HP HCNR201, HCNR200 Datasheet

1-418

H

High-Linearity Analog

Optocouplers

Technical Data

HCNR200

HCNR201

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

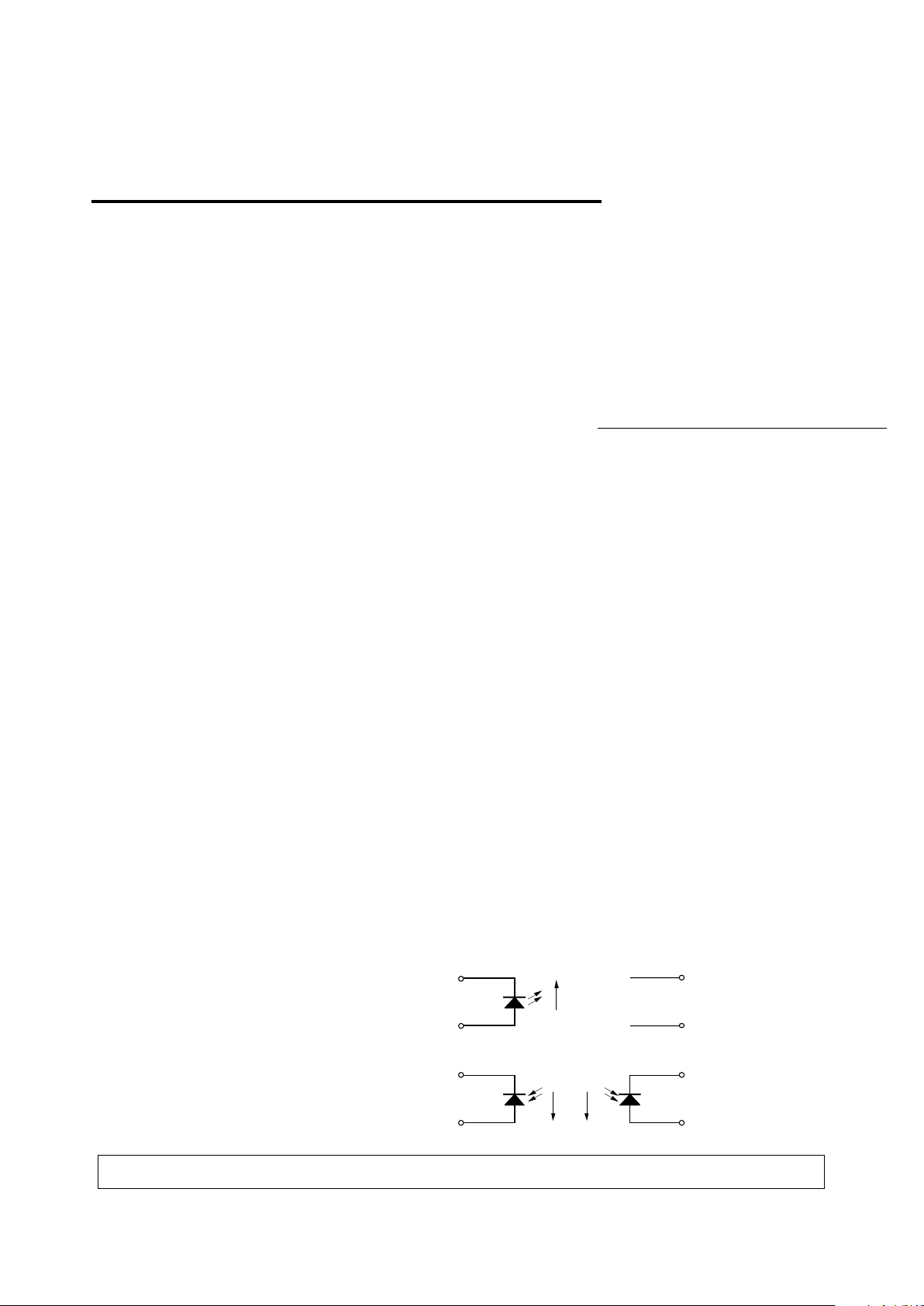

3

4

1

2

V

F

–

+

I

F

I

PD1

6

5

I

PD2

8

7

NC

NC

PD2 CATHODE

PD2 ANODE

LED CATHODE

LED ANODE

PD1 CATHODE

PD1 ANODE

Features

• Low Nonlinearity: 0.01%

• K3 (I

PD2/IPD1

) Transfer Gain

HCNR200: ± 15%

HCNR201: ± 5%

• Low Gain Temperature

Coefficient: -65 ppm/°C

• Wide Bandwidth – DC to

>1 MHz

• Worldwide Safety Approval

- UL 1577 Recognized

(5 kV rms/1 min Rating)

