Page 1

User’s Manual

CNC Pilot 4290

NC Software

625 952-xx

V7.1

English (en)

4/2010

Page 2

Page 3

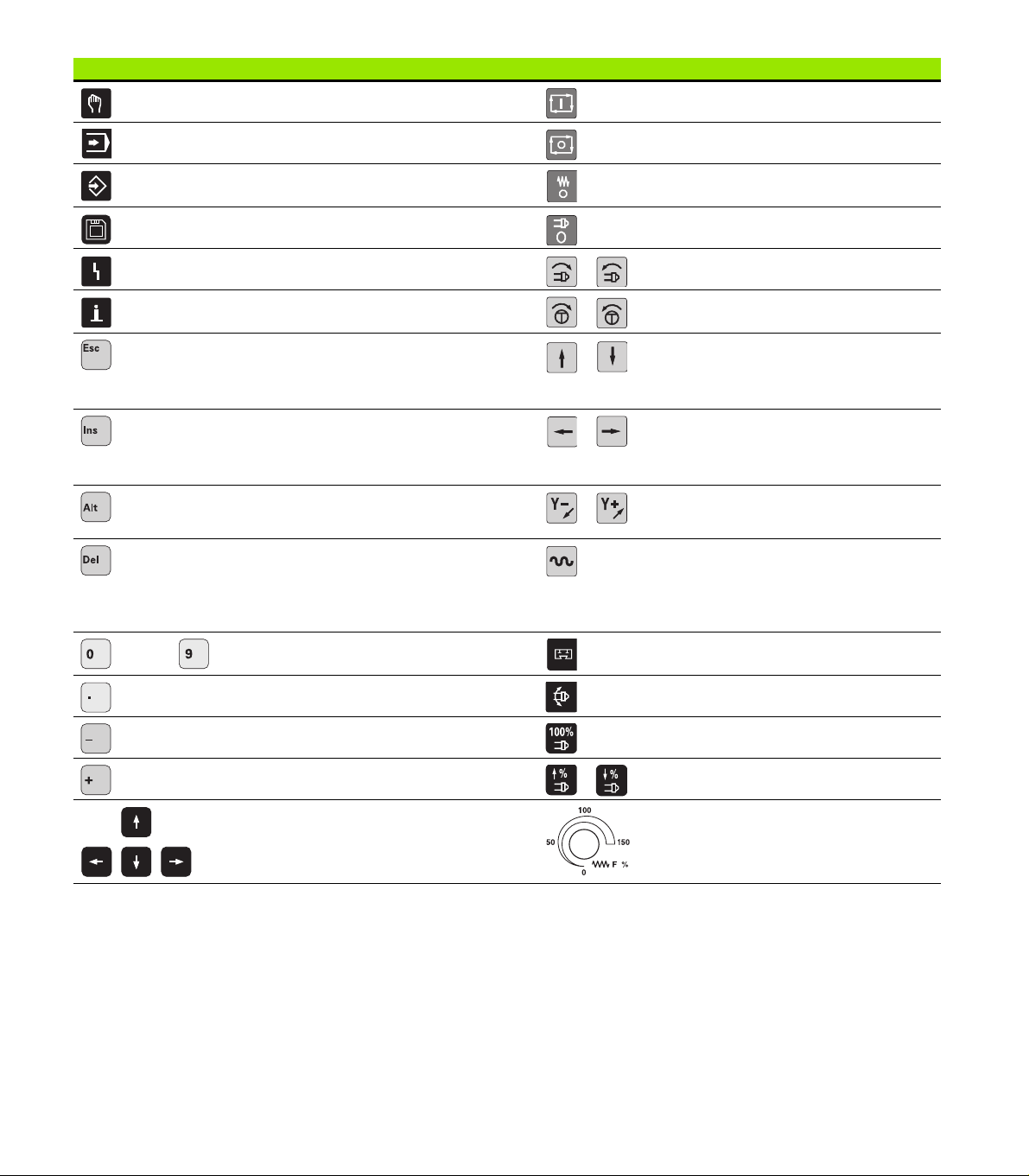

Data input keypad Machine operating panel

Manual control operating mode Cycle start

Automatic operating mode Cycle stop

Programming modes (DIN PLUS, simulation, TURN

PLUS)

Organization modes (parameter, service, transfer) Spindle STOP

Display error status Spindle on - M3/M4 direction

Call the info system Spindle jog - M3/M4 direction (The spindle

ESC

Back by one menu level

Close dialog box, do not save data

INS

Insert list element

Close dialog box, save data

ALT

Edits a list element

DEL

Deletes the list element

Deletes the selected character or the character to the

left of the cursor

. . . Numerals for entering values and

selecting soft keys

Decimal point Spindle change key

Feed rate stop

turns until you press the key.)

Manual direction keys +X/–X

Manual direction keys +Z/–Z

Manual direction keys +Y/–Y

Rapid-traverse key

Slide change key

Minus as algebraic sign Spindle speed at the programmed value

“Continue key” for special functions (e.g. marking) Increase/decrease spindle speed by 5%

Cursor keys Override button for feed-rate override

HEIDENHAIN CNC PILOT 4290 3

Page 4

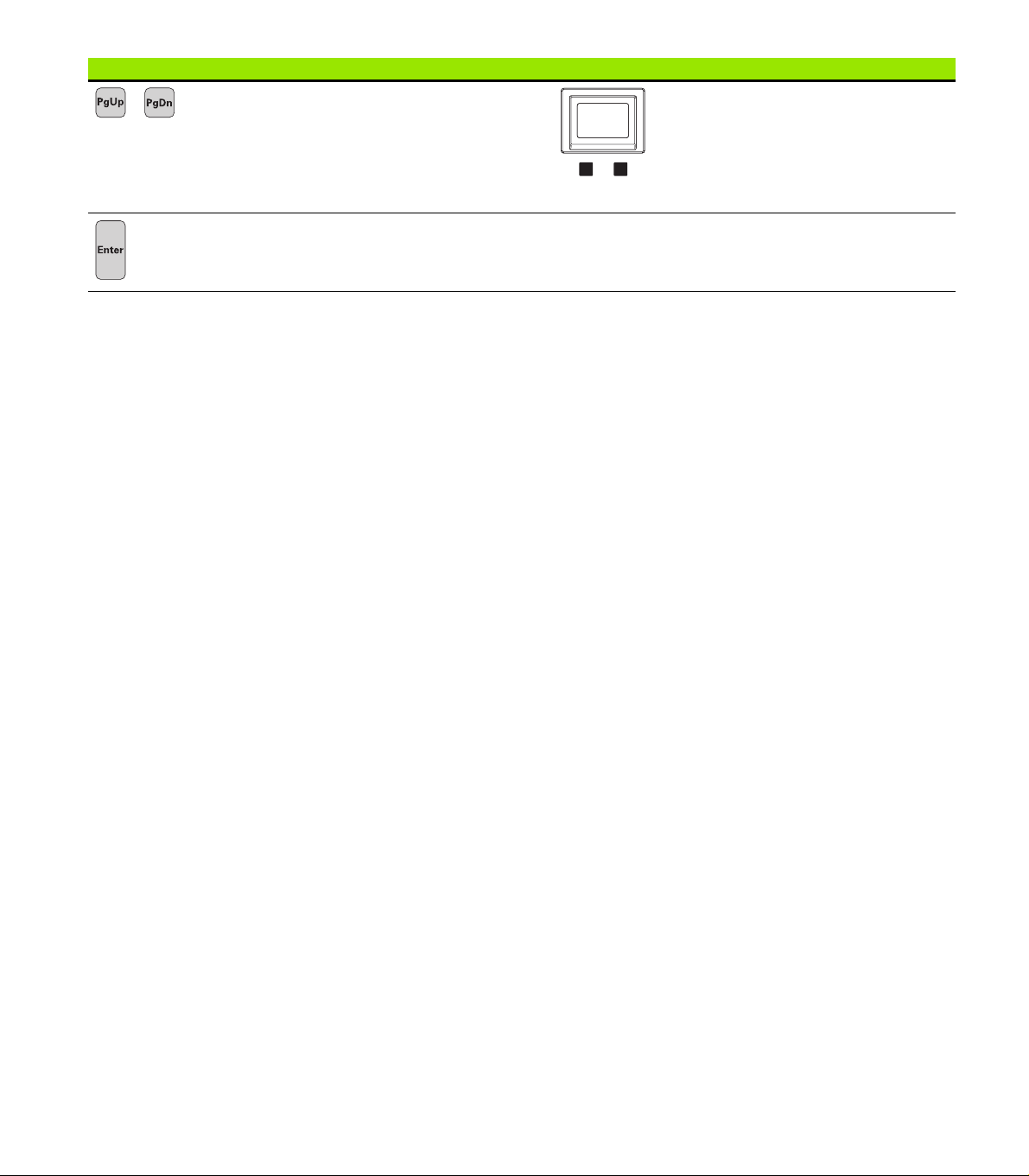

Data input keypad Machine operating panel

Page up, Page down (PgUp/PgDn)

Change to previous/next screen page

Change to previous/next screen dialog box

Switches between input windows

Enter – Confirmation of input

Touchpad with right and left mouse key

4

Page 5

CNC PILOT 4290, Software and Functions

This manual describes functions that are available in the CNC

PILOT 4290 with NC software number 625 (Release 7.1). For

programming the B and Y axes, please refer to the User's Manual

“CNC PILOT 4290 with B and Y Axes”. It is not described in this

manual.

The machine manufacturer adapts the features offered by the control

to the capabilities of the specific lathe by setting machine parameters.

Therefore, some of the functions described in this manual may not be

among the features provided by the CNC PILOT on your machine tool.

CNC PILOT functions that may not be available on your machine

include:

Machining with the C Axis

Machining with the B axis

Machining with the Y-axis

Full-surface machining

Tool monitoring

Graphically supported interactive contour definition

Automatic or graphically supported interactive DIN PLUS program

generation

Please contact your machine manufacturer for detailed information on

the features that are supported by your machine tool.

Many machine manufacturers and HEIDENHAIN offer programming

courses for the CNC PILOT controls. We recommend these courses

as an effective way of improving your programming skill and sharing

information and ideas with other CNC PILOT users.

