Greenheck G-060-G Manual

Centrifugal Roof Downblast Exhaust Fans

• General Clean Air |

• Light Contaminants |

• Seismic |

• High Wind |

Models G and GB |

|

July 2009

Centrifugal Roof Exhaust Fans

Spun Aluminum • Downblast

Greenheck models G and GB centrifugal roof exhaust fans provide the industry’s best performance and durability for general clean air applications.

•Broadest performance in the industry, up to 3.25 in. wg

(810 Pa) and 45,000 cfm (76,500 m3/hr).

•Most advanced motor cooling of any fan in its class.

•Performance as cataloged is assured. All fan sizes are tested in our AMCA Accredited Laboratory, and all models are licensed to bear the AMCA sound and air performance seals.

•UL Listed for electrical.*

•Greenheck subjects these products to extensive life testing, assuring you that the fans will provide years of reliable performance.

Greenheck Fan Corporation certifies that the Models G, and GB fans shown herein are licensed to bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and Publication 311 and comply with the requirements of the AMCA Certified Ratings Program. The certified ratings for Models G, and GB are shown on pages 17 to 55.

G and GB models are listed for electrical (UL/cUL 705) File no. E40001

*UL/cUL is optional and must be specified

Model

Model Comparison

|

Mounting |

Airfl ow |

|

Application |

|

Drive Type |

Performance |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Roof Curb |

Exhaust |

General/Clean Air |

|

Maximum Operating Temperature |

|

High Wind (150 mph) |

Belt |

Direct |

Maximum Volume cfm (m3/hr) |

Maximum Static Pressure in. wg (Pascals) |

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

|

|

|

130°F |

|

|

|

4,300 |

1.0 |

|

|

(54°C) |

|

(7,306) |

(249) |

|||||||

GB |

|

|

|

180°F |

|

|

44,700 |

3.25 |

(82°C) |

(75,946) |

(810) |

2

Table of Contents

Model Comparison . . . . . . . . . . . . . . |

. . . 2 |

Typical Installations. . . . . . . . . . . . . . |

12-13 |

Codes & Certifications . . . . . . . . . . . |

. . . 4 |

Severe-Duty Curbs Anchoring . . . . . |

14-15 |

Applications: |

|

Performance and Dimensions: |

|

General Clean Air . . . . . . . . . . . . . . |

. . . 4 |

Model Number Code . . . . . . . . . . . |

. . 16 |

Seismic . . . . . . . . . . . . . . . . . . . . . . |

. . . 5 |

Direct Drive (by size). . . . . . . . . . . . . |

17-26 |

Vari-Green Motors . . . . . . . . . . . . . |

. . . 5 |

Belt Drive (by size) . . . . . . . . . . . . . . |

27-55 |

High Wind & Hurricane . . . . . . . . . |

. . . 6 |

Typical Specifications. . . . . . . . . . . . |

56-59 |

Roof Curbs . . . . . . . . . . . . . . . . . . . |

. . . 7 |

Quick Build Programs . . . . . . . . . . . . |

. . 60 |

Standard Construction Features . . . |

. .8-9 |

Warranty . . . . . . . . . . . . . . . . . . . . . . |

. . 60 |

Options & Accessories . . . . . . . . . . . |

10-11 |

|

|

Leading Edge Technical Support

When product and IOM (Installation, Operation and Maintenance Manual) information is needed, our products are supported by the industry’s best product literature, electronic media, and Computer Aided Product Selection (CAPS) program. You’ll also find this information on our web site at www.greenheck.com

Our national and international representative organizations provide personal service and expertise. To locate your nearest Greenheck representative, call 715-359-6171 or visit our web site at www.greenheck.com

Outstanding Customer Service

Your local Greenheck representative has a wealth of industry and product knowledge to answer your questions. Our representatives receive the latest

product information and can have orders processed directly to our factory. With our direct order processing system, we can ship orders as fast as the next day. With Greenheck’s experienced staff, we can answer questions and provide solutions.

World Class Manufacturing

Greenheck’s skilled production workers use cost-effective machines and unique dies designed and built by our own engineers to add innovative features and greater strength to our centrifugal exhaust fans. Our advanced manufacturing processes and quality control procedures always ensure the highest product quality. And just to be sure you get the peace-of-mind you expect when you specify Greenheck, our assembly inspectors test run and monitor every fan before it leaves the factory. Results of these tests are kept in permanent records for future reference.

3

Codes and Certifications &

Applications: General Clean Air

Codes and Certifications

UL 705 - Power Ventilators

Intended to assure the buyer of the safety of electrical components and connections within power ventilators and duct fans. Limited to fans connected to permanently installed wiring that meet NFPA 70 and the National Electric Code. Tests under this standard relate to extremes of current, temperature, fuses, motor windings, bearing temperatures, and water that a fan could be subject to.

AMCA Certified Ratings Program

Ensures that all data is accurate. The 211 test for air performance certifies that the fan has been tested to the appropriate AMCA standards in a licensed test facility and that the air performance displayed in catalogues and selection software is accurate. The 311 test for air and sound performance certifies that the fan has been tested to the appropriate AMCA sound standards in a licensed facility and that the sound performance displayed in catalogues and selection software is accurate. AMCA Certified Ratings Program is designed to ensure that the products perform as stated and that a third party organization has verified all published data for accuracy and consistency.

