Page 1

OPERATING MANUAL

RSH-600

Rotary Sensor Head

IPN 153800-G

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2012 INFICON

®

OPERATING MANUAL

RSH-600

Rotary Sensor Head

IPN 153800-G

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

Scotch-Brite® is a registered trademark of 3M.

Teflon® is a registered trademarks of E. I. du Pont de Nemours and Company or its affiliates.

Windows® and Microsoft® are registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2012 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 6

Page 7

Chapter 1

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.4 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5.1 Returning Your Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.7.1 Base Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.8 Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

RSH-600 Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Introduction

Chapter 2

Installation

2.1 Crystal Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 Adjustable Flange Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.4 Copper Head Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

IPN 153800-G

2.6 Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.7 Crystal Position Feedback Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.8 Protection from Evaporant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Chapter 3

Troubleshooting and Maintenance

3.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Troubleshooting the RSH-600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Maintain the Temperature of the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Use the Optimum Crystal Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 Crystal Concerns when Opening the Chamber . . . . . . . . . . . . . . . . . . . . . . 3-4

TOC - 1

Page 8

3.6 Crystal Holder Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.7 Crystal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Chapter 4

4.1 Accessories and Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter 5

RSH-600 Operating Manual

Accessories and Replacement Parts

Outline Drawings

TOC - 2

IPN 153800-G

Page 9

1.1 Introduction

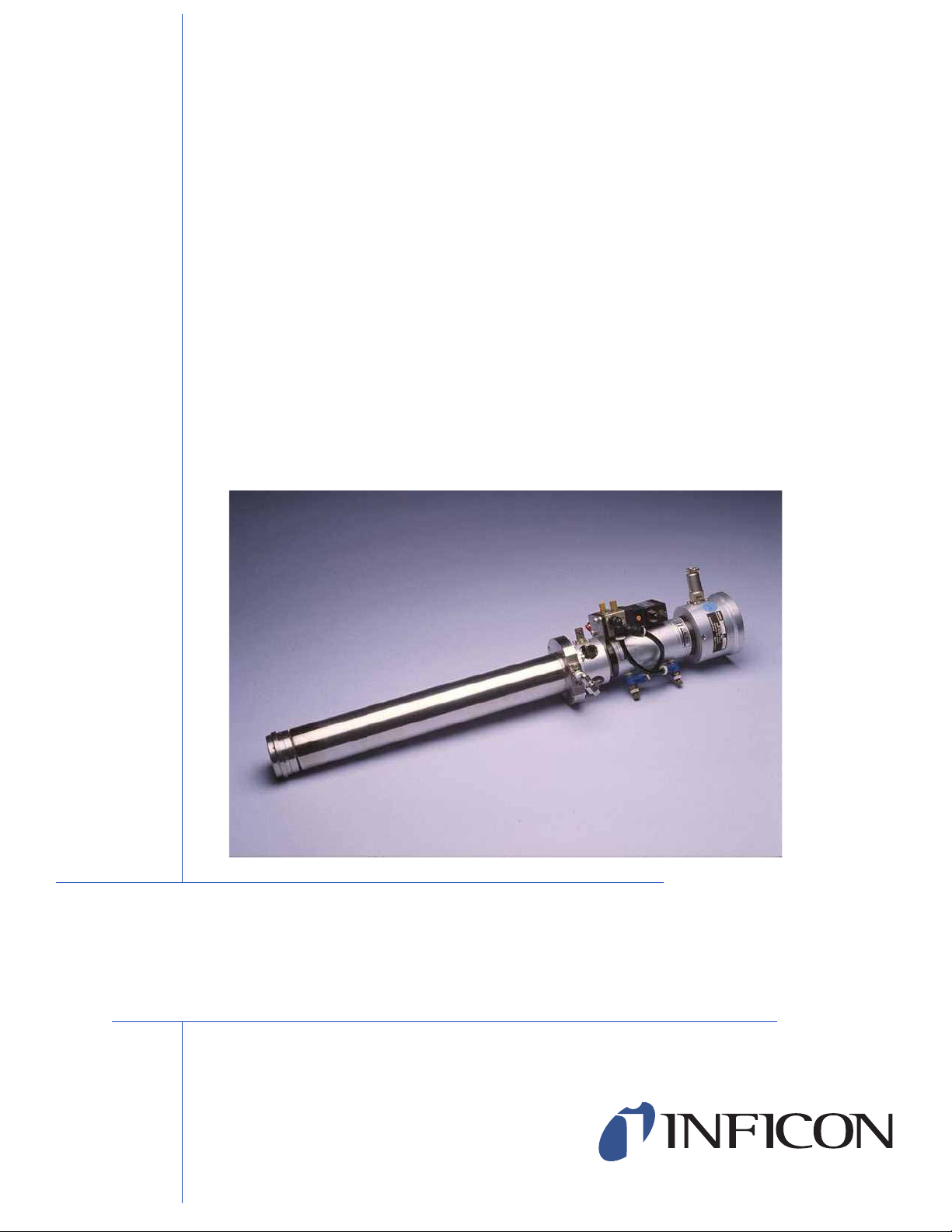

The RSH-600 rotary sensor, see Figure 1-1, is designed for the most demanding

processes employing very thick films and several different materials. Switching the

crystal without venting the system makes it possible to run automatically with

continuous deposition. The fixed position of the crystal being measured also makes

it unnecessary to change the tooling factor.

The RSH-600 can be used to deposit a different material on each of six crystals

providing greater measurement accuracy. Upon completion of deposition of one

material, the deposition controller may be programmed to switch crystals for the

next material. It may also be actuated manually.

