Page 1

Page 2

Page 3

HP Designjet Z6100 Printer series

Quick reference guide

Page 4

Legal notices

The information contained in this document is

subject to change without notice.

The only warranties for HP products and services

are set forth in the express warranty statements

accompanying such products and services.

Nothing herein should be construed as constituting

an additional warranty. HP shall not be liable for

technical and editorial errors or omissions

contained herein.

Adobe®,Photoshop®, and PostScript® are

trademarks of Adobe Systems Incorporated.

Microsoft® and Windows® are U.S. registered

trademarks of Microsoft Corporation.

PANTONE®* is *Pantone, Inc.'s check-standard

trademark for color.

Page 5

Table of contents

1 Introduction

2 Handle the paper

3 Handle the ink system

Using this guide ..................................................................................... 1

Introduction ........................................................................... 1

Warnings and Cautions ......................................................... 1

The printer's main components ................................................................. 1

Front view 42–in printer ......................................................... 1

Front view 60–in printer ......................................................... 2

Rear view 42–in and 60–in printers ......................................... 3

Take-up reel motor ................................................................. 3

The front panel ...................................................................... 4

Turn the printer on and off ....................................................................... 6

Access the Embedded Web Server ........................................................... 7

Printing paper info ................................................................................. 7

Load a roll onto the spindle ..................................................................... 9

Load a roll into the printer ..................................................................... 11

Unload a roll from the printer ................................................................. 15

The normal procedure (roll attached to spindle) ....................... 15

Roll is detached from spindle ................................................ 16

No paper visible ................................................................. 16

Use the take-up reel .............................................................................. 16

Attach a roll to the take-up reel .............................................. 17

Unload a roll from the take-up reel ......................................... 22

View information about the paper .......................................................... 23

Perform paper advance calibration ........................................................ 24

Overview of the paper advance procedure ............................. 25

Return to default calibration .................................................. 25

Download paper profiles ...................................................................... 25

Remove an ink cartridge ....................................................................... 27

Insert an ink cartridge ........................................................................... 29

Remove a printhead ............................................................................. 29

Insert a printhead ................................................................................. 32

Align the printheads ............................................................................. 34

Use the Printhead status plot .................................................................. 35

Print the Printhead status plot ................................................. 35

Interpret the Printhead status plot ........................................... 36

Corrective action ................................................................. 37

What to do if problems persist .............................................. 37

Remove the maintenance cartridge ......................................................... 38

Insert the maintenance cartridge ............................................................ 39

Check the status of the ink system ........................................................... 40

iii

Page 6

4 Manage print options

Select print quality ................................................................................ 41

Use the Embedded Web Server ............................................. 41

Use a driver ........................................................................ 41

Use the front panel .............................................................. 42

Select page size .................................................................................. 42

Custom page sizes .............................................................. 42

Use the Embedded Web Server ............................................. 42

Use a driver ........................................................................ 43

Use the front panel .............................................................. 43

Adjust margins and layout options .......................................................... 43

Use the Embedded Web Server ............................................. 44

Use a driver ........................................................................ 44

Use the front panel .............................................................. 45

Print crop lines ..................................................................................... 45

Use the Embedded Web Server ............................................. 45

Use a driver ........................................................................ 45

Use the front panel .............................................................. 46

Nest jobs to save paper ........................................................................ 46

Configure the nesting option ................................................. 46

How job compatibility is defined ........................................... 47

Nest with crop lines ............................................................. 48

5 Manage calibration

Color calibration .................................................................................. 49

Color profiling ..................................................................................... 50

Create your own profile ....................................................... 51

Use a third-party profile ........................................................ 52

Color adjustment options ....................................................................... 52

Color emulation modes ......................................................................... 53

CMYK color emulation ......................................................... 54

RGB color emulation ............................................................ 56

6 Troubleshoot print-quality issues

General advice .................................................................................... 57

The Embedded Web Server Print Quality Troubleshooting wizard .............. 57

Lines are too thick, too thin, or missing .................................................... 58

Lines appear stepped or jagged ............................................................. 59

Parts of lines or text are missing ............................................................. 59

Lines are printed double or in wrong colors ............................................. 60

Lines are blurred (ink bleeds from lines) .................................................. 60

Dark or light horizontal lines across the image (banding) .......................... 61

The image is grainy .............................................................................. 62

The image has a metallic hue (bronzing) ................................................. 63

The printed output is not flat .................................................................. 63

The print smudges when touched ........................................................... 63

Ink marks appear on the paper .............................................................. 64

Smears on the front of coated paper ...................................... 64

Smears or scratches on the front of glossy paper ..................... 64

iv

Page 7

Defects near the top of a print ................................................................ 64

Colors are inaccurate ........................................................................... 65

The output is completely blank ............................................................... 66

The output contains only a partial print ................................................... 66

The image is clipped ............................................................................ 66

One image overlays another on the same print ........................................ 67

The image has a wood-grain appearance (aeroworms) ............................ 68

7 Troubleshoot paper issues

The paper cannot be loaded successfully ................................................ 69

The paper has jammed ......................................................................... 69

Check the printhead path ..................................................... 69

Check the paper path .......................................................... 70

Automatic paper-cutter does not function ................................................. 71

Take-up reel paper jammed ................................................................... 71

Take-up reel does not wind .................................................................... 71

8 Troubleshoot ink system issues

Clean the printheads ............................................................................ 74

Align the printheads ............................................................................. 74

Reinsert printheads procedure ............................................... 75

Image Quality Maintenance menu procedure .......................... 76

Scan errors during alignment ................................................ 77

9 Front-panel error messages

10 Get help

Introduction ......................................................................................... 82

HP Instant Support ................................................................................ 82

HP Proactive Support ............................................................................ 82

HP Customer Care ............................................................................... 82

Telephone numbers .............................................................. 84

HP Designjet Online ............................................................................. 86

Other sources of information .................................................................. 86

11 Legal information

Hewlett-Packard Limited Warranty—HP (HP Designjet Z6100 Printer

series) ................................................................................................. 87

A. Extent of HP Limited Warranty .......................................... 87

B. Limitation of warranty ....................................................... 89

C. Limitations of liability ....................................................... 89

D. Local law ........................................................................ 89

Hewlett-Packard Software License Agreement .......................................... 89

HP SOFTWARE LICENSE TERMS .......................................... 90

Open source software ........................................................................... 91

Open source acknowledgments ............................................. 91

Open source written offer ..................................................... 91

Regulatory notices ................................................................................ 91

v

Page 8

Material Safety Data Sheet ................................................... 91

Regulatory Model Number .................................................... 92

Regulatory Statements .......................................................... 92

DECLARATION OF CONFORMITY ......................................................... 96

Index .................................................................................................... 98

vi

Page 9

1

Introduction

Using this guide

The Hp Start-up Kit CD/DVD is the most complete source of information about this

product and is organized into the following chapters.

Introduction

This chapter provides a brief introduction to the printer and its documentation. The

remaining chapters offer information about how to use and maintain the printer, and

how to troubleshoot issues.

Warnings and Cautions

Symbols are used in this manual to ensure the proper use of the printer and to prevent

printer damage. Follow the instructions that are marked with these symbols.

WARNING! Failure to follow the guidelines that are marked with this

symbol could result in serious personal injury or death.

CAUTION: Failure to follow the guidelines that are marked with this

symbol could result in minor personal injury or damage to the product.

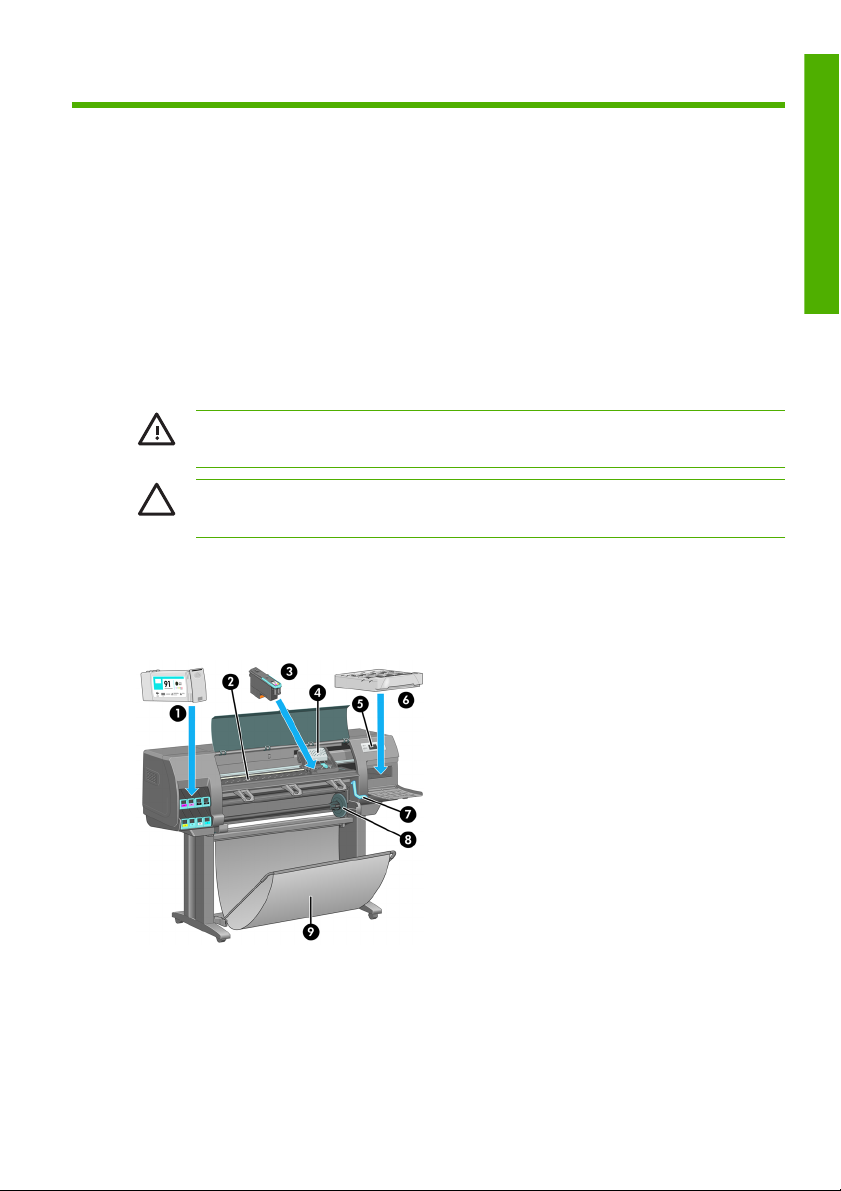

The printer's main components

The following views illustrate the main components of the HP Designjet Z6100 42–

in and 60–in Printers.

Front view 42–in printer

Introduction

Ink cartridge

1.

Platen

2.

Using this guide

1

Page 10

Printhead

Introduction

3.

Printhead carriage

4.

Front panel

5.

Maintenance cartridge

6.

Paper-load lever

7.

Spindle

8.

Bin

9.

Front view 60–in printer

Ink cartridge

1.

Platen

2.

Printhead

3.

Printhead carriage

4.

Front panel

5.

Maintenance cartridge

6.

Paper-load lever

7.

Spindle

8.

Take-up reel deflector

9.

Take-up reel motor

10.

Take-up reel cable and sensor housing unit

11.

2 Chapter 1 Introduction

Page 11

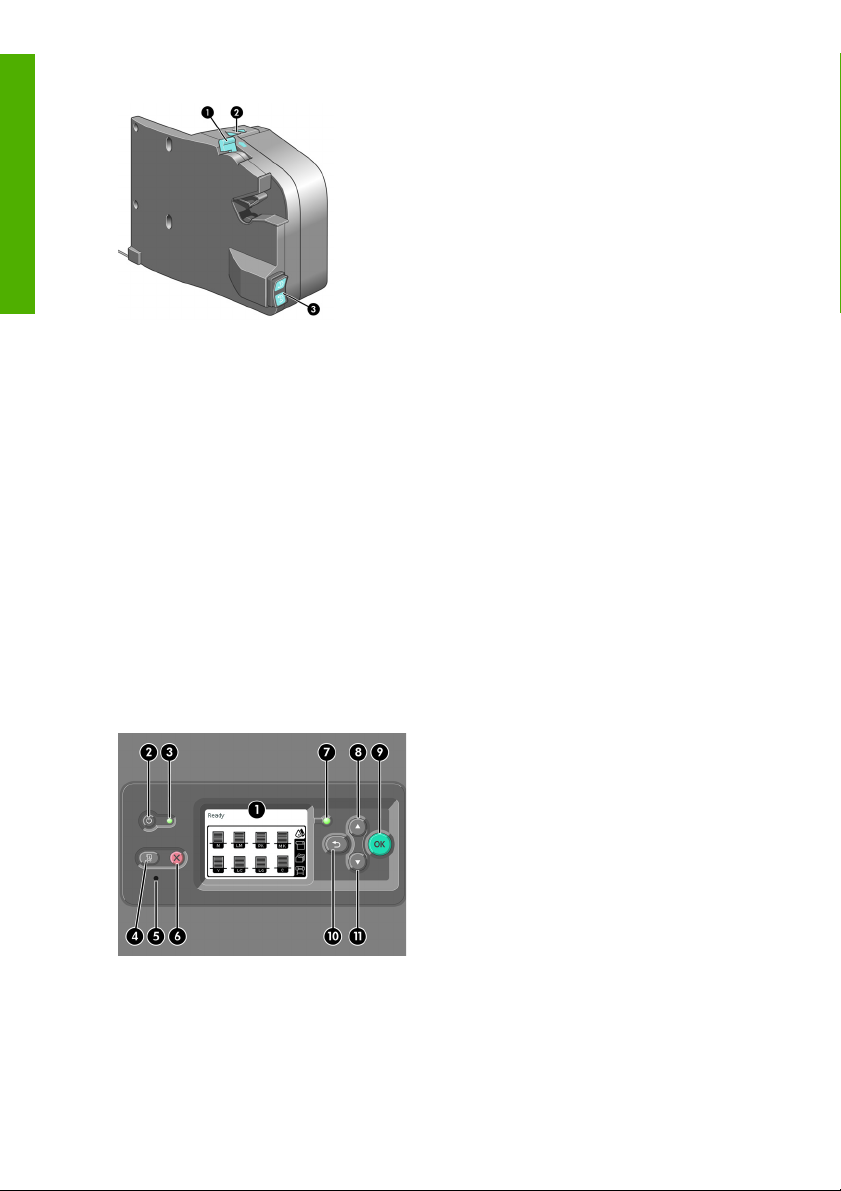

Take-up reel sensor

12.