HEIDENHAIN also offers the PC software DataPilot 4290, which is

designed for use with the CNC PILOT 4290. The DataPilot is suitable

for both shop-floor programming as well as off-location program

creation and testing. It is also ideal for training purposes.

Intended place of operation

The CNC PILOT 4290 complies with the limits for a Class A device in

accordance with the specifications in EN 55022, and is intended for

use primarily in industrially-zoned areas.

HEIDENHAIN CNC PILOT 4290 5

Page 6

Page 7

Contents

Introduction and Fundamentals

1

Basics of Operation

2

Manual Control and Automatic Modes

3

ISO Programming

4

Graphic Simulation

5

TURN PLUS

6

Parameters

7

Operating Resources

8

Service and Diagnosis

9

Tr a n s f e r

10

Tables and Overviews

11

HEIDENHAIN CNC PILOT 4290 7

Page 8

Page 9

1 Introduction and Fundamentals ..... 29

1.1 The CNC PILOT ..... 30

Programming ..... 30

The C axis ..... 31

The Y axis ..... 32

Full-surface machining ..... 33

The B axis ..... 34

1.2 The Modes of Operation ..... 35

1.3 Expansion Stages (Options) ..... 37

1.4 Fundamentals ..... 39

Position encoders and reference marks ..... 39

Axis designations and coordinate system ..... 40

Machine reference points ..... 40

Absolute and incremental workpiece positions ..... 41

Units of measure ..... 42

1.5 Tool Dimensions ..... 43

2 Basics of Operation ..... 45

2.1 User Interface ..... 46

Screen displays ..... 46

Controls and displays ..... 47

Selecting the operating mode ..... 48

Data input, selection of functions ..... 48

2.2 Info and Error System ..... 50

The info system ..... 50

Context-sensitive help ..... 52

Direct error messages ..... 52

Error display ..... 53

Additional information on error messages ..... 54

PLC display ..... 54

2.3 Data Backup ..... 55

2.4 Explanation of Terms ..... 56

3 Manual Control and Automatic Modes ..... 57

3.1 Switch-On, Switch-Off, Reference Run ..... 58

Switch-on ..... 58

Reference run for all axes ..... 58

Reference jog for single axis ..... 59

Monitoring EnDat encoders ..... 59

Switch-off ..... 60

HEIDENHAIN CNC PILOT 4290 9

Page 10

3.2 Manual Control Mode ..... 61

Entering the machine data ..... 62

M commands in Manual Control mode ..... 63

Manual turning operations ..... 64

Handwheel ..... 65

Spindle and manual direction keys ..... 65

Slide/spindle change key ..... 66

3.3 Table for Tools and Chucking Equipment ..... 67

Setting up a tool list ..... 68

Comparing a tool list with an NC program ..... 70

Transferring the tool list from an NC program ..... 71

Simple tools ..... 71

Tool life management ..... 72

Setting up the chucking table ..... 74

3.4 Setup Functions ..... 75

Setting the tool changing point ..... 75

Shifting the workpiece zero point ..... 76

Defining the protection zone ..... 77

Setting up machine dimensions ..... 78

Tool measurement ..... 79

Calculate the tool compensation ..... 80

3.5 Automatic Mode ..... 81

Program selection ..... 82

Finding a start block ..... 84

Modifying the program run ..... 85

Compensation ..... 87

Tool life management ..... 88

Inspection mode ..... 89

Block display, variable output ..... 93

Graphic display ..... 94

Mechatronic tailstock ..... 95

Post-process measuring status ..... 96

3.6 Machine Display ..... 97

Switching the display ..... 97

Display elements ..... 97

3.7 Load Monitoring ..... 100

Machining using load monitoring ..... 101

Reference machining ..... 102

Production using load monitoring ..... 103

Editing limit values ..... 103

Analyzing reference machining ..... 104

Load monitoring parameters ..... 105

10

Page 11

4 DIN Programming ..... 107

4.1 DIN Programming ..... 108

Introduction ..... 108

DIN PLUS screen ..... 109

Linear and rotary axes ..... 110

Units of measurement ..... 111

Elements of a DIN program ..... 111

4.2 Programming Notes ..... 113

Configuring the DIN editor ..... 113

Parallel editing ..... 114

Selecting submenus, positioning the cursor ..... 114

Making, editing and deleting NC blocks ..... 115

Search functions ..... 116

Conversational or free editing ..... 117

Geometry and machining commands ..... 117

Contour programming ..... 118

List of G functions ..... 120

Address parameters ..... 120

Tool programming ..... 121

Subprograms, expert programs ..... 122

NC program conversion ..... 122

Fixed cycles ..... 123

4.3 The DIN PLUS Editor ..... 124

Overview of main menu ..... 124

Overview of geometry menu ..... 125

Overview of machining menu ..... 126

New NC program ..... 127

NC program management ..... 128

Graphics window ..... 129

Workpiece-blank programming ..... 130

Block numbering ..... 130

Programming instructions ..... 131

Block group menu ..... 133

HEIDENHAIN CNC PILOT 4290 11

Page 12

4.4 Program Section Code ..... 135

PROGRAM HEAD section ..... 136

TURRET section ..... 137

CHUCKING EQUIPMENT section ..... 142

CONTOUR section ..... 143

BLANK section ..... 143

FINISHED PART section ..... 143

AUXILIARY CONTOUR section ..... 144

FRONT section ..... 144

REAR SIDE section ..... 144

SURFACE section ..... 144

MACHINING section ..... 144

END code ..... 144

ZUORDNUNG [ASSIGNMENT] instruction $.. ..... 144

SUBPROGRAM section ..... 145

RETURN code ..... 145

CONST code ..... 145

4.5 Definition of Workpiece Blank ..... 146

Chuck piece: bar/tube G20-Geo ..... 146

Casting G21-Geo ..... 146

4.6 Basic Contour Elements ..... 147

Starting point of turning contour G0-Geo ..... 147

Line segment in a contour G1-Geo ..... 147

Circular arc of turning contour G2/G3-Geo ..... 148

Circular arc of turning contour G12/G13-Geo ..... 150

4.7 Contour Form Elements ..... 152

Recess (standard) G22-Geo ..... 152

Recess (general) G23-Geo ..... 153

Thread with undercut G24-Geo ..... 155

Undercut contour G25-Geo ..... 156

Thread (standard) G34-Geo ..... 159

Thread (general) G37-Geo ..... 160

Hole (centric) G49-Geo ..... 162

4.8 Attributes for Contour Description ..... 163

Precision stop ..... 164

Surface roughness G10-Geo ..... 164

Feed rate reduction factor G38-Geo ..... 165

Attributes for superimposed elements G39-Geo ..... 165

Blockwise oversize G52-Geo ..... 166

Feed per revolution G95-Geo ..... 166

Additive compensation G149-Geo ..... 167

4.9 C-Axis Contours—Fundamentals ..... 168

Milling contour position ..... 168

Circular pattern with circular slots ..... 169

12

Page 13

4.10 Front and Rear Face Contours ..... 172

Starting point of front/rear face contour G100-Geo ..... 172

Line segment in front/rear face contour G101-Geo ..... 172

Circular arc in front/rear face contour G102/G103-Geo ..... 173

Bore hole on front/rear face G300-Geo ..... 174

Linear slot on front/rear face G301-Geo ..... 175

Circular slot on front/rear face G302/G303-Geo ..... 175

Full circle on front/rear face G304-Geo ..... 176

Rectangle on front/rear face G305-Geo ..... 176

Eccentric polygon on front/rear face G307-Geo ..... 177

Linear pattern on front/rear face G401-Geo ..... 177

Circular pattern on front/rear face G402-Geo ..... 178

4.11 Lateral Surface Contours ..... 179

Starting point of lateral surface contour G110-Geo ..... 179

Line segment in a lateral surface contour G111-Geo ..... 179

Circular arc in lateral surface contour G112-/G113-Geo ..... 180

Hole on lateral surface G310-Geo ..... 181

Linear slot on lateral surface G311-Geo ..... 182

Circular slot on lateral surface G312/G313-Geo ..... 182

Full circle on lateral surface G314-Geo ..... 183

Rectangle on lateral surface G315-Geo ..... 183

Eccentric polygon on lateral surface G317-Geo ..... 184

Linear pattern on lateral surface G411-Geo ..... 185

Circular pattern on lateral surface G412-Geo ..... 186

4.12 Tool Positioning ..... 187

Rapid traverse G0 ..... 187

Setting the tool change position G14 ..... 187

Rapid traverse to machine coordinates G701 ..... 188

4.13 Simple Linear and Circular Movements ..... 189

Linear path G1 ..... 189

Circular path G2/ G3 ..... 190

Circular path G12/ G13 ..... 191

4.14 Feed Rate and Spindle Speed ..... 192

Rotational speed limiting G26 ..... 192

Acceleration (slope) G48 ..... 192

Interrupted feed G64 ..... 193

Feed per minute for rotary axes G192 ..... 193

Feed per tooth Gx93 ..... 194

Constant feed rate G94 (feed per minute) ..... 194

Feed per revolution Gx95 ..... 194

Constant surface speed Gx96 ..... 195

Speed Gx97 ..... 195

HEIDENHAIN CNC PILOT 4290 13

Page 14

4.15 Tool-Tip and Cutter Radius Compensation ..... 196

G40: Switch off TRC/MCRC ..... 197

G41/G42: Switch on TRC/MCRC ..... 197

4.16 Zero Point Shifts ..... 198

Zero point shift G51 ..... 199

Parameter-dependent zero offset G53, G54, G55 ..... 199

Additive zero point shift G56 ..... 200

Absolute zero point shift G59 ..... 201

Mirror/shift contour G121 ..... 202

4.17 Oversizes ..... 204

Switch off oversize G50 ..... 204

Axis-parallel oversize G57 ..... 204

Contour-parallel oversize (equidistant) G58 ..... 205

4.18 Safety Clearances ..... 206

Safety clearance G47 ..... 206

Safety clearance G147 ..... 206

4.19 Tools, Types of Compensation ..... 207

Tool call – T ..... 207

(Changing the) tool edge compensation G148 ..... 208

Additive compensation G149 ..... 209

Compensation of right-hand tool tip G150

Compensation of left-hand tool tip G151 ..... 210

Adding tool dimensions G710 ..... 211

4.20 Contour-Based Turning Cycles ..... 212

Working with cycles ..... 212

Longitudinal roughing G810 ..... 212

Face roughing G820 ..... 215

Contour-parallel roughing G830 ..... 218

Contour-parallel with neutral tool G835 ..... 220

Recessing G860 ..... 222

Recessing cycle G866 ..... 224

Recess turning cycle G869 ..... 225

Finish contour G890 ..... 228