The RSH-600 sensor holds six crystals in a thermally shielded, water cooled

housing, insuring excellent crystal performance in temperature environments up to

300ºC. Crystals are housed in an easily removable Teflon

crystal holder.

RSH-600 Operating Manual

Introduction

®

and stainless steel

Chapter 1

Crystal position is incremented by applying a one second pulse to a 110/115 V (ac)

or 24 V (dc) pneumatic valve. A 7-pin connector provides an indication of the

number of the active crystal. This may be used to interface with a thin film controller

for automatic crystal switching operation. Refer to your controller operating manual

for programming instructions.

Figure 1-1 RSH-600 and Sensor Head Options

IPN 153800-G

1 - 1

Page 10

RSH-600 Operating Manual

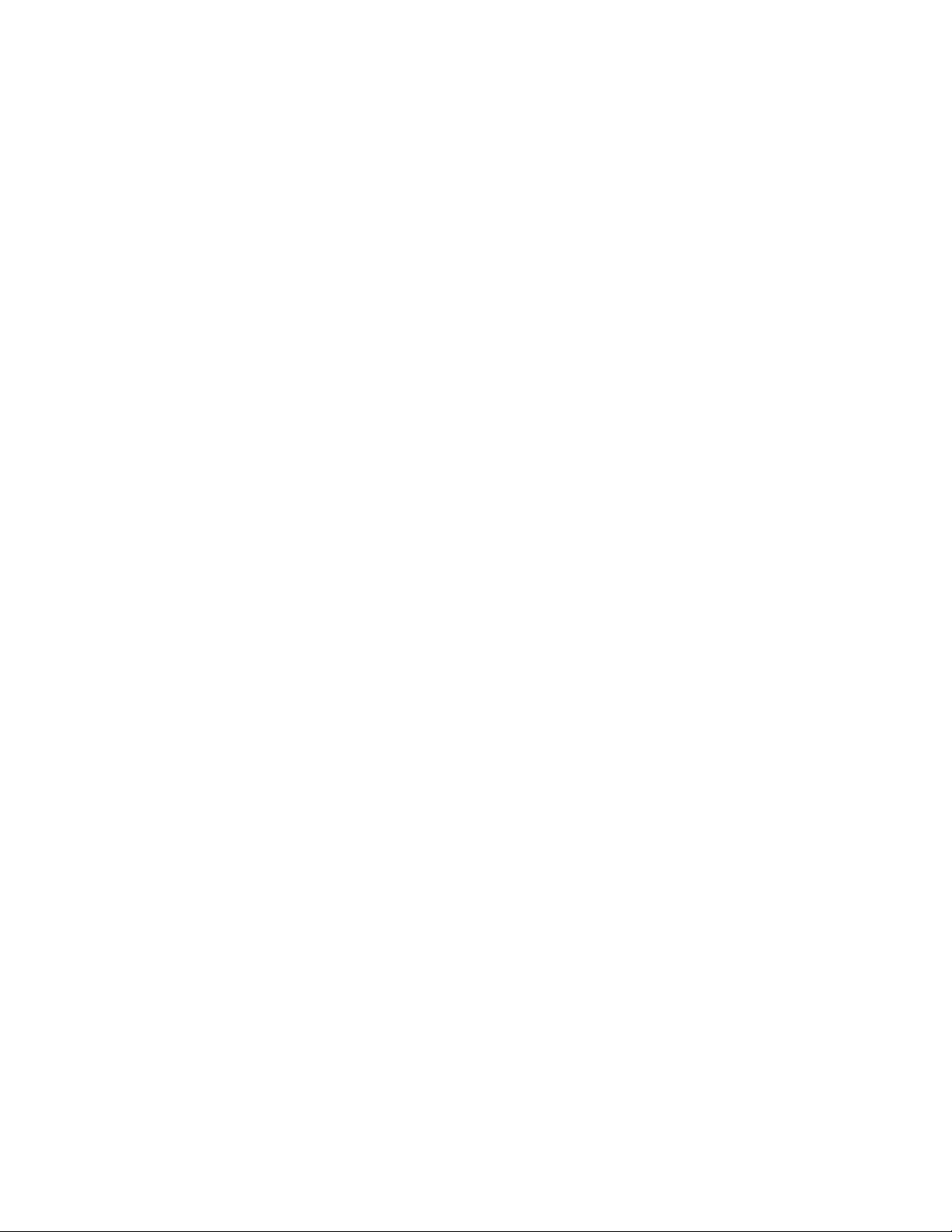

1.2 Configurations

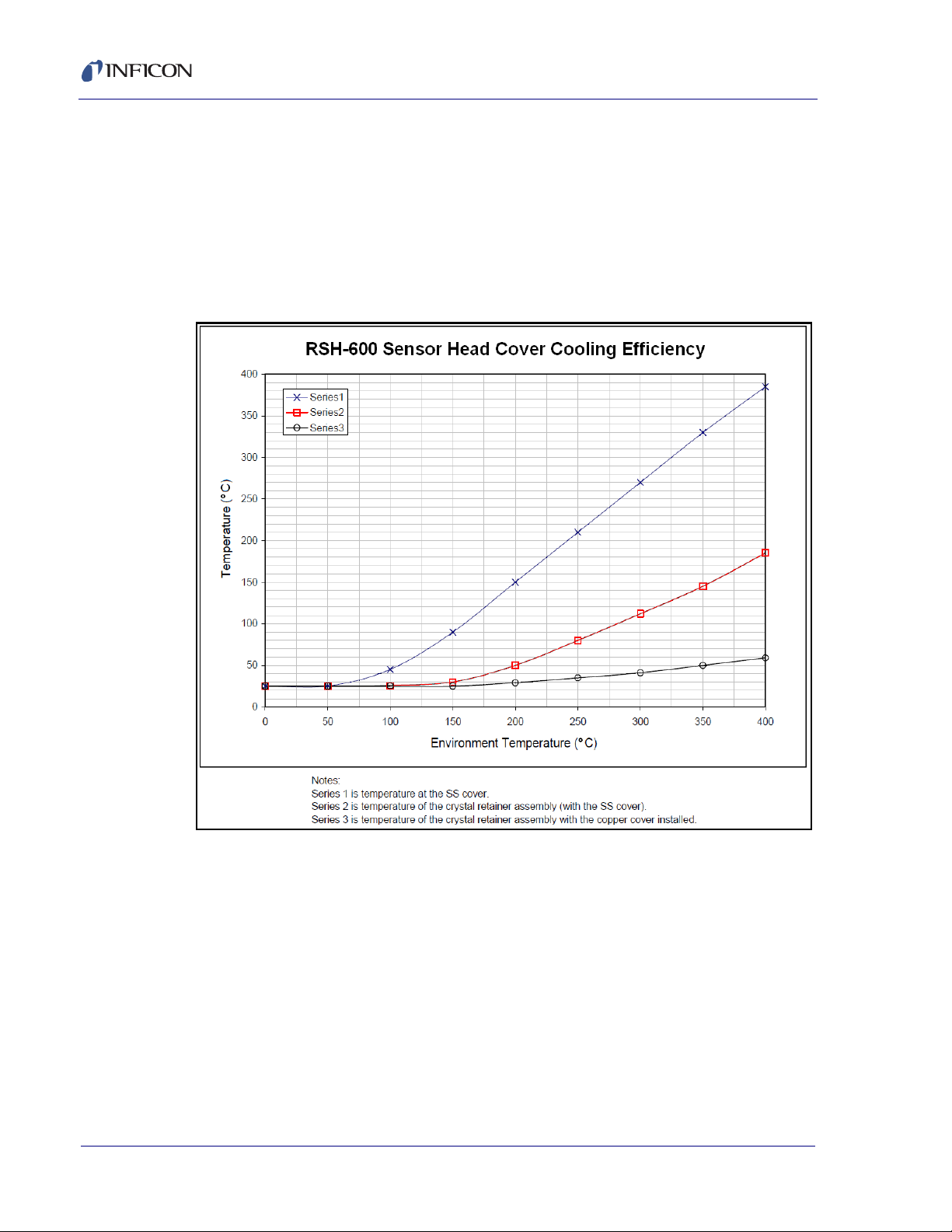

The RSH-600 can be configured with a flat head or a 45º angled head. This allows

for mounting in various locations within your vacuum chamber. Standard head

covers are made of stainless steel. Copper head covers are available for

applications where temperature is a concern (see Figure 1-2). All versions of the

RSH-600 are fixed to their specified lengths, but may be adapted to be adjustable

in length using the optional adjustable mounting flange (see Chapter 4).

Figure 1-2 RSH-600 Sensor Head Cooling Efficiency.

1.3 Mounting

The RSH-600's smooth sealing surface mounts to an O-ring sealed nipple (not

included). The optional adjustable flange allows for the in-vacuum length to be

adjustable up to the RSH-600's original length. A flat head cover is typically used

for centered top mount applications while the angled heads may be used for either

off-center top mount or side mount applications. The customer must supply

