Page 1

HP Designjet Z6100 Printer series

Service manual

Page 2

For HP Internal Use Only

©Copyright Hewlett-Packard

Company 2008

This document contains

proprietary information that is

protected by copyright. All

rights are reserved. No part of

this document may be

photocopied, reproduced, or

translated to another language

without the prior written

consent of Hewlett-Packard

Company.

First Edition, March 2007

Second edtion, May 2008

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes

no warranty of any kind

with regard to this

material, including, but

not limited to, the implied

warranties of

merchantability and

fitness for a particular

purpose.

Hewlett-Packard shall not be

liable for errors contained

herein or for incidental or

consequential damages in

connection with the furnishing,

performance, or use of this

material.

WARNING

The procedures described in

this manual are to be

performed by HP-qualified

service personnel only.

Electrical Shock Hazard

Serious shock hazard leading

to death or injury may result if

you do not take the following

precautions:

- Ensure that the ac power

outlet (mains) has a protective

earth (ground) terminal.

- Disconnect the Printer from the

power source prior to

performing any maintenance.

- Prevent water or any other

liquids from running onto

electrical components or

circuits, or through openings in

the enclosure.

Electrostatic Discharge

Refer to the beginning of

Chapter 4of this manual, for

precautions you should take to

prevent damage to the Printer

circuits from electrostatic

discharge.

WARN ING

The Warning symbol calls

attention to a procedure,

practice, or the like, which, if

not correctly performed or

adhered to, could result in

personal injury. Do not

proceed beyond a Warning

symbol until the indicated

conditions are fully understood

and met.

CAUTION

The Caution symbol calls

attention to an operating

procedure, practice, or the like,

which, if not correctly

performed or adhered to, could

result in damage to or

destruction of part or all of the

product. Do not proceed

beyond a Caution symbol until

the indicated conditions are

fully understood and met.

Customer Assurance

Customer Experience Section

Large Format Printing Division

Hewlett-Packard Espanola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Valles

Spain

Safety Symbols

General definitions of safety

symbols are given immediately

after the table of contents.

Page 3

HP Designjet Z6100 Printer series

Service manual

Page 4

Using this Manual

Purpose

This Service Manual contains information necessary to test, calibrate and service:

• HP Designjet Z6100 42-inch Printer (Model Q6651A)

• HP Designjet Z6100 60-inch Printer (Model Q6652A)

For information about using these printers, refer to the corresponding User and Quick Reference Guides.

Readership

The procedures described in this Service Manual are to be performed by HP Certified service personnel

only.

Part Numbers

Part Numbers for Printer options, accessories and service parts are located in Chapter 7.

Conventions

A small arrow ⇒ is used to indicate other parts of the Service Manual where you can find information

related to the topic you are consulting.

Page 5

1Table of Contents

1 Troubleshooting

Troubleshooting the printer......................................................................................................... 2

Printer Education and Training..................................................................................... 2

Firmware upgrade ..................................................................................................... 2

Troubleshooting system error codes............................................................................................. 2

Performing a service test on a failed assembly.............................................................................. 2

Performing the necessary service calibrations ............................................................................... 3

Solving print quality problems .................................................................................................... 3

The printer does not power on.................................................................................................... 3

Printer hangs during printing and displays ‘processing’ ................................................................. 3

The printer continuously rejects printheads ................................................................................... 4

A new Maintenenace Cartridge is incorrectly detected as ‘used’ .................................................... 4

Cover sensors are not working ................................................................................................... 4

The line sensor has problems detecting media .............................................................................. 5

Troubleshooting Media Jams/Printhead Crashes........................................................................... 5

Troubleshooting shutdowns ........................................................................................................ 5

Printhead Maintenance Cartridge Path ......................................................................... 6

Paper Path ................................................................................................................ 6

Printhead path ........................................................................................................... 6

PWM shutdown ......................................................................................................... 6

Velocity shutdown ...................................................................................................... 6

Energy shutdown ....................................................................................................... 6

Vacuum suction much lower at high altitudes................................................................................ 7

Banding at variable extreme environmental conditions .................................................................. 7

Printhead Crashes/Smears on High Density Prints Using Coated Media .......................................... 7

Banding due to ink cartridge replacement while printing ............................................................... 7

34" Rice Paper not supported .................................................................................................... 8

Worm marks on HP Coated media with light area fills .................................................................. 8

Solving Media-Handling Problems .............................................................................................. 8

Difficult to load media “Too much skew” ..................................................................................... 8

Troublshooting a failure with the Take UP Reel (TUR) ..................................................................... 9

Take Up Reel LED status information ............................................................................. 9

Checking the Take Up Reel is correctly installed ........................................................... 10

How the Take UP Reel Works .................................................................................... 11

Using the buzzer at power-up for troubleshooting problems........................................... 11

Using the Power-up Sequence to Troubleshoot ............................................................. 12

Corrective Actions for Power-Up Problems ................................................................... 14

Troubleshooting OMAS problem .............................................................................................. 14

Using the Power Switch LEDs to Troubleshoot ............................................................................. 15

Using the PCA LEDs to Troubleshoot.......................................................................................... 16

Interconnect PCA ..................................................................................................... 16

PrintMech PCA ........................................................................................................ 17

Identifying faults from LED status ................................................................................ 17

How to Interpret the Service Information Pages ........................................................................... 19

Main Characteristics ................................................................................................ 20

Current Configuration............................................................................................... 21

Current Media, Printhead and Ink Information ............................................................. 22

v

Page 6

Printer Usage Information.......................................................................................... 23

Media Used Sections................................................................................................ 24

Event Logs............................................................................................................... 25

Calibrations Status ................................................................................................... 26

Connectivity Configuration........................................................................................ 28

When the main window is open and the printer is printing (safety compliance) .............................. 29

General RIP tips and tricks ....................................................................................................... 29

Frequently Asked Questions ...................................................................................... 30

How to troubleshoot the 79:04 System Error .............................................................................. 31

Introduction............................................................................................................. 31

Possible causes........................................................................................................ 32

Troubleshooting based on symptoms .......................................................................... 38

2 System Error Codes

Introduction............................................................................................................................ 44

System Error Codes and Warnings - Explanation........................................................................ 44

Continuable and Non-Continuable Error Codes.......................................................................... 47

3 Ink Supplies

What are Ink Supplies? ........................................................................................................... 80

Ink Cartridges.......................................................................................................... 80

Printheads............................................................................................................... 81

Maintenance Cartridge............................................................................................. 82

General Information About the Ink Supplies ............................................................................... 82

General Precautions When Handling Ink Supplies ...................................................................... 82

Priming the Ink System............................................................................................................. 83

When Should You Replace the Ink Supplies?.............................................................................. 83

Obtaining Ink Cartridge Information ......................................................................................... 83

Obtaining Printhead Information............................................................................................... 85

Ink Cartridge Status Messages................................................................................... 86

Ink Cartridge Status While Printing............................................................................. 86

Ink Cartridge Status While Replacing ......................................................................... 86

Printhead Status Messages While Printing ................................................................... 87

Printhead Status Messages While Replacing................................................................ 87

Maintenance Cartridge Status Messages While Printing ............................................... 88

Maintenance Cartridge Status Messages While Replacing ............................................ 88

Summary of Solving Ink Supplies Problems................................................................................. 88

Problems reseating the printhead ............................................................................... 88

You Cannot Insert the Ink Cartridge Into the Printer....................................................... 89

You Cannot Insert the Printhead Into the Printer ............................................................ 89

You Cannot Insert the Maintenance Cartridge Into the Printer ........................................ 89

Troubleshooting Printhead Error Codes...................................................................................... 90

Carriage Interconnect Wiper ................................................................................................... 91

Warranty Information for Ink Supplies ....................................................................................... 91

Ink Cartridge........................................................................................................... 91

Printheads............................................................................................................... 92

4 Service Tests and Utilities

Introduction............................................................................................................................ 94

Diagnostics - Self Test.............................................................................................................. 94

Phone Support........................................................................................................................ 94

Service Tests (Diagnostics) ....................................................................................................... 94

Entering the Service Tests Menu................................................................................................ 96

1. Scan Axis Test ..................................................................................................... 97

2. Paper Drive Test................................................................................................. 101

3. Electronics Module Test....................................................................................... 105

4. Carriage Assembly Test ...................................................................................... 112

5. Sensors Test ...................................................................................................... 112

6. Ink Delivery System Test ...................................................................................... 115

7. SVS Test ........................................................................................................... 116

