Page 1

GESTRA

GESTRA Steam Systems

NRS 1-51

Installation Instructions 818955-01

Level Switch

NRS 1-51

EN

English

1

Page 2

2

Contents

Page

Application

Usage for the intended purpose ..............................................................................................................4

Function .................................................................................................................................................4

Directives and Standards

Pressure Equipment Directive (PED) 97/23/EC ........................................................................................

Functional Safety acc. to IEC 61508 ........................................................................................................

VdTÜV Bulletin “Wasserstand 100” (= Water Level 100) ..........................................................................

LV (Low Voltage) Directive and EMC (Electromagnetic Compatibility) .......................................................5

ATEX (Atmosphère Explosible) .................................................................................................................5

Functional Safety acc. to IEC 61508

Safety characteristics of the subsystem NRG 1...-51 / NRS 1-51 .............................................................

Terms and abbreviations .........................................................................................................................6

Determination of the Safety Integrity Level (SIL) for safety-related systems .............................................7

Technical Data

NRS 1-51

Name plate / marking ...........................................................................................................................10

Dimensions and Functional Elements

NRS 1-51..............................................................................................................................................11

Important Notes

Safety note ...........................................................................................................................................12

Scope of supply ....................................................................................................................................12

Installation

............................................................................................................................................ 8, 9

5

5

5

6

Mounting level switch NRS 1-51 ........................................................................................................... 13

Page 3

Contents – continued –

Page

Electrical Connection

Mains supply ........................................................................................................................................13

Connection of level electrode ................................................................................................................ 13

Connection of control circuit .................................................................................................................13

Connection of logic unit (standby input).................................................................................................13

Connection for signal output .................................................................................................................14

Tools .....................................................................................................................................................14

Wiring diagram for level switch NRS 1-51 .............................................................................................15

Schematic representations of arrangements .........................................................................................16

Explanatory notes to schematic respresentations .................................................................................. 16

Basic Settings

Factory setting ......................................................................................................................................16

Commissioning Procedure

Checking switchpoint and function .......................................................................................................17

Operation, Alarm and Test

Indicators and adjustors ........................................................................................................................18

Troubleshooting

Indication, diagnosis and remedy .................................................................................................... 18, 19

Further Notes

Action against high frequency interference ...........................................................................................20

Interlock and interlock deactivation .......................................................................................................20

Checking the switchpoints .................................................................................................................... 20

Decommissioning / replacing level switch .............................................................................................20

Disposal................................................................................................................................................20

Note on the Declaration of Conformity / Declaration by the Manufacturer .........................................20

3

Page 4

4

Application

Usage for the intended purpose

The level switch NRS 1-51 is used in conjunction with level electrodes NRG 1...-.. as high level alarm in

steam boilers and (pressurised) hot-water plants.

A high level alarm prevents the water level from exceeding the preset max. water level (HW) and for this

purpose switches off e. g. the feedwater supply.

Depending on the specified directives or standards, the level switch NRS 1-51 is intended to be used in

combination with the following level electrodes:

Level electrode NRG 1...-..

PED Pressure Equipment Directive

97/23/EC +

Functional Safety IEC 61508 SIL 3

VdTÜV Bulletin “Wasserstand 100”

(= Water Level 100)

Function

The level switch NRS 1-51 is designed for different electrical conductivities of the boiler water and for

connecting one level electrode.

See section Schematic representations of arrangements on page 16.

When the water level exceeds the MAX limit, the level electrode enters the liquid and an alarm is

triggered in the level switch. This switchpoint is determined by the length of the electrode rod

(level electrode NRG 1...-51, NRG 1...-12).

After the de-energizing delay has elapsed, both output contacts of the level switch will open the control

circuit, e. g. for the feedwater supply. If the deactivation of the feedwater supply is interlocked in the

external control circuit, the lockout can only de deactivated when the level electrode is exposed again.

An alarm will also be raised if a malfunction occurs in the level electrode and/or the electrical connection.

If the level electrode is installed in an isolatable level pot outside the boiler, make sure that the connecting

lines are rinsed regularly.

minutes.

(standby input, controlled by the logic unit SRL 6-50).

If the connecting lines for steam ≥ 40 mm and water ≥ 100 mm, the installation is considered to be

internal. In this case the rinsing processes do not have to be monitored.

An autmatic self-testing routine monitors the safety functions of the level switch. In the event of a

malfunction the control circuit opens instantaneously and switches off e. g. the feedwater supply.

Alarm and malfunction messages are indicated by LEDs, and the signal output is instantaneously

energized.

An alarm can be simulated by pressing the test button.

During the rinsing process the water level cannot be measured in the level pot for 5

The level switch therefore bypasses the level electrode and monitors the rinsing and bypass time

NRG 16-51 NRG 17-51 NRG 19-51

NRG 16-51

NRG 16-12

NRG 17-51

NRG 17-12

NRG 19-51

NRG 19-12

Note

n A high level alarm prevents the water level from exceeding the preset max. liquid

level (HW). For this purpose it can, for instance, interrupt the feedwater supply. If the

interruption of the feedwater supply endangers the heating surfaces in the feedwater

preheater (economizer), the heating must be switched off, too.

