Inficon Sensistor ISH2000 Series, Sensistor ISH2000C, Sensistor ISH2000, Sensistor ISH2000P Operating Manual

Page 1

Hydrogen Leak Detector

Sensistor ISH2000

Instrument SW version 6.22

Probe SW version 1.08

EN

Operating Manual

Publication: INFICON AB - nina60e1-d (1304) - All information can be modified without prior notice

Page 2

Page 3

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Contents

1 User information........................................................................................................................... 6

1.1 Notes and safety notices..........................................................................................................6

1.2 Document outline.................................................................................................................... 6

1.3 Conventions used in this book.................................................................................................6

2 Description of equipment............................................................................................................. 7

2.1 Sensistor ISH2000.................................................................................................................... 7

2.2 Sensistor ISH2000C .................................................................................................................8

2.3 Sensistor ISH2000P..................................................................................................................9

3 Controls and connections........................................................................................................... 10

3.1 Display ..................................................................................................................................10

3.2 Push-buttons ......................................................................................................................... 11

3.3 LEDs ...................................................................................................................................... 11

3.4 Ports and connections ...........................................................................................................11

4 Precautions .................................................................................................................................. 14

4.1 When working with gas ........................................................................................................14

4.2 Hydrogen Tracer Gas for leak detection ................................................................................. 15

4.3 Interferences .........................................................................................................................15

5 Working principle....................................................................................................................... 16

5.1 Gas Sensor Technology ......................................................................................................... 16

5.2 Condition for leak detection .................................................................................................. 16

5.3 Leak Detection mode............................................................................................................. 16

6 Operating the detector............................................................................................................... 17

6.1 To Detect Leaks .................................................................................................................... 17

6.2 To Locate Leaks .................................................................................................................... 17

6.3 To Quantify Leaks .................................................................................................................18

7 Calibrate the leak detector......................................................................................................... 19

7.1 Introduction ..........................................................................................................................19

7.2 Calibration Leak or Calibration Gas........................................................................................ 19

7.3 Unit Conversion..................................................................................................................... 19

7.4 Calibration procedure............................................................................................................20

7.5 Calibration value with Calibration leak................................................................................... 20

7.6 Calibration value with Calibration gas.................................................................................... 21

8 Reference section........................................................................................................................ 22

8.1 Menu system.........................................................................................................................22

8.2 Button functions.................................................................................................................... 23

8.3 Stored values and setups .......................................................................................................23

8.4 Engineering format................................................................................................................ 23

8.5 Change Test Mode ................................................................................................................ 23

8.6 Calibration ............................................................................................................................23

8.7 Locating Mode Settings ......................................................................................................... 27

8.8 Measuring Mode Settings......................................................................................................29

8.9 APC Settings* .......................................................................................................................31

8.10 Display Settings .....................................................................................................................32

8.11 General Settings .................................................................................................................... 32

8.12 Service Settings .....................................................................................................................34

8.13 Combined Mode ...................................................................................................................36

8.14 Probe ....................................................................................................................................36

8.15 Probe Control Port................................................................................................................. 37

8.16 Printer port............................................................................................................................39

8.17 Sensistor ISH2000P installation .............................................................................................. 45

8.18 Default parameters................................................................................................................46

9 Trouble-shooting......................................................................................................................... 49

10 Sensistor ISH2000 specifications................................................................................................ 50

11 Spare parts and accessories........................................................................................................

12 Support by INFICON.................................................................................................................... 53

12.1 How To Contact INFICON ......................................................................................................53

12.2 Returning your instrument to INFICON................................................................................... 53

EN

52

OM-Sensistor ISH2000-EN-201304 3

Page 4

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

13 Menu Overview .......................................................................................................................... 54

14 Declaration of conformity .......................................................................................................... 56

15 Recycling...................................................................................................................................... 57

4 OM-Sensistor ISH2000-EN-201304

Page 5

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Welcome to Sensistor ISH2000

Dear customer,

You have just bought an INFICON Hydrogen Leak Detector Sensistor ISH2000. The

Sensistor ISH2000 is an extremely sensitive and selective detector for hydrogen gas (H2).

It is especially designed for leak detection using Hydrogen Tracer Gas (Hydrogen diluted

with Nitrogen down to a safe concentration) which is the most effective and economical

tracer gas for leak testing.

Sensistor ISH2000 detects hydrogen in air at atmospheric pressure with no need for

vacuum pumping. It is especially suitable for applications where high sensitivity and

selectivity is required in combination with simplicity, reliability and low cost.

This product complies with the requirements of European

Directives, listed in the Declaration of Conformity found on

page 56 in this document. These Directives are amended by

Directive 93/68/E.E.C (E.C. Marking).

Copyright/Intellectual property

The use of INFICON AB products are subject to copyright and

intellectual property rights in force in any jurisdiction.

All rights reserved, including copying this document in whole

or in any part without prior written authorization from

INFICON AB.

EN

Though INFICON AB believes reasonable efforts have been

made to ensure the accuracy of the information contained in

the document, it may include inaccuracies or typographical

errors. INFICON AB reserves the right to change the

information inside the document without further notice.

OM-Sensistor ISH2000-EN-201304 5

Page 6

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

1 User information

Read this user manual carefully before using the Sensistor ISH2000.

1.1 Notes and safety notices

This manual contains warnings and cautions concerning the safe use of the product.

See definitions below.

WARNING!

Warning indicates a hazardous situation which, if not

avoided, could result in death or serious injury. It is

important not to proceed until all stated conditions

are met and clearly understood.

CAUTION!

Caution indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury. It is

important not to proceed until all stated conditions

are met and clearly understood.

NOTICE!

Notice indicates instructions that must be

followed to avoid damage to the Sensistor

ISH2000 or other equipment.

Note: A Note is used to indicate information that is important for trouble-free and optimal

use of the Sensistor ISH2000.

1.2 Document outline

The document is divided in two main parts:

• Getting started

• Reference section

The Getting started part consists of step by step case examples, explaining how to use

the Sensistor ISH2000 in a variety common situations. The Reference section consists of

in depth explanation and additional information, which completes the user manual

with all relevant information.

1.3 Conventions used in this book

In this user manual the following text style (hardware command) is used for references

to hardware commands or button labels, while this text style (

used for references to software commands and menu choices.

software command) is

6 OM-Sensistor ISH2000-EN-201304

Page 7

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

2 Description of equipment

Sensistor ISH2000 can be purchased in one of three versions. A desktop model

(Sensistor ISH2000), a battery operated model (Sensistor ISH2000C), and a panel

mount model (Sensistor ISH2000P).

