Page 1

SETUP & OPERATION MANUAL

FEATURES

Quick lock control levers easily position

tool rest.

Large 12″ inboard bowl turning capacity.

Stable cast-iron frame, head & tailstock to

reduce chatter and vibration for smoother

turning.

Maximum distance of 17 5⁄16″ between

centers.

Maximum distance of 49″ between centers with optional bed extension (Item

#25-205).

Quick release belt tension lever for faster,

easier speed changes.

Three variable speed ranges: 300 to 900,

600 to 1800 & 1200 to 3600 rpm.

Digital spindle speed display.

12″ tool rest with sturdy 1″ diameter sup-

port post.

Forward/reverse switch.

Features positive spindle indexing in 10°

increments - total 36 index positions.

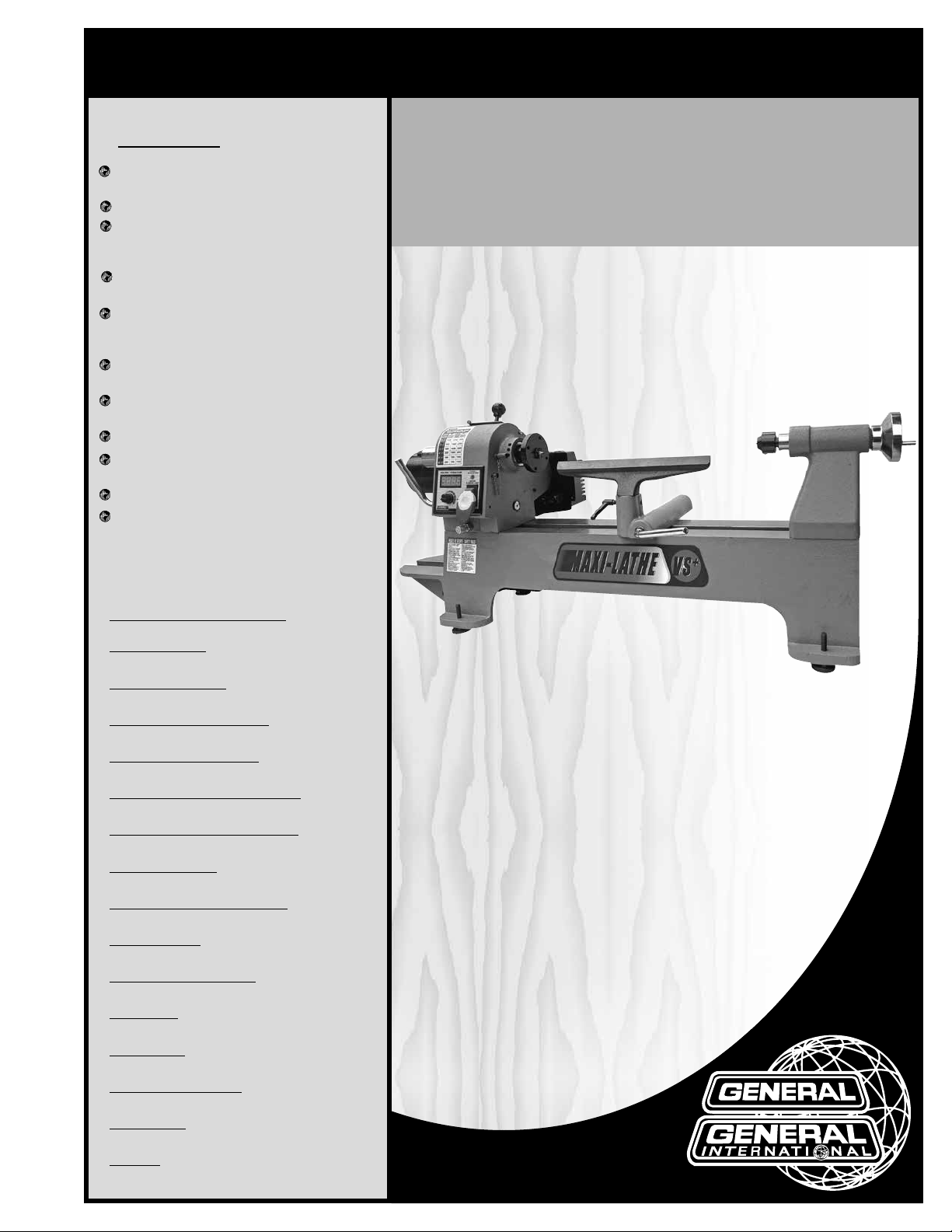

“MAXI-LATHE VS+”

12″ X 17″ WOOD LATHE

-

VARIABLE SPEED

SPECIFICATIONS

SPINDLE SPEED

(VARIABLE) 300 TO 3600 RPM

SWING OVER BED

12″ (304 MM)

SWING OVER TOOL REST

9 1/4” (236 MM)

SWING OVER SIDE BED

19 1/4” (490 MM)

SWING OVER SIDE TOOL REST

16 5/8” (424 MM)

DISTANCE BETWEEN CENTERS

17 5⁄16″ (440 MM)

SPINDLE THREAD

1″ (25.4 MM) - 8 TPI

TAILSTOCK THROUGH HOLE

3/8” (10 MM)

MORSE TAPER

MT #2

SELF EJECTING TRAVEL

2 1/8” (55 MM)

TOOL REST

12″ (305 MM)

FACE PLATE

3 1/8” (80 MM)

INDEXING POSITION

36 X 10°

MOTOR M1

3/4 HP, 110 V, 8 A, 2500 RPM

WEIGHT

146 LBS (66.5 KG)

MODEL

#25-200

VERSION 2_REVISION 2 - November 2015 (S/N:25855611)

© Copyright General® International

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this Variable Speed Maxi Lathe VS+ model 25-200

®

by General

and if properly used and maintained, will provide you with years of reliable service. To ensure

optimum performance and trouble-free operation, and to get the most from your investment,

please take the time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features of this unit as well as the set-up, maintenance and identification of its parts and components. This manual is not intended as a substitute for formal woodworking instruction, nor to

offer the user instruction in the craft of woodworking. If you are not sure about the safety of

performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

All component parts of General® International products are carefully tested and inspected during all stages of

production, and each product is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of

24 months from date of purchase, any genuine part or parts which, upon examination, prove to be defective in

workmanship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

International. This unit has been carefully tested and inspected before shipment

GENERAL® INTERNATIONAL WARRANTY

Disclaimer: The information and specifications in this manual

pertain to the unit as it was supplied from the factory at the

time of printing. Because we are committed to making constant improvements, General® International reserves the right

to make changes to components, parts or features of this

unit as deemed necessary, without prior notice and without

obligation to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure that the

specifications and information in this manual corresponds with

that of the unit with which it was supplied. However, special

orders and “after factory” modifications may render some or

all information in this manual inapplicable to your machine.

