Ford Escort 1986-1989 User Manual

Chapter 1

Routine maintenance and servicing

Air cleaner element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Alternator drivebelt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . .27

Automatic transmission selector mechanism check . . . . . . . . . . . .28

Battery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Brake components check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Contact breaker points adjustment - models with contact

breaker distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Contact breaker points renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Crankcase emission control filter renewal . . . . . . . . . . . . . . . . . . . .35

Distributor lubrication - models with contact breaker distributor . .12

Driveshaft check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Exhaust manifold nut check - RS Turbo models . . . . . . . . . . . . . . . .9

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Fluid leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Front brake disc pad check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Fuel filter renewal - fuel injection engines . . . . . . . . . . . . . . . . . . . .36

Hinge and lock check and lubrication . . . . . . . . . . . . . . . . . . . . . . .31

Idle speed and mixture adjustment . . . . . . . . . . . . . . . . . . . . . . . . .10

Ignition system components check . . . . . . . . . . . . . . . . . . . . . . . . .11

Ignition timing check - models with contact breaker distributor . . .14

Intensive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Manual transmission oil level check . . . . . . . . . . . . . . . . . . . . . . . . .26

Oil filler cap cleaning - OHV and HCS engines . . . . . . . . . . . . . . . . .7

Rear brake shoe lining check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Roadwheel check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Spark plug renewal - RS Turbo models . . . . . . . . . . . . . . . . . . . . . .15

Suspension and steering check . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Turbocharger-to-manifold nut check - RS Turbo models . . . . . . . .23

Tyre checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Valve clearance adjustment - OHV and HCS engines . . . . . . . . . . .21

1•1

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult, suitable

for competent DIY

mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Contents

1

Engine

Oil filter type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C104

Valve clearances (cold):

OHV engines:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.22 mm (0.008 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.59 mm (0.023 in)

HCS engines:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.22 mm (0.008 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.32 mm (0.012 in)

Cooling system

Recommended antifreeze concentration . . . . . . . . . . . . . . . . . . . . . . . . 45% by volume

Fuel system

Idle speed:

Carburettor models:

All except Weber 2V TLDM carburettor . . . . . . . . . . . . . . . . . . . . . 750 to 850 rpm

Weber 2V TLDM carburettor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700 to 800 rpm

Bosch K-Jetronic fuel injection models . . . . . . . . . . . . . . . . . . . . . . . 750 to 850 rpm

Bosch KE-Jetronic fuel injection models:

1985 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 to 900 rpm

1986 models onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 920 to 960 rpm

Electronic Fuel Injection (EFI) models . . . . . . . . . . . . . . . . . . . . . . . . . 900 ± 50 rpm

Idle mixture CO content:

Bosch K-Jetronic fuel injection models . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.5 %

Bosch KE-Jetronic fuel injection models:

1985 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 0.75%

1986 models onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 to 1.1%

Electronic Fuel Injection (EFI) models . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 ± 0.25% (cooling fan running)

Air filter element type:

1.1 litre and 1.3 litre OHV engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W153

1.1 litre and 1.3 litre HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W225

1.1 litre and 1.3 litre CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W127

1.4 litre CVH engine:

Carburettor engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W179

Central Fuel Injection (CFI) engines . . . . . . . . . . . . . . . . . . . . . . . . Champion W201

1.6 litre CVH engine (except XR3 models):

Up to 1986 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W169

1986 to October 1988 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W201

October 1988 on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W226

1.6 litre CVH engine (XR3 models) . . . . . . . . . . . . . . . . . . . . . . . . . Champion W201

Ignition system

Contact breaker points gap:

Bosch distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.50 mm (0.016 to 0.02 in)

Lucas distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.59 mm (0.016 to 0.023 in)

Dwell angle (contact breaker ignition system) . . . . . . . . . . . . . . . . . . . . 48º to 52º

Ignition timing *:

OHV engines:

Up to 1984 (contact breaker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12º BTDC at idle speed

1984-on (contact breaker) and all electronic ignition . . . . . . . . . . . . . 6º BTDC at idle speed

CVH engines (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12º BTDC at idle speed

* Note:

Ignition timing on models with either a Distributorless Ignition Sytem (DIS) or a programmed ignition system (ESC) cannot be adjusted.

Refer to Chapter 5, Part B for further information.

Spark plugs:

Type:

OHV and HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RS9YCC or RS9YC

CVH engines:

Carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RC7YCC or RC7YC

Bosch K-Jetronic fuel injection and

Electronic Fuel Injection (EFI) models . . . . . . . . . . . . . . . . . . . . . . . Champion C6YCC or RC6YC

Bosch KE-Jetronic fuel injection models . . . . . . . . . . . . . . . . . . . . Champion C61YC

Central Fuel Injection (CFI) models . . . . . . . . . . . . . . . . . . . . . . . . . Champion RC7YCC or RC7YC4

Electrode gap:

All except HCS and CFI models:

RS9YCC, RC7YCC, C6YCC spark plugs . . . . . . . . . . . . . . . . . . . . 0.8 mm (0.032 in)

RS9YC, RC7YC, RC6YC, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.7 mm (0.028 in)

HCS and CFI models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm (0.039 in)

1•2 Servicing Specifications

Servicing Specifications 1•3

1

Brakes

Minimum front brake disc pad thickness . . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm (0.06 in)

Minimum rear brake shoe lining thickness . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm (0.04 in)

Tyres

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Weekly checks” on page 0•16

Torque wrench settings Nm lbf ft

Exhaust manifold nuts - RS Turbo models . . . . . . . . . . . . . . . . . . . . . . . 14 to 17 10 to 13

Turbocharger-to-manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 to 26 15 to 19

Spark plugs:

OHV and HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 to 20 10 to 15

CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 38 18 to 28

Seat belt anchor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 21 to 30

Roadwheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 to 100 52 to 74

Capacities

Engine oil (drain and refill)

OHV engine:

With filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25 litres (5.7 pints)

Without filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.75 litres (4.8 pints)

CVH engine:

Carburettor engines with filter change:

Pre-July 1982 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.75 litres (6.6 pints)

July 1982 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.50 litres (6.2 pints)

Carburettor engines without filter change:

Pre-July 1982 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.50 litres (6.2 pints)

July 1982 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25 litres (5.7 pints)

Fuel-injected engines with filter change . . . . . . . . . . . . . . . . . . . . . . . 3.85 litres (6.8 pints)

Fuel-injected engines without filter change . . . . . . . . . . . . . . . . . . . . 3.60 litres (6.3 pints)

Fuel tank

All models (except XR3i and Van) pre-May 1983 . . . . . . . . . . . . . . . . . . 40 litres (8.8 gallons)

All other models (except Van) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 litres (10.6 gallons)

Van . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 litres (11.0 gallons)

Cooling system

1.1 litre OHV engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 litres (11.8 pints)

1.1 litre CVH engine:

With small radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2 litres (11.0 pints)

With large radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2 litres (12.6 pints)

1.3 litre OHV engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1 litres (12.5 pints)

1.3 litre CVH engine:

Pre-1986 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1 litres (12.5 pints)

1986 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6 litres (13.3 pints)

1.4 litre CVH engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6 litres (13.3 pints)

1.6 litre CVH engine:

Pre-1986 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.9 litres (12.1 pints)

1986 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8 litres (13.7 pints)

Transmission

4-speed manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8 litres (4.9 pints)

5-speed manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 litres (5.5 pints)

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 litres (13.9 pints)

The maintenance intervals in this manual are provided with the

assumption that you, not the dealer, will be carrying out the work. These

are the minimum maintenance intervals recommended by the

manufacturer for vehicles driven daily. If you wish to keep your vehicle

in peak condition at all times, you may wish to perform some of these

procedures more often. We encourage frequent maintenance, because

it enhances the efficiency, performance and resale value of your vehicle.

If the vehicle is driven in dusty areas, used to tow a trailer, or driven

frequently at slow speeds (idling in traffic) or on short journeys, more

frequent maintenance intervals are recommended.

When the vehicle is new, it should be serviced by a factoryauthorised dealer service department, in order to preserve the factory

warranty.

Ford Escort maintenance schedule

1•4 Maintenance schedule

Every 6000 miles (10 000 km) or

6 months – whichever comes first

In addition to all the items in the 250 mile (400 km) service, carry

out the following:

mm Renew the engine oil and filter (Section 6)

mm On OHV and HCS engines, remove and clean the oil

filler cap (Section 7)

mm Check the hoses, hose clips and visible joint gaskets for

leaks and any signs of corrosion or deterioration (Section 8)

mm Visually check the fuel pipes and hoses for security,

chafing, leaks and corrosion (Section 8)

mm Check the fuel tank for leaks and any sign of damage or

corrosion (Section 8)

mm On RS Turbo models check the tightness of the

exhaust manifold retaining nuts (Section 9)

mm Check and if necessary adjust the idle speed and

mixture settings (Section 10)

mm Clean the distributor cap, coil tower and HT leads and

check for tracking (Section 11)

mm On contact breaker point distributors lubricate the

distributor shaft and cam (Section 12)

mm On contact breaker point distributors check and if

necessary adjust the points gap (dwell angle), then

check the ignition timing (Sections 13 and 14)

mm On RS Turbo models renew the spark plugs (Section 15)

mm Check the front disc pad thickness (Section 16)

mm Check the rear brake shoe lining thickness (Section 17)

mm Check the steering and suspension components for

any signs of damage and wear (Section 18)

mm Check the security of the front suspension lower arm

balljoint (Section 18)

mm Check the seat belt webbing for cuts or damage and

check the seat belt operation (Section 19)

mm Carefully inspect the paintwork for damage and the

bodywork for corrosion (Chapter 11)

mm Check the condition and adjustment of the alternator

drivebelt (Section 20)

Every 12 000 miles (20 000 km) or

12 months - whichever comes first

In addition to all the items in the 6000 mile (10 000 km) service,

carry out the following:

mm On OHV and HCS engines check and if necessary

adjust the valve clearances (Section 21)

mm Check the exhaust system condition and security

(Section 22)

mm On RS Turbo models check the tightness of the

turbocharger-to-manifold nuts (Section 23)

mm Renew the spark plugs (Sections 24 and 15)

mm On contact breaker point distributors renew the contact

breaker points (Section 25)

mm Check and if necessary top-up the manual transmission

oil (Section 26)

mm Check the automatic transmission fluid level - where

applicable (Section 27)

mm Check the operation of the automatic transmission

selector mechanism (Section 28)

mm Check the driveshafts for damage or distortion and

check the condition of the constant velocity joint

bellows (Section 29)

mm Inspect the roadwheels for damage (Section 30)

mm Check the tightness of the roadwheel bolts (Section 30)

mm Lubricate all hinges, door locks, check straps and the

bonnet release mechanism (Section 31)

mm Check the operation of all door, tailgate, bonnet release

and window regulator components (Section 31)

mm Carry out a road test (Section 32)

Every 36 000 miles (60 000 km) or

3 years - whichever comes first

In addition to all the items listed in the previous services, carry out

the following:

mm On CVH engines renew the timing belt (Section 37)

mm Make a thorough inspection of all brake components

and rubber seals for signs of leaks, general

deterioration and wear (Section 38)

mm Renew the brake fluid (Section 39)

Every 24 000 miles (40 000 km) or

2 years - whichever comes first

In addition to all the items in the 12 000 mile (20 000 km) and

6000 mile (10 000 km) services, carry out the following:

mm Renew the coolant (Section 33)

mm Renew the air cleaner element (Section 34)

mm On CVH engines renew the crankcase emission control

filter (Section 35)

mm On fuel-injected engines renew the fuel filter (Section 36)

Every 250 miles (400 km) or weekly

mm See "Weekly checks"