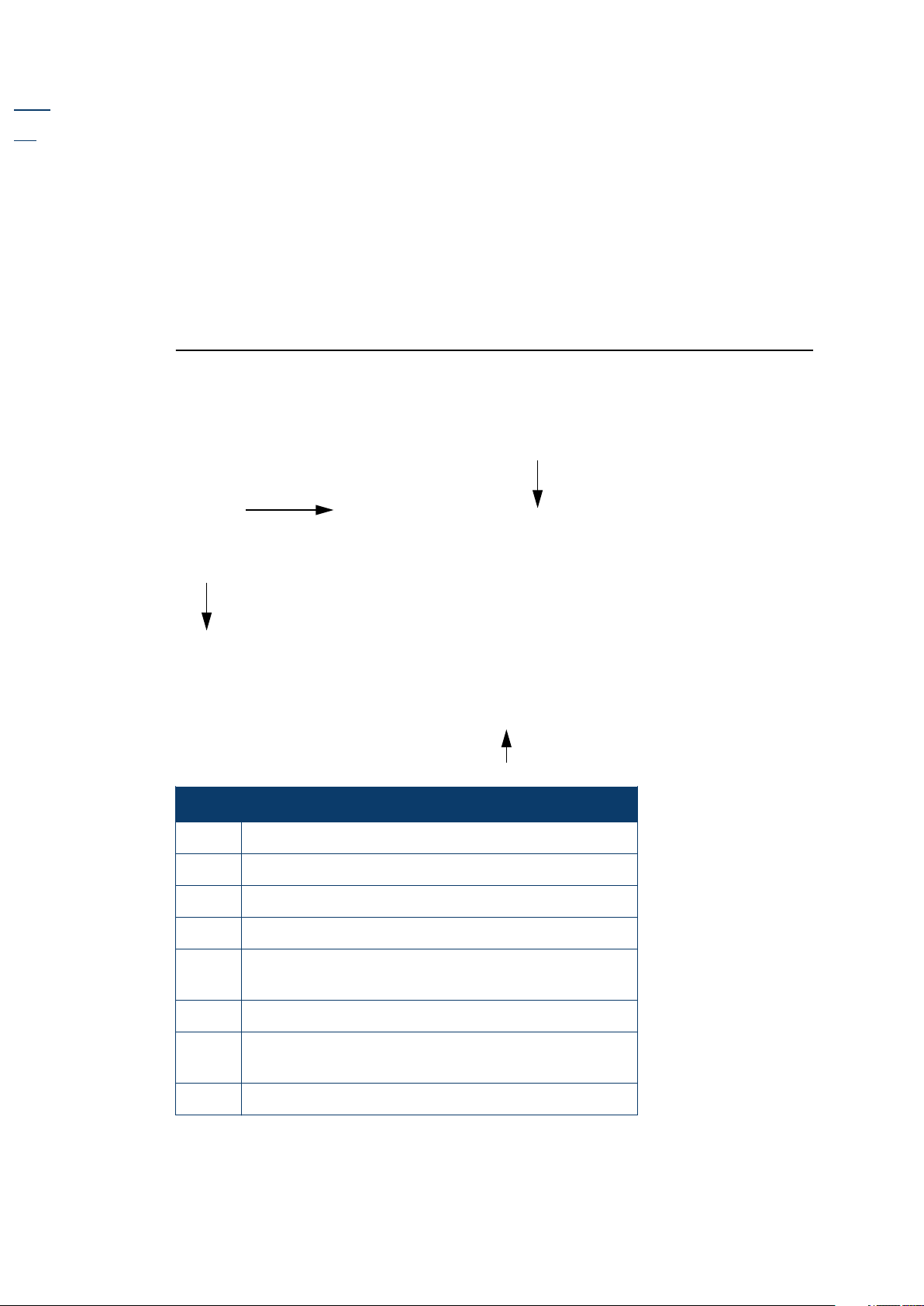

2.1 Sensistor ISH2000

Sensistor ISH2000 is equipped with a number of powerful functions making it very

easy to integrate in a semi or fully automatic test system. The functions range from

output of all necessary status signals and printer/communication port to an

advanced Active Probe Control system (APC). This makes the detector capable of

controlling advanced sample collecting devices down to simple test fixtures.

Fig 2-1. The desktop model consists of seven parts.

1

2

EN

3

Item Description

1

Detector instrument

2

Hand Probe P50 (shown) or Active Probe with

sensor

3

Probe cable C21

4

Power cable (the power cable is country specific

and may differ)

5

User manual (not shown)

6

User manual in electronic form

(on CD or USB memory stick)

7

Product return form (not shown)

OM-Sensistor ISH2000-EN-201304 7

Page 8

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

2.2 Sensistor ISH2000C

The battery operated model, Sensistor ISH2000C, has all the Sensistor ISH2000

features apart from the APC system. This means that only passive probes (for

example Hand Probe P50) can be used. This is due to power management control.

The battery, a Li-ion battery at 14.8 V, can not support the current required to

operate external probes.

On the display a symbol in the upper right corner shows the battery charge status.

Sensistor ISH2000C will operate for 14 hours on a fully charged battery with

screensaver and mute function. And 9 hours without screensaver and mute function.

One hour charging will give about one hour of operating time. This can be done

when necessary, but it is important to regularly fully charge the battery.

Fig 2-2. The battery operated model consists of seven parts.

4

1

2

Item Description

1

Detector Instrument

2

Hand Probe P50 (shown) or P50-Flex

3

Probe cable C21

4

Carrying case

5

Battery charger (the battery charger are country

specific and may differ, not shown).

6

User manual (not shown)

3

7

User manual in electronic form

(on CD or USB memory stick)

8

Product return form (not shown)

8 OM-Sensistor ISH2000-EN-201304

Page 9

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

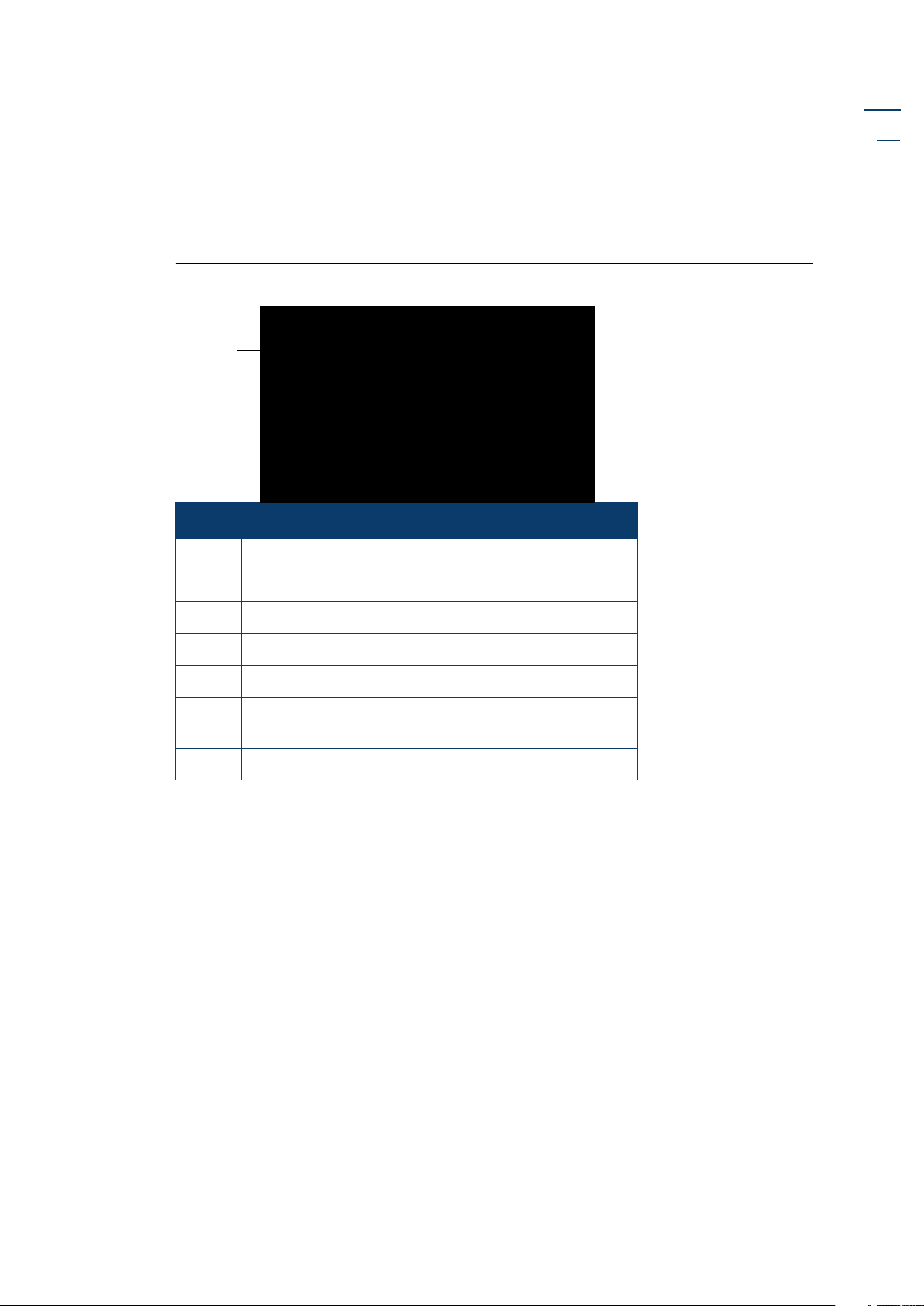

2.3 Sensistor ISH2000P

The panel mount model, Sensistor ISH2000P, has identical features of the Sensistor

ISH2000.