8. Air Pump System Test ......................................................................................... 116

9. Vacuum Fans Test .............................................................................................. 117

vi

Page 7

10. OMAS Module Test.......................................................................................... 118

11 EEROM Reset ................................................................................................... 118

12. Color Sensor Test ............................................................................................. 119

13. Aerosol Test .................................................................................................... 122

14. Primer Test ...................................................................................................... 122

15.1 Service Special Utilities >>> Bag Broken Recovery............................................. 124

15.2 Service Special Utilities >>> Error 71:19 Recovery ............................................ 126

15.3 Service Special Utilities >>> IO Information ...................................................... 128

15.4 Service Special Utilities >>> Unit Information .................................................... 128

15.5 Service Special Utilities >>> Check Ink Supplies ................................................ 129

Emergency Firmware Upgrade ................................................................................ 130

Service Utilities..................................................................................................................... 132

Entering the Service Utilities Menu............................................................................ 133

1. Turn Drive Roller ................................................................................................ 134

2. Prime Tubes....................................................................................................... 135

3. Set SN.............................................................................................................. 138

4. Reset Life Counters ............................................................................................. 138

5. Diagnostic Print ................................................................................................. 140

6. Sleep Mode ...................................................................................................... 141

7. Replace Cutter ................................................................................................... 142

8. Set RTC Clock.................................................................................................... 142

9. Enable/Disable Firewall ..................................................................................... 143

10. Prime Printhead X............................................................................................. 144

11. Open/Close SOL............................................................................................. 145

12. Disk Wipe DoD 5330.22’M ............................................................................. 145

13. Enable/Disable SCAPA .................................................................................... 148

14. Spectrophotometer test (Colormeter test).............................................................. 148

5Service Calibrations

Service Calibrations.............................................................................................................. 152

Entering the Service Calibrations Menu ................................................................................... 153

1. Scan Axis Calibration......................................................................................... 154

2. Paper Advance Calibration ................................................................................. 157

3. Drop Detector Calibration ................................................................................... 162

4. Line Sensor Calibration....................................................................................... 163

5. Vacuum Calibration ........................................................................................... 166

6. OMAS Calibration............................................................................................. 167

7. Primer Calibration.............................................................................................. 173

8. Platen Blue Line Calibration................................................................................. 177

6 Print Quality

How to Use the Image Quality Service Diagnostic Print ............................................................. 181

What is the Image Quality Service Diagnostic Print? .................................................. 181

Considerations for Printing the Diagnostic Print .......................................................... 182

Printing the Image Quality Service Print .................................................................... 182

Diagnostic Part 1: Printhead Problems ...................................................................... 183

Diagnostic Part 2: Alignment Test............................................................................. 184

Diagnostic Part 3: Printheads & Paper Advance Test................................................... 185

No Printing Defects Found in the Diagnostic Print ....................................................... 186

Visual Alignment Diagnostic Print ............................................................................. 187

Plot for escalation only............................................................................................ 190

Force Drop Detection.............................................................................................. 192

Disable Paper Advance Sensor ................................................................................ 192

Fix paper advance issues........................................................................................ 192

Clean the paper advance sensor window ................................................................. 194

The User Advance Calibration. ................................................................................ 194

Visual Paper Advance Plot ...................................................................................... 195

Interpreting plot results............................................................................................ 196

Image quality issues by symptom ............................................................................................ 199

There is banding in the image ................................................................................. 199

Lines are too thick, too thin, or missing ..................................................................... 200

vii

Page 8

Lines appear stepped or jagged .............................................................................. 200

Parts of lines or text are missing ............................................................................... 201

Lines are blurred (ink bleeds from lines) .................................................................... 202

Lines are slightly warped ........................................................................................ 202

Dark or light horizontal lines across the image (banding)............................................ 202

The image is grainy. .............................................................................................. 203

The image has a metallic hue (bronzing)................................................................... 204

The printed output is not flat .................................................................................... 204

The print smudges when touched ............................................................................. 205

Defects near the top of a print ................................................................................. 205

There are ink marks on the paper ............................................................................ 205

Colors are inaccurate ............................................................................................. 206

Colors between different HP Designjets do not match ................................................. 207

The output is completely blank ................................................................................. 209

The output contains only a partial print ..................................................................... 209

The image is clipped .............................................................................................. 209

The image is in one portion of the printing area......................................................... 210

The image is unexpectedly rotated ........................................................................... 210

The print is a mirror image of the original ................................................................. 210

The print is distorted or unintelligible ........................................................................ 210

One image overlays another on the same print.......................................................... 210

Pen settings seem to have no effect .......................................................................... 210

The image has a wood-grain appearance (aeroworms) .............................................. 210

CAD Lines look misaligned, images are blurred ......................................................... 211

Some media might deform when printing high area fill ............................................... 211

Printheads fail repeatedly........................................................................................ 211

Working with other commercially available media ................................................................... 213

7 Parts and Diagrams

Printer Support ..................................................................................................................... 222

Center Covers ...................................................................................................................... 224

Electronics Module................................................................................................................ 226

Right Cover.......................................................................................................................... 228

Left Cover ........................................................................................................................... 230

Right Hand Assemblies.......................................................................................................... 232

Left Hand Assemblies ............................................................................................................ 234

Carriage Assembly ............................................................................................................... 236

Scan-Axis Assemblies............................................................................................................ 238

Drive Roller and Media-Axis Motor ......................................................................................... 240

Paper Path Assemblies .......................................................................................................... 242

Center Guide and Pinchwheel Assembly.................................................................................. 244

Media Entry Assemblies ........................................................................................................ 246

Take-Up Reel Assembly.......................................................................................................... 248

Miscellaneous Parts............................................................................................................... 250

8 Removal & Installation

Service Part Order ................................................................................................................ 253

Disassembly Order ............................................................................................................... 255

Introduction.......................................................................................................................... 257

Safety Precautions.................................................................................................. 257

Electrostatic Discharge (ESD) Precautions .................................................................. 257

Required Tools....................................................................................................... 257

Screw Types ........................................................................................................................ 259

Window (42-inch) ................................................................................................................ 260

Installation of New Window ................................................................................... 261

Window (60-inch) ................................................................................................................ 262

Right Cover.......................................................................................................................... 264

Right Trim ............................................................................................................................ 267

Left Cover ............................................................................................................................ 270

Left Trim............................................................................................................................... 272

Top Cover (42-inch) .............................................................................................................. 273

viii

Page 9

Top Cover (60-inch) .............................................................................................................. 277

Rear Door (42-inch) .............................................................................................................. 281

Rear Door (60-inch) .............................................................................................................. 283

Right Connector Cover .......................................................................................................... 285

Left Connector Cover (42-inch) ............................................................................................... 287

Electronics Module Extension (60-inch only) ............................................................................. 288

Window Position Sensor........................................................................................................ 289

Front Panel........................................................................................................................... 292

Primer Assembly ................................................................................................................... 294

Primer Valves ....................................................................................................................... 296

Service Station ..................................................................................................................... 300

Vacuum Fan......................................................................................................................... 304

Aerosol Fan and Filter ........................................................................................................... 307

Drop Detector....................................................................................................................... 309

Ink Supply Tubes and Trailing Cable ....................................................................................... 312

ISS to Cartridge Cables ......................................................................................................... 318

Cutter Assembly.................................................................................................................... 319

Ink Supply Station (ISS).......................................................................................................... 321

APS Assembly ...................................................................................................................... 324

Left Spittoon ......................................................................................................................... 328

Encoder Strip and Encoder Sensor .......................................................................................... 331

Carriage PCA ...................................................................................................................... 334

Carriage Flex Cables ............................................................................................................ 337

Carriage Assembly ............................................................................................................... 339

Belt Assembly....................................................................................................................... 345

Scan-Axis Motor ................................................................................................................... 346

Media-Axis Motor................................................................................................................. 349

Optical Media Advance Sensor (OMAS) ................................................................................. 351

Interconnect PCA .................................................................................................................. 357

EIO to PCA Interface Card..................................................................................................... 360

OMAS Controller Card ......................................................................................................... 362

OMAS Cable....................................................................................................................... 364

Sausalito PCI PCA ................................................................................................................ 369

CPU Fan.............................................................................................................................. 371

Memory Module................................................................................................................... 373

Main PCA Formatter ............................................................................................................. 375

Hard Disk Drive (HDD) .......................................................................................................... 377

Power Supply Unit (PSU)........................................................................................................ 379

PrintMech PCA ..................................................................................................................... 384

Formatter Battery .................................................................................................................. 386

Electronics Module................................................................................................................ 388

Line Sensor Assembly ............................................................................................................ 390

Color Sensor Assembly.......................................................................................................... 392

Color Sensor Actuator Assembly ............................................................................................. 395

Media Deflector ................................................................................................................... 397

Output Platen ....................................................................................................................... 398

Center Platen ....................................................................................................................... 400

Cartridge Tray...................................................................................................................... 409

Input Roller .......................................................................................................................... 411

Maintenance Cartridge Door ................................................................................................. 413

Maintenance Cartridge Door Sensor ....................................................................................... 414

Media Sensor ...................................................................................................................... 415

Encoder Disc and Sensor ....................................................................................................... 417

Media Lever Assembly .......................................................................................................... 420

Media Lever Sensor .............................................................................................................. 423

Pinchwheel Assembly ............................................................................................................ 425

Center Guide ...................................................................................................................