Maintenance - Component location 1•5

1

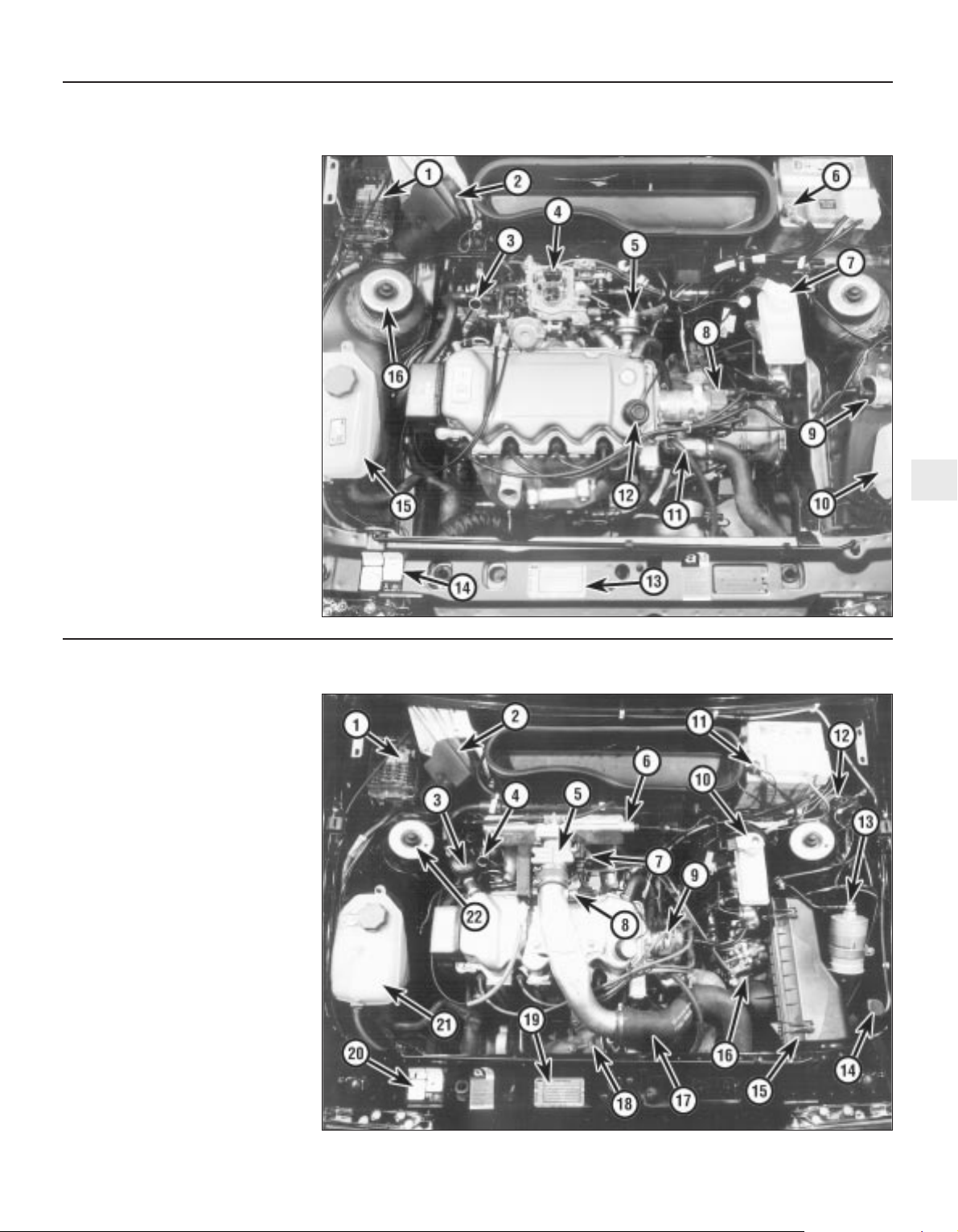

1 Fuse and relay box

2 Windscreen wiper motor

3 Engine oil dipstick

4 Carburettor

5 Fuel pump

6 Battery negative terminal

7 Brake master cylinder reservoir

8 Distributor

9 Ignition coil

10 Washer reservoir

11 Thermostat housing

12 Oil filler cap

13 Vehicle identification plate

14 Engine tuning decal

15 Cooling system expansion tank

16 Suspension strut top mounting

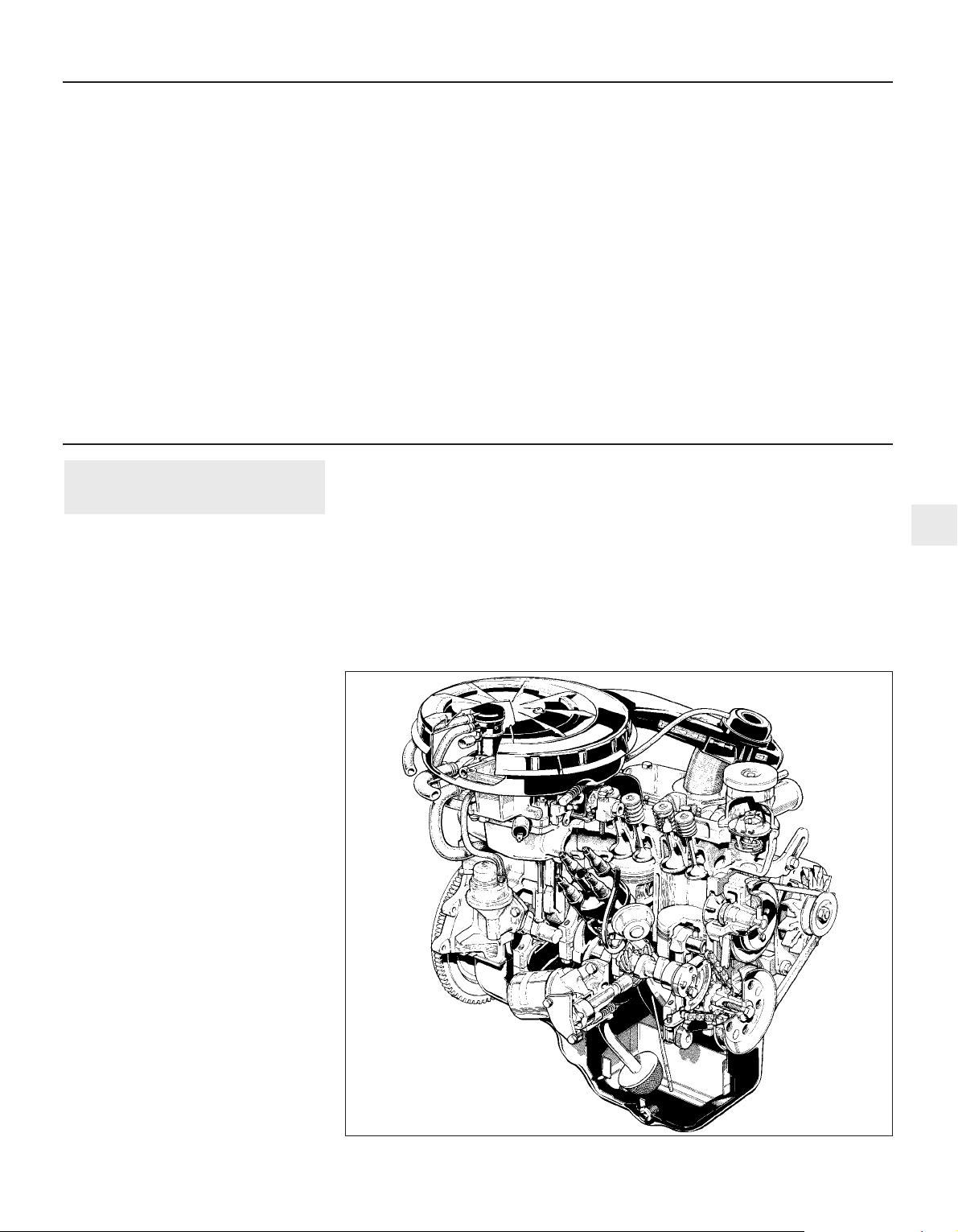

Engine and under bonnet component location on 1986 1.4 litre models (air cleaner removed for clarity)

1 Fuse and relay box

2 Windscreen wiper motor

3 Crankcase emission control filter

4 Engine oil dipstick

5 Throttle housing

6 Inlet manifold

7 Throttle position sensor

8 Charge air temperature sensor

9 Distributor

10 Brake master cylinder reservoir

11 Battery negative terminal

12 Ignition coil

13 Fuel filter

14 Washer reservoir

15 Air cleaner

16 Fuel distributor

17 Inlet air hose

18 Turbocharger

19 Vehicle identification plate

20 Engine tuning decal

21 Cooling system expansion tank

22 Suspension strut top mounting

Engine and under bonnet component locations on 1986 RS Turbo models

1•6 Maintenance - Component location

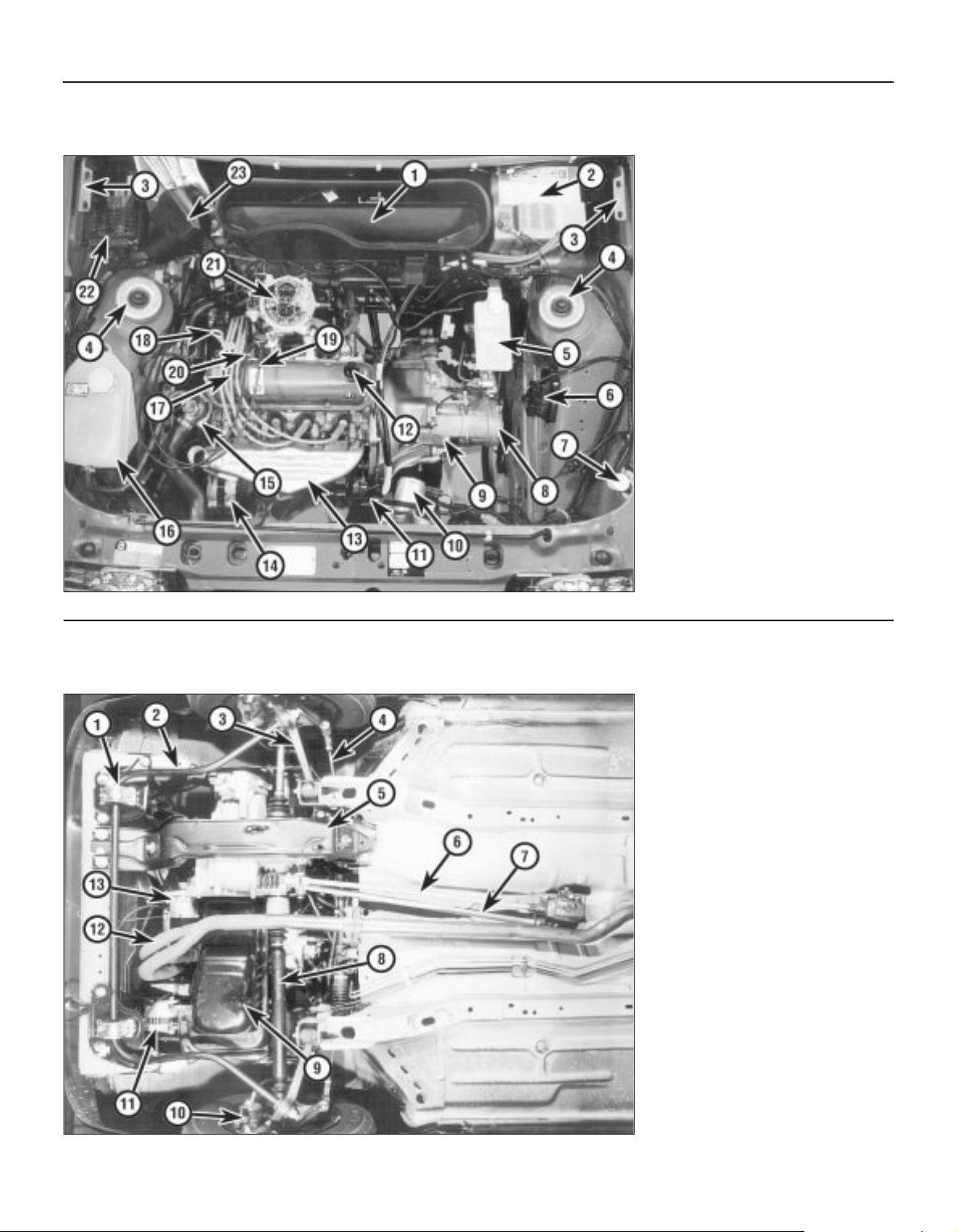

1 Ventilation air inlet duct

2 Battery

3 Bonnet hinge

4 Suspension strut upper mounting

5 Brake system fluid reservoir

6 Ignition system ESC module

7 Windscreen washer reservoir filler cap

8 Transmission housing

9 Clutch release lever

10 Cooling fan motor

11 Starter motor

12 Engine oil filler neck (cap removed)

13 Exhaust manifold shield

14 Alternator

15 Coolant thermostat and fan thermal

switch

16 Coolant expansion tank

17 Spark plug HT leads

18 Engine oil dipstick

19 Throttle cable

20 Choke cable

21 Carburettor

22 Fusebox

23 Windscreen wiper motor

Engine and underbonnet components location on 1989 1.3 litre HCS model (air cleaner removed for clarity)

1 Anti-roll bar clamp

2 Anti-roll bar

3 Front suspension lower arm

4 Steering tie-rod

5 Transmission support crossmember

6 Gearchange rod

7 Gearchange stabiliser

8 Driveshaft

9 Engine oil drain plug

10 Brake caliper

11 Alternator

12 Exhaust front pipe

13 Starter motor

Front underbody view of a 1986 1.4 litre Saloon model

Maintenance procedures 1•7

1

General information

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

The Chapter contains a master

maintenance schedule, followed by Sections

dealing specifically with each task on the

schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of the various components.

Servicing of your vehicle in accordance with

the mileage/time maintenance schedule and

the following Sections will provide a planned

maintenance program, which should result in

a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals will not produce the same results.

As you service your vehicle, you will

discover that many of the procedures can and should - be grouped together because of

the particular procedure being performed, or

because of the close proximity of two

otherwise unrelated components to one

another. For example, if the vehicle is raised

for any reason, the exhaust can be inspected

at the same time as the suspension and

steering components.

The first step in this maintenance program

is to prepare yourself before the actual work

begins. Read through all the Sections relevant

to the work to be carried out, then make a list

and gather together all the parts and tools

required. If a problem is encountered, seek

advice from a parts specialist, or a dealer

service department.

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely and frequent checks are made of fluid

levels and high wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition and

the need for additional work will be minimised.

It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

If engine wear is suspected, a compression

test will provide valuable information

regarding the overall performance of the main

internal components. Such a test can be used

as a basis to decide on the extent of the work

to be carried out. If for example a

compression test indicates serious internal

engine wear, conventional maintenance as

described in this Chapter will not greatly

improve the performance of the engine, and

may prove a waste of time and money, unless

extensive overhaul work is carried out first.

The following series of operations are those

most often required to improve the

performance of a generally poor-running

engine.

a) Clean, inspect and test the battery

(Section 5).

b) Check the levels of all the engine related

fluids (Section 3).

c) Check the condition and tension of the

alternator drivebelt (Section 20).

d) Check the condition of the spark plugs

and renew if necessary (Section 15).

e) Check the condition of the air cleaner

element, and renew if necessary (Section 34).

f) Check the condition of all hoses and

check for fluid leaks.

g) Check and if necessary adjust the idle

speed (where possible) (Section 10).