specifications regarding mounting holes, exterior diameter of flange and the

system mating flange.

1 - 2

IPN 153800-G

Page 11

RSH-600 Operating Manual

CAUTION

WARNING

1.4 Safety

1.4.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the Notes, Cautions, and

Warnings found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum efficiency when

followed.

Failure to heed these messages could result in damage

to the instrument.

Failure to heed these messages could result in personal

injury.

IPN 153800-G

1 - 3

Page 12

RSH-600 Operating Manual

1.5 How To Contact INFICON

Worldwide customer support information is available under Support at

www.inficon.com where you can contact:

a Technical Support Engineer with questions regarding applications.

a Service Engineer with questions regarding troubleshooting, diagnosing or

repairing a defective sensor.

Sales and Customer Service, to find the INFICON Sales office nearest to you.

Repair Service, to find the INFICON Service Center nearest to you.

If you are experiencing a problem with your sensor, please have the following

information readily available:

the serial number of your sensor,

a description of your problem,

an explanation of any corrective action that you may have already attempted,

and the exact wording of any error messages that you may have received.

1.5.1 Returning Your Instrument

Do not return any component of your sensor to INFICON without first speaking with

a Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your

instrument.

Prior to being given an RMA number, you may be required to complete a

Declaration Of Contamination (DOC) form if your sensor has been exposed to

process materials. DOC forms must be approved by INFICON before an RMA

number is issued. INFICON may require that the sensor be sent to a designated

decontamination facility, not to the factory.