Roller .......................................................................................................................... 433

Drive

Right Rollfeed Module Assembly ............................................................................................. 439

.... 430

ix

Page 10

Left Rollfeed Module Assembly ............................................................................................... 440

Take-Up Reel Motor .............................................................................................................. 442

Take-Up Reel Left Hand Module.............................................................................................. 444

Take-Up Reel Deflector Supports ............................................................................................. 445

Take-Up Reel Sensors ............................................................................................................ 447

9 Preventive Maintenance

Preventive Maintenance......................................................................................................... 452

Moisture on the Printer............................................................................................ 452

Noisy Carriage Bushing ......................................................................................... 452

Belt Swelling ......................................................................................................... 452

Cleaning the Printer ............................................................................................... 452

General Cleaning .................................................................................................. 452

Cleaning the Drive Roller and Overdrive................................................................... 452

Cleaning the Platen ................................................................................................ 453

Clean the Encoder Strip .......................................................................................... 454

Clean the paper-advance sensor window.................................................................. 457

Applying Oil to the Overdrive ................................................................................. 458

Lubricating the Carriage Assembly........................................................................... 458

Change the maintenance absorber .......................................................................... 459

Scheduled Maintenance ......................................................................................... 460

Level of Printer Usage ............................................................................................. 460

x

Page 11

1 Troubleshooting

• Troubleshooting the printer ..................................................................................... 2

• Printer Education and Training.......................................................................... 2

• Firmware upgrade .......................................................................................... 2

• Troubleshooting system error codes.......................................................................... 2

• Performing a service test on a failed assembly........................................................... 2

• Performing the necessary service calibrations............................................................ 3

• Solving print quality problems................................................................................. 3

• The printer does not power on ................................................................................ 3

• Printer hangs during printing and displays ‘processing’ .............................................. 3

• The printer continuously rejects printheads ................................................................ 4

• A new Maintenenace Cartridge is incorrectly detected as ‘used’.................................. 4

• Cover sensors are not working ................................................................................ 4

• The line sensor has problems detecting media........................................................... 5

• Troubleshooting Media Jams/Printhead Crashes ....................................................... 5

• Troubleshooting shutdowns ..................................................................................... 5

• Vacuum suction much lower at high altitudes............................................................. 7

• Banding at variable extreme environmental conditions ............................................... 7

• Printhead Crashes/Smears on High Density Prints Using Coated Media ....................... 7

• Banding due to ink cartridge replacement while printing............................................ 7

• 34" Rice Paper not supported ................................................................................. 8

• Worm marks on HP Coated media with light area fills ............................................... 8

• Solving Media-Handling Problems........................................................................... 8

• Difficult to load media “Too much skew”................................................................... 8

• Troublshooting a failure with the Take UP Reel (TUR) .................................................. 9

• Using the buzzer at power-up for troubleshooting problems ....................................... 11

• Using the Power-up Sequence to Troubleshoot .......................................................... 12

• Troubleshooting OMAS problem ............................................................................ 14

• Using the Power Switch LEDs to Troubleshoot............................................................ 15

• Using the PCA LEDs to Troubleshoot........................................................................ 16

• How to Interpret the Service Information Pages .........................................................19

• When the main window is open and the printer is printing (safety compliance)........... 29

• General RIP tips and tricks.................................................................................... 29

• How to troubleshoot the 79:04 System Error ............................................................ 31

Troubleshooting

1

Page 12

Troubleshooting the printer

Refer to Section 6 for troubleshooting Image Qulaity issues.

Printer Education and Training

Before any attempt is made to troubleshoot the printer, it is critical that you have the relevant training on

Troubleshooting

the HP Designjet Z6100 Printer series. If you are not trained on this printer, please contact HP Education

or HP Training to enquire about becoming ‘HP Service Qualified’ for this printer.

Firmware upgrade

The first step to take when trying to clear an errror with the printer is to check that the firmware installed

in the printer is the latest available. Firmware updates often include fixes for some of the problems that

are found in the following pages, simply updating the firmware can often resolve the problem. New

firmware can be downloaded from the following url: http:www.hp.com/go/designjet/downloads

If the error with the printer does not allow you to upgrade the firmware using the normal process, try

upgrading the firmware using the emergency .plt file procedure

Troubleshooting system error codes

Chapter 2, System Error Codes contains a list of system error codes and their respective descriptions and

recommended corrective actions. Only try one recommended action at a time and check if the error code

has disappeared.

⇒ page 130

If you have an error code which is not documented in this Service Manual or you have an error which

you cannot resolve, then report the error to the HP Response Center or the nearest HP Support Office.

When reporting the error, have the following information ready:

• Model and Serial Number of the printer.

• Which firmware revision the printer is using (See Note below). Check firmware in Utilities / Statistics

/ Code rev.

• The complete error number.

NOTE: When reporting the System Error Code, make sure that you supply the full Error Code

and the firmware version. Without this information, HP Support Personnel cannot help you.

• The Service Configuration Print.

• The Current configuration sheet.

• Which software application the customer is using (name, version, etc.).

Performing a service test on a failed assembly

If possible, always perform a Service Test on the component/assembly that you are about to replace, just

to make sure that is the component/assembly that has failed.

NOTE: If the test on that component/assembly passes, you should NOT replace it.

For information on the Service Tests and how to use them see Chapter 4, Service Tests and Utilities.

2 Chapter 1 Troubleshooting

Page 13

Performing the necessary service calibrations

Is the printer calibrated correctly after replacing a component? For information on the Service Calibrations

and how to use them see Chapter 5, Service Calibrations.

NOTE: Remember that certain Calibrations are required even if an Assembly has been

disassembled to gain access to another Assembly or Component.

Solving print quality problems

Whenever a Print Quality problem appears, it is advisable to print the Diagnostic Print to help diagnose

the problem. The Diagnostic Print will help you differentiate between possible printhead errors and other

problems such as incorrect front-panel selection, driver or RIP configuration or mechanical problems. For

information on solving Print Quality problems see Chapter 6, Print Quality.

The printer does not power on

To resolve printer power up problems, do the following:

1. Check that the power cord is connected correctly to the Printer and to the Power Socket.

2. Check that the Power Switch on the BACK of the Printer is in the ON position.

Troubleshooting

3. Check to see if any of the LEDs on the Power Switch are On. If any of the LEDs are On, then refer to

See page 15 for more information.

4. Check that the Front-Panel Cable is correctly connected to the Electronics Module. Also make sure

that the Front-Panel cable is not damaged.

5. Replace the CPU Fan

6. Replace the Power Supply Unit

⇒ See page 371

⇒ See page 379.

Printer hangs during printing and displays ‘processing’

It has been seen under certain circumstances that the printer hangs whilst printing, this may happen

immediately after printing, or only a partial print. In some cases when this occurs if the machine is

rebooted a system error 79:04 is displayed, although rebooting again appears to clear this error. After

this point, although the printer displays that it is in the “Ready” state, attempting to print anymore plots

will once again hang the printer, including internal demo plots.

Reason

The reason for this error is that a large spooled file (11Gb for example) has been sent to the printer and

has been placed in the disk partition which is related to the print queue. The file completely fills up all the

disk space, because of this it will never successfully print, and so the file remains in the disk partition.

Even after restarting the printer the file remains, subsequent print requests also fail as there is not sufficient

space available in the partition to process anything else.

Solution

Perform the following few steps to clear the error.