The difference is that the Sensistor ISH2000P can be installed in the operator’s panel

or any other flat surface. The instrument operates on an external +24VCD power

supply, provided by the customer. Mounting brackets and a panel rubber seal are

delivered with the detector. See “Sensistor ISH2000P installation” on page 45.

Fig 2-3. The panel mount model consists of seven parts.

1

Item Description

1

Detector instrument

EN

2

Brackets (not shown)

3

Screws (not shown)

4

O-rings seal (not shown)

5

User manual (not shown)

6

User manual in electronic form

(on CD or USB memory stick)

7

Product return form (not shown)

OM-Sensistor ISH2000-EN-201304 9

Page 10

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

3 Controls and connections

The controls and connections are discussed and shown in this chapter.

Fig 3-1. Sensistor ISH2000 controls and indicators

1

Sensistor ISH2000

Combined Mode

0.0

Volume Sens Cal Menu

2

3

cc/s

Air

(1.00E+01)

6

4

5

Item Description

1 Display

2 Loudspeaker

3 Control push-buttons

4 Earphone socket

5 Probe connector

6 LEDs

3.1 Display

The display shows:

• Indicator bar in Locating Mode and the figures in Measuring Mode.

• Eight main menus. Their positions are indicated on a horizontal scale. Change from

one menu to another using the < and > buttons.

• Main menus have sub-menus, which are also indicated by horizontal scales and can

be selected using the < and > buttons.

• Scales for setting numeric values, languages, etc.

• Messages.

Sensistor ISH2000C:

• A battery status indicator in the upper right corner.

10 OM-Sensistor ISH2000-EN-201304

Page 11

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

3.2 Push-buttons

The functions of the push-buttons are shown at the lower edge of the display. In this

manual the buttons are numbered, from left to right, 1, 2, 3, and 4. The push-buttons

are used to:

• Change from one menu item to another using the < and > buttons.

• Press Enter to move down to the nearest sub-menu.

• Press Save to save the set value.

• Press Undo to restore the previously set value.

• Press Esc to move up to the nearest higher level(s).

• Shortcut to reach functions as Volume Sensitivity (Sens), Calibration (Cal) and

Menu.

3.3 LEDs

The two LEDs indicate the status of the instrument as follows:

• Green flashing slowly, during warming up phase.

• Green fixed light indicates that instrument is ready and hydrogen signal is below

Reject Level limit.

• Periodically flashing green or red calls for calibration.

• Alternating red and green light while the instrument establishes probe

communication.

• Red fixed light together with Reject on display means the instrument has detected a

leak larger than the set Reject Level limit.

• Red flashing rapidly, check message on screen. (See “Trouble-shooting” on

page 49.)

EN

3.4 Ports and connections

The ports and connections are shown in Figure 3-2 on the next page.

NOTICE!

Always connect all four wires to the Power connector to

24VDC in order to operate.

OM-Sensistor ISH2000-EN-201304 11

Page 12

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Sensistor ISH2000

Fig 3-2. Sensistor ISH2000 ports and connections (rear view).

Rear View

Item Description

1 Data output

2 Probe control port

3 Fuse

1

1

2

4

6

2

1

3

4

2

5

3

6

3

4

5

5

6

4 Power switch

5 Power input, 100-240 VAC

6 Screw hole for mounting plate

Sensistor ISH2000C

Fig 3-3. Sensistor ISH2000C ports and connections (rear view).

1

2

3

4

Item Description

1 Power switch

2 Printer port

3 Power input (From Battery charger)

4 Screw hole for mounting plate

12 OM-Sensistor ISH2000-EN-201304

Page 13

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Sensistor ISH2000P

Fig 3-4. Sensistor ISH2000P ports and connections (rear view).

1

Item Description

1 Probe connection

2 Ground screw

3 Power input (24 VDC)

4 Probe control port

EN

2

3

4

5

5 Printer port

OM-Sensistor ISH2000-EN-201304 13

Page 14

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

4 Precautions

Read this user manual carefully before using the instrument. Hydrogen Leak

Detector Sensistor ISH2000 is extremely selective. Only Hydrogen Sulphide

(extremely toxic) gives a comparable response to hydrogen.

4.1 When working with gas

The normal risks associated with working with all compressed gases must be

considered.

WARNING!

Pure hydrogen is a flammable gas. Only use

ready-made Hydrogen Tracer Gas of 5%

Hydrogen in Nitrogen. This is a standard

industrial gas mixture used in various industrial

applications.

Note: Whenever the word Hydrogen is used in this

manual it implies that the hydrogen gas is safely

mixed with Nitrogen in the proportions 5% H2 95% N2.

WARNING!

Since the tracer gas mix contains no oxygen,

releasing large amounts of gas in a confined

space may lead to asphyxiation.

WARNING!

Compressed gases contain a great deal of stored

energy. Always carefully secure gas bottles

before connecting pressure regulator. Never

transport gas bottle with the pressure regulator

fitted.

Before connecting tracer gas: confirm that the connectors and test object is

designed for working at the test pressure.

WARNING!

Pressurising objects at too high pressures can

result in a burst object. This in turn can result in

serious injury or even death.

Never pressurise objects that have not

previously been burst tested or otherwise

approved for the chosen test pressure.

Note: INFICON AB can not take any responsibility for the consequences arising from the

inappropriate use of certain test pressures.

14 OM-Sensistor ISH2000-EN-201304

Page 15

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Pressure shocks might cause strong sounds which can cause impairment of hearing.

Check that all relevant legislation and safety standards are complied with before

putting Sensistor ISH2000 into service.

4.2 Hydrogen Tracer Gas for leak detection

When pure hydrogen gas is released in air its flammability range spans from 4% to

75% of hydrogen in air. Below 4% there is insufficient chemical energy available for

a flame to occur. Above 75% hydrogen there is not enough oxygen left to support a

flame.

When, for example, a mixture of less than 5.5% hydrogen in nitrogen mixes with air

there is not sufficient energy to support a flame, irrespective of the ratio of air-togas.

When a mixture of more than 5.5% hydrogen in nitrogen is released into air there is

a region of ratios of air-to-gas where the mixture is flammable. When, for example,

a mixture of 10% hydrogen in nitrogen mixes with air there is still very little energy

available. Only in exceptional circumstances can a flame be self-supporting.

However, such mixtures cannot detonate.

WARNING!

Hydrogen/nitrogen mixtures containing

approximately more than 15% hydrogen can

detonate when mixed in certain proportions

with air.

EN

NOTICE!

Never make your own mixtures. Only use readymade mixtures or use a certified hydrogen/

nitrogen mixture mixer installed by your gas

supplier.

4.3 Interferences

Most tracer gas methods suffer from some sort of interference. Either the detector is

sensitive to other gases or vapors, or there are other sources of the gas present to

which the detector is sensitive.

Some examples of possible hydrogen sources:

• Engine exhaust

• Battery charging stations

• Cigarette smoke

• Breathing air

• Human flatulence

• Scratching on aluminum surfaces

OM-Sensistor ISH2000-EN-201304 15

Page 16

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

5 Working principle

5.1 Gas Sensor Technology

The Sensistor ISH2000 leak detector is using an extremely sensitive hydrogen gas

sensor based on a metal-oxide-semiconductor field-effect-transistor (MOS-FET).

The gas sensitivity appears when hydrogen absorbs into the sensor through a metal

alloy (metal hydride) layer.

Only hydrogen can diffuse into the metal and this makes the sensors practically

insensitive to other substances that do not contain free hydrogen molecules.

The signals from the sensors are processed by a microprocessor which also controls

the sensor temperature with high accuracy, and other sensor diagnostics in order to

ensure perfect functionality. It also automatically compensates for background gas.

5.2 Condition for leak detection

To use the leak detector the test object must be filled and pressurized by tracer gas

(95% N

welding gas of industry quality, easy to obtain at low cost. The generic name is

Forming Gas. Appropriate gas filling equipment can be obtained from the leak

detector supplier.

/ 5% H2) to get a gas flow through the leak. The tracer gas is a standard

2

Be careful of how tracer gases are handled after use. Released tracer gas

contaminates the surrounding air with hydrogen and can complicate the following

measurements for a time. Ensure that the tracer gas is ventilated away from the

target area, preferably to the outside of the building.