- CSA Approved

- BSI Certified

- VDE 0884 Approved

V

IORM

= 1414 V peak

(Option #050)

• Surface Mount Option

Available

(Option #300)

• 8-Pin DIP Package - 0.400"

Spacing

• Allows Flexible Circuit

Design

• Special Selection for

HCNR201: Tighter K1, K

3

and Lower Nonlinearity

Available

Applications

• Low Cost Analog Isolation

• Telecom: Modem, PBX

• Industrial Process Control:

Transducer Isolator

Isolator for Thermocouples

4 mA to 20 mA Loop Isolation

• SMPS Feedback Loop, SMPS

Feedforward

• Monitor Motor Supply

Voltage

• Medical

Description

The HCNR200/201 high-linearity

analog optocoupler consists of a

high-performance AlGaAs LED

that illuminates two closely

matched photodiodes. The input

photodiode can be used to

monitor, and therefore stabilize,

the light output of the LED. As a

result, the nonlinearity and drift

characteristics of the LED can be

virtually eliminated. The output

photodiode produces a photocurrent that is linearly related to the

light output of the LED. The close

matching of the photodiodes and

advanced design of the package

ensure the high linearity and

stable gain characteristics of the

optocoupler.

The HCNR200/201 can be used to

isolate analog signals in a wide

variety of applications that

require good stability, linearity,

bandwidth and low cost. The

HCNR200/201 is very flexible

and, by appropriate design of the

application circuit, is capable of

operating in many different

modes, including: unipolar/

bipolar, ac/dc and inverting/noninverting. The HCNR200/201 is

an excellent solution for many

analog isolation problems.

Schematic

5965-3577E

1-419

Ordering Information:

HCNR20x

0 = ± 15% Transfer Gain, 0.25% Maximum Nonlinearity

1 = ± 5% Transfer Gain, 0.05% Maximum Nonlinearity

Option yyy

050 = VDE 0884 V

IORM

= 1414 V peak Option

300 = Gull Wing Surface Mount Lead Option

500 = Tape/Reel Package Option (1 k min.)

Option data sheets available. Contact your Hewlett-Packard sales representative or authorized distributor for

information.

