Greenheck Temperature Interlock User Manual

Document #471738

Temperature Interlock

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage!

Product Specification

Temperature Interlock

International Mechanical Code (IMC) 2006 section 507.2.1.1 Compliant Electrical Package

Provide Greenheck Fan Corporation temperature interlock electrical package as shown on plans and in accordance with the following specification:

The temperature interlock(s) consists of an adjustable thermostat, junction box, fire proof/leak proof threaded fitting (Evergreen Quik-Seal® and/or Evergreen Compression Seal), and shall be a self-contained unit or as part of another pre-engineered electrical control package.

The temperature interlock package shall close a relay powering the fans when the set temperature is reached at the thermostat. The interlock shall hold the circuit closed upon fan switch being turned off until the temperature at the sensor decreases below the set point at which point the timed relay will begin a countdown. Once the countdown has expired and as long as the temperature has remained below the set point, the fans shall shut down.

The temperature interlock package shall be constructed by Greenheck Fan Corporation in accordance with International Mechanical Code. The manufacturer shall provide, upon request, the necessary data that confirms compliance with the code listed above.

Due to continuous research, Greenheck Fan Corporation reserves the right to change specifications without notice.

General Description

Description

The temperature interlock is designed to automatically start kitchen hood exhaust fans and keep them running while heat is being generated from the cooking appliances. Hood systems should always be manually started before equipment is turned on. If the fans are forgotten to be turned on, the interlock will turn the fans on once heat is detected. The interlock consists of an adjustable thermostat, junction box, Evergreen QuikSeal threaded fitting, and is contained in a stand alone box or can be added to a pre-engineered fan control center.

Purpose

To meet IMC 2006 section 507.2.1.1, interlock between exhaust fans and cooking equipment. This system will utilize a temperature sensor in the exhaust duct collar or in capture area of hood to detect heat generated from cooking operations and automatically activate the exhaust fans if not already turned on. Field wiring may be required depending on location of components.

Product Application

The temperature interlock is designed to be used with Type I and Type II Hoods. It is not to be used in conjunction with exhaust fire dampers. Greenheck recommends using one interlock per hood system (activates all fans linked to system simultaneously).

Performance Goals

Automatically energize the exhaust fans when cooking equipment generates heat. Basic controls will be provided with a thermostat and will consist of an 8 x 8 electrical box with controls and a labeled terminal strip to hook-up incoming power and fan starters.

An adjustable delay is used to keep the exhaust fans running when the thermostat initially closes to prevent the fan from cycling on and off at startup and shut down. Fans will shut down automatically 20 minutes after the thermostat opens its contact. The time delay can be adjusted from 1-100 minutes based on jobsite requirements.

Temperature Interlock 1

®

Table of Contents

Product Specification . . . . . . . . . . . . . . . . . . . . . . . . 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Receiving and Handling. . . . . . . . . . . . . . . . . . . . . . . 2

Installation

Hood Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Duct Collar Mounting . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Connections

Thermostat Connections . . . . . . . . . . . . . . . . . . . 4

Breaker Panel to Control Box or

Fan Control Center . . . . . . . . . . . . . . . . . . . . . . 4

Circuit Connections . . . . . . . . . . . . . . . . . . . . . . . 4

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Circuit Diagrams . . . . . . . . . . . . . . . . . . . . 5-6

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . 8

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Codes and Standards Compliance . . . . . . . . . . . . . . 8

Our Commitment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Receiving and Handling

Upon receiving the equipment, check for both obvious and hidden damage. If damage is found, record all necessary information on the bill of lading and file

a claim with the final carrier. Check to be sure that all parts of the shipment, including accessories, are

accounted for. Make sure the equipment does not suffer any heavy vibrations or knocks.

Storage

If a temperature interlock must be stored prior to installation it must be protected from dirt and moisture. Indoor storage is recommended. For outdoor storage, cover the hood with a tarp to keep it clean, dry, and protected from UV (ultraviolet) radiation damage.