2 Intensive maintenance

1 Introduction

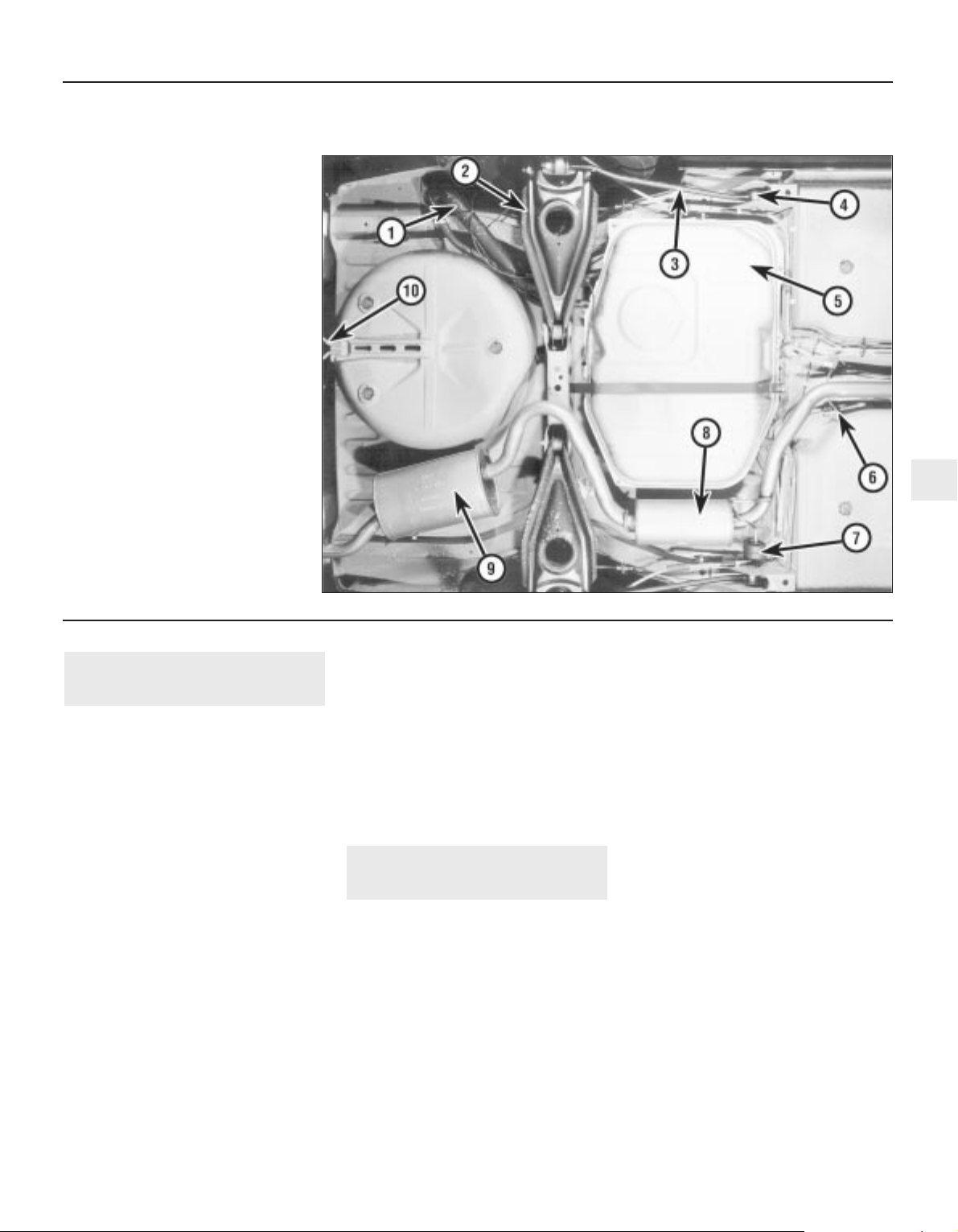

1 Fuel filler pipe

2 Suspension lower arm

3 Tie-bar

4 Tie-bar front mounting

5 Fuel tank

6 Handbrake cable adjuster

7 Exhaust mounting

8 Exhaust intermediate silencer

9 Exhaust rear silencer

10 Rear towing eye

Rear underbody view of a 1986 1.4 litre Saloon model

1 Frequent oil and filter changes are the most

important preventative maintenance

procedures that can be undertaken by the DIY

owner. As engine oil ages, it becomes diluted

and contaminated, which leads to premature

engine wear.

2 Before starting this procedure, gather

together all the necessary tools and materials.

Also make sure that you have plenty of clean

rags and newspapers handy to mop up any

spills. Ideally, the engine oil should be warm,

as it will drain better and more built-up sludge

will be removed with it. Take care, however,

not to touch the exhaust or any other hot

parts of the engine when working under the

vehicle. To avoid any possibility of scalding,

and to protect yourself from possible skin

irritants and other harmful contaminants in

used engine oils, it is advisable to wear rubber

gloves when carrying out this work. Access to

the underside of the vehicle will be greatly

improved if it can be raised on a lift, driven

onto ramps or jacked up and supported on

axle stands (see “Jacking and Vehicle

Support”). Whichever method is chosen,

make sure that the vehicle remains as level as

possible, to enable the oil to drain fully.

3 Remove the oil filler cap from the rocker cover,

then position a container beneath the sump.

4 Clean the drain plug and the area around it,

then slacken it using a suitable socket or

spanner (see illustration). If possible, try to

keep the plug pressed into the sump while

unscrewing it by hand the last couple of turns.

As the plug releases from the threads, move it

away sharply so the stream of oil issuing from

the sump runs into the container, not up your

sleeve!

5 Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the container as the oil flow slows to a trickle.

6 After all the oil has drained, wipe off the

drain plug with a clean rag and check the

condition of the sealing washer. Renew the

washer if necessary. Clean the area around

the drain plug opening, then refit and tighten

the plug to the specified torque setting.

7 Move the container into position under the

oil filter. The oil filter is located at the rear of

the cylinder block, and is accessible from

under the vehicle (see illustration)

8 Using an oil filter removal tool, slacken the

filter initially. Loosely wrap some rags around

the oil filter, then unscrew it and immediately

position it with its open end uppermost to

prevent further spillage of oil. Remove the oil

filter from the engine compartment and empty

the oil into the container.

9 Use a clean rag to remove all oil, dirt and

sludge from the filter sealing area on the

engine. Check the old filter to make sure that

the rubber sealing ring hasn’t stuck to the

engine. If it has, carefully remove it.

10 Apply a light coating of clean oil to the

sealing ring on the new filter, then screw it into

position on the engine. Tighten the filter firmly

by hand only - do not use any tools. Wipe

clean the exterior of the oil filter.

11 Remove the old oil and all tools from

under the vehicle, then (if applicable) lower the

vehicle to the ground.

12 Fill the engine with the specified quantity

and grade of oil, as described in “Weekly

checks”. Pour the oil in slowly, otherwise it

may overflow from the top of the rocker cover.

Check that the oil level is up to the correct

level on the dipstick, then refit and tighten the

oil filler cap.

13 Run the engine for a few minutes, and

check that there are no leaks around the oil

filter seal and the sump drain plug.

14 Switch off the engine and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

now completely full, recheck the level on the

dipstick and add more oil if necessary.

15 Dispose of the used engine oil safely with

reference to “General repair procedures” in

the Reference Sections at the end of this

manual.

6 Engine oil and filter renewal

Every 6000 miles or 6 months

1•8 Maintenance procedures

See “Weekly checks” starting on Page 0•10. See “Weekly checks” starting on Page 0•10. See “Weekly checks” starting on Page 0•10.

