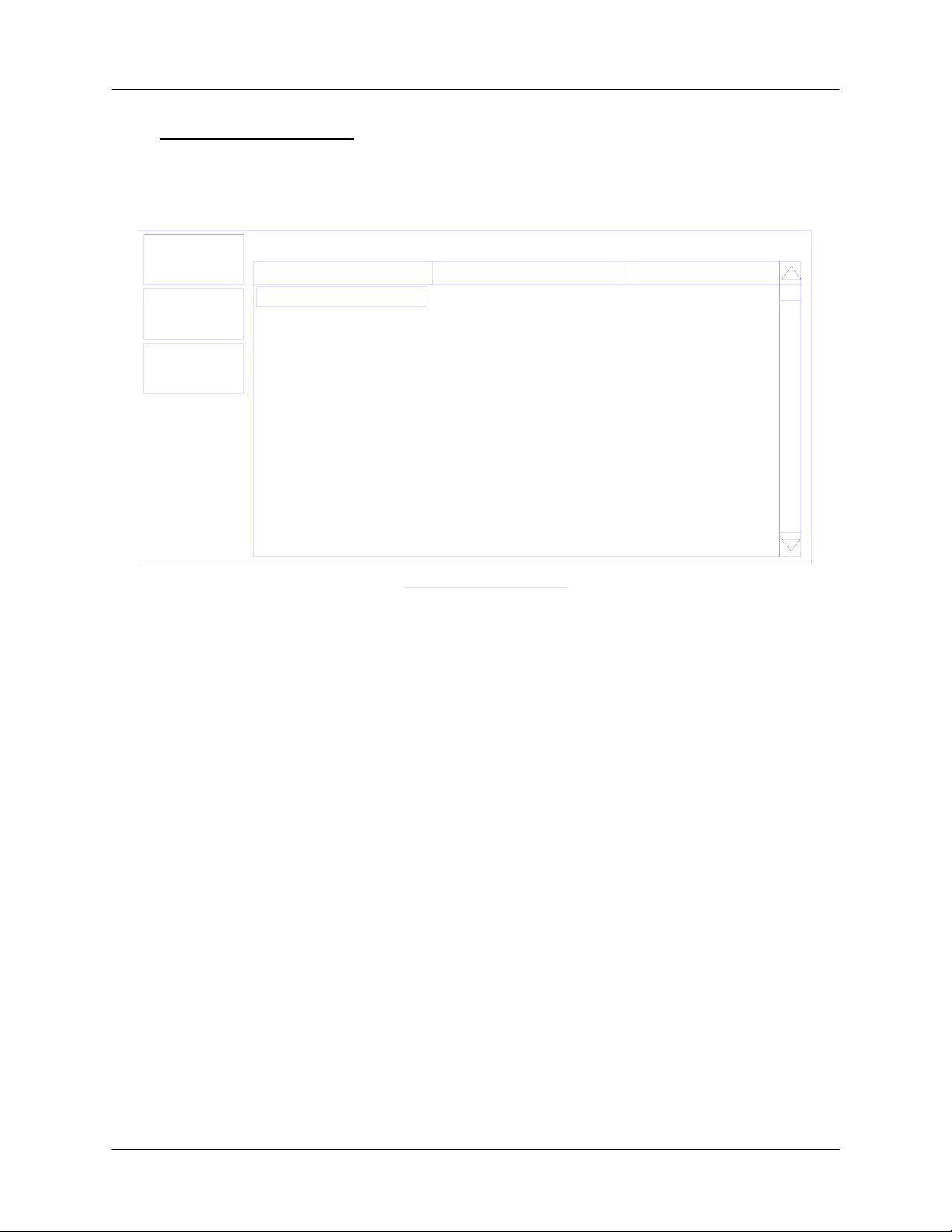

The power-up screen for the SQC-222 is shown below.

Next

Menu

Process 1 : Layer 1 of 1 Run # :0

Stopped

Power (% vs. Time)

100.0

0:00:00

Quick

Edit

Process

Menu

50.0

Film

Menu

0.0

System

Params

Start

Out#

1

2

3

4

0.0

R a te (A /S )

0.00

0.00

0.00

0.00

6.2

12.5

Dev(%)

00.0

00.0

00.0

00.0

18.8

Thick(kA )

0.000

0.000

0.000

0.000

25.0

Pow(%)

0.0

0.0

0.0

0.0

M a in S c re e n

At the top of the screen you will find informa tion about the current process, layer, and

run status. Immediately below is the current deposition phase and error conditions.