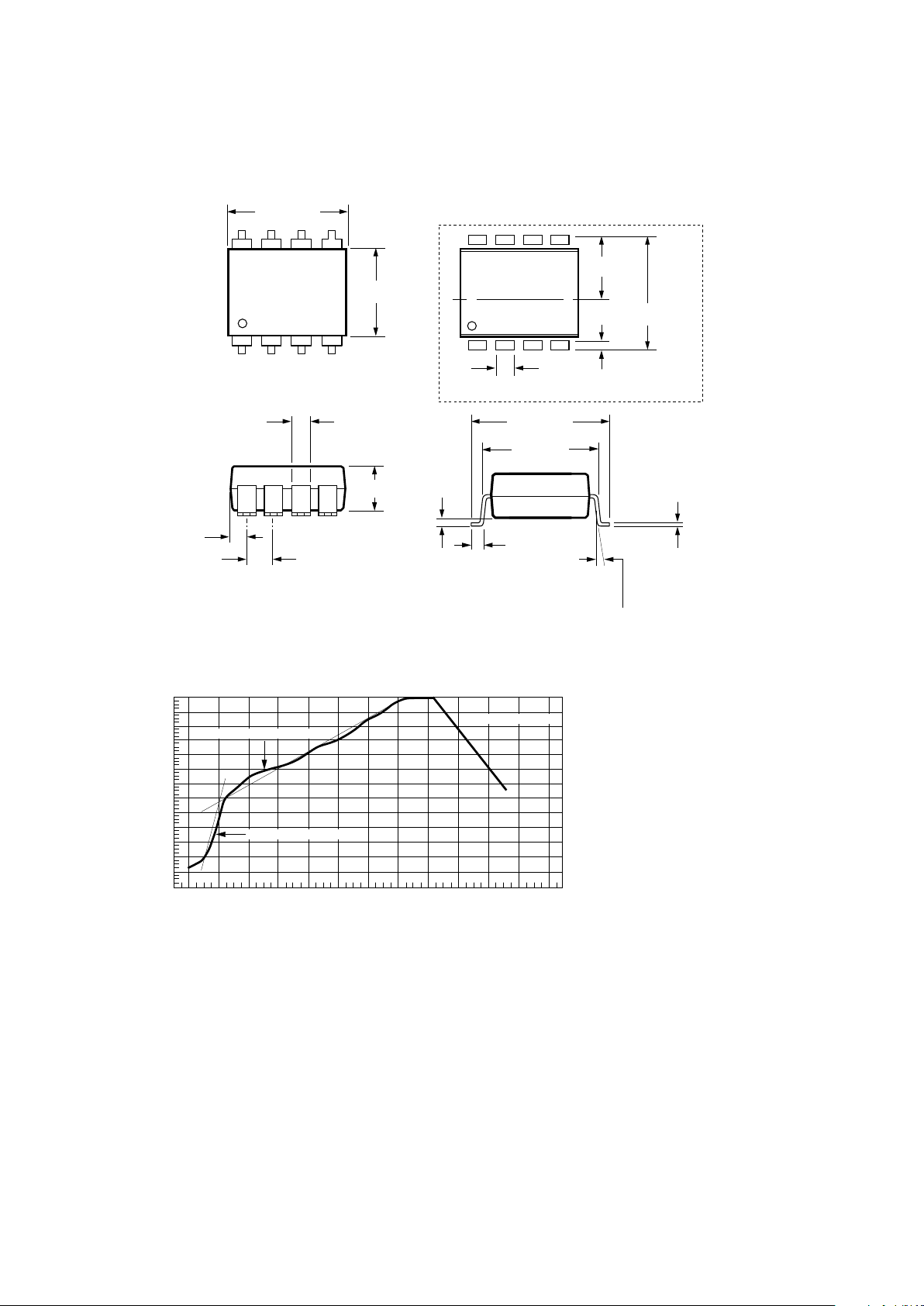

Package Outline Drawings

Figure 1.

0.40 (0.016)

0.56 (0.022)

1

2

3

4

8

7

6

5

1.70 (0.067)

1.80 (0.071)

2.54 (0.100) TYP.

0.51 (0.021) MIN.

5.10 (0.201) MAX.

3.10 (0.122)

3.90 (0.154)

DIMENSIONS IN MILLIMETERS AND (INCHES).

NC

PD1

K

1

11.30 (0.445)

MAX.

PIN

ONE

1.50

(0.059)

MAX.

HP

HCNR200Z

YYWW

OPTION

CODE*

DATE

CODE

8 7 6 5

1

2 3 4

9.00

(0.354)

TYP.

0.20 (0.008)

0.30 (0.012)

0°

15°

11.00

(0.433)

MAX.

10.16

(0.400)

TYP.

K

2

PD2

NC

LED

* MARKING CODE LETTER FOR OPTION NUMBERS.

"V" = OPTION 050

OPTION NUMBERS 300 AND 500 NOT MARKED.

