Page 1

Page 2

In this user manual we have tried to describe the matters

concerning the operation of this CNC system to the greatest extent.

However, it is impossible to give particular descriptions for all

unnecessary or unallowable operations due to length limitation and

products application conditions;Therefore, the items not presented

herein should be regarded as “impossible” or “unallowable”.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It

is illegal for any organization or individual to publish or reprint this

manual. GSK CNC Equipment Co., Ltd. reserves the right to ascertain

their legal liability.

Page 3

GSK988T Turning CNC System User Manua(Volume Ⅱ)

Preface

Your Excellency,

We are honored by your purchase of this GSK 988 Turning CNC

System made by GSK CNC Equipment Co., Ltd.

This book is User Manual Volume II –“Installation and Debugging”.

To ensure safe and effective running, please read this manual carefully

before installation and operation.

Warning

Accident may occur by improper connection and operation!This

system can only be operated by authorized and qualified personnel.

Special caution:

The power supply fixed on/in the cabinet is exclusively used for the

CNC system made by GSK.

It can't be applied to other purposes, or else it may cause serious

danger!

II

Page 4

Cautions

■ Delivery and storage

● Packing box over 6 layers in pile is unallowed.

● Never climb the packing box, stand on it or place heavy objects on it.

● Do not move or drag the products by the cables connected to it.

● Forbid collision or scratch to the panel and display screen.

● Avoid dampness, insolation and drenching.

■

Open-package inspection

● Confirm that the products are the required ones.

● Check whether the products are damaged in transit.

● Confirm that the parts in packing box are in accordance with the packing list.

Precautions

● Contact us in time if any inconsistence, shortage or damage is found.

■ Connection

● Only qualified personnel can connect the system or check the connection.

● The system must be earthed, and the earth resistance must be less than 0.1Ω.

The earth wire cannot be replaced by zero wire.

● The connection must be correct and firm to avoid any fault or unexpected

consequence.

● Connect with surge diode in the specified direction to avoid damage to the

system.

● Switch off power supply before plugging out or opening electric cabinet.

■ Troubleshooting

● Switch off power supply before troubleshooting or changing components.

● Check the fault when short circuit or overload occurs. Restart can only be done

after troubleshooting.

● Frequent switching on/off of the power is forbidden, and the interval time should

be at least 1 min.

III

Page 5

GSK988T Turning CNC System User Manual (Volume Ⅱ)

ANNOUNCEMENT!

z This manual describes various possibilities as much as possible. However,

operations allowable or unallowable cannot be explained one by one due to

so many possibilities that may involve with, so the contents that are not

specially stated in this manual shall be regarded as unallowable.

WARNING!

z Please read this manual and a manual from machine tool builder carefully

before installation, programming and operation, and strictly observe the

requirements. Otherwise, products and machine may be damaged,

workpiece be scrapped or the user be injured.

CAUTION!

z Functions, technical indexes (such as precision and speed) described in

this user manual are only for this system. Actual function configuration and

technical performance of a machine tool with this CNC system are

determined by machine tool builder’s design, so functions and technical

indexes are subject to the user manual from machine tool builder.

z Though this system adopts standard operation panel, the functions of the

keys on the panel are defined by PLC program (ladder diagram). It should be

noted that the keys functions described herein are for the standard PLC

program (ladder diagram).

z For functions and effects of keys on control panel , please refer to the user

manual from machine tool builder.

This manual is subject to change without further notice.

IV

Page 6

Precautions

Safety Responsibility

Manufacturer’s Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided CNC systems and accessories.

——Be responsible for the safety of the provided CNC systems and accessories.

——Be responsible for the provided information and advice for the users.

User’s Responsibility

——Be trained with the safety operation of CNC system and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering to the

original CNC systems and the accessories.

——Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

This manual is reserved by end user.

We are full of heartfelt gratitude to you for supporting us in the

use of GSK’s products.

V

Page 7

GSK988T Turning CNC System User Manual (Volume Ⅱ)

VI

Page 8

Contents

Contents

CHAPTER I INSTALLATION LAYOUT ..............................................................................................1

1.1 Overall Dimension of GSK988T and Accessories...................................................................1

1.1.1 Overall Dimension of the GSK988T Mainframe............................................................1

1.1.2 Overall Dimension of GSK988T-H Mainframe..............................................................2

1.1.3 Overall Dimension of GSK988T Operation Panel MPU02A .........................................3

1.1.4 Overall Dimension of GSK988T Operation Panel MPU02B .........................................4

1.1.5 Overall Dimension of GSK988T- H Operation Panel MPU03A.....................................5

1.1.6 Overall Dimension of GSK988T-H Operation Panel MPU03B......................................6

1.1.7 Overall Dimension of I/O Deconcentrator MCT01 ........................................................7

1.1.8 Overall Dimension of I/O Deconcentrator MCT02 ........................................................7

1.2 Structure of GSK988T Control System ...................................................................................8

1.2.1 Front /Rear Panel Illustrations......................................................................................8

1.2.2 General Connection Diagram .....................................................................................10

1.3 GSK988T Installation............................................................................................................11

1.3.1 Conditions of Electric Cabinet Installation ..................................................................11

1.3.2 System Grounding Requirements ..............................................................................11

1.3.3 Interference Prevention Methods ...............................................................................11

CHAPTER II INTERFACE SIGNAL DEFINITION AND CONNECTION.............................................13

2.1 Connection with Drive Unit ...................................................................................................13

2.1.1 Definition of the Drive Interface ..................................................................................13

2.1.2 Signal Instruction........................................................................................................13

2.1.3 Connection with the Drive Unit Interface ....................................................................16

2.2 Connection with the Spindle .................................................................................................18

th

2.2.1 The 5

Axis · Spindle Interface Definition ...................................................................18

2.2.2 Signal Instruction........................................................................................................19

2.2.3 Connection with the Servo Spindle Drive Unit ............................................................20

2.2.4 Connection with the Spindle Inverter Interface...........................................................21

2.3 Connection with the Spindle Encoder...................................................................................22

2.3.1 Interface Definition of the Spindle Encoder ................................................................22

2.3.2 Signal Instruction........................................................................................................22

2.3.3 Connection with the Spindle Encoder Interface..........................................................22

nd

2.4 Connection with the 2

2.4.1 Definition of the 2

Spindle............................................................................................23

nd

Spindle (Analog Spindle) Interface ..............................................23

2.4.2 Connection with the 2nd Spindle Inverter Interface .....................................................23

2.5 Connection with MPG...........................................................................................................24

2.5.1 Definition of MPG Interface ........................................................................................24

2.5.2 Signal Instruction........................................................................................................24

2.5.3 Connection with MPG Interface..................................................................................24

2.6 Connection with the Machine Panel .....................................................................................25

2.6.1 Communication Interface Definition............................................................................25

2.7 GSK988T General I/O Interface Definition ...........................................................................25

2.7.1 Definition of Input & Output Addresses.......................................................................25

2.7.2 Input Signal ................................................................................................................26

VII

Page 9

GSK988T Turning CNC System User Manual (Volume Ⅱ)

2.7.3 Output Signal .............................................................................................................27

2.8 Connection with the Power Supply....................................................................................... 28

2.8.1 Definition of Power Supply Interface ..........................................................................29

2.8.2 Connection between GSK988T and GSK-PB2 Power Supply Box ............................ 29

2.9 Connection with the External Equipment..............................................................................29

2.9.1 RS-232 Interface Definition ........................................................................................30

2.9.2 Definition of GSKLINK Bus Interface..........................................................................30

2.9.2 Network Interface Definition .......................................................................................31

2.9.3 USB Interface Definition.............................................................................................31

CHAPTER III MACHINE TOOL DEBUGGING-OPERATION ............................................................32

3.1 Parameter Setting ................................................................................................................32

3.1.1 System Parameters....................................................................................................32

3.1.2 Servo Parameters ......................................................................................................34

3.2 Instruction of PC Communication Software GSKComm-M...................................................37

3.2.1 Preparation for GSKComm-M .................................................................................... 37

3.2.2 File Download (PC→CNC).........................................................................................38

3.2.3 Upload File (CNC→PC) .............................................................................................39

3.3 Usage of U Disk ...................................................................................................................40

3.3.1 File Management Screen ...........................................................................................40

3.3.2 Program Screen .........................................................................................................41

3.3.3 PLC Screen................................................................................................................42

3.4 PLC Operation .....................................................................................................................43

3.4.1 PLC Execution and Stop ............................................................................................44

3.4.2 PLC Monitoring and Diagnosis...................................................................................45

3.4.3 PLC Data Viewing and Setting ...................................................................................48

3.4.4 PLC On-line Modification............................................................................................50

3.4.5 PLC Program Transmission ....................................................................................... 58

3.5 CNC Diagnosis.....................................................................................................................58

3.6 Servo Diagnosis ...................................................................................................................60

CHAPTER IV MACHINE DEBUGGING-FUNCTIONS.......................................................................62

4.1 Emergency Stop and Hardware Limit...................................................................................62