5.3 Leak Detection mode

The detector operates in three modes:

• Locating Mode is mainly used for detecting and locating leaks but not quantifying

them.

• Measuring Mode measures the concentration of hydrogen.

• Combined Mode, (default mode) which is a combination of Locating and Measuring

Mode.

The Locating Mode operates continuously while the Measuring Mode determines

the hydrogen concentration (and calculates a corresponding leak rate) in a step

measurement. Locating Mode gives no numbers. It therefore needs no actual

calibration. The sensitivity of the sound signal and the moving bar on the display is

set manually or automatically, see below.

When using the instrument in Measuring Mode, it must be calibrated as described.

See “Calibrate the leak detector” on page 19 in order to give correct figures.

16 OM-Sensistor ISH2000-EN-201304

Page 17

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

6 Operating the detector

6.1 To Detect Leaks

If all you wish to do is to detect the presence of a leak, that is, find out whether there is

a leak or not, then use the Locating Mode (or use the Locating bar in Combined

Mode). The definition of Leak/No Leak will then simply be ”A leak is a leak when it can

be detected by the detector, set to a specific sensitivity”.

To set up:

The operation in

increase and decrease with the gas concentration. Therefore, there is no actual

calibration to be done, but rather a setting of the sensitivity to a desired level.

A typical set-up procedure for Locating Mode is:

• Set up a Calibration leak which corresponds to the smallest leak you wish to detect.

• Put the probe close to the Calibration leak and note approximately what reaction

you get (no reaction, small, medium, high, full scale) within the first few seconds.

• Set the sensitivity. This can be done permanently under the menu Locating Mode

Settings or temporarily as a Direct Sensitivity Adjustment on the display (unless

you have set this function to OFF under the Locating Mode Settings menu).

There is also an Auto ranging function which can be selected under the Locating

Mode Settings menu.

Locating Mode is not quantitative. The audio and visual signal will

EN

Note: If the

Locating Mode is used and the alarm function is required to be

activated at a particular calibrated level, then the unit must be calibrated in

accordance with the instructions, see “Calibrate the leak detector” on

page 19. The reason for this is that the alarm is based on the Measuring

Mode when the

6.2 To Locate Leaks

Note: The Locating Mode (or use the Locating bar in Combined Mode) is used to

locate leaks. This mode is semi-quantitative, that is, it gives an audio and visual

signal which increases as a leak is approached (a higher gas concentration)

and decreases as you move the probe away from the leak. It does not display

figures. In this mode of operation leaks can easily be detected using a

sensitivity which can be preset. See “Sensitivity” on page 28 and “Direct

Sensitivity Adjustment” on page 28.

Leaks can be located very accurately, even when there are other leaks nearby. If, for

example, you are trying to locate a leak on a product and the product has a major

leak, then you will get an audio signal as soon as the probe is placed close to the

product. When the probe is moved around and over the product, the signal will

increase as the probe approaches the leak. If the signal goes out of scale, simply

reduce the sensitivity setting to bring the signal within the scale. Working with the

sensitivity setting this way you will be able to locate multiple leaks that are in close

proximity to each other.

Locating Mode is displayed.

Note: Working inside a confined space such as, for example, a cabinet or a narrow

passage on a combustion engine there is a risk that the background

concentration accumulates to levels close to the upper detection limit of the

detector. In such case it will not be possible to locate leaks as easily as in open

spaces.

OM-Sensistor ISH2000-EN-201304 17

Page 18

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Hint: It is good practice to detect a leak, locate it, and immediately remove the probe

to avoid saturation. The probe is not damaged by the exposure but it will recover more

slowly. After excessive exposure it will be less sensitive for a short period of time.

6.3 To Quantify Leaks

The Measuring Mode (or use the figures in Combined Mode) is used for measuring

the size of a leak (or the concentration of a gas sample). To be able to do this

measurement and obtain correct values, the instrument must first be calibrated using

the calibration function.

In the Measuring Mode the detector determines the gas concentration from the

change, as the probe goes from being exposed to background to being exposed to a

certain gas concentration. The detector does not continuously monitor the gas

concentration but takes just one reading instead. Another suitable alternative name

for this mode could be Sampling Mode. It is important to keep this in mind when using

the detector in this mode.

In Measuring Mode the probe should be moved directly from a background situation

to the test point. The size of the leak in cc/s, or any other selected units, is shown on

the display. The probe can and should be removed from the measuring point as the

measured value steady and remains on the display. The period during which the

measured value is displayed can be adjusted in the Measuring Mode Settings menu.

The leak detector operates in the range 0.5 - 2000 ppm H

giving linearity between 0.5

2

and 500 ppm. To obtain greatest accuracy over this range, follow the calibration

recommendation. See “Calibrate the leak detector” on page 19.

CAUTION!

• Do not open detector! Service of this equipment may only be carried out by service organizations authorized therefore by INFICON, Sweden.

• If the detector gets outer damage it must be controlled and repaired by service

organization authorized by INFICON.

• Do not expose the probe to a hydrogen concentration higher than 0.1% when

the instrument is not put into operation, this might damage or destroy the probe

sensor.

• When the instrument is put into operation the sensor withstands temporary

exposure to hydrogen concentration up to 100%. Avoid long exposures to high

concentrations.

18 OM-Sensistor ISH2000-EN-201304

Page 19

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

7 Calibrate the leak detector

7.1 Introduction

The leak detector is the instrument and the probe together.

This section of the operating manual consists of step by step examples on how to

calibrate the detector in the most common cases. For more about the calibration

routine, see the reference section.

The instrument must be calibrated by using the integrated calibration function to

make sure it displays the correct values in Measuring Mode. After calibration, the

instrument will show the correct measured values on the display in

and in Combined Mode. The calibration parameters will be stored in the probe.

7.2 Calibration Leak or Calibration Gas

There is a possibility to calibrate the detector by using Calibration Gas or a

Calibration Leak.

A Calibration Gas contains a well-defined concentration of Hydrogen gas mixed

with air. A Certificate will normally follow the gas bottles. Calibration Gas can be

ordered from local gas suppliers.

EN

Measuring Mode

A Calibration Leak is a well–defined gas leak. The Calibration Leak should be fed by

the same gas used in the detection test and with a gas pressure defined in the

Calibration Leak certificate. Calibration Leak can be ordered from the detector

provider.

Choose a calibration leak or calibration gas size, as follows:

• Same or higher than the Reject Level (but maximum 10 times higher)

• In one of the following ranges:

5 to 400 ppm H

1x10-5 to 4x10-3 cc/s (mbarl/s) defined for air

3 to 120 g/yr defined for R134a

Please contact the provider of the detector for help to select optimal calibration

reference for your application.

7.3 Unit Conversion

When using flow units (other than “ppm” and “custom”), the instrument

automatically converts between the calibration unit and the measurement unit. The

conversion is saved in the Correlation value and is updated when Calibration Unit or

Measuring Unit is changed. Leak Gas and Displayed Gas will not change Correlation

Value, but will have effect on the measured figures.

If “ppm” or custom unit is chosen (Measuring or Calibration Unit), the Correlation

Value must be set by operator. To set Correlation Value go to menu General

Settings.

2

Correlation Value can be modified even otherwise.

OM-Sensistor ISH2000-EN-201304 19

Page 20

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

7.4 Calibration procedure

Before calibration, the Calibration Value, Calibration Unit and Leak Gas in the Calibration

must be set. See “Calibration value with Calibration leak” and “Calibration

Menu

value with Calibration gas” below.

Let the instrument be in operation for at least 30 minutes to achieve the best

conditions for a calibration.

When calibrating, do the following steps:

1. Go to Menu then Calibration/Calibrate/Enter or just push the button “Cal” on the

main screen.

2. Expose the probe to background.

3. Push the

4. Expose the probe for the Calibration gas/leak

The probe does not have to be exposed to the calibration gas during the entire

Calibration Time (the time set in the Calibration menu while the bar is moving). The

instrument only measures the change as the probe goes from the background air to

calibration gas.

