Greenheck MSSC Installation Manual

|

Document 476372 |

|

Model MSSC |

® |

Motor Starter Standard Control |

with  smartstart™

smartstart™

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage!

NEMA 3R

16ga. Steel Enclosure

Precautions and Warnings

To prevent injury and property damage, follow these instructions. Failure to adhere to installation/operation procedures and all applicable codes may result in hazards as indicated by warning codes outlined below:

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. This signal word is to limited to the most extreme situations.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situtation which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices.

This is the safety alert symbol. Read and follow instructions carefully to avoid a dangerous situation.

This symbol alerts the user to the presence of “dangerous voltage” inside the product that might cause harm or electrical shock.

Table of Contents

Installation

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Low Voltage Wiring. . . . . . . . . . . . . . . . . . . . . . . . . .2

Torque Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Wiring Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Program Switches . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Protective Features . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electronic Overload Operation. . . . . . . . . . . . . . . . .3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Keypad Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . .3

LED Status Indicators. . . . . . . . . . . . . . . . . . . . . . . .3

I/O Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Our Commitment . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Instructions

DANGER

Equipment can start automatically. Lockout/tagout before servicing.

CAUTION

As with all electrical products, read manual thoroughly. Only qualified, expert personnel should perform maintenance and installation. Contact the nearest authorized service facility for examination, repair, or adjustment. Do not disassemble or repair unit unless described in this manual; death or injury to electrical shock or fire hazard may result. Specifications and manual data subject to change. Consult factory for additional information.

DANGER

HAZARDOUS VOLTAGE

•Disconnect and lock out all power before installing or servicing equipment.

•This equipment may require locking out multiple power sources prior to service.

•Install and wire in accordance with all applicable local and national electrical and construction codes.

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR SERIOUS INJURY.

Motor Starter Standard Control 1

®

Installation

Mounting

Mount the starter on a vertical surface, with the line terminals facing up. Install using 1/4-inch diameter hardware suitable for the mounting surface.

WARNING

•To maintain overcurrent and short circuit protection, the manufacturer’s instructions for selecting current elements and setting the instantaneous-trip circuit breaker must be followed.

•Tripping of the instantaneous-trip circuit breaker is an indication that a fault current has been interrupted. Current-carrying components of the

magnetic motor controller should be examined and replaced if damaged to reduce the risk of fire or electric shock.

•Do not locate starter in an environment subject to flammable gases, dusts or materials. Contact arcing can induce explosion or fire.

•Locate starter in a location appropriate to enclosure ratings and operational ratings. (e.g. NEMA-1 should only be located in a dry, protected environment).

•Do not allow any metal shavings or debris from installation to enter enclosure.

Wiring

Wire main power input and motor leads to the appropriate terminals tightened to specified torques indicated in the torque table. Use only copper conductors rated at least 60°C for applications less than 100A and at least 75°C ≥ 100A. Maintain proper clearances and verify that no possibility of an electrical short exists between the power conductors or enclosure. Ensure that wires are not under stress and all insulation is intact. Verify voltage input matches label and the control power is tapped per schematic.

Low Voltage Wiring

Automation system control wiring should be run in a separate conduit. The control terminals accept 26~14AWG wire torqued to 3.5 in-lb.