Performing the necessary service calibrations 3

Page 14

1. Check that the firmware is the latest available (at least 7.0.03)

2. Turn Off and ON the printer.

3. Set Queue to OFF.

4. Set ‘When Start Printing’ to ‘Immediately’.

Please guide the customer through the front panel of the printer to set up the “Queue” to “OFF” and

Troubleshooting

“When Start Printing” to “Immediately”.

Wipe disk solution

If the above procedure does not clear the error, use the wipe the hard disk procedure (Unsecure mode)

⇒ See page 145. This will delete all previous jobs, ICC profile, media profiles that were present on the

hard disk. This procedure has an advantage for the customer in that it solves the issue without the need

to wait for an onsite engineer to come to their premises and remove and replace the HDD (which would

also have the same affect of deleting all the previous jobs, ICC profiles and media profiles). The whole

procedure should not take more than 30-35 minutes.

Important step is that you need to select the Unsecure mode

The printer continuously rejects printheads

To resolve printhead rejection problems, do the following:

1. Clean the flex contacts on the Printhead and in the Carriage Assembly using the Carriage Intercon-

nect Wiper (Refer to Chapter 3) and try again.

2. If ALL the Printheads are rejected (the status message on the Front Panel does NOT show “OK” for

ALL the Printheads) then perform the Electronic Systems Test

⇒ See page 105.

A new Maintenenace Cartridge is incorrectly detected as ‘used’

This can occur if the printer has detected the previous Maintenenace Cartridge was nearly full, and when

a new Maintenenace Cartridge is installed the Front Panel displays an error that the cartridge is ‘used’.

To resolve the problem, do the following:

1. Ensure the firmware installed in the printer is the latest available.

2. Once the latest firmware is installed repeat the Maintenance installation procedure with the same

cartridge.

3. Manuall reset the counter of the Maintenance Cartridge

⇒ See page 138

Cover sensors are not working

To resolve cover sensor problems, do the following:

1. Perform the Sensors Test

2. Check if the cable for the faulty sensor is not damaged and is connected correctly.

3. Replace the faulty Sensor.

4 Chapter 1 Troubleshooting

⇒ See page 112.

Page 15

The line sensor has problems detecting media

To resolve line sensor media detection problems, do the following:

1. Check the type of media that is being used since the Line sensor may have problems detecting trans-

parent media or some types of Non-HP media. Try loading white HP media in to the Printer and

check if the Line sensor detects it.

2. Excessive ink deposits on the Platen surface can fool the sensor by reflecting the light. Clean the

Center Platen.

3. Clean the Encoder Strip ⇒ See page 454.

4. The Line Sensor is not calibrated correctly. Perform the Line Sensor Calibration ⇒ See page 163.

5. The Line Sensor is damaged or faulty. Replace the Line Sensor ⇒ See page 390.

Troubleshooting Media Jams/Printhead Crashes

NOTE: If you are using HP Coated Media when the problem occurred, please also refer to

Page 1-6.

The failure modes “media jam” and “head crash” are grouped together because in many cases a media

jam causes the media to lift up into the Carriage path and cause a Printhead crash, thus causing many

media jam failures to be reported as head crashes.

Troubleshooting

1. Did the media jam occur when loading media?

NOTE: When clearing a media jam, sometimes media is stuck in the paper path. To clear

this, you must lift the Media Lever and insert thicker media into the paper path to push out the

media that is still stuck there.

• If the client has had media jams, it is common for pieces of media to get stuck in the media

path. Clear the media path.

2. Is the customer using non-HP media?

• The use of non-HP media can easily be the cause of media jams and head crashes (especially

head crashes because HP media is specially formulated to avoid cockle, one of the primary

causes of head crashes). If the media is not HP approved, advise the customer to use HP media

and check to see if the problem is now solved.

3. Check that the Vacuum Fan works correctly.

Troubleshooting shutdowns

If a shutdown occurs, you will get the message “Switch Power Off” followed by one of these messages:

• Check Maintenance Cartridge Path.

• Check Paper Path.

The line sensor has problems detecting media 5

Page 16

• Check Printhead Path.

NOTE: A shutdown in each path will require different steps to resolve the problem as

explained below. In each case, make sure that you power OFF the printer before attempting

any procedures to resolve the problem.

Printhead Maintenance Cartridge Path

Troubleshooting

Open the right door of the printer and check for any visible obstacles restricting the movement of the

Service Station. Manually move the Service Station, checking for smooth and free movement.

Paper Path

To resolve paper path problems, do the following:

1. Open the Window and check for any visible obstacles restricting the movement of the Drive Roller.

Make sure that the mylar is not damaged. If there is a wrinkled mass of media inside the paper

path, lift the Pinch wheels (using the Media Load Handles) and clear the obstruction.

2. If this shutdown happens at the end of a Roll of Media, it could be because the media is stuck firmly

to the Roll. Lift the Pinch wheels (using the Media Load Handles) and pull the media clear.

3. Replace media spindle if broken.

4. Replace the Media-Axis Motor

Printhead path

When a shutdown occurs in the Printhead path, you will get the message “Switch Power Off / Check

Printhead Path (*). The (*) will be a number, which will give an indication on where the failure occurred:

PWM shutdown

To resolve a PWM shutdown, do the following:

1. Clean Slider Rods and Apply Oil along the complete axis of the Slider Rods. After applying the Oil,

perform the Scan-Axis Test

2. Clean the Encoder Strip ⇒ See page 454.

3. Replace the Scan-Axis Motor

Velocity shutdown

To resolve a velocity shutdown, do the following:

1. Open the Window and check for any visible obstacles restricting the movement of the Carriage

Assembly. Try and move the Carriage Assembly manually, checking for smooth and free movement.

⇒ See page 349.

⇒ See page 97 and check that the values are within the given limits.

⇒ See page 346.

2. Check that the Encoder Strip is clean. If necessary, clean Encoder Strip using a damp cloth.

Energy shutdown

To resolve an energy shutdown, do the following:

1. Clean Slider Rods and Apply Oil along the complete axis of the Slide Rods. After applying the Oil,

perform the Scan-Axis Test

2. Clean the Encoder Strip ⇒ See page 454.

6 Chapter 1 Troubleshooting

⇒ See page 97 and check that the values are within the given limits.

Page 17

3. Replace the Scan-Axis Motor ⇒ See page 346.

Vacuum suction much lower at high altitudes

At altitudes above 3,000 meters, the vacuum force holding down the media will be lower, therefore the

media will not be held in place properly causing:

• Ink Smearing on the Media.

• Printhead crashes against the Media.

• Roll Media loading problems (low probability).

PRINTER LIMITATION - NO SOLUTION AVAILABLE.

Banding at variable extreme environmental conditions

NOTE: This problem is only applicable if the OMAS is disabled.

Since the Accuracy Calibration has been done at normal environmental conditions, printing in extreme

environmental conditions will cause banding because the advance of the Drive Roller does not correspond

to the same conditions that the calibration was done in. To solve the problem, try the following:

Perform the Accuracy Calibration in the new environmental conditions (Refer to the User’s Guide).

Printhead Crashes/Smears on High Density Prints

Troubleshooting

Using Coated Media

High density prints can cause cockle mainly on HP Coated Media. This causes two main problems:

1. Cockling in the borders - Because the printer places too much ink on the Coated Media, the borders

of the print become raised, causing the Printhead to crash against the media. To solve the problem,

try the following:

• Change the paper margins to 15mm, either in the Front Panel or in the Driver. If the customer is

printing PostScript images, send them a PPD file containing the extended margins of 15mm.

2. Cockling within the print - If the Printer places too much ink within the print, the media starts to rip-

ple, causing the Printhead to smear against the media. To solve the problem, try the following:

• Check in the Front Panel if Ink Limiting is ON or OFF. If Ink Limiting is OFF, turn it ON.

• Never use HP Coated Media for High Density prints. As a substitute use HP Heavy Coated

Media.

Banding due to ink cartridge replacement while printing

A user has removed the Ink Cartridge while the printer was printing, which has caused the printer to stop.

If the user does not replace the Ink Cartridge immediately, when the printer starts to print again, a band

will appear in the position where the printing restarted. This is because the wet ink interacts with the dried

ink on the media causing the band to appear. To solve the problem, try the following:

Vacuum suction much lower at high altitudes 7

Page 18

• Do NOT remove the Ink Cartridge while the Printer is Printing. Only replace/remove Ink Cartridges

in between Prints.

• If the Ink Cartridge was replaced due to the “Empty” status on the Front Panel, then advise the

customer to replace the Ink Cartridge when the “Very Low” status is showing on the Front Panel.

