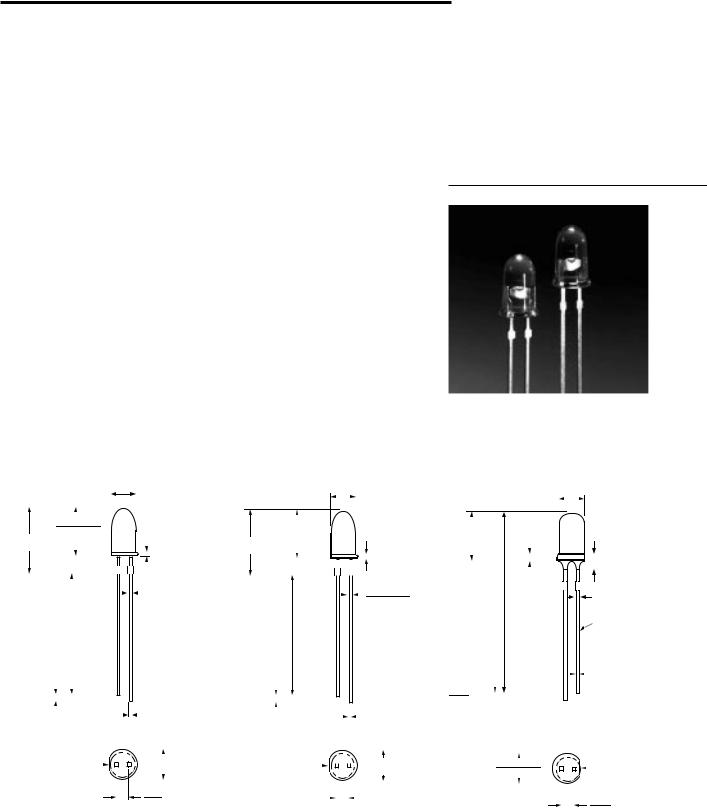

HP HLMP-8100, HLMP-8102, HLMP-8103, HLMP-C100, HLMP-C110 Datasheet

T-13/4 (5 mm) High Performance TS AlGaAs Red LED Lamps

Technical Data

Features

•Exceptional Brightness

•Outstanding LED Material Efficiency

•High Light Output Over a Wide Range of Drive Currents

•Viewing Angle: Narrow or Wide

•Low Forward Voltage

•Low Power Dissipation

•CMOS/MOS Compatible

•Red Color

Package Dimensions

4.82 ± 0.25

(0.190 ± 0.010)

8.80 ± 0.38

(0.347 ± 0.015)

12.3 ± 0.5

(0.485 ± 0.020)

0.76 ± 0.13

(0.030 ± 0.005)

1.17 ± 0.15

(0.046 ± 0.006)

(0.90)23.0 MIN.

1.27

(0.050) NOM.

0.64 SQUARE

(0.025) NOMINAL

5.80 ± 0.30 CATHODE ±

5.80 ± 0.30 CATHODE ±

(0.228 0.012)

2.54 NOM.

(0.100)

Description

These T-13/4, untinted, nondiffused lamps utilize a highly optimized LED material technology, transparent substrate aluminum gallium arsenide (TS AlGaAs). This LED technology has a very high luminous efficiency, capable of producing high light output over a wide range of drive currents (500 μA to 50 mA). The color is deep red at a dominant wavelength of 644 nm. TS AlGaAs is a flip-chip LED technology, die attached to the anode lead and wire bonded to the cathode lead.

|

|

|

|

|

4.82 ± 0.25 |

|||||||||||

|

|

|

|

|

(0.190 ± 0.010) |

|||||||||||

|

8.80 ± 0.38 |

|

|

|

|

|

|

|

|

|

|

|

|

|||

11.3 ± 0.5 |

|

(0.347 ± 0.015) |

|

|

|

|

|

|

|

|

|

|

|

|

||

(0.445 ± 0.020) |

|

|

0.76 ± 0.13 |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(0.030 ± 0.005) |

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

1.17 ± 0.15 |

|||||||||||||

|

|

|

(0.046 ± 0.006) |

|||||||||||||

|

|

|

|

|

|

|||||||||||

|

23.0 |

|

MIN. |

|||||||||||||

|

|

(0.90) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.27

(0.050) NOM.

