Ford 7.3L Service Manual

|

Table of contents |

|

|

Introduction |

2 |

|

|

|

|

Diesel information |

4 |

|

|

|

|

Warning lights |

7 |

|

|

|

|

Starting |

9 |

|

|

|

|

Driving tips |

14 |

|

|

|

|

General maintenance information |

19 |

|

|

|

|

Scheduled maintenance |

32 |

|

|

|

|

Minor troubleshooting guide |

33 |

|

|

|

|

Capacities and specifications |

36 |

|

|

|

|

Service points |

38 |

|

|

All rights reserved. Reproduction by any means, electronic or mechanical including photocopying, recording or by any information storage and retrieval system or translation in whole or part is not permitted without written authorization from Ford Motor Company.

Copyright r 1999 Ford Motor Company

1

Introduction

The following warning may be required by California law:

California Proposition 65 Warning: Diesel engine exhaust, some of its constituents, and certain vehicle components contain or

may emit chemicals known to the State of California to cause cancer or birth defects or other reproductive harm.

Your new diesel engine will feel, drive and function somewhat differently than a gasoline engine. Therefore it is very important that you read and thoroughly familiarize yourself and others operating the vehicle with this guide.

This guide will acquaint you with the Power Stroke (7.3L DIT) diesel engine. It provides recommendations on engine care and operating procedures. For complete vehicle information, also refer to the Owner Guide included with the vehicle. It also describes equipment and gives specifications for equipment that was in effect when this guide was approved for printing, and should be considered a permanent part of the vehicle.

Ford may discontinue models or change specifications without any notice and without incurring obligations.

IMPORTANT NOTICE

Ford vehicles are suitable for producing ambulances only if equipped with the Ford Ambulance Preparation Package. In addition, Ford urges ambulance manufacturers to follow the recommendation of the

Ford Incomplete Vehicle Manual, Ford Truck Body Builder's Layout Book (and pertinent supplements) and the ªQualified Vehicle Modifiers Guidelines.º Using a Ford vehicle without the Ford Ambulance Preparation Package to produce an ambulance voids the Ford warranty and could result in elevated underbody temperatures, fuel overpressurization and the risk of fuel expulsion and fires. To determine whether the vehicle is equipped with the Ford Ambulance Preparation Package, inspect the information plate on the driver's side door pillar. Contact the manufacturer of your vehicle to determine whether the ambulance manufacturer's followed Ford's recommendations.

2

Introduction

WARNINGS

Throughout this guide, you will find warnings. Warnings remind you to be especially careful to avoid personal injury.

NEW VEHICLE BREAK-IN

Your vehicle does not need an extensive break-in. Try not to drive continuously at the same speed for the first 1 600 km (1 000 miles) of new vehicle operation. Vary your speed to allow parts to adjust themselves to other parts.

Drive your new vehicle at least 800 km (500 miles) before towing a trailer.

Do not add friction modifier compounds or special break-in oils during the first few thousand kilometers (miles) of operation, since these additives may prevent piston ring seating. See ªEngine oilº in the General Maintenance Information chapter for more information on oil usage.

3

Diesel information

DIESEL ENGINE INFORMATION

The diesel engine fuel system consists of:

²a frame-mounted electric fuel supply pump

²an engine mounted fuel filter/water separator

²a fuel restriction sensor

²a unit injector for each cylinder

The combination fuel filter/water separator removes both water and impurities from the fuel. The filter should be changed at the recommended service interval. Refer to the ªService Guideº for more information. The filter bowl should be drained at regular intervals or when the ªWATER IN FUELº light illuminates in the instrument cluster.

The fuel injectors are located in the center of the combustion chambers in the cylinder head between the rocker arm assemblies. The glow plug system and fuel injection system are controlled through the powertrain control module (PCM).

Fuel is drawn from the fuel tank by a frame-mounted electric fuel pump. The fuel pump provides pressurized fuel to the engine and is electronically controlled by the fuel pump PCM relay. The fuel pump contains a pressure relief valve for overpressure protection in the event of restricted flow.

Lubrication system

It is important to change the engine oil at the recommended service intervals, because oil viscosity is important in maintaining the oil pressure required to actuate the fuel injectors. Extended oil change intervals can negatively affect engine performance and fuel economy.

The turbocharger, which is supplied pressurized oil, is also used to actuate an exhaust backpressure warm-up system (if equipped). Pressurized oil returning to the turbocharger is routed to the exhaust backpressure actuator. During exhaust backpressure operation, the engine's sound will be altered and you may notice a change in engine performance while it's engaged. This function occurs only during cold weather warm-up cycle.

