HP 8640b schematic

TM 11-6625-2780-14&P

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS FOR

SIGNAL GENERATORS SG-1 112(V)1/U

(NSN 6625-00-566-3067)

AND SG-1l12(V)2/U (NSN 6625-00-500-6525)

(HEWLETT-PACKARD MODEL 8640B,

OPTIONS 001 AND 004)

HEADQUARTERS, DEPARTMENT OF THE ARMY

31 DECEMBER 1980

By Order of the Secretary of the Army:

E. C. MEYER

General, United States Army

Official: Chief of Staff

J. C. PENNINGTON

Major General, United States Army

The Adjutant General

DISTRIBUTION:

To be distributed in accordance with distribution list.

This manual contains copyright material reproduced by permission of the Hewlett-Packard Company.

|

TM 11-6625-2780-14&P |

T E C H N I C A L M A N U A L |

HEADQUARTERS |

|

DEPARTMENT OF THE ARMY |

No. 11-6625-2780-14&P |

WASHINGTON, DC 31 December 1980 |

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

AND GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

FOR

SIGNAL GENERATORS SG-1112(V)1/U (NSN 6625-00-566-3067)

AND SG-1112(V)2/U (NSN 6625-00-500-6525)

(HEWLETT-PACKARD MODEL 8640B, OPTIONS 001 AND 004)

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you know of a way to improve the procedures, please let us know. Mail your letter, DA Form 2028 (Recommended Changes to Publications and Blank Forms), or DA Form 2028-2 located in the back of this manual, direct to: Commander, US Army Communications and Electronics Materiel Readiness Command and Fort Monmouth, ATTN: DRSEL-ME-MQ,

Fort Monmouth, NJ 07703.

In either case, a reply will be furnished direct to you.

This manual is an authentication of the manufacturer’s commercial literature which, through usage, has been found to rover the data required to opersaate and maintain this equipment. The manual was not prepared in accordance with military specifications; therefore, the format has not been structured to consider categories of maintenance.