Improper storage which results in damage to the unit will void the warranty.

2 Temperature Interlock

®

Installation

Control Box Mounting

Locate an area with enough space to mount the control box and fasten to the wall. Avoid installing the control box in environments with high magnetic and/or radio frequency interference.

NOTE

Control box may be factory mounted. If so, continue to the next section.

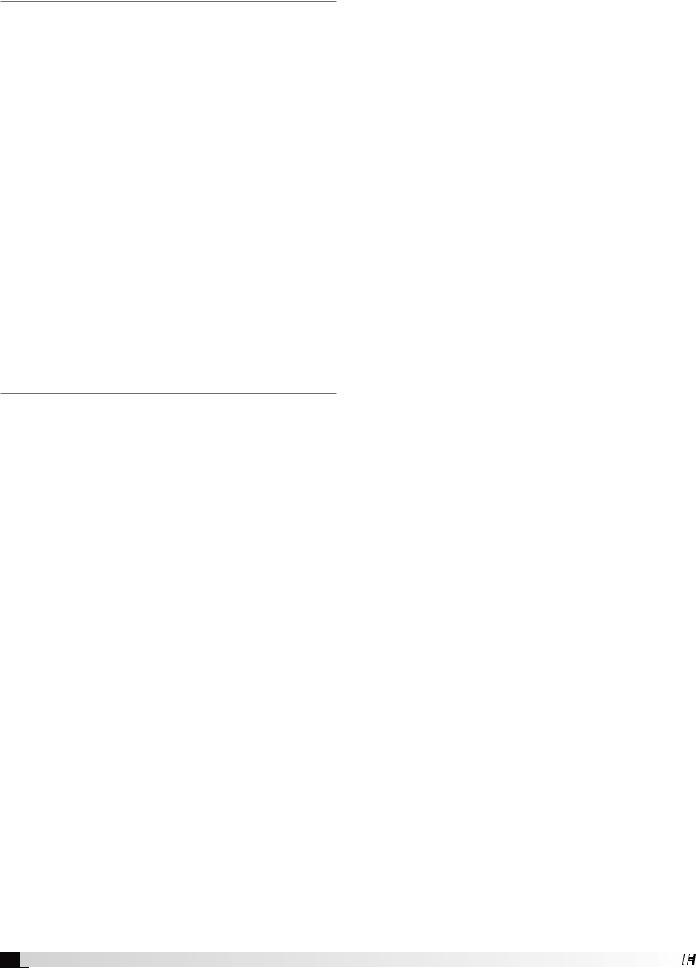

Thermostat Installation - Hood Mounting

Recommended thermostat mounting location is in the flat interior of the hood and at least 8 inches (20.32 cm) from light fixture.

3 inch air space

19.525 inches

Exhaust Area |

2 inch typical |

Sensor Install |

|

(cut out area) |

|

Supply Area |

|

(optional) |

|

Hood Plan View

1. Locate the flat

area(s) at the top |

(28.58 to 31.75 mm) |

|

|||

interior of the hood |

|

|

|

|

|

|

|

|

|

|

|

in front of the |

|

|

|

|

|

filters, towards the front |

|

||||

of the hood. A 11⁄8 to |

|

|

|

|

|

1¼ inch (28.58 to 31.75 |

|

|

|

|

|

|

|

||||

mm) diameter hole must |

|

|

|

|

|

be cut into the top of |

|

|

|

|

|

the capture tank. Make |

|

|

|

Hood Surface |

|

|

|||||

sure the thermostat will |

|

||||

not interfere with the fire system nozzles and is not within 8 inches (20.32 cm) of the light fixtures.

2.Insert the Evergreen Compression Seal fitting into the hole from the inside of the hood, making sure the gasket is placed on the fitting before inserting it into the hole. Install the lock washer and 11⁄2 inch (38 mm) nut on the threaded portion of the compression seal fitting and tighten securely.