• Reprint the file (without remove the Ink Cartridge).

Troubleshooting

34" Rice Paper not supported

Roll length is 34" (Non-standard) and the pinch wheels can't control edge of media causing ink smears

and Printhead crashes in middle of prints with or without area fills.

PRINTER LIMITATION - NO SOLUTION AVAILABLE.

Worm marks on HP Coated media with light area fills

Light bands (S-shaped) in Paper axis direction where light area fills are printed, causing unacceptable

Image Quality defect.

• Print the Service Configuration Print and check if the level of Humidity is very low (below 30%).

Increasing humidity may help in reducing the severity of the problem.

NOTE: The media is causing the problem and NOT the Printer. Do not attempt to try and

replace Printer parts to solve this problem.

Solving Media-Handling Problems

The Front Panel Keeps Indicating that Media Is Misaligned or Incorrectly Positioned.

• The roll may be loaded the wrong way. The paper should load over the roll toward you.

• Check that the paper is correctly loaded onto the spindle.

• The paper may be loaded at an angle. The right-hand edge must be aligned with the blue line on

the Print Platen.

NOTE: Ensure that the paper is wrapped tightly on the roll. This is a very important step to

remember because if this is not done, the media may be loaded at an angle, causing the

media to be rejected.

Difficult to load media “Too much skew”

If you encounter a high failure rate when loading media and the Front Panel reports “Too Much Skew” it

is likely that:

• The encoder strip must be cleaned (this can be carried out by the customer using the User

Maintenance Kit).

• The Line Sensor must be cleaned.

• The Blue Line calibration must be performed (see “8. Platen Blue Line Calibration” on page 177).

8 Chapter 1 Troubleshooting

Page 19

Troublshooting a failure with the Take UP Reel (TUR)

Use this section to troubleshoot failures with the TakeUP Reel.

Take Up Reel LED status information

LED

status

Blinking

quickly

Blinking

slowly

Solid red Take Up Reel

Solid green Take Up Reel

Solid green Take Up Reel

Issue Print job

Take Up Reel

not winding

Take Up Reel

not winding

not winding

not winding

winding in the

wrong direction, and not

stoppinjg the

job.

Possible cause Print job

interupted

Yes Sensor beam blocked for

more than 3 seconds

No The sensor cables are

loose or unplugged

No There is too much resis-

tance on the Take Up Reel

motor

No The Take Up Reel power

switch is in the Off position

No The Take Up Reel wind

direction switch is in the

wrong winding position.

after 3 seconds, the

printer will recognize the

problem and interupt the

print job. In this case, see

the first error listed in this

table.

Troubleshooting

interrupted?

Ensure the Take Up Reel sensors

are not blocked by a strip of

paper, the collection bin or other

objects.

Also ensure the Take Up Reel

power switch is in the On position.

Ensure the sensor cables are correctly connected.

ENSURE THAT THE TUR Spindle

Lever is CLOSED! Ensure the

paper is not winding too tightly.

A loop-shaping core should be

inserted and hanging down.

Ensure the Take Up Reel power

switch is in the On position.

Flip the Take Up Reel wind-direction switch to the correct position.

NOTE: If the LED is flashing but there is no message on the front panel, restart the printer.

Troublshooting a failure with the Take UP Reel (TUR) 9

Page 20

Checking the Take Up Reel is correctly installed

Many system error codes are displayed as a result of the Take UP Reel not being installed correctly or

because parts have moved or become dislodged from their correct positions. This troubleshooting

procedure checks the machnical installation of the Take Up Reel.

1. Check that the Take UP Reel sensor unit is correctly installed on the right foot.

Troubleshooting

2. To correctly install the foot, the wheel has to be positioned as shown.

3. Check the cables linking the sensors to the Take Up Reel Motor Assembly are correctly connected.

4. Check that the Take UP Reel motor assembly is correctly connected to the rear of the printer.

10 Chapter 1 Troubleshooting

Page 21

How the Take UP Reel Works

There are two different setups:

1. The Take Up Reel has been installed via the front panel from the media menu – how to check it: If the

words 'Take Up Reel installed' is blanked out, this means that the Take Up Reel is not installed in the

front panel.

2. The Take UP Reel has not been install via the front panel – how to check it: When selecting the

media menu, there is no line ‘Take Up Reel installed’. This does not mean that the Take Up Reel will

not work, it just means that if there is a paper jam detected by the Take Up Reel, there will be no

warning system error displayed on the front panel. The printer will not stop.

How to install the Take Up Reel:

From the Media menu -> Take Up Reel -> Enable Take Up Reel. The main differences between the two

modes (Take Up Reel installed or not installed on the front panel), what will happen if the Take Up Reel

is installed:

• In case of Take Up Reel Paper jam system error, a warning is reported on the front panel, and the

printer is no more printing (pause)

• The cutter is disabled between jobs

• When unloading the media, the front panel will ask you to manually cut the media.

How it works?

When the bottom of the 'loop shaper' is lower enough and it cuts the signal between the 2 sensors, the

Take Up Reel starts to move the motor until the signal between the 2 sensors is passing through again.

If after the few seconds of turning the Take Up Reel, the signal between two sensors is still cut, the Take

Up Reel reports a 'Take Up Reel paper jam' error:

• In all case, the LED of the Take Up Reel is blinking quickly

Troubleshooting

• and if the Take Up Reel is enabled on the front panel, a 'Take Up Reel' paper jam will be displayed.

Using the buzzer at power-up for troubleshooting problems

When the Printer is powered up, it doesn’t make a “Beeping Sound” until it is completely powered-up and

ready to use. If there is a beep during the power-up sequence, this may signify that there is a problem

within the Electronics Module. The following table will help you to use the “Beeping Sound” to diagnose

certain problem:

Number

of

Beeps

1 Processor absent

2Faulty Main PCA or PSU

3 Faulty Memory Module

Problem Description Corrective Action

•

Replace the Main PCA ⇒ See page 375.

Replace the Main PCA ⇒ See page 375.

•

• Replace the PSU ⇒ See page 379.

Check that the Memory Module is installed cor-

•

rectly.

• Try installing the Memory Module in the other Mem-

ory slot and check if the problem reappears.

• If the problem reappears, r

⇒ See page 373.

ule

• If the problem does NOT reappear, then the original

eplace

slot could be faulty. In this case, replace the Main

⇒ See page 375.

PCA

the Memory Mod-

Troublshooting a failure with the Take UP Reel (TUR) 11

Page 22

Number

of

Beeps

Problem Description Corrective Action

Troubleshooting

4

5Faulty PCI Card

6BIOS Damaged

7 Motherboard damaged

Faulty Video Card (not

used)

Replace the Main PCA ⇒ See page 375.

•

•

Replace the Main PCA ⇒ See page 375

•

Replace the Main PCA ⇒ See page 375

•

Replace the Main PCA ⇒ See page 375

Remove the Main PCA Cover and (with the Printer

•

switch On) check that the HDD is spinning (you

should feel it spinning when you touch it or at least

hear it spinning). If the HDD is not spinning, then it

8

Hard Disk Drive

damaged or missing

could be damaged. In this case, replace the HDD

⇒ See page 377.

• Make sure that ALL cables connected to the HDD

are not damaged and are connected correctly.

• Replace the HDD ⇒ See page 377

• Replace the Main PCA ⇒ See page 375

Using the Power-up Sequence to Troubleshoot

When the Printer is powered up, it performs the Boot-UP sequence which initializes the major components

of the Printer. If for some reason the Boot-Up sequence fails because a components has failed to initialize,

the following explanations will help you to locate the failing component.

Step Initialization Process

BULNEX KERNEL BOOT

30 rc.sysinit rerun through initlog.

Environmental variables PATH, NETWORKING, HOSTNAME set.

29

28

27 Set the system clock.

26 Load keymap.

•

• Source /etc/init.d functions.

Fix console loglevel.

•

• Mount /proc.

• Dismount the initrd, if necessary.

• Configure kernel parameters.

12 Chapter 1 Troubleshooting

Page 23

Step Initialization Process

25 Load system font.

24 Start up swapping.

Set the hostname.

23

•

• Initialize USB controller and HID devices

•

Set variables for options to be later used for filesystem check

22

21 Perform file system check on root volume.

20 Update quotas if fsck was run on root

19 Setup pnp

18

17

16

15 Mount local filesystems.

14 Check remaining quotas other than root.

• Turn Off DMA on CD-ROMs

• Turn On Hard Disk optimization

Remount the root filesystem read-write.