i

Model 8640B Option 004 |

Table of Contents |

CONTENTS

S e c t i o n |

|

|

|

|

|

|

Page |

|

o |

INTRODUCTION . . . . . . . . . . . . . . . . . . . 0-1 |

|||||||

I |

GENERAL |

|

INFORMATION |

|

. . . . . . . 1-1 |

|||

1-1. |

Introduction . . . . . . . . . ...1-1 |

|||||||

1-6. |

Specifications . . . . . . . . . . . . 1-1 |

|||||||

1-8. |

Instruments Covered by Manual . . . . . . 1-1 |

|||||||

1-13. |

General Description . . . . . . . . . . 1-2 |

|||||||

1-19. |

Performance Characteristics . . . . . . . 1-2 |

|||||||

1-20. |

Spectral Purity . . . . . . . . . . 1-2 |

|||||||

1-26. |

Frequency Counter . . . . . . . . . 1-3 |

|||||||

1-31. |

Phase-Lock Mode . . . . . . . . . 1-3 |

|||||||

1-37. |

Amplitude Modulation . . . . . . . . 1-4 |

|||||||

1-42. |

Pulse Modulation . . . . . . . . . . 1-4 |

|||||||

1-45. |

Frequency Modulation . . . . . . . . 1-4 |

|||||||

1-48. |

Standard and Optional Audio Oscillators . . 1-5 |

|||||||

1-51. |

Multi-Function Meter and Annunciators . . 1-5 |

|||||||

1-57. |

Output Level . . . |

. |

. |

1-6 |

||||

1-61. |

Options . . . . . . . . . |

. |

. . . . |

1-6 |

||||

1-65. |

Accessories |

Supplied . . . . |

. |

. . . . |

1-6 |

|||

1-69. |

Equipment |

Available . . . . |

. |

. . . . |

1-6 |

|||

1-76. |

Service and User Aids . . . . |

. |

. . . . |

1-7 |

||||

1-82. |

Test Equipment Required . . . |

. |

. . . . |

1-7 |

||||

II |

INSTALLATION . . . . . . |

. |

. . . . |

2-1 |

||||

2-1. |

Introduction . . . . . . . |

. |

. . . . |

2-1 |

||||

2-3. |

Initial |

Inspection . . . . . . |

. |

. . . . |

2-1 |

|||

2-5. |

Preparation |

for |

Use . . . . . |

. |

. . . . |

2-1 |

||

2-6. |

Power |

Requirements . . . |

. |

. . . . |

2-1 |

|||

2-8. |

Line Voltage Selection . . . |

. |

. . . . |

2-2 |

||||

2-11. |

Power |

Cable . . . . . . |

. |

. . . . |

2-2 |

|||

2-13. |

Mating Connectors . . . . |

. |

. . . . |

2-3 |

||||

2-15. |

Operating Environment . . |

. |

. . . . |

2-3 |

||||

2-18. |

Bench |

Operation . . . . . |

. |

. . . . |

2-3 |

|||

2-20. |

Rack |

Mounting . . . . . |

. |

. . . . |

2-3 |

|||

2-22. |

Storage and Shipment . . . . |

. |

. . . . |

2-3 |

||||

2-23. |

Environment . . . . . . |

. |

. . . . |

2-3 |

||||

2-25. |

Packaging . . . . . . . |

. |

. . . . |

2-3 |

||||

III |

OPERATION |

. . . . . . . |

. |

. . . |

3-1 |

|||

3-1. |

Introduction . . . . . . . |

. |

. . . . |

3-1 |

||||

3-3. |

Panel |

Features . . . . . . |

. |

. . . . |

3-1 |

|||

3-5. |

Operator’s |

Checks . . . . . |

. |

. . . . |

3-1 |

|||

3-7. |

Operating |

Instructions . . . . |

. |

. . . . |

3-1 |

|||

3-9. |

Operator’s |

Maintenance . . . |

. |

. . . . |

3-1 |

|||

IV |

PERFORMANCE TESTS . . . |

. |

. . . . |

4-1 |

||||

4-1. |

Introduction . . . . . . . |

. |

. . . . |

4-1 |

||||

4-4. |

Equipment |

Required . . . . |

. |

. . . . |

4-1 |

|||

4-6. |

Test |

Record . . . . . . . |

. |

. . . . |

4-1 |

|||

4-8. |

Test |

Procedures . . . . . . |

. |

. . . . |

4-1 |

|||

4-12. |

Basic |

Functional Checks . . . |

. |

. . . . |

4-5 |

|||

Section |

|

|

|

|

|

|

|

Page |

|

IV PERFORMANCE TESTS (cont’d) |

|

||||||||

4-13. |

Frequency |

|

Range |

Test . . . . . . . |

4-13 |

||||

4-14. Frequency Accuracy and Fine Tune Test . |

4-14 |

||||||||

4-15. Frequency Stability Vs Time and |

|

||||||||

|

Restabilization |

Time Test . . . . |

4-16 |

||||||

4-16. Frequency Stability Vs Temperature Test. |

4-18 |

||||||||

4-17. Frequency Stability Vs Line Voltage Test . |

4-19 |

||||||||

4-18. Frequency Stability Vs Load, Level, and |

|

||||||||

|

Mode Test . . . . . . . . . . |

4-20 |

|||||||

4-19. |

Harmonics |

Test . . . . . . . . . |

4-21 |

||||||

4-20. Sub-Harmonics and Non-Harmonic |

|

||||||||

|

Spurious |

Test . . . . . . . . |

4-23 |

||||||

4-21. Single Sideband Phase Noise Test . . . |

4-25 |

||||||||

4-22. Single Sideband Broadband Noise Floor |

|

||||||||

|

Test . . . . . . . . . . . . |

4-27 |

|||||||

4-23. |

Residual AM Test . . . . . . . . |

4-30 |

|||||||

4-24. |

Residual |

FM |

Test . . . . . . . . |

4-31 |

|||||

4-25. Output Level Accuracy Test (abbreviated). |

4-34 |

||||||||

4-26. Output Level Accuracy Test (complete) . |

4-39 |

||||||||

4-27. |

Output Level Flatness Test . . . . . |

4-45 |

|||||||

4-28. |

Output Impedance Test (Signal-Frequency) . 4-47 |

||||||||

4-29. |

Output Impedance Test (Broadband) . . . |

4-49 |

|||||||

4-30. |

Auxiliary Output Test . . . . . . . . |

4-50 |

|||||||

4-31. |

Output Leakage Test . . . . . . . . |

4-51 |

|||||||

4-32. |

Internal |

Modulation |

Oscillator Test . . . . |

4-53 |

|||||

4-33. Internal |

Modulation |

Oscillator |

|

||||||

|

Distortion Test (Option 001) . . . . . |

4-55 |

|||||||

4-34. |

AM 3 dB Bandwidth Test . . . . . . . |

4-56 |

|||||||

4-35. |

AM Distortion Test . . . . . . . . . |

4-58 |

|||||||

4-36. |

AM Sensitivity and Accuracy Test . . . . |

4-59 |

|||||||

4-37. |

Peak Incidental Phase Modulation Test . . |

4-62 |

|||||||

4-38. |

Demodulated Output Accuracy Test . . . |

4-65 |

|||||||

4-39. |

AM Phase Shift Test . . . . . . . . . |

4-69 |

|||||||

4-40. |

AM Flatness Test . . . . . . . . . . |

4-71 |

|||||||

4-41. |

Pulse Modulation Test . . . . . . . . |

4-73 |

|||||||

4-42. |

Pulse |

On/Off |

Ratio |

Test . . . . . . . |

4-77 |

||||

4-43. |

FM 3 dB Bandwidth Test . . . . . . . |

4-78 |

|||||||

4-44. |

FM Distortion Test . . . . . . . . . |

4-79 |

|||||||

4-45. |

FM Sensitivity and Accuracy Test . . . . |

4-81 |

|||||||

4-46. |

Incidental AM Test . . . . . . . . . |

4-85 |

|||||||

4-47. |

Counter External Sensitivity Test . . . . |

4-87 |

|||||||

4-48. |

Internal |

Reference |

Accuracy Test . . . . |

4-88 |

|||||

4-49. Internal Reference Drift Rate (Stability) |

|

||||||||

|

Test . . . . . . . . . . . . |

.4-89 |

|||||||

4-50. Phase Lock Restabilization Time Test . . . 4-92 |

|||||||||

V |

ADJUSTMENTS . . . . . . . . . . |

5-1 |

|||||||

|

|

|

|

|

. |

|

|

|

|

5-1. |

Introduction . . . . . . . . . . . |

5-1 |

|||||||

5-3. |

Safety |

Considerations . . . . . . . . |

5-1 |

||||||

5-9. Test Equipment Required . . . . . . . |

5-1 |

||||||||

5-11. |

Posidriv |

Screwdrivers . . . . . . . |

5-1 |

||||||

ii

Model 8640B Option 004 |

Table of Contents |

SERVICE SHEETS

Service Sheet |

|

Page |

|

1 |

Overall Block |

Diagram . . . . . . . . |

8-18 |

2 |

FM Circuits and RF Oscillator |

|

|

|

Troubleshooting . . . . . . . . . |

8-20 |

|

3 |

AM/AGC Circuits and Output Amplifier |

|

|

|

Troubleshooting . . . . . . . . . |

8-22 |

|

4 |

Counter/Lock Circuits Troubleshooting . . |

8-24 |

|

5 |

RF Oscillator |

(A3) . . . . . . . . . |

8-26 |

6FM Amplifiers (A3, A5, A9, A13) . . . . 8-28

7FM Shaping Circuits and Phase Lock

|

|

Loop |

Filter (A7, A9) . . . . . . . |

8-30 |

8 |

Over-Deviation Detector and Meter |

|

||

|

Control Circuits (A6, A7, A9) . . . . |

8-32 |

||

9 |

Fixed-Frequency Modulation Oscillator |

|

||

|

(A1l, |

A13) . . . . . . . . . . |

8-34 |

|

9A Variable-Frequency Modulation |

|

|||

|

Oscillator for Option 001 |

|

||

|

(A1l, |

A13) . . . . . . . . . . |

8-36 |

|

10 |

RF |

Filters (A10A1) . . . . . . . . . |

8-38 |

|

11 |

RF |

Dividers (A10A2) . . . . . . . . |

8-40 |

|

12AGC Amplifiers and Amplitude Modulator

(A26, A26A3, A26A4) . . . . . . . 8-42

13RF Amplifier, Pulse Switching, and

Step Attenuators (A1A1, A19A1,

A26, A26A1, A26A2) . . . . . . . 8-44 14 AM Preamplifier (A13, A26A2) . . . . . 8-46