Page 5

Directives and Standards

Pressure Equipment Directive (PED) 97/23/EC

The level switch NRS 1-51 in conjunction with level electrode NRG 1...-51 is EC type approved

according to EN 12952/EN 12953. These Directives state, among other things, the requirements made

on limiting systems and equipment for steam boiler plants and (pressurised) hot-water installations.

Functional Safety acc. to IEC 61508

The level switch NRS 1-51 is certified acc. to IEC 61508 only if used in combination with level elec

trode NRG 1...-51. This standard describes the functional safety of safety-related electrical/electronic/

programmable electronic systems.

The equipment combination NRG 1...-51 + NRS 1-51 corresponds to a type B subsystem with Safety

Integrity Level (SIL) 3.

VdTÜV Bulletin “Wasserstand 100” (= Water Level 100)

The level switch NRS 1-51 in conjunction with the level electrodes NRG 1...-51 and NRG 1...-12 is type

approved according to the VdTÜV Bulletin "Water Level 100".

The VdTÜV Bulletin “Wasserstand (=Water Level) 100” specifies the requirements made on water level

control and limiting equipment for boilers.

LV (Low Voltage) Directive and EMC (Electromagnetic Compatibility)

The level switch NRS 1-51 meets the requirements of the Low Voltage Directive 2006/95/EC and the

EMC Directive 2004/108/EC.

ATEX (Atmosphère Explosible)

According to the European Directive 94/9/EC the level switch NRS 1-51 must

explosive areas.

Note

The level electrodes NRG 1...-51, NRG 1...-12 are simple items of electrical equipment

as specified in EN 60079-11 section 5.7. According to the European Directive 94/9/EC

the equipment must be equipped with approved Zener barriers if used in potentially

explosive areas. Applicable in Ex zones 1, 2 (1999/92/EC).

The equipment does not bear an Ex marking. The suitability of the Zener barriers is

certified in a separate document.

Note that the requirements of the IEC 61508 are not met if the NRG 1...-51,

NRG 1...-12 + Zener barriers + NRS 1-51 are interconnected!

not be used in potentially

-

5

Page 6

6

Functional Safety acc. to IEC 61508

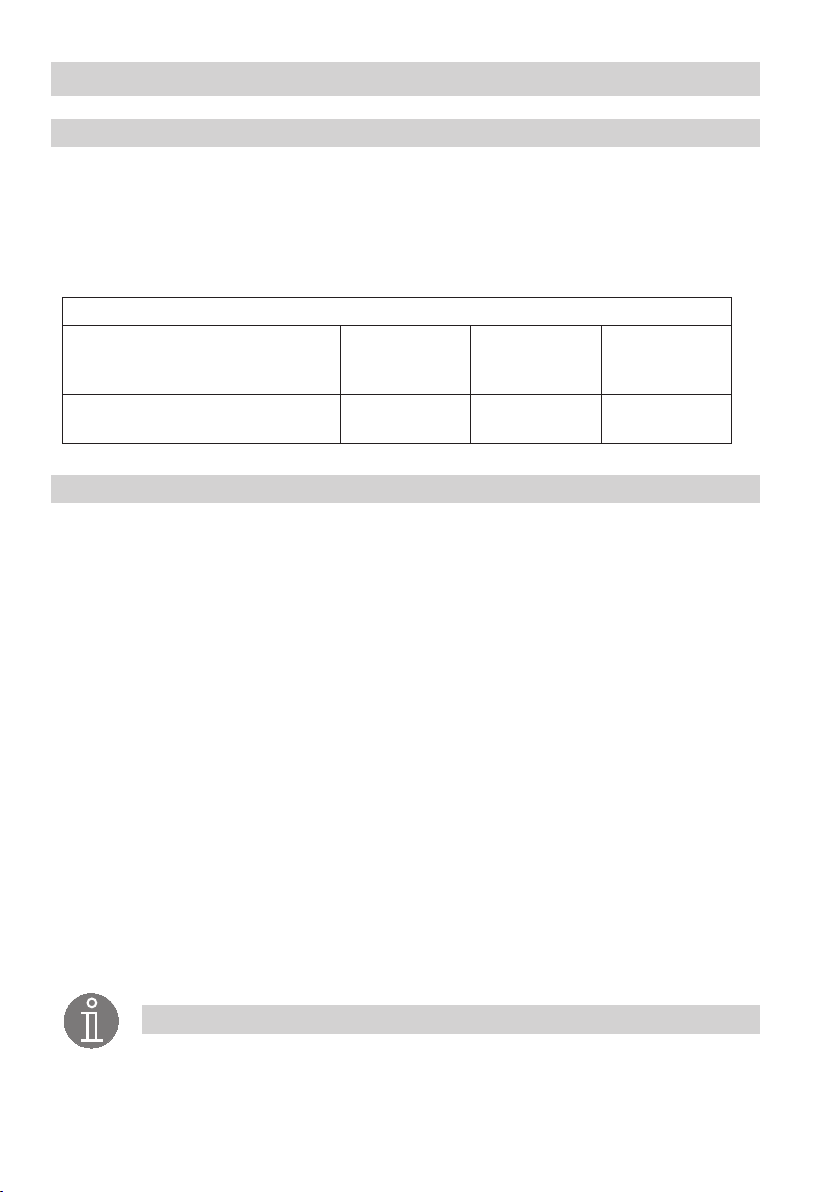

Safety characteristics of the subsystem NRG 1...-51 / NRS 1-51

The level switch NRS 1-51 is certified acc. to IEC 61508 only if used in combination with level electrodes

NRG 1...-51.