Clean Air Applications

Models G and GB

These spun aluminum fans are specifically designed for roof mounted applications. General clean exhaust air is discharged downward, toward the roof surface.

•Most advanced motor cooling of any fan in its class.

•Performance as cataloged is assured. All fan sizes are tested in our AMCA Accredited Laboratory and all models are licensed to bear the AMCA Sound and Air Performance seal.

•Greenheck subjects these products to extensive life testing, assuring you the fans will provide many years of reliable performance.

Direct Drive, G

•Typically used for short and/or low resistance ductwork

Belt Drive, GB

•Typically used for average length and/or average resistance ductwork

•High volume/average pressure

Belt Drive, GB-HP

•Typically used for long and/or high resistance ductwork

•Low volume/high pressure

4

Applications:

Seismic and Vari-Green Motor

Seismic Applications

Models G and GB

The International Building Code has been adopted on the state and local level throughout most of the fifty states. The adoption of this code has resulted in the adherence of buildings, along with electrical and mechanical components, to new previsions in the code. In particular, there is an emphasis on seismic compliance. As an industry leader, Greenheck introduces the fi rst seismic compliant centrifugal roof exhaust fan available for general clean

air applications.

Greenheck offers products certifi ed for the worst plausible seismic event that would be found on the IBC Spectral Response Map. Models G and GB are rated for seismic design categories A-F, which allows Greenheck to provide a seismic ventilation solution regardless of the location in the country.

Rigorous Testing

•Third-party FEA (Finite Element Analysis) by licensed Professional Engineers

•Tested in Accordance with ICC ES AC-156 acceptance criteria utilizing shake table testing to simulate the worst case scenario.

Vari-Green Motor Applications

Model G available in sizes 080 thru 131

The Greenheck Vari-Green motor blends technology, controllability and energy-effi ciency into a low maintenance package changing the way the industry designs, specifi es and operates air movement equipment.

The Vari-Green motor is the industry’s fi rst fully controllable fractional horsepower (hp) motor available in 1/4 hp, 1/2 hp and 3/4 hp. The VariGreen motor is cost-effective with less than one-year payback. The motor is available with a potentiometer speed control dial mounted right on the motor to make system balancing a breeze. It can also be provided with 0-10 volt control wire inputs for easy integration into a Building Automation System (BAS) or any controller that can output a 0-10 volt signal.

Seattle, WA, 03/05/01 -- Damage in Pioneer Square from the 02/28 earthquake. FEMA/Photo by: Liz Roll/FEMA News Photo

State P.E. Calculations

Models have been reviewed by licensed Professional Engineers to ensure they conform to the requirements of ASCE 7-05 Minimum Design Loads for Buildings and Other Structures and the International Building Code.

How Can Greenheck Provide a Seismic Solution?

While adhering to rigorous testing standards, Greenheck Fan Corporation is striving to provide a comprehensive selection of equipment to address the HVAC industry’s seismic needs. The offerings cover all soil site classes. For the simplifi cation of the submittal process, the consulting engineer simply needs to specify seismic compliant equipment.

Greenheck is leading the charge in the LEED and Green Building initiative. Greenheck became one of the fi rst manufacturers in the Air Movement and Control industry to join the LEED/green movement when they joined the United States

Green Building Council (USGBC) in 2005. Greenheck has been actively researching qualifi cation requirements

for our products to meet LEED credits

and prerequisites. The Vari-Green motor signifi cantly helps qualifi cation efforts for the Energy and Atmosphere credits and prerequisites;

specifi cally credit one, Optimize Energy Performance and prerequisite two, Minimum Energy Performance.

For more detailed information refer to the Vari-Green Motor brochure.

5

Applications:

High Wind and Hurricane

High Wind and Hurricane

Models G and GB

Greenheck is leading the High Wind Standard for roof top fans and ventilators. Forceful winds and wind-borne debris are the cause of most hurricane damage. Hurricane winds start at 75 mph. At speeds over 150 mph, wind can exert a force of 75 pounds per square foot of pressure or over 900 pounds on a fan and curb. Forceful winds are not the only problem, wind-borne debris can also cause detrimental effects to objects and structures. High winds and extreme forces are

the cause of most storm damage. By analyzing calculations, computer simulations, actual testing, and other standards—Greenheck developed the High Wind Standard.

Protocols designed to protect against wind-borne debris and severe wind loads:

Structural |

A static load that is 1.5 times the design load (91.5 pounds per square foot of pressure) |

|

is applied both positively and negatively to simulate wind force loads in each direction. |

||

Performance Load |

||

Structural Performance per Dade County Protocol TAS-202 (ASTM-E330). |

||

|

|

|

Miami-Dade |

Greenheck has gone the extra mile and worked with Miami-Dade County to design |

|

a High Velocity Hurricane Zone standard for rooftop fans. The model USGF has |

||

County Test |

||

become the first rooftop fan certified and approved by the Miami-Dade Building Code |

||

Protocols |

||

Compliance office and Texas Department of Insurance for use in hurricane zones. |

||

|

||

|

|

|

|

The certifications can be viewed on the Miami-Dade County Web site under the NOA |

|

Miami-Dade NOA |

numbers listed below. Models G and GB are the first downblast aluminum fans in the |

|

Numbers |

industry that have received a Miami-Dade NOA for high wind (150 mph) and hurricane |