Take-up reel spindle hub

13.

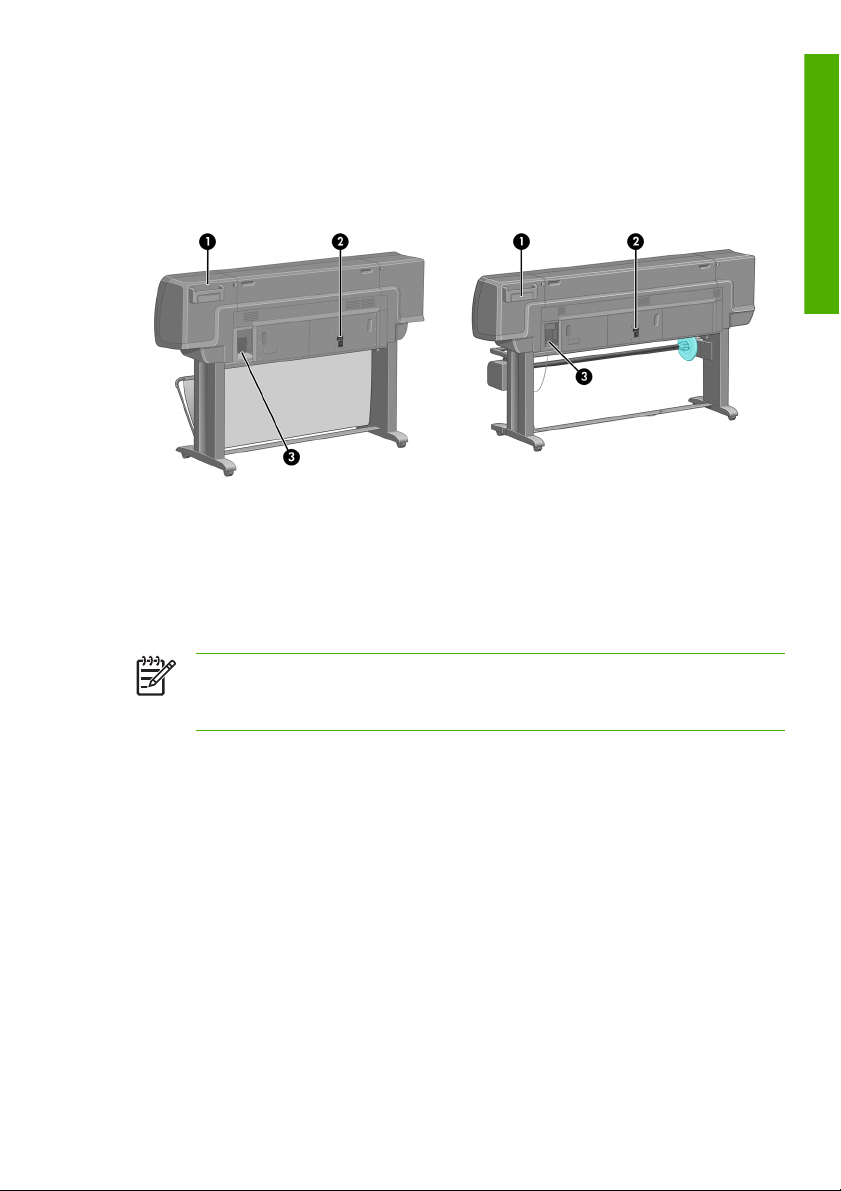

Rear view 42–in and 60–in printers

HP Designjet Z6100 42–in Printer HP Designjet Z6100 60–in Printer

Quick Reference Guide holder

1.

Hard power switch and power-cord plug in

2.

Sockets for communication cables and optional accessories

3.

Take-up reel motor

NOTE: The take-up reel is a standard feature on the HP Designjet Z6100

60–in Printer. It is an optional accessory on the HP Designjet Z6100 42–in

Printer.

Introduction

The printer's main components

3

Page 12

Introduction

1.

2.

3.

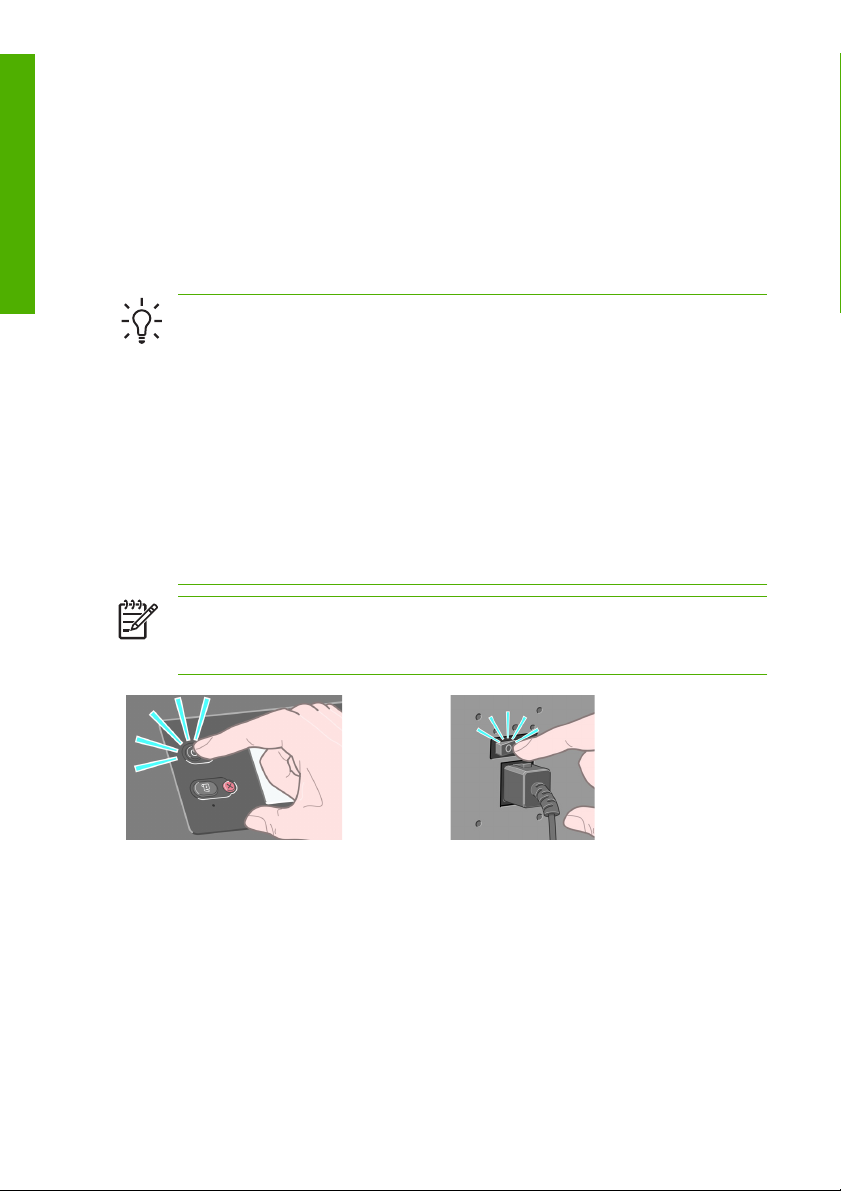

The front panel

Your printer's front panel is located on the front of the printer, on the right-hand side.

Use if for the following functions:

●

●

●

●

●

Take-up reel spindle lever

Manual winding buttons

Wind-direction switch

Use it to perform certain operations, such as loading and unloading paper.

View up-to-date information about the status of the printer, the ink cartridges,

the printheads, the maintenance cartridge, the paper, the print jobs, and other

parts and processes.

Get guidance in using the printer.

See warning and error messages, when appropriate.

Use it to change the values of printer settings and the operation of the printer.

However, settings in the Embedded Web Server or in the driver override

changes made on the front panel.

4 Chapter 1 Introduction

Page 13

The front panel has the following components:

The display area, shows information, icons, and menus.

1.

The Power button turns the printer on and off. If the printer is in sleep mode, this

2.

button will wake it up. (This is different from the hard power switch on the back

of the printer. See

The Power light is off when the printer is off. This light is amber when the printer

3.

Turn the printer on and off on page 6.)

is in sleep mode, green when the printer is on, green and flashing when the

printer is in transition between off and on.

The Form Feed and Cut button normally advances and cuts the roll. Here is a

4.

list of its other functions:

If the printer is waiting for more pages to be nested, this button cancels the

●

waiting time and prints the available pages immediately.

If the printer is drying the ink after printing, this button cancels the waiting

●

time and releases the page immediately.

If the take-up reel is enabled, this button advances the paper 10 cm (3.9

●

inches), but does not cut the paper.

The Reset button restarts the printer (as if it were turned off and turned on again).

5.

You will need a non-conductive implement with a narrow tip to operate the

Reset button.

The Cancel button cancels the current operation. It is often used to stop the

6.

current print job.

The Status light is off when the printer is not ready to print: the printer is either

7.

off, or in sleep mode. The Status light is green when the printer is ready and

idle, green and flashing when the printer is busy, amber when a serious internal

error has occurred, and amber and flashing when the printer is awaiting human

attention.

The Up button moves to the previous item in a list, or increases a numerical

8.

value.

The OK button is used to select the item that is currently highlighted.

9.

The Back button is used to return to the previous menu. If you press it repeatedly,

10.

or hold it down, you return to the main menu.

The Down button moves to the next item in a list, or decreases a numerical value.

11.

To highlight an item on the front panel, press the Up or Down button until the item is

highlighted.

To select an item on the front panel, first highlight it and then press the OK button.

Introduction

The printer's main components

5

Page 14

Introduction

The four front-panel icons are all found on the main menu. If you need to select or

highlight an icon, and you do not see the icons in the front panel, press the Back

button until you can see them.

Sometimes this guide shows a series of front panel items like this: Item1 > Item2

> Item3. A construction like this indicates that you should select Item1, select

Item2, and then select Item3.

You will find information about specific uses of the front panel throughout this guide.

Turn the printer on and off

TIP: Turn the printer on with the hard power switch on the back of the printer

or by pressing the Power button on the front panel. You can leave the printer

on without wasting energy. Leaving it on improves response time and overall

system reliability. When the printer has not been used for a certain period of

time, it saves power by going into sleep mode. Any interaction with the printer

returns it to active mode, and it can resume printing immediately.

If you want to turn the printer on or off, the normal and recommended method

is to use the Power button on the front panel. When you turn off the printer

this way, the printheads are automatically stored with the maintenance

cartridge, which prevents them from drying out.

However, if you plan to leave the printer turned off for a long period of time,

you are recommended to turn it off using the Power button, and then also

switch off the power switch at the rear.

NOTE: In sleep mode, the printer wakes up from time to time to do

maintenance service to the printheads. This avoids the need of doing long

preparation after long idle periods.

To turn it back on later, use the power switch at the rear, and then press the Power

button.

When the printer is turned on, it will take some time to initialize itself. This time is

about 10 minutes for the HP Designjet Z6100 Printer series.