IPN 153800-G

1 - 4

Page 13

1.6 Specifications

Number of Crystals. . . . . . . . . . . . . . 6

Crystal Size . . . . . . . . . . . . . . . . . . . 0.550 in. diameter

Installation Aperture . . . . . . . . . . . . . 2.0 in. diameter

Overall Length

RSH-600 w/flat head . . . . . . . . . 8.19 in. (208 mm) plus in-vac length

RSH-600 w/angled head . . . . . . 8.62 in. (219 mm) plus in-vac length

Adjustable in Vacuum Length . . . 7.9 in. (200 mm) (standard)

Power Requirement . . . . . . . . . . . . . 115 V (ac) @ 50 mA or 24 V (dc) @ 20 mA

Crystal Switching Method. . . . . . . . . Air Actuated @ 55 psi (4 kg/cm

Cooling Method . . . . . . . . . . . . . . . . Water-cooled @ 5 L/m at 2 kg/cm

RSH-600 Operating Manual

13.8 in. (350 mm)

17.7 in. (450 mm)

21.3 in. (540 mm)

25.6 in (650 mm)

2

) regulated

2

(28 psi)

Air and Water Connections. . . . . . . . (3) 1/4 in. quick connects

Operating Temperature . . . . . . . . . . 300°C max with water cooling and Standard

Head Cover

400°C max with water cooling and Copper

Head Cover

Weight . . . . . . . . . . . . . . . . . . . . . . . RSH-600 - Flat - 8.5 lb. (3.8 kg)

RSH-600 - Angled - 9.9 lb. (4.5 kg)

IPN 153800-G

1 - 5

Page 14

RSH-600 Operating Manual

1.7 Unpacking and Inspection

1 If the RSH-600 rotary sensor has not been removed from its shipping container,

do so now.

2 Carefully examine your RSH-600 sensor for damage that may have occurred

during shipping. This is especially important if you notice obvious rough

handling on the outside of the container. Immediately report any damage to the

carrier and to INFICON.

3 Do not discard the packing materials until you have taken inventory and have

at least performed a functional verification (see section 1.8.)

4 Take an inventory of your order by referring to your order invoice and verifying

that the items listed in section 1.7.1 were received.

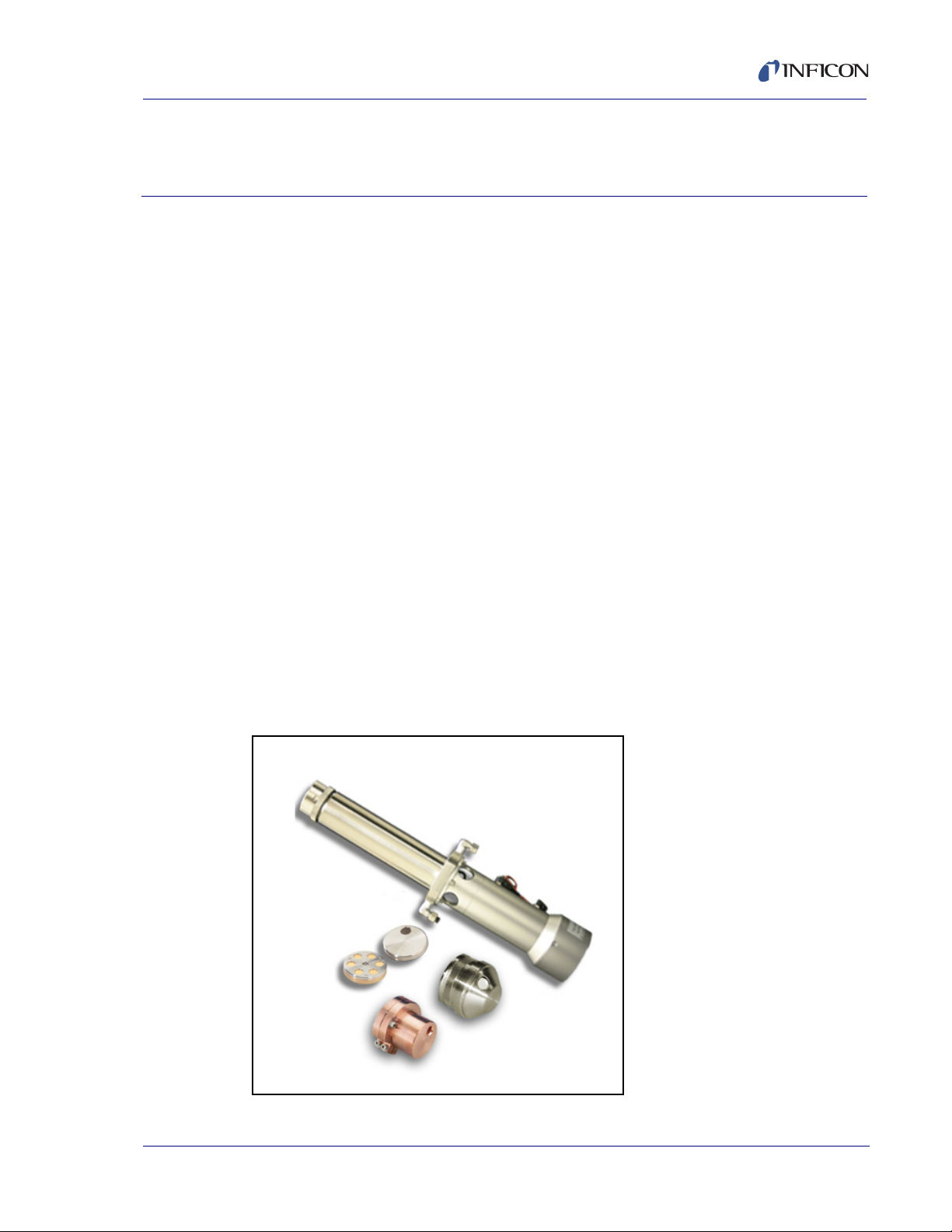

1.7.1 Base Configuration

RSH-600 Rotary Sensor Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15320X-XX

Consult Figure 1-3 below for possible configurations.