1-420

Gull Wing Surface Mount Option #300

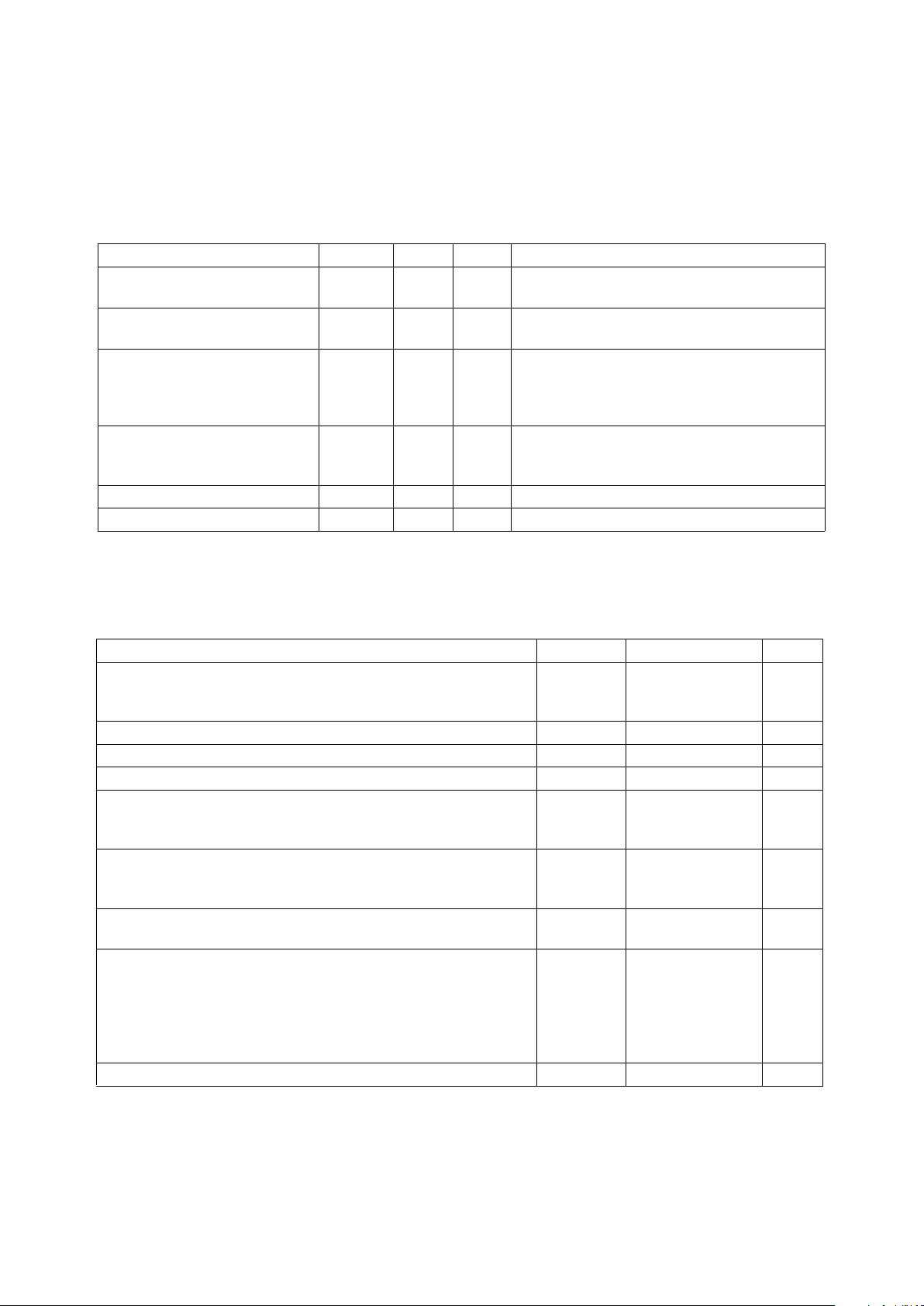

240

∆T = 115°C, 0.3°C/SEC

0

∆T = 100°C, 1.5°C/SEC

∆T = 145°C, 1°C/SEC

TIME – MINUTES

TEMPERATURE – °C

220

200

180

160

140

120

100

80

60

40

20

0

260

123456789101112

(NOTE: USE OF NON-CHLORINE ACTIVATED FLUXES IS RECOMMENDED.)

Maximum Solder Reflow Thermal Profile

Regulatory Information

The HCNR200/201 optocoupler

features a 0.400" wide, eight pin

DIP package. This package was

specifically designed to meet

worldwide regulatory requirements. The HCNR200/201 has

been approved by the following

organizations:

UL Recognized under UL

1577, Component

Recognition Program,

FILE E55361

CSA Approved under CSA

Component Acceptance

Notice #5, File CA

88324

BSI Certification according

to BS415:1994;

(BS EN60065:1994);

BS EN60950:1992

(BS7002:1992) and

EN41003:1993 for Class

II applications

VDE Approved according to

VDE 0884/06.92

(Available Option #050

only)

1.00 ± 0.15

(0.039 ± 0.006)

7° NOM.

12.30 ± 0.30

(0.484 ± 0.012)

0.75 ± 0.25

(0.030 ± 0.010)

11.00

(0.433)

5

6

7

8

4

3

2

1

11.15 ± 0.15

(0.442 ± 0.006)

9.00 ± 0.15

(0.354 ± 0.006)

1.3

(0.051)

12.30 ± 0.30

(0.484 ± 0.012)

6.15

(0.242)

TYP.

0.9

(0.035)

PAD LOCATION (FOR REFERENCE ONLY)

1.78 ± 0.15

(0.070 ± 0.006)

4.00

(0.158)

MAX.