|

|

zones. Miami-Dade NOA 08-0519.02 for models G and GB. |

|

|

|

|

Texas Department |

The certifications can be viewed on the Texas Department of Insurance Windstorm |

|

of Insurance |

Web site under TDI number RV-42. |

|

|

|

|

|

Structural calculations performed by a licensed Professional Engineer (P.E.) on models |

|

|

G and GB include Finite Element Analysis (FEA) and a stamped P.E. report of the fans |

|

State Licensed |

compliance to ASCE 7-02 Minimum Design Loads for Buildings and Other Structures |

|

P.E. Calculations |

Standard and the Florida Building Code. The ASCE 7-02 Standard meets the IBC, |

|

|

Florida and Miami-Dade codes. The models have been proven to withstand winds in |

|

|

excess of 150 mph (61 psf). |

Certified

Independent

Third-Party

Testing

Each of the Greenheck models have been subjected to extensive testing procedures. The G and GB have been certified by an independent third party to the ASTM E-330 Static Pressure Difference Standard, Florida Building Code Test Protocol

TAS-201 (large missile impact), 202 (static pressure difference) and 203 (cyclic pressure) Static Pressure Difference.

Computational Fluid Dynamics (CFD)

All Greenheck high wind models have been analyzed using Computational Fluid Dynamics (CFD). CFD is computer software designed to simulate the flow of high speed (150 mph) winds over the surface of objects. The software records the force profile exerted on the fan so it can be utilized in Finite Element Analysis (FEA).

Finite Element

Analysis (FEA)

Utilizing the results from CFD analysis Greenheck can accurately predict the stress, strain, and deflection resulting from high wind loads. Greenheck high wind units have been proven to withstand 150 mph winds through Finite Element Analysis utilizing CFD results.

6

Applications: Severe-Duty Roof Curbs for High Wind and Hurricane

High-wind and severe-duty roof curbs are provided as standard with models G and GB. The severe-duty roof curb models can ship separately to allow

for final finishing of the roof prior to the fan arrival and installation.

Model GPF — This roof curb is specifically designed for high wind applications up to 150 mph (61 psf), used on fan models G and GB. Standard height is 12 inches (305 mm), fully-welded straight sides with a 5-inch flashing flange. GPF is available up to 24 inches (460 mm) in height to meet greater height requirements.

Models SD and SDP — The severe-duty curbs are specifically designed for high wind applications up to 150 mph and used on models G and GB fans. Model SD is for use on flat roofs and model SDP for pitched roofs. They are attached directly to the building structure with extremely high structural design load requirements. Maximum design load is 130 psf. The severe-duty curbs are 12 gauge coated steel with a 13⁄4-inch lip on the top and a 4-inch flange on the bottom. Available heights include 12–24 inches. Heights greater than

18 inches are reinforced in the interior with

12 gauge x 2-inch angles.

Mounting details for the roof curb to the roof substrate and the fan to the curb are illustrated on the following pages and are included with each model G and GB installation manual.

7

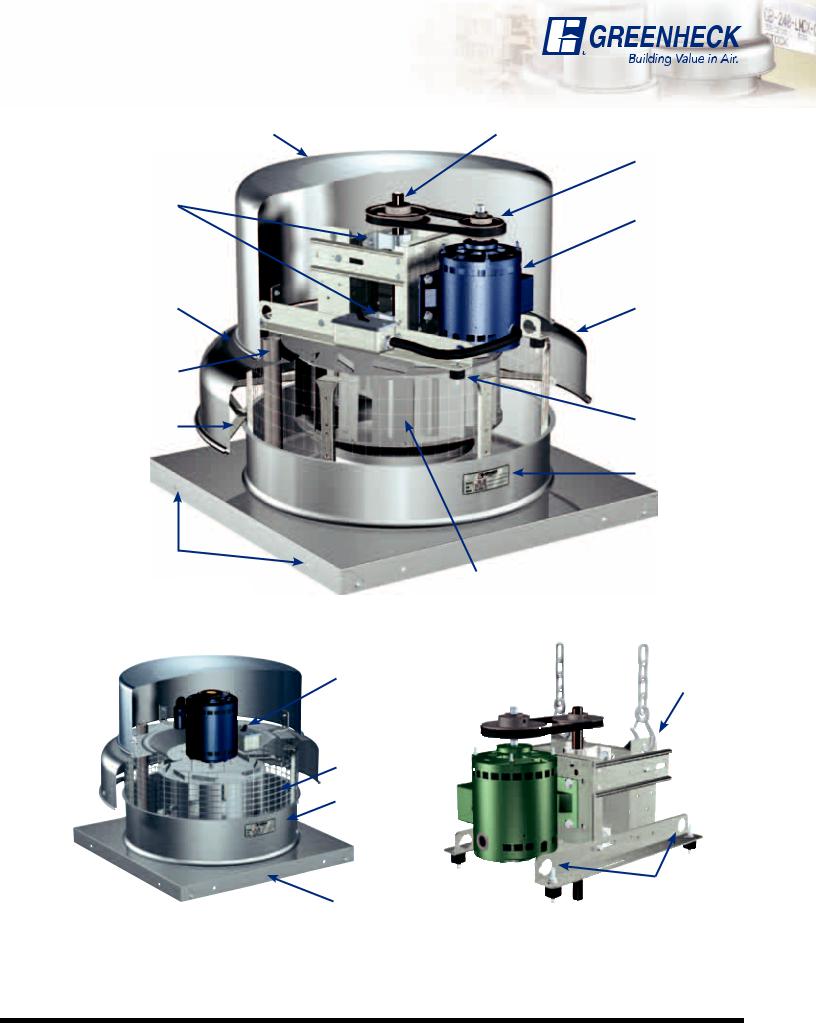

Standard Construction

Features

|

Standard Construction Features |

G and GB |

|

|

|

|

|

|

An aluminum, backward-inclined, non-overloading centrifugal wheel is utilized to generate |

