Greenheck CUE, CUBE User Manual

Document 471560

Upblast Centrifugal Roof Exhaust Fans

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage!

Model CUE

Direct Drive

Model CUE is a direct drive upblast centrifugal exhaust fan. These fans are specifically designed for roof mounted application. Performance

capabilities |

range |

up to |

6,400 |

cfm (10,874 |

m3/hr) |

and |

up to |

3 in. wg (747 |

Pa) of static pressure. |

||

The maximum continuous operating

temperature for fan sizes 098-200 is 400°F (204°C) and for fan sizes 060095 is 160°F (71°C). CUE fans are

available in fourteen sizes with nominal wheel diameter ranging from 9 to 20 inches (229 to 508 mm) (060 - 200

unit sizes). Each fan shall bear a permanently affixed manufacturers engraved metal nameplate containing the model number and individual serial number.

General Safety Information

Model CUBE

Belt Drive

Model CUBE is a belt drive upblast centrifugal exhaust fan. These fans are specifically designed

for roof mounted applications.

Performance capabilities range up to 30,000 cfm (50,970 m3/hr) and up to 5.0 in. wg (1240 Pa) of static

pressure. The maximum continuous

operating temperature is 400°F (204°C). CUBE fans are available in

fourteen sizes with nominal wheel diameter ranging from 9 to 48 inches (229 to 1219 mm) (098 - 480 unit sizes). Each fan shall bear a permanently affixed manufacturers engraved metal nameplate containing the model number and individual serial number.

Only qualified personnel should install this fan. Personnel should have a clear understanding of these instructions and should be aware of general safety precautions. Improper installation can result in electric shock, possible injury due to coming in contact with moving parts, as well as other potential hazards. Other considerations may be required if high winds or seismic activity are present. If more information is

needed, contact a licensed professional engineer before moving forward.

DANGER

Always disconnect, lock and tag power source before installing or servicing. Failure to disconnect power source can result in fire, shock or serious injury.

CAUTION

When servicing the fan, motor may be hot enough to cause pain or injury. Allow motor to cool before servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

1.Follow all local electrical and safety codes, as well as the National Electrical Code (NEC) and the National Fire Protection Agency (NFPA), where applicable. Follow the Canadian Electrical Code (CEC) in Canada.

2.The rotation of the wheel is critical. It must be free to rotate without striking or rubbing any stationary objects.

3.Motor must be securely and adequately grounded.

4.Do not spin fan wheel faster than max cataloged fan RPM. Adjustments to fan speed significantly affects motor load. If the fan RPM is changed, the motor current should be checked to make sure it is not exceeding the motor nameplate amps.

5.Do not allow the power cable to kink or come in contact with oil, grease, hot surfaces or chemicals. Replace cord immediately if damaged.

6.Verify that the power source is compatible with the equipment.

7.Never open access doors to a duct while the fan is running.

Upblast Centrifugal Roof Exhaust Fans 1

®

Receiving

Upon receiving the product, check the bill of lading to ensure all items were received. Inspect each crate for shipping damage before accepting delivery. All

damage should be noted on all the copies of the bill of lading and a claim should be filed with the carrier. Any physical damage to the unit after acceptance is not the responsibility of Manufacturer.

Unpacking

Verify that all required parts and the correct quantity of each item have been received. If any items are

missing, report shortages to your local representative to arrange for obtaining missing parts. Sometimes it is not possible that all items for the unit be shipped together due to availability of transportation and truck space. Confirmation of shipment(s) must be limited to only items on the bill of lading.