5 Battery check4 Tyre checks3 Fluid level checks

Weekly checks

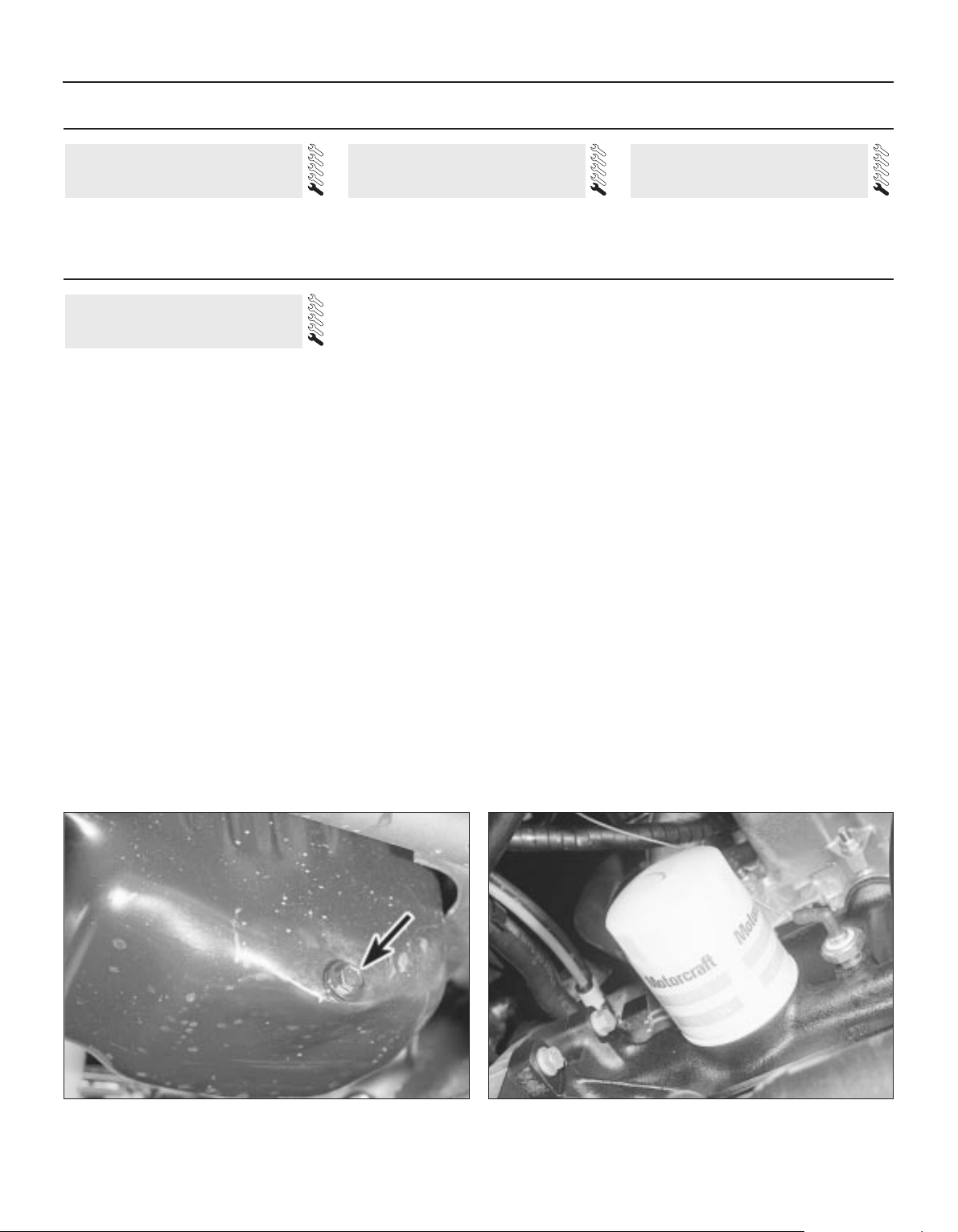

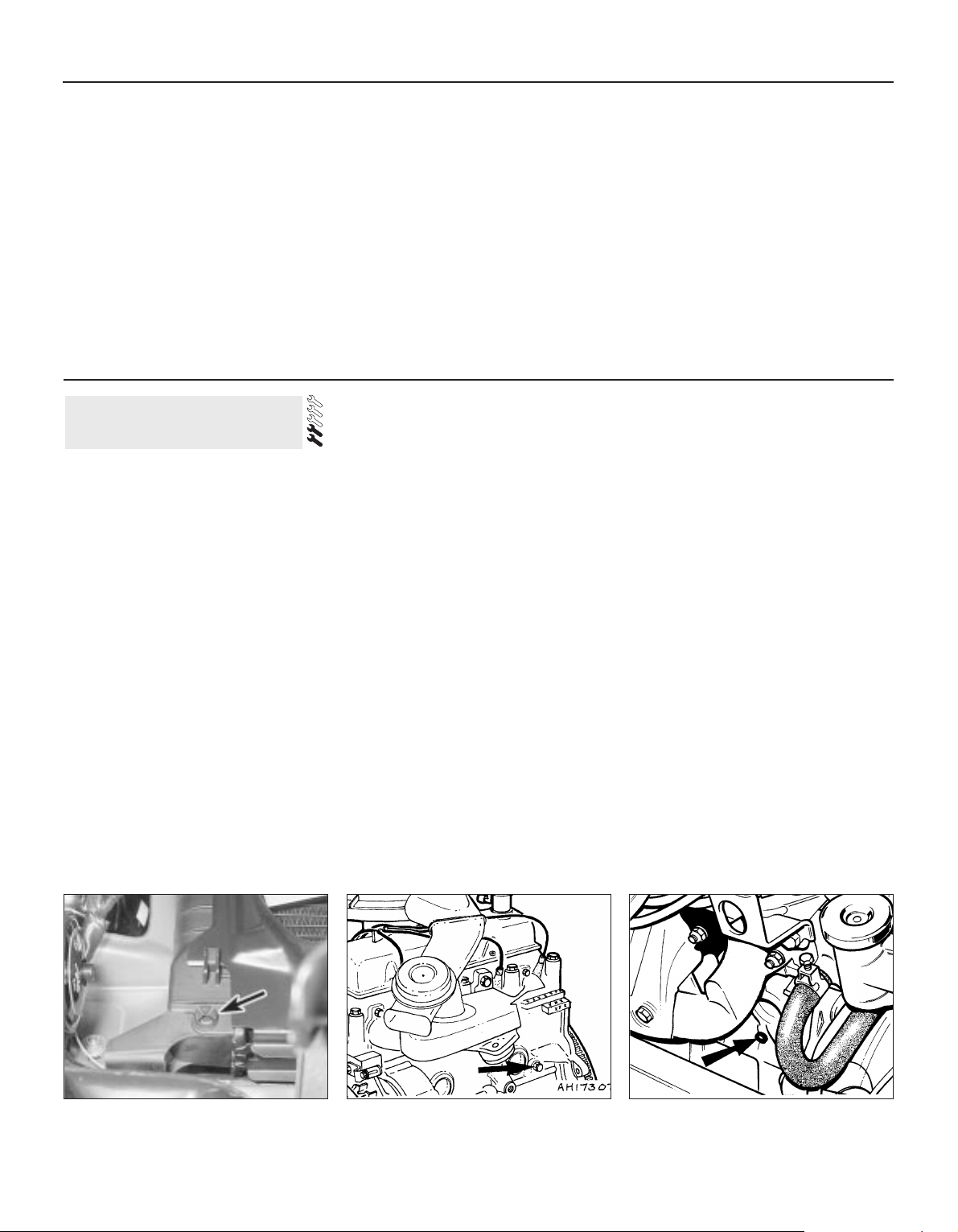

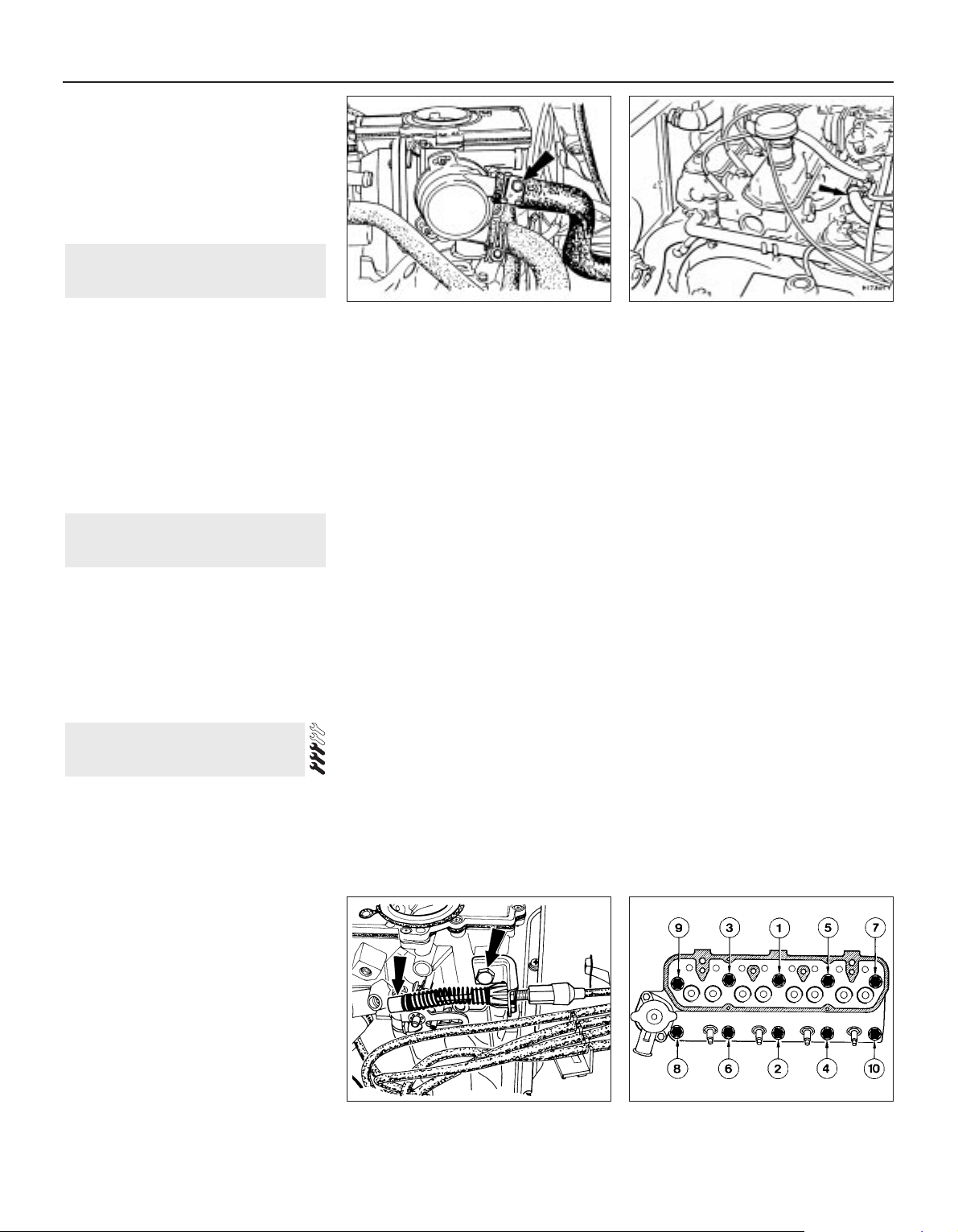

6.7 Oil filter location - CVH engine6.4 Engine oil drain plug (arrowed) -

CVH engine

Every 6000 miles or 6 Months 1•9

1

1 Simply pull the oil filler cap from the rocker

cover and, where applicable, disconnect the

hose(s) from the cap.

2 Inspect the filler cap, and if necessary clean

the cap using clean petrol to remove any

deposits.

3 Ensure that the cap is completely dry

before refitting.

1 Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the rocker cover, cylinder head, oil

filter and sump joint faces. Bear in mind that

over a period of time some very slight

seepage from these areas is to be expected

but what you are really looking for is any

indication of a serious leak. Should a leak be

found, renew the offending gasket or oil seal

by referring to the appropriate Chapter(s) in

this manual.

2 Similarly, check the transmission for oil

leaks, and investigate and rectify and

problems found.

3 Check the security and condition of all the

engine related pipes and hoses. Ensure that

all cable-ties or securing clips are in place and

in good condition. Clips which are broken or

missing can lead to chafing of the hoses,

pipes or wiring which could cause more

serious problems in the future.

4 Carefully check the condition of all coolant,

fuel and brake hoses. Renew any hose which

is cracked, swollen or deteriorated. Cracks

will show up better if the hose is squeezed.

Pay close attention to the hose clips that

secure the hoses to the system components.

Hose clips can pinch and puncture hoses,

resulting in leaks. If wire type hose clips are

used, it may be a good idea to replace them

with screw-type clips.

5 With the vehicle raised, inspect the fuel

tank and filler neck for punctures, cracks and

other damage. The connection between the

filler neck and tank is especially critical.

Sometimes a rubber filler neck or connecting

hose will leak due to loose retaining clamps or

deteriorated rubber.

6 Similarly, inspect all brake hoses and metal

pipes. If any damage or deterioration is

discovered, do not drive the vehicle until the

necessary repair work has been carried out.

Renew any damaged sections of hose or pipe.

7 Carefully check all rubber hoses and metal

fuel lines leading away from the petrol tank.

Check for loose connections, deteriorated

hoses, crimped lines and other damage. Pay

particular attention to the vent pipes and

hoses which often loop up around the filler

neck and can become blocked or crimped.

Follow the lines to the front of the vehicle

carefully inspecting them all the way. Renew

damaged sections as necessary.

8 From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

9 Where applicable, check the condition of

the oil cooler hoses and pipes.

10 Check the condition of all exposed wiring

harnesses.

11 Also check the engine and transmission

components for signs of fluid leaks.

Check the tightness of the exhaust

manifold securing nuts using a torque wrench.

Note: Before carrying out any carburettor

adjustment, ensure that the contact breaker

points, ignition timing and spark plug gaps (as

applicable) are set as specified and that the

distributor is operating correctly (where

applicable). To carry out the adjustments an

accurate tachometer will be required and the

use of an exhaust gas analyser (CO meter) is

also preferable.

Models with Ford VV carburettor

Idle speed

1 With the engine at normal operating

temperature, connect a tachometer in

accordance with the manufacturer’s

instructions.

2 Disconnect the wiring multi-plug from the

radiator cooling fan thermostatic switch in the

thermostat housing and bridge the two

contacts in the plug using a suitable length of

wire. This is necessary so that the cooling fan

runs continuously during adjustment.

3 On automatic transmission models slacken

the adjuster screw on the throttle valve shaft

lever to give clearance of 2 to 3 mm (0.079 to

0.118 in) - see Chapter 7, Part B.

4 Ensure that the air cleaner is fitted and that

its vacuum hoses are not in any way trapped

or pinched, particularly between the air cleaner

body and the top face of the carburettor.

5 Run the engine at 3000 rpm for 30 seconds,

then allow it to idle and note the idle speed. If

using an exhaust gas analyser it should be

noted that initially the CO% reading will rise,

but then fall and stabilise after a period of 5 to

25 seconds. The CO reading should then be

as specified.

Idle mixture

6 If necessary, adjust the idle speed

adjustment screw to give the specified idle

speed (see illustration).

7 Adjustment of the CO content (mixture) is

not normally required during routine

maintenance, but if the reading noted in

paragraph 5 is not as given in the

Specifications first remove the tamperproof

plug, prising it free using a small screwdriver.

8 Run the engine at 3000 rpm for 30 seconds,

then allow it to idle. Adjust the mixture screw

(see illustration 10.6) within 30 seconds. If

more time is required run the engine at 3000

rpm again for 30 seconds.

9 Adjust the idle speed if necessary and

recheck the CO content.

10 Fit a new tamperproof plug to the mixture

adjuster screw on completion. It should be

noted that mixture adjustment without a CO

analyser is not accurate and therefore not

recommended.

11 On completion disconnect the

instruments, remove the cooling fan bridging

wire and reconnect the multi-plug.

12 On automatic transmission models adjust

the downshift linkage (Chapter 7, Part B).

Models with Weber 2V carburettor

13 The procedure is the same as for the Ford

VV carburettor as described previously in this

Section, but the adjusting screw locations are

as shown (see illustrations).

Models with Bosch K-Jetronic

fuel injection system

14 The idle speed and fuel mixture

adjustments will normally only be required

after the installation of new components.

10 Idle speed and mixture

adjustment

9 Exhaust manifold nut check -

RS Turbo models

8 Fluid leak check

7 Oil filler cap cleaning - OHV

and HCS engines

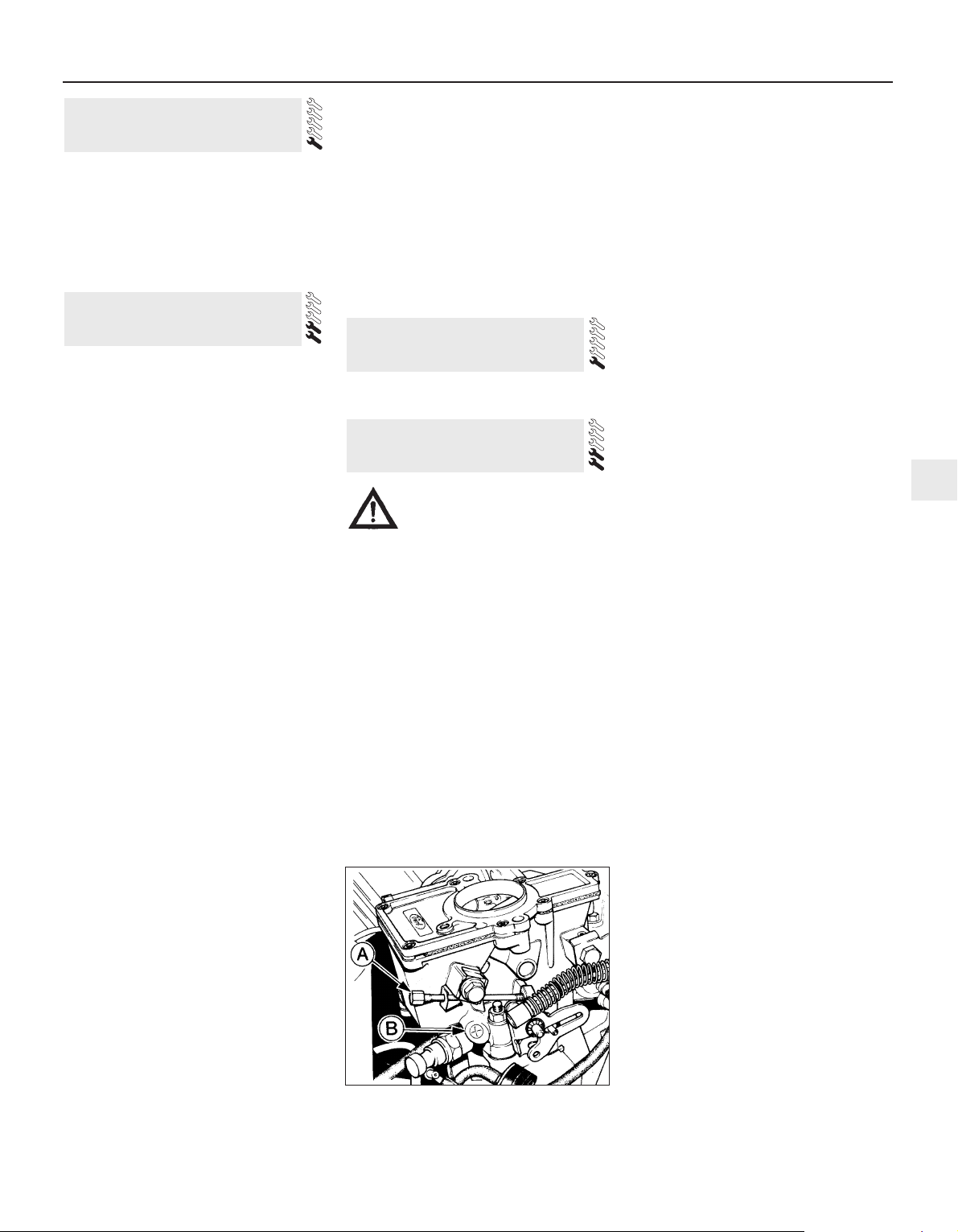

10.6 Idle speed adjustment screw (A) and

mixture adjustment screw (B) - Ford VV

carburettor

Caution: Certain adjustment

points in the fuel system are

protected by “tamperproof”

caps, plugs or seals. In some

EEC countries (though not yet in the UK)

it is an offence to drive a vehicle with

broken or missing tamperproof seals.

Before disturbing a tamperproof seal,

satisfy yourself that you will not be

breaking any local or national laws by

doing so, and fit a new seal after

adjustment is complete where required by

law. Do not break tamperproof seals on a

vehicle which is still under warranty.

Refer to the caution at the beginning of this

Section before proceeding.

15 On early models the idle speed

adjustment screw is located on the rear of the

throttle housing, but access is severely limited

unless the heater plenum chamber top cover

is removed as described in Chapter 4, Part B

(see illustration).

16 On later models the idle speed adjustment

screw is located on top of the throttle housing

beneath a tamperproof plug (see illustration).

Hook out the plug with a sharp pointed tool to

gain access.

17 Before making any adjustments, warm the

engine up to normal operating temperature

and connect a tachometer in accordance with

the manufacturer’s instructions.

18 Increase the engine speed to 3000 rpm

and hold it at this speed for 30 seconds, then

allow the engine to idle, check the tachometer

reading and if necessary turn the idle speed

adjustment screw as required until the engine

is idling at the specified speed.

19 To check the mixture adjustment an

exhaust gas analyser is needed and should be

connected in accordance with the

manufacturer’s instructions. A 3 mm Allen key

will also be required to make any adjustments.

20 Before making any adjustments to the

mixture, ensure that the idle speed is correct.

21 Remove the tamperproof plug from the

top of the mixture adjustment screw tube on

top of the fuel distributor (see illustration).

22 Stabilise the exhaust gases (paragraph 18).

23 Insert the Allen key into the mixture screw

tube and engage the adjusting screw. Turn

the screw as necessary until the correct CO

reading is obtained, then if required readjust

the idling speed.

24 If the mixture adjustment cannot be

finalised within 30 seconds from the moment

of stabilising the exhaust gases, repeat the

operations in paragraph 18 before continuing

the adjustment procedure.

25 On completion fit a new tamperproof plug

and disconnect the tachometer and exhaust

gas analyser.

Models with Bosch KE-Jetronic

fuel injection system

26 The idle speed and fuel mixture

adjustments will normally only be required

after the installation of new components.

27 The idle speed adjustment screw is

located on the side of the throttle housing

(see illustration).

28 Before making any adjustments, warm the

engine up to normal operating temperature

and connect a tachometer in accordance with

the manufacturer’s instructions.

29 Disconnect the wiring multi-plug at the

pressure actuator on the side of the fuel

distributor (see illustration).