4.2 Basic Axis Parameters Setting .............................................................................................63

4.2.1 Axis Property ..............................................................................................................63

4.2.2 GSKLink Communication Setting of Axis and Servo ..................................................64

4.3 Servo Related Setting ..........................................................................................................65

4.3.1 CNC Servo Parameter Setting ...................................................................................65

4.4 Gear Ratio Adjustment .........................................................................................................66

4.4.1 Gear Ratio Calculation ...............................................................................................67

4.4.2 Gear Ratio Setting......................................................................................................67

4.5 Acceleration/Deceleration Characteristic Adjustment ...........................................................68

4.6 Reference Point and Software Limit .....................................................................................69

4.6.1 Reference Point of Absolute Encoder Setting ............................................................70

4.6.2 Reference Point Setting with Dog ..............................................................................71

4.6.3 Reference Point Setting without Dog .........................................................................72

4.6.4 Setting of Stored Stroke Check ..................................................................................73

VIII

Page 10

Contents

4.7 Pitch Error Compensation ....................................................................................................75

4.8 Backlash Compensation.......................................................................................................78

4.9 Spindle Function Adjustment ................................................................................................80

4.9.1 Spindle Encoder .........................................................................................................80

4.9.2 Spindle Speed Analog Voltage Control .......................................................................81

4.9.3 Double-Spindle Control ..............................................................................................83

CHAPTER V PARAMETER INSTRUCTION ...................................................................................84

5.1 Parameters of System Setting..............................................................................................85

5.2 Parameters of the Interfaces of Input and Output.................................................................85

5.3 Parameters of Axis Control/Setting Unit ...............................................................................85

5.4 Parameters of the Coordinate System..................................................................................89

5.5 Parameters of the Stroke Detection......................................................................................91

5.6 Parameters of the Feedrate..................................................................................................94

5.7 Parameters of Control of Acceleration/Deceleration.............................................................98

5.8 Parameter of Servo and Backlash Compensation..............................................................100

5.9 Parameter of Input/Output ..................................................................................................104

5.10 Parameter of Display and Editing .....................................................................................106

5.11 Parameter of Programming ..............................................................................................109

5.12 Parameters of the Screw Pitch Error Compensation ........................................................ 111

5.13 Parameters of the Spindle Control....................................................................................113

5.14 Parameters of the Tool Compensation .............................................................................117

5.15 Parameters of the Canned Cycle .....................................................................................120

5.15.1 Parameters of the Drilling Canned Cycle ...............................................................121

5.15.2 Parameters of the Thread Cutting Cycle ................................................................121

5.15.3 Parameters of the Combined Canned Cycle ..........................................................121

5.16 Parameters of the Rigid Tapping ......................................................................................123

5.17 Parameters of the Polar Coordinates Interpolation...........................................................125

5.18 Parameters of the User Macro Program...........................................................................126

5.19 Parameters of the Skip Function ......................................................................................127

5.20 Parameters of the Graphic Display...................................................................................128

5.21 Parameter of Run Hour and Parts Count Display.............................................................128

5.22 Parameter of MPG Feed ..................................................................................................129

5.23 Parameter of PLC Axis Control.........................................................................................131

5.24 Parameters of the Basic Function.....................................................................................134

5.25 Parameters of GSKLink Communication Function ...........................................................135

CHAPTER VI STANDARD PLC FUNCTION CONFIGURATION.....................................................136

6.1 Standard Panel on the Machine Tool ..................................................................................136

6.2 Addresses X, Y Definition ...................................................................................................137

6.2.1 General I/O Interface on Machine Tool .....................................................................137

6.2.2 MPG Interface ..........................................................................................................141

6.2.3 Spindle Interface .....................................................................................................142

6.2.4 Standard Operation Panel........................................................................................143

6.3 Standard PLC Functions.....................................................................................................147

6.3.1 Cycle Start and Feed Hold........................................................................................147

6.3.2 Feed/Spindle Hold....................................................................................................148

IX

Page 11

GSK988T Turning CNC System User Manual (Volume Ⅱ)

6.3.3 Program Lock...........................................................................................................149

6.3.4 Feedrate Override ....................................................................................................149

6.3.5 Spindle Override.......................................................................................................149

6.3.6 Spindle CCW/CW Control ........................................................................................ 150

6.3.7 Spindle Jog...............................................................................................................151

6.3.8 Spindle 8-Point Pre-Orientation................................................................................152

6.3.9 Spindle Speed Binary Control...................................................................................154

6.3.10 Spindle Gear Control.............................................................................................. 154

6.3.11 Cooling Control....................................................................................................... 155

6.3.12 Lubricating Control .................................................................................................156

6.3.13 Chuck Control ........................................................................................................157

6.3.14 Tailstock Control .....................................................................................................158

6.3.15 Low Pressure Detection .........................................................................................159

6.3.16 Overtravel Signal of Axes....................................................................................... 160

6.3.17 Tool Change Control...............................................................................................160

6.3.18 Emergency Stop.....................................................................................................165

6.3.19 Tri-Colored Lamp ...................................................................................................166

6.4 Standard PLC Parameter Instruction..................................................................................166

6.4.1 Parameter K ............................................................................................................. 166

6.4.2 Parameter DT...........................................................................................................167

6.4.3 Parameter DC .......................................................................................................... 168

6.4.4 Parameter D.............................................................................................................169

6.5 Signals G, F Used in Standard PLC....................................................................................169

6.5.1 Signal G ...................................................................................................................169

6.5.2 Signal F....................................................................................................................171

APPENDIX A ALARM LIST ..........................................................................................................173

A.1 Program Alarms (P/S Alarms)............................................................................................173

A.2 Parameter Alarms ..............................................................................................................183

A.3 Pulse Encoder Alarms........................................................................................................184

A.4 Servo Alarms .....................................................................................................................184

A.5 Overtravel Alarms ..............................................................................................................185

A.6 Spindle Alarms...................................................................................................................185

A.7 System Alarms...................................................................................................................185

A.8 PLC Alarms........................................................................................................................186

A.9 GSKLink Communication Prompts.....................................................................................188

A.10 Servo Inner Alarms ..........................................................................................................189

APPENDIX B MOTOR TYPE CODE LIST....................................................................................193

B.1 DAT2000C Series Motor Model Code List .........................................................................193

B.2 DAP03C,DAY3025C Model Code List ...............................................................................194

APPENDIX C COMMON ALARM REMEDY ................................................................................. 195

C.1 CNC Common Alarm Remedy........................................................................................... 195

C.2 DAT Feed Servo Alarm Remedy........................................................................................ 195

C.3 Spindle Servo Alarm Remedy ............................................................................................201