|

|

Wheel |

high-efficiency and minimal sound. Wheel cones are carefully matched to the venturi |

|

|

for maximum efficiency. Each wheel is robotically welded and statically and dynamically |

|||

|

|

||

|

balanced for long life and quiet operation. |

|

|

|

|

|

|

Disconnect |

NEMA-1 switch is factory mounted and wiring is provided from the motor as standard |

|

|

(other switches are available). All wiring and electrical components comply with the |

|||

Switch |

|||

National Electric Code (NEC) and are either UL Listed or Recognized. |

|

||

|

|

||

|

|

|

|

|

Precisely sized, ground and polished so the first critical speed is at least 25% over |

|

|

Fan Shaft |

the maximum operating speed. Where the shaft makes contact with bearings, close |

||

|

tolerances result in longer bearing life. |

|

|

|

|

|

|

Bearings |

100% factory tested and designed specifically for air handling applications with a |

|

|

minimum L10 life in excess of 100,000 hours (L 50 life of 500,000 hours). |

|||

|

|

||

Motor |

Carefully matched to the fan load and is mounted out of the airstream. |

|

|

|

|

|

|

Motor Cover |

Constructed of aluminum, machine-punched, and attached with stainless steel hardware |

|

|

for easy removal and access to motor compartment and drive assembly. |

|||

|

|

||

|

|

|

|

|

Cooling fins located on top of the fan wheel draw outside air through a large space |

|

|

Motor Cooling |

between the fan shroud and the motor cover directly into the motor compartment. |

||

|

Positive motor cooling with fresh air results in maximum motor life. |

|

|

|

|

|

|

Lifting Points |

Various lifting points are located on the drive frame and bearing plate (on select sizes). |

|

|

|

|

|

|

True Vibration |

Vibration isolators, with no metal-to-metal contact, support the drive assembly and wheel |

|

|

Isolation |

for long life and quiet operation. |

||

|

|||

|

|

|

|

Drive Assembly |

Belts, pulleys, and keys are oversized 150% of driven horsepower. Machined cast pulleys |

|

|

|

are adjustable for final system balancing. Belts are static-free and oil-resistant. |

|

|

Lower Windband |

Heavy-gauge aluminum with formed edges for added strength and provides |

|

|

|

weather resistance. |

|

|

Curb Cap |

Curb cap (with integral deep spun venturi) is constructed of aluminum and is one-piece for a |

|

|

weather-tight fit. |

|||

|

|

||

|

|

|

|

Internal Conduit |

A large diameter conduit for installing electrical wiring through the curb cap into the |

|

|

Chase |

motor compartment. |

||

|

|||

|

|

|

|

Nameplate |

Permanent stamped aluminum plate for exact model and serial number identification. |

|

|

|

|

|

|

Galvanized |

Rigid wire protects the fan discharge from birds and small objects. |

|

|

Birdscreen |

|||

|

|

||

|

|

|

|

Fan Shroud |

One-piece, heavy-gauge aluminum with a rolled bead for extra strength directs exhaust |

|

|

air downward. |

|||

|

|

||

|

|

|

|

Mounting Holes |

Curb cap has prepunched mounting holes to ensure correct attachment to the roof. |

|

|

|

|

|

|

Internal Supports |

Heavy-gauge supports and bracing are added for additional strength to withstand |

* |

|

|

a wind of 150 mph (61 psf). |

|

|

|

High-wind load fans are certified with one of two Greenheck high-wind roof curbs. |

* |

|

Roof Curb |

Standard 12-inch (305 mm) in height GPF curb has a 5-inch (127 mm) flashing flange. Roof |

||

|

curbs ship separate for field installation with attachment details provided. |

|

|

|

|

|

* Applicable to fans with high wind option only.

8

Standard Construction Features

Models G and GB

Motor Cover |

Fan Shaft |

Bearings

Motor Cooling

Space

Conduit Chase

Shroud Brace

Mounting Holes

Wheel

Drive Assembly

Motor

Fan Shroud

True Vibration

Isolators

Nameplate

Bearing Plate

Disconnect Lifting Points

Switch

Birdscreen

Lower

Windband

|

Drive Frame |

Curb Cap |

Lifting Points |

9

Options and

Accessories

Roof Curbs Prefabricated roof curbs reduce installation time and costs by ensuring compatibility between the fan, the curb and roof opening. All curbs are insulated with fiberglass. A wide variety of roof

curbs are available, including: flanged, pitched and sound-absorbing. For more information on severeduty curbs refer to the information on page 7.

Hinged Curb Cap with Cables (Field Installed) Mounted to the curb cap, allows entire fan to tilt away from curb for access to wheel and ductwork. Includes restraint cables.

Hinged Base (Factory Mounted) Allows for easy maintenance. Hinge and restraining cables are factory mounted to a subbase attached directly to curb without additional height added.