Service Sheet |

|

Page |

|

15 |

AM Interconnections, RF ON/OFF Switch |

|

|

|

and Demodulation Amplifier |

|

|

|

(A9, |

A26A8) . . . . . . . . . . |

8-48 |

16 |

RF Vernier (A19A1, A26) . . . . . . . 8-50 |

||

17 |

Meter Circuits (A2, A4, A6) . . . . . . |

8-52 |

|

18 |

Counter RF Scaler (A8A1, A8A3) . . . . 8-54 |

||

19 |

Counter Time Base (A8A3, A9) . . . . . 8-56 |

||

20 |

Up/Down Counter & Display (A8A2, A8A4) . 8-58 |

||

21 Counter Phase Lock Circuits (A8A2) . . . 8-60 |

|||

22 |

Power Supply Circuits |

|

|

|

(A12, A14, A20, A22) . . . . . . . 8-62 |

||

23 |

–5.2V Regulator and Fan Circuits |

|

|

|

(A16, |

A18). . . . . . . . . . . |

8-64 |

24Power Supply Mother Board (A17) . . . . 8-67

25Modulation/Metering Mother Board (A13) . 8-68 A Al and A19 Assemblies Removal

|

and |

Disassembly . . . . . . . . . |

8-70 |

B |

A3 Assembly Removal and Disassembly . . |

8-72 |

|

C |

A8 Assembly Removal and Disassembly . . |

8-74 |

|

D |

A9 and All Assemblies Removal |

|

|

|

and |

Disassembly . . . . . . . . . |

8-76 |

EAl0 Assembly Removal and Disassembly . . 8-78

FA26 Assembly Removal and Disassembly . . 8-80

GGeneral Removal Procedures and

|

Top Internal Views . . . . . . |

. . |

8-82 |

H |

Rear Panel and Bottom Internal Views |

. . |

8-85 |

|

|

|

|

|

|

TABLES |

|

|

|

|

Table |

|

|

|

|

Page |

Table |

|

|

Page |

|

1-1. |

Specifications . . . . . . . . . . |

. . |

1-8 |

6-4. |

Code List of Manufacturers . . . |

. . |

6-45 |

|||

1-2. |

Recommended Test Equipment . . . . |

. . |

1-14 |

7-1. |

Manual Changes by Serial Number . |

. . |

7-1 |

|||

1-3. |

Recommended Test Accessories . . . . |

. . |

1-19 |

7-2. |

Summary of Changes by Component |

. . |

7-2 |

|||

4-1. |

Recommended |

Test |

Abridgements . . . |

. . |

4-2 |

8-1. |

Etched Circuit Soldering Equipment |

. . |

8-4 |

|

4-2. |

Recommended |

Test |

Equipment |

|

|

8-2. |

Logic Levels . . . . . . . . |

. . |

8-6 |

|

|

(Basic Functional Checks) . . . . . |

. . |

4-5 |

8-3. |

Assembly Information Index . . . |

. |

8-14 |

|||

4-3. |

Record of Basic Functional Checks . . . |

. . |

4-11 |

8-4. |

Schematic Diagram Notes . . . . |

. . |

8-15 |

|||

4-4. |

Performance Test |

Record . . . . . . |

. . |

4-94 |

8-5. |

Meter Drive Amplifier Data . . . |

. . |

8-52 |

||

5-1. |

Factory Selected Components . . . . |

. . |

5-3 |

8-6. |

Total Count of Time Base Reference |

. . |

8-56 |

|||

5-2. |

Post-Repair Test and Adjustments . . . |

. . |

5-4 |

|

Counters U13, U14, and U15 . |

|||||

5-3. |

RF Filter |

Check . . . . . . . . . |

. . |

5-32 |

8-7. |

Count Modes of Counters A8A3U13 |

|

|

||

6-1. |

Part Numbers for Exchange Assemblies |

. . . 6-2 |

|

and U14 . . . . . . . . |

. . |

8-56 |

||||

6-2. |

Reference Designations and |

|

|

8-8. |

Count Modes of Counter A8A3U15 |

. . |

8-56 |

|||

|

Abbreviations . . . . . . . . . |

. . |

6-3 |

8-9. |

Data Inputs of Decimal Point |

|

|

|||

6-3. |

Replaceable |

Parts . . . . . . . . |

. . 6-5 |

|

Shift Register . . . . . . . |

. . |

8-56 |

|||

6 - 5 . P a r t N u m b e r - N a t i o n a l S t o c k N u m b e r |

|

|

|

|

||||||

|

Cross |

Reference Index. . . |

. |

6 - 4 5 |

|

|

|

|

||

|

|

APPENDIXES |

|

A. References . . . . |

. . |

. .. A-l |

C . |

B . C o m p o n e n t s o f E N D |

I t e m |

L i s t . B - 1 |

D . |

A d d i t i o n a l A u t h o r i z a t i o n List |

N . A . |

M a i n t e n a n c e A l l o c a t i o n . |

D - 1 |

|

i v |

Table of contents |

Model 8640B Option 004 |

ILLUSTRATIONS

1-1. |

HP Model 8640B Option 004 Signal Generator |

|

|

|||||

|

(Option 001) and Accessories Supplied |

1-0 |

||||||

1-2. |

Measured |

Single Sideband Noise vs Offset |

|

|

||||

|

from Carrier . . . . . . . . .. |

|

1-2 |

|||||

1-3. |

Specified Signal-to-Phase Noise Ratio . . . |

|

1-3 |

|||||

1-4. |

AM Distortion vs AM Rate . . . . . . |

|

1-4 |

|||||

1-5. |

Pulsed |

RF . . . . . . . . . . . |

|

.1-5 |

||||

1-6. |

FM Distortion vs FM Rate . . . . . . . |

1-5 |

||||||

1-7. |

520/1040 |

MHz Notch |

Filter . . . . . . |

|

1-20 |

|||

1-8. |

FM Linearity |

Circuit . . . . . . . . |

|

1-20 |

||||

1-9. |

|

|||||||

Noise Phase Lock Circuit . . . . . . . |

|

1-21 |

||||||

|

|

|||||||

2-1. |

Line Selector . . . . . . . . . . . |

|

2-1 |

|||||

2-2. |

Power Cables Available , . . . . . . . |

|

2-2 |

|||||

2-3. |

Preparation for Rack Mounting . . . . . |

|

2-4 |

|||||

3-1. |

Lamp |

Replacement . . . . . . . . . |

|

3-1 |

||||

3-2. |

Front Panel Controls, Indicators, and |

|

|

|||||

|

connectors . . . . . . . . . .. |

|

3-2 |

|||||

3-3. |

Internal AC/DC Switch , . . . . . . . |

|

3-6 |

|||||

3-4. |

Rear Panel Controls and Connectors . . . |

3-7 |

||||||

3-5. |

Operator's |

Checks . . . . . . . . . |

|

3-8 |

||||

3-6. |

Setting the Frequency and Amplitude |

|

|

|||||

|

|

|

||||||

|

Controls . . . . . . . . . .. |

|

3-13 |

|||||

3-7.. |

Setting |

the Modulation Controls. . . . . |

|

3-16 |

||||

4-1. Frequency Stability vs Time and Restabiliza- |

|

|

||||||

|

tion |

Time |

Test |

Setup . . . . . . . |

|

4-16 |

||

4-2. |

Frequency Stability vs Temperature |

|

|

|||||

|

Test |

Setup |

. . |

. |

. . . . . . . |

.4-18 |

||

4-3. Frequency Stability vs Line Voltage |

|

|

||||||

|

Test |

setup |

. . |

. |

. . . . . . . |

.4-19 |

||

4-4. Frequency Stability vs Load, Level, and |

|

|

||||||

|

Mode |

Test |

Setup. . . . . . . . . |

|

4-20 |

|||

4-5. SubHamonics and Non-Harmonic |

|

|

||||||

|

Spurious Test |

Setip . . . . |

|

4-24 |

||||

4-6. Single sideband Phase Noise Test Setup . . 4-25

4-7. Single sideband Broadband Noise |

|

|

|

Floor Test Setup . . . . . . . . . |

4-28 |

4-8. |

Residual AM Test Setup . . . . . . . |

4-30 |

4-9. |

Residual FM Test Setup . . . . . . . |

4-32 |

4-10. |

Output Level Accuracy Test Setup |

|

|

(Abbreviated) . . . . . . . . . . |

4-34 |

4-11. Output Level Accuracy Test Setup |

|

|

|

(Complete). . . . . . , . . . . |

4-41 |

4-12. |

Output Level Flatness Test Setup . . . . |

4-45 |

4-13. Output Impedance Test Setup |

|

|

|

(Signal Frequency) . . . . . . . . |

4-47 |

4-14. |

Output Impedance Test (Broadband) . . . |

4-49 |

4-15. |

Output Leakage Test Setup . . . . . . |

4-52 |

4-16. |

Internal Modulation Oscillator Test |

|

|

setup . . . . . . . . . . . . |

4-54 |

Figure |

|

|

Page |

4-17. Internal Modulation Oscillator Distortion |

|

||

|

Test |

Setup . . . . . . . . . . |

.4-55 |

4-18. |

AM 3 dB Bandwidth Test Setup . . . . . |

4-56 |

|

4-19. |

AM Distortion Test Setup . . . . . . . |

4-58 |

|

4-20. AM Sensitivity and Accuracy Test Setup . . 4-60 |

|||

4-21. Peak Incidental Phase Modulation |

|

||

|

Test |

Setup . . . . . . . . . . |

.4-63 |

4-22. Demodulated Output Accuracy Test |

|

||

|

Setup . . . . . . . . . . . |

.4-65 |

|

4-23. |

AM Phase Shift Test Setup . . . . . . |

4-69 |

|

4-24. |

Lissajous Display . . . . . . . . . . |

4-70 |

|

4-25. |

AM Flatness Test Setup . . . . . . . |

4-72 |

|

4-26. |

Pulse Modulation Test Setup . . . . . . |

4-74 |

|

4-27. |

Pulse Measurements . . . . . . . . . |

4-75 |

|

4-28. |

FM 3 dB Bandwidth Test Setup . . . . . |

4-78 |

|

4-29. |

FM Distortion Test Setup . . . . . . . |

4-80 |

|

4-30. FM Sensitivity and Accuracy Test Setup . . 4-82 |

|||

4-31. |

Incidental AM Test Setup . . . . . . . |

4-85 |

|

4-32. Counter External Sensitivity Test Setup . . 4-87 4-33. Internal Reference Accuracy Test Setup . . 4-88

4-34. Internal Reference Drift Rate (Stability) |

|

||||||

|

Test |

Setup . . . . . . . . . . |

.4-90 |

||||

5-1. |

RF Detector Offset Adjustment Test |

|

|||||

|

Setup . . . . . . . . . . . . |

5-13 |

|||||

5-2. |

Output Level Vernier and Meter Adjustment |

|

|||||

|

Test Setup . . . . . . . . . . . |

5-15 |

|||||

5-3. |

Preliminary AM Adjustments . . . . . . |

5-17 |

|||||

5-4. |

AM Accuracy Adjustment Test Setup . . . |

5-19 |

|||||

5-5. |

VT |

Pot |

Adjustment . . . . . . . . . |

5-24 |

|||

5-6. Location of RF Oscillator Stop Adjustments. |

|

||||||

|

Shown in Maximum ccw Position. Top |

|

|||||

|

View with Instrument Upside Down . . 5-26 |

||||||

5-7. |

RF Oscillator Output Power Adjustment |

|

|||||

|

Test Setup . . . . . . . . . . . |

5-28 |

|||||

5-8. |

Filter |

Terminology . . . . . . . . . |

5-29 |

||||

5-9. |

RF |

Filter |

Adjustment Test Setup . . . . |

5-30 |

|||

5-10.256-512 MHz High Band Capacitor |

|

||||||

|

Adjustment |

Orientation . . . . . . |

5-33 |

||||

5-11. FM Linearity |

Adjustment Test Setup . . . |

5-36 |

|||||

5-12. FM Linearity |

Display . . . . . . . . |

5-38 |

|||||

5-13. FM Linearity Adjustment (Alternate) |

|

||||||

|

Test |

Setup . . . . . . . . . . |

.5-39 |

||||

5-14. FM Sensitivity Adjustment Test Setup . . . 5-41 |

|||||||

5-15. Internal Reference Frequency Adjustment |

|

||||||

|

Test Setup . . . . . . . . . . |

.5-42 |

|||||

6-1. |

Cabinet |

Parts . . . . . . . . . .. |

6-43 |

||||

6-2. |

Type |

“N” |

Connector . . . . . . . . |

6-44 |

|||

v

Model 8640B Option 004 |

Table of Contents |

ILLUSTRATIONS (cont'd)