The equipment combination NRG 1...-51 / NRS 1-51 corresponds to a type B subsystem with Safety

Integrity Level (SIL) 3. Type B means that the behaviour under fault conditions of the used components

cannot be completely determined. The functional safety of the equipment combination refers to the

detection and evaluation of the water level and, as a consequence, the contact position of the output

relays.

The design of the equipment combination NRG 1...-51 / NRS 1-51 corresponds to the architecture

1oo2 D. This architecture consists of two channels that detect and diagnose faults in each other. If a fault

is detected, the equipment combination NRG 1...-51 / NRS 1-51 will go to the safe state, which means

that the contacts of both output relays will open the control circuit.

Safety characteristics

General 3 1oo2 D 20 20

Level switch NRS 1-51 alone 98.54 % 1.18 x 10

Level switch NRS 1-51 in conjunction with one

level electrode NRG 1...-51

Fig. 1

Terms and abbreviations

Terms

Abbreviations

Safety Integrity Level

SIL

Lifetime (a) Functional safety: Lifetime in years

Safe Failure Fraction

SFF

Probability Failure per Demand

(Low Demand)

PFD

av

Probability Failure per Hour

PFH

av

λ

DU

Classification of the Safety Integrity Level acc. to IEC 61508

Percentage of failures without the potential to put the safety-related system into

a dangerous state

Average probability of failure on demand for low demand mode (once a year)

Probability of failure per hour

Failure rate for all dangerous undetected failures (per hour) of a channel of a

subsystem

Fig. 2

SIL Architecture Lifetime

SFF PFD

98.17 % 1.69 x 10

av

-4

3.73 x 10

-4

4.54 x 10

Description

PFH

(a)

Proof Test

Interval (a)