Figure 1-3 RSH-600 Configurations

1 - 6

Crystals (2 boxes, 10 total). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103200-2

IPN 153800-G

Technical Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153800 on 074-5000-G1 CD

Page 15

1.8 Functional Verification

Control

Voltage

115 V (ac)

or

24 V (dc)

J1 RSH

Switch

The RSH-600 is equipped to operate on a 115 V (ac), 60 Hz line or a 24 V (dc)

supply depending on the model number. You can verify the required voltage on the

body of the pneumatic valve mounted on the side of the RSH-600. The RSH-600

may be bench checked using the following procedure:

1 Connect air pressure (55 psi) via 1/4 in. plastic tubing to the air inlet fitting at

the base of the solenoid valve marked P.

2 Connect the RSH-600 as shown in Figure 1-4 or any convenient method of

applying and removing the control voltage. The RSH-600 will advance when

the voltage is applied and latch into position when it is removed. The electrical

pulse duration should be at least one second.

Figure 1-4 Electrical Connection

RSH-600 Operating Manual

IPN 153800-G

1 - 7

Page 16

RSH-600 Operating Manual

This page is intentionally blank.

1 - 8

IPN 153800-G

Page 17

RSH-600 Operating Manual

CAUTION

Chapter 2

Installation

During installation, special care must be taken to protect

the barrel surface from being damaged. Scratches or

gouges may prevent the RSH-600 from forming a good

vacuum seal to the O-ring.

Successful operation of any crystal sensor depends on proper placement,

compatibility of its construction with its operating environment and connection to

proper utilities.

NOTE: The RSH-600 should be clean and grease free when installed in the

vacuum chamber. The sensor should be handled while wearing clean

nylon gloves. If parts do become contaminated, clean them thoroughly

using a suitable solvent to avoid outgassing and excessive peeling of

deposition material from the sensor’s surfaces.

2.1 Crystal Sensor Installation

Generally, install the sensor as far as possible from the evaporation source (a

minimum of 12 in. or 30.5 cm) while still being in a position to accumulate thickness

at a rate proportional to accumulation on the substrate. Figure 2-1 shows proper

and improper methods of installing sensors.

Figure 2-1 Sensor Installation Guidelines

IPN 153800-G

2 - 1

Page 18

RSH-600 Operating Manual

J2

J1

6 in. Coaxial Cable

Oscillator

10 ft. Coaxial Oscillator

Water In

Optional Flange

Water Out

Air Solenoid Valve

Cable to QCM

To guard against spattering, use a source shutter to shield the sensor during the

initial soak periods. If the crystal is hit with even a minute particle of molten

material, it may be damaged and stop oscillating. Even in cases when it does not

completely stop oscillating, it may immediately become unstable, or shortly after

deposition begins instability may occur.

Plan the installation to insure that there are no obstructions blocking a direct path

between the sensor and the source. Install sensors in such a manner that the

center axis of the crystal is aimed directly at the source to be monitored. Verify that

the angle of the sensor location (with reference to the source) is well within the

evaporant stream.

2.2 Mounting

NOTE: The head cover must be removed from the RSH-600 prior to installation.

To remove the standard stainless steel head cover: Loosen the retainer

ring nut. Push the head cover inward while turning it counterclockwise until

it stops (1/16 of a turn). Pull the head cover outward.

To remove the optional copper head cover: Loosen the Allen head screws

that clamp the head to the RSH-600 then gently pull the head off of the

RSH-600 barrel.

The vacuum system has to be equipped with a 2.0 in. diameter aperture port. This

port must have an O-ring to provide vacuum seal to the fixed flange on the

RSH-600. If the head cover has been removed, simply slide the RSH-600 through

the 2.0 in. port. Secure the RSH-600 to the port using four 1/4-24 bolts minimum.

Reinstall the head cover. See Figure 2-2.

Figure 2-2 Typical Mounting Configuration

IPN 153800-G

2 - 2

Page 19

2.3 Adjustable Flange Installation

1 Apply a small amount of vacuum compatible grease to the entire surface of the

O-ring that is included with the Adjustable Flange and then install the O-ring

into the O-ring groove in the Adjustable Flange.

2 Loosen the Hex Socket Head screw on the Adjustable Flange.

3 Remove the cover from the RSH-600 sensor.

4 If the Crystal Holder contains any crystals, remove the holder and remove the

crystals. Reinstall the Crystal Holder.

5 Cut a piece of Kapton® tape (or equivalent), 1.5 in. (3.8 cm) to 2 in. (5 cm) wide,

to a length of approximately 6.3 in. (16 cm).

6 Position the Kapton tape with the bottom edge of the tape on the beveled

surface just below the knurled ring. Not starting at any of the three bayonet

pins, wrap the tape around the circumference of the sensor. Fold the excess

tape over the top of the Crystal Holder. See Figure 2-3.

Figure 2-3 Wrap Kapton Tape

RSH-600 Operating Manual

IPN 153800-G

7 Stand the RSH-600 sensor upright on a firm surface. Place the Adjustable

Flange, with smooth side up, over the top of the sensor barrel. With the flange

seating surface perpendicular to the sensor barrel, forcefully push the flange

downward, sliding the flange onto the sensor barrel. See Figure 2-4.

2 - 3

Page 20

RSH-600 Operating Manual

Figure 2-4 Slide Flange Onto Sensor Barrel

8 Slide the Adjustable Flange to the desired position on the sensor barrel and

then secure the flange to the barrel by tightening the Hex Socket Head screw

on the flange.

9 Remove the Kapton tape. Use a lint-free cloth dampened with Reagent grade

Isopropyl Alcohol to clean the surfaces that were in contact with the tape.