Figure |

|

|

|

|

|

|

Page |

Figure |

|

|

|

Page |

|

7-1. |

|

A26A2 AM Offset and Pulse Switching Assembly |

|

8-26. A5 FM Amplifier Assembly Component |

|

||||||||

|

|

|

Backdating (Change C) . . . . . . . |

. |

7-6 |

Locations . . . . . . . . . .. |

8-29 |

||||||

7-2. |

|

A12 Rectifier Assembly Component Locations |

|

|

8-27. FM Amplifiers Schematic Diagram . . . . 8-29 |

||||||||

|

|

|

Backdating |

(Change C) . . . . . . . |

. |

7-7 |

8-28. P/O A7 FM Shaping Assembly |

|

|||||

7-3. |

A12 Rectifier Assembly Backdating |

|

|

Component |

Locations . . . . . . |

8-31 |

|||||||

|

|

|

(Change) . . . . . . . . . . . |

. |

7-7 |

8-29. FM Shaping Circuits and Phase Lock Loop |

|

||||||

7-4. |

A3A4 Connector Board Assembly |

|

|

Filter Schematic |

Diagram . . . . . |

8-31 |

|||||||

|

|

|

Backdating (Change G) . . . . . . . |

. |

7-9 |

8-30. P/O A6 Annunciator Assembly |

|

||||||

7-5. |

|

A8A1 RF Scaler Assembly Component |

|

|

Component |

Locations . . . . . . |

8-32 |

||||||

|

|

|

Locations Backdating (Change H) . . . . |

7-10 |

8-31. P/O A9 Peak Deviation and Range Switch |

|

|||||||

7-6. |

|

A22 +20V and -20V Regulator Assembly |

|

|

Assembly Component Locations. . 8-32 |

||||||||

|

|

|

Component Locations Backdating |

|

|

8-32. P/O A7 FM Shaping Assembly |

|

||||||

|

|

|

(Change I) . . . . . . . . . . . |

.7-12 |

Component |

Locations . . . . . . |

8-33 |

||||||

7-7. |

|

Power Supply Circuits Backdating |

|

|

8-33. Over-Deviation Detector and Meter Control |

|

|||||||

|

|

|

(Change |

I) . . . . . . . . . . . . |

|

7-13 |

Circuits |

Schematic |

Diagram . . . . . |

8-33 |

|||

7-8. |

A22 +20V and -20V Regulator Assembly |

|

|

8-34. All Fixed-Frequency Modulation Oscillator |

|

||||||||

|

|

|

Backdating (Change I) . . . . . . . . |

|

7-14 |

Component |

Locations . . . . . . |

8-35 |

|||||

7-9. |

Modified |

Line Switch Wiring . . . . . . . |

7-18 |

8-35. Fixed-Frequency Modulation Oscillator |

|

||||||||

8-1. |

|

Signal Generator with Circuit Boards on |

|

|

Schematic |

Diagram . . . . . |

8-35 |

||||||

|

|

|

E x t e n d e r s . . . . . . . . . . . |

. 8 - 2 |

8-36. All Variable-Frequency Modulation |

|

|||||||

8-2. |

Examples of Diode and Transistor |

|

|

Oscillator Assembly (Option 001 ) |

|

||||||||

|

|

|

Marking |

Methods . . . . . . . . . |

. |

8-4 |

Component |

Locations . . . . . . . |

8-37 |

||||

8-3. |

Open Collector Output Stage (AND Gate) . |

. |

8-6 |

8-37. Variable-Frequency Modulation Oscillator |

|

||||||||

8-4. |

|

Binary Symbols . . . . . . . . . . |

. |

8-6 |

(Option |

001) Schematic Diagram . . . |

8-37 |

||||||

8-5. |

Triggered |

Flip-Flop . . . . . . . . . |

. |

8-7 |

8-38. Action of RANGE |

Switch . . . . . . . |

8-38 |

||||||

8-6. |

D |

F l i p - F l o p . . . . . . . . . . . . |

|

8 - 7 |

8-39. A10A1 RF Filter Assembly Component |

|

|||||||

8-7. |

Schmitt |

Trigger . . . . . . . . . . |

. |

8-7 |

Locations . . . . . . . . . .. |

8-38 |

|||||||

8-8. |

J/K Flip-Flop. . . . . . . . . . . |

. |

8-8 |

8-40. RF Filters |

Schematic Diagram . . . . . |

8-39 |

|||||||

8-9. |

Multiple Input J/K Flip-Flop . . . . . . |

. |

8-8 |

8-41. Simplified Logic Diagram of the Filter |

|

||||||||

8-10. |

Binary |

Latch . . . . . . . . . |

...8-9 |

Divider |

Assembly . . . . . . . |

8-40 |

|||||||

8-11. |

Binary Shift Register . . . . . . . . |

. |

8-9 |

8-42. A10A2 RF Divider Assembly Component |

|

||||||||

8-12. |

Basic Decade Counter (Scaler) . . . . . |

. |

8-9 |

Locations . . . . . . . . . .. |

8-41 |

||||||||

8-13. |

Programmable Counter . . . . . . . . . |

|

8-10 |

8-43. RF Dividers |

Schematic Diagram . . . . . |

8-41 |

|||||||

8-14. |

Programmable Up/Down Counter . . . . . 8-12 |

8-44. A26A3 Modulator Assembly Component |

|

||||||||||

8-15. |

Operational Amplifier . . . . . . . . . |

|

8-13 |

Locations . . . . . . . . . .. |

8-43 |

||||||||

8-16. |

Comparator . . . . . . . . . ...8-14 |

8-45. A26A4 AGC Amplifier Assembly |

|

||||||||||

8-17. |

Simplified Block Diagram . . . . . . . . |

8-19 |

Component |

Locations . . . . . . |

8-43 |

||||||||

8-18. |

Overall Block Diagram . . . . . . . . . |

8-19 |

8-46. AGC Amplifiers and Amplitude Modulator |

|

|||||||||

8-19. |

FM Circuits and RF Oscillator Block |

|

|

Schematic |

Diagram . . . . . . . . |

8-43 |

|||||||

|

|

|

Diagram . . . . . . . . . . . |

..8-21 |

8-47. A26A1 Power Amplifier and AGC Detector |

|

|||||||

8-20. |

AM/AGC Circuits and Output Amplifier |

|

|

Assembly Component Locations. . . . 8-45 |

|||||||||

|

|

|

Block |

Diagram . . . . . . . . . . |

8-23 |

8-48. P/O A26A2 AM Offset and Pulse Switching |

|

||||||

8-21. Counter/Lock Circuits Block Diagram . . . . 8-25 |

Assembly Component Locations. . . . 8-45 |

||||||||||||

8-22. |

P/O A3A4 Connector Board Assembly |

|

|

8-49. RF Amplifier, Pulse Switching, and Step |

|

||||||||

|

|

|

Component Locations . . . . . . . . |

8-27 |

Attenuator Schematic Diagram . . . . 8-45 |

||||||||

8-23. |

RF |

Oscillator |

Simplified Diagram . . . . . |

8-27 |

8-50. P/O A26A2 AM Offset and Pulse Switching |

|

|||||||

8-24. P/O A3A4 Connector Board Assembly |

|

|

Assembly Component Locations. . . . 8-47 |

||||||||||

|

|

|

Component |

Locations . . . . . . . . |

8-28 |

8-51. AM Preamplifier Schematic Diagram . . . 8-47 |

|||||||

8-25. P/O A9 Peak Deviation and Range Switch |

|

|

8-52. A26A8 Demodulation Amplifier |

|

|||||||||

|

|

Assembly |

Component Locations. . . . . |

8-28 |

Assembly Component Locations. . . . |

8-49 |

|||||||

vi

Model 8640B Option 004

To avoid the possibility of injury or death, the following precautions must be followed before the instrument is switched on:

a.If this instrument is to be energized via an autotransformer for voltage reduction, make sure that the common terminal is connected to the earthed pole of the power source.

b.The power cable plug shall only be inserted into a socket outlet provided with a protective earth contact. The protective action must not be negated by the use of an extension cord without a protective conductor (grounding).

c.Before switching on the instrument, the protective earth terminal of the instrument must be connected to a protective conductor of the power cord. This is accomplished by ensuring that the instrument’s internal earth terminal is correctly

connected to the instrument’s chassis and that the power cord is wired correctly (see Service Sheet 22).