Further, as several generations of this model of wood lathe and

several versions of this manual may be in circulation, if you

own an earlier or later version of this unit, this manual may not

depict your tool exactly. If you have any doubts or questions

contact your retailer or our support line with the model number

of your unit for clarification.

Page 3

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General® International disclaims any real or implied warranty and holds itself harmless for any injury that

may result from improper use of its equipment.

1. Do not operate the wood lathe when tired, distrac ted, or under the effects of drugs, alcohol or any

medication that impairs reflexes or alertness.

2. The working area should be well lit, clean and free

of debris.

3. Keep children and visitors at a safe distance when

the wood lathe is in operation; do not permit them

to operate the wood lathe.

4. Childproof and tamper proof your shop and all

machinery with locks, master electrical switches

and switch keys, to prevent unauthorized or unsu pervised use.

5. Stay alert! Give your work your undivided atten tion. Even a momentary distraction can lead to seri ous injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector and

wear eye, ear and respiratory protection devices.

7. Do not wear loose clothing, gloves, bracelets, neck laces or other jewelry while the wood lathe is in

operation. Wear protective hair covering to contain

long hair and wear non-slip footwear.

12. Before turning on the wood lathe, make sure the

workpiece is securely installed between centers

and that all locking levers and moveable or remov able parts are tightened down and secured.

13. Adjust the cutting tool parallel and as close as pos sible to the workpiece and, before starting the

lathe, turn the workpiece by hand, at least one

full rotation to make sure that it does not come in

contact with the cutting tool.

14. Maintain turning tools with care. Keep turning tools

sharp and clean for best and safest performance.

15. Avoid working from awkward or off balance posi tions. Do not overreach and keep both feet on

floor.

16. Keep guards in place and in working order. If a

guard must be removed for maintenance or clea ning be sure it is properly re-attached before using

the tool again.

17. Use of parts and accessories NOT recommended

by

ment malfunction or risk of injury.

18. Never stand on machinery. Serious injury could

result if the tool is tipped over.

GENERAL® INTERNATIONAL

may result in equip-

8. Be sure that adjusting wren ches, tools, drinks and

other clutter are removed from the machine before

operating.

9. Keep hands well away from the spindle, the spin

ning workpiece, and all moving parts. Use a brush,

not hands, to clear away chips and dust.

10. Do not use stock containing defects such as che-

cks, splits, cracks, knots or foreign objects. Before

starting, inspect stock and remove all foreign ob jects such as dirt, nails, staples or any object that

could damage a tool or become dislodged and

fly free and cause injury.

11. Select appropriate turning speed for the size and

type of workpiece being turned and use lowest

speed when starting a new workpiece.

19. Always disconnect the tool from the power source

before servicing, changing accessories, perfor ming any maintenance or cleaning, or if the

machine will be left unattended.

20. Make sure that switch is in

plugging in the power cord.

21. Make sure the tool is properly grounded. If equip ped with a 3-prong plug it should be used with a

three-pole receptacle. Never remove the third

prong.

22. Do not use this wood lathe for any purpose other

than its intended use. If used for other purposes,

GENERAL® INTERNATIONAL

implied warranty and holds itself harmless for any

injury, which may result from that use.

the “OFF”

disclaims any real or

position before

3

Page 4

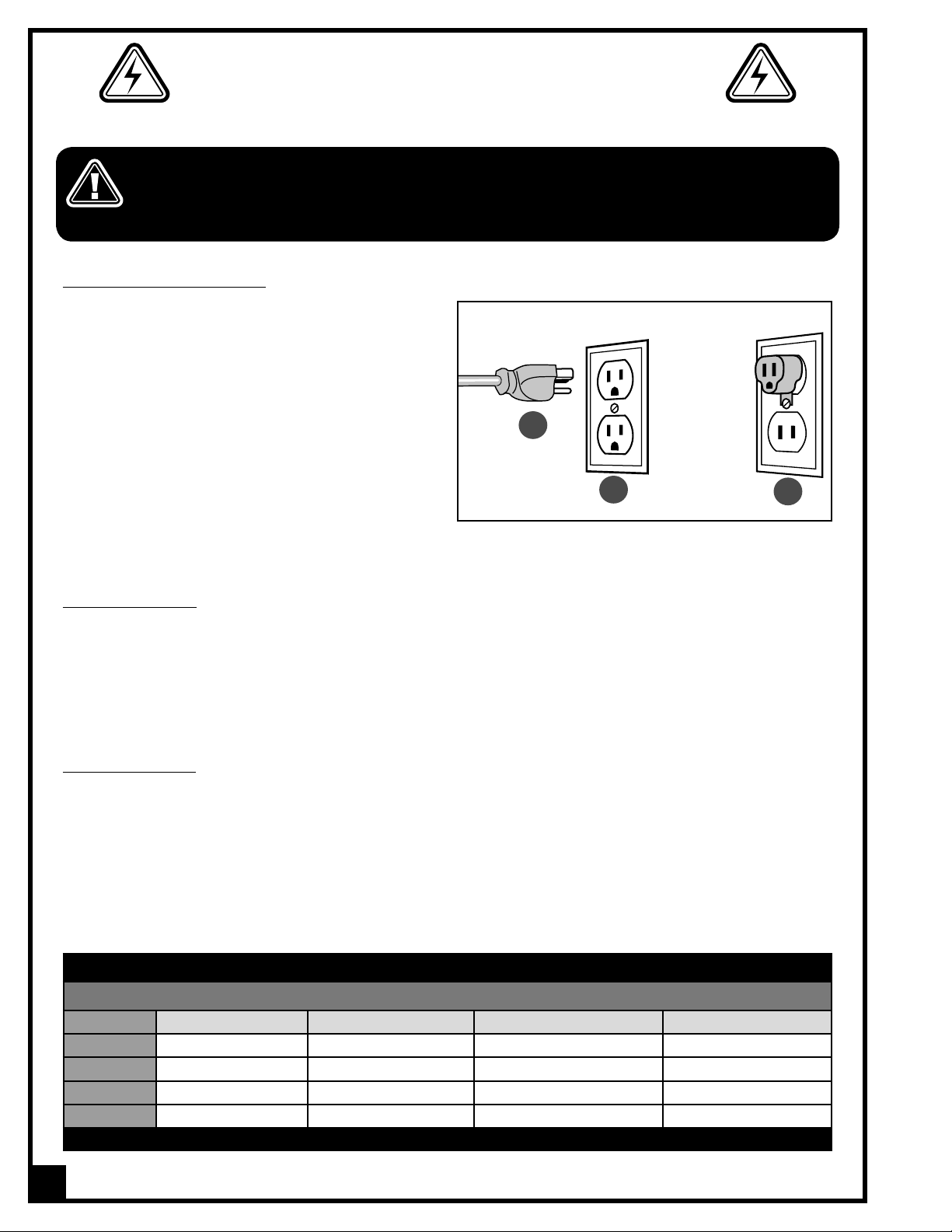

ELECTRICAL REQUIREMENTS

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE, VERIFY THAT THE VOLTAGE OF YOUR POWER SUPPLY CORRESPONDS WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE WITH GREATER VOLTAGE THAN

NEEDED CAN RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE TO THE MACHINE. IF IN DOUBT, CONTACT A

QUALIFIED ELECTRICIAN BEFORE CONNECTING TO THE POWER SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit, grounding reduces the risk of electric shock. The

motor of this machine is wired for 110V single phase

operation and is equipped with a 3-conductor cord

and a 3-prong grounding plug A to fit a grounded type

receptacle B.