av

-8

-8

λ

DU

7.33 x 10

9.33 x 10

-8

/h

-8

/h

Page 7

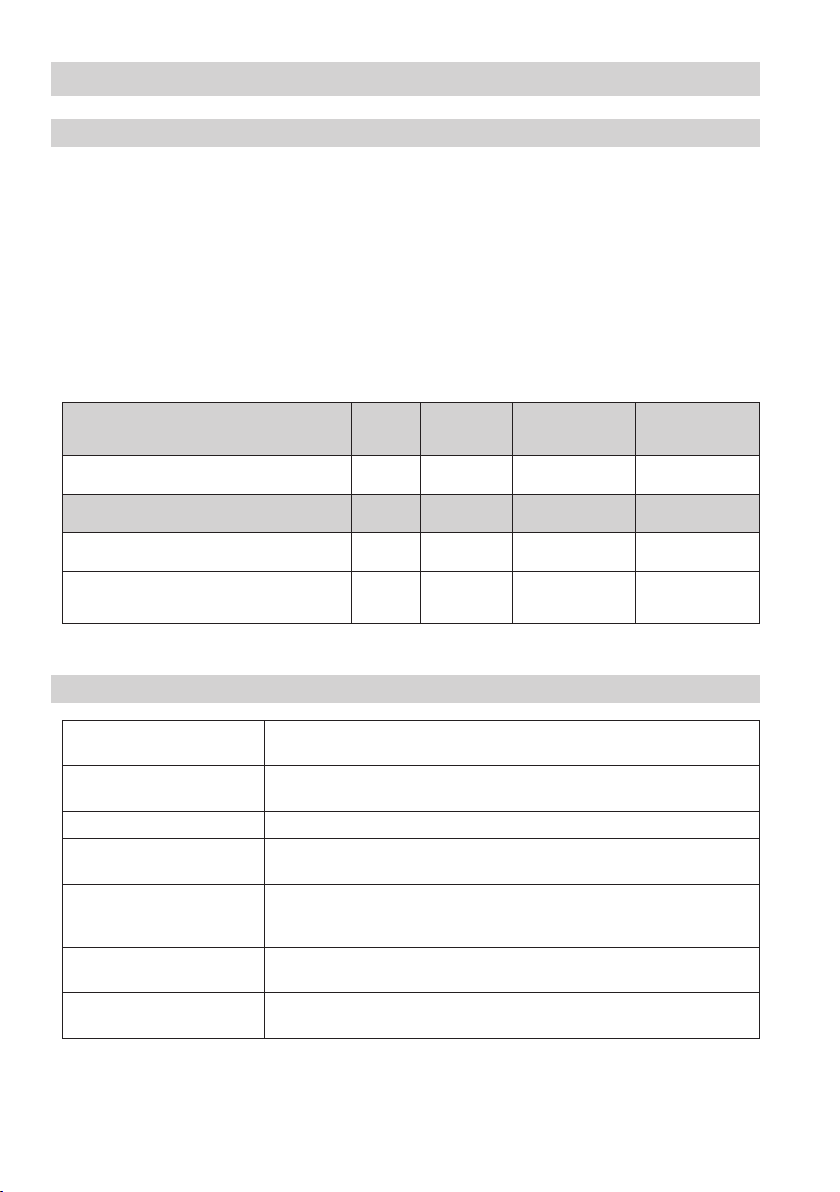

Functional Safety acc. to IEC 61508 – continued –

Determination of the Safety Integrity Level (SIL) for safety-related systems

Level electrode, level switch and actuators (auxiliary contactors in control circuit) are subsystems and

together constitute a safety-related system that executes a safety function.

The specification of the safety-related characteristics Fig. 1 refers to the level electrode and the level

switch including the output contacts. The actuator (e. g. an auxiliary contactor in the control circuit) is

installation specific and, according to IEC 61508, must be considered separately for the whole safetyrelated system.

Table Fig. 3 shows the dependence of the Safety Integrity Level (SIL) on the average probability of failure

on demand of a safety function for the whole safety-related system (PFD

is here considered for a water level limiter, which means that the frequency of demands for operation of

the safety-related system is no greater than one per year.

). The “Low demand mode”

sys

Low demand mode PFD

-5

... < 10

≥ 10

-4

... < 10

≥ 10

-3

... < 10

≥ 10

-2

... < 10

≥ 10

Safety Integrity Level

sys

-4

-3

-2

-1

(SIL)

4

3

2

1

Fig. 3

The table in Fig. 4 indicates the attainable Safety Integrity Level (SIL) as a function of the Safe Failure

Fraction (SFF) and the Hardware Fault Tolerance (HFT) for safety-related systems.

Hardware Fault Tolerance (HFT) for type B

0 1 2

SIL 1 SIL 2

SIL 1 SIL 2

SIL 2

SIL 3 SIL 4 90 % – < 99 %

SIL 3 60 % – < 90 %

SIL 3 SIL 4 SIL 4 ≥ 99 %

Safe Failure Fraction

(SFF)

< 60 %

Fig. 4

7

Page 8

8

Technical Data

NRS 1-51

Supply:

Mains voltage

24 VDC +/– 20%, 0.3 A or 100 – 240 VAC +10/–15 %, 47 – 63 Hz, 0.2 A

External fuse

0.5 A (semi-delay)

Power consumption

7 VA

Inputs:

Electrical connection of level electrode

1 input for level electrode NRG 1...-51, NRG 1...-12, 4-poles with screen

Sensitivity 0.5 μS/cm or 10 μS/cm (at 25 °C).

Stand-by input

1 volt-free input, 18-36 VDC, for monitoring the purging and bypass time.

Max. bypass time: 5 minutes.

Outputs:

Control circuit

2 volt-free make contacts, 24 V DC – 250 V AC, max. 6 A (resistive/inductive),

Contact material AgNi.

Delay of response: 3 seconds.

Provide inductive loads with RC combinations according to manufacturer's specification to ensure

interference suppression.

Signal output

1 volt-free output for instantaneous external signalling, 24 – 230 V AC/DC, max. 100 mA.

Indicators and adjustors

2 buttons for test and diagnosis,

2 red/green LEDs for indicating the operating mode and alarm.

3 red LEDs for diagnosis.

Housing

Housing material: base: polycarbonate, black; front: polycarbonate, grey.

Cross section of connection: 1 x 4.0 mm

1 x 2.5 mm

2 x 1.4 mm

2

per stranded wire with sleeve to DIN 46228 or

2

per stranded wire with sleeve to DIN 46228; terminal strips can be detached

2

solid per wire or

Fixing of housing: Mounting clip on supporting rail TH 35, EN 60715

Electrical safety

Degree of contamination: 2, overvoltage category III to EN 61010-01.