30 Increase the engine speed to 3000 rpm

and hold it at this speed for 30 seconds, then

allow the engine to idle. Check the

tachometer reading and if necessary turn the

1•10 Every 6000 miles or 6 Months

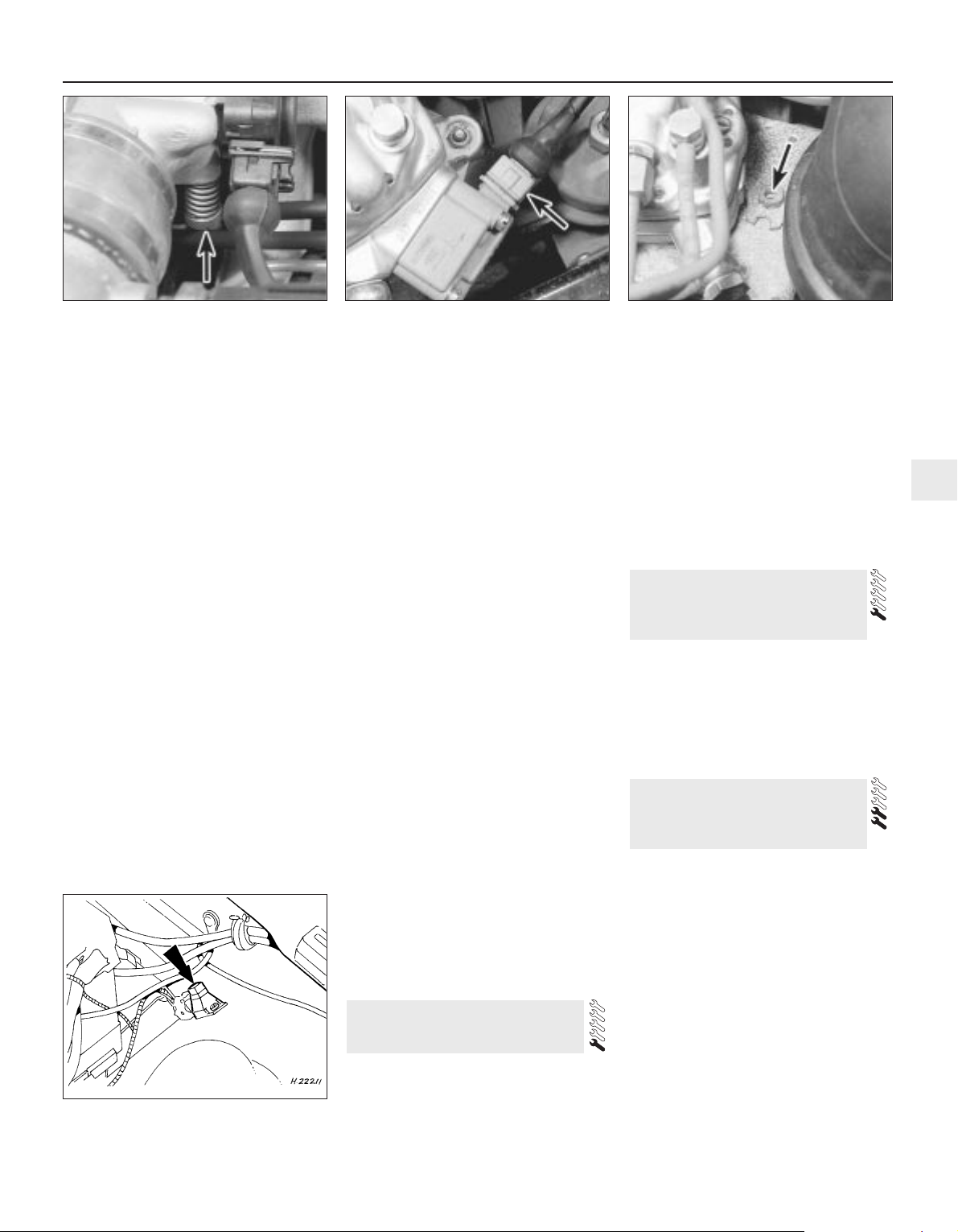

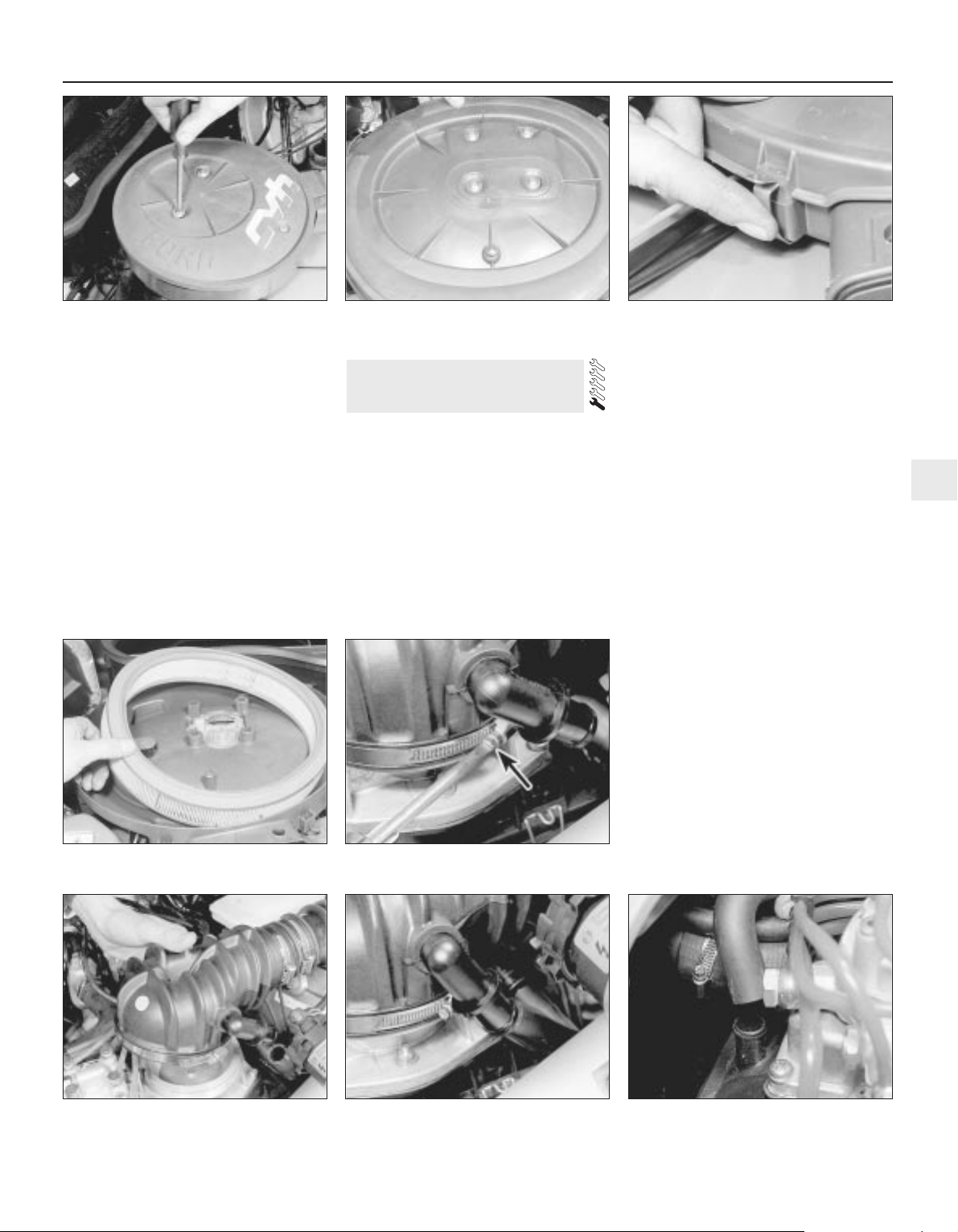

10.16 K-Jetronic system idle speed

adjustment screw (arrowed) on later

models

10.13b Weber 2V carburettor mixture adjustment screw (A) and

idle speed adjustment screw (B) - 1.6 litre models

10.15 Idle speed adjustment screw

(arrowed) on early K-Jetronic systems

10.13c Idle speed screw (A) and mixture

adjustment screw (B) on Weber 2V TLDM

carburettor (1.1 and 1.3 HCS engines)

10.13a Weber 2V carburettor idle speed adjustment screw (A) and

mixture screw (B) - XR3 and 1.4 litre models

10.21 K-Jetronic system mixture

adjustment screw location (arrowed)

Every 6000 miles or 6 Months 1•11

1

idle speed adjustment screw as required until

the engine is idling at the specified speed.

31 To check the mixture adjustment an

exhaust gas analyser is needed and should be

connected in accordance with the

manufacturer’s instructions. A 3 mm Allen key

will also be required to make any adjustments.

32 Before proceeding ensure that the idle

speed is correct.

33 Unscrew the tamperproof plug from the

mixture adjustment orifice on top of the fuel

distributor (see illustration).

34 Stabilise the exhaust gases (paragraph 30).

35 Insert the Allen key into the mixture

adjustment orifice and push down to engage

the adjustment screw. Turn the adjustment

screw clockwise to increase the CO reading

and anti-clockwise to decrease it. Remove the

Allen key, plug the orifice and check the CO

reading.

36 If the mixture adjustment cannot be

finalised within 30 seconds from the moment

of stabilising the exhaust gases, repeat the

operations in paragraph 30 before continuing

the adjustment procedure. Make sure that the

Allen key is removed before increasing the

engine speed otherwise the fuel distributor

will be damaged.

37 Continue adjustment until the correct CO

reading is obtained, then if necessary readjust

the idle speed.

38 Refit the tamperproof screw and

reconnect the pressure actuator multi-plug.

Disconnect the tachometer and exhaust gas

analyser.

Models with Central (single-point)

Fuel Injection (CFI) system

39 Both the idle speed and mixture are

controlled by the engine management system.

Adjustment requires the use of specialist

equipment. If the idle speed is suspected of

being incorrect, the vehicle must be taken to a

Ford dealer for diagnostic checks and, if

necessary, adjustment.

Models with Electronic Fuel

Injection (EFI) system

40 Idle speed is controlled by the EEC IV

module, and cannot be adjusted.

41 To adjust the mixture (CO content), first

run the engine until it reaches normal

operating temperature.

42 Connect a CO meter and a tachometer in

accordance with the manufacturer’s

instructions.

43 Clear any excess fuel in the inlet manifold

by running the engine at 3000 rpm for

approximately 15 seconds, then allow the

engine to idle.

44 Wait for the test instrument readings to

stabilise, then record the CO content and the

idle speed.

45 If adjustment of the CO content is

required, remove the tamperproof cap from

the CO adjustment potentiometer (located on

the wing panel behind the left-hand

suspension turret) and adjust the screw to

obtain the correct CO setting at the specified

idle speed (see illustration). Note that any

adjustment must be made within 30 seconds

of the instrument readings stabilising,

otherwise the procedure described in

paragraph 43 must be repeated.

46 On completion of adjustment, stop the

engine and disconnect all test equipment. Fit

a new tamperproof cap to the CO adjustment

potentiometer.

1 Where applicable, remove the distributor

cap and thoroughly clean it inside and out

with a dry lint-free cloth. Examine the four HT

lead segments inside the cap. If the segments

appear badly burnt or pitted, renew the cap.

Make sure that the carbon brush in the centre

of the cap is free to move and that it protrudes

significantly from its holder.

2 Check the distributor cap for signs of

tracking (indicated by thin black lines on the

surface of the cap). Renew the cap if tracking

is evident.

3 Wipe clean the HT leads and the coil tower.

4 Check the condition and security of all

leads and wiring associated with the ignition

system. Make sure that no chafing is

occurring on any of the wires and that all

connections are secure, clean and free from

corrosion.

1 Remove the distributor cap and the rotor

arm.

2 Apply a couple of drops of light oil to the

felt pad in the top of the shaft.

3 Wipe clean the distributor cam, then apply

a trace of high melting-point grease to the

four cam lobes.

4 Refit the rotor arm and the distributor cap.

1 Spring back the retaining clips or undo the

screws as appropriate and lift off the

distributor cap.

2 Withdraw the rotor arm from the distributor

shaft.

3 Using a screwdriver, gently prise the

contact breaker points open to examine the

condition of their faces. If they are rough,

pitted or dirty they should be renewed as

described in the next Section.

4 Assuming that the points are in a satisfactory

condition or that they have just been renewed,

the gap between the two faces should be

checked and if necessary adjusted. This can be

done using feeler blades as described in the

following paragraphs, or preferably by using

the more accurate dwell angle method as

described from paragraph 8 onwards.

13 Contact breaker points

adjustment - models with

contact breaker distributor

12 Distributor lubrication -

models with contact breaker

distributor

11 Ignition system component

check

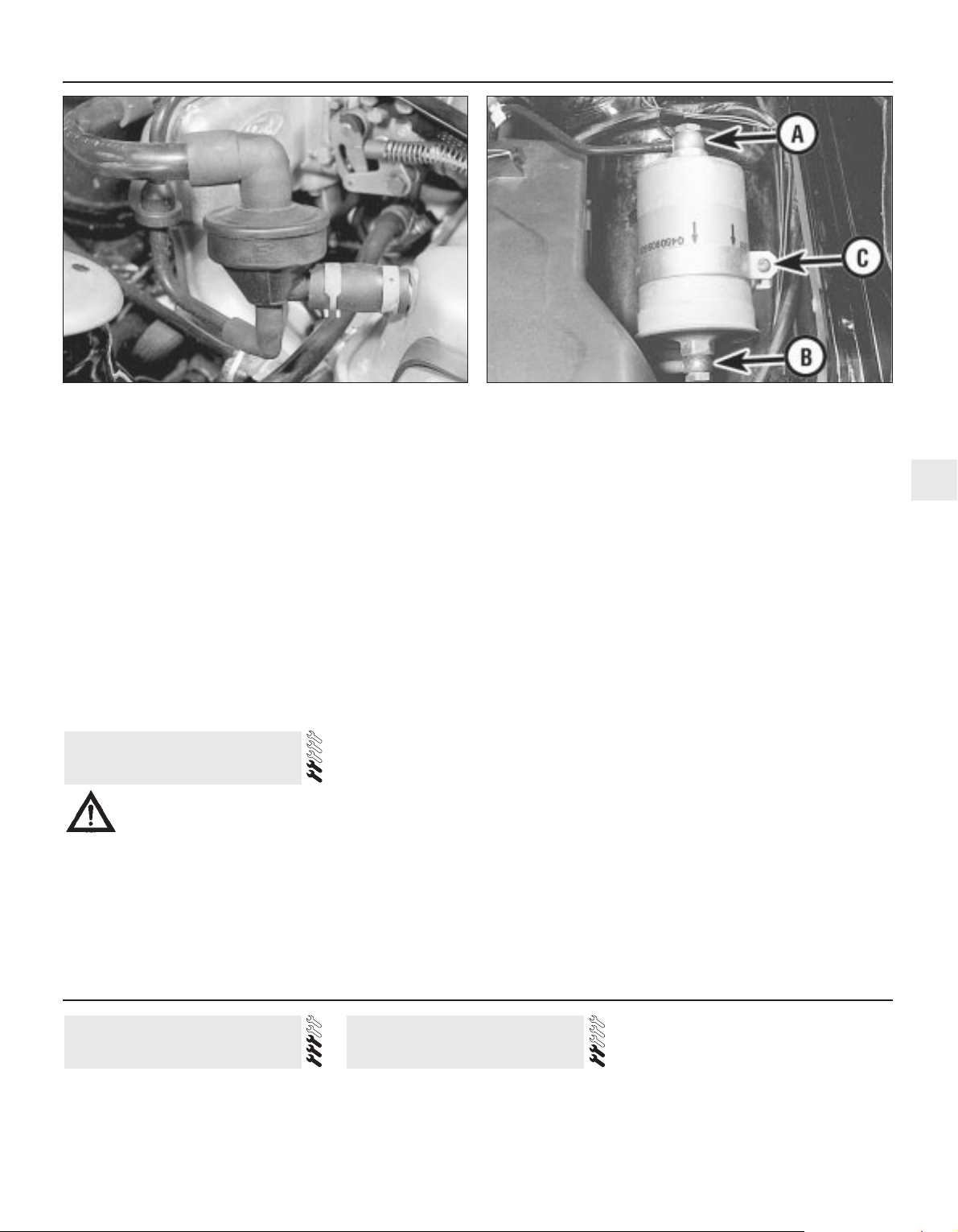

10.29 Pressure actuator wiring multi-plug

(arrowed) - KE-Jetronic system

10.27 Idle speed adjustment screw

(arrowed) on KE-Jetronic system

10.45 CO adjustment potentiometer

location (arrowed) - 1.6 EFI engine

10.33 KE-Jetronic system mixture

adjustment tamperproof plug (arrowed)

5 To adjust the points using feeler blades,

turn the crankshaft using a spanner on the

crankshaft pulley bolt until the heel of the

contact breaker arm is on the peak of one of

the four cam lobes and the points are fully

open. A feeler blade of thickness equal to the

contact breaker points gap as given in the

Specifications should now just slide between

the point faces (see illustrations).