Curb Seal

Rubber seal between fan and curb to assure proper sealing when attached to a curb.

Curb Extensions

Extensions raise the fan discharge above the roofline and provide an accessible mounting location for dampers. Insect screen

bases, constructed with a removable fine mesh, are recommended for applications where insect entry must be prevented.

Disconnect Switches

A wide selection of NEMA rated switches are available for positive electrical shutoff and safety, including: dust-tight, rainproof, and corrosion-resistant. Switches may be internally

or externally mounted.

Birdscreen

Galvanized mesh is standard,

optional aluminum or stainless steel rigid wire are also available.

Dampers

Designed to prevent outside air from entering back into the building when fan is off. Includes gravity and motorized dampers. Damper sizes are shown on each performance data page.

Tie-Down Points

Four brackets located on the shroud for securing the fan in high wind applications. Cables and anchors by others.

Speed Controllers Available for use with shaded pole and permanent split capacitor (PSC) open motors on model G fans. They provide an economical means of system balancing with direct drive fans.

UL/cUL 705

G and GB models are listed for electrical (UL/cUL 705) File no. E40001

*UL/cUL is optional and must be specified

10

Options and

Accessories

Coatings

A wide variety of coatings and colors are available. Greenheck coatings and resistance charts can be found in the Performance Coatings Commercial and Industrial Fans catalog and in our Product Application Guide—Performance Coatings for Ventilation Products.

PRIMER

PERMATECTORTM

HI-PRO

POLYESTER

Primer is applied at the factory to allow for final finish in the field.

Permatector™ is our standard coating. Typically used for applications that require corrosion resistance in indoor and outdoor environments.

Hi-Pro Polyester is resistant to salt water, chemical fumes and moisture in more corrosive atmospheres. Typically used for applications that require superior chemical resistance, excellent abrasion and outdoor UV protection. This coating exceeds protective qualities of Air Dried Heresite and Air Dry Phenolic.

Baked Enamel Decorative Coatings are heat cured enamels applied either as wet paints or electrostatic powders. Customers can choose from 16 standard decorative colors or color match any color.

The chart below shows which options and accessories are available on

Greenheck’s centrifugal roof exhaust fans.

Options and Accessories |

G |

GB |

|

|

|

Roof Curbs |

|

|

|

|

|

Hinged Curb Cap |

|

|

|

|

|

Hinged Base |

* |

* |

|

|

|

Curb Seal |

|

|

|

|

|

Curb Extensions |

|

|

|

|

|

Disconnect Switches |

|

|

|

|

|

Birdscreen |

|

|

|

|

|

Dampers |

|

|

|

|

|

Tie-Down Points |

|

|

|

|

|

Speed Controllers |

|

|

|

|

|

UL 705 |

|

|

|

|

|

Coatings |

|

|

|

|

|

* Not available on units with high wind resistant construction.

11

Typical

Installations

General Clean Air

Models G and GB exhaust fans are designed to meet the needs of general clean air applications. Tests were conducted to assure safe, rugged and reliable fans.

Due to the varying types of airstreams encountered in commercial ventilation, system designers must be aware of national, state, and local codes and guidelines governing these installations. Local code authorities should be consulted before proceeding with any ventilation project.

•When roofing materials extend to the top of the curb, roof curbs should be 11/2 inches (3/4 inch on each side) less than the unit curb cap to allow for roofing and flashing.

•For recommended duct size, damper size, and roof opening dimensions, refer to the performance data pages.

•Installation must include a means for inspecting, cleaning and servicing the exhaust fan.

Factory Wired from Motor to Disconnect

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/4 in. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 or 12 in. |

||||||||||

Wiring by |

(19 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(203 or 305 mm) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Others |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Damper |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

11/4 in. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Recommended |

|

|

|

|

|

11/4 in. |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Duct and |

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

(32 mm) |

|

|

|

|

|

|

|

Damper Size |

|

|

|

|

|

(32 mm) |

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Recommended |

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roof Opening |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

Models G & GB

High Wind and Hurricane Option

Models G and GB exhaust fans are designed to meet the needs of general clean air applications. Tests were conducted to assure safe, rugged and reliable fans.

Due to the varying airstreams encountered in commercial ventilation, system designers must be aware of national, state, and local codes and guidelines governing these installations. Local code authorities should be consulted before proceeding with any ventilation project.

•Roofing materials can extend to the top of the curb, roof curbs should be 1-inch (25 mm) total, or 1/2 inch (13 mm) on each side, less than the unit curb cap to allow for roofing and flashing.

•For recommended duct size, damper size and roof opening dimensions, refer to the performance data pages.

•Installation must include a means for inspecting, cleaning and servicing the exhaust fan.

•See pages 14 and 15 for specific mounting instructions

Factory Wired from Motor to Disconnect

|

|

1/4 in. (6 mm) |

|

|

|

Fastener |

|

|

4 in. (102 mm) |

8 - 24 in. |

|

1/2 in. (13 mm) |

(203 - 610 mm) |

||

From Curb Edge |

|||

Wiring by |

H-GPF or SD Curb |

||

|

|||

|

|

||

Others |

|

|

|

|

Damper |

|

|

|

Recommended |

|

|

11/4 in. (32 mm) |

Duct and |

11/4 in. (32 mm) |

|

|

Damper Size |

|

|

|

Recommended |

|

|

|

Roof Opening |

|

Models G & GB

Note: The typical installations shown above are recommendations based on national codes. Local authority may supersede these recommendations.