While the calibration time bar is moving, the probe should be exposed to the

Calibration gas or Calibration leak. Wait until the instrument shows “Gas detected”

and gives a sound signal. Repeat until you can save the calibration by pressing

probe button. If the calibration is not saved, the instrument will revert to the

previous value after one minute.

Start button or push the probe button.

Save or

Note: You will need to repeat the gas exposure procedures 2-3 times to get

Calibration OK after changing setup or probe. The text “Calibration failed! Check

leak/gas and sensor status”

(or a custom text) will appear after 5 attempts.

• Allow at least 30 seconds between each exposure for best accuracy!

• If the message “

No gas or Unstable Signal” is displayed repeatedly - go back to

Locating Mode and check functionality.

• If “

Calibration in progress. Please repeat again” is displayed it means that the

measured value deviated more than 10% from the previous calibration. Repeat

the calibration procedure.

7.5 Calibration value with Calibration leak

When measuring leak flow you will, in normal cases, calibrate the detector with a

Calibration leak.

Set the

set the

Calibration leak. Finally set the Leak Gas that the leak is defined for. These values

can be found on the calibration certificate issued for the leak. Finally set the Leak

Gas that the leak is defined for. These values can be found on the calibration

certificate issued for the leak.

Calibration Value equal to the calibrated flow of your Calibration leak. Also

Calibration Unit to the same unit as that used to express the leak rate of the

Example: Calibration leak rate is defined to: 4.2E-5 mbarl/s for Helium.

1- Set

2- Set

20 OM-Sensistor ISH2000-EN-201304

Calibration Value = 4.2E-05.

Calibration Unit = “mbarl/s

Page 21

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

3- Set Leak Gas = Helium

Note: Feed the Calibration leak with hydrogen tracer gas at the pressure stated on

the Calibration certificate. If another pressure is used you must correlate the

resulting flow and use this value as

Calibration Value.

Note: The resulted concentration from the Calibration leak should be within the

concentration range of 5 ppm - 400 ppm H

7.6 Calibration value with Calibration gas

When measuring hydrogen concentration (instead of leak flow) in most cases you

will calibrate the detector to a Calibration gas with a known concentration.

Set the

gas. This can be found on the certificate of analysis issued for the gas. Also set the

Calibration Unit to ppm.

Example: Calibration gas contains 10 ppm Hydrogen in synthetic air.

1- Set the

2- Set the

Calibration Value equal to the Hydrogen concentration in your Calibration

Calibration Value = 10

Calibration Unit = “PPM”

EN

2.

OM-Sensistor ISH2000-EN-201304 21

Page 22

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

8 Reference section

This section of the user manual consists of an in-depth explanation and additional

information, which completes the operating manual with all relevant information.

8.1 Menu system

The menu system is designed as a tree structure similar to that used in mobile

telephones. The display shows all the levels when browsing down through the

menus so that you can always see exactly where you are.

See “Menu Overview” on page 54.

Fig 8-1. Sensistor ISH2000 start screen.

Combined Mode

0.0

(1.00E+01)

cc/s

Air

CalSensVolume Menu

1 2 3 4

To enter the menus, press

Fig 8-2. Sensistor ISH2000 main menu screen

Press

< and > (button 2 and button 3) to choose between main menus.

If no setting is made in a menu or its sub menus within 60 seconds, the instrument

will revert to the

Locating Mode/Measuring Mode.

Menu (button 4).

Change Test Mode

MenuEsc < >

For more information about the menu, see “Menu Overview” on page 54.

22 OM-Sensistor ISH2000-EN-201304

Page 23

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

8.2 Button functions

The buttons may change functions in different menus. Always read the text, just

above the buttons in the display, for the button functions.

All changes in values are valid only when saved using the

(button 4). All changes is saved into the instrument. Only Trigg Level is stored into

the probe.

Use the

Undo or Esc button (button 1) to delete a change in value and revert to the

previous setting.

Use the

position

To change quickly from

Esc button (button 1) to browse backwards through the menus to the start

Locating Mode/Measuring Mode.

Locating Mode to Measuring Mode or vice versa, press button 4

three times in succession.

8.3 Stored values and setups

All values and instrument setups is saved into the instruments memory. Only the Trig

Level is stored into the hand probes memory. That mean that you easily can change

the probe to another one and still keep your setup.

8.4 Engineering format

EN

Save or Enter button

Some of the parameters of the detector are written in engineering format. This

format can represent a very wide range of numbers from very small to very large

numbers.

The following examples describes the format used in the detector:

1.00E+01 = 1.00 x 10

1.00E+00 = 1.00 x 10

1.25E-02 = 1.25 x 10-2 = 0.0125

8.5 Change Test Mode

Choose the test method you will use in the menu Change Test Mode. There are

three different methods to choose:

• Measuring Mode

• Locating Mode

• Combined Mode*

* Not in ILS500 Mode

See Reference section for a description of the functions.

8.6 Calibration

1

= 10

0

= 1

Calibrate

The instrument must be calibrated by using the integral calibration function to

ensure it displays the correct values in

calibration the instrument will show the correct measured values on the display.

If the probe is replaced with another probe a new calibration must be performed.

OM-Sensistor ISH2000-EN-201304 23

Measuring Mode/Combined Mode. After

Page 24

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Sensitivity too low for reject level

The Detector will warn if sensitivity of sensor is too low to safely detect a leak equal

to the set Reject Level limit. The warning can be ignored and calibration updated

and the CAL_CONF output will be set.

High signal! Check calibration leak/gas!

The Detector will warn if the calibration signal is unreasonably high. This can occur,

for example, if 5% tracer gas mix has been used instead of proper Calibration gas or

if the Calibration leak has an extra non-intentional leak. The warning can be

ignored and the calibration updated and the CAL_CONF output will be set.

Sensor condition indicator

The indicator bar extends in length when the sensor is detecting Calibration gas.

This indicator can be used for an early warning as to when a sensor replacement will

be needed.

Fig 8-3. Sensor condition indicator.

Calibration

Expose to calibration gas

Calibration Value = 1.00+01 PPM

Gas detected

Esc

The length of the bar shows the condition of the sensor. The bar will become shorter

if the sensor has lost some in sensitivity. The scaling of the indicator is not precise

enough to say at exactly what length the sensor must be replaced. You will learn

when this happens for your particular application. The instrument will also tell you

in clear text when sensitivity is too low. See further in the next section below.

Calibration messages

Table 8-1. Different messages that can be displayed during calibration.

Message Explanation Action

Expose to background... Prepare the probe for

calibration.

Gas detected Gas signal is detected.

The probe has had

enough gas exposure.

Calibration in progress

Please Repeat again

Calibration OK Calibration was within

Calibration was not

within 10% of last.

acceptable limit.

Hold the probe in

hydrogen free

background.

Remove the probe from

the calibration gas or

leak.

Wait 30 s and calibrate

again.

Press Save (button 4) to

store calibration in

memory.

24 OM-Sensistor ISH2000-EN-201304

Page 25

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Message Explanation Action

No gas or unstable signal. No gas signal or no stable

signal detected during

calibration.

Signal when Calibration

gas is shut off. Happens

for Calibration gas only.

Background is higher

than Calibration gas

concentration.

Sensitivity too low for

Reject level

High signal! Check

Calibration leak/gas!

Sensitivity of sensor is too

low to guarantee correct

response to a gas flow or

concentration equal to

the Reject level. The most

likely reason is that

sensor is too old.

Calibration leak/gas

signal is abnormally high.

Check if Calibration leak/

gas valve is shut.

Check that probe tip is

not clogged.

Check the calibrate gas

valve.

Improve ventilation

Check Calibration leak/

gas. Gas valve may be

shut.

Check that probe tip is

not clogged.

Check setting of Reject

Level.

Replace sensor if problem

remains.

Check that Calibration

gas mix is not replaced

with tracer gas mix.

Check condition of

Calibration leak.

Check that Calibration

leak connections has no

leaks.

EN

Note: If calibration fails you can still use the instrument. Last valid calibration

parameters will be used. You should, however, check that the instrument

reacts to the Calibration leak/gas.

Calibration Value

Your Calibration should have a concentration or flow equal to or slightly above

what you want to measure. See the examples below for specific recommendations.