Torque Table

NEMA |

Input (lb-in) |

Output (lb-in) |

|

Size |

Standard |

Combination |

Motor Leads |

|

|

|

|

00 |

15.6 |

18 |

20 |

0 |

15.6 |

18 |

20 |

1 |

15.6 |

18 |

20 |

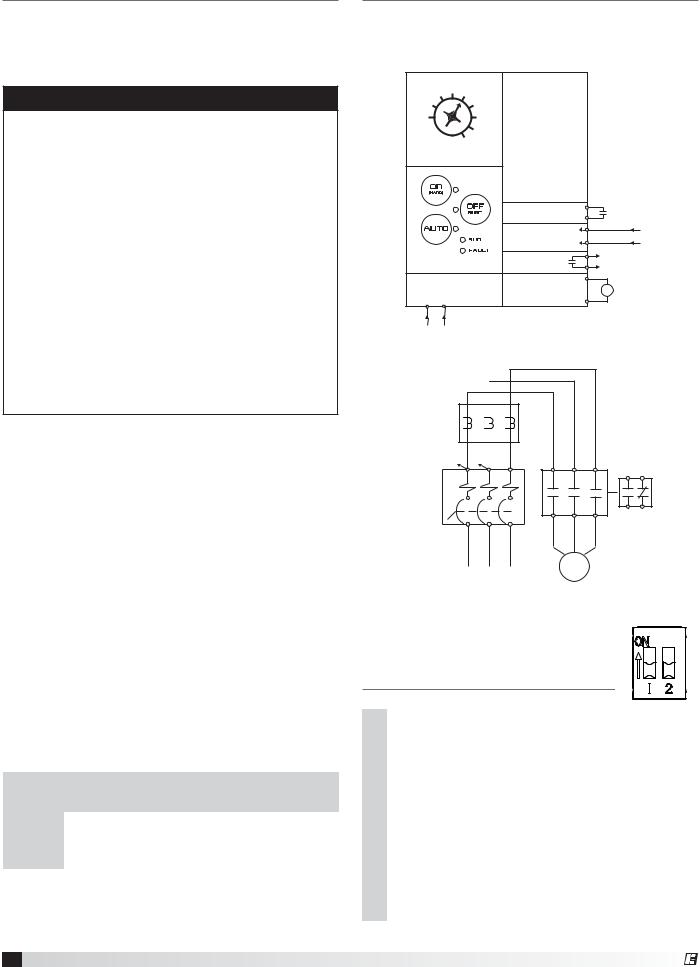

Wiring Schematic

Standard product wiring diagram shown. As-built product wiring may vary. Product wiring diagram located on stater enclosure.

10 |

15 |

20 |

|

|

|

|

|

|

|

|

|

||

5 |

|

25 |

|

|

|

|

1 |

|

30 |

|

|

|

|

FLA (A) |

35 |

|

|

|

|

|

40 |

|

|

|

|

||

|

|

|

|

|

|

|

Overload Setting |

|

|

|

|

||

|

|

|

Dry |

Auto Run |

Normally |

|

|

|

|

Input |

Open Input |

||

|

|

|

|

|||

|

|

|

Voltage |

Auto Run |

12-250VAC/DC Input |

|

|

|

|

Input |

|

|

|

|

|

|

Relay |

|

Status |

|

|

Keypad |

Output |

|

|||

|

|

|

|

|||

|

|

|

|

|

A1 |

24VDC output |

|

|

|

Contactor |

|

24V |

|

|

|

|

|

M |

to 24VAC |

|

|

|

|

Coil |

|

Output to |

|

PCB Power |

|

A2 |

contactor coil |

|||

|

|

contactor coil |

||||

|

|

208-600VAC |

|

|

|

|

H1 |

H4 |

40VA Max. |

|

|

|

|

OL

H1 |

H4 |

|

|

43 |

31 |

MCP |

M |

|

(Optional) |

|

|

44 32

T1 T2 T3 AUX

CONT

208-600VAC |

L1 |

L2 |

MTR |

||||||

Input |

L3 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3PH

Program Switches

|

Smartstart Bypass: Disables the Smartstart features |

|

1 |

when on. Smartstart protects the motor by detecting |

|

several common potentially damaging fault conditions. |

||

SWITCH |

||

When Smartstart is active, the starter will shut off under |

||

|

||

|

the following conditions: if locked rotor condition is |

|

|

present for 0.5 seconds, if the motor takes more than |

|

|

10 seconds to start, or if the FLA setting is determined |

|

|

to be incorrect. |

|

|

|

|

2 |

(ON) - Fault reset: Depress the “OFF” button for |

|

5 seconds to reset a fault trip. Starter will return to |

||

SWITCH |

||

“OFF” mode. |

||

|

||

|

(OFF) - Automatic Fault Reset: The starter will make 3 |

|

|

attempts at an auto fault reset separated by 5 minutes |

|

|

intervals. Also allows manual reset as above. |

|

|

|

2 Motor Starter Standard Control

®

Loading...

Loading...