2.4 Copper Head Installation

The optional copper head must be installed after the RSH-600 has been mounted

on the vacuum system. The copper head has two main pieces, the clamping ring

and the head cover.

1 Loosen the Allen head screw on the clamping ring and on the clamp portion of

the head cover.

2 Attach the clamping ring to the head cover.

3 Remove the crystal retainer to expose two gold springs. One spring makes

contact with the backside of the retainer. The other spring makes contact with

one of the individual crystal contacts.

4 You have to align the hole in the head cover so that the crystal, that this spring

contacts, is exposed. Note the position of this spring and replace the crystal

retainer.

5 Carefully slide the cover over the barrel of the RSH-600 until it touches the

crystal retainer, then rotate the cover so that the crystal, in contact with the

spring, is centered in the hole in the cover.

IPN 153800-G

2 - 4

6 Tighten the Allen screws on the clamping ring.

Page 21

The clamping ring should be left attached to the head during crystal changing. Only

the head cover should be removed so the alignment process will not have to be

repeated unless the head is removed from the chamber.

If no flange was ordered and you are making your own adjustable flange, the

factory can provide essential dimensions and O-rings.

2.5 Cooling System

The direction of the water flow is not important. Use 1/4 inch plastic tubing to

connect one port to a water supply. The water flow rate should be 5 L/m (1.3 g/m)

at 2 kg/cm

2

(28 psi). Water temperature should be less than 30°C. Connect the

other port to a drain or water recycle system.

2.6 Air Supply

Use 1/4 in. plastic tubing to connect the air inlet port to an air supply. Make sure the

plastic tube is rated higher than 55 psi. The air pressure should be regulated to

4 kg/cm

2

(55 psi).

RSH-600 Operating Manual

2.7 Crystal Position Feedback Connections

The Crystal Position Connector has 7 pins. Pin numbers 1 through 6 correspond to

the six crystals and pin number 7 is the common pin. A short between pin 7 and

one of the pins 1 through 6 indicates the active crystal. For example, if pin 7 is

shorted to pin 1, then crystal 1 is the active crystal.

Use this connector to interface with your controller for automatic crystal selection.

Refer to your controller’s operating manual for programming instruction.

Figure 2-5 Crystal Position Connector

IPN 153800-G

2 - 5

Page 22

RSH-600 Operating Manual

Figure 2-6 Mating Connector (Male) - Crystal Position Connector

The RSH-600 provides a switch closure through connector J2 that can be used to

indicate which crystal is being used at a given time. Switch closure will be effected

by crystal positions.

Figure 2-7 Crystal Position Feedback Diagram

2.8 Protection from Evaporant

It is advisable to cover the head cover and barrel of the RSH-600 with aluminum

foil to protect it from evaporants.

2 - 6

IPN 153800-G

Page 23

3.1 Troubleshooting

WARNING

If the RSH-600 fails to function, or appears to have diminished performance, the

following Symptom/Cause/Remedy charts may be helpful.

There are no user serviceable components within the

RSH-600 sensor.

Refer all maintenance to qualified INFICON personnel.

A useful tool for diagnosing sensor head problems is the DMM (Digital Multi-Meter).

Disconnect the short oscillator cable from the feedthrough and measure the

resistance from the center pin to ground. If the reading is less than 10 megohms

the source of the leakage should be found and corrected.

RSH-600 Operating Manual

Chapter 3

Troubleshooting and Maintenance

3.2 Troubleshooting the RSH-600

Table 3-1 General Troubleshooting

SYMPTOM CAUSE REMEDY

1. Crystal fail signal on front

panel of unit will not

disappear.

IPN 153800-G

2. Unit will not advance when

crystal switch key is pressed.

Xtal switch error message

displayed.

a. Damaged crystal. a. Replace crystal.

b. Loss of electrical signal. b. Check for electrical

continuity at the BNC

connector.

a. Loss of pneumatic supply

or pressure is insufficient for

proper operation.

b. Operation has been

impaired as a result of

peeling of the material

accumulated on the face of

the aperture plate.

a. Establish air supply and

regulate to 55 psi.

b. Remove accumulated

material.

3 - 1

Page 24

RSH-600 Operating Manual

Table 3-1 General Troubleshooting (continued)

SYMPTOM CAUSE REMEDY

3. Crystal not centered in

aperture.

4. Large jumps of thickness

reading during deposition.

a. Improper alignment. a. The RSH-600 should

realign automatically. Be

sure the correct air pressure

(55 psi) is used. Contact

INFICON if the issue

persists.

a. Mode hopping. a. Mode hopping is a by

product of active oscillation

with a heavily damped

crystal. Temperature

stabilization is key in

diminishing this. Replace the

crystal.

b. Crystal near the end of its

b. Replace crystal.

life.

c. Scratches or foreign

particles on the crystal holder

seating surface.

d. Insufficient crystal cooling.

c. Clean, polish the crystal

seating surface of the crystal

holder.

d.Check water flow and

temperature.

5. Crystal ceases to oscillate

during deposition before it

reaches its "normal" life.

6. Crystal does not oscillate

or oscillates intermittently.

(both in vacuum and in air)

a. Crystal is being hit by small

droplets of molten material

a. Move the sensor further

away from the evaporant.

from the evaporation source.

b.Damaged crystal. b. Replace crystal.

c. Deposition material

built-up on the edge of the

d. Clean the crystal carousel

aperture plate.

crystal carousel aperture

plate and touching the

crystal, partially masking full

crystal area.

a. Defective or damaged

a. Replace crystal.

crystal.

b. Existence of electrical

short or poor electrical

contacts.