X

Page 12

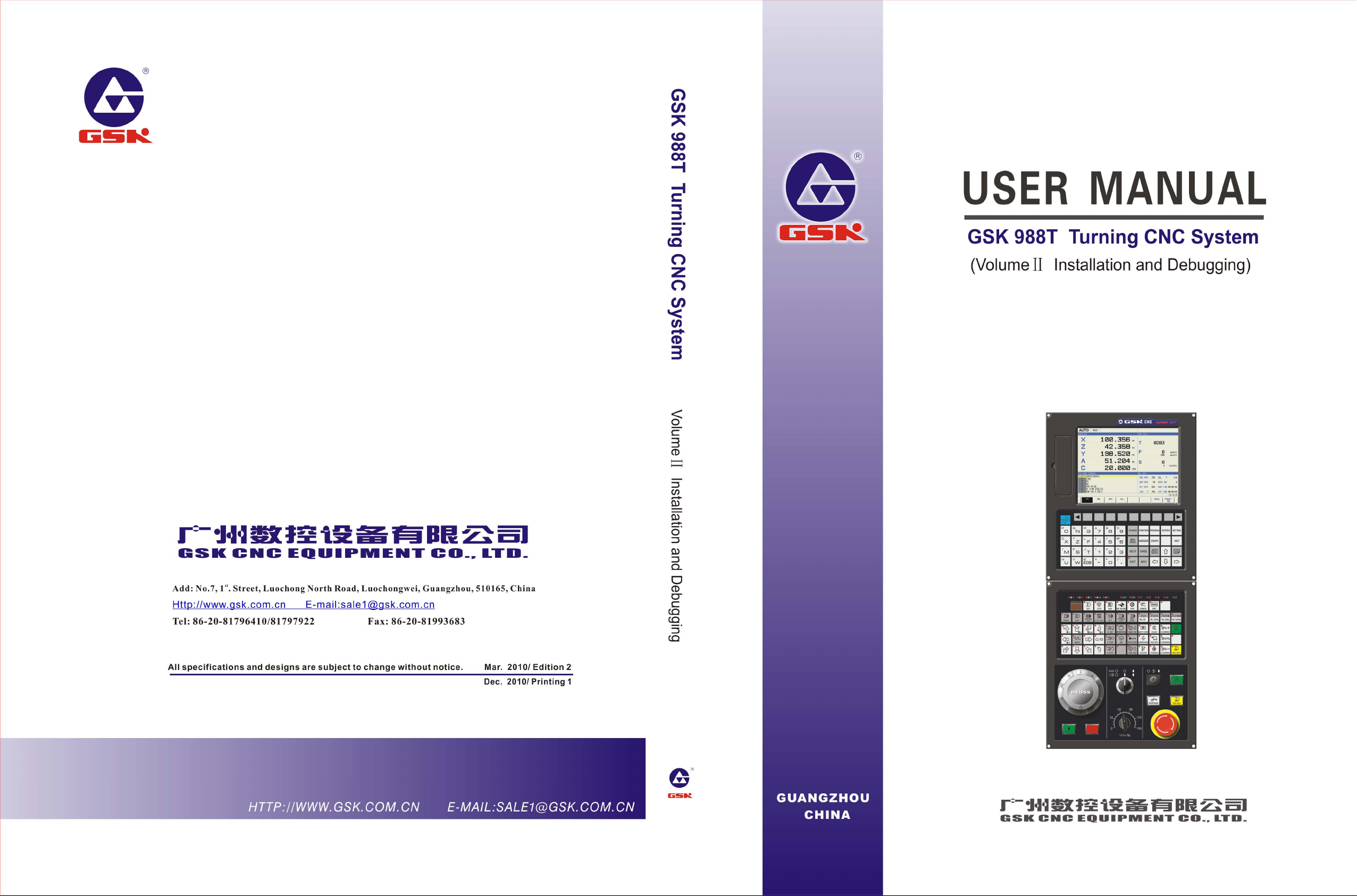

Chapter I Installation Layout

CHAPTER I INSTALLATION LAYOUT

1.1 Overall Dimension of GSK988T and Accessories

1.1.1 Overall Dimension of the GSK988T Mainframe

1

Page 13

GSK988T Turning CNC System User Manual (Volume Ⅱ)

1.1.2 Overall Dimension of GSK988T-H Mainframe

Note: The panel of GSK988T-H is horizontal.

2

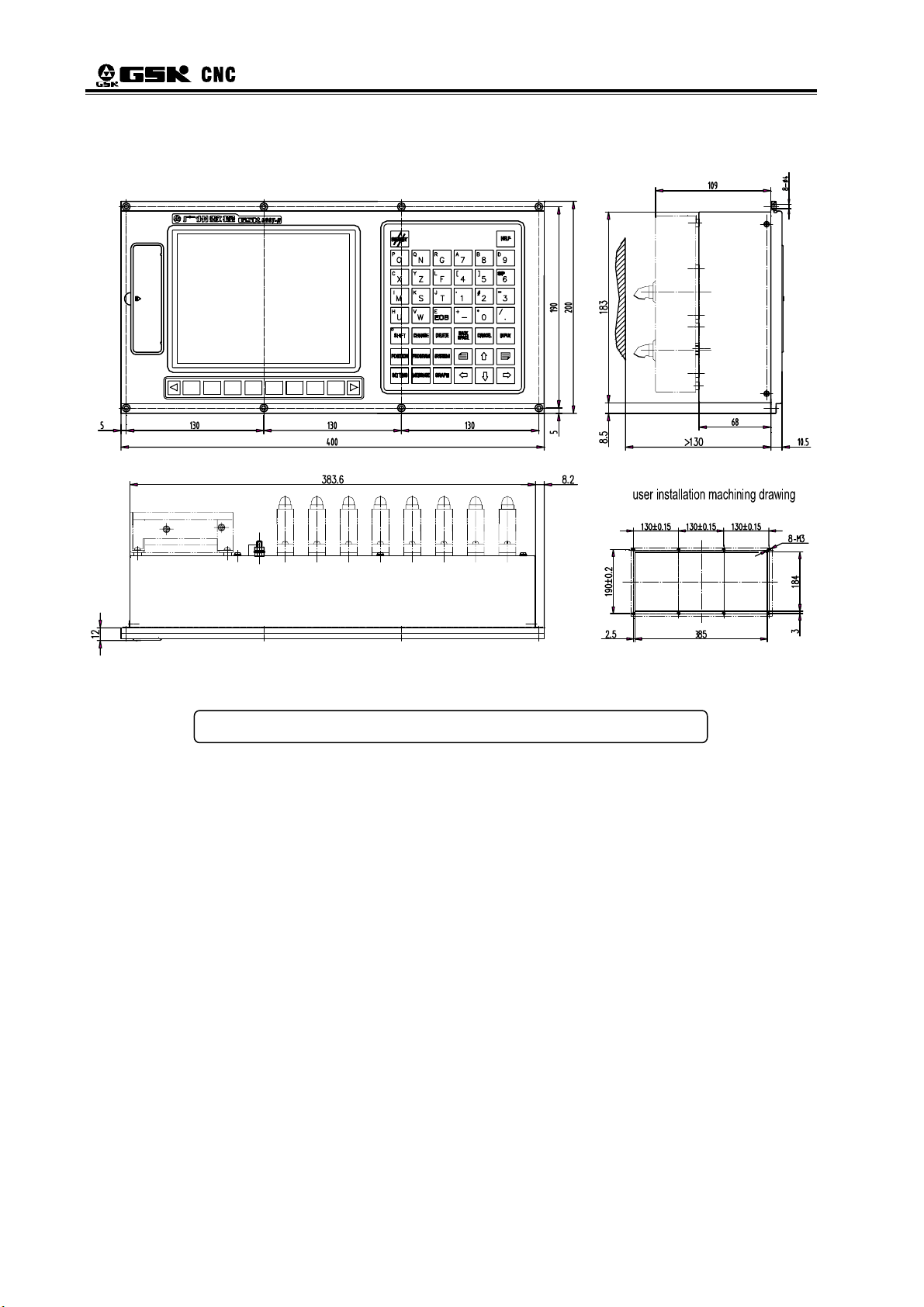

Page 14

Chapter I Installation Layout

1.1.3 Overall Dimension of GSK988T Operation Panel MPU02A

0

9

0

1

0

2

0

3

0

0

8

0

7

0

6

0

4

50

30

3

Page 15

GSK988T Turning CNC System User Manual (Volume Ⅱ)

1.1.4 Overall Dimension of GSK988T Operation Panel MPU02B

30

4

Page 16

Chapter I Installation Layout

1.1.5 Overall Dimension of GSK988T- H Operation Panel MPU03A

30

5

Page 17

GSK988T Turning CNC System User Manual (Volume Ⅱ)

1.1.6 Overall Dimension of GSK988T-H Operation Panel MPU03B

30

6

Page 18

Chapter I Installation Layout

1.1.7 Overall Dimension of I/O Deconcentrator MCT01

1.1.8 Overall Dimension of I/O Deconcentrator MCT02

7

Page 19

GSK988T Turning CNC System User Manual (Volume Ⅱ)

1.2 Structure of GSK988T Control System

1.2.1 Front /Rear Panel Illustrations

Connect to spindle encoder

ENCODER ENCODER 2

CN21

ST

1 AXIS

CN11

COM WITH

MACHINE PANEL

+24V

0V

-12V

0V

+12V

0V

+5V

+5V

+5V

CN1

MPG

GSKLINK(A)

CN53

CN31CN22

ND RD TH

CN12

3 AXIS 2 AXIS

4 AXIS

CN13 CN14

INPUT OUTPUT

CN54

CN61 CN62

GSKLINK(B)

CN52

ND

2 SPINDLE

CN41

TH

5 AXIS SPINDLE

CN15

Connect to spindle encoder 2

(It can be used as the 2nd MGP)

Used for communication between

CNC and remote I/O unit

Used for communication between

CNC and servo drive uni

Connect to MPG

Connect to the 2nd spindle

Feed axis interface (connect to

the 1~4 axes servo drive unit)

Output interface from CNC

to machine tool

Connect to spindle servo

drive unit/invertor/the 5th

axis servo drive unit

Input interface from

machine tool to CNC

Connect to machine tool panel

8

Power supply interface

Fig. 1-2-1 The layout of GSK988T mainframe rear cover interfaces

Note: These interfaces are compatible with GSK988T-H system. See Fig.1-2-1

Page 20

Chapter I Installation Layout

ENCODER ENCODER 2

CN21

CN22

AXIS 2AXIS 1

MPG

CN31

AXIS 3

GSKLINK(A)

CN53

AXIS 4

CN14CN13CN11 CN12

GSKLINK(B)

CN52

SPINDLE 2

CN41

MACHINE PANEL

CN54

AXIS 5 SPINDLE

CN15

INPUT OUTPUT

+24V

0V

-12V

0V

+12V

0V

+5V

+5V

+5V

CN61CN62

CN1

Fig. 1-2-2 The layout of GSK988T-H mainframe rear cover interfaces

Fig. 1-2-3 The layout of GSK988T front panel interfaces

9

Page 21

GSK988T Turning CNC System User Manual (Volume Ⅱ)

1.2.2 General Connection Diagram

GSK 988T

10

Fig. 1-2-4 GSK988T connection diagram

Page 22

Chapter I Installation Layout

1.3 GSK988T Installation

1.3.1 Conditions of Electric Cabinet Installation

¾ Prevent the entry of dust, coolant and organic solution.