4.21 Simple Turning Cycles ..... 231

End of cycle G80 ..... 231

Simple longitudinal roughing G81 ..... 231

Simple face roughing G82 ..... 232

Simple contour repeat cycle G83 ..... 234

Undercut cycle G85 ..... 235

Recessing G86 ..... 236

Radius cycle G87 ..... 238

Chamfer cycle G88 ..... 238

14

Page 15

4.22 Thread Cycles ..... 239

Thread switch G933 ..... 239

Thread cycle G31 ..... 240

Simple thread cycle G32 ..... 242

Thread single path G33 ..... 244

4.23 Drilling Cycles ..... 246

Drilling cycle G71 ..... 246

Boring, countersinking G72 ..... 248

Tapping G73 ..... 249

Tapping G36 ..... 250

Deep-hole drilling G74 ..... 251

4.24 C-Axis Commands ..... 253

No. of C axis G119 ..... 253

Reference diameter G120 ..... 253

Zero point shift, C axis G152 ..... 254

Standardize C axis G153 ..... 254

4.25 Front/Rear-Face Machining ..... 255

Rapid traverse on front/rear face G100 ..... 255

Linear segment on front/rear face G101 ..... 256

Circular arc on front/rear face G102/G103 ..... 257

4.26 Lateral Surface Machining ..... 258

Rapid traverse, lateral surface G110 ..... 258

Line segment on lateral surface G111 ..... 259

Circular arc on lateral surface G112/G113 ..... 260

4.27 Milling Cycles ..... 261

Contour milling G840—Fundamentals ..... 261

Pocket milling, roughing G845 – Fundamentals ..... 270

Pocket milling, finishing G846 ..... 276

Thread milling, axial G799 ..... 278

Engraving on front face G801 ..... 279

Engraving on lateral surface G802 ..... 280

Character set for engraving ..... 280

HEIDENHAIN CNC PILOT 4290 15

Page 16

4.28 Assignment, Synchronization, Workpiece Transfer ..... 282

Converting and mirroring G30 ..... 282

Spindle with workpiece G98 ..... 283

Workpiece group G99 ..... 284

One-sided synchronization G62 ..... 284

Synchronization marking G162 ..... 285

Synchronous start of slides G63 ..... 285

M97 Synchronous function ..... 286

Spindle synchronization G720 ..... 286

C-angle offset G905 ..... 287

Measuring angular offset during spindle synchronization G906 ..... 288

Traversing to a fixed stop G916 ..... 288

Controlled parting using lag error monitoring G917 ..... 291

Controlled parting using spindle monitoring G991 ..... 292

Values for controlled parting G992 ..... 293

4.29 Contour Follow-Up ..... 294

Saving/loading contour follow-up G702 ..... 294

Contour follow-up G703 ..... 294

K default branch G706 ..... 295

4.30 In-process and Post-process Measuring ..... 296

In-process measuring ..... 296

Post-process measurement G915 ..... 298

4.31 Load Monitoring ..... 300

Fundamentals of load monitoring ..... 300

Specifying the monitoring zone G995 ..... 301

Type of monitoring G996 ..... 301

16

Page 17

4.32 Other G Functions ..... 302

Period of dwell G4 ..... 302

Precision stop G7 ..... 302

Precision stop off G8 ..... 302

Precision stop G9 ..... 302

Move rotary axis G15 ..... 303

Switch off protection zone G60 ..... 303

Chucking equipment in simulation G65 ..... 304

Component position G66 ..... 305

Waiting for time G204 ..... 305

Update nominal values G717 ..... 305

Move lag error G718 ..... 306

Actual values in variables G901 ..... 306

Zero-point shift in variables G902 ..... 306

Lag error in variables G903 ..... 306

Block speed monitoring off G907 ..... 306

Feed rate override 100% G908 ..... 307

Interpreter stop G909 ..... 307

Velocity feedforward G918 ..... 307

Spindle override 100% G919 ..... 307

Deactivate zero-point shifts G920 ..... 308

Deactivate zero-point shifts, tool lengths G921 ..... 308

T no. internal G940 ..... 308

Transferring magazine compensation values G941 ..... 309

Servo lag limit G975 ..... 309

Activating zero-point shifts G980 ..... 309

Activate zero-point shifts, tool lengths G981 ..... 310

Sleeve monitoring G930 ..... 310

Shaft speed with V constant G922 ..... 311

4.33 Data Input and Data Output ..... 312

Output window for # variables WINDOW ..... 312

Input of # variables INPUT ..... 312

Output of # variables PRINT ..... 313

V variable simulation ..... 313

Output window for V variables WINDOWA ..... 313

Input of V variables INPUTA ..... 314

Output of V variables PRINTA ..... 314

4.34 Programming with Variables ..... 315

# variables ..... 316

V variables ..... 318

HEIDENHAIN CNC PILOT 4290 17

Page 18

4.35 Conditional Block Run ..... 322

Program branching IF..THEN..ELSE..ENDIF ..... 322

WHILE..ENDWHILE program repeat ..... 323

SWITCH..CASE—program branching ..... 324

Skip level /.. ..... 326

Slide code $.. ..... 326

4.36 Subprograms ..... 327

Subprogram call: L"xx" V1 ..... 327

Dialog texts in subprogram call ..... 328

Help graphics for subprogram calls ..... 329

4.37 M Commands ..... 330

M commands for program-run control ..... 330

Machine commands ..... 331

4.38 Lathes with Multiple Slides ..... 332

Multi-slide programming ..... 332

Program run ..... 334

Positioning the steady rest ..... 334

Traveling steady rest ..... 336

Two slides work simultaneously ..... 338

Two slides work in succession ..... 340

Machining with four-axis cycle ..... 342

4.39 Full-surface machining ..... 344

Fundamentals of full-surface machining ..... 344

Programming of full-surface machining ..... 345

Full-surface machining with opposing spindle ..... 346

Full-surface machining with single spindle ..... 349

4.40 DIN PLUS Program Example ..... 351

Example of a subprogram with contour repetitions ..... 351

4.41 DIN PLUS Templates ..... 354

Starting templates ..... 354

Structure templates ..... 354

Design of structure templates ..... 355

Transfer parameters for structure templates ..... 355

Editing structure templates ..... 356

Help graphics for structure templates ..... 356

Template menu ..... 356

Template example ..... 357

4.42 Connection between Geometry and Machining Commands ..... 359

Turning ..... 359

C-axis machining – front/rear face ..... 360

C-axis machining – lateral surface ..... 360

18

Page 19

5 Graphic Simulation ..... 361

5.1 Simulation Mode of Operation ..... 362

Screen layout, soft keys ..... 363

Graphic elements ..... 364

Displays ..... 364

Zero point shifts ..... 366

Path display ..... 367

Simulation window ..... 368

Setting the simulation window ..... 369

Configuring the simulation ..... 370

Adjusting the section (zoom function) ..... 371

Errors and warnings ..... 372

How to activate the simulation function ..... 372

Simulation mode ..... 373

5.2 Contour Simulation ..... 374

Functions of the contour simulation ..... 374

Contour dimensioning ..... 375

5.3 Machining Simulation ..... 376

Checking the workpiece machining ..... 376

Protection zone and limit switch monitoring (machining simulation) ..... 377

Dynamic limit switch monitoring ..... 377

Contour checking ..... 378

Saving the generated contour ..... 378

Displaying the tool tip reference point ..... 379

5.4 Motion Simulation ..... 380

Real-time simulation ..... 380

Protection zone and limit switch monitoring (motion simulation) ..... 381

Contour checking ..... 381

5.5 3-D View ..... 382

Influencing the 3-D view ..... 382

5.6 Debugging Functions ..... 383

Simulation with starting block ..... 383

Displaying variables ..... 384

Editing variables ..... 385

5.7 Checking Multi-channel Programs ..... 386

5.8 Time Calculation, Synchronous Point Analysis ..... 387

Time Calculation ..... 387

Synchronous point analysis ..... 388

HEIDENHAIN CNC PILOT 4290 19

Page 20

6 TURN PLUS ..... 389

6.1 TURN PLUS Mode of Operation ..... 390

TURN PLUS concept ..... 390

TURN PLUS files ..... 391

TURN PLUS program management ..... 391

Operating notes ..... 392

6.2 Program Head ..... 393

Generating programs for automatic lathes ..... 394

6.3 Workpiece Description ..... 396

Entering the workpiece blank contour ..... 396

Entering the finished part contour ..... 397

Superimposing form elements ..... 398

Integrating overlay elements ..... 399

Entering contours machined with the C axis ..... 400

6.4 Contours of Workpiece Blanks ..... 402

Bar ..... 402

Tube ..... 402

Cast blank (or forged blank) ..... 403

6.5 Contours of Finished Parts ..... 404

Notes on defining contours ..... 404

Starting point of contour ..... 404

Linear elements ..... 405

Circular element ..... 406

6.6 Form Elements ..... 408

Chamfer ..... 408

Rounding ..... 408

Undercut type E ..... 409

Undercut type F ..... 409

Undercut type G ..... 409

Undercut type H ..... 410

Undercut type K ..... 410

Undercut type U ..... 410

Recess general ..... 411

Recess type D (sealing ring) ..... 412

Relief turn (type FD) ..... 413

Recess type S (guarding ring) ..... 413

Thread ..... 414

(Centric) Hole ..... 415

6.7 Overlay Elements ..... 418

Circular arc ..... 418

Wedge/rounded wedge ..... 418

Pontoon ..... 419

Linear superimposition (“linear overlay”) ..... 419

Circular superimposition (“circular overlay”) ..... 420

20

Page 21

6.8 C-Axis Contours ..... 421

Position of a front or rear face contour ..... 421

Position of a lateral surface contour ..... 421

Milling depth ..... 421

Entering the C-axis contour dimensions ..... 422

Front or rear face: Starting point ..... 422

Front or rear face: Linear element ..... 423

Front or rear face: Circular element ..... 424

Front or rear face: Single hole ..... 426

Front or rear face: Circle (full circle) ..... 428

Front or rear face: Rectangle ..... 429

Front or rear face: Polygon ..... 430

Front or rear face: Linear slot ..... 431

Front or rear face: Circular slot ..... 432

Front or rear face: Linear hole or figure pattern ..... 433

Front or rear face: Circular hole or figure pattern ..... 434

Lateral surface: Starting point ..... 435

Lateral surface: Linear element ..... 436