Protection

Housing: IP 40 to EN 60529

Terminal strip: IP 20 to EN 60529

Weight

approx. 0.5 kg

Page 9

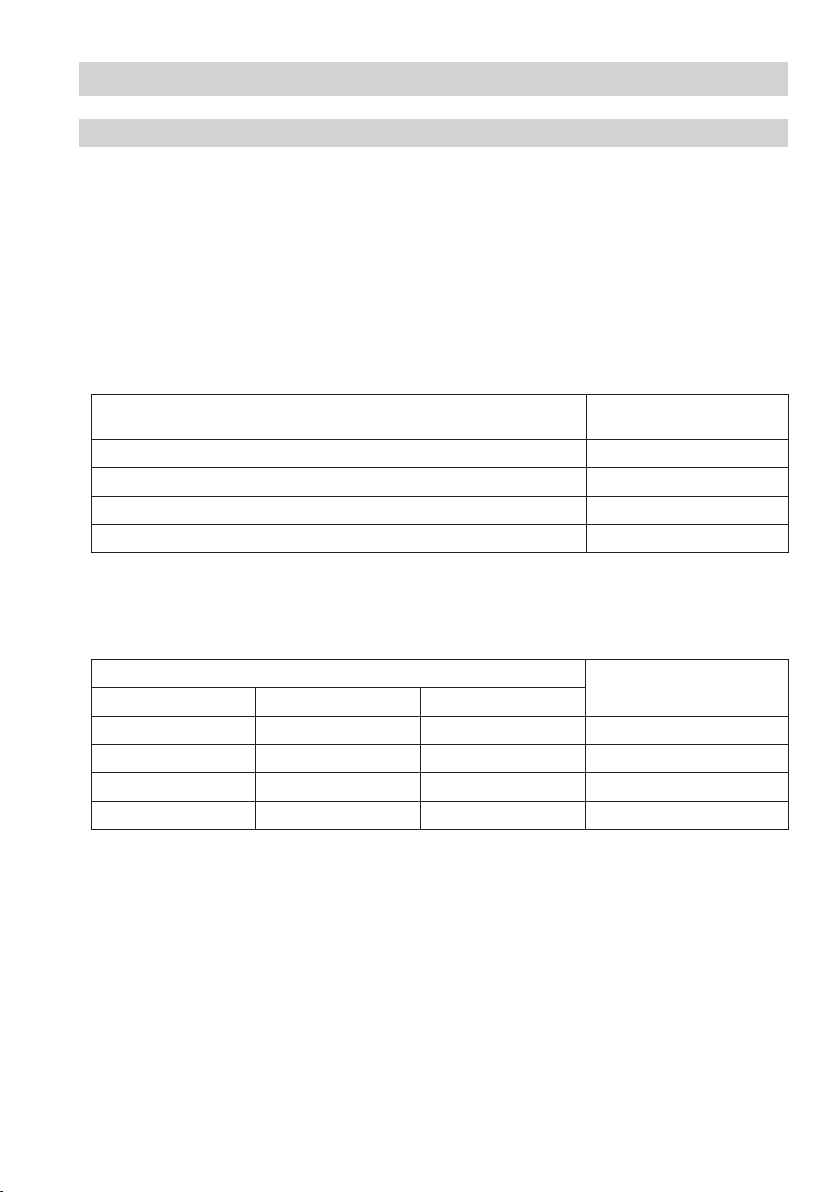

Technical Data – continued –

NRS 1-51 – continued –

Further conditions:

Water quality

(max. admissible electrical conductivity of the boiler water)

steam boiler plants / (pressurised) hot-water installations < 10000 µS/cm (at 25 °C)

Ambient temperature

when system is switched on: 0 ... 55 °C

during operation: –10 ... 55 °C

Transport temperature

–20 ... +80 °C (< 100 hours), defrosting time of the de-energized equipment before it can be put into

operation: 24 hours.

Storage temperature

–20 ... +70 °C, defrosting time of the de-energized equipment before it can be put into operation:

24 hours.

Relative humidity

max. 95%, no moisture condensation

Site altitude

max. 2000 m

Approvals

EC Prototype approval PED Pressure Equipment Directive 97/23/EC

EN 12952-11, EN 12953-09: Requirements made on

limiting equipment for boilers.

Functional safety IEC 61508 Functional safety of safety-related electrical/

SIL 3 electronic/programmable electronic systems

TÜV type approval VdTÜV Bulletin “Wasserstand 100” (= Water Level 100):

Requirements made on water level limiting & control equipment.

Type approval no. TÜV · SWB / SHWS · XX-XXX

(see name plate)

9

Page 10

10

Technical Data – continued –

24V =

+ / - 20%

NL

(+)

M 0,5A

(-)

NRS 1 - 51

Tamb = 55°C (131°F)

IP 40 (IP20)

7 VA

Betriebsanleitung

beachten

See installation

instructions

Voir instructions de

montage

Alarm

extern

24-230 VAC/DC

100 mA

0525

250V

T 2,0A

TÜV . SWB/SHWS . 09-...

GESTRAAG

Münchener Str.77

D-28215 Bremen

Niveauschalter

Level switch

Commutateur de niveau

20 21

N L

1. / 2.

3sec.

6 7

Funktionale Sicherheit

Functional safety

Sécurité fonctionnelle

IEC 61508

SIL 3

10 µS/cm

2

NRG 1...-51

1

2

3

1

3

4

5

16

17

232426

27

NRS 1-51

MAX

SRL

+

-

Hochwasserstandsicherung

High water level limiter

Limiteur de niveau d’eau haut

Name plate / marking

Safety

note

Type

designation

Mains voltage/

Protection

Ambient

temperature /

sensitivity

Wiring

diagram

Manufacturer

Fig. 5

Wire link,

provided on site

Control

circuit

Fuse, provided

on site

Approvals

Disposal

note

Page 11

Dimensions and Functional Elements

NRS 1-51

6

100

73

7

1

2

3

Fig. 6

Key

1 Upper terminal strip

2 Lower terminal strip

3 Fixing screws (cross recess head screws M3)

6 Enclosure

7 Supporting rail type TH 35, EN 60715

118

11

Page 12

12

Important Notes

Safety note

High water level alarms are safety devices and must only be installed, wired and commissioned by

qualified and competent staff.