Do not remove the 3rd prong (grounding pin) to make

it fit into an old 2-hole wall socket or extension cord. If

an adaptor plug is used C, it must be attached to the

metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some

areas. Check your local codes. If you have any doubts

or if the supplied plug does not correspond to your

electrical outlet, consult a qualified electrician before

proceeding.

A

B

C

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of handling the amperage draw from your machine, as

well as any other machines that could be operating on the same circuit. If you are unsure, consult a qualified

electrician.

If the circuit breaker trips or the fuse blows regularly, your machine may be operating on a circuit that is close

to its amperage draw capacity. However, if an unusual amperage draw does not exist and a power failure still

occurs, contact a qualified technician or our service department.

EXTENSION CORDS

If you find it necessary to use an extension cord with your machine, use only 3-wire extension cords that have

3-prong grounding plug and a matching 3-pole receptacle that accepts the tool’s plug. Repair or replace a damaged extension cord or plug immediately.

Make sure the cord rating is suitable for the amperage listed on the motor I.D. plate. An undersized cord will cause

a drop in line voltage resulting in loss of power and overheating.

The accompanying chart shows the correct size extension cord to be used based on cord length and motor I.D.

plate amp rating. If in doubt, use the next heavier gauge. The smaller the number, the heavier the gauge.

TABLE - MINIMUM GAUGE FOR CORD

EXTENSION CORD LENGTH

AMPERES 50 feet 100 feet 200 feet 300 feet

< 5

6 to 10

10 to 12

12 to 16

*NR = Not Recommended

18 16 16 14

18 16 14 12

16 16 14 12

14 12 *NR *NR

4

Page 5

VARIABLE SPEED MAXI-LATHE VS+

25-200

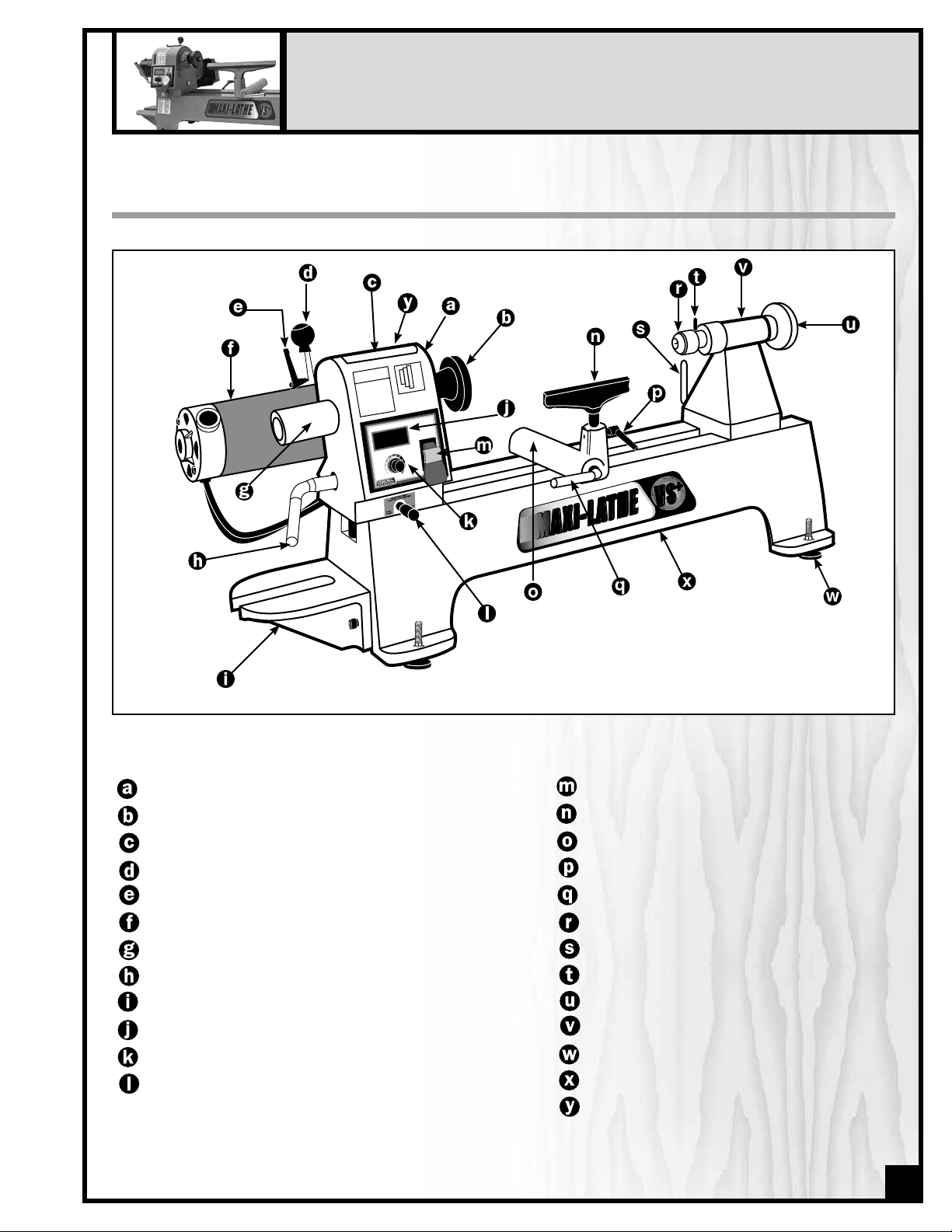

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

/MIN

VITESSE TR

/

SPEED RPM

8.8.8.8.

ON/OFF

EN MARCHE/ARRÊT

MAX.

.

