General Aire Humidifier Owners Manual

This is a basic humidifier diagnostic tool for the complete line of General

Aire humidifiers. Most of the modern models have complete installation and

owner's manuals located on their perspective pages on this website. Go to

their specific page to locate it. This is a basic tool which covers the most

typical problems on most humidifiers.

General 709, 990, 1040, 1042, SL-16, and 1099 Series Power Humidifiers

This manual is an aid to servicing and troubleshooting General 709, 990, 1040,

1042, and 1099 Series power humidifiers. These humidifiers operate on the most

efficient and economical means of evaporating water to air. Air circulation, water

distribution and electrical circuitry all function in an elementary manner providing the

utmost in simplicity and therefore the highest degree of reliability.

Models 709, 990, 1040, 1042, SL-16, and 1099 (Drain Models)

Air circulation in these humidifiers is based on the bypass principal. Warm air is

bypassed from the warm air plenum or positive pressure side, through the

humidifier, and then to the return air or negative pressure side of the blower system.

At typical bonnet pressures, 150 to 200 CFM will move through the humidifier. The

air flow may be controlled with the manual air control. Closing the manual control

will reduce the evaporative capacity of the humidifier.

The water supply for drain type humidifiers is controlled by the electric solenoid

valve connected in parallel with the furnace blower circuit. The water flows through a

monel wire cloth filter, through a metering orifice to provide the proper amount of

water, and to the distributor trough to be evenly distributed over the top of the

evaporator pad,.

The evaporator pad is coated with a non-soluble wetting agent to increase

humidifier efficiency. Some of the coating may dust off during transit. This will not

affect the efficiency of the evaporator pad. In operation, the water flows from the "V"

notches in the distributor trough, down through the pad, and aided by the wetting

agent, to almost all surfaces of the evaporator pad. As warm air moves through the

pad, a percentage of the water is picked up by the air through evaporation. This

percentage of evaporation is affected by the temperature of the air, its relative

humidity and quantity of air moving through the humidifier. Excess water is collected

by the drain pan and is carried off by the drain hose to a suitable sewer or drain

connection. The excess water performs a useful function in washing down the

evaporator pad to remove some of the minerals and dust that collect on the pad. The

709, 990, 1040, 1042, and 1099 are evaporative humidifiers. Minerals are left on the

pad and are not blown into the air stream to collect in the living area.

The standard orifice will supply approximately 3.5 GPH of water on the 709, 990,

1040, and 1042 models and 4.8 GPH on the 1099 model, at a line water pressure of

60 psi. For low water pressure (20-40 psi) a slightly larger orifice is available to

provide the same flow at the lower pressure. At typical water rates, the water

consumption will cost approximately $1.50 per month.

Models 709-L, 990-L, 1040-L, SL-16, 1099-L, 709-LH, 1040-LH, 1042-LH,

and 1099-LH

These humidifiers are identical to the drain models except that a 24V. solenoid

valve and transformer are supplied allowing a 24V. control circuit. This facilitates

wiring a humidistat located in the living area or return air duct. The low voltage

humidistat is included in the 709-LH, 1040-LH, 1042-LH, and the 1099-LH models.

Models 709-R, 990-R, 1040-R, 1042-R, 1099-R (Recirculating Models)

These models are variations of the drain models, eliminating the need for the

external drain or sewer.

The electric solenoid valve is eliminated and the water supply is controlled by a

motor driven, adjustable flow pump. The pump is mounted in a reservoir where the

water level is maintained by a float valve. The pump supplies water to the distributor

trough where it is evenly distributed to the evaporator pad. Water that is not

evaporated drains back into the reservoir and is recirculated. The pump motor is

connected in parallel with the furnace blower circuit. A line voltage humidistat may

be installed for automatic control.

If low voltage control is desired for the recirculating models, a Honeywell RA89A

low voltage relay may be used for this purpose.