6 Chapter 1 Introduction

Page 15

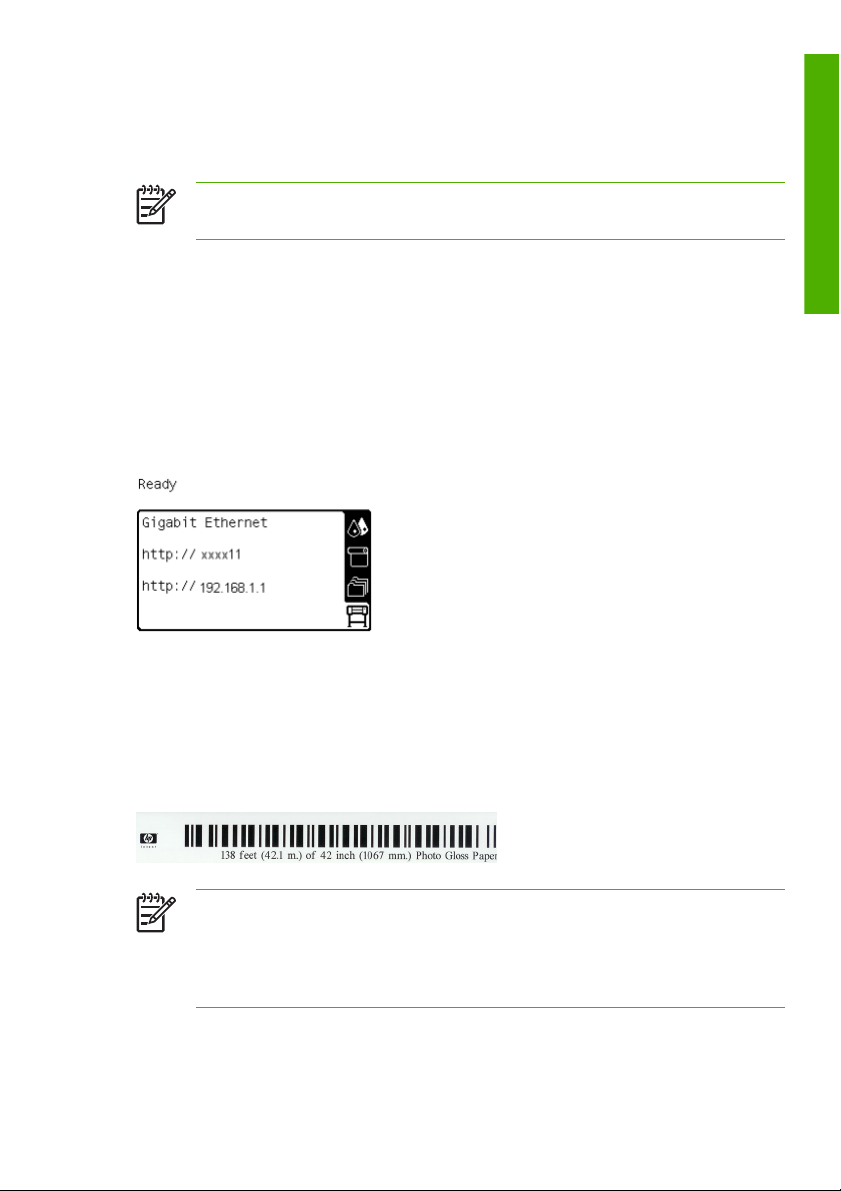

Access the Embedded Web Server

Use the Embedded Web Server to manage your printer remotely through an ordinary

Web browser running on any computer.

NOTE: To use the Embedded Web Server, you must have a TCP/IP

connection to your printer.

The following browsers are known to be compatible with the Embedded Web Server:

Internet Explorer 5.5 or later for Windows

●

Safari 1, 2, 3 or later for Mac OS X

●

Netscape Navigator 6.01 or later

●

Mozilla 1.5 or later

●

Mozilla Firefox 1.0 or later

●

To use the Embedded Web Server on any computer, open your Web browser and

type the printer address. The printer address appears on the status screen on the

printer's front panel (192.168.1.1 in this example):

If you follow these instructions but fail to open the Embedded Web Server, see Cannot

access the embedded web server in Using your printer.

Printing paper info

Enable the Printing paper info option to see the printer's estimation of the

remaining roll length. The information is a combination of barcode and text that is

printed on the leading edge of the roll when the paper is unloaded from the printer.

Introduction

NOTE: The paper-length estimation is only available if the printer

registered the amount of paper that was on the roll when you loaded it. To

provide this informations to the printer, specify the roll length on the front

panel when loading the paper, or load a roll that has the paper-data barcode

printed on it.

Access the Embedded Web Server

7

Page 16

Introduction

To enable the Printing paper info option, select the icon in the printer's front

panel, and then select Paper handling options > Enable Printing paper

info.

8 Chapter 1 Introduction

Page 17

2

Handle the paper

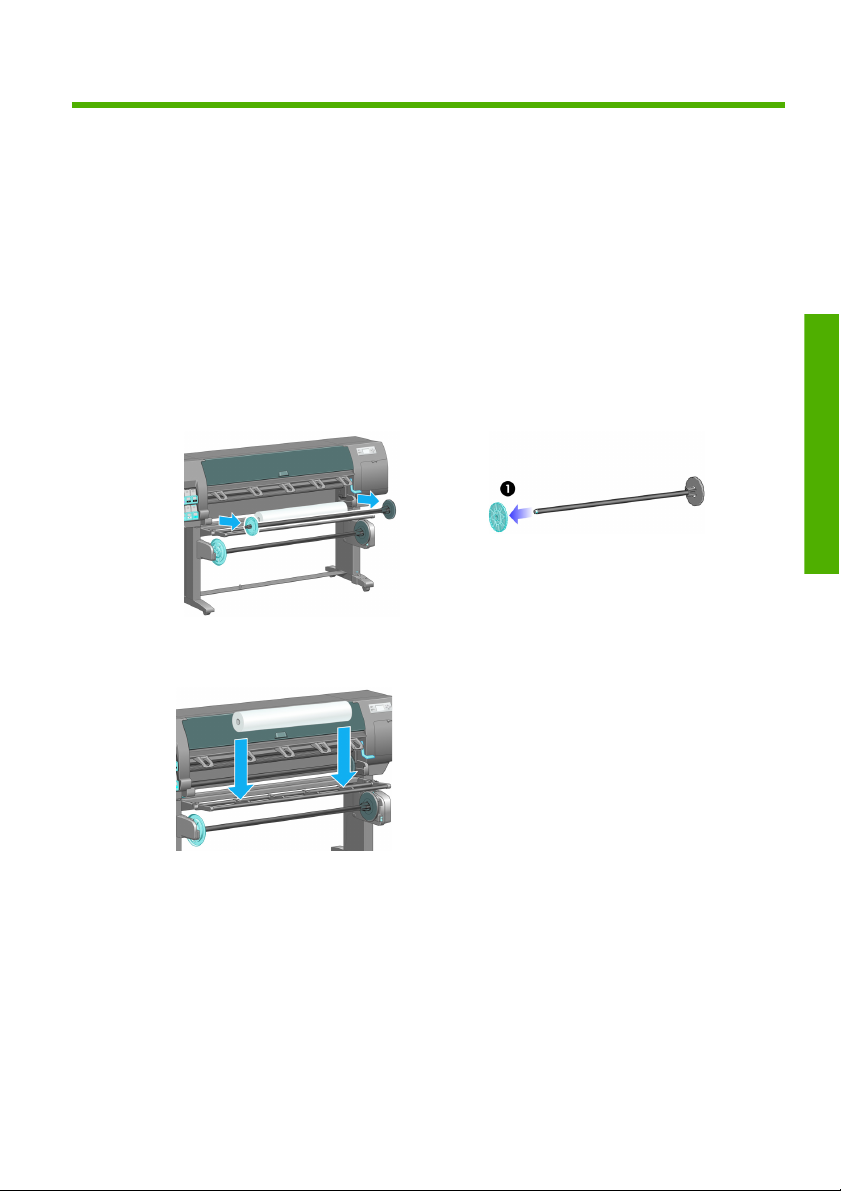

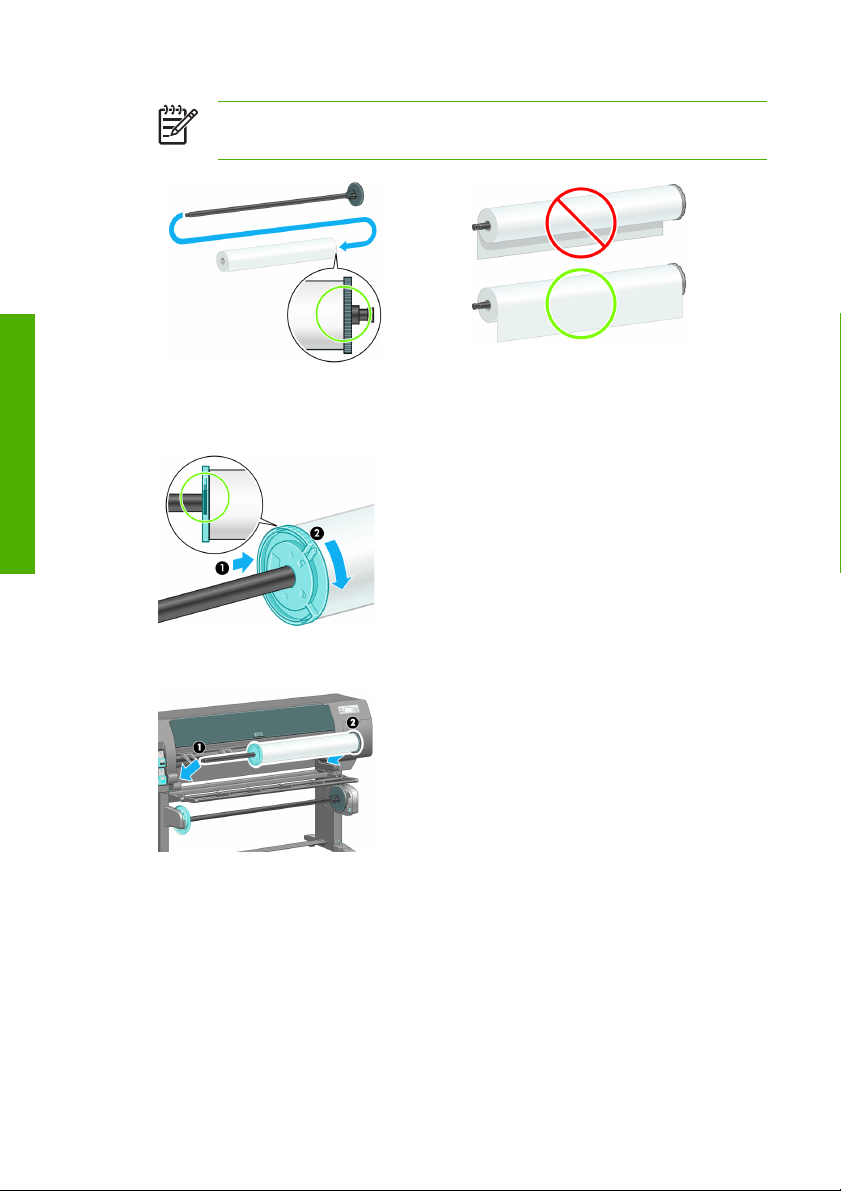

Load a roll onto the spindle

Make sure that the printer wheels are locked (the brake lever is pressed down)

1.

to prevent the printer from moving.

Remove the first end of the spindle from the right side of the printer, and then

2.

move the spindle to the right in order to extract the other end. Do not insert your

fingers into the spindle supports during the removal process.

The spindle has a hub at each end to keep the roll in position. Remove the blue

hub at the left end to mount a new roll. The hub slides along the spindle to hold

rolls of different widths.

Slide the lever-lock on the blue spindle hub to the unlocked position and remove

the hub (1) from the left end of the spindle.

Rest the roll of paper that you want to load on the take-up reel deflector. The

3.

roll might be long and heavy, and you might need two people to handle it.

Handle the paper

Slide the spindle into the roll. Make sure that no space exists between the roll

4.

and the fixed hub at the right end of the spindle.

Make sure that the paper will wind off the roll in the correct direction. If it does

not, remove the spindle from the roll, turn the roll 180° and rest it on the

deflector. Then slide the spindle into the roll.

Load a roll onto the spindle

9

Page 18

NOTE: A label on the spindle also shows the correct winding

direction.

Handle the paper

Put the blue hub on to the upper end of the spindle, and push it towards the end

5.

of the roll as shown in step 1 in the following image. Then slide the lever-lock

to the locked position as shown in step 2.

With the blue hub on the left, insert the spindle into the left side of the printer

6.

(1), and then into the right side of the printer (2).

If you regularly use different paper types, you can change rolls more quickly if you

pre-load rolls of different paper types on different spindles. Extra spindles are

available for purchase.