MIN

Ù HEADSTOCK

FACE PLATE

BELT GUARD

BELT TENSION RELEASE LEVER

BELT TENSION LOCK LEVER

MOTOR

FLYWHEEL

HEADSTOCK LOCKING LEVER

OUTBOARD BED EXTENSION

SPINDLE SPEED READOUT

SPINDLE SPEED CONTROLLER

HEADSTOCK PIVOT PIN

ON/OFF SWITCH (KEY SWITCH)

TOOL REST

TOOL REST CARRIAGE

TOOL REST LOCKING LEVER

TOOL REST CARRIAGE LEVER

LIVE CENTER

LIVE CENTER

TAILSTOCK LOCKING LEVER

TAILSTOCK QUILL LOCKING LEVER

QUILL MOVEMENT HANDWHEEL

TAILSTOCK

LEVELING FOOT

LATHE BED

FORWARD/REVERSE SWITCH

(NOT SHOWN)

5

Page 6

UNPACKING & SET UP

UNPACKING

This model 25-200 is heavy – 146 lbs (66.5 kg). Do not over-exert. The help of an assistant will be needed for the

following step.

Carefully unpack and remove the wood lathe and its components from the box and check for damaged or missing items as per the list of contents below.

NOTE: Please report any damaged or missing items to your General International distributor immediately.

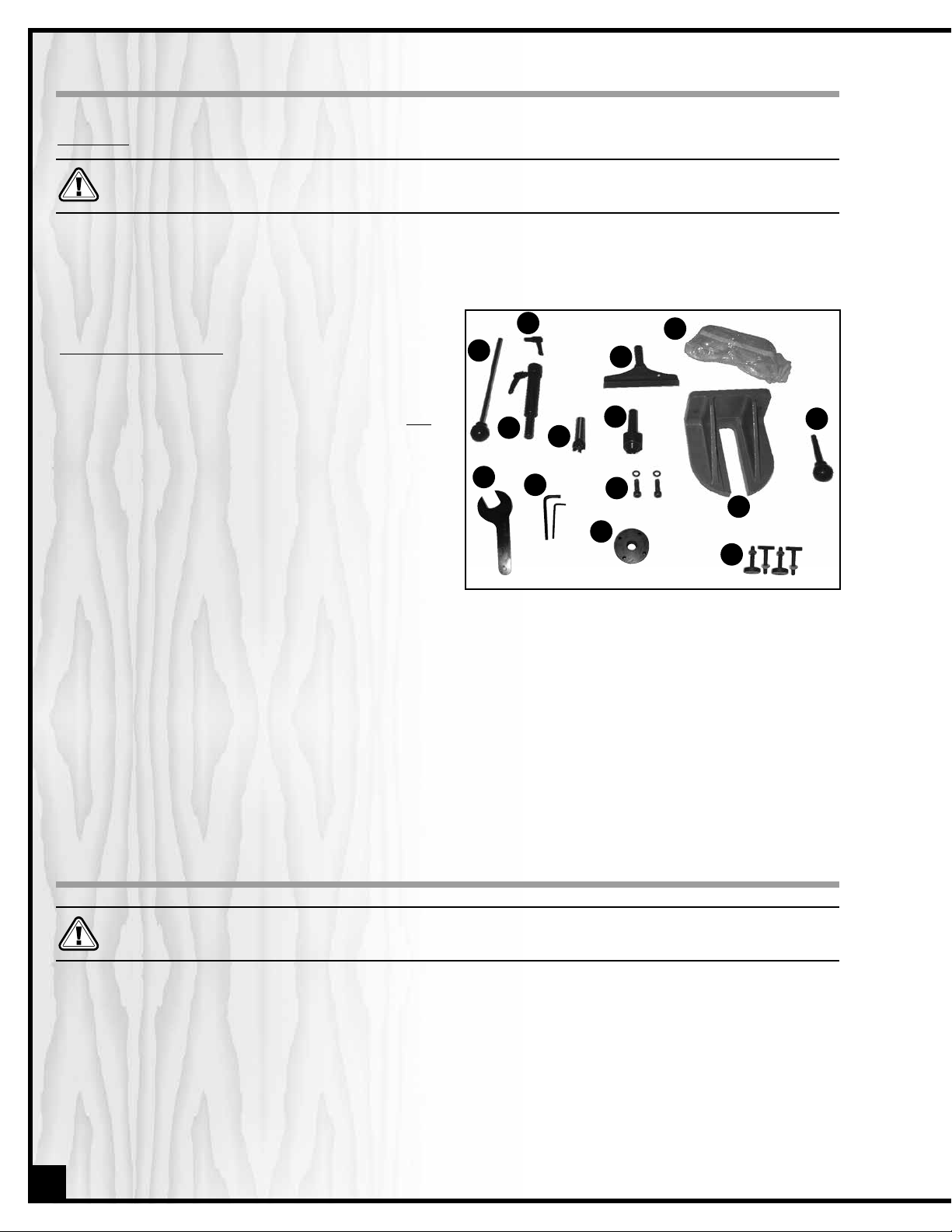

LIST OF CONTENTS

Once the parts have been removed from the

packaging, you should have the following items:

Qty

A- TOOL REST LOCKING LEVER 1

B- TOOL REST 1

C- HEADSTOCK SPUR CENTER 1

D- TAILSTOCK LIVE CENTER 1

E- TOOL REST EXTENSION POST 1

F- KNOCK OUT BAR 1

G- OUTBOARD EXTENSION HARDWARE 2

H- SAFETY GLASSES 1

I- OUTBOARD BED EXTENSION 1

J- BELT TENSION LEVER 1

K- LEVELING FEET (with nuts) 4

L- FACE PLATE 1

M- FACE PLATE WRENCH 1

N- ALLEN KEYS (3 MM AND 6 MM) 1

O- LATHE WITH HEADSTOCK, TAILSTOCK AND TOOL

REST CARRIAGE (NOT SHOWN) 1

A

F

E

M

C

N

B

D

G

L

H

J

I

K

CLEAN UP

Be sure to work in a well ventilated area for the clean-up process.

The unpainted cast-iron surface of the lathe bed is covered with a protective coating that helps prevent rust from

forming during shipping and storage. Remove this protective coating by rubbing with a rag dipped in kerosene,

mineral spirits or paint thinner. (Handle and dispose of potentially flammable solvent soaked rags according to

manufacturers’ safety recommendations.)

A putty knife held flat to avoid scratching the surface, may also be used to scrape off the coating followed by

clean-up with solvent. Avoid rubbing the lathes painted surfaces as many solvent based products will remove

paint.

To prevent rust, apply a light coating of paste wax or use regular applications of any after-market surface protectant or rust inhibitor.

6

Page 7

INSTALLATION & ASSEMBLY

For your convenience this lathe is shipped from the factory partially assembled and requires only minimal assembly and set-up before being put into service.