Retrofitting and maintenance work must only be performed by qualified staff who – through adequate

training – have achieved a recognised level of competence.

Danger

The terminal strips of the NRS 1-51 are live during operation.

This presents the danger of electric shock!

Always cut off power supply to the equipment before mounting, removing or connecting

the terminal strips!

Attention

The name plate specifies the technical features of the equipment. Note that any piece of

equipment without its specific name plate must neither be commissioned nor operated.

Scope of supply

NRS 1-51

1 Level switch NRS 1-51

1 Installation manual

Page 13

Installation

Mounting level switch NRS 1-51

The level switch NRS 1-51 is clipped onto the support rail

cabinet. Fig. 6

7 type TH 35, EN 60715 in the control

Electrical Connection

Mains supply

Provide the level switch NRS 1-51 with an external semi-delay fuse 0.5 A.

Connection of level electrode

To connect the level electrode use screened multi-core control cable with a min. conductor size

0.5 mm2, e.g. LiYCY 4 x 0.5 mm2 .

Max. length 100 m with an electrical conductivity of the boiler water > 10 μS/cm at 25 °C.

Max. length 30 m with an electrical conductivity of the boiler water < 10 μS/cm at 25 °C.

Wire terminal strip in accordance with the wiring diagram. Fig. 5.

Connect screens only to terminal 5.

Connection of control circuit

Connect the control circuit for the feedwater supply / heating to terminals 23, 24 and 26, 27. Wenn

used as high water level alarm to TRD, EN 12952 / EN 12953 connect the output contacts of both

monitoring channels by fitting a wire link between the terminals 24 and 26.

Fuse the output contacts with a 2 A or 1 A (for 72 hours operation acc. to TRD 604) slow-blow fuse.

Note

n A high level alarm prevents the water level from exceeding the preset max. liquid

level (HW). For this purpose it can, for instance, interrupt the feedwater supply. If the

interruption of the feedwater supply endangers the heating surfaces in the feedwater

preheater (economizer), the heating must be switched off, too.

n In the event of an alarm the level switch NRS 1-51 does not interlock automatically.

If a lockout function is required by the installation it must be provided in the follow-up

circuitry (control circuit). The circuitry must meet the requirements of the EN 50156.

Connection of logic unit (standby input)

For connecting the level switch with the logic unit use a control cable, e. g. 2 x 0.5 mm2.

The control voltage must not exceed 36 V DC.

13

Page 14

14

Electrical Connection – continued –

Connection for signal output

A signal output for the connection of external signalling equipment is allocated to the monitoring

channel in the level switch, max. load 100 mA. For connecting the level switch with the logic unit use

a control cable, e.g. 2 x 0.5 mm

(terminals 20, 21) closes instantaneously.

Danger

n For the supply of the level switch NRS 1-51 with 24 V DC use a safety extra-low

voltage (SELV) power supply unit that must be electrically isolated from dangerous

contact voltages and must meet at least the requirements on double or reinforced isolation acc. to DIN EN 50178 or DIN EN 61010-1 or DIN EN 60730-1 or DIN EN 60950

(safe electrical isolation).

n Any item of equipment that you want to connect to terminals 6, 7 (standby input 1)

must be certified to have at least double or reinforced isolation according to DIN

EN 50178 or DIN EN 61010-1 or DIN EN 60730-1 or DIN EN 60950 (safe electrical

isolation) between the standby inputs and the live parts of the installation that are not

supplied with safety extra-low voltage (SELV).

Attention

n Fuse the level switch NRS 1-51 with an external semi-delay fuse 0.5 A.

n Connect screens of electrode wires only to terminal 5.

n To protect the switching contacts fuse the safety circuit with a slow-blow fuse 2 A or 1

A (for 72 hrs. operation acc. to TRD 604).

n When switching off inductive loads, voltage spikes are produced that may impair the

operation of control and measuring systems. Connected inductive loads must be provided with suppressors such as RC combinations as specified by the manufacturer.

n When used as high water level alarm according to TRD, EN 12952 / EN 12953 connect

terminals 24 and 26 by fitting a wire link.

n Install connecting lines to level electrodes and logic unit separated from power cables.

n Do not use unused terminals as support point terminals.

2

. In the event of an alarm or error message the signal output

Tools

n Screwdriver for slotted screws, size 3.5 x 100 mm, completely insulated according to VDE 0680-1.