Lateral surface: Circular element ..... 437

Lateral surface: Single hole ..... 438

Lateral surface: Circle (full circle) ..... 440

Lateral surface: Rectangle ..... 441

Lateral surface: Polygon ..... 442

Lateral surface: Linear slot ..... 443

Lateral surface: Circular slot ..... 444

Lateral surface: Linear hole or figure pattern ..... 445

Lateral surface: Circular hole or figure pattern ..... 446

6.9 Help Functions ..... 447

Unresolved contour elements ..... 447

Selections ..... 448

Zero point shift ..... 452

Copying a contour section in linear series ..... 452

Copying a contour section in circular series ..... 453

Copying a contour section by mirroring ..... 453

Calculator ..... 454

Digitizing ..... 455

Checking contour elements (inspector) ..... 456

Error messages ..... 457

6.10 Importing of DXF Contours ..... 458

Fundamentals for DXF import ..... 458

Configuring the DXF Import ..... 459

DXF import ..... 460

HEIDENHAIN CNC PILOT 4290 21

Page 22

6.11 Manipulating Contours ..... 461

Editing the contours of a blank part ..... 461

Deleting contour elements ..... 462

Editing contour elements or form elements ..... 462

Adding a contour or contour element ..... 463

Closing the contour ..... 464

Resolving a contour ..... 464

Trimming – Linear element ..... 465

Trimming – Length of contour ..... 466

Trimming – Radius of arc ..... 466

Trimming – Diameter of linear element ..... 467

Transformations – Fundamentals ..... 467

Transformations – Shifting ..... 468

Transformations – Rotating ..... 468

Transformations – Mirroring ..... 469

Transformations – Inverting ..... 469

6.12 Assigning Attributes ..... 470

Attributes for workpiece blanks ..... 470

Attributes – Oversize ..... 471

Attributes – Feed rate ..... 472

Attributes – Peak-to-valley ..... 472

Attributes – Additive compensation ..... 473

Machining attributes – Measure ..... 473

Machining attributes – Threading ..... 474

Machining attributes – Drill – Retraction plane ..... 475

Machining attributes – Drilling combinations ..... 475

Machining attributes – Contour milling ..... 476

Machining attributes – Area milling ..... 477

Machining attributes – Deburring ..... 478

Machining attributes – Engraving ..... 479

Machining attributes – Precision stop ..... 479

Machining attributes – Separation point ..... 480

Attributes – Exclusion from machining ..... 480

Deleting machining attributes ..... 481

22

Page 23

6.13 Preparing a Machining Process ..... 482

Preparing a machining process – Fundamentals ..... 482

Chucking a workpiece at the spindle ..... 483

Chucking a workpiece at the tailstock ..... 483

Defining the cutting limit ..... 484

Deleting the chucking data ..... 484

Rechuck – Standard machining ..... 485

Rechuck – 1st setup after 2nd setup ..... 486

Parameters for two-jaw, three-jaw or four-jaw chucks ..... 488

Collet chuck parameters ..... 489

Parameters for face drivers (“without chuck”) ..... 489

Parameters for face drivers with jaws (“Three-jaw chuck indirect”) ..... 490

Setting up and managing tool lists ..... 490

HEIDENHAIN CNC PILOT 4290 23

Page 24

6.14 Interactive Working Plan Generation (IWG) ..... 494

Working plan exists ..... 495

Generating a work block ..... 496

Calling a tool ..... 497

Cutting data ..... 497

Cycle specification ..... 498

Overview of roughing operations ..... 499

Roughing longitudinal (G810) ..... 500

Roughing transverse (G820) ..... 501

Roughing contour-parallel (G830) ..... 502

Residual roughing – longitudinal ..... 503

Residual roughing – transverse ..... 504

Residual roughing – contour-parallel ..... 505

Roughing hollowing – neutral tool (G835) ..... 506

Overview of recessing operations ..... 507

Contour recessing radial/axial (G860) ..... 508

Recessing radial/axial (G866) ..... 509

Recess turning radial/axial (G869) ..... 510

Parting ..... 512

Parting and workpiece transfer ..... 513

Overview of drilling operations ..... 516

Centric predrilling (G74) ..... 517

Centering, countersinking (G72) ..... 518

Drilling, reaming, deep-hole drilling ..... 519

Tapping ..... 520

Finishing ..... 521

Finishing – Clearance turning ..... 524

Finishing – undercut ..... 524

Thread machining (G31) ..... 525

Overview of milling operations ..... 526

Contour milling – Roughing/Finishing (G840) ..... 527

Deburring (G840) ..... 529

Engraving (G840) ..... 530

Pocket milling – Roughing/Finishing (G845/G846) ..... 531

Special machining (SM) ..... 532

6.15 Automatic Working Plan Generation (AWG) ..... 534

Generating a working plan ..... 534

Machining sequence – Fundamentals ..... 535

Editing and managing machining sequences ..... 536

Overview of machining sequences ..... 538

6.16 Control Graphics ..... 547

Adjusting the section (zoom function) ..... 547

Setting the control graphics ..... 548

24

Page 25

6.17 Configuring TURN PLUS ..... 549

General settings ..... 549

Configuring windows (views) ..... 550

Configuring the control graphics ..... 550

Setting the coordinate system ..... 551

6.18 Machining Information ..... 552

Tool selection, turret assignment ..... 552

Contour recessing, recess turning ..... 553

Drilling ..... 553

Cutting data, coolant ..... 553

Hollowing ..... 554

Inside contours ..... 555

Drilling ..... 556

Shaft machining ..... 557

Multi-slide machines ..... 559

Full-surface machining ..... 560

6.19 Example ..... 562

Creating a program ..... 562

Defining the workpiece blank ..... 563

Defining the basic contour ..... 563

Defining form elements ..... 564

Preparing the machining process, chucking ..... 565

Generating and saving a working plan ..... 565

7 Parameters ..... 567

7.1 The Parameter Mode of Operation ..... 568

7.2 Editing Parameters ..... 569

Current parameters ..... 569

Parameter lists ..... 569

Editing configuration parameters ..... 570

7.3 Machine Parameters (MP) ..... 571

General machine parameters ..... 571

Machine parameters for slides ..... 572

Machine parameters for spindles ..... 573

Machine parameters for C axes ..... 574

Machine parameters for linear axes ..... 575

7.4 Control Parameters ..... 577

General control parameters ..... 577

Control parameters for simulation ..... 579

Control parameters for machine display ..... 580

7.5 Set-Up Parameters ..... 583

HEIDENHAIN CNC PILOT 4290 25

Page 26

7.6 Machining Parameters ..... 585

1 – Global parameters for finished parts ..... 585

2 – Global technology parameters ..... 586

3 – Centric predrilling ..... 588

4 – Roughing ..... 591

5 – Finishing ..... 594

6 – Recessing and contour recessing ..... 597

7 – Thread cutting ..... 599

8 – Measuring ..... 600

9 – Drilling ..... 600

10 – Milling ..... 602

Load monitoring ..... 603

20 – Direction of rotation for rear-side machining ..... 604

21 – Name of the subroutines ..... 605

22 – Sequence of tool selection ..... 605

23 – Template management ..... 606

24 – Parameter of the rechucking subroutines ..... 606

8 Operating Resources ..... 607

8.1 Tool Database ..... 608

Tool editor ..... 608

Overview of tool types ..... 612

Tool parameters ..... 614

Tool holder, tool mount ..... 624

8.2 Database for Chucking Equipment ..... 628

Chucking equipment editor ..... 628

Chucking equipment lists ..... 629

Chucking equipment data ..... 630

8.3 Technology Database ..... 641

Editing the technology data ..... 642

Cutting-value tables ..... 643

26

Page 27

9 Service and Diagnosis ..... 645

9.1 The Service Mode of Operation ..... 646

9.2 Service Functions ..... 647

Access authorization ..... 647

System service ..... 648

Fixed-word lists ..... 649

9.3 Maintenance System ..... 650

Maintenance dates and intervals ..... 651

Displaying maintenance actions ..... 652

9.4 Diagnosis ..... 655

Information and display ..... 655

Log files and network settings ..... 656

Software update ..... 657

10 Transfer ..... 659

10.1 The Transfer Mode of Operation ..... 660

Overview of data transfer methods ..... 661

Configuring Windows networks ..... 663

Configuring the serial interface or “printer” ..... 666

10.2 Data Transfer ..... 668

Enabling, file types ..... 668

Basics of operation ..... 669

Transmitting and receiving files ..... 671

10.3 Parameters and Operating Resources ..... 674

Transmitting parameters/operating resources ..... 675

Loading parameters/operating resources ..... 676

Backing up and restoring data ..... 677

Viewing parameter, operating-resource or backup files ..... 679

10.4 File Organization ..... 680

Fundamentals for file organization ..... 680

Managing files ..... 681

HEIDENHAIN CNC PILOT 4290 27

Page 28

11 Tables and Overviews ..... 683

11.1 Undercut and Thread Parameters ..... 684

Undercut DIN 76, Parameters ..... 684

Undercut DIN 509 E, Parameters ..... 686

Undercut DIN 509 F, Parameters ..... 686

Thread Parameters ..... 687

Thread pitch ..... 688

11.2 Pin Layouts and Connecting Cables for the Data Interfaces ..... 694

RS-232-C/V.24 interface for HEIDENHAIN devices ..... 694

Non-HEIDENHAIN devices ..... 695

RS-422/V.11 interface ..... 696

Ethernet interface RJ45 socket ..... 696

11.3 Technical Information ..... 697

Specifications ..... 697

Accessories ..... 698

User functions ..... 698

28

Page 29

Introduction and Fundamentals

HEIDENHAIN CNC PILOT 4290 29

Page 30

1.1 The CNC PILOT

The CNC PILOT is a contouring control designed for complex lathes

and turning centers. In addition to turning operations, the control can

also perform milling, drilling and boring operations. The C, Y and B

axes enable you to drill and mill on the front and rear faces, the lateral

surface and oblique planes. And as always, the CNC PILOT supports

full-surface machining with dual-spindles.