10 Chapter 2 Handle the paper

Page 19

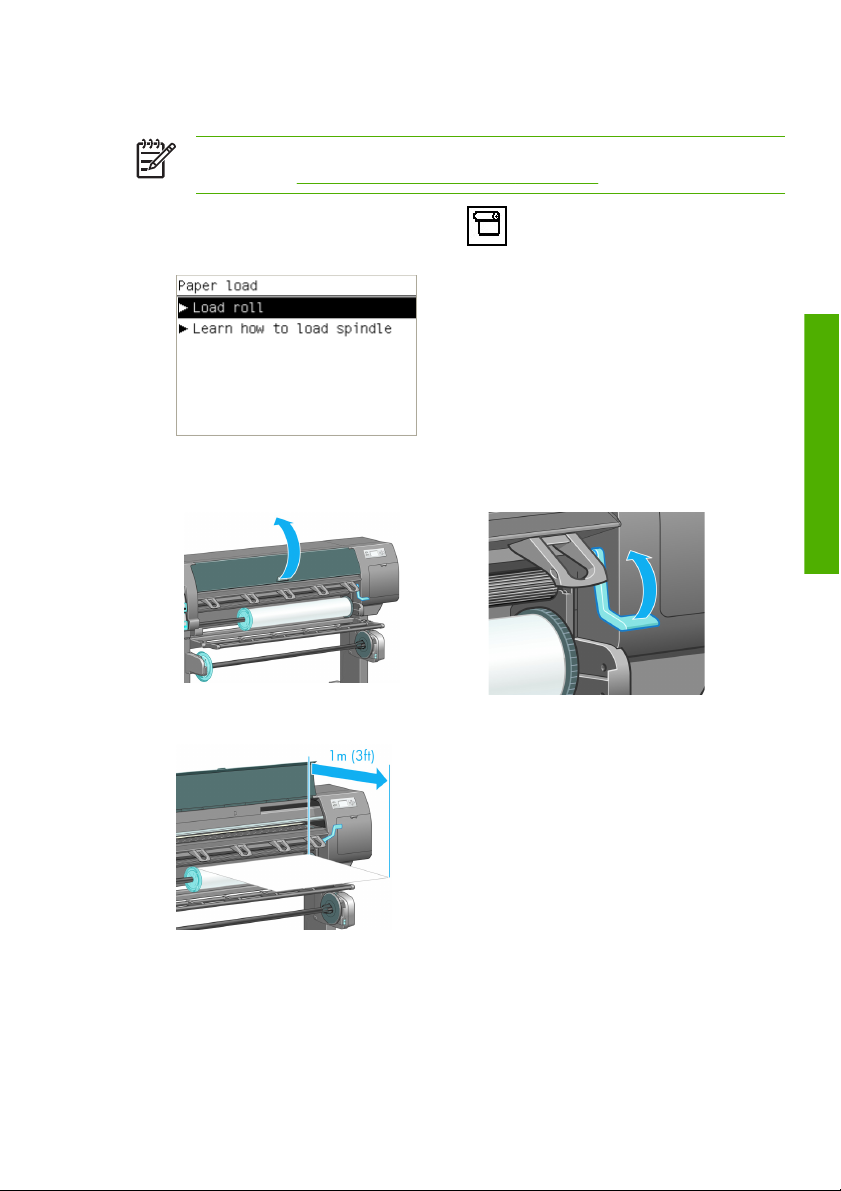

Load a roll into the printer

NOTE: To start this procedure, you need to have a roll loaded on the

spindle. See

1.

At the printer's front panel, select the

> Load roll.

Wait until the front panel prompts you to open the printer window.

2.

After you have opened the printer window, lift the paper-load lever.

Pull out approximately 1 m (3 feet) of paper.

3.

Load a roll onto the spindle on page 9.

icon, and then select Paper load

Handle the paper

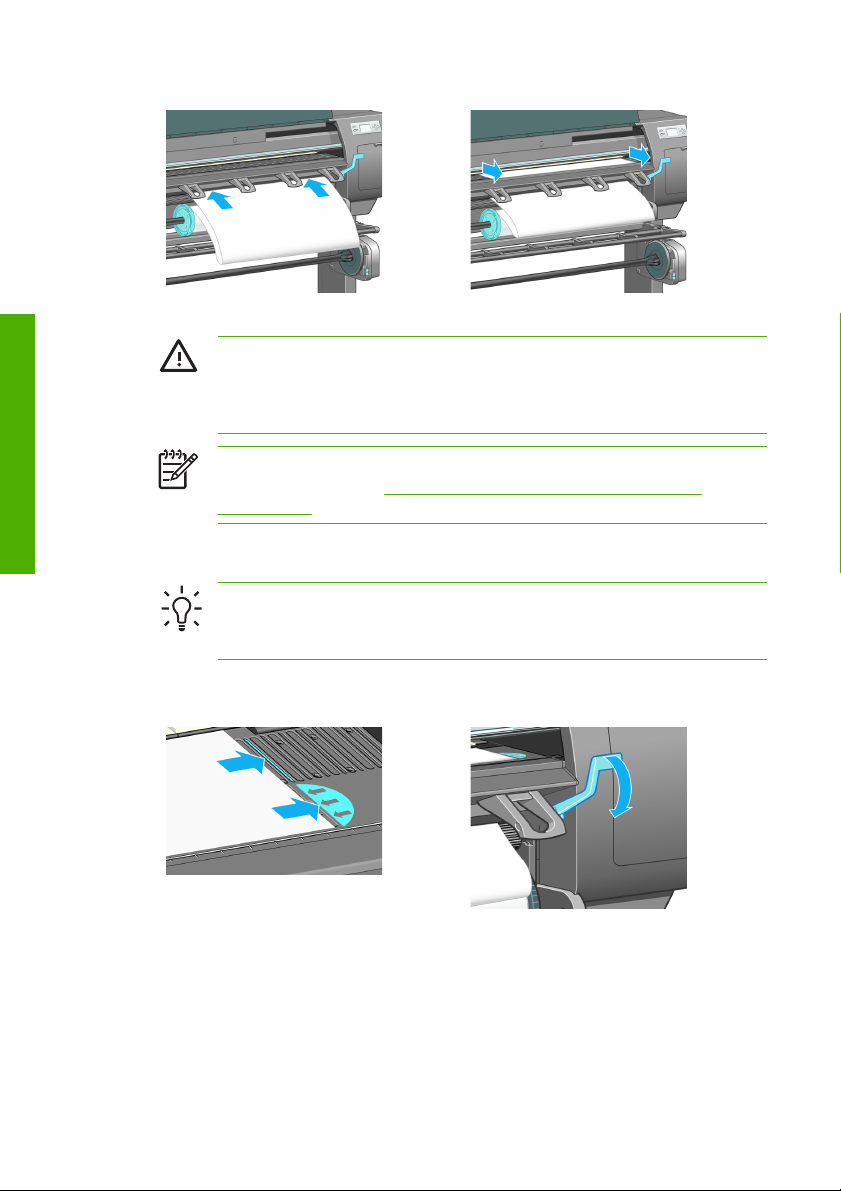

Carefully insert the leading edge of the roll above the black-ribbed roller.

4.

Wait until the paper emerges from the printer.

Load a roll into the printer

11

Page 20

Handle the paper

WARNING! Take care not to touch the rubber wheels on the platen

while loading paper. These wheels can rotate and trap skin, hair, or

clothing. Take care not to push your fingers inside the printer's paper

path.

NOTE: If you have an unexpected problem at any stage of the paper

loading process, see

The paper cannot be loaded successfully

on page 69.

Align the edge of the paper with the blue line and the left edge of the semi-circle

5.

to the right of the platen.

TIP: It may be helpful to also align the lead edge of the paper with

the front edge of the platen. You can use a blade or scissors to improve

the lead edge of the paper if it is not straight or is not cut well.

When the paper is correctly aligned with the blue line and half-circle, lower the

paper-load lever.

Wait for the front-panel message that prompts you to wind excess paper onto

6.

the roll.

Wind the excess paper onto the roll. Use the hub to turn the roll in the direction

shown.

12 Chapter 2 Handle the paper

Page 21

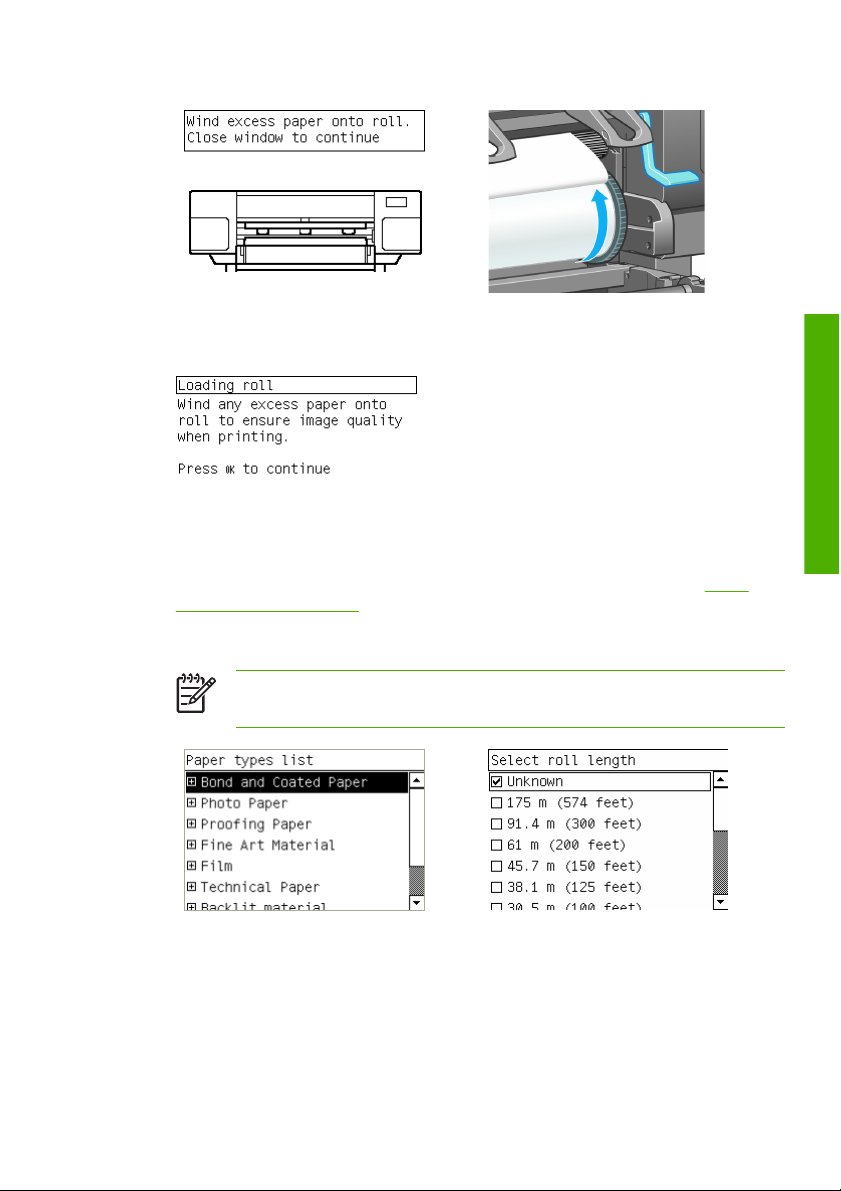

Lower the printer window.

7.

Wait for the front panel to again prompt you to wind excess paper onto the roll.

8.

The printer will perform a color calibration if it has not already calibrated the

9.

paper type you are using, and if color calibration is turned on. See

calibration on page 49.

Select the paper category and paper type of the roll you are loading. Then select

10.

the length of the roll you are loading.

NOTE: If it is not clear which paper category or paper type to select,

see the Supported paper types section in the HP Start-up Kit CD/DVD.

Handle the paper

Color

Load a roll into the printer

13

Page 22

NOTE: If the paper that you are using has a paper-data barcode

printed on the leading edge of the roll, the paper information is

automatically loaded into the printer.