Whenever it is likely that the protection has been impaired, the instrument must be made inoperative and be secured against any unintended operation.

Any interruption of the protective (grounding) conductor inside or outside the instrument or disconnection of the protective earth terminal is likely to make the instrument dangerous. Intentional interruption is prohibited.

HIGH VOLTAGE

Any adjustment, maintenance, and repair of the opened instrument under voltage should be avoided as much as possible and, if inevitable, should be carried out only by a skilled person who is aware of the hazard involved.

Capacitors inside the instrument may still be charged even if the instrument has been disconnected from its source of supply.

FUSES

Make sure that only fuses with the required rated current and of the specified type (normal blow, time delay, etc.) are used for replacement. The use of repaired fuses and the short-circuiting of fuseholders must be avoided.

Cautions/Warnings

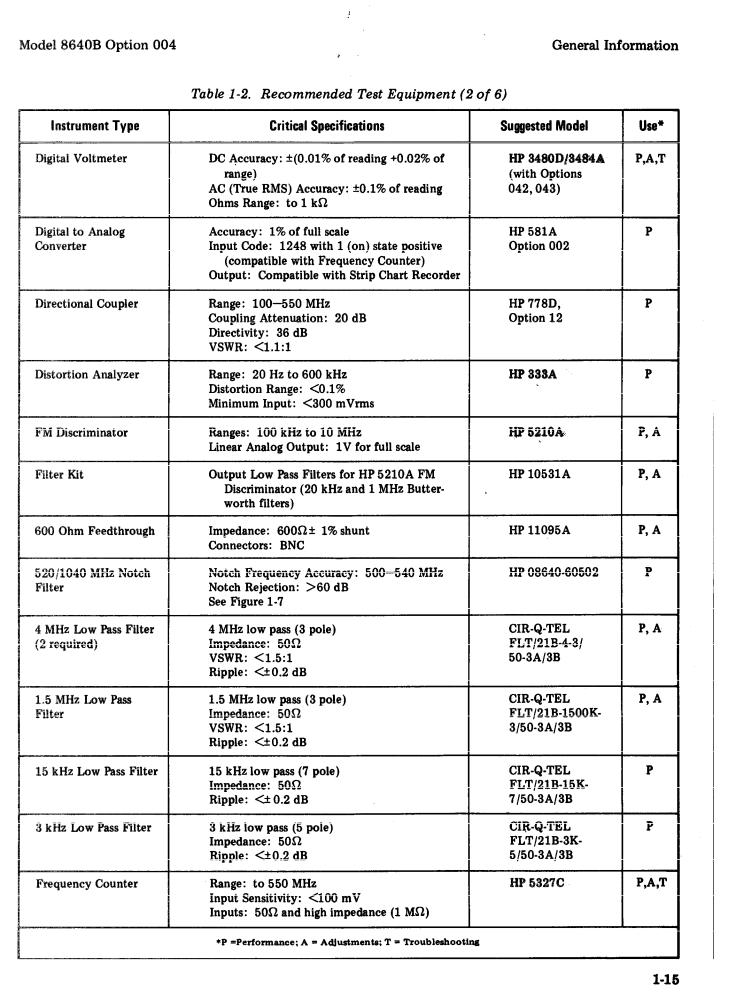

GROUNDING

Any interruption of the protective (grounding) conductor inside or outside the instrument is likely to cause damage to the instrument. To avoid damage, this instrument and all line powered devices connected to it must be connected to the same earth ground (see Section II).

LINE VOLTAGE

Be sure to select the correct fuse rating for the selected line voltage (see LINE VOLTAGE SELECTION in Section II); fuse ratings are listed on the fuse compartment.

To prevent damage to the instrument, make the line voltage selection BEFORE connecting the line power. Also ensure that the line power cord is connected to a line power socket that is provided with a protective earth contact.

SAFETY

To avoid the possibility of damage to test equipment, read completely through each test before starting it. Make any preliminary control settings necessary for correct test equipment operation.

COUNTER INPUT

Do not apply a dc voltage or >+15 dBm to

COUNTER INPUT.

SEMI-RIGID COAX

While working with and around the semi-rigid coaxial cables-in the generator, do NOT bend the cables more than necessary. Do NOT torque the RF connectors to more than 2 INCH-POUNDS.

v i i i

General Information |

Model 8640B Option 004 |

|

MODEL 8640B OPTION 004

RACK MOUNTING KIT

DEMO CAL LABELS |

LINE POWER CABLE |

Figure 1-1. HP Model 8640B Option 004 Signal Generator (Option 001) and Accessories Supplied

1-0

General Information

1-12. For information concerning a serial number prefix not covered in this manual,

contact your nearest Hewlett-

Packard office.

1-13. GENERAL DESCRIPTION

1-14. The Model 8640B Option 004 Signal Generator is an adaptation of the Model 8640B specifically designed for testing ILS, VOR, and UHF communications receivers used in aviation as well

as general Purpose HF, VHF and UHF receivers. The Signal Generator covers the frequency range

500 kHz to 512 MHz (450 kHz to 550 MHz with band over-range) a n d c a n b e e x t e n d e d t o 1100 MHz with an external doubler. An optional variable audio oscillator is also available to extend the CW output range of the generator down to 20 Hz.

1-15. This solid-state generator has an output level range of +15 to -142 dBm (1.3V to 0.018 µV) that is calibrated and metered. The output is leveled to within ±0.5 dB from 108 to 336 MHz and within ±0.75 dB across the full frequency range of the instrument.

1-16. The generator also provides AM, FM and pulse modulation for a wide range of receiver test applications. AM and FM can be performed independently or simultaneously in either the internal or external modes. This modulation is calibrated and metered for direct readout under all operating conditions. External pulse modulation is also available.

1-17. For avionics testing (VOR/ILS), an external audio generator’ is required to provide the composite modulation. When used with a suitable external audio generator the Option 004 has flat AM response and minimum phase shift from 30 Hz to 10 kHz as well as constant group delay between 9 kHz and 11 kHz for accurate VOR and ILS testing. A front panel jack also provides a very accurate demodulated audio signal (AC/DC 0-1 Vrms or AC only 0-5 Vrms) for precise AM settings.

1

e . g . , B e n d i x R V G 3 3 A — V O R A u d i o G e n e r a t o r

R I G 3 2 A — |

I L S |

A u d i o G e n e r a t o r |

|

C o l l i n s 4 7 9 S - 4 A |

— |

I L S |

A u d i o S i g n a l G e n e r a t o r |

T e l - I n s t r u m e n t

C o r p o r a t i o n T - 2 0 A — V O R / I L S A u d i o S i g n a l G e n e r a t o r

Model 8640B Option 004

1-18. Other significant features are extremely low noise, built in phase lock and counter, and front panel controls designed for operating convenience and flexibility.

1-19. PERFORMANCE CHARACTERISTICS

1-20. Spectral Purity

1-21. The basic frequency source of the Signal Generator is a mechanically-tuned high-Q cavity oscillator that operates over the frequency range 230-550 MHz. This oscillator has an inherent stability of better than 10 ppm/10 min and exceptionally low noise characteristics. The lower 9 frequency ranges are obtained by dividing the basic oscillator frequency and filtering the unwanted harmonics. Using this technique, sub-harmonic and non harmonic-spurious signals are virtually eliminated. A band overlap of 7% to 10% adds convenience when operating near the nominal band edges.

Figure 1-2. Measured Single Sideband Noise vs Offset from Carrier. (Stated in a 1 Hz Bandwidth at 256 and 512 MHz Carrier Frequencies on 256-512 MHz Band. ) Markers indicate specified limits.

1-22. Frequency within a band is selected with a FREQUENCY TUNE control of approximately 8 turns (see Figure 3-2) for fast selection of the desired output frequency. A mechanical FINE TUNE control has a tuning range of 1000 ppm for precision frequency setting.

1-2

Model 8640B Option 004

1-23. Restabilization time is short when tuning the frequency across any one band. The total frequency excursion after any frequency change is typically <20 ppm and within 15 minutes the o u t p u t h a s r e s t a b i l i z e d t o t h e s p e c i f i e d 10 ppm/10 min. When not phase locked, no restabilization time is required when switching frequency binds for a fixed position cm the frequency tune control.