The CNC PILOT controls up to six slides, four spindles, two C axes,

one B axis and a pocket-oriented tool magazine. The control can

machine up to four workpieces simultaneously.

1.1 The CNC PILOT

Programming

Depending on the type and complexity of the parts to be machined

and your organization, you can choose the type of programming best

suited to your tasks.

In TURN PLUS you describe the contour of the blank and finished part

using interactive graphics. Then you call the automatic working plan

generation (AWG), and the NC program will be generated fully

automatically on a keystroke. An alternative is the interactive working

plan generation (IWG). When using the IWG, you determine the

sequence of machining and other technical details.

Every working step is shown in the control graphics and can be

corrected immediately. The result of program creation with TURN

PLUS is a structured DIN PLUS program.

TURN PLUS minimizes the number of entries required, but it requires

that the the tool data and cutting data has already been entered.

If TURN PLUS fails to create the optimal NC program for

technologically sophisticated machining operations, or if you

primarily want to reduce the machining time, write the NC program

with DIN PLUS.

In DIN PLUS you first describe the contour of the workpiece blank and

finished part. The “simplified geometry programming” calculates

nondimensioned coordinates if, for example, the drawing is not

dimensioned for conventional NC. Then you write the NC program

using powerful fixed cycles.

Both TURN PLUS and DIN PLUS support a C or Y axis and full-surface

machining. DIN PLUS cycles are available for working with the B axis.

As an alternative, you can machine your workpiece in DIN PLUS with

linear and circular movements and simple turning cycles, as you are

accustomed to in conventional DIN programming.

30

Page 31

The graphic simulation feature enables you to subject your NC

programs to a realistic test. The CNC PILOT displays the machining of

up to four workpieces in the working space. The simulation shows

workpiece blanks and finished parts, chucking equipment and tools to

scale. When working with the tilted B axis, the working plane is also

shown tilted. This enables you to see, without distortion, the holes and

milling contours to be machined.

You can program your NC programs and test them—even during

machining operations—directly on the machine.

Regardless of whether you are machining a simple or complex part,

producing a single part or a series of parts, or a whole batch on a

turning center, the CNC PILOT always gives you optimum support.

The C axis

With a C axis you can drill and mill a workpiece on its front, back and

lateral surfaces.

When the C axis is used, one axis interpolates linearly or circularly with

the spindle in the given working plane, while the third axis interpolates

linearly.

The CNC PILOT supports part program creation with the C axis in:

DIN PLUS

TURN PLUS contour definition

TURN PLUS working plan generation

1.1 The CNC PILOT

HEIDENHAIN CNC PILOT 4290 31

Page 32

The Y axis

With a Y axis you can drill and mill a workpiece on its front, back and

lateral surfaces.

During use of the Y-axis, two axes interpolate linearly or circularly in

the given working plane, while the third axis interpolates linearly. This

enables you to machine slots or pockets, for example, with plane

floors and perpendicular edges. By defining the spindle angle, you can

determine the position of the milling contour on the workpiece.

The CNC PILOT supports part program creation with the Y axis in:

DIN PLUS

TURN PLUS contour definition

1.1 The CNC PILOT

TURN PLUS working plan generation

32

Page 33

Full-surface machining

Functions like angle-synchronous part transfer with rotating spindle,

traversing to a stop, controlled parting, and coordinate transformation

ensures efficient machining as well as simple programming of fullsurface machining.

The functions for full-surface machining are available in:

DIN PLUS

TURN PLUS contour definition

TURN PLUS working plan generation

The CNC PILOT supports full-surface machining for all common

machine designs.

Examples: Lathes with

Rotating gripper

Movable opposing spindle

Several spindles, slides and tool carriers

1.1 The CNC PILOT

HEIDENHAIN CNC PILOT 4290 33

Page 34

The B axis

The B axis makes it possible to drill, bore and mill in oblique planes.

To make programming easy, the coordinate system is tilted in such a

way that you can define the drilling patterns and milling contours in the

YZ plane. The actual drilling or milling operation is then performed in

the tilted plane.

During work on the tilted plane, the tool is perpendicular to the plane.

The tilting angle of the B axis and the angle of the tilted plane are

identical.

Another advantage of the B axis is the flexible use of tools during

turning operations. By tilting the B axis and rotating the tool you can

1.1 The CNC PILOT

bring it into positions that enable you to use one and the same tool to

machine in the longitudinal and transverse (or radial and axial)

directions on the main and opposing spindles.

In this way, you need fewer tools and fewer tool changes.

The CNC PILOT supports part program creation with the B axis in

DIN PLUS.

The graphical simulation shows the machining operation in a tilted

working plane in the familiar lathe and front windows, as well as in the

“side view (YZ).”

User's Manual for the B and Y axes

The manual and automatic control functions a well as the

programming and testing of NC programs for the B and Y

axes are described in a separate User's Manual. Please

contact HEIDENHAIN if you require a copy of this User's

Manual.

34

Page 35

1.2 The Modes of Operation

Operating modes

Manual mode: In the Manual Control mode you set up

the machine and move the axes manually.

Automatic mode: NC in Automatic mode, NC programs

are executed from start to end. You control and monitor

the machining of the workpieces.

DIN PLUS programming mode: You write the

structured NC programs in DIN PLUS. First you define

the geometry of the blank and finished part, and then

program the machining of the workpiece.

Simulation programming mode: The Simulation mode

graphically depicts contours, tool movements and cutting

processes. The working space, tools and chucking

equipment are shown true to scale.

During simulation, the CNC PILOT calculates the

machining and idle-machine times for every tool. For

lathes with several slides, the synchronous point

analysis enables you to optimize your NC program.

TURN PLUS programming mode: In TURN PLUS you

describe the workpiece contour interactively in a graphic.

If you then define the material and chucking equipment,

the Automatic Working plan Generation (AWG) will

generate the NC program automatically at a keystroke.

As an alternative, you can create the working plan with

the aid of interactive graphics (IAG).

1.2 The Modes of Operation

Parameter organization mode: The system behavior of

the CNC PILOT is controlled by parameters. In this mode,

you set the parameters to adapt the control to your

situation.

In addition, in this mode you describe the operating

resources (tools and chucking equipment) and the

cutting values.

HEIDENHAIN CNC PILOT 4290 35

Page 36

Operating modes

Service organization mode: In Service you log in for

password-protected functions, select the conversational

language and make system settings. This operating

mode also provides diagnostic functions for

commissioning and checking the system.

Transfer organization mode: In Transfer, you exchange

data with other systems, organize your programs and

back-up your data.

The actual control is not accessible to the machinist. You should know,

however, that your CNC PILOT stores all TURN PLUS and DIN PLUS

programs that you enter on an integrated hard disk. This allows you to

save a vast number of programs.

For data exchange and data backup, you can use the Ethernet

interface and the USB memory medium. Data exchange on the basis

of the serial interface (RS-232) is also possible.

1.2 The Modes of Operation

36

Page 37

1.3 Expansion Stages (Options)

The machine manufacturer configures the CNC PILOT according to

the capabilities of the specific lathe. The following upgrades (options)

are available, which enable you to adapt the control to your specific

requirements:

TURN PLUS – Basis (ID 354 132-01):

Graphically supported interactive contour definition

Graphic program entry for describing the workpiece blank and

finished part

Geometry program for calculating and depicting contour points for

which dimensional data are missing

Simple entry of standardized form elements such as chamfers,

rounding arcs, undercuts, recesses, threads, fits

Simple handling of transformations such as datum shift, rotation,

mirroring, duplication

Graphically supported interactive DIN PLUS program generation

Individual selection of the operating mode

Selection of the tool and specification of cutting data

Direct graphic verification of the metal removing operation

Direct compensation capability

Automatic DIN PLUS program generation

Automatic tool selection

Automatic generation of the working plan

TURN PLUS – C-axis option (ID 354 133-01):

Depiction of programming in the XC plane (front/rear face) and ZC

plane (unrolled lateral surface view)

Hole pattern and figure pattern; any milled contours

Interactive or automatic generation of the working plan, including C-

axis machining

TURN PLUS – option for opposing spindles

(ID 354 134-01):

Rechucking with expert program

Interactive or automatic generation of the working plan, including

rechucking and machining the second setup

TURN PLUS – DXF import (ID 526 461-01):

In TURN PLUS, read in the contours (blank and finished part

contours, milled contours, contour trains) that are available in DXF

format

View and select DXF layers

Load DXF contour into TURN PLUS

1.3 Expansion Stages (Options)

HEIDENHAIN CNC PILOT 4290 37

Page 38

Opposing spindle—full-surface machining of a workpiece

(ID 518 289-01):

Spindle synchronism (G720)

Parting control (G917, G991, G992)

Traversing to a dead stop (G916)

Mirroring and converting (G30)

In-process measurement—measuring on the machine

(ID 354 536-01):

With touch trigger probe

For tool setup

For workpiece measurement

Post-process measurement—measuring on external measuring

stations

(ID 354 537-01):

Connecting the measuring equipment over the RS-232 interface

Evaluating the measurement results in the NC program

Y axis (ID 354 138-01)

Support of Y axis programming in DIN PLUS, TURN PLUS and in

1.3 Expansion Stages (Options)

simulation

Depiction of programming in the XY (front/rear face) and YZ (lateral

surface view) planes

DIN PLUS and TURN PLUS: Drilling, boring and figure patterns; any

milling contours

DIN PLUS: Cycles for drilling, boring and milling

TURN PLUS: Interactive or automatic generation of the working

plan, including Y-axis machining

B axis (ID 589 963-01)

Support of B axis programming in DIN PLUS and in simulation

The coordinate system is transformed to a tilted place in order to

describe hole and figure patterns as well as any desired contours in

the YZ plane

Fixed cycles work in a tilted plane

Options can usually be retrofitted. Your machine manufacturer can

give you more information.