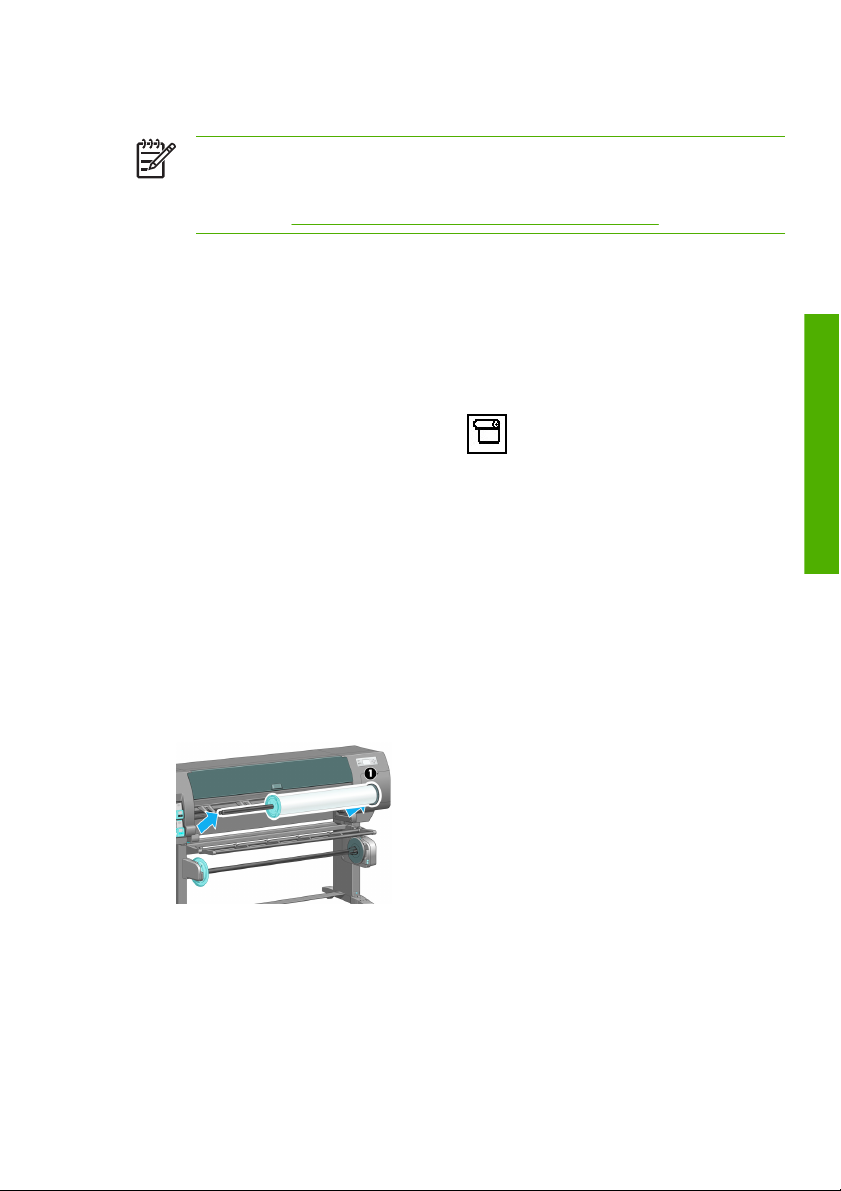

If you have a take-up reel (a standard feature on the 60–in printer and an

11.

optional accessory on the 42–in printer) and it is enabled, you will see the “Takeup reel enabled” message on the front-panel Paper tab. In this case, a message

will appear on the front panel asking if you want to load paper into the reel. If

Handle the paper

you select No (or if you do not have a take-up reel) the front panel displays

the Ready message and the printer is ready to print. If you select Yes, a

message will appear on the front panel asking if you want to load the take-up

reel now or during printing.

● If you want to load the take-up reel now, select Load take-up reel

now, read through the introductory text in the section Use the take-up

reel on page 16, and then continue to step 3 of the procedure.

●

If you want to load the take-up reel during printing, select Load it during

printing, read through the introductory text in the section

Use the take-up

reel on page 16, and then continue to step 3 of the procedure.

NOTE: Familiarize yourself with the procedural steps, because

loading the take-up reel while printing requires you to complete the

procedure while the printer is feeding and printing paper. Loading

the take-up reel during printing saves approximately 1 m (3 feet)

of paper.

If the take-up reel is not enabled and you would like to enable it, select the

icon, and then select Take up reel > Enable.

NOTE: During the initial printer set up, printhead alignment and color

calibration is performed automatically after the roll is loaded into the printer.

14 Chapter 2 Handle the paper

Page 23

Unload a roll from the printer

NOTE: If you used the take-up reel (a standard feature on the 60–in printer

and an optional accessory on the 42–in printer) during printing, unload the

printed roll from the take-up reel before attempting to remove the roll from the

printer. See

Initiate the procedure for unloading a roll from the printer the front panel or by lifting

the paper-load lever. In either case, a front-panel animation guides you through the

remainder of the procedure.

Before unloading a roll, check whether the end of the roll is still attached to the

spindle, and follow the appropriate procedure as described in the following sections.

The normal procedure (roll attached to spindle)

If the end of the roll is still attached to the spindle, use the following procedure.

1.

At the printer's front panel, select the

paper.

The paper is ejected from the printer.

2.

If for some reason the paper is not automatically ejected from the printer, the

front-panel display prompts you to lift the paper-load lever and wind the roll by

hand until the paper leaves the printer. When you have finished, lower the

paper-load lever.

Turn the hub by hand, until the paper is fully wound onto the roll.

3.

Press the OK button.

4.

Remove the roll from the printer, pulling out the right end on the right side of the

5.

printer first. Do not insert your fingers into the spindle supports during the

removal process.

Unload a roll from the take-up reel on page 22.

icon, and then select Unload

Handle the paper

Unload a roll from the printer

15

Page 24

Roll is detached from spindle

Use the following procedure if the end of the roll is visible but no longer attached to

the spindle:

1. If you have already selected Paper unload at the front panel, press the

Cancel button to cancel that procedure.

Lift the paper-load lever. If the front panel shows a warning about the lever,

2.

ignore it.

Pull out the paper from the front of the printer.

3.

Remove the empty spindle from the printer, pulling out the end on the right side

4.

Handle the paper

of the printer first. Do not insert your fingers into the spindle supports during the

removal process.

Lower the paper-load lever.

5.

If the front panel shows a warning message, press the OK button to clear it.

6.

No paper visible

Use this procedure if the end of the roll has entirely disappeared into the printer:

Press the Form Feed and Cut button on the front panel to eject the remaining

1.

paper.

Remove the empty spindle from the printer, pulling out the end on the right side

2.

of the printer first. Do not insert your fingers into the spindle supports during the

removal process.

Use the take-up reel

CAUTION: Make sure the printer is turned off when installing the take-up

reel motor on the printer.

The take-up reel must be enabled and operated from the front panel. When the takeup reel is enabled, the “Take-up reel enabled” message appears on the Paper tab

on the front panel. If the take-up reel is not enabled and you would like to enable it,

select the

Follow these guidelines when taping rolls to the take-up reel spindle core:

Make sure that the paper is straight when it is attached to the spindle core.

●

Otherwise it skews as it winds onto the core.

The spindle core on the take-up reel must be the same width as the paper that

●

you are using.

16 Chapter 2 Handle the paper

icon and then select Take up reel > Enable.

Page 25

Check that neither side of the spindle core has end caps, and make sure the

●

spindle core is pushed firmly into both spindle guides.

If you are using a HP Designjet Z6100 42–in Printer, make sure that the bin

●

loop is placed behind the foot brace so that it does not block the take-up reel

sensors.

NOTE: If you want to load the take-up reel during printing, familiarize

yourself with the procedural steps. Loading the take-up reel during printing

requires you to complete the procedure while the printer is feeding and

printing paper. Loading the take-up reel during printing saves approximately

1 m (3 feet) of paper.

Attach a roll to the take-up reel

1.

On the printer's front panel, select the

reel > Load take-up reel.

2. If you want to load the take-up reel now, select Load take-up reel now on

the front panel. If you want to load the take-up reel during printing, select Load

it during printing on the front panel.

icon, and then select Take-up

Handle the paper

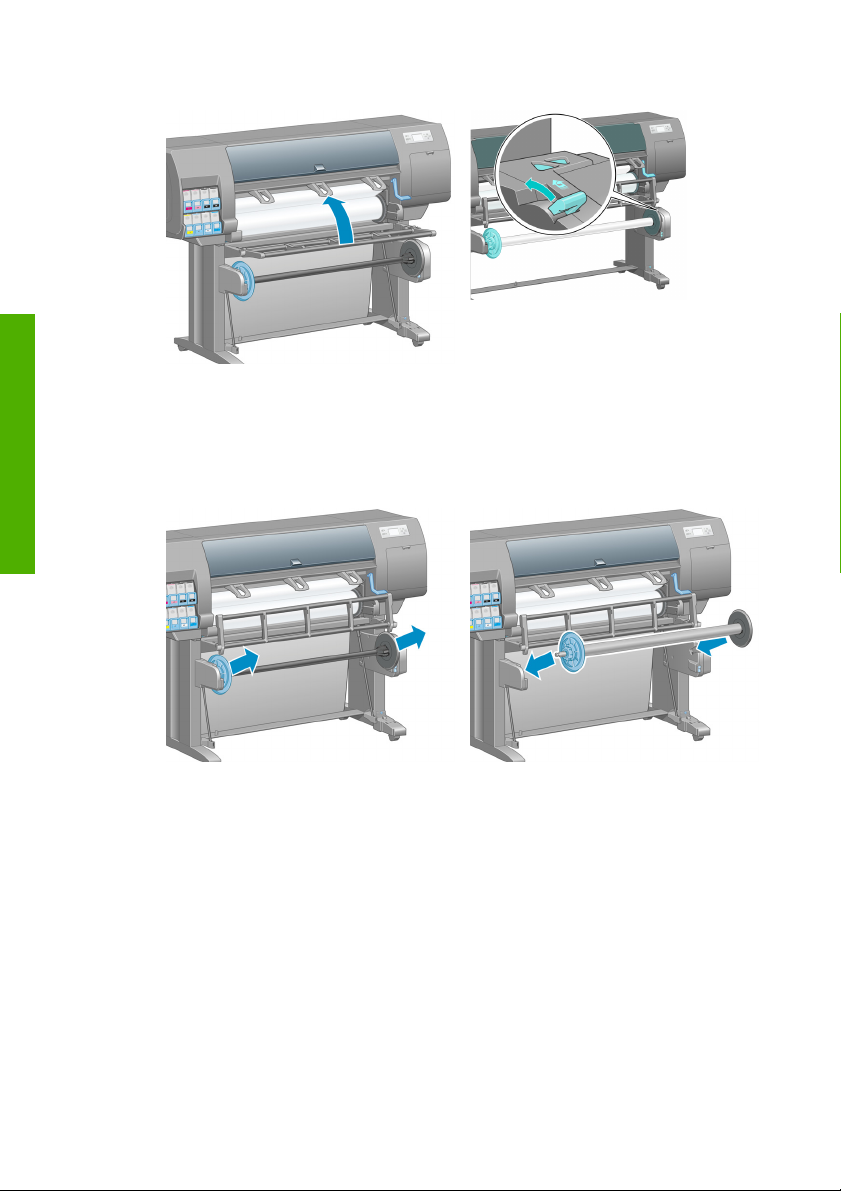

Make sure that the take-up reel deflector is in its upright position.

3.

Unlock the take-up reel spindle by pushing the spindle lever to its uppermost

position.

Use the take-up reel

17

Page 26

Handle the paper

Remove the take-up reel spindle.

4.

The front-panel display guides you through the process of loading the take-up

reel spindle core onto the take-up reel spindle. When that task is complete, load

the take-up reel spindle into the printer by pushing firmly on both ends of the

spindle.

Press the OK button on the front panel.

5.

The printer advances the paper. Make sure that the paper passes in front of the

take-up reel deflector.

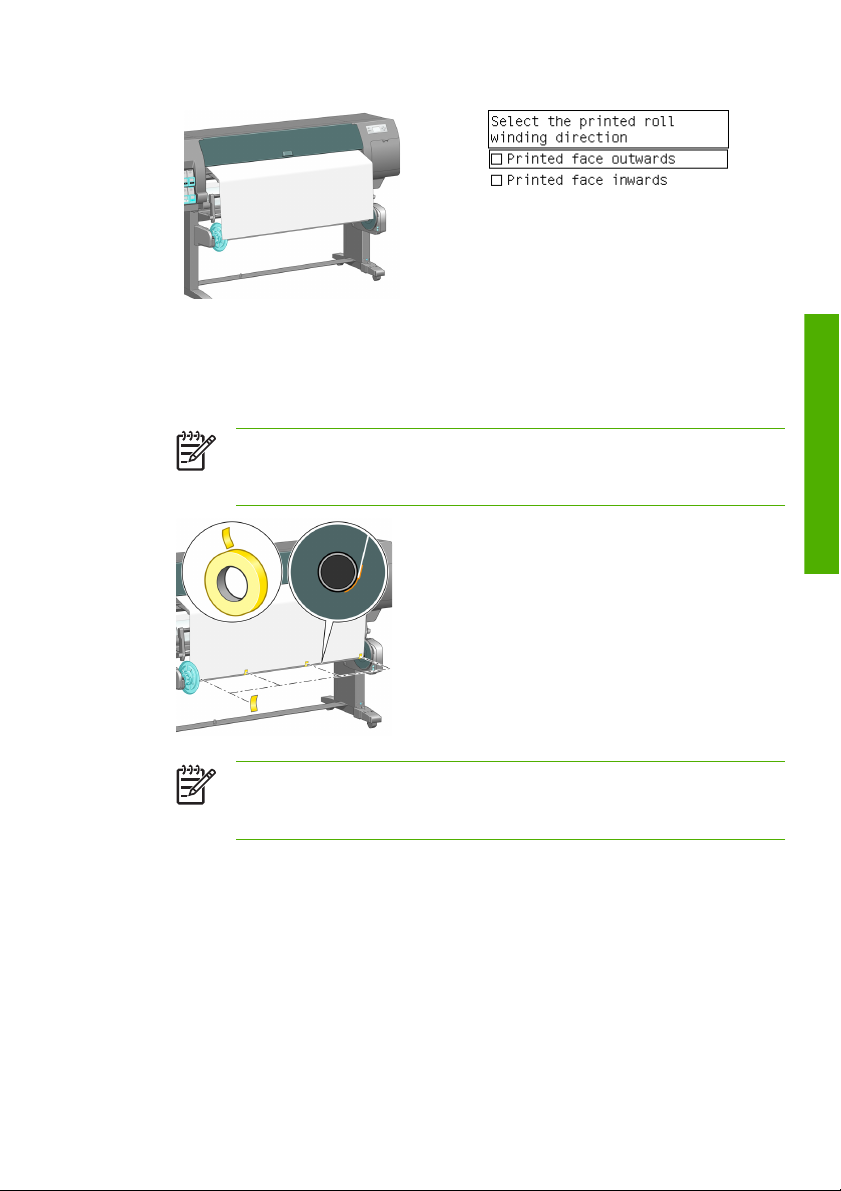

On the front panel, select a winding direction.