1-24. Noise performance of the generator is excellent. The high-Q cavity oscillator has been optimized with use of a low noise microwave transistor for a spectrally pure output signal. Figure 1-2 shows the typical measured single-side- band noise performance in a 1 Hz bandwidth for various offsets from a (256 and 512 MHz) carrier. The low close-in noise characteristic is ideally suited for the stringent adjacent channel tests that are commonly made on a wide variety of communication receivers.

1-25. Figure 1-3 gives a plot of the specified SSB noise perfomance for a 20 kHz offset from the carrier for the 256-512 MHz band. From 230 to 450 MHz, noise is >130 dB/Hz below the carrier level and rises to 122 dB/Hz at 500 MHz. This signal-to-noise ratio decreases by approximately 6 dB for each division of the output frequency down to the broadband noise floor of better than

Figure 1-3. Specified Signal-to-Phase Noise Ratio at 20 kHz Offset vsus Carrier Frequency (MHz). (Stated in a 1 Hz Bandwidth.) For lower bands, phase-noise decreases approximately 6 dB per frequency division down to the broadband noise floor.

General Information

130 dB/Hz. This exceptional noise performance is also preserved in the phase lock mode and only slightly degraded during FM.

1-26. Frequency Counter

1-27. The Signal Generator has a built-in 550 MHz frequency counter and phase lock synchronizer. The 6-digit light-emitting diode (LED) display gives a normal resolution of 10 kHz at 500 MHz and 10 Hz at 500 kHz. The resolution can be increased using the X10 or X100 EXPAND buttons near the display. In the X100 EXPAND mode, the resolution is 100 Hz at 500 MHz and 0.1 Hz at 500 kHz.

1-28. This resolution, combined with the high stability of the generator, allows precise frequency selection and meaningful measurements on high performance receiver systems. When selecting the external doubler band, the counter displays the doubled output frequency directly.

1-29. When using the expand modes, it is possible for significant digits or the decimal points to be shifted off the display. When this occurs, an OVERFLOW light reminds the operator that the display is not showing the complete output frequency.

1-30. The built-in counter can also be used to count external input signals from 1 Hz to 550 MHz and eliminates the need for a separate frequency counter in many measurement systems. Input sensitivity is <100 mV into 50. Using the EXPAND buttons, it is possible to achieve a resolution of 1 Hz in the 0-10 MHz EXTERNAL count mode or 100 Hz in the 0-550 MHz mode.

1-31. Phase-Lock Mode

1-32. Also included in the Signal Generator is a built-in phase lock synchronizer that locks the RF output frequency to the crystal time base used in the counter. In this locked mode, output stability is better than 5 x 10-8/h while the spectral purity and FM capability of the unlocked mode are preserved. For higher stability, it is possible to lock to an externally applied 5 MHz standard. Two Model 8640B’s can also be locked to a common timebase reference for performing various two-tone measurements.

1-33. Phase locking the generator is simple - just push the front panel LOCK button. The generator is then locked to the frequency shown on the LED display. If lock is broken (for example by tuning

1-3

General Information

to a new output frequency or during warmup), there is an immediate indication: the LED display flashes. The generator can be relocked by releasing the LOCK button and then relocking.

1-34. The generator can be locked in the normal mode of the counter or in the X10 EXPAND mode if the OVERFLOW light is not on. It is normally not possible nor recommended to lock in the X100 EXPAND mode or when counting external inputs. Maximum resolution in the locked mode is 1 kHz at 500 MHz, increasing to 1 Hz at 500 kHz.

1-35. If an output frequency between adjacent counter indications is required, a TIME BASE VERNIER is provided with a range of ±20 ppm. This fine tunes the internal crystal time base and sets the output frequency between adjacent counts (i.e., the least significant digits of the display). This gives continuous coverage of all output frequencies even in the phase lock mode. An UNCAL annunciator near the vernier will light when this mode has been selected indicating that the counter display is incorrect.

1-36. When phase locked, the narrow bandwidth of the phase lock loop (<5 Hz) preserves full FM capabilities down to rates of 50 Hz and assures no degradation in noise from the unlocked mode (residual FM is not changed by phase locking).

1-37. Amplitude Modulation

1-38. AM is variable from 0 to 100% with the rates, accuracy, and low incidental FM required for the most stringent AM applications. The front panel meter gives a direct readout of percent AM in either the internal or external mode and autoranges the 0-100% scale to 0-30% for improved nettability at low modulation depths.

1-39. For precision measurement of AM, the front panel DEMOD OUTPUT jack provides a demodulated AM signal (either 0 - 1 Vrms or 0 -5 Vrms) which is directly proportional to percent AM. The DEMOD CAL label lists values of this voltage by which percent AM can be set very accurately (within 1%) with an ac voltmeter. The label was prepared when the instrument was calibrated. A new label should be prepared whenever the generator is recalibrated.

1-40. DEMOD OUTPUT can also be connected to the Demod Input of some modulation sources for sensing the phase relationship of the output RF envelope and the input modulating signal.

1-4

Model 8640B Option 004

1-41. AM up to rates of 50 kHz is possible depending on carrier frequency and modulation depths. Distortion is specified at 400 Hz and 1000 Hz to be <1% up to 50% AM, <3% to 90% AM. Figure 1-4 shows measured AM distortion characteristics for other modulation frequencies. Note that for 0-50% AM, distortion is <1% to approximately 90 kHz for an output frequency of 200 MHz.

Figure 1-4. AM distortion us AM rate measured at 200 MHz and +10 dBm, but applies to all bands. (Supplemental information only.)

1-42. Pulse Modulation

1-43. Also included on the AM function switch is a position for external PULSE modulation. In this mode, pulse inputs with repetition rates to 500 kHz and widths down to 2 µ S can be applied to modulate the RF carrier. Rise and fall times vary with output frequency down to <1 µ S from 8 to 512 MHz.

1-44. Pulse inputs turn the RF on. Hence with no pulse inputs the RF will read approximately zero on the built-in level meter. For pulse inputs greater than 0.5V, the RF output is on, calibration is preserved and the level meter reads the pulse-on power of the RF output. For repetition rates below that specified, the pulsed RF output is still available but the pulse-on level is no longer calibrated or metered.

1-45. Frequency Modulation

1-46. FM is calibrated, metered and constant with RF frequency and band changes. Peak deviations to at least 0.57. of carrier frequency are available (i.e., 1% of the minimum frequency in each octave band). On the 256-512 MHz band, for example,

Model 8640B Option 004 |

General Information |

Figure 1-5. Pulsed RF 20 MHz Carrier Frequency a t-400 kHz Pulse Rate and 1 µs Pulse Width.

the maximum deviation is 2.56 MHz peak or 5.12 MHz peak-to-peak. With this wide deviation capability, it is possible to sweep the generator, using the dc coupled FM mode and a sawtooth input, to test and align IF filters and discriminators.

1-47. For narrowband FM applications, a minimum full scale deviation of 5 kHz is provided on the meter and the PEAK DEVIATION range switch. When switching from the CWto FM mode, there is negligible shift in carrier frequency and no degradation in spectral purity for these narrow deviations. With the generator in the phase lock mode it is possible to modulate at rates down to 50 Hz while maintaining accurate FM calibration and the carrier drift stability of a crystal oscillator. Using the unlocked mode, it is possible to modulate from dc to 250 kHZ with a carrier drift stability of <10 ppm/10 min.

1-48. Standard and Optional Audio Oscillators

1-49. Standard tones for internal modulation are 400 Hz and 1000 Hz. These tones are also available at the front panel and can be varied in output level from 1 V to <10 mV into 600 Ω. Total harmonic distortion is typically <0.25%.

1-50. Optionally available on the Signal Generator is a built-in variable frequency oscillator covering the range 20 Hz to 600 kHz (fixed tones of 400 Hz and 1000 Hz are also provided). This internal oscillator has a wide range of standard modulation frequencies and is useful for testing receiver audio bandwidth. Output from this modulation souce is

available separately at the front panel and can be varied in level from 3V to <20 mV into 600 Ω. This audio oscillator, Option 001, extends the usable CW range of the generator down to 20 Hz.

1-51. Multi-Function Meter and Annunciators

1-52. The front panel meter on the Signal Generator monitors the RF output level in dBm and volts, the AM modulation percentage, and the FM peak deviation in kHz or MHz. The accuracy of this meter is usually better then ±3% of reading. Pushbuttons select the meter function, and scale lights indicate the range on which the meter reading should be made. For RF output level and AM%, the scales autorange for better resolution. For FM, the appropriate scale is selected by the PEAK DEVIATION range switch.

