Greenheck ERCH-45H Manual

Energy Recovery with Cooling & Heating

Model ERCH

• Commercial • Institutional

•10,000 cfm

•1.5 in. wg external static pressure

February

2005

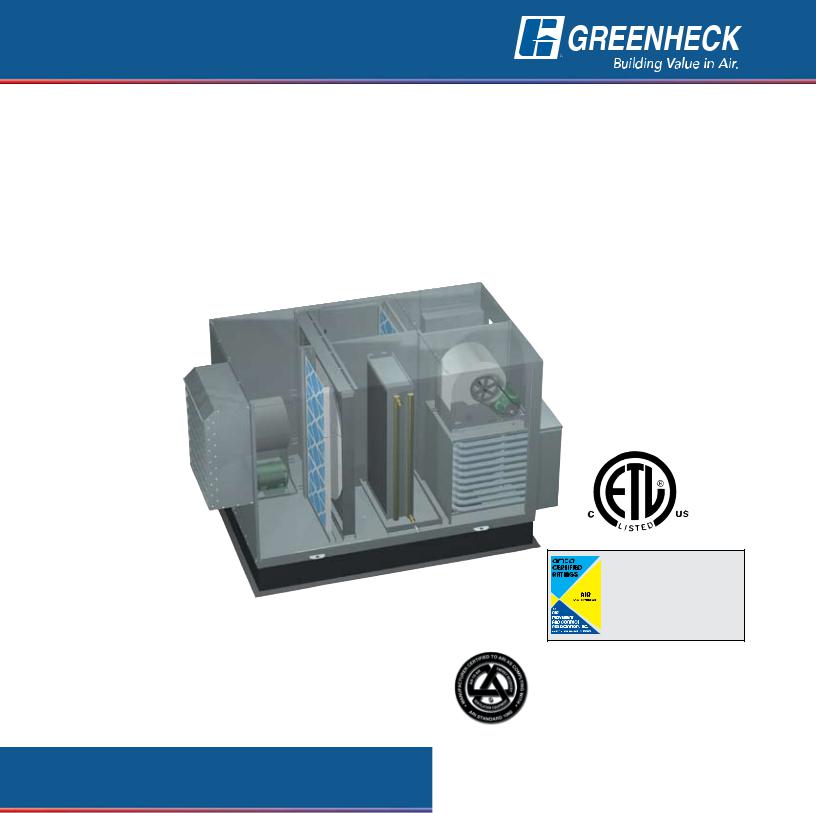

Product Features

Model ERCH

Energy Recovery Ventilator With Cooling & Heating

The model ERCH combines the benefits of the total energy wheel with supplemental heating and cooling. The result is a product that is specifically designed to process 100% outdoor air to desired

supply conditions. Four housing sizes provide air flow capacities from 1,000 cfm to 10,000 cfm with external static pressures up to 1.5 in. wg (for requirements above this performance, refer to Model ERT or APEX).

Standard Construction

Single Point Wiring is standard. A disconnect switch and low voltage terminal strip are provided.

Hinged Access Doors provide easy access to blowers, energy wheel, filters, and coil section for inspection and routine service.

Product operation is simple:

•Fresh outdoor air is pre-conditioned by the total enthalpy wheel, recovering a majority of the energy from the exhaust air.

•The coil section further conditions the outdoor air to desired conditions (typically near room conditions).

The Coil Section provides supplemental cooling or heating of the outdoor air after pre-conditioning by the

energy wheel. Tempering options include chilled water, direct expansion, hot water, electric heat, and indirect gas.

Forward Curved Blowers are mounted on neoprene vibration isolators.

Double Wall Housing is constructed of heavy gauge steel with 1-inch insulation. The supply and exhaust side are internally lined with galvanized steel.

Model ERCH shown with optional chilled water coil and indirect gas heater.

A Control Box is furnished with motor starters for the supply blower, exhaust blower and wheel motors. Also included is a 24 volt control circuit.

Greenheck Fan Corporation certifies that the ERCH models shown herein are licensed to bear the AMCA seal. The ratings shown are based on tests and procedures performed

in accordance with AMCA publication 211 and comply with the requirements of the AMCA Certified Ratings Program.

Energy recovery wheels certified by the ARI Air- to-Air Energy Recovery Ventilation Equipment Certification Program in accordance with ARI Standard 1060. Actual performance in packaged equipment may vary. Certified Ratings are available in the Certified Product Directory at http://www.airdirectory.org/ari/erv.php

Benefits

Healthy Buildings: Ventilate buildings adequately without losing control of indoor humidity levels. The ERCH is capable of conditioning summer air to room design conditions. Also, it helps prevent overly dry winter air that can contribute to respiratory irritation.

System Design Simplicity: The ERCH is designed specifically to provide outdoor air to the space at desired conditions. This effectively de-couples the outdoor air load from the building load, enabling the traditional VAV system to perform as it was intended in response to building loads.