Handling

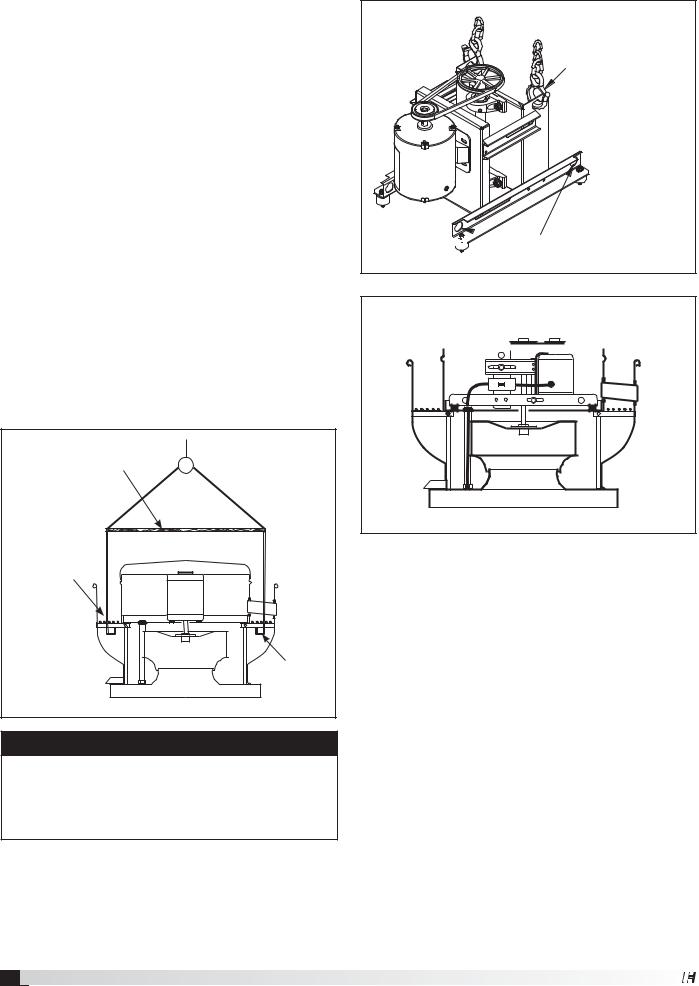

CUE Direct Drive

Lift unit on to the roof utilizing hooks under the horizontal supports. Evenly space the hooks using a minimum of four lifting straps. Use a spreader bar to ensure the straps do not come in contact with the unit (see figure 1).

Fig. 1

Spreader Bar

Lifting

Strap

Hook

CAUTION

Do not lift by the fan hood. Avoid lifting fans in a way that will bend or distort fan parts. Never pass slings or timbers through the venturi of fan. Fans with special coatings or paints must be protected in handling to prevent damage.

Fig. 2

Hook With

Safety Latch (Supplied by others)

(2) Bearing Plate

(2) Bearing Plate

Lifting Points

(4) Drive Frame

(4) Drive Frame

Lifting Points

Fig. 3

Screw

Screw

Screw

CUBE Belt Drive

When lifting the unit onto the roof, use either the four lifting points on the drive frame or the two lifting points on the bearing plate if present (see figure 2 for lifting points). Access to the drive frame is accomplished by removing the screws pointed out in figure 3. The cover can then be removed and placed on a flat surface in an area protected from strong winds.

When CUE/CUBE unit is on the roof, move fan to desired location using lifting points and fasten securely through mounting holes in base. Shims may be necessary depending upon roofing material thickness.

The motor amperage and voltage ratings must be checked for compatibility to supply voltage prior to final electrical connection. For CUE/CUBE installations, the electrical supply should be routed through the conduit chase located between the curb cap and the bottom of the motor compartment or through the motor cooling tube. Wiring must conform to local and national codes.

2 Upblast Centrifugal Roof Exhaust Fans

®

Storage

Fans are protected against damage during shipment. If the unit cannot be installed and operated immediately, precautions need to be taken to prevent deterioration of the unit during storage. The user assumes responsibility of the fan and accessories while in storage. The manufacturer will not be responsible for damage during storage. These suggestions are provided solely as a convenience to the user.

Indoor

The ideal environment for the storage of fans and accessories is indoors, above grade, in a low humidity atmosphere which is sealed to prevent the entry of blowing dust, rain or snow. Temperatures should be evenly maintained between 30° to 110°F (-1° to 43°C) (wide temperature swings may cause condensation and “sweating” of metal parts). All accessories must be stored indoors in a clean, dry atmosphere. Remove any accumulations of dirt, water, ice or snow and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts allow cold parts to reach room temperature. To dry parts and packages, use a portable electric heater to get rid of any moisture buildup. Leave coverings loose to permit air circulation and to allow for periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off the floor on wooden blocks covered with moisture proof paper or polyethylene sheathing. Aisles between parts and along all walls should be provided to permit air circulation and space for inspection.

Outdoor

Fans designed for outdoor applications may be stored outdoors, if absolutely necessary. Roads or aisles for portable cranes and hauling equipment are needed.