The central graph displays either Rate, Rate Deviation, or Output Power. If multiple

materials are being deposited, the graph shows each material in a different color.

Below the graph is a display of deposition readings. This display always shows the

current rate and thickness readings. The remaining columns can be set to display

either Power and Deviation readings or Rate and Thickness setpoints. For a standard

SQC-222 there will be two lines, corresponding to the two control outputs. With an

expansion card installed there will be four lines, as shown.

The Main Screen SoftKey legends will change based on the Menu selection and the

current process status. The three different menus for the main screen are accessed by

press Next Menu SoftKey.

3-1

Page 40

Chapter 3 Menus

3.1 Main Screen, Menu 1

The table below describes the function of each SoftKey on Main Screen, Menu 1.

Next

Menu

Quick

Edit

Auto / Manual

Zero Zeros the thickness reading. Useful for resetting or extending

Next

Layer

Start

Layer

Sequences through each of the three Main Screen menus.

Displays the Quick Setup Menu of commonly changed process

values. If this key is not visible, the active process has no

layers defined.

Toggles between Auto and Manual power control. When

Auto/Manual is shown, output power is set by the SQC-222 to

achieve the programmed deposition rate. When Manual/Auto

is shown, the control knob sets the output power.

the current deposition layer.

Sequences through each process layer. Use this key to start

or restart the process at any layer. Only visible when the

process is stopped.

Each layer in a process can be defined as Auto Start or Manual

Start. Auto Start layers begin immediately on completion of the

previous layer. Manual start layers wait for the operator to

press Start Layer. Only visible when waiting to start a Manual

Start layer.

Start/Stop Starts or halts the current process. Sets all outputs to zero.

3-2

Page 41

Chapter 3 Menus

3.2 Main Screen, Menu 2

The table below describes the function of each SoftKey on Main Screen, Menu 2.

Next

Sequences through each of the three Main Screen menus.

Menu

Next

Graph

Sequences through the graph options for the Main Screen.

Choose between Rate, Rate Deviation, and Power graphs.

The Y axis of the Rate Deviation graph can be scaled in the

System Params menu. A fourth “graph” screen displays rate,

thickness, and power in large text format for easy viewing.

Next

Displays

Toggles between data display options at the bottom of the

Main Screen. The first display option shows Rate, Rate

Deviation, Thickness, and Power readings. The second option

shows Rate measurements in the first column; Rate setpoints

in the second column. Thickness measurements are shown in

the third column, then Thickness setpoints in the fourth.

Sensor Info Replaces the Main Screen with the Sensor screen.

Sensor #

Exit

Enable

Freq

Life

Sensor Info

Next

Layer

Start Layer

Sequences through each process layer. Use this key to start

or restart the process at any layer.

Each layer in a process can be defined as Auto Start or Manual

Start. Auto Start layers begin immediately on completion of the

previous layer. Manual start layers wait for the operator to

press Start Layer. Only visible when waiting to Manual Start.

Start/Stop Starts or halts the current process. Sets all outputs to zero.

3-3

Page 42

Chapter 3 Menus

3.3 Main Screen, Menu 3

Menu 3 is can accessed only while the process is stopped. This menu gives access to

process, film, and system setup parameters that cannot be altered while a process is

running.

To change these parameters when a process is running: Stop the process; modify the

parameters; then restart the process at the desired layer.

The table below describes the function of each SoftKey on Main Screen Menu 3.

Next

Menu

Process

Menu

Film

Menu

System

Params

The remainder of this chapter provides a detailed explanation of each sub menu and its

settings.

Sequences through each of the three Main Screen menus.

A process is a sequence of layers of deposited film(s). The

Process Menu selection allows you to build and edit the

sequence of process layers.

A film is basically a material plus the setup information

necessary to deposit that material. Settings on the Film Menu

include pre/post conditioning, deposition error controls, and the

physical chamber setup for that material.

System parameters control the overall operation of the SQC-

222. Tooling, crystal frequency, and operating modes are

examples of settings found on the System Para me ter s Men u.

3-4

Page 43

Chapter 3 Menus

3.4 Quick Setup Menu

The Quick Setup Menu provides access to the most commonly adjusted parameters for

the current process and layer.

Process 1 --> Layer 1 --> Film 1

Parameter Value Units

Init R ate 0.2 A/s

Fnl Thk

P Term 70 None

I Ter m

D Term

Max. Power

Slew Rate

Material

Density

Zfac to r 1.0 0

3.0

0.1

0.0

99.0

99.0

Aluminum

2.73

Q u ic k Ed it Men u

kA

Sec.