This description covers all options. The operating

sequences described in this manual may therefore deviate

from those on your machine whenever a certain option is

not supported by your system.

38

Page 39

1.4 Fundamentals

Zref

Xref

M

Position encoders and reference marks

The machine axes are equipped with position encoders that register

the positions of the slide or tool. When a machine axis moves, the

corresponding position encoder generates an electrical signal. The

control evaluates this signal and calculates the precise actual position

of the machine axis.

If there is a power interruption, the calculated position will no longer

correspond to the actual position of the machine slide. To recover this

association, incremental position encoders are provided with

reference marks. The scales of the position encoders contain one or

more reference marks that transmit a signal to the control when they

are crossed over. From the signal the CNC PILOT can re-establish the

assignment of displayed positions to machine positions. For linear

encoders with distance-coded reference marks the machine axes

need to move by no more than 20 mm, for angle encoders by no more

than 20°.

With absolute encoders, an absolute position value is transmitted to

the control immediately upon switch-on. In this way the assignment

of the actual position to the machine slide position is re-established

directly after switch-on.

X

MP

X (Z,Y)

1.4 Fundamentals

HEIDENHAIN CNC PILOT 4290 39

Page 40

Axis designations and coordinate system

+Y

+X

+Z

+C

+B

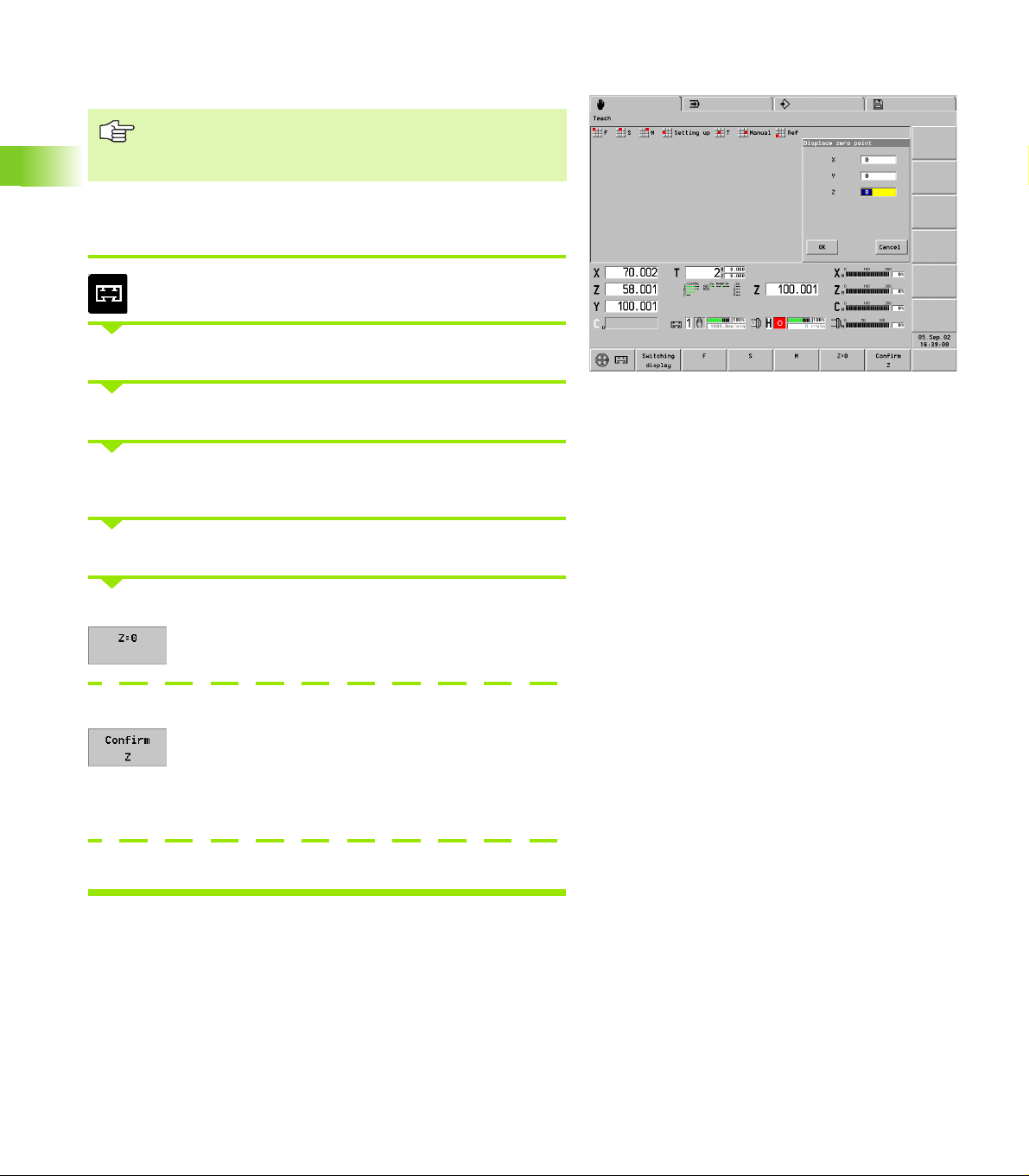

M

Z

Z+

Y+

X

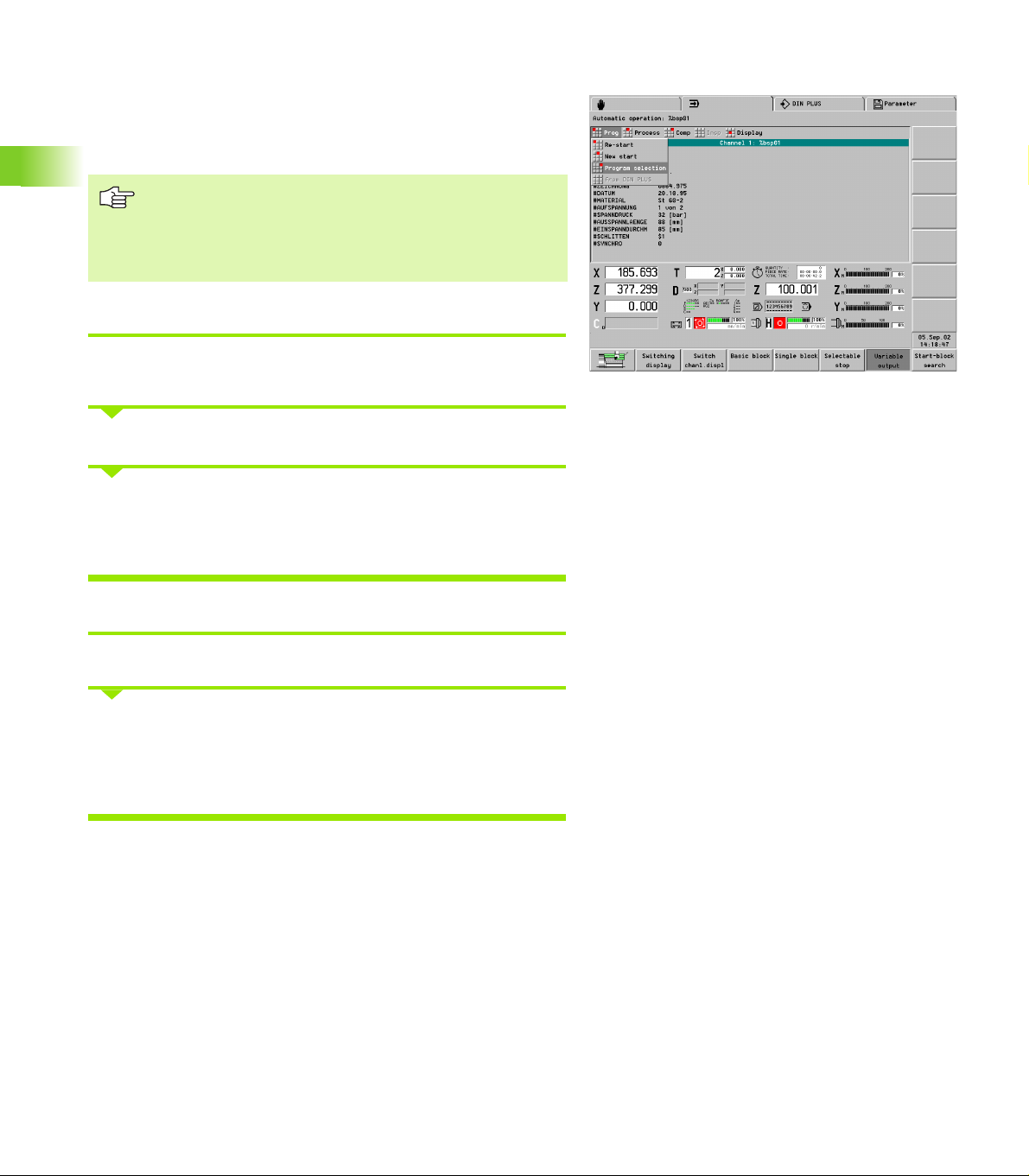

X+

Coordinate system

The meanings of the coordinates X, Y, Z, B, C are specified in DIN

66 217.

The coordinates entered for the principle axes X and Z are referenced

to the workpiece zero point. The angular data for the rotary axes B and

C are given with respect to the zero point of the respective rotary axis.

On lathes, C axis movements are realized by turning the workpiece

and B axis movements by tilting the tool (swivel head).

1.4 Fundamentals

Axis designations

The cross slide is referred to as the X axis and the saddle as the Z

axis.

All X-axis values that are displayed or entered are regarded as

diameters. In TURN PLUS you can define whether the X axis values

are diameters or radii.

Lathes with Y axis: The Y axis is perpendicular to the X axis and Z axis

(Cartesian system).