2

Load Reduction: The energy wheel saves 3 to 4 tons of cooling AND 50-60 MBH of heating for every 1,000 cfm of outdoor air for many climates.

Low Maintenance:

Servicing is minimal. All components have a well established history of reliable operation.

ASHRAE 62 Compliance: By assuring that minimum outdoor air volumes are delivered to the room spaces, compliance with the ASHRAE 62 Standard is clearly demonstrated.

Cooling and Heating

Capabilities

To expand the cooling and heating capabilities of the energy recovery wheel, a variety of tempering options are available. The coil section of the ERCH accommodates a cooling coil, a heating coil, or both.

A description of the cooling and heating |

|

|

|

processes along with a psychrometric |

|

|

|

illustration is shown below. Cooling and heating |

|

2 |

3 |

coil options are also listed. |

1 |

Consult your Greenheck representative for coil |

4 |

|

|

selections or for tempering options not listed. |

|

COOLING

Supplemental cooling is recommended when the air conditions leaving the energy recovery wheel have not been cooled or dehumidified to the desired leaving conditions.

Cooling Options

•Chilled Water

•Direct Expansion

Re-heat Options

•Electric

•Hot Water

•Indirect Gas

1. Outdoor air enters ERCH unit. |

|

|

|

|

|

|

|

|

|

|

|

|

2. The energy recovery wheel cools and |

|

|

|

|

|

|

90% |

|||||

dehumidifies outdoor air using energy |

|

|

|

|

|

80 |

||||||

|

|

|

|

|

|

|||||||

from the exhaust airstream. Load is |

|

|

|

|

|

|

|

|

||||

reduced by 3 to 4 tons per 1,000 cfm |

|

m |

p |

. |

|

|

|

|||||

for many climates. |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

T |

|

|

|

|

|

||

|

|

|

|

|

lb |

e |

|

|

|

|

|

|

|

|

|

|

|

70 |

|

|

|

|

|||

3. The cooling coil provides |

|

|

|

|

u |

|

|

|

|

|

||

|

|

|

t |

|

|

|

|

|

|

|

||

|

|

|

|

e |

B |

|

|

|

|

|

|

Wheel |

supplemental cooling to |

|

|

|

W |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|||

further treat the outdoor |

|

|

60 |

|

|

Cooling |

|

|||||

|

|

|

|

|

|

|||||||

air to desired supply |

|

|

|

|

|

|

|

|

Coil |

Room Air |

||

50 |

|

|

|

|

|

|

|

|

|

|||

conditions. |

3 |

|

|

|

|

|

|

|

|

|||

|

|

Reheat 4 Supply Air |

|

|||||||||

|

|

|

|

|||||||||

4. Optional reheat available to provide space neutral air.

70 |

% |

|

|

50 |

% |

||

|

|||

|

|

||

|

Outdoor Air |

||

1 30%

10%

50 |

60 |

70 |

80 |

90 |

100 |

Dry Bulb Temp.

180

160

140

120 |

Humidity |

|

|

||

100 |

Specific |

|

80 |

||

|

60

40

20

110

HEATING

Supplemental heating is recommended when the air conditions leaving the energy recovery wheel have not been heated

to the desired leaving conditions.

Heating Options

•Electric

•Hot Water

•Indirect Gas

1. Outdoor air enters ERCH unit.

2. The energy recovery wheel heats and humidifies

|

winter outdoor air using energy from the |

|

|

|

|

|

|

|

|

% |

||||||||

|

exhaust airstream. Heating bills are |

|

|

|

|

|

|

|

|

|

|

80 |

90 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

significantly reduced and overly dry |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

||||

|

indoor conditions are eliminated. |

|

|

|

|

|

m |

p |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

3. The heating coil or furnace |

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

lb |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

t |

u |

|

70 |

|

|

|

|

|

|

|

|

||

|

provides supplemental heating |

|

e |

B |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

to further treat the outdoor |

|

W |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

air to desired supply |

|

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

conditions. |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

40 |

|

|

|

|

|

|

|

|

|

|

Room Air |

|

|

||||

|

|

|

|

Heating |

|

|

|

|

|

|

|

|||||||

|

30 |

Wheel |

|

|

|

|

|

|

|

|

|

|||||||

1 |

2 |

|

|

Coil |

|

|

3 |

|

Supply Air |

|||||||||

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Outdoor Air

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

Dry Bulb Temp.

|

|

|

180 |

|

70% |

|

|

160 |

|

50% |

|

140 |

|

|

|

|

|

||

|

|

|

Humidity |

|

|

|

|

100 |

|

|

|

|

120 |

|

|

30 |

% |

|

Specific |

|

|

80 |

||

|

|

|

||

|

|

|

|

|

|

|

|

60 |

|

|

|

|

40 |

|

|

% |

|

|

|

|

10 |

|

20 |

|

|

|

|

|

|

90 |

100 |

|

110 |

|

3

Loading...

Loading...