Compression Seal

PN 452614

Gasket |

Octagon Extension |

PN 830125

Junction Box Plate

PN 732396

Lock Washer

Nut

Nut

Exploded View (Components)

3.Place the junction box provided over the fitting on top of the hood, keeping the fitting centered in the box.

4.Thread the thermostat into the compression seal fitting and tighten to 35 ft-lbs. (4.84 m-kgs).

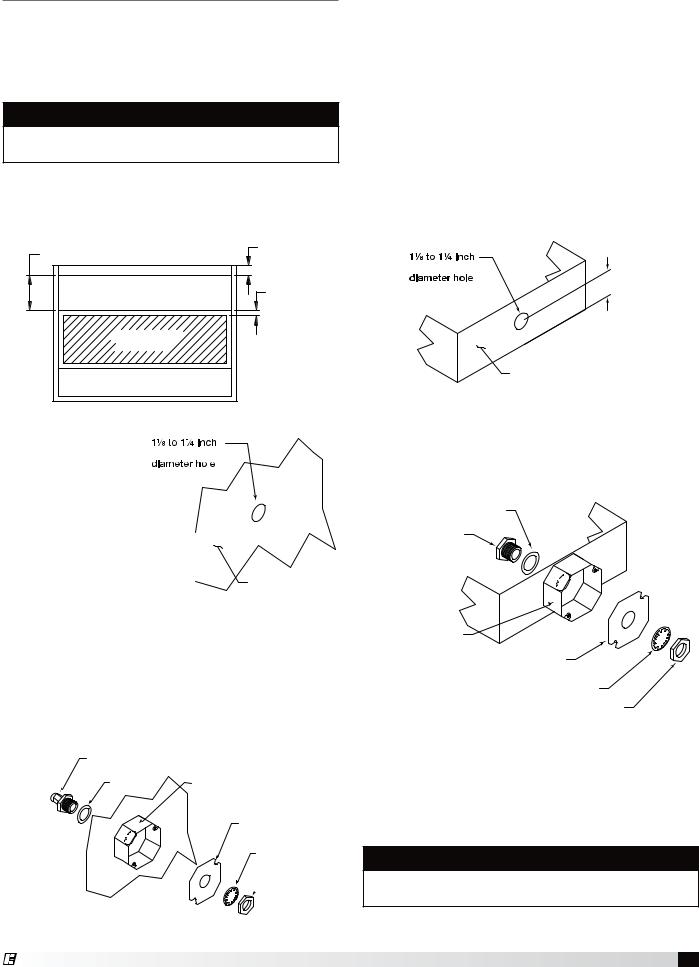

Duct Collar Mounting

1.Locate the exhaust duct on top of the hood. A 11⁄8 to 1¼-inch (28.58 to 31.75 mm) diameter hole must be cut into the duct 2 inches (50.8 mm) above the hood top. Center the hole along the side of the duct. Make sure that the thermostat will not interfere with any fire system nozzles, or other items installed in the exhaust duct. If an exhaust fire damper is present the hood exhaust collar, it must be removed prior to thermostat installation.

(28.58 to 31.75 mm)

2 inches (50.8 mm)

Hood Exhaust Collar (front side)

2.Insert the Evergreen Quik-Seal fitting into the hole from the inside of the duct, making sure the gasket is placed on the fitting before inserting it into the hole. Install the lock washer and 11⁄2 inch (38.1 mm) nut

on the threaded portion of the Evergreen Quik-Seal fitting and tighten securely.

Gasket

1/2 inch Quik-Seal

PN 451168

Octagon Extension

PN 830125

Junction Box Plate

PN 732396

Lock Washer

Nut

Exploded View (Components)

3.Place the junction box provided over the fitting and tack weld the junction box to the exhaust duct keeping the fitting centered in the box. (Welding optional).

4.Thread thermostat into Evergreen Quik-Seal fitting and tighten to 35 ft-lbs (4.84 m-kgs).

NOTE

All field installation and wiring of electrical equipment must be done to meet NEC and local codes.

Temperature Interlock 3

®

Loading...

Loading...