18 Chapter 2 Handle the paper

Page 27

Pull the paper taut to the take-up reel spindle core. Do not attempt to pull more

6.

paper out of the printer. Use tape to secure the paper to the spindle core. You

might need to use more tape than is shown in the following image. The paper

should be secure enough to support the weight of the loop-shaping core, which

you insert in step 10.

NOTE: If you are loading the take-up reel during printing you do not

need to pull the paper taut. Tape the paper to the spindle core when an

adequate length of paper has fed from the printer after printing begins.

NOTE: To avoid having the paper skew as it winds onto the spindle

core, make sure the paper is straight when you attach it. It is sometimes

useful to use the core grooves to align the paper.

Handle the paper

Use the take-up reel

19

Page 28

Use the wind-direction switch on the take-up reel motor to select the winding

7.

direction. Setting 1 winds the paper so that the printed image faces in.

Setting 2 winds the paper so that the printed image faces out.

The front panel shows you to the correct setting based on the winding-direction

decision you made in step 5.

Handle the paper

Gently lower the take-up reel deflector, and then press the OK button on the

8.

front panel. The printer advances the paper.

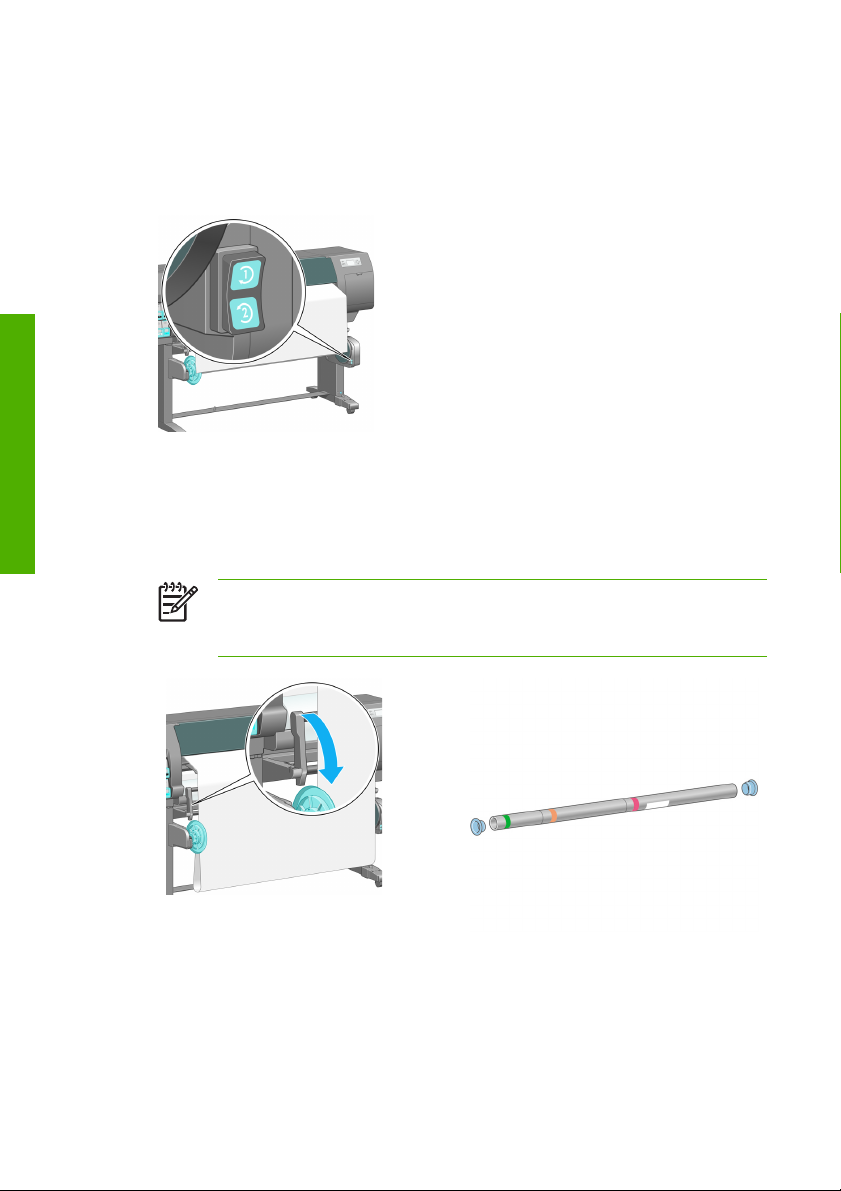

Assemble a loop-shaping core by matching the shape-coded and color-coded

lengths of plastic tubing. The loop-shaping core must be the same width as the

paper that you are using. Make sure that both end caps are firmly fitted on the

ends of the loop-shaping core.

NOTE: The front-panel display shows the required length of the loop-

shaping core based on the width of the roll that you have loaded into

the printer.

20 Chapter 2 Handle the paper

Page 29

Press the OK button on the front panel. The printer advances the paper.

9.

NOTE: Make sure that you insert the loop-shaping core. The take-up

reel will not function correctly without it. The loop-shaping core must

have end caps. Make sure that the end caps extend over the edges of

the paper.

Carefully insert the loop-shaping core, and the press the OK button on the front

10.

panel. The Ready message appears.

NOTE: You are not required to press the OK button if you are loading

the take-up reel during printing.

NOTE: Make sure the loop-shaping is inserted. The take-up reel will

not function correctly without it. The loop-shaping core must have end

caps. Make sure that the end caps extend over the edges of the paper.

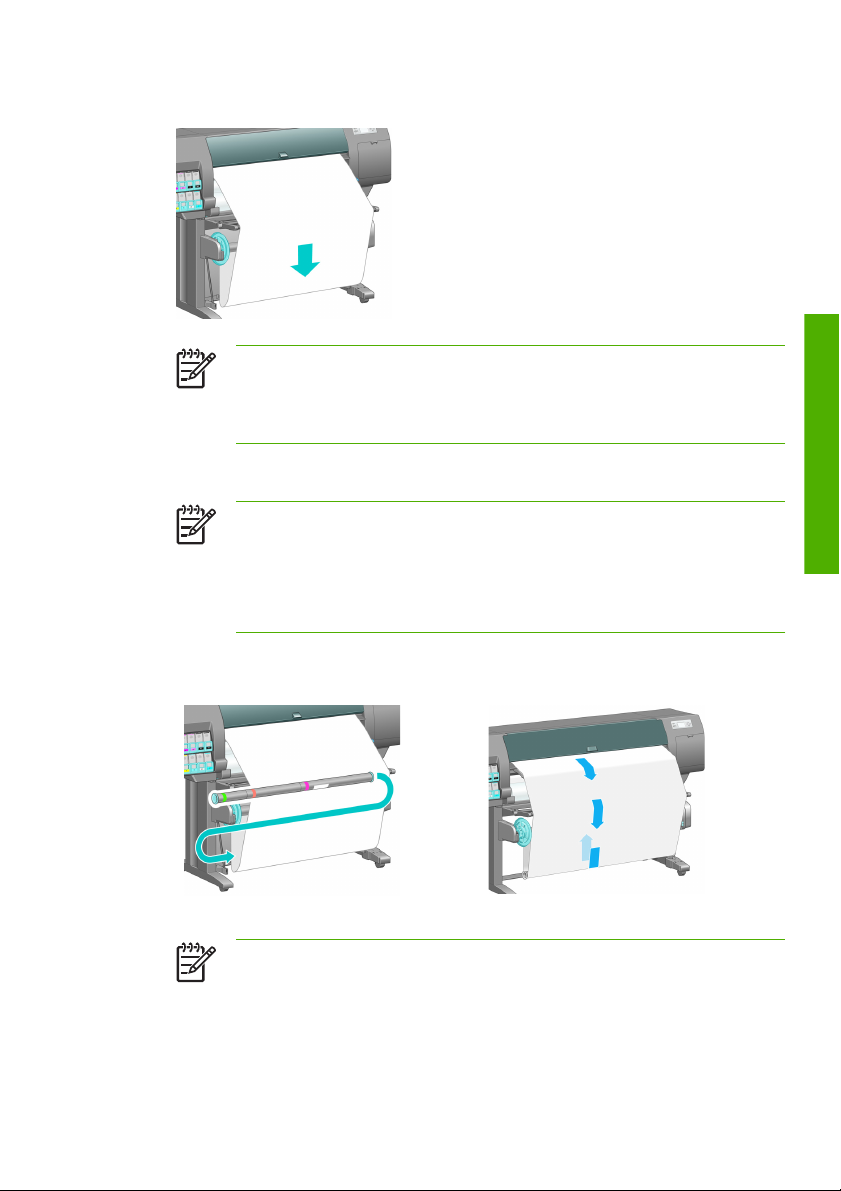

When the printer is printing and the take-up reel is operating, the paper is fed

from the printer, drops down in a loop, and then up into the take-up reel spindle.

Handle the paper

NOTE: While the take-up reel is operating, make sure that the take-

up reel sensors are not blocked.

Use the take-up reel

21

Page 30

NOTE: The automatic paper-cutter is disabled when the take-up reel

is in use.

Unload a roll from the take-up reel

1.

At the printer's front panel, select the

Unload roll.

The printer advances the paper to allow for cutting.

Lift the take-up reel deflector to its upright position.

2.

Switch the wind-direction switch to the Off position. The switch is in the off

Handle the paper

position when it is centered (in other words, when the switch is neither in position

1 nor position 2).

Remove the loop-shaping core.

3.

Use the winding button on the take-up reel motor to wind the excess paper

around the take-up reel spindle.

icon, then Paper unload >

Press the OK button on the front panel.

4.

The printer knows if the type of paper that is loaded is suitable for the automatic

5.

paper-cutter. The paper is cut if it is suitable. If the paper is not suitable, cut the

paper manually.

22 Chapter 2 Handle the paper

Page 31

NOTE: The automatic paper-cutter feature is disabled for some of the

heaviest media types, because they can damage the cutter.

Use the winding button on the take-up reel motor to wind the remainder of the

paper around the take-up reel spindle.

Press the OK button on the front panel.

6.

The amount of printed paper that is on the take-up reel spindle appears on the

front panel.

Unlock the take-up reel spindle by pushing the spindle lever to its uppermost

7.

position.

Remove the roll from the printer, pulling out the end on the right side of the

printer first. Do not insert your fingers into the spindle supports during the

removal process.

Handle the paper

To remove the roll from the printer after you have unloaded the take-up reel,

8.

Unload a roll from the printer on page 15.

see

View information about the paper

On the printer's front panel, select the icon, and then select View loaded

paper > View paper details.

View information about the paper

23

Page 32

The following information appears on the front panel:

The roll status

●

The paper type you have selected

●

The width of the paper in millimeters (estimated by the printer)

●

The length of the paper in millimeters (estimated by the printer)

●

If no paper is loaded, the message Out of paper appears.

The same information appears on the Embedded Web Server's Supplies page.

Perform paper advance calibration

The printer is calibrated to advance correctly when printing all the papers that appear

Handle the paper

on the front panel. When you select the type of loaded paper, the printer adjusts the

rate at which it advances the paper while printing. However, to fine-tune the image

quality of your print, you might need to calibrate the rate at which the paper

advances. See

paper-advance calibration is the solution for your issue.

Accurate paper advance controls proper placement of dots on the paper. If the paper

is not advanced correctly, light or dark bands appear in the printed image and the

grain in the image might increase.

Troubleshoot print-quality issues on page 57 to determine whether

To check the paper advance calibration status of the paper, select the

then select View loaded paper > View paper details. The status appears:

●

DEFAULT: this status appears when an HP paper is loaded. Unless you

experience image-quality problems in your printed image, such as banding or

graininess, HP recommends that you do not calibrate the paper advance.

●

RECOMMENDED: this status appears when you create a new paper. The

paper advance values for this paper are inherited from the family type. HP

recommends that you perform a paper advance calibration to optimize the

values.

●

OK: this status indicates that the loaded paper has been calibrated previously.

However, you might need to repeat the calibration if you experience imagequality problems, such as banding or graininess in your printed image.