When programming paths of traverse, remember to:

Program a positive value to depart the workpiece.

Program a negative value to approach the workpiece.

Machine reference points

Machine zero point

The point of intersection of the X and Z axes is called the machine

zero point. On a lathe, the machine zero point is usually the point of

intersection of the spindle axis and the spindle surface. The machine

zero point is designated with the letter “M”.

Workpiece zero point

For machining a workpiece, it is easier to reference all input data to a

zero point located on the workpiece. By programming the zero point

used in the workpiece drawing, you can take the dimensions directly

from the drawing, without further calculation. This point is the

“workpiece zero point.” The workpiece zero point is designated with

the letter “W”.

40

Page 41

Absolute and incremental workpiece positions

If the coordinates of a position are referenced to the workpiece zero

point, they are referred to as absolute coordinates. Each position on

a workpiece is clearly defined by its absolute coordinates.

Incremental coordinates: Incremental coordinates are given with

respect to the last programmed position. They specify the distance

from the last active position and the subsequent position. Each

position on a workpiece is clearly defined by its incremental

coordinates.

Absolute and incremental polar coordinates: Positions located on

the face or lateral surface can either be entered either in Cartesian

coordinates or polar coordinates.

When programming with polar coordinates, a position on the

workpiece is clearly defined by the entries for diameter and angle.

Absolute polar coordinates refer to the pole and the angle reference

axis. Incremental polar coordinates always refer to the last

programmed nominal position of the tool.

1.4 Fundamentals

HEIDENHAIN CNC PILOT 4290 41

Page 42

Units of measure

You can program the CNC PILOT either in the metric or inch system.

The units of measurement listed in the table below apply to all inputs

and displays.

Measure Metric Inches

Coordinates mm inches

Lengths mm inches

Angle degrees degrees

Shaft speed rpm rpm

1.4 Fundamentals

Cutting speed m/min ft/min

Feed per revolution mm/rev inch/rev

Feed per minute mm/min inch/min

Acceleration m/s

2

ft/s

2

42

Page 43

1.5 Tool Dimensions

The CNC PILOT requires information on the specific tools for a variety

of tasks, such as calculating the cutting radius compensation or the

proportioning of cuts.

Tool dimensions:All position values that are programmed and

displayed are referenced to the distance between the tool tip and

workpiece zero point. Since the control only knows the absolute

position of the tool carrier (slide), The CNC PILOT needs the

dimensions XE and ZE to calculate and display the position of the tool

tip, and for Y axis machining, it also needs the dimension in Y.

Tool compensation: The tool tip is subjected to wear during

machining processes. To compensate for this wear, the CNC PILOT

uses compensation values. The system automatically adds the

compensation values to the values for length.

Tool radius compensation (TRC): The tip of a lathe tool has a certain

radius. When machining tapers, chamfers and radii, this results in

inaccuracies which the CNC PILOT compensates with its cutting

radius compensation function.

Programmed paths of traverse are referenced to the theoretical tool

tip S. The TRC function compensates for this error by calculating a

new path of traverse, the equidistant line.

Milling cutter radius compensation (MCRC):In milling operations,

the outside diameter of the milling cutter determines the contour.

When the MCRC function is not active, the system defines the center

of the cutter as the zero point for paths of traverse. The MCRC

function compensates for cutter radius by calculating a new path of

traverse, the equidistant line.

1.5 Tool Dimensions

HEIDENHAIN CNC PILOT 4290 43

Page 44

1.5 Tool Dimensions

44

Page 45

Basics of Operation

HEIDENHAIN CNC PILOT 4290 45

Page 46

2.1 User Interface

Screen displays

1 Operating mode bar: Shows the status of the operating modes.

The active mode is shown with a dark-gray background.

Programming and organization operating modes:

The selected mode of operation is shown at right next to the

2.1 User Interface

2 Menu bar and pull-down menu enable you to select functions.

3 Working window: Size and content depend on the operating

4 Machine display: Shows the current status of the machine (tool

5 Status bar

6 Calendar date and service “traffic light”

7 Soft-key row: Shows the current meaning of the soft keys.

8 Vertical soft-key row: Shows the current meaning of the soft

symbol.

Additional information such as the selected program,

submode, etc. are shown below the operating mode

symbol.

mode.

position, the cycle and spindle situation, active tool, etc.). The

machine display is configurable.

Simulation, TURN PLUS: Displays the current settings or

information on the next operating steps.

Other operating modes: Displays the most recent error

message

Date and time

A colored background signalizes an error or a PLC message.

The “traffic light” indicates the maintenance status of the

machine.

keys. For more information: see the machine manual.

46

Page 47

Controls and displays

Operating elements of the CNC PILOT:

Screen with

Horizontal and vertical soft keys: The meaning is shown above or

next to the soft keys.

Auxiliary key 1: Acts as the Esc key

Auxiliary key 2: Acts as the Insert key

Auxiliary keys 3: PLC keys

Keyboard with

Alphabetic keyboard with integrated numeric keypad

Keys for operating mode selection

Touchpad: For cursor positioning (menu or soft key selection,

selection from lists, selecting edit boxes, etc.)

Machine operating panel with

Operating elements for the manual and automatic operation of the

lathe (cycle keys, manual direction keys, etc.)

Handwheel for exact positioning in manual mode

Override button for feed-rate override

Operating information on the touchpad: Normally you use the

touchpad as an alternative to the cursor keys. In the following, the

keys below the touchpad are referred to as the left and right mouse

keys.

The functions and operation of the touchpad are similar to the mouse

operation of the Windows operating systems.

Single click of the left mouse key or tap on the mouse pad:

Positions the cursor in lists or input windows.

Activates menu points, soft keys or buttons.

Double click of the left mouse key or double tap on the mouse pad:

Activates the selected element in lists (activates the input

window).

Single click of the right mouse key:

Same function as the Esc key. Prerequisite: the ESC key is

permitted in this situation (for example to go back by one menu

level).

Same function as the left mouse key when selecting soft keys or

buttons.

2.1 User Interface

HEIDENHAIN CNC PILOT 4290 47

Page 48

Selecting the operating mode

Keys for operating mode selection

Manual control operating mode

Automatic operating mode

Programming modes

2.1 User Interface

You can usually switch operating mode at any times. In some

situations, you cannot switch operating modes when a dialog box is

open. In this case, close the dialog box before changing operating

modes. After the change, the new mode starts in the function in which

it was last exited.

In the Programming and Organization operating modes, the CNC

PILOT differentiates between the following situations:

No operating mode is selected (no entry next to the operating mode

symbol): Select the desired mode from the menu.

Operating mode selected (indicated next to the operating mode

symbol): The functions of this operating mode are available.

Within the programming or organization modes, you can switch the

modes by soft key or by repeatedly pressing the corresponding

mode key.

Organization modes

Data input, selection of functions

Data are entered and edited in input windows. An input window

consists of several input fields. You position the cursor with the

touchpad or with the PgUp/PgDn keys to the input box.

Once the cursor is located in the box, you can enter your data or

overwrite existing data. With the right/left arrow keys you can place

the cursor on a position within the input box in order to delete

characters or add data. The “up/down” arrow keys or “Enter” confirm

and terminate the entry.

Some dialogs have more input fields than a window can show. In

these cases, more than one input window appears on the screen, one

superimposed on the other. You will recognize this through the

window number in the top line. To toggle between input windows,

use the PgUp/PgDn keys.

48

Page 49

When you press the OK button, the control accepts the data entered

or edited. As an alternative you can press the Ins key to confirm the

data, regardless of the cursor position. If you leave the input window

by pressing the “Cancel” button or the ESC key, entries or changes

will be lost.

If the dialog consists of more than one input window, you already

confirm the data when pressing the PgUp/PgDn key.

Note: Instead of selecting the OK or Cancel button, you

can press the Ins or Esc key.

List operations: DIN PLUS programs, tool lists, parameter lists, etc.

are displayed as lists. You can scroll through a list with the touchpad

or arrow keys to check data, to select the position where you wish to

enter data, or to highlight items for operations like deleting, copying,

editing, etc.

After having selected the desired list position or a list item, press the

ENTER, INS, ALT or DEL key to execute the operation.

Menu selection: The individual menu items are preceded by the 9field symbol with one field marked. This key represents the key on the

numeric keypad. Press the marked button to select the function.

The function selection begins in the horizontal menu row, then goes

to the pull-down menus. In the pull-down menu you again press the

marked key. As an alternative you can select the menu item with the

touchpad or with the Up/Dn arrow keys and then press ENT.

Soft keys: The meaning of the soft keys is dependent on the current

operating situation. The CNC PILOT indicates the function of the soft

keys with symbols or keywords.

Some soft keys work like “toggle switches.” A function is active when

the associated field in the soft-key row is highlighted in color. The

setting remains in effect until the function is switched off.

Screen buttons: Example of screen buttons are the OK and Cancel

buttons for terminating a dialog box or the buttons contained in the

“Extended inputs” window.

Select the button by cursor and press ENT, or select the button using

the touchpad and press the left mouse button.

2.1 User Interface

HEIDENHAIN CNC PILOT 4290 49

Page 50

2.2 Info and Error System

The info system

The info system calls excerpts from the User's Manual to the screen.

The header shows the selected topic.

You'll usually find information on the current operating situation

(context-sensitive help). if no context-sensitive help is available for a

specific situation look for the topics in the following sources:

The table of contents

The subject index

The search functions

Cross references are marked in the text. Click the cross references by

touchpad to jump to that topic.

Calling and exiting the info system:

2.2 Info and Error System

U Call the info system

U Exit the info system

Contents, subject index, search function: When called, the info

system opens the standard window (figure at upper right). Use the

soft key to switch to the Content/Index window in order to find topics

through the table of contents or subject index, or through the search

function (figure at lower right).

Content/Index window:

U Soft key active: Window is displayed.

U Soft key not active: Window is not displayed.

Size of the info window: Use the soft key to switch the window to

maximum size.

Large window or standard window:

U Soft key active: The info is displayed in the large

window.

U Soft key not active: The info is displayed in the

standard window.

50

Page 51

Navigating in the info system:

U You navigate by touchpad as is usual in Windows

programs.