4

Diesel information

Fast start glow plug system

The glow plug system consists of:

²eight glow plugs

²the glow plug relay

²engine oil temperature (EOT) sensor

²barometric pressure (BARO) sensor

The glow plug system is electronically controlled by the PCM. The PCM energizes the glow plugs immediately after the ignition is placed in the ON position, then determines how long the glow plugs will be on according to the EOT and BARO sensors. The required time for the glow plugs to be energized decreases as the engine oil temperature and barometric pressure increase.

Engine cooling system

The cooling system contains an engine oil cooler which is mounted to the side of the cylinder block. The cooler's function is to regulate engine oil temperature.

Engine governed speed

The engine governor is controlled by the PCM. The PCM controls fuel input to limit maximum engine speed. It will not, however, prevent engine overspeeding resulting from downshifting at high vehicle speed or by descending steep grades at too high a vehicle speed for the selected transmission gear.

For maximum vehicle speed in various gears, refer to the ªTransmission shift speedº chart in the Driving tips chapter. Do not exceed 3,600 rpm. Maximum engine governed speed is 3,000±4,000 rpm depending on engine load. Excessive rpm can only be achieved by manually downshifting at too high of a vehicle speed.

Operating the engine beyond the governed speed can cause severe engine damage.

5

Diesel information

Air filter restriction gauge

The restriction gauge, located on the clean-air side of the air cleaner upper housing, shows if the air filter is clogged. Refer to ªEngine Compartmentº in Service Points chapter.

The air filter element should be replaced when the yellow band on the gauge reaches the CHANGE FILTER mark. Engine performance and fuel economy are adversely affected when maximum restriction is reached. After servicing the air filter element, reset the restriction gauge by pressing the button the end of the gauge.