Check for electrical continuity

and short in sensor cable,

electrical connection

assembly, feedthroughs, and

crystals carousel.

d. Insufficient crystal cooling.

d.Check water flow and

temperature.

IPN 153800-G

3 - 2

Page 25

Table 3-1 General Troubleshooting (continued)

SYMPTOM CAUSE REMEDY

RSH-600 Operating Manual

7. Crystal oscillates in

vacuum but stops oscillation

after open to air.

8. Thermal instability: large

changes in thickness reading

during source warm-up

(usually causes thickness

reading to decrease) and

after the termination of

deposition (usually causes

thickness reading to

increase.)

a. Crystal was near the end

of its life; opening to air

causes film oxidation which

increases film stress.

b. Excessive moisture

accumulates on the crystal.

a. Inadequate cooling

water/cooling water

temperature too high.

b. Excessive heat input to the

crystal.

c. Crystal not seated properly

in holder.

a. Replace crystal.

b. Turn off cooling water to

sensor prior to venting, flow

warm water through sensor

while chamber is open.

a. Check cooling water flow

rate, be certain that cooling

water temperature is less

than 30°C.

b. If heat is due to radiation

from the evaporation source,

move sensor further away

from source and use

sputtering crystals for better

thermal stability.

c. Clean or polish the crystal

seating surface on the crystal

holder.

9. Poor thickness

reproducibility.

a. Variable source flux

distribution.

a. Move sensor to a more

central location to reliably

sample evaporant, ensure

constant relative pool height

of melt, avoid tunneling into

the melt.

b. Sweep, dither, or position

where the electron beam

IPN 153800-G

strikes the melt has been

changed since the last

deposition.

b. Maintain consistent source

distribution by maintaining

consistent sweep

frequencies, sweep

amplitude and electron beam

position settings.

c. Material does not adhere

to the crystal.

c. Make certain the crystal

surface is clean; avoid

touching crystal with fingers,

make use of an intermediate

adhesion layer.

3 - 3

Page 26

RSH-600 Operating Manual

3.3 Maintain the Temperature of the Crystal

Periodically, measure the water flow rate through the crystal sensor to verify that it

meets or exceeds the value specified in section 2.5 on page 2-5. Depending upon

the condition of the cooling water used, the addition of an in-line water filtering

cartridge system may be necessary to prevent flow obstructions. Many system

coaters use parallel water supply taps that provide high total flows. An obstruction

or closed valve in the pipe that supplies water to the sensor head would not result

in a noticeable reduction of total flow. The best test is to directly monitor the flow

leaving the sensor.

The crystal requires sufficient water cooling to sustain proper operational and

temperature stability. Ideally, a constant heat load is balanced by a constant flow of

water at a constant temperature. INFICON quartz crystals are designed to provide

the best possible stability under normal operating conditions. No crystal can

completely eliminate the effects of varying heat loads. Sources of heat variation

include radiated energy emanating from the evaporant source and from substrate

heaters.

3.4 Use the Optimum Crystal Type

Certain materials, especially dielectrics, may not adhere strongly to the crystal

surface and may cause erratic readings. For many dielectrics, adhesion is

improved by using crystals with alloy coated electrodes. Gold is preferred for other

applications.

3.5 Crystal Concerns when Opening the Chamber

Thick deposits of some materials, such as SiO, Si and Ni will normally peel off the

crystal when it is exposed to air, due to changes in film stress caused by gas

absorption. When peeling material is observed, replace the crystal.

3.6 Crystal Holder Maintenance

In many applications, the surface where the crystal contacts the crystal holder may

require periodic cleaning. Material buildup on this surface can cause erratic or poor

electrical contact between the crystal and the sensor body. This buildup can also

cause a reduction in thermal transfer from the crystal to the sensor body. Both of

these can result in excessive rate noise or premature or intermittent crystal failure.

Cleaning may be accomplished by gently buffing the crystal holder to crystal

seating surface with a white Scotch-Brite™ pad followed by an ultrasonic bath in

soap solution followed by thorough rinsing in deionized water and drying or by

ultrasonic cleaning and rinsing only.

IPN 153800-G

3 - 4

Page 27

NOTE: The crystal holder seating surface is machined to a very fine finish

CAUTION

(16 micro inches rms). This high quality finish is essential to provide good

electrical and thermal contact with the crystal. Applying excessive force

during cleaning or using overly abrasive cleaning materials may damage

this finish and reduce sensor performance.

3.7 Crystal Replacement

Always use clean nylon lab gloves and clean plastic tweezers when handling the

crystal. Handle the crystals only by their edges. Anything that comes in contact with

the crystal surfaces may leave contamination, which may lead to poor film

adhesion. Poor film adhesion will result in high rate noise and premature crystal

failure.

Do not use metal tweezers to handle crystals. Metal

tweezers may chip the edge of the crystal.

RSH-600 Operating Manual

1 Remove aluminum foil (if installed).

2 Remove the stainless steel head cover.

2a Loosen the retainer ring nut.

2b Push the head cover inward while turning it counterclockwise until it stops

(1/16 of a turn.)

2c Pull the head cover outward and remove head cover from the head barrel.

3 Remove the copper head cover.

3a Loosen the three Allen head screws that attach the head cover to the copper

clamping ring. (Leave clamping ring attached.)

3b Carefully slide the head off of the barrel of the RSH.

4 Loosen center screw of the head to release crystal retainer.

IPN 153800-G

5 Remove the remaining three screws (on the backside of the retainer) to

separate the head from the spring retainer.