¾ The distance between CNC rear cover and the cabinet should not be less than 20cm.

Ensure that the temperature difference (outside and inside the cabinet) will be less than

10℃ in case of temperature rising in the cabinet.

¾ A radiator fan can be installed inside the cabinet to ensure ventilation.

¾ The display panel should be installed in proper place to avoid the coolant ejection.

¾ The interference of external electrical equipments to the CNC should be taken into

consideration and be reduced to the greatest extent.

1.3.2 System Grounding Requirements

The following grounding systems are for CNC machine tool:

¾ Signal ground

It provides the reference voltage of telecommunication system (0V).

¾ Frame ground

It is used for the sake of safety. The shell of frame unit, panel and the interface cables

shield should be connected together. It can also suppress the internal and external

noise.

¾ System ground

It is used to connect the devices and the frame ground with the ground.

Note 1: The connection between signal and frame ground in the CNC control unit is only made at one

place.

Note 2: Use the AC power line with grounding wire to ensure grounding during power supply.

1.3.3 Interference Prevention Methods

Measures such as shielding electromagnetic radiation, absorbing impulse current and

filtering power noise are taken into CNC design, which, to some extent, protects the CNC to

external interference. To ensure a steady working of CNC, it is necessary to take following

measures during CNC installation:

① Keep CNC far away from the interference source (such as inverter, AC contactor, static

generator, high pressure generator and sectioning for power line, etc.)

② The power to CNC should be supplied via insulation transformer; the machine installed

with CNC should be grounding; the CNC and drive unit should be connected with

independent grounding wire via grounding point.

③ Interference suppression: connect the RC circuits parallelly at two ends of the AC coil;

the RC circuit should be installed to the inductive load as near as possible; fly-wheel

diode should be inversely connected in serial at two ends of the DC coil ; surge absorber

should be connected in parallel at the winding head of AC motor (see Fig. 1-3-1).

11

Page 23

GSK988T Turning CNC System User Manual (Volume Ⅱ)

Fig. 1-3-1

④ The outgoing cable of CNC is twisted shielded cable or shielded cable; the shielding

layer of the cable is single-end earthed at CNC side; the signal line should be as short

as possible.

⑤ To reduce the interference between CNC signal cables and high-voltage cable, the

following principles should be followed when wiring:

Group Cable type Group Cable type

AC power line DC coil (24VDC)

A

C

Wiring Requirements:

¾ The cable should be twisted pair.

¾ Bundle the cables of group A separately from the cables in groups B, C, and the distance

should be no less than 10cm; or, make electromagnetic shielding for the cables in group A.

¾ Bundle the cables of group C separately from the cables in group A, and the distance should

be no less than 10cm; or, make electromagnetic shielding for the cables in group C; the

distance between group C cables and group B cables should be no less than 10cm.

¾ Bundle the cables of group B separately from the cables in group A; or, make

electromagnetic shielding for the cables in group B; cables in group B should be bundled

separately from the group C cables as far as possible.

Cables between CNC and servo

AC coil DC relay (24VDC)

Cables between CNC and high-voltage

AC contactor

drive unit

B

electric cabinet

Cables between CNC and machine tool

12

Page 24

Chapter II Interface Signal Definition and Connection

CHAPTER Ⅱ INTERFACE SIGNAL DEFINITION AND

CONNECTION

2.1 Connection with Drive Unit

2.1.1 Definition of the Drive Interface

1:nCP+

2:nDIR+

3:nPC

4:+24V

5:nALM

6:nSET

7:nEN

Fig. 2-1-1 CN11, CN12, CN13 and

CN14 interfaces (15 pins, D-type

注:n 代表 1、2、3 或 4, 以下相同;

female)

Note: CN1 is the 1st servo axis interface, CN2 is the 2nd one, CN3 the 3rd one, and CN4 the 4th one. Each

controlled axis outputs the corresponding servo axis interface, which is set by parameter NO.1023.

9: nCP-

10:nDIR11:0V

12:+5V

13:+5V

14:0V

15:0V

Signal Description

nCP+、nCP-

nDIR+、nDIR-

nPC Zero point signal

nALM Drive unit alarm signal

nEN Axial enable signal

nSET Pulse inhibition signal

nRDY Servo ready signal

Command pulse signal

Command direction signal

2.1.2 Signal Instruction

(1) Command pulse signal and nCP and command direction signal nDIR

nCP+ and nCP- are command pulse signals, nDIR+ and nDIR- are command direction

signals, the two groups of signals all are difference (AM26LS31) output, the external is suggested

to use AM26LS32 for receiving, refer to the following Fig.2-1-2 about the internal circuit:

Fig. 2-1-2 Internal circuit of nCP and nDIR

(2) Drive unit alarm signal nALM

The drive alarm level is low or high, which is set by 0 bit of parameter 1816; refer to Fig.2-1-3

for the internal circuit.

13

Page 25

GSK988T Turning CNC System User Manual (Volume Ⅱ)

Fig. 2-1-3. Internal circuit of nALM

Input circuit of this type requires that the drive should provide the signal through the methods

in the following Fig. 2-1-4:

Method 1: Method 2:

Fig. 2-1-4. Methods of the drive unit providing signals

(3) Servo ready signal nRDY

nRDY signal is connected to the servo drive unit ready signal. See Fig. 2-1-5.

(4) Axial enable signal nEN

When CNC is running normally, nEN signal output is valid (nEN signal connects with 0V),

and the drive or the emergency stop alarms, CNC switched off, nEN signal outputs (nEn signal

cuts off 0V). About the internal interface circuit, refer to the following Fig. 2-1-6:

Fig. 2-1-5 Internal circuit of nRDY

Fig. 2-1-6. Internal circuit of nEN

(5) Pulse inhibition signal nSET

nSET signal indicates the servo input inhibition. To improve the anti-interference ability

between CNC and the drive, the signal is low-level when CNC outputs the pulse signal, if there

14

Page 26

Chapter II Interface Signal Definition and Connection

isn’t any pulse signals, it is high level; refer to the following Fig. 2-1-7 about the internal interface

circuit:

Fig. 2-1-7 Pulse forbidden signal circuit

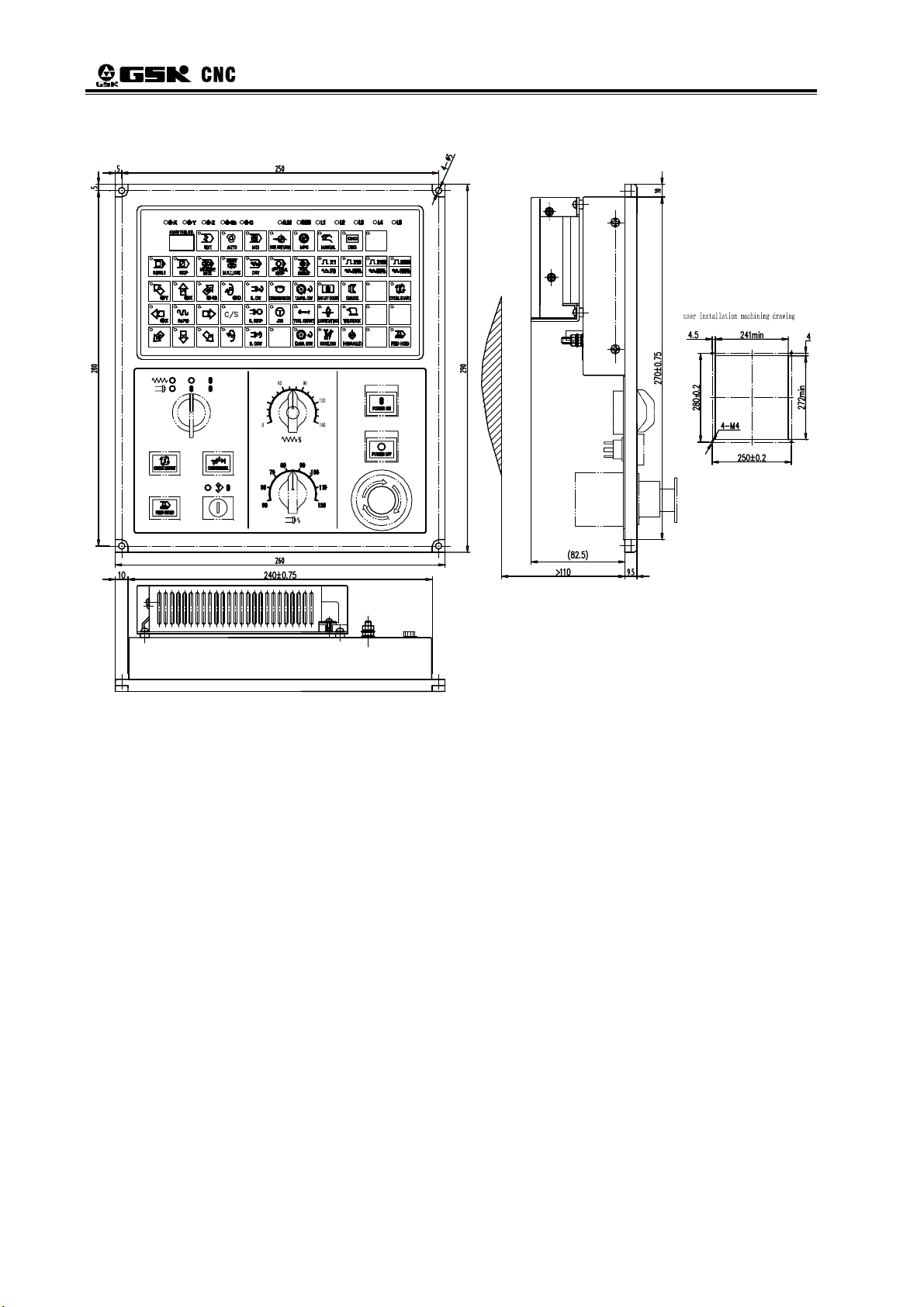

(6) Zero point signal nPC

Take one-rotation signal of motor encoder or proximity switch signal as zero signals. About

the internal connection circuit, refer to Fig. 2-1-8:

Fig. 2-1-8 Zero point signal circuit

① The illogram of PC signals provided by user is shown in Fig. 2-1-9:

Fig. 2-1-9 Signal illogram

Note: During machine zero return, after releasing the deceleration switch, CNC determines the position of

the reference point through detecting PC signal jumping, and the rising edge check and the falling

edge check are both valid.

② Refer to Fig. 2-1-10 for the connection method of taking one NPN-type Hall unit as the

deceleration signal:

15

Page 27

GSK988T Turning CNC System User Manual (Volume Ⅱ)

Fig. 2-1-10 Connection with NPN-type Hall unit

③ Refer to the following Fig. 2-1-11 about the connection method of taking one Hall unit in

PNP type as one deceleration signal:

Fig. 2-1-11 Connection with Hall unit in PNP type

2.1.3 Connection with the Drive Unit Interface

The connection between GSK988T system and GSK DA98B drive unit is shown in the

following figure.

16

Page 28

Chapter II Interface Signal Definition and Connection

Fig. 2-1-12 Connection between GSK988T and DA98B

The connection between GSK988T and GSK DAT2000C drive unit is shown as follows:

Fig. 2-1-13 Connection between GSK988T and DAT2000C drive unit

17

Page 29

GSK988T Turning CNC System User Manual (Volume Ⅱ)

2.2 Connection with the Spindle

The spindle interface of GSK988T is CN15 (the fifth axis · spindle interface). It is equipped

with the function of pulse output and analog voltage output, and can be adopted with the servo

th

spindle drive unit or the common spindle Inverter, or taken as an independent 5

servo axial

interface. Moreover, GSK988T system is also equipped with the 2nd spindle interface CN41 (refer

to following chapters for details), and it can output 0~+10V analog voltage for extending the 2

nd

spindle or the power unit.

2.2.1 The 5th Axis · Spindle Interface Definition

1:SCP+

2:SDIR+

3:GND

4:SALM

5:X5.0(VPO)

6:X5.1(SAR/PAR)

7:SRDY

8:X5.2(ZSP)

9:GND

10:SPC

11:+24V

12:AGND

13:SVC

Fig. 2-2-1 CN15 servo spindle interface (25 cords, D type female)

14:SCP15:SDIR16:GND

17:+24V

18:SSET

19:SEN

20:Y5.0(VP)

21:Y5.1(TAP)

22:Y5.2(SFR)

23:Y5.3(SRV)

24:GND

25:AGND

18

Page 30

Chapter II Interface Signal Definition and Connection

Signal

Definition

SCP+, SCP-

SDIR+,SDIR-

SALM Drive unit alarm signal /

SRDY

SSET

SEN

SPC

SVC

AGND

X5.0 (VPO)

X5.1 (SAR/PAR)

X5.2 (ZSP)

Y5.0 (VP)

Y5.1 (TAP) Address of PLC signal, binary output

Y5.2 (SFR)

Y5.3 (SRV)

+24V

GND

Command pulse signal

Command direction signal

Servo ready signal

Pulse forbidden signal

Axial enable signal

Zero point signal

0~+10V analog voltage output

Analog voltage output ground

Address of PLC signal, binary input

Address of PLC signal, binary input

Address of PLC signal, binary input

Address of PLC signal, binary output

Address of PLC signal, binary output

Address of PLC signal, binary output

+24V

0V (binary input & output signal ground ) /

Explanation

Function Defined by Standard

Spindle speed/position status signal

Spindle position/speed reaching signal

Spindle output at zero speed signal

Spindle speed/position switch signal

Spindle speed loop gain selection

signal 2 (used for tapping)

PLC Address

/

/

/

/

/

/

/

/

Spindle CW signal

Spindle CCW signal

/

2.2.2 Signal Instruction

In the 5th axis • spindle interface, the internal circuits of SCP+, SCP-, SDIR+, SDIR-, SALM,

SRDY, SSET, SEN are consistent with that of the similar signal in the drive interfaces CN11,

CN12, CN13, CN14. Refer to section 2.1.2.

(1) Zero point signal SPC

SPC signal is valid at low level. It is different with the nPC signal in CN11, CN12, CN13,

CN14 interfaces (high-level nPC signal is valid). The internal circuit of SPC is shown in Fig. 2-2-2:

Fig. 2-2-2 Internal circuit of SPC

(2) Signals X5.0, X 5.1, X 5.2, X 5.3, X5.4

Signals X5.0, X 5.1, X 5.2, X 5.3, X 5.4 are the PLC signal addresses; binary input; the

internal circuit is shown in Fig.2-2-3.

19

Page 31

GSK988T Turning CNC System User Manual (Volume Ⅱ)

Fig.2-2-3

Note: In the 5th axis • spindle interface, low-level signals X5.0, X5.1, X5.2, X5.3, X5.4 are valid. The X

address in general input CN61 (X0.0~X0.7, X1.0~X1.7, X2.0~X2.7, X3.0~X3.7) are valid during

high-level input.

(3) Signals Y5.0, Y 5.1, Y 5.2, Y 5.3, Y 5.4

Signals Y5.0, Y 5.1, Y 5.2, Y 5.3, Y 5.4 are the PLC signal addresses; binary output. The

internal circuit is shown in Fig. 2-2-4:

Fig. 2-2-4

2.2.3 Connection with the Servo Spindle Drive Unit

Connection between GSK988T and GSKDAP03C servo spindle drive unit is shown in the

following figure. This connection can also be applied in spindle servo drive unit such as GSK

DAP03/DAY3025C/DAY3025/DAY3100.

20

Page 32

Chapter II Interface Signal Definition and Connection

Fig. 2-2-5 Connection between GSK988T and DAP03C drive unit

2.2.4 Connection with the Spindle Inverter Interface

The 5th axis ·spindle interface (CN15) SVC port outputs 0~+10V voltage, the connection

between GSK988T and the spindle inverter is shown in the following figure:

Fig. 2-2-6 Connection between GSK988T and inverter

21

Page 33

GSK988T Turning CNC System User Manual (Volume Ⅱ)

2.3 Connection with the Spindle Encoder

GSK988T is equipped with two-channel encoder input interfaces (CN21 and CN22), CN21

interface is used as feedback input of spindle speed by default. When multi-spindle control

function is started, select the encoder interface which receives the feedback pulse for the system

control, through the selection signal PC2SLC (G28.7) of spindle encoder in PLC. When the

interface (CN22) of encoder 2 does not connect to the encoder and the selection signal PC2SLC

of the position encoder is not set to 1, CN21 interface is taken as the feedback input of the

spindle speed.

2.3.1 Interface Definition of the Spindle Encoder

8:PAS/HA1

7:*PAS

6:PBS/HB1

5:*PBS

4:PCS

3:*PCS

2:

1:

15:0V

14:0V

13:+5V

12:+5V

11:0V

10:

9:

Fig. 2-3-1 Encoder interface of CN21

and CN22 (15 pins, D-type, male)

Signal Description

*PAS/PAS Encoder phase A pulse

*PBS/PBS Encoder phase B pulse

*PCS/PCS Encoder phase C pulse

The 2

HA1 (Only CN22 is

with the signal)

HB1 (Only CN22 is

with the signal)

(When it’s not used in the 2

spindle encoder, it can be used

The 2

(When it’s not used in the 2

spindle encoder, it can be used

phase A signal

to extend the 2

nd

MPG phase B signal

to extend the 2

nd

MPG

nd

nd

MPG)

MPG.)

nd

nd

2.3.2 Signal Instruction

*PCS/PCS, *PBS/PBS and *PAS/PAS are difference input signals of phase C, B and A

respectively; *PAS/PAS and *PBS/PBS is the orthogonal square wave with difference of 90°, the

maximum signal frequency <1MHz: The quantity of GSK988T encoder pulses is set by parameter

nd

No.3773 (the quantity of the spindle encoder pulses) and No.3803 (the quantity of the 2

spindle

encoder).