AIR F |

IL |

A |

TER G UGE |

||

CHANGE FILT |

ER |

C H |

|

ANGE FILTER |

|

AIR F |

IL |

|

A |

TER G |

UGE |

||

CHANGE FILTE |

R |

C H |

|

|

|

ANGE FILTER |

|

6

Warning lights

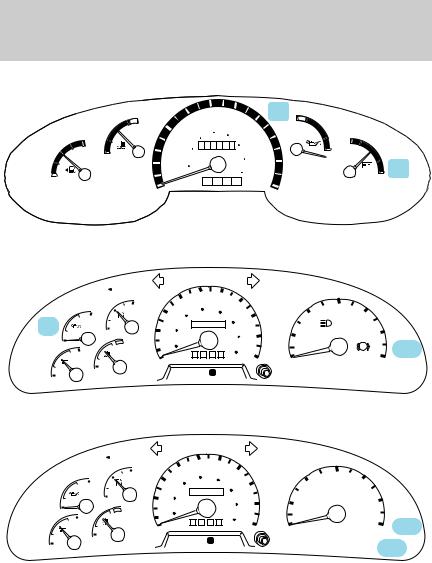

ECONOLINE

|

|

|

|

|

50 |

|

|

WAIT |

|

|

|

|

|

|

|

60 |

|

TO |

|

|

|

|

|

|

40 |

|

START |

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

H |

80 |

100 |

70 |

H |

|

|||

|

|

30 60 |

|

120 |

80 |

|

|

|||

F |

C |

|

40 |

0 0 0 0 0 0 |

|

L |

18 |

|||

2020 km/h |

|

|

140 90 |

|||||||

|

|

|

|

|

WATER |

|||||

|

|

10 |

|

|

|

|

|

|

|

8 FUEL |

E |

|

|

|

|

|

|

160 |

|

IN |

|

|

0 |

MPH |

0 0 |

0 0 |

|

100 |

|

|

||

|

|

|

|

|

||||||

F±250/350, EXCURSION

|

|

|

|

50 |

60 |

|

|

|

|

FUEL FILL |

|

40 |

70 |

|

3 |

|

|

|

|

|

|

|

|

4 |

||

|

F |

30 |

|

80 |

100 |

2 |

|

|

|

|

60 |

80 |

|

|

|||

|

H |

|

|

120 |

|

|

||

WATER |

|

|

|

|

FUEL |

|

||

IN |

E |

20 |

40 |

0 0 0 0 0 0 |

90 1 |

RESET |

5 |

|

FUEL |

|

140 |

|

|||||

|

L |

|

|

|

|

|

||

|

H |

10 |

20 |

|

|

|

ABS |

WAIT |

|

|

MPH 0 0 0 |

0 km/h 160 |

100 0 |

|

TO |

||

|

18 |

|

RPM X1000 |

START |

||||

|

C |

0 |

|

|

|

|

|

6 |

|

|

|

P R N D |

2 1 |

|

|

|

|

|

8 |

|

|

|

|

|

||

F±450/550

FUEL FILL |

|

40 |

50 |

60 |

|

|

3 |

|

|

|

|

|

|

70 |

|

|

|

||||

|

|

|

|

|

|

|

4 |

|

||

F |

30 |

|

|

80 |

100 |

|

2 |

|

|

|

|

60 |

|

|

80 |

|

|

|

|||

H |

|

|

|

120 |

|

|

|

|||

|

|

|

|

|

|

|

|

|||

E |

20 |

40 |

|

0 0 0 0 0 0 |

140 90 1 |

|

5 |

|

||

|

|

|

|

|

||||||

L |

|

|

|

|

|

|

|

|

||

H |

10 |

20 |

|

|

|

160 |

|

|

|

|

|

|

0 0 0 |

0 km/h |

100 0 |

|

|

WAIT |

|||

18 |

|

MPH |

RPM X1000 |

6 |

||||||

0 |

|

|

|

|

TO |

|||||

C |

|

|

|

|

|

|

|

START |

||

|

|

P R N D |

2 1 |

|

|

|

|

|

||

8 |

|

|

|

|

|

WATER |

||||

|

|

|

|

|

|

|

|

|

IN |

|

|

|

|

|

|

|

|

|

|

FUEL |

|

7

Warning lights

WAIT TO START

With the key in the ON position, the WAIT TO START light will illuminate if glow plug heat is necessary as a starting aid. Wait until the light goes off before starting. The light should

always illuminate briefly, when the ignition key is in the ON position. If the light does not illuminate, there may be a problem. Refer to the Starting chapter in this guide. After the engine starts, the light should remain off.

The light should always illuminate at least momentarily when the engine is cold and the ignition is turned to ON. If it does not illuminate, the glow plug system should be checked and repaired promptly to avoid difficulty in cold starting.

WATER IN FUEL

During refueling, it is possible for water-contaminated diesel fuel to be pumped into your tank. Your vehicle fuel system is equipped with a fuel filter/water separator to remove

water from the fuel. The WATER IN FUEL light will illuminate when the ignition is turned to START (as part of the light function check) and when the fuel filter/water separator has a significant quantity of water in it.

If the light illuminates when the engine is running, stop the vehicle as soon as safely possible, shut off the engine, then drain the filter bowl. Refer to the General maintenance chapter for drain procedure.

Allowing water to stay in the system could result in extensive damage to, or failure of, the fuel injection system.

Do not drain the water separator while the engine is running. Fuel may ignite if the separator is drained while the engine is

running or the vehicle is moving.

8

Starting

STARTING THE ENGINE

Read all starting instructions carefully before you start your vehicle. Starting procedures are also shown on the vehicle visor. For temperatures below 0°C (32°F), the use of the correct grade engine oil is essential for proper operation.

If your vehicle is equipped with a manual transmission, make sure the parking brake is set fully before you turn the key. Depress the clutch pedal and place the gearshift in the neutral position. The clutch must be fully depressed in order to operate the starter. Do not press the accelerator during starting.

If your vehicle is equipped with an automatic transmission, ensure the gearshift lever is in P (Park) and the parking brake is set before you turn the key. Do not press the accelerator during starting.

COLD WEATHER STARTING

Do not crank the engine for more than 30 seconds at a time as starter damage may occur. If the engine fails to start, turn the key to OFF and wait 30 seconds before trying again.

Do not use starting fluid such as ether in the air intake system (see Air Cleaner Decal). Such fluid could cause immediate explosive damage to the engine and possible personal injury.

Do not add gasoline, gasohol or alcohol to diesel fuel. This practice creates a serious fire hazard and causes engine performance problems.

1.Make sure all vehicle occupants have buckled their safety belts. For more information on safety belts and their proper usage, refer to Seating and safety restraints chapter in the owner guide.

2.Make sure the headlamps and vehicle accessories are off.

3.Turn the key to the ON position. WAIT

When the WAIT TO START light goes off, turn the key to START. (For Canadian vehicles, the daytime running lamps will be on if the

parking brake is not applied and the key is turned to ON.)

4. When the engine starts, release the key. The glow plugs will continue to be activated for up to two minutes. If the engine is not started before the activation ceases, the glow plug system must be reset by turning the ignition key to OFF.