12

Typical

Installations

Fan Inlet Connections

In order to assure proper fan performance, caution must be exercised in fan placement and connection to the ventilation system. Obstructions, transitions, poorly designed elbows, improperly selected dampers, etc., can cause reduced performance, excessive noise, and increased mechanical stress. For performance to be as published, the system must provide uniform and stable airflow into the fan.

Good

Poor |

Poor |

Good |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dampers must open |

Avoid sharp turns or |

Provide uniform |

|

Provide uniform airflow |

|||||||||||||||||||||||||||||||

fully. Use motorized |

entrance conditions |

airflow at fan inlet |

|

at fan inlet and through |

|||||||||||||||||||||||||||||||

dampers in low |

which cause uneven |

to assure optimum |

|

the damper to assure |

|||||||||||||||||||||||||||||||

airflow applications |

flow. Use turning vanes |

performance. |

|

optimum performance. |

|||||||||||||||||||||||||||||||

to reduce losses. |

in elbows to reduce |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

adverse effects. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Wheel Rotation

Direction of rotation is very critical. Rotation in the wrong direction will result in excessive horsepower, possible motor burnout, and increased noise levels. Check rotation by energizing the unit only momentarily. The rotation should be the same as the rotation decals affixed to the unit and is clockwise when viewed from the top of the unit.

Clockwise

13

Severe-Duty Curbs Anchoring: |

|

|

Hurricane and Seismic Fans |

|

|

Concrete Deck Anchoring |

|

|

|

Outside of Roof Curb |

|

|

1 inch (25 mm) less |

|

|

than Fan Curb Cap |

Use 3/8 inch (10 mm) expansion anchor or |

|

|

equal into concrete. |

8 to 24 inches (203 to 610 mm) |

|

Fasteners one on each corner as detailed. |

1-inch (25 mm) insulation |

Each side at center of unit as required. |

|

GPF, SD, or SDP curb or |

|

|

|

|

|

equivalent by others. |

|

|

|

Roof opening |

21⁄2 inches (64 mm) |

Minimum concrete |

|

|

|

Minimum embedment |

|

strength of 2000 PSI |

|

|

|

|

|

Minimum 5 inches |

|

|

(127 mm) edge distance |

5 inches (127 mm) |

Center fasteners |

|

||

|

Mounting flange |

on flange |

|

Outside flange |

|

11/4 inch

(32 mm)

Metal Building/Steel Deck Anchoring

Outside of Roof Curb  1 inch (25 mm) less

1 inch (25 mm) less

than Fan Curb Cap

8 to 24 inches (203 to 610 mm)

Use 1/4-14 self-drilling screws or equal.

Fasteners one on each corner as detailed.

Each side at center of unit as required.

GPF, SD, or SDP curb or  1-inch (25 mm) insulation equivalent by others.

1-inch (25 mm) insulation equivalent by others.

Roof opening

Corrugated roof deck

Corrugated roof deck

|

Minimum 12 gauge steel |

|

Roof Truss |

5 inches (127 mm) |

|

|

|

|

|

Mounting flange |

Center fasteners |

|

Outside flange |

on flange |

|

|

11/4 inch

(32 mm)

Corner Detail for all Severe Duty Deck Anchoring

Wood Deck Anchoring

|

|

|

|

|

|

|

Outside of Roof Curb |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

1 inch (25 mm) less than |

|

|

|

|

|||

|

|

|

|

|

|

|

|

Fan Curb Cap |

|

|

|

|

||

|

|

|

|

|

|

|

1-inch (25 mm) insulation |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||||

8 to 24 inches (203 to 610 mm) |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

GPF, SD, or SDP curb or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

equivalent by others. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roof opening |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wood decking

5 inches (127 mm)

5 inches (127 mm)

Wood support member Mounting flange nominal 4 x 4, 6, 8

Outside flange

14

Use 3/8 inch lag screws or equal into minimum No. 1/No. 2 southern pine wood support.

Fasteners one on each corner as detailed. Each side at center of unit as required.

3 inches (76 mm) Minimum embedment

Center fasteners on flange

Severe-Duty Curbs Anchoring:

Hurricane and Seismic Fans

Required Severe Duty Curb to Roof Anchoring

Seismic |

Hurricane |

|

Square Dimensions |

|

Concrete |

Metal/ |

Wood |

|||||

|

|

|

|

|

|

|

|

|

|

Steel |

|

|

G |

GB |

G |

GB |

|

Fan |

Roof |

Outside |

Fasteners Per Side |

||||

Size |

Size |

Size |

Size |

Curb Cap |

Opening |

Flange |

||||||

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

060 - 075 |

|

060 - 075 |

|

17 |

(432) |

101/2 (267) |

26 |

(660) |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

080 - 095 |

|

080 - 095 |

|

17(432) |

121/2 (318) |

26 |

(660) |

|

2 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

101 - 121 |

071 - 131 |

101 - 121 |

071 - 131 |

19 |

(483) |

141/2 (368) |

28 |

(711) |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

131 - 141 |

141 - 161 |

131 - 141 |

141 - 161 |

22 |

(559) |

181/2 (470) |

31 |

(787) |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150 |

|

150 |

|

26 |

(660) |

181/2 (470) |

35 |

(889) |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

160 - 180 |

180 - 200 |

160 - 180 |

180 - 200 |

30 |

(762) |

201/2 (521) |

39 |

(991) |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

220 - 240 |

|

220 - 240 |

34 |

(864) |

261/2 (673) |

43 |

(1092) |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

260 - 540 |

|

260 - 300 |

40 |

(1016) |

321/2 (826) |

49 |

(1245) |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All dimensions in inches (millimeters). *The outside flange dimension above is for the GPF curbs. Subtract 2 inches (51 mm) if the SD or SDP Curb is being used.