The fan should be placed on a level surface to prevent water from leaking into the fan. The fan should be elevated on an adequate number of wooden blocks so that it is above water and snow levels and has enough blocking to prevent it from settling into soft ground. Locate parts far enough apart to permit air circulation, sunlight and space for periodic inspection. To minimize water accumulation, place all fan parts on blocking supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these cause condensation of moisture from the air passing through heating and cooling cycles.

Fan wheels should be blocked to prevent spinning caused by strong winds.

Inspection and Maintenance

During Storage

While in storage, inspect fans once per month. Keep a record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts, the source should be located and eliminated. At each inspection, rotate the wheel by hand ten to fifteen revolutions to distribute lubricant on motor. If paint deterioration begins, consideration should be given to touch-up or repainting. Fans with special coatings may require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be restored to good condition promptly if signs of rust occur. Immediately remove the original rust preventive coating with petroleum solvent and clean with lint-free cloths. Polish any remaining rust from surface with crocus cloth or fine emery paper and oil. Do not destroy the continuity of the surfaces. Thoroughly wipe clean with Tectyl® 506 (Ashland Inc.) or the equivalent. For hard to reach internal surfaces or for occasional use, consider using Tectyl® 511M Rust Preventive, WD-40® or the equivalent.

Removing From Storage

As fans are removed from storage to be installed in their final location, they should be protected and maintained in a similar fashion until the fan equipment goes into operation.

WARNING

Installation, troubleshooting and parts replacement is to be performed only by qualified personnel. Consult and follow all applicable national, state and local codes. They will supercede this document.

WARNING

Disconnect power before installing or servicing.

Upblast Centrifugal Roof Exhaust Fans 3

®

Installation

Typical Roof Mounting Installation

1.On the roof surface, cut an appropriate sized hole and follow manufacturer’s instructions on curb

installation. Caulk and flash the curb to ensure a ter

tight seal.

Roof Curb

Installation

2.If unit is equipped with a backdraft damper, it should be installed now.

3.Remove motor cover. Access to the motor compartment is accomplished by removing the screws as shown in figure 3.

4.For CUBE Belt Drive fans only. On the drive frame use the lifting lugs to lift and place the unit on top of roof curb. (Refer to figure 2 on page 2).

5.Secure fan to curb using a minimum of eight lag screws, metal screws or other suitable fasteners. Shims may be required depending upon curb installation and roofing material.

6.Verify power line wiring is de-energized before connecting fan motor to power source.

7.Connect power supply wiring to the motor as indicated on the motor nameplate or terminal box cover. Check the power source for compatibility with the requirements of your equipment.

8.Check fan wheel for free rotation, re-center if necessary.

9.Check all fasteners for tightness.

10.Mount and wire safety disconnect switch under motor cover. Wire control switches at ground level, refer to figure 4.

Typical Wiring Diagram

MOTOR |

MOTOR |

|

SUPPLY VOLTAGE |

SUPPLY VOLTAGE |

|

115/208-230/60/1 |

||

208-230/460/60/3 |

||

J-BOX |

J-BOX |

|

L1 |

L1 |

|

L2 |

L2 |

|

L3 |

||

Fig. 4 |

||

|

11.Replace motor cover.

12.For restaurant and UL Listed for smoke evacuation applications, the electrical supply must enter the motor compartment through the breather tube. For other non-flammable applications the electrical supply can be routed through the conduit chase between the curb cap and the bottom of the motor compartment.