9

Starting

5. After the engine starts, allow it to idle for about 15 seconds. (Do not increase engine speed until the oil pressure gauge indicates normal pressure.)

STOPPING THE ENGINE

Turn the ignition to OFF. To prolong engine life (after extended high speed or maximum GVW operation), it is recommended that a hot engine be allowed to operate at low idle for about 7±10 minutes which would allow sufficient time for the turbocharged engine to cool down.

COLD WEATHER OPERATION

Changing to a lighter grade engine oil also makes starting easier under these conditions. Refer to ªEngine Oil Specificationsº in the General maintenance information chapter.

At temperatures below ±7°C (20°F), Number 2±D diesel fuel may thicken enough to clog the fuel filter. Your engine is equipped with a fuel filter/heater/water/separator to keep the wax melted which will help prevent fuel filter clogging. However, if the engine starts but stalls after a short time and will not restart, the fuel filter may be clogged. For best results in cold weather, use Number 1±D diesel fuel or ªwinterizedº Number 2±D diesel fuel which has an additive to minimize wax formation.

Your vehicle is also equipped with a bypass relief valve, located on the in-tank fuel sending unit, which provides fuel flow to the engine if the fuel pickup should become plugged by ice or wax. To allow this bypass valve to function and avoid engine fuel starvation, it is recommended that, during cold weather operation 0°C (32°F) or below, the fuel level in your tank should not be allowed to drop below 1/4 full. This will help prevent air from entering the fuel system and stalling the engine.

In cold weather below 0°C (32°F) your diesel engine will slowly increase to a higher idle speed if left idling in P (Park). The sound of the engine may change also, as an exhaust device engages to improve heater performance and reduce exhaust smoke.

Operation in snow

Vehicle operation in heavy snowfall or in dry loose snow that may swirl around the front of the vehicle may feed excessive amounts of snow into the air intake system. This could plug the air cleaner with snow and cause the engine to stall.

10

Starting

Operation in standing water

Ingestion of water into the diesel engine can result in immediate and severe damage to the engine. If driving through water, slow down to avoid splashing water into the intake. If the engine stalls, and ingestion of water into the engine is suspected, do not try to restart the engine. Consult your dealer for service immediately. Follow the cylinder compression test procedure outlined in the Workshop Manual, then check the engine oil for contamination.

Engine block heater (if equipped)

Refer to the Starting chapter in your Owner Guide.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames, sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Do not push start your vehicle. You could damage the catalytic converter.

Batteries contain sulfuric acid which burns skin, eyes, and clothing.

Preparing your vehicle

Also see the label on the battery.

1.Use only a 12±volt supply to start your vehicle. If you connect your battery to a 24±volt power supply you can damage your starter, ignition system and other electrical components. Do not attach the jumper cables to the glow plug relay as this could severely damage the glow plugs, injector driver module and PCM.

2.Do not disconnect the battery of the disabled vehicle as this could damage the vehicle's electrical system.

3.Park the booster vehicle close to the hood of the disabled vehicle making sure they do not touch. Set the parking brake on both vehicles and stay clear of the engine cooling fan and other moving parts.

11

Starting

4.Check all battery terminals and remove any excessive corrosion before you attach the battery cables.

5.Turn the heater fan on in both vehicles to protect any electrical surges. Turn all other accessories off.

Connecting the jumper cables |

|

|

1. Position the vehicles so that they |

|

|

do not touch one another. |

4 |

1 |

|

||

2. Switch off the engine. Switch off |

|

|

|

|

|

any unnecessary electrical |

|

|

equipment. |

|

+ |

3. Connect the positive (+) terminal |

|

– |

|

|

|

of the discharged battery to the |

|

|

positive (+) terminal of the booster |

|

– |

battery. Do not jump start the |

|

|

|

+ |

|

driver's side or frame mounted |

|

2 |

battery. |

|

3 |

4. Connect one end of the second |

|

|

|

|

|

lead to the negative (-) terminal of |

|

|

the booster battery and the other |

|

|

end to a metal part of the engine to be started, not to the negative (-) terminal of the discharged battery.

5. Make sure that the jump leads are clear of moving parts of the engine.

Do not connect the end of the second cable to the negative (-) terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

Jump starting

1.Start the booster vehicle and run the engine at moderately increased speed.

2.Start the engine of the vehicle with the discharged battery.

3.Once the engine has been started, run both vehicles for a further three minutes before disconnecting the leads.

12

Loading...

Loading...