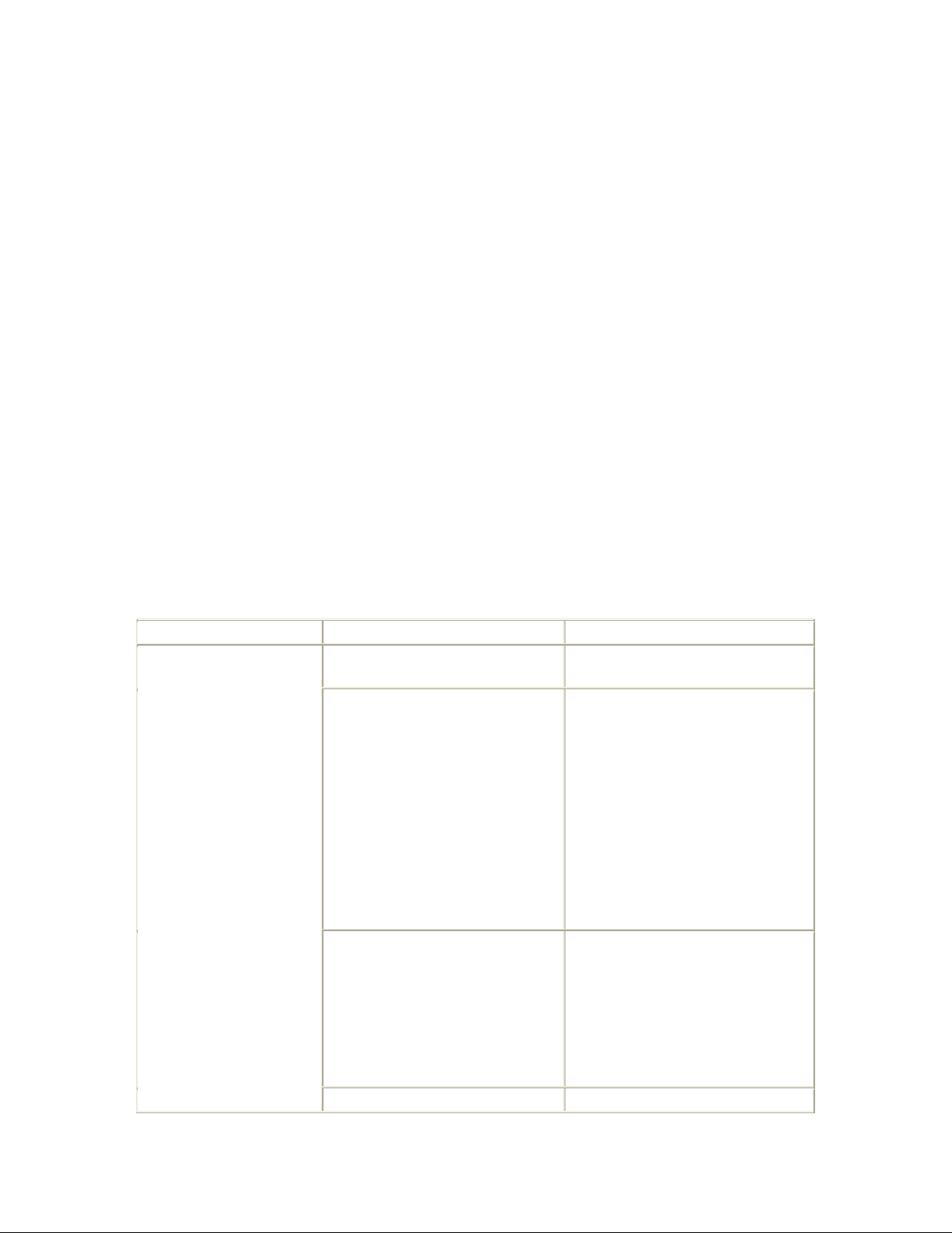

Troubleshooting

The following guide to troubleshooting 709, 990, 1040, 1042 and 1099 Series

humidifiers lists problems that occasionally occur, their cause and correction.

Troubleshooting is a process of elimination. A complaint or problem exists and by

noting all possible causes, the fault can be located by inspection and test.

Problem

Cause

Correction

Plugged orifice or orifice

strainer.

Disassemble and clean orifice

on inlet side of solenoid valve.

No electric power to

humidifier.

Replace blown fuse.

Reset circuit breaker.

Furnace fan not running when

humidifier is wired per

instructions, furnace fan must

be running for humidifier to

operate.

If humidistat is applied check

for proper setting.

Solenoid valve not opening.

Solenoid will make audible

click when energized. With

furnace blower running and

humidistat turned on high

humidity, check circuit for

loose connections. Check

continuity through solenoid

cell.

No water flow.

Saddle valve closed or

Open valve and check for

plugged.

water flow to solenoid valve.

Partially plugged orifice or

strainer.

Disassemble and clean orifice

and strainer.

Slow water flow. (Less

than 3 gal. per hour or

1 qt. in five minutes

on 709, 990, 1040

and 1042 models.) (5

gal. per hour or 1 qt.

in three minutes on

1099 models.)

Low water pressure (20-40

psi)

Install low pressure orifice.

Excessive water flow.

(Greater than 6 gal.

per hour on 709, 990,

1040, and 1042

models.) (Greater

than 8 gal. per hour

on 1099 models.)

Enlarged orifice.

Replace orifice fitting.

See Installation Instructions

for proper orifice size.

Improper wiring.

Chech circuitry. Solenoid

should be connected in parallel

with furnace blower motor on

the blower side of the fan

control.

Worn seat in electric valve.

Use manufacturer's valve

wrench to disassemble valve

for inspection. If valve leaks at

seat, replace valve.

Valve plunger sticks in open

position.

Inspect valve sleeve and

plunger for excessive dirt.

Clean plunger and sleeve

assembly.