Example for Calibration gas:

• Reject Level is set at 8 ppm

• For good accuracy, use a Calibration gas between 5-80 ppm hydrogen.

• 8 ppm hydrogen in synthetic air will give best results.

Example for Calibration leak

• Reject Level is set at 2.0E-4 atm. cc/s

• For best accuracy use Calibration leak within 2.0E-4 - 2.0E-3 atm cc/s.

• A Calibration leak calibrated to 2.0E-4 atm. cc/s will give best accuracy.

Calibration Unit

The Calibration Unit is set in the Calibration menu. Select ppm, cc/s, cc/min, SCCM, g/yr,

oz/yr, mbarl/s, mm

enter any unit as long as it contains a maximum of 12 characters.

3

/s, mm3/min, Pa m3/s or Custom. When you select Custom you can

OM-Sensistor ISH2000-EN-201304 25

Page 26

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Calibration can be performed with:

• a known hydrogen concentration

• a known flow leak

The following characters can be used: Upper and lower case Roman letters, the

numbers ü,

Note: The space (““) is not supported. The leak rate unit string will be cut short at

the first space found. See “Engineering format” on page 23.

Leak Gas

Leak Gas is the gas the Calibration Leak is defined to.

Calibration Time

The Calibration Time decides how long time the detector looks for a Calibration

signal before giving up. If the calibration is set to, for example, 6 seconds the

detector will record the maximum signal during 6 seconds after that the operator

(or external hardware) orders a calibration.

It is very important that all delays in gas exposure as well as reaction time of sensor

are taken into consideration when setting the calibration time. Calibration will not

be correct if the maximum signal comes after that the calibration time has

terminated.

ü, Å, Ä,Ö, å,ä,ö,%,/,(,),and - (dash).

Interval

This is also the timeout of the Calibration line in an APC program.

Calibration is a natural part of leak measurement and an important factor in quality

assurance. It is impossible to specify an exact requirement for the interval between

the calibrations because the applications for which the instrument is used can vary

considerably.

There will be some oxidation of the probe sensor, which reduces the sensitivity, if

the probe sensor:

• is not subjected to gas for a lengthy period or

• is exposed to a very small gas concentration (less than 10 ppm) with long

intervals between exposure.

If the instrument is subjected to a very large gas concentration over a long period, a

certain amount of insensitivity can occur directly afterwards. This saturation can

make it difficult to detect very small leaks. Therefore, make it a habit of removing

the probe from the measuring point as soon as the measured value is displayed. This

gives the detector an opportunity to recover.

In the menu Calibration/Interval there is a setting where it is possible to set a

reminder to calibrate the instrument. The interval can be set between 1 min to over

100 days. When it is time to calibrate, the instrument will signal with the text

Calibrate! in the display together with sound. If the interval time is set to 0, the

reminder function is switched off.

Function Calibration Interval can be used to remind the operator to perform a

calibration.

26 OM-Sensistor ISH2000-EN-201304

Page 27

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Password Protected Calibration

If desired, the calibration can be set under the general password to prevent the

operator from calibrating by mistake. In this case you will have to enter the

password to start the calibration routine. Setting password protection on calibration

is done in the

General Settings menu. Note that you must also set a password. The

instrument is delivered with no password set.

8.7 Locating Mode Settings

In Locating Mode, the signal is displayed in the form of a bar. The length of the bar

varies with the gas concentration.

To Detect Leaks

If all you wish to do is to detect the presence of a leak, that is, to find out whether

there is a leak or not, then use the Locating Mode. The definition of Leak/No Leak

will be” A leak is a leak when it can be detected by the detector, set to a specific

sensitivity”.

To set up:

The operation in Locating Mode is not quantitative. No figures are given but the

signal is still increasing and decreasing with gas concentration. Therefore, there is

no actual calibration to be done, but rather a setting of the sensitivity to a desired

level.

EN

A typical set-up procedure for the Locating Mode is:

• Set up a Calibration leak which corresponds to the smallest leak you wish to

detect.

• Put the probe close to the Calibration leak and note approximately what

reaction you get (no reaction, small, medium, high, full scale) within the first

few seconds.

• Set the sensitivity. This can be done permanently under the menu

or temporarily as a

this function to OFF under menu

ranging function which can be selected under the

If the sensitivity is set very high, you may find the baseline annoyingly unsteady.

Note: If the Locating Mode is used and the alarm function is required to be activated

at a particular calibrated level, then the unit must be calibrated. The reason

for this is that the alarm is immediately based on the Measuring Mode when

the Locating Mode is displayed, due to inaccuracies in the Locating Mode

signal.

To Locate Leaks

Locating mode is semi-quantitative, that is, it gives an audio and visual signal which

increases as a leak is approached (a higher gas concentration) and decreases as you

move the probe away from the leak. It does not display figures.

Locating Mode

Direct Sensitivity Setting on the display (unless you have set

Sensitivity Settings. There is also an Auto

Locating Mode Settings menu.)

In this mode of operation leaks can easily be detected using a sensitivity which can

be preset. Leaks can be located very accurately, even when there are other leaks

nearby.

If, for example, you are trying to locate a leak on a refrigerator condenser tubing

and the tubing has a major leak, then you will get an audio signal as soon as the

probe is placed close to the condenser tubing. When the probe is moved around

OM-Sensistor ISH2000-EN-201304 27

Page 28

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

over the condenser, the signal will increase as the probe approaches the leak. If the

signal goes off the scale, simply reduce the sensitivity setting to bring the signal

within the scale. By working with the sensitivity setting in this way, you will be able

to locate multiple leaks that are in close proximity to each other.

Do not expose the probe to more gas than is necessary, because it will slowly

saturate with time. It is good practice to detect a leak, locate it, and immediately

remove the probe to avoid saturation. The probe is not damaged by the exposure

but it will recover more slowly. After excessive exposure it will be less sensitive for a

short period of time.

Background Compensation

There is always some hydrogen gas in the background. In fresh air this is as low as

0.5 ppm (parts per million).

Sensistor ISH2000 actively adjusts itself to the background. This is done

automatically at start-up and thereafter, it slowly adapts itself to slow variations in

the background concentration. By adjusting slowly (minutes) it avoids mistaking an

actual leak for an increased background and vice versa. Therefore, a sudden rise in

background concentration will be detected. However, if the concentration remains

constant it will be gradually canceled out over a period of several minutes.

For example, if the background concentration for some reason should suddenly rise

to 10 ppm H

slowly decline to zero. If you thereafter expose the probe to a leak which gives rise

to another 10 ppm H

there were no background concentration.

, then the detector will give a corresponding signal which will very

2

, then the detector will give essentially the same signal as if

2

Sensitivity

Sensitivity of audio signal and signal bar in Locating Mode.

Note: This does not affect the Measuring Mode.

Auto Range

Set this parameter to ON for auto ranging of sensitivity in Locating Mode. Sensitivity

will decrease two steps if the signal reaches full scale. Sensitivity is restored to

selected Sensitivity when signal returns to zero.

Direct Sensitivity Adjustment

Setting this parameter to OFF will remove the sensitivity adjustment from the

Locating Mode display. Sensitivity can still be adjusted in the Sensitivity Settings menu

after entering password (if set).

Note: The sensitivity setting only affects the Locating Mode and Combined Mode.

Audio Threshold

Makes it possible to mute the sound to a set level in Locating Mode. The level is in %

of full Locating bar.

Reject Indication

Makes it possible to show the indication Reject in Locating Mode.

28 OM-Sensistor ISH2000-EN-201304

Page 29

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Audio Ready Pulse

This sets the standby sound to a silent or pulsating tone.

8.8 Measuring Mode Settings

In Measuring Mode the measured value is displayed in figures. The default unit is in

cc/s but it is possible to choose other units, See “Default parameters” on page 46.

To Measure Leaks

The Measuring Mode is used for measuring the size of a leak (or the concentration

of a gas sample). To be able to do this measurement and obtain correct values, the

instrument must first be calibrated using the calibration function.