NOTE: Whenever you update the printer firmware, the paper-

advance calibration values are reset to the factory default.

NOTE: Colored papers, glossy canvas, and transparent materials

such as translucent bond, clear film, natural tracing paper, and vellum

are not suitable for paper-advance calibration.

24 Chapter 2 Handle the paper

icon, and

Page 33

Overview of the paper advance procedure

1.

On the front panel, select the

maintenance > Paper advance calibration > Calibrate paper

advance. The printer automatically calibrates the paper-advance and prints a

paper advance calibration image.

Wait until the front panel shows the status screen, and then reprint your image.

2.

NOTE: The calibration procedure takes approximately six minutes.

The front-panel display shows any errors in the process.

If you are satisfied with your image, continue using this calibration for your

paper type. If you see improvement in your image, continue with step 3. If you

are dissatisfied with the calibration, return to the default calibration. See

to default calibration on page 25.

3.

To fine-tune the calibration, select the

quality maintenance > Paper advance calibration > Adjust paper

advance.

Select the percentage of change from -100% to 100%. To correct light banding,

4.

decrease the percentage. To correct dark banding, increase the percentage.

Press the OK button on the front panel to save the value.

5.

Wait until the front panel shows the status screen, and then reprint your image.

6.

icon, and then select Image quality

icon, and then select Image

Return to default calibration

Returning to the default calibration sets all the paper-advance calibration to zero. To

return to the default paper advance-calibration value, you must reset the calibration.

1.

On the front panel, select the

maintenance > Paper advance calibration > Reset paper

advance.

Wait until the front panel shows that the operation has been successfully

2.

completed before you press the Back button to return to the Ready screen.

icon, and then select Image quality

Return

Handle the paper

Download paper profiles

Each supported paper type has its own characteristics. The printer changes the way

it prints on each different paper type. For example, some might need more ink and

some might require a longer drying time. The printer requires a description of the

requirements of each paper type. This description is called the “paper profile”.

Download paper profiles

25

Page 34

The paper profile contains the ICC profile, which describes the color characteristics

of the paper. It also contains information about other characteristics and requirements

of the paper that are not directly related to color. Existing paper profiles for your

printer are installed in the printer's software.

Your printer contains paper profiles for only the most commonly used paper types. If

you buy a paper type for which your printer has no profile, you cannot select that

paper type in the front panel.

You can assign a profile for a new paper type in three ways:

Use a HP factory paper profile by selecting the closest category and type on the

●

front panel, in HP Easy Printer Care (Windows), or in HP Printer Utility (Mac

OS)

Handle the paper

NOTE: Because colors might not be accurate, this method is not

recommended for high-quality prints.

●

http://www.hp.com/go/designjet/downloads and click the HP

Go to

Designjet ICC/Media profiles and PANTONE tables link. Select from

the HP Designjet media profiles drop-down menu.

NOTE: HP only provides profiles for HP paper types. If you do not

find the paper profile that you want on the Web, it might have been

added to the latest firmware for your printer. Check the firmware release

notes for information.

Add a custom paper type and create an ICC profile for either HP or non-HP

●

papers.

26 Chapter 2 Handle the paper

Page 35

3

Handle the ink system

Remove an ink cartridge

CAUTION: The procedure to remove an ink cartridge must be initiated

from the front panel. Do not remove an ink cartridge until the front panel

prompts you.

Ink cartridges should be removed for the following two reasons:

The ink cartridge is very low and you want to replace it with a full cartridge for

●

unattended printing. You can use the remaining ink in the first cartridge at a

more convenient time.

The ink cartridge is empty or faulty, and you must replace it to continue printing.

●

CAUTION: Do not try to remove an ink cartridge while printing.

CAUTION: Remove an ink cartridge only if you are ready to insert another

one.

WARNING! Make sure that the printer wheels are locked (the brake lever

is pressed down) to prevent the printer from moving.

1.

At the printer's front panel, select the

cartridges.

Grip the blue tab in front of the cartridge that you want to remove.

icon, and then select Replace ink

Remove an ink cartridge

Handle the ink

27

Page 36

Handle the ink

Pull the blue tab down and then pull it outwards, towards you.

2.

The cartridge comes out, in its drawer.

Lift the cartridge out of its drawer.

3.

The front-panel display identifies the missing ink cartridge.

NOTE: Avoid touching the end of the cartridge that is inserted into the

printer, because the connection might be coated with ink.

NOTE: If necessary, store a partially-used ink cartridge in the same

position as if it were inserted in the printer. Avoid using a partially-used

cartridge that has been stored on its end.

28 Chapter 3 Handle the ink system

Page 37

Insert an ink cartridge

Pick up the new ink cartridge and find the label that identifies the ink color. Hold

1.

the ink cartridge so that you can see the label at the top of the side that is facing

you.

Check that the colored label above the empty slot in the printer matches the

2.

color of the label on the cartridge.

Shake the cartridge vigorously for about 15 seconds.

3.

Insert the ink cartridge into the cartridge drawer.

4.

Slide the drawer and cartridge into the slot until they lock into position. If you

have difficulty, see Cannot insert an ink cartridge in Using your printer.

The front-panel display confirms that all cartridges have been correctly inserted.

5.

Remove a printhead

WARNING! Make sure that the printer wheels are locked (the brake lever

is pressed down) to prevent the printer from moving.

Insert an ink cartridge

Handle the ink

29

Page 38

Handle the ink

Printhead replacement must be performed after the printer has been turned on at the

hard power switch.

1.

At the printer's front panel, select the

icon, and then select Replace

printheads.

The printer moves the carriage into the correct position.

2.

CAUTION: If the carriage remains in the removal position for more

than 3 minutes without inserting or removing any printheads, it will

attempt to return back to its home position to the right.

When the carriage has stopped moving, the front panel prompts you to open

3.

the printer window.

Locate the carriage on the right side of the printer.

4.

Pull up and release the latch on top of the carriage.

30 Chapter 3 Handle the ink system

Page 39

Lift up the cover. This provides access to the printheads.

5.

To remove a printhead, lift up the blue handle.

6.

Using the blue handle, gently disengage the printhead.

Gently pull the blue handle upward until the printhead is released from the

7.

carriage.

CAUTION: Do not pull abruptly. That action can damage the

printhead.

The front-panel display identifies the missing printhead.

Remove a printhead

Handle the ink

31

Page 40

Insert a printhead

If the printhead is new, shake it vigorously before removing the protective caps.

1.

Hold the printhead upright (with the protective caps facing down) and shake

the printhead vigorously in a smooth up and down motion for about 15 seconds.

Remove the orange protective caps by pulling them down.

The printhead is designed to prevent you from accidentally inserting it into the

Handle the ink

2.

wrong slot. Check that the colored label on the printhead matches the colored

label of the carriage slot into which the printhead is to be inserted.

Insert the new printhead into its correct slot in the carriage.

3.

NOTE: Be careful not to strike the printhead against anything while

shaking it, because this could cause damage.

CAUTION: Insert the printhead slowly and vertically, straight down.

It can be damaged if you insert it too quickly, or at an angle, or if you

rotate it as you insert it.

Push down as indicated by the arrow.

CAUTION: You might feel some resistance when installing the new

printhead, so you need to press it down firmly but smoothly. You should

hear a beep and see confirmation on the front-panel display that the

printhead has been inserted. If you have difficulty, see Cannot insert a

printhead in Using your printer.

32 Chapter 3 Handle the ink system

Page 41

Insert all of the other printheads that need to be installed, and close the carriage

4.

cover.

Make sure that the end of the blue handle catches the wire loop on the near

side of the carriage.

Lower the handle to rest on the carriage cover.

5.

When all of the printheads have been inserted correctly and the printer has

accepted them, the printer beeps.

Handle the ink

NOTE: If the printer does not beep when you insert the printhead and

the Replace message appears on the front-panel display, you might

need to reinsert the printhead.

Insert a printhead

33

Page 42

Close the printer window.

6.

The front-panel display confirms that all of the printheads are correctly inserted.

7.

The printer starts checking and preparing the printheads. The default routine

process, when all printheads are changed, takes about 18 minutes. If the printer

identifies a problem when preparing the printheads, the process takes longer,

up to 30 minutes. For a single printhead insertion, the time varies between 10

and 20 minutes. After all printheads are checked and prepared, the printhead

realignment procedure runs automatically if paper is loaded. See

printheads on page 34.

Align the printheads

The printer performs printhead alignment whenever printheads are replaced. If no

paper is loaded when a printhead is replaced, the printer will perform the alignment

the next time you load paper.

Also align the printheads if the Printhead status plot indicates an alignment error.

Use the Printhead status plot on page 35.

See

Make sure that you have a roll of opaque, white paper loaded in the printer.

1.

Colored papers, glossy canvas, and transparent materials such as translucent

bond, clear film, tracing paper, and vellum are not suitable for printhead

alignment.

Handle the ink

Align the

34 Chapter 3 Handle the ink system

Page 43

To request printhead alignment (if the alignment is not being performed

2.

automatically), go to the front panel, select the

Image quality maintenance > Align printheads.

The process takes about 10 minutes and starts immediately, unless an image is

currently being printed. If a print job is in process, the alignment will be done

as soon as the current print job is finished.

NOTE: Occasionally, if the paper in the printer is very close to the

beginning of a roll, the front panel might report that the printer needs to

feed up to 3 m (≈ 10 ft) of paper before starting the printhead

alignment. This is necessary to ensure a successful alignment. You can

continue with the printhead alignment and allow the printer to feed as

much paper as necessary, delay the alignment until later, or cancel the

alignment.

Use the Printhead status plot

The Printhead status plot consists of patterns that are designed to highlight printheadreliability problems. It helps you to check the performance of the printheads that are

currently installed in your printer, and to determine whether any printhead is

experiencing clogging or other problems.

Print the Printhead status plot

To print the Printhead status plot:

Use the same paper type that you were using when you detected a problem.

1.

Verify that the selected paper type is the same as the paper type that is loaded

2.

into the printer.

3.

On the printer's front panel, select the

quality maintenance > Printhead diagnostics image.

It takes about 2 minutes to print the Printhead status plot.

icon, and then select

Handle the ink

icon, and then select Image

Use the Printhead status plot

35

Page 44

Interpret the Printhead status plot

The print is divided into two parts, both of which test printhead performance.

Part 1 (top) consists of rectangles of pure colors, one for each printhead. This

●

part represents the print quality that you will get from each color.

Part 2 (bottom) consists of small dashes, one for each nozzle on each printhead.

●

This part complements the first, and detects how many faulty nozzles are on

each printhead.

First look at the top part of the print. Each colored rectangle should be a uniform

color without any horizontal lines across it.

Then look at the bottom part of the print. For each individual colored pattern, make

sure that most of the dashes are present.

If you see horizontal lines in the top part and also see missing dashes in the bottom

Handle the ink

part for the same color, the printhead for that color needs to be cleaned. However,

if the rectangles look solid, do not worry about a few missing dashes in the bottom

part, because the printer can compensate for a few clogged nozzles.

The graphic shown illustrates printhead 2 in a bad state:

36 Chapter 3 Handle the ink system

Page 45

Corrective action

Clean any faulty printheads. See

1.

reprint the Printhead status plot to see whether the problem has been solved.

If the problem persists, clean the printheads again, and reprint the Printhead

2.

status plot to see whether the problem has been solved.

If the problem persists, consider cleaning your printheads manually. See

3.

the printheads on page 74. Also try reprinting your current print job, in case

it now prints satisfactorily.

If the problem continues to persist, replace any persistently faulty printheads.

4.

What to do if problems persist

If you still experience print-quality problems after applying the advice in this chapter,

here are some additional tips to consider:

Try using a higher print-quality option. See

●

Check the driver you are using to print with. If it is a non-HP driver, consult the

●

driver vendor about the problem. You could also try using the correct HP driver,

if that workaround is acceptable to you. Download the latest HP drivers from

http://www.hp.com/go/designjet/.

If you are using a non-HP raster image processing (RIP), its settings might be

●

incorrect. See the documentation that came with the RIP.

Verify that your printer firmware is up to date.

●

Clean the printheads on page 74. Then

Clean

Handle the ink

Select print quality on page 41.

Use the Printhead status plot

37

Page 46

Verify that you have the correct settings in your software program.

●

Contact HP Support.

●

Remove the maintenance cartridge

A message appears on the front panel when you must change the maintenance

cartridge. Follow these precautions when removing a maintenance cartridge:

Be careful not to get ink on your hands. Ink might be on, around, and inside the

●

replaced maintenance cartridge.

Always handle and store the replaced maintenance cartridge upright to avoid

●

spilling any ink.

CAUTION: A message appears on the front panel when the maintenance

cartridge is almost full and again when it is completely full and must be

changed. You can ignore the alert and continue printing by pressing the OK

button on the front panel. However, HP strongly recommends that you change

the maintenance cartridge when prompted. Ignoring the alert can result in

serious damage to the printer.

WARNING! Make sure that the printer wheels are locked (the brake lever

is pressed down) to prevent the printer from moving.