Page 15

2716

1 2 3 4 5 6 7 8

17 18 19 20 21 22 23 249251026

11 12281329143015

NRG 1...-51

1

2

3

+ -

M 0,5A

Electrical Connection – continued –

Wiring diagram for level switch NRS 1-51

L N

8

(+) (-)

9 0

0

M 0.5A

a

b

Fig. 7

Key

c

8 Mains supply

9 Signal output 1 for external alarm 24-230 V AC/DC 100 mA

0 Control circuit, input and output

a Wire link, fitted on site, when used as high water level alarm acc. to TRD, EN 12952 / EN 12953

b Stand-by input 1, 24 V DC, for connecting the logic unit SRL 6-50

c Level electrode NRG 1...-51, NRG 1...-12

15

Page 16

16

Electrical Connection – continued –

Schematic representations of arrangements

d

e

f

Fig. 8

Key

Steam boiler plants according to TRD 604, EN 12952-07 / EN 12953-06, 72 h operation

Fig. 8

Combination consisting of 1 level electrode NRG 1...-51 and 1 level switch NRS 1-51 as high water level

alarm. Functional safety IEC 61508, SIL 3.

Further applications in accordance with national sets of regulations

Fig. 9

Combination consisting of 1 level electrode NRG 1...-51 and 1 level switch NRS 1-51 as high water level

alarm

. The level switch opens two separate control circuits. Functional safety IEC 61508, SIL 3.

d

e

f

Fig. 9

d Level electrode(s) NRG 1...-51

e Level switch NRS 1-51

f Control circuit

Basic Settings

Factory setting

Level Switch NRS 1-51

The level switch features the following factory set default values:

n De-energizing delay: 3 sec.

Page 17

Commissioning Procedure

Checking switchpoint and function

Level electrode 1

Test & diagnosis

button

LED alarm 1 /

Fig. 14

Activity Indication Function

Apply mains voltage.

Lower water level in boiler

until the level falls below

the switchpoint high water

level (HW). Level electrode is

exposed.

Raise level in boiler until the

switchpoint “high water level

(HW)” is ecxeeded. Level

electrode enters the water.

operating mode

Diagnosis LED

All LEDs are illuminated.

All LEDs are illuminated for more

than 10 sec.

Green LED

for level electrode 1 is illuminated

Checking switchpoint and function

Red LED

for level electrode 1 is flashing

Red LED

for level electrode 1 is illuminated

Start

System is being started and tested, this takes

approx. 10 sec. Output contacts are open.

Signal output 1 closed.

System malfunction. Possible causes:

Faulty power supply, level switch defective.

Output contacts are closed.

Signal output 1 is open.

De-energizing delay is running.

Signal output 1 is closed instantaneously.

Delay time has elapsed, output contacts open.

Signal output 1 is closed.

Possible installation faults

Status and indication Fault Remedy

Replace electrode rod and cut new rod to the

length dictated by the switchpoint HW.

Clean seating surfaces and screw in level

electrode with metallic joint ring. Do not

insulate the electrode with hemp or PTFE

tape!

Set response sensitivity of the level switch to

0.5 μS/cm.

Check installation of level electrode. Make

sure that the level in the protection tube corresponds to the actual water level.

Cut electrode rod to the length dictated by the

switchpoint HW.

Check installation of level electrode. Make

sure that the level in the protection tube

corresponds to the actual water level.

Sightglass indicates high

water level (HW) exceeded,red

LED for level electrode 1 is

not illuminated. Safety circuit

closed.

Water level sufficient. Red

LED for level electrode 1 is

illuminated. Safety circuit is

open.

The electrode rod is too short.

The earth connection to the vessel

is interrupted.

Electrical conductivity of the boiler

water too low.

If installed inside the boiler: Upper

vent hole in protection tube does

not exist or is obstructed.

Electrode rod is too long.

Upper vent hole flooded.

17

Page 18

18

Operation, Alarm and Test

Indicators and adjustors

Level electrode 1

Test & diagnosis

button

LED alarm 1 /

Fig. 14

Activity Indication Function

Level electrode exposed

Level electrode submerged,

high water level (HW)

exceeded.

During operation:

Press and hold down key 1

until the end of the test, level

switch must function as if there

were an alarm.

operating mode

Diagnosis LED

Green LED

for level electrode 1 is illuminated

Red LED

for level electrode 1 is flashing

Red LED

for level electrode 1 is illuminated

Red LED

for level electrode 1 is flashing

Red LED

for level electrode 1 is illuminated

Operation

Output contacts are closed.

Signal output 1 is open.

Alarm

De-energizing delay is running.

Signal output 1 is closed instantaneously.

Delay time has elapsed, output contacts open.

Signal output 1 is closed.

Test channel 1

Alarm simulated in channel 1 or 2.

De-energizing delay is running.

Signal output 1 is closed instantaneously.

Delay time has elapsed, output contacts open.

Signal output 1 is closed. Test finished.

Troubleshooting

Indication, diagnosis and remedy

Attention

Before carrying out the fault diagnosis please check:

Mains supply:

Is the level switch supplied with the mains voltage specified on the name plate?

Wiring:

Is the wiring in accordance with the wiring diagram and the relevant schematic

representation of arrangement?

Page 19

Troubleshooting – continued –

Indication, diagnosis and remedy – continued –

Malfunction in level electrode

Status and indication Fault Remedy

Water level sufficient. Red

LED for level electrode 1 is

illuminated. Safety circuit is

open.

Status Diagnosis Function Next activity

Faulty evaluation of level

electrode 1, channel 1

Malfunction in level

switch detected.