Sec.

%

%

gm/cm^2

To

To

M a in

Edit

Next

Layer

Returns to the Ma in Screen Menu 1.

Main

Edit Selects the highlighted parameter for edit. SoftKey functions

change to:

Next: Store parameter and move to next for editing.

Cancel: Stop editing and undo changes to selected parameter.

Enter: Stop editing and save values for selected pa rameter.

Control Knob: Turn to adjust value. Push to store value and

move to next parameter.

Prev Layer Displays the parameters for the previous layer in the process.

Next Layer Displays the parameters for the next layer in the process.

Quick Setup parameters are described below:

Initial Rate: The beginning rate of deposition for this layer.

Final Thickness: The desired final thickness of this layer. The deposition phase of this

layer will end when this thickness is reached.

3-5

Page 44

Chapter 3 Menus

P Term: Sets the gain of the control loop. High gains yield more responsive (but

potentially unstable) loops. Try a value of 50, then gradually increase/decrease the

value to respond to step changes in rate setpoint.

I Term: The integral term controls the time constant of the loop response. A small I

term, say .5 to 1 seconds, will smooth the response of most loops.

D Term: The differential term causes the loop to respond quickly to changes. Use 0 or

a very small value to avoid oscillations.

Max Power: The maximum output power allowed for the selected output. The Scale

output voltage is a function of the deposition power supply input specifications, and is

set in the System Parameters menu. Max Power controls the maximum power that can

be used by this process layer.

Slew Rate: The maximum pow er change al l owed on an output, per second. If power or

rate ramps exceed this value, an error will occur.

Material: Selects a material assigned to this film. As materials change, their density

and Z-Factor are updated.

Density: Sets the density for this material. Material density has a significant impact on

deposition calculations.

Z-Factor: Sets the Z-factor, an empirically determined measure of a material’s effect on

quartz crystal frequency change. Z-Factor is the ratio of the acoustic impedance of the

sensor to that of the deposited material. It is used to match the acoustic (oscillation)

properties of the material to the quartz sensor. If you know the “acoustic impedance” of

your material, divide it by 8.83 (the acoustic impedance of SiO2) to obtain the material’s

Z-Factor.

3-6

Page 45

Chapter 3 Menus

3.5 Process Menus

There are several tiers of Process Menus. The first menu (shown below) selects the

current process. The current process is the process that is ready to run, and also the

process that is selected for editing.

Main Screen

Prev

Menu

To

M a in

Prev

Menu

Edit

Film

Conds.

Deposit

Controls

Process 1

Scroll Processes with Knob

1. Process1

2. <E mpty >

3. <E mpty >

4. <E mpty >

5. <E mpty >

6. <E mpty >

7. <E mpty >

8. <E mpty >

9. <E mpty >

10. <Empty>

11. <Empty>

12. <Empty>

13. <Empty>

Process Select Menu

Returns to the Ma in Screen, Menu 3.

Steps back through the sequence of process menus: Process

Select <–> Layer Select <–> Layer Edit. On this topmost

Process Menu, returns to the Main Menu.

Select /

Edit

Select sets the highlighted process as the current process.

Edit displays the Layer Select Menu for the current process.

Delete Deletes the highlighted process and all of its layers.

3-7

Page 46

Chapter 3 Menus

Selecting Edit on the Process Select Menu shows the se quence of layers that will be

deposited in the selected process.

Main

Screen

Prev

Menu

M a in

Screen

Prev

Menu

Edit

Cut /

Paste

Inse rt

Layer

Process 1 -> Layer 1 -> Film 1

Layer Value

Layer 1

Layer Select Menu

Film 1

Returns to the Ma in Screen Menu 3.

Returns to the Process Select Menu.

Edit Displays the Layer Edit Menu for the highlighted layer (see the

next section).

Cut /

Paste

Used to develop the sequence of layers in a process. Pressing

Cut/Paste displays a sub menu.

The highlighted layer may be Cut (removed from the process)

or Copied to the clipboard. The layer on the clipboard can then

be Pasted anywhere in the list of layers (see next page).

Insert

Layer

Shows the list of 25 films. Select a film, then press Insert

Normal or Insert CoDep to insert the film as a new layer.