0.64 SQUARE

(0.025) NOMINAL

5.80 ± 0.30 CATHODE ±

5.80 ± 0.30 CATHODE ±

(0.228 0.012)

2.54 NOM.

(0.100)

HLMP-8100 |

HLMP-8102/-8103 |

NOTES:

1.ALL DIMENSIONS ARE IN MILLIMETERS/INCHES.

2.THE LEADS ARE MILD STEEL, SOLDER DIPPED.

3.AN EPOXY MENISCUS MAY EXTEND ABOUT 1 mm (0.040") DOWN THE LEADS, UNLESS OTHERWISE NOTED.

H

HLMP-810X Series

HLMP-C100

HLMP-C110

5.00 ± 0.20

(0.197 ± 0.008)

1.14 ± 0.20

8.70 ± 0.20 (0.045 ± 0.008)

(0.343 ± 0.008)

2.35

(0.093) MAX.

0.70

(0.028) MAX.

31.4 |

|

CATHODE |

|

MIN. |

|

(1.23) |

|

0.50 ± 0.10

(0.020 ± 0.004) SQUARE

1.27

(0.050) NOM.

5.80 |

± 0.20 |

CATHODE |

(0.228 |

± 0.008) |

|

2.54

(0.100) NOM.

HLMP-C100/-C110

1-44 |

5964-9291E |

Axial Luminous Intensity and Viewing Angle at TA = 25°C

|

|

|

Typical Radiant |

2θ1/2[1] |

Part Number |

Minimum Intensity |

Typical Intensity |

Intensity |

|

HLMP- |

(mcd) @ 20 mA |

(mcd) @ 20 mA |

(mW/sr) @ 20 mA |

Degrees |

|

|

|

|

|

8103 |

2000 |

3000 |

35.3 |

7 |

|

|

|

|

|

8102 |

1400 |

2000 |

23.5 |

7 |

|

|

|

|

|

8100 |

290 |

1000 |

11.8 |

19 |

|

|

|

|

|

C100 |

290 |

750 |

8.8 |

30 |

|

|

|

|

|

C110 |

200 |

400 |

4.7 |

40 |

|

|

|

|

|

Note:

1. θ1/2 is the off axis angle from optical centerline where the luminous intensity is 1/2 the on-axis value.

Absolute Maximum Ratings at TA = 25°C

Peak Forward Current[2] .......................................................... |

|

|

300 mA |

Average Forward Current (@ I |

= 300 mA) [1,2] |

................... 30 mA |

|

PEAK |

|

|

|

DC Forward Current[3] ............................................................... |

|

|

50 mA |

Power Dissipation .................................................................... |

|

|

100 mW |

Reverse Voltage (IR=100 μA) ........................................................... |

|

|

5 V |

Transient Forward Current (10 μs Pulse)[4] |

............................ |

500 mA |

|

Operating Temperature Range ...................................... |

|

|

- 55 to +100°C |

Storage Temperature Range .......................................... |

|

|

- 55 to +100°C |

LED Junction Temperature ....................................................... |

|

|

110°C |

Lead Soldering Temperature |

|

260°C for 5 seconds |

|

[1.6 mm (0.063 in.) from body] .......................... |

|

||

Notes:

1.Maximum IAVG at f = 1 kHz, DF = 10%.

2.Refer to Figure 6 to establish pulsed operating conditions.

3.Derate linearly as shown in Figure 5.

4.The transient peak current is the maximum non-recurring peak current the device can withstand without damaging the LED die and wire bonds. It is not recommended that the device be operated at peak currents above the Absolute Maximum Peak Forward Current.

1-45

Loading...

Loading...