6 If adjustment is required, slacken the

retaining screw slightly and move the fixed

point as necessary to achieve the desired gap

(see illustrations). After adjustment tighten

the retaining screw and recheck the gap.

7 Refit the rotor arm and the distributor cap.

8 If a dwell meter is available adjust the

contact breaker points by measuring and

setting the dwell angle as follows.

9 The dwell angle is the number of degrees of

distributor cam rotation during which the

contact breaker points are closed; ie the

period from when the points close after being

opened by one cam lobe, until they are

opened again by the next cam lobe. The

advantages of setting the points by this

method are that any wear of the distributor

shaft or cam lobes is taken into account and

the inaccuracies associated with using feeler

blades are eliminated. Also, on 1.1 litre CVH

engines the static ignition timing is accurately

set in production and adjustment of the

ignition timing in service has been deleted

from the maintenance schedule. Therefore

dwell angle adjustment is far more critical on

these engines.

10 In general a dwell meter should be used in

accordance with the manufacturer’s

instructions. However, the use of one type of

meter is outlined as follows.

11 Remove the distributor cap and rotor arm

and connect one lead of the dwell meter to

the “+” terminal on the coil and the other lead

to the coil “-” terminal.

12 Whilst an assistant turns on the ignition

and cranks the engine on the starter, observe

the reading on the dwell meter scale. With the

engine cranking the reading should be equal

to the dwell angle given in the Specifications.

13 If the dwell angle is too small, the contact

breaker points gap should be reduced and if

the dwell angle is excessive the gap should be

increased.

14 Adjust the points gap while the engine is

cranking using the method described in

paragraph 6. When the dwell angle is

satisfactory, disconnect the meter, then refit

the rotor arm and distributor cap.

15 Check the ignition timing (Section 14).

1•12 Every 6000 miles or 6 Months

13.5a Contact breaker points gap (A) - Bosch distributor

13.6a Contact breaker point components - Bosch distributor

A LT lead connector B Contact breaker retaining screw

13.6b Contact breaker point components - Lucas distributor

A Secondary movement cam and peg B Contact breaker retaining screw

13.5b Contact breaker points gap (A) - Lucas distributor

The points can be easily

moved by engaging a

screwdriver in the slot on the

end of the fixed point and

levering against the corresponding slot

or raised pips on the baseplate.

Note: With modern ignition systems the only

suitable way to time the ignition accurately is

with a stroboscopic timing light. However, for

initial setting up purposes (ie after major

overhaul, or if the timing has been otherwise

completely lost) a basic initial static setting

may be used to get the engine started Once

the engine is running, the timing should be

accurately set using the timing light. Before

carrying out any of the following, ensure that

the contact breaker points are correctly

adjusted as described in Section 13.

1 In order that the engine can run efficiently, it

is necessary for a spark to occur at the spark

plug and ignite the fuel/air mixture at the

instant just before the piston on the

compression stroke reaches the top of its

travel. The precise instant at which the spark

occurs is determined by the ignition timing

and this is quoted in degrees before top dead

centre (BTDC).

2 If the timing is being checked as a

maintenance or service procedure, refer to

paragraph 11 onwards. If the distributor has

been dismantled or renewed, or if its position

on the engine has been altered, obtain an

initial static setting as follows.

Static setting

3 Pull off the plug lead and remove No 1

spark plug (nearest the crankshaft pulley).

4 Place a finger over the plug hole and turn

the crankshaft in the normal direction of

rotation (clockwise from the crankshaft pulley

end) until pressure is felt in No 1 cylinder. This

indicates that the piston is commencing its

compression stroke. The crankshaft can be

turned with a spanner on the pulley bolt.

5 Continue turning the crankshaft until the

notch on the pulley is aligned with the

appropriate mark on the timing scale for the

engine being worked on (see Specifications).

On OHV engines the timing scale is cast into

the timing cover and situated just above and

to the right of the pulley. On CVH engines the

scale is moulded into the timing belt cover

and is situated directly above the pulley. On

all engines the “O” mark on the scale

represents Top Dead Centre (TDC) and the

raised projections to the left of TDC are in

increments of 4° BTDC (see illustrations).

6 Remove the distributor cap and check that

the rotor arm is pointing towards the No 1

spark plug lead segment in the cap.

7 Slacken the distributor clamp pinch bolt

(OHV engines) or the three distributor flange

securing bolts (CVH engines) (see

illustration).

8 Turn the distributor body anti-clockwise

slightly until the contact breaker points are

closed, then slowly turn the distributor body

clockwise until the points just open. Hold the

distributor body in this position and tighten

the clamp pinch bolt or flange securing bolts

as applicable.

9 Refit the distributor cap, No 1 spark plug

and the plug lead.

10 It should now be possible to start and run

the engine enabling the timing to be

accurately checked with a timing light as

follows.

Stroboscopic setting

11 Refer to the Specifications for the timing

setting applicable to the engine being worked

on and then highlight the appropriate mark on

the timing scale and the notch in the pulley

with a dab of white paint (see paragraph 5).

12 Connect a timing light to the engine in

accordance with the manufacturer’s

instructions (usually between No 1 spark plug

and plug lead).

13 Disconnect the vacuum hose at the

distributor vacuum unit and plug the hose.

14 Start the engine and allow it to idle.

15 Point the timing light at the timing marks.

They should appear to be stationary with the

crankshaft pulley notch in alignment with the

appropriate notch on the scale.

16 If adjustment is necessary (ie the marks are

not aligned) slacken the distributor clamp pinch

bolt or flange securing bolts as applicable, and

turn the distributor body as necessary to align

the marks. Tighten the pinch bolt or flange

bolts when the setting is correct.

17 A secondary use of the timing light is to

check that the centrifugal and vacuum

advance functions of the distributor are

working.

18 The tests are not of course precise as

would be the case if sophisticated equipment

were used, but will at least indicate the

serviceability of the unit.

19 With the engine idling, timing light

connected and vacuum pipe disconnected

and plugged as described in the preceding

paragraphs, increase the engine speed to

2000 rpm and note the approximate distance

which the pulley mark moves out of alignment

with the mark on the scale.

20 Reconnect the vacuum pipe to the

distributor and repeat the test when for the

same increase in engine speed, the alignment

differential of the timing marks should be

greater than previously observed.

21 If the timing marks did not appear to move

during the first test, a fault in the distributor

centrifugal advance mechanism is indicated.

No increased movement of the marks during

the second test indicates a punctured

diaphragm in the vacuum unit, or a leak in the

vacuum line.

22 On completion of the adjustments and

checks, switch off the engine and disconnect

the timing light.

1 The correct functioning of the spark plugs is

vital for the correct running and efficiency of

the engine. It is essential that the plugs fitted

are appropriate for the engine, and the

suitable type is specified at the end of this

chapter. If this type is used and the engine is

in good condition, the spark plugs should not

need attention between scheduled

replacement intervals. Spark plug cleaning is

rarely necessary and should not be attempted

unless specialised equipment is available as

damage can easily be caused to the firing

ends.

15 Spark plug renewal -

RS Turbo models

14 Ignition timing check - models

with contact breaker distributor

Every 6000 miles or 6 Months 1•13

1

14.5b Crankshaft pulley notch (arrowed)

and timing scale - CVH engine

14.7 Distributor clamp pinch-bolt location

(arrowed) - OHV engines

14.5a Timing mark identification OHV engines

A Notch on crankshaft pulley

B Timing scale cast into timing cover

2 To remove the plugs, first mark the HT

leads to ensure correct refitment, then pull

them off the plugs. When removing the leads,

pull the terminal insulator at the end of the

lead - not the lead itself.

3 Using a spark plug spanner or deep socket

and extension bar, unscrew the plugs and

remove them from the engine (see

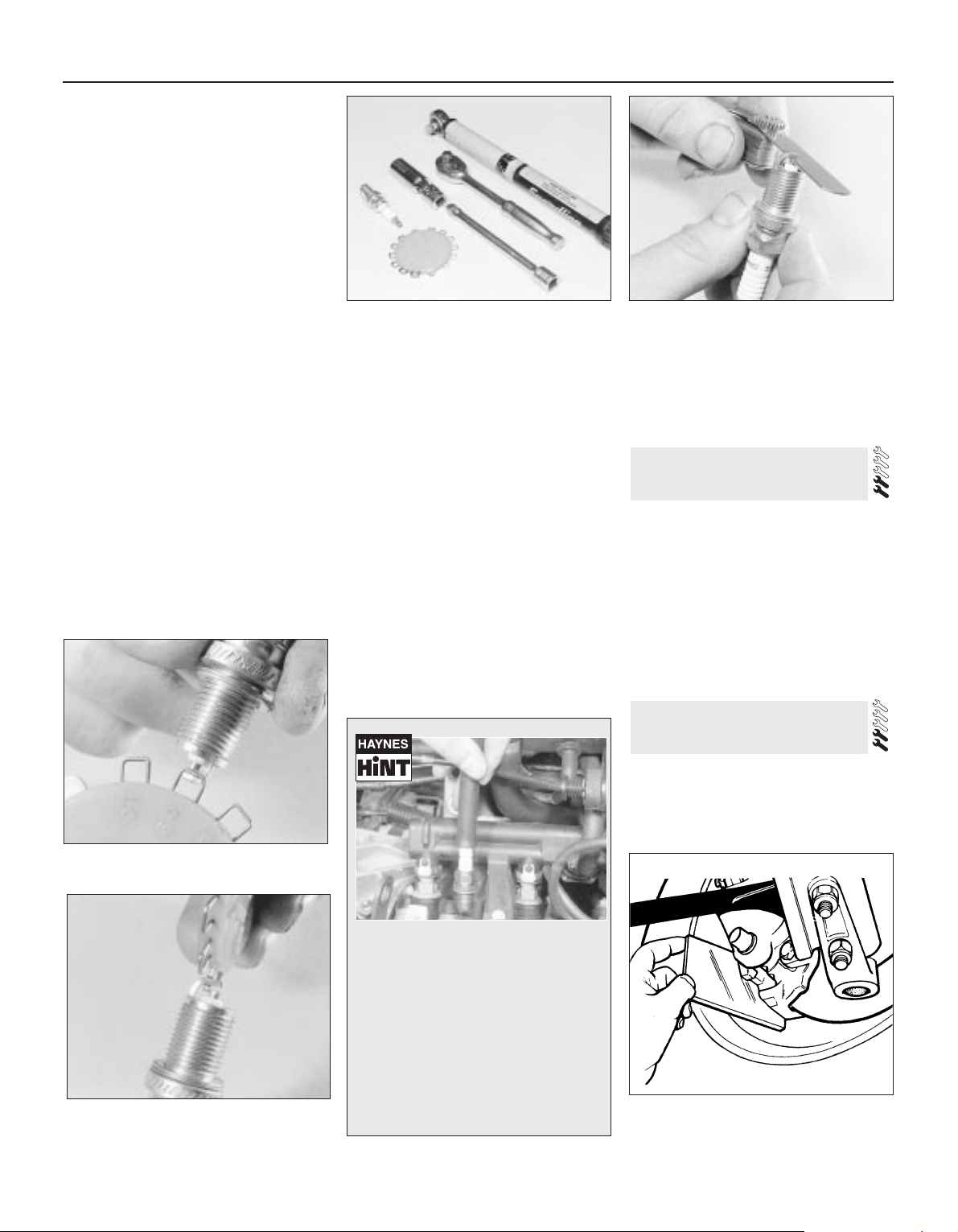

illustration).

4 The condition of the spark plugs will also

tell much about the condition of the engine.

5 If the insulator nose of the spark plug is

clean and white, with no deposits, this is

indicative of a weak mixture, or too hot a plug.

(A hot plug transfers heat away from the

electrode slowly - a cold plug transfers it away

quickly.)

6 If the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

7 If the insulator nose is covered with light tan

to greyish brown deposits, then the mixture is

correct and it is likely that the engine is in

good condition.

8 The spark plug gap is of considerable

importance, as if it is too large or too small,

the size of the spark and its efficiency will be

seriously impaired. The spark plug gap should

be set to the figure given in the Specifications

at the beginning of this Chapter.

9 To set it, measure the gap with a feeler

blade, and then bend open, or close, the outer

plug electrode until the correct gap is

achieved (see illustration). The centre

electrode should never be bent as this may

crack the insulation and cause plug failure, if

nothing worse.

10 Special spark plug electrode cap

adjusting tools are available from most motor

accessory shops (see illustrations).

11 Before fitting the plugs first ensure that the

plug threads and the seating area in the

cylinder head are clean, dry and free of carbon.