2.3.3 Connection with the Spindle Encoder Interface

The connection between GSK988T and the spindle encoder with the twisted pair line is

shown in Fig. 2-3-2, and Changchun Yiguang ZLF-12-102.4BM-C05D encoder is taken as one

example:

22

Page 34

Chapter II Interface Signal Definition and Connection

Changchun

GSK988T(CN21、CN22)

*PC

3

S

Yiguang 1024

encoder

8

ZZ

PCS

4

*PB

S

5

PBS

6

7

8

11

*PA

PAS

0

+5V

S

V

12

Metal cabinet

Fig. 2-3-2 Connection between GSK988T and the encoder

2

6

3

7

5

4

11

B

B

AA

0

V

+5V

2.4 Connection with the 2nd Spindle

988T supports multi-spindle function. Two spindle analog voltage output interfaces include

5th axis ·spindle (CN15) interface and the 2nd spindle (CN41) interface. They are controlled by

nd

PLC signals. The 2

spindle interface can be used to the 2nd inverter spindle or the unit head.

2.4.1 Definition of the 2nd Spindle (Analog Spindle) Interface

5:SVC

4:GND

3:Unused

2:Unused

1:Unused

CN41 analog spindle interface

(9pins, D-type, male)

1

Fig.2-4-1

6

9:Unused

8:Unused

7:Unused

6:Unused

Signal Description

SVC 0~+10V analog voltage output

GND analog voltage output ground

2.4.2 Connection with the 2nd Spindle Inverter Interface

The 2nd spindle interface SVC port outputs 0~10V voltage. The connection is shown in Fig.

2-4-2:

Fig. 2-4-2 Connection between GSK988T and the 2

nd

spindle inverter

23

Page 35

GSK988T Turning CNC System User Manual (Volume Ⅱ)

2.5 Connection with MPG

2.5.1 Definition of MPG Interface

9: X6.3

8: X6.2

7: Unused

6: X6.1

5: X6.0

4: HB3: HB+

2: HA1: HA+

Fig. 2-5-1 CN31 MPG interface

(26 pins, D-type male)

18: +24V

17: +24V

16: +5V

15: +5V

14: +5V

13: 0V

12: 0V

11: 0V

10: 0V

26: X7.0

25: X6.7

24: X6.6

23: X6.5

22: X6.4

21: Unused

20: Unused

19: Unused

Signal Description

HA+, HA- MPG phase A signal input

HB+, HB- MPG phase B signal input

X6.0~X7.0

PLC signal address; binary

input

2.5.2 Signal Instruction

HA+, HA- and HB+, HB- are difference input signals of MPG phase A and B respectively.

X6.0~X7.0 interfaces are input addresses defined by PLC interface, and it can also be used for

axial selection of external MPG box and gear signal input.

Fig. 2-5-2 Inside circul of X6.0~X7.0 signal

2.5.3 Connection with MPG Interface

The typical connection between GSK988T and MPG is shown as the following figure:

24

Page 36

Chapter II Interface Signal Definition and Connection

2.6 Connection with the Machine Panel

Connect between GSK988T system and the machine panel through communication.

2.6.1 Communication Interface Definition

Fig. 2-6-1 Standard machine panel interface CN54

(15 pins, D-type male)

Pin No. Signal IN/OUT Description

1 RXDA IN Receive data difference signal

2 RXDB IN Receive data difference signal

4 TXDA OUT Send data difference signal

5 TXDB OUT Send data difference signal

7 RESET OUT Panel resetting signal

2.7 GSK988T General I/O Interface Definition

2.7.1 Definition of Input & Output Addresses

Table 2-11 Definition of input & output addresses

Interface

CN61 (male)

input

CN61

Pin No.

1 X0.0 1 Y0.0

2 X0.1 2 Y0.1

3 X0.2 3 Y0.2

4 X0.3 4 Y0.3

5 X0.4 5 Y0.4

6 X0.5 6 Y0.5

7 X0.6 7 Y0.6

8 X0.7 8 Y0.7

9 X1.0 9 Y1.0

10 X1.1 10 Y1.1

11 X1.2 11 Y1. 2

12 X1.3 12 Y1.3

13 X1.4 13 Y1.4

14 X1.5 14 Y1.5

15 X1.6 15 Y1.6

16 X1.7 16 Y1.7

29

30

31

32

33

PLC

Address

X2.0

X2.1

X2.2

X2.3

X2.4

Interface

CN62 (female)

output

CN62

Pin No.

29

30

31

32

33

PLC

Address

Y2.0

Y2.1

Y2.2

Y2.3

Y2.4

25

Page 37

GSK988T Turning CNC System User Manual (Volume Ⅱ)

34

35

36

37

38

39

40

41

42

43

44

17

18

19

20

25

26

X2.5

X2.6

X2.7

X3.0

X3.1

X3.2

X3.3

X3.4

X3.5

X3.6

X3.7

X4.0

X4.1

X4.2

X4.3

X4.4

X4.5

34

35

36

37

38

39

40

41

42

43

44

17~19, 26~28

20~25

Y2.5

Y2.6

Y2.7

Y3.0

Y3.1

Y3.2

Y3.3

Y3.4

Y3.5

Y3.6

Y3.7

0V

+24V

27

28

21~24

X4.6

X4.7

0V

2.7.2 Input Signal

Input signal is the one which the machine electric wire or the machine panel transmits to

CNC, and after connecting the input signal and +24V, the input is valid; if they are cut off, the

input is invalid. The input signal of contacts on the machine side should satisfy the following

conditions:

Contact capacity: DC30V, 16mA above;

Leakage current between contacts during opening: Below 1mA;

Voltage drop between contacts during closing: Below 2V (Current 8.5mA, including the cable

potential drop).

There are two methods of external input for input signals: one is switch input with contacts,

the connection is shown in Fig. 2-7-1:

26

Fig. 2-7-1

Page 38

Chapter II Interface Signal Definition and Connection

The other is switch (transistor) input free of contacts; connection is shown in Fig. 2-7-2 and

Fig. 2-7-3.

Fig. 2-7-2 NPN type

Fig. 2-7-3 PNP type

2.7.3 Output Signal

Output signal is used for the drive machine electrical wire side or the relay and the indicator

on the machine panel side. When the output signal connects with 0V, the output function is valid

(Y output signal is 1); cut off 0V, the output function is invalid (Y output signal is 0). The circuit is

shown in the following Fig. 2-7-4:

Fig. 2-7-4. Internal circuit of the output signals

Therefore, the signal has two output statuses: OV output or high resistance. The typical

application is as below:

z Drive light diode

Use ULN2803 to output drive light diode and need the serial connection with one resistance,

27

Page 39

GSK988T Turning CNC System User Manual (Volume Ⅱ)

limit the current from light diode (normally 10mA), which is shown in Fig. 2-7-5:

Fig. 2-7-5: Drive light diode

z Indicator in drive filament type

ULN2803 is used to output the indicator in drive filament type, and externally connect with

one preheated resistance to reduce the current shock during break-over, and the value of the

preheated resistance is based on that the indicator is off, which is shown in Fig. 2-7-6:

Fig. 2-7-6

z Drive inductive loading (such as the relay)

Output the drive inductive loading in ULN2803 type and it requires connecting the fly-wheel

diode close to the circuit, which is to protect the output circuit and reduce the interference, which

is shown in Fig. 2-7-7:

Fig. 2-7-7

2.8 Connection with the Power Supply

GSK988T uses GSK-PB2 power supply box, There are 4 groups of voltage: +5V (3A), +12V

(1A), -12V (0.5A) and +24V (0.5A), and common port COM (0V).

28

Page 40

Chapter II Interface Signal Definition and Connection

2.8.1 Definition of Power Supply Interface

The interfaces of power supply are shown in Fig. 2-8-1 and 2-8-2:

+24V

0V

-12V

0V

+12V

0V

+5V

+5V

+5V

Fig. 2-8-1 power supply interface CN1 Fig. 2-8-2 power supply interface on the panel

2.8.2 Connection between GSK988T and GSK-PB2 Power Supply Box

When GSK988T is dispatched from the factory, GSK-PB2 power supply box and GSK988T

power supply interface has been already connected, so the user just need to connect to 220V AC

power supply. The connection between GSK-PB2 power supply box and GSK988T power supply

interface is shown in Fig. 2-8-3:

Fig. 2-8-3

2.9 Connection with the External Equipment

There are three interfaces on the left side of GSK988T LCD display screen: USB (flash

driver), internet and RS-232 interfaces, which are shown in the following figure. All the three

interfaces can be used for processing the file, two-way transmission between the system Para file

and PLC file and upgrading the system software. Among them, the internet interface can also be

used for remote monitor from PC to 988T system.