Before starting the assembly, make sure that the switch is in the “OFF” position and that the power cord is

unplugged. Do not plug in or turn on the lathe until you have completed the assembly and installation steps

described in this section of the manual.

SPEED RPM / VITESSE TR/MIN

ON/OFF

EN MARCHE/ARRÊT

8.8.8.8.

MIN.

MAX.

SPEED RPM / VI

8.8.8.8.

MIN.

N

TR/MI

TESSE

OFF

ON/

EN MARCHE/ARRÊT

.

MAX

The unit should be installed on a flat, sturdy and

stable surface able to support the weight of the

machine and the workpiece with ease.

Install the leveling feet and set the lathe on your

workbench. Adjust the leveling feet to ensure that

all four feet sit firmly on the bench. Make sure that

the machine does not rock.

For your safety it is essential that the machine does not rock or tip during operation. Upon start-up or during operation, if you notice any rocking, tipping or chattering of the base turn the machine off immediately and re-adjust

the leveling feet as needed to stabilize the lathe on the bench.

Never install the machine over the edge of a

table or workbench.

If you prefer an optional steel stand (item 25-195N)

is available from your local General International

dealer. The stand is equipped with mounting

holes allowing the lathe, after removing the leveling feet, to be bolted directly to the stand.

If a permanent shop placement is practical,

consider removing the leveling feet on the

base and drilling matching through-holes in

the mounting surface of your workbench or

stand to bolt the lathe in place (hardware not

included) on your workbench.

A

B

C

A. Lathe

B. Hex head bolt

C. Flat washer

D. Workbench

or stand

E

F

D

G

E. Flat washer

F. Lock washer

G. Hex nut

7

Page 8

SE TR/MIN

ON/OFF

EN

MA

R

C

HE/

AR

R

ÊT

MAX.

8.8.8.8.

SPEED RPM / VITES

SE TR/MIN

ON/OFF

EN

MA

R

C

HE/

AR

R

ÊT

MIN.

MAX.

8.8.8.8.

SPEED RPM / VITES

SE TR/MIN

ON/OFF

EN MARCHE/ARRÊT

MAX.

8.8.8.8.

AR

R

ÊT

SPEE

MIN.

A

SPEED RPM / VITES

C

MIN.

B

Release the headstock locking lever A and pull

the headstock pivot pin B outwards and pivot the

headstock 180º. Lock the headstock in place by

pulling the headstock locking lever forward C.

Top View

D

Side View

Use the 2 mounting bolts and lock washers D to

attach the outboard bed extension to the bed as

shown.

D RPM / VITESSE TR/MIN

ON/OFF

EN MARCHE/ARRÊT

8.8.8.8.

MAX.

MIN.

Install the belt tension release lever as shown.

E

F

Install the tool rest on the tool rest carriage.

TOP VIEW

G

Thread the face plate onto the headstock spindle E and tighten using the supplied face plate

Then lock the face plate by tightening the two set

screws G using a 3 mm Allen key.

wrench (Insert the knock-out bar in the spindle

hole F to keep the spindle from turning while tightening the face plate).

Installez le levier de blocage du porte-outils sur la

tige de rallonge du porte-outils et mettez de côté

la tige, que vous utiliserez pendant le tournage

extérieur.

8

Page 9

BASIC ADJUSTMENTS & CONTROLS

ON/OFF POWER SWITCH:

The wood lathe is equipped with a rocker type ON/OFF switch located on the headstock A, that is equipped with a lock-out key.

To prevent unwanted or unauthorized start-up or usage remove the lock-out key and store it in a safe place B.

To start the lathe, insert the lock-out key and pull up the switch C. To stop the lathe, push down on the power switch D.

B

A

FORWARD / REVERSE SWITCH

ALWAYS BE SURE TO STOP THE LATHE SPINDLE COMPLETELY BEFORE CHANGING DIRECTION. WHEN MOUNTING A FACE PLATE,

ALWAYS MAKE SURE THE SET SCREWS IN THE FACE PLATE ARE TIGHTENED SECURELY AFTER THE FACE PLATE IS INSTALLED.

FAILURE TO DO SO MAY RESULT IN THE FACE PLATE UNSCREWING FROM THE SPINDLE.

The Forward/Reverse switch E is located on the rear of the

headstock F.

Forward: The spindle rotates toward to the operator from the

top of the workpiece.

Reverse: The spindle rotates backward to the operator from

the top of the workpiece.

Pull UP to START

E

Press DOWN to STOP

C

D

F

CHANGING SPINDLE SPEED:

This model 25-200 MAXI-LATHE VS + is equipped with an electronic variable speed controller allowing the user to

change the speed of the spindle (within the 3 different spindle speed ranges: 300-900, 600-1800 & 1200-3600 rpm) by

simply turning the speed control dial. The digital spindle speed readout will indicate the operating spindle speed.

Note: Turning speeds vary depending on the size and diameter of the workpiece as well as which stage you are at in the

overall turning process. When turning a smaller diameter workpiece, a higher spindle speed is recommended. Proper spindle speed selection comes with practice and experience and when in doubt always start at a slower speed increasing

when you are sure that it is safe to do so.

SPEED RECOMMENDATIONS

DIAMETER

OF WORK

UNDER 2” 1500 2650 3600

2 TO 4” 800 1400 2000

4 TO 6” 800 1400 2000

6 TO 8” 800 1400 2000

8 TO 10” 300 700 1000

10 TO 12” 300 700 1000

Use the chart as a basic guideline for selecting the

appropriate spindle speed.

ROUGHING

RPM

GENERAL

CUTTING RPM

FINISHING

RPM

Changing between the 3 speed ranges requires

moving the drive belt from one set of drive pulleys

3 SPEED RANGES

High : 1200-3600 RPM

H

M

Medium : 600-1800 RPM

L

Low : 300 to 900 RPM

to another. The speed range will vary.

9

Page 10

To reposition the belt and change spindle speed ranges:

A

Turn off and unplug the lathe from the power

1.

source.

2. To access the belt and pulleys, loosen the belt

guard locking screw A and open the belt guard

located on the headstock B.

E

L

M

H

B

C

3. Release the belt tension locking lever C.

4. Release the tension on the belt by pulling the

belt tension release lever backward D.

D

GF

Set the belt by hand to the required pulley posi-

5.

tion (High/Medium/Low) E.

7. To verify the belt positioning and ensure the belt

will run smooth on the pulleys; rotate the fly

wheel A by hand to turn the spindle while

observing the belt movement. If the belt moves

smoothly re-install the belt guard – if the belt

wobbles between the pulleys repeat steps 3-6 as

needed.