1-53. Also provided are three front panel annunciators that indicate when certain settings of RF level and modulation controls exceed specified limits. Besides giving a warning indication, the annunciators instruct the operator about returning the instrument to proper operation.

Figure 1-6. FM distortion vs FM rate measured in the 8-16 MHz band, but applies to all bands (supplemental information only).

1-54. The REDUCE PEAK POWER annunciator lights whenever the combined settings of RF output and AM modulation levels exceed allowable knits. The specification allows for up to 100% AM on all RF output ranges except the +16 dBm range. On the +16 dBm range RF levels with up to 50% AM are normally possible before the annunciator will light. When the annunciator lights it is necea-

1-5

General Information |

Model 8640B Option 004 |

sary to reduce either the OUTPUT LEVEL 10 dB switch or the AM MODULATION control.

1-55. The REDUCE PEAK DEVIATION annunci- a t o r l i g h t s w h e n e v e r t h e P E A K D E V I A T I O N RANGE switch has been set to exceed the allowable limits for any output FREQUENCY RANGE. The specification allows for a maximum peak deviation of 1% of the minimum frequency in each band (e.g., 2.56 MHz on the 256-512 MHz band). When the annunciator lights, the FM is automatically turned off and the FM meter reads zero.

1-56. The REDUCE FM VERNIER annunciator lights whenever the FM input and FM vernier setting combine to exceed the 1 volt drive level required to achieve the maximum deviation indicated on the PEAK DEVIATION range switch. When this occurs, either the FM vernier or the a m p l i t u d e o f t h e i n c o m i n g m o d u l a t i o n s i g n a l s h o u l d b e r e d u c e d t o o b t a i n s p e c i f i e d F M performance.

1-57. Output Level

1-58. The wide output range of the generator is achieved with a 20 dB step attenuator, a 1 dB step attenuator and a 2 dB vernier. Output levels can be read directly on the attenuator dials or (for greater accuracy) on the autoranging meter. The meter scales are automatically selected to give the maximum indicator resolution for any output level.

1-59. The maximum output level of +15 dBm permits high level tests on receiver IF’s, amplifiers, and mixers without additional power amplification. At the same time, extremely low leakage ensures receiver sensitivity measurements down to levels of 0.03 µV in a shielded system.

1-60. For improved accuracy at low output levels, the meter, in conjunction with the attenuators, is factory-calibrated against a precision standard to remove much of the error that is accumulated from the attenuator’s steps. Using a power meter and calibrating the output for one output frequency and vernier setting, it is then possible to make sensitivity measurements to better than ±1 dB accuracy down to output levels of --127 dBm.

1-61. OPTIONS

1-62. Option 001. Option 001 (covered in this manual ) provides a modulation oscillator that is continuously settable from 20 Hz to 600 kHz. The

1-6

oscillator can also be set for 400 Hz or 1 kHz fixed tones.

1-63. Option 002. Option 002 (an internal frequency doubler available in the standard Model 8640B) is not compatible with the Model 8640B Option 004 and thus is not covered in this manual.

1-64. Option 003. Option 003 (either factory built or retrofitted) protects the generator’s output circuits from accidental applications of reverse power up to 25 watts. Option 003 is documented in a separate manual supplement.

1-65. ACCESSORIES SUPPLIED

1-66. The Model 8640B Option 004 is supplied with the following accessories (they are shown in Figure 1-1):

Rack Mounting Kit (HP 5060-8740) Line Power Cable (HP 8120-1378) 2 Amp Fuse (HP 2110-0002)

1.25 Amp Fuse (HP 2110-0094) Demod Cal Labels (HP 7120-4244)

1-67. The rack mounting kit, the cable, and the fuses are fully described in Section II.

1-68. The following accessories are mounted inside the instrument’s chassis and are available for adjustment and repair (for more information, see Sections V and VIII):

Combination Wrench (HP 5001-0135) Spare fuses for power supply circuit boards 30-pin Extender Board (HP 08640-60036)

1-69. EQUIPMENT AVAILABLE

1-70. Fuseholder. The HP Model 11509A Fuseholder attaches to the RF OUT jack and prevents accidental damage to the generator’s output attenuator by externally applied R F. It is primarily used when testing transceivers.

The fuseholder may not protect the output amplifier against a fast pulse of reverse power on the top two ranges, of the OUTPUT LEVEL 10 dB switch.

1-71. Termination. The HP Model 11507A Termination maintains the generator’s output level calibration when the output is connected to load impedances other than 50 ohms. It can provide source impedances of 25 and 5 ohms, and it can simulate a broadcast-band dummy antenna. The frequency range is 50 kHz to 65 MHz.

Model 8640B Option 004

1-72. 75 Ohm Adapter. The HP Model 11687A 50 to 75 Ohm Adapter connects to the generator’s output to provide a source impedance of 75 ohms.

1-73. Doubler. The HP Model 11690A Doubler extends the usable frequency range of the generator one octave to 1024 MHz (actually to 1100 MHz with 7% frequency over-range). Conversion low in the doubler is typically <13 dB.

1-74. Mixer. The HP Model 10514A Double Balancedi Mixer can be used at the generator's output as a nanosecond pulse modulator or as a balanced mixer.

1-75. Protective Cover. The HP 5060-8767 Control Panel Cover protects the panel from dust and impact damage.

1-76. SERVICE AND USER AIDS

1-77. Video Tapes. Video tapes covering instrument use, application, and service are available. Contact the nearest Hewlett-Packard Sales and Service Office for a list of presently available tapes.

1-78. Application Notes. Informative notes concerning the use of signal generators are also available from the nearest Hewlett-Packard Sales and Service Office.

1-79. Service Notes. Hewlett-Packard makes design improvements to its current line of instrument on a continuing basis. Many of these improvements can be incorporated in earlier produced instruments. Modification and general ser-

General Information

vice information is passed on in the form of Service Notes. To obtain the Service Notes contact the nearest Hewlett-Packard Sales and Service Office.

1 - 80 . Deleted .

1 - 81 . Deleted .

1-82. TEST EQUIPMENT REQUIRED

1-83. Tables 1-2 and 1-3 list the test equipment and accessories required to check, adjust and repair the Model 8640B Option 004. (Table 4-2 is a separate list of relatively inexpensive, commonly available test equipment for the Basic Functional Check only.) Refer to the Mac in Appendix D for Army test equipment requirements .

NOTE

The safety classification of this instrument is Safety Class I. It has been designed and tested according to IEC Publication 348 SAFETY REQUIREMENTS FOR ELECTRONIC MEASURING APPARATUS and has been supplied in safe condition. The instruction manual contains in formation, warnings, and cautions which must be followed by the user to ensure safe operation and to retain the instrument in safe condition.

1-7

Model 8640B Option 004 General Information

Table 1-1. Specifications (2 of 6)

F R E Q U E N C Y C H A R A C T E R I S T I C S ( C o n t ’ d )

Restabilization Time: |

|

|

|

|

|

|

|

|

|

|

Normal |

Lockedl |

|

|

|

|

|

|

|

|

|

||

|

After frequency |

|

<15 min |

<1 min |

|

|

|

|

change |

|

after |

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

relocking |

|

|

|

After band change |

|

|

None |

|

|

|

|

|

|

to be within |

|

|||

|

|

|

|

|

|

||

|

After 1 min in RF |

|

|

|

|

||

|

|

<10 min |

0.1 ppm of |

|

|||

|

OFF Mode2 |

|

steady-state |

|

|||

|

|

|

|

|

frequency |

|

|

|

|

|

|

|

|

|

|

|

SPECTRAL |

|

PURITY |

|

|

|

|

Harmonics: (on IV, +10 dBm, output range and below) |

Residual AM: (Averaged rms) |

||||||

>35 dB below fundamental of 0.5 to 128 MHz. |

|

|

|

|

|

||

|

|

Post-detection Noise Bandwidth |

|||||

>30 dB below fundamental of 128 to 512 MHz. |

|

|

|||||

|

300 Hz to 3 kHz |

|

20 Hz to 15 kHz |

||||

|

|

|

|

|

|||

Subharmonic and Nonharmonic Spurious: (excluding |

|

|

|

|

|

||

|

>85 dB down |

|

>78 dB down |

||||

frequencies within 15 kHz of carrier whose effects |

|

|

|||||

are specified in Residual AM and FM): >100 dB |

|

|

|

|

|

||

|

|

|

|

|

|||

below carrier. |

Residual FM: (Averaged |

rms) |

|||||

|

|

|

|||||

Noise: Averaged rms noise level below carrier stated in a 1 Hz bandwidth.