Display 1 and activity Display 2 Fault Remedy

LED alarm 1 and

diagnosis LED 1

illuminated. Press and hold

down key 1.

LED alarm 1 or 2

and Diagnosis LED 3

illuminated. Press and hold

down key 1 or 2.

Once the fault is eliminated, the level switch returns to normal operation.

After elimination of the fault switch off the mains voltage and switch it on again after approx. 5 sec.

The insulation of the level

electrode is dirty or faulty.

Further fault indications

Diagnosis LED 1 and

LED alarm 1 illuminated.

Diagnosis LED 3 and

LED alarm 1 or 2

illuminated.

Diagnosis

LED 1

flashing.

Diagnosis

LED 2

flashing.

Diagnosis

LED 3

flashing.

Diagnosis

LED 1

flashing.

Diagnosis

LED 2

flashing.

Diagnosis

LED 3

flashing.

Malfunction in level

electrode 1, malfunction in

level switch, faulty wiring,

faulty measuring voltage.

Malfunction in level

electrode 1, malfunction in

level switch, faulty wiring.

Interference voltage causing

malfunction, boiler earth

without PE

Malfunction in processor,

stand-by fault.

Internal voltage fault.

Malfunction in relay.

Clean or, if necessary, replace level electrode.

Output contacts are opened instantaneously.

Signal output 1 closes instantaneously.

Output contacts are opened instantaneously.

Signal outputs 1/2 are closed instantaneously.

Diagnosis

Check wiring,

replace level switch.

Provide screen and earthing, connect

boiler with PE.

Observe operating instructions for the

logic unit SRL. Replace level switch.

Replace level switch.

next:

Press key 1.

next:

Press key 1

or key 2.

If faults occur that are not listed above or cannot be corrected, please contact our service centre or

authorized agency in your country.

19

Page 20

20

Further Notes

Action against high frequency interference

Should sporadic failures occur in installations susceptible to faults (e. g. malfunctions due to out-ofphase switching operations) we recommend the following actions in order to suppress interferences:

n Provide inductive loads with RC combinations according to manufacturer's specification to ensure

interference suppression.

n Increase the distance to sources of interference.

n Check screens and shields.

n HF interference suppression by means of hinged-shell ferrite rings.

Interlock and interlock deactivation

In the event of an alarm the level switch NRS 1-51 does not interlock automatically.

If a lockout function is required by the installation it must be provided in the follow-up circuitry (control

circuit). The circuitry must meet the requirements of the EN 50156.

Checking the switchpoints

To check the switchpoint “High water level (HW) exceeded” you have to fill the boiler until the max.

water level is reached. As soon as the high level is reached the level switch must trigger an alarm and

open the control circuit after the de-energizing delay has elapsed The deactivation of the heating is

interlocked in the control circuit and the lockout can only be reset when the level electrode is exposed

again. Always check the switchpoint when commissioning the equipment, after replacing the level

electrode and at regular intervals, e. g. every year.

Decommissioning / replacing level switch

n Switch off mains voltage and cut off power supply to the equipment.

n Unscrew the right and left fixing screws 3 and remove the upper and lower terminal strips 1 2,

Fig. 6

n Undo the fixing slide in order to snap out the level switch and take it off the supporting rail.

Disposal

Remove the level switch and separate the waste materials in accordance with the material

specification.

Electronic component parts such as the circuit board must be disposed of separately!

For the disposal of the levels switch observe the pertinent legal regulations concerning waste disposal.

Note on the Declaration of Conformity / Declaration by the Manufacturer

For details on the conformity of our equipment according to the European Directives see our

Declaration of Conformity or our Declaration of Manufacturer.

The current Declaration of Conformity / Declaration of Manufacturer are available in the Internet under

www.gestra./de/documents or can be requested from us.

Page 21

For your Notes

21

Page 22

22

For your Notes

Page 23

For your Notes

23

Page 24

Agencies all over the world:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 0034 91 / 5 15 20 32

Fax 0034 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve GB Limited

Abex Road

Newbury, Berkshire RG14 5EY

Tel. 0044 16 35 / 46 99 90

Fax 0044 16 35 / 3 60 34

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 0039 02 / 66 32 51

Fax 0039 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 0048 58 / 3 06 10 - 02

0048 58 / 3 06 10 - 10

Fax 0048 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 00351 22 / 6 19 87 70

Fax 00351 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve GESTRA U.S.

2341 Ampere Drive

Louisville, KY 40299

Tel. 001 502 / 267-2205

Fax 001 502 / 266-5397

E-mail: FCD-Gestra-USA@flowserve.com

GESTRA AG

P. O. Box10 54 60, D-28054 Bremen

Münchener Str. 77 , D-28215 Bremen

Telephone 0049 (0) 421 / 35 03- 0

Fax 0049 (0) 421 / 35 03 - 393

E mail gestra.ag@flowserve.com

Internet www.gestra.de

818955-01/12-2009cm (808806-01) · GESTRA AG · Bremen · Printed in Germany

24

Loading...

Loading...