TOOL REST CARRIAGE & TOOL REST ADJUSTMENTS:

6. Push the belt tension release lever forward to

re-tension the belt F and lock the belt tension

lever G.

A

C

B

The tool rest carriage can be moved along the

1.

bed slide ways as needed. Loosen the tool rest

carriage lever B and move the carriage to the

desired location. Retighten the lever securely

after adjustment.

10

2. The tool rest should be adjusted so that its top is

1/8” above the center of the workpiece. Loosen

the tool rest locking lever C and adjust the

height and position of the tool rest as needed.

Retighten the lever securely after adjustment.

Page 11

MOUNTING & REMOVING HEADSTOCK SPUR CENTER:

E

D

The headstock spindle has an MT#2 taper hole

1.

into which the spur center fits D. Make sure the

shank of the spur center and the spindle hole

are clean and free of debris, then fit the spur

center firmly in the spindle hole by hand E.

MOUNTING & REMOVING TAILSTOCK LIVE CENTER:

The tailstock has an MT#2 taper hole into which

1.

the live center fits. Make sure the shank of the

live center and the tailstock hole are clean and

free of debris and fit the live center firmly in the

spindle hole by hand.

2. To remove the headstock spur center, knock it

out from the opposite end of the spindle

using the supplied knock-out-bar.

Note: When knocking out the spur center, always

hold it by hand to prevent it from falling.

Back View

H

G

F

2. To remove the live center from the tailstock

quill, loosen the tailstock quill locking lever

F and move the quill out by turning the quill

movement handwheel G until the quill end

is nearly inside the tailstock and the live center

can be removed by hand.

Note: When removing the live center, always hold

it by hand to prevent it from falling H.

MOVE TAILSTOCK QUILL IN/OUT:

The tailstock quill can be moved in and out of the tailstock casting by turning the tailstock quill movement handwheel.

B

Back View

A

1. To move the tailstock quill, loosen the quill lock ing lever A.

3. Retighten the quill locking lever to secure the

quill in its new position.

Back View

2. Turn the the quill movement handwheel B to

move the quill as needed.

11

Page 12

TAILSTOCK MOVEMENT:

The tailstock is used to support the other end of the workpiece to be turned and can be moved along the bed

slideways to suit the length of the workpiece. To move the tailstock on the bed:

A

1. Loosen the tailstock locking lever A.

2. Move the tailstock by hand to the desired loca-

B

tion on the bed.

3. Retighten the tailstock locking lever B to secure

the tailstock in its new position.

MOUNTING A WORKPIECE TO THE FACEPLATE:

TOP VIEW

For turning applications where the workpiece cannot be

secured between the headstock and tailstock centers (such

as bowl turning) the faceplate must be used to secure the

workpiece to the headstock spindle.

REMOVE THE FACE PLATE

A

Unlock the face plate by loosening and removing the two set

1.

screws A using a 3 mm Allen key.

2. Loosen the face plate by inserting the supplied knock

B

out bar in the spindle hole to keep the spindle from

turning while loosening the face plate using the supplied face plate wrench, as shown in B, then unscrew

and remove the face plate.

3. With the face plate removed from the lathe, mount the workpiece onto the faceplate with wood screws (not

inzcluded) through the mounting holes on the face plate. Make sure the screws are not so long that they will enter

the area of the workpiece where the material is to be removed.

4. Re-install the face plate on the headstock.

PIVOTING THE HEADSTOCK (FOR OUTBOARD TURNING):

For outboard bowl turning on larger diameter work pieces the headstock can be pivoted 180°

To pivot the headstock:

C

A

B

1. Loosen the headstock locking lever

A.

2. Unscrew the knurled end of the indexing pin

(turn counter clock

wise) and pull out on the

headstock pivot pin to release the headstock B.

3. Rotate the headstock 180° to outboard position.

C and D.

4. Release the headstock pivot pin and Retighten

it (turn clockwise) on its shaft.

5. Adjust the positioning of the headstock on the

bed and tighten the headstock locking lever to

secure the headstock in place.

12

D

Page 13

CHECKING ALIGNMENT BETWEEN CENTERS:

There is a small amount of play built into the headstock on the bed to allow the headstock to pivot freely.

Whenever the headstock is pivoted back from the outboard position, the alignment between the headstock and

tailstock centers should be double checked and adjusted as needed.

To check the alignment between the headstock and tailstock centers:

A

1. Pivot the headstock to its normal spindle turn ing position and lock it in place.

2. Install a spur center in the headstock and a

live center in the tailstock.

3. Release the tailstock locking lever and ad vance the tailstock on the bed A until the

points of the 2 centers just barely touch each

other.

4. Using the tailstock locking lever, secure the tail

stock on the bed with the points still touching.

B

5. Look down at the two centers from above to ver ify that the points are in alignment. If the points

line up B, proceed with normal turning opera tions.

6. If the points are not lined up release the head stock locking lever and manually adjust the

headstock position using the play in the head-

stock to line up the center points C

.

7. With the points lined up, hold the headstock in

place and tighten the headstock locking lever.

C

8. With the points lined up, proceed with normal

turning operations.

INDEXING

For advanced turners, the indexing features on this lathe allows the user to lock the spindle in place at 36 evenly

spaced 10° intervals (360°/36 positions = 10°) while the workpiece is installed between the centers. This is primarily

used for reeding or fluting (cutting decorative grooves vertically up the length of the spindle) usually with the help

of a shop made jig and a router.

NEVER TURN ON THE LATHE WHEN THE HEADSTOCK SPINDLE IS LOCKED IN PLACE. ALWAYS, TURN OFF AND UNPLUG THE LATHE FROM

THE POWER SOURCE, BEFORE INSERTING THE INDEXING PIN TO LOCK THE SPINDLE.

TURNING ON THE LATHE AFTER THE INDEXING PIN (OR ANY OTHER OBJECT) HAS BEEN INSERTED INTO THE HEADSTOCK INDEXING

HOLE, THEREBY PREVENTING THE HEADSTOCK SPINDLE FROM TURNING, CAN LEAD TO SERIOUS INJURY, DAMAGE TO THE WORKPIECE,

OR DAMAGE TO THE LATHE AND THE MOTOR.

To lock the spindle, turn the spindle slowly by hand

until one of the 36 indexing holes is aligned with the

first hole in the headstock and then screw the indexing

pin into it.

Note: The 3 holes A allow more flexibility when locking the

spindle. If the user wants to keep the workpiece in its exact

position and it is not possible to lock the spindle with the

first hole because the spindle hole and the headstock hole

are not aligned, screw the indexing pin into one of the two

other holes.

Complete the desired cut, groove or other operation

on the spindle and then remove the indexing pin. If

further grooves are required, turn the spindle by hand

to set the workpiece to the required position and then

screw the indexing pin into the required hole in the

headstock.