12 Screw the plugs in by hand initially and

then fully tighten to the specified torque. If a

torque wrench is not available, tighten the

plugs until initial resistance is felt, then tighten

by a further

1

⁄16 of a turn for the taper seat plugs

fitted to OHV engines, or

1

⁄4 of a turn for the

gasket seat type fitted to CVH engines. Do not

over-tighten the spark plugs, otherwise

damage to the threads may occur and they

will also be extremely difficult to remove in the

future.

13 Refit the plug leads in the correct order

ensuring that they are a secure fit over the

plug ends. Periodically wipe the leads clean to

reduce the risk of HT leakage by arcing and

remove any traces of corrosion that may

occur on the end fittings.

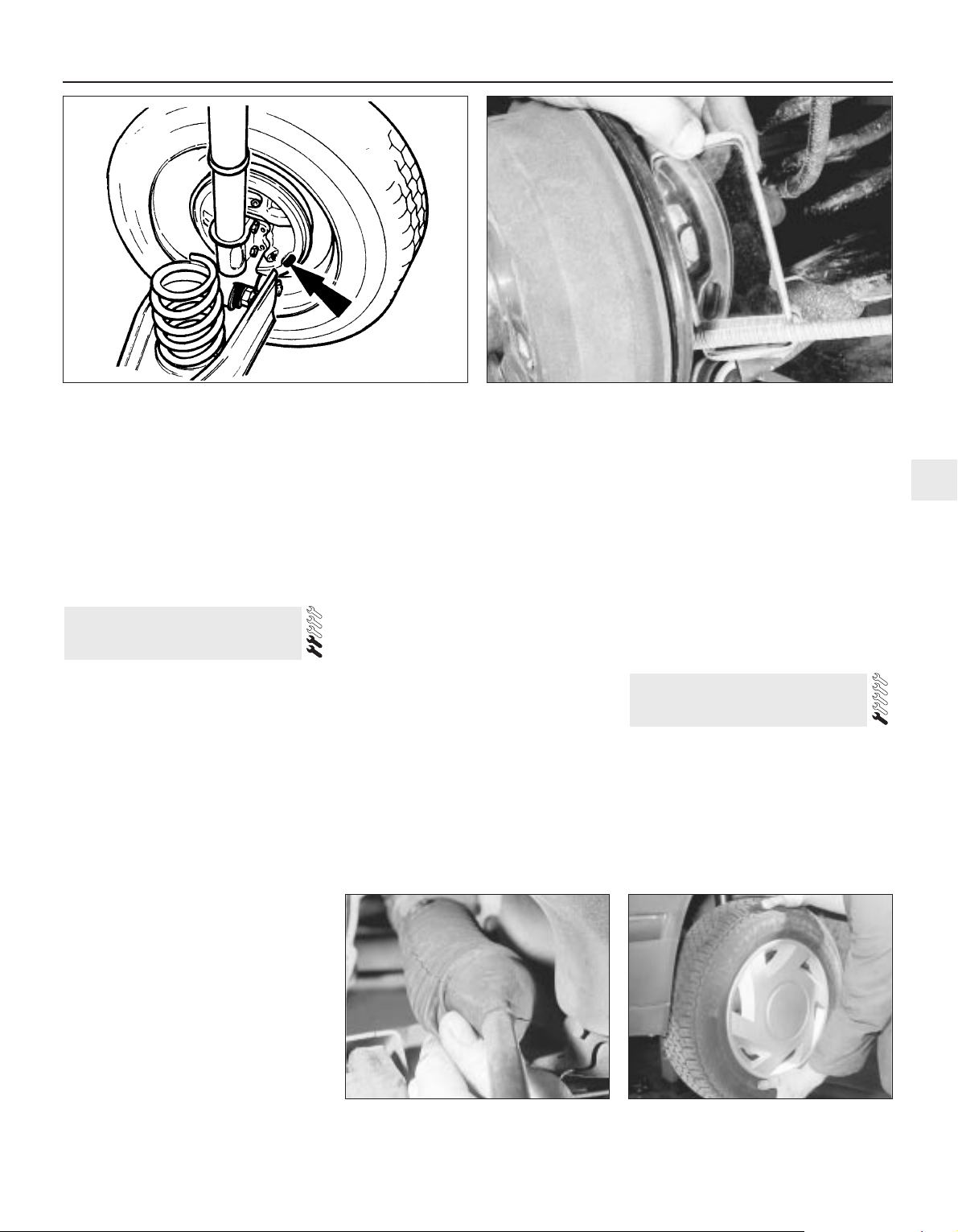

1 Place a mirror between the roadwheel and

the caliper and check the thickness of the

friction material of the disc pads (see

illustration). If the material has worn down to

the specified minimum or less, the pads must

be renewed as an axle set (four pads).

2 For a comprehensive check, the brake

pads should be removed and cleaned. This

will permit the operation of the caliper to be

checked, and the condition of the brake disc

itself to be examined on both sides. Refer to

Chapter 9 for further information.

1 Due to the fact that the rear brake drums

are combined with the hubs, which makes

removal of the drums more complicated than

is the case with detachable drums, inspection

of the shoe linings can be carried out at the

17 Rear brake shoe lining check

16 Front brake disc pad check

1•14 Every 6000 miles or 6 Months

15.9 Measuring the spark plug gap with a

feeler blade

15.10a Measuring the spark plug gap with

a wire gauge . . .

16.1 Checking the front disc pad wear

using a mirror

15.10b . . . and adjusting the gap using a

special adjusting tool

15.3 Tools required for spark plug

removal, gap adjustment and refitting

It is very often difficult to insert spark

plugs into their holes without crossthreading them. To avoid this

possibility, fit a short length of 5/16inch internal diameter rubber hose

over the end of the spark plug. The

flexible hose acts as a universal joint

to help align the plug with the plug

hole. Should the plug begin to crossthread, the hose will slip on the spark

plug, preventing thread damage to the

aluminium cylinder head.

specified intervals by prising out the small

inspection plug from the brake backplate and

observing the linings through the hole using a

mirror (see illustrations).

2 A minimum thickness of friction material

must always be observed on the shoes. If it is

worn down to this level, renew the shoes.

3 Do not attempt to re-line shoes yourself but

always obtain factory re-lined shoes.

4 Renew the shoes in an axle set (four shoes),

even if only one is worn to the minimum.

Front suspension and steering

check

1 Raise the front of the vehicle, and securely

support it on axle stands (see “Jacking and

Vehicle Support”).

2 Visually inspect the balljoint dust covers

and the steering rack-and-pinion gaiters for

splits, chafing or deterioration (see

illustration). Any wear of these components

will cause loss of lubricant, together with dirt

and water entry, resulting in rapid

deterioration of the balljoints or steering gear.

3 Grasp the roadwheel at the 12 o’clock and

6 o’clock positions, and try to rock it (see

illustration). Very slight free play may be felt,

but if the movement is appreciable, further

investigation is necessary to determine the

source. Continue rocking the wheel while an

assistant depresses the footbrake. If the

movement is now eliminated or significantly

reduced, it is likely that the hub bearings are

at fault. If the free play is still evident with the

footbrake depressed, then there is wear in the

suspension joints or mountings.

4 Now grasp the wheel at the 9 o’clock and 3

o’clock positions, and try to rock it as before.

Any movement felt now may again be caused

by wear in the hub bearings or the steering

track-rod balljoints. If the inner or outer balljoint

is worn, the visual movement will be obvious.

5 Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected as the mountings

are made of rubber, but excessive wear

should be obvious. Also check the condition

of any visible rubber bushes, looking for splits,

cracks or contamination of the rubber.

6 With the car standing on its wheels, have an

assistant turn the steering wheel back and

forth about an eighth of a turn each way.

There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previously

described, but in addition, check the steering

column universal joints for wear, and the rackand-pinion steering gear itself.

7 Visually check that each lower arm balljoint

is correctly located in the hub carrier, ensuring

that the Torx type pinch-bolt is fully engaged

in the groove in the balljoint stud.

Suspension strut/shock absorber

check

8 Check for any signs of fluid leakage around

the suspension strut/shock absorber body, or

from the rubber gaiter around the piston rod.

Should any fluid be noticed, the suspension

strut/shock absorber is defective internally,

and should be renewed. Note: Suspension

struts/shock absorbers should always be

renewed in pairs on the same axle.

9 The efficiency of the suspension

strut/shock absorber may be checked by

bouncing the vehicle at each corner.

Generally speaking, the body will return to its

normal position and stop after being

depressed. If it rises and returns on a

rebound, the suspension strut/shock

absorber is probably suspect. Examine also

the suspension strut/shock absorber upper

and lower mountings for any signs of wear.

1 Periodically check the belts for fraying or

other damage. If evident, renew the belt.

2 If the belts become dirty, wipe them with a

damp cloth using a little detergent only.

3 Check the tightness of the anchor bolts and

if they are ever disconnected, make quite sure

that the original sequence of fitting of

washers, bushes and anchor plates is

retained.

19 Seat belt check

18 Suspension and steering

check

Every 6000 miles or 6 Months 1•15

1

17.1a Brake shoe viewing hole location (arrowed) in backplate 17.1b Checking rear brake lining wear with a mirror

18.3 Rocking the roadwheel to check

steering/suspension components

18.2 Checking a steering gear gaiter

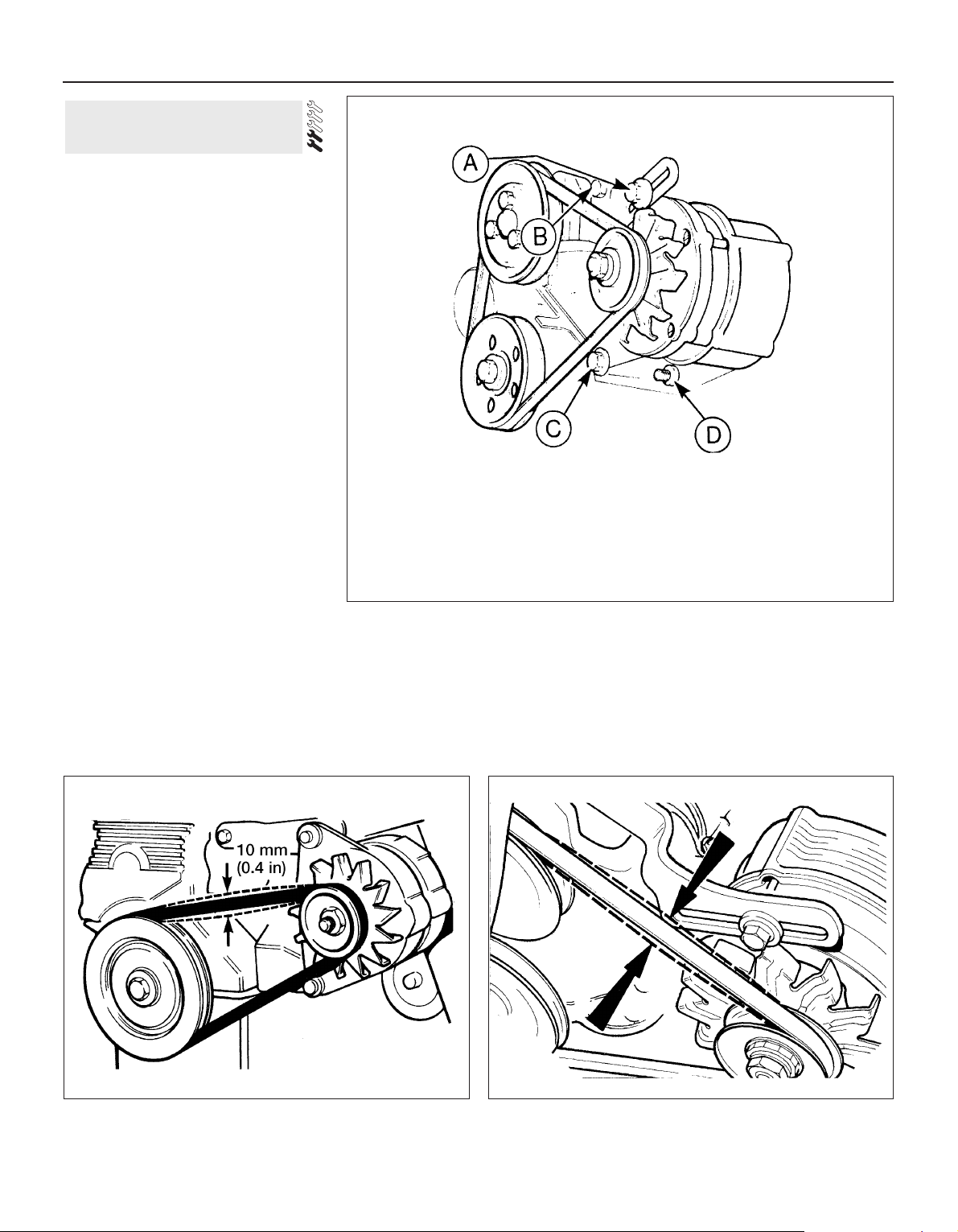

1 A conventional vee drivebelt is used to

drive both the alternators and water pump

pulleys on OHV and HCS engines, and the

alternator pulley only on CVH engines, power

being transmitted via a pulley on the engine

crankshaft.

2 To remove the drivebelt, slacken the

alternator mounting bolts and the bolts on the

adjuster link and push the alternator in

towards the engine as far as possible (see

illustration).

3 Withdraw the belt from the pulleys. In some

instances it may also be necessary to remove

the adjuster link-to-alternator bolt to avoid

straining the drivebelt.

4 Fit the belt by slipping it over the pulley

rims. If necessary remove the adjuster link-toalternator bolt, if not already done, to avoid

straining the belt. Never be tempted to

remove or refit the drivebelt by prising it over

a pulley rim otherwise the pulley or the

drivebelt internal webbing will be damaged.

5 To tension the belt pull the alternator away

from the engine until the belt is fairly taut, and

tighten the adjuster link-to-alternator bolt.

Check that the total deflection of the belt,

using finger pressure at a point midway

between the alternator and crankshaft or

water pump pulleys, is 10 mm (0.4 in) (see

illustrations). A little trial and error may be

necessary to obtain the correct tension. If the

belt is too slack, it will slip in the pulleys and

soon become glazed or burnt. This is often

indicated by a screeching noise as the engine

is accelerated, particularly when the

headlights or other electrical accessories are

switched on. If the belt is too tight the

bearings in the water pump and/or alternator

will soon be damaged.

6 Once the tension is correct, tighten the

remaining adjuster link bolt, front mounting

bolt and rear mounting bolt in that order.

7 If a new belt has been fitted the tension

should be rechecked and adjusted again if

necessary after the engine has run for

approximately ten minutes.