29

Page 41

GSK988T Turning CNC System User Manual (Volume Ⅱ)

USB interface

Internet interface

RS-232 interface

Fig. 2-9-1 GSK988T front panel interface

2.9.1 RS-232 Interface Definition

RS-232 communication interface:

1

5: GND

4:

3: TXD

2: RXD

1:

6

9:

8:

7:

6:

Fig. 2-9-2 RS-232 interface

(9 holes, D type female )

GSK988T executes communication through RS232 with PC (GSKComm-M communication

software should be installed). The connection is shown in Fig. 2-9-3:

Pin No. Signal

2 RXD

3 TXD

5 GND

Fig. 2-9-3 Connection between GSK988T and PC

2.9.2 Definition of GSKLINK Bus Interface

GSK988T is with GSKLink interfaces of two routes for connecting with the remote IO units

and the servo drive unit with GSKLink communication function. Among them, CN53 (GSKLINK

serial bus A) is for communication between CNC and the servo drive unit to realize real-time

monitor of servo parameter configuration and servo unit; CN52 (GSKLINK serial bus B) is for

30

Page 42

Chapter II Interface Signal Definition and Connection

communication between CNC and remote IO unit.

1:GND

2:CANn_L

3:

4:GND

1

6

6:

7:CANn_

8:

9:

H

5:

Fig 2-9-4 GSKLink bus interface CN53 and

CN52 (9 holes, D type female)

2.9.2 Network Interface Definition

Network interface (standard):

Pin No. Signal Pin No. Signal

1 TXDLAN+ 9 LINK_LED

2 TXDLAN- 11 LAN_LED

3 RXDLAN+ 10, 12 VDD33

6 RXDLAN- 13, 14 Chassis ground

Signal Description

CANn_L

Low level of data

difference signal

CANn_H High level of data

difference signal

GND Signal ground

2.9.3 USB Interface Definition

Main USB interface (standard):

Pin No. Signal

1

2

3

4

5, 6

VCC(+5V)

USB_DN0

USB_DP0

GND

Chassis ground

31

Page 43

GSK988T Turning CNC System User Manual (Volume Ⅱ)

CHAPTER III MACHINE TOOL DEBUGGING-OPERATION

3.1 Parameter Setting

The modification, backup and recovery of GSK988T system parameters and servo parameters

can only be done under such conditions: higher than 3rd management level; parameter switch is ON

and the system is in MDI mode. The operation of turning ON the parameter switch is shown as

follows:

Enter into System

Setting screen

1.Unlock the

program switch

2. Press SET key

3.Press CNC Setting

4.Press System Setting

5.Move the cursor

to “Parameter Switch”

6.Press to turn ON

the parameter switch

Note 1: After parameters are modified, the modification is valid to some parameters immediately;

some will be valid only after power on again. For details, please refer to chapter 5 Parameter

Instruction.

Note 2: To view or modify the servo parameters in CNC, please ensure the correctness of servo

system connection and servo slave configuration.

3.1.1 System Parameters

Press -> -> to enter into system parameter setting screen.

The system parameters can be set and modified on this screen. The current set parameters can

be backed up, and system default parameter or backup parameters can be recovered.

(1) Bit type parameters setting

Method 1:

① Select the parameter to be modified through keys

32

, , , ; or press

Page 44

Chapter Machine Ⅲ Tool Debugging-operation

softkey and input the parameter number, then press softkey, the cursor

will move too the desired parameter.

② Press key

parameter in the figure below:

to make the selected parameter modifiable. For example, the No.0000

③ Press the numeric keys to input 8 binary values, and then, press

setting. (When the number input values is less than 8, fills the vacated bits with 0.)

④ Select other parameters through keys

Method 2:

①

Select the parameter to be modified through keys

Select the bits to be modified through keys

③ Press repeatedly, to switch the parameter bit between 0 and 1.

④ Move the cursor to complete the setting.

⑤ Select other parameters through keys , , , .

(2) Numeric type parameter setting

① Select the parameter to be modified through keys

softkey and input the parameter number, then press softkey, the cursor will

move to the desired parameter.

, , , .

, , , .

and .

to complete the

, , , ; or press

② Press key

to make the selected parameter modifiable.

33

Page 45

GSK988T Turning CNC System User Manual (Volume Ⅱ)

③ Input the numbers to be set through numeric keys, then press

④ Select other parameters through keys , , , .

(3) Parameters backup and recovery

Before modification, the parameters can be backed up through softkey. When the

modification is erroneous or the parameter does not need to be modified, press

backup parameters or system default parameters can be recovered.

¾ Parameter backup

① Press

②

Press

¾ Parameter recovery:

① Press

② Press

on the parameter screen, will be displayed.

to back up the current set parameters.

, will be displayed.

key to restore the backup parameters; Press to restore the

to complete the setting.

softkey, the

system default parameters; press to exit from the parameter screen.

3.1.2 Servo Parameters

(1) Modification and save

When the GSKLink communication is in normal state, on system screen, press

, to enter into servo parameter screen.

->

34

Page 46

Chapter Machine Ⅲ Tool Debugging-operation

Servo parameters can be viewed, modified, saved, backed up and restored through servo

parameter screen on the CNC side.

Axes switching: Press

parameters.

Parameter modification: Press key

parameter value directly, then press

Parameter saving: after the modification, press

parameter remains the same after servo is turned ON again.

Parameter backup: Press

to back up the file.

Parameter recovery: Press , the following dialogue box will pop up, the press

to restore the backup file.

, or to switch the displayed servo

and input the parameter value, or, input the

to complete the modification.

to save the parameter. The saved

, the following dialogue box will pop up, then press

Select effective parameter: if the parameters are modified on the servo, after power-on, the

system will issue prompt No.5030 “*the servo parameter in current parameter file of axis servo is

inconsistent with the read servo parameter.” Switch to the servo parameter screen this time, see Fig.

3-1-6 , then press

, see Fig. 3-1-7.

Fig.3-1-6

35

Page 47

GSK988T Turning CNC System User Manual (Volume Ⅱ)

Fig. 3-1-7

Press

read from the servo; press

(2) Restore motor default parameter

a. Refer to appendix B.1 to find the index value in the current software version of drive unit

b. Modify servo parameter PA1 to make it equal to the searched motor index value.

c. After modifying PA1, the system automatically update the default parameter

to validate the servo parameters in CNC; press to validate the parameters

to return to the screen shown in Fig. 3-1-6.

which is connected to the motor according to the motor type given on the motor

nameplate.

corresponding to the motor. The parameter value is valid immediately after modification.

36

Fig. 3-1-8

Page 48

Chapter Machine Ⅲ Tool Debugging-operation

3.2 Instruction of PC Communication Software GSKComm-M

This section is a simple instruction for the usage of the GSKComm-M during machine

tool debugging. For the details, please refer to the GSKComm-M Instructions on the CD.

GSKComm-M is a communication management software especially provided for the machine

tool builders. The GSKComm-M screen is shown as follows. It can realize the following functions:

upload and download of files between PC and CNC, DNC communication, CNC parameter editing,

part program management and editing, viewing tool compensation data and screw pitch error

compensation data, ladder diagram editing, etc. It is convenient, efficient and reliable.

3.2.1 Preparation for GSKComm-M

(1) RS-232 series port connection

¾ Connection between PC and CNC

When both PC and CNC are power-off, the communication cable should be connected as

follows: DB9 male is plugged into the RS-232 communication interface on the CNC; DB9 female

is plugged into the 9 pins serial ports on the PC (COM0 or COM1).

¾ Baudrate setting in CNC

The baudrate is set by parameter No.0123. When data transmission is processed between

CNC and PC, the setting value should not be less than 4800. (ex-factory value:115200)

¾ Baudrate setting in PC

After the communication software is executed, left-click

the menu and select “Communication->Communication Setup”,

shown in right figure.

Setting: select the serial port communication.

Port selection: select ports used for communication

(COM1, COM2, COM3, COM4)

Baudrate: Select the baudrate

(4800, 9600, 19200, 18400, 57600, 115200) (unit: bps)

(2) Network connection

¾ Connection between PC and CNC:

Connect the network port of GSK988T to the PC or router with normal network cable.

37

Page 49

GSK988T Turning CNC System User Manual (Volume Ⅱ)

¾ IP setting on CNC:

Press -> -> , to enter into IP setting page to set the IP address and

gateway.

¾ IP setting on PC:

After the communication software runs, left-click the menu,

and select “Communication->Communication Setup”,

shown in right figure.

Communication setting: Select network communication.

Network setting: Fill in the IP set in CNC.

(3) Authority setting

During upload and download using GSKComm, corresponding authority should be set in

advance, otherwise, the operation will fail.