Required Severe Duty Fan to Curb Mounting

Models G & GB

5/16 inch (8 mm) recommended 1/4-inch fastener minimum. Fastener quantities listed below.

Seismic |

Hurricane |

|

Fasteners |

|||

|

|

|

|

|

|

|

G |

GB |

G |

GB |

Fasteners |

Total |

|

Size |

Size |

Size |

Size |

Per Side |

Fasteners |

|

|

|

|

|

|

|

|

060 - 141 |

071 - 161 |

060 - 141 |

071 |

- 161 |

3 |

12 |

|

|

|

|

|

|

|

150 - 180 |

180 - 540 |

150-180 |

180 |

- 300 |

5 |

20 |

|

|

|

|

|

|

|

Fasteners on each side of the fan are to be installed with one fastener 4 inches (102 mm) from each edge and one fastener centered. The remaining fasteners are to be equally spaced.

15

Model Number Code

The model number code system is designed to completely identify the fan. The correct code letters must be specified to designate belt or direct drive. The remainder of the model code is determined by the size and performance.

GB - 240 HP - 5 or A

Configuration |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G - Direct Drive |

Fan Size |

|

|

|

|

|

|

|

|

||

GB - Belt Drive |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

060 through 540 |

|

|

|

||||||||

|

|

|

|

||||||||

|

Wheel Pressure Level |

|

|

|

|

||||||

|

|

|

|

|

|||||||

|

HP - High Pressure |

|

|

|

|||||||

Performance & Dimension

Page Number by Model Size

Size |

Direct Drive |

Size |

Belt Drive |

|

|

|

|||

G |

GB |

|||

|

|

|||

060 |

p. 17 |

071 |

p. 27 |

|

065 |

081 |

p. 28 |

||

|

||||

070 |

p. 18 |

091 |

p. 29 |

|

|

|

|

||

075 |

101 |

p. 30 |

||

|

||||

|

|

|

|

|

080 |

p. 19 |

101HP |

p. 31 |

|

085 |

121 |

p. 32 |

||

|

||||

090 |

p. 20 |

131 |

p. 33 |

|

|

|

|

||

095 |

141 |

p. 34 |

||

|

||||

|

|

|

|

|

101 |

p. 21 |

141HP |

p. 35 |

|

121 |

161 |

p. 36 |

||

|

||||

131 |

p. 22 |

161HP |

p. 37 |

|

|

|

|

||

141 |

180 |

p. 38 |

||

|

||||

|

|

|

|

|

150 |

p. 23 |

180HP |

p. 39 |

|

160 |

p. 24 |

200 |

p. 40 |

|

170 |

p. 25 |

200HP |

p. 41 |

|

|

|

|

|

|

180 |

p. 26 |

220 |

p. 42 |

|

|

|

|

|

|

|

|

220HP |

p. 43 |

|

|

|

240 |

p. 44 |

|

|

|

|

|

|

|

|

240HP |

p. 45 |

|

|

|

|

|

|

|

|

260 |

p. 46 |

|

|

|

|

|

|

|

|

300 |

p. 47 |

|

|

|

300HP |

p. 48 |

|

|

|

|

|

|

|

|

330 |

p. 49 |

|

|

|

|

|

|

|

|

360 |

p. 50 |

|

|

|

360HP |

p. 51 |

|

|

|

420 |

p. 52 |

|

|

|

|

|

|

|

|

480 |

p. 53 |

|

|

|

|

|

|

|

|

500 |

p. 54 |

|

|

|

540 |

p. 55 |

16

Motor HP (Belt Drive only)

6 = 1/6 |

10 |

= 1 |

50 |

= 5 |

4 = 1/4 |

15 |

= 11/2 |

75 |

= 71/2 |

3 = 1/3 |

20 |

= 2 |

100 = 10 |

|

5 = 1/2 |

30 |

= 3 |

150 = 15 |

|

7 = 3/4 |

|

|

|

|

Motor RPM (Direct Drive only)

A = 1725 |

D = 1550 |

B = 1140 |

E = 1050 |

C = 860 |

G = 1300 |

Roof Downblast - Direct Drive

G-060 and G-065

193⁄8

193⁄8

(492)

*121⁄8

(308)

13⁄4 (44)

17

(432)

Damper Size = 18 x 18 (457 x 457) Roof Opening = 201/2 x 201/2 (521 x 521) Shroud Thickness = 0.064 (1.6) Motor Cover Thickness = 0.040 (1.0) Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor. ^Weight shown is largest cataloged Open Drip-Proof motor.