In the Measuring Mode the detector determines the gas concentration from the

change, as the probe goes from being exposed to background to being exposed to a

certain gas concentration. The detector does not continuously monitor the gas

concentration but takes just one reading instead. Another suitable alternative name

for this mode could be Sampling Mode. It is important to keep this in mind when

using the detector in this mode.

In Measuring mode the probe should be moved directly from a background

situation to the test point. The size of the leak in ppm, is shown on the display. The

probe can and should be removed from the measuring point as the measured value

remains on the display.

EN

The period during which the measured value is displayed can be adjusted in the

Measuring Mode Settings menu.

Reject Level

Threshold level for Reject decisions. When this level has passed Reject it will be

indicated by audio and LED signals.

Note: The frequency of the acoustic signal in Measuring Mode is controlled by Reject

Level

frequency despite the actual signal strength.

Measuring Unit

The Custom Measuring Unit is the unit to be displayed during measurement.

The measured value will be automatically calculated for other flow units. For

example, if you calibrate with cc/s and want the instrument to show cc/min, the

displayed value is adjusted by a internal factor of 60.

If PPM or Custom units are selected there will not be an automatic conversion factor

calculation. If a unit conversion is needed, the conversion factor must be calculated

manually and inserted into the Correlation Value (under General Settings).

The

Correlation Value is always set to 1 when the PPM or Custom units are selected,

but is adjustable afterwards.

. A signal equal to the Reject Level will always give the same audio

The

Measuring Unit is a text string with a maximum of 12 characters.

The following letters can be used; Upper and lower case English letters, the numbers

0 to 9, Å, Ä, Ö, å, ä, ö, %, /, and -. Space (““) is not supported. The string will be

shortened after the first space found.

OM-Sensistor ISH2000-EN-201304 29

Page 30

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Displayed Gas

Displayed Gas is the unit shown on the display. If another gas is chosen, the

measured value is automatically recalculated.

Note: When selecting different types of gas it is assumed that the same type of

tracer are used in both calibration leak and test objects (typically 95% N2 /5%

H2). The conversion of different types of gas assumes laminar flow in the leak,

which is normal. The instrument displays the total flow of the tracer gas.

Multipoint Measuring

Summing up of the Measuring result. A fixed or moving number of measurements

with a maximum 25 measurement points can be chosen.The instrument must be in

Measuring Mode or Combined Mode for this function to be active. Standard probe

button functions is not available when using Multipoint Measuring, only in Locating

Mode.

To use Multipoint Measuring

If a fixed number of measurement points is used then measure according to the

following steps:

1. Push the probe button to begin the first measurement.

2. Place the probe on the measurement point during the time the bar moves. The

instrument registers the results.

3. You might need to wait until the next measurement. The instrument signals-

4. Repeat the procedure for the next measuring point.

Wait.

When all measurements are made the sum of all leaks is shown. If the sum of all

leaks is greater or the same as the

leaks is under the

greater than

Reject Level then ACCEPT is shown. And if the sum of all leaks is

Reject Level before all measurements are made then REJECT is shown.

Reject Level then REJECT is shown. If the sum of all

Use < > to view individual measurements.

To begin a new measurement action or to stop a current measurement push the

probe button and hold the button for a moment.

It is possible to measure or search in Combined Mode for a leak without registering

the measurement. The measurement value registers only when the staple moves

(Multipoint Measuring Time).

If a dynamic number of measurement points is selected then do the measurement in

the following steps:

1. Push the probe button to begin the first measurement.

2. Place the probe near the measurement point during the time the staples move

(Multipoint Measuring Time).

3. You might need to wait until the next measurement. The instrument signals-

Wait.

4. Repeat the procedure for the next measuring point.

5. To sum up all the measurements, push and hold the probe button a short time.

Multipoint Measuring Time

Set the time for each measurement.

30 OM-Sensistor ISH2000-EN-201304

Page 31

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Min Presentation Time

Signal values in Measuring Mode will never be presented shorter than this time.

Values are, however, always presented until the signal has recovered. The default

value is 1 second, but values from 0 - 120 seconds can be used.

Display Threshold

Hides all measurements under a set % of Reject Level.

Audio Threshold

Instrument is silent under a set % of Reject Level.

Reject Indications

There are three choices of Reject Level indications except the LEDs indication:

• Flashing screen

• Chopped audio signal

• Combination of indication 1 and 2.

Show Reject Level

Shows the Reject Level value on the display.

EN

Audio Ready Pulse

This sets the standby sound to a silent or pulsating tone.

8.9 APC Settings*

APC is an abbreviation for Active Probe Control. APC is used to control an active

probe via the Probe Control Port. There are several active probes available. Choose

correct probe under the menu Probe Type. Customized APC drivers can be

downloaded from a PC.

There is a possibility to adapt how to measure by adjusting the timers and

.

Level

* Not in Battery Mode

Probe Type

Select the connected probe. When a custom driver is downloaded, it will replace

“No driver installed”.

APC Time A-D

Adjustable timer used by the APC system. APC timer can be used for general

purposes in a custom APC program.

Purge

Purge Level

Standard probes that support active sampling use the Purge Level for fast

interruption of sampling.

Setting

cycle times for those probes.

OM-Sensistor ISH2000-EN-201304 31

Purge Level equal to, or just above, Reject Level will give the fastest possible

Page 32

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Quick purging also enhances signal repeatability.

Note: Purge level interrupts active sampling of APC probes. This means that higher

signals will be underestimated as the sensor is purged before full signal has

developed.

Reset Signal

Reset the sensor signal in Measuring mode and Locating mode.

8.10 Display Settings

This section describes the different display settings of the Sensistor ISH2000.

Contrast

Contrast level of display. Higher value gives higher contrast. The contrast may need

adjustment if ambient temperature changes.

Brightness

Brightness of the display lamp.

Invert Colors

Change the black to white and white to black. Useful in a dark environment to keep

a high readability.

Screen Save Timeout

Display lamp will turn off if instrument is left idle for the number of minutes set by

this parameter. The screen save timeout can be set between 1 and 60 minutes, the

function is deactivated if set to OFF. The display lamp will return to the set

brightness if any of the display or probe buttons are pressed, if a gas signal is

detected or an instrument error is detected.

8.11 General Settings

This part describes the general settings of the Sensistor ISH2000.

Correlation Value

Correlation Value is used when it is necessary to correct the relation between the

detector signal and the displayed number. This might be necessary if the hydrogen

concentration of the Tracer Gas, inserted into the test object is changed, e.g. when

the Tracer Gas is mixed with existing air in the test object

Language

The Sensistor ISH2000 user interface contains the following languages:

• English

• French

• German

• Italian

• Spanish

• Swedish

32 OM-Sensistor ISH2000-EN-201304

Page 33

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Measure/Print Button

Setting this parameter to ON displays Measure or Print above the button 1. Measure

will be displayed for an APC-Probe or

initiate a sample cycle. Pressing

measurement to the printer port.

Probe Button

This is for setting the different functions with the probe button. These functions are

as follows:

• Toggle Mode-makes it possible to switch between Measuring mode and

Locating mode.

• Zero Locating signal in Locating mode.

• Measure/Print- makes it possible to initiate sample cycles or send the values

from the hand probe measurement to the printer port.

• Probe Lamp- makes it possible to turn on and off the Probe Lamp.

Probe Lamp

Makes it possible to have the Probe Lamp ON even if the other Probe Button

function is chosen.

EN

Print for a Hand Probe. Pressing Measure will

Print will send the values from the hand probe

Change Password

The user password is a text string (max 12 alphanumerical characters) used to lock

critical parameters. Setting password to an empty string (no characters) means that

no password is needed to modify the critical parameters. The default is no password

(“”).

Contact INFICON AB if you have lost your user password. If the

Calibration parameter is set to ON you will be prompted for a password when starting

a calibration.

Note: Setting Password Protected Calibration to ON has no effect if no password is set.

Note: APC controlled calibration can be started from the bus in both cases.

Password Protection Level

Password Protection Level sets the protection level.

Standard is used when the main parameters shall be protected. High is used to

protect all settings, such as sound and display properties.