If the topic of information exceeds the window size:

U Navigate with the up/down cursor keys and PgUp/

PgDn keys through the displayed topic. Prerequisite:

The cursor must be located in the topic window and

not in the Content/Index window.

Moving the cursor:

U Press the soft keys. The cursor switches between the

topic window and the Content/Index window.

Next/previous topic:

U Call the next topic from the table of contents.

U Call the previous topic from the table of contents.

Next/previous topic: The info system saves the history.

U Go to the previous topic.

U Go to the next topic.

OEM help: This soft key is only operable if the machine tool builder

has saved information in the online help.

U Call the OEM help.

2.2 Info and Error System

HEIDENHAIN CNC PILOT 4290 51

Page 52

Context-sensitive help

You'll usually find information on the current operating situation

(context-sensitive help). if no context-sensitive help is available for a

specific situation look for the topics in the following sources:

The table of contents

The subject index

The search functions

Direct error messages

The CNC PILOT uses a direct error message whenever immediate

error correction is possible. Confirm the message and correct the

error.

Example: The input value of the parameter is out of range.

Information of the error message:

2.2 Info and Error System

Error description: Explains the error

Error number: For service questions

Time of day: Time when the error occurred (for your information)

Symbols

Warning: The CNC PILOT indicates the problem. The

program run / operation continues.

Error: The program run/operation is stopped. You must

correct the error before you can continue the current job.

52

Page 53

Error display

If during the system start or program run or other operation an error

occurs, it is indicated in the date box, displayed in the status line, and

saved in the error display.

The date and time remain highlighted in red until all of the errors have

been canceled.

Information of the error message:

Error description: Explains the error

Error number: For service questions

Channel number: Slide for which the error occurred.

Time of day: Time when the error occurred (for your information)

Error class (only with errors):

Background: This message serves as information, or merely a

“small” error has occurred.

Cancel: The current operation (cycle run, traverse command, etc.)

was cancelled. You can resume operation once the error has been

cleared.

Emergency stop: All traverse and the execution of the DIN

program was stopped. You can resume operation once the error

has been cleared.

Reset: All traverse and the execution of the DIN program was

stopped. Switch off the control for a moment, then restart.

Contact your machine manufacturer if the error occurs again.

System error, internal error: If a system error or internal error

occurs, write down all information on the displayed message and

inform your machine manufacturer. You cannot correct an internal

error. Switch off the control and restart.

Warnings during the simulation: In the event of problems during

simulation of an NC program, the CNC PILOT displays a warning in the

top line.

Viewing and deleting error messages:

U Activate the error display. The error system shows all

accumulated errors.

U If more than one error is shown, navigate with the

cursor keys within the error display.

U Deletes the error message marked with the cursor.

2.2 Info and Error System

U Deletes all error messages.

U Display further information on the error marked with

the cursor.

U Exit the error display.

HEIDENHAIN CNC PILOT 4290 53

Page 54

Additional information on error messages

When an error message occurs, press the info key, or place the cursor

on the error message in the error display and then press the info key,

to get further information on the respective error.

Meaning of the soft keys:

U Information on the next error message.

U Information on the previous error message.

U Switches to the general info system

U Switches to the general info system

2.2 Info and Error System

PLC display

The PLC window is used for PLC messages and the PLC diagnosis.

Your machine manual provides more detailed information on the PLC

window.

Activating the PLC display:

U Opens the “error display”

U Switches to the PLC window

U Close PLC window

U Return to error display

The PLC window is shown as alternative to the error window.

54

Page 55

2.3 Data Backup

The CNC PILOT stores NC programs, operating-resource data and

parameters on the hard disk. Since the possibility of damage to the

hard disk due to excessive vibration or shock cannot be eliminated,

HEIDENHAIN recommends making regular backup copies of your

programs, operating resource data and parameters on a PC or on USB

memory media.

You can use DataPilot 4290, the WINDOWS “Explorer” or other

suitable programs for backing up your data on a PC.

For data exchange and data backup, you can use the Ethernet

interface and the USB interface. Data exchange on the basis of the

serial interface (RS-232) is also possible.

2.3 Data Backup

HEIDENHAIN CNC PILOT 4290 55

Page 56

2.4 Explanation of Terms

MP: With machine parameters (MP) the control is interfaced to the

machine, settings are made, etc.

Cursor: In lists, or during data input, a list item, an input field or a

character is highlighted. This “highlight” is called a cursor.

Cursor keys: You can move the cursor with the arrow keys, PgUp,

PgDn of the touchpad.

Navigating: Within a list or an input box, you can move the cursor

to any position you would like to check, change, delete or add to. In

other words, you "navigate" through the list.

Active/inactive functions, menu items: Functions or soft keys

that at present cannot be selected are shown in gray.

Dialog box: Dialog boxes are also called input windows.

Editing: Editing is changing, deleting and adding to parameters,

2.4 Explanation of Terms

commands, etc. within programs, tool data or parameters.

Default value: If the parameters of DIN commands or other

parameters are preassigned values, these values are referred to as

“default values.”

Byte: The capacity of a storage disk is indicated in bytes. Since the

CNC PILOT features a hard disk, the individual program lengths (file

sizes) are expressed in bytes.

Extension: File names consist of the actual name and the

extension. The name part and the extension part are separated by a

dot “.”. The extension indicates the type of file. Examples:

„*.NC“DIN programs

„*.NCS“DIN subprograms

„*.MAS“Machine parameters

56

Page 57

Manual Control and Automatic Modes

HEIDENHAIN CNC PILOT 4290 57

Page 58

3.1 Switch-On, Switch-Off,

Reference Run

Switch-on

In the header, the CNC PILOT displays the individual steps of the

system start and then prompts you to select an operating mode.

Whether the reference run is necessary depends on the encoders

installed:

EnDat encoder: Reference run is not necessary.

Distance-coded encoders: The position of the axes is ascertained

after a short reference run.

Standard encoder: The axes move to known, machine-based points.

After completion of the reference run:

This position display is activated.

Automatic mode can be selected.

The software limit switches are active only after you

have traversed the reference marks.

Reference run for all axes

Select Ref > Reference automatic.

3.1 Switch-On, Switch-Off, Reference Run

The “Status of reference run approach” dialog box informs you of the

current status.

Either set the slides that need to find a reference or set “All slides”

(“reference automatic” dialog box)

To start the reference run, press Cycle Start.

“Feed stop” interrupts the reference run. Cycle start

resumes the reference run.

“Cycle stop” interrupts the reference run.

The sequence in which the axis make their reference run

is defined in MPs 203 and 253 ff.

58

Page 59

Reference jog for single axis

Select Ref > Reference jog.

The “Status of reference run approach” dialog box informs you of the

current status.

Set slides and axes (“Reference jog” dialog box)

The reference run is conducted for as long as the

Cycle Start key stays pressed. To interrupt the

reference run, release the key.

“Cycle stop” interrupts the reference run.

Monitoring EnDat encoders

If your machine is equipped with EnDat encoders, the control saves

the axis positions during switch-off. During switch-on, the CNC PILOT

compares for each axis the position during switch-on with the position

saved during switch-off.

If there is a difference, one of the following messages appears:

“Axis was moved after the machine was switched off.” Check the

current position and confirm it if the axis was in fact moved.

“Saved encoder position of the axis is invalid.” This message is

correct if the control has been switched on for the first time, or if the

encoder or other control components involved were exchanged.

“Parameters were changed. Saved encoder position of the axis is

invalid.” This message is correct if configuration parameters were

changed.

The cause for one of the above listed messages can also be a defect

in the encoder or control. Please contact your machine supplier if the

problem recurs.

3.1 Switch-On, Switch-Off, Reference Run

HEIDENHAIN CNC PILOT 4290 59

Page 60

Switch-off

“Shutdown” is available in the programming and organization modes

if no operating mode is selected.

U Press the soft key to switch off the CNC PILOT.

U Confirm the security query with OK. After a few

seconds, the CNC PILOT requests you to switch off

the machine.

Proper switch-off is recorded in the error log file.

3.1 Switch-On, Switch-Off, Reference Run

60

Page 61

3.2 Manual Control Mode

The Manual Control mode offers various functions for setting up the

machine, for measuring tool dimensions and for manually machining

workpieces.

Options of operation:

Manual mode: With the “machine keys” and the handwheel, you

can control the spindle and move the axes to machine the

workpiece.

Setup mode: Here you enter the tools to be used, set the

workpiece datum, the workpiece change point, the protection zone

dimensions etc. In this way you prepare the machine to machine the

workpieces.

Determining the tool dimensions: You can find the tool

dimensions by touching the workpiece with the tool or with a touch

probe. As an alternative you can measure the dimensions with a

gauge and enter them in the tool database.

For manual control you can configure the machine display for up to

six variants (see “Machine Display” on page 97). You adjust by soft

key which variant will be displayed.

In Manual Control mode, the data are entered and

displayed according to control parameter 1 either in

meters or in inches.

Remember: If the machine has not been referenced:

The position display is not valid.

The software limit switches are not active.

3.2 Manual Control Mode

Soft keys for manual and setup functions

Assign a handwheel to an axis

Set the handwheel transmission

Switch the machine display

Turret one position backward

Turret one position forward

Enter the feed per revolution

Spindle speed, entering

Enter the M function

HEIDENHAIN CNC PILOT 4290 61

Page 62

Entering the machine data

Setting the feed rate

In the menu group F you define a feed rate per revolution or per

minute.

Setting the feed per revolution:

U Select F > Feed per revolution

U Enter the feed rate in mm/rev (or inches/rev)

Setting the feed rate per minute:

U Select F > Feed per minute

U Enter the feed rate in mm/min (or inches/min) and press OK.

Setting the spindle speed or spindle position

In the menu group S, you define the spindle speed, a constant cutting

speed, or you position the spindle.

3.2 Manual Control Mode

Setting the spindle speed:

U Select S > Spindle speed S

U Enter the speed in rpm

Setting the constant surface speed:

U Select S > V constant.

U Enter the cutting speed in m/min (or ft/min) and press OK.

You can enter a constant cutting speed only for slides with

an X axis.

Entering the speed limitation

Available as of software version 625 952-05.