cfm |

Model |

Motor |

Fan |

|

|

|

|

Static Pressure in Inches wg |

|

|

|

|||

Number |

HP |

RPM |

|

0 |

0.05 |

0.1 |

0.125 |

0.15 |

0.2 |

0.25 |

0.3 |

0.375 |

0.4 |

|

|

|

CFM |

138 |

116 |

90 |

73 |

53 |

|

|

|

|

|

060-E |

1/200 |

1050 |

BHP |

0.00 |

0.00 |

0.01 |

0.01 |

0.01 |

|

|

|

|

|

|

|

|

Sones |

1.7 |

1.7 |

1.7 |

1.7 |

1.7 |

|

|

|

|

|

|

|

|

CFM |

170 |

153 |

135 |

125 |

113 |

85 |

|

|

|

|

060-G |

1/100 |

1300 |

BHP |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

|

|

|

|

|

|

|

Sones |

2.9 |

2.8 |

2.8 |

2.7 |

2.7 |

2.6 |

|

|

|

|

|

|

|

CFM |

203 |

188 |

173 |

166 |

158 |

140 |

120 |

92 |

|

|

060-D |

1/60 |

1550 |

BHP |

0.01 |

0.01 |

0.01 |

0.01 |

0.02 |

0.02 |

0.02 |

0.2 |

|

|

|

|

|

Sones |

4.2 |

3.9 |

3.8 |

3.8 |

3.8 |

3.7 |

3.7 |

3.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CFM |

187 |

161 |

130 |

110 |

87 |

|

|

|

|

|

065-E |

1/100 |

1050 |

BHP |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

|

|

|

|

|

|

|

|

Sones |

2.2 |

2.1 |

1.9 |

1.8 |

1.7 |

|

|

|

|

|

|

|

|

CFM |

231 |

211 |

189 |

178 |

163 |

130 |

92 |

|

|

|

065-G |

1/60 |

1300 |

BHP |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

|

|

|

|

|

|

Sones |

3.2 |

3.1 |

3.0 |

2.9 |

2.9 |

2.8 |

2.7 |

|

|

|

|

|

|

CFM |

276 |

259 |

241 |

232 |

223 |

201 |

176 |

145 |

96 |

|

065-D |

1/30 |

1550 |

BHP |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

|

|

|

|

Sones |

4.9 |

4.6 |

4.5 |

4.5 |

4.4 |

4.3 |

4.3 |

4.1 |

4.0 |

|

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for installation type A: free inlet hemispherical sone levels.

17

Roof Downblast - Direct Drive

G-070 and G-075

193⁄8

(492)

*121⁄8

(308)

13⁄4 (44)

17

(432)

Damper Size = 18 x 18 (457 x 457) Roof Opening = 201/2 x 201/2 (521 x 521) Shroud Thickness = 0.064 (1.6) Motor Cover Thickness = 0.040 (1.0) Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 142 lb. (64 kg)

All dimensions in inches (millimeters). *May be greater depending on motor. ^Weight shown is largest cataloged Open Drip-Proof motor.

cfm |

Model |

Motor |

Fan |

|

|

|

|

Static Pressure in Inches wg |

|

|

|

|||

Number |

HP |

RPM |

|

0 |

0.05 |

0.1 |

0.125 |

0.15 |

0.2 |

0.25 |

0.3 |

0.375 |

0.4 |

|

|

|

CFM |

253 |

226 |

195 |

179 |

152 |

|

|

|

|

|

070-E |

1/100 |

1050 |

BHP |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

|

|

|

|

|

|

|

|

Sones |

2.7 |

2.1 |

1.7 |

1.5 |

1.2 |

|

|

|

|

|

|

|

|

CFM |

314 |

292 |

269 |

2557 |

244 |

214 |

171 |

|

|

|

070-G |

1/60 |

1300 |

BHP |

0.01 |

0.1 |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

|

|

|

|

|

|

Sones |

4.1 |

3.7 |

3.4 |

3.3 |

3.2 |

2.9 |

2.6 |

|

|

|

|

|

|

CFM |

374 |

356 |

337 |

327 |

317 |

297 |

274 |

244 |

190 |

|

070-D |

1/30 |

1550 |

BHP |

0.02 |

0.02 |

0.02 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

|

|

|

|

Sones |

5.6 |

5.4 |

5.2 |

5.2 |

5.1 |

4.9 |

4.7 |

4.5 |

4.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CFM |

297 |

260 |

222 |

200 |

176 |

|

|

|

|

|

075-E |

1/80 |

1050 |

BHP |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

|

|

|

|

|

|

|

|

Sones |

3.6 |

3.1 |

2.9 |

2.8 |

2.6 |

|

|

|

|

|

|

|

|

CFM |

367 |

338 |

309 |

293 |

277 |

241 |

195 |

|

|

|

075-G |

1/50 |

1300 |

BHP |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

0.02 |

|

|

|

|

|

|

Sones |

4.1 |

3.9 |

3.7 |

3.7 |

3.7 |

3.6 |

3.5 |

|

|

|

|

|

|

CFM |

438 |

413 |

389 |

377 |

364 |

337 |

309 |

277 |

214 |

|

075-D |

1/25 |

1550 |

BHP |

0.03 |

0.03 |

0.3 |

0.04 |

0.04 |

0.04 |

0.04 |

0.04 |

0.03 |

|

|

|

|

Sones |

6.1 |

5.8 |

5.6 |

5.4 |

5.3 |

5.1 |

4.9 |

4.9 |

4.8 |

|

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects of a birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for installation type A: free inlet hemispherical sone levels.

18

Loading...

Loading...