Note: There are 36 evenly spaced holes in the headstock

spindle allowing for indexing at 10° increments (360°/36

positions = 10°), allowing for a wide variety of symmetrical

decorative grooves or patterned cuts.

.

A

13

Page 14

PERIODIC MAINTENANCE

•

Keep the unit clean and free of dust by wiping with a cloth or vacuuming off any woodchips or dust after

each use.

•

All bearings are sealed and permanently lubricated and no further lubrication is required.

• Regular applications of any after-market surface protectant or rust inhibitor will help prevent rust and keep the

tool rest, head, and tailstock sliding smooth on the bedway.

•

Always turn off and unplug the lathe when you have completed turning and to avoid unauthorized use,

remove the switch key and store it in a safe place.

• Periodically inspect the power cord and plug for damage. Replace the power cord and the plug at the first

signs of visible damage.

RECOMMENDED OPTIONAL ACCESSORIES

A large range of optional aftermarket accessories can be used with this lathe. Your local dealer may

be able to offer suggestions based on what is readily available in your area.

Key issues to keep in mind when shopping for aftermarket accessories are:

Headstock and tailstock feature a MT#2 taper – to avoid damaging the lathe use only headstock

and tailstock centers with a matching taper.

Headstock spindle threads are 1” diameter x 8 threads per inch (T.P.I.) – to avoid stripping or damaging the threads, use only threaded headstock attachments (such as face plates and jaw chucks)

that have matching threads.

We also offer a large variety of optional accessories to help you increase productivity, accuracy and

safety when using your lathe. Here’s a small sampling of accessories available from you local General

International dealer.

For more information about our products, please visit our website at www.general.ca

32″ BED EXTENSION

(FOR 49 5⁄16″ BETWEEN

CENTERS) - #25-205

Steel support stand for

maxi-lathes - #25-195N

Free-up valuable bench

space in your shop and

mount your lathe to

dedicated stand. Easy

to assemble. This sturdy

steel stand is designed

specifically to fit General

International models

25-100, 25-114, 25-114QC &

25-200 Maxi Lathes.

STEEL SUPPORT STAND

FOR MAXI-LATHE BED

EXTENSIONS - #25-196

For models:

25-100,

25-114,

25-114QC

and 25-200.

#25-105 │ 4” - 4 JAW SCROLL

CHUCK 1” - 8

Designed specifically for use

on lathes with

1” dia. x 8 TPI headstock

threads.

Portable Dust Collector

- #10-050M1

Designed for flexibility

and mobility. Featuring

an adjustable multi-position support arm and a

wide, rotating dust hood

this unit is ideal for use

on wood lathes.

14

Page 15

1

2

3

4

5

7

8

6

9

10

88

17

18

20

19

20

21

22

13

106

27

26

108

28

29 30

31

32

33

25

104

23

41

24

25

23

40

39

37

13

38

36

35

47

107

48

43

49

48

107

99

101

103

53

54

52

51

102

58

59

60

61

62

63

64

65

71N

70

72

73

74N

74A

70

77

78

79

68

69

4

66

67

65

80

81

82

83

84

85

86

87

109

89

90

65

36

91

92

93

78

79

94

98

96

95

97

1

2

9

1

8

3

7

4

2

6

5

12

11

10

7

8

19

1

2

3

6

18

17

15

5

16

12

13

14

11

10

100

100

9

4

43

45

105

44

42

75

73

76

10

10

105

15

Page 16

PARTS LIST

25-200

IMPORTANT: When ordering replacement parts, always give the model number, serial number

of the machine and part number. Also a brief description of each item and quantity desired