IMPORTANT

|

|

ELECTRICAL - If fan motor is NOT thermally protected, |

|

|

remote overload protection must be installed having |

|

|

adequate rating as to voltage, frequency, horsepower, and |

|

|

full load current per phase. Where connected to a circuit |

|

|

protected by fuses, use time delay fuses. For supply |

|

|

connection use wires rated for at least 194˚F (90˚C). |

|

|

|

Power |

INSTALLATION - When connecting electrical power to this |

|

Ventilator |

fan, do not restrict motor movement for possible future belt |

|

565L |

or wheel adjustment. |

|

|

|

CAUTION - Mount with the lowest moving part at least |

|

|

8 ft (2.5m) above floor or grade level. Not required on roof |

|

|

mounted ventilators or duct mounted ventilators provided |

|

|

with belt guards. |

|

|

|

CUE - Direct Drive

Model |

|

Curb |

Damper |

Roof |

*Approx. |

||

|

Cap |

Opening |

Weight |

||||

|

|

|

|

|

|

|

|

CUE 060, 065, 070, 075 |

17 |

(432) |

8 (203) |

101⁄2 |

26 (12) |

||

(267) |

|||||||

|

|

|

|

|

|

||

CUE 080, 085, 090 |

|

19 |

(483) |

10 (254) |

121⁄2 |

33 (15) |

|

|

(318) |

||||||

|

|

|

|

|

|

||

CUE 095 |

|

19 |

(483) |

10 (254) |

121⁄2 |

36 (16) |

|

|

(318) |

||||||

|

|

|

|

|

|

||

CUE 098, 099, 101, 121, 131 |

19 |

(483) |

12 (305) |

141⁄2 |

67 (30) |

||

(368) |

|||||||

|

|

|

|

|

|

||

CUE 141, 161 |

|

22 |

(559) |

16 (406) |

181⁄2 |

85 (39) |

|

|

(470) |

||||||

|

|

|

|

|

|

||

CUE 180-200 |

|

30 |

(762) |

18 (457) |

201⁄2 |

142 (64) |

|

|

(521) |

||||||

|

|

|

|

|

|

||

CUBE - Belt Drive |

|

|

|

|

|

||

Model |

Curb |

Shaft |

Damper |

Roof |

*Approx. |

||

Cap |

Bearings |

Opening |

Weight |

||||

|

|

|

|

|

|

|

|

CUBE 098, 099, 101, |

19 |

1⁄2 (19) |

12 (305) |

1 |

66 (30) |

||

101HP, 121, 131 |

14 ⁄2 |

||||||

(483) |

|

|

|

(368) |

|

||

CUBE 141, 141HP, |

22 |

1⁄2 (19) |

16 (406) |

1 |

87 (39) |

||

161, 161HP, 161XP |

18 ⁄2 |

||||||

(559) |

|

|

|

(470) |

|

||

CUBE 180 |

30 |

3⁄4 (19) |

18 (457) |

201⁄2 |

126 (57) |

||

|

(762) |

|

|

|

(521) |

|

|

CUBE 180HP |

30 |

1 |

(25) |

18 (457) |

201⁄2 |

126 (57) |

|

(762) |

(521) |

||||||

|

|

|

|

|

|||

CUBE 200 |

30 |

3⁄4 (19) |

18 (457) |

201⁄2 |

142 (64) |

||

|

(762) |

|

|

|

(521) |

|

|

CUBE 200HP |

30 |

1 |

(25) |

18 (457) |

201⁄2 |

142 (64) |

|

(762) |

(521) |

||||||

|

|

|

|

|

|||

CUBE 220, 220HP |

34 |

1 |

(25) |

24 (610) |

261⁄2 |

174 (79) |

|

(864) |

(673) |

||||||

|

|

|

|

|

|||

CUBE 240, 240HP, |

34 |

1 |

(25) |

24 (610) |

261⁄2 |

175 (79) |

|

240XP |

(864) |

(673) |

|||||

|

|

|

|

||||

CUBE 300, 300HP, |

40 |

1 |

(25) |

30 (762) |

321⁄2 |

313 |

|

300XP |

(1016) |

(826) |

(142) |

||||

|

|

|

|||||

CUBE 360, 360HP, |

46 |

1 |

|

|

381⁄2 |

440 |

|

360XP |

(1168) |

1 ⁄4 (32) |

36 (914) |

(978) |

(200) |

||

|

52 |

1 |

|

42 |

441⁄2 |

578 |

|

CUBE 420 |

(1321) |

1 ⁄4 (32) |

(1067) |

(1130) |

(262) |

||

|

|

|

|

|

|

|

|

|

58 |

1 |

|

48 |

501⁄2 |

675 |

|

CUBE 480 |

(1473) |

1 ⁄2 (38) |

(1219) |

(1283) |

(306) |

||

•All dimensions are in inches (millimeters). *Approximate weight shown in lbs. (kg.) is the largest cataloged Open Drip Proof motor.

•The roof curb should be 1½ in. (38 mm) less than the curb cap to allow for roofing and flashing.

4 Upblast Centrifugal Roof Exhaust Fans

®

Loading...

Loading...