SSB Phase Noise at 20 kHz offset from carrier. (See Figures 1-2 and 1-3.)

256 MHz to 512 MHz: >130 dB from 230 to 450 MHz increasing linearly to >122 dB down at. 550 MHz.

0.5 MHz to 256 MHz: Decreases approximately

6 dB for each divided frequency range until it reaches SSB Broadband Noise Floor of

>140 dB.

SSB Broadband Noise Floor greater than 1 MHz offset from carrier (see Figures 1-2 and 1-3):

>130 dB down.

|

CW and up to |

Up to maxi- |

||

|

1/8 maximum |

mum allowable |

||

|

allowable peak |

peak |

||

|

deviation |

deviation |

||

|

|

|

|

|

Post-detection |

300 Hz |

20 Hz |

300 Hz |

20 Hz |

Noise |

to |

to |

to |

to |

Bandwidth |

3 kHz |

15 kHz |

3 kHz |

15 kHz |

|

|

|

|

|

230 to 550 MHz |

<5 Hz |

<15 Hz |

<15 Hz |

<30HZ |

|

|

|

|

|

Note: Residual FM decreases by approximately 1/2 for each divided frequency range until limited by broadband noise floor. This limit for 300 Hz to 3 kHz is about 1 Hz, and for 20 Hz to 15 kHz is about 4 Hz. These are measured values in the 230 to 550 MHz range and calculated for divided ranges, knowing the noise distribution.

1

OUTPUT CHARACTERISTICS

Range: +15 dBm to –142 dBm (1.3V to 0.018 µV). Attenuators: a 10 dB step attenuator, and a 1 dB step attenuator with vernier allow selection of

any output level over the full output level range. Vernier: >2 dB continuously variable from a CAL

detent position.

Level Flatness:

<±0.75 dB from 0.5 to 512 MHz referred to output at 190 MHz.

<±0.5 dB from 108 to 336 MHz referred to output at 190 MHz.

(Flatness applies to +10 to -10 dBm.)

1These specifications are given for the 8640B Option 004 internal reference. when using an external reference. drift in the locked mode will depend on the external reference characteristics.

2This specification apply only if the RF ON/OFF switch has been wired to turn the RF Oscillator off.

1-9

General Information |

Model 8640B Option 004 |

|

Table 1-1. Specifications (3 of 6) |

|

|

|

OUTPUT CHARACTERISTICS (Cont’d) |

Impedance: 50 Ω, ac coupled, VSWR. <2.0 on 3V and IV output ranges; <1.3 on all other ranges.

Reverse Power Damage Level: 40 Vdc maximum. 20 dBm maximum on 3V and IV output ranges; 27 dBm maximum on all other ranges.

Reverse Power Protection (Option 003): Protects signal generator from accidental applications of up to

25 watts (+44 dBm) of RF power (between dc and 1100 MHz) into generator output.

Auxiliary Output: Rear panel BNC output is >–5 dBm into 50 Ω, source impedance is approximately 500 Ω.

Leakage: (With all unused outputs terminated properly.) Leakage limits are below those specified in MIL-I- 6181D. Furthermore, less than 3 µV is induced in a 2-turn, l-inch diameter loop 1 inch away from any surface and measured into a 50 Ω receiver. This permits receiver sensitivity measurements to at least <0.03 µV in a shielded system.

Level Accuracy:

Note: Level Accuracy error consists of allowances for meter accuracy, detector linearity, temperature flatness, attenuator accuracy, and twice the measurement error. All but the attenuator accuracy and the measurement error can be calibrated out with a power meter at a fixed frequency and a fixed vernier setting.

MODULATION CHARACTERISTICS

General

Types: Internal AM and FM.

External AM, FM, and PULSE.

Simultaneous AM and FM, or PULSE and FM.

Internal Modulation Sources: (independently adjustable output is available at front panel).

Standard:

Frequency: Fixed 400 Hz and 1 kHz, ±2%. Output Level: Indicated 10 mVrms to 1 Vrms,

into 600 Ω

Optional: (Internal Variable Audio Oscillator, Option 001).

Frequency: Variable 20 Hz to 600 kHz,±l0% in 5 decade continuous bands plus fixed 400 Hz and 1 kHz ±3%.

Output Level: 20 mVrms to 3 Vrms into 600 Ω.

Total Harmonic Distortion:

<0.25% 400 Hz and 1 kHz fixed tones

<0.5% 20 Hz to 2 kHz

<1.0% 2 kHz to 600 kHz

Amplitude Modulation

(Not applicable when OUTPUT LEVEL 10 dB switch in +16 dBm position).1

Depth: 0 to 100%.

AM Rates: INT and EXT ac; 20 Hz to AM 3 dB bandwidth. EXT dc; dc to AM 3 dB bandwidth.

1AM is possible in tbe +16 dBm output range with AM depths typically up to 50%, however DEMOD OUTPUT is not calibrated in this range and degradation of other AM specifications should be expected.

AM 3 dB Bandwidth: (See Figure 1-4.)

|

Frequency |

0 to |

50 to |

|

|

Bands |

50% AM |

90% AM |

|

|

|

|

|

|

|

0.5-2 MHz |

15 kHz |

12.5 kHz |

|

|

2-8 MHz |

30 kHz |

20 kHz |

|

|

8-512 MHz |

50 kHz |

35 kHz |

|

|

|

|

|

|

1-10

General Information |

|

|

|

|

|

|

|

Model 8640B Option 004 |

||||

|

|

Table 1-1. Specifications (5 of 6) |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||

|

MODULATION CHARACTERISTICS (Cont’d) |

|

|

|

||||||||

|

|

|

Pulse Modulation |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency Bands (MHz) |

|

0.5-1 |

|

1-2 |

|

2-8 |

|

8-32 |

|

32-512 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rise and Fall Times |

|

<9 µs |

<4 µs |

|

<2 µs |

|

|

<1 µs |

|

||

|

Pulse Repetition Rate |

|

50 Hz to |

|

50 Hz to |

|

50 Hz to |

|

50 Hz to |

|

||

|

|

50 kHz |

|

100 kHz |

|

250 kHz |

|

500 kHz |

|

|||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pulse Width Minimum |

|

10 µs |

|

|

5 µs |

|

|

2 µs |

|

||

|

for level accuracy within |

|

|

|

|

|

|

|||||

|

1 dB of CW (>0.1% duty cycle) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pulse ON/OFF ratio |

|

|

|

|

|

|

>40 dB |

|

|

|

|

|

|

|

|

|

||||||||

|

Peak Input Required |

|

Nominally > +0.5V (5V max) sinewave or pulse return to zero, |

|

||||||||

|

|

into 50 Ω. |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency |

Modulation |

|

|

|

|

|

|||

Deviation: Maximum allowable deviation equals 1% of lowest frequency in each band as below.

Frequency Band |

|

Maximum Peak |

(MHz) |

|

Deviation (kHz) |

|

|

|

0.5-1 |

5 |

|

1 - 2 |

10 |

|

2 - 4 |

20 |

|

4 - 8 |

40 |

|

8-16 |

80 |

|

16-32 |

160 |

|

32-64 |

320 |

|

64-128 |

640 |

|

128-256 |

1280 |

|

256-512 |

2560 |

|

512-1024 |

5120 |

|

|

|

|

FM 3 dB Bandwidth:1

Internal and External ac; 20 Hz to 250 kHz. External dc; dc to 250 kHz.

FM Distortion: (at 400 Hz and 1 kHz rates) See Figure 1-6.

<1% for deviations up to 1/8 maximum allowable. <3% for maximum allowable deviation.

External FM Sensitivity: 1 volt peak yields maximum deviation indicated on PEAK DEVIATION switch with FM vernier at full cw position.

External FM Sensitivity Accuracy: ±6% from 15 to 35°C for FM excluding maximum peak deviation position. Maximum peak deviation position, ±9% typically.

Indicated FM Accuracy: (400 Hz and 1 kHz rates using internal meter) ±10% of meter reading (for greater than 10% of full scale).

Incidental AM: (at 400 Hz and 1 kHz rates)

<0.5% AM for FM up to 1/8 maximum allowable deviation.

<1% AM for FM at maximum allowable deviation.

1 With 8640B Option 004 in LOCKED MODE, external FM is possible only for rates greater than 50 Hz.

1-12

Loading...

Loading...