6 Remove the used crystals and replace new ones into the crystal holder. Make

sure to place the crystal so that the solid electrode is facing out of the head.

7 Put the spring retainer and crystal housing back together and tighten the three

screws being careful not to deform the crystal springs or break the crystals.

8 Place the complete crystal retainer assembly back on the head barrel, observe

and line it up with the indexed pin. Tighten the screw.

9 Replace the head cover.

NOTE: Crystal replacement time can be reduced by using a spare crystal holder.

3 - 5

Page 28

RSH-600 Operating Manual

This page is intentionally blank.

3 - 6

IPN 153800-G

Page 29

Accessories and Replacement Parts

4.1 Accessories and Replacement Parts

Flat Copper Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153731

Angled Copper Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153731-2

Flat Stainless Steel Head Cover (See Figure 4-1) . . . . . . . . . . . . . . . . . . . 153708

Angled Stainless Steel Head Cover (See Figure 4-2) . . . . . . . . . . . . . . . . 153713

Flat Crystal Retainer Assembly (See Figure 4-1). . . . . . . . . . . . . . . . . . . . 153204

Angled Crystal Retainer Assembly (See Figure 4-2) . . . . . . . . . . . . . . . . 153204-2

Flat Crystal Holder (See Figure 4-1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153710

Angled Crystal Holder (See Figure 4-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 153716

RSH-600 Operating Manual

Chapter 4

Flat Spring Retainer Assembly (See Figure 4-1) . . . . . . . . . . . . . . . . . . . . 153706

Angled Spring Retainer Assembly (See Figure 4-2) . . . . . . . . . . . . . . . . . 153714

Flat Spring Retainer Contact Kit (See Figure 4-1) . . . . . . . . . . . . . . . . . . . 153724

Spring Contact (See Figure 4-1 and Figure 4-2) . . . . . . . . . . . . . . . . . . . . 153726

Flat Retainer Screw (See Figure 4-1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153709

Angled Retainer Screw (See Figure 4-2) . . . . . . . . . . . . . . . . . . . . . . . . . . 153715

Angled Retainer Spacer (See Figure 4-2) . . . . . . . . . . . . . . . . . . . . . . . . . 153717

M3x6 Screw for Flat Crystal Retainer Assembly (See Figure 4-1). . . . . . . 144-101

M3x12 Screw for Angled Crystal Retainer Assembly (See Figure 4-2) . . . 144-224

IPN 153800-G

Solenoid Valve Assembly, 24 V (See Figure 5-1). . . . . . . . . . . . . . . . . . . . 153707

Crystal Position Male Connector (See Figure 5-1). . . . . . . . . . . . . . . . . . . 889128

Adjustable Flange (See Figure 5-1 and Figure 5-2) . . . . . . . . . . . . . . . . . . 153202

O-ring for Adjustable Flange (see Figure 5-1) . . . . . . . . . . . . . . . . . . . . . . 803188

4 - 1

Page 30

RSH-600 Operating Manual

Stainless Steel Cover

Crystal Holder

P/N 153708

P/N 153710

Spring Contact

Retainer Screw

Spring Retainer

Spring Retainer

P/N 153726

P/N 153709

Copper Cover (not shown)

P/N 153731

M3x6 Screw

P/N 144-101

Contact Kit (set of 6)

P/N 153724

Assembly

P/N 153706

Crystal Retainer

Assembly

P/N 153204

Figure 4-1 Rotary Sensor Head - Flat

IPN 153800-G

4 - 2

Page 31

Figure 4-2 Rotary Sensor Head - Angled

Stainless Steel Cover

Copper Cover (not shown)

Crystal Holder

P/N 153716

P/N 153713

P/N 153731-2

Spring Retainer

Assembly

P/N 153714

Crystal Retainer

Assembly

P/N 153204-2

Retainer Screw

P/N 153715

M3x12 Screw

P/N 144-224

Spring Contact

P/N 153726

Retainer Spacer

P/N 153717

RSH-600 Operating Manual

IPN 153800-G

4 - 3

Page 32

RSH-600 Operating Manual

This page is intentionally blank.

4 - 4

IPN 153800-G

Page 33

Figure 5-1 Sensor Head

φ50

208

(43)

Flat Head ±2

(21)

Ø50

Ø74

(43.5)

(Ø58)

15

Solenoid Valve

Air Inlet

Tube O.D. Ø1/4 in

Flat Head

350 mm (13.8 in)

540 mm (21.3 in)

650 mm (25.6 in)

450 mm (17.7 in)

200 mm (7.9 in)

Crystal Aperture

Connector

Crystal Position

BNC Connector

Sensor Crystal

O-Ring

Optional

Mounting Flange

Mounting Surface

7.1

Ø50

φ50

19.1

Crystal Aperture

FLAT HEAD

ANGLE HEAD

Angle Head ±2

Angle Head

361 mm (14.2 in)

551 mm (21.7 in)

661 mm (26.0 in)

461 mm (18.2 in)

211 mm (8.3 in)

Water Inlet

Crystal Aperture

BCD Ø74 4-Ø5.5

15

Mounting Holes

74

74

(118.1)

Ø84

(Tube Ø1/4")

DIMENSIONS IN mm EXCEPT WHEN NOTED

Water Outlet

(Tube 1/4 in. diameter)

RSH-600 Operating Manual

Chapter 5

Outline Drawings

IPN 153800-G

5 - 1

Page 34

RSH-600 Operating Manual

5 - 2

Figure 5-2 Adjustable Flange (dimensions in inches)

IPN 153800-G

Loading...

Loading...