1.

On the printer's front panel, select the

maintenance ctg.

Handle the ink

The maintenance cartridge is located in a slot underneath the front panel, at the

front of the printer. Open the door.

icon, and then select Replace

The maintenance cartridge has a handle on the front. To remove the cartridge,

2.

press inward and upward as indicated by the arrow, until the cartridge is

released.

Lift up the maintenance cartridge to remove it from the slot, and slide it out.

38 Chapter 3 Handle the ink system

Page 47

Insert the maintenance cartridge

The plastic bag in which the new maintenance cartridge comes can be used to

dispose of the old maintenance cartridge.

Insert the maintenance cartridge into the slot, in the direction indicated by the

1.

arrow.

When the maintenance cartridge has been pushed all the way in, press inwards

and downwards as indicated, until it clicks into place.

If you have difficulty, see Cannot insert the maintenance cartridge in Using your

printer.

NOTE: The front panel will not show the new maintenance cartridge

until the door is closed.

Handle the ink

Insert the maintenance cartridge

39

Page 48

When you have inserted the maintenance cartridge into the printer, close the

2.

door.

NOTE: The printer needs all the ink cartridges, printheads and

maintenance cartridge to be installed before it can continue.

If no paper is loaded, the front panel will instruct you to load some.

3.

NOTE: Make sure that the printer window and the door to the right are

closed after you replace the supplies. The printer will not print while these are

open.

Check the status of the ink system

Access the Embedded Web Server.

1.

Handle the ink

2. Go to the Supplies page on the Main tab.

The Supplies page shows you the status of the ink cartridges (including the ink levels),

the printheads, the maintenance cartridge, and the loaded paper.

40 Chapter 3 Handle the ink system

Page 49

4

Manage print options

Select print quality

The printer has various print-quality options. The best quality printing requires some

loss of speed, while maximum-speed printing can cause some reduction in print

quality. The printer has four different print-quality options.

NOTE: If you have set the print quality in the printer driver or through the

Embedded Web Server, that setting overrides a print-quality setting

established on the front panel.

NOTE: You cannot change the print quality of pages that the printer is

already receiving or has already received (even if they have not started to

print yet).

Use the Embedded Web Server

To specify the print quality through the Embedded Web Server, go to the Submit

Job page on the Main tab. In the Job Settings tree, select Basic settings and

then select one of the settings from the Print quality drop-down menu: Fast,

Normal-Fast, Normal, or Best.

NOTE: Be aware that when you submit more than one job at a time by

clicking the Add files button in the Embedded Web Server, all of the jobs

that you submit will adopt the settings of the final job that you submit.

However, none of the jobs in the print queue are affected.

Use a driver

You can specify the print quality in the following ways:

●

In the Windows HP-GL/2 or Postscript driver, go to the Paper/Quality tab

and look at the Print Quality section. If you select Standard Options, you

can use the slider to select some compromise between speed and quality. If you

select Custom Options, you can choose Fast, Normal-Fast, Normal

or Best.

●

In the Mac OS Print dialog box, go to the Image Quality panel. If you

select Standard quality options, you can use the slider to select some

compromise between speed and quality. If you select Custom quality options,

you will see the specific print-quality options.

NOTE: In the Windows driver dialog box, the rendering resolution for your

job appears in the Custom Print Quality Optionsdialog box. In the Mac

OS Print dialog box, it appears in the Summary panel.

Select print quality

41

Print options

Page 50

Use the front panel

On the front panel, select the icon, and then select Printing preferences

> Select quality level.

Select page size

Select the page size through the Embedded Web Server, in a driver, or on the front

panel. The size that you select should be the page size in which the document was

created. You can resize the document for printing. See Resize a print in Using your

printer.

NOTE: If you set the page size from your computer, that setting overrides

the page size setting on the front panel.

Custom page sizes

Custom page sizes can be defined in a driver or through the Embedded Web Server.

The two types of custom page sizes are differentiated by how they were created, and

therefore, which users have accessibility to them.

●

Custom papers: custom papers are custom page sizes that have been defined

in a driver and that reside on the user's hard drive. Therefore, custom papers

are not available to other users in the network.

Printer forms: printer forms are custom page sizes that have been defined

●

through the Embedded Web Server and are visible to all network users who

share that print queue. Users require at least Print operator network permissions

to create printer forms.

Use the Embedded Web Server

To select the page size through the Embedded Web Server, go to the Submit

Job page on the Main tab. In the Job Settings tree, select Advanced

settings > Paper > Page size and then select Standard or Custom page size.

● Standard: use the drop-down menus to set the Size and Orientation.

●

Custom: use the free-text fields to specify a Width and Length, and use the

Page size drop-down menu to define the units of measurement.

NOTE: Be aware that when you submit more than one job at a time by

clicking the Add files button in the Embedded Web Server, all of the jobs

that you submit will adopt the settings of the final job that you submit.

Print options

42 Chapter 4 Manage print options

However, none of the jobs in the print queue are affected.

Page 51

Use a driver

Select the page size in the following ways:

●

In the Windows HP-GL/2 or PostScript driver, click the Paper/Quality tab,

and then select Document Size.

●

In the Mac OS Print driver dialog, select Page Setup from the File menu,

select your printer in the Format for popup menu, and then select Paper

size.

To define a custom paper size that does not appear in the list of paper sizes:

In the Windows and PostScript drivers, use one of two different methods:

●

●

In the driver dialog, select Custom from the Document size drop-down

menu on the Paper/Quality tab. Type a name for the custom size and

click Save. Then specify the paper dimensions and click OK to save your

custom paper size.

NOTE: The custom paper size you define is not available for

selection in the list of custom sizes until you have exited and

opened the Printing Preferences/Properties again. Then, you can

select More from the Document sizedrop-down menu and find

the custom paper size in the list.

●

On the Start menu, select Printers and Faxes, and then from the

File menu select Server Properties. On the Forms tab, click the

Create a new form check box, specify the name and dimensions of the

new form, and then click Save Form.

●

In Mac OS X V10.4, select Paper Size > Manage Custom Sizes in the

Page Setup dialog box.

●

In Mac OS X V10.2 or V10.3, select Settings > Custom Paper Size in

the Page Setup dialog box.

Use the front panel

On the front panel, select the icon, and then select Printing preferences

> Paper options > Select paper size.

Adjust margins and layout options

The printer margins determine the area between the edges of your image and the

edges of the paper. For information about the exact sizes (in millimeters) of the

available margin settings, see Margins in Using your printer.

Adjust margins and layout options

Print options

43

Page 52

Depending on the method that you use to adjust the margins, at least some of the

following layout options are available.

● Standard. Your image is printed on a page of the size that you have selected,

with a narrow margin between the edges of the image and the edges of the

paper. The image should be small enough to fit between the margins.

●

Oversize. Your image is printed on a page slightly larger than the size that

you have selected. If you cut off the margins, the remaining page is the size you

selected, with no margins between your image and the edges of the paper.

●

Clip Contents By Margins. Use this setting when the contents have white

borders and a size equal to that of the paper that you have selected in the driver.

The printer uses the white border for its margins and you get a page size that

is equal to what was selected in the driver.

See the Usage and Preview sections of the Paper/Quality tab for tips about

deciding which margins and layout option best suit your needs.

NOTE: If margins are set in the printer driver or through the Embedded

Web Server, they override the margins that are set on the front panel.

Use the Embedded Web Server

To set the margins through the Embedded Web Server, go to the Submit Job page

on the Main tab. In the Job Settings tree, select Advanced settings > Paper

> Layout/Margins. Then use the Select margins drop-down menu to set the

margins. Select from: Default, Small, Normal and Extended.

NOTE: Be aware that when you submit more than one job at a time by

clicking the Add files button in the Embedded Web Server, all of the jobs

that you submit will adopt the settings of the final job that you submit.

However, none of the jobs in the print queue are affected.

Use a driver

Specify the margins in the following ways:

● In the Windows HP-GL/2 Normal margins and Standard layout are selected

by default. To change the margins and layout options, click the Paper/

Quality tab and click the Layout button.

●

In the Windows PostScript driver, Normal margins and Standard layout are

selected by default. To change the margins, click the Paper/Quality tab,

Print options

44 Chapter 4 Manage print options

select More from the Document size drop-down menu, and then select the

desired page size and the margins at the same time. Click the Layout button

to change the layout options.

● In the Mac OS driver, select Page Setup from the File menu, select your printer

in the in the Format for popup menu, and then select Paper size. You select

the page size and the margins at the same time.

Page 53

NOTE: In the Windows PostScript driver, you have the option of selecting

a paper size with no margins. The No margins option should only be

selected in conjunction with the Oversized and Clip contents by

margins layout settings.

NOTE: In Mac OS driver, the available margins options depend on the

paper size that you selected in the Page Setup dialog box.

You have the option of selecting a paper size with no margins. To select

the No margins option, click the Printing dialog, select the Finishing

panel, and then click the Layout tab. The No margins option should only

be selected in conjunction with the Oversized and Clip contents by

margins layout settings.

Use the front panel

On the front panel, select the icon, and then select Printing preferences

> Margins > Select margins.

Print crop lines

Crop lines are lines that are printed onto the paper during a print job to indicate

where the paper should be cut to achieve a specific paper size. Crop lines can be

printed for individual jobs or for multiple jobs that are printed with the nesting feature.

For information about how to print crop lines for multiple jobs that are printed with

the nesting feature, see

Use the Embedded Web Server

To enable crop lines through the Embedded Web Server, go to the Submit Job

page on the Main tab. In the Job Settings tree, select Advanced settings >

Roll options and then select a setting from the Enable crop lines drop-down

menu.

Nest with crop lines on page 48.

NOTE: Be aware that when you submit more than one job at a time by

clicking the Add files button in the Embedded Web Server, all of the jobs

that you submit will adopt the settings of the final job that you submit.

However, none of the jobs in the print queue are affected.

Use a driver

●

In the Windows driver, go to the Features tab and in the Roll Options

section, select the Enable Crop lines checkbox

●

In the Mac OS Print dialog box, go to the Finishing panel and select the

Crop lines check box.

Print crop lines

Print options

45

Page 54

Use the front panel

On the front panel, select the icon, and then select Printing preferences

> Paper options > Enable crop lines.

Nest jobs to save paper

Nesting means placing pages side-by-side on the paper, rather than one after the

other. Do this to avoid wasting paper. The graphic below to the left illustrates the

general concept of nested print jobs. The graphic below to the right illustrates three

that have been print jobs printed with the nesting feature disabled.

Configure the nesting option

On the printer's front panel: select the icon, and then select Job

management options > Nest options > Enable nesting and select Off, In

order, or Optimized order.

The following are three nesting options:

●

Off

Select the Off setting to disable the nesting feature.

●

In order

Pages are nested on the roll in the same order in which they are submitted to

the printer. The nest is broken and printed as soon as one of three conditions is

met:

The nest is full, meaning that the remaining paper on the roll is insufficient

●

to accommodate the next page that is submitted.

The nesting timeout elapses.

●

The next page to arrive is incompatible with the pages that are already

●

nested.

Print options

For more information about the compatibility of a page, see

compatibility is defined on page 47.

The advantage of In-order nesting is that the wait time for pages to nest – and

therefore the total printing time – is typically reduced because more conditions

exist to break the nest. The disadvantage is that the nest is broken by the first

incompatible page submitted, even if a sufficient length of paper and additional

How job

46 Chapter 4 Manage print options

Page 55

compatible pages are in the queue. This means that a higher probability exists

that the paper will not be used efficiently.

● Optimized order

Pages are nested on the roll independent of when they are submitted to the

printer. An incompatible page does not break a nest. Instead, the printer waits

for more compatible pages and queues the incompatible pages until one of

three conditions is met:

The nest is full, meaning that the remaining length of paper on the roll is

●

too small to accommodate the next page submitted

The nesting timeout elapses

●

The incompatible-page queue is full. The printer queues up to six

●

incompatible pages while it nests compatible pages. Upon receiving the

seventh incompatible page, the nest is broken and printed. Then the pages

in the incompatible-page queue print.

For more information about the compatibility of a job, see

is defined on page 47.

The advantage of Optimized order nesting is that it typically wastes less paper

because the nest is not broken when an incompatible page is submitted. The

disadvantage is the overall printing time is typically longer because the printer

waits for compatible pages.

NOTE: Pages might not be printed in the order that the were submitted

to the printer when the Optimized order option is selected.

How job compatibility is defined

In order to be in the same nest, the individual pages must be compatible in all of the

following ways:

All pages must have the same print-quality setting.

●

●

The Maximum Detail setting must be the same on all pages.

●

The Mirror setting must be the same for all pages.

●

The Rendering Intent must be the same for all pages.

●

The Cutter setting must be the same for all pages.

The color adjustment settings must be the same for all pages. These are known

●

as Advanced Color Settings in the Windows driver, and CMYK

Settings in the Mac OS driver.

Pages must be all color or all grayscale. The pages cannot be a mix of color

●

and grayscale.

How job compatibility