1.55

(0.061)

MAX.

2.54

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

LEAD COPLANARITY = 0.10 mm (0.004 INCHES).

0.254

+ 0.076

- 0.0051

(0.010

+ 0.003)

- 0.002)

MAX.

1-421

VDE 0884 (06.92) Insulation Characteristics (Option #050 Only)

Description Symbol Characteristic Unit

Installation classification per DIN VDE 0110/1.89, Table 1

For rated mains voltage ≤ 600 V rms I-IV

For rated mains voltage ≤ 1000 V rms I-III

Climatic Classification (DIN IEC 68 part 1) 55/100/21

Pollution Degree (DIN VDE 0110 Part 1/1.89) 2

Maximum Working Insulation Voltage V

IORM

1414 V peak

Input to Output Test Voltage, Method b* V

PR

2651 V peak

VPR = 1.875 x V

IORM

, 100% Production Test with

tm = 1 sec, Partial Discharge < 5 pC

Input to Output Test Voltage, Method a* V

PR

2121 V peak

VPR = 1.5 x V

IORM

, Type and sample test, tm = 60 sec,

Partial Discharge < 5 pC

Highest Allowable Overvoltage* V

IOTM

8000 V peak

(Transient Overvoltage, t

ini

= 10 sec)

Safety-Limiting Values

(Maximum values allowed in the event of a failure,

also see Figure 11)

Case Temperature T

S

150 °C

Current (Input Current IF, PS = 0) I

S

400 mA

Output Power P

S,OUTPUT

700 mW

Insulation Resistance at TS, VIO = 500 V R

S

>10

9

Ω

*Refer to the front of the Optocoupler section of the current catalog for a more detailed description of VDE 0884 and other product

safety regulations.

Note: Optocouplers providing safe electrical separation per VDE 0884 do so only within the safety-limiting values to which they are

qualified. Protective cut-out switches must be used to ensure that the safety limits are not exceeded.

Insulation and Safety Related Specifications

Parameter Symbol Value Units Conditions

Min. External Clearance L(IO1) 9.6 mm Measured from input terminals to output

(External Air Gap) terminals, shortest distance through air

Min. External Creepage L(IO2) 10.0 mm Measured from input terminals to output

(External Tracking Path) terminals, shortest distance path along body

Min. Internal Clearance 1.0 mm Through insulation distance conductor to

(Internal Plastic Gap) conductor, usually the direct distance

between the photoemitter and photodetector

inside the optocoupler cavity

Min. Internal Creepage 4.0 mm The shortest distance around the border

(Internal Tracking Path) between two different insulating materials

measured between the emitter and detector

Comparative Tracking Index CTI 200 V DIN IEC 112/VDE 0303 PART 1

Isolation Group IIIa Material group (DIN VDE 0110)

Option 300 – surface mount classification is Class A in accordance with CECC 00802.

1-422

Absolute Maximum Ratings

Storage Temperature .................................................. -55°C to +125°C

Operating Temperature (TA)........................................ -55°C to +100°C

Junction Temperature (TJ) ............................................................125°C

Reflow Temperature Profile ... See Package Outline Drawings Section

Lead Solder Temperature ..................................................260°C for 10s

(up to seating plane)

Average Input Current - IF............................................................ 25 mA

Peak Input Current - IF................................................................. 40 mA

(50 ns maximum pulse width)

Reverse Input Voltage - VR.............................................................. 2.5 V

(IR = 100 µA, Pin 1-2)

Input Power Dissipation ......................................... 60 mW @ TA = 85°C

(Derate at 2.2 mW/°C for operating temperatures above 85°C)

Reverse Output Photodiode Voltage ................................................ 30 V

(Pin 6-5)

Reverse Input Photodiode Voltage................................................... 30 V

(Pin 3-4)

Recommended Operating Conditions

Storage Temperature .................................................... -40°C to +85°C

Operating Temperature ................................................. -40°C to +85°C

Average Input Current - IF....................................................... 1 - 20 mA

Peak Input Current - IF................................................................. 35 mA

(50% duty cycle, 1 ms pulse width)

Reverse Output Photodiode Voltage ........................................... 0 - 15 V

(Pin 6-5)

Reverse Input Photodiode Voltage .............................................. 0 - 15 V

(Pin 3-4)

Loading...

Loading...