Description of the different Password Protection Level

Password

protected

settings/

functions

Non

(No password has

been set)

Standard

Standard

+

Password

Protected

Calibration

Password Protected

High

High

+

Password

Protected

Calibration

Change Test Mode Yes Yes

Calibration

(function)

OM-Sensistor ISH2000-EN-201304 33

Yes Yes

Page 34

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Password

protected

settings/

functions

Calibration

(settings)

Locating Mode

Settings

Measuring Mode

Settings

Display Settings Yes Yes

General Settings Yes Yes Yes Yes

Service Settings* Yes Yes Yes Yes Yes

Non

(No password has

been set)

Standard

Yes Yes Yes Yes

Yes Yes Yes Yes

Standard

+

Password

Protected

Calibration

High

Yes Yes

* For password to access Service Setting, please contact INFICON.

Audio Base Frequency

This sets the lowest audio base frequency tone in Measuring and Locating Mode.

High

+

Password

Protected

Calibration

Set Clock

Real time set as hh:mm:ss. Hours and minutes can be adjusted. Seconds will

automatically be set to 00 when hours and minutes have been set. Clock runs even

when detector is disconnected from the power supply.

Set Date

Real time clock date set as YY-MM-DD. Clock runs even when detector is

disconnected from the power supply.

Data Output*

The Sensistor ISH2000 is equipped with a serial (RS232) printer port for data output.

See “Printer port” on page 39.

* Not in ILS500 Mode

Info

Contains information about software versions, Serial number, and Internet contact

information.

8.12 Service Settings

Service Settings contains important settings that the customer should not change

without supervisor guidance. To enter Service Settings menu a password is required.

Contact your local supplier for help.

34 OM-Sensistor ISH2000-EN-201304

Page 35

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

Show Password

Shows the chosen password in case the customer has forgotten the password.

Contact INFICON AB to have the code sent to you. See the web address under the

section-Info.

Instrument System Reset

Resets all parameters to default settings. Contact INFICON AB to have the code sent

to you. See the web address under the section-Info.

Detector Signal Level

The Detector Signal Level is the level which the sensor is considered to have recovered

from the last gas signal. It decides when the DET_SIGNAL output will come on. this

signal can be used to block the start of a calibration or new test cycle in semi and

fully automatic testers.

IF DET_SIGNAL is high then this means that the sensor has detected hydrogen and

has not yet recovered.

Detector Signal Level can be adjusted in the Service Settings menu. You can increase

Detector Signal Level if you have many small disturbing signals. A high setting of

Detector Signal Level gives better tolerance to “noise” gas signals at the expense of

accuracy. A low setting gives best accuracy but lower tolerance for “noise” gas

signals. The

Detector Signal Level is set as 1 to 100% of the Reject Level.

EN

Note: Increasing the Detector Signal Level may give poorer accuracy.

Trigg Level

Upper Limit setting for Peak hold in Measuring Mode.

Min Calibration Time

Lower limit setting for the timer which is used during calibration. Contact INFICON

AB to have the code sent to you. See the web address under section-Info.

Calibration Tolerance

The maximum difference between the different calibration measurements to

approve a calibration.

Battery Mode

Selection of battery power. Only used to adapt software for the battery model.

ILS500 Mode

This mode is used to adapt the ISH2000 for use into Leak Detector System ILS500.

Combine Mode and Printer Port is not available when ILS500 Mode is active. ISH2000

always start in Measuring Mode at startup.

Number of Significant Digits

Setting of significant numbers in Measuring and Combined Mode. It is used when a

more exact measurement is needed. A good control of the environment and

OM-Sensistor ISH2000-EN-201304 35

Page 36

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

calibration is required to be useful. Contact INFICON AB to have the code sent to

you. See the web address under section-Info.

Debug Mode

This mode is used during service and software development.

Service Mode

This mode contains useful information to analyze the gas sensor behavior and the

APC I/O‘s and timers.

8.13 Combined Mode

In Combined Mode the bar and the sound in Locating Mode is combined with the

figures in

The loud speaker sound follows the Locating Mode signal.

Note: After a system reset the default mode is Combined Mode.

When you have located the leak then you can measure its size in the following way:

1. Remove the probe from the leak.

2. Wait until 0.0 appears on the display

3. Then put the tip of the probe on the leak.

Measuring Mode.

8.14 Probe

The Hand Probe P50 is a non-sniffing probe. Gas Measuring takes place in a sensor

that is in the tip of the probe. The probe is equipped with a function button,

indicator lamps, and lighting. The probe can be ordered with a flexible neck.

During operation the heat of the probe tip is 50ºC

Note: There are a variety of different probes that can be connected to the Sensistor

ISH2000. When using an active probe please refer to the respective probe

manual.

Changing the Probe

After attaching a probe the Sensistor ISH2000 needs to stabilize, and the green LED

should blink. If it does not, then there is a fault in the cable or the hydrogen sensor

inside the probe is faulty.

When the stabilization period is over the green LED should stay on. Before using the

Sensistor ISH2000 the instrument needs to be calibrated. Repeat calibration after

one hour to achieve greatest accuracy.

Changing the Probe Tip

The probe tip (sensor for P50) is replaceable and is locked with a union nut. The

union nut seals against contact with moisture. If you are not sure about changing

the probe tip then we recommend that you send it to an authorized service center.

To change the probe tip do the following steps:

1. Turn off the instrument.

2. Loosen the safety nut with a 10 mm wrench.

36 OM-Sensistor ISH2000-EN-201304

Page 37

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

3. Remove the union nut by hand. The o-ring in the union nut creates some friction.

4. Remove the probe tip by drawing it straight out.

5. Mount a new probe tip. Make sure it is in correct position.

6. Observe the contact area between the probe pipe and the probe neck. They

should contact each other.

7. Refit the union nut.

8. Tighten with a 10 mm wrench.

8.15 Probe Control Port

The Sensistor ISH2000 is equipped with a parallel Probe Control port. This Probe

control port

supervising computer system.

can be used for controlling active probes, feeding status signals to a

CAUTION!

The Probe Control Port (25-pin D-type) on the

back of the instrument is not a computer or

printer port. Connecting a printer or any other

computer device may cause permanent damage

to the connected device.

EN

Note: Battery operated model Sensistor ISH2000C does not have a Probe Control Port.

Pin configuration for the different detector models is described under Model

Specific Specifications below.

See “Sensistor ISH2000 specifications” on page 50 for electrical specifications.

See “Status signal patterns” on page 38 for signal patterns.

Probe Control Port Connector

The control port connector is a 25-pin female D-sub. Refer to Table 8-2 for the pin

configuration.

Table 8-2. Pin configuration.

Pin Type Signal name

1 - GND

2 - GND

3 - GND

4 IN IN_0

5 IN IN_1

6 IN IN_2

7 IN IN_3

8 IN IN_4

9 OUT CAL_CONF

10 OUT OUT_6

11 - GND

OM-Sensistor ISH2000-EN-201304 37

Page 38

Hydrogen leak detector Sensistor ISH2000 - Operating Manual

EN

Pin Type Signal name

12 - GND

13 - GND

14 OUT DET_ERROR

15 OUT LEAK_OUT

16 OUT DET_ON

17 OUT DET_SIGNAL

18 OUT DET_WAIT

19 OUT OUT_0

20 OUT OUT_1

21 OUT OUT_2

22 OUT OUT_3

23 OUT OUT_4

24 OUT OUT_5

25 OUT 24 VDC OUT

Status signal patterns

Table 8-3. Status signals for pin 14 - 18.

Signal Function

DET_SIGNAL Gas detected / Sensor not recovered.

DET_WAIT High during warm-up.

DET_ON High when detector is on.

LEAK_ALARM Leak above Reject Level detected.

DET_ERROR High if Probe, Sensor or Cable is broken.

DET_ERROR will go high for a short time (1-5 seconds) when the detector is switched

on. It will go low when the sensor has been checked.

In normal operation, DET_ERROR = HIGH means that there is a problem with the

sensor, probe, or cable.

DET_WAIT is high when instrument is in warm-up mode after switching on power.

Instrument will also go into warm-up if there is a temporary fault in the sensor or

sensor connection.

The timing of the status signals in relation to different events is described by the

following two examples:

Example: Input signals issued to control the APC system should have a pulse length

of at least 40 ms.