20 Alternator drivebelt check

1•16 Every 6000 miles or 6 Months

20.5a Drivebelt tension checking point - CVH engines 20.5b Drivebelt tension checking point - OHV engines

20.2 Alternator mounting and adjuster link bolts

A Adjuster link-to-alternator bolt

B Adjuster link-to-engine bolt

C and D Alternator mounting bolts

Maintenance procedures 1•17

1

OHV engines

1 This operation should be carried out with

the engine cold and the air cleaner and rocker

cover removed.

2 Using a ring spanner or socket on the

crankshaft pulley bolt, turn the crankshaft in a

clockwise direction until No 1 piston is at TDC

on its compression stroke. This can be

verified by checking that the pulley and timing

cover marks are in alignment and that the

valves of No 4 cylinder are rocking. When the

valves are rocking, this means that the

slightest rotation of the crankshaft pulley in

either direction will cause one rocker arm to

move up and the other to move down.

3 Numbering from the thermostat housing

end of the cylinder head, the valves are

identified as follows.

Valve No Cylinder No

1 Exhaust 1

2 Inlet 1

3 Exhaust 2

4 Inlet 2

5 Exhaust 3

6 Inlet 3

7 Exhaust 4

8 Inlet 4

4 Adjust the valve clearances by following the

sequence given in the following table. Turn

the crankshaft pulley 180º (half a turn) after

adjusting each pair:

Valves rocking Valves to adjust

7 and 8 1 (Exhaust), 2 (Inlet)

5 and 6 3 (Exhaust), 4 (Inlet)

1 and 2 7 (Exhaust), 8 (Inlet)

3 and 4 5 (Exhaust), 6 (Inlet)

5 The clearances for the inlet and exhaust

valves are different (see Specifications). Use a

feeler blade of the appropriate thickness to

check each clearance between the end of the

valve stem and the rocker arm. The gauge

should be a stiff sliding fit. If it is not, turn the

adjuster bolt with a ring spanner. These bolts

are of stiff thread type and require no locking

nut. Turn the bolt clockwise to reduce the

clearance and anti-clockwise to increase it

(see illustration).

6 Refit the air cleaner and rocker cover on

completion of adjustment.

HCS engines

7 The procedure is as described previously

for OHV engines, but note that the valve

arrangement has been altered and is now as

shown below. Take care not to overtighten the

rocker cover bolts on refitting, as this can

result in leaks.

Valve No Cylinder No

1 Exhaust 1

2 Inlet 1

3 Exhaust 2

4 Inlet 2

5 Inlet 3

6 Exhaust 3

7 Inlet 4

8 Exhaust 4

With the vehicle raised on a hoist or

supported on axle stands (see “Jacking and

Vehicle Support”), check the exhaust system

for signs of leaks, corrosion or damage and

check the rubber mountings for condition and

security (see illustration). Where damage or

corrosion are evident, renew the system

complete or in sections, as applicable, using

the information given in Chapter 4, Part E.

Check the tightness of the turbocharger-toexhaust manifold securing nuts using a torque

wrench.

The procedure is as described for RS Turbo

models in Section 15.

1 Spring back the retaining clips or undo the

screws as appropriate and lift off the

distributor cap.

2 Withdraw the rotor arm from the distributor

shaft.

3 On the Bosch distributor disconnect the

contact breaker points LT lead at the spade

connector. On the Lucas distributor ease the

contact breaker spring arm out of the plastic

insulator and slide the combined LT and

condenser lead out of the hooked end of the

spring arm.

4 Undo the retaining screw and withdraw the

contact breaker points from the distributor

baseplate. Take care not to drop the screw

and washer inside the distributor during

removal and refitting. If possible use a

magnetic screwdriver, or alternatively, retain

the screw on the end of the screwdriver using

a dab of grease.

5 Wipe clean the distributor cam, then apply

a trace of high-melting-point grease to the

four cam lobes. Also, on OHV engines apply

two drops of light oil to the felt pad at the top

of the distributor shaft.

25 Contact breaker points

renewal

24 Spark plug renewal

23 Turbocharger-to-manifold

nut check - RS Turbo models

22 Exhaust system check

21 Valve clearance adjustment -

OHV and HCS engines

21.5 Valve clearance adjustment 22.1 Exhaust silencer mounting

Every 12 000 miles or 12 months

6 Locate the new contact breaker points on

the baseplate and secure with the retaining

screw, lightly tightened only at this stage. On

the Lucas distributor ensure that the

secondary movement cam is engaged with

the peg, and that both washers are refitted

with the retaining screw (see illustration

13.6b).

7 Reconnect the LT lead, then refer to

Section 13 and adjust the contact breaker

points gap.

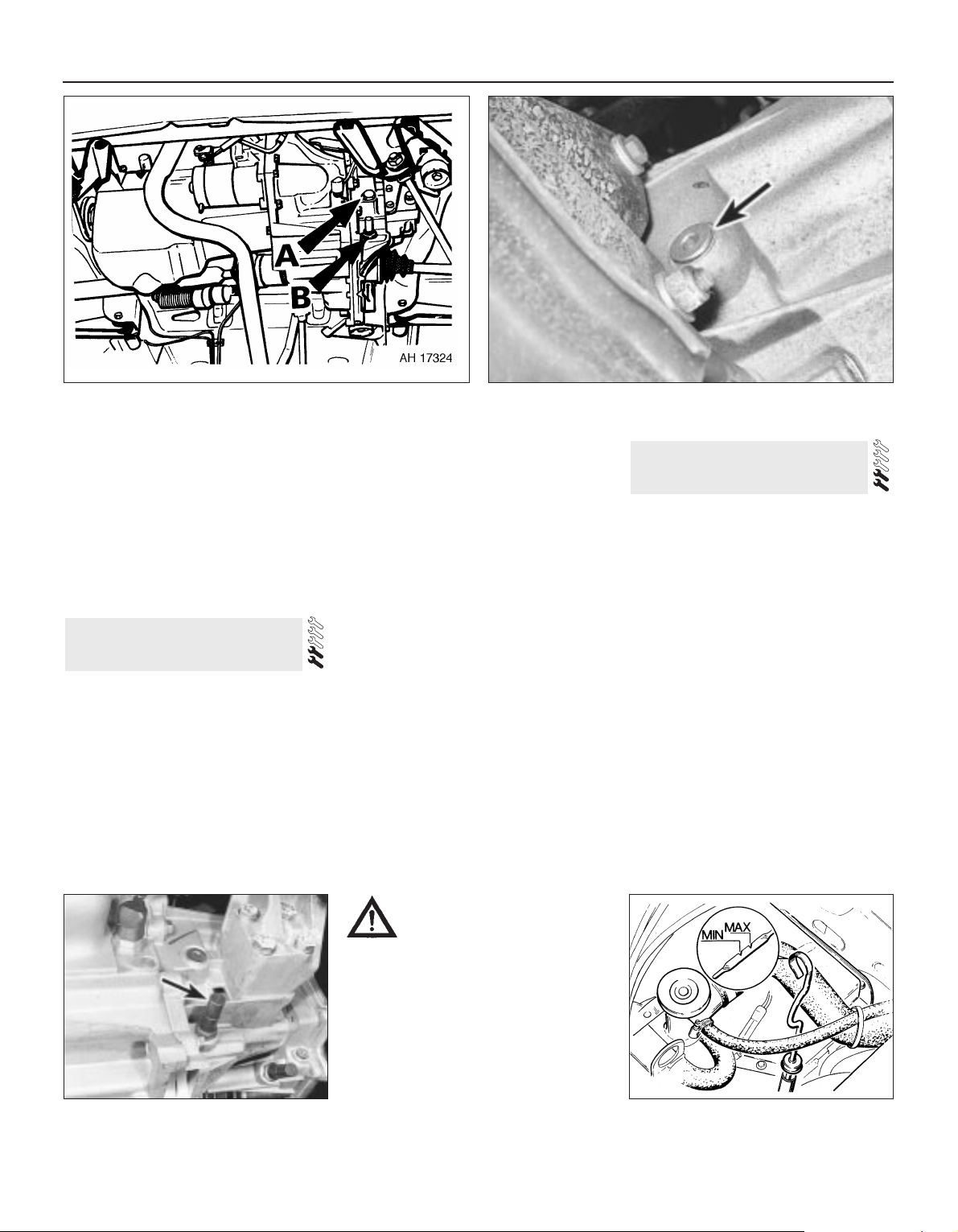

1 With the car on level ground wipe the area

around the filler plug, then unscrew the plug

using a socket spanner, or on later versions a

suitable Torx or Allen key or socket bit, as

applicable. Access can be gained from above

or below the car (see illustrations).

2 Locate the aluminium build code tag, which

is secured to one of the transmission housing

upper bolts, and note the transmission part

number stamped on the tag. If the last letter of

the part number suffix is a D then the

transmission was manufactured prior to

August 1985. Transmissions manufactured

from August 1985 have an E as the last letter

of the part number suffix.

3 On the early type transmission (suffix letter

D) the oil level must be maintained between 5

and 10 mm (0.2 and 0.4 in) below the lower

edge of the filler plug hole.

4 If the transmission is of the later type (suffix

letter E) the oil level must be maintained

between 0 and 5 mm (0.2 in) below the lower

edge of the filler plug hole.

5 To simplify the checking procedure a

dipstick can be made from thin rod bent at

right angles and having marks on one “leg”

made with a file at 5 mm (0.2 in) intervals. Rest

the unmarked leg on the lower edge of the

filler plug hole with the marked leg immersed

in the oil. Remove the dipstick, read off the

level and top-up if necessary using the

specified grade of oil. Refit the filler plug on

completion.

6 Renewal of the transmission oil is not a

service requirement, but if draining is

necessary prior to a repair or overhaul task

place a suitable container beneath the

selector shaft locking mechanism cap nut

located just below the filler plug (see

illustration). Unscrew the cap nut, remove

the spring and interlock pin and allow the oil

to drain.

1 The automatic transmission fluid level must

be checked when the engine and

transmission are at normal operating

temperature; preferably after a short journey.

2 Park the car on level ground, then fully

apply the handbrake.

3 With the engine running at its normal idle

speed, apply the footbrake and simultaneously

move the selector lever through the full range

of positions three times then move it back to

the P position. Allow the engine to run at idle

for a further period of one minute.

4 With the engine still idling, extract the

transmission fluid level dipstick and wipe it

dry, with a clean non-fluffy cloth. Fully reinsert

the dipstick and then extract it again and

check the fluid level mark, which must be

between the “MAX” and “MIN” markings (see

illustration)

5 If topping-up is necessary, use only the

specified fluid type and pour it through the

dipstick tube, but take care not to overfill. The

level must not exceed the “MAX” mark.

27 Automatic transmission fluid

level check

26 Manual transmission oil level

check

1•18 Every 12 000 miles or 12 Months

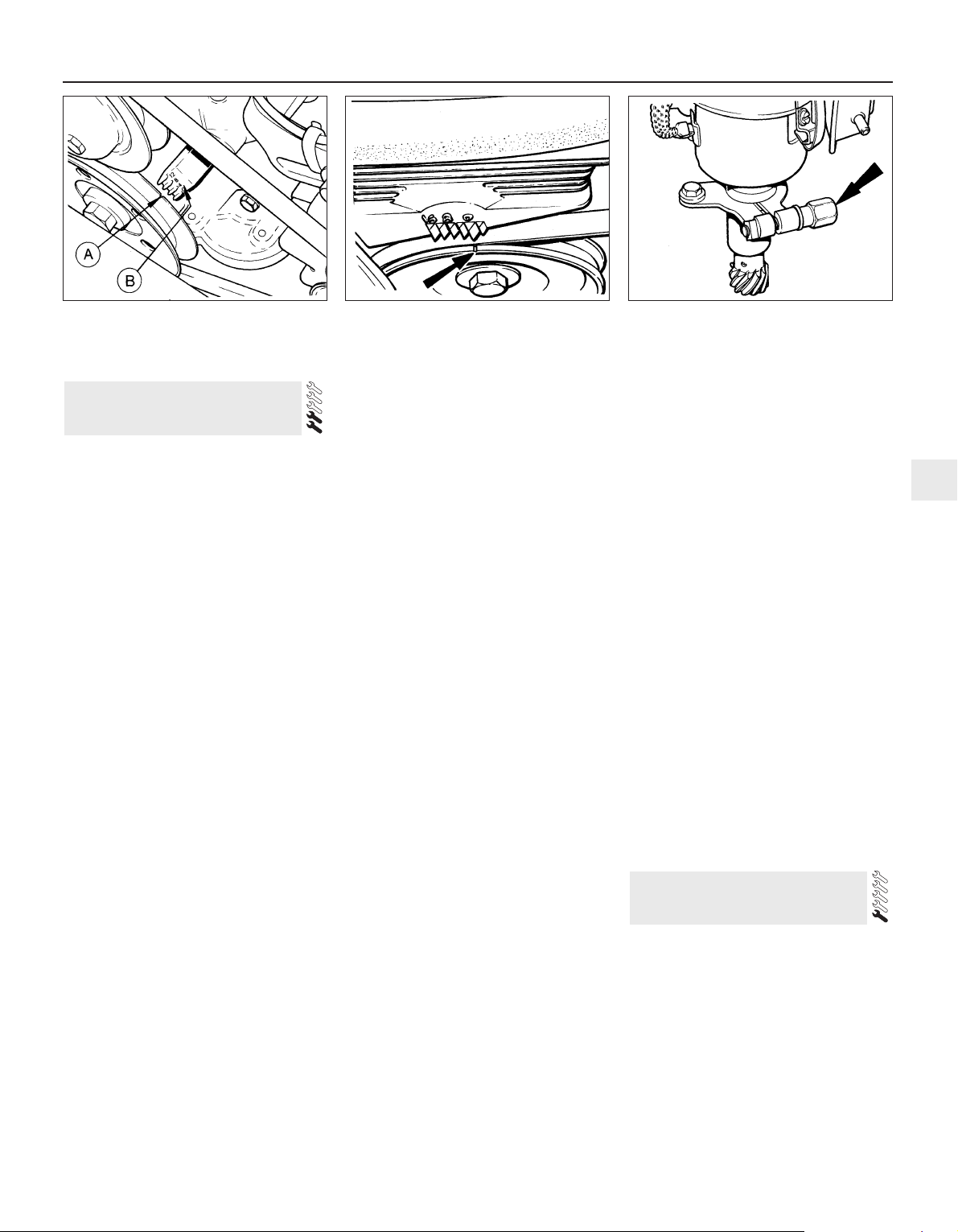

26.6 Selector shaft locking mechanism

cap nut (arrowed)

26.1a Transmission oil filler plug (A) and selector shaft locking

mechanism cap (B)

26.1b Allen type transmission filler plug (arrowed) as fitted to

later models

27.4 Transmission fluid level dipstick

location and level markings

Caution: Take care when