PART N0. REF. N0. DESCRIPTION SPECIFICATIONS QTY

25200-001 910092-000 MOTOR DC90V/0.75HP 1

25200-002 921457-000 LOCK LEVER 5/16”-18UNC-3/4”L 1

25200-003 006002-049 FLAT WASHER 8.5 X 16 X 2t 1

25200-004 250372-615 KNOB 2

25200-005 380571-901 HANDLE 1

25200-006 171960-902 MOTOR PLATE 1

25200-007 000403-107 FLAT HEAD SCREW M6 X 1.0P X 16 3

25200-008 000104-111 CAP SCREW M8 X 1.25P X 35 1

25200-009 090246-000 MOTOR PULLEY 1

25200-010 000203-102 SET SCREW M6 X 1.0P X 8 4

25200-013 000201-101 SET SCREW M4 X 0.7P X 6 3

25200-017 WN02-06 POWER CORD 1

25200-018 250589-000 WINDOW 1

25200-019 171959-000 HEADSTOCK COVER 1

25200-020 011001-105 SPRING PIN 3 X 10 2

25200-021 000101-101 CAP SCREW M4 X 0.7P X 8 2

25200-022 171961-901 SENSOR BRACKET 1

25200-023 003303-204 ROUND HEAD SCREW 3/16”-24NC X 3/4” 2

25200-024 021102-000 RELIEF ACC-2.5 4

25200-025 009003-200 NUT 3/16” X -24NC 4

25200-026 003303-207 ROUND HEAD SCREW 3/16”-24NC X 5/8” 1

25200-027 021805-000 STRAIN RELIEF NB-1216 1

25200-028 000205-101 SET SCREW M10 X 1.5P X 12 1

25200-029 030408-000 BEARING 6005-2NK 1

25200-030 012003-007 KEY 5 X 5 X 20 1

25200-031 WN02-53 SPINDLE 1

25200-032 050966-902 FACE PLATE 1

25200-033 921458-000 SPUR CENTER ASS’Y 1

25200-033-1 380407-901 SPUR CENTER 1

25200-033-2 380443-906 CENTER POINT FOR SPUR CENTER 1

25200-035 240056-907 SPINDLE FLYWHEEL 1

25200-036 003201-101 SET SCREW 1/4”-20NC X 1/4” 3

25200-038 030407-000 BEARING 6004-2NK 1

25200-039 660114-000 MAGNETIC RING 1

25200-040 380562-901 STOP RING 2

25200-041 050719-000 HEADSTOCK 1

25200-042 006502-200 SPROCKET WASHER 5.3 X 10 X 0.6t(BW-5) 1

25200-043 001901-103 SET SCREW M5 X 0.8P X 15L 4

25200-044 014320-000 BELT 140J-5R 1

25200-045 090167-000 SPINDLE PULLEY 1

25200-047 380552-907 HANDLE 1

25200-048 010209-000 E-RING ETW-15 3

25200-049 130190-000 ECCENTRIC RING 1

25200-051 WN02-31 CONTROL BOX WITH PANEL 1

25200-051-1 490468-000 DISPLAY BOARD 110V,61HZ 1

25200-051-2 250679-615 CONTROL BOX 1

16

Page 17

PARTS LIST

25-200

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

25200-051-3 572469-000 CONTROL BOX LABEL GENERAL 1

25200-051-4 937338-000 SAFETY SWITCH 1

25200-051-5 172302-000 CONTROL BOX COVER 1

25200-051-6 021501-000 RELIEF 10 X 14 X 3.5 3

25200-051-7 240057-000 VR KNOB 1

25200-051-8 490464-000 VR B50K 1

25200-051-9 001101-205 TAP SCREW M3 X 1.06P X 6 7

25200-051-10 003303-203 ROUND HEAD SCREW M5 X 0.8P X 10 1

25200-051-11 006502-200 SPROCKET WASHER 5.3 X 10(BW-5) 2

25200-051-12 006001-131 FLAT WASHER 5.3 X 10 X 2t 1

25200-052 380554-905 HEADSTOCK PIVOT PIN 1

25200-053 280141-000 SPRING 1

25200-054 360732-905 LOCK NUT 1

25200-058 380514-901 ADJUSTMENT SCREW 1

25200-059 050622-000 HEADSTOCK PIVOT BASE 1

25200-060 130196-903 SLIDE RING 1

25200-061 009101-200 HEX NUT 3/4”-10UNC 1

25200-062 003104-111 CAP SCREW 5/16”-18NC X 1-1/2” 2

25200-063 006305-100 LOCK WASHER 8.2 X 15.4 2

25200-064 050722-000 OUTBOARD EXTENSION BED 1

25200-065 290072-902 STOPPER 3

25200-066 380559-905 KNOCKOUT BAR 1

25200-067 050718-000 BED 1

25200-068 009006-200 HEX NUT 3/8”-16NC 4

25200-069 230081-000 LEVELING FOOT 4

25200-071N 070034-904 TOOL REST 12” 1

25200-072 380553-902 TOOL REST EXT.BAR 1

25200-074A TOOL REST ASSEMBLY 1

25200-74A-10 000203-102 SET SCREW M6 X 1.0P X 8 4

25200-74A-70 921455-000 LOCK LEVER 5/16”-18UNC-15L 1

25200-74A-73 010003-000 S-RING STW-12 2

25200-74A-74N 051085-049 TOOL REST CARRIAGE 1

25200-74A-75 160058-000 BUSHING 1

25200-74A-76 380561-907 ECCENTRIC ROD 1

25200-74A-77 380411-902 ADJUSTMENT SCREW 1

25200-74A-78 160053-901 SLIDE RING 2

25200-74A-79 008308-200 LOCK NUT M10 X 1.5P 1

25200-080 380415-901 CENTER POINT FOR LIVE CENTER 1

25200-081 380413-901 LIVE CENTER 1

25200-082 030001-000 BEARING 6002Z 1

25200-083 380414-901 LIVE CENTER SHAFT 1

25200-084 360361-000 TAILSTOCK SPINDLE 1

25200-085 360369-901 TAILSTOCK SCREW 1

25200-086 010208-000 E-RING ETW-12 1

25200-087 050720-000 TAILSTOCK 1

25200-088 012002-007 KEY 4 X 4 X 20 1

25200-089 380558-907 ECCENTRIC ROD 1

25200-090 010001-000 S-RING STW-10 1

25200-091 240053-906 TAILSTOCK HANDWHEEL 1

17

Page 18

PARTS LIST - 25-200

PART N0. REF. N0. DESCRIPTION SPECIFICATIONS QTY

25200-092 380444-906 HANDLE 1

25200-093 380408-905 ADJUSTMENT SCREW 1

25200-094 172318-904 FACE PLATE WRENCH #38 1

25200-095 040006-000 ALLEN WRENCH 6 MM 1

25200-096 040003-000 ALLEN WRENCH 3 MM 1

25200-097 042602-000 SAFETY GOGGLES 1

25200-098 040002-000 ALLEN WRENCH 2.5 MM 1

25200-099 380764-902 INDEX PIN 1

25200-100 000303-202 ROUND HEAD SCREW M5 X 0.8P X 8 4

25200-101 380765-906 CHAIN 1

25200-102 003303-207 ROUND HEAD SCREW 3/16”-24NC X 5/8” 1

25200-103 010203-000 E-RING ETW-6 1

25200-104 006001-131 FLAT WASHER 5.3 X 10 X 2t 1

25200-105 000203-102 SET SCREW M6 X 1.0P X 8 4

25200-106 021316-000 STRAIN RELIEF MG16A-10B-ST 1

25200-107 010030-000 S-RING STW-19 2

25200-108 WN02-58 PWM CONTROLER 1

25200-108-1 490490-000 THERMO RELAY 12AMP 1

25200-108-2 471002-005 CONNECT WIRE SJT X 16AWG X 1C 1

25200-108-3 250716-615 PWM CONTROLER BOX* 1

25200-108-4 490465-000 PWM PC BOARD* PWM(AC120V,60HZ/DC 90V,8A),800~2000 1

25200-108-5 310169-000 HEAT SINK 1

25200-108-6 020001-000 RELIEF SB6R-3 1

25200-108-7 000302-202 ROUND HEAD SCREW M4 X 0.7P X 8 4

25200-108-8 006002-001 FLAT WASHER 4.3 X 10 X 1.0t 4

25200-108-9 021306-000 STRAIN RELIEF PGA16-14B 1

25200-108-10 172468-902 PWM CONTROLER BRACKET 1

25200-108-11 042502-000 COVER D9.5 1

25200-108-12 003303-203 ROUND HEAD SCREW M5 X 0.8P X 10 1

25200-108-13 006502-200 GEAR WASHER 5.3 X 10(BW-5) 2

25200-108-14 006001-131 SPROCKET WASHER 5.3 X 10 X 2t 1

25200-108-15 250748-621 BUSHING 4

25200-108-16 540277-000 HEAT SINK 1

25200-108-17 490693-000 FWD/REV PC BOARD 1

25200-108-18 000302-102 ROUND HEAD SCREW M4 X 0.7P X 8 4

25200-108-19 490694-000 FWD/REV SWITCH 10A125A 6(2)A250V 1

25200-109 921456-000 LOCK LEVER 5/16”-18UNC-20L 1

25200-110 004402-101 SET SCREW 1/4”-20NC X 1/4” 1

18

* PULSE WIDTH MODULATION

NOTES

Page 19

NOTES

19

Page 20

MODEL #25-200

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Tel.: (514) 326-1161

Fax: (514) 326-5565 - Parts & Service / Fax: (514) 326-5555 - Order Desk

orderdesk@general.ca

www.general.ca

Follow us:

Loading...

Loading...