Continuous water

flow. Electric valve

does not shut off

supply.

Valve installed incorrectly.

Water must flow in direction

of arrow or as described by

"In and Out" shown on valve.

Assemble correctly.

Noisy or buzzing

solenoid valve.

Dirt in valve sleeve and

plunger assembly.

Disassemble valve with

manufacturer's valve wrench

and clean all foreign matter

from sleeve assembly and

plunger.

Water blowing out of

distributor trough.

High bonnet pressure forcing

air up through distributor

trough.

Install distributor trough and

trough cover tightly.

Excessive lime accumulation

and corrosion on evaporator

pad.

Replace evaporator pad.

Water blowing off

evaporator pad.

Excessive water flow.

(Greater than 6 GPH on 709,

990, 1040, and 1042

models.) (Greater than 8 GPH

on 1099 models.)

Check orifice for enlargement.

Reduce humidifier pump

output (recirculating models

only.)

High static pressure--systems

equipped with central air

conditioning may have high

static pressures and/or two

speed blowers.

Use "Low" blower speed for

heating when humidification is

required.

Close manual air control on

humidifier to reduce air flow.

Install permanent restriction in

bypass pipe to reduce air flow

through humidifier.

Drain pan overflowing.

Accumulation of mineral

deposits plugging pan outlets

or drain hose.

Clean drain pan and flush

drain hose. Be sure drain line

has a continual slope to the

drain with no kinks.

Do not connect humidifier

drain to a "T". This creates an

obstruction which could collect

mineral deposits.

Short in humidistat wires, or

unit will not shut off.

Check humidistat wires to be

sure they are not shorted.

Electricians staples will often

short low voltage wires.

Excessive

humidification with

humidistat installed.

Continuous water flow.

See previous section on

continuous water flow.

Excessive

humidification without

humidistat.

Incorrect setting on manual

air control.

If over humidification is a

chronic problem reduce air

flow through unit by closing air

control. A humidistat may be

installed to give positive

control of relative humidity.

Incorrect measurement of

relative humidity.

Check relative humidity with

sling psychrometer. Bacharach

Model SAC is recommended.

Periodic cleaning has been

neglected.

Thoroughly clean humidifier

and replace evaporator pad or

any worn part.

Homeowner not aware of

recommended relative

humidity.

Bring attention to maximum

values on homeowner's

service card.

Incorrect installation.

Review Installation

Instructions to determine if

unit is installed correctly. The

bypass pipe must be installed.

Lack of humidification.

Water not flowing through all

holes in distributor trough.

Adjust humidifier so that the

distributor trough is exactly

level in all directions. If

surface tension seems to

prevent flow of water through

on or two "V" notches, brush

notches with a non-sudsing

liquid detergent. On 1042

humidifiers, brush detergent

on water dividing target area

in center of the distributor

trough.

Slow water flow.

See previous section on slow

water flow.

Humidifier air shutter set on

low.

Make certain manual air

control is open.

Insufficient air flow. (Less

than 100 CFM.)

Seldom a problem with bypass

humidifiers. In rare cases,

however, such as gravity

conversion furnaces, unusually

low bonnet pressure (less than

.05" of water) may not provide

air flow through humidifiers.

To correct problem, enlarge

bypass duct to the next larger

size, using proper transition

from humidifier to bypass

duct.

Air changes in home

occurring more rapidly than

normal (1 air change per

hour is average). Excessive

infiltration can be caused by

open windows and prolonged

use of kitchen and bathroom

exhaust fans. These factors

can increase the air changes

in a home to 4 per hour,

greatly increasing the

humidification load.

Keep windows and dampers

closed and exhaust fans off as

much as possible. While a

fireplace is being used, a lower

relative humidity will be

experienced due to the large

increased draft up chimney.

Homes with make-up air

devices or energy recovery

ventilators can increase the

air changes in the home

many times, lowering the

performance of the

humidifier.

The output of drain type

humidifiers may be increased

4.3 gallons per day with

hookup to 140 degrees hot

water. Use copper water

supply tubing with insulation.

Flow adjustment on

recirculating pump set too

low.

Set flow rate per Installation

Instructions by moving

standpipe in the direction

shown on pump lid.

Pump not raising

water to humidifier.

(Recirculation models

only.)

Clogged pump or supply

hoses.

Disassemble pump. Clean

pump housing, brass supply

tubing and vinyl hoses. Reset

pump output at no more than

6 GPH (1 qt. in 2/12 minutes

on 709, 990, 1040, and 1042).

(No more than 8 GPH, 1 qt.

every 2 minutes on 1099).

Faulty float valve.

Replace float valve shield and

float orifice nut. Remove float

assembly and clean mineral

deposits from all parts.

Reverse position of valve seat

if it shows wear.

Pump reservoir

overflowing.

Grooves in valve seat.

Replace any worn parts.

Loading...

Loading...