Data to be

downloaded

PLC files 2 level

parameters 3 level Parameter switch is ON

Part programs 3 level Program switch is ON

Macro variables 4 level Program switch is ON

Tool compensation

data

Pitch error

compensation data

Tool life files 5 level

CNC least

authority level

4 level

5 level Parameter switch is ON

Remark

3.2.2 File Download (PC→CNC)

Through GSKComm, files in the PC can be transferred to CNC altogether or one by one.

(1) Add files

First, press the type of file to be added (for example, system file, part program file or ladder

diagram file)

Then, press

(shown in the left figure), select the desired file (hold down “shift” key to select more files), then click

“Open” to complete the action.

or right-click, select “Add Files”, a dialog box for adding file will pop up

38

Page 50

Chapter Machine Ⅲ Tool Debugging-operation

(2) Add multiple files

First, select the project to be transferred; then, click

“Send to CNC”, the following dialog box will pop up. (Shown in the right figure above)

In this dialog box, click the left options to select the files to be transferred. Arrow “->” points to

the file name saved in CNC, double-click it, you can change the file name.

Click “Start sending” you can transfer the selected file (with the saved file name) into CNC.

(3) Download single file

Select the file to be downloaded, then click

file and select “Send to CNC”, a dialog box will pop up. You can change

the file name to be saved in the CNC, and then click “OK” to transfer

the file.

, or right-click the

or right-click the project and select

3.2.3 Upload File (CNC→PC)

First, select a project, then, click , or select menu "Communication->Receive Files from

CNC”, a dialog box will pop up, (shown in the left figure below). Select the file to be uploaded, then

39

Page 51

GSK988T Turning CNC System User Manual (Volume Ⅱ)

click “Receive”, a “Browse File” dialog box pops up (shown in the right figure below).

Select the file folder in which the uploaded file to be saved, and click “OK” to upload the selected file.

3.3 Usage of U Disk

The U disk function in GSK988T supports the bi-directional transmission of files involving

machining program, PLC program, parameters, tool compensation data and pitch error compensation

data. It can be operated on three screens: file management screen, program screen and ladder

diagram screen.

3.3.1 File Management Screen

When U disk is already inserted in the USB port, press → to enter into file

management screen.

Under this screen, bi-directional transfer of system files (system parameters, tool compensation

data, pitch error compensation data etc.), ladder diagrams and part programs can be executed. The

procedure is shown as follows:

40

Page 52

Chapter Machine Ⅲ Tool Debugging-operation

Press

Press

to switch between the system content and U disk content.

softkey to copy the selected program into local directory or U disk directory.

3.3.2 Program Screen

The operation of U disk directory is the same as in the local directory. In

this section, we only introduce the program transfer in U disk. For details,

please refer to GSK988T User Manual.

When the system USB port is inserted with U disk, press

(left figure below), press

into U disk directory screen, operations to the programs in U disk directory such as load, open, copy,

paste, create, save as, delete, rename, search, etc, can be performed.

, the extended softkeys will be displayed. Then, press to enter

to enter into program directory

41

Page 53

GSK988T Turning CNC System User Manual (Volume Ⅱ)

prog

¾ Program bi-directional transmission

① Press

② Move the cursor to the program to be copied through

Then, press

Press

to view the extended softkeys (the right figure above),

to copy the selected program into local directory or U disk directory.

and to switch between the local directory and U disk directory.

and ,

③ When the copied program already exists, a dialog box pops up (see the right figure). Press

“Yes” softkey to cover the existed program; or press “No”, a dialog box

pops up, then

input the program name for saving; press “Cancel” to cancel the operation.

Note 1: When transmission is made from the U disk directory to local directory, the machining

programs can be read only when it is stored in the root directory “NCPROG” file in the U

disk.

Note 2: When transmission is made from local directory to the U disk directory, if the “NCPROG”

file does not exist in the U disk, the file will be created automatically, and the machining

rams will be output to the files.

3.3.3 PLC Screen

When the USB port is inserted a U disk, press on the ladder diagram screen, the

screen is shown in Fig. 3-3-4 (Local directory screen). Press

to switch to the U disk directory

screen, shown in Fig. 3-3-5.

42

Fig. 3-3-4

Page 54

Chapter Machine Ⅲ Tool Debugging-operation

Fig. 3-3-5

Programs in the U disk directory can be copied to local directory through softkey

versa.

Take the U disk for example, the procedures are shown as follows:

① Press softkey

② Select the ladder diagram programs to be copied through

to enter into U disk directory;

and , then, press

to copy it to the local directory.

Note 1: When PLC transmission is made from the U disk directory to local directory, the PLC

programs can be read only when it is stored in the root directory “LDFILE” file in the U

disk.

Note 2: When PLC transmission is made from local directory to the U disk directory, if the

“LDFILE” file does not exist in the U disk, the file will be created automatically, and the PLC

programs will be output to the files.

3.4 PLC Operation

, vice

Press function key and then press softkey to enter into PLC screen. This screen

includes pages such as version information, monitor, PLC data, PLC state, program directory. Press

corresponding softkeys, you can view the desired content.

After entering the PLC screen, the contents of

is displayed. The version page includes

the information about the PLC version, current running PLC program and the running state, etc.

43

Page 55

GSK988T Turning CNC System User Manual (Volume Ⅱ)

3.4.1 PLC Execution and Stop

On PLC screen, press softkey , then press → , the following screen is

displayed:

On this page, you can select PLC program through

running, stop, save, create, delete and backup can be performed.

¾ Execution of PLC programs

and , then press to start running.

44

Select the PLC program through

Note: The current running PLC program is marked with .

and , then operations such as edit,

Page 56

Chapter Machine Ⅲ Tool Debugging-operation

¾ Stop PLC program execution

Move the cursor to the current running program through

the system will be in no PLC running state.

and , then press ,

3.4.2 PLC Monitoring and Diagnosis

(1) Monitor the PLC program state

On the PLC screen, press softkey

current running PLC program.

to enter to the monitoring display screen for the

You can view the state of current contact, coil conducting ON/OFF and the current value of timer

and counter. When the contact and coil conduction is ON, it is indicated by green color; if not, the

45

Page 57

GSK988T Turning CNC System User Manual (Volume Ⅱ)

color is the background color of the screen. For example: means the contact X0.5 is

conducted,

means the coil Y25.2 is not conducted.

¾ View blocks

On monitoring page, there are four softkeys for monitoring four blocks:

, . Each of them corresponds to a block and the corresponding PLC will be

displayed on the screen.

Note 1: Softkeys for windows 1~4 are shortcut keys which enable quick view of the

corresponding blocks.

Note 2: The blocks corresponding to windows 1~4 can be changed, but the change will not be

effective after power-off. The default block after power-on is the first four blocks in the

PLC programs.

¾ Select block

① Select the screen as needed.

② Press softkey

, the following figure is displayed:

, ,

Press③ keys

④ Press softkey

softkey

to cancel the selection and return to the previous menu.

, , , to select the desired window.

to complete the selection, then, return to the previous menu; press

¾ Search for parameters, commands and network

Select the window in which the command, parameter or network to be searched, i.e. press

, , , to display the corresponding blocks of PLC program,

then, search for the command, parameter or network.

46

Page 58

Chapter Machine Ⅲ Tool Debugging-operation

② Press softkey

③ Press softkeys

command, network on the corresponding screen, and move the cursor to the corresponding position.

to enter to search page, shown as follows:

, , respectively you can search for the parameters,

④ Press

(2) PLC I/O state diagnosis

On PLC screen, press

following figure.

, to move the cursor to the first line and last line of the block.

and to enter to PLC state display page, as shown in the

¾ View the state of signals

Press softkey

softkey

, the state of signals R, A, K will be displayed.

, the state of signals X, Y, F, G will be displayed on the screen; press

47

Page 59

GSK988T Turning CNC System User Manual (Volume Ⅱ)

Press

Press

signals.

or to switch between softkeys X, Y, F, G signal and R, A, K signal.

, , , to view the information about X, Y, F,G signals or R, A, K

3.4.3 PLC Data Viewing and Setting

On PLC screen, press to enter into PLC data state page. It includes the setting of K, D,

DT, DC parameters.

(1) K parameter setting

On PLC data page, press

figure above:

Parameter setting method:

① Press keys

bit to be modified; or press softkey

and move the cursor to the parameter. The meaning of the status bit is displayed at the

bottom of the screen.

② Press

of the selected K parameter status bit.

③ Press

(2) D parameter setting

, , , , , , you can select the parameter statues

repeatedly in K variable status bit to switch between 0 and 1, modify the status

, , , to move the cursor to complete the modification.

softkey to enter into parameter K setting page, shown in the

to input the K variable to be selected, then press

On PLC data page, press

the following figure.

48

to enter to the D parameter setting display page, shown in

Page 60

Parameter setting method:

Chapter Machine Ⅲ Tool Debugging-operation

① Press keys

modified; or press softkey

move the cursor to the parameter. The meaning of the status bit is displayed at the bottom of the

screen.

② Press

③ Input the modified value, and press

(3) DT parameter setting

On PLC data page, press

the following figure.