•

• LVM initialization.

• Clear mtab.

• Enter root, /proc and (potentially /proc/bus/usb and devfs into mtab.

• Remove /lib/modules/preferred and /lib/modules/default.

• Tweak isapnp settings if needed.

• Load sound modules if the need persistent DMA buffers.

•

Load modules from /etc/rc.modules.

• File system check.

• Add raid devices.

Setup Logical Volume Management.

•

• Check filesystems on all volumes found on /etc/fstab.

Troubleshooting

13 Enable local filesystem quotas.

Configure machine if necessary (if the respective configure files exist).

12

10

•

• Reread in network configuration data.

Clean out /etc, (w/u)tmpx files, /var.

•

• Reset pam_console permissions.

• Cleanup utmp/wtmp.

11

• Delete X locks.

• Delete VNC and X locks.

• Delete Postgres sockets.

• Turn On swap in case we swap to files.

•

Initialize the Serial Ports.

• If a SCSI tape has been detected, load the st module unconditionally.

• Load usb storage to match most other things.

• If ide-scsi is required, load it.

• Generate a header that defines the boot kernel.

•

Dump the syslog ring in /var/log/dmesg.

9

• Keep kernel symbols in /var/log/ksyms.

• Create the crash indicator flag to warn on crashes, offer fsck with timeout.

8 Export this variable BOOT_PART and INSTALL_PART.

PRINT APPLICATION STARTING POINT

7 IO kernel mode initialization (basically).

6 Printer Application Infrastructure startup.

Troublshooting a failure with the Take UP Reel (TUR) 13

Page 24

Step Initialization Process

5Printer IO startup.

Front Panel application startup (but wait for engine launching, i.e. Front Panel is not cleared

4

yet).

3 Engine startup, start EE and Mechanical initialization.

Troubleshooting

2 HPGL/PS parsers startup.

All subsystems launched.

1

Wait for Front Panel application to clear the Front Panel and start signaling the initialization

sequence.

Corrective Actions for Power-Up Problems

To resolve power-up problems, use the following corrective actions:

1. If the Printer's Power-Up process stops when the front panel is displaying the number 17, this indi-

cates that there is a problem with the file system on the Printer's Hard Disk Drive, so the Printer is

checking the whole file system and making any necessary corrections. This problem can arise when

there has been a power cut while the Printer was switched On, or if there is a physical problem with

the Hard Disk Drive.

Checking the whole file system normally takes about half an hour (but could take much

longer). There is nothing that can be done to speed up the file checking process. If you turn

Off the Printer during the checking process, the file system check will restart whenever you

turn it On again.

If you experience this problem repeatedly when there has been no power cut, then this

could mean that the Hard Disk Drive is faulty. In this case, replace the Hard Disk Drive

See page 377.

2. If the printer's start-up process stops when the front panel is displaying any number between 1 to

30, then try the following:

⇒

• Switch the Power OFF from the back of the Printer and disconnect the Power cord. Reconnect

the power cord and power On the Printer.

If the Printer continues to stop during the power-up process, replace the

•

page 377.