3-8

Page 47

Chapter 3 Menus

3.6 Layer Edit Menu

Each layer consists of a film (i.e. a material), plus the deposition rate and thickness that

are desired for the layer. The Layer Edit Menu provides access to these layer

parameters:

To

Main

Prev

Menu

Edit

To

Process 1 -> Layer 1 -> Film 1

Parameter Value Units

Init Rate 0.0

Fnl Thk

Time Setpoint

Thickness Limit

Start Mode

Ramp1

Ramp2

0.000

0:00:00 h:mm :ss

50.0

Manual

Disabled

Disabled

Layer Edit Menu

Returns to the Main Menu.

A/s

k/A

%

Au to/Man.

En/Dis

En/Dis

Main

Prev

Returns to the Layer Select Menu.

Menu

Edit Selects the highlighted parameter for edit. SoftKey functions

change to:

Next: Store parameter and move to next for editing.

Cancel: Stop editing and undo changes to selected parameter.

Enter: Stop editing and save values for selected pa rameter.

Control Knob: Turn to adjust value. Push to store value and

move to next parameter.

Control Knob Scrolls through the list of layer parameters.

A description of each parameter on the Layer Edit Menu follows:

Initial Rate: The beginning rate of deposition for this layer.

Final Thickness: The desired final thickness of this layer. The deposition phase of this

layer will end when this thickness is reached.

3-9

Page 48

Chapter 3 Menus

Time Setpoint: Sets an arbitrary time, after deposition begins, when the time setpoint

relay is activated.

Thickness Limit: Sets an arbitrary thickness when the thickness limit relay is activated.

Start Mode: Determines whether a layer begins automatically upon completion of the

previous layer. If Manual start is selected, the previous layer ends at its idle power and

waits for the user to push the Start button.

Output: Selects the control voltage output that is active for the selected layer.

Max Power: The maximum output power allowed for the selected output. The Scale

output voltage is a function of the deposition power supply input specifications, and is

set in the System Parameters menu. Max Power controls the maximum power that can

be used by this process layer.

Slew Rate: The maximum pow er change al l owed on an output, per second. If power or

rate ramps exceed this value, an error will occur.

Sensor 1-4: Allows each quartz crystal Sensor to be selected for the selected film. If

multiple sensors are assigned to a film, their readings are averaged. If multiple sensors

are assigned to a film, and one fails, it is excluded from measur e me nts.

Other selections, besides Sensor On/Off, may appear if certain relays or inputs are

assigned in the System Parameters, I/O Setup menu:

If a Dual Crystal Shutter relay is assigned to Sensor 1 or 3 in the I/O Setup Menu,

Sensor 1 or 3 becomes the primary sensor and Sensor 2 or 4 are a secondary sensor.

If the primary sensor fails, measurement automatically switches to the secondary

sensor. The secondary sensor will be used until the process completes or is aborted.

The next process run will return to the primary sensor.

If a Multi Crystal Move relay is assigned to a sensor in the I/O Setup Menu, a Xtal

Switch selection is also shown in this menu. If a sensor fails, a relay is pulsed to move

to the next sensor in the head. Selection continues until a good sensor is found, or all

crystals in the multi-crystal head have failed.

If Multi Xtal Ready inputs are assigned in I/O Setup, you can select a specific crystal of

the multi-crystal head for each layer. This is useful for depositing only one type of

material on each crystal. If a specific sensor of a multi-crystal head is selected, and that

sensor fails, the process halts or goes into timed power.

3-10

Page 49

Chapter 3 Menus

Ramp 1: During the deposition of a layer, it may be desirable to change the deposition

rate. For example, you may want to deposit slowly at first, then increase the rate once

an initial thickness is reached. Enabling rate ra mps provides that capability. Once

enabled, these parameters are added to the list.

Start Thickness: The deposited thickness at which the new rate will begin.

Ramp Time: Time allowed for the rate to change from initial rate to new rate.

New Rate: The rate of deposition, which is reached at the end of Ramp 1.

Ramp 2: Two rate ramps are available for each layer. The start thickness for Ramp 2

should be greater than the start thickness for Ramp 1.

3-11

Page 50

Chapter 3 Menus

3.7 Cut/Copy and Insert Menus

Cut/Copy and Insert menus are used to build and edit a sequence of process layers.

The Layer Select Menu below shows a process consisting of four layers. The first three

layers will be co-deposited with Layer 1 (note the indentation of layers 2 and 3). The

fourth layer will be deposited after layers 1-3 are codeposited.

To

Process 1 -> Layer 1 -> F ilm 1

Main

Prev

Menu

Layer

Layer1

Layer2