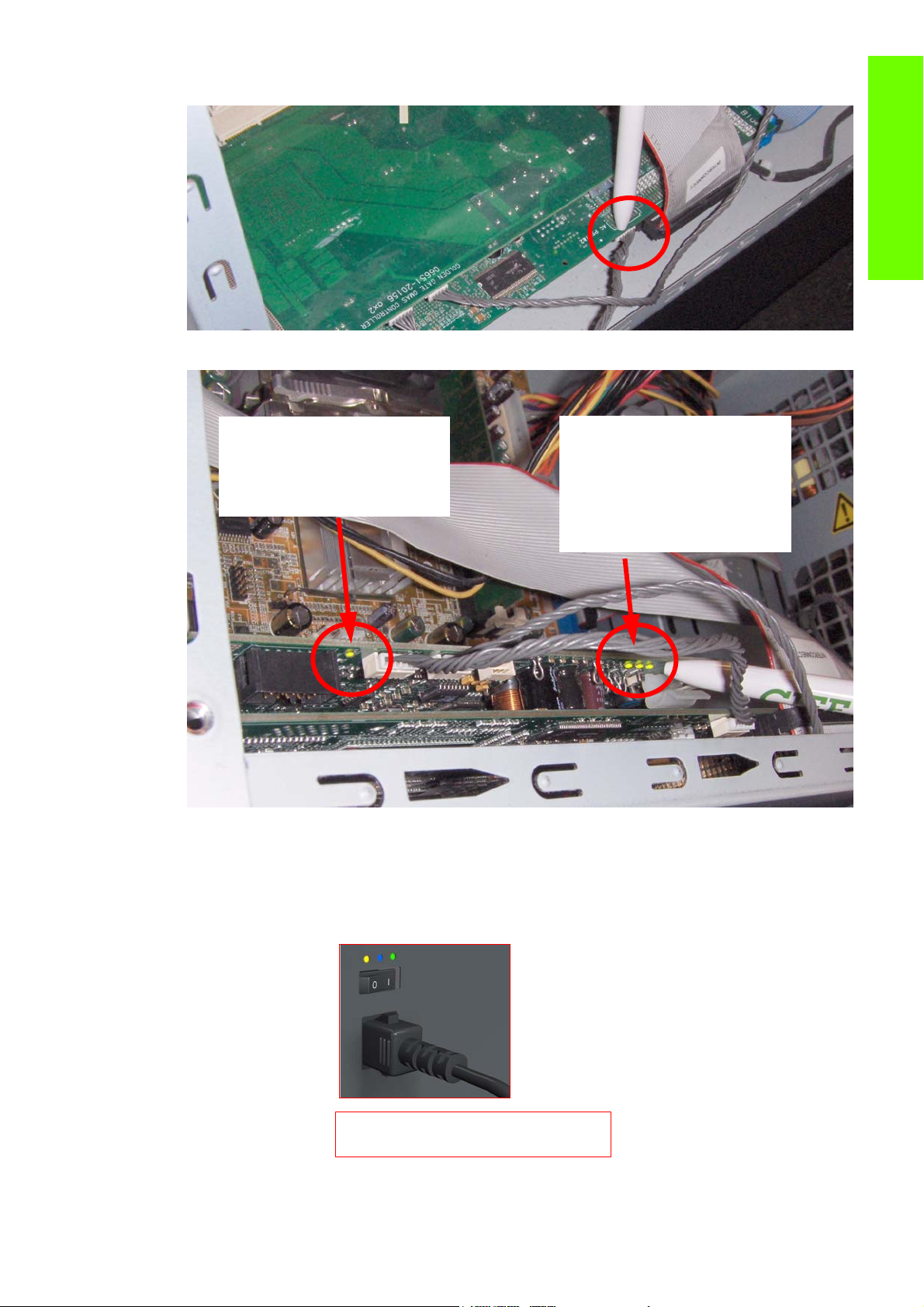

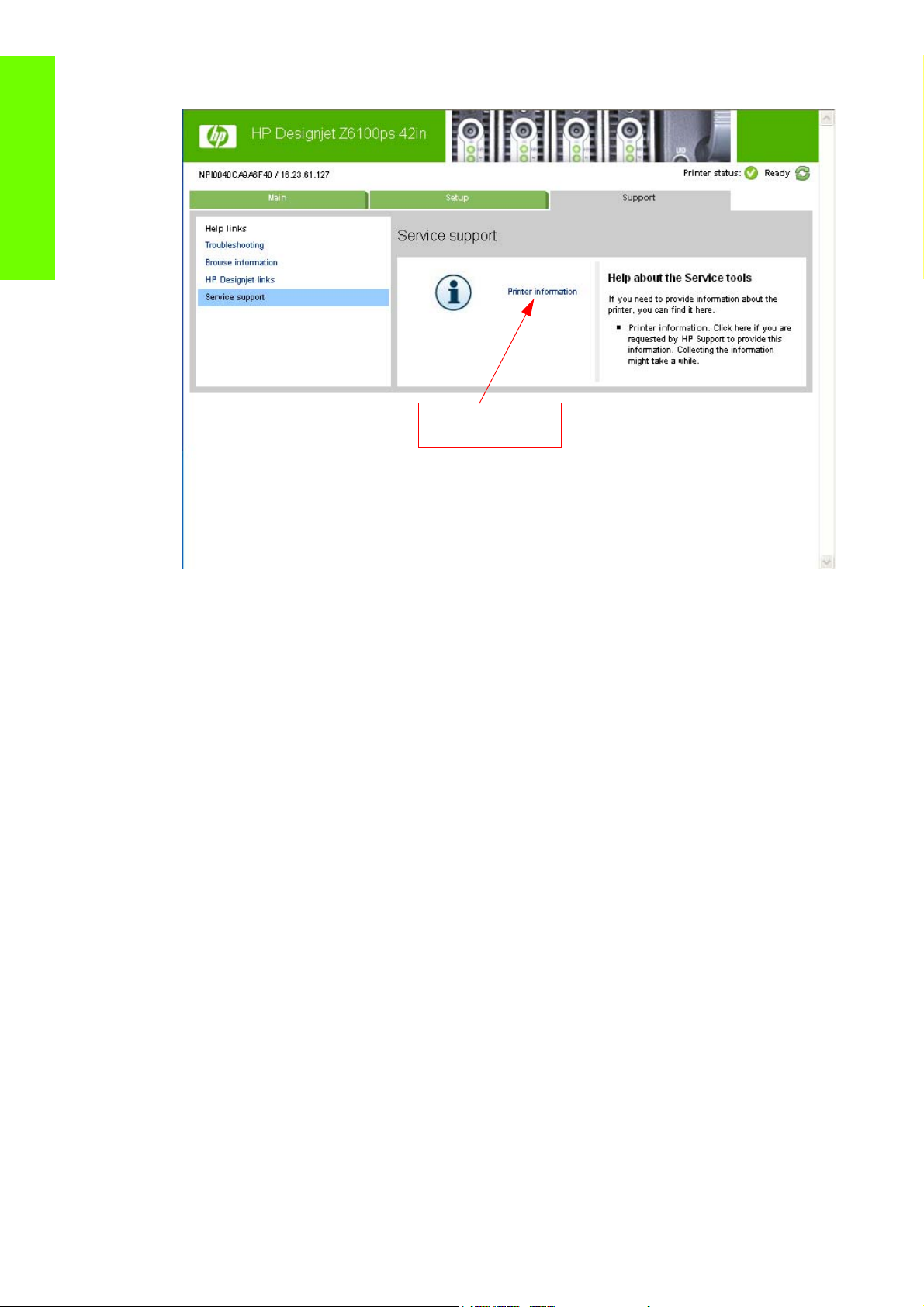

Troubleshooting OMAS problem

A problem with the OMAS board may cause the printer to display a 50.2:10 service error, this can

be fixed by checking the following connections.

1. Check the CAN Cable is correctly connected.

Hard Disk Drive ⇒ See

14 Chapter 1 Troubleshooting

Page 25

2. Check the other end of the CAN cable is also correctly connected

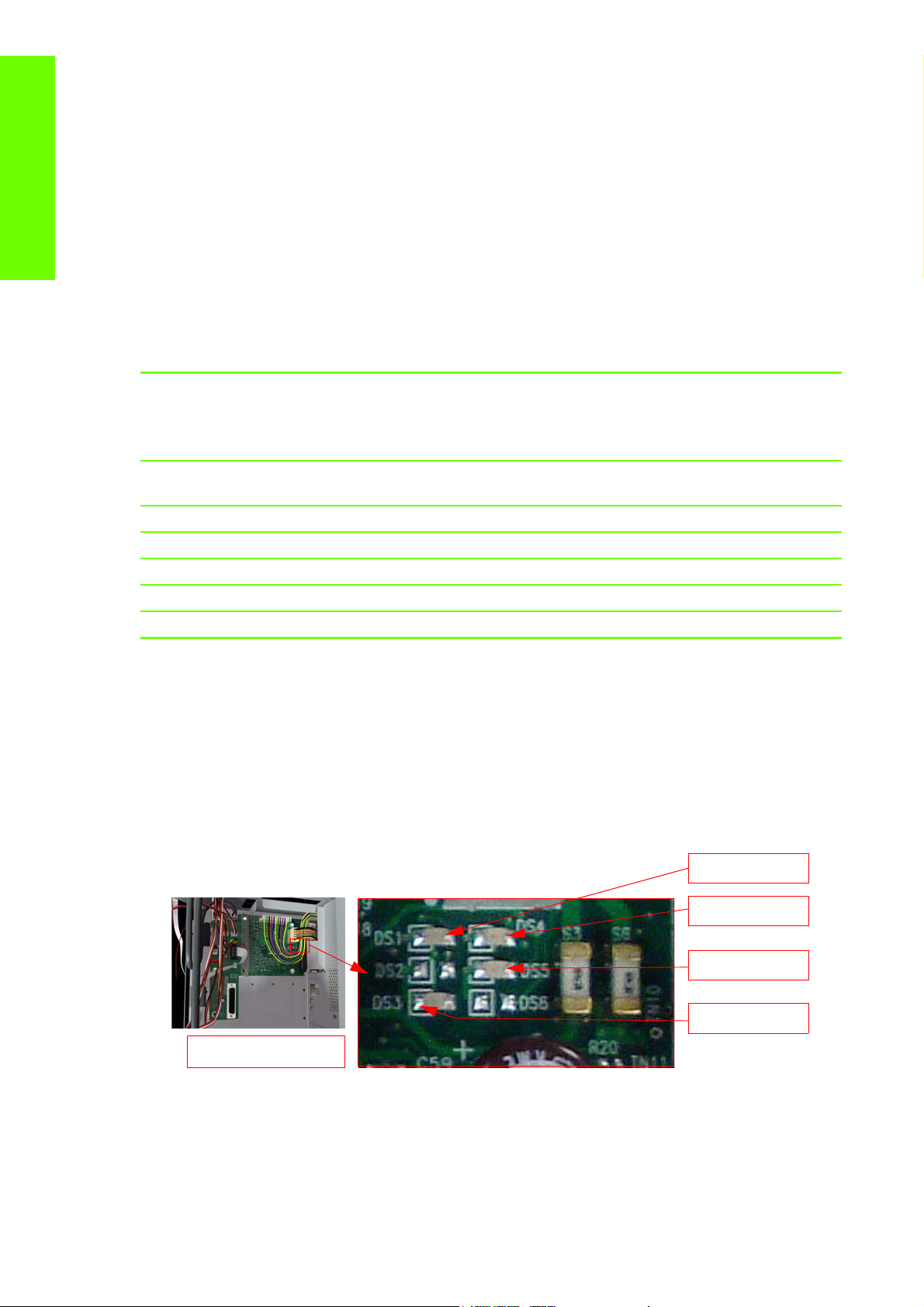

This LED only comes on for the first

20 seconds after the printer is

turned On. When the firmware has

succesfully loaded into the memory

the LED will switch OFF.

These LEDs come On and stay lit.

From right to left:

1st LED=24 volts

2nd LED=5 volts

3rd LED=3.3 volts

Amber is on the Left

Blue is in the center

Green is on the Right

Make sure you look directly at the LEDs

and not at an angle.

3. Check the LEDs under the OMAS board.

Troubleshooting

Using the Power Switch LEDs to Troubleshoot

In certain circumstances, the LEDs located on top of the power switch (located at the rear of the Printer)

Using the Power Switch LEDs to Troubleshoot 15

can help to troubleshoot the Printer. The LEDs can either be ON or Off and using different combinations

can indicate different problems:

Page 26

1. When only the Amber LED is On:

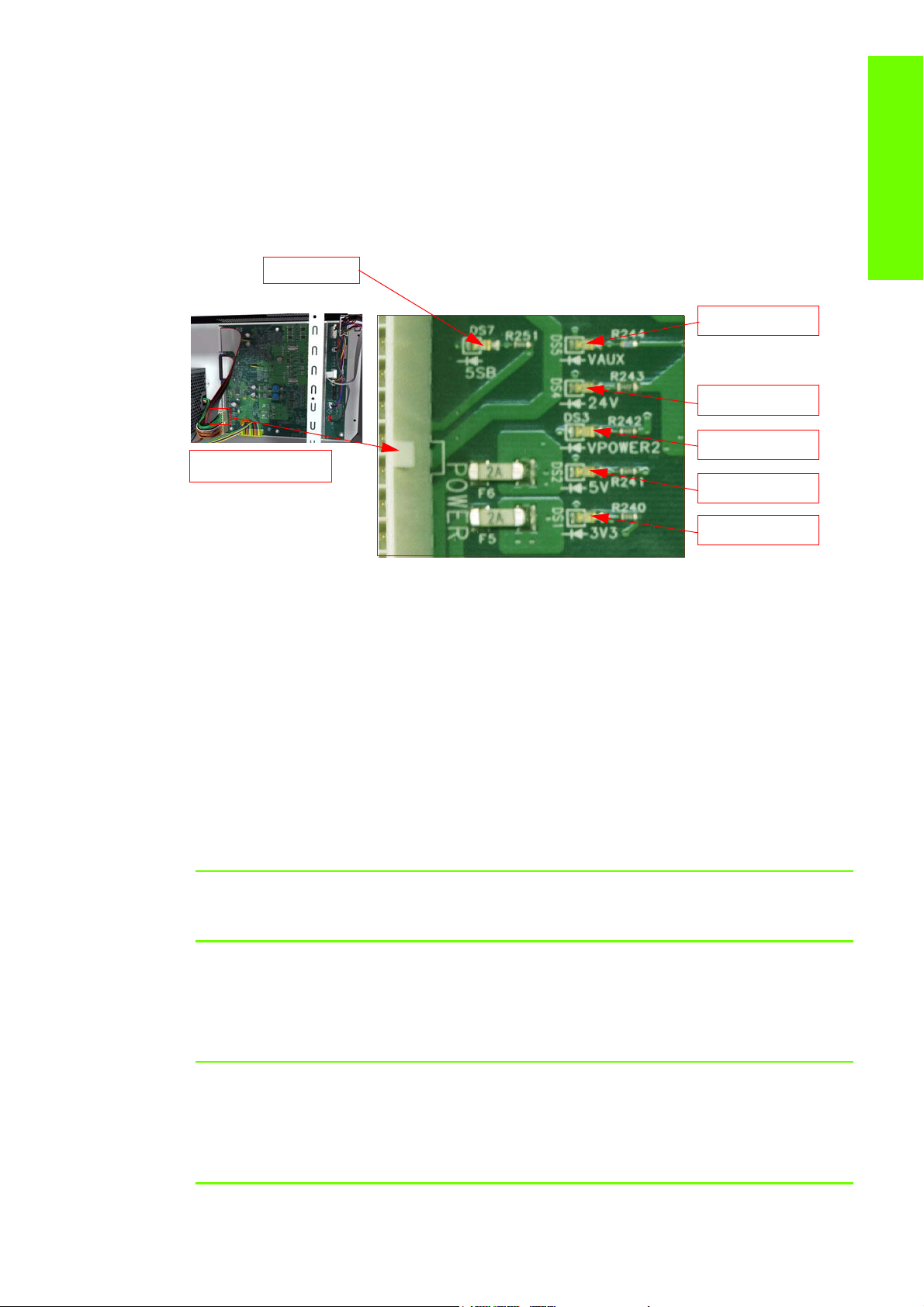

Interconnect PCA

DS5: 5V

DS3: 5Vsb

DS1: 24V

DS4: VPOWER2

• The Printer has been switched Off from the Front Panel (after having pressed the On/Off but-

ton).

• The Power Supply Unit only delivers a 5 V “Standby”; power that is needed to restart the Printer

after the Front Panel On/Off button is pressed (the Formatter/Main PCA will initiate the Printer

to start).

Troubleshooting

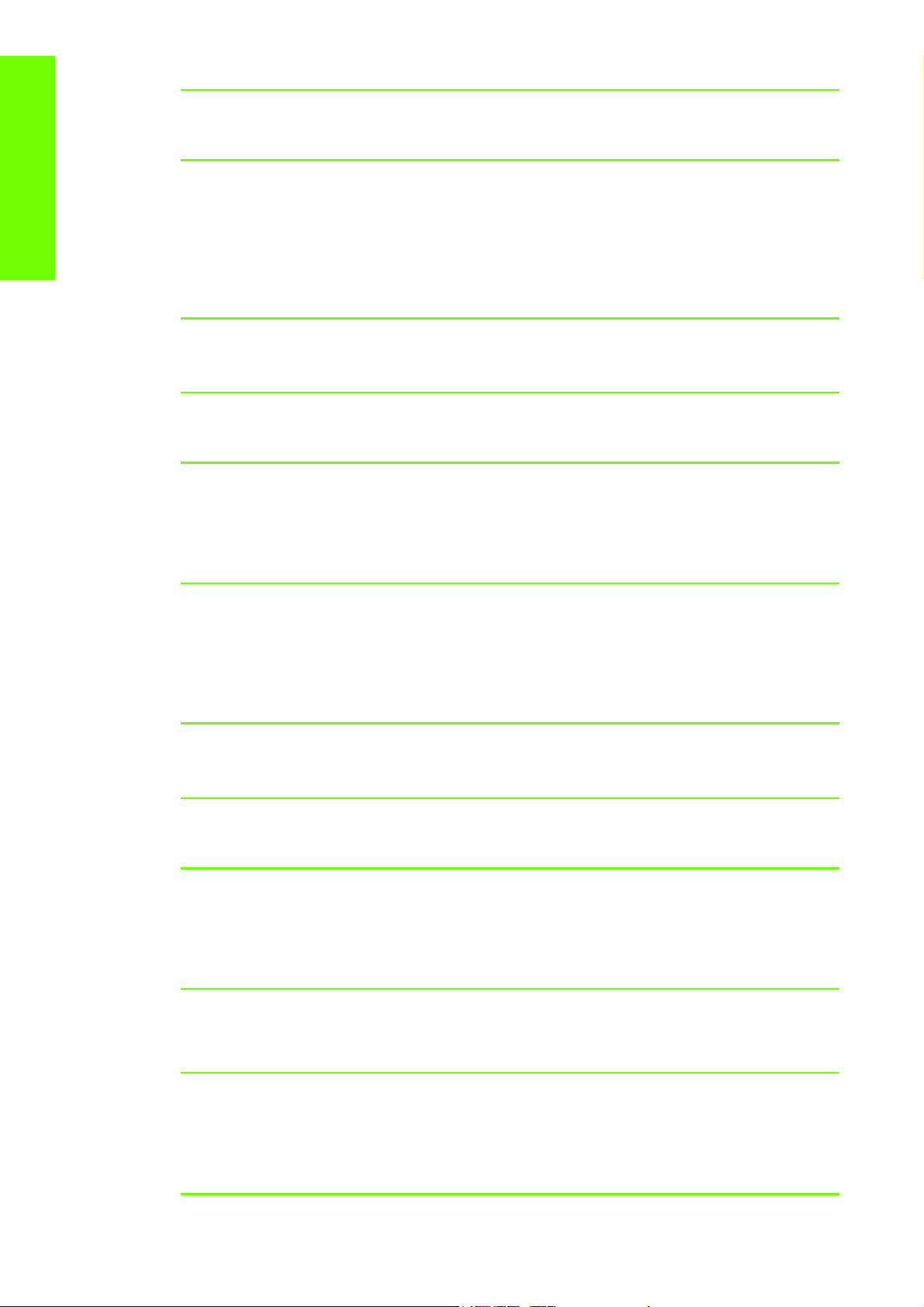

2. When the Blue LED is On: Deliver standard “ATX” power for the Electronics Module PCAs (+12V,

+5V, -5V, -12V, etc...). All the functions of the Electronics Module are fully operational (EWS, etc...).

3. When the Green LED is On: Deliver “analog” 24V and 42V to enable printing.

The Printer monitors and reports different signals: PSU fan issues, 24V and 42V delivery failures (specific

System Error reported pointing to PSU failure).

PSU Blue

LED

Status

ON OFF Red (Front Panel Black)

ON OFF Green (flashing) Initializing

ON ON Green Ready (but not printing)

ON ON Green Printing or preparing to print

OFF ON Any Not possible

ON ON Red (Front Panel Black) Not possible

PSU

Green

LED

Status

Left LED (on Front

Panel) Status

Using the PCA LEDs to Troubleshoot

Printer Status

Standby (with Embedded Web Server up and

running)

In certain circumstances, the LEDs located on the Interconnect PCA and PrintMech PCA can help to

troubleshoot the Printer. The LEDs can either be ON or Off and using different combinations can indicate

different problems.

Interconnect PCA

The following illustration shows the locations of the LEDs on the Interconnect PCA

5V - Comes from the PSU after the fuse on Interconnect PCA. Used to power On Front Panel and some

Interconnect Electronics. Should be ON at the same time as Blue Power Switch LED.

5Vsb - Comes from the PSU after the fuse on Interconnect PCA. Used to power On the Printer from the

Front Panel. Should be ON at